Page 1

R

UPStation GXT™

700-3000 VA

230V

USER MANUAL

English / Deutsch / Français /

Italiano / Español

Page 2

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Do not attempt to service this product yourself except to replace

the battery. Opening or removing the cover may expose you to dangerous

voltages, even when the AC cord is disconnected from the electrical outlet.

Refer all servicing to qualified service personnel.

1. SAVE THESE INSTRUCTIONS. THIS MANUAL CONTAINS IMPORTANT

SAFETY INSTRUCTIONS. Read all safety and operating instructions before

operating the Uninterruptible Power System (UPS). Adhere to all warnings

on the unit and in this manual. Follow all operating and user instructions.

2. This product is designed for Commercial/Industrial use only. It is not

intended for use with life support and other designated “critical” devices.

Maximum load must not exceed that shown on the UPS rating label. If

uncertain, consult your dealer. See Limited Warranty.

3. WHEN REPLACING THE BATTERIES, USE THE APPROPRIATE

LIEBERT-APPROVED REPLACEMENT BATTERY KIT. PROPER

DISPOSAL OF BATTERIES IS REQUIRED. REFER TO YOUR LOCAL

LAWS AND REGULATIONS FOR DISPOSAL REQUIREMENTS.

4. Always turn off the UPS and unplug it before starting the battery

replacement procedure. To replace batteries, refer to the battery

replacement procedure. If you feel unqualified to replace the batteries, do

not open the battery door. Refer all servicing to qualified service personnel.

5. CAUTION: Do not open or mutilate the batteries. Released electrolyte is

harmful to skin and eyes and may be toxic.

6. The mains supply socket or means of isolation must be within 2 meters of

the equipment and accessible to the operator. The UPS is designed for data

processing equipment.

7. The UPS comes with two output power leads with molded connectors - do

not modify these leads. Consult dealer if connector does not match the load

socket. UPS must be grounded at all times while in use. Turn UPS off

before unplugging it, or the safety earth will be removed.

8. The UPStation GXT™ models 700 VA, 1000 VA, 1500 VA, and 2000 VA are

not supplied with an input power lead for connection to the mains supply

socket. Use the input mains supply power lead from your data processing

equipment to connect the UPS to the mains supply. For the 3000 VA model,

use the supplied 16 ampere rated input mains supply lead. For UK supply

systems, consult a qualified electrician to connect the lead supplied for the

3000 VA model to the mains supply.

CAUTION: The UPS and the connected load combined total earth leakage

current must not exceed 3.5 milliamperes. If the connected load earth

leakage current is likely to exceed 2.0 milliamperes or you are unsure, then

convert the input lead attachment to either a fixed wiring installation or an

industrial plug/socket (e.g. CEE 17 connector). This task should be carried

out by a competent electrical engineer who is conversant with local electrical

codes/regulations.

Page 3

3

9. The UPS output supply sockets may be electrically live whenever the input

power lead is plugged into the mains supply socket. Turning the UPS off

does not electrically isolate the internal parts. To isolate the UPS, turn the

UPS off then isolate it from the mains supply.

10. When installing the UPS or making input and output connections, comply

with relevant safety standards (e.g. IEC950, VDE0805, EN50091-1).

11. This equipment complies with the requirements of the EMC Directive

89/336/EEC and the published technical standards. Continued compliance

requires installation in accordance with these instructions and the use of

manufacturer approved accessories with output cables not exceeding 10

metres (30 ft.) in length. Use a shielded cable for the external

communications interface.

12. Operate UPS only from a properly earthed, 50 Hz or 60 Hz, 208-240 VAC

mains supply. Models are available for 100-127 VAC supply voltages.

13. Route power supply cords so they are not walked on or pinched.

14. Never block or insert any object into the ventilation holes or other openings.

Maintain a minimum clearance of 100 mm (4 inches) in front and rear of the

UPS for proper air flow and cooling.

15. Operate the UPS in an indoor environment only with an ambient temperature

range of 0° C to +40° C (32° F to +104° F). Install it in a clean environment,

free from moisture, flammable liquids, gasses, or corrosive substances.

16. Storing magnetic media on top of the UPS may result in data loss or

corruption.

17. Turn the UPS off and unplug the UPS before cleaning. Use only a soft cloth,

never liquid or aerosol cleaners.

18. This equipment can be operated by individuals without previous training.

Page 4

4

INTRODUCTION AND SYSTEM DESCRIPTION

Congratulations on your choice of the UPStation GXT™ Uninterruptible Power

System (UPS). It provides conditioned power to microcomputers and other

sensitive electronic equipment.

Upon generation, AC power is clean and stable. However, during transmission

and distribution it may be subject to voltage sags, spikes, or complete power

failure which may interrupt computer operations, cause data loss, or even

damage equipment. The UPStation GXT™ protects equipment from these

disturbances.

The UPStation GXT™ comes in nominal power ratings of 700, 1000, 1500, 2000,

or 3000 VA. Complete specifications appear near the end of this section.

The UPStation GXT™ is a compact, “on-line” UPS. An “on-line” UPS

continuously conditions and regulates its output voltage, whether the mains

power is present or not. It supplies connected equipment with clean sinewave

power. Sensitive electronic equipment operates best from sinewave power.

For ease of use, the UPStation GXT™ contains a light emitting diode (LED)

display to indicate either “load percentage” or “battery capacity” depending upon

the mode of operation. It also provides self-diagnostics, a combination On/Alarm

Silence/Manual Battery Test button, a combination Off/Bypass button, and two

levels of alarms when the unit is operating on battery.

The UPStation GXT™ has an interface port for communications between the

UPS and a LAN server or other computer system. This port provides detailed

operating information including voltages, currents, and alarm status to the host

system when used in conjunction with the SiteNet® 2 software. SiteNet® 2

software can also remotely control UPS operation.

