Page 1

WTE.. 24/06

7082 296-00

Operating instructions

for wine cooler

GB

Page 2

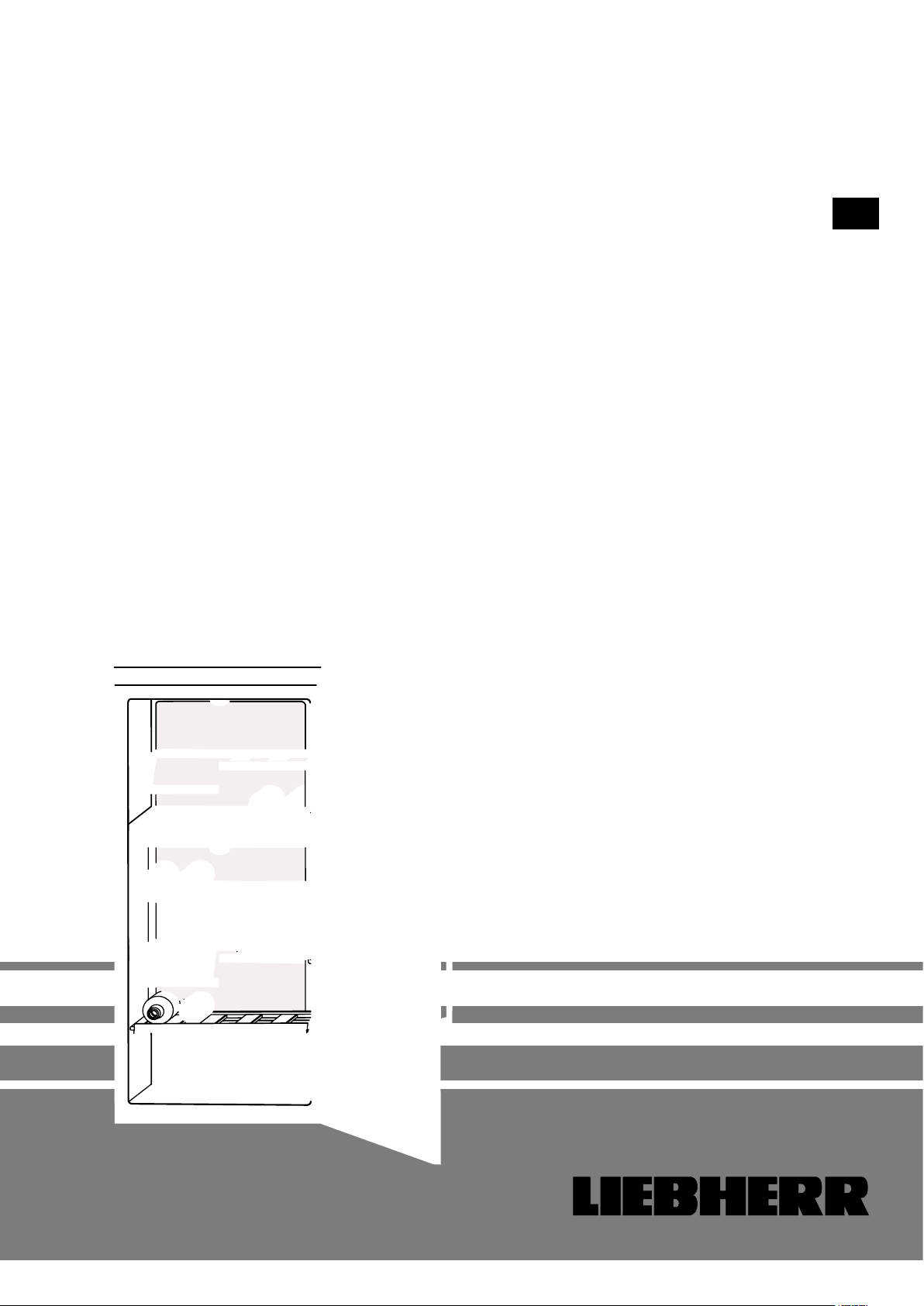

12

WTE...6

Please keep the operating instructions in a safe place and pass

them on to any new owner, if necessary.

