Page 1

INSTALLATION,

O

PERATION AND

MAINTENANCE

MANUAL

TRANSIENT VOLTAGE SURGE SUPPRESSION

AccuVar ACV

Liebert

Page 2

Surge

®

Suppression

Systems

LIEBERT ACCUVAR® ACV SERIES

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

TABLE OF CONTENTS

UNPACKING AND INSTALLATION

Unpacking and Preliminary Inspection......................................................................................3

Storage...........................................................................................................................................3

Location Considerations..............................................................................................................3

ELECTRICAL CONNECTIONS

Voltage Ratings & Power Source Configurations....................................................................4

Overcurrent Protection .................................................................................................................4

Connection.....................................................................................................................................5

System Grounding & Bonding....................................................................................................5

OPERATION.......................................................................................................................................7

Summary Alarm Contact Option................................................................................................7

TROUBLESHOOTING / MAINTENANCE / SERVICING

Inspection and Cleaning..............................................................................................................7

Troubleshooting............................................................................................................................7

Corrective Maintenance...............................................................................................................7

Servicing ........................................................................................................................................7

LIMITED WARRANTY.......................................................................................................................9

DECLARATION OF CONFORMITY..............................................................................................11

FIGURES

Figure 1. AccuVar ACV Series Dimensions............................................................................2

Figure 2. Installation Diagram...................................................................................................8

TABLES

Table 1. Terminal Wire Size Range & Suggested Wiring Overcurrent Protection............4

Table 2. Voltage Ratings & Power Source Configurations...................................................6

Installation, Operation ACV Series

and Maintenance Manual - 1 - Rev 2, 3/00

Page 3

Surge

®

Suppression

Systems

INSTALLATION INSTRUCTIONS FOR THE LIEBERT

ACCUVAR® ACV SERIES SURGE PROTECTIVE DEVICE

WITH OPTIONAL FILTERING

The Liebert AccuVar® ACV Series Surge

Protective Device (SPD) is a high quality, high

energy surge current diversion system designed to

protect sensitive equipment from damaging

transient surges and electrical line noise. Proper

installation is required for maximum system

performance.

The installer should perform the following steps to

assure a quality installation. The entire installation

manual should be read before starting installation.

These instructions do not replace national or local

electrical codes. Check applicable electrical codes

to ensure compliance. Installation of the Liebert

AccuVar ACV Series Surge Protective Device

should only be performed by qualified personnel.

Figure 1. AccuVar ACV Series Dimensions.

Installation, Operation ACV Series

and Maintenance Manual - 2 - Rev 2, 3/00

Page 4

Surge

®

UNPACKING AND INSTALLATION

Suppression

Systems

Unpacking and Preliminary Inspection

1. Inspect the shipping crate(s) for damage or

signs of mishandling before unpacking the

unit.

2. If any damage as a result of shipping is

observed, immediately file a claim with the

shipping agency and forward a copy to your

local Liebert Sales Representative.

Storage

The unit should be stored in a clean, dry

environment. Storage temperature range is -55ºC

(-67ºF) to +85ºC (+185ºF). Care should be taken

to avoid condensation. All packing and shipping

materials should be left intact until the unit is

ready for final installation. If the unit has been

stored for an extended period of time, the unit

should be cleaned and carefully inspected before

placing into service.

Location Considerations

Environment – The unit is designed for operation

indoors in ambient temperatures of -40ºC (-40ºF)

to +50ºC (+122ºF) with a relative humidity of 0%

to 95% (non-condensing).

The cover screws and “O” rings are supplied inside

of the unit in the small plastic bag that also

contains the wiring ring terminals. To properly

attach the cover to the enclosure the four “O” rings

must be used with the four screws provided, prior

to placing the screw in hole of cover. Screws

should be torqued between 4 and 10 inch-pounds.

Note: To maintain the integrity of the “O”

rings, protection against direct sunlight is

advised.

Equipment Performance – For maximum system

performance, the unit must be located as close to

the protected circuit as practical to minimize

interconnecting wiring length.