GLOSSARY OF SYMBOLS USED ON PRODUCT

Indicates AC Input

Indicates AC Output

Indicates Caution: Note the accompanying instruction

indicates the position of a fuse

Indicates the position of a fuse

Requests the user to consult the manual for additional

information

Indicates that the unit contains a valve regulated lead acid

battery

Page 5

5

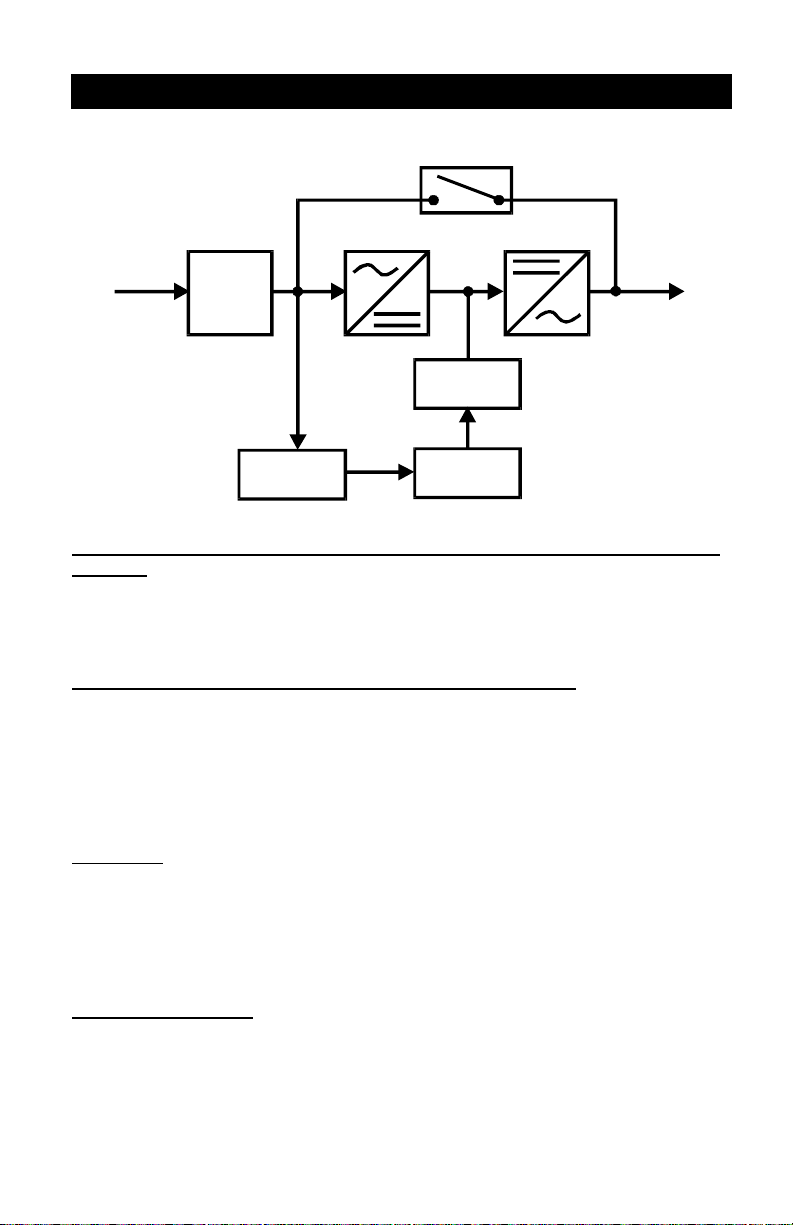

MAJOR COMPONENTS

Dynamic

Bypass

Inverter

OUTPUT

INPUT

TVSS

and

EMI/RFI

Filters

Battery

Charger

Rectifier/PFC

DC to DC

Converter

Battery

TRANSIENT VOLTAGE SURGE SUPPRESSION (TVSS) AND EMI/RFI

FILTERS

These UPS components provide surge protection, and filter both electromagnetic

interference (EMI) and radio frequency interference (RFI). They minimize any

surges or interference present in the mains line and keep the sensitive

equipment protected.

RECTIFIER/POWER FACTOR CORRECTION (PFC) CIRCUIT

In normal operation, the rectifier/power factor correction (PFC) circuit converts

mains AC power to regulated DC power for use by the inverter, while ensuring

that the waveshape of the input current used by the UPS is near ideal.

Extracting this sinewave input current achieves two objectives: the mains power

is used as efficiently as possible by the UPS, and the amount of distortion

reflected on the mains is reduced. This results in cleaner power being available

to other devices in the building not being protected by the UPStation GXT™.

INVERTER

In normal operation, the inverter utilizes the DC output of the power factor

correction circuit and “inverts” it into precise, regulated sinewave AC power.

Upon a mains power failure, the inverter receives its required energy from the

battery through the DC-DC converter. In both modes of the operation, the UPS

inverter is on-line and continuously generating clean, precise, regulated AC

output power.

BATTERY CHARGER

The battery charger utilizes energy from the mains power and precisely regulates

it to continuously “float” charge the battery system. The battery system charges

whenever the UPStation GXT™ is plugged in.

Page 6

6

DC TO DC CONVERTER

The DC-DC converter utilizes energy from the battery system and raises the DC

voltage to the optimum operating voltage for the inverter. This allows the inverter

to operate continuously at its optimum efficiency and voltage, thus increasing

reliability.

BATTERY

The UPStation GXT™ employs valve regulated, nonspillable, lead acid batteries.

At typical room temperatures and with the UPS float charging, the battery system

will last many years. Optional external battery cabinets are available to provide

extended run times for the rack-tower (RT) models. For battery run times, refer

to the Typical Battery Discharge Curves.

DYNAMIC BYPASS

The UPStation GXT™ provides an alternate path for mains power to the

connected load, in the unlikely event of a UPS malfunction. Should the UPS

have an overload, over temperature, or UPS failure condition, the UPS

automatically transfers the connected load to bypass. Bypass operation is

indicated by an alarm and an illuminated Bypass LED (other LED’s may be

illuminated to indicate the diagnosed problem). To manually transfer the

connected load from the inverter to bypass power, press the Off button once.