Congratulations on the purchase of your new appliance. With this purchase you have chosen all the advantages of the latest refrigeration technology, guaranteeing you a high quality appliance with a long life span and

high operating safety.

The equipment of your appliance gives you the highest level of ease of operation on a day-to-day basis.

With this appliance, manufactured in an environmentally-friendly process using recyclable materials, you and

we are together making an active contribution to the conservation of our environment.

To get to know about all the advantages of your new appliance, please read the information in these instructions carefully.

We hope you enjoy your new appliance.

Contents

Operating instructions Page

Contents ............................................................. 12

Definitions .......................................................... 12

Information on energy saving .............................. 12

Information for Test Institutes .............................. 12

Appliance at a glance .............................................. 13

Disposal advice .................................................. 14

Safety and warning information .......................... 14

Technical safety ................................................. 14

Safety when using .............................................. 14

Installation instructions ....................................... 14

Connecting to the electrical supply ..................... 14

Installation ............................................................... 15

Appliance dimensions ........................................ 15

Changing over door hinges ................................ 15

Information on building in .................................... 16

Fastening and mounting .......................................... 17

Operating elements and controls ............................. 18

Wine storage ...................................................... 18

Switching on and off ........................................... 18

Setting the temperature ...................................... 18

Temperature display ........................................... 18

Alarm - Acoustic warning .................................... 18

Ventilator switch .................................................. 18

Additional functions ............................................ 19

Child safety device ...................................... 19

Brightness ................................................... 19

Light setting dim mode ................................ 19

Equipment ............................................................... 19

Interior lighting .................................................... 19

Labels ................................................................. 19

Wooden shelves ................................................. 19

Cleaning .................................................................. 20

General .............................................................. 20

Active carbon filter .............................................. 20

Condensation water drainage channel ............... 20

Faults - Problems ..................................................... 21

Customer service ..................................................... 21

Disposal ................................................................... 21

Definitions

W The appliance is intended for cooling wine. It is designed for

domestic use. If put to another use, problem-free operation

cannot be guaranteed.

W Depending on the climatic class, the appliance is designed

for operation at the ambient temperature limits indicated.

They should not be exceeded at either end of the range! The

climatic class relating to your appliance is printed on the rating

plate. It means:

Climatic class designed for

Ambient temperatures of

SN +10 °C to +32 °C

N +16 °C to +32 °C

ST +18 °C to +38 °C

T +18 °C to +43 °C

- The refrigerant cycle is tested for tightness.

- The appliance conforms to the relevant safety regulations and

the EC Directives 73/23/EC and 89/336/EC.

Information on energy saving

W Make sure that the ventilation sections are kept free.

W Only open the door of the appliance for as brief a time as

possible.

W Arrange the food in a logical order. Do not exceed the maxi-

mum storage times given.

W In the event of a power cut, keep the door of the appliance

closed. This delays the loss of cold. The quality of the frozen

food is retained for longer.

Information for Test Institutes:

As there are currently no energy efficiency guidelines for wine

coolers, the two wine compartments are rated as cellar compartments in the energy efficiency classification.

Page 3

13

WTE...6

GB

Page 4

14

WTE...6

Installation instructions

W When installing/building in, make sure that the pipes of the

refrigerant circuit are not damaged.

W The installation space for your appliance must have a volume

of 1 m3 per 8 g of refrigerant R 600a in accordance with the

standard EN 378, so that in the event of a leak in the refrig-

erant circuit no flammable gas-air mixture can occur in the

appliance’s installation space. The details of the amount of

refrigerant contained is to be found on the rating plate inside

the appliance.

W Avoid sites in the area of direct sunlight, near cookers, heat-

ers and the like, and in damp areas or where water can be

splashed.

W The ventilation grilles must not be blocked. Always en-

sure good ventilation! For more information on this subject,

please see the installation and conversion instructions.

W Do not place any appliances that give off heat, e.g. micro-

wave, toaster, etc. on the appliance.

W Remove all transport safety devices,

- remove sticky tape or spacers from the shelves.

- Remove all protective films: on the front and side walls*.

