Liebert Series 600T Installation Manual

POWER AVAILABILITY

Series 600T™ UPS

INSTALLATION MANUAL

Single Module

Three-Phase

65-225 kVA

60 Hz

The following WARNING applies to all battery cabinets supplied

with UPS systems:

INTERNAL BATTERY STRAPPING MUST BE VERIFIED BY MANUFACTURER PRIOR TO MOVING A BATTER Y CABINET.

Battery cabinets contain non-spillable batteries.

Keep units upright.

Do not stack.

Do not tilt.

Failure to heed this warning could result in smoke, fire or electric

hazard. Call 1-800-LIEBERT prior to moving battery cabinets.

INSTALLATION MANUAL

TABLE OF CONTENTS

1. SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. INSTALLATION CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. UNLOADING AND HANDLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.1. External Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.2. Internal Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. EQUIPMENT LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. BATTERY INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.1. Battery Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.2 Battery Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.3 Open-Rack Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. CONFIGURING YOUR NEUTRAL AND GROUND CONNECTIONS . . . . . . . . . . . . . . . . . . . . . 7

7.1. Preferred Grounding Configuration, Isolated Power Distribution Units. . . . . . . . . . . . . . 8

7.2. Alternative Grounding Configuration, Isolated Power Distribution Units, . . . . . . . . . . . 9

7.3. Preferred Grounding Configuration, 480 or 600 VAC Input, 208VAC Output . . . . . . . . . 10

7.4. Preferred Grounding Configuration, 208 VAC Input and Output, Non-Isolated Load . . .11

7.5. Grounding Configuration, Delta Source or Impedance-Grounded Wye . . . . . . . . . . . . . . 12

7.6. Preferred Grounding Configuration with Power-Tie™ Switchgear . . . . . . . . . . . . . . . . . 13

7.7. Preferred Grounding Configuration, Battery Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8. WIRING CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1. Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.2. Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3. Battery Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9. WIRING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.1 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.2 Specific Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10. WIRING INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

!

WARNING

LOCATE CENTER OF GRAVITY SYMBOLS

AND DETERMINE UNIT WEIGHT BEFOR E HANDLING CABINET

If you require assistance for any reason, call the toll-free Liebert Global Services number,

1-800-543-2378. Please have the following information available:

Part Number: ________________________________________________________

Serial Number: ________________________________________________________

kVA Rating ________________________________________________________

kW Rating ________________________________________________________

Date Purchased ________________________________________________________

Date Installed ________________________________________________________

Location: ________________________________________________________

Input Voltage ________________________________________________________

Output Voltage ________________________________________________________

Battery Reserve Time: __________________________________________________

i

TABLES

Table 1. Power Wiring Terminals - Factory Supplied ..............................................................................22

Table 2. Torque Specifications...................................................................................................................22

Table 3. Field-Supplied Lugs.....................................................................................................................23

Table 310-16, NEC Allowable Ampacities of Insulated Conductors............................................................24

FIGURES

Figure 1. Preferred Grounding Configuration, 480 or 600 VAC input and output . . . . . . . . . . . . . . . . . . . 8

Figure 2. Alternative Grounding Configuration, 480 or 600 VAC input and output . . . . . . . . . . . . . . . . . 9

Figure 3. Preferred Grounding Configuration, 480 or 600 VAC input and 208 VAC output . . . . . . . . . . 10

Figure 4. Preferred Grounding Configuration, 208 VAC input and output . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 5. Preferred Grounding Configuration with Delta Source Input . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6. Preferred Grounding Configuration, Power-Tie™ Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 7. Preferred Battery Cabinet Grounding Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

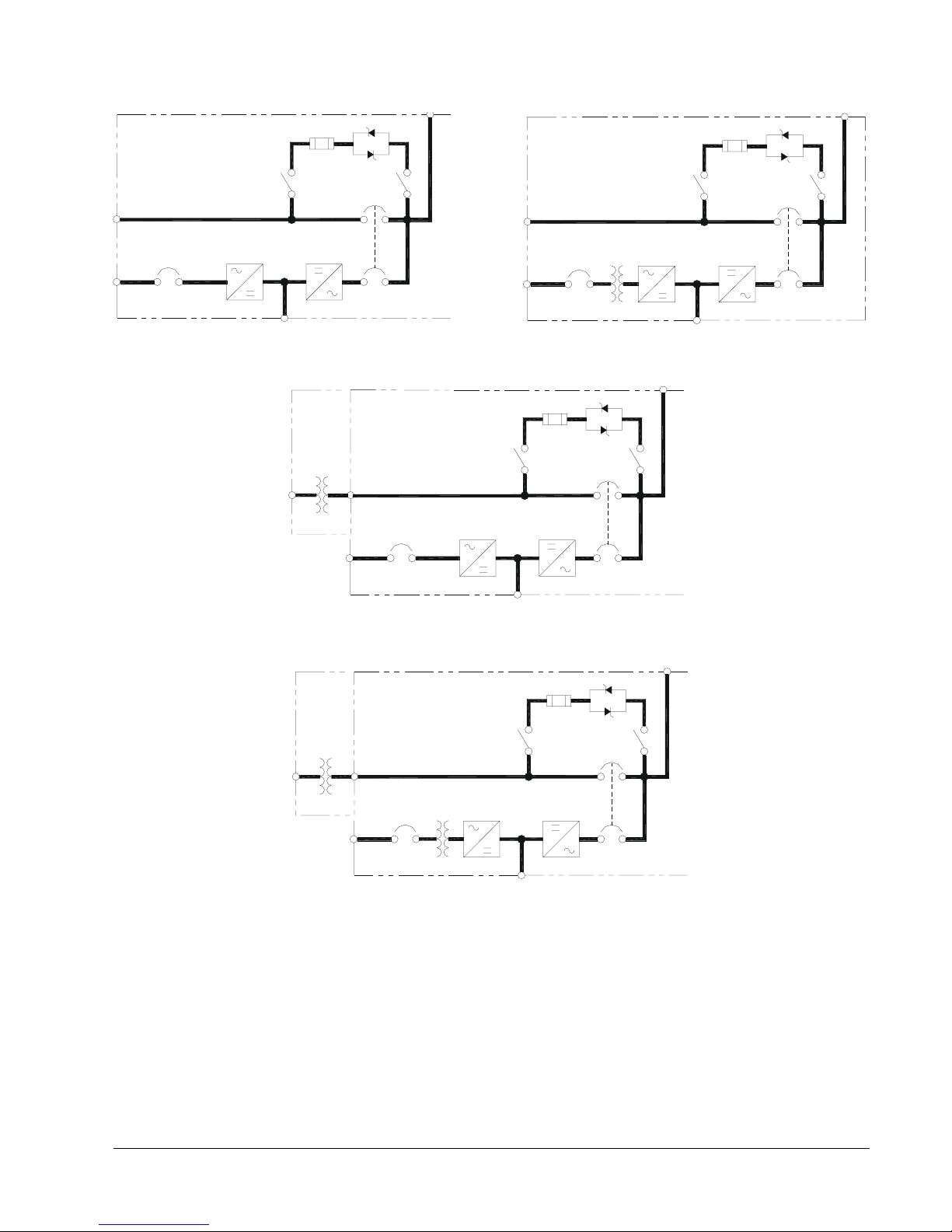

Figure 8. Typical One-Line Diagrams for SMS with Standard Dual Input . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. Typical One-Line Diagrams of SMS with optional single input. . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 10. Typical One-Line Diagrams of SMS with optional Maintenance Bypass Cabinets . . . . . . . . 18

