Page 1

Surge Protection

For Business-Critical Continuity

Interceptor II, SAD Hybrid Advantage, Type SS, LM, AccuVar,

PowerSure LPM/LPL Series, ATF Series, PanelGuard Extension, AccuGuide Products

Installation, Operation and Maintenance Manual

™

Page 2

Page 3

Surge Suppression Systems

LIEBERT SURGE PROTECTIVE DEVICE

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

TABLE OF CONTENTS

UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking and Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Handling Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Location Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Door Closing Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings Defi ned . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

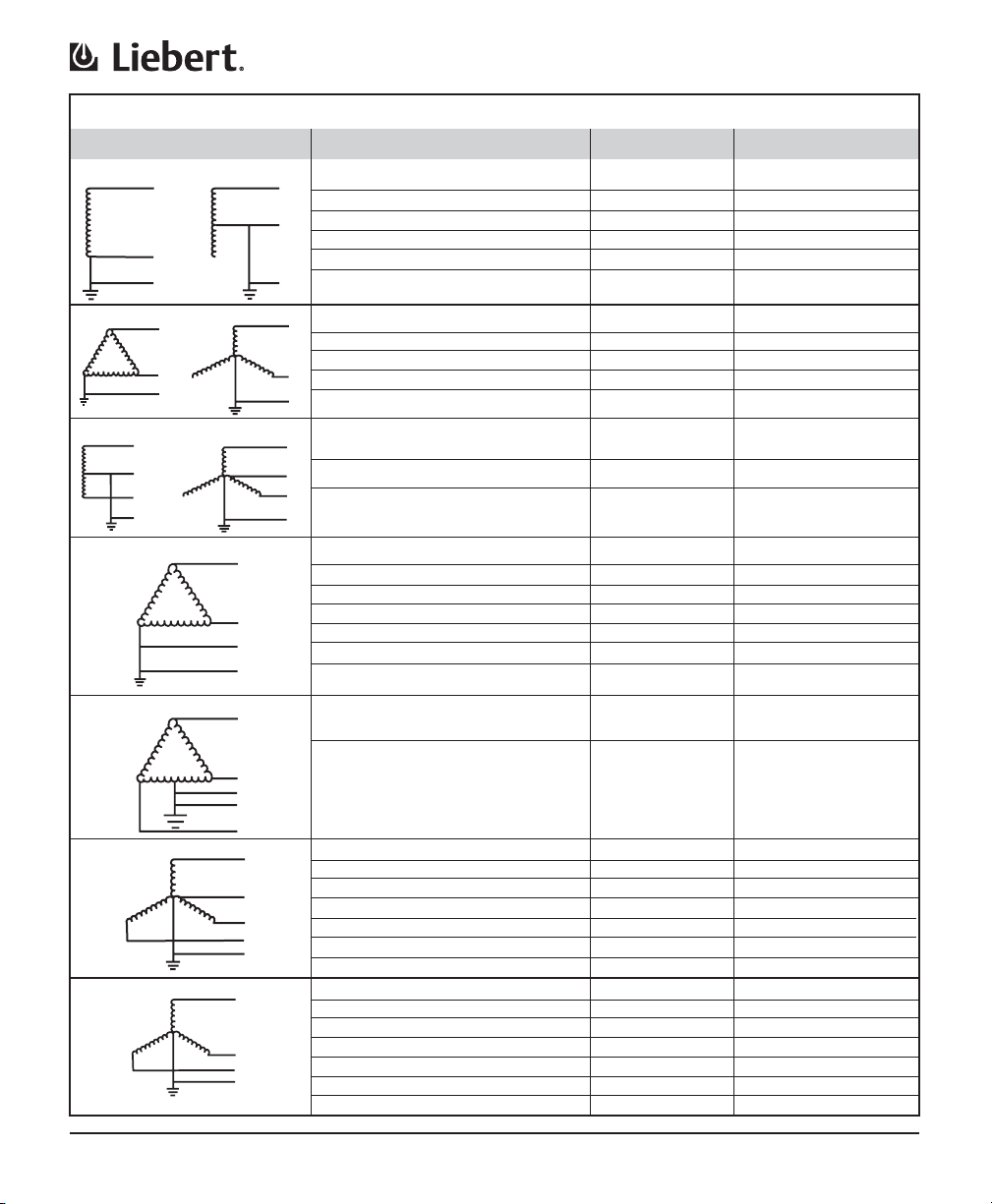

Voltage Ratings and Power Source Confi gurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Parallel Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Voltage Ratings and Power Source Confi gurations (Chart) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Parallel Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Grounding and Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SPD Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TROUBLESHOOTING / SERVICING / MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Corrective Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preventative Maintenance (Inspection and Cleaning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PRODUCT INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Typical Parallel Installation – Type SI, H, SS, LM, ACV, AII, LPM, & LPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Active Tracking Filter – Type F Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PanelGuard Series - Type LPGE Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

AccuGuide Series – Type ACG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DIMENSIONAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Interceptor II Series – Type SI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hybrid Advantage Series – Type H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

AccuVar Series - Type ACV & AII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Active Tracking Filter Series – Type F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SS Series – Type SS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LM Series – Type LM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PowerSure Medium Exposure Series – Type LPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PowerSure Low Exposure Series – Type LPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PanelGuard Series - Type LPGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EXAMPLE INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

10 Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation, Operation and Maintenance Manual 1 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 4

INSTALLATION INSTRUCTIONS

The Liebert Surge Protective Devices (SPDs) are high quality,

high energy surge current diversion systems designed to

protect sensitive equipment from damaging transient voltage

surges. Proper installation is required for maximum system

performance.

UNPACKING AND INSTALLATION

Unpacking and Preliminary Inspection

1. Inspect the shipping crate(s) for damage or signs of

mishandling before unpacking the unit.

2. Remove any securing bands and cardboard packing and

inspect the unit for any obvious shipping damages.

3. If any damage as a result of shipping is observed, immediately

fi le a claim with the shipping agency and forward a copy to

your local Liebert Sales Representative.

Handling Considerations

Larger units are bolted to a shipping pallet to facilitate handling

by forklift or pallet jack. Check the size and weight. Refer to

the cabinet data furnished with the unit.

Storage

The unit should be stored in a clean, dry environment. Storage

temperature range is -55ºC (-67ºF) to +85ºC (+185ºF). Care

should be taken to avoid condensation. All packing and

shipping materials should be left intact until the unit is ready

for fi nal installation. If the unit has been stored for an extended

period of time, the unit should be cleaned and carefully

inspected before placing into service.

Location Considerations

Environment — The unit is designed for operation indoors in

ambient temperatures of -40ºC (-40ºF) to +60ºC (+140ºF) with

a relative humidity of 0% to 95% (non-condensing).

The unit is provided in an industrial use enclosure, which is

dust-tight and drip-tight and should not be installed in areas

with excessive dust, corrosive vapors, fl ammable materials or

explosive atmospheres.

Audible Noise — The audible noise of the unit is less than

40 dB at 5 feet, which allows its placement within almost any

room if desired.

Service Clearances — Service clearance is needed for units with

hinged doors on the front that are capable of being opened.

Thirty-six inches (36 in/914 mm) minimum is recommended.

Surge Suppression Systems

The installer should perform the following steps to assure a

quality installation. The entire installation manual should be

read before starting installation. These instructions do not

replace national or local electrical codes. Check applicable

electrical codes to ensure compliance. Installation of the Liebert

SPD system should only be performed by qualifi ed personnel.

EQUIPMENT PERFORMANCE!!

To maximize system performance locate unit as

close as possible to protected circuit and keep inter connecting wiring less than 5 ft.

For optimum transient surge protection, coordinated surge

suppression should be applied at the service entrance and all

other electrical connections to the building (telephone, CATV,

etc.), at known surge generating loads within the building

(large motors, arc welders, switched capacitors, etc.), as well

as at sensitive electronic loads (such as computers, electronic

appliances, solid state motor drives, etc.). For interconnected

electronic loads (such as by way of data cabling), transient surge

suppression should also be applied to the interconnecting

wiring (data cables).

Mounting — Unit is intended to be wall mounted. Refer to

individual instruction sheet or unit submittal drawings for

typical mounting dimensions and weight.

Warnings Defi ned

Danger: Indicates an imminently

hazardous situation that, if not

avoided, will result in death or

serious injury. This signal word

is to be limited to the most

extreme situations.

Warning: Indicates a potentially

hazardous situation that, if not

avoided, could result in death or

serious injury.

Caution: Indicates a potentially

hazardous situation that, if not

avoided, may result in minor or

moderate injury. It may also be used

to alert against unsafe practices.

Installation, Operation and Maintenance Manual 2 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 5

ELECTRICAL CONNECTIONS

Surge Suppression Systems

All electrical connections should be installed by a qualifi ed

(licensed) electrician only. All wiring must comply with the

National Electrical Code (NEC) and applicable local codes.

VERIFY THAT ALL POWER CIRCUITS ARE

DE-ENERGIZED AND LOCKED OUT BEFORE

MAKING ELECTRICAL CONNECTIONS.

Voltage Ratings and Power Source Confi gurations

Before making connections to the unit, verify that the unit

model number and nameplate voltage rating are appropriate

for connection to the intended power source. See the chart

on page 4 for voltage rating applications with typical power

source confi gurations.

