Page 1

S [017-032]

HIGH PERFORMANCE AIR COOLED CHILLER

SERVICE MANUAL

English

Cod. 272902

Rev. 25.05.2005

Issued by T.D.Service

Page 2

Page 3

Caution

It is recommended that:

S the manual is retained for the entire service life of the machine;

S the user reads the manual carefully before carrying out any operations on the machine;

S the machine is used exclusively for the purpose for which it is intended; incorrect use of the machine shall release the

manufacturer from any liability.

This manual has been prepared to enable the end ---user to carry out only those operations that can be done with the panels

closed. Any operations that require the opening of doors or equipment panels must be carried out only by qualified personnel.

Each machine is equipped with an electric isolating device which allows the operator to work in conditions of safety. This

device must always be used to eliminate risks during maintenance (electric shocks, scalds, automatic restarting, moving

parts and remote control).

The panel key supplied with the unit must be kept by the person responsible for maintenance.

For identification of the unit (model and serial no.) in case of the necessity for assistance or spare parts, read the identification

labels affixed to the outside and inside of the unit.

IMPORTANT:

Index

1-- Introduction 1...............................................................................

1.1 --- Foreword 1....................................................................................

1.2 --- Responsibility 1................................................................................

1.3 --- Inspection 1...................................................................................

1.4 --- General description 1............................................................................

2 -- Preliminary Operations 1....................................................................

2.1 --- Operating limits 1...............................................................................

2.2 --- Sound pressure levels 1.........................................................................

2.3 --- Transport 2....................................................................................

2.4 --- Foundations 2..................................................................................

2.5 --- Service area 2..................................................................................

3 -- Installation 2................................................................................

3.1 --- Hydraulic connections 2.........................................................................

3.2 --- Connection of the safety valve discharge 3.........................................................

3.3 --- Electrical connections 4..........................................................................

4 -- Start--Up and Operation 4...................................................................

4.1 --- Initial check 4..................................................................................

4.2 --- First start ---up (or after a long stop) 5...............................................................

4.3 --- Starting and stopping 5..........................................................................

4.4 --- Chillers serving special plants 5...................................................................

4.5 --- Freecooling 5..................................................................................

4.6 - -- Microprocessor control 5.........................................................................

5 -- Refrigerant and Oil Charge 5.................................................................

5.1 --- Refrigerant charge 5............................................................................

5.2 --- Oil charge 5...................................................................................

6 -- Safety Devices Settings 6....................................................................

6.1 --- Setting thermostatic expansion valve 6.............................................................

7 -- Maintenance 7..............................................................................

7.1 --- Spare parts 7..................................................................................

7.2 --- Dismantling the unit 7...........................................................................

8 -- Options and Accessories 7...................................................................

8.1 --- Pump set 7....................................................................................

8.2 --- Water chiller with partial heat recovery (20%) 7......................................................

8.3 --- Water chiller with total heat recovery (100%) 8.......................................................

8.4 --- Hydraulic circuit accessories 8....................................................................

8.5 --- Water chiller with inertia tank 8....................................................................

This manual may be subject to modification; for complete and up --- to ---date information the user should

always consult the manual supplied with the machine.

Ta b l e s 9..........................................................................................

Drawings 15......................................................................................

Circuits 23........................................................................................

Page 4

1 --- Introduction

C

1.1 --- Foreword

This handbook is aimed at enabling both the installer and the operator to carry out the correct installation, operation and maintenance of the refrigerating machine, without damaging it or causing injuries to the relevant staff.

The handbook is thus an aid for the qualified staff in the arrangement of the specific equipment for the correct installation,operation and maintenance in compliance with the local regulations

in force.

The MATRIX S [017 --- 032] water chillers can be identified as fol-

lows:

BH023

Cooling C apacity “kW”

Nominal cooling capacity x 10

Compressor:

H Hermetic Scroll

Version:

B Base

L Low Noise

Q Quiet

Execution:

C Chiller

S Superchiller

1.2 --- Responsibility

Liebert Hiross accepts no present or future responsibility for

damage to persons, things or to the machine itself due to operators’ negligence, failing to comply with the installation, operation

and maintenance instructions of this handbook, failed application of the safety norms in force for the system and the qualified

staff charged with the operation and maintenance.

1 . 3 --- I n s p e c t i o n

All units are fully assembled and wired in the manufacturing

plant. Before shipment they are charged with the necessary

quantities of refrigerant and oil and then tested at the operating

conditions normally required by the customer. The machine’s

hydraulic circuit is equipped with drain plugs and open vent

valves; the freecooling coils are supplied dry to avoid possible

problems due to frostin the storage period. Immediately inspect

the machine carefully on delivery to check for damage during

transportation or missing components; possible claims must be

made immediately to the carrier and the factory or its representative.

1 . 4 --- G e n e r a l d e s c r i p t i o n

MATRIX S units with air cooled condensers have been designed

and manufactured for producing chilled water.

They are also available in versions with a built -- -in freecooling

module, in versions with heat recovery for simultaneous heating

of thermal circuit water, with a pump assembly installed on the

machine and/or inertial buffer tank inside the machine; the chilling units can be equipped with several options indicated in the

price list.

The ”MATRIX S” product line has been designed utilising the

state---of---the---art techniques available nowadays in the indus-

try, and includes all the components necessary for automatic

and efficient operation.

Each unit is completely factory assembled; after evacuation, the

necessary quantity of refrigerant is added to the refrigerant circuit(s) and the unit is tested.

All the units are equipped with oneor two independent refrigerating circuits, each one composed of: an air cooled condenser , a

hermetic Scroll compressors and a braze --- welded plate evaporator. The components of the liquid line are the charging valves,

filters dryers, solenoid valve, shut---off valve, moisture indicator

and thermostatic expansion valve.

The hydraulic circuit -- - with max. working pressure 5 bar --- is

made up of carbon steel pipes connected with grooved--- end

(Victaulic) fittings and couplings and include also a flow switch

(optional) and, in the freecooling versions, chilled water coils

and a three ---way valve.

The hermetic scroll compressors are complete with the following

protection/safety devices: oil heater, electronic protection monitoring the temperature of the motor windings and the direction

of rotation (the latter may be enclosed in the electronics of the

compressororexternal, depending on the model). The ”MATRIX

S” water chillers are controlled by the ”MICROFACE” microprocessor,managing all the unit operating conditions.The user can

change and/or modify the operating parameters through the display keyboard installed on the electrical panel.

The electrical control board is equipped with all the safety and

operating devices required for reliable operation. The compressor motors are equipped with protection on all three phases and

are started by three --- pole contactors.

2 --- Preliminary Operations

2.1 --- Operating limits

The units can operate within the indicated operating ranges (see

Tab. 7). These limits apply to new machines, subject to correct

installation and maintenance.

S Ambient air minimum temperature: ---25ûC for Superchiller,

+15ûC for Chiller without fan speed control (Operation allowed only in summer mode), --- 10ûC for Chiller with continuous fan speed control (Either Triac or EC fan);

S Maximum outdoor air temperature is in relation to each mod-

el, as indicated in Tab. 7. In any case outdoor temperatures

aver 45ûC are not admitted; such limits are determined by

electrical and electronic components fitted on units;

S Maximum water flow allowed: depending on the pressure

drop corresponding to the required thermal difference (usually not lower than 3.5ûC --- 4 ûC);

S Minimum allowed water flow: compatible with a sufficient

evaporation temperature, to avoid the intervention of the

safety devices (to be evaluated for a thermal difference not

higher than 8ûC);

S Temperature range of the water exiting the evaporator: 4ûC

--- 1 5 ûC;

S Maximum temperature of the water entering the unit: 20ûC;

higher temperatures are allowed only at the system start--up and not during normal operation;

S Maximum glycol concentration: 50% (35% with the optional

pump assembly installed on the machine);

S Minimum allowed glycol concentration: depending on the

minimum temperature of the ambient air expected at the

installation site (see Tab. a);

S Maximum pressure of the hydraulic circuit: 5 bar;

S Voltage range for the electric supply: 400 V

phase difference: 3%; tolerance on frequency: 1%.

Storage conditions: from --- 20ûCto45ûCforallMATRIXSmod-

els

Note:

Avoid positioning in areas with strong dominant winds that may

impair the operation and effect the indicated limits.

+

/

10%; max.

---

1

Page 5

2.2 --- Sound pressure levels

The Tab. 4 shows the noise data for the units in standard configuration (without pumps), operating continuously and measured

according to the ISO 3744 norm, in free field conditions.

The highest noise levels are detected on the condenser coil side.

Note:

Avoid positioning in areas with possible reverberation of the

sound waves, which can adversely effect the noise levels.

2 . 3 --- T r a n s p o r t

S Handle the unit by lifting it with a crane from above;

S The lifting holes are positioned in the frame’s base (when lift-

ing, use spreader bars to protect the sides, see Fig. 2).

Note:

Place the lifting tubes in the holes in the base indicated by ”LIFT

HERE”. Lock the ends of the tubes with the locking pins and

splits pins as shown in Fig. 2.

The capacity of the lifting gear must be adequate to lift the load

in question. Check the weight of the units, the capacity of the lifting gear and ropes and the condition and suitability of the aforementioned equipment.

2.4 --- Foundations

S The unit must be placed on a level surface which will support

its weight.

S If necessary, position the unit on suitable anti ---vibration sup-

ports that can be supplied as an option (in rubber or spring --type). Refer to the manual ”Installation of the spring anti --vibration supports” for their correct positioning.

S When positioned, level the unit.

Note:

For weight distribution see Fig. 3.

Note:

The weights and their distribution refer to standard units without

options; if the pump assembly, or other options are installed on

the machine, add the weights of the installed accessories to

those of the standard units (see Tab. 8).

2.5 --- Service area

S In order to allow free air flow and maintenance of the unit, a

minimum area must be left free of obstructions around the

unit (see Fig. 1).

S The hot air expelled by the fans must be allowed to rise unim-

peded by obstacles for a minimum height of 2.5 m.

S Avoid recirculation of hot air between the suction and dis-

charge, otherwise the unit performance may be impaired or

the standard operation can be interrupted.