Figure 11. Outline Drawing Single and Multi Module 65 & 80 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 12. Outline Drawing, 100 through 225 kVA Module with SpaceSaver Top-Entry Configuration 26

Figure 13. Outline Drawing, 100 through 225 kVA Module with Standard Top & Bottom Entry . . . . . . 27

Figure 14. Bypass Transformer Cabinet, 65 & 80 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 15. Bypass Transformer Cabinet, 100-225 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 16. Battery Power Pack, 65 & 80 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17. Battery Power Pack, Size A, 100-225 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 18. Outline Drawing, 3-Breaker MBC, 65 & 80 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 19. Outline Drawing, 3-Breaker MBC with Bypass Transformer, 65 & 80 kVA . . . . . . . . . . . . . . 33

Figure 20. Outline Drawing, 3-Breaker MBC, 125-350 Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 21. Outline Drawing, 3-Breaker MBC, 450 to 800 Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 22. Outline Drawing, 3-Breaker MBC, 600-800 Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 23. Line-up Detail, 65 & 80 kVA SMS with Bypass Transformer Cabinet . . . . . . . . . . . . . . . . . . 37

Figure 24. Line-up Detail, 100-225 kVA Space Saver with Bypass Transformer Cabinet . . . . . . . . . . . . 38

Figure 25. Line-up Detail, 100-225 kVA Standard SMS with Bypass Transformer Cabinet . . . . . . . . . . 39

Figure 26. Line-up Detail, 65 & 80 kVA SMS with Battery Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 27. Line-up Detail, 100-225 kVA Space Saver with Battery Cabinets . . . . . . . . . . . . . . . . . . . . . . 41

Figure 28. Line-up Detail, 100-225 kVA Standard SMS with Battery Cabinets . . . . . . . . . . . . . . . . . . . . 42

Figure 29. Line-up Detail, 65 & 80 kVA with 3-Breaker MBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 30. Line-up Detail, 65 & 80 kVA with Bypass Transformer and 3-Breaker MBC . . . . . . . . . . . . 44

Figure 31. Line-up Detail, 100-225 kVA Space Saver with 3-Breaker MBC . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 32. Line-up Detail, 100-225 kVA Space Saver with Bypass Cabinet and 3-Breaker MBC . . . . . . 46

Figure 33. Line-up Detail, 100-225 kVA with 3-Breaker MBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 34. Line-up Detail, 100-225 kVA with Bypass Transformer Cabinet and 3-Breaker MBC . . . . . 48

Figure 35. Terminal Details, 65 & 80 kVA Single Module Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 36. Terminal Details, 100 & 125 kVA Space Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 37. Terminal Details, 150 & 225 kVA Standard SMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 38. Terminal Details, 100 & 125 kVA Standard SMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 39. Terminal Details, 150 & 225 kVA Standard SMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 40. Control Connection Locations, 65 & 80 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 4

Figure 41. Control Connection Locations, 100 through 225 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 42. Standard Control Wiring, Single Module System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 43. Option Wiring, Alarm Status Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 44. Option Wiring, Maintenance Bypass Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 45. Option Wiring, Remote Status Panel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 46. Option Wiring, Remote Terminal IFM (RS-232 Communications) . . . . . . . . . . . . . . . . . . . . . 60

Figure 47. Option Wiring, SiteScan Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 48. Option Wiring, Customer Alarm Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 49. Option Wiring, Battery Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 50. Option Wiring, SNMP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 51. Option Wiring, Internal Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 52. Option Wiring, Maintenance Bypass Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 53. Module Battery Disconnect, 65 through 125 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 54. Module Battery Disconnect, 150 & 225 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 55. Remote Status Panel, Surface Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 56. Circuit Breaker Schedule, 65 through 225 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 57. Circuit Breaker Schedule, Battery Cabinets, 65 to 500 kVA . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 58. Circuit Breaker Schedule, Maintenance Bypass Cabinet, 65 through 225 kVA . . . . . . . . . . . 72

iii

INSTALLATION

1. SAFETY PRECAUTIONS

Read this manual thoroughly, paying special

attention to the sections that apply to you, before

working with the UPS. Retain this manual for

use by installing personnel.

Under typical operation and with all UPS doors

closed, only normal safety precautions are

necessary. The area around the UPS system should

be kept free from puddles of water, excess

moisture, or debris.

Special safety precautions are required for

procedures involving handling, installation, and

maintenance of the UPS system or the battery.

Observe all safety precautio n s in this manual

before handling or installing the UPS system.

Observe all precau t ion s in the Operation and

Maintenance Manual, before and during

performance of all maintenance proced ures.

Observe all battery safe ty precautions before

working on or near the battery.

This equipment contains several circuits that

are energized with high voltage. Only test

equipment designated for troubleshooting should

be used. This is particularly true for oscilloscopes.

Always check with an AC and DC voltmeter to

ensure safety before making contact or using tools.

Even when the power is turned Off, dangerously

high potentials may exist at the capacitor banks

and at the batteries.

when performing the actions described by that

text.

A Danger signals immediate hazards resulting in

severe personal injury or death. For example:

DANGER

A DANGER SIGNALS IMMEDIATE

HAZARDS WHICH WILL RESULT IN

SEVERE PERSONAL INJURY OR DEATH.

A Warning signals the presence of a possible

serious, life-threatening condition. For example:

WARNING

LETHAL VOLTAGES MAY BE PRESENT

WITHIN THIS UNIT EVEN WHEN IT IS

APPARENTLY NOT OPERATING.

OBSERVE ALL CAUTIONS AND

WARNINGS IN THIS MANUAL. FAILURE

TO DO SO COULD RESULT I N SERIOUS

INJURY OR DEATH. D O NOT WO RK ON O R

OPERATE THIS EQUIPMENT UNLESS

YOU ARE FULLY QUALIFIED TO DO SO!!

