Page 1

DISCONTINUED

PRODUCT

POWER PROTECTION

Series 600T™ UPS

Multi-Module Three Phase

65 kVA to 750 kVA; 60 Hz

Operation & Maintenance

Manual

Page 2

DISCONTINUED

PRO DU C T

Page 3

TABLE OF CONTENTS

2.2.3 BatteryChargingCircuit.............................................................17

3.1 DisplayScreenandOperatorControls .................................................23

3.1.2 Monitor/MimicDisplayScreen........................................................31

3.1.5 SystemConfigurationScreens ........................................................48

3.1.6 AlarmLimitSettingsScreen..........................................................55

3.1.7 LoadTransferProceduresScreen......................................................57

3.1.8 Start-UpProceduresScreen...........................................................58

3.1.9 ShutdownProceduresScreen .........................................................60

3.1.11 MeterCalibrationScreen ............................................................65

3.1.12 BatteryEqualizeScreen .............................................................66

3.1.13 AlarmandStatusMessages...........................................................67

3.1.14 CommunicationInterfaces ...........................................................75

1.0 INTRODUCTION

1.1 System Description . . . ..............................................................3

1.2 Reliability . .......................................................................7

1.3 Safety Precautions ..................................................................8

1.4 Modes of Operation . . . ..............................................................9

1.4.1 Normal(LoadonUPS)...............................................................9

1.4.2 InputPowerFailure..................................................................9

1.4.3 Recharge..........................................................................9

1.4.4 Overload ..........................................................................9

1.4.5 Redundant . . . ......................................................................9

1.4.6 Bypass(Internal)....................................................................9

1.4.7 MaintenanceBypass.................................................................9

1.4.8 Off-Battery ........................................................................9

1.5 Operator Controls .................................................................10

1.6 Options..........................................................................12

2.0 THEORY OF OPERATION

2.1 General Component Descriptions . ....................................................13

2.2 Detailed Component Descriptions. ....................................................15

2.2.1 Controls..........................................................................15

2.2.2 Rectifier/Charger...................................................................16

2.2.4 Inverter ..........................................................................18

2.2.5 StaticBypass......................................................................19

2.2.6 Redundant Mode ...................................................................22

3.0 OPERATION

3.1.1 MasterMenuScreen................................................................29

3.1.3 Walk-InDisplayScreen..............................................................40

3.1.4 StatusReportsScreens ..............................................................41

3.1.10 Battery Time Screen (Module Only) ....................................................62

3.2 Modes of Operation . . . .............................................................78

3.2.1 LoadOnBypass ...................................................................78

3.2.2 OKToTransfer....................................................................79

DISCONTINUED

PRO DU C T

i

Page 4

3.2.3 MomentaryOverloads ..............................................................81

3.2.4 InputPowerFailure(LoadOnBattery).................................................82

3.2.5 OneModuleOff-Line...............................................................83

3.2.6 OffBattery .......................................................................84

3.2.7 Emergency Modules Off . ...........................................................85

3.2.8 EmergencyPowerOff ..............................................................86

3.2.9 SystemShutdown..................................................................87

3.2.10 MaintenanceBypass................................................................88

3.3 ManualProcedures................................................................ 90

3.3.1 Start-UpProcedure.................................................................91

3.3.2 LoadTransferProcedures............................................................97

3.3.3 ShutdownProcedures...............................................................99

3.4 Automatic Operations ............................................................ 103

3.4.1 Overloads(WithoutTransfer)........................................................103

3.4.2 AutomaticTransferstoBypass.......................................................104

3.4.3 AutomaticRetransferstoUPS.......................................................104

3.4.4 Automatic Module Off-Line.........................................................105

3.4.5 Automatic Emergency Modules Off...................................................105

4.0 MAINTENANCE

4.1 Safety Precautions ............................................................... 106

4.2 LiebertCustomerServiceandSupport ............................................... 108

4.3 Routine Maintenance ............................................................. 109

4.3.1 RecordLog......................................................................109

4.3.2 AirFilters.......................................................................109

4.3.3 BatteryMaintenance ..............................................................110

4.3.4 TorqueRequirements..............................................................115

4.4 Detection of Trouble ............................................................. 115

4.5 ReportingaProblem ............................................................. 116

4.6 Corrective Actions ............................................................... 116

4.7 Recommended Test Equipment ..................................................... 116

5.0 SPECIFICATIONS AND RATINGS

5.1 Rating......................................................................... 117

5.2 Environmental Conditions ........................................................ 118

5.3 Adjustments . . . ................................................................. 119

5.4 BatteryOperation................................................................ 119

5.5 ElectricalSpecifications .......................................................... 120

ii

DISCONTINUED

PRO DU C T

Page 5

FIGURES

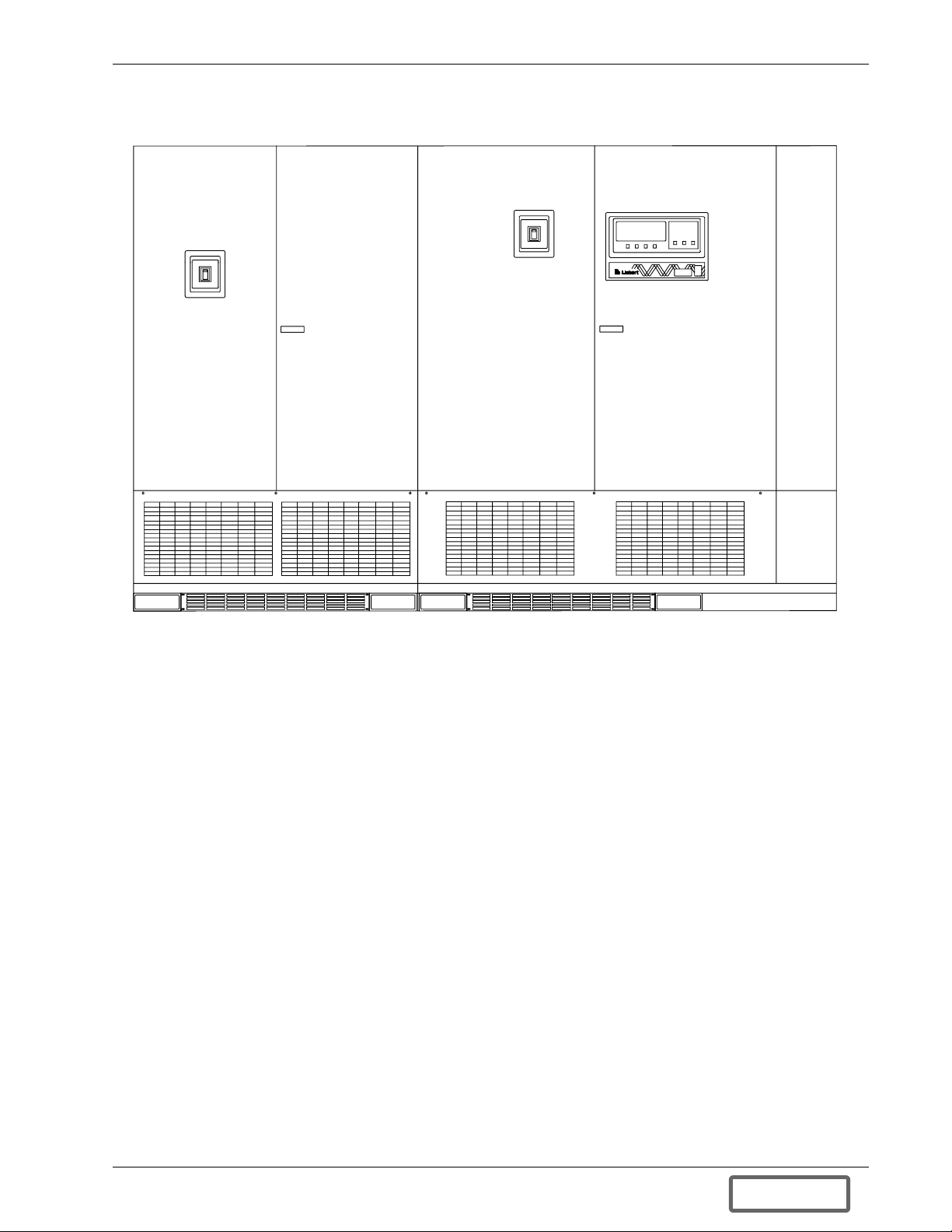

Figure3 SystemControlCabinets(SCCs) ..........................................................6

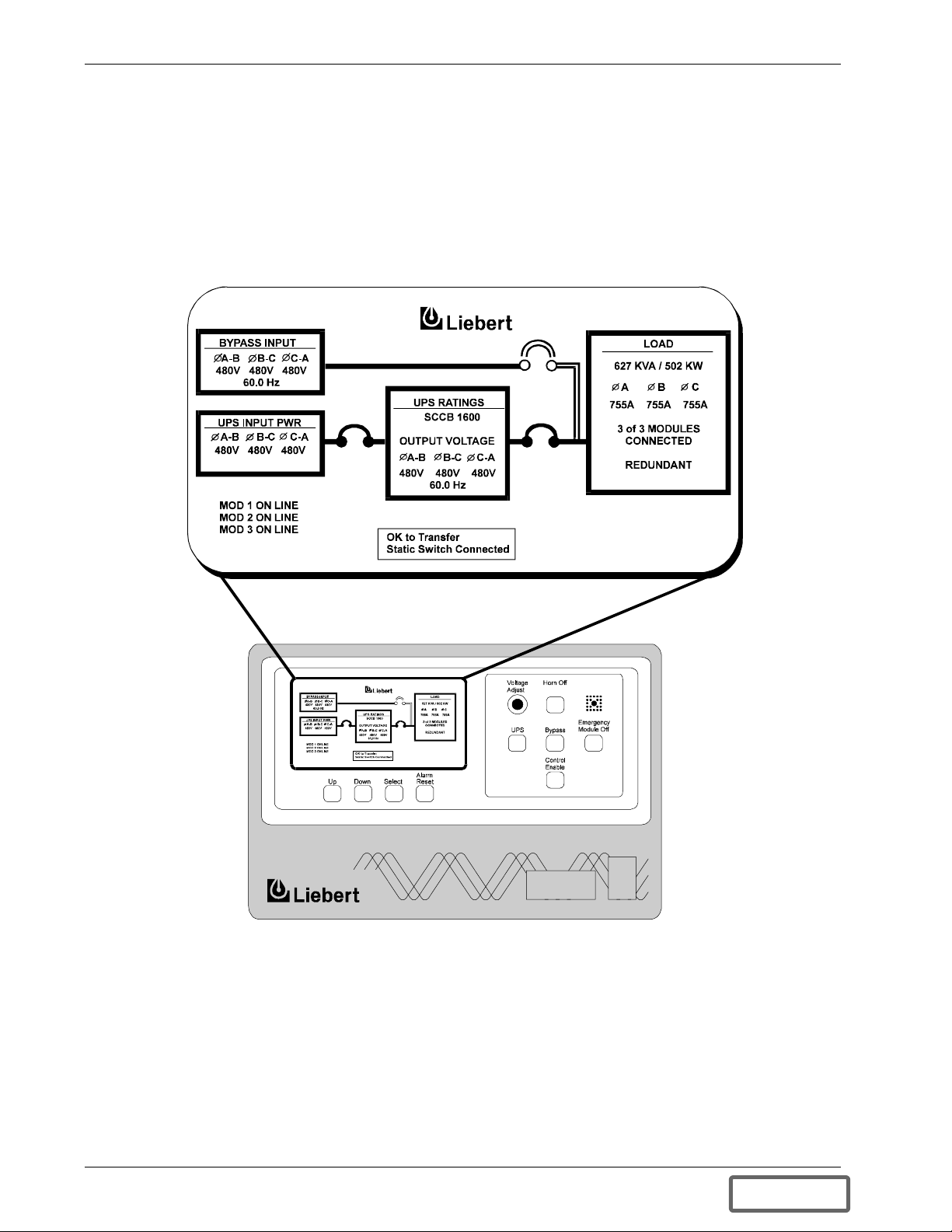

Figure4 SCCControlsandDisplayScreenwithExampleoftheMonitor/MimicScreen .....................10