Connecting to the electrical supply

Type of current (alternating current) and voltage

at the installation site must match the details on the rating

plate. This is located on the left-hand side inside the appliance,

W Only connect the appliance via a correctly installed

shockproof socket.

W The power point must be protected with a fuse of 10 A or

higher, be outside the area of the back of the appliance and

be easily accessible.

W Do not

- connect the appliance to island power inverters (e.g. battery),

- operate the appliance in combination with so-called energy-

saving plugs - the electronics can be damaged,

- connect the appliance with other appliances via an extension

cable - danger of overheating.

W When taking the mains cable from the back of the appliance

remove the cable holder - otherwise vibration noises!

Disposal notes

The packaging is made of recyclable materials.

- Corrugated board/board

- EPS moulded parts

- Polythene sheets

- Polypropylene straps

•

Keep packaging materials away from children - poly-

thene sheets and bags can cause suffocation!

•

Please return the packaging to an official collection

point.

Technical safety

W To avoid personal injury and material damage, only transport

the appliance when packed in the packaging materials and

install with two people present.

W The refrigerant contained within the appliance, R 600a, is

environmentally friendly, but flammable.

W Do not damage the pipes of the refrigerant circuit. Spurting

refrigerant may lead to eye injuries or may ignite.

W If refrigerant escapes, remove naked flames or sources of igni-

tion from near where it is escaping, pull out the mains plug and

ventilate the room well.

W In the event of damage to the appliance, check with the sup-

plier immediately - before connecting to the mains supply.

W To ensure safe operation of the appliance, only install and

connect the appliance in accordance with the operating instructions.

W In the event of fault, disconnect the appliance from the mains

supply: remove the mains plug (do not pull on the mains cable

to do this) or remove or turn off the fuse.

W Only have repairs and interventions on the appliance

carried out by the Customer Care Service, otherwise serious risks to the user may arise. The same

applies to changing the mains cable.

Safety when using

W Do not store any explosive materials or aerosols with flam-

mable propellants, such as butane, propane, pentane, etc. in

the appliance. Any leaking gases could be ignited by electrical

components. You can recognise such aerosols by the printed

contents or by a flame symbol.

W High-proof alcohol should only be stored tightly sealed and

upright.

W Do not handle naked flames or ignition sources inside the ap-

pliance.

W Do not use any electrical devices inside the appliance (e.g.,

steam cleaners, heaters, etc.)

W Plinth, drawers, doors, etc. are not intended to be stood on, so

do not mistreat them in this way.

W This appliance is not designed for use by persons (or children)

with physical, sensory or mental impairment or persons, who

do not have sufficient experience and knowledge, unless they

have been instructed or initially supervised by a person, who

is responsible for their safety, in the use of the appliance. Children should not be left unsupervised to make sure that they do

not play with the appliance.

W Avoid long skin contact with cold surfaces or cooled products.

This can lead to pain, feelings of numbness and frostbite. In

the event of skin contact lasting a while, take protective steps,

e.g. use gloves.

W Do not consume food that has been stored for too long, it can

cause food poisoning.

Safety and warning information

The wires in the mains lead are coloured in accordance with the

following code: green/yellow = earth, blue = neutral, brown = live.

Warning! This appliance must be earthed.

Non-rewireable plugs BS 1363

If this machine or appliance is fitted with a non-rewireable plug,

the following information applies: If the socket outlets are not

suitable for the plug supplied with this product, it must be cut off

and an appropriate plug fitted. The plug cut from the flexible cord

should be disposed of and on no account be inserted into a 13 A

socket elsewhere in the house (electric shock hazard).

The fuse cover must be re-fitted when changing the fuse, and if

the fuse cover is lost the plug must not be used until a suitable

replacement is obtained. The colour of the correct replacement

cover is that of the coloured insert in the base of the plug, or the

colour that is embossed in words on the base of the plug (as applicable to the design of the plug fitted). The correct rating of the

replacement fuses that are ASTA approved to BS 1362 should be

fitted. Replacement fuse covers may be purchased from your local electrical suppliers, electricity showroom or approved service

agent.