NEVER WORK ALONE.

A Caution indicates a condition that could

seriously damage equipment and possibly injure

personnel. For example:

ONLY qualified service personnel should

perform maintenance on the UPS system.

When performing maintenance with any part of

the equipment under power, service personnel and

test equipment should be standing on rubber mats.

The service personnel should wear insulat ing

shoes for isolation from direct contact with the

floor (earth ground).

Unless all power is removed from the equipment,

one person should never work alone. A second

person should be standing by to assist and

summon help in case an accident should occur.

Four types of messages are used throughout the

manual to stress important text. Carefully read the

text below each Danger, Warning, Caution, and

Note and use professional sk ills and prudent care

Liebert Series 600T UPS, 65-225 kVA, Single Module 1

CAUTION

Extreme care is necessary when removing

shoring braces. Do not strike the cabinet

with hammers or other tools.

A Note emphasizes important text. If the note is

not followed, equipment could be damaged or may

not operate properly. For example:

NOTE

If the UPS system has a blown fuse, the

cause should be determined before you

replace the fuse. Contact Liebert Global

Services.

2. INSTALLATION CONSIDERATIONS

Install your Series 600T UPS in accordance

with the submittal drawing package and the

following procedures.

A Liebert authorized representative must

perform the initial system check-out and startup to ensure prop er sy st e m ope rat ion .

Equipment warranties will be voided unless

system start-up is performed by a Liebert

authorized representative. Contact your local

Liebert sales representative or Liebert Global

Services at 1-800-543-2378 to arrange for

system start-up.

CAUTION

Read this manual thoroughly before

attempting to wire or operate the unit.

Improper installation is the most

significant cause of UPS start-up

problems.

Do not install this equipment near gas

or electric heaters. It is preferable to

install the UPS in a restricted location

to prevent access by unauthorized

personnel.

1. Proper planning will speed unloading,

location, and connection of the UPS. Refer

to Figures 11 through 58 and the Site

Planning Data (Appendix A).

2. Be certain that the floor at the final

equipment location and along the route

(inside the facility) to the installation site

can support the cabinet weight an d the

weight of any material handling

equipment. The UPS modules can weigh

up to two tons. The battery cabinets weigh

between 2300 and 5000 pounds each.

4. Refer to information later in this manual

regarding the optional Battery Cabinet(s),

Maintenance Bypass Cabinets,

Panelboards and Switchboa rds. Observe

all battery safety precautions when

working on or near the battery.

5. Use the shortest output distribution cable

runs possible, consistent with logical

equipment arrangements and with

allowances for future additions if planned.

6. Recommended ambient operating

temperature is 25C (77F). Relative

humidity must be less than 95%, noncondensing. Note that room ventilation is

necessary, but air conditioning may not be

required. Maximum ambient operating

temperature for the UPS and switchgea r is

40C (104F) without derating. The

batteries should not exceed 25 C (77F). At

elevations above 4,000 feet (1219 meters)

temperature derating may be required for

full power output (consult your Liebert

sales representative).

7. Even though your Li ebert UPS unit is 92.5

to 94% efficient, the heat output is

substantial. For more specific information,

see the Site Planning Data (Appendix A).

Be sure environmental conditioning

systems can accommodate this BTU load,

even during utility outages.

8. The installer should attempt to balance the

load between the three out put phases . The

UPS will operate safely with an unbalanced load, but will give optimum performance if the three output phases are

loaded within 20 percent of each other.

3. Plan the routing to ensure that the unit

can move through all aisle ways, doorways,

and around corners without risking

damage. If the modules and batteries must

be moved by elevator, check the size of the

door openings and the weight-carrying

capacity of the elevator.

2 Installation Manual

3. UNLOADING AND HANDLING

4. INSPECTIONS

Because the weight distribution in each UPS and

ancillary cabinet is uneven, use extreme care

during handling and transport. Your installation

may also include Battery Cabinets, a Bypass

Transformer Cabinet and a Maintenance Bypass

Cabinet, Panelboard or Switchboard.

WARNING

EXERCISE EXTREME CARE WHEN

HANDLING UPS CABINETS TO AVOID

EQUIPMENT DAMAGE OR INJURY TO

PERSONNEL. THE UPS MODU LE CAN

WEIGH UP TO TWO TONS. THE BATTERY

CABINETS WEIGH UP TO 5100 POUNDS.

THE UPS MODULES ARE HEAVIER IN

THE BACK THAN THE FRONT BECAUSE

OF THE WEIGHT OF THE MAGNETICS.

LOCATE CENTER OF GRAVITY SYMBOLS

BEFORE HANDLING CABINET. TEST LIFT

AND BALANCE THE CABINET BEFORE

TRANSPORTING. MAINTAIN MINIMUM

TILT FROM VERTICAL AT ALL TIMES.

4.1. External Inspections

1. While the UPS system is still o n the truck,

inspect the equi p men t and shi ppin g

container(s) for any signs of damage or

mishandling. Do not attempt to install the

system if damage is apparent. If any damage is

noted, file a damage claim with the shipping

agency within 24 hours and contact Liebert

Global Services at 1-800-543-2378 to inform

them of the damage claim an d the cond it ion of

the equipment.

2. Locate the bag co ntaining the keys fo r the front

access door. The bag is attached to the cabinet.

3. Compare the contents of the shipment with the

bill of lading. Report any missing items to the

carrier and to Liebert Global Services

immediately.

4. Check the nameplate on the cabinet to verify

that the model number corresponds with the

one specified. Record the model number and

serial number in the front of this installation

manual. A record of this information is

necessary should servicing become required.

WARNING

INTERNAL BATTERY CABINET

STRAPPING MUST BE VERIFIED BY

MANUFACTURER PRIOR TO MOVING

THIS UNIT.

THIS UNIT CONTAINS NON-SPILLABLE

BATTERIES. KEEP UNIT UPRIGHT. DO

NOT STACK. DO NOT TIP.

FAILURE TO HEED THIS WARNING

COULD RESULT IN SMOKE, FIRE OR

ELECTRICAL HAZARD. CALL 1-800LIEBERT PRIOR TO RELOCATING

BATTERY CABINET (AFTER INITIAL

INSTALLATION).

4.2. Internal Inspections

1. Verify that all items have been received.

2. If spare parts were ordered, verify arrival.

3. Open doors and remove cabi net panels to check

for shipping damage to internal components.

4. Check for loose connections or unsecured

components in the cabinet(s).

5. Check for installation of circuit breaker line

safety shields. There should be no exposed

circuit breaker terminals when the cabinet

doors are opened.