3 --- Installation

3.1 --- Hydraulic connections

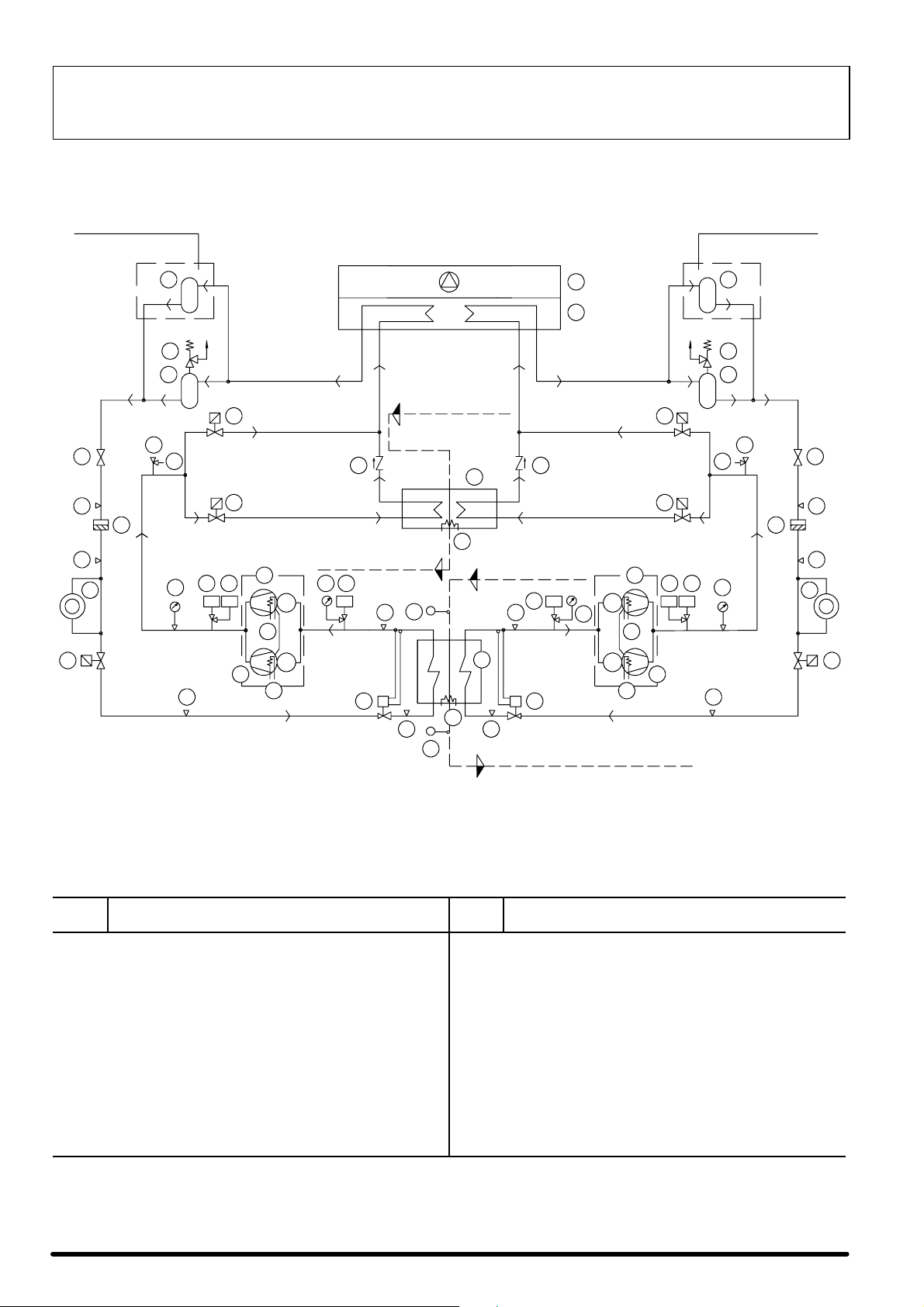

3.1.1 -- Hydraulic circuit construction (Fig. a)

The piping must be connected to the chiller. Construct a chilled

water circuit as described below, see Fig. a:

1) Place shut ---off valves within the circuit to allow servicing;

2) Install a pump system suitable for the flow rate required at

a pressure head equal to the sum of all the pressure drops

(see project data).

Matrix S chillers can be equipped, upon request, with

pumps having performance as indicated in Tab. 8;

3) Install manometers at the chiller inlet/outlet;

4) Install thermometers at the chiller inlet/outlet;

5) Connect the pipes to the chiller by flexible joints to avoid

transmitting vibrations and to balance the thermal expansion; proceed in the same way even if the pump set is outside the chiller;

6) It is useful to include a water pressure switch to give an early

warning of low water pressure;

7) Place a mesh filter at the inlets of the pump and water chiller

(Can be supplied as an optional accessory --- Not fitted);

8) Install, at the highest points in the circuit, apparatus which

allows the bleeding of air and possibly the filling of glycol;

9) Place a drain valve at the lowest point in the circuit and immediately at the outlet of the water chiller;

10) Install a water filling set including the following:

a) filling water meter;

b) manometer;

c) non---return valve;

d) air separator;

e) removable supply tube, which must be disconnected

after each charge/top---up;

11) For maximum protection ensure that all tubing exposed to

low outdoor temperatures is fitted with anti ---freeze heaters

and insulated using closed cell synthetic rubber (elastomer);

12) The circuit must include an expansion vessel (with safety

valve) of suitable capacity;

13) Connect the lines avoiding stresses on the machine inner

parts.

Note:

If the water chiller is complete with an expansion vessel (supplied as an option), check if the capacity is enough, and install

a second vessel in the circuit, if required (see par. 8.4).

Follow the indications in Fig. c for the correct sizing.

Note:

The whole circuit must contain a water volume suitable for the

capacity of the installed chiller. Check if the inertial capacity given by the sum of the hydraulic volume inside the machine (including the volume of the optional interna tank, if fitted) and the

system volume is sufficient, or possibly install a tank in the circuit.

Follow the indications in Fig. b for the correct sizing.

Note:

The hydraulic circuit must ensure a constant water supply to the

evaporator in every operating condition. Otherwise, the compressors may be damaged by repeated returns of liquid refrigerant on their suction.

Note:

The water flow switch is a compulsory safety component that

must be installed and correctly wired to the Matrix S chillers,

otherwise the guarantee will be invalidated.

It is installed, as standard, on units with the optional on --- board

pump set, and is available as a option for units without pumps

on board: in the latter case the flow switch, if not installed on the

machine, can be installed on the hydraulic circuit by the installer,

butitiscompulsorythatitiswiredtotheelectricpanelterminal

board, as indicated on the wiring diagram.

3.1.2 -- Addition of water and ethylene glycol

Very important:

Add water and ethylene glycol to the circuit with a % depending

on the minimum temperature of the outside air expected at the

installation site. Do not exceed the nominal operating pressure

of the circuit’s components.

Notes:

S To avoid stratification run the circulation pump for at least 30

minutes after adding any glycol.

S After adding water to the hydraulic circuit always discon-

nect the water supply coming from the sanitary supply;

this avoids the danger of glycol entering the sanitary water

system.

S After any topping --- up of the water check the concentration

and add glycol if necessary.

3.1.3 -- Water--glycol mixture

Water---glycol mixtures are used as the thermal carrier fluid in

very cold climates or with temperatures below zero degrees centigrade. Determine the ethylene glycol % which must be added

to the water, with the assistance of Tab. a.

2

Page 6

Tab.a--Ethyleneglycoltobeaddedtowater

(% in weight of total mixture)

Ethylene glycol

(% in weight)

Freezing tempera-

(*)

ture, ûC

Mixture density at

(*)

,kg/l

20ûC

(*) Values are for Shell antifreeze 402. For different brands, check

manufacturer’s data.

For the chiller internal water volume refer to Tab. 1. If the optional

buffer tank is installed on the machine, add the tank hydraulic

volume.

0 10 20 30 40 50

0 --- 4 . 4 ---9 . 9 --- 1 6 . 6 --- 2 5 . 2 --- 3 7 . 2

--- 1.017 1.033 1.048 1.064 1.080

ALWAYS CHARGE THE HYDRAULIC CIRCUIT WITH THE REQUIRED GLYCOL % NECESSARY FOR THE MINIMUM AMBIENT TEMPERATURE AT THE INSTALLATION SITE. FAILING

TO COMPLY WITH THIS INSTRUCTION SHALL INVALIDATE

THE UNIT WARRANTY.

3 . 2 --- C o n n e c t i o n o f t h e s a f e t y v a l v e

discharge

Safety valves are installed on the high pressure side of the refrigeration circuit: the discharge of these valves must be conveyed

outside through a suitable pipe, having a diameter of at least that

of the valve outlet, without burdening the valve body.Convey the

discharge to areas where the jet cannot harm people and the

surrounding environment.

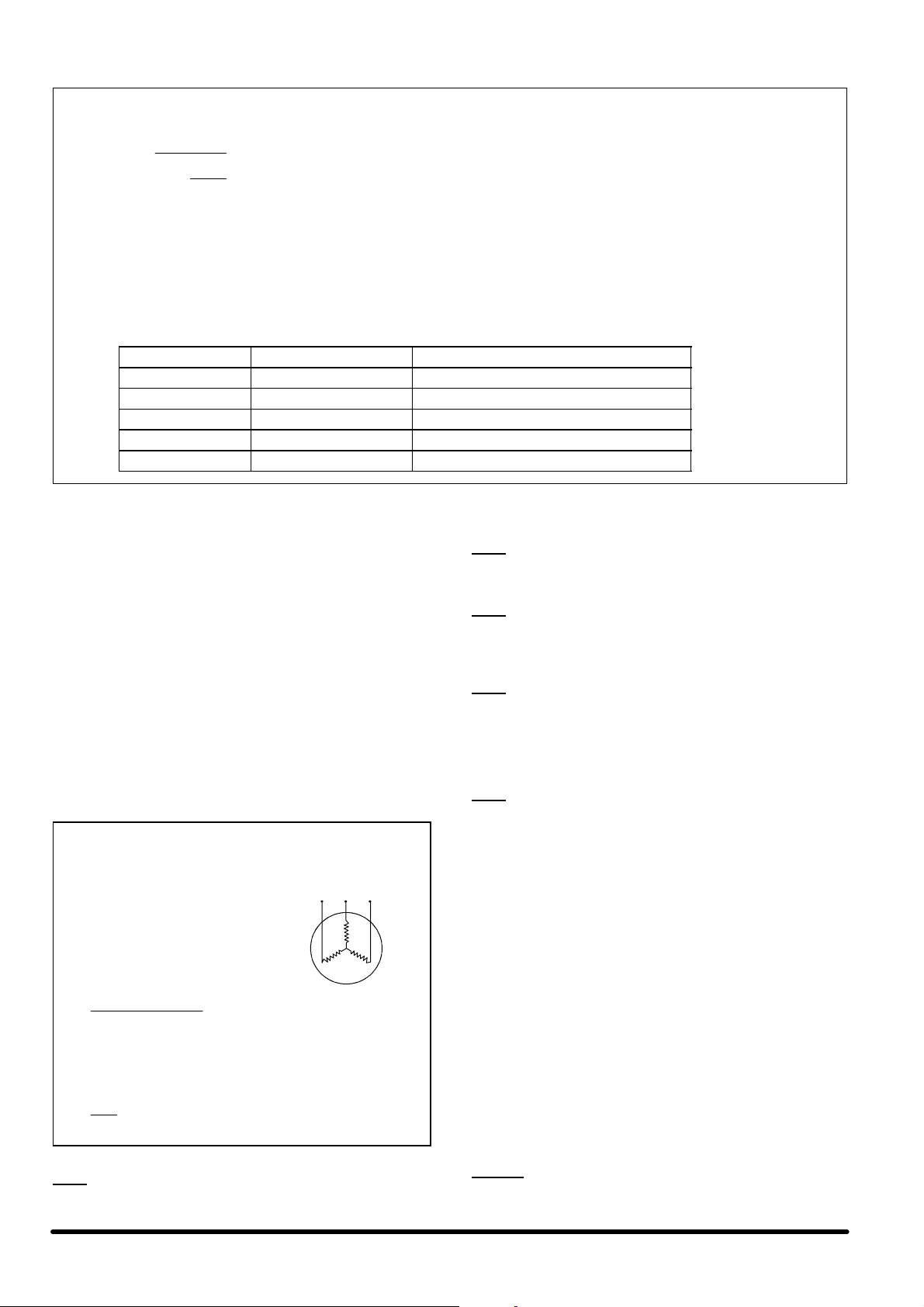

Fig. a --Ideal chilled water circuit

disconnect af-

ter charge

10e

10d10c10b10a

12

Fig. b --Inertia tank sizing

The total optimum hydraulic volume of the system where the Matrix S chiller is installed can be calculated by the

following formula:

