Page 1

Liebert® EXM™BDC

User Manual—10-100kVA, 60Hz

Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SAVE THESE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

GLOSSARY OF SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.0 LIEBERT EXM BDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Normal (UPS) Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Maintenance Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Locating the Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4 Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4.1 Wiring Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4.2 Power Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4.3 Input/Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.4 Accessory Fuses and Back-Feed Breaker Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5 Bolting Cabinets Together. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.5.1 Floor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.5.2 Cable Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.5.3 Optional Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1.6 Liebert EXM UPS Bypass Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.6.1 Liebert EXM BDC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.0 INSTALLATION DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.0 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

FIGURES

Figure 1 Single input UPS with external Liebert EXM BDC with optional internal transformer—Typical

configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2 Liebert EXM BDC—Access plate removed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 3 Accessory fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4 Liebert EXM BDC with distribution, single input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Figure 5 Liebert EXM BDC wiring, without transformer option, single input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6 Liebert EXM BDC wiring with transformer option, single input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 7 Wiring for LDMF with panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 8 Wiring for LDMF with subfeed breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 9 Bolting Liebert EXM UPS to a Liebert EXM BDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10 Cabinet arrangement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 11 Liebert EXM UPS bypass assembly connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12 Input dry contacts—J26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 13 Output dry contacts and EPO wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

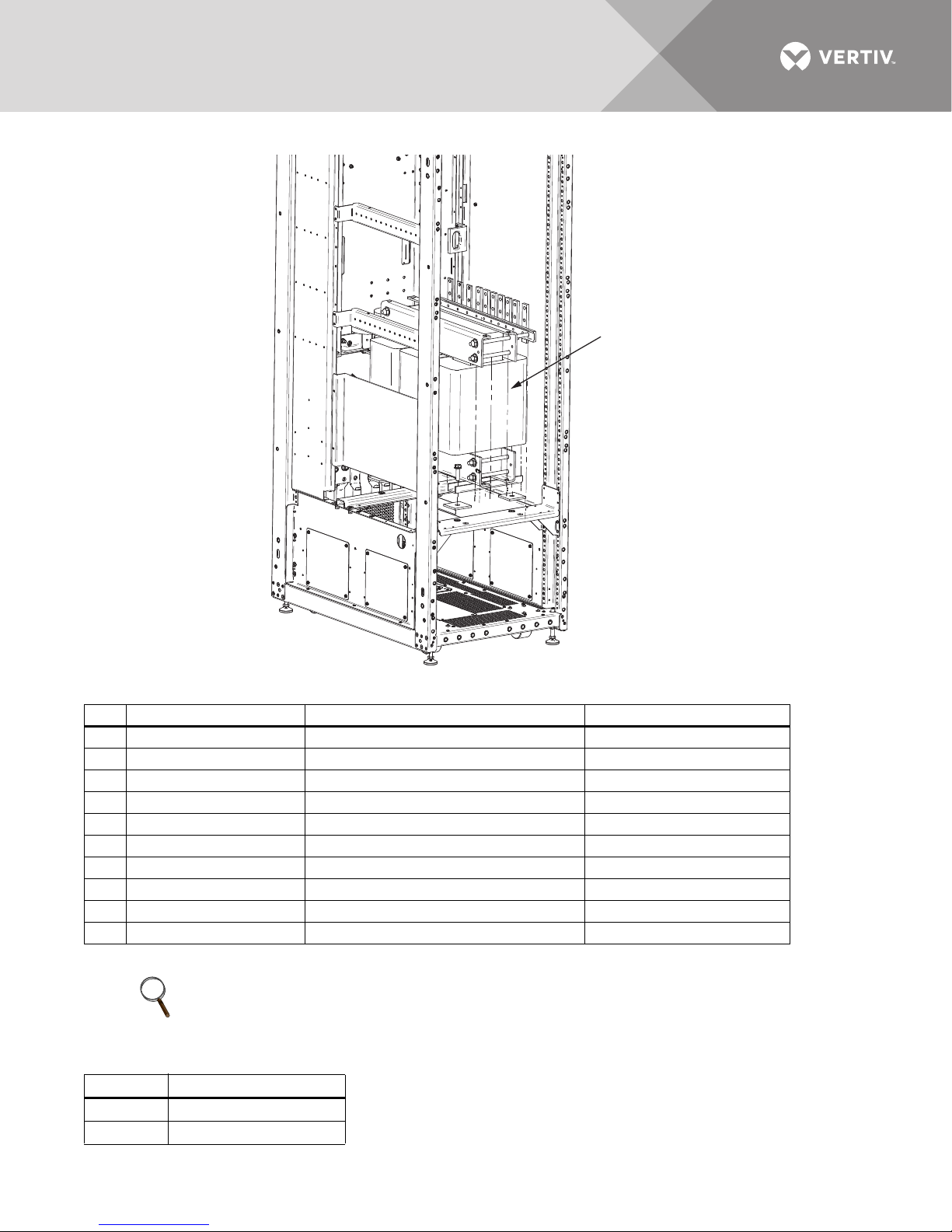

Figure 14 Liebert EXM BDC with 225A or 400A panelboards—Main components. . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 15 Liebert EXM BDC with two subfeed breakers—Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 16 Liebert EXM BDC with optional SKRU and transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 17 Busbars—Liebert EXM BDC with panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vertiv |Liebert® BDC User Manual | Rev. 3 | 01/18 | i

Page 4

Figure 18 Busbars—Liebert EXM BDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

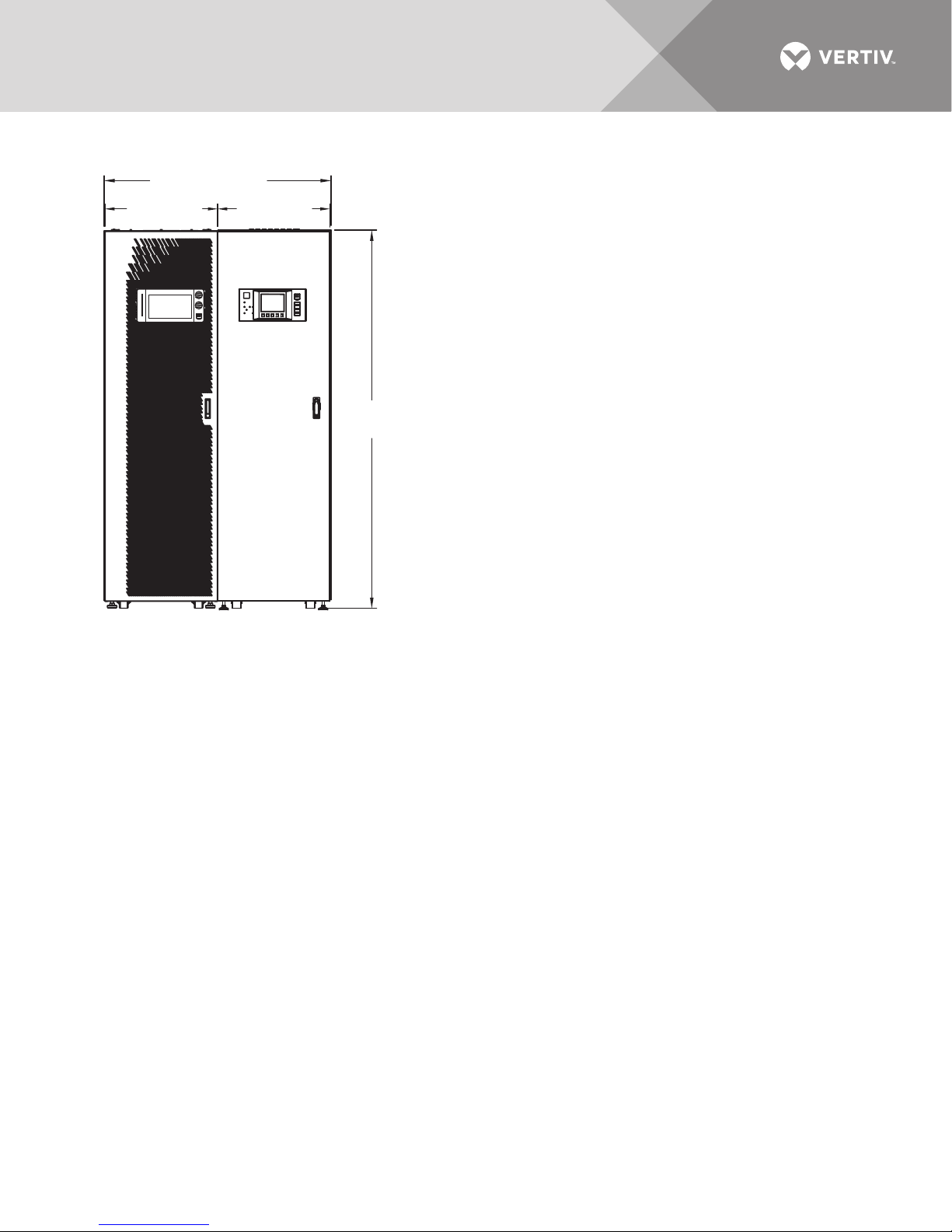

Figure 19 Lineup arrangement, Liebert EXM with Liebert EXM BDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 20 Outline drawing, Liebert EXM BDC for Liebert EXM, 10-100kVA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 21 Liebert EXM BDC transformer location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 22 One-line diagram, 208V single input 10-100kVA UPS with three-breaker Liebert EXM BDC

and panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 23 One-line diagram, 208V single input 10-100kVA UPS with three-breaker Liebert EXM BDC,

input isolation transformer and panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 24 One-line diagram, 208V single input 10-100kVA UPS with three-breaker Liebert EXM BDC

and two subfeed breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 25 One-line diagram, 208V single input 60-100kVA UPS with three-breaker Liebert EXM BDC,

input isolation transformer and two subfeed breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 26 One-line diagram, 208V dual input 10-100kVA UPS with three-breaker Liebert EXM BDC

and panelboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 27 One-line diagram, 208V dual input 10-100kVA UPS with three-breaker Liebert EXM BDC

and two subfeed breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

TABLES

Table 1 Control wiring for Liebert EXM to Liebert EXM BDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Table 2 Liebert EXM BDC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Table 3 Output dry contact relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Table 4 Wiring for Liebert EXM to Liebert EXM BDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 5 Hardware torque values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 6 Physical standards and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 7 Mechanical characteristics, Liebert EXM BDC, 10-100kVA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 8 Liebert EXM BDC, 60-100kVA, mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 9 Liebert EXM BDC heat dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 10 Liebert EXM BDC input currents, single input, main, without transformer . . . . . . . . . . . . . . . . . . . . . . 36

Table 11 Liebert EXM BDC input currents, dual input, rectifier, without transformer. . . . . . . . . . . . . . . . . . . . . 36

Table 12 Liebert EXM BDC output currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 13 Liebert EXM BDC input currents, dual input, bypass, without transformer . . . . . . . . . . . . . . . . . . . . . 37

Table 14 Busbar torque for power wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 15 Terminal block torque with compression lugs for control wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 16 Recommended lug sizes (compression type) M12, 1/2" bolt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 17 Electrical data—Liebert EXM BDC, 480VAC input, 208VAC output, single input, with

480V:208V transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 18 Electrical data—Liebert EXM BDC, 600VAC input, 208VAC output, single input, with

600V:208V transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 19 Electrical data—Liebert EXM BDC, 208VAC or 220VAC input, single input, with

208V:208V or 220V:220V transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 20 Breaker torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Vertiv |Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | ii

Page 5

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during installation of the Liebert EXM BDC

(bypass distribution cabinet).

Read this manual thoroughly, paying special attention to the sections that apply to your installation, before

working with the UPS. Retain this manual for use by installing personnel.

A properly trained and qualified electrical contractor should oversee the installation of the equipment.

The Liebert EXM BDC cannot be put into operation until it is commissioned by the manufacturer or authorized

engineer. Otherwise, human safety may be endangered and damage to the UPS will not be covered by the

warranty.

The Liebert EXM BDC is designed for commercial and industrial uses and cannot be used as life support

equipment.

WARNING

Risk of moving heavy equipment and electric shock. Can cause equipment damage, injury and death.

Exercise extreme care when handling UPS cabinets to avoid equipment damage or injury to personnel.

The Liebert EXM BDC’s weight ranges from 660 to 1752 lb. (300 to 794kg).

Determine the unit’s weight and locate the center of gravity symbols before handling the Liebert EXM

BDC. Test lift and balance the cabinet before transporting it. Never tilt equipment more than 15

degrees from vertical.

In case of fire involving electrical equipment, use only carbon dioxide fire extinguishers or those approved

for use in fighting electrical fires.

Extreme caution is required when performing maintenance.

Be constantly aware that the UPS system contains high DC as well as AC voltages.

Check for voltage with both AC and DC voltmeters prior to making contact.

AVERTISSEMENT

Risque lors du déplacement de l'équipement lourd et de décharge électrique pouvant entraîner des

dommages matériels, des blessures et même la mort.

Faites preuve d'une extrême prudence lors de la manutention des armoires ASC afin d'éviter de les

endommager ou de blesser le personnel. Les armoires Liebert EXM BDC pèsent de 660 à 1752 lb (de 300

à 794 kg).

Déterminez le poids de l'unité et trouvez les symboles de centre de gravité avant de déplacer l'armoire

Liebert EXM BDC. Faites des essais de levage et d'équilibre avant de transporter l'armoire. N'inclinez

jamais l'équipement à plus de 15 degrés à la verticale.

En cas d'incendie associé à du matériel électrique, n'utilisez que des extincteurs à dioxyde de carbone ou

homologués pour la lutte contre les incendies d'origine électrique.

Les opérations d'entretien requièrent une extrême prudence.

Soyez toujours conscient du fait que le système ASC contient des tensions c.c. et c.a. élevées.

Vérifiez les tensions avec des voltmètres c.a. et c.c. avant d'établir tout contact.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 1

Page 6

WARNING

Risk of electric shock. Can cause equipment damage, injury and death.

As with other types of high power equipment, dangerous voltages are present within the UPS and battery

enclosure even after input power has been disconnected. The risk of contact with these voltages is

minimized as the live component parts are housed behind a metal panel. Further internal safety screens

make the equipment protected to IP20 standards. Never remove panels or covers or open doors that will

expose internal components to contact.

Read and follow all warnings, cautions and safety and operating instructions to avoid serious injury or

death from electric shock. No risk exists to any personnel when operating the equipment in the normal

manner, following the recommended operating procedures.

All equipment maintenance and servicing procedures involve internal access and should be carried out

only by trained personnel.

AVERTISSEMENT

Risque de décharge électrique pouvant entraîner des dommages matériels, des blessures et même la

mort.

À l'instar des autres types d'équipement haute puissance, des tensions dangereuses sont présentes à

l'intérieur de l'armoire ASC et du châssis de batteries même après le débranchement de l'alimentation

d'entrée. Le risque de contact avec ces tensions est diminué, car les parties de composants sous tension

sont abritées derrière un panneau métallique. D'autres écrans de sécurité internes protègent

l'équipement en conformité avec les normes IP20. Ne retirez jamais les panneaux ou les couvercles et

n'ouvrez pas les portes donnant accès aux composants internes avec lesquels vous pouvez entrer en

contact.

Veuillez lire et suivre l'ensemble des avertissements, des mises en garde et des instructions de sécurité et

de fonctionnement afin d'éviter des blessures graves, voire la mort, pouvant être causées par une

décharge électrique. Il n'y a aucun risque pour le personnel lorsque l'équipement est utilisé normalement,

en suivant les procédures de fonctionnement recommandées.

Toutes les procédures de réparation et d'entretien de l'équipement exigent un accès à l'intérieur de

l'armoire et devraient être menées uniquement par du personnel compétent.

Ground Leakage Currents

WARNING

Risk of electric shock from high leakage current. Can cause injury, property damage and death.

EARTH CONNECTION IS ESSENTIAL BEFORE CONNECTING THE INPUT SUPPLY.

Earth leakage current exceeds 3.5 mA and is less than 1000 mA.

Transient and steady-state earth leakage currents, which may occur when starting the equipment, should

be taken into account when selecting instantaneous RCCB or RCD devices.

Residual Current Circuit Breakers (RCCBs) must be selected sensitive to DC unidirectional pulses (Class

A) and insensitive to transient current pulses.

Note also that the earth leakage currents of the load will be carried by this RCCB or RCD.

This equipment must be earthed in accordance with the local electrical code of practice.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 2

Page 7

AVERTISSEMENT

Risque de décharge électrique due à un courant de fuite élevé pouvant causer des blessures, des

dommages matériels et même la mort.

IL EST PRIMORDIAL D'ASSURER UNE CONNEXION DE TERRE AVANT DE BRANCHER

L'ALIMENTATION D'ENTRÉE. La fuite à la terre est supérieure à 3,5 mA et inférieure à 1 000 mA.

Vous devez tenir compte des fuites de courant transitoires et permanentes à la terre, susceptibles de se

produire au démarrage de l'équipement, lors de la sélection des dispositifs DDFT instantanés.

Vous devez sélectionner des disjoncteurs différentiels de fuite à la terre (DDFT) sensibles aux impulsions

unidirectionnelles c.c. (classe A) et insensibles aux impulsions de courant transitoires.

Notez également que les courants de fuite à la terre de la charge seront acheminés par ce dispositif

DDFT.

Cet équipement doit être mis à la terre conformément au code national de l'électricité.

WARNING

Risk of electric shock. Can cause injury, property damage and death.