6. Remove any orange shipping braces or

brackets fr om the transformers.

7. Check for any unsafe condition that may be a

potential safety hazard.

Liebert Series 600T UPS, 65-225 kVA, Single Module 3

5. EQUIPMENT LOCAT ION

1. Handle cabinet(s) in accordance with WARNINGS in Section 3. Use a suitable material

handling device to move each cabinet to its

final location. Exercise extreme care

because of the uneven weight distribution. Carefully lower the cabinets to the floor

and position them for reconnection, if applicable.

2. Verify that the UPS system is installed in a

clean, cool and dry location. Observe the

location of overhead water lines for fire

sprinkler systems. Avoid placing the UPS and

related equipment directly under water lines

or within range of a sprinkler head.

3. Installation and serviceability will be easier if

adequate access is provided on all sides of the

equipment, but only front access is required.

a. Verify that there is adequate clearance to

open cabinet doors (4 feet is recommended ).

See drawings and local codes.

b. V erify that there is adequate area in fron t of

circuit breakers to perform maintenance.

Check installation drawings for location of

breakers. Check with local codes.

c. Verify that there is adequate clearance

above all cabinets to allow exhaust air to

flow without restriction (2 feet minimum,

unobstructed).

4. Connec t the cabinets, internal cables and bus

bars, if applicable.

6. BATTERY INSTALLATION

6.1. Battery Safety Precautions

Battery installation and servicing should be

performed or supervised by personne l

knowledgeable of batteries and the required

precautions. Keep unauthorized personnel away

from batteries.

Be sure to observe the grounding recommendations

in Section 7 when installing batteries. When

replacing batteries, use the same number and type

of batteries.

CAUTION

Lead-acid batteries contain hazardous

materials. Batteries must be ha ndled,

transported, and recycled or discarded in

accordance with federal, state, and local

regulations. Because lead is a toxic

substance, lead-acid batteries should be

recycled rather than discarded.

Do not open or mutilate the battery or

batteries. Released electrolyte is harmful

to the skin and eyes. It may be toxic. Do

not dispose of battery or batteries in a fire.

The battery may explode.

A battery can present a risk of electrical

shock and high short-circuit current. The

following precautions should be observed

when working on batteries:

1. Remove watches, rings, or other metal

objects.

2. Use tools with insulated handles.

3. Wear rubber gloves and boots.

4. Do not lay tools or metal parts on top of

batteries.

5. Disconnect charging source prior to

connecting or disconnecting battery

terminals.

6. Determine if the battery is inadvertently grounded. If it is inadvertently

grounded, remove source of ground.

Contact with any part of a grounded

battery can result in electrical shock.

The likelihood of such shock will be

reduced if such grounds are removed

during installation and maintenance.

Lead-acid batteries can present a risk of

fire because they generate hydrogen gas.

The following procedures should be

followed:

1. DO NOT SMOKE when near batterie s.

2. DO NOT cause flame or spark in

battery area.

3. Discharge static electricity from body

before touching batteries by first

touching a grounded metal surface.

4 Installation Manual

BATTERY SAFETY PRECAUTIONS IN

FRENCH PER CSA REQUIREMENTS

INSTRUCTIONS IMPORTANES

CONCERNANT LA SÉCURITÉ

CONSERVER CES INSTRUCTIONS

AVERTISSEMENT

DES PIECES SOUS ALIMENTATION SERONT

LAISSEES SANS PROTECTION DURANT CES

PROCEDURES D'ENTRETIEN. UN

PERSONNEL QUALIFIE EST REQUIS POUR

EFFECTUER CES TRAVAUX.

LES FUSIBLES A C.C. DE LA BATTERIE

D'ACCUMULATEURS OPERENT EN TOUT

TEMPS A LA TENSION NOMINALE. LA

PRESENCE D'UN FUSIBLE A C.C. BRULE

INDIQUE UN PROBLEME SERIEUX. LE

REMPLACEMENT DE CE FUSIBLE, SANS

AVOIR DETERMINE LES RAISONS DE LA

DEFECTUOSITE, PEUT ENTRAINER DES

BLESSURES OU DES DOMMAGES SERIEUX A

L'EQUIPEMENT. POUR ASSISTANCE,

APPELER LE DEPARTEMENT DE SERVICE A

LA CLIENTELE DE LIEBERT.

DANGER

Les accumulateurs plomb-acide contiennent de la

matière comportant un certain risque. Les

accumulateurs doivent être manipulés, transportés

et recyclés ou éliminés en accord avec les lois

fédérales, provinciales et locales. Parce que le

plomb est une substance toxique, les

accumulateurs plomb-acide devraient être recyclés

plutôt qu'éliminés.

Il ne faut pas brûlé le ou les accumulateurs.

L'accumulateur pourrait alors explosé.

Il ne faut pas ouvrir ou endommager le ou les

accumulateurs. L'électrolyte q u i pourrait s'en

échapper est dommageable pour la peau et les

yeux.

Un accumulateur représente un risque de choc

électrique et de haut courant de court-circuit.

Lorsque des accumulateurs sont manipulés, les

mesures préventives suivantes devraient être

observées:

1. Retirer toutes montre, bagues ou autres objets

métalliques.

2. Utiliser des outils avec manchon isolé.

3. Porter des gants set de s bo tte s deca utchouc.

4. Ne pas déposer les outils ou les pièces

métalliques sur le dessus des accumulateurs.

5. Interrompre la source de charge avant de

raccorder ou de débrancher les bornes de la

batterie d'accumulateurs.

6. Déterminer si l'accumulateur est mis à la terre

par erreur. Si oui, défaire cette mise à la terre.

Tout contact avec un accumulateur mis à la

terre peut se traduire en un ch oc élec trique. La

possibilitié de tels chocs sera réduite si de

telles mises à la terre sont débranchées pour la

durée de l'installation ou de l'entretien.

Les accumulateurs plomb-acide présentent un

risque d'incendie parce qu'ils génèrent des gaz à

l'hydrogène. Les procédures suivantes devront être

respectées.

1. NE PAS FUMER lorsque près des

accumulateurs.

2. NE PAS produire de flammes ou d'étincelles

près des accumulateurs.

3. Décharger toute électricité statique présente

sur votre corps avant de toucher un

accumulateur en touchant d'abord une surface

métallique mise à la terre.

DANGER

L'électrolyte est un acide sulfurique dilué qui est

dangereux au contact de la peau et des yeux. Ce

produit est corrosif et aussi conducteur electrique.

Les procédures suivantes devront être observées:

1. Porter toujours des vêtements protecteurs

ainsi que des lunettes de protection pour les

yeux.