43 x Rt

V =

where:

--- V=minimum required total water volume expressed in litres

--- Rt=refrigeration capacity expressed in kW

--- Xd=differential band set on the control and expressed in degrees centigrade

Xd

flow

9

Vpt

Ta n k

1 1327436

5

T T

CHILLER

5 5 9

USER

11

11

4

8

Please note that the sum of the hydraulic volume of the Matrix S chiller (Vm) plus the volume of the hydraulic circuit

connected to it (Vpc) must be greater than, or equal to the minimum required total water volume (V). If this condition is not satisfied, it is necessary to install an inertia tank (Vpt, as indicated in the Fig. a) with a volume at least

equal to the following value: Vpt=V ---Vm---Vpc

3

Page 7

Fig. c --Sizing of the expansion vessel

The total volume of the expansion vessel is calculated with the following formula:

C x e

V =

1 --

Pi

Pf

where:

-- - C=quantity of water inside the system expressed in litres

-- - e=water expansion coefficient, with water at 10ûC as a reference

-- - Pi=absolute pressure of initial charging, equivalent to the vessel pre --- charge pressure (typical value

2.5 bara)

-- - Pf=absolute final tolerated pressure, lower than the operating pressure of the safety valve calibration

pressure (typical value 4.0 bara).

Use the values of the water expansion coefficient indicated in the table below:

H2OT[°C] Density [kg/m3] Expansion coefficient “e”

10 999.6 --- --- ---

20 997.9 0.0017

30 995.6 0.0040

40 992.2 0.0075

50 988.1 0.0116

3.3 --- Electrical connections

1) Before proceeding with the electrical connections, ensure

that:

S all electrical components are undamaged;

S allterminalscrewsaretight;

S the supply voltage and frequency are in accordance with

the rating (with tolerance in accordance with IEC 8--- 6

norms, March 1990)

S the allowed phase to phase variability is 3% maximum

(see Fig. d). Variability in excess of 3% invalidates the

guarantee.

2) Supply cable connections (see Tab. 6):

S Connect the cable to the supply terminals.

S Use appropriately sized 3--- pole cable. An earth wire

must also be connected.

S After having opened the passagein the framework (pre -- -

punched knock ---outs) for the supply line entry, restore

the original degree of protection using suitable accessories for the wiring and junction boxes.

Fig. d --Example of calculating phase

1) The 400 V supply has

2) The average voltage is:

3) The maximum deviation from the average is:

4) Thephasetophasevariabilityis:

Note:

The power supply should never be disconnected, except when

performing maintenance.

to phase variability

the following variability:

RS = 388 V

ST = 401 V

RT = 402 V

388 + 401 + 402

3

402 --- 397 = 5 V

5

x 100 = 1.26 (acceptable)

397

RS T

= 397

Operate (open) the main switch before carrying out any maintenance work on electrical components.

Note:

It is forbidden to work on the electrical components without

using insulating platforms, and in the presence of water or fog

or mist.

Note:

The supply to the external pump assembly mustbe made before

starting the chiller and must be kept on as long as the chiller is

in use. Incorrect operation will cause the unit to lock--- out because of the internal protections (flow switch intervention).

Note:

The compressors are equipped with an electronic protectiondevice blocking their start if the phase sequence is not correct, or

stopping their operation if a thermal relay intervenes. This device

is essential for the integrity of the mechanical and electrical components of the compressors. Reset the standard functions by

isolating this device and removing the causes of the lock---out.

Note:

The chillers are equipped with their own microprocessor control

adjustment. The use of the remote ON --- OFF input (located in

the electric panel terminal board) as a system temperature control element is forbidden.

4 --- S t a r t --- U p a n d O p e r a t i o n

4.1 --- Initial check

1) Check all water connections.

2) Open the shut---off valve on the liquid line.

3) Ensure that the intake pressure is higher than 4.0 bar; if this

is not the case, prolong pre --- heating of the compressor (if

possible) and check that the refrigerant shut --- off valve is

properly sealed, see Fig. 9.

4) Open all isolating valves and/or water ball valves.

5) In case of climates with temperatures below zero degrees C,

make sure the chilled water circuit is filled with the correct

concentration of water/glycol.

6) Bleed all air out of the chilled water circuit.

7) Verify the water flow rate and its direction.

8) Ensure that the thermal load is sufficient for start---up.

Caution:

The ambient air temperature probe must be positioned in the

shade and protected against the weather.

4

Page 8

4 . 2 --- F i r s t s t a r t --- u p

(or after a long stop)

Operate as follows:

1) At least 8 hours before the start ---up, power the crank-

case heaters by setting the main isolator switch ON.

Make sure the auxiliary circuit has been powered and

check the operation (a fault due to an incorrect procedure will invalidate the compressor guarantee).

2) Open the valves of the refrigeration circuit that had been

closed before the initial check.

3) Check the machinery supplying the thermal load connected

with the unit and start the system pump(s).

4) MAKE SURE THE COMPRESSOR OIL HAS BEEN HEATED

FOR AT LEAST 8 HOURS; start the unit only then.

5) Make sure the fans rotate in the correct direction (anticlockwise): check the electrical connections, if necessary .

6) Make sure the pumps rotate in the correct direction.

7) During the unit start ---up an inlet water temperature

higher than 20ûC is allowed. Under standard operating

conditions check that the limits indicated in paragraph

2.1 are not exceeded.

8) Check the correct operation of the control and safety devices.

9) Check the outlet temperature of the chilled water (check if

the set--- point set on the controller is reached).

10) Check the oil level in both compressors.

11) With the compressors at full load, check there are no

bubbles visible in the frefrigerant sight glass. If there are any,

charge the unit according to par. 5.

4.3 --- Starting and stopping

ALWAYS ENSURE THAT THE COMPRESSOR OIL HAS BEEN

PREHEATED.

FOR BRIEF STOPPAGES MAINTAIN THE SUPPLY TO THE

CRANKCASE HEATER.

S Start the unit setting the Microprocessor switch ON.

S Stop the unit setting the Microprocessor switch OFF.

S In case of long stops, turn the machine off using the Micro-

processor switch OFF.

In this case the compressor crankcase heaters remain powered.

S For seasonal shutdown of the unit operate the main switch

locatedon the main electrical power supply. This will disconnect the compressor crankcase heaters.

4.4 --- Chillers serving special plants

The units are capable of cooling a water ---glycol mixture to temperatures close to 0ûC without the need for significant modifications. In the case of modification, the set values of the safety and

control components must also be changed. This can be carried

out in the factory (at the time of testing) or at the time of installation, only by qualified and authorised personnel.

4 . 5 --- F r e e c o o l i n g

The “freecooling” is a system of pre ---cooling and/or cooling the

water/glycol mixture using ambient air when the latter is at a temperature below the return mixture temperature. If the outside

temperature is sufficiently low to dissipate the entire heat load,

the refrigeration compressors automatically switch off, and the

mixture’s temperature is controlled by the fan speed adjustment.

If the mixture temperature is too high for freecooling, the compressors will operate as long as necessary to ensure the correct

water/glycol mixture temperature.

4.6 --- Microprocessor control

Consult the ”Microface and Hiromatic” Service Manual.

5 --- R e f r i g e r a n t a n d O i l C h a r g e

All work on pipes or components of the refrigerating circuit under pressure must be exclusively carried out by qualified staff,

competent in such works.

5 . 1 --- R e f r i g e r a n t c h a r g e

WHILST REPAIRING THE REFRIGERATING CIRCUIT RECOVER ALL THE REFRIGERANT IN A CONTAINER: DO NOT

ALLOW IT TO ESCAPE. NEVER U SE THE COMPRESSOR

FOR THE SYSTEM VACUUM (THIS INVALIDATES THE

WARRANTY).

S The unit is delivered charged according to the Tab. 5.

Warning for the refrigerant charge:

S Ensure there are no refrigerant leaks.

S Check the refrigerant type in the refrigeration circuit: a unit

originally charged by the manufacturer with R407C cannot

be charged with R22 and vice versa; possibly apply to the

Technical Support Department.

S Charge with the compressor in operation, connecting the

cylinder with the charge connector after the thermostatic expansion valve.

Flush the connection pipe between the cylinder and the

charging point; tighten the seal joint and then start charging

the unit. It is imperative that the cylinder is weighed both before and after the operation.

S For the units with R407C the refrigerant charge must be

made exclusively with liquid refrigerant.

S Charge the unit until the bubbles in the sight glass have dis-

appeared and the working conditions of the entire refrigeration circuit have returned to normal (sub ---cooling and superheating within the limits indicated below).

S Measure the superheating as follows:

1) Detect the temperature on the suction line, close to the

bulb of the thermostatic expansion valve, using a contact

thermometer.

2) Connect a pressure gauge (by max. a 30 --- cm pipe) with

the Schraeder connection and read the corresponding

saturated evaporating temperature.

3) The superheating is the difference between the two

readings.

4) For the units with R407C refer to the pressure gauge

scale indicated with the initials D.P. (Dew Point)

S Verify that the superheating is 5ûC --- 8 ûC.

S Measure the sub---cooling as follows:

1) Detect the temperature on the liquid line using a contact

thermometer.

2) Connect a pressure gauge (by max. a 30 --- cm pipe) with

the Schraeder connection on the liquid line and read the

corresponding saturated condensing temperature.

3) The sub --- cooling is the difference between the two readings.

4) For the units with R407C refer to the pressure gauge

scale indicated with the initials B.P. (Bubble Point)

S Verify that at the condenser outlet, sub--- cooling is 3ûC---

5ûC.

IT IS IMPORTANT TO CARRY OUT CHARGING CORRECTLY.

An excess of refrigerant causes an increase in sub ---coolingand

consequent operating difficulties in the hot season; a shortage

of charge generates an increase in superheating and possible

compressor stoppages. Whenever work is carried out on the

unit, ensure afterwards that the working conditions are correct,

checking sub---cooling and superheating.

5 . 2 --- O i l c h a r g e

Contact the TechnicalSupport Department for the specifications

of the oil to be used for topping up; the oil changes according to

thetypeofusedrefrigerant.

NEVER MIX DIFFERENT OILS TOGETHER. CLEAN THE PIPING COMPLETELY BEFORE CHANGING THE TYPE OF OIL

USED.

5

Page 9

TOP ---UPS OF UP TO 20---30% OF THE TOTAL AMOUNT OF

OIL CONTAINED IN THE COMPRESSOR CRANKCASE ARE

PERMITTED; FOR LARGER PERCENTAGES CONTACT THE

TECHNICAL SUPPORT DEPARTMENT.

5.2.1 -- Procedure for oil topping--up

If there has been any loss of oil then this must be topped up as

follows:

1) T ake a clean, dry, transparent container (with volume calibrations) and fill it with at least twice the amount of oil required.