Under typical operation and with all UPS doors closed, only normal safety precautions are necessary. The

area around the UPS system should be kept free of puddles of water, excess moisture and debris.

Special safety precautions are required for procedures involving handling, installation and maintenance of

the UPS system and the internal batteries (internal batteries accommodated by the 10-40kVA frame

only). Observe all safety precautions in this manual before handling or installing the UPS system as well

as during all maintenance procedures. Observe all battery safety precautions before working on or near

the battery.

This equipment contains several circuits that are energized with high voltage. Only test equipment

designed for troubleshooting should be used. This is particularly true for oscilloscopes. Always check with

AC and DC voltmeters to ensure safety before making contact or using tools. Even when the power is

turned Off, dangerously high electric charges may exist within the UPS.

All power and control wiring should be installed by a qualified electrician. All power and control wiring

must comply with the NEC and applicable local codes.

ONLY qualified service personnel should perform maintenance on the UPS system. When performing

maintenance with any part of the equipment under power, service personnel and test equipment should

be standing on rubber mats. The service personnel should wear insulating shoes for isolation from direct

contact with the floor (earth ground).

Never work alone, even if all power is removed from the equipment. A second person should be standing

by to assist and summon help in case an accident should occur.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 3

Page 8

AVERTISSEMENT

Risque de décharge électrique pouvant causer des blessures, des dommages matériels et même la mort.

Les précautions de sécurité habituelles suffisent lorsque le système ASC est en mode de fonctionnement

normal et que toutes les portes sont fermées. La zone entourant le système ASC doit être exempte de

flaques d’eau, d’humidité excessive et de débris.

Des précautions de sécurité spéciales sont requises pour les procédures associées à la manutention, à

l’installation et à l’entretien du système ASC. Observez toutes les précautions de sécurité décrites dans le

présent manuel avant de manipuler ou d’installer le système ASC, ainsi que pendant toutes les

procédures d’entretien.

Cet équipement comporte plusieurs circuits à haute tension. Seuls des équipements d’essai conçus pour

le dépannage doivent être utilisés. Cette mise en garde couvre notamment les oscilloscopes. Utilisez

toujours des voltmètres c.a. et c.c. pour vérifier les tensions avant d’établir un contact ou d’utiliser des

outils. Des tensions dangereusement élevées peuvent demeurer dans le système ASC même une fois

l’alimentation coupée.

Tous les câbles d’alimentation et de contrôle doivent être installés par un électricien qualifié. Tous les

câbles d’alimentation et de contrôle doivent être conformes au Code national de l’électricité des ÉtatsUnis (NEC) et celui du Canada, ainsi qu’aux codes locaux en vigueur.

L’entretien du système ASC ne doit être confié qu’à des professionnels qualifiés.

Les responsables de l’entretien et l’équipement d’essai doivent reposer sur des tapis de caoutchouc lors

de toute intervention sur une pièce d’équipement sous tension. Les responsables de l’entretien doivent

porter des chaussures isolantes pour prévenir tout contact direct avec le plancher.

Ne travaillez jamais seul, même si toute l’alimentation d’entrée est coupée de l’équipement. Une seconde

personne devrait toujours être présente pour porter assistance ou chercher de l’aide en cas d’accident.

NOTICE

Risk of improper ground connection. Can cause equipment damage.

Ground connection is essential before connecting the input supply. This equipment must be grounded in accordance with

local electrical codes. Maximum load must not exceed that shown on the UPS rating label.

NOTICE

Risk of improper electromagnetic shielding. Can cause radio communication interference.

This unit complies with the limits for a Class A digital device, pursuant to Part 15 Subpart J of the FCC rules. These limits

provide reasonable protection against harmful interference in a commercial environment. This unit generates, uses and

radiates radio frequency energy and, if not installed and used in accordance with this instruction manual, may cause

harmful interference to radio communications. This unit is not designed for use in a residential area. Operation of this unit

in a residential area may cause harmful interference that the user is solely responsible for correcting.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 4

Page 9

GLOSSARY OF SYMBOLS

!

PbH2SO4

-

+

R

Risk of electrical shock

Indicates caution followed by important instructions

AC input

AC output

i

Requests the user to consult the manual

Indicates the unit contains a valve-regulated lead acid battery

Recycle

DC voltage

AC voltage

Equipment grounding conductor

Bonded to ground

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 5

Page 10

1.0 LIEBERT EXM BDC

The Liebert EXM BDC is designed to operate in UPS normal mode, static bypass mode and maintenance mode.

The Liebert EXM BDC offers 10-100kVA capacity to match the associated Liebert EXM frame offerings. Each of

the Liebert EXM BDC capacities offer optional input 208V, 220V, 480V and 600V internal transformers as well as

multiple output distribution selections.

Figure 1 Single input UPS with external Liebert EXM BDC with optional internal transformer—Typical configuration

BYPASS DISTRIBUTION CABINET

* System

AC Input

3 Wire + GND

NOTES

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. UPS system input and output cables must be run

in separate conduits.

4. Control wiring must be run in separate conduits.

5. Optional 54-pole, 225A for 10-40kVA frame only or

optional 54-pole 400A for 60-100kVA frame only.

6. Transformer available: 208, 220, 480, 600V input.

BIB MIB

UPS CABINET

BATTERY

MBB

STATIC BYPASS

(Optional)

54 Pole

See Note 5

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection by Others

Field-Supplied Wiring

EXM1104

Rev. 0

AC Output

208V

4 Wire + GND

Local Grounding

Electrode

See Note 1

1.1 Normal (UPS) Mode

While the Liebert EXM BDC is in Normal mode (MBB open; BIB/MIB closed), the UPS is supplying the connected

load with continuous, high-quality AC power. In this mode of operation, the load is protected by the UPS.

1.2 Maintenance Mode

When the Liebert EXM BDC is in Maintenance mode (MBB closed; BIB/MIB open), it provides an alternate path

for power to the connected equipment should the UPS need to be taken out of service for limited maintenance

or repair. In this mode of operation, no power is supplied to the UPS and the load is NOT protected by the UPS.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 6

Page 11

1.3 Locating the Cabinet

This Liebert EXM BDC may be mounted to the right of the UPS or installed as a stand-alone unit. Ensure that the

unit is in a well-ventilated area and that there is clearance for access to the switches and cable connections as

required by national and local codes.

When the BDC is ordered as a stand-alone cabinet, connecting cables are not included.

1.4 Cable Installation

1.4.1 Wiring Preparation

Be sure that the unit is not connected to any AC utility power source or UPS before installing any wiring to this

unit. This Liebert EXM BDC should be installed by a qualified / certified electrician.

WARNING

Risk of electrical shock and arc flash. Can cause property damage, injury and death.

Read this section thoroughly before attempting to install wiring to this unit. Read and comply with all

warnings and cautions in this manual.

Removing the Cover Plates

Plates cover the input and output terminals on the front of the Liebert EXM BDC (see Figure 2). Remove these

and keep the screws and plates for reinstallation.

Figure 2 Liebert EXM BDC—Access plate removed

1.4.2 Power Cable Installation

Refer to Table 42 when selecting cables.

NOTE

Transient and steady state earth leakage currents may occur when starting the equipment. This should be taken

into account when selecting ground current detection devices because these will carry the earth leakage

currents of both the UPS equipment and the load.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 7

Page 12

1.4.3 Input/Output Wiring

Follow the steps below to connect the input wiring:

NOTE

Input wiring must be installed using conduit if cabinet is not mounted to the immediate right of the UPS.

1. Locate the input wiring access (top or bottom access), remove the conduit landing plate and punch the appropriate size

hole for the size conduit being used. Pull the three/four input wires through it, allowing some slack for installation. For

cabinets that are located to the immediate left of the UPS, the access plate is on the lower right of the cabinet. Remove the

access plate and verify that the edge guarding is installed and intact.

2. Secure the conduit to the access plate of the Liebert EXM BDC.

3. Input power cables connect to the system input bus; refer to Figure 14 and to Tabl e 5 .

4. Connect the ground (earth) wire to the earth busbar and tighten it to 428 lb-in (48Nm) for M12 bolt.

5. Locate UPS input and output cables and access panel to UPS on lower right side.

NOTE

If the Liebert EXM BDC is not to be bolted to the UPS, use either top or bottom access plate.

6. Connect the system ground cable between the Liebert EXM BDC and UPS and tighten the connections to 428 lb-in

(48Nm) for M12 bolt.

7. Connect the system input cables between the Liebert EXM BDC “UPS Input” Busbars (A-B-C N terminals) and UPS input

busbars (A-B-C N terminals) and tighten the connections to 428 lb-in (48Nm) for M12 bolt.

8. Connect the system output cables between the Liebert EXM BDC “UPS Output” Busbars (A-B-C N terminals) and UPS

output busbars (A-B-C N terminals) and tighten the connections to 428 lb-in (48Nm) for M12 bolt.