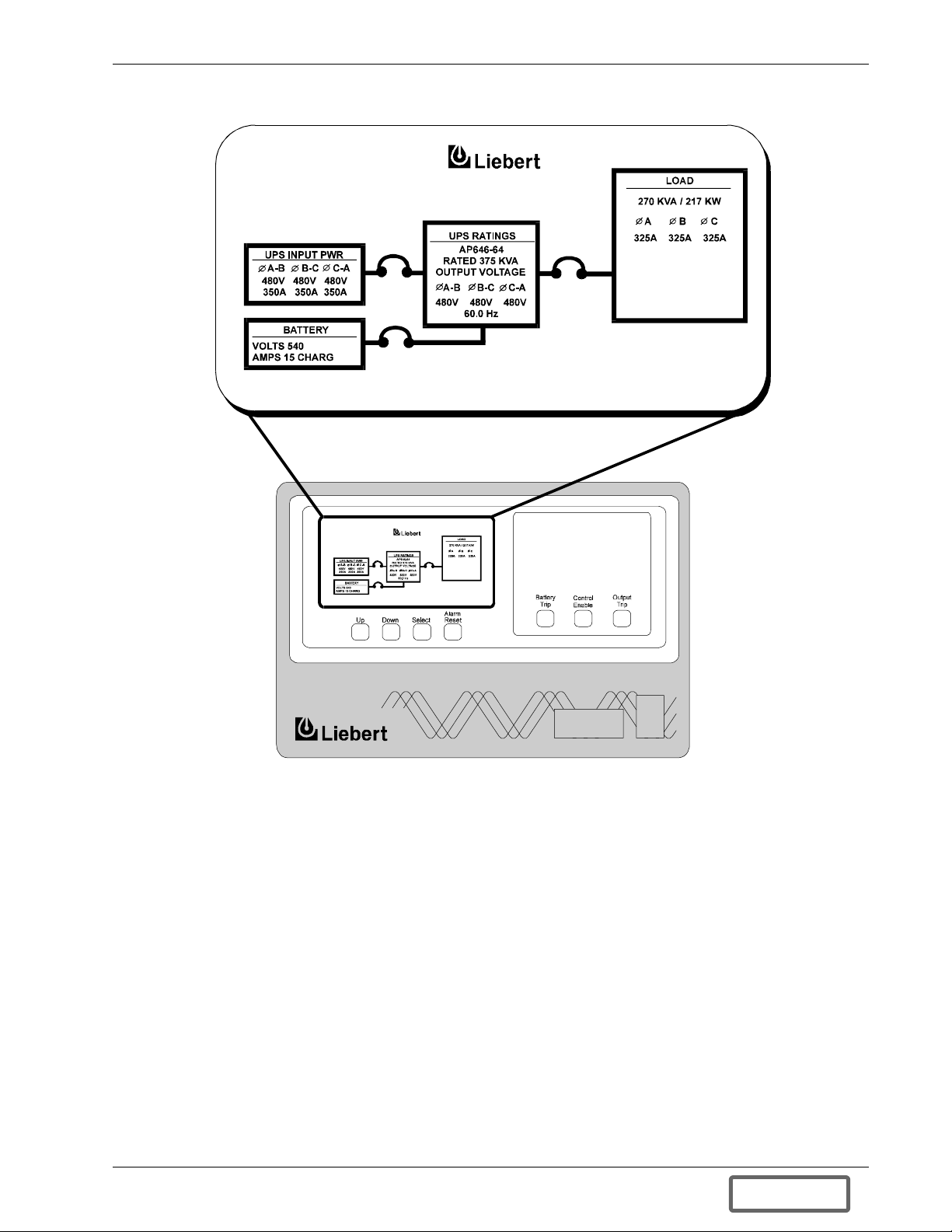

Figure5 ModuleControlsandDisplayScreenwithExampleoftheMonitor/MimicScreen...................11

Figure7 SystemControlCabinet(SCC)BlockDiagram ..............................................19

Figure8 OperatorControls,65to80kVA(left)and100to500kVA(right) ...............................24

Figure9 SystemControlCabinetOperatorControls(SCCBPictured) ...................................25

Figure10 Series600TUPSandSCCOperatorControlPanels ..........................................26

Figure11 SwitchesBehindSCCControlPanelDoor ..................................................27

Figure14 SCCMonitor/MimicDisplayScreen ......................................................31

Figure15 ModuleMonitor/MimicDisplayScreen ....................................................33

Figure16 Monitor/MimicDisplayScreenExamples:NormalPowerFlowe.................................35

Figure17 Monitor/MimicDisplayScreenExamples:UtilityFail.........................................36

Figure21 Walk-InDisplayScreenDuringStart-Up ...................................................40

Figure23 PresentStatusReportScreens ............................................................42

Figure24 EventHistoryReportScreen .............................................................43

Figure25 HistoryStatusReportScreens ............................................................44

Figure26 BatteryCycleMonitorScreen............................................................46

Figure27 BatteryCycleMonitoringSummaryScreen .................................................47

Figure28 TypicalDataonDischargeCyclesof91to240Seconds Duration................................47

Figure29 SCCSystemConfigurationScreen ........................................................48

Figure34 MaximumAuto-RetransferAttemptsScreen ................................................53

Figure35 ModuleAlarmLimitSettingsScreen ......................................................55

Figure36 LoadTransferProceduresScreen .........................................................57

Figure37 SCCStart-UpProceduresScreen .........................................................58

Figure38 ModuleStart-UpProceduresScreen ......................................................59

Figure39 SCCShutdownProceduresScreen ........................................................60

Figure40 ModuleShutdownProceduresScreen......................................................61

Figure41 BatteryTimeScreenExample-15MinuteDischarge .........................................62

Figure42 BatteryTimeScreenExample-45MinuteDischarge .........................................63

Figure43 RangeofValuesforCalculatedBatteryTimes ...............................................64

Figure44 MeterCalibrationScreen................................................................65

Figure46 SCCStatusandAlarmMessageAreas .....................................................67

Figure47 LoadonBypass(UPSNotAvailable) ......................................................78

Figure48 LoadonBypass(UPSAvailable) .........................................................79

Figure49 LoadonUPS(BypassAvailable) .........................................................80