For optimum transient surge protection,

coordinated surge suppression should be applied at

the service entrance, at all other electrical

connections to the building (telephone, CATV,

etc.), and at known transient surge generating

loads within the building (large motors, arc

welders, switched capacitors, etc.). Electrical line

noise protection should also be applied close to the

point of usage for sensitive electronic loads

(computers, electronic appliances, solid state

motor drives, etc.). For interconnected electronic

loads (such as by way of data cabling),

communication line protectors may also be applied

to the interconnect wiring.

The unit is provided in a NEMA 12, 4, and 4X

rated industrial use enclosure, which is dust, drip,

and water tight and should not be installed in areas

with flammable materials or explosive

atmospheres.

Outdoor Use – To assure water tightness for

outdoor use, “O” rings must be used with screws

to secure cover!

Installation, Operation ACV Series

and Maintenance Manual - 3 - Rev 2, 3/00

Mounting – The unit is to be wall mounted. Refer

to Figure 1 for mounting dimensions.

Page 5

Surge

®

WARNING

!!

ELECTRICAL CONNECTIONS

Suppression

Systems

All electrical connections should be installed by a

qualified (licensed) electrician only. All wiring

must comply with the National Electrical Code

(NEC) and applicable local codes.

VERIFY THAT ALL POWER

CIRCUITS ARE DE-ENERGIZED AND

LOCKED OUT BEFORE MAKING

ELECTRICAL CONNECTIONS.

Terminals are provided inside the Liebert AccuVar

SPD units for the line (phase), neutral (if used),

and transient ground connections.

Voltage Ratings &

Power Source Configurations

Before making connections to the unit, verify that

the unit model number and nameplate voltage

rating are appropriate for connection to the

intended power source. See Figure 2 for voltage

rating applications with typical power source

configurations and assure that system voltages do

not exceed the maximum continuous operating

voltage (MCOV) on the unit’s data label.

Surge Voltage Ratings – To obtain the

suppression voltage ratings (SVRs), as obtained by

Underwriters Laboratories, Incorporated, in

accordance with the Standard for Safety, Surge

protective devices, (SPD), Standard 1449, Second

Edition, dated August 15, 1996, marked on this

product, #10 AWG wire must be utilized to

connect the AccuVar® to your facilities’ power

grid. Connections made with other that #10 AWG

conductors may result in different suppression

voltage ratings.

Circuit Ampacity Limitations – Representative

samples of this device have been investigated by

Underwriters Laboratories, Incorporated to

withstand, without exposing live circuits or

components on power sources, with voltage of two

times (2x) the device ratings, and fault currents of

up to 300,000 AIC, as described in the Standard

for Safety, Surge protective devices, (SPD),

Standard 1449, Second Edition, dated August 15,

1996.

Overcurrent Protection

The SPD unit conducts practically no current

under normal operation and only conducts during

very short duration transient conditions. The

Liebert AccuVar ACV Series SPD units contain

UL approved 300 kAIC internal system fusing to

protect against device failure. This overcurrent

protection, while not currently required by SPD

safety agencies or installation codes (NEC Article

280), has proven to be prudent engineering

practice.

External overcurrent protection is not specifically

required, nor is it desired since it impedes the

performance of the transient surge suppressor. If

overcurrent protection of the conductors to the

transient surge suppressor is desired, the suggested

fuse sizes based on the unit’s transient surge

current capabilities and suggested wire sizes are

shown in Table 1.

Table 1. Terminal Wire Size Range and Suggested Wiring Overcurrent Protection (All Models).

SUGGESTED

WIRE SIZE

(AWG)

10* 6-32 screw ring or spade terminal required. 30A

12 (Spare terminal screws enclosed) 20A

Installation, Operation ACV Series

and Maintenance Manual - 4 - Rev 2, 3/00

SPECIAL NOTES

* Must be used for UL1449 performance.