Parallel Connection (see Figures on page 5)

EQUIPMENT PERFORMANCE!!

For maximum system performance, the unit must be

located as close to the protected circuit as practical

to minimize interconnecting wiring length.

To reduce the wiring impedance to surge currents, it is

recommended that the phase, neutral (if required), and ground

conductors are twisted together and routed in the same

raceway (conduit). Avoid any sharp bends in the conductors.

Wire Sizing — With parallel connection, the size of the

wiring to the SPD unit is independent of the protected

circuit’s ampacity. For suggested wire size refer to individual

product sheet.

NEC Article 285-21(B) requires surge suppressor connecting

conductors to be at least #14 copper or #12 aluminum.

Overcurrent Protection — The SPD unit conducts practically

no current under normal operation and only conducts very

short duration transient surge currents.

The following is from the National Electric Code 2002 Edition.

285.21 Connection. Where a TVSS is installed, it shall be

connected as follows:

(A) Location.

(1) Service Supplied Building or Structure. The transient

voltage surge suppressor shall be connected on the

load side of a service disconnect overcurrent device

required in 230.91.

(2) Feeder Supplied Building or Structure. The transient

voltage surge suppressor shall be connected on the

load side of the fi rst overcurrent device at the building

or structure.

Exception to (1) and (2): Where the TVSS is also listed as a surge

arrestor, the connection shall be as permitted by Article 280.

(3) Separately Derived System. The TVSS shall be

connected on the load side of the fi rst overcurrent

device in a separately derived system.

Disconnect Switch (If Provided) — All SPD units must still be

connected to the load side of the main service disconnect, or

load side of a protected circuit’s disconnecting means.

Surge Voltage Ratings — To obtain the suppression voltage

ratings (SVRs), as obtained by Underwriters Laboratory,

Incorporated, in accordance with the Standard for Safety,

Transient Voltage Surge Suppressors (TVSS), Standard 1449,

Second Edition, dated August 15, 1996, marked on this

product, the wire size listed for each product must be utilized

to connect the unit to your facilities’ power grid. Connections

made with conductors other than the wire size listed may

result in different SVRs.

Circuit Ampacity Limitations — Representative samples

of these products have been investigated by Underwriters

Laboratories, Incorporated to withstand, without exposing

live circuits or components at system voltages and fault

currents ranging from 14,000 AIC up to 200,000 AIC, as

described in the Standard for Safety, Transient Voltage Surge

Suppressor (TVSS), Standard 1449, Second Edition, dated

August 15, 1996. Verify each products fault current rating on

the individual installation pages that follow.

Installation, Operation and Maintenance Manual 3 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 6

Source Confi gurations

Single Phase L-N, 2 W + G

Single Phase L-L, 2 W + G

Single Phase, 3 W + G

Three Phase Delta, 3 W + G

Three Phase Delta Hi Leg, 4 W + G

L

N

G

L1

L2

G

L1

N

L2

G

Surge Suppression Systems

VOLTAGE RATINGS AND POWER SOURCE CONFIGURATIONS

Nominal Operating Voltage

L-N L-G L-L

100 100 N/A

L

110 110 N/A

120 120 N/A

N

230 230 N/A

277 277 N/A

G

347 347 N/A

N/A 208 208

L1

N/A 240 240

N/A 400 400

L2

N/A 480 480

G

N/A 600 600

120 120 208, 240

L1

240, 277 240, 277 480

N

L2

347 347 600

G

N/A 208 208

A

B

C

GG

B

N/A 240 240

N/A 380 380

N/A 400 400

N/A 415 415

N/A 480 480

N/A 600 600 580 L-L

120/240/120 120/240/120 240 150 L-N 240N

Maximum Continuous

150 L-N

150 L-N

150 L-N

275 L-N

320 L-N

420 L-N

130 L-L

150 L-L

275 L-L

275 L-L

420 L-L

150 L-N 120S

320 L-N

420 L-N

250 L-L 208D

320 L-L

580 L-L

580 L-L

580 L-L

580 L-L

Model Voltage Code

(Found in part number)

120 N or 120-

120 N or 120-

120 N or 120-

230 N or 230-

277 N or 277-

347 N or 347-

208L or 208-

240L or 240-

400L or 400-

480L or 480-

600L or 600-

240S

347S

240D

400D

400D

400D

480D

600D

A

N

G

Three Phase Wye, 4 W + G

C

A

N

B

C

G

Three Phase Wye, 3 W + G No Neutral

A

B

C

G

240/480/240 240/480/240 480 250 L-N

120 120 208

127 127 220

220 220 380

230 230 400

254 254 440

277 277 480

347 347 600

N/A 120 208

N/A 127 220

N/A 220 380

N/A 230 400

N/A 254 440

N/A 277 480

N/A 347 600

150 L-N

150 L-N

320 L-N

320 L-N

320 L-N

320 L-N

420 L-N

150 L-G

150 L-G

320 L-G

320 L-G

320 L-G

320 L-G

420 L-G

480H

120Y

127Y

230Y

230Y

254Y

277Y

347Y

120X

127X

230X

230X

254X

277X

347X

Installation, Operation and Maintenance Manual 4 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Note 1: For other voltages or source confi gurations, consult factory.

Page 7

Surge Suppression Systems

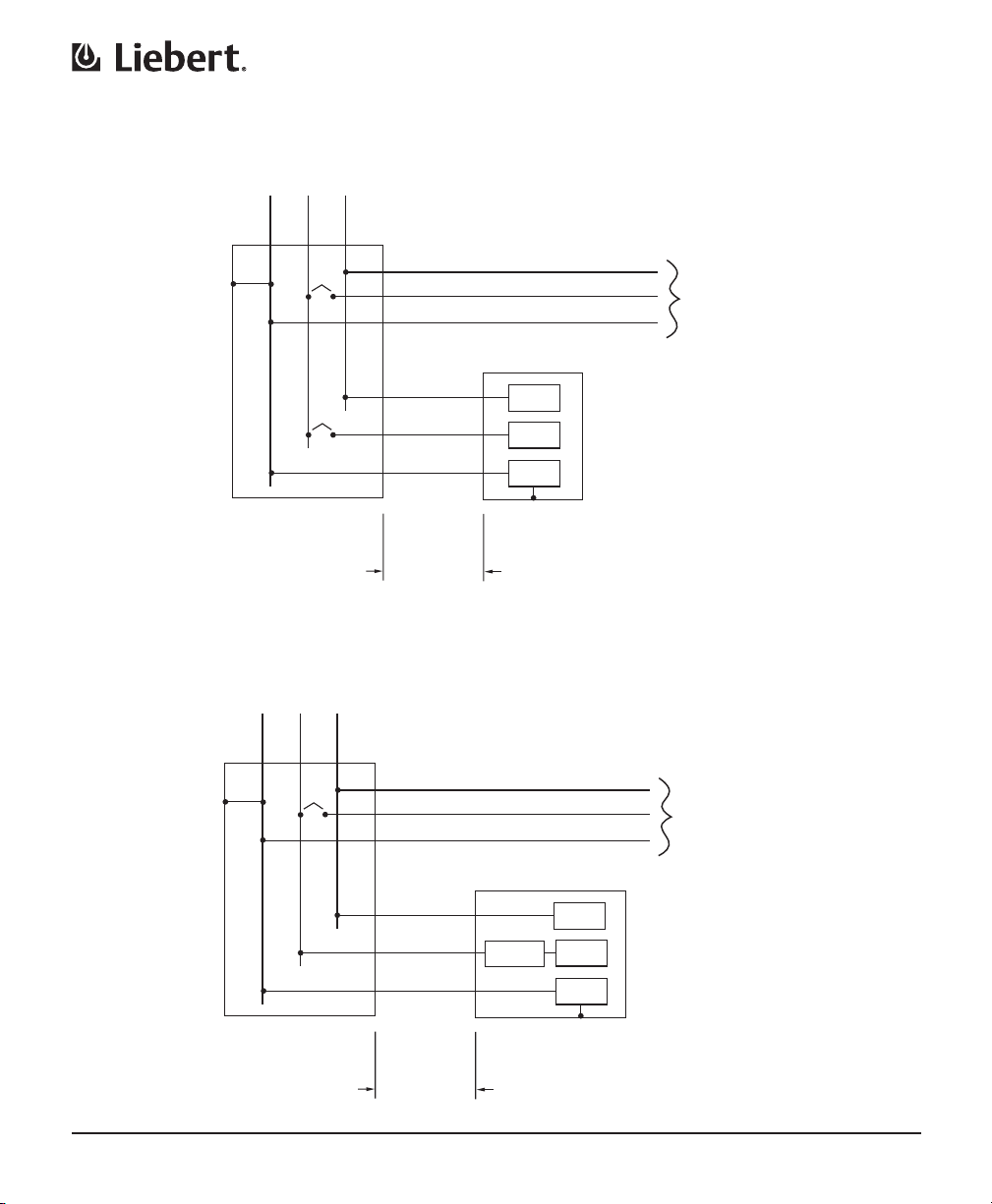

Typical Parallel Connections (without Internal Rotary Disconnect)

Ground

Phases

Neutral

To

Protected

Loads

Protected

Panel

Wire should be

less than 5 feet

and straight

as possible

Neutral

Phase(s)

Transient

Ground

Safety

Ground

Liebert

Surge

Protective

Device

Typical Parallel Connections (with Internal Rotary Disconnect)

Ground

Protected

Panel

Phases

Neutral

Wire should be

less than 5 feet

and straight

as possible

Rotar y

Disconnect

Neutral

Phase(s)

Transient

Ground

Safety

Ground

Liebert

Surge

Protective

Device

To

Protected

Loads

Installation, Operation and Maintenance Manual 5 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 8

System Grounding and Bonding

The performance and safety of any SPD system is dependent

on proper grounding and bonding. Grounding is required for

safety. Correct implementation also enhances equipment

performance. Incorrect grounding can reduce or impede the

SPD’s operation.