2) Isolate the compressor by closing the cock on the liquid line.

3) Connect to the fittings on the compressor body (Schraeder

valves) and empty it of refrigerant until atmospheric pressure (1 bar) is reached.

4) Using a pipe, connect the oil containerto the oil service fitting

on the lower part of the compressor.

5) Open the oil service cock, lifting the container, so that the oil

flows by gravity.

6) Charge the required quantity of oil (make sure the tube always remains below the oil level in the container).

7) Stop the oil flow by closing the oil service fitting, open the

shut---off cock on the refrigerating circuit and restore the

drained refrigerant charge.

6 --- Safety Devices Settings

The water chiller has already been tested and set up by the manufacturer. The following setting values are suggested in the field.

COMPONENT SETTING NOTES

diff.set

Operation with R407C/R22

Low pressure switch (LP)

(standard factory setting):

START : 3.6 bar

DIFF. : 0.8 bar

STOP : 2.8 bar

0.2

5

1.5

0.5

bar

bar

Operation with R407C/R22

(standard factory setting):

High pressure switch (HP)

STOP : 26 bar

START : 20 bar

DIFF. : 6 bar (fixed)

The settings for the safety valves installed on the machine are indicated below:

MODELS SETTINGS SAFETY VALVE

CBH/CLH/CQH 017 --- 020 ---023 ---025 ---028

SBH/SLH 017---020---023 ---025 ---028

SQH 017 ---020 ---023 ---025

6.1 --- Setting the rmostatic expansion

valve

THIS OPERATION MUST BE PERFORMED BY AN EXPERIENCED REFRIGERATION TECHNICIAN.

Before beginning this adjustment be sure that the refrigerant

charge is correct, checking the the sub --- cooling (3ûC --- 5ûC, as

specified in par. 5.1).

The valve has already been factory --- set and should be reset

when the superheating is not between 5ûC --- 8 ûC, as follows:

1) Important:

Ensure that the instructions in par.5.1 have been carried out.

2) Allow the compressor to operate for 15 mins.

3) Measure the superheating as follows:

a) Connect a manometer to the Schraeder connection lo-

29 bar high pressure side

a) Remove the protective cover;

b) Turn the adjustment screw to return to the optimum val-

ues, tightening it in a clockwise direction to increase the

superheating, or slackening it to reduce the superheat-

ing.

c) Wait about 10 minutes;

d) Measure the superheating and repeat the operation if

necessary.

N.B:

If the superheating is too low, there is a risk of poor lubrication

and consequent breakage of the compressor as a result of pressure shock.

If the superheating is too high the output of the system is limited

and the compressor overheats.

cated on the evaporator outlet tube, and read the manometric temperature on the scale for the refrigerant used

(for the units with R407C refer to the pressure gauge

scale indicated with the initials D.P. = Dew Point).

b) Using a contact thermometer, measure the temperature

on the tube coming out of the evaporator, next to the

socket used for the manometer.

c) The superheating is the difference between the two

readings (b ---a).

4) The superheating must be 5ûC --- 8 ûC; if not, set the expan-

sion valve as follows:

reset

6

Page 10

7 --- Maintenance

The Maintenance Programme below must be carried out by a

qualified technician, preferably working under a maintenance

contract.

Before any intervention on the unit or accessing the inner components (removing the outer panels), always ensure the machine is switched off. If the front upper panels are removed (coil

compartment) wait for the fan(s) to come to a complete stop before accessing the compartment; if the front lower panels are removed, pay special attention when working near the compressor upper part and the discharge line: they are very hot;

possibly wait for them to cool. Be very careful when operating

closeto the finned coils, as the fins are very sharp. Do not remove

the fan protection grille before electrically isolating the whole

machine. Do not insert foreign matter through the fan protection

grille. After the maintenance interventions, always close the unit

with the suitable panels, fastened by the tightening system.

Maintenance programme -- Monthly check

S Check that the fan motor rotates freely without any abnormal noise, and ensure that the

FANS

CONDENSER AND AIR FILTER

CONTROL S Check that the control equipment, LEDs and display are operating correctly.

ELECTRICAL CIRCUIT

REFRIGERATION CIRCUIT

CHILLED WATER CIRCUIT

bearings are not running hot.

S Also check the current absorption.

S Check the conditions of the filters (if they are supplied); if necessary clean them (including

the electrical panel ventilation filter).

S Check the condenser coils and clean if necessary with compressed air or soft brushes.

S Check the electrical supply on all phases.

S Ensure that all electrical connections are tight.

S Check the condensing and the evaporating pressures (to be done by a refrigeration techni-

cian).

S Check the compressor’s current absorption, the delivery temperature and possible unusual

noises.

S Check the refrigerant charge by means of the sight glass.

S Check that the safety devices operate correctly.

S Check the correct operation of the thermostatic valve (superheating between 5ûC --- 8ûC).

S Check that the oil level indicated by the compressor sight glass is higher than the min. value.

S Ensure that there are no water leaks.

S Bleed any air out of the hydraulic circuit using the bleed valves.

S Verify that the water flow rate is correct.

S Check the inlet --- outlet liquid temperature and pressure.

S Check the correct operation of the three--- way valve (Versions with free--- cooling only).

S Check if the system is charged with the specified glycol percentage and that no ice has

formed in the hydraulic circuit.

S Check the evaporator cleanliness.

7.1 --- Spare parts

The use of original spare parts is recommended.

When placing an order refer to the ”Component List” enclosed

with the machine and quote the unit model no. and serial no.

7.2 --- Dismantling the unit

The machine has been designed and built to ensure continuous

operation.

The working life of some of the main components, such as the

fans and the compressors, depends on the maintenance that

they receive.

If the unit has to be dismantled, the job must be done by skilled

refrigeration technicians.

The refrigerant and the lubricating oil in the circuit must be disposedofinconformitywiththelawsinforceinyourcountry.

8 --- O p t i o n s a n d A c c e s s o r i e s

8 . 1 --- P u m p s e t

The centrifugal pump units are direct driven, with cl ose--coupled motors and a single shaft; the induction motor has 2

poleswithIP55protectionandclassFinsulation.

Pump casings and impellers are in cast iron EN -- -GJL 200, shafts

are in stainless steel, the shaft seal is a unbalanced, mechanical

shaft seal with dimensions according to DIN 24 960 and assembly length according to EN 12 756, brass neck ring permits ideal

conditions for the use of water mixtures containing ethylene glycol. The pump housing, the motor stool and the motor stator

housing are electrocoated.

The pump units have been chosen and sized to operate within

specific limits, namely:

S Water / ethylene glycol mixtures up to 65% / 35% by weight;

S Temperatures of the standard pumped fluid not lower than

4°C.

The motor stool forms connection between the pump housing

and the motor, and is equipped with a manual air vent screw for

venting of the pump housing and the shaft seal chamber. It is

very important to carry out this operation as the circulation of liq-

uid through the duct of the air vent screw ensures lubrication and

cooling of the shaft seal.

Between the outlets of the two chambers and the discharge

flange, twin --- head pumps have a non --- return flap valve in

EPDM rubber. The flap is opened by the flow of the pumped liquid and cuts off the port of the idle pump chamber.

In the electrical panel there are automatic circuit breakers for

each pump; the microprocessor control manages the operating

rotation between the two pumps and start - --up of the stand--- by

pump if the primary pump fails.

For the technical features of the pumps and the hydraulic schematic see Tab. 8, Fig. 10 and Fig. 11.

8.2 --- Water chiller with partial heat

recovery (20%)

This option enables the recovery of up to 20% of the heat normally rejected by the condensers (see Tab. 2). The system does not

require any adjustment and is made up of plate heat exchangers

installed on each circuit before the condenser. The exchangers

are protected by a suitable anti---frost heater that operates when

7

Page 11

the system is stopped. It is recommended that a safety valve be

installedin the hydraulic circuit to avoid hazards due to overpressures, if there is no water flow through the recuperator.

The water temperature at the recuperator inlet (in stable operating conditions) must be in the range of 25ûC---45ûC, with an out-

let differential of between 3.5ûC --- 8 ûC.

8.3 --- Waterchillerwithtotalheatrecovery

(100%)

All heat discharged by the unit to the condenser is recovered

(see Tab. 3).

The system includes an additional refrigerating circuit made up

of 2 two - --way solenoid valves, supplying --- in case of hot water

demand --- a plate exchanger, usually by --- passed and sized so

as to discharge all condensing heat (also installed before the

finned air condenser in series with it); a check valve, a liquid receiver at the exit of the finned air condenser working as storage

for the needed additional refrigerant charge (see refrigerating

scheme). The recuperator is insulated with closed cell polyurethane and is equipped with heaters activated when the recuperator is deactivated to prevent frost in winter with the system

stopped or not perfectly drained.

The operation in total recovery mode is enabled by an external

contact. The Microface control will simultaneously suit the fan

speed changing the fan speed setpoint differently from the standard operation without recovery (practically slowing the fans

down till they switch off); anyway, the operation in recovery

mode is enabled also without load at the users. Indeed, if the users do not demand heat, the water flowing to the condenser

reaches a temperature that does not enable the total condensation of the compressed gas, and the remaining portion of the

phase change can thus take place in finned coil without interrupting the recovery process through the intervention of the machine safety devices.

If the plate exchanger is supplied with too cold water, or if the system is not preset by the installation technician with a three or

two---way proportional adjustment valve for the exchanger bypass (indispensable for cold starts, see following “Recommended hydraulic circuit” ), the condensing pressure tends to

decrease too much; a prolonged condition of low condensing

temperature below the safety threshold leads the Microface microprocessor control to disable the heat recovery, protecting the

system from any possible malfunctioning.

Fig. e -- Recommended hydraulic circuit

8.5--- Waterchillerwithinertiatank

The machine can be supplied complete with a buffer tank; it performs the inertial stabilizer function, for a better compressor operation, summed up in the following two points:

S it reduces the frequency of the compressor start up and con-

sequent high current peaks, which is higher when the system thermal inertia is lower, improving their performance.

S it naturally eliminates the operation troubles caused by sud-

den load variations (shown by variations of the chilled water

temperature).

The buffer tank is supplied complete with manometer and temperature sensor well, air purge valve, discharge valve and sinking connection for electric heaters; max operating pressure: 6

bar.Builtincarbonsteelandcoatedwithanti---condensateinsulation with PVC film proper for outdoor installation. It is

installed inside a cabinet which can be supplied either already

connected to the unit (mechanically and hydraulically jointed to

it) or loose (completely separate from the unit).

Technical data:

S Internal volume: 1000 litres

S Net weight: 400 kg

S Working weight: 1400 kg

Heat recovery

users

Heat recovery

exchanger

8.4 --- Hydraulic circuit accessories

Made up of an expansion vessel (pre --- charged at 1.5 bar, max.

operating pressure 10 bar) and a safety valve, set at 5 bar. Their

position in the hydraulic circuit is illustrated in Fig. 10, Fig. 11.

S Expansion vessel volume: 12 litres for all units.

It is recommended that the total required expansion vessel ca-

pacity is always checked, depending on the unit’s internal hydraulicvolume(withthevolumeofthebuffertank,ifinstalled),

the user circuit volume, the glycol percentage in the mixture, and

the expected maximum temperature variation of the mixture.

