Page 1

Precision Cooling

For Business-Critical Continuity™

Liebert VFD Condenser — Model TCDV

Product Information Manual - 50/60Hz

™

Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 DIMENSIONAL AND ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.0 GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Fan Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Head Pressure Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.7 TVSS and Unit Disconnect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.8 Alarm Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.9 Electrical Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FIGURES

Figure 1 Liebert Model TCDV Condenser—2-fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2 Major electrical control components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 3 Cabinet and anchor dimensional data—VFD control condensers, 50 and 60Hz. . . . . . . . . . . . . . . 5

Figure 4 Electrical field connections, VFD control condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TABLES

Table 1 Electrical data—50 and 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2 VFD condensers for indoor units, 50 and 60Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 3 Condenser performance, 60Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 4 Condenser performance, 50Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 5 Physical data—VFD control condensers, 50 and 60Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

i

Page 4

ii

Page 5

1.0 INTRODUCTION

1.1 Description

The Liebert VFD Control Condenser, Model TCDV, is an air cooled direct-drive refrigeration condenser designed to reject the heat from a precision air conditioning unit to the outdoor air. The condenser uses a Variable Frequency Drive (VFD) to control fan speed, which provides positive

refrigerant head pressure control for outdoor ambients as low as -20°F (-28.9°C).

Figure 1 Liebert Model TCDV Condenser—2-fan

Introduction

1.2 Application

The VFD Control Condenser is applied to precision air conditioning units with dual refrigeration circuits, including units with digital scroll compressors.

1.3 Features and Benefits

• Variable Frequency Drive (VFD)—Programmed at the factory to integrate fluctuating head pressure signals created by compressor unloading, including digital scroll compressors, and varying

condenser capacity created by lower ambient temperatures.

• The VFD adjusts fan speed to provide stable fan speeds and condensing temperatures.

• Provides protection for motor overload and incoming power supply phase loss, undervoltage

and overvoltage.

• Built-in EMC filter—Electromagnetic emission levels comply with EN61800-3 (Second Environment - Light Industrial Applications).

• Inverter duty motor with permanently lubricated ceramic ball bearings for reliability

• Transducers on each circuit sense refrigerant pressures, providing input to the VFD

• Standard TVSS—Transient Voltage Surge Suppression increases condenser reliability by building in a layer of electrical protection against electrical failure caused by transient voltage surges

from unconditioned power sources and atmospheric discharges.