All electrical circuits to the SPD must include an equipmentgrounding conductor as required by the NEC and local codes.

An insulated grounding conductor is required in addition to any

metallic raceway, which may be used as a grounding conductor.

For parallel-connected SPDs, the grounding conductor should

be the same wire size as the associated power conductors.

Grounding conductors must be routed with the associated

power conductors in the same raceway (conduit).

When metallic raceways are used, adequate electrical

continuity must be maintained at all raceway connections,

particularly raceway terminations to the electrical enclosures.

The use of isolating bushings or other means to interrupt a

metallic conduit run is a potential safety hazard and is not

recommended.

Grounding Electrode — Surge protective devices do not

discharge all surges to ground (earth). Surge protective

devices divert the surge current back to its source to complete

the electrical circuit.

In the case of lightning whose potential is developed with

respect to the earth, the SPD diverts the surge current to

the grounding electrode (earth connection). However, for

most transient surges that are developed by switching loads,

the SPD diverts the surge current back to its source without

involving the grounding electrode.

For proper SPD performance, the service entrance grounding

electrode system must comply with the NEC by having all

available electrodes (building steel, metal water pipe, driven

rods, concrete encased electrodes, etc.) properly bonded

together and connected to the power system grounding.

The use of a separate grounding electrode to ground the SPD

defeats the effectiveness of the SPD, is a potential safety hazard,

may cause equipment damage, is an NEC violation (reference

NEC 250-51 and 250-54), and is not recommended.

Surge Suppression Systems

FOR PROPER AND SAFE OPERATION, THE NEUTRAL, (IF

PROVIDED), MUST BE RELIABLY CONNECTED TO THE

NEUTRAL OF THE SOURCE. FAILURE TO PROVIDE A RELIABLE

NEUTRAL CONNECTION MAY RESULT IN MODULE FAILURE!

SPD Monitoring

External Status Indicators — These indicators provide a

summary of the status of the surge SPD module. For normal

conditions, the green “OK” LED is illuminated and the red

“Service” LED is extinguished. If the surge SPD module

requires replacement, the green “OK” LED is turned off and

the red “Service” LED illuminated.

Summary Alarm Contact (if applicable) — Summary alarm

Form C (1 N.O. and 1 N.C.) relay contacts may be provided for

remote indication of the failed surge SPD module.

Contacts are rated 5 amps at 250 VAC maximum with a power

factor of 1.0. For units with Summary Alarm Contacts, access

to the contacts are typically provided via contact terminals

located on the printed circuit board mounted on the inside of

the unit’s cover.

Transient Counter (if applicable) – Transient counters are

provided for transient voltage surge monitoring. The counter

totalizes surges monitored since the last counter reset.

The transient counter monitors line transient voltages. The

circuit counts all surges that deviate from the line sine wave.

The factory setting is 30% over nominal line voltage. Other

settings include 50%, 70%, and 100%.

Swell Counter (if applicable) — The swell counter monitors

line to line & line to neutral voltages. It is factory set to record

whenever the peak voltage on any normal mode exceeds the

nominal voltage of the TVSS for more than 10ms. This counter

records temporary line over voltages that may result from

utility switching, line regulation problems, etc.

Audible Alarm (if applicable) — If the surge SPD module

requires replacement, an audible alarm is activated to draw

attention to the fact that repair service is required to restore

the system to normal operation. An audible alarm disable is

provided to silence the alarm. The system will automatically

reset itself after repair. The audible alarm switch and “Service”

LED can be tested by activating the “Test” switch on the

system monitor panel. For information on the AccuVar Series

Alarm, see page 16.

Installation, Operation and Maintenance Manual 6 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 9

Surge Suppression Systems

Troubleshooting / Servicing / Maintenance

Troubleshooting

If status failure indication occurs or Form C relay has changed

states, a qualifi ed electrician shall fi rst determine if the

systems voltage and proper phasing exists.

If the SPD remains in an alarm condition once the electrician

is satisfi ed that the electrical system and its connections are

normal, the unit should be repaired. At this point consult the

factory, having available the following information:

• Unit identifi cation number – (refers to the model and serial

numbers detailed on the data label and is located on the front

or upper left [hinge] side of the enclosure.)

• Nature of problem – (including status of all status indicators

and alarms).

Servicing

ONLY QUALIFIED PERSONNEL SHOULD PERFORM

MAINTENANCE ON THE SYSTEM.

HAZARDOUS VOLTAGES ARE PRESENT INSIDE THE UNIT

DURING NORMAL OPERATIONS.

ELECTRICAL SAFETY PRE-CAUTIONS MUST BE FOLLOWED

WHEN SERVICING THIS UNIT.

TO PREVENT RISK OF ELECTRICAL SHOCK, TURN OFF AND

LOCK OUT ALL POWER SOURCES TO THE UNIT BEFORE

SERVICING UNIT.

(For servicing assistance, contact your local Liebert

Sales Representative or Liebert at 800-288-6169 or

607-724-2484.)

Corrective Maintenance

The Liebert SPD is designed for years of trouble-free operation.

However, even the most reliable equipment may fail under

abnormal conditions.

Diagnostic indicators are provided to indicate when the unit

needs replacement (see individual SPD operation of this

manual for details). To ensure continuity of surge protection,

failed units should be replaced at the earliest convenient

service opportunity.

When replacing surge modules, other components should

be inspected for damage and replaced if necessary. Standard

electrical troubleshooting procedures should be used to

isolate problems other than failed surge current diverter

modules.

When replacing components, for continued proper operation

and safety, replace only with identically rated components.

Please contact factory for information on replacement parts.

Preventative Maintenance (Inspection and Cleaning)

Periodic system inspections, cleaning, and connection checks

are recommended to ensure reliable system performance and

continued surge transient protection.

It is diffi cult to establish a schedule for preventative

maintenance since conditions vary from site to site. Inspections

for failed surge modules using available diagnostics should be

done routinely (weekly or monthly).

Installation, Operation and Maintenance Manual 7 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 10