NOTE: The bypass power path does NOT protect the connected equipment

from disturbances on the mains supply.

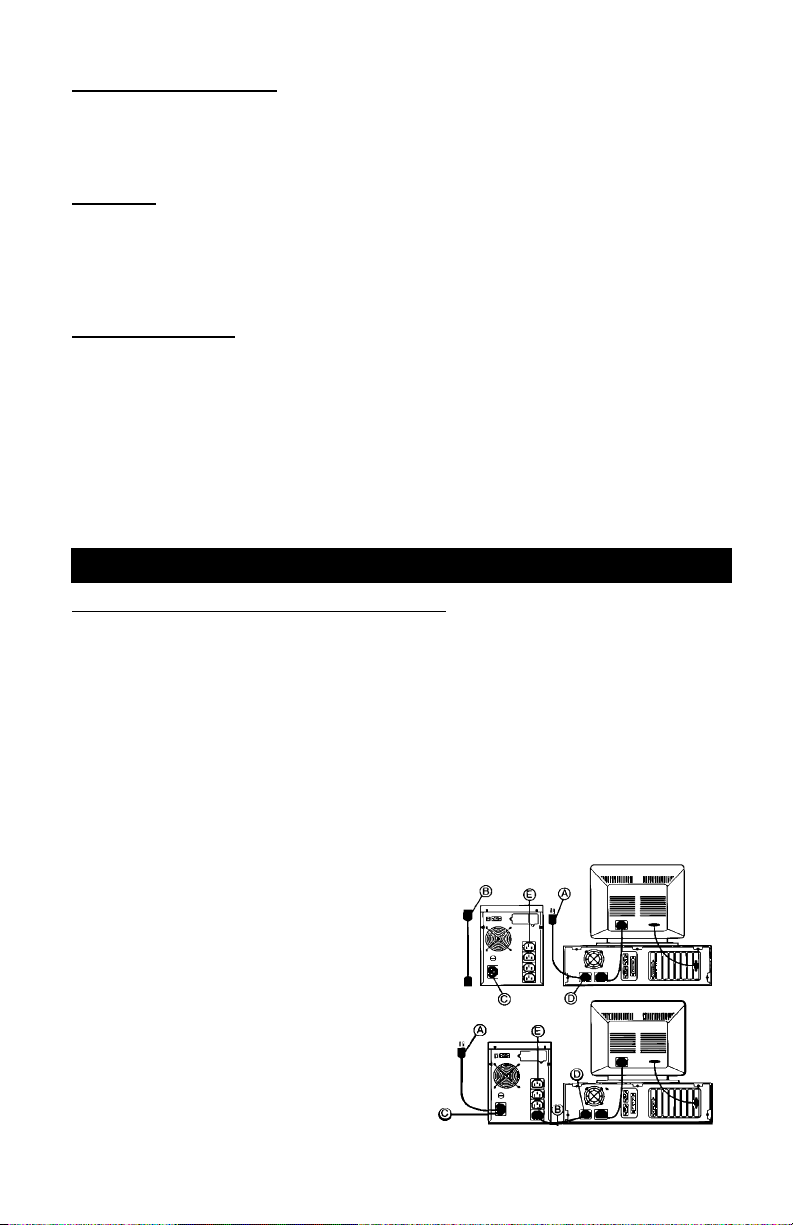

GENERAL INSTALLATION

MINI-TOWER/TOWER UPS INSTALLATIONS

1. Unpack the UPS carefully noting the packing method. Retain the box and

packing material for possible future shipment.

2. CAUTION: The UPS is heavy (see specifications). Take proper precautions

when lifting or moving it.

3. Visually inspect the UPS for freight damage. Report damage to the carrier

and your dealer.

4. Locate the UPS indoors in a controlled environment, where it cannot be

accidentally disconnected. Locate it in an area with unrestricted airflow,

away from water, flammable liquids, gases, or corrosives. Maintain a

minimum of 100 mm (4 inches)

clearance around the UPS.

Maintain an ambient temperature

range of 0° to 40° C (32° to 104° F).

NOTE: UPS operation in

temperatures above 25° C (77° F)

reduces battery life. Ensuring load

equipment is turned off, plug all

loads into the UPS output sockets.