The water flow switch is a compulsory device protecting the unit.

It is installed, as standard, on units with the optional on --- board

pump set, and is available as a option for units without pumps

on board: in the latter case the flow switch, if not installed on the

machine, must be installed on the hydraulic circuit by the installer and wired to the electric panel terminal board, as indicated on

the wiring diagram.

8

Page 12

Tab. 1 --- Internal hydraulic volume

Model

s

Model

s

Model

s

7

4

CQH/SQH023---02

5

CLH/SLH02

8

CQH/SQH02

8

6

4

Model Unit volume

017 --- 020 37 017 --- 020 134

CBH

CLH

CQH

(*) Add the tank’s volume for the units with optional buffer tank

023 --- 025 45

028 51

030 --- 032 60 030 --- 032 203

017 --- 020 37 017 --- 020 134

023 --- 025 45

028 51

030 --- 032 60 030 --- 032 166

017 --- 020 37 017 --- 020 156

023 --- 025 45

028 51

030 60 030 166

(*)

[l] Model Unit volume

SBH

SLH

SQH

023 --- 025 164

028 170

023 --- 025 164

028 194

023 --- 025 188

028 157

Tab. 2 --- Partial heat recovery (20%)

Model 017 020 023 025 028 030 032

Heating capacity

Water flow

Water pressure drop

Water connections

Working conditions: outdoor temperature 35° C, water inlet/outlet 12/7ûC (Chiller versions), glycol mixture 30% inlet/outlet 15/10ûC (SuperChiller versions).

Heat recovery conditions: water inlet/outlet 40/45°C.

kW

l/s

kPa

B S P --- T

40 48 56 62 68 79 86

1.91 2.29 2.68 2.96 3.25 3.77 4.11

15 20 16 19 16 17 20

2”

(*)

[l]

Tab. 3 --- Total heat recovery (100%)

Model 017 020 023 025 028 030 032

Heating capacity

Water flow

Water pressure drop

Water connections

Working conditions: water inlet/outlet 12/7ûC (Chiller versions). Heat recovery conditions: water inlet/outlet 40/45ûC.

kW

l/s

kPa

D N --- i n c h

212 238 290 320 357 412 453

10.13 11.37 13.86 15.29 17.06 19.68 21.64

52 65 71 82 83 85 99

DN 80 --- 3”

Tab. 4 --- Noise levels

The following table indicates the overall sound pressure level at full load conditions, measured 1m from the unit, according to ISO 3774,

with an outdoor temperature of 35ûC and referred to free field conditions.

Models

CBH/SBH 017---020

CBH/SBH 023---025

CBH/SBH 028

CBH/SBH 030---032

Tota l

sound level

[dB(A)]

73

74

75

Models

CLH/SLH 017---020

CLH/SLH 023---025

CLH/SLH 030---032

Tota l

sound level

[dB(A)]

67

68

69

Models

CQH/SQH 017 ---020

CQH/SQH 023 ---025

CQH/SQH 028

CQH/SQH 030

Tota l

sound level

[dB(A)]