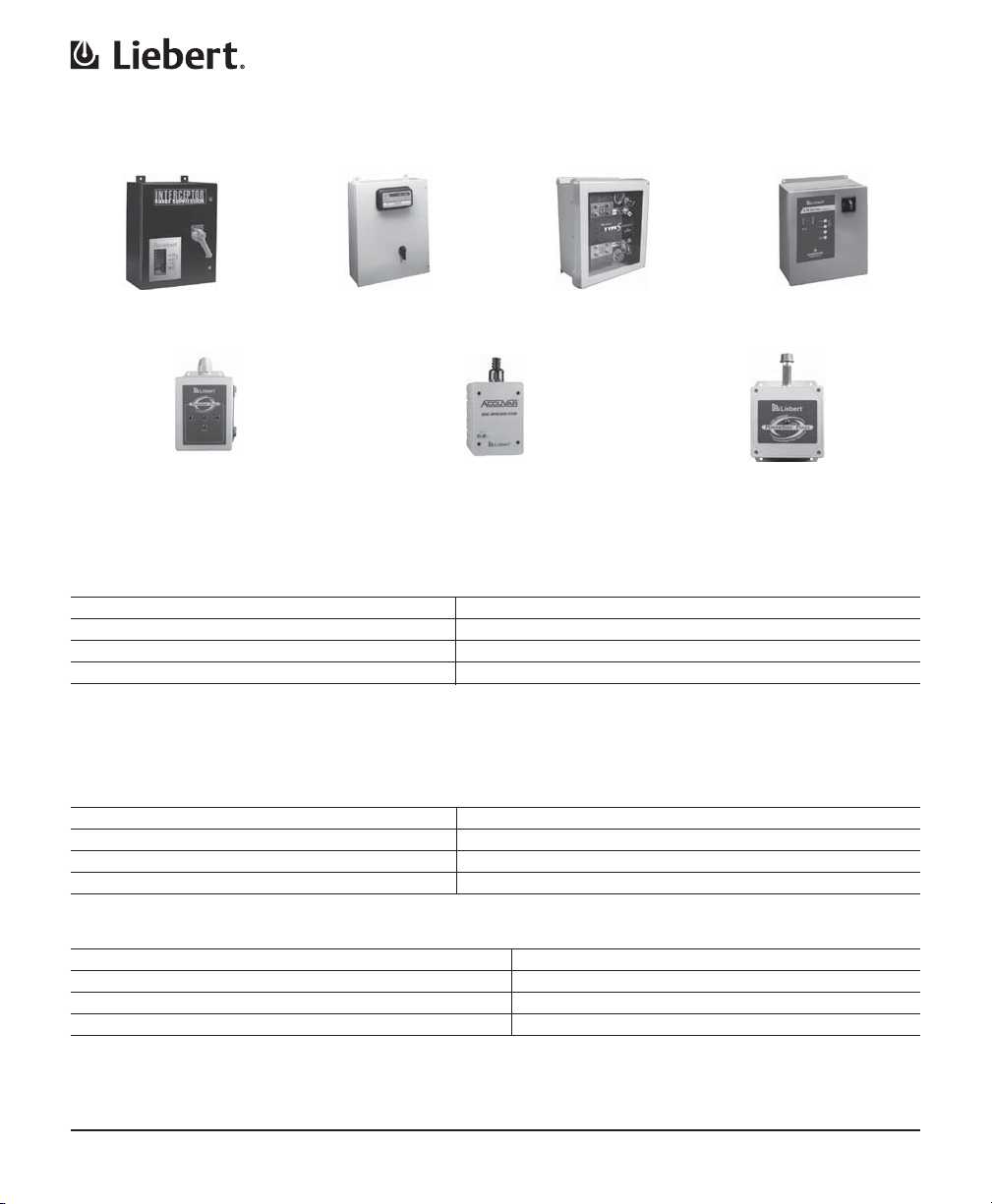

Interceptor II Series

Type SI

Typical Parallel Installations

Surge Protective Devices (SPD)

Hybrid Advantage Series

Typ e H

Surge Suppression Systems

Type SS Series Type LM Series

PowerSure Medium Exposure Series AccuVar Series PowerSure Low Exposure Series

Type LPM Type ACV & AII Type LPL

Installation Instructions

1. Insure that all power is removed before beginning installation. A qualifi ed licensed electrician shall install all electrical

connections.

2. The SPD is provided in the enclosure type listed below. NEMA 12 enclosures are suitable for use in indoor installations. NEMA

3R, NEMA 4 or NEMA 4X enclosures are suitable for use in indoor or outdoor installations.

SPD Standard Enclosure Optional Enclosures SPD Standard Enclosure Optional Enclosures

Type SI NEMA 4 NEMA 4X Type ACV/AII NEMA 4X N/A

Type H NEMA 12 NEMA 3R, 4, 4X Type LPM NEMA 12 NEMA 3R, 4, 4X

Type SS NEMA 4X N/A Type LPL ABS Plastic 94V-0 NEMA 1

Type LM NEMA 12 NEMA 3R, 4, 4X

3. Determine where the SPD is to be mounted, allowing for minimum length of wire between itself and the input power terminals

of the service panel. Punch or cut the proper hole size in the side of the SPD closest to the knockout to be utilized in the service

panel. Drill mounting holes in wall at location picked for SPD next to service panel using mounting dimensions shown in the

tables on the “Dimensional Information” pages in this manual. Mount surge suppressor using the hardware listed.

SPD Mounting Hardware SPD Mounting Hardware

Type SI (Page 15) 3/8" Type ACV/AII (Page 16) #8

Type H (Page 16) 3/8" Type LPM (Page 20) #10

Type SS (Page 18) 1/4" Type LPL (Page 21) #6

Type LM (Page 19) 1/4"

4. The SPD has obtained the short circuit current rating shown below.

SPD Short Circuit Current Rating SPD Short Circuit Current Rating

Type SI 200,000 Symmetrical Amperes Type ACV/AII 200,000 Symmetrical Amperes

Type H 200,000 Symmetrical Amperes Type LPM 65,000 Symmetrical Amperes

Type SS 65,000 Symmetrical Amperes Type LPL 14,000 Symmetrical Amperes

Type LM 200,000 Symmetrical Amperes

Circuit Ampacity Limitations. Representative samples of these products have been investigated by Underwriters Laboratories,

Incorporated to withstand, without exposing live circuits or components at system voltages and fault currents of up to the rating

shown above, as described in the Standard for Safety, Transient Voltage Surge Suppressor (TVSS), Standard 1449, Second Edition,

dated August 15, 1996.

Installation, Operation and Maintenance Manual 8 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 11

Surge Suppression Systems

7. An external circuit breaker is not necessary for over-current protection for most units (LPL Units require a 30A or less circuit

breaker). However, it is recommended that the SPD be connected in series with a circuit breaker denoted in the tables below

(also indicated on the “Dimensional Information” pages in this manual). The SPD shall be connected in accordance with all

national and local electrical codes.

5. Connect black wires (line or phase) marked L1/A, L2/B or L3/C, the white wire (neutral) marked N, and the green wire (ground)

marked G, of the SPD using the wire range listed below. To yield the best performance of the SPD within the electrical

distribution system, keep all conductors as short as possible and avoid sharp bends.

If the SPD model is a Wye confi gured unit (4W+G),

and a Neutral connection is not available, please contact factory.

TVSS

Series

Interceptor II

Hybrid Advantage

Type SS Series

LM Series

AccuVar

PowerSure LPM

PowerSure LPL

Model #

SI016 – SI025

SI032 – SI050

SI060 – SI075

SI100

Hxxxxx111 (250kA)

Hxxxxx222 (320kA)

Hxxxxx333 (400kA)

Hxxxxx444 (750kA)

All Units

LM060 – LM080

LM100 – LM150

LM200 – LM250

All Units

LPM 100-2

LPM 160

N/A

Circuit Breaker Size

With Dis connect Without Disconnect With Disconn ect Without Disconnect

15A – 150A

15A – 175 A

15A – 175A

15A – 175A

15A – 150A

15A – 175A

15A – 175A

15A – 175A

N/A

15A – 150A

15A – 175A

15A – 175A

N/A

N/A

N/A

Allowable Range Factory Suggested Size

Connection Wire Size

#14 – 1/O

15A – 175A

15A – 175A

15A – 175A

15A – 100A

15A – 30A

30 Amp

30 Amp or less 30 Amp Required

#14 – 2/O

#14 – 2/O

#14 – 2/O

#14 – 1/O

#14 – 2/O

#14 – 2/O

#14 – 2/O

N/A

#14 – 1/O

#14 – 2/O

#14 – 2/O

N/A

N/A

N/A

#14 – 2/O

#14 – 2/O

#14 – 2/O

#14 – #2

#14 – #10

N/A

N/A

Circuit Breaker

Size

60 Amp

80 Amp

80 Amp

100 Amp

60 Amp

80 Amp

80 Amp

80 Amp

80 Amp

40 Amp

40 Amp

100 Amp

30 Amp

30 Amp

Connection

Wire Size

#6

#4

#4

#2

#6

#4

#4

#4

#4

#8

#8

#2

#10

#12 Provided

#12 Provided

Surge Voltage Ratings. To obtain the suppression voltage ratings (SVRs), as obtained by Underwriters Laboratory, Incorporated,

in accordance with the Standard for Safety, Transient Voltage Surge Suppressors (TVSS), Standard 1449, Second Edition, dated August

15, 1996, marked on this product, the suggested wire size must be utilized to connect the unit to your facilities power grid.

Connections made with conductors other than the size provided may result in different SVRs.

6. Connection to Form ‘C’ contacts shall be with #18 – 22 AWG. The ratings of the Form ‘C’ contacts are 5 amps at 250 VAC

maximum with a power factor of 1.0. For additional information on Interceptor II connections, see page 15.

7. Apply power. The surge protector is fully operational when the GREEN LEDs on the modules and the front door of enclosure are

illuminated. If the GREEN LEDs are extinguished or a RED LED is illuminated, check to ensure that power is applied to the SPD.

If an abnormal indication is present, remove power to the SPD and contact Liebert/Emerson Network Power Surge Protection

at 1-800-288-6169 or 1-607-724-2484.

8. Periodically monitor the status of the LEDs. Reduced protection exists if the GREEN LEDs are extinguished or the RED LED is

illuminated. Please contact Liebert/Emerson Network Power Surge Protection at 1-800-288-6169 or 1-607-724-2484.

9. The protection modules in these SPDs may be replaceable, contact Liebert/Emerson Network Power Surge Protection for

replacement. (Note: ACV, LPM, & LPL units do not have replaceable modules).

Installation, Operation and Maintenance Manual 9 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 12

Surge Suppression Systems

Liebert Active Tracking Filter Series — Type F

Surge Protective Device (SPD)

Installation Instructions

1. Ampacity: The fi lter’s maximum continuous current (Ampere) rating must be greater than or equal to the protected load’s full

load amps or overcurrent protection (Circuit Breaker) rating.

2. Insure that all power is removed before beginning installation. A qualifi ed licensed electrician shall install all electrical

connections.

3. The SPD is provided in a NEMA 3R, NEMA 4, NEMA 4X or NEMA 12 enclosure. The SPD is suitable for use in indoor (NEMA 12)

or outdoor (NEMA 3R, 4, 4X) installations.