SUGGESTED

FUSE / CIRCUIT BREAKER

AMPACITY (IF USED)

Page 6

Surge

®

Suppression

Systems

Connection

With the AccuVar’s parallel connection, the length

of wiring to the transient voltage surge suppression

(SPD) unit must be minimized for best

performance. Wire lengths longer than 10 feet

must be avoided. Wiring connections may be

made directly into circuit breakers.

To reduce the wiring impedance to surge currents,

the phase, neutral (if required), and ground

conductors are recommended to be twisted

together and routed in the same raceway (conduit).

Avoid any sharp bends in the conductors.

Wire Sizing - With parallel connection, the size of

the wiring to the SPD unit is independent of the

protected circuit’s ampacity. Suggested wire sizes

based on the unit’s transient surge current

capabilities are shown in Table 1.

System Grounding & Bonding

The performance and safety of any SPD system is

dependent on proper grounding. Grounding is

required primarily for safety. Correct

implementation also enhances equipment

performance. Incorrect grounding can reduce or

impede the SPD’s operation.

All electrical circuits to or from the SPD must

include an equipment grounding conductor as

required by the NEC and local codes.

An insulated grounding conductor is recommended

for the SPD. The grounding conductor should be

the same wire size as the associated power

conductors and should be connected in close

proximity to the SPD.

Grounding Electrode – Contrary to popular

belief, transient surge suppressors do not discharge

all surges to ground (earth). Transient surge

suppressors divert the surge current back to its

source to complete the electrical circuit.

In the case of lightning, whose potential is

developed with respect to the earth, the SPD

diverts the surge current to the grounding electrode

(earth connection). However, for most transient

surges which are developed by switching loads,

the SPD diverts the surge current back to its source

without involving the grounding electrode.

For proper SPD performance, the service entrance

grounding electrode system must comply with the

NEC by having all available electrodes (building

steel, metal water pipe, driven rods, concrete

encased electrodes, etc.) properly bonded together

and connected to the power system grounding.

The use of a separate grounding electrode to

ground the SPD defeats the effectiveness of the

SPD, is a potential safety hazard, may cause

equipment damage, is an NEC violation

(reference NEC 250-51 and 250-54), and is not

recommended.