63

64

9

Page 13

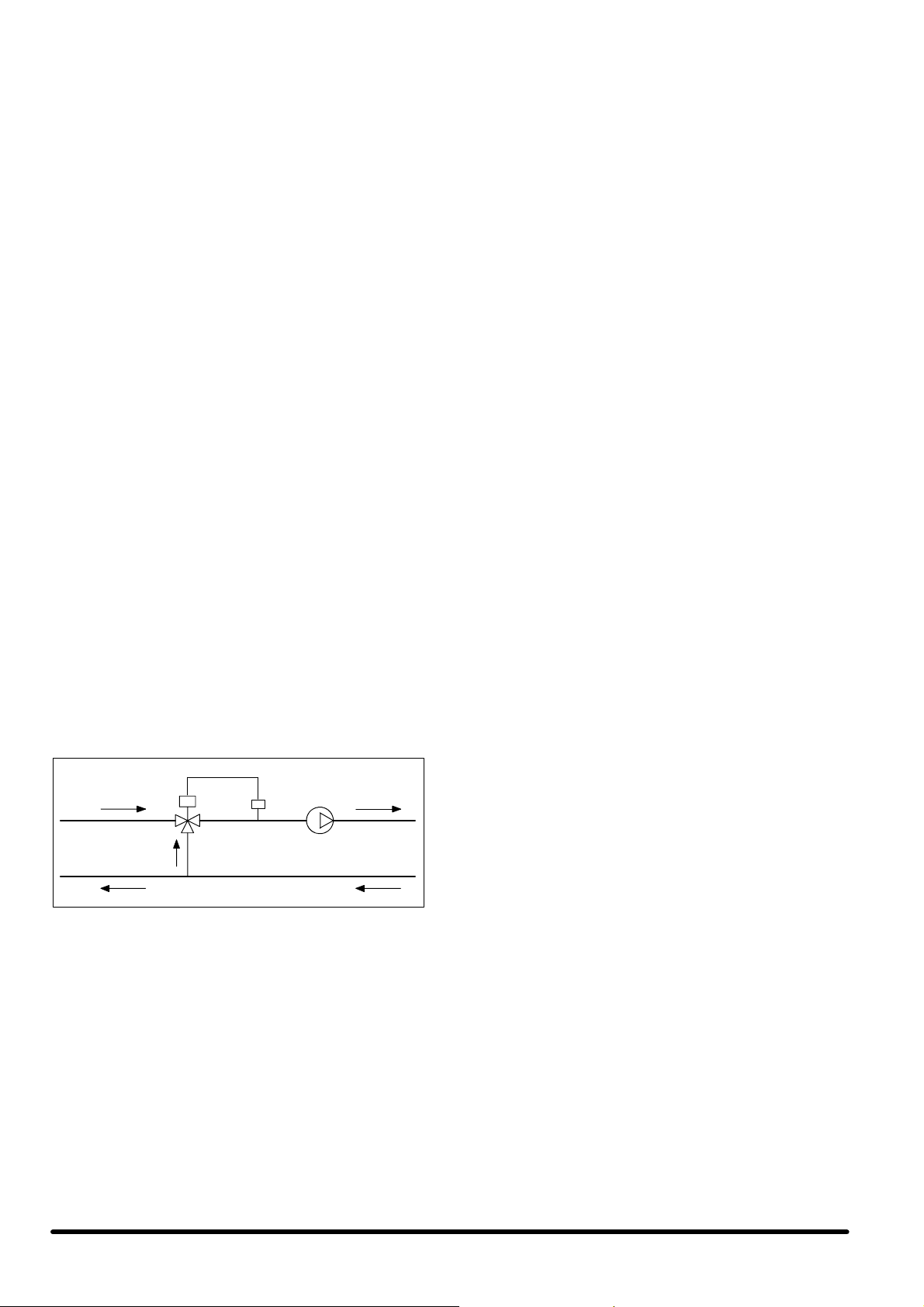

Tab. 5 --- R 407C refrigerant and oil charge

Models: CBH 017 020 023 025 028 030 032

Refrigerant charge (each circuit) [kg] 19.5 20.1 28.6 28.7 34.5 42.0 42.1

Oil charge (each circuit) [lt] 12.4 14.2 16.0 16.0 16.0 16.0 16.0

Models: CLH 017 020 023 025 028 030 032

Refrigerant charge (each circuit) [kg] 22.5 23.1 32.8 32.9 39.4 42.0 42.1

Oil charge (each circuit) [lt] 12.4 14.2 16.0 16.0 16.0 16.0 16.0

Models: CQH 017 020 023 025 028 030

Refrigerant charge (each circuit) [kg] 23.0 23.6 32.8 32.8 39.4 42.0

Oil charge (each circuit) [lt] 12.4 14.2 16.0 16.0 16.0 16.0

Models: SBH 017 020 023 025 028 030 032

Refrigerant charge (each circuit) [kg] 19.5 20.1 28.6 28.7 30.3 37.0 37.1

Oil charge (each circuit) [lt] 12.4 14.2 16.0 16.0 16.0 16.0 16.0

Models: SLH 017 020 023 025 028 030 032

Refrigerant charge (each circuit) [kg] 19.5 20.1 28.6 28.7 34.4 37.0 37.1

Oil charge (each circuit) [lt] 12.4 14.2 16.0 16.0 16.0 16.0 16.0

Models: SQH 017 020 023 025 028 030

Refrigerant charge (each circuit) [kg] 23.0 23.6 32.8 32.8 34.4 37.0

Oil charge (each circuit) [lt] 12.4 14.2 16.0 16.0 16.0 16.0

10

Page 14

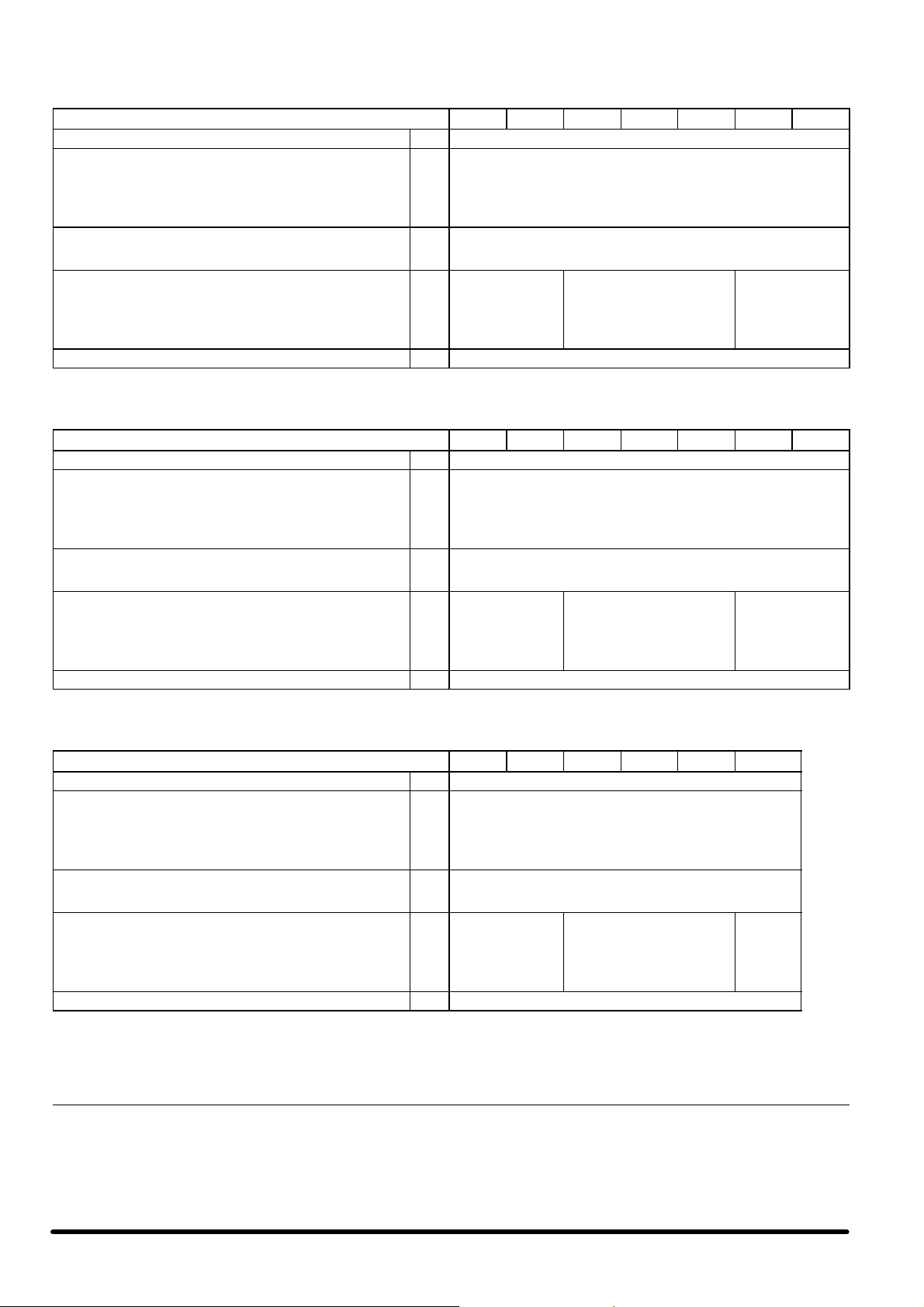

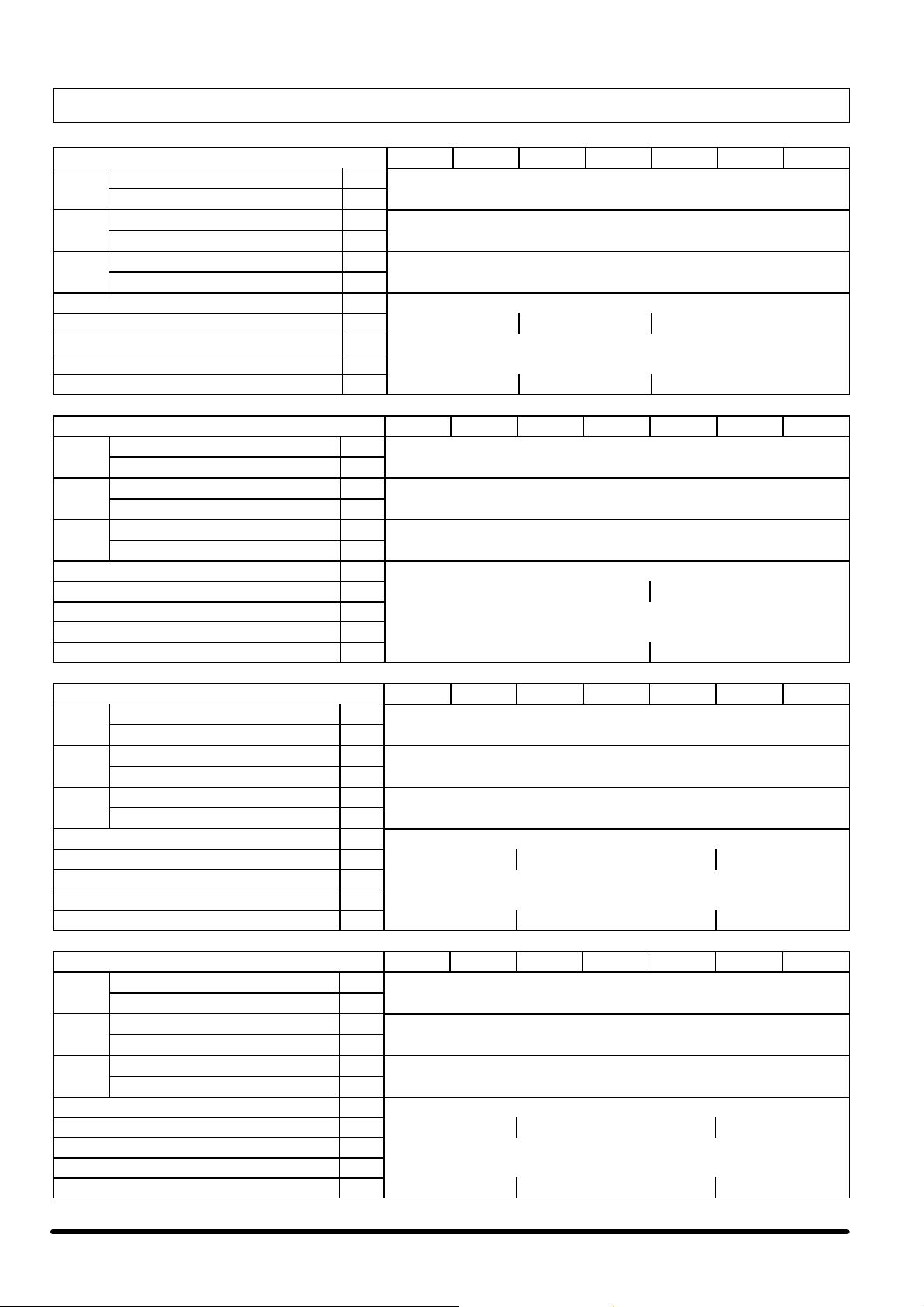

Tab. 6 --- Electrical characteristics

CBH -- R 407C

Size 017 020 023 025 028 030 032

Power supply --- 400 V / 3 Ph / 50 Hz

(1)

OA

FLA

LRA

Compressors power input

Compressors nominal current

Compressor max. current

Fan power input

Fan nominal current

Fan max. current

Std. head pressure pump model (Opt.)

Std. head pressure pump motor max. power

Std. head pressure pump max. current

High head pressure pump model (Opt.)

High head pressure pump motor max. power

High head pressure pump max. current

Electrical cable section (min.) mm

(1) Outdoor air temperature 35ûC ; water inlet/outlet temperature 12/7ûC

(1)

(1)

CLH -- R 407C

Size 017 020 023 025 028 030 032

Power supply --- 400 V / 3 Ph / 50 Hz

(1)

OA

FLA

LRA

Compressors power input

Compressors nominal current

Compressor max. current

Fan power input

Fan nominal current

Fan max. current

Std. head pressure pump model (Opt.)

Std. head pressure pump motor max. power

Std. head pressure pump max. current

High head pressure pump model (Opt.)

High head pressure pump motor max. power

High head pressure pump max. current

Electrical cable section (min.) mm

(1) Outdoor air temperature 35ûC ; water inlet/outlet temperature 12/7ûC

(1)

(1)

kW

kW

kW

kW

kW

kW

kW

kW

A

107

A

151

A

291

54.5

A

96

A

35

A

A

---

A

---

A

2

70 95 120 150 185 185 185

A

103

147

A

287

A

54.4

96

A

35

A

A

A

---

A

---

A

2

70 95 120 150 185 185 185

65--- 190/2

2.2

4.45

65--- 260/2

4.0

8.00

65--- 190/2

2.2

4.45

65--- 260/2

4.0

8.00

119

181

346

63.6

108

50

115

177

342

63.3

108

50

138

214

379

74.2

124

50

65--- 230/2

65--- 260/2

133

209

374

74.0

124

50

65--- 230/2

65--- 260/2

3.0

5.95

4.0

8.00

3.0

5.95

4.0

8.00

158

252

453

85.7

144

69

1.8

3.6

4.0

151

247

448

85.3

142

69

0.95

2.2

2.4

170

290

491

92.5

156

69

165

287

488

90.2

154

69

188

300

548

101.0

170

72

65--- 260/2

4.0

8.00

65--- 340/2

5.5

11.20

189

293

541

107.0

178

72

65--- 260/2

4.0

8.00

65--- 340/2

5.5

11.20

210

306

554

116.0

192

72

209

299

547

119.9

198

72

CQH -- R 407C

Size 017 020 023 025 028 030

Power supply --- 400 V / 3 Ph / 50 Hz

(1)

OA

FLA

LRA

Compressors power input

Compressors nominal current

Compressor max. current

Fan power input

Fan nominal current

Fan max. current

Std. head pressure pump model (Opt.)

Std. head pressure pump motor max. power

Std. head pressure pump max. current

High head pressure pump model (Opt.)

High head pressure pump motor max. power

High head pressure pump max. current

Electrical cable section (min.) mm

(1) Outdoor air temperature 35ûC ; water inlet/outlet temperature 12/7ûC

(1)

(1)

kW

kW

kW

kW

A

101

145

A

285

A

54.1

96

A

35

A

A

A

---

A

---

A

2

70 95 120 150 185 185

65--- 190/2

2.2

4.45

65--- 260/2

4.0

8.00

111

175

340

62.9

106

50

133

207

372

75.5

126

50

65--- 230/2

65--- 260/2

0.70

1.3

1.5

3.0

5.95

4.0

8.00

153

245

446

86.8

146

69

169

283

484

96.5

162

69

65--- 260/2

65--- 340/2

4.0

8.00

5.5

11.20

193

289

537

113.1

186

72

11

Page 15

SBH -- R 407C

Size 017 020 023 025 028 030 032

Power supply --- 400 V / 3 Ph / 50 Hz

(1)

OA

FLA

LRA

Compressors power input

Compressors nominal current

Compressor max. current

Fan power input

Fan nominal current

Fan max. current

Std. head pressure pump model (Opt.)

Std. head pressure pump motor max. power

Std. head pressure pump max. current

High head pressure pump model (Opt.)

High head pressure pump motor max. power

High head pressure pump max. current

Electrical cable section (min.) mm

(1) Outdoor air temperature 35ûC; 30% glycol water mixture; water inlet/outlet temperature 15/10ûC

(1)

(1)

kW

kW

kW

kW

A

111

A

151

A

291

57.1

A

100

A

35

A

A

---

A

---

A

2

70 95 120 150 185 185 185

65--- 260/2

4.0

8.00

65--- 340/2

5.5

11.20

123

181

346

66.3

112

50

145

215

380

78.5

130

50

165

253

454

90.2

150

69

1.9

3.8

4.0

65--- 340/2

5.5

11.20

65--- 410/2

7.5

15.20

SLH -- R 407C

Size 017 020 023 025 028 030 032

Power supply --- 400 V / 3 Ph / 50 Hz

(1)

OA

FLA

LRA

Compressors power input

Compressors nominal current

Compressor max. current

Fan power input

Fan nominal current

Fan max. current

Std. head pressure pump model (Opt.)

Std. head pressure pump motor max. power

Std. head pressure pump max. current

High head pressure pump model (Opt.)

High head pressure pump motor max. power

High head pressure pump max. current

Electrical cable section (min.) mm

(1) Outdoor air temperature 35ûC; 30% glycol water mixture; water inlet/outlet temperature 15/10ûC

(1)

(1)

kW

kW

kW

kW

A

111

A

147

A

287

60.3

A

104

A

35

A

A

---

A

---

A

2

70 95 120 150 185 185 185

65--- 260/2

4.0

8.00

65--- 340/2

5.5

11.20

125

177

342

70.4

118

50

145

209

374

82.7

136

50

165

247

448

95.6

156

69

1.0

2.3

2.4

65--- 340/2

5.5

11.20

65--- 410/2

7.5

15.20

187

291

492

103.8

172

69

178

288

489

100.4

166

69

203

301

549

111.5

184

72

198

294

542

112.7

186

72

65--- 410/2

7.5

15.20

65--- 460/2

11.0

21.40

65--- 410/2

7.5

15.20

65--- 460/2

11.0

21.40

229

307

555

128.6

210

72

222

300

548

129.4

210

72

SQH -- R 407C

Size 017 020 023 025 028 030

Power supply --- 400 V / 3 Ph / 50 Hz

(1)

OA

FLA

LRA

Compressors power input

Compressors nominal current

Compressor max. current

Fan power input

Fan nominal current

Fan max. current

Std. head pressure pump model (Opt.)