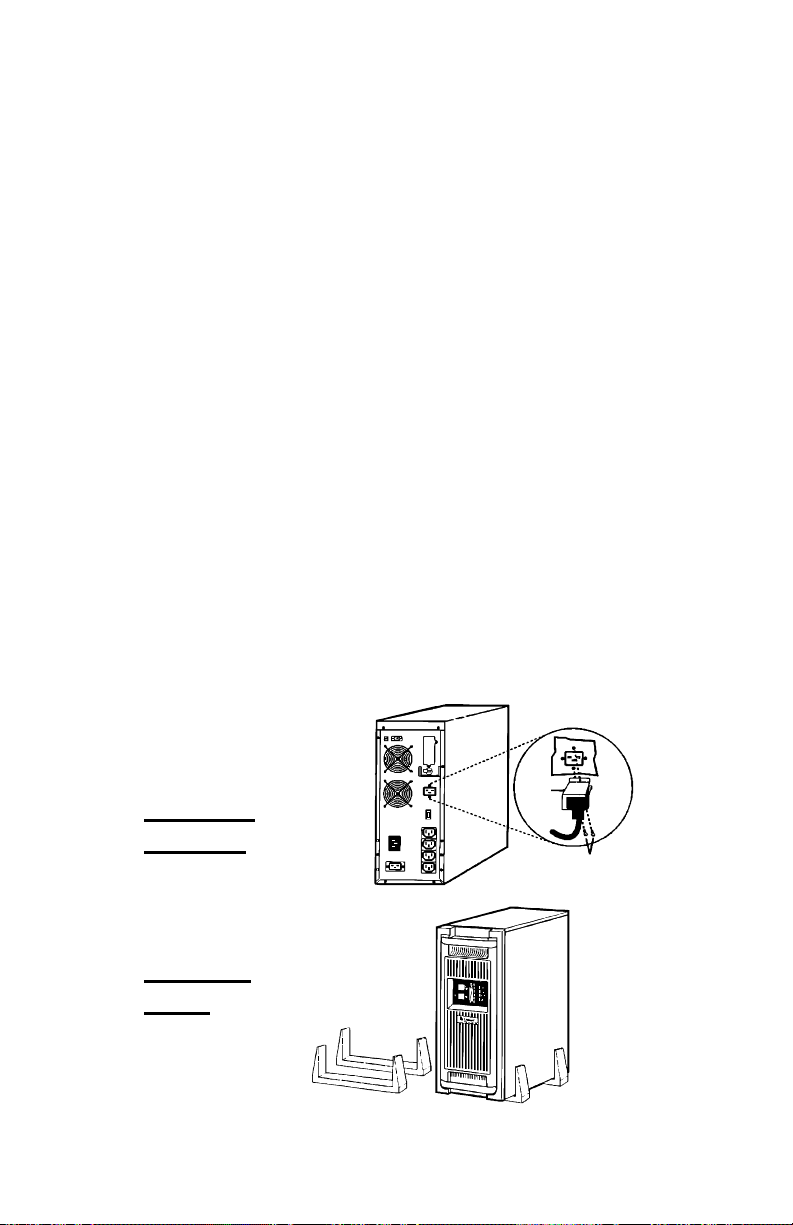

5. For 700-2000 VA models, unplug

power input cable (A) from load

equipment input socket (D) and

plug it into UPS input socket (C).

Page 7

7

Re-plug the power input cable (A) into mains supply socket. Proceed

with step 9.For 3000 VA models, a CEE 19 input cable is supplied. Proceed

with the next step.

6. Connect the molded connector of the mains AC input supply cable into the

UPS.

7. Fit the supplied retainer bracket around the input supply cable and secure

the bracket to the rear of the UPS using the two supplied screws.

8. The free end of the input supply cable should be connected to the electrical

supply distribution system in accordance with local rules and conditions.

NOTE: The UPS On/Alarm Silence/Manual Battery Test button does not

electrically isolate the internal parts. To isolate the UPS, provide an isolator

that is accessible to the operator and located within two meters of the UPS.

The wires in the mains lead are colored with the following code:

Green and Yellow = Earth, Blue = Neutral, Brown = Live

As the color of the wires in the mains lead may not correspond with the

colored marking identifying the terminals in the plug, proceed as follows: The

green and yellow wire must be connected to the terminal in the plug that is

marked with the letter “E” or by the earth symbol, or colored green and

yellow. The blue wire must be connected to the terminal that is marked with

the letter “N” or colored black. The brown wire must be connected to the

terminal that is marked with the letter “L” or colored red.

9. Connect the supplied CEE 22 output cable (B) between the load equipment

input socket (D) and one of the UPS AC output sockets (E). Connect all

load equipment to the UPS in this way.

10. Turn on the UPS by pressing the On button for at least one half second; then

turn on the connected load equipment. The UPS is ready for normal

operation.

Retainer

Retainer

Bracket

Bracket

Screws

Support

Base

Page 8

8

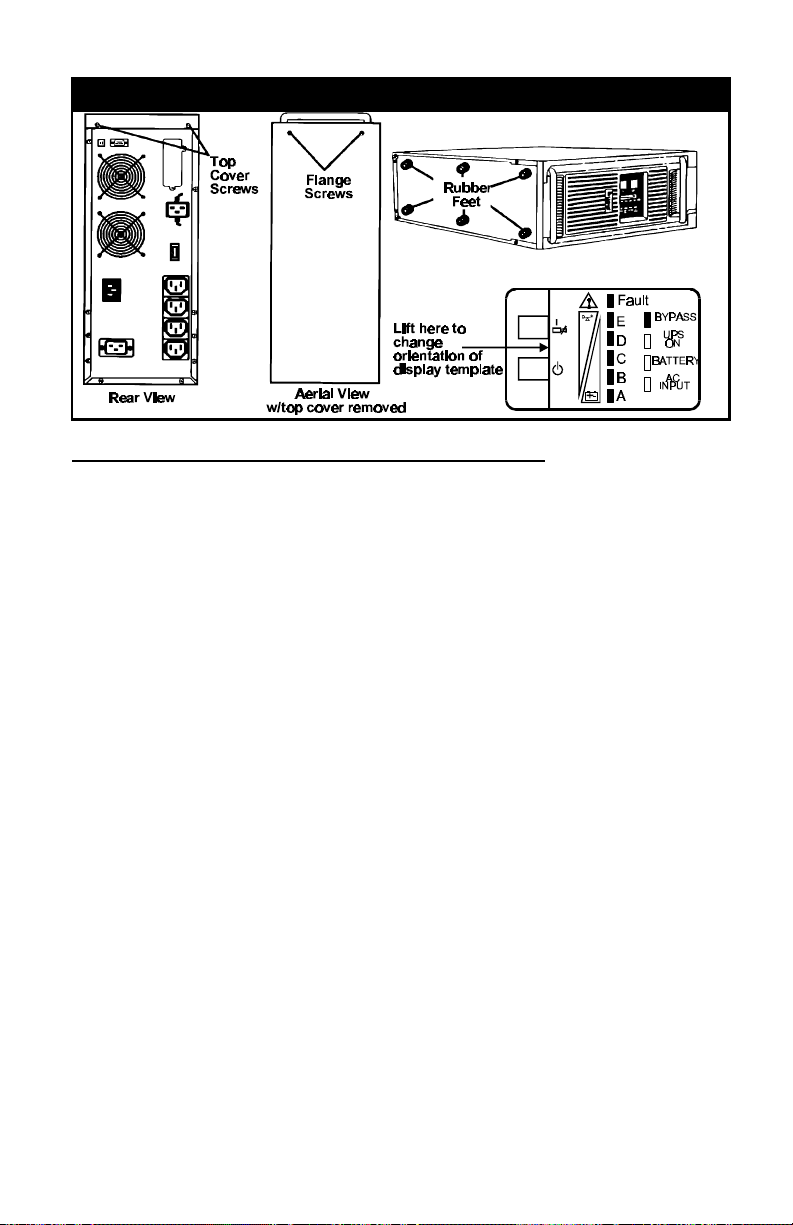

RACK-MOUNT CONVERSION DIAGRAMS

RACK-MOUNT UPS CONVERSION AND INSTALLATION

1. Unpack the UPS carefully noting the packing method. Retain the box and

packing material for possible future shipment.