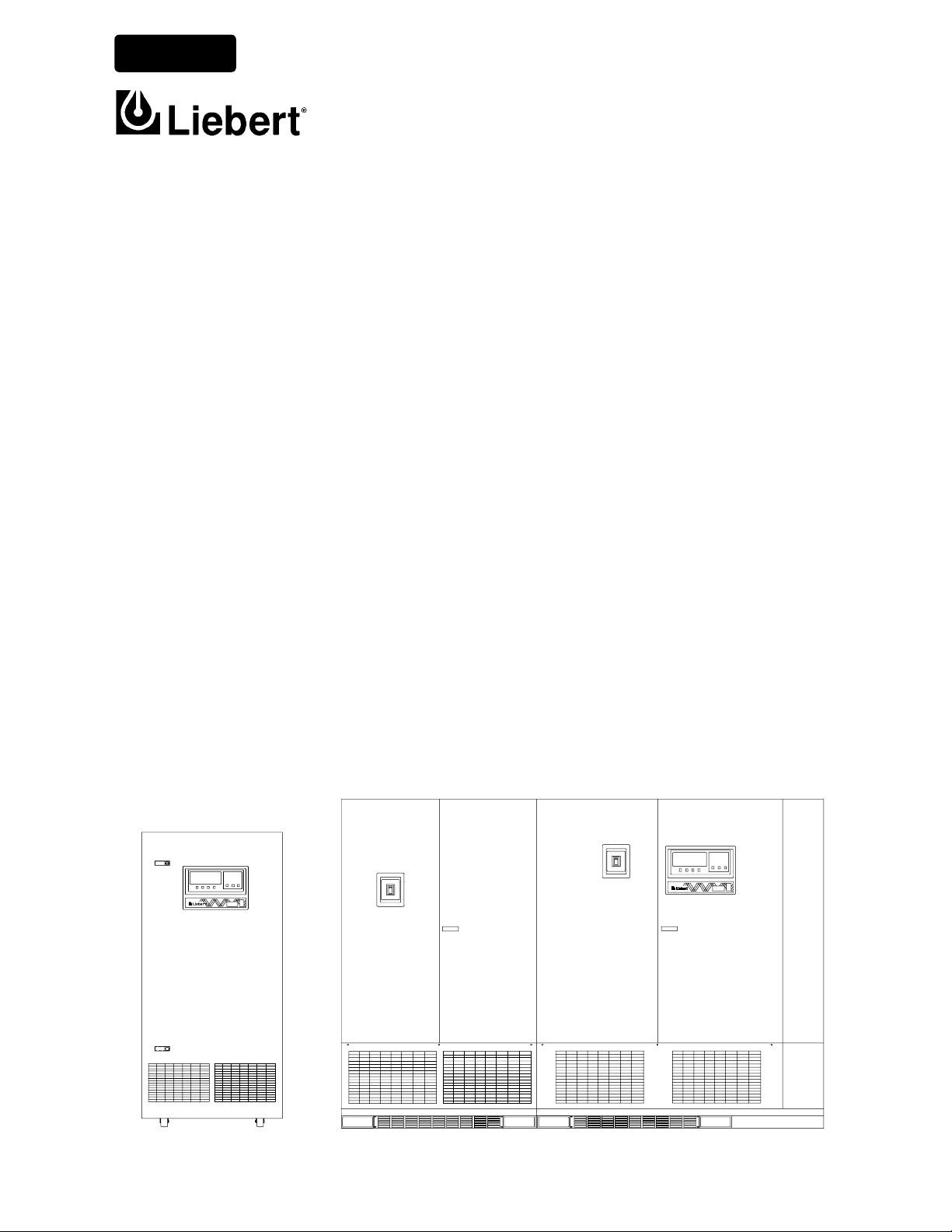

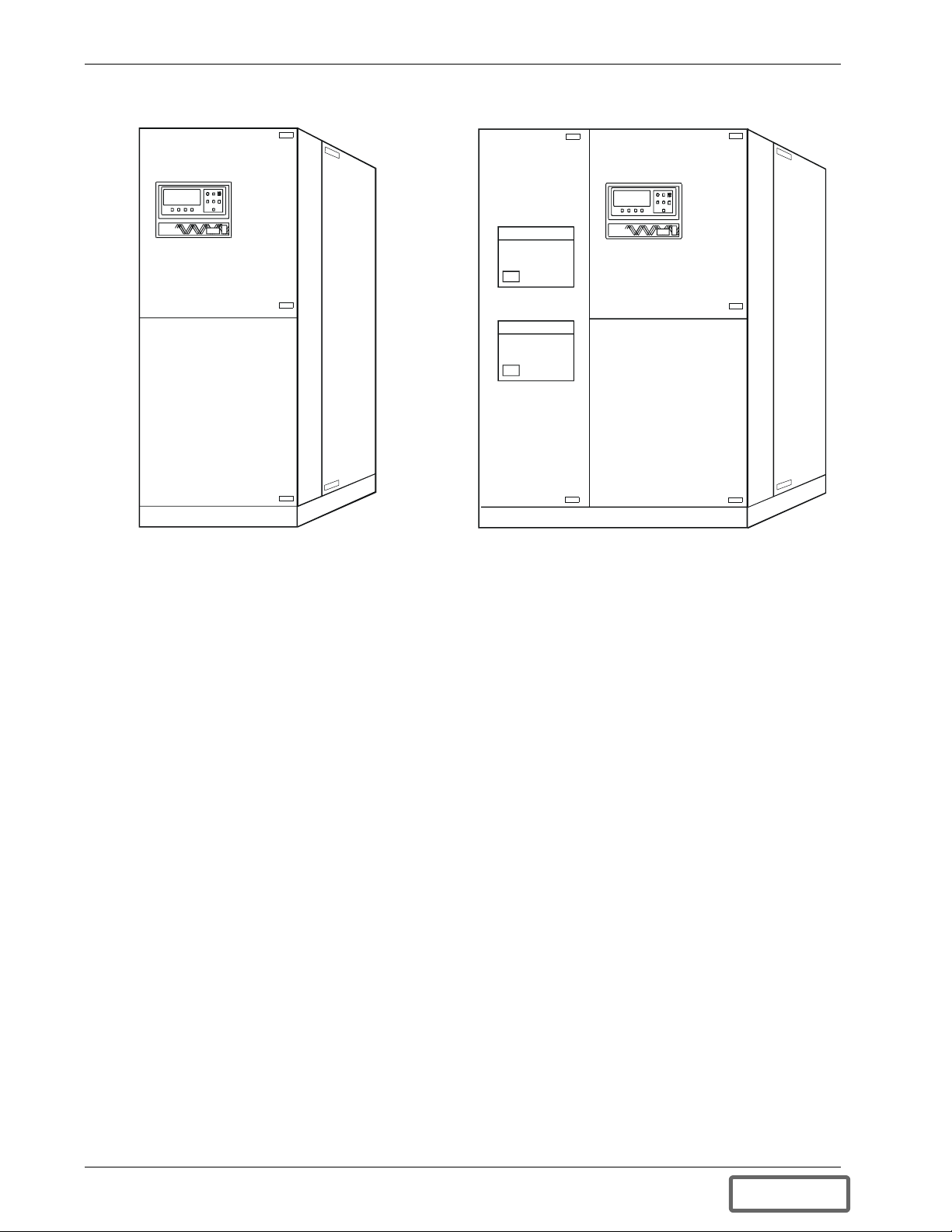

Figure 1 Multi-Module UPS, 65-80 kVA (left) and 100-500 kVA (right) ...................................3

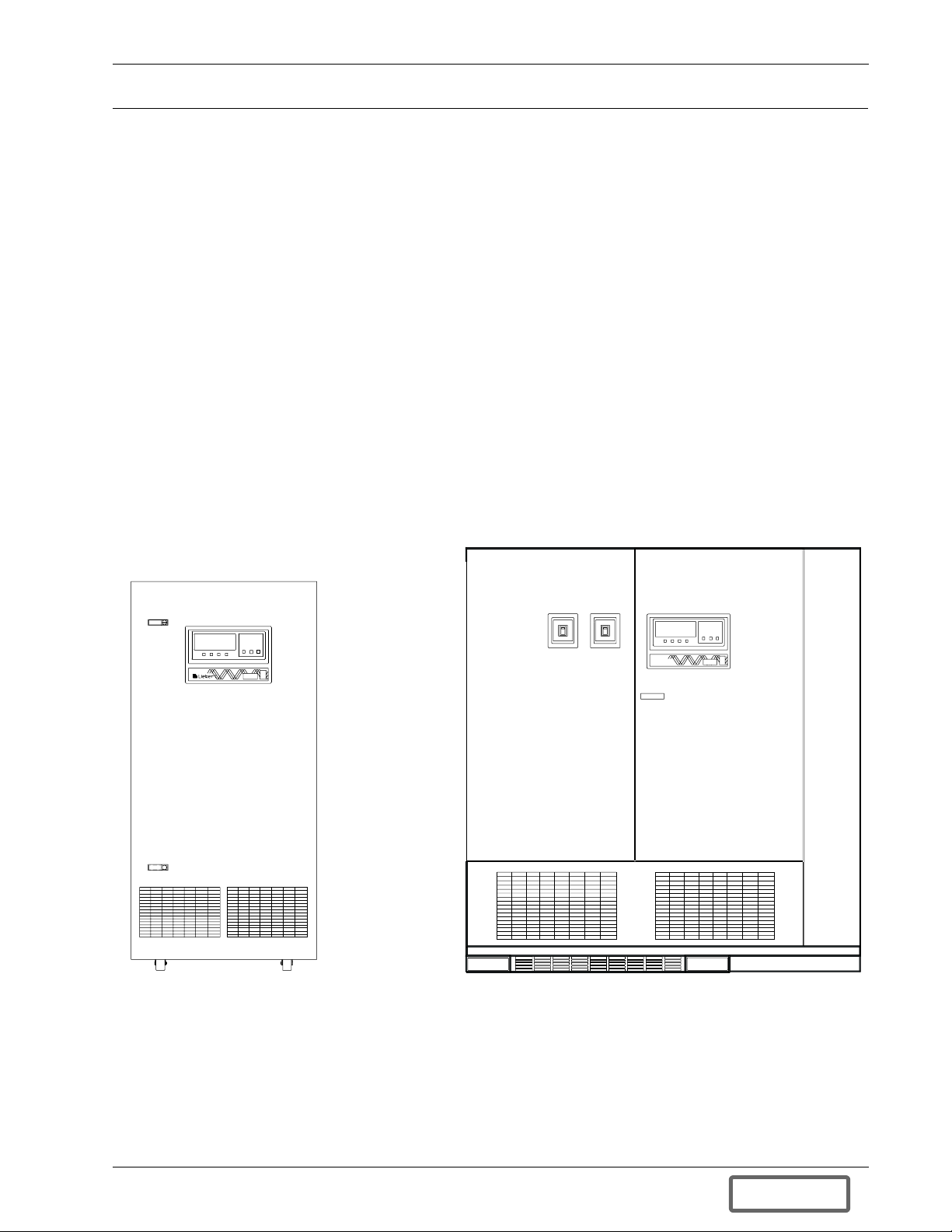

Figure 2 Multi-Module 500-750 kVA UPS ..........................................................5

Figure6 UPSModuleBlockDiagram.............................................................14

Figure12 MenuTree ...........................................................................28

Figure 13 Master Menu Screens, SCC (above) and Module (below).......................................29

Figure 18 Monitor/Mimic Display Screen Examples: Load on Bypass, UPS Modules On and Charging Battery . . . . 37

Figure 19 Monitor/Mimic Display Screen Examples: Load on UPS, One UPS Module Off Line ................38

Figure 20 Monitor/Mimic Display Screen Examples: Load on Bypass, All UPS Modules Off Line . . . . . . . . . . . . . . 39

Figure22 StatusReportsScreen ..................................................................41

Figure30 DateScreen ..........................................................................49

Figure31 TimeScreen ..........................................................................50

Figure32 AutoDialSettingScreen ................................................................51

Figure33 ModemBaudRate .....................................................................52

Figure45 BatteryEqualizeScreen ................................................................66

DISCONTINUED

PRO DU C T

iii

Page 6

Figure50 MomentaryOverload(PulsedStaticBypassSwitch)..........................................81

Figure57 LoadonMaintenanceBypass(TwoBreakers) ...............................................88

Figure58 LoadonMaintenanceBypass(ThreeBreakers)..............................................89

Figure63 ModuleShutdownProceduresScreen ....................................................101

Figure64 Current-Versus-TimeCurveofModuleOverloadCapacity....................................103

Table1 AlarmMessages-MeaningandCorrectiveAction ...........................................70

Table4 TorqueSpecifications(UnlessOtherwiseLabeled) ..........................................115

Figure51 InputPowerFail(LoadonBattery) .......................................................82

Figure52 OneModuleOff-Line(LoadonUPS) .....................................................83

Figure53 LoadonUPS(BatteryNotAvailable) .....................................................84

Figure 54 Emergency Modules Off ................................................................85

Figure55 EmergencyPowerOff .................................................................86

Figure56 SystemShutdown .....................................................................87

Figure59 SCCStart-UpProceduresScreen .........................................................93

Figure60 ModuleStart-UpProceduresScreen ......................................................95

Figure61 LoadTransferProceduresScreen .........................................................97

Figure62 SCCShutdownProceduresScreen ........................................................99

TABLES

Table2 AlarmMessages-Summary .............................................................74

Table3 Series600TTerminalCommands.........................................................77

Table5 RecommendedTestEquipmentandTools..................................................116

iv

DISCONTINUED

PRO DU C T

Page 7

IMPORTANT SAFETY INSTRUCTIONS

Save These Instructions.

This manual contains important instructions that should be followed during installation and maintenance of your

Series 600T UPS and batteries.

WARNING

EXERCISE EXTREME CARE WHEN HANDLING UPS CABINETS TO

AVOID EQUIPMENT DAMAGE OR INJURY TO PERSONNEL. REFER TO

SEPARATE INSTALLATION MANUAL FOR EQUIPMENT HANDLING

INFORMATION AND INSTALLATION PROCEDURES.

FOLLOW ALL BATTERY SAFETY PRECAUTIONS IN 4.0 MAINTENANCE WHEN INSTALLING, CHARGING, OR SERVICING

BATTERIES. IN ADDITION TO THE HAZARD OF ELECTRIC SHOCK,

GAS PRODUCED BY BATTERIES CAN BE EXPLOSIVE AND SULFURIC

ACID CAN CAUSE SEVERE BURNS.

IN CASE OF FIRE INVOLVING ELECTRICAL EQUIPMENT, USE ONLY

CARBON DIOXIDE FIRE EXTINGUISHERS, OR OTHERS APPROVED

FOR USE IN ELECTRICAL FIRE FIGHTING.

EXTREME CAUTION IS REQUIRED WHEN PERFORMING

MAINTENANCE.

BE CONSTANTLY AWARE THAT THE UPS SYSTEM CONTAINS HIGH

DC AS WELL AS AC VOLTAGES. WITH INPUT POWER OFF AND THE

BATTERY DISCONNECTED, HIGH VOLTAGE AT FILTER CAPACITORS

AND POWER CIRCUITS SHOULD BE DISCHARGED WITHIN 30

SECONDS. HOWEVER, IF A POWER CIRCUIT FAILURE HAS

OCCURRED, YOU SHOULD ASSUME THAT HIGH VOLTAGE MAY

STILL EXIST AFTER SHUTDOWN. CHECK WITH A VOLTMETER

BEFORE MAKING CONTACT.

AC VOLTAGE WILL REMAIN ON THE SYSTEM BYPASS (SBB) AND UPS

OUTPUT CIRCUIT BREAKERS, AND THE STATIC BYPASS SWITCH,

UNLESS ASSOCIATED EXTERNAL CIRCUIT BREAKERS ARE OPENED.

CHECK FOR VOLTAGE WITH BOTH AC AND DC VOLTMETERS PRIOR

TO MAKING CONTACT.

WHEN THE UPS SYSTEM IS UNDER POWER, BOTH THE OPERATOR

AND ANY TEST EQUIPMENT MUST BE ISOLATED FROM DIRECT

CONTACT WITH EARTH GROUND AND THE UPS CHASSIS FRAME BY

USING RUBBER MATS.

SOME COMPONENTS WITHIN THE CABINETS ARE NOT CONNECTED

TO CHASSIS GROUND. ANY CONTACT BETWEEN FLOATING

CIRCUITS AND THE CHASSIS IS A LETHAL SHOCK HAZARD.

EXERCISE CAUTION THAT THE TEST INSTRUMENT EXTERIOR DOES

NOT MAKE CONTACT EITHER PHYSICALLY OR ELECTRICALLY

WITH EARTH GROUND.

DISCONTINUED

PRO DU C T

1

Page 8

OVERVIEW OF THIS MANUAL

The manual is organized so that information can be found quickly. Each major topic is separated by sections, and

the Table of Contents contains major headings within each section. The names of the sections and their contents

are described below.