Std. head pressure pump motor max. power

Std. head pressure pump max. current

High head pressure pump model (Opt.)

High head pressure pump motor max. power

High head pressure pump max. current

Electrical cable section (min.) mm

(1) Outdoor air temperature 35ûC; 30% glycol water mixture; water inlet/outlet temperature 15/10ûC

•

Nominal power supply = 400 V; 3 Ph; 50 Hz

•

Nominal power supply tolerance = 400 V ±10 %

•

Max. voltage unbalance = 3 %

•

The cables have to be sized in compliance with local standards and according to the type and characteristics of installation. Suggested cables section are re ferred to PVC insulation with a max. working temperature of 70ûC and an ambient temperature of 30ûC.

(1)

(1)

kW

kW

kW

kW

A

106

146

A

286

A

57.9

100

A

35

A

A

A

---

A

---

A

2

70 95 120 150 185 185

65--- 260/2

4.0

8.00

65--- 340/2

5.5

11.20

118

176

341

67.3

112

50

141

207

372

81.8

134

50

94.2

0.75

1.4

1.5

65--- 340/2

11.20

65--- 410/2

15.20

161

245

446

154

69

5.5

7.5

177

283

484

102.5

170

69

205

289

537

121.9

198

72

65--- 410/2

7.5

15.20

65--- 460/2

11.0

21.40

12

Page 16

Tab. 7 --- Operating limits

CBH -- R 407C

Size 017 020 023 025 028 030 032

Working Ra nge

Max. outdoor air temperature

High pressure switch

High pressure safety valve

Low pressure switch

(1)

With nominal air flow; water flow outlet at 7ûC; full load

CLH -- R 407C

Max. outdoor air temperature

High pressure switch

High pressure safety valve

Low pressure switch

(1)

With nominal air flow; water flow outlet at 7ûC; full load

CQH -- R 407C

Max. outdoor air temperature

High pressure switch

High pressure safety valve

Low pressure switch

(1)

With nominal air flow; water flow outlet at 7ûC; full load

SBH -- R 407C

Max. outdoor air temperature

High pressure switch

High pressure safety valve

Low pressure switch

(2)

With nominal air flow; mixture flow outlet at 10ûC; full load

SLH -- R 407C

Max. outdoor air temperature

High pressure switch

High pressure safety valve

Low pressure switch

(2)

With nominal air flow; mixture flow outlet at 10ûC; full load

SQH -- R 407C

Max. outdoor air temperature

High pressure switch

High pressure safety valve

Low pressure switch

(2)

With nominal air flow; mixture flow outlet at 10ûC; full load

(1)

Safety Device Settings

(1)

Size 017 020 023 025 028 030 032

Working Ra nge

(1)

Safety Device Settings

(1)

Size 017 020 023 025 028 030

Working Ra nge

(1)

Safety Device Settings

(1)

Size 017 020 023 025 028 030 032

Working Ra nge

(2)

Safety Device Settings

(2)

Size 017 020 023 025 028 030 032

Working Ra nge

(2)

Safety Device Settings

(2)

Size 017 020 023 025 028 030

Working Ra nge

(2)

Safety Device Settings

(2)

ûC

Barg

Barg

Barg

ûC

Barg

Barg

Barg

ûC

Barg

Barg

Barg

ûC

Barg

Barg

Barg

ûC

Barg

Barg

Barg

ûC

Barg

Barg

Barg

45.0 41.5 45.0 43.0 44.0 45.0 43.5

26.0

29.0

2.8

45.0 41.5 45.0 43.0 45.0 42.0 41.5

26.0

29.0

2.8

45.0 41.5 44.0 42.0 41.5 39.5

26.0

29.0

2.8

42.5 39.5 42.5 40.5 38.5 41.0 39.0

26.0

29.0

2.8

40.0 37.0 39.5 37.5 40.0 40.0 38.5

26.0

29.0

2.8

42.0 39.0 40.5 38.5 39.0 36.5

26.0

29.0

2.8

13

Page 17

Tab. 8 --- Pump set characteristics (opt.)

2 pole pump set, standard head pressure (data refers to each pump)

Models 017 020 023 025 028 030 032

CBH

CLH

CQH

Water flow

Available head pressure

Water flow

Available head pressure

Water flow

Available head pressure

Pump quantity

Pump rotor model

Nominal motor power

Noise level

(*)

Pump weight

2 pole pump set, high head pressure (data refers to each pump)

Models 017 020 023 025 028 030 032

CBH

CLH

CQH

Water flow

Available head pressure

Water flow

Available head pressure

Water flow

Available head pressure

Pump quantity

Pump rotor model

Nominal motor power

Noise level

(*)

Pump weight

2 pole pump set, standard head pressure (data refers to each pump)

Models 017 020 023 025 028 030 032

SBH

SLH

SQH

30% glycol/water mixture flow

Available head pressure

30% glycol/water mixture flow

Available head pressure

30% glycol/water mixture flow

Available head pressure

Pump quantity

Pump rotor model

Nominal motor power

Noise level

(*)

Pump weight

2 pole pump set, high head pressure (data refers to each pump)

Models 017 020 023 025 028 030 032

SBH

SLH

SQH

Pump quantity

Pump rotor model

Nominal motor power

Noise level

Pump weight

(*) According to ISO 3744

30% glycol/water mixture flow

Available head pressure

30% glycol/water mixture flow

Available head pressure

30% glycol/water mixture flow

Available head pressure

(*)

m3/h

kPa

m3/h

kPa

m3/h

kPa

Nr.

---

kW

dB(A)

kg

m3/h

kPa

m3/h

kPa

m3/h

kPa

Nr.

---

kW

dB(A)

kg

m3/h

kPa

m3/h

kPa

m3/h

kPa

Nr.

---

kW

dB(A)

kg

m3/h

kPa

m3/h

kPa

m3/h

kPa

Nr.

---

kW

dB(A)

kg

26.88 29.22 36.76 39.56 44.86 55.16 57.02

119 107 130 116 141 91 55

26.92 29.32 36.81 39.69 45.48 51.35 55.83

119 107 130 114 139 105 67

27.01 29.39 36.38 39.19 43.67 49.55 ---

119 106 133 117 149 119 ---

1/2 1/2 1/2 1/2 1/2 1/2 1/2

65---190/2 65---230/2 65--- 260/2

2.2 2.2 3.0 3.0 4.0 4.0 4.0

60 60 59 59 63 63 63

57.9/116.4 69.3/139.2 74.3/149.2

26.88 29.22 36.76 39.56 44.86 53.16 57.02

197 187 176 165 227 188 159

26.92 29.32 36.81 39.69 45.48 51.35 55.83

197 186 176 162 224 199 169

27.01 29.39 36.38 39.19 43.67 49.55 ---

197 186 179 166 232 210 ---

1/2 1/2 1/2 1/2 1/2 1/2 1/2

4.0 4.0 4.0 4.0 5.5 5.5 5.5

63 63 63 63 63 63 63

31.91 34.52 43.66 46.77 51.05 62.43 66.46

107 83 131 101 86 75 25

30.71 33.14 42.18 45.06 52.22 62.00 66.16

117 95 144 118 61 102 54

31.58 34.21 42.52 45.60 51.46 57.51 ---

127 107 132 103 101 147 ---

1/2 1/2 1/2 1/2 1/2 1/2 1/2

65---260/2 65--- 340/2 65 --- 410/2

4.0 4.0 5.5 5.5 5.5 7.5 7.5

63 63 63 63 63 68 68

74.3/149.2 89.2/178.9 91.1/182.7

31.91 34.52 43.66 46.77 51.05 62.43 66.46

187 165 223 195 174 139 95

30.71 33.14 42.18 45.06 52.22 62.00 66.16

197 176 234 211 150 166 123

31.58 34.21 42.52 45.60 51.46 57.51 ---

207 189 223 196 188 206 ---

1/2 1/2 1/2 1/2 1/2 1/2 1/2

65---340/2 65---410/2 65 --- 460/2

5.5 5.5 7.5 7.5 7.5 11.0 11.0

63 63 68 68 68 65 65

89.2/178.9 91.1/182.7 149.4/306.4

65---260/2 65---340/2

74.3/149.2 89.2/178.9

14

Page 18

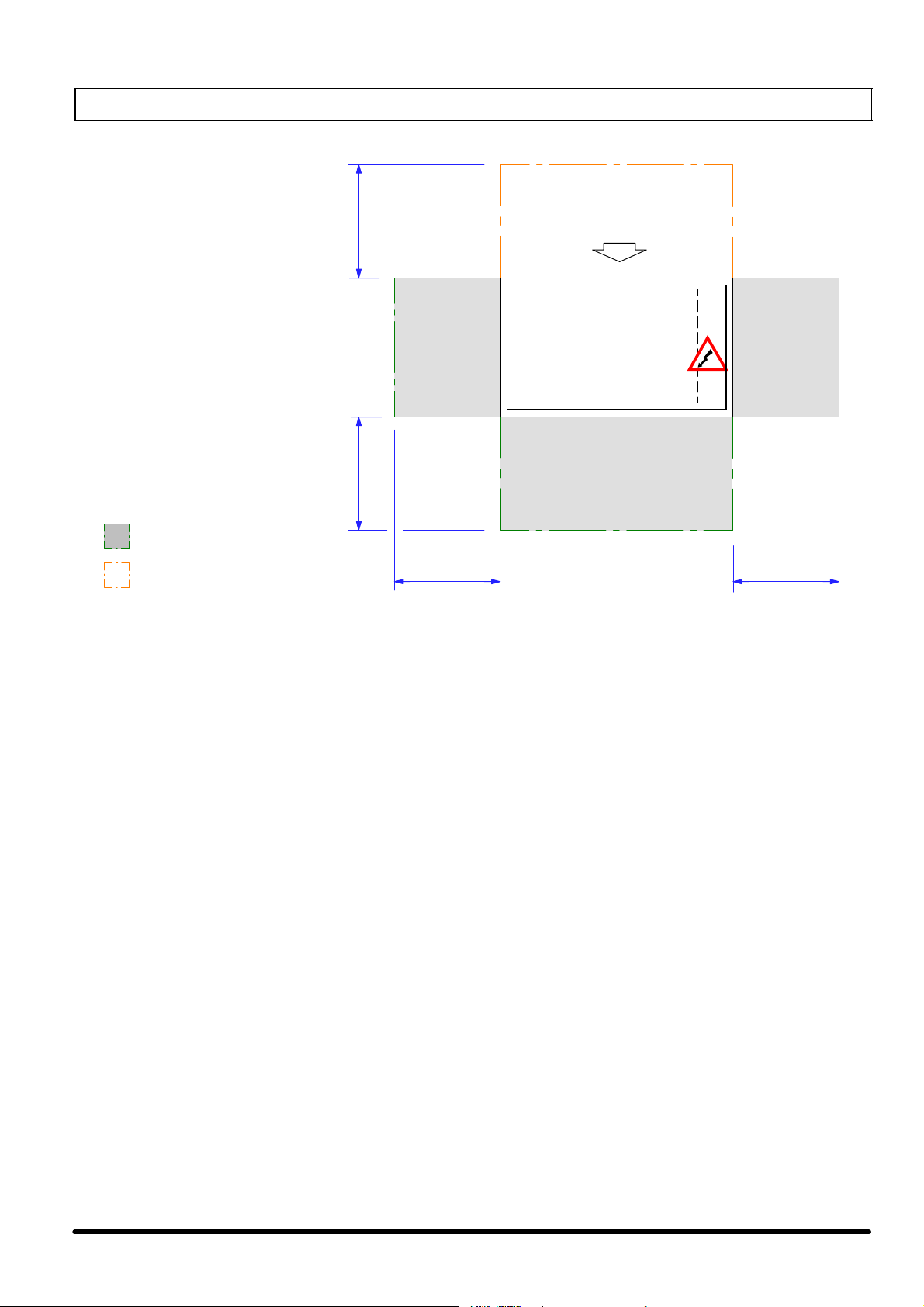

Fig. 1 --- Service areas (top view)