2. CAUTION: The UPS is heavy (see specifications). Take proper precautions

when lifting or moving it.

3. Visually inspect the UPS for freight damage. Report damage to the carrier

and your dealer.

4. Remove the two screws located at the rear of the top cover with a Phillips

(cross head) screwdriver. Push the top cover towards back of UPS and lift

off. Remove and retain the two flange screws located at the front of UPS.

5. Gently lay unit on its right side and remove the six rubber feet with the

screwdriver. Remove and retain screws from the two front feet.

NOTE: The rubber feet are not used for rack-mount installations.

6. Locate securing flanges in the top of packing material and fasten to the UPS

using the flange screws from steps 4 and 5.

7. Remove display template to change the orientation of the display. You may

also rotate the “Liebert UPStation GXT™” plate located at left of display

area.

8. NOTE: UPS unit MUST be supported by a shelf, brackets or slide rails on

each side. The securing flanges WILL NOT support the weight of the UPS.

9. For slide rail installations, securing hardware is provided with the UPS and is

located in the packing material (slide rails sold separately). Fasten the

slides into position with the screws per the instructions included with the

slide rails.

10. The UPS automatically starts up in the bypass mode once the UPS is

plugged into the mains socket. The UPS is now ready to be placed into the

equipment rack.

Page 9

9

11. Ensure the load equipment is turned off, and plug all loads into the UPS

output sockets.

12. For 700-2000 VA models, unplug power input cable from load equipment

input socket and plug it into UPS input socket. Re-plug the power input

cable into mains supply socket. Proceed with step 16. For 3000 VA models,

a CEE 19 input cable is supplied. Proceed with the next step.

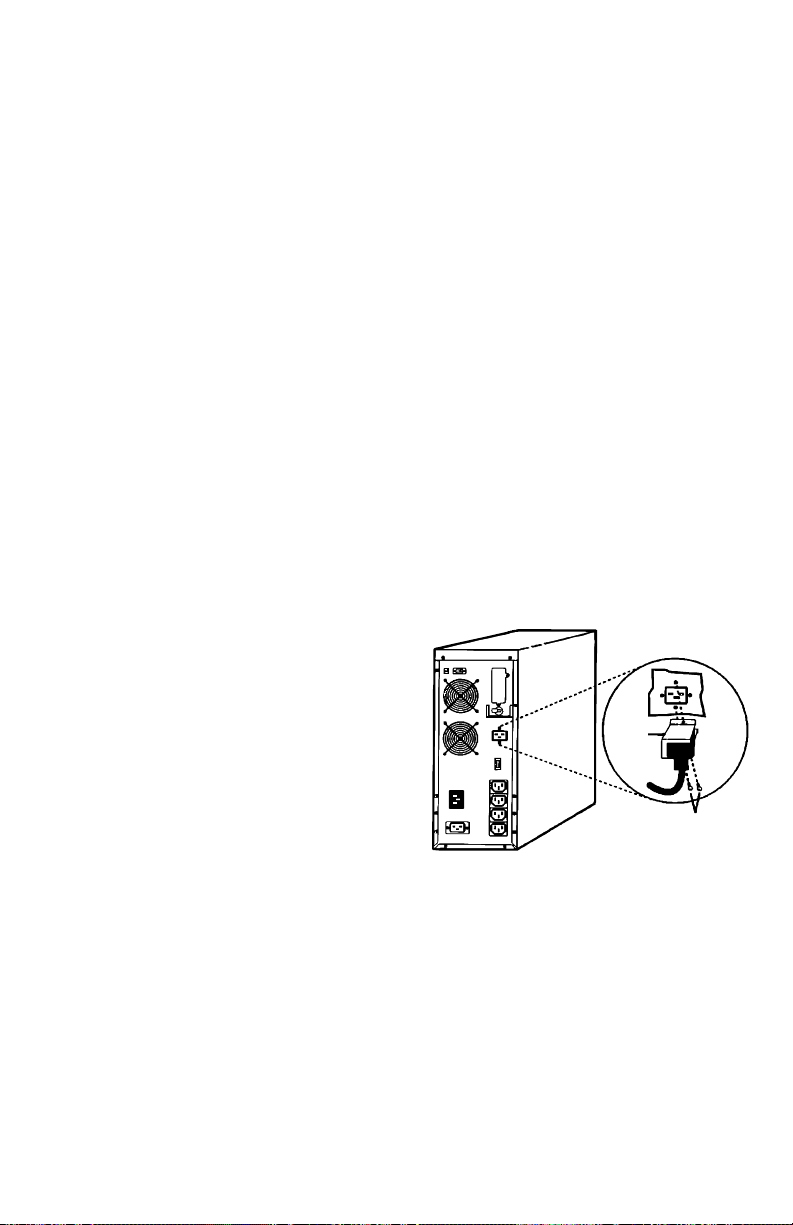

13. Connect the molded connector of the mains AC input supply cable into the

UPS.

14. Fit the supplied retainer bracket around the input supply cable and secure

the bracket to the rear of the UPS using the two supplied screws.

15. The free end of the input supply cable should be connected to the electrical

supply distribution system in accordance with local rules and conditions.

Note: The UPS On/Alarm Silence/Manual Battery Test button does not

electrically isolate the internal parts. To isolate the UPS, provide an isolator

that is accessible to the operator and located within two meters of the UPS.