Installation, Operation ACV Series

and Maintenance Manual - 5 - Rev 2, 3/00

Page 7

Surge

®

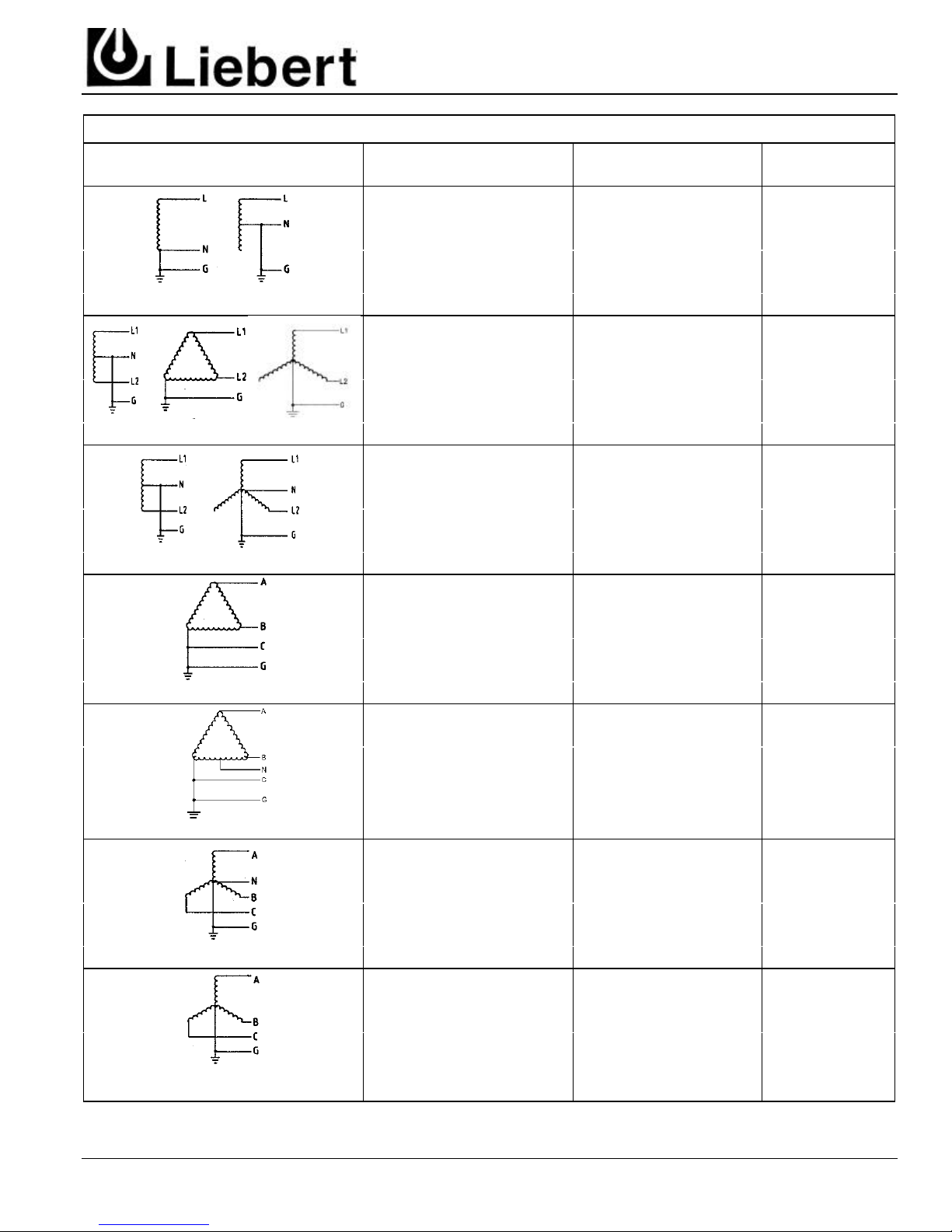

Split Single Phase, 3 W + G

Single Phase L-N, 2 W +G

Three Phase Wye, 3 W + G

VOLTAGE RATINGS & POWER SOURCE CONFIGURATIONS

Suppression

Systems

Source Configurations

Single Phase L-L, 2 W + G

Three Phase Delta, 3 W + G

Nominal

Operating Voltage

Maximum Continuous

Operating Voltage

Model Voltage

Code

100 130 L-N 100N

110 130 L-N 110N

120 150 L-N 120N

230 275 L-N 230N

277 320 L-N 277N

347 420 L-N 347N

208 130 L-L 208L

240 150 L-L 240L

400 275 L-L 400L

480 275 L-L 480L

600 420 L-L 600L

120 / 208 or 120 / 240 150 L-N 120S

277 / 480 320 L-N 277S

347 / 600 420 L-N 347S

208 250 L-L 208D

240 320 L-L 240D

380 420 L-L 380D

415 580 L-L 415D

480 580 L-L 480D

600 680 L-L 600D

120 / 240 150 L-N 240H

208 / 240 250 L-N 240H

Three Phase Delta Hi Leg, 4 W + G

Three Phase Wye, 4 W + G

No Neutral

Table 2. Voltage Ratings and Power Source Configurations.

For other voltages or source configurations, consult factory.

Installation, Operation ACV Series

and Maintenance Manual - 6 - Rev 2, 3/00

120 / 208 150 L-N 120Y

220 / 380 320 L-N 220Y

240 / 415 320 L-N 240Y

277 / 480 320 L-N 277Y

347 / 600 420 L-N 347Y

120 130 L-L 120Y

230 275 L-L 230Y

277 320 L-L 277Y

347 420 L-L 347Y

Page 8

Surge

®

WARNING

!!

Suppression

Systems

OPERATION

Liebert AccuVar ACV Series SPD Systems

require little or no operator intervention after

installation. The units are provided with status

LED, which assist in determining when the unit

needs service (see Troubleshooting/Repair/

Maintenance Section).