• Standard Locking disconnect

• Contacts for monitoring VFD and TVSS alarm conditions

• Available in 2-, 3- or 4-fan, dual-circuit condenser models

1

Page 6

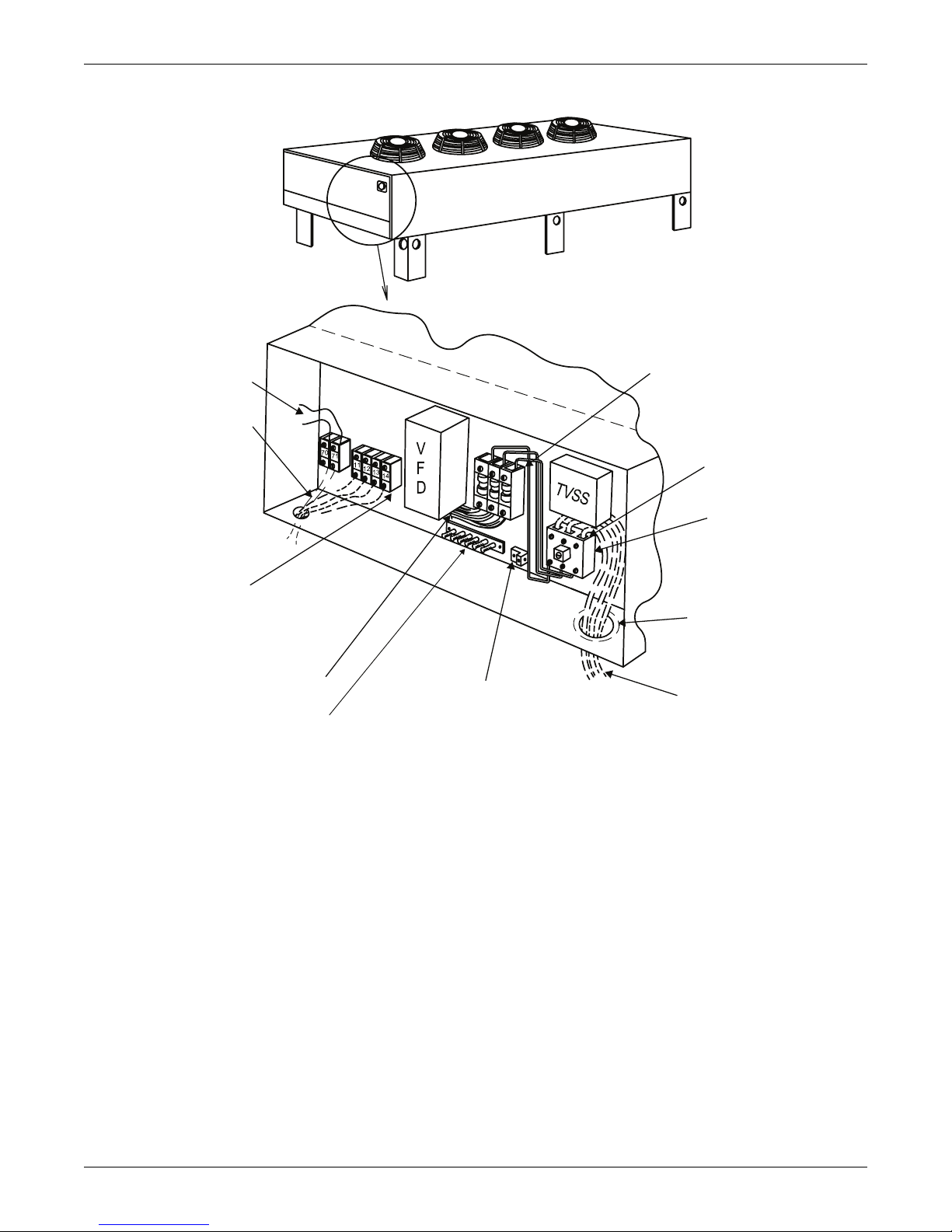

Figure 2 Major electrical control components

Variable

Frequency

Drive control

Table 1 Electrical data—50 and 60 Hz

Model # 165, 205 251, 308 415, 510

Number of Fans 2 3 4

Input Voltage Ph Hz Motor Hp FLA WSA OPD FLA WSA OPD FLA WSA OPD

208/230

460 3.5 4.0 15 5.2 5.7 15 6.9 7.4 15

200/230

380/415 3.5 * * 5.2 * * 6.9 * *

FLA = Full Load Amps; WSA = Wire Size Amp; OPD = Maximum Overcurrent Protection Device Rating

* = Follow local electrical code to determine WSA and OPD

60

3

0.75

50

Introduction

Liebert’s

Transient

Vol tag e

Surge

Suppression

Locking

Disconnect

7.2 8.1 15 10.7 11.6 15 14.2 15.1 20

7.2 * * 10.7 * * 14.2 * *

Table 2 VFD condensers for indoor units, 50 and 60Hz

R-22 R-407C

Outdoor Design Ambient Temperature

Indoor Unit

DH/VH75A N/A N/A TCDV165 N/A N/A N/A

DH/VH114A TCDV165 TCDV165 TCDV205 N/A N/A N/A

DH/VH125A TCDV165 TCDV165 TCDV205 N/A N/A N/A

DH/VH199A TCDV205 TCDV308 TCDV308 N/A N/A N/A

DH/VH245A TCDV308 TCDV308 TCDV415 N/A N/A N/A

DH/VH290A TCDV308 TCDV415 TCDV415 N/A N/A N/A

DH/VH380A TCDV415 TCDV510 N/A N/A N/A N/A

DS/VS028A TCDV165 TCDV165 TCDV205 TCDV205 TCDV205 TCDV251

DS/VS035A TCDV165 TCDV205 TCDV205 TCDV205 TCDV205 TCDV251

DS/VS042A TCDV205 TCDV205 TCDV308 TCDV205 TCDV251 TCDV308

DS/VS053A TCDV205 TCDV308 TCDV308 TCDV251 TCDV308 TCDV415

DS/VS070A TCDV308 TCDV415 TCDV415 TCDV308 TCDV415 TCDV415

DS/VS077A TCDV308 TCDV415 TCDV510 TCDV308 TCDV415 TCDV510

DS/VS105A TCDV415 TCDV510 N/A TCDV415 N/A N/A

95°F (35°C) 100°F (38°C) 105°F (41°C) 95°F (35°C) 100°F (38°C) 105°F (41°C)