1.0 - Introduction is a summary of the Series 600T UP S System. It describes some of the unique features and

benefits of the Series 600T, as well as the design principles and standards that Liebert follows in the manufacture

of each system. Descriptions of the Series 600T system and an overview of its functions are also included.

2.0 - Theory of Operation is an explanation of the major circuit groups of the Series 600T UPS. This section is

for individuals who want to know both the basics and the specifics of each major component. The text explains

how the UPS handles electrical disturbances and interruptions.

3.0 - Operation is written for facility personnel responsible for the operation of the system. It details the procedures required to start-up each module and the system, to transfer the load between the available sources, and to

shut down each module and the system. Both manual and automatic operations are described. Operator controls

and displays, including the solid state liquid crystal display (LCD) screen, are illustrated and explained for the

UPS Module and for the System Control Cabinet (SCC).

4.0 - Maintenance lists routine maintenance checks and helps the user pinpoint and quickly resolve problems if

they arise.

5.0 - Specifications and Ratings gives detailed specifications about the Series 600T UPS System. This technical

information is of use to installing contractors, engineers, and service personnel.

If you require assistance for any reason, call the toll-free Liebert Global Services number: 1-800-543-2378. For

LGS to assist you expediently, please have the following information available:

Part Numbers:

Serial Numbers:

kVA Rating:

Date Purchased:

Date Installed:

Location:

Input Voltage:

Output Voltage:

Battery Reserve Time:

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

2

DISCONTINUED

PRO DU C T

Page 9

1.0 INTRODUCTION

1.1 System Description

The role of the pa rallel-redundant multi-module UPS system is to supply uninterruptible, clean power to the critical load. It maintains a full-voltage, low-distortion output, even if the utility source power sags or becomes distorted.

If there is an outage of the source power, the UPS maintains power to the load until an alternate source of power

is activated, or until the original power source is restored. If input AC power is not restored, the UPS maintains

the load (with the battery plant) long enough that the critical equipment can be shut down in an orderly manner.

The Series 600T UPS module displays the rate of battery discharge and calculates the amount of battery time

remaining based on the actual connected load. The time that the battery will maintain the load depends on the

capacity of the battery backup plant and the size of the load.

The system control logic automatically manages critical bus operation. System logic is resident in Application

Specific Integrated Circuits (ASICs) for precise control and improved reliability.

If the critical load current exceeds the rated load of the Series 600T UPS system, the control logic determines the

magnitude of the overload and reacts appropriately. Overloads are usually the result of inrush current requirements. The UPS system supports loads that are 150% of the rated load for up to 30 seconds and 125% of the

rated load for up to ten minutes. If the system is operating in the non-redundant mode (e.g., a UPS module is off

line), the overload limits are automatically adjusted.

Figure 1 Multi-Module UPS, 65-80 kVA (left) and 100-500 kVA (right)

If the load surpasses the overload capacity of the UPS, the load is automatically transferred to bypass without

interruption. When the load returns to within the UPS rating, it is either automatically or manually returned

Introduction 3

DISCONTINUED

PRO DU C T

Page 10

(retransferred) to the UPS. How and when the load is returned to the UPS depends on several factors: how long

the overload lasted, how many overload conditions occurred before transfer, whether there is an imminent failure

of any part of the UPS, e tc. Refer to 3.4 - Automatic Operations.

In the unlikely event of a fault within the UPS, the SCC control logic, which continuously monitors all critical

circuits within the UPS system, transfers the load to bypass without interruption and simultaneously sets off local

and remote alarms. If a fault is detected in an individual UPS module, that module is automatically disconnected

from the critical bus and shut down. A Module Off Line status message will appear at the SCC display. The

module can be manually returned to service when the fault has been corrected.

If the multi-module UPS system is operating in the redundant mode (at least one extra module is available for the

connected critical load), the load will remain on the UPS system if one individual module is disconnected from

the critical bus (off line). If the UPS system is operating in the non-redundant mode, the load will be automatically transferred to bypass if a module goes off line.

The Series 600T UPS display system provides precise monitoring of the UPS, fast alarm response, and quick

troubleshooting. For easy manual operations, menu-driven software provides access to several step-by-step help

screens. All operator functions are performed using menu-prompted displays and a minimum number of operator

controls. The System Control Cabinet includes external communication capability with both automatic dial-out

and dial-in features for early warning and diagnosis of abnormal conditions.

The system software allows the operator, or Liebert Global Services, to enter application specific information.

Overload, overvoltage, battery discharge, and shutdown limits can be set by the operator. In effect, the software

is tailored for each site.

The UPS system protects critical equipment from source power disturbances and outages, load faults, and UPS

malfunctions. This triple protection virtually eliminates computer and computing equipment downtime as a

result of utility source power problems.

4 Introduction

DISCONTINUED

PRO DU C T

Page 11

Figure 2 Multi-Module 500-750 kVA UPS

Introduction 5

DISCONTINUED

PRO DU C T

Page 12

Figure 3 System Control Cabinets (SCCs)

Types of System Control Cabinets (SCCs)

• SCCT -- A stand-alone cabinet containing system control logic for up to six UPS modules, a static bypass

switch, manually operated disconnects for the static bypass switch, and two motor-operated system circuit

breakers.

• SCCB -- Similar to the SCCT, e xcept that external sheet metal matches that of the UPS modules.

• SCCP -- Similar to the SCCB, except narrower and designed for two UPS modules.

• SCCI -- System control logic and static bypass switch are integrated into a switchboard cabinet manufac-

tured by others, which also includes the system circuit breakers.

• SCCC -- An integrated configuration like the SCCI, but with a static switch rated for continuous duty.

6 Introduction

DISCONTINUED

PRO DU C T

Page 13

1.2 Reliability

Reliability is the most important design goal for Uninterruptible Power Systems. Liebert Series 600 UPS systems

have demonstrated reliability by achieving a field-proven critical bus MTBF in e xcess of one million hours. In

addition, our Quality Assurance program is certified to the requirements of ISO 9001 standards.

Liebert Large UPS systems are ETL listed to the requirements of UL 1778. All equipment and components are

manufactured to applicable UL, NEC, NEMA, ANSI, IEEE, and CSA standards and guidelines.

Designed for Success

The keys to reliability in the design of the UPS system are using conservatively rated components, minimizing

transfers to bypass, making operator controls understandable, and providing easy access for maintenance and

repair. Liebert UPS systems lead the industry in all these areas.

For example, the Series 600T can clear substantial overloads through the solid state static bypass switch without

transferring to the bypass source. By minimizing transfers to bypass, the Series 600T minimizes operation of circuit breakers and enhances system reliability.

As another example, the system control logic has been packaged into Application-Specific Integrated Circuits

(ASICs) to eliminate the failure-prone discrete logic boards used in other brands of UPS products. Furthermore,

these ASICs are isolated from heat-generating components to ensure optimal operating temperatures.

Other Factors to Consider

Reliability depends on more than just UPS module design. Improper installation can cause any system to fail. To

prevent this, Customer Engineers from Liebert Global Services thoroughly inspect the installation of all our systems to ensure they are installed properly and operating within performance specifications.

Once a UPS is properly installed, you—the on-site equipment operator—are the most important factor in preventing critical bus failures or unplanned transfers to bypass. To make your task easier, the Series 600T UPS provides easy-to-follow, prompted instructions on the industry’s largest operator display screen.

If you ever need help, call Liebert Global Services (24 hours a day at 1-800-543-2378). Your attention to proper

installation, operation, and periodic maintenance will ensure that your mission-critical operations receive the

best possible protection from electrical disturbances and outages.

Introduction 7

DISCONTINUED

PRO DU C T

Page 14

1.3 Safety Precautions

Read this manual thoroughly, paying special attention to the sections that apply to you, before working with the

UPS. Also read the battery m anufacturer’s manual before working on or near the battery.

Under typical operation and with all UPS doors closed, only normal safety precautions are necessary. The area

around the UPS system and Battery should be kept free from puddles of water, excess moisture, or debris.

Special safety precautions are required for procedures involving handling, installation, and maintenance of the

UPS system or the battery. Observe precautions in the separate Installation Manual before handling or installing

the UPS system. Observe precautions in 4.0 - Maintenance, before a s well as during performance of all maintenance procedures. Observe all battery safety precautions in 4.0 - Maintenance before working on or near the

battery.

This equipment contains several circuits that are energized with high voltage. Only test equipment designated for troubleshooting should be used. This is particularly true for oscilloscopes. Always check with an AC

and DC voltmeter to ensure safety before making contact or using tools. Even when the power is turned Off, dangerously high potentials may exist at the capacitor banks. Observe all battery precautions when near the battery

for any reason.

ONLY qualified service personnel should perform maintenance on the UPS system. When performing

maintenance with any part of the equipment under power, service personnel and test equipment should be standing on rubber mats. The service personnel should wear insulating shoes for isolation from direct contact with the

floor (earth ground).

Unless all power is removed from the equipment, one person should never work alone. A second person should

be standing by to assist and summon help in case an accident should occur. This is particularly true when work is

performed on the battery.

Three types of messages are used throughout the manual to stress important text. Carefully read the text below

each Warning, Caution, and Note and use professional skills and prudent care when performing the actions

described by that tex t.

A Warning signals the presence of a possible serious, life-threatening condition. For example:

WARNING

LETHAL VOLTAGES MAY BE PRESENT WITHIN THIS UNIT EVEN

WHEN IT IS APPARENTLY NOT OPERATING. OBSERVE ALL

CAUTIONS AND WARNINGS IN THIS MANUAL. FAILURE TO DO SO

COULD RESULT IN SERIOUS INJURY OR DEATH. DO NOT WORK ON

OR OPERATE THIS EQUIPMENT UNLESS YOU ARE FULLY QUALIFIED

TO DO SO!! NEVER WORK ALONE.

A Caution indicates a condition that could seriously damage equipment and possibly injure personnel. For

example:

CAUTION

Make sure you understand the proper sequence before operating any circuit

breaker. Operating a Maintenance Bypass circuit breaker out of sequence could

cut off power to the critical load.

A Note emphasizes important text. If the note is not followed, equipment could be damaged or may not operate

properly. For example:

NOTE

If the UPS system has a blown fuse, the cause should be determined before you

replace the fuse. Contact Liebert Global Services.

8 Introduction

DISCONTINUED

PRO DU C T

Page 15

1.4 Modes of Operation

Refer to 2.0 - Theory of Operation and 3.0 - Operation for more details.

1.4.1 Normal (Load on UPS)

The utility AC source provides power to the rectifier/charger in each UPS module. Each rectifier/charger converts the utility AC power to DC and supplies DC power to the UPS module inverter while simultaneously float

charging the battery plant. Each UPS module inverter converts DC to AC and furnishes AC power to the critical

bus. The System Control Cabinet (SCC) is the tie point for the paralleled modules and monitors and controls the

critical bus performance.

1.4.2 Input Power Failure

If the utility source power fails or is outside the acceptable range, the battery plant becomes the primary supplier

of DC power to the inverter.

1.4.3 Recharge

After the utility source power is restored, or an alternate power source becomes available, each rectifier/charger

slowly walks-in to once again power the inverters and recharge the battery plant.

1.4.4 Overload

Overloads in critical systems may be caused by inrush currents during connected equipment start-up or by faults

in the critical load. The Liebert Series 600T UPS system can maintain full output voltage regulation while sustaining the following overloads:

• Up to 150% for 30 seconds

• Up to 125% for 10 minutes

• Up to 104% for an indefinite period of time

Also, for clearing momentary faults above 155% of rated SCC current, the static switch turns on for 40 milliseconds to supply power from the bypass source. Up to 1000% of the rated current can be supplied for less than one

cycle, while up to 500% of rated load can be sustained for the full 40 milliseconds of pulsed-parallel operation.