Page 5

15

WTE...6

GB

Appliance dimensions

As required, you can changing over door hinges .

If you do not want to change the side on which the door hangs,

please move to the section Information on building in.

Important: The glass door weighs around 25 kg!

Please make sure you secure the door sufficiently

when taking it off.

Changing over door hinges

Installation

W Remove covers 1and plugs 2.

W Remove limit stop 3by unscrewing

screw 4

W Undo bearing bracket 5 by unscrewing screw 6.

- make sure that the door is made safe. If possible, have a

second person hold it.

- Avoid risk of damage to the bottom edge of the door by using

something soft on the floor.

W Now lift door from lower bolt 7of

the bearing bracket 8and lay

down carefully.

W If the handle has already been attached, undo this now.

W Now push up the bracket pin 9 by moving the bearing

bracket 5. Pull out the lifted bracket pin 9 using a pair of

pliers and put to one side.

min.

38

min.

550

560-

57

0

m

in

.

3

8

557

5

max.

210

0

1

221

-1

225

min.

200 cm

2

1218

1234

min. 200 cm²

90°

kg

➀➁➀

➄

➅

➂

➃

➇

Page 6

16

WTE...6

Information on building in

W Only build the fridge/freezer into units that are firmly fixed

W Make cupboard level using spirit level and set square. If

necessary, even out by placing something underneath. Floor

and side wall of the cupboard must be perpendicular to one

another.

W The ventilation sections must be maintained:

- The depth of the ventilation shaft on the back wall of the cupboard must be at least 38 mm.

- For the ventilation sections in the plinth of the cupboard and at

the top of the cupboard at least 200 cm2 is required. Basically:

the bigger the ventilation section, the more energy saving the

operation of the appliance.

W Check the dimensions of the appliance and recess for

building in.

W Pull the plastic plug bl out of the door bracket.

Remove the limit stop bm .

Move the limit stop bm to the new hinge side of the door.

Insert the plug bl snugly on the new handle side of the

door. Ensure that the plug is not twisted.

W Attach the handle.

W Remove bearing

bracket 8and angle

bracket 9 (if already

affixed). To do this fold

up the cover of the

angle bracket. Swap

each of the parts to the

opposite side. Screw

on the bearing bracket

8 through the third and sixth slot from the outside.

W Move bearing bracket 5 to the other side and turn through

180°. Fix bearing bracket at the side.

W Move lower bracket pin

7

W Place the door on the

lower bracket pin 7.

W Align the top of the door with

the bearing bracket 5 and

insert upper bracket pin 9.

Installation

W Fasten stop limit 3 through the

white slide element bo with screw

4

W Re-affix covers 1and plugs 2 on the opposite side.

Page 7

17

WTE...6

GB

Fastening in the kitchen cupboard

W All fasteners are supplied with the applaince.

W Attach aligning panel 1with

screws 2into the pre-bored holes

in the top of the appliance

W Stick cover strip 3 onto the side wall of the

appliance on the handle side and flush with the

front. Remove protective film and stick the strip

on. If necessary, shorten the strip to the

height of the recess.

W With 16 mm thick cupboard walls =

568 mm wide recess: Clip spacer 4

onto the bearing bracket 5in the slot

area .

- With 19 mm thick cupboard walls =

562 mm wide recess. The spacer is not

required.

W Position the mains cable using a

piece of string so that the appliance can easily be connected to

the electricity supply after it has

been built-in.

- Push the appliance 3/4 of the way

into the recess.

W Push appliance into the recess until the

lower bearing bracket 6 touches the front

of the cupboard wall. The bearing bracket

must be on the floor of the recess.

W Check the fit of the appliance and the door. If necessary, make

level:

- The appliance must lie tightly against the top of the side wall

on the hinge side.

- Align the door 6 flush to the surrounding cupboard doors using the slots in the bearing bracket.

W Screw plastic angle 7 with M5 screws

8 at the bottom of the appliance, and

align flush with the front edge of the

floor of the cupboard .

W Fasten/fix appliance in the recess with

fixing plate screws .

Through the upper bearing bracket

5screw in screw bl , pressing the

appliance firmly against the cupboard

wall.