4. Determine where the SPD is to be mounted. Punch or cut proper hole size in the side of the SPD closest to the knockout to be

utilized in the service panel. Wall Mounted Units: Drill mounting holes in wall at location picked for SPD next to service panel

using mounting dimension from the tables on page 17. Mount surge suppressor using 3/8-16 hardware or equivalent.

5. Units up to 225 amps are suitable for short circuit current ratings up to 25,000 amps. For short circuit currents up to 50,000

amps, Class RK5 fuses sized up to 125% of the fi lter’s continuous current rating are required. Units rated at 400 to 800 amps

are suitable for available symmetrical short circuit currents up to 50,000 amps. For short circuit currents up to 100,000 amps,

Class L Fuses sized up to 125% of the fi lter’s continuous current rating are required. Units 1200 amps and above are suitable for

available symmetrical short circuit currents up to 200,000 amps.

6. For best performance, keep input and output wiring separated as much as practical to eliminate input-to-output coupling

of noise and transients. Do not route input and output wiring in the same raceway. If practical, terminate input and output

raceways (conduits) at opposite ends of the active tracking fi lter enclosure (input near the top and output near the bottom).

7. The Liebert Active Tracking Filter System is wired in-line (in series) with the protected load(s). See Figures on the following

page.

8. Terminals are provided inside the Liebert Active Tracking Filter System for the line (phase), neutral (if used), transient ground,

and equipment safety ground connections. See page 11 for terminal wire size ranges.

9. Connect black wires (line or phase) marked L1/A, L2/B or L3/C, the white wire (neutral) marked N, and the green wire (ground)

marked G, of the SPD using the wire range listed in the table on page 12 in accordance with the National Electric Code (NEC)

Article 285 and all local codes. To yield the best performance of the SPD within the electrical distribution system, avoid sharp

bends.

10. Connection to the Form ‘C’ contacts shall be with #18 – 22 AWG. Contacts are rated 5 amps at 250 VAC maximum with a

power factor of 1.0.

11. Apply power. The surge protector is fully operational when the GREEN LEDs on the modules and the front door of enclosure

are illuminated. If the GREEN LEDs are extinguished or the RED LED is illuminated, check to ensure that power is applied to

the SPD. If an abnormal indication is present, remove power to the SPD and contact Liebert/Emerson Network Power Surge

Protection at 1-800-288-6169 or 1-607-724-2484.

12. Periodically monitor the status of the LEDs. Reduced protection exists if the GREEN LEDs are extinguished or the RED LED is

illuminated. Please contact Liebert/Emerson Network Power Surge Protection at 1-800-288-6169 or 1-607-724-2484.

13. The protection modules in these SPDs are replaceable, contact Liebert/Emerson Network Power Surge Protection

for replacement.

Installation, Operation and Maintenance Manual 10 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 13

Surge Suppression Systems

Typical Series Connections for Wye (4 Wire + Ground) or Single Phase (3 Wire + Ground) System

Liebert

Active Tracking

Filter System

INPUT OUTPUT

’s

Phase (s)

Phase (s)

Neutral

(required)

Ground

N

G

Neutral Neutral

Transient

Ground

Safety

Ground

“Protected”

Load (s)

}

To

Typical Series Connections for Delta (3 Wire + Ground) System

Liebert

Active Tracking

Filter System

INPUT OUTPUT

’s

Ground

G

Phase (s) Phase (s)

Transient

Ground

Safety

Ground

“Protected”

Load (s)

}

To

TERMINAL WIRE SIZE RANGE

FILTER CONTINUOUS PHASE AND TRANSIENT SAFETY

CURRENT RATING NEUTRAL TERMINALS GROUND TERMINAL GROUND TERMINAL

30 –100 A # 14 – 2/0 (1) # 14 – 2/0 (5) # 14 - # 4 (4)

225 A # 6 – 250 kcmil (1) # 14 – 2/0 (5) # 10 – 1/0 (4)

400 A # 6 – 250 kcmil (2) # 6 – 250 kcmil (2) # 6 – 250 kcmil (4)

800 A 2.75 x .50 Cu Busbar (3) # 6 – 250 kcmil (2) # 6 – 250 kcmil (4)

1200 A (2x) 6.0 x .25 Cu Busbar (3) # 6 – 250 kcmil (2) # 6 – 250 kcmil (4)

2000 A (3x) 6.0 x .25 Cu Busbar (3) # 6 – 250 kcmil (2) # 6 – 250 kcmil (2)

4000 A (5x) 6.0 x .25 Cu Busbar (3) # 6 – 250 kcmil (2) # 6 – 250 kcmil (2)

NOTES:

1. Single lug with single connection for Input and Output.

2. Single lug with dual connection for Input and Output.

3. Units must be installed with Busbar(s) only! Wire lugs are not U.L. approved.

4. Single lug with single connection.

5. Single lug with dual connection.

Installation, Operation and Maintenance Manual 11 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 14

Surge Suppression Systems

Liebert PanelGuard Series - Type LPGE

Surge Protective Device (SPD)

Installation Instructions

1. Insure that all power is removed before beginning installation. A qualifi ed licensed electrician shall install all electrical

connections

2. The unit is provided in a NEMA 1 rated industrial-use enclosure and should be installed in areas only appropriate for NEMA 1.

3. The unit is to be wall mounted in an area where suffi cient access and working space around the cabinet can be assured. (See

NEC Section 110-16.) Position the SPD opposite the incoming feed to the panelboard. For example, if the panelboard is

supplied through the top of its enclosure, mount the SPD at the bottom of the panelboard.

4. Knockouts for connection of the suppressor to the panelboard back box are provided on top, bottom, and sides of the unit’s

enclosure. The diameters of the knockouts vary to accommodate conduit / collar diameters of 1/2 in. to 1 1/4 in. The proper

size busing (diameter and length) must be selected to protect the conductors as they transition from the SPD to the panelboard

conductor, and to maintain the cosmetic integrity of the Liebert LPGE Series Surge Protection Device.

5. When connecting the SPD to the panelboard, it is important that the panelboards interior and the SPD are protected from any

metal shavings, which may result. An inspection and cleaning of the LPGE should be performed before applying power.

6. Representative samples of this product have been investigated by Underwriters Laboratories, Incorporated to withstand,

without exposing live circuits or components at system voltages and fault currents of up to 200,000 AIC, as described in the

Standard for Safety, Transient Voltage Surge Suppressor (TVSS), Standard 1449, Second Edition, dated August 15, 1996.

7. An external circuit breaker is not necessary for over-current protection. However, it is recommended that the SPD be connected

in series with a 30A circuit breaker. The SPD shall be connected in accordance with all national and local electrical codes.

8. To obtain the suppression voltage ratings (SVRs), as obtained by Underwriters Laboratory, Incorporated, in accordance with

the Standard for Safety, Transient Voltage Surge Suppressors (TVSS), Standard 1449, Second Edition, dated August 15, 1996,

marked on this product, #8 AWG wire must be utilized to connect the unit to your facilities power grid. Connections made

with conductors other that #8 AWG may result in different SVRs.

9. Connect black wires (line or phase) marked L1/A, L2/B or L3/C, the white wire (neutral) marked N, and the green wire (ground)

marked G, of the SPD using the wire range listed in the table below in accordance with the National Electric Code (NEC) Article

285 and all local codes. To yield the best performance of the SPD within the electrical distribution system, keep all conductors

as short as possible and avoid sharp bends.

10. Connection to the Form ‘C’ contacts shall be with #18 – 22 AWG. Contacts are rated 5 amps at 250 VAC maximum with a

power factor of 1.0.

11. Apply power. The surge protector is fully operational when the GREEN LEDs are illuminated. If the GREEN LEDs are extinguished,

check to ensure that power is applied to the SPD. If an abnormal indication is present, remove power to the SPD and contact

Liebert/Emerson Network Power Surge Protection at 1-800-288-6169 or 1-607-724-2484.

12. Periodically monitor the status of the LEDs. Reduced protection exists if the GREEN LEDs are extinguished. Please contact

Liebert/Emerson Network Power Surge Protection at 1-800-288-6169 or 1-607-724-2484.

13. The protection modules in these SPDs are replaceable, contact Liebert/Emerson Network Power Surge Protection

for replacement.

Installation, Operation and Maintenance Manual 12 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 15

Surge Suppression Systems

Liebert AccuGuide Series — Type ACG

SPD Interconnect Assembly

Installation Instructions

All electrical connections shall be installed by a qualifi ed (licensed) electrician. All wiring must comply with the National Electrical

Code (NEC) and applicable local codes.

National Electrical Code (NEC) Considerations

The National Electrical Code Article 240-21 details specifi c tap rules that should be considered before installation.

NEC 240.21 Location in Circuit. Over current protection shall be provided in each ungrounded circuit conductor and shall

be located at the point where the conductors receive their supply except as specifi ed in 240.21(A) through (G). No conductor

supplied under the provisions of 240.21(A) through (G) shall supply another conductor under those provisions, except through

an over current protective device meeting the requirements of 240.4.

(A) Branch-Circuit Conductors. Branch-circuit tap conductors meeting the requirements specifi ed in 210.19 shall be

permitted to have over current protection located as specifi ed in that section.

(B) Feeder Taps. Conductors shall be permitted to be tapped, without over current protection at the tap, to a feeder as

specifi ed in 240.21(B)(1) through (5).