If the unit is energized and the green LED is off

(and / or the red LED is on), the AccuVar is not

fully functional and will require replacement.

Summary Alarm Contact Option

Optional Form C ( 1 N.O. and 1 N.C.) relay

contacts may be provided for remote indication of

TROUBLESHOOTING / MAINTENANCE / SERVICING

Inspection and Cleaning

Periodic system inspections, cleaning, and

connection checks are recommended to ensure

reliable system performance and continued

transient protection.

(For any other problems not listed below, or if

cause of the problem cannot be determined,

please call Control Concepts at 800-288-6169 or

607-724-2484.)

phase loss, undervoltage (70% of line voltage,

typical), power loss, and suppression failure. If the

status of the contacts change (indicating a

problem), one of these conditions exists.

The summary alarm contact terminals are located

inside the unit. Contacts are rated for 5 amps at

125 VAC maximum.

Note: Wiring for the Form C contacts may be

routed through the flexible conduit with the phase

wiring. All wire must comply with the National

Electrical Code (NEC) and applicable local codes.

provided to indicate when the unit needs

replacement (see operation section of this manual

for details). To ensure continuity of surge

protection, failed units should be replaced at the

earliest convenient service opportunity.

Servicing

Troubleshooting

If status failure indication occurs or Form C relay

has changed states, a qualified electrician should

first determine if the systems voltage and proper

phasing exists.

If the AccuVar SPD remains in an alarm condition

once the technician is satisfied that the electrical

system and its connections are normal, the unit

should be replaced.

Corrective Maintenance

The Liebert AccuVar ACV Series SPD is designed

for years of trouble-free operation. However, even

the most reliable equipment may fail under

abnormal conditions. Diagnostic indicators are

Installation, Operation ACV Series

and Maintenance Manual - 7 - Rev 2, 3/00

ONLY QUALIFIED PERSONNEL

SHOULD PERFORM MAINTENANCE

ON THE SYSTEM.

HAZARDOUS VOLTAGES ARE

PRESENT INSIDE THE UNIT DURING

NORMAL OPERATIONS.

ELECTRICAL SAFETY PRECAUTIONS MUST BE FOLLOWED

WHEN SERVICING THIS UNIT.

TO PREVENT RISK OF ELECTRICAL

SHOCK, TURN OFF AND LOCK OUT

ALL POWER SOURCES TO THE UNIT

BEFORE SERVICING UNIT.

Page 9

Surge

®

Suppression

Systems

*

*

Figure 2. Installation Diagram.

*If neutral is provided, a reliable neutral must be pulled to the AccuVar.

Installation, Operation ACV Series

and Maintenance Manual - 8 - Rev 2, 3/00

Page 10

Surge

®

Suppression

Systems

LIMITED WARRANTY

This Warranty is given ONLY to purchasers who buy for commercial or industrial use in the ordinary course of each purchaser's business.

General:

Control Concepts' products are in our opinion the finest available. We take pride in our products and are pleased that you have chosen them. Under certain

circumstances, we offer with our products the following Five-Year Warranty Against Defects in Material and Workmanship. Please read your Warranty carefully.

This Warranty sets forth our responsibilities in the unlikely event of defect and tells you how to obtain performance under this Warranty.

FIVE YEAR LIMITED WARRANTY AGAINST DEFECTS IN MATERIAL AND WORKMANSHIP

CONTROL CONCEPTS PRODUCTS COVERED: AccuVar®.

Terms of Warranty:

As provided herein, the Control Concepts product is warranted to be free of defects in material and workmanship for a period of five (5) years from the date of

delivery of the product to User. The delivery date will be determined only from the Control Concepts bill of lading. If any of the Control Concepts products fail to

conform to the warranty within the warranty period, Control Concepts, at its option, will furnish new or factory remanufactured parts for repair or replacement of

that part.