Screw on the lower bearing

bracket 6 with screw 9 .

Screw on plastic angle

7with screw 9. Fold down

the flap of the angle.

- Attach the aligning panel 1 from below with

two screws bm

- Make sure that all screws are tightly fastened.

The manufacturer is constantly working on the development of

all models. Please understand therefore that we must reserve the

right to make changes to form, equipment and technology.

Fastening and mounting

9

10

7

4

11

8

1

2

3

1

x

1

x

2

2

x

x

1

x

4

1

4 x 29

M 5 x 15

x

x

1

x

1

x

4x19

4x14

3,5x9,5

SW 5

19 mm

3

x

➀

➁

➃

➄

➅

➆

➇

➄

➉

➈

➅

➆

➈

➀

11

➂

Page 8

18

WTE...6

Operating elements and controls

Wine storage

23 Bordeaux bottles can be stored in the upper compartment and

in the lower compartment up to 41 Bordeaux bottles .

Switching on and off

W To switch on: Press On/Off , so that the temperature displays

light up/flash.

W To switch off: Press On/Off for about a second, so that

the temperature displays go out.

Setting the temperature

The wine cooler zone can be set between 5 and 18 °C .

W The wine cooler zone is divided into two areas, which can be

set to different temperatures, if required.

The “Up” and “Down” buttons on the left of the

display control the upper compartment .

The “Up” und “Down” buttons on the right of the

display control the lower compartment.

W To lower the temperature/colder: Press the Down button.

W To raise the temperature/warmer: Press the Upbutton.

- During setting, the setting value set flashes in the display.

- When the temperature setting buttons are pressed for the first

time, the last value set appears in the display(= desired value).

- Repeated short presses on the buttons changes the value set

in 1 °C steps. longer presses change the value continuously.

- About 5 seconds after the last press of the buttons, the electronics automatically change over and the actual fridge temperature (= actual value) is displayed.

- The altered temperature gradually adjusts itself slowly to the

new value.

Temperature display

In normal operation:

- the average wine cooler temperature is displayed

The display flashes, when

- you alter the temperature setting,

- the wine cooler temperature is too cold or

- the temperature has risen by several degress, as an indication

of a loss of cold, e.g. when re-arranging the bottles. After you

have finished storing or re-arranging bottles, the electronics

automatically adjust the temperature to the last setting.

W If a “F 0” to “F 5” should appear in the display, there is a fault

with the appliance. Then please contact your Customer Care

Service and inform them of this message. This facilitates fast,

targeted service.

Alarm - Acoustic warning

The acoustic warning helps you to protect your stored wine and

to save energy.

W The acoustic tone stops when the Alarm Off button is

pressed

- automatically, when a cold enough storage temperature

is reached again or

- the door is closed.

Door alarm

- It always sounds, when the door is open for longer than about 60

seconds.

The tone remains switched off until the door is opened. When

the door is closed, the alarm function is automatically readied

again.

Temperature alarm

It always sounds, when the wine storage temperature is too warm

or too cold

The temperature display continues to flash until the alarm condition has ended. Then it switches from flashing to being permanently lit. At the same time the acoustic warning is again automatically readied for operation.

Ventilator switch

The ventilator switch increases the relative air humidity in the

wine cooler zone. This achieves an environment in the interior

which corresponds to that of a wine cellar. The increased air

humidity prevents the corks drying out.

W To switch on:

- Briefly press “Ventilation” button so that it lights up.

W To switch off: briefly press again, so that the ventilator sym-

bol in the display goes out.

The ventilator then runs only in parallel with the compressor =

lower air humidity.

Note:

- When the ventilator is switched on, energy consumption is

increased.

- To save energy, the ventilator switches off automatically when

the door is open.

1 Temperature display and settings display

2 Setting buttons for temperature, lower wine cooler zone

3 Alarm button

4 Setting buttons for temperature, upper wine cooler zone

5 On/Off button

6 Ventilator button

7Light setting

Ventilation

Light

6 5

4 1 2 3 7

Page 9

19

WTE...6

GB

Operating elements and controls

Additional functions

Via the setting mode you can use the child safety device and

change the brightness of the display. With the child safety device

you can protect the appliance against being switched off unintentionally.