9. Connect TB1 from the Liebert EXM BDC to J23, J24 and J26 on the Liebert EXM.

NOTICE

Risk of improper wiring connection. Can cause equipment damage.

The control wire must be installed to ensure proper operation of the system and fully protect the load when switching

between bypass cabinet and UPS.

NOTES

1. All interconnection hardware supplied by Vertiv.

2. AC connections must be made to the UPS module before attaching Liebert EXM BDC to UPS module.

3. All cabling will be field-supplied when a Liebert EXM BDC is configured as a stand-alone cabinet.

4. Liebert EXM BDC’s must attach to the right side only of the Liebert EXM UPS.

5. Refer to the individual drawing of each piece of equipment for additional details.

Table 1 Control wiring for Liebert EXM to Liebert EXM BDC

From To

Liebert EXM UPS Bypass

Module (X9 J23, J24 and J26)

J24-3 TB1-7

FH1-B TB1-8

J26-15 TB1-6

J26-13 TB1-5

J26-11 TB1-4

J26-9 TB1-3

J23-4 TB1-11

J23-6 TB1-12

FH1-N J24-1

Refer to Figure 3 for the location of fuse block FH1 and to Figure 11 for the location of J23, J24 and J26

Liebert EXM BDC

Terminal Strip (TB1)

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 8

Page 13

1.4.4 Accessory Fuses and Back-Feed Breaker Wiring

Alber BDSUi Fuse Block,

FH2 (optional for Alber

battery monitoring feature)

Back-Feed

Breaker Fuse

Block, FH1

Fuse Blocks are

on the front of the

Liebert EXM UPS.

The back-feed breaker fuse block provides power to trip the BIB breaker. It is at the lower right of the

input/output panel on the front of the Liebert EXM UPS. See Figure 3 for fuse block locations.

Figure 3 Accessory fuses

The back-feed breaker fuse block provides 120V and is connected to the UPS output (L-N). The fuse is rated for

8A. Figures 4,5 and6 show the back-feed breaker wiring; the connections are made to the static bypass

assembly as shown in Table 1.

For additional details about the FH1 fuse block refer to the Liebert EXM UPS manuals, SL-25648 and SL-25650.

The manuals ship with the UPS and are available at Liebert’s Web site www.liebert.com

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 9

Page 14

Figure 4 Liebert EXM BDC with distribution, single input

Factory-Supplied Wiring

Field-Supplied Wiring

Notes

1. Customer-furnished electrode conductor must be installed

in accordance with national and local electrical codes.

2. See installation manual for additional connection information.

3. Optional 54-pole, 225A for 10-40kVA frame only or optional 54 pole,

400A for 60-100kVA frame only. Or two 225A subfeeds for 60-100kVA only

4. Optional transformer: 208/220/480/600V input.

5. Overcurrent protection is based on 80% rated devices.

6. MBB auxiliary switch connections are on the normally closed and common positions.

7. MIB auxiliary switch connections are on the normally opened and common positions.

8. When the Liebert BDC is connected to the UPS module, all control and power wiring

is supplied by Vertiv. When the Liebert BDC is remote from the UPS module,

the cables between the Liebert BDC and UPS module must be supplied by others.

Input Neutral

Main Ground Busbar

BIB

MIB

See Note 7

MBB

See Note 6

W07

W08

W09

W04

W05

W06

W85

W86

W87

AC Input

W88

W89

W90

AC Output

Optional

54-Pole/Two Subfeeds

See Note 3

Output Neutral

Output

Ground

Ground to

Unit Frame

Ground to

Unit Frame

Utility

Fuse

UPS

Kirk

Key K2

(2)

Fuses

2A

702

ØB

ØC

ØA

TB1

See Note 1

AC Output

AC 120V

Lamp

Push

Button

Optional

SKRU - Solenoid

Key Release Unit

KO - Key Operator

SKRU

KO

710

704

100

703

706

1

A

B

C

mN

oN

oA

oB

oC

PE

2345

6 7 8 9 10 1112

EXM1405

Rev. 0

X9J26

GND_DRY15

GND_DRY11

Q5_STATUS13

Q3_STATUS 9

BFP_O1

BFP_S3

BFP_C5

INV_D2

INV_S4

INV_C6

X9J23

MFP_C5

MFP_S3

MFP_D1

Main_obnl_S4

Main_obnl_C6

Main_obnl_O2

X9J24

Detail A

Detail BDetail A

Detail B

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 10

AC Output

FH1

FH2

*Option

BLK

Fuse

oN

oA

oB

oC

UPS

Page 15

Figure 5 Liebert EXM BDC wiring, without transformer option, single input

WIRING LEGEND

Factory-Supplied Wiring

Factory - or Field-Supplied

Customer

Input Neutral

Customer Main

Ground Busbar

Customer Main

Input Busbars

Phase A

Phase B

Phase C

BIB

W07

W08

W09

W04

W05

W06

Detail A

Detail B

DETAIL A

DETAIL B

607509

Pg. 1, Rev. 3

W88

UPS

Fuse

W89

W90

AC Output

AC Input

Ground to

Unit Frame

Utility

Input

TB1

MBB

Output Neutral

Ground

Neutral

W85

W83 W84

W86

W87

MIB

NOTES

1. Wiring furnished by factory.

2. Customer-furnished grounding electrode

conductor to be installed in accordance

with National Electric Code Article 250-26.

AUX.

C

N/O

N/C

AUX.

C

N/O

N/C

Ground Electrode

See Note 2

To Panelboard

or Subfeed

Refer to

Table 1

Refer to

Table 1

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 11

Page 16

Figure 6 Liebert EXM BDC wiring with transformer option, single input

NOTES

1. Wiring furnished by factory.

2. Customer-furnished grounding electrode

conductor to be installed in accordance

with National Electric Code Article 250-26.

WIRING LEGEND

Factory-Supplied Wiring

Factory - or Field-Supplied

Customer

Input Neutral

Customer Main

Ground Busbar

Ground Electrode

See Note 2

Isolation

Transformer

BIB

W07

W08

W09

W04

W05

W06

Detail A

Detail B

To Panelboard

or Subfeed

DETAIL A

DETAIL B

607509

Pg. 2, Rev. 3

W88

W89

W90

AC Output

AC Input

Ground to

Unit Frame

Ground to

Unit Frame

MBB

Output Neutral

W85

W83

W10

W84

W86

W87

MIB

AUX.

T

H1

W01

W02

W03

H2

H3

X-A

X-B

X-C

X0

A

B

C

A

B

C

mN

PE

C

N/O

N/C

AUX.

C

N/O

N/C

UPS

Fuse

G15, G61, G71, G81

G91, G93, G101 Only

Refer to

Table 1

Refer to

Table 1

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 12

Page 17

Figure 7 Wiring for LDMF with panelboard

76

88

81

Factory- or Field-Supplied

WIRING LEGEND

Fuse

5A

60770

Pg. 5, Rev. 2

1. Wiring furnished by factory.

2. Customer-furnished grounding electrode

conductor to be installed in accordance

with National Electric Code, Article 250-26.

DB9 to Accent

Ribbon Cable to P16

Ribbon Cable to P8

Ribbon Cable to P9

Ribbon Cable to P15

CT STRIP-1

CT STRIP-2

50 Pin

50 Pin

50 Pin

50 Pin

LEFT SIDE RIGHT SIDE

Rear View

Rear View

P16 (50 Pin)

P15 (50 Pin)

P8 (50 Pin)

P9 (50 Pin)

Pin 1

Pin 1

W508 (Black)

W512 (Black)

W511 (Black)

W510 (Black)

Load

Line

C-Phase

B-Phase

A-Phase

W505 (Blk)

W507

W504 (Wht)

W504 (Wht)

W503 (Blk)

W503 (Blk)

W501 (Red)

W502

(Blk)

Customer-Supplied

Wiring

Panel Board

Output

Neutral

Input

Neutral

Ground

Busbar

CT3

CT4

CT5

CT2

CT1

Ribbon Cable

from LCD

Twisted Pair

from LCD

77

74

75

73

72

78

80

50

AC (N)

AC (L)

+Vout

NC

-Vout

NC

NC

P38 (34 Pin)

Factory-Supplied Wiring

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 13

Page 18

Figure 8 Wiring for LDMF with subfeed breakers

A-Phase

C-Phase

B-Phase

CB2

CB1

A-Phase

B-Phase

C-Phase

Front View

Subfeed Breaker

50

WIRING LEGEND

Factory-Supplied Wiring

Factory- or Field-Supplied

Neutral

Output

Ground

Busbar

Input

Neutral

MIB

607740

Pg. 5, Rev. 2

MBB

P5

P6

(9 Pin)

(9 Pin)

1. Wiring furnished by factory.

2. Customer-furnished grounding electrode

conductor to be installed in accordance

with National Electric Code, Article 250-26.