Warranty Extends to First Purchaser for Use, Non-transferable:

This Warranty is extended to the first person, firm, association or corporation for whom the Control Concepts product specified herein is originally installed for

use in the United States (the "User"). This Warranty is not transferable or assignable without the prior written permission of Control Concepts.

Assignment of Warranties:

Control Concepts assigns to User any warranties which are made by manufacturers and suppliers of components of the Control Concepts product and which are

assignable, but Control Concepts makes NO REPRESENTATIONS as to the effectiveness or extent of such warranties, assumes NO RESPONSIBILITY for any

matters which may be warranted by such manufacturers or suppliers and extends no coverage under this warranty to such components.

Descriptions:

Control Concepts warrants for the period and on the terms of the Warranty set forth herein that the Control Concepts product will conform to the descriptions

contained in Control Concepts' final invoices, orders and Control Concepts' product brochures. Control Concepts does not control the installation and use of any

Control Concepts product. Accordingly, it is understood that the Descriptions are NOT WARRANTIES OF PERFORMANCE and NOT WARRANTIES OF

FITNESS FOR A PARTICULAR PURPOSE.

Obtaining Performance Under This Warranty:

Within a reasonable time, but in no case to exceed thirty (30) days, after User's discovery of a defect, User shall contact Control Concepts and request a return

authorization number. User shall ship the product, with proof of purchase, to Control Concepts freight prepaid. Control Concepts products shipped to Control

Concepts without a return authorization number will be refused and returned freight collect to User at User's expense. Control Concepts products shipped by User

to Control Concepts which have incurred freight damage due to User's improper packaging of the product will not be covered by this Warranty and any repairs or

replacement parts, components or products needed will be invoiced in the full current price amount and returned freight collect to User.

Subject to the limitations specified herein, Control Concepts will repair or replace, at its option, without charge for Control Concepts labor or materials,

subsequent to its inspection and F.O.B. Control Concepts' facility, the Control Concepts product shipped to Control Concepts with a return authorization number

and warranted hereunder which does not conform to the Warranty. Replacement parts, components or products shipped to User prior to Control Concepts' receipt

and inspection of the product claimed to be defective, shall be invoiced in the full current price amount and shipped freight collect F.O.B. Control Concepts'

facility. Warranty coverage will be extended only after Control Concepts' receipt of the claimed defective product within thirty (30) days of shipment of any

replacement parts, components or products, if applicable, Control Concepts' inspection discloses the claimed defect and the returned product shows no signs of

treatment or use which would void the coverage of this Warranty.

Items Not Covered By Warranty:

THIS WARRANTY DOES NOT COVER DAMAGE OR DEFECT CAUSED BY misuse, improper application, wrong or inadequate electrical current or

connection, inadequate water or drain services, negligence, inappropriate on site operating conditions, corrosive atmosphere, repair by non-Control Concepts

designated personnel, accident in transit, tampering, alterations, a change in location or operating use, exposure to the elements, Acts of God, theft or installation

contrary to Control Concepts' recommendations or specifications, or in any event if the Control Concepts serial number has been altered, defaced or removed.

THIS WARRANTY DOES NOT COVER shipping costs, installation costs, circuit breaker resetting or maintenance or service items and further, except as

provided herein, does NOT include labor costs or transportation charges arising from the replacement of the Control Concepts product or any part thereof or

charges to remove same from any premises of the User.

THIS WARRANTY DOES NOT COVER DAMAGE OR DEFECT CAUSED BY use of the Control Concepts product in combination with any electrical or

electronic components, circuits, systems, assemblies, or other materials not furnished by Control Concepts. Control Concepts does NOT warrant the suitability for

use or the results of the Control Concepts product in combination with the products of others.

REPAIR OR REPLACEMENT OF A DEFECTIVE PRODUCT OR PART THEREOF DOES NOT EXTEND THE ORIGINAL WARRANTY PERIOD.

Installation, Operation ACV Series

and Maintenance Manual - 9 - Rev 2, 3/00

Page 11

Surge

®

Suppression

Systems

Limitations:

• THIS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

• USER'S SOLE AND EXCLUSIVE REMEDY IS REPAIR OR REPLACEMENT OF THE CONTROL CONCEPTS PRODUCT AS SET FORTH

HEREIN.