2

Page 7

Table 3 Condenser performance, 60Hz

Total Heat Rejection BTU/Hr (kW) Based on TD

Introduction

Model

Number

R-22 Refrigerant

TCDV165

TCDV205

TCDV251

TCDV308

TCDV415

TCDV510

R-407C Refrigerant

TCDV165

TCDV205

TCDV251

TCDV308

TCDV415

TCDV510

TD = Difference between Entering Air Temperature and Condensing Temperature

30°F TD

(16.7°C)

178,410

(52.2)

264,930

(77.6)

298,170

(87.3)

384,180

(112.5)

507,690

(148.7)

552,240

(161.7)

143,160

(41.9)

242,100

(70.9)

277,380

(81.2)

337,890

(98.9)

472,320

(138.3)

452,820

(132.6)

25°F TD

(13.9°C)

148,675

(43.5)

220,775

(64.6)

248,475

(72.8)

320,150

(93.7)

423,075

(123.9)

460,200

(134.8)

119,300

(34.9)

201,750

(59.1)

231,150

(67.7)

281,575

(82.4)

393,600

(115.3)

377,350

(110.5)

20°F TD

(11.1°C)

118,940

(34.8)

176,620

(51.7)

198,780

(58.2)

256,120

(75.0)

338,460

(99.1)

368,160

(107.8)

95,440

(27.9)

161,400

(47.3)

184,920

(54.1)

225,260

(66.0)

314,880

(92.2)

301,880

(88.4)

15°F TD

(8.3C)

89,205

(26.1)

132,465

(38.8)

149,085

(43.7)

192,090

(56.2)

253,845

(74.3)

276,120

(80.9)

71,580

(21.0)

121,050

(35.4)

138,690

(40.6)

168,945

(49.5)

236,160

(69.2)

226,410

(66.3)

1°F TD

(0.6°C)

5,947

(3.1)

8,831

(4.7)

9,939

(5.2)

12,806

(6.7)

16,923

(8.9)

18,408

(9.7)

4772

(2.5)

8070

(4.3)

9246

(4.9)

112 63

(5.9)

15744

(8.3)

15094

(8.0)

CFM

(CMH)

13,300

(22,597)

11,200

(19,029)

20,250

(34,405)

18,600

(31,602)

24,800

(42,135)

19,200

(32,621)

13,300

(22,597)

11, 200

(19,029)

20,250

(34,405)

18,600

(31,602)

24,800

(42,135)

19,200

(32,621)

Sound

dBA

75.5 2

77.3 3

78.5 4

75.5 2

77.3 3

78.5 4

Fan

Qty

3

Page 8

Table 4 Condenser performance, 50Hz

Total Heat Rejection BTU/hr (kW) based on TD

Introduction

Model

Number

30°F TD

(16.7°C)

25°F TD

(13.9°C)

20°F TD

(11.1°C)

15°F TD

(8.3°C)

R-22 Refrigerant

TCDV165

TCDV205

TCDV251

TCDV308

TCDV415

TCDV510

162,660

(47.6)

233,040

(68.2)

270,150

(79.1)

343,080

(100.5)

454,680

(133.1)

479,040

(140.3)

135,550

(39.7)

194,200

(56.9)

225,125

(65.9)

285,900

(83.7)

378,900

(110.9)

399,200

(116.9)

108,440

(31.8)

155,360

(45.5)

180,100

(52.7)

228,720

(67.0)

303,120

(88.8)

319,360

(93.5)

81,330

(23.8)

116,520

(34.1)

135,075

(39.6)

171,540

(50.2)

227,340

(66.6)

239,520

(70.1)

R-407C Refrigerant

TCDV165

TCDV205

TCDV251

TCDV308

TCDV415

TCDV510

TD = Difference between Entering Air Temperature and Condensing Temperature

129,960

(38.1)

212,280

(62.2)

250,920

(73.5)

301,950

(88.4)

422,400

(123.7)

391,800

(114.7)

108,300

(31.7)

176,900

(51.8)

209,100

(61.2)

251,625

(73.7)

352,000

(103.1)

326,500

(95.6)

86640

(25.4)

141520

(41.4)

167280

(49.0)

201300

(58.9)

281600

(82.5)

261200

(76.5)

64,980

(19.0)

106,140

(31.1)

125,460

(36.7)

150,975

(44.2)

211,200

(61.8)

195,900

(57.4)

1°F TD

(0.6°C)

5,422

(2.9)

7,768

(4.1)

9,005

(4.7)

11,436

(6.0)

15,156

(8.0)

15,968

(8.4)

4,332

(2.3)