To activate setting mode:

• Press ventilator button for about 5 seconds - the ventilator button flashes - the display shows c for child safety

device.

Note: The respective value to be changed flashes.

• By pressing the Up/Down button, select the desired function:

c = child safety device, h = brightness

• Now by pressing the ventilator button briefly, select/confirm

the function:

When c = child safety device

by pressing the Up/Down button, select

c1 = child safety device on or

c0 = child safety device off and confirm with the

ventilator button. When the symbol is lit, the child safety device

is active.

When h = brightness

by pressing the Up/Down button, select

h1= minimum to

h5 = maximum brightness and confirm with the venti-

lator button.

To leave setting mode:

• Press the On/Off button to end setting mode; after 2

mins. the electronics automatically switch over. Normal

operation is active again.

Equipment

Light setting dim mode

You have the option of setting the dim mode using the “Light” button. You can select the intensity with which the light shines after

the door is closed.

W If the button is not lit, after the door is closed, the light dims

slowly and then goes out completely.

W To activate the dim mode, briefly press the “Light” button,

until it lights up.

By additionally pressing the lower “Up” or “Down”

buttons,you can set the brightness.

With “Light” and “Up” the light is set more brightly,

with “Light” and “Down” the light is set more dimly.

Both wine cooler zones are controlled at the same time.

Interior light

An LED light is integrated in the upper and lower compartment.

The interior light can be switched on and off with the “Light” button.

The light may only be changed by the Customer

Care Department or by technicians trained to do so.

CAUTION

Laser radiation class 1M.

When cover is open, do not look at directly with

optical instruments.

Labels

The appliance is fittedwith one label holder per wooden shelf. Use

these labels to identify the wine

type stored on the wooden shelf.

Use a soft pencil to write on the

labels. The writing can then be

easily corrected or erased,if necessary.

Additional labels can be bought from your dealer .

Fastening: Clip the label holder on the wooden shelf at the

desired place. The label is then pushed in under the label holder

from the side.

Folding down the wooden shelf

In each wine cooler compartment

your appliance has a wooden

shelf that can be folded down. Use

this option to safely store bottles

of wine that have already been

opened.

To fold down the wooden shelf,

press the catch that is located

under the panel to the side. The

wooden shelf folds down.

Taking out the wooden shelves

The fold-down wooden shelf runs

on pull-out rails. To take out the

wooden shelf, lift the shelf upwards

off the pull-out rail and then pull it

out forwards. Make sure that the

wooden shelf does not remain

caught on the hook at the back. To

put back, push the shelf under the

hook at the back and then press

the wooden shelf onto the rails, so that they audibly engage.

All other wooden shelves are only

set on the rails and do not have to

be hooked on.

Light

Ventilation

Page 10

20

WTE...6

Cleaning

Changing the active carbon filter

Wines continue to develop all the time depending on the environmental conditions; therefore the quality of the air is of prime importance for conservation. In each wine cooler compartment an

active carbon filter is installed to ensure an optimum air throughput. To see the position, please see the appliance overview.

We recommend the annual replacement of the filter portrayed

here, which you can order from your dealer.

Changing the filter:

W Take hold of the filter by the han-

dle. Turn it 90° to the right or the

left. Then the filter can be pulled

out.

W Insert filter: Insert the filter with

the handle in a vertical position.

Turn it 90° to the right or the left,

until it engages into place.

W Before cleaning, always switch the appliance off.

Remove the mains plug from the power point or

unscrew or take out the fuses.

W

Clean external walls, interior and fittings, with the exception of the wooden shelves, by hand with lukewarm

water and a little washing up liquid. Do not use steam

cleaners - risk of injury and damage!

W Soft cleaning cloths and an all-purpose cleaner with a neutral

pH-value is recommended. Only use cleaners and maintenance

products that are not harmful to food in the interior of the appliance.

W Make sure that no cleaning water gets into the drainage chan-

nel, ventilation grills and electrical parts. Dry the appliance

with a cloth.