• IF USER'S REMEDY IS DEEMED TO FAIL OF ITS ESSENTIAL PURPOSE BY A COURT OF COMPETENT JURISDICTION, CONTROL

CONCEPTS' RESPONSIBILITY FOR PROPERTY LOSS OR DAMAGE SHALL NOT EXCEED ONE TIMES THE NET PRODUCT PURCHASE

PRICE.

• IN NO EVENT SHALL CONTROL CONCEPTS ASSUME ANY LIABILITY FOR INDIRECT, SPECIAL, INCIDENTAL, OR ECONOMIC

CONSEQUENTIAL DAMAGES OF ANY KIND WHATSOEVER, INCLUDING WITHOUT LIMITATION, LOST PROFITS, BUSINESS

INTERRUPTION OR LOSS OF DATA, WHETHER ANY CLAIM IS BASED UPON THEORIES OF CONTRACT, NEGLIGENCE, STRICT

LIABILITY, TORT OR OTHERWISE.

Miscellaneous:

• NO SALESPERSON, EMPLOYEE OR AGENT OF CONTROL CONCEPTS IS AUTHORIZED TO ADD TO OR VARY THE TERMS OF THIS

WARRANTY. Warranty terms may be modified, if at all, only in a writing signed by a Control Concepts' officer.

• This Warranty is effective as of the date of Control Concepts receipt of payment and supersedes all previous warranties. Control Concepts reserves the right

to supplement or change the terms of this Warranty in any subsequent warranty offering to User or others.

• In the event that any provision of this Warranty should be or becomes invalid and/or unenforceable during the warranty period, the remaining terms and

provisions shall continue in full force and effect.

• This Warranty is given in and is intended to be construed under the laws of the State of New York.

• This Warranty represents the entire agreement between Control Concepts and User with respect to the subject matter herein and supersedes all prior or

contemporaneous oral or written communications, representations, understandings or agreements relating to this subject.

Installation, Operation ACV Series

and Maintenance Manual - 10 - Rev 2, 3/00

Page 12

Surge

®

Suppression

Systems

DECLARATION OF CONFORMITY

All models of the AccuVar Series are in compliance with the EMC Directive 89/336/EEC, conforming to

EMC standard IEC 1000-4-4 and IEC 1000-4-5.

----- Office of the Vice-President of Engineering, Binghamton, NY USA, June 1996.

Installation, Operation ACV Series

and Maintenance Manual - 11 - Rev 2, 3/00

Page 13

TRANSIENT VOLTAGE SURGE SUPPRESSION

A World Leader in

Computer Support

Systems

Environment Control

Power Protection

Site Monitoring /

Control

Liebert Corporation

designs, manufactures

and markets complete

systems for improvement of computer

uptime and performance. The result is

improved business

operations, increased

productivity and higher

return on the computer

investment. Liebert

Systems provide

dependable environmental control and

electrical power protection, combined with

centralized monitoring

and control. This

approach represents a

single-source

integrated computer

support network.

Based on over two

decades of experience

and over 80,000

installations worldwide, Liebert is

committed to offering

the highest quality

products and services

for applications

requiring computer

support.

Control Concepts Corporation

A Subsidiary of the Liebert Corporation

328 Water Street, P.O. Box 1380

Binghamton, NY 13902 USA

Tel: 607/724-2484

800/288-6169

Fax: 607-722-8713

While every precaution has been taken to

ensure accuracy and completeness in this

manual. Liebert Corporation assumes no

responsibility, and disclaims all liability for

damages resulting from use of this

information or for any errors or omissions.

©1999 Liebert Corporation

All rights reserved throughout the world.

Specifications subject to change without

notice.

®Liebert and the Liebert logo are registered

trademarks of Liebert Corporation.

Printed in U.S.A

SL-502 (3/00)

Loading...

Loading...