The wires in the mains lead are colored with the following code:

Green and Yellow = Earth, Blue = Neutral, Brown = Live

As the color of the wires in the mains lead may not correspond with the

colored marking identifying the terminals in the plug, proceed as follows:

The green and yellow wire must be connected to the terminal in the plug that

is marked with the letter “E” or by the earth symbol, or colored green and

yellow. The blue wire must be connected to the terminal that is marked with

the letter “N” or colored black. The brown wire must be connected to the

terminal that is marked with the letter “L” or colored red.

16. Connect the supplied CEE 22 output

cable between the load equipment

input socket and one of the UPS AC

output sockets. Connect all load

equipment to UPS in this way.

17. Turn on the UPS by pressing the On

button; then turn on the connected

load equipment. The UPS is ready

for normal operation.

Retainer

Bracket

Screws

Page 10

10

OPTIONAL BATTERY CABINET(S) INSTALLATION

Up to two optional battery cabinets may be connected to the UPS to provide

additional run time. Battery cabinets are designed to be placed on either side or

beneath the UPS.

1. Unpack the UPS battery cabinet(s) carefully noting the packing method.

Retain the box and packing material for possible future shipment.

2. CAUTION: The battery cabinet(s) are heavy (see specifications). Take

proper precautions when lifting or moving them.

3. Visually inspect the UPS for freight damage. Report damage to the carrier

and your dealer.

4. Follow the same installation instructions used earlier for the UPS (tower or

rack-mount).

5. Attach external battery cabinets as shown, using the enclosed metal

securing plate to prevent tip-over.

6. Connect the supplied cable to the battery cabinet then to the UPS.

7. Turn on the breaker on the rear of the battery cabinet.

Battery Cabinet Installation Diagram

SECURING PLATE

BREAKER

Page 11

11

FERRITE BEAD INSTALLATION

Serial Communications

Attach the smaller enclosed ferrite bead

clamp to the communication cable as

shown in the drawing using the following

directions:

• Open the ferrite bead.

• Place the communication cable inside

the ferrite bead grove.

• Position the ferrite beads as close as

possible to the end of the cable that

connects to the DB9 connector of the

UPS.

• Close the ferrite bead so that the

ferrite bead’s case snaps closed with

the cable routed inside the ferrite

bead’s case.

SNMP Installation

Attach the larger enclosed ferrite bead

clamp to the network cable as shown in

the drawing using the following directions:

• Open the ferrite bead.

• Place the network cable inside the

ferrite bead grove.

• Wrap the cable once around the

bead.

• Position the ferrite cable as close as

possible to the end of the cable that

connects to the UPS.

• Close the ferrite bead so that the

ferrite bead’s case snaps closed with

the cable routed inside the ferrite

bead’s case.

Page 12

12

On/Alarm Silence/

Manual Battery Test

Button

Load/Battery Level

Mini-Tower

Rack Tower

Rack Tower

Rack Tower

6

2

4

6

6

2

2

4

4

3

5

7

3

5

3

3

1- Output Receptacles

2- DB-9 Interface Port

Communications Port

5- Circuit Protector or fuse

5

Off/ Bypass Button

3- AC Inlet

4- Intellislot TM

UPSTATION GXT™

Fault Indicator

Bypass Indicator

UPS On Indicator

Battery Indicator

AC Input Indicator

Indicators

6- Output Voltage Selector

Switches

7- Battery Cable Connector

6 4

2

7

5

3

700/1000 VA

1

1000/1500 VA

7

1

2000 VA

3000 VA

Page 13

13

CONTROLS AND INDICATORS

On/Alarm Silence/Manual Battery Test Button

This button controls output power to connected load(s) and has three functions:

On, Alarm Silence, and Manual Battery Test. Pressing this button will start up

the UPS in order to provide conditioned and protected power into the mains

socket.

To silence alarms, press this button for at least one half second while alarm

conditions are present. After the alarm is silenced, the UPStation GXT™ will

reactivate the alarm system to alert of additional problems.

NOTE: The low battery and bypass reminder alarms cannot be silenced.

To initiate a manual battery test, press this button for at least one half second

while operating from mains power and no alarm conditions are present. If the

bottom two LEDs do not illuminate during a Battery Test, allow the UPS to

recharge the batteries for 24 hours. After 24 hours, retest the batteries. If the

batteries have been retested and the bottom two LEDs still do not illuminate,

contact your dealer or Liebert Technical Support (LTS) for a battery replacement

kit.

Off/Bypass Button

This button controls output power to connected load(s) and has dual functions:

Off and Bypass.

CAUTION: Pressing this button once will cause the load to be transferred to

bypass power. Pressing this button a second time within 4 seconds will result in

loss of power to the output sockets and connected loads. Perform all necessary

shutdown procedures on connected loads before pressing this button twice.

Load/Battery Level Indicators (4 Green, 1 Amber)

The Load/Battery Level indicators have dual functions. During normal mode

operation LED indicators display the approximate electrical load placed upon the

UPS; and during battery mode operation LED indicators display approximate

battery capacity. Refer to the Typical Battery Discharge Curves to determine the

approximate amount of back up time with respect to your connected load

percentage.

The UPStation GXT™ is equipped with automatic and remote battery test

features. The automatic test occurs every 14 days if mains has not been

interrupted (14 day timer resets if unit goes to battery). Should the battery fail

this test, the fault indicator along with the A and C diagnostic LEDs will illuminate

and an alarm will sound (refer to Troubleshooting Guide). The remote test

feature functions with either SiteNet® 2 or SiteNet® SNMP Manager software

and can remotely initiate the battery test.

Fault Indicator (Red)

The Fault indicator is illuminated if the UPS has detected a problem. Also, one or

more of the load/battery level indicators may be illuminated (refer to

Troubleshooting Guide).

Bypass Indicator (Amber)

The Bypass indicator is illuminated when the UPS is operating from bypass

power. An alarm will sound indicating the UPS detected a problem, or the

manual bypass function has been activated.

Page 14

14

UPS On Indicator (Green)

Fault

BYPASS

BATTERY

76-100%

The UPS On indicator is illuminated when the UPS inverter is operating and

supplying power to your connected loads.