80

81

536952G2

J1

J3

78

53834G1

from LCD

Ribbon Cable

from LCD

Twisted Pair

53694P1

77

552454P2

552454P2

Pin 1

Pin 1

P16 (50 Pin)

P15 (50 Pin)

P8 (50 Pin)

P9 (50 Pin)

P38 (34 Pin)

DB9 to Accent

88

W501

(Red)

+Vout

NC

-Vout

TB6

W502

NC

(Blk)

NC

Line

W505 (Blk)

Load

AC (N)

AC (L)

Fuse

5A

76

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 14

W504

(Wht)

W503

(Blk)

W503 (Blk)

W504 (Wht)

Page 19

1.5 Bolting Cabinets Together

A

DETAIL A

Washer

Flat, M10

Washer

Split, M10

Hex Head Bolt,

M10 x 30mm

Place cabinets so mounting holes are aligned.

A bolt from the adjacent cabinet may be screwed into the threaded top hole, or a bolt may be

inserted through the lower hole and screwed into the threaded hole in the adjacent cabinet.

NOTE

UPS wiring must be completed before the cabinets are bolted together.

1. Line up cabinets so that mounting holes are aligned.

Figure 9 Bolting Liebert EXM UPS to a Liebert EXM BDC

2. Using supplied hardware, bolt the cabinets together. The bolts may be inserted from either the UPS side or from the

Liebert EXM BDC side, whichever is more convenient.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 15

Page 20

WARNING

Risk of heavy units tipping over while being moved. Can cause property damage, injury and death.

The Liebert EXM BDC and battery cabinets must be properly prepared and secured for lifting. Improper

lifting may cause the cabinets to fall, causing equipment damage, personal injury and death.

Vertiv recommends lifting the units with one of the following methods:

• Installing four eyebolts in the factory-fabricated holes, one at each corner of the unit, attaching

cables or similar strapping to the eyebolts and lifting with a suitable mechanism.

• Placing suitable straps on the Liebert EXM BDC or battery cabinet. The straps must go under the

unit to be lifted.

AVERTISSEMENT

Le centre de gravité élevé des appareils présente un risque de renversement lors des déplacements,

pouvant entraîner des dommages matériels, des blessures et même la mort.

Les armoires Liebert EXM BDC et de batterie doivent être correctement préparées et sécurisées avant

d’être levées. Un mauvais levage peut faire tomber les armoires, causant des dommages à l'équipement,

des blessures, voire la mort.

Vertiv recommande de soulever les unités en suivant l'une des méthodes suivantes :

• En installant quatre anneaux de levage dans les ouvertures fabriquées en usine, avec un anneau

dans chaque coin de l’appareil, pour ensuite fixer les câbles ou sangles aux anneaux afin d'effectuer

le levage à l'aide d'un mécanisme approprié.

• En plaçant des sangles convenables sur l'armoire Liebert ou de batterie. Les sangles doivent

passer sous l'unité à soulever.

1.5.1 Floor Installation

If the Liebert EXM BDC is to be placed on a raised floor, the UPS should be mounted on a pedestal that will

support the equipment point loading. Refer to the Liebert EXM UPS manual, SL-25648 or SL-25650, to design

this pedestal.

1.5.2 Cable Entry

Cables can enter the Liebert EXM BDC from the top or bottom through removable metal plates.

Some plates have factory-punched holes and others are designed to allow the personnel to punch holes for

fitting and securing the conduit. Once the conduit holes are punched, these plates should be reattached to the

UPS. The conduit size and wiring method must be in accordance with all local, regional and national codes and

regulations, including NEC ANSI/NFPA 70.

NOTE

When installing the UPS, the customer must provide a disconnect with overcurrent protection at the output

of the UPS.

1.5.3 Optional Cabinets

The Liebert EXM BDC must be bolted to right side of the Liebert EXM (see Figure 10).

The Liebert EXM BDC must be cabled and bolted to the Liebert EXM before the UPS and bypass distribution

cabinet are moved into their final position. Connect input wiring to the Liebert EXM BDC ONLY after the units are

internally cabled and positioned.

Battery cabinets may be bolted only to the left side of the Liebert EXM; see Figure 10.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 16

Page 21

Figure 10 Cabinet arrangement

Liebert

EXM

Bypass

Distribution

Cabinet

Bypass

Distribution

Cabinet

Liebert

EXM

Battery

Cabinet

Battery

Cabinet

Liebert EXM UPS connected only

to Liebert EXM BDC

(The Liebert EXM BDC must be on right side of

the Liebert EXM UPS)

Liebert EXM UPS connected to Liebert EXM BDC and Battery Cabinets

(BDC must be on right side of the Liebert EXM)

(Battery Cabinets must be on the left side of the Liebert EXM UPS)

ALL UNITS VIEWED FROM ABOVE

Liebert IntelliSlot

Bays 1, 2, 3

Ready Switch

J1

J19

J20 J21 J22

J26

J23 J24 J25

1.6 Liebert EXM UPS Bypass Assembly

Figure 11 Liebert EXM UPS bypass assembly connections

The Static Bypass Assembly has three Liebert IntelliSlot™ interface card bays and connections for ancillary

cabinets (Liebert EXM BDC and battery) and for options.

1.6.1 Liebert EXM BDC Interface

The Liebert EXM BDC interface is on the Auxiliary Terminal Block at J26. Refer to Figure 12 for circuit details.

Table 2 Liebert EXM BDC interface

Position Name Description

J26.1 Q1 STA Main input switch status signal

J26.5 Q2 STA Bypass input switch status signal

J26.9 Q3 STA External maintenance switch status signal

J26, 3, 7, 9 GND Ground for dry contacts

These contacts cannot be active unless they are set via software.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 17

Page 22

Figure 12 Input dry contacts—J26

J26

2468

10 12

14

16 18 20

22 24

26

28

30 32

GEN MODE

+12V_DR

Y

GND_DR

Y

GND_DR

Y

TMP BATT IN

_

RESERVED

ENV_DET

GND_DR

Y

CHG SHUT

GND_DR

Y

RESV1

UT2 485+

UT2 485-

GND_DR

Y

NC

NC

135791113151719212325272931

Q1 STATUS

GND_DRY

Q2 STATUS

GND_DRY

Q3 STATUS

GND_DRY

Q5 STATUS

GND_DRY

GND_DRY

RESV2

RESV3

GND_DRY

UT1 485+

GND_MON

UT1 485-

NC

BFP_O

J23

J25

J24

BFP_S

BFP_C

INV_O

INV_S

INV_C

MAIN_O

MAIN_S

MAIN_C

MFP_O

MFP_S

MFP_C

RESV_O

RESV_S

RESV_C

RESV_O

RESV_S

RESV_C

1

3

5

1

3

5

1

3

5

24

6

24

6

24

6

NOTE

All auxiliary cables of terminal must be double-insulated. Wire should be 20-16AWG stranded for maximum runs

between 80 and 200 feet (25-60m), respectively.

NOTE

Refer to Table 1 and Figure 4 for the Liebert EXM BDC wiring.

Figure 13 Output dry contacts and EPO wiring

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 18

Page 23

Table 3 Output dry contact relays

Port Pin Name Description

1 MFP_O Rectifier back-feed normally open contact. Open when there is no back-feed.

J24

J23

J23

J24

3 MFP_S Rectifier back-feed common contact.

5 MFP_C Rectifier back-feed normally closed contact. Closed when there is no back-feed.

2 INV_O Inverter state normally open contact. Open when the inverter is abnormal.

4 INV_S Inverter state common contact.

6 INV_C Inverter state normally open contact. Closed when the inverter is normal.

1 BFP_O Bypass back-feed normally open contact. Open when there is no back-feed.

3 BFP_S Bypass back-feed common contact.

5 BFP_C Bypass back-feed normally closed contact. Closed when there is no back-feed.

2 MAIN_O Rectifier input state normally open contact. Open when the rectifier is abnormal.

4 MAIN_S Rectifier input state common contact.

6 MAIN_C Rectifier input state normally closed contact. Closed when the rectifier is normal.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 19

Page 24

2.0 INSTALLATION DRAWINGS

TOP

BOTTOM

FRONT

FRONT

Door Removed

RIGHT SIDE

Panel Removed

LEFT SIDE

Panel Removed

78.5"

(1994mm)

MBB

Panelboard

MIB

BIB

System

Input

Bus

Ground Bus

Neutral Bus

23.6"

(600mm)

37.5"

(953mm)

NOTES

1. Dimensions are in inches (mm).

2. Control wiring and power wiring must be

run in separate conduits.

3. All wiring must be in accordance with national

and local electrical codes.

4. If bypass distribution cabinet is attached to the

right side of the UPS, Vertiv will supply the

interconnection cables.

See Figure 18.