The critical load remains on the UPS modules for the above conditions. If the UPS system overload capacity is

exceeded, an automatic transfer to bypass is initiated, which closes the system bypass circuit breaker (SBB) and

opens the UPS output circuit breaker.

Whenever you have an overload condition, you should determine the cause of the overload.

1.4.5 Redundant

If the multi-module UPS system includes one more module than the number required to supply the critical load,

the UPS system can operate in the redundant m ode. This means that the load will remain on the UPS system if

one of the modules is disconnected because of an overload, an internal fault, or for maintenance. If the additional

module is not included in the system design, or if the additional module is disconnected from the critical bus, the

UPS system operates in the non-redundant mode.

1.4.6 Bypass (Internal)

The SCC control logic initiates an automatic transfer to the bypass source if the overload-current-versus-time

curve is exceeded or if specified UPS system faults occur. You can also manually transfer the load to the bypass

(without interruption) if you must take the UPS module out of service for maintenance.

The SCC internal maintenance bypass will allow most key components and operating modes to be checked without disturbing the critical bus. However, certain key power-carrying components, such as the output and bypass

circuit breakers, will require complete system shutdown or isolation through an external maintenance bypass

cabinet for 100% service.

1.4.7 Maintenance Bypass

The installation of a Maintenance Bypass Cabinet, Panelboard or Switchboard is recommended to allow you to

totally isolate the UPS from all power sources. Use of the Maintenance Bypass is described in 3.0 - Op eration.

1.4.8 Off-Battery

The battery plant can be disconnected from the rectifier/charger by using an external Module Battery Disconnect

(MBD circuit breaker). The UPS module continues to function normally, though it does not have power outage

back-up capability until the battery plant is reconnected.

Introduction 9

DISCONTINUED

PRO DU C T

Page 16

1.5 Operator Controls

The Liebert Series 600T UPS System Control Cabinet (SCC) and each individual module are equipped with a

microprocessor-based Operator Display Screen and Control Panel designed for convenient and reliable operation.

The front panel location of t he monitoring and control system enables the user to quickly identify the current status of the UPS and to perform most of the manual operations. The operator display screen is driven by an easyto-follow menu-prompted software program that controls and monitors the UPS system.

Figure 4 SCC Controls and Disp lay Screen with Exa mple of the Monitor/Mimic Screen

The operator controls and Monitor/Mimic screen for the System Control Cabinet (SCC) are shown in Figure 4.

The controls and display screen for each UP S module are shown in Figure 5. Each cabinet (SCC or module) has

the displays and controls required to monitor and perform its functions.

Figure 4 shows a three-module system designed for redundant operation. A multi-module UPS system may

include up to six (6) modules for each SCC.

Detailed instructions on how to interpret the displays and use the controls are in 3.0 - Operation.

10 Introduction

DISCONTINUED

PRO DU C T

Page 17

Figure 5 Module Controls and Display Screen with Example of the Monitor/Mimic Screen

Introduction 11

DISCONTINUED

PRO DU C T

Page 18

1.6 Options

A number of standard pre-designed options are available from Liebert for your UPS system. Described below are

the most frequently provided options. Note that the battery items (1-3) are required to complete the UPS system.

The remaining options provide improved system performance or convenience.

1. Battery

The batteries provide power in the event of a power outage. The Liebert UPS can use a variety of battery

types, provided the battery plant is designed for the UPS DC voltage range and the load requirements of

your application.

2. Battery Racks or Cabinets

The battery racks are specifically designed for stationary service batteries. They are painted with electrolyteresistant paint for corrosion resistance. Battery cabinets are available for 150 through 600 kVA modules.

3. Module Battery Disconnect

The UPS system utilizes a separate Module Battery Disconnect for remotely located batteries. A sensing circuit in the UPS module, set at the battery low voltage limit, trips the Module Battery Disconnect to safeguard the battery from excessive discharge. The Module Battery Disconnect has an undervoltage release

mechanism designed to ensure that during any shutdown or failure mode all battery potential is removed

from the U PS system

4. Input Distortion Filter

This filter reduces rectifier input current reflected harmonic distortion to less than 7% THD, and less than

4% THD for modules with the optional 12-pulse rectifier. The filter is factory installed within the UPS. This

filter also improves the input power factor to better than 0.92 lagging.

5. 12-Pulse Rectifier

Certain models may be ordered with the optional 12-pulse rectifier section. This provides input isolation and

reduces reflected input current THD to less than 9%, or less than 4% with optional input filter.

6. Isolation Transformers

An optional rectifier input isolation transformer is available in a matching transformer cabinet. A bypass isolation transformer is also available.

7. Three Breaker Maintenance Bypass

This switchboard provides make-before-break maintenance bypass. It includes: UPS Bypass Input Breaker

(BIB), Maintenance Bypass Breaker (MBB), and Maintenance Isolation Breaker (MIB).

8. Two Breaker Maintenance Bypass

This switchboard provides make-before-break maintenance bypass. It includes: Maintenance Bypass

Breaker (MBB) and Maintenance Isolation Breaker (MIB).

9. Load Bus Synchronization (LBS)

The Load Bus Sync (LBS) option keeps two independent UPS systems (and therefore their critical load

buses) in sync, even when the modules are operating on batteries or asynchronous AC sources. This means

that critical loads connected to both load buses through a Static Bus Transfer Switch can be switched seamlessly between the two.

10. SiteScan Central Monitoring System

Liebert manufactures a central monitoring system that automatically displays key UPS measurements and

alarms, as well as data from a variety of sensors. This monitoring system signals alarms so corrective action

can be taken. Events and data can be printed in hard copy. Data can be logged for analysis.

11. Remote Monitor Panel

The UPS system may also be provided with an optional Remote Monitor Panel. This Panel provides eight

LED indicators and may be placed at a convenient location near the critical load. A functional description of

the Remote Monitor Panel is provided in 3.0 - Operation of this manual.

12. Customer Alarm Interface

This optional interface board allows the input and display of 8 alarms from customer-supplied contacts, each

with a customer-selected name of up to 16 characters. The following attributes can be user programmed for

each alarm: latching, summary, freeze history, sound horn, auto-dial, and time delay (0 to 999.9 seconds).

12 Introduction

DISCONTINUED

PRO DU C T

Page 19

2.0 THEORY OF OPERATION

2.1 General Component Descriptions

The UPS system includes all of the equipment necessary to continuously provide computer-grade AC power to a

critical load, even when there is an interruption of the utility line power. It consists of a System Control Cabinet

(SCC), UPS modules, and a back-up battery plant. Refer to Figure 6 and Figure 7. Except where otherwise

noted, the configuration is presumed to be parallel-redundant (with at least one more UPS module than required

to support the rated load).

System Control Cabinet

The System Control Cabinet (SCC) includes system controls, static bypass switch, load transfer control, protective devices, and other accessories. The system controls simultaneously monitor two or more parallel UPS modules sharing a critical load for increased capacity and/or redundancy. The two (2) motor-operated system circuit

breakers (system bypass breaker—SBB and UPS output breaker) may be contained within the SCC, depending

on the configuration designed for your installation.

System Controls: The system control logic automatically manages critical bus operation and monitors performance of the UPS modules. Microprocessor technology and dedicated firmware provide advanced logic control

and a comprehensive display of information. The system control logic synchronizes the output of the UPS system to the bypass source. The SCC includes ports for communicating with external devices. Liebert Multi-Module Units do not require an SCC for load sharing. Automatic, parallel module load sharing is a function built into

the modules themselves; however interconnection through the SCC enables the modules to share data for more

precise control. Modules do not require master clocks or controls in order to load share or free-run at 60.0 Hz.

Static Bypass Switch: The static (solid-state) bypass switch immediately transfers the load from the inverter to

the bypass AC power source in the event of a severe overload on the system or a failure within the UPS. This

transfer takes place without any interruption of the power supplied to the load. The system includes redundant

circuits to detect and isolate shorted SCRs in the static switch.

Fuses are installed in series with the static bypass circuit to ensure reliable overload protection in the unlikely

event of a catastrophic output condition (e.g., a dropped wrench) electrically close to the output of your UPS system. The static switch SCRs themselves are rated to easily handle the fuse-blowing current.

Bypass Circuit: The bypass circuit consists of electrically operated circuit breakers and associated synchronizing and control circuitry to transfer the load to/from the bypass source.

Theory of Operation 13

DISCONTINUED

PRO DU C T

Page 20

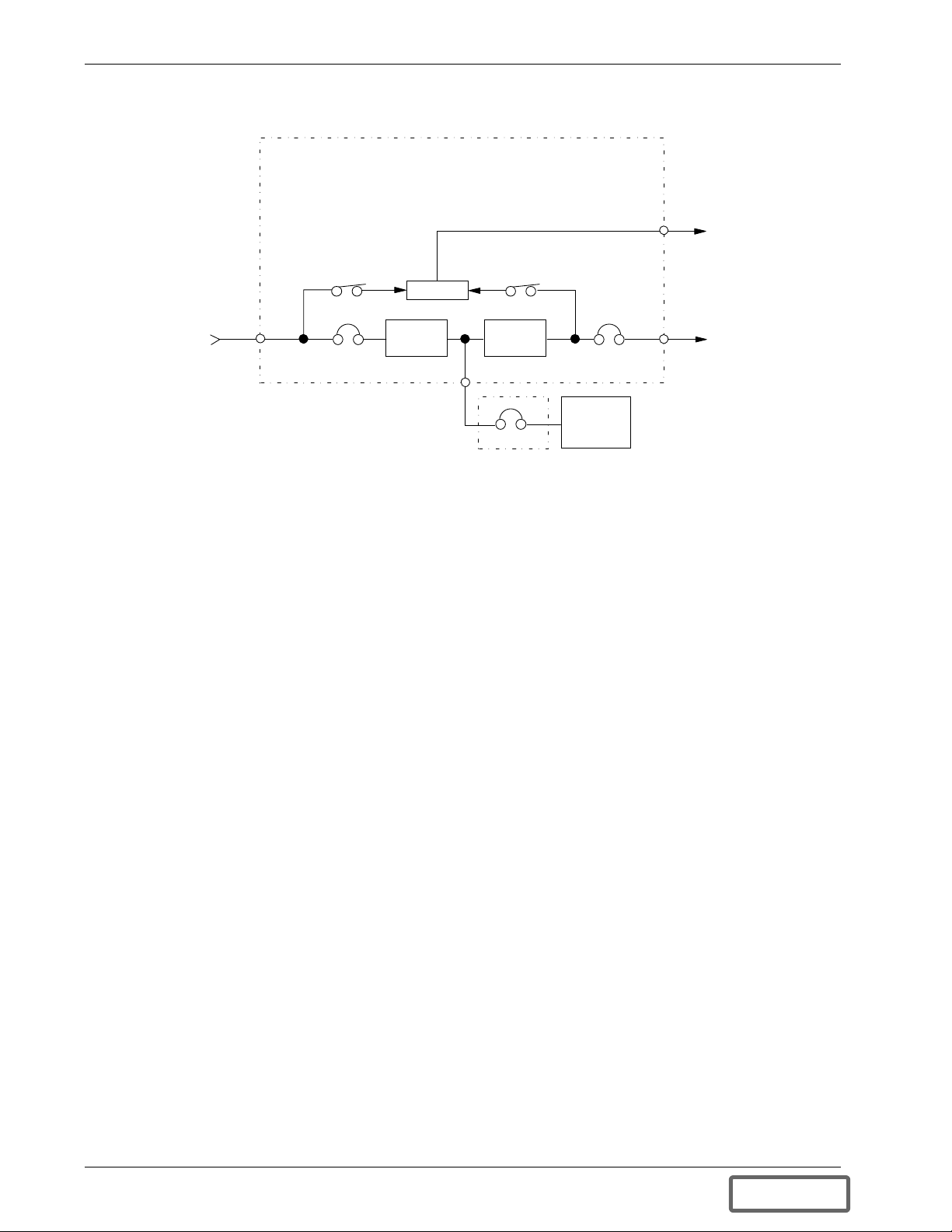

Figure 6 UPS Module Block Diagram

MULTI-MODULE UPS SYSTEM

CONTROL POWER

Control

Wiring

To SCC

Controls

Utility

Input

Power

Input

CB

Rectifier/

Charger

Inverter

Output

CB

Battery

MBD

CB - Circuit Breaker

MBD - Module Battery Disconnect

SCC - Syste m Control Cabinet

Output

Power

To SCC

UPS Module

The UPS module consists of module controls, a rectifier/charger, an inverter, protective devices, and other accessories.