2. Si l'électrolyte entre en contact avec l a peau,

nettoyer immédiatement en rinçant avec de

l'eau.

3. Si l'électrolyte entre en contact avec les yeux,

arroser immédiatement et généreusement avec

de l'eau. Demander pour de l'aide médicale.

4. Lorsque l'électrolyte est renversée, la surface

affectée devrait être nettoyée en utilisant un

agent neutralisant adéquat. Une prati que courante est d'utiliser un mélange d'appro ximativement une livre (500 grammes) de

bicarbonate de soude dans approximativement

un gallon (4 litres) d'eau. Le mélange de bicarbonate de soude devra être ajouté jusqu'à ce

qu'il n'y ait plus apparence de réaction

(mousse). Le liquide résiduel devra être nettoyé à l'eau et la surface concernée devra être

asséchée.

Liebert Series 600T UPS, 65-225 kVA, Single Module 5

6.2 Battery Cabinets

Optional battery cabinets are available from

Liebert and other qualified vendors. Consult your

submittal package for details.

The same model battery cabinet may be paralleled

in multiple cabinet strings for additional capacity.

Battery capacity (in minutes) a t your installation

will depend on cabinet model, number of cabinets,

and amount of critical load on the UPS.

1. Handling. The Battery Cabinet weighs up to

5100 pounds. Fork lift slots are provided in the

base of 100-225 kVA cabinets for easy

handling. Fork lift forks or a pallet jack can be

used between the casters of the 65 and 80 kVA

battery cabinets.

2. Cabinet Inspection. Remove all panels and

visually inspect the batteries, bus connections,

and cabinet for any damage. If any foam blocks

were placed between shelves to restrain

movement during shipment, remove them now.

Exercise caution; voltage is present

within the Battery Cabinet even before

installation. If there are signs of damage, do

not proceed. Call Liebert Global Services at 1800-542-2378.

3. Battery Storage. The batteries used in the

Battery Cabinet retain their charge well. The

batteries can be stored for up to six months

without any appreciable deterioration. Selfdischarge rate of the ba tteries is app roximately

3% per month when the batteries are stored in

temperatures of 15°C to 25°C (59°F to 77°F). If

the Battery Cabinet must be stored for longer

than six months, contact Liebert Global

Services.

4. Installation. The Battery Cabinet(s) can be

located conveniently to the left side of the 65225 kVA UPS module. The front-access-onlydesign eliminates side and rear service

clearance requirements.

7. Service Clearance. Allow fron t acc es s to the

Battery Cabinet at all times for maintenance

and servicing. Electrical codes require that the

Battery Cabinet be installed with no less than

3 feet (1 meter) of clearance at the front of the

cabinet when operating. Side and rear pan els

do not require service clearance.

8. Side Panels. Remove protective side panels to

connect battery cabinets together. Do not

remove the shield plate, explained below.

9. Shield Plate. The shield plate in 125 kVA

Battery Cabinets should be on the side toward

the UPS system. Mov e the shie ld if req uir ed by

your Battery Cabinet location.

10. Cables. Cables may be run between battery

cabinets through cutouts in the top of the

cabinets, eliminating the need for external

conduit runs. Route cables before moving

cabinets into fi nal position for bolting

together. Remove top panels for access. Refer

to Figures 16 and 17 or your submittal

drawings for instructions on wiring cabinets in

parallel.

11. Grounding. The battery cabinets have ground

studs near the bus bar connections. Use an

equipment grounding conductor to connect the

lugs of the cabinets to gether and to connect the

cabinets to the ground bus bar in the UPS

module.

CAUTION

Cables between batteries and modules

should be run in matched pairs, positivewith-negative. Grouping like-polarity

cables together (i.e. positive-with-positive

and negative-with-negative) can cause

stress or damage to the cables, conduit or

buswork.

5. Re-Installation. If it later becomes necessary

to move the Battery Cabinet to another

location, contact Lieb ert Global Services to

inspect the internal battery hold-down straps.

6. Environment. Locate the Battery Cabinet in

a clean, dry environment. Recommended

temperature range for optimum performance

and lifetime is 20-25°C (68-77°F).

6 Installation Manual

6.3 Open-Rack Batteries

When batteries other than Liebert Battery

Cabinets are used, a remote battery disconnect

switch with overcurrent protection is required per

the National Electrical Code. Refer to Figures 53

and 54. Contact your Liebert sales representative.

1. Install battery racks/cabinets and batteries per

manufacturer's installation and maintenance

instructions.

2. Verify battery area has adequate ventilation

and battery operating temperature complies

with manufacturer's specification.

3. Ensure that battery racks are properly

grounded according to code requirements in

your area.

If you have any questions concer ning batteries,

battery racks, or accessories, contact Liebert

Global Services at 1-800-543-2378.

CAUTION

Cables between batteries and modules

should be ru n in matche d pairs, positivewith-negative. Grouping like-polarity

cables together (i.e. positive-with-positive

and negative-with-negative) can cause

stress or damage to the cables, conduit or

buswork.

7. CONFIGURING YOUR NEUTRAL AND

GROUND CONNECTIONS

Improper grounding is the largest single cause of

UPS installation and start-up problems. This is not

an easy subject, since grounding techniques vary

significantly from site to site, depending on several

factors. The questions you should ask are:

• What is the configuration of the input power

source? Most of the recommended schemes f or

UPS grounding require grounded-wye service. The UPS system requires a bypass neutral for sensing and monitoring the quality of

the bypass input. If the building service is

ungrounded delta or corner-grounded delta,

contact your Liebe rt re pres ent ati ve to ens ure

your system includes the Artificial Neutral or

Isolated Neutral kit.

• Does the system have a bypass isolation

transformer? Systems with 480 VAC (or 600

VAC) input and 208 VAC output require a

bypass isolation transformer. In some cases,

it may be necessary to treat that transformer

as a “separat ely derived source” with its own

grounding electrode. See page 10 for details.

• What are the UPS input and output voltages?

Systems with 480 VAC input and output have

significantly different needs than systems

with 480/208 VAC or 208/208 VAC.

• What is the connected load? Does the critical

load consist of one or more Power Distribution Units (PDUs)? Do the PDUs have isolation transformers?

The following sections discuss recommended

grounding procedures for various system

configurations.

Liebert Series 600T UPS, 65-225 kVA, Single Module 7

NOTE

Some UPS modules are equipped with

input isolation transformers. However,

these transformers have no effect upon any

system grounding considerations. These

modules will be grounded exactly as shown

in the following examples.