7,076

(3.7)

8,364

(4.4)

10,065

(5.3)

14,080

(7.4)

13,060

(6.9)

CFM

(CMH)

11,100

(18,859)

9,300

(15,801)

16,800

(28,543)

15,450

(26,250)

20,600

(35,000)

16,000

(27,184)

11,100

(18,859)

9,300

(15,801)

16,800

(28,543)

15,450

(26,250)

20,600

(35,000)

16,000

(27,184)

Sound

dBA

71.0 2

72.8 3

74.0 4

71.0 2

72.8 3

74.0 4

Fan

Qty

4

Page 9

Dimensional and Electrical Data

2.0 DIMENSIONAL AND ELECTRICAL DATA

Figure 3 Cabinet and anchor dimensional data—VFD control condensers, 50 and 60Hz

Eyebolts for lifting condenser

Provided on four-fan models only

A

m

8

7

7

(

1

"

0

7

)

m

43-9/16"

(1107mm)

37-7/8"

(962mm)

18" (457mm)

Heigh t to top

of fan guard:

43-1/8" (1095mm)

(1097mm)

C

43-3/16"

Unit Anchor Plan

Disconnect

Switch

Cabinet Dimensions

B

D

4 legs furnished for 2- and 3-fan

models

6 legs furnished for 4-fan models

Clearance of 36" (914.4mm) on all

sides is recommended for proper

operation and component access

37-11/16"

(957mm)

Typical Diameter

9/16" (14.3mm)

1-7/8”

(47.6mm)

1-7/8”

(47.6mm)

4-1/4”

(108mm)

1-3/4”

(44.5mm)

Table 5 Physical data—VFD control condensers, 50 and 60Hz

Number

Model #

TCDV165 2 91-1/2 (2324) 84 (2134) 82 (2083) -- 425 (193)

TCDV205 2 91-1/2 (2324) 84 (2134) 82 (2083) -- 495 (225)

TCDV251 3 131-1/2 (3340) 124 (3150) 122 (3099) -- 500 (227)

TCDV308 3 131-1/2 (3340) 124 (3150) 122 (3099) -- 670 (305)

TCDV415 4 171-1/2 (4356) 164 (4166) 82 (2083) 80 (2032) 815 (370)

TCDV510 4 171-1/2 (4356) 164 (4166) 82 (2083) 80 (2032) 1188 (540)

All condenser fan motors are 3/4 hp

of Fans

4-1/4”

(108mm)

Typical Footprint

1-3/4”

(44. 5mm)

DPN001049

Rev. 0

A B C D Net Weight

in (mm) in (mm) in (mm) in (mm) lb (kg)

5

1”

(25.4mm)

Page 10

Figure 4 Electrical field connections, VFD control condensers

A

Factory-wired to 24V

control circuit.

Control interlock (70, 71)

Field-supplied

Class 1 wiring to

interlock condenser 24V

controls to Liebert

room unit; 7/8 in.

(22.2mm) diameter

hole provided in

bottom of electric box.

larm Connections

Field-supplied 24V Class 1

wiring to remote alarm circuits

Variable Frequency Drive (VFD)

alarm contact connections (11, 12)

Transient Voltage Surge Suppressor (TVSS)

alarm contact connections (13, 14).

Factory wired to components

on electric panel.

Earth ground bar (optional on 50Hz only).

Connection terminals with factory

ground from each high voltage

component for field-supplied

earth grounding wire.

NOTE: Refer to specification sheet for Full Load Amp and Wire Size Amp ratings.

Earth ground connection (60Hz).

Connection terminal for

field-supplied earth grounding wire

when factory disconnect is supplied.

Dimensional and Electrical Data

Factory-installed fuse block on

60Hz units. Circuit breaker supplied

in lieu of fuse block on 50Hz units.

Electric service connection

terminals with factorysupplied disconnect.

Factory-installed

disconnect switch.

Electric service entrance.

A 7/8" (22.2mm) diameter

hole in a 1-1/8 in (28.6mm)

knockout provided in bottom

of electric box.

Electric service,

not by Liebert

DPN001051

Rev. 0

6

Page 11

3.0 GUIDE SPECIFICATIONS

3.1 General

Each condenser shall consist of housing, condenser coil, propeller fans direct-driven by individual fan

motors, fan guards, electrical controls and mounting legs. The air-cooled condenser shall have a

_____volt, 3-phase, _____ Hz power supply.

3.2 Coil

Liebert manufactured coil shall be constructed of copper tubes in a staggered tube pattern. Tubes are

expanded into continuous, corrugated aluminum fins. The fins have full depth fin collars completely

covering the copper tubes, which are connected to heavy wall Type "L" headers. Inlet coil connector

tubes pass through relieved holes in the tube sheet for maximum resistance to piping strain and

vibration. Coils are factory leak-tested at a minimum of 300 psig (2068kPag), dehydrated, then filled

with a nitrogen holding charge and sealed for shipment.