Module Controls: The module control logic monitors performance of the UPS module. The UPS module status

is displayed locally and is also sent to the System Control Cabinet.

Rectifier/Charger: The rectifier/charger converts utility power from AC to DC to charge the battery and provide the DC input to the inverter. Its design limits reflected harmonic current distortion to source power and provides low-ripple DC power for charging batteries. Multiple rectifier/chargers can share a common battery plant,

if that configuration i s preferred for your application.

Inverter: The inverter converts DC power into the precise AC power required to supply a sensitive critical load.

The inverter converts DC power into a pulse-width-modulated (PWM)/six-step waveform that is easily filtered

into a clean sine wave output. The PWM/stepwave also minimizes the harmonic voltage distortion caused by

typical switching power supplies and other non-linear load components used in computers and related electronics.

Battery Plant

The battery is used as the alternate source of power to supply DC power to the inverter if the AC supply voltage

is outside the acceptable range. The battery supplies power to the inverter until the utility power is restored or

until an alternate power source is available. If AC source power is not restored or an alternate power source is not

available, the battery can be sized to provide power long enough for an orderly shutdown of the load.

14 Theory of Operation

DISCONTINUED

PRO DU C T

Page 21

2.2 Detailed Component Descriptions

2.2.1 Controls

Hardware

The Series 600T UPS Operator Interface Display System is designed to provide all of the information that is

required for the operation of each UPS cabinet (the System Control Cabinet and each module). The following is

a list of the hardware features:

1. The control logic performs automatic operations with minimal operator interface. The limited number of

manual controls are easy-to-use.

2. Each Series 600T UPS cabinet is equipped with an easy-to-read 640 x 200 pixel liquid crystal display (LCD)

screen. It presents information in a way that is easy to understand at an eye-level front panel location.

3. The display is controlled by a dedicated microprocessor with a non-volatile (EPROM) program and a

battery-backed event memory.

4. The Series 600T System Control Cabinet (SCC) has communication ports (terminal board connections) for:

a. Transmission of present status information to remote terminals via resident auto-dial communications

program and an external modem. This port also responds to inquiries of the UPS system status and

history from the remote terminal.

b. Reporting UPS system status and history information in response to inquiries from a local terminal (no

modem required).

c. Reporting to a local monitor the information requested from the local terminal.

d. Reporting information to a Liebert SiteScan central monitoring system.

e. Relaying selected alarm messages to a Liebert Remote Monitor Panel and to a separate terminal board

for customer use.

f. Relaying performance and status information to your network monitoring system via SNMP interface.

NOTE

All external communication devices are optional equipment.

Firmware

The Operator Interface Display System software enables the operator to monitor the UPS system status, to control the power flow through the UPS, to monitor all of the meter readings, to execute the start-up, shutdown, and

the load transfer procedures, to access the event history files, and to make adjustments to the programmable

parameters. The following is a list of the firmware features:

1. The menu-driven software prompts the operator for input.

2. Step-by-step instructions assist the operator during start-up, shutdown, and load transfer procedures. This

helps to eliminate operator errors.

3. Graphics-based mimic diagrams illustrate circuit breaker status and the power flow through the UPS system.

4. The Present Status screen reports information about the system’s present status. The History Status screen

chronicles the events leading up to and immediately after a fault. The Event History screen lists all of the

alarm messages that have been logged over a period of time.

5. The Battery Cycle Monitor records information on up to 132 battery discharge events. Information includes

date, time, length of discharge, highest current demand, lowest battery voltage, and cumulative battery amp

hours d ischarged.

Refer to 3.0 - Operation for a description of the controls and indicators located on the Operator Control Panel.

2.2.2 Rectifier/Charger

The UPS module rectifier/charger consists of an input circuit breaker, optional input isolation transformer, AC

current limiting circuit, battery equalize charge circuit, DC filter, battery charge current limiting circuit, and

bridge rectifiers.

Operation

The rectifier/charger converts the AC input power to DC power. This conversion is accomplished by 3-phase

bridge rectifiers using SCRs. All phases are individually fused. Reflected input current THD is less than 7% at

Theory of Operation 15

DISCONTINUED

PRO DU C T

Page 22

full load with optional input filter. For modules 500 kVA and larger, the optional 12-pulse rectifier reduces

reflected THD to less than 4% with optional filter, or 9% without.

The filtered output of the rectifier/charger provides regulated DC power to drive the inverter and charge the batte r y.

Input Circuit Breaker

The input circuit breaker (CB1) is sized to allow enough current to recharge the battery and supply a full rated

load at the same time. The circuit breaker contains a thermal magnetic trip mechanism and an undervoltage

release that interrupts power, preventing damage to the system, if there is an internal AC over-current condition

or a short circuit. The circuit breaker also opens during certain alarmed faults. This circuit breaker must be closed

manually.

Isolation Transformer

The optional input isolation transformer has a dry type core, and copper windings with class H insulation. The

transformer on modules with standard 6-pulse rectifier has wye primary and delta secondary windings. For models with the optional 12-pulse rectifier, the transformer has a delta primary, with delta and wye secondary windings. The isolation transformer provides the initial step of critical bus isolation. This reduces the AC shock

hazard at the battery and at other DC components, and prevents a DC fault from disrupting upstream AC circu i try.

The transformer has a nominal tap and one tap 6% below the rated nominal input voltage (normally used for 460

VAC input).

Input Current Limit

AC input current-sensing transformers (CTs) are used to measure current levels. Control circuitry connected to

the CTs restricts the AC current to less than 125% of the full input current rating by reducing the battery charging

voltage. This current limit is adjustable from 100 to 125% and is factory set at 115%. A second (optional) level

of input current limit can be initiated by an external contact closure (field supplied for use with back-up generator), and is adjustable from 85 to 100% (factory set at 100%).

During a start-up procedure, the current slowly ramps up (walks-in) from 20% of the rated input current to 100%

over a 15 to 21 second period. The maximum rate of change of the AC input current is 15% per second. The

input current walk-in reduces the start-up surge distortion effects on all other equipment connected to the same

source and prolongs the service life of internal components.

Input Current Inrush

The maximum sub-cycle of inrush current due to the optional input isolation transformer is less than 500-800%

of the rated input current for the first 1/2 cycle. Without the optional transformer, inrush current is typically less

than 2-3 times normal.

Input Power Factor

The rated input power factor is no less than 0.85 lagging at the nominal input voltage and the full rated UPS load.

The optional input filter will improve the power factor to better than 0.92 lagging at full load. Refer to published

specifications for your UPS model.

2.2.3 Battery Charging Circuit

The UPS module charging circuit is capable of recharging the battery plant to 95% of full capacity within 10

times the discharge time. Recharging the last 5% takes longer because of characteristics inherent in the battery.

DC ripple voltage is limited to less than 0.5% RMS to preserve battery life during long-term float charging while

the UPS system is operating on utility source power.

Multiple UPS module rectifier/chargers can share a common battery plant, if that configuration is preferred for

your application.

Operation After Discharge

When commercial power is interrupted, the battery continues to supply DC power to the inverter without interruption to the critical load. If the AC source power is restored before the battery has fully discharged, the rectifier

automatically restarts and resumes carrying the inverter and battery recharge load requirements.

16 Theory of Operation

DISCONTINUED

PRO DU C T

Page 23

Operation After End-of-Discharge

The battery time screen displayed on the control panel enables you to estimate when battery shutdown will occur.

You will have enough time to energize an alternate AC power source or to initiate an orderly shutdown of the

critical load. If the battery plant discharges to the shutdown point during an outage, the UPS automatically disconnects the load, the AC input, and the battery. After AC input power is restored, the rectifier can be manually

restarted by the user.

Battery Disconnect

The external module battery disconnect (MBD) circuit breaker is used to isolate the UPS module from the battery during maintenance and to automatically disconnect the battery from the inverter at the end of battery discharge. The MBD circuit breaker can be opened or tripped automatically, from the control panel, or manually. It

must be closed manually.

Battery Charge Current Limiting

The battery recharge current, after a battery discharge, is limited to between 1 and 25% (adjustable) of the full

load discharge current. An additional (optional) charge-limiting c ircuit can be activated by external dry contact

closure (field supplied) for use when operating on a back-up generator. These two levels of control regulate the

amount of current that flows from the power source to the battery while the battery is recharging.

The battery charge current limit is factory set at 10% for normal operation and at 1% for alternate power source

recharge operation.

Battery Equalize Charge Circuit

The battery equalize charge feature can be manually initiated or it can be programmed to operate automatically.

Either can be selected from the battery equalize screen displayed on the control panel.

The battery equalizing charge circuit increases the rectifier/charger output voltage to charge the battery any time

there is a power outage of 30 seconds or longer. The equalizing voltage is slightly higher than the float voltage.

This decreases the time required to recharge the battery.

NOTE

Do not use equalize charging with valve-regulated lead-acid batteries

Consult the battery manufacturer's manual for specific information about equalize

charging.

Theory of Operation 17

DISCONTINUED

PRO DU C T

Page 24

2.2.4 Inverter

The inverter is a solid state device that converts the DC output of the rectifier/charger or the battery to AC power.

Operation

The inverter converts DC power—from either the battery or the rectifier/charger—into three pulse-width-modulated/six-step waveforms. These waveforms are filtered into low-distortion sine wave power. The inverter is controlled by an Application-Specific Integrated Circuit (ASIC). This integrated circuit controls the precise

synchronization, amplitude, and frequency of the output voltage.

In addition to the inverter efficiently supplying a regulated AC output from a DC source, the output isolation

transformer acts as a second stage of isolation between the critical load bus and the commercial source power.

The inverter is configured to handle most critical load inrush surges. It maintains output voltage Total Harmonic

Distortion (THD) within specifications even when handling non-linear computer loads. Refer to non-linear load

characteristics.

Output Regulation and Overload Performance

The inverter is capable of sustaining full output voltage ±2% of the nominal voltage) for up to 150% overload at

the output for as long as 30 seconds without reducing the output voltage. It can also handle at least 125% of the

rated current for up to 10 minutes and 104% of the rated current continuously. The System Control Cabinet

(SCC) will transfer the critical load to the bypass source if the overload exceeds the system capacity or the capacity of the modules on-line. The multi-module overload capacity (in terms of percent of rated full load current of

modules on-line) is 140% for 20 seconds, 108% for 10 minutes, and 104% continuously.

Note that in normal operation the SCC will transfer the load to bypass before a UPS module exceeds its overload

capacity. If a module overload condition is sustained (beyond inverter capacity) the UPS module is automatically

taken off-line (disconnected from the critical bus) and is shut down. If the UPS system is operating in the redundant mode, the load may remain on the UPS system. Refer to 3.4 - Automatic Operations.

Non-Linear Load Characteristics

Computers and computer equipment with switching power supplies generate non-linear currents rich in fifth and

seventh harmonics.