GROUNDING

ELECTRODE

PER NEC 250-24

Figure 1. Preferred Grounding Configuration, 480 or 600 VAC input and output

7.1. Preferred Grounding Configuration,

480 or 600 VAC Input and Output,

Isolated Power Distribution Units,

Wye-Connected Service

One of the most-common configurations of the

Series 600T UPS is the Single Module System with

480 VAC input, 480 VAC output, and a connected

load consisting of multiple Power Distribution

Units (PDUs) with isolation transformers in the

PDUs to produce 208 VAC. For Canadian

customers, the UPS modules usually have 600 V AC

input and output. The same principles apply if the

connected load is an isolation transformer feeding

various loads. Figure 1 above shows a typical

installation.

Notice that the UPS module main input and

bypass input are connected to a grounded-wye

service. In this configuration, the UPS module is

not considered a separately derived source. The

UPS module output neutral is solidly connected to

the building service neutral, which is bonde d to the

grounding conductor at the service entrance

equipment

The isolation transformers in the PDUs are

considered a separately derived source. Therefore

the PDU neutral should be bonded to the PDU

grounding conductor and connected to a local

grounding electrode in compliance with NEC 250-

26.

Advantages of this configuration include:

• A measure of common-mode noise attenuation, since the isolation (common-mode rejection) occurs as close to the load as practical

(i.e. at the PDU).

• The UPS module can be located remotely

from the PDU without compromising common-mode noise performance.

• By using UPS modules with 480 VAC input

and output and creating 208 V AC at the PDU,

smaller and less costly power feeders can be

used and less voltage drop (as a percent of

nominal) occurs.

NOTE

Impedance-grounded wye sources must be

grounded in accordance with Section 7.5.

8 Installation Manual

Figure 2. Alternative Grounding Configuration, 480 or 600 VAC input and output

7.2 Alternative Grounding

Configuration, 480 or 600 VAC Input

and Output, Isolated Power

Distribution Units, Wye-Connected

Service

This configuration is similar to that shown in

Section 7.1, except that the service entrance

neutral is not brought into the UPS module. In this

configuration, the UPS output transformer is

considered a separately derived source. The UPS

module neutral is bonded to the UPS ground,

which is connected to a local groundi ng electrode in

accordance with NEC 250-26.

Please note that this configuration represents a

price/performance trade-off. Whenever the UPS

module transfers to or from bypass, two AC sources

(input and bypass) are briefly connected together

and circulating current must flow. In the previous

configuration, the current flows through the

neutral conductor. In this configuration, the

current flows through the ground path, possibly

tripping ground fault interruptors (GFIs) and

distorting the bypass waveform reference. Proper

adjustment of ground fault interrupters is

necessary to avoid unwanted tripping.

This configuration is reserved for those

applications which meet all the following criteria:

• The facility has Wye-connected service

• The module rectifier input and bypass input

are fed from the same source

• The connected load is strictly 3-wire (such as

one or more PDUs ) an d doe s no t require a

neutral from the UPS

• Special precautions are taken to prevent tripping the ground fault interruptors. The time

delay should be set to at least 30 cycles to prevent tripping when the UPS performs a

transfer or retransfer operation.

CAUTION

Failure to properly set the ground fault

interruptors could cause loss of power to

the critical load.

Liebert Series 600T UPS, 65-225 kVA, Single Module 9

C 250

LOCAL GROUNDING

ELECTRODE

PER NEC 250-30

GROUNDING

ELECTRODE

PER NE

-24

Figure 3. Preferred Grounding Configuration, 480 or 600 VAC input and 208 VAC output

7.3. Preferred Grounding Configuration,

480 or 600 VAC Input, 208VAC

Output, and Isolated Bypass

Another configuration in this power range is the

Single Module System with 480 or 600 VAC input,

208 VAC output, a Bypass Isolation Transformer

and a connected load consisting of multiple

distribution panelboards or switchboards. Figure 3

above shows a typical installatio n.

The Bypass Transformer provides isolation and

steps down the voltage to the bypass inputs. The

Bypass T ra ns former and t he UPS modul e toget her

constitute a separately derived system, since there

is no direct electrical connection bet ween the input

(service entrance) circuit conductors and the

output circuit conductors.

NOTE

The illustration above shows a wyeconnected source, but the same grounding

scheme would apply for a delta source at

the service entrance.

The bonding of the neutral to the grounding

conductor can theoretically be done at either the

UPS module or the Bypass Transformer. However,

we recommend bonding at the Bypass Transformer

because the UPS module will sometimes be

powered down for maintenance and its output

transformer will be out of the circuit. The neutral

should be bonded to ground and a local grounding

electrode should be installed at the Bypass

Transformer, per NEC 250-30.

Features of this configuration include:

• The UPS receives its bypas s neutral from the

Bypass Transformer

• The output is isolated from the input circuit

conductors, and

• Some amount of common-mode noise attenuation can be obtained for sensitive loads if the

UPS module and Bypass Transformer are

located close to sensitive loads.

10 Installation Manual

GROUNDING

ELECTRODE

PER NEC 250-24

Figure 4. Preferred Grounding Configuration, 208 VAC input and output

7.4. Preferred Grounding Configuration,

208 VAC Input and Output, NonIsolated Load, Wye-Connected

Service

A few applications in this power range have 208

VAC input and output, and a connected load

consisting of multiple Power Distribution Units

(PDUs), panelboards, switchboards or other items

of load equipment which do not have isolation

transformers.

Notice in Figure 4 above that the UPS module

main input and bypass input are connected to a

grounded-wye service. In this configura tion, the

UPS module is not considered a separately d erived

source.

The UPS module output neutra l and the load

neutral are solidly connected to the building

service neutral, which is bonded to th e grounding

conductor at the service entrance equipment.

This arrangement is typical for systems with 208

VAC input and output. However, it does not

provide any isolation or common-mode noise

attenuation for sensitiv e loa d s.

Liebert Series 600T UPS, 65-225 kVA, Single Module 11

GROUNDING

0

ELECTRODE

PER NEC 250-24

LOCAL

GROUNDING

ELECTRODE

PER NEC 250-30

LOCAL

GROUNDING

ELECTRODE

PER NEC 250-30

GROUNDING

ELECTRODE

PER NEC 250-24

Figure 5. Preferred Grounding Configuration with Ungrounded Delta Source Input (top) and

Corner-Grounded Delta (bottom)

7.5. Grounding Configuration, 480 or 600

VAC Input and Output, Delta Source

or Impedance-Grounded Wye

As previously mentioned, Series 600T UPS

modules require a bypass input neutral for sensing

and monitoring. With a wye-connected input

source, the installer should always connect the

building service neutral to the module output

neutral to achieve this. When the building service

is delta-connected, however, the installer must

take special steps to ensure reliable UPS

functioning.