(1) Taps Not Over 3 m (10 ft) Long. Where the length of the tap conductors does not exceed 3 m (10 ft) and the tap

conductors comply with all of the following:

(1) The Ampacity of the tap conductors (25 Amps in our case) is

a. Not less than the combined computed loads on the circuits supplied by the tap conductors, and

b. Not less than the rating of the device supplied by the tap conductors or not less than the rating of the over

current protective device at the termination of the tap conductors.

(2) The tap conductors do not extend beyond the switchboard, panelboard, disconnecting means, or control devices

they supply.

(3) Except at the point of connection to the feeder, the tap conductors are enclosed in a raceway, which shall extend

from the tap to the enclosure of an enclosed switchboard, panelboard, or control devices, or to the back of an

open switchboard.

(4) For fi eld installations where the tap conductors leave the enclosure or vault in which the tap is made, the rating

of the over current device on the line side of the tap conductors shall not exceed 10 times the Ampacity of the

tap conductor.

(2) Taps Not Over 7.5 m (25 ft) Long. Where the length of the tap conductors does not exceed 7.5 m (25 ft) and the tap

conductors comply with all of the following:

(1) The Ampacity of the tap conductors is not less than one-third of the rating of the over current device protecting the

feeder conductors (75 Amp maximum in our case).

(2) The tap conductors terminate in a single circuit breaker or a single set of fuses that will limit the load to the

Ampacity of the tap conductors. This device shall be permitted to supply any number of additional over current

devices on its load side.

(3) The tap conductors are suitably protected from physical damage or are enclosed in a raceway.

(3) Taps Supplying a Transformer. Not Applicable

(4) Taps Over 7.5 m (25 ft) Long. Not Applicable

(5) Outside Taps of Unlimited Length. Not Applicable

Flexible liquid tight non-metallic conduit in lengths greater than six feet must be installed in accordance with NEC 351-27.

Installation, Operation and Maintenance Manual 13 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 16

Surge Suppression Systems

Connection

The AccuGuide assembly is provided in standard lengths of 5, 8, 10, 12, 15, and 20 feet. Each end of the assembly will include an

additional fi ve feet of #10, 8, 6, or 4 AWG pigtails for connection to the service and to the surge protective device (SPD). Gauge of

the pigtail is based on the SPD lug size. See chart below for units and acceptable wire ranges. An additional 10 gauge-grounding

conductor is provided with the AccuGuide assembly for use as an equipment ground.

Interceptor II Units Acceptable Wire Range

All Units - No Disconnect #14 – 2/O

SI016-025 – With Disconnect #8 – 1/O

SI032-100 – With Disconnect #14 – 2/O

LM Units Acceptable Wire Range

All Units - No Disconnect #14 – #2

LM060-080 – With Disconnect #8 – 1/O

LM100-250 – With Disconnect #14 – 2/O

Conduit

The AccuGuide assembly is sold without conduit. If conduit housing is required, the following conduit and fi tting sizes apply:

No. of Conductors Conduit Size (in.)

1 Coax Cable, 1 GND 1

2 Coax Cable, 1 GND 1-1/4

3 Coax Cable, 1 GND 1-1/4

4 Coax Cable, 1 GND 1 1/4

5 Coax Cable, 1 GND 1 1/2

6 Coax Cable, 1 GND 1 1/2

7 Coax Cable, 1 GND 1 1/2

Equipment Performance

The ideal SPD installation locates the suppression as close to the protected bus as possible. This product was designed to address

those instances when a close installation is not possible. However, while the voltage drop experienced with an AccuGuide

assembly is signifi cantly reduced, care should be taken to keep connection lengths to a minimum.

Each end of the AccuGuide assembly is shipped with fi ve-foot pigtails. The length is offered as a worst-case need for the panel or

switchgear end (our SPD will be much less than 5 feet). We recommend cutting the pigtail to the shortest length possible.

Caution: Pigtails must be supported if pulling AccuGuide assembly through conduit. Grip only the blue coaxial cable

body when pulling the assembly through conduit. Do not pull AccuGuide assembly using the pigtails or damage

may occur.

Installation, Operation and Maintenance Manual 14 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 17

Summary Alarm Contacts (X2)

Pin 1 = Normally Open

Pin 2 = Common

Pin 3 = Normally Closed

1 2 3 1 2 3

TB1 TB2

E

F

(4X)

Surge Suppression Systems

Dimensional Information

Interceptor II Series - Type SI

Phase L1/A

Service Panel for

Loads to be Protected

Dedicated

Disconnect

(Optional)

C

A

D

Recommended Wire

Entrance

Phase L2/B

Phase L3/C

Disconnect/Main

Breaker for

Panel

Neutral Buss

Ground Buss

B

1.840

Max.

Interceptor II, Type SI

Unit

SI016

SI025

SI032

SI040

SI050

SI060

SI075

SI100

Dimensions (Inches)

A B C D E F

16

12

8

17.25

9.5

0.44

16

16

8

17.25

10

0.44

16

8

21.25

10

14

0.44

0.44

20

20

20

8

21.25

Weight

(lbs)

35

49

55

85

Suggested

Breaker Size

60 A

80 A

80 A

100 A

Suggested

Wire Size

(AWG)

#6

#4

#4

#2

Allowable

Breaker

Range

15A – 175A

15A – 175A

15A – 175A

15A – 175A

Allowable

Wire Range

#14 – 2/O

#14 – 2/O

#14 – 2/O

#14 – 2/O

Interceptor II, Type SI, with Rotary Disconnect

Unit

SI016

SI025

Dimensions (Inches)

A B C D E F

16

16

8

17.25

10

0.44

Weight

(lbs)

45

Suggested

Breaker Size

60 A

Suggested

Wire Size

(AWG)

#6

SI032

SI040

0.44

58

80 A

#4

20

16

8

21.25

10

SI050

SI060

SI075

SI100

Installation, Operation and Maintenance Manual 15 Liebert TVSS Units SL-22085 Rev 2, 11/2006

20

20

20

24

8

21.25

14

0.44

8

21.25

18

0.44

85

95

80 A

100 A

#4

#2

Allowable

Breaker

Range

15A – 150A

15A – 175A

15A – 175A

15A – 175A

Allowable

Wire Range

#14 – 1/O

#14 – 2/O

#14 – 2/O

#14 – 2/O

Page 18

Surge Suppression Systems

/

Unit

111

222

333

444

Hybrid Advantage Series — Type H

E

B

F

Max.

A

D

2.625

(4X)

Hybrid Advantage

Dimensions (Inches)

A B C D E F

20

24

24

30

16

20

24

24

21.25

9

21.25

9

25.25

9

31.25

9

10

14

18

18

0.44

0.44

0.44

0.44

C

1.840

Max.

Weight

(lbs)

56

82

115

153

Service Panel for

Loads to be Protected

Recommended Wire

Suggested

Breaker Size

60 A

80 A

80 A

100 A

Dedicated

Disconnect

(Optional)

Entrance

Suggested

Wire Size

(AWG)

#6

#4

#4

#2

Phase L1/A

Phase L2/B

Phase L3/C

Allowable

Breaker

Range

15A – 150A

15A – 175A

15A – 175A

15A – 175A

Disconnect/Main

Breaker for

Panel

Neutral Buss

Ground Buss

Allowable

Wire Range

#14 – 1/O

#14 – 2/O

#14 – 2/O

#14 – 2/O

AccuVar Series – Type ACV & AII

Service Panel for

Loads to be Protected

Dedicated

Disconnect

(Optional)

3.088

4.125

0.212

6.875

STATUS

7.375

1/2 Flexible Conduit

9.00 Minimum

Trim to Fit

8.125

4.750

Slots Will Accept

8-32 Screws

AccuVar Series

Weight

(lbs)

Suggested

Breaker Size

Suggested

Wire Size

(AWG)

8 30A #10 15A -30A #14 - #10

Installation, Operation and Maintenance Manual 16 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Allowable

Breaker

Range

Phase L2/B

Phase L3/C

STATUS

Allowable

Wire Range

Disconnect/Main

Breaker for

Panel

Neutral Buss

Ground Buss

Alarm Enable/Disable Feature

Audible Alarm — AccuVar Series

*Alarm ENABLED Alarm DISABLED

Jumper Jumper AlarmAlarm

*Factory Setting

Jumper located next to alarm

Page 19

Active Tracking Filter Series - Type F

F

Large Bezel 2.0” Max. (Options)

Small Bezel .50” Max. (No Options)

Surge Suppression Systems

A

D

E

B

2.0” Max.