Ordinary

maintenance area

Extraordinary

maintenance area

15001500

AIR

1000 1000

Notes:

Minimum distance between 2 units from condensing coil side = 3 m

Do not obstruct the air exiting the fans for a minimum distance of 2.5 m

15

Page 19

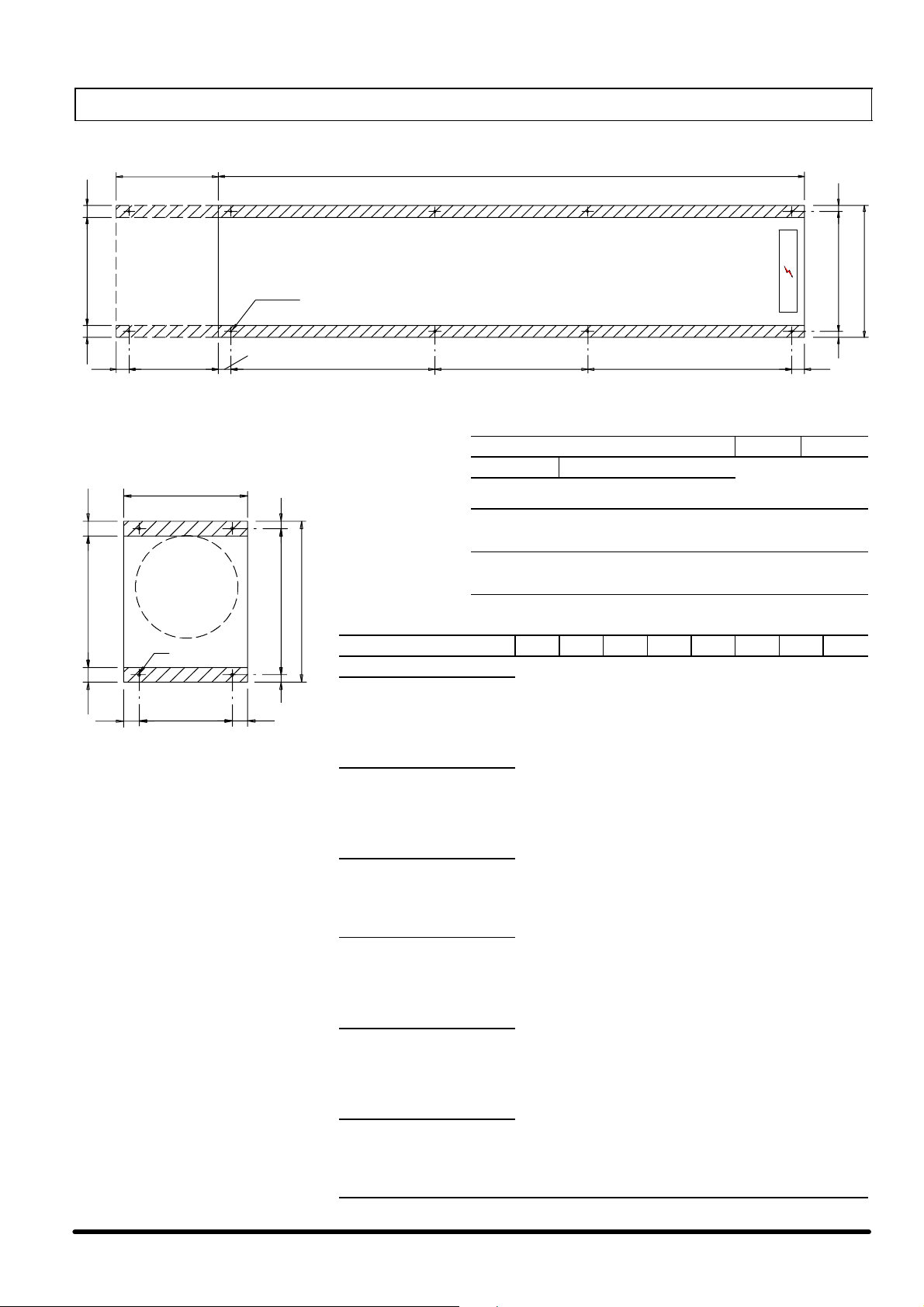

Fig. 2 --- Lifting instructions with tubes

PROTECTION PLANK

RIGID STRUTS

(POSSIBILY STEEL)

BELT OR CHORD

BLOCKING PEG

(NOT SUPPLIED)

SPLIT PIN

(NOT SUPPLIED)

LIFTING TUBE

(NOT SUPPLIED)

(BASE HOLES Ø56)

N.B: Place the lifting tubes in the holes in the base indicated by the words “LIFT HERE”. Lock the ends of the tubes in position with

the locking pins and split pins as shown above. The capacity of the lifting gear must be adequate to lift the load in question.

Check the weight of the unit, the capacity of the lifting gear and ropes and the condition and suitability of the aforementioned

equipment. Lift the unit with a speed suitable for the load to be moved, so as not to damage the structure.

Lifting

Models

CBH / CLH 017 ---020 ---023 ---025 ---028 ---030 ---032

CQH 017 --- 020 --- 023 --- 025 --- 028 --- 030

SBH / SLH 017 ---020 ---023 ---025 ---028 --- 030 ---032

SQH 017 --- 020 --- 023 --- 025 --- 028 --- 030

“A”

(m)

1.8 ' 5.0 ' 9.0

“B”

(m)

“C”

(m)

16

Page 20

Fig. 3 --- Support positions and loads

1000

TANK MOUNTED

WT1

WT2

(OPTION)

W1 W2 W3

W5

1201060120

125

125 875

Tan k

(supply not mounted on unit)

1000

1201060

WA WB

FOOT PRINT

120

d=20

125

WDWC

750 125

WA = WB = 406 kg

WC = WD = 299 kg

d=20

1180 60

60

”A”

FOOT PRINT

W6 W7

”B” 1500 ”B” 125

Dimensions

Dimensions (mm)

Model Size

C B H --- S B H

C L H --- S L H

C B H --- S B H

C L H --- S L H

C Q H --- S Q H

C B H --- S B H

C L H --- S L H

C Q H --- S Q H

017 --- 020

017 --- 020

023 --- 025 --- 028

023 --- 025

017 --- 020

030 --- 032

028 --- 030 --- 032

023 --- 025 --- 028 --- 030

3750 1000

4750 1500

5750 2000

1300

Weight distribution without tank

Weight Distribution (kg)

Model Size

CBH 017

CLH

CQH

SBH

SLH

SQH

020

023

025

028

030

032

017

020

023

025

028

030

032

017

020

023

025

028

030

017

020

023

025

028

030

032

017

020

023

025

028

030

032

017

020

023

025

028

030

W1 W2 W3 W4 W5 W6 W7 W8

234

170

177

206

206

225

257

257

183

189

220

220

248

257

256

193

196

225

225

248

256

232

238

279

279

284

326

325

233

239

279

279

317

304

304

267

269

312

312

295

304

170

177

206

206

225

257

257

183

189

220

220

248

257

256

193

196

225

225

248

256

232

238

279

279

284

326

325

233

239

279

279

317

304

304

267

269

312

312

295

304

206

223

292

292

306

364

375

222

239

313

313

363

369

379

258

279

346

346

363

376

263

280

370

370

369

440

450

266

284

374

374

436

420

431

333

354

438

438

420

427

206

223

292

292

306

364

375

222

239

313

313

363

369

379

258

279

346

346

363

376

263

280

370

370

369

440

450

266

284

374

374

436

420

431

333

354

438

438

420

427

234

247

276

276

290

324

326

240

253

282

282

305

325

328

251

259

290

290

305

327

265

278

310

310

319

357

360

268

281

313

313

341

351

354

286

295

332

332

336

353

247

276

276

290

324

326

240

253

282

282

305

325

328

251

259

290

290

305

327

265

278

310

310

319

357

360

268

281

313

313

341

351

354

286

295

332

332

336

353

W4

W8

“A” “B”

284

311

391

391

394

459

476

291

319

400

400

448

467

485

336

368

445

445

448

480

300

327

412

412

415

481

498

306

333

419

419

469

485

502

357

388

466

466

477

497

60118060

284

311

391

391

394

459

476

291

319

400

400

448

467

485

336

368

445

445

448

480

300

327

412

412

415

481

498

306

333

419

419

469

485

502

357

388

466

466

477

497

1300

17

Page 21

Weight Distribution with tank

3

315

315

315

6

3

3

3

3

3

3

023

432

432

315

315

315

462

462

337

337

337

030

455

455

382

382

382

479

479

402

402

402

0

0

3

3

3

3

3

3

6

0

6

0

3

3

3

023

440

440

332

332

332

460

460

347

347

347

030

453

453

386

386

386

479

479

408

408

408

023

436

436

360

360

360

462

462

382

382

382

025

436

436

360

360

360

462

462

382

382

382

5

390

390

390

8

8

3

8

3

8

3

8

6

3

6

3

3

3

3

023

478

478

384

384

384

463

463

372

372

372

030

497

497

450

450

450

482

482

436

436

436

6

6

388

388

388

6

378

378

378

023

476

476

388

388

388

464

464

378

378

378

030

481

481

433

433

433

483

483

435

435

435

023

491

491

443

443

443

466

466

421

421

421

025

491

491

443

443

443

466

466

421

421

421

Weight Distribution (kg)

Model Size

CBH 017

CLH 017

CQH 017

SBH 017

SLH 017

SQH 017

020

023

025

028

030

032

020

023

025

028

030

032

020

025

028

030

020

023

025

028

030

032

020

023

025

028

030

032

020

025

028

030

WT1 W1 W2 W3 W4 WT2 W5 W6 W7 W8

431

428

4

432

444

450

439

436

44

440

451

448

436

430

436

451

449544933923392339264796479

472

469

47

478

481

492

471

468

47

476

494

477

484

478

491

477

478 478943994399439 484 484644464446444

431

233

233

233

451

451

244

244

251

251

315

328

391

248

265

332

377

395

280

300

360

377

286

304

384

385

459

289

307

388

444

442

348

368

443

429

456

456

462

462

467

479

450

455

4

460

467

479

452

453

462

467

453

459

4

463

469

482

455