If building service is ungrounded delta (and there

is no intent to operate with one corner of the delta

grounded, either on purpose or accidentally), the

UPS requires the Series 600T Artificial Neutral

Kit for proper operation. This kit uses a resistor

network to create a reference point for the bypass

input. In this case, the UPS output neutral must be

bonded to the UPS ground. See Figure 5 above.

If the building service is corner-grounded delta or

an impedance-grounded wye, the UPS requires the

Series 600T Isolated Neutral Kit. This kit uses

control isolation transformers to create a reference

point. For this application, the UPS output neutral

must not be bonded to the UPS ground.

LOCAL

GROUNDING

ELECTRODE

PER NEC 250-3

12 Installation Manual

GROUNDING

ELECTRODE

PER NEC 250-24

GROUNDING

ELECTRODE

PER NEC 250-24

Figure 6. Preferred Grounding Configuration, Power-Tie™ Systems

7.6. Preferred Grounding Configuration,

480 or 600 VAC Input and Output,

with Power-Tie™ Switchgear

Single Module Systems c an be used wit h Power-T ie

switchgear to provide dual critical load busses. The

Power-Tie switchgear permits transferring critical

loads from one critical bus to the other so that one

UPS module and associated breakers can be deenergized for maintenance. Certain configurations

of Power-T ie equipment also permit th e operator to

continuously parallel the output of the UPS

modules.

In tied systems, each UPS module must have its

neutral solidly connected to its own building

service neutral and to the Power-Tie switchgear

neutral. See Figure 6 above.

NOTE

It is essential to run a neutral connection

between the tie switchgear and both UPS

modules as shown in the illustration above.

Liebert Series 600T UPS, 65-225 kVA, Single Module 13

GROUNDING

ELECTRODE

PER NEC 250-24

Figure 7. Preferred Battery Cabinet Grounding Configuration

TO OUTPUT

DISTRIBUTION

7.7. Preferred Grounding Configuration,

Battery Systems

Large, open-rack battery systems are normally

either locally grounded or left ungrounded,

depending on local code requirements.

Battery cabinet systems, on the other hand, should

be grounded to the UPS ground bus bar. Figure 7

above illustrates how a simple one-cabinet system

would be grounded. For systems with multiple

cabinets, the same configuration would apply.

However , for simplicity the installer can connect all

the battery cabinet grounds together and run a

single ground conductor (in the same conduit as

the phase conductors) to the UPS ground.

14 Installation Manual

8. WIRING CONSIDERATIONS

8.1. Power Wiring

Refer to Site Planning Data (Appendix A) and the

installation drawings. Determine AC currents for

your system based on kVA, kW, voltage, and

options. Also refer to equipment nameplate for the

model number, rating, and voltage. For wire

termination data, refer to Tables 1-3.

1. Power wiring -- rectifier input, bypass input,

UPS output, and battery cables -- must be run

in individual, separate conduit or cable tray.

Refer to the Outline and Terminal Details

drawings (Figures 11-13 and 35-39) for location

of the various power connections within the

UPS.

CAUTION

Power and control wiring must be

separated!

2. Observe local, state and national electrical

codes. Verify utility power and its overcurrent

protection rating will accommodate the UPS

input rating, including battery recharging.

3. A safety ground wire must be run from

building ground to ground point in the UPS

Module Cabinet, the Battery Cabinet and the

Power-Tie™ switchgear cabinet. See Sections

7.1 through 7.7. The g rounding conducto r shall

comply with the following conditions of

installation:

a. The insulated grounding conducto r must be

sized in accordance with the NEC and local

codes. It must be green (with or without

yellow stripes) and be installed as part of

the branch circuit that supplies the unit or

system.

connected to earth ground at the service

equipment.

4. Observe clockwise phase rotation of all power

wiring. Phase A leads Phase B leads Phase C.

A qualified electrician should check the phase

rotation.

5. Power cables must be rated for less than 2 volts

line drop at maximum rated system current.

6. Use 75°C copper wire. Select wire size based on

the ampacities in Table 310-16 and associated

notes of the National Electrical Code (NFPA

70) reprinted on page 24 of this manual.

CAUTION

The weight of power cables must be

adequately supported to avoid stress on

bus bars and lugs. The following

restraining method is recommended to

both to support cable weight and control

cable movement during external fault

conditions: Wrap line cables together at 6

inches and 12 inches from the terminals

with 5 wraps of 3/8 inch nylon rope or

equivalent (tensile strength of 2000

pounds). Support remainder of cable w ith

5 wraps every 6 inches or 1 wrap every 1

inch.

7. If site equipment includes a backup generator

and automatic transfer switch(es), consult the

manufacturers of those devices for information

on sizing and interfacing to the UPS system.

8. The installing contractor can remove the access

plates from the top left or top right sides of the

UPS in order to cut entry hole s for conduit . For

units with bottom-entry cable access, there is a

separate (third) access plate in the base of the

unit, under the cable access wireway.

b. The grounding conductor described abo ve is

to be grounded to earth at th e se rvic e equi pment or, if supplied by a separately derived

system, at the supply transformer or motorgenerator set in accordance with the

instructions in Section 7 of this Manual.

c. The attachment-plug receptacles in the

vicinity of the unit or system are al l to be of

a grounding type, and the grounding conductors serving these receptacles are to be

Liebert Series 600T UPS, 65-225 kVA, Single Module 15

CAUTION

After cutting holes in the access plates, be

certain that no foreign matter (metal

shavings, sawdust, insulation or wire

fragments, etc.) remains inside the UPS.

Likewise be certain to block any “extra”

holes in the plates through which foreign

matter could later enter the UPS.

CB3

CB3

CB1

CB1

Standard SMS, with 208/208, 480/480 or 600/600

Standard SMS, with 208/208, 480/480 or 600/600

VAC input/output.

VAC input/output.

CB2

CB2

Bypass

Isolation

Xfmr

CB3

CB3

Input Iso

Input Iso

Transformer

Transformer

CB1

CB1

SMS with input isolation transformer and 208/208,

SMS with input isolation transformer and 208/208,

480/480 or 600/600 VAC input/output.

480/480 or 600/600 VAC input/output.

CB3

CB2

CB2

CB1

CB2

600/208 VAC module with external bypass

isolation transformer.

Bypass

Isolation

Xfmr

CB3

Input Isolation

Transformer

CB1

CB2

480/208 or 600/208 VAC module with both

internal input isolation transformer and external

bypass isolation transformer.

Figure 8. Typical One-Line Diagrams for SMS with Standard Dual Input

16 Installation Manual

CB3

Input Isolation

Transformer

CB3

CB1

CB2

Standard single-input SMS with 208/208, 480/480

or 600/600 VAC input/output.