B

A

12”

C

Typical Cabinet Data (30 to 400Amps) Typical Cabinet Data (800 to 4000Amps)

Current Model Dimensions (Inches) Weight

Rating XXX = VOLTAGE Application

A B C D E F Lbs Kg

FxxxN/L30 Single Phase 24.0 20.0 9.0 21.25 10.0 .44 35 15.9

FxxxS30 Split Phase 24.0 20.0 9.0 25.25 14.0 .44 45 20.4

30A

FxxxD30 Three Phase Delta 24.0 20.0 9.0 25.25 14.0 .44 50 22.7

FxxxY30 Three Phase Wye 24.0 20.0 9.0 25.25 14.0 .44 60 27.2

FxxxN/L60 Single Phase 24.0 20.0 9.0 21.25 10.0 .44 35 15.9

FxxxS60 Split Phase 24.0 20.0 9.0 25.25 14.0 .44 45 20.4

60A

FxxxD60 Three Phase Delta 24.0 20.0 9.0 25.25 14.0 .44 50 22.7

FxxxY60 Three Phase Wye 24.0 20.0 9.0 25.25 14.0 .44 60 27.2

FxxxN/L100 Single Phase 30.0 24.0 9.0 25.25 14.0 .44 60 27.2

FxxxS100 Split Phase 30.0 24.0 9.0 31.25 18.0 .44 70 31.8

100A

FxxxD100 Three Phase Delta 30.0 24.0 9.0 31.25 18.0 .44 70 31.8

FxxxY100 Three Phase Wye 30.0 24.0 9.0 31.25 18.0 .44 80 36.3

FxxxN/L225 Single Phase L – N 30.0 24.0 9.0 25.25 14.0 .44 60 27.2

FxxxS225 Split Phase 30.0 24.0 9.0 31.25 18.0 .44 70 31.8

225A

FxxxD225 Three Phase Delta 30.0 24.0 9.0 31.25 18.0 .44 70 31.8

FxxxY225 Three Phase Wye 30.0 24.0 9.0 31.25 18.0 .44 80 36.3

FxxxD400 Three Phase Delta 48.0 36.0 12.0 49.25 30.0 .44 275 125

400A

FxxxY400 Three Phase Wye 48.0 36.0 12.0 49.25 30.0 .44 300 136

Current

Dimensions (Inches) Weight

Rating

A B C Lbs Kg

FxxxD800 Three Phase Delta 60.0 48.0 12.0 500 227

800A

FxxxY800 Three Phase Wye 60.0 48.0 12.0 530 241

FxxxD1200 Three Phase Delta 60.0 48.0 20.0 700 318

1200A

FxxxY1200 Three Phase Wye 60.0 48.0 20.0 750 340

FxxxD2000 Three Phase Delta 60.0 48.0 20.0 875 397

2000A

FxxxY2000 Three Phase Wye 60.0 48.0 20.0 950 431

FxxxD4000 Three Phase Delta 60.0 48.0 20.0 1175 533

4000A

FxxxY4000 Three Phase Wye 60.0 48.0 20.0 1300 590

Model

XXX = VOLTAGE

Application

NOTE: Consult factory for special instructions on caseless and switchgear models.

Installation, Operation and Maintenance Manual 17 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 20

Service Panel For

Loads to be Protected

L1

N

Dedicated

Disconnect

(Optional)

Phase L1

Phase L2

Disconnect/Main

Breaker For

Panel

Type SS Series

Surge Suppression Systems

B

F

L2

A

B

Unit

1 Phase

3 Phase

N

Neutral Buss

Service Panel For

Loads to be Protected

Dedicated

Disconnect

(Optional)

C

GND

Phase A

Phase B

Phase C

Ground Buss

Type SS Series

Dimensions (Inches)

A B C D E F

13.32

6.6

9.6

14.75

18.751012

15.32

19.32

17.32

Disconnect/Main

Breaker For

Panel

Neutral Buss

Weight

0.32

0.322643

(lbs)

Suggested

Breaker Size

80 A

80 A

Polycarbonate Window

E

Suggested

Wire Size

(AWG)

#4

#4

A

C

Allowable

Breaker

Range

15A – 175A

15A – 175A

Allowable

Wire Range

#14 – 2/O

#14 – 2/O

D

Installation, Operation and Maintenance Manual 18 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 21

Surge Suppression Systems

Type LM Series

Phase L1/A

Service Panel for

Loads to be Protected

E

(4X)

F

A

D

C

Dedicated

Disconnect

(Optional)

Recommended Wire

Entrance

Phase L2/B

Phase L3/C

Disconnect/Main

Breaker for

Panel

Neutral Buss

Ground Buss

Unit

LM060

LM080

LM100

LM125

LM150

LM200

LM225

LM250

Unit

LM060

LM080

LM100

LM125

LM150

LM200

LM225

LM250

B

1.840

Max.

LM Series

Dimensions (Inches)

A B C D E F

14

8

16.75

12

12

10

0.31

0.31

0.44

16

16

20

14

16

8

16.75

9

21.25

LM Series, with Rotary Disconnect

Dimensions (Inches)

A B C D E F

14

8

16.75

12

12

10

0.31

0.31

0.44

16

16

20

14

16

8

16.75

9

21.25

Weight

(lbs)

32

41

56

Weight

(lbs)

32

41

56

Suggested

Breaker Size

40 A

40 A

100 A

Suggested

Breaker Size

40 A

40 A

100 A

Suggested

Wire Size

(AWG)

#8

#8

#2

Suggested

Wire Size

(AWG)

#8

#8

#2

Allowable

Breaker

Range

15A –100A

Allowable

Breaker

Range

Allowable

Wire Range

#14 – #2

Allowable

Wire Range

15A –150A #14 – 1/O

15A –175A

15A –175A

#14 – 2/O

#14 – 2/O

Installation, Operation and Maintenance Manual 19 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 22

0.375

Surge Suppression Systems

PowerSure Medium Exposure Series — Type LPM 100-2

Phase L1/A

Service Panel

for Loads to

be Protected

Dedicated

Disconnect

(Optional)

Phase L2/B

Phase L3/C

Disconnect/Main

Breaker for

Panel

Neutral Buss

Ground Buss

0.500

6.750

0.500

Phase A Phase B Phase C

Service

2.000

4.000

4.000

6.000

.31

(4X)

Phase A Phase B Phase C

Service

3.000

Unit is equipped with Summary

Alarm Contacts. The #18 wires

are designated as follows:

YELLOW = Normally Open

ORANGE = COMMON

BLUE = Normally Closed

PowerSure Medium Exposure Series — Type LPM 160

0.375

8.750

3.500

8.000

Unit is supplied from the

factory with a minimum

length of 18” of #12

wire for connection. It

is recommended that a

30A circuit breaker be

used for installation.

Unit is supplied from

the factory with a

minimum length

of 18” of #10 wire

for connection. It is

recommended that a

30A circuit breaker be

used for installation.

.31 (4X)

Ground Buss

Neutral Buss

Disconnect/Main

Breaker for Panel

Phase L3/C

Phase L2/B

Phase L1/A

Dedicated

Disconnect

(Optional)

Service Panel

for Loads to

be Protected

Installation, Operation and Maintenance Manual 20 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 23

1/2” Offset

Conduit Nipple

PowerSure Low Exposure Series - Type LPL

Service Panel

for Loads to

be Protected

Dedicated

Disconnect

Sta

tus

3.500

4.700

.188

5.250

(4X)

5.700

Surge Suppression Systems

Phase L1/A

Phase L2/B

Phase L3/C

Disconnect/Main

Breaker for

Panel

Neutral Buss

Ground Buss

Status

3.00 Max.

2.400

Unit is equipped with Summary

Unit is supplied from the factory with a

minimum length of 18” of #12 wire for

connection. It is REQUIRED that a 30A circuit

breaker or less be used for installation.

Installation, Operation and Maintenance Manual 21 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Alarm Contacts. The #18 wires

are designated as follows:

YELLOW = Normally Open

ORANGE = COMMON

BLUE = Normally Closed

Page 24

Surge Suppression Systems

PanelGuard Series — Type LPGE

Customer

Supplied

PanelBoard

Neutral Bar

Uninsulated

Ground Bar

3 Pole,

Conduit

Conduit

Collar

Collar

30 Amp

Circuit

Breaker

Slots for

Sliding Trim

To Ensure

Liebert

Proper Fit

Supplied

LPGE Unit

Installation, Operation and Maintenance Manual 22 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Summary Alarm

Contacts Inside

Module

(Remove Cover for Access)

Page 25

Example Installations

Surge Suppression Systems

Installation, Operation and Maintenance Manual 23 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 26

Surge Suppression Systems

Installation, Operation and Maintenance Manual 24 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 27

Surge Suppression Systems

Limited Warranty

This Warranty is given ONLY to purchasers who buy for commercial or industrial use in the ordinary course of each purchaser’s business.

General:

Liebert Corporation products and systems are in our opinion the fi nest available. We take pride in our products and are pleased that you have chosen

them. Under certain circumstances we offer with our products the following Ten Year Warrant y Against Defects in Material and Workmanship.

Please read your Warranty carefully. This Warranty sets forth our responsibilities in the unlikely event of defect and tells you how to obtain

performance under this Warranty.

TEN YEAR LIMITED WARRANTY AGAINST DEFECTS IN MATERIAL AND WORKMANSHIP

LIEBERT PRODUCTS COVERED:

Interceptor

AccuVar

Terms of Warranty:

As provided herein, the Liebert product is warranted to be free of defects in material and workmanship for a period of ten (10) years from the date

of product shipment from Liebert. The shipment date will be determined only from the Liebert bill of lading. If any part or portion of the Liebert

product fails to conform to the warranty within the warranty period, Liebert, at its option, will furnish new or factory remanufactured parts for

repair or replacement of that part or portion.