Figure 14 Liebert EXM BDC with 225A or 400A panelboards—Main components

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 20

Page 25

Figure 15 Liebert EXM BDC with two subfeed breakers—Main components

RIGHT SIDE

Panel Removed

NOTES

1. All dimensions are in inches (mm).

2. Control wiring and power wiring must be run in separate conduits.

3. Copper cables only are recommended.

4. All wiring is to be in accordance with national and local electrical codes.

5. When the Liebert EXM BDC is attached to the UPS,

Vertiv will supply the interconnection cables.

6. 225A panelboard for 10k-40kVA only. 400A panelboard for 60-100kVA only

BOTTOM

TOP

23.6" (600mm)

37.5" (953mm)

Ground

Busbar

System

Input

Bus

Neutral

Bus

EXM16013

Rev. 0

Neutral

Busbar

Subfeed

Breakers

MIB

MBB

BIB

LEFT SIDE

Panel Removed

FRONT

Door Removed

LDMF

inside front

door

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 21

Page 26

Figure 16 Liebert EXM BDC with optional SKRU and transformer

Key

Operator

FRONT VIEW

With Covers

Lamp

Kirk

Keys

MBB

BIB

System

Input

Bus

FRONT VIEW

Door Removed

LDB

Transformer

Option for 208V,

220V, 480V

or 600V Input

MIB

Neutral Bus

Ground Bus

EXM15007

Rev. 0

RIGHT SIDE VIEW

Panel Removed

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 22

Page 27

Figure 17 Busbars—Liebert EXM BDC with panelboard

See Figure 18

for details

about busbars

Neutral

Busbar

MBB

BIB

23.6" (600mm)

37.5" (953mm)

Ground

Busbar

Panelboard

MIB

LEFT SIDE

Panel Removed

FRONT

Door Removed

Notes:

1. All dimensions are in inches (mm).

2. Control wiring and power wiring must be run in separate conduits.

3. All wiring is to be in accordance with national and local electrical codes.

4. Vertiv will supply the interconnection cables when the Liebert EXM

BDC is attached to the UPS.

5. 225A panelboard for 10k-40kVA only. 400A panelboard for 60-100kVA only.

RIGHT SIDE

Panel Removed

EXM16012

Rev. 0

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 23

Page 28

Figure 18 Busbars—Liebert EXM BDC

See Figure 14.

UPS Bus

Ø 0.44"

(11mm)

Typical

System Input Bus

See Detail B

Input/Output

Bus, Typical

1.5" x 8.9" (38mm x 227mm)

Ø 0.44"

(11mm)

Typical

1.38" (35mm)

1.38" (35mm)

2.44" (62mm)

2.44" (62mm)

Ground Bus

5" x 4" (127mm x 102mm)

Neutral Bus

5" x 8.9" (127mm x 227mm)

Ø 0.44"

(11mm)

Typical

1.75"

(44.5mm)

Typical

All Busbars

Ø 0.56"

(14mm)

Typical

DETAIL A

Input

Breaker

Input

Ground

Bus

System

Input

Busbar

at Rear, Typical

System

Input

Connections

1.38"

(35mm)

1.38" (35mm)

Ø 0.56"

(14mm)

Typical

Shown with

Optional SKRU

Neutral

Input/Output

Connections

Ø 0.56"

(14mm)

Typical

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 24

DETAIL B

Iso-View Front Left

Corner Post Removed

Page 29

Figure 19 Lineup arrangement, Liebert EXM with Liebert EXM BDC

47.6" (1208mm)

23.6"

(600mm)

23.6"

(600mm)

NOTES

1. Dimensions are in inches (mm).

2. 24" (610mm) minimum clearance above unit.

36" (914mm) front access required for service.

For seismic mounting only 5" (102mm) in rear

for mounting brackets

3. Keep cabinet within 15 degrees of vertical.

4. Top and bottom cable entry available through removable

78.7"

(2000mm)

access plates.

Remove, punch to suit conduit size and replace.

5. Unit bottom is structurally adequate for forklift handling.

6. Control wiring and power wiring must be run in

separate conduits.

7. All wiring is to be in accordance with national and

local electrical codes.

8. Bypass distribution cabinet must be positioned on the right

side of the UPS.

UPS BDC

FRONT VIEW

EXM13028

Rev. 2

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 25

Page 30

1. All dimensions are in inches (mm).

2. 24" (610) minimum clearance above unit; 36" (914) front access required for service.

3. Keep cabinet within 15 degrees of vertical.

4. Top and bottom cable entry available through removable access plates.

Remove, punch to suit conduit size and replace.

5. Control wiring and power wiring must be run in separate conduits.

6. All wiring is to be in accordance with national and local electrical codes.

Cable Entry Area

11.4" x 13.2"

(290 x 335mm)

Cable Entry Area

6.2" x 13.2"

(57 x 335mm)

6.5" (164mm)

Outside Panel

6.5" (164mm)

Outside Panel

11.5" (292mm)

Outside Panel

5.5"

(140mm)

34.6"

(870mm)

23.7"

(602mm)

23.6"

(600mm)

39.5" (1000mm)

78.7"

(2000mm)

28.3"

(719mm)

Bracket

Centers

6.4" (162mm)

Outside Panel

24"

(609mm)

FRONT

RIGHT SIDE

UAM06008

Rev. 5

Leveling

Feet

BOTTOM VIEW

TOP VIEW

Maximum

Door Swing - 120°

Figure 20 Outline drawing, Liebert EXM BDC for Liebert EXM, 10-100kVA

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 26

Page 31

Figure 21 Liebert EXM BDC transformer location

Transformer

REAR OF CABINET

RIGHT SIDE

Table 4 Wiring for Liebert EXM to Liebert EXM BDC

Run From To Conductors

A Utility AC source BDC System Input Bus Phase A, B, C

B Utility AC Source BDC System Input Bus Neutral

C BDC Bypass Isolation Breaker UPS Main Input Phase A, B, C

D BDC Bypass Isolation Breaker UPS Main Input Neutral

E UPS Output Liebert EXM BDC Maintenance Isolation Breaker Phase A, B, C

F UPS Output Liebert EXM BDC Maintenance Isolation Breaker Neutral

G BDC Panelboard Load AC Connection Phase A, B, C

H BDC Panelboard Load AC Connection Neutral

I Utility AC Source All Ground Connections Ground

J BDC Terminal Block TB1 UPS Static Bypass Module J23, J24 and J26 Wiring for KO on Liebert EXM BDC

See Figure 4 and Tabl e 1 for additional details.

NOTE

Interconnection wiring between the UPS and bypass distribution cabinet is supplied by Vertiv when the

Liebert EXM BDC and Liebert EXM UPS are ordered as a system.

Table 5 Hardware torque values

Hardware Two Belleville Washers

M10 (3/8") 240 lb-in. (27 Nm)

M12 (1/2") 428 lb-in (48Nm)

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 27

Page 32

Figure 22 One-line diagram, 208V single input 10-100kVA UPS with three-breaker Liebert EXM BDC and panelboard

MBB

BIB

MIB

BYPASS DISTRIBUTION CABINET

STATIC BYPASS

UPS CABINET

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection by Others

AC Output

208V

4 Wire + GND

(Optional)

54 Pole

See Note 6

* System

AC Input

4 Wire + GND

Field-Supplied Wiring

BATTERY

NOTES

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. A neutral is required from the system AC input source.

4. UPS system input and output cables must be run in

separate conduits.

5. Control wiring must be run in separate conduits.

6. Optional 54 pole, 225A for 10-40kVA frame only or optional 54 pole

400A for 60-100kVA frame only.

EM11003

Rev. 0

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 28

Page 33

Figure 23 One-line diagram, 208V single input 10-100kVA UPS with three-breaker Liebert EXM BDC, input isolation

transformer and panelboard

BYPASS DISTRIBUTION CABINET

* System

AC Input

3 Wire + GND

UPS CABINET

BATTERY

NOTES

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. UPS system input and output cables must be run

in separate conduits.

4. Control wiring must be run in separate conduits.

5. Optional 54-pole, 225A for 10-40kVA frame only or

optional 54-pole 400A for 60-100kVA frame only.

6. Transformer available: 208, 220, 480, 600V input.

BIB MIB

MBB

STATIC BYPASS

(Optional)

54 Pole

See Note 5

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection by Others

Field-Supplied Wiring

AC Output

208V

4 Wire + GND

Local Grounding

Electrode

See Note 1

EXM1104

Rev. 0

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 29

Page 34

Figure 24 One-line diagram, 208V single input 10-100kVA UPS with three-breaker Liebert EXM BDC and two subfeed

NOTES

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. A neutral is required from the system AC input source.

Vertiv recommends a full capacity neutral conductor and

grounding conductors.

4.UPS system input and output cables must be run

in separate conduits.

5. Control wiring must be run in separate conduits.

6. Optional (2) 225A LDB for 60-100kVA frame only.

Optional single 225A LDB for 10-40kVA frame.