- Do not damage the rating plate inside the appliance or remove

it - it is important for the Customer Care Department.

W The refrigerating unit with the heat exchanger - metal grille

on the back of the appliance - should be

cleaned and dust removed once a year.

Dust deposits increase energy consumption.

W Make sure that no cables or other com-

ponents are torn, kinked or damaged.

W After this, connect/switch on the appli-

ance again and load the cooled goods

as the temperature starts to fall.

Cleaning condensation water drainage

channel

Condensed water evaporates due to the heat of the condensor

- water droplets on the back wall are caused by operation and

are completely normal.

W Make sure that the condensed water can flow unhindered

through the drainage hole in the back wall

W To clean the condensed

water drainage channel

on the back wall, do the following: Take out the wooden shelves and remove the

pull-out rails. Remove the

caps and screws from the

metal cover and place to

one side 1. Lift the metal

cover 2 and pull forwards

3. Clean the drainage

channel, if required, with a

cotton bud or similar

W Wipe the rubber lip of the

control panel with a damp

cloth and a ph-neutral cleaning agent.

If the appliance is not to be used for a while, then empty the

appliance, remove the mains plug from the power point, clean as

described and leave the appliance door open, to avoid the build

up of unpleasant smells.

1

1

2

1

2

3

Page 11

21

WTE...6

GB

Your appliance is constructed and manufactured to give functional safety and a long life.

Should however a fault occur during operation, then please

check whether the fault can possibly be due to an operator’s error, because in this case you must pay for the costs arising, even

during the warranty period.

You can remedy the following faults yourself by checking the possible causes:

Fault possible cause and remedy

Appliance is not working, display is dark

- Is the appliance switched on properly?

- Is the mains plug in the power point properly?

- Is the fuse in the plug OK?

Noises are too loud

- Is the appliance standing firmly on the floor, are units or objects standing next to it made to vibrate by the running of the

refrigerating unit? Perhaps move the appliance away a little,

even up using the adjustable feet, move bottles and containers away from one another.

- The following are normal: flowing sounds, a bubbling or

splashing, these come from the refrigerant that flows in the

refrigerant circuit.

A slight clicking sound, this always happens when the refriger-

ating unit (the motor) automatically switches on or off.

A humming motor. It is a little louder briefly, when the unit

switches itself on. After the door has been open a long time,

the refrigerating capacity automatically increases.

Alarm sounds, temperature is not cold enough

- Is the appliance door closed properly?

- Is the ventilation sufficient?

Perhaps free up the ventilation grilles.

- Is the ambient temperature too warm?

(see section “Definitions”)

- Has the appliance been open too often or for too long?

- Perhaps wait and see if the required temperature is re-set by

itself.

- Please be aware that, as with other forms of storage, depending on the type of label adhesive, a slight mould can form. The

remedy in this case is to carefully clean adhesive residues

from the bottles.

Appliance sometimes feels warm on the outside surfaces

- This is completely normal. The heat of the refrigerant circuit is

used to prevent condensation.

Faults - Problems?

Your old appliance: This contains some reusable

materials and should be disposed of properly - not

simply with unsorted household refuse.

•

Discarded appliances should be disabled: Remove

the plug, cut through the connection cable and

render the catch unusable so that children cannot

become trapped inside.

•

Ensure that the refrigerant circuit is not damaged when the

appliance that is no longer needed is taken away for disposal.

•

Details of the refrigerant can be found on the type plate.

•

Appliances which are no longer needed must be disposed of

in a professional and appropriate way, in accordance with the

current local regulations and laws.

When there are none of the above causes and you have

not been able to remedy the problem yourself or when

a “F 0” to “ F 5” appears in the temperature display, this

means: there is a fault. In this case, contact your nearest

Customer Service Centre (directory enclosed). Inform them of

this message, also the

name of the appliance 1,

service number2,

appliance number 3

from the rating plate. This facilitates fast,

targeted service. The rating plate is located

on the left-hand side inside the appliance.

Leave the appliance closed until the Customer Care Department engineer arrives, to prevent a further loss

of cold.

Disposal

Customer Care Department and rating plate

Loading...

Loading...