The inverter pulse-width-modulated/six-step waveform, coupled with the output filter, provides a natural path

for reducing the fifth and seventh harmonic currents produced by the load. The inverter/filter limits the output

voltage THD to less t han 5% with up to 100% typical electronic data processing (EDP) loads. EDP equipment

characteristically includes both non-linear and linear load components.

Unbalanced Load Characteristics

Unbalanced loads are actively regulated. The phase-to-phase voltage balance is maintained to within 2%, even

with a 50% load imbalance.

The three-phase, root mean square (RMS—approximately 70% of the peak) average voltage is also regulated

through a separate control circuit (phase-to-phase sensing).

18 Theory of Operation

DISCONTINUED

PRO DU C T

Page 25

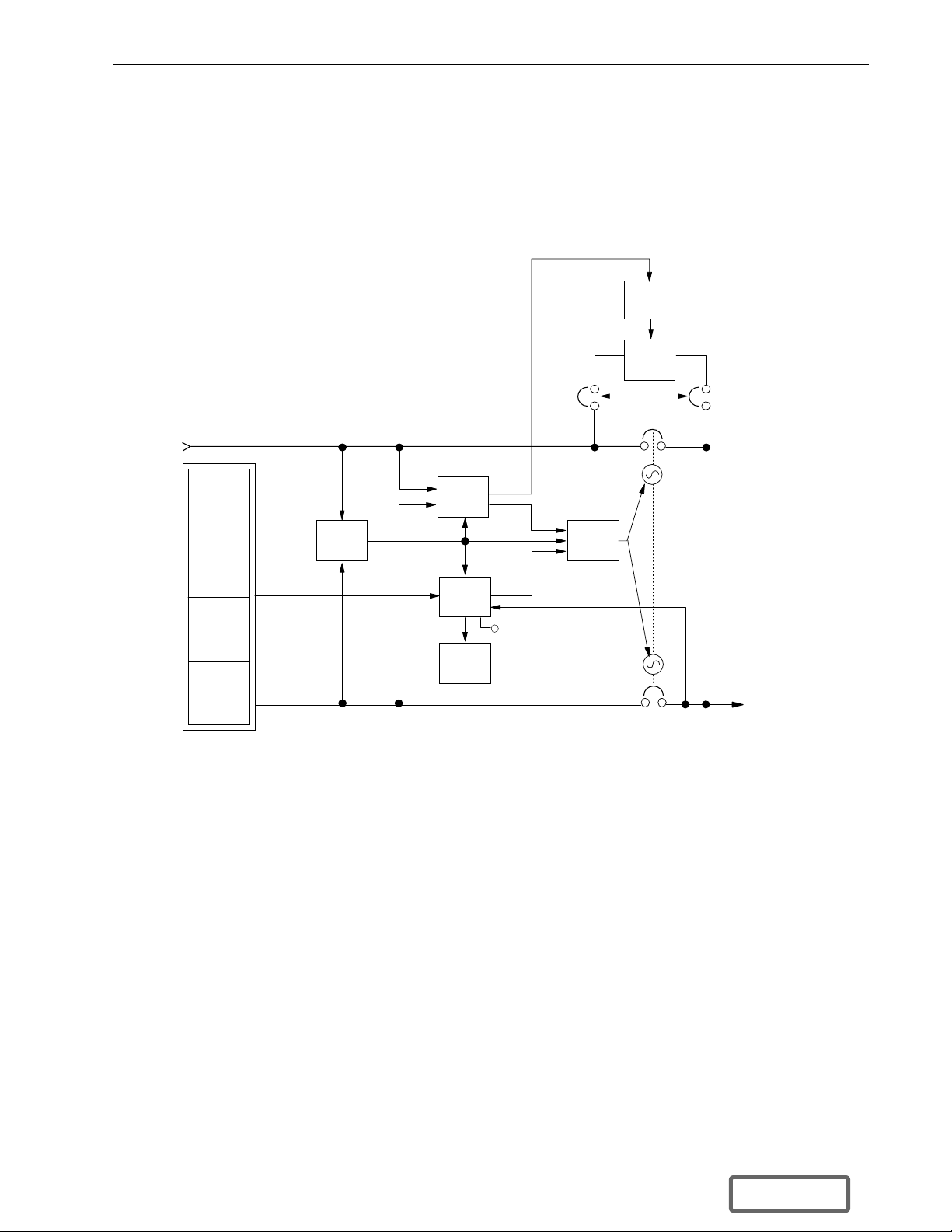

2.2.5 Static Bypass

A static bypass is an integral part of the UPS System Control Cabinet (SCC). Refer to Figure 7. The static

bypass consists of solid-state switching devices working in conjunction with the motor-operated System Bypass

Breaker (SBB). An automatic transfer control circuit senses the status of the operator controls, UPS logic signals

and alarm messages, and c ritical bus operating conditions. If the UPS modules can no longer supply the critical

load, the static bypass switch (in conjunction with the SBB and UPS Output Breaker) automatically transfers the

critical load to the bypass source without interruption.

Figure 7 System Control Cabinet (SCC) Block Diagram

Bypass Line

Syn c &

Transfer

Control

Power

UPS

System

Modules

Supply

System

Monitor

Voltage

Adjust

Static Bypass Breaker

Transfer

Control

Gate

Driver

Static

Bypass

Switch

Static Switch

Disconnects

Alarms

To Crit ical

UPS Output

Load

Fuse Protection

The static bypass switch path uses two back-to-back SCRs per phase. Each phase is individually protected by a

fuse sized to clear only in the event of a catastrophic fault. This is a more reliable method than depending on

external protection devices. The fuses are in the circuit to protect the critical bus distribution equipment against

catastrophic faults. The static switch SCRs are oversized to easily handle any current surges that may blow the

fuses.

Shorted SCR Monitoring

The static bypass system has redundant shorted SCR sensing c ircuits and disconnects. This will prevent UPS output power backfeed to the distribution system even if two component failures exist simultaneously. If a shorted

SCR is detected, the static bypass switch is isolated and annunciated at the SCC control panel, and the critical

load remains on UPS output power.

Static Switch Isolation

The motor-operated system bypass circuit breaker (SBB), wired in parallel with the static switch, automatically

closes in approximately 200 milliseconds after the load is transferred to the bypass power source, removing the

static switch from the power flow.

Theory of Operation 19

DISCONTINUED

PRO DU C T

Page 26

Also, if required for maintenance, the static switch can be isolated from the bypass line by opening (to the OFF

position) the Static Switch Disconnects.

Pulsed Parallel Operation

When an overload condition such as magnetic inrush current or a branch load circuit fault exceeds the overload

capacity of the connected modules, the static bypass switch pulses on for 40 milliseconds. This allows up to

1000% of the rated full load current from the bypass line to clear the overload without closing the bypass circuit

breaker. The bypass source is briefly in parallel with the UPS system, permitting the bypass source to carry the

initial overload current. If the overload clears before 40 milliseconds, a load transfer to bypass is not made. If the

overload condition continues, the automatic transfer is made (maintaining the load voltage within the specified

limits).

This pulsed static switch operation reduces nuisance operation of motor-operated circuit breakers for such shortterm conditions.

Load Transfers

Transfers to (transfer) or from (retransfer) the bypass may be performed automatically or manually in a makebefore-break sequence. This is accomplished through the overlapping operation of the UPS output and the system bypass power switching devices.

Manual load transfers and retransfers are initiated by the operator from the System Control Cabinet (SCC).

In a manual operation, or an automatic retransfer, the two motorized circuit breakers—UPS output and system

bypass—are both closed simultaneously for a short period of time (overlap).

Automatic transfers are initiated by the SCC system control logic when an overload is beyond the specified capabilities of the UPS system or when a fault occurs within a non-redundant UPS module. An automatic retransfer is

initiated if this function is enabled and if system conditions for a retransfer are present.

In an automatic transfer, the circuit breakers do not overlap, but during the short time gap bypass power is supplied to the critical load through the solid state static switch.

20 Theory of Operation

DISCONTINUED

PRO DU C T

Page 27

Transfer and Retransfer Conditions

1. Automatic Transfers to Bypass

Critical bus conditions that will initiate an automatic transfer of the critical load from the UPS system to the

bypass source are:

a. System Overload: overcurrent condition in excess of the overload rating of the System Control Cabinet

(SCC).

b. Output Overload: overcurrent condition in excess of the c urrent-versus-time overload capacity of UPS

modules ON LINE.

c. Over/Under Voltage (OV/UV): critical bus voltage is outside the allowable tolerance.

d. Non-redundant UPS Module Inoperative: an essential UPS module is taken OFF LINE for one of the

reasons below.

1. Battery discharged to the shutdown voltage.

2. Inverter overload capacity exceeded.

3. Inverter or rectifier fault condition (power, logic, or over-temperature) present or imminent.

4. Failure of UPS module logic or logic power.

e. SCC Logic:

1. Emergency Module Off (EMO) circuit activated.

2. Failure of UPS system logic or logic power.

2. Manual Transfers

Manual transfers may be initiated at any time provided no transfer inhibition conditions are present.

3. Transfer Inhibited

A manual transfer to the bypass source shall be inhibited if any of the following conditions exist:

a. Bypass frequency deviates ±0.5 Hz from the nominal.

b. UPS system to bypass voltage difference ( V) exceeds a predetermined percentage (normally 5%).

c. Static switch disconnects (manual switches) open.

d. OK to Transfer signal from the control logic is not present.

NOTE

A load transfer to the bypass line will be completed whenever an automatic transfer

to bypass is initiated If the Static Switch Unable alarm message is present for any

reason (including a ±20° phase lock synchronization error), the automatic transfer

will be interrupted for 40 to 120 milliseconds. Because of the reliability of the UPS

components, an interrupted load transfer is a very unlikely occurrence.

4. Automatic Retransfers to UPS

Critical bus conditions that must be present to initiate an automatic retransfer (Auto-Rexfer) of the critical

load from the bypass source to the UPS system a re:

a. The number of Auto-Rexfer Attempts selected must be greater than zero (0). If zero (0) is selected, no

automatic retransfer will occur.

b. Critical load was initially transferred to the bypass source due to a system overload only.

c. Overload has since dropped below 100% of the rated SCC current.

d. Enough UPS modules are ON LINE to supply the critical load.

e. OK to Transfer signal received from the control logic for at least 10 seconds, within 5 minutes of the

overload transfer. (A manually initiated retransfer from bypass is required for overloads lasting 5

minutes or more.)

f. Cyclic-type system overloads, which occur up to five (select range is 0 to 5) times in 60 m inutes, are

automatically returned to the UPS system for each event including the Nth overload. A manually

initiated retransfer from bypass is required for the N+1 overload.

Theory of Operation 21

DISCONTINUED

PRO DU C T

Page 28

5. Manual Retransfers

Manual retransfers may be initiated at any time provided no retransfer inhibition conditions are present.

6. Retransfer Inhibited

A retransfer from the bypass source to the UPS system shall be inhibited if any of the following conditions

exist:

a. Manual (and Automatic) Retransfer Inhibitions:

1. Bypass frequency exceeds ±0.5 Hz of the nominal.

2. UPS system-to-bypass voltage difference ( V) exceeds a predetermined percentage (normally

5%).

3. System circuit breaker (UPS output or SBB) is inoperative.

4. OK to Transfer signal from the control logic is not present.

5. Not enough UPS modules are ON LINE to supply the connected critical load.

b. Automatic Retransfer Inhibitions (in addition to those above):

1. The load transfer to bypass was not caused by a system overload.

2. Excessive cyclical overloads within a one-hour period.

3. Retransfer conditions are not satisfied within 5 minutes of the initial transfer.

2.2.6 Redundant Mode

The typical multi-module UPS system is configured with a back-up (redundant) UPS module, connected in parallel to share the critical load with the other module(s). This parallel redundant system includes one more module

than is required to supply the full critical load.