Warranty Extends to First Purchaser for Use, Non-transferable:

This Warranty is extended to the fi rst person, fi rm, association or corporation for whom the Liebert product specifi ed herein is originally installed

for use (the “User”) in the fi fty United States (excluding territories) or Canada. This Warranty is not transferable or assignable without the prior

written permission of Liebert.

Assignment of Warranties:

Liebert assigns to User any warranties which are made by manufacturers and suppliers of components of the Liebert product and which are

assignable, but Liebert makes NO REPRESENTATIONS as to the effectiveness or extent of such warranties, assumes NO RESPONSIBILITY for any

matters which may be warranted by such manufacturers or suppliers and extends no coverage under this warranty to such components.

Drawings, Descriptions:

Liebert warrants for the period and on the terms of the Warrant y set forth herein that the Liebert product will conform to the certifi ed drawings, if any,

applicable thereto, to Liebert’s fi nal invoices, and to applicable Liebert product brochures and manuals current as of the date of product shipment

(“Descriptions”). Liebert does not control the installation and use of any Liebert product. Accordingly, it is understood that the Descriptions are

NOT WARRANTIES OF PERFORMANCE and NOT WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE.

Obtaining Performance Under This Warranty:

Within a reasonable time, but in no case to exceed thirty (30) days, after User’s discovery of a defect, User shall contact Liebert at 1-800-LIEBERT

(543-2378) and request a return authorization number. User shall ship the product, with proof of purchase, to Liebert freight prepaid. Liebert

products shipped to Liebert without a return authorization number will be refused and returned freight collect to User at User’s expense. Liebert

products shipped by User to Liebert which have incurred freight damage due to User’s improper packaging of the product will not be covered by

this Warranty and any repairs or replacement parts, components or products needed will be invoiced in the full current price amount and returned

freight collect to User.

Subject to the limitations specifi ed herein, Liebert will repair or replace, at its option, without charge for Liebert labor or materials, subsequent

to its inspection F.O.B. Liebert’s facility, the Liebert product warranted hereunder which does not conform to the Warranty. Replacement parts,

components or products shipped to User prior to Liebert’s receipt and inspection of the product claimed to be defective shall be invoiced in the

full current price amount and shipped freight collect F.O.B. Liebert’s facility. Warranty coverage will be extended only after Liebert’s receipt of

the claimed defective product within thirty (30) days of shipment of any replacement parts, components or products, if applicable, and only if

Liebert’s inspection discloses the claimed defect and the returned product shows no signs of treatment or use which would void the coverage of

this Warranty. All defective products and component parts replaced under this Warranty become the property of Liebert.

Warranty Performance of Component Manufacturers:

It is Liebert’s practice, consistent with its desire to remedy Warranty defects in the most prompt and effective manner possible, to cooperate

with and utilize the services of component manufacturers and their authorized representatives in the performance of work to correct defects

in the product components. Accordingly, Liebert may utilize third parties in the performance of Warranty work, including repair or replacement

hereunder, where, in Liebert’s opinion, such work can be performed in less time, with less expense, or in closer proximit y to the Liebert product.

®

Transient Voltage Surge Suppressors, Interceptor® Active Tracking® Filters, Hybrid Advantage Transient Voltage Surge Suppressors,

®

Transient Voltage Surge Suppressors, and Type SS Transient Voltage Surge Suppressors.

Installation, Operation and Maintenance Manual 25 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 28

Items Not Covered By Warranty:

THIS WARRANTY DOES NOT COVER DAMAGE OR DEFECT CAUSED BY misuse, improper application, wrong or inadequate electrical current or

connection, negligence, inappropriate on site operating conditions, corrosive atmosphere, repair by non-Liebert designated personnel, accident

in transit, tampering, alterations, a change in location or operating use, exposure to the elements, Acts of God, theft or installation contrary to

Liebert’s recommendations or specifi cations, or in any event if the Liebert serial number has been altered, defaced or removed. Notwithstanding

the foregoing, the following Acts of God are covered: lightning-induced surges, which are transients, spikes or other sub-cycle, discontinuous

events impinging on normally applied voltage as defi ned by reference data in the latest version of IEEE C62.41 and the Liebert product performance

specifi cations.

THIS WARRANTY DOES NOT COVER shipping costs, installation costs, circuit breaker resetting or maintenance or service items and further, except

as provided herein, does NOT include labor costs or transportation charges arising from the replacement of the Liebert product or any part thereof

or charges to remove or reinstall same at any premises of the User.

THIS WARRANTY DOES NOT COVER DAMAGE OR DEFECT CAUSED BY use of the Liebert product in combination with any electrical or electronic

components, circuits, systems, assemblies, or other materials not furnished by Liebert. Liebert does NOT warrant the suitability for use or the

results of the Liebert product in combination with the products of others.

THE PRODUCTS LISTED IN THIS WARRANTY ARE NOT DESIGNED FOR USE IN THE FOLLOWING APPLICATIONS: (i) ANY NUCLEAR OR RELATED

APPLICATIONS; AND (ii) LIFE SUPPORT AND PATIENT-CONNECTED AND APPLIED MEDICAL AND DENTAL APPLICATIONS.

REPAIR OR REPLACEMENT OF A DEFECTIVE PRODUCT OR PART THEREOF DOES NOT EXTEND THE ORIGINAL WARRANTY PERIOD.

Limitations:

• THIS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

• USER’S SOLE AND EXCLUSIVE REMEDY IS REPAIR OR REPLACEMENT OF THE LIEBERT PRODUCT AS SET FORTH HEREIN.

• IF USER’S REMEDY IS DEEMED TO FAIL OF ITS ESSENTIAL PURPOSE BY A COURT OF COMPETENT JURISDICTION, LIEBERT’S RESPONSIBILITY FOR

PROPERTY LOSS OR DAMAGE SHALL NOT EXCEED THE NET PRODUCT PURCHASE PRICE.

• IN NO EVENT SHALL LIEBERT ASSUME ANY LIABILITY FOR INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND

WHATSOEVER, INCLUDING WITHOUT LIMITATION, LOST PROFITS, BUSINESS INTERRUPTION OR LOSS OF DATA, WHETHER ANY CLAIM IS BASED

UPON THEORIES OF CONTRACT, NEGLIGENCE, STRICT LIABILITY, TORT OR OTHERWISE.

Miscellaneous:

• NO SALESPERSON, EMPLOYEE OR AGENT OF LIEBERT IS AUTHORIZED TO ADD TO OR VARY THE TERMS OF THIS WARRANT Y. Warranty terms may

be modifi ed, if at all, only in a writing signed by a Liebert offi cer.

• Liebert obligations under this warranty are conditioned upon Liebert timely receipt of full payment of the product purchase price and any other

amounts due. Liebert reserves the right to supplement or change the terms of this Warranty in any subsequent warranty offering to User or

others.

• In the event that any provision of this Warranty should be or becomes invalid and/or unenforceable during the warranty period, the remaining

terms and provisions shall continue in full force and effect.

• This Warranty shall be governed by, and construed under, the laws of the State of Ohio, without reference to the confl ict of laws principles

thereof.

• This Warranty represents the entire agreement between Liebert and User with respect to the subject matter herein and supersedes all prior or

contemporaneous oral or written communications, representations, understandings or agreements relating to this subject.

Installation, Operation and Maintenance Manual 26 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 29

Limited Warranty

Surge Suppression Systems

Installation, Operation and Maintenance Manual 27 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 30

Items Not Covered By Warranty:

Installation, Operation and Maintenance Manual 28 Liebert TVSS Units SL-22085 Rev 2, 11/2006

Page 31

Liebert Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229

800 877 9222 Phone

(US & Canada Only)

614 888 0246 (Outside U.S.)

614 841 6022 FAX

Via Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD)

Italy

39 049 9719 111 Phone

39 049 5841 257 FAX

Emerson Network Power Asia Pacifi c

7/F., Dah Sing Financial Centre

108 Gloucester Road, Wanchai

Hong Kong

852 25722201 Phone

852 28029250 FAX

Liebert.com

Technical Support

607 724 2484 Phone

607 722 8713 FAX

800 288 6169 Toll-Free

While every precaution has been taken to ensure the accuracy and

completeness of this literature, Liebert Corporation assumes no

responsibility and disclaims all liability for damages resulting from use

of this information or for any errors or omissions.

© 2006 Liebert Corporation All rights reserved throughout the world.

Specifi cations subject to change without notice.

® Liebert and the Liebert logo are registered trademarks of Liebert

Corporation. All names referred to are trademarks or registered

trademarks of their respective owners.

SL-22085 (11/06) Rev. 2 82290 Printed in USA

Emerson Network Power.

The global leader in enabling Business-Critical Continuity

AC Power

Connectivity

DC Power

Emerson Network Power, the Emerson Network Power logo and Business-Critical Continuity are trademarks and service marks of Emerson Electric Co.

©2006 Emerson Electric Co.

Embedded Computing

Embedded Power

Monitoring

™

. Emerson Network Power.com

Outside Plant

Power Switching & Controls

Precision Cooling

Racks and Integrated Cabinets

Services

Surge Protection

Loading...

Loading...