Battery Indicator (Amber)The Battery indicator is illuminated when the UPS is

operating from the battery system.

AC Input Indicator (Green)

The AC Input indicator is illuminated when mains power is available and within

the input specification.

Output Voltage Selector Switches

The Output Voltage Selector Switches, located on the rear of the UPS, are

designed to allow selecting or changing the desired output voltage to match the

mains. The settings to choose from are 208, 220, 230, and 240 VAC output. The

factory default setting is 230 VAC.

NOTE: Never change the switch settings while UPS is on and powering

connected loads. Switch positions for voltages:

208 VAC

220 VAC

230 VAC

240 VAC

NOTE: Setting output voltage to 208 VAC will cause UPS unit to be derated to

90% of the VA and Watt rating listed in specification section.

OPERATION

NORMAL MODE OPERATION

During normal operation, mains power provides energy to the UPS. The filters,

the power factor conditioning circuit and the inverter process this power to

provide computer grade power to connected loads. The UPS maintains the

batteries in a fully charged state.

The four green LEDs indicate an approximate level of load in 25% increments. If

the UPS becomes loaded beyond full rating, the fifth (amber) LED indicator will

illuminate and sound an alarm.

The display template indicates the percentage of load on the UPS output. Figure

1 displays approximately 51-75% loading.

Figure 1- Normal Mode Operation at 51-75% loading

!

100%

51-75%

26-50%

0-25%

INPUT

UPS

ON

AC

Page 15

15

BATTERY MODE OPERATION

Fault

BYPASS

BATTERY

100-81%

Battery mode occurs in event of an extreme input voltage condition or complete

mains failure. The battery system supplies power through the DC-DC converter

to the inverter to generate power for the connected load.

During battery mode an alarm sounds every 10 seconds. This will change to 2

beeps every 5 seconds when battery runs low (approximately 2 minutes

remaining). The AC Input LED will extinguish, and the Battery LED will illuminate

to warn that a mains problem has occurred. Each load/battery level indicator

represents a 20% capacity level. As capacity decreases, fewer indicators remain

illuminated. Refer to the Troubleshooting Guide.

For battery run times, refer to the Typical Battery Discharge Curves. To increase

this time, turn off non-essential pieces of equipment (such as idle computers and

monitors) or add the optional external battery cabinet.

NOTE: External battery cabinets can only be added to rack-tower (RT) models.

CAUTION: Turning off the UPS while in battery mode will result in loss of output

power.

Figure 2 displays approximately 61-80% battery capacity remaining.

BATTERY RECHARGE MODE

Once mains power is restored, the UPS resumes normal operation. At this time,

the Battery Charger begins recharging the battery.

!

20-0%

40-21%

60-41%

UPS

ON

Figure 2 – Battery Mode Operation at 61-80% battery capacity

80-61%

AC

INPUT

Page 16

16

COMMUNICATIONS INTERFACE PORT

The UPStation GXT™ UPS contains a standard DB-9 female connector located

on the rear of the UPS unit. Several signals are provided on this port and are

assigned as follows:

PIN ASSIGNMENT DESCRIPTION

1 Low Battery (open collector)

2 UPS TxD (typical RS-232 levels)

3 UPS RxD (typical RS-232 levels)

4 Remote Shutdown (5-12V); battery operation

5 Common

6 Remote Shutdown (short to pin 5); all modes of operation

7 Low Battery (open emitter)

8 Mains Fail (open emitter)

9 Mains Fail (open collector)

PIN ASSIGNMENT COLLECTOR TO EMITER*

Open Collector

Open Emitter

(+)

(-)

330 Ohms

*Maximum voltage and current on pins 1,7,8,9 is 80V DC; 10.0 mA.

UPS MONITORING

The UPStation GXT™ UPS has the capability of being monitored with stand

alone computers, network workstations, network servers, or UNIX hosts via the

DB-9 female connector located on the rear of the UPS.

This capability is used in applications requiring the UPS to provide status and

power monitoring information to the computer system. For example, during a

mains power failure, the information can be used by the computer’s operating

system or application program to automatically save information in buffers, to

close files, and shut down operations prior to battery capacity depletion.

Monitoring of the UPS via a computer system is easily made with a Liebert

SiteNet® 1 shutdown kit (sold separately). Consult your local Liebert

representative to determine the correct software kit for your application. The kit

includes special purpose cable and shutdown software.

Page 17

17

UPS INTELLIGENT COMMUNICATIONS

The UPStation GXT™ UPS has the capability to communicate intelligently with

stand alone computers, network workstations, network servers, or UNIX hosts via

the DB-9 female connector located at the rear of the UPS. By purchasing the

optional Liebert SiteNet® 2 software package (sold separately), intelligent

communications allows the following capabilities:

- Quantitative monitoring of mains and UPS power

- Quantitative monitoring of internal UPS parameters

- Periodic tests of battery quality and replacement notification

- Timed and delayed shutdown of the UPS

- Logging of power disturbances and anomalies

Consult your local Liebert sales representative for more information about

SiteNet® 2 software.

UPS INTELLISLOT™ COMMUNICATIONS

The UPStation GXT™ UPS contains an Intellislot™ communications port for the

optional internal Ethernet SNMP card. Optional SiteNet® SNMP Manager

software is available to allow communication through several network

management systems. Contact your local Liebert representative, dealer, or

reseller.

CAUTION: TO MAINTAIN SAFETY (SELV) BARRIERS AND FOR

ELECTROMAGNETIC COMPATABILITY, SIGNAL CABLES SHOULD BE

SEGREGATED AND RUN SEPARATE FROM ALL OTHER POWER CABLES,

WHERE APPLICABLE.

MAINTENANCE

The UPStation GXT™ UPS requires very little maintenance. The batteries are

valve regulated, nonspillable, lead acid, and should be kept charged to obtain

their designed life. The UPS continuously charges the batteries when connected

to the mains supply.

When storing the UPS for any length of time, it is recommended to plug the UPS

in for at least 24 hours every four to six months to ensure full recharge of the

batteries.