MBB

BIB

MIB

BYPASS DISTRIBUTION CABINET

STATIC BYPASS

UPS CABINET

LDB - Load Distribution Breaker

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection by Others

AC Output

208V

4 Wire + GND

Field-Supplied Wiring

EXM11005

Rev. 0

BATTERY

* System

AC Input

4 Wire + GND

LDB

LDB

(Optional)

(2) 225A

See Note 6

breakers

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 30

Page 35

Figure 25 One-line diagram, 208V single input 60-100kVA UPS with three-breaker Liebert EXM BDC, input isolation

NOTES

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. UPS system input and output cables must be run

in separate conduits.

4. Control wiring must be run in separate conduits.

5. Optional (2) 225A LDB for 60-100kVA frame only.

Optional single 225A LDB for 10-40kVA frame.

6. Transformer available: 208, 220, 480, 600V input.

MBB

BIB

MIB

BYPASS DISTRIBUTION CABINET

STATIC BYPASS

UPS CABINET

LDB - Load Distribution Breaker

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection by Others

AC Output

208V

4 Wire + GND

* System

AC Input

3 Wire + GND

Field-Supplied Wiring

EXM11006

Rev. 0

BATTERY

LDB

LDB

(Optional)

(2) 225A

See Note 5

Local Grounding

Electrode

See Note 1

transformer and two subfeed breakers

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 31

Page 36

Figure 26 One-line diagram, 208V dual input 10-100kVA UPS with three-breaker Liebert EXM BDC and panelboard

NOTES

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. A neutral is required from the system AC input source.

Vertiv recommends a full capacity neutral conductor.

4. Bypass and rectifier inputs and output cables

must be run in separate conduits.

5. Control wiring must be run in separate conduits.

6. Optional 54-pole, 225A for 10-40kVA frame only or

optional 54-pole 400A for 60-100kVA frame only.

7. Customer must supply shunt trip breaker with 120V coil.

8. Remove bypass jumper busbars inside the UPS to configure

a dual input system.

MBB

BIB MIB

BYPASS DISTRIBUTION CABINET

STATIC BYPASS

UPS CABINET

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection by Others

AC Output

208V

4 Wire + GND

* Rectifier

AC Input

4 Wire + GND

See Note 7

(Optional)

54 Pole

See Note 6

* Bypass

AC Input

4 Wire + GND

Field-Supplied Wiring

EXM11007

Rev. 0

BATTERY

See Tables 12 and13 for

details.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 32

Page 37

Figure 27 One-line diagram, 208V dual input 10-100kVA UPS with three-breaker Liebert EXM BDC and two subfeed breakers

See Tables 12 and13 for

details.

* Bypass

AC Input

4 Wire + GND

* Rectifier

AC Input

4 Wire + GND

See Note 7

BYPASS DISTRIBUTION CABINET

STATIC BYPASS

UPS CABINET

BATTERY

MBB

LDB

LDB

MIBBIB

(Optional)

(2) LDB

See Note 6

AC Output

208V

4 Wire + GND

Notes

1. Install in accordance with national and local electrical codes.

2. Input and bypass must share the same single source.

3. A neutral is required from the system AC input source.

Vertiv recommends a full capacity neutral conductor and

grounding conductors.

4. Bypass and rectifier inputs and output cables

must be run in separate conduits.

5. Control wiring must be run in separate conduits.

LDB - Load Distribution Breaker

BIB - Bypass Isolation Breaker

MBB - Maintenance Bypass Breaker

MIB - Maintenance Isolation Breaker

* External Overcurrent Protection By Others

Field-Supplied Wiring

EXM11008

Rev. 0

6. Optional (2) 225A LDB for 60-100kVA frame only.

7. Customer must supply shunt trip breaker with 120V coil.

8. Remove bypass jumper busbars inside the UPS to configure

a dual input system.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 33

Page 38

3.0 SPECIFICATIONS

Table 6 Physical standards and parameters

Bypass Distribution Cabinet Parameters Values

Standard Color Black (ZP-7021)

Front Door Opening (for serviceability)

Degree of Protection for UPS Enclosure

Minimum Clearance, Top 24" (610mm)

Minimum Clearance, Back 0" (5" [127mm] when seismic brackets are used)

Minimum Clearance, Sides 0"

Standards & Conformities

Environmental

Storage Temperature Range, °F (°C) -13°F to 158°F (-25°C to 70°C)

Operating Temperature Range, °F (°C)

Relative Humidity

Maximum Altitude Above MSL, ft (m)

IP 20 (with and without front door open)

Cable Entrance Top or Bottom

UL 1778 5th Ed.; CSA 22.2 107.3-14

FCC Part 15, Class A; ISTA Procedure 1H; WEEE;

32°F to 86°F (0-30°C) when seismic brackets are used

4920 (1500) (as per IEC 62040/3) -

1% Maximum kW derate / 100m rise between 1500-3000m

More than 180°

IBC 2012/CBC 2010

32°F to 104°F (0 to 40°C)

up to 95% Non-Condensing

(Operating and Non-Operating)

The following are approved branch breakers for the panel boards used in the EXM BDC.

Listed (DIVQ), Schneider Electric Square D branch circuit breakers:

• Type QOB, rated 22 kA, 150 A maximum

• Type QO, rated 22 kA, rated 100 A maximum

• Type QOB, rated 10 kA, rated 100 A maximum

• Type QO, rated 10 kA, rated 100 A maximum

Table 7 Mechanical characteristics, Liebert EXM BDC, 10-100kVA

Dimensions, W x D x H, in (mm)

Frame SizemmRating

kVA

600 10-40 525 (238) 625 (283) 914 (415) 1014 (460)

600 60 550 (249) 650 (295) 1123 (509) 1223 (555)

600 80 550 (249) 650 (295) 1249 (567) 1349 (612)

600 100 550 (249) 650 (295) 1365 (619) 1465 (665)

Add 27 lb. (12 kg) for monitoring.

No Transformer

No Distribution

23.625 x 39.375 x 78.73

Weight, lb. (kg)

No Transformer With

Panel Board or

Subfeed Breaker

With Transformer

No Distribution

With Transformer

and Panel Board or

Subfeed Breaker

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 34

Page 39

Table 8 Liebert EXM BDC, 60-100kVA, mechanical characteristics

Rated Power, kVA 60-100

Dimensions, W x D x H, in (mm) 23.625 x 39.375 x 78.75 (600 x 1000 x 2000)

Weight, lb (kg)

No Distribution 550 (250)

Two 225A Subfeed Breakers 660 (300)

400A Panelboard 660 (300)

No Distribution & 480V Transformer 1549 (704)

No Distribution & 600V Transformer 1538 (699)

Two 225A Subfeed Breakers & 480V Transformer 1669 (759)

Two 225A Subfeed Breakers & 600V Transformer 1648 (749)

400A Panelboard & 480V Transformer 1669 (759)

400A Panelboard & 600V Transformer 1648 (749)

Color ZP 7021 (Black)

Protection Degree IEC (60529) IP20 (finger-proof with front doors open or closed)

Table 9 Liebert EXM BDC heat dissipation

Liebert EXM BDC

Liebert EXM BDC

Rating, kVA

10 1966 (0.576) 1808 (0.530) 1723 (0.505) 1750 (0.513)

15 2504 (0.734) 2320 (0.680) 2474 (0.725) 2453 (0.719)

20 2938 (0.861) 2593 (0.760) 2958 (0.867) 2986 (0.875)

30 4847 (1.421) 4408 (1.292) 4343 (1.273) 4896 (1.435)

40 5676 (1.664) 5166 (1.514) 5005 (1.467) 4988 (1.462)

60 7479 (2.192) 6804 (1.994) 6670 (1.955) 6445 (1.899)

80 9612 (2.817) 8711 (2.553) 9001 (2.638) 8892 (2.606)

100 9728 (2.851) 8881 (2.603) 9953 (2.917) 10042 (2.943)

Heat Dissipation

208:208 Transformer

BTU/Hr (kW)

Liebert EXM BDC

Heat Dissipation

220:220 Transformer

BTU/Hr (kW)

Liebert EXM BDC

Heat Dissipation

480:208 Transformer

BTU/Hr (kW)

Liebert EXM BDC

Heat Dissipation

600:208 Transformer

BTU/Hr (kW)

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 35

Page 40

3.1 Electrical Characteristics

NOTE

The breakers and cables used must be in accordance with NEC ANSI/NFPA 70. A disconnect breaker must be

provided for AC input, Bypass and AC output. Recommended cable sizes are suitable for operation at a

maximum temperature of 104°F (40°C).