Internal

Bypass

Isolation

Xfmr

CB3

CB1

CB2

480/208 VAC single-input SMS with bypass

isolation transformer. Single-input modules are

not available with both byp ass and in put isolation

transformers.

CB1

CB2

Single-input SMS with input isolation tra nsformer

and 208/208, 480/480 or 6 00/ 600 VAC input/output.

External

Bypass

Isolation

Transformer

CB3

CB1

CB2

600/208 VAC single-input SMS with bypass

isolation transformer. Single-input modules are

not available with both byp ass and in put isolation

transformers.

Figure 9. Typical One-Line Diagrams of SMS with optional single input.

Liebert Series 600T UPS, 65-225 kVA, Single Module 17

MBB

MBB

MIB

CB3

CB1

CB2

CB1

2-breaker Maintenance Bypass Cabinets for standard (left) and single-input (right) modules.

MBB

BIB

CB1

MIB

CB3

CB2

RIB

CB1

3-breaker Maintenance Bypass Cabinets for standard (left) and single-input (right) modules.

MIB

CB3

CB2

MBB

MIB

CB3

CB2

MBB

MIB

CB3

CB2

BYPASS

ISO XFMR

(OPT.)

CB1

BIB

MBB

CB3

CB2

MIB

RIB

CB1

BYPASS

ISO XFMR

(OPT.)

BIB

3-breaker and 4-breaker Maintenance Bypass Cabinets for stepdown-voltage applications.

Figure 10. Typical One-Line Diagrams of SMS with optional Maintenance Bypass Cabinets

Abbreviations for Circuit Breakers

BIB

MBB

MIB

RIB

Bypass Isolation Breaker

Maintenance Bypass Breaker

Maintenance Isolation Breaker

Rectifier Input Breaker

18 Installation Manual

8.2. Control Wiring

8.3. Battery Wiring

Control wiring must be stranded and tinned and

run in individual separate steel conduit. Control

wiring must be separated from power wiring. In

addition, each control wiring cable group should be

run in a separate conduit to minimize control

signal interference.

If your system has any in stalled options, special

wire lists will be included in your Submittal

Drawing Package. Contact your Liebert Sales

Representative for assistance if the Submittal

drawings have been lost or misplaced.

All control cable groups are connected to different

Interface Modules (IFMs) inside the UPS. Figure

29 shows the typical location of each IFM inside

the UPS. The position of a particular IFM may be

different for your UPS, depending upon the model

and the installed options.

NOTE

The UPS control and communication

wiring are considered Class 2 circuits by

NEC standards. However, NEC Class 1

wiring methods are required for these

circuits to ensure proper operation of the

UPS.

Power wiring to the Battery Cabinet connects

positive, negative, and ground power cables from

the Battery Cabinet to the associated UP S.

Connection of the UPS to the Battery Cabinet

serves to both charge and discharge the batteries

(when needed). The battery disconnect (circuit

breaker) requires a control cable. Liebert Battery

Cabinets include power and control cables to join

multiple cabinets together into a system.

Additional (field-supplied) power or control wiring

might be necessary to connect the battery cabinet

system to the UPS. Refer to Figures 16-17.

DANGER

A BATTERY INTERCELL CONNECTION

ON EACH TIER IS DISCONNECTED FOR

SAFETY DURING SHIPMENT. DO NOT

COMPLETE THESE CONNECTIONS. THE

LIEBERT GLOBAL SERVICES REPRESENTATIVE WILL COMPLETE THESE CONNECTIONS AS PART OF START-UP. A N IMPROPERLY INSTALLED UNIT CAN

RESULT IN INJURY TO PERSONNEL OR

DAMAGE TO EQUIPMENT.

CAUTION

Be sure polarity is correct when wiring

the Battery Ca binet to the connected

equipment (positive to positive; negative

to negative). If polarity is not correct, fuse

failures or equipment damage can result.

CAUTION

DC power cables should be installed in

conduit with conductors in matched pairs

(positive and negative).

NOTE

Inspection of the battery installation is a

service that can be provided by Liebert. A

Battery Specialist can perform a detailed

inspection of the entire battery system to

ensure it meets current IEEE standards.

This inspection service is recommended

because batteries are a critical part of the

UPS system.

Liebert Series 600T UPS, 65-225 kVA, Single Module 19

9. WIRING CONNECTIONS

9.2 Specific Connections

9.1 Warnings

DANGER

VERIFY THAT ALL INCOMING HIGH AND

LOW VOLTAGE POWER CIRCUITS ARE

DE-ENERGIZED AND LOCKED OUT

BEFORE INSTALLING CABLES OR

MAKING ELECTRICAL CONNECTIONS.

ALL POWER CONNECTIONS MUST BE

COMPLETED BY A LICENSED

ELECTRICIAN EXPERIENCED IN WIRING

UPS EQUIPMENT, AND IN ACCORDANCE

WITH ALL APPLICABLE NATIONAL AND

LOCAL ELECTRICAL CODES.

IMPROPER WIRING MAY CA USE DA MAGE

TO THE UPS OR INJURY TO PERSONNEL.

CAUTION

All shielded cables, non-shielded cables,

non-shielded control wires, non-shielded

battery breaker control wires, and nonshielded remote control wires must be

housed in individual, separate, steel

conduits. Placing multiple cables in the

same conduit with other control or power

wiring may cause system failure.

Refer to the drawings in this manual and any other

drawings provided by Liebert for this installation.

Make all of the following connections:

a. AC power cables from input power source

circuit breaker to UPS Module Input. Observe

phase rotation.

CAUTION

See Section 7 of this Manual for an

explanation of proper grounding

techniques.

b. AC power cables from bypass power source cir-

cuit breaker to UPS Module Bypass input.

Observe phase rotation.

c. AC power cables from UPS Module Output to

critical load. Observe phase rotation.

NOTE

If your installation includes a

Maintenance Bypass Cabinet, Switchboard

or Panelboard, some (or all) power cables

will be terminated in these cabinet(s).

Make sure all required wiri ng betw een

UPS module and the optional cabinet(s) is

completed. Observe phase rotation.

d. The UPS Module Output Neutral must be con-

nected to one common point and solidly

grounded per requirements of the National

Electrical Code. See Section 7.

20 Installation Manual

CAUTION

UPS bypass and output neutral must be

connected to only one common point in

the UPS. This neutral line must be

grounded at the source.

e. For Battery Cabinets:

DC power cables and ground from Battery Cabinet to UPS Module, and between Battery Cabinets. Observe polarity. DC power cables

should be installed in matched pairs (positive

and negative).

Loading...

Loading...