A parallel redundant system will always be in the Redundant Mode if all modules are ON LINE. In addition, if

the critical load is reduced so that not all ON LINE modules are required, the UPS system can also operate in the

Redundant Mode with one or more modules OFF LINE. The critical load will remain on the UPS system—even

if one or more of the modules is taken OFF LINE for maintenance or because of an internal fault—as long as the

remaining ON LINE modules can carry the full connected system load.

The system control logic monitors the connected critical load and the number of UPS modules ON LINE. If the

UPS system is operating in the Redundant Mode, the REDUNDANT status message will be displayed at the

System Control Cabinet (SCC). If the UPS system is operating in the Non-Redundant Mode (redundant module

is OFF LINE or was not included in the system configuration), the NON-REDUNDANT status message is displayed at the SCC. In the Non-Redundant Mode, the critical load will be transferred to bypass if any UPS module

goes OFF LINE and the remaining ON LINE module(s) cannot carry the connected load without being overloaded.

The system control logic, located in the SCC, automatically adjusts the allowable overload limits based on the

connected load and the number of modules ON LINE.

22 Theory of Operation

DISCONTINUED

PRO DU C T

Page 29

3.0 OPERATION

3.1 Display Screen and Operator Controls

Each Liebert Series 600T UPS cabinet is equipped with a microprocessor-based Operator Control Panel and Display Screen and System Control Panel designed for convenient and reliable operation. The System Control Cabinet (SCC) performs different functions than the UPS modules. Each cabinet has the controls and displays

required to operate and monitor its functions. The locations of operator controls are shown in Figure 8 through

Figure 11.

The front location of the control panel enables the user to quickly identify the current status of the UPS system

and to perform most of the manual operations. The operator display screen is driven by an easy-to-follow menuprompted software program.

Features

The Series 600T interface display system enables the operator to easily perform the following:

• Obtain a quick indication of operational status:

• Is the critical bus OK?

• Is the UPS system OK?

• Which UPS modules are available?

• Is the battery available?

• Is the bypass line available?

• Monitor the power flow through the UPS system and monitor all meter readings:

• Is the critical load being supplied power from the UPS system or bypass?

• Are input, battery, and output voltage, frequency, and current readings at nominal levels?

• How much battery time is still available during an outage?

• Is the battery recharging after discharge?

• Execute operational procedures:

• Perform critical bus transfer/retransfer between the UPS system and the bypass line.

• Start-up and shut down the UPS system and each module.

• Shutdown the system and all modules instantly in the event of an emergency.

• Access status reports and history files:

• Obtain a complete listing of the present status of the UPS system and all modules (input, output, and

battery voltage, frequency, and current readings, and any alarms that may be present).

• Review a complete history report of all events leading up to and immediately after a fault condition.

• Examine an archive listing of all alarm conditions that have occurred over a period of time.

• Make adjustments to programmable parameters (access limited by Security Access function):

• Set the date and the time functions.

• Change the auto-dial phone number and the modem options.

• Select the number of auto-retransfer attempts.

• Make adjustment to the UPS output voltage before performing a manual load transfer.

Operation 23

DISCONTINUED

PRO DU C T

Page 30

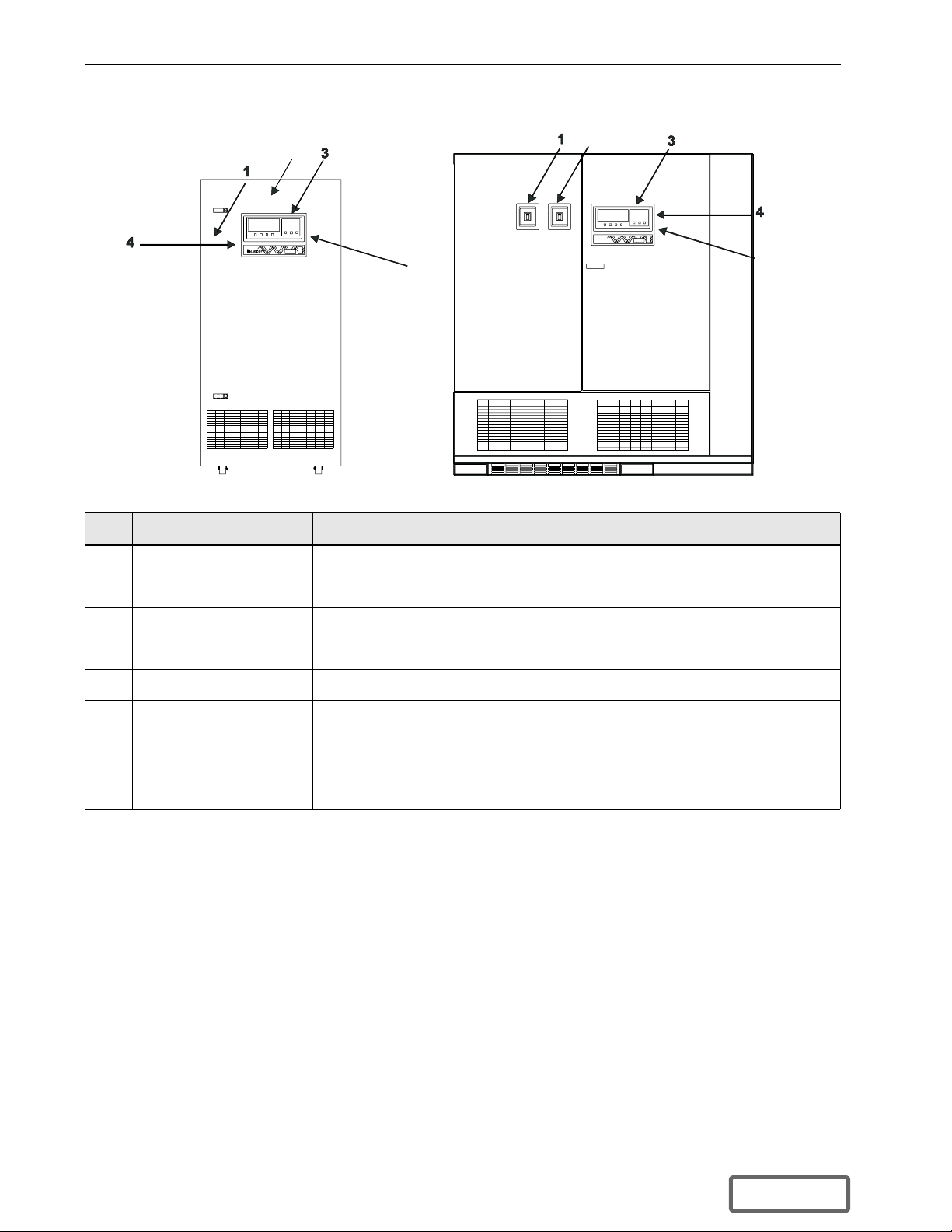

Figure 8 Operator Contro ls, 65 to 80 kVA (left) and 100 to 500 kVA (right)

2

5

Item Description Function

1 Input Circuit Breaker

(behind door of 65-80

kVA) (CB1)

This manually operated circuit breaker provides power to the UPS module rectifier.

In 625-750 kVA modules and some 500 kVA modules, this breaker is located in the

transformer cabinet.

2

5

2 Module Output Circuit

Breaker (behind door of

65-80 kVA) (CB2)

3 Operator Control Panel Refer to Figure 10 for controls available on this panel.

4 Control Disconnect

(behind inner door)

5 Interlock Button

(on rear of Control Panel)

This manually operated circuit breaker connects the UPS module inverter output to

the UPS System Control Cabinet.

These two fuses provide power to the controls. They are normally closed (ON).

Turn Control Power OFF (by opening the two fuse holders) only for maintenance

procedures.

Press this button to make authorized changes to any parameter protected by the

Security Access function. This includes time, date, auto-dial phone numbers, etc.

24 Operation

DISCONTINUED

PRO DU C T

Page 31

Figure 9 System Control Cabinet Operator Controls (SCCB Pictured)

Item Description Function

1 UPS Output Circuit

Breaker

2 System Bypass Circuit

Breaker

3 Operator Control Panel Refer to Figure 10 for controls available on this panel.

4 Interlock Button

(on rear of Control Panel)

5 Close Bypass Switch

(behind door)

6 Bypass Reset Switch

(behind door)

7 Static Switch Disconnects

(behind door)

8 Reset Switches (SW1) for

Static Switch Disconnects

(behind door)

9 Control Power Disconnect

(behind door)

This motorized circuit breaker connects the c ritical load to the UPS system output.

This motorized circuit breaker connects the critical load to the bypass line.

Refer to Figure 11.

Refer to Figure 11.

Refer to Figure 11.

These manually operated switches disconnect the static switch from the bypass

line and from the critical load. They are normally ON (closed). Turn them OFF

(open) only to isolate (disconnect) the static switch for maintenance procedures.

Press these two switches before closing Static Switch Disconnects when

recovering from a shutdown that includes loss of Control Power. Green LED on

means Control Power is available. Red LED on means Reset Switch needs to be

pushed.

Normally ON. Turn OFF Control Power only when required for maintenance

procedures.

Operation 25

DISCONTINUED

PRO DU C T

Page 32

Figure 10 Series 600T UPS and SCC Operator Control Panels

Ite m Description (Location) Function

1 Display Screen

(SCC and modules)

2 Up

(SCC and modules)

3 Down

(SCC and modules)

4 Select

(SCC and modules)

5 Alarm Reset

(SCC and modules)

6 Voltage Adjust

(SCC only)

7 UPS

(SCC only)

8 Bypass

(SCC only)

9 Control Enable

(SCC and modules)

10 Horn Off

(SCC only)

11 Alarm Horn and

Red LED (SCC only)

12 Emergency Module

Off (SCC only)

13 Battery Trip

(modules only)

14 Output Trip

(modules only)

This screen displays all vital UPS information in one convenient location. All of the UPS

monitoring functions and conditions are indicated here.

This touch-sensitive pad (button) is used to move the cursor up through various

selections present on the display screen. Note that all pads on this control panel have

touch-sensitive switches behind them.

Similar to the Up pad, this pad is used to move the cursor down through the various

selections present on the display screen.

After choosing the desired item (with highlighted cursor) from the display screen with

the Up and Down pads, pushing this pad tells the microprocessor to go to the

highlighted selection.

This pad is used to c lear all of the alarm conditions that are no longer present.

However, all active alarms remain in memory and on the applicable screens until they

are corrected. This pad also resets the History Status Report memory buffer when held

until the screen clears.

This push-to-turn knob permits adjustment of the UPS output voltage to meet load

requirements or to match the bypass voltage before transferring the load to or from

bypass.

This pad activates the circuits that connect the UPS to the critical load (a retransfer).

When this pad is pushed (along with Control Enable), the UPS output circuit breaker

closes and the bypass circuit breaker opens.

This pad activates the circuits that connect the bypass line to the critical load (a

transfer). When this button is pushed (along with Control Enable), the bypass circuit

breaker closes and the UPS output circuit breaker opens.

This pad must be pressed simultaneously with the UPS, Bypass, Battery Trip, or Output

Trip pads to activate them.

This pad is used to silence the alarm horn after it is activated. When this switch is

pressed, the alarm horn is silenced but the active and latched alarm messages remain

on the screen. The alarm messages still displayed stop flashing to indicate they have

been acknowledged.

This electronic horn sounds to alert nearby personnel whenever a new alarm occurs. A

red LED (light emitting diode) is located in the middle of the alarm horn.

During an emergency, pressing this guarded switch will transfer the load to bypass and

then shut down the UPS modules. The load will remain on bypass power. (Refer to

3.3.3 - Shutdown Procedures.)

This pad can be used (along with Control Enable) to trip the module battery disconnect

(MBD) circuit breaker open (disconnecting the battery from the UPS module).

This pad can be used (along with Control Enable) to trip the module output circuit