Table 10 Liebert EXM BDC input currents, single input, main, without transformer

Vol tag e

3-Ph, 60 Hz

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

BDC Rating

kVA

10 34 3W + N + G 45 65 (1) #6 (1) #4 M12

15 51 3W + N + G 70 85 (1) #4 (1) #2 M12

20 68 3W + N + G 90 115 (1) #2 (1) 1/0 M12

30 102 3W + N + G 150 175 (1) 2/0 (1) 4/0 M12

40 136 3W + N + G 175 230 (1) 4/0 (2) 1/0 M12

60 205 3W + N + G 300 400 (2) 3/0 (2) 4/0 M12

80 273 3W + N + G 350 460 (2) 4/0 (2) 300kcmil M12

100 341 3W + N + G 450 610 (2) 350kcmil (2) 400kcmil M12

System Input

Current, A, Max Phase

Recommended

Upstream

Protection, A

75°C Wire

Current, A, Total Copper Wire

Aluminum

Wire Bolt Size

Table 11 Liebert EXM BDC input currents, dual input, rectifier, without transformer

Rectifier

Vol tag e

3-Phase, 60Hz

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

Refer to Figures 26 and27 for additional details about this system configuration.

BDC Rating,

kVA

10 34 45 3W + N + G 65 (1) #6 (1) #4 M12

15 51 70 3W + N + G 85 (1) #3 (1) #2 M12

20 68 90 3W + N + G 115 (1) #2 (1) 1/0 M12

30 102 150 3W + N + G 175 (1) 2/0 (1) 4/0 M12

40 136 175 3W + N + G 230 (1) 4/0 (2) 1/0 M12

60 205 300 3W + N + G 400 (2) 3/0 (2) 4/0 M12

80 273 350 3W + N + G 460 (2) 4/0 (2) 300kcmil M12

100 341 450 3W + N + G 610 (2) 350kcmil (2) 400kcmil M12

Rectifier Input

Current RIB, A, Max

Recommended

Upstream

Protection, A Phase

75°C Wire

Current, A, Total Copper Wire

Aluminum

Wire Bolt Size

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 36

Page 41

Table 12 Liebert EXM BDC input currents, dual input, bypass, without transformer

Vol tag e

3-Ph, 60 Hz

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

Refer to Figures 26 and27 for additional details about this system configuration.

BDC Rating

kVA

10 28 40 3W + N + G 50 (1) #6 (1) #4 M12

15 42 70 3W + N + G 85 (1) #4 (1) #2 M12

20 56 80 3W + N + G 115 (1) #2 (1) #2 M12

30 83 125 3W + N + G 130 (1) 1/0 (1) 2/0 M12

40 111 175 3W + N + G 175 (1) 3/0 (1) 4/0 M12

60 167 250 3W + N + G 285 (1) 350kcmil (2) 2/0 M12

80 222 350 3W + N + G 400 (2) 3/0 (2) 4/0 M12

100 278 450 3W + N + G 460 (2) 4/0 (2) 300 kcmil M12

Bypass Input

Current

BIB/MBB, A, Max

Bypass Recommended

Upstream Protection, A Phase

75°C Wire

Current, A Total

Table 13 Liebert EXM BDC output currents

Vol tag e

3-Ph, 60Hz)

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

208/120

220/127

System

BDC

Rating, kVA

10 28 3W + N + G 40 50 (1) #6 (1) #4 M12

15 42 3W + N + G 60 85 (1) #4 (1) #2 M12

20 56 3W + N + G 70 115 (1) #2 (1) #2 M12

30 83 3W + N + G 110 130 (1) 1/0 (1) 2/0 M12

40 111 3W + N + G 150 175 (1) 3/0 (1) 4/0 M12

60 167 3W + N + G 225 285 (1) 350kcmil (2) 2/0 M12

80 222 3W + N + G 300 400 (2) 3/0 (2) 4/0 M12

100 278 3W + N + G 350 460 (2) 4/0 (2) 300kcmil M12

Output

Current

A, Max Phase

Recommended

Upstream

Protection, A

75°C

Wire

Current

A, Total

Copper

Wire

Copper

Wire

Aluminum

Wire

Aluminum

Wire Bolt Size

Bolt

Size

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 37

Page 42

Table 14 Recommended lug sizes (compression type) M12, 1/2" bolt

Cable Size

#6AWG 256-030695-868 —

#4AWG 256-030695-733 —

#2-3AWG 54811BE —

#1AWG 54857BE —

#1/0AWG 256-30695-593 —

#2/0AWG 54862BE 60238

#3/0AWG 54864BE 60244

#4/0AWG 54866BE 60250

250kcmil 54868BE 60256

300kcmil 54870BE 60262

350kcmil 54872BE 60267

400kcmil 54874BE 60269

500kcmil 54876BE 60273

600kcmil 54878BE 60275

700kcmil 54879BE 60277

750kcmil 54880BE 60278

T&B Copper

Two Hole

T&B Aluminum

Two Hole

3.2 Torque Requirements

All electrical connections must be tight.

Tables 15 and16 provide the torque values for the connections to the Liebert EXM BDC. Use these values unless

the equipment is labeled otherwise.

Table 15 Busbar torque for power wiring

Bolt Shaft Size

3/8" (M10) 192 (22)

1/2" (M12) 428 (48)

Tor qu e

Lb-in (Nm)

Table 16 Terminal block torque with compression lugs for control wiring

AWG W ire Size

or Range

#22 - #14 3.5 to 5.3 (0.4 to 0.6)

Tor qu e

Lb-in (Nm)

NOTE

Refer to the manufacturer’s data for proper torque for circuit breaker power connections.

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 38

Page 43

Table 17 Breaker torque

Manufacturer Part Number Torque, Nm

Tma x2 7.0

Tma x3 8.0

ABB

Siemens

Tma x5 25 .0

XT1 6

XT3 8

D Frame 5.5

F Frame 22.0

J Frame 31.0

Table 18 Electrical data—Liebert EXM BDC, 480VAC input, 208VAC output, single input, with 480V:208V transformer

Liebert EXM

BDC Rating, kVA

10 15 3W + G 20 40 (1) #8 (1) #8 M12

15 23 3W + G 30 40 (1) #8 (1) #8 M12

20 31 3W + G 40 40 (1) #8 (1) #8 M12

30 46 3W + G 60 65 (1) #6 (1) #4 M12

40 61 3W + G 80 85 (1) #4 (1) #2 M12

60 91 3W + G 125 150 (1) #2 (1) 1/0 M12

80 122 3W + G 175 200 (1) 1/0 (1) 3/0 M12

100 152 3W + G 200 205 (1) 4/0 (1) 250 kcmil M12

See Notes on Tables 18 through20. on page 40.

Maximum System

Input Current, A Phase

Recommended

Upstream

Protection, A

75°C Wire

Current, A, Total Copper Wire

Aluminum

Wire Bolt Size

Table 19 Electrical data—Liebert EXM BDC, 600VAC input, 208VAC output, single input, with 600V:208V transformer

Liebert EXM

BDC Rating, kVA

10 12 3W + G 20 40 (1) #8 (1) #8 M12

15 18 3W + G 25 40 (1) #8 (1) #8 M12

20 25 3W + G 35 40 (1) #8 (1) #8 M12

30 37 3W + G 50 50 (1) #8 (1) #6 M12

40 49 3W + G 70 65 (1) #5 (1) #4 M12

60 73 3W + G 100 90 (1) #3 (1) #2 M12

80 98 3W + G 125 120 (1) #1 (1) 1/0 M12

100 122 3W + G 175 150 (1) 1/0 (1) 3/0 M12

See Notes on Tables 18 through20. on page 40.

Maximum System

Input Current, A Phase

Recommended

Upstream

Protection, A

75°C Wire

Current, A, Total Copper Wire

Aluminum

Wire Bolt Size

Table 20 Electrical data—Liebert EXM BDC, 208VAC or 220VAC input, single input, with 208V:208V or 220V:220V

transformer

Liebert EXM

BDC Rating, kVA

10 36 3W + G 45 65 (1) #6 (1) #4 M12

15 53 3W + G 70 85 (1) #4 (1) #2 M12

20 71 3W + G 90 100 (1) #3 (1) #1 M12

30 107 3W + G 150 175 (1) 2/0 (1) 4/0 M12

Maximum System

Input Current, A Phase

Recommended

Upstream

Protection, A

75°C Wire

Current, A, Total Copper Wire

Aluminum

Wire Bolt Size

Vertiv | Liebert® EXM™ BDC User Manual | Rev. 3 | 01/18 | 39

Page 44

Table 20 Electrical data—Liebert EXM BDC, 208VAC or 220VAC input, single input, with 208V:208V or 220V:220V

transformer

Liebert EXM

BDC Rating, kVA

40 141 3W + G 200 230 (1) 4/0 (1) 300 kcmil M12

60 211 3W + G 300 335 (1) 400 kcmil (2) 4/0 M12

80 281 3W + G 400 460 (2) 4/0 (2) 300 kcmil M12

100 352 3W + G 450 510 (2) 250 kcmil (2) 400 kcmil M12

See Notes on Tables 18 through20. below.

Maximum System

Input Current, A Phase

Recommended

Upstream

Protection, A

75°C Wire

Current, A, Total Copper Wire

Aluminum

Wire Bolt Size

Notes on Tables 18 through20.