3.3 Fans

Fans shall have aluminum blades secured to corrosion protected steel hubs. Fans shall be secured to

the fan shaft by means of a heavy-duty keyed hub and dual setscrews. Fan diameter shall be 26"

(660mm) or less. Fans shall be factory balanced and run before shipment. Fan guards shall be heavy

gauge, close-meshed steel wire with corrosion resistant PVC finish that shall be rated to pass a

675-hour salt spray test.

Guide Specifications

3.4 Fan Motors

The variable speed fan motor shall be an inverter duty motor with permanently lubricated ceramic

bearings. The Liebert variable frequency drive control system shall provide overload protection for

the variable speed motor. Each ambient-temperature-controlled fan motor shall have built-in overload protection. All motors shall have rain slingers, permanently lubricated bearings and shall be rigidly mounted on die-formed galvanized steel supports.

3.5 Head Pressure Control

The Liebert VFD Condenser control system shall include a variable frequency drive, inverter duty fan

motor operating from 0% to 100% motor RPM based on head pressure, refrigerant pressure transducers, ambient-temperature thermostat(s), motor overload protection and electrical control circuit, factory-wired in the control panel. VFD control shall be furnished on the fan adjacent to the connection

end of the condenser, which runs continuously with the compressors. Other condenser fans shall be

controlled by ambient thermostats and are either On or Off. This system permits operation at temperatures as low as -20°F (-28.9°C).

3.6 Housing

The condenser housing shall be constructed of bright aluminum sheet and divided into individual fan

sections by full width baffles. Structural support members, including coil support frame, motor and

drive support, are galvanized steel for strength and corrosion resistance. Aluminum legs are provided

with rigging holes for hoisting the unit into position.

3.7 TVSS and Unit Disconnect Switch

Transient Voltage Surge Suppression and locking disconnect shall be factory-installed and wired in

the enclosed condenser electrical panel section.

3.8 Alarm Contacts

Normally open, dry contacts shall be provided for indication of VFD and TVSS alarm condition.

3.9 Electrical Controls

All electrical connections and controls shall be provided in a weatherproof enclosure. The enclosure

shall be integral with the condenser for pleasing appearance as well as functional protection.

7

Page 12

Ensuring The High Availability

0f Mission-Critical Data And Applications.

Emerson Network Power, the global leader in enabling business-critical

continuity, ensures network resiliency and adaptability through

a family of technologies—including Liebert power and cooling

technologies—that protect and support business-critical systems.

Liebert solutions employ an adaptive architecture that responds

to changes in criticality, density and capacity. Enterprises benefit

from greater IT system availability, operational flexibility and

reduced capital equipment and operating costs.

While every precaution has been taken to ensure the accuracy

and completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use of

this information or for any errors or omissions.

© 2007 Liebert Corporation

All rights reserved throughout the world. Specifications subject to change

without notice.

® Liebert and the Liebert logo are registered trademarks of Liebert

Corporation. All names referred to are trademarks

or registered trademarks of their respective owners.

Technical Support / Service

Web Site

www.liebert.com

Monitoring

800-222-5877

monitoring@emersonnetworkpower.com

Outside the US: 614-841-6755

Single-Phase UPS

800-222-5877

upstech@emersonnetworkpower.com

Outside the US: 614-841-6755

Three-Phase UPS

800-543-2378

powertech@emersonnetworkpower.com

Environmental Systems

800-543-2778

Outside the United States

614-888-0246

Locations

United States

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

Europe

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD) Italy

+39 049 9719 111

Fax: +39 049 5841 257

Asia

7/F, Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 2572220

Fax: 852 28029250

SL-10065 _REV0_12-06

Emerson Network Power.

The global leader in enabling Business-Critical Continuity.

AC Power

Connectivity

DC Power

Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co.

©2007 Emerson Electric Co.

Embedded Computing

Embedded Power Power Switching & Controls

Monitoring

Outside Plant

Precision Cooling

EmersonNetworkPower.com

Racks & Integrated Cabinets

Services

Surge Protection

Loading...

Loading...