The UPStation GXT™ UPS is designed to allow the user to safely replace the

batteries. Read the safety cautions before proceeding. Contact your dealer to

obtain the appropriate replacement battery kit.

Page 18

18

BATTERY REPLACEMENT PROCEDURES

B

a

t

t

e

r

y

c

o

n

n

e

c

t

o

r

Battery door screws

CAUTION – A battery can present a risk of electrical shock and high short circuit

current. The following precautions should be observed before replacing the

batteries:

- Turn off and disconnect the UPS from the mains power prior to opening the

battery replacement door.

- Remove rings, watches, and other metal objects.

- Use a Phillips (cross head) screwdriver with insulated grips.

- Do not lay tools or other metal objects on top of the batteries.

- If the battery replacement kit is damaged in any way or shows signs of

leakage, contact your dealer immediately.

- Do not dispose of batteries in a fire, the batteries may explode.

- If you feel unqualified to replace the batteries, do not open the battery door.

Call Liebert Technical Support (LTS). World Wide Technical Support

numbers are located at the end of this section.

MINI-TOWER BATTERY REPLACEMENT

FOR 700/1000 VA MINI-TOWER MODELS:

1. Gently lay the UPS on its right side.

2. Loosen and remove the five screws on the battery door. Remove the door

by sliding it toward the rear of UPS and lifting it off. Lay the battery door

aside for reassembly.

3. Gently pull battery wiring out and disconnect the battery connector.

4. Grasp the battery assembly, and pull it out of the UPS.

5. Unpack the new battery assembly taking care not to destroy the packing.

Compare new and old battery assemblies to make sure they are the same

quantity and voltage rating (see specifications). If so, proceed with step 6;

otherwise STOP and contact your dealer or LTS.

6. Slide the new battery assembly into the cavity, noting the connector is facing

outward. Connect the battery connector together.

NOTE: There will be a small spark when connecting the battery connector.

This is normal and will not harm you or the UPS.

7. Replace battery door by inserting the three metal tabs into the slots and

pushing it toward the front of the UPS. Replace and tighten the five screws

to lock the battery door closed.

Page 19

19

8. Carefully stand the UPS upright. Connect the UPS to the mains supply

socket and turn on the UPS by pressing the on button. The UPS is ready for

normal operation.

9. Dispose of batteries in accordance with your local laws and regulations.

FOR 1000 TO 3000 VA RACK/TOWER MODELS:

CAUTION: The battery assembly is heavy. Take proper precautions when lifting

or moving it.

TOWER MODELS ONLY:

- Remove top cover by removing the two screws located on rear of top cover.

Push the top cover towards the back of UPS and lift off. Remove the two

flange screws near the front of UPS.

- Gently lay the UPS on its right side and remove the two front rubber feet.

Continue with Rack/Tower Models battery replacement procedures.

RACK/TOWER MODELS:

1. Grasp the front bezel (cover) and pull forward for removal.

NOTE: The two securing flanges must be removed before front bezel

(cover) can be removed.

2. Remove the two screws from the small battery door. Remove the door by

pulling it forward and lifting it off. Lay aside for reassembly.

NOTE: For 2000/3000 VA models, the small door contains a connector that

disconnects battery into a lower, safer voltage.

3. Loosen the five screws of the large battery door. Remove the door by

pulling it forward and lifting it off. Lay aside for reassembly.

4. Pull battery assembly out approximately 50mm (2 in). Gently pull the battery

wiring out and disconnect the battery connector.

5. Completely remove battery assembly from the UPS.

6. Unpack the new battery assembly taking care not to destroy the packing.

Compare new and old battery assemblies to make sure they are the same

quantity and voltage rating (see specifications). If so, proceed with the next

step; otherwise STOP and contact your dealer or LTS.

7. Slide the new battery assembly into the cavity, leaving 50mm (2 in).

8. Connect the battery wire connectors together.

NOTE: On 1000/1500 VA models, there will be a small spark when

connecting the connectors. This is normal and will not harm you or the UPS.

9. Slide battery assembly completely into the UPS, reposition the large battery

door and replace the screws removed in step 3.

10. Reposition small battery door and replace the screws removed in step 2 to

lock top battery door closed. On 2000/3000 VA models, make sure the top

door connection is made.

11. Replace front bezel (cover) on UPS. Replace the securing flanges (for Rack

Tower procedures) and flange screws to secure bezel in place. For Tower

procedures, replace the two front rubber feet, stand unit upright, and replace

the top cover. Connect the UPS to the mains supply socket and turn on the

UPS by pressing the On button. The UPS is ready for normal operation.

12. Dispose of batteries in accordance with your local laws and regulations.

Page 20

20

RACK / TOWER BATTERY REPLACEMENT

Large battery door

small battery door

Small battery door

Front bezel (cover)

w/top cover removed

Top cover

screws

Rear View Aerial View

Two front

rubber feet

Flange

screws

Large battery

door

Screw hidden by

Battery connector

Page 21

21

UPSTATION GXT BATTERY RUN TIMES

(Discharge times are at 25° C ambient)

Internal Battery (minutes)

Load% 700MT 1000MT 1000RT 1000RTE 1500RT 2000RT 3000RT

10% 52 94 94 169 78 160 101

20% 40 45 45 127 39 83 51

30% 32 33 33 94 27 47 28

40% 24 24 24 68 20 34 20

50% 18 18 18 49 15 27 15

60% 15 14 14 36 11 21 12

70% 12 12 12 28 9 18 10

80% 10 9 9 23 7 15 8

90% 8 7 7 19 6 13 7

100% 6 6 6 17 5 11 6

Internal Battery + 1 External Battery Cabinet (minutes)

Load% 700MT 1000MT 1000RT 1000RTE 1500RT 2000RT 3000RT

10% N/A N/A 479 552 408 343 273

20% N/A N/A 255 335 215 204 140

30% N/A N/A 150 210 126 133 78

40% N/A N/A 110 152 95 100 57

50% N/A N/A 85 115 75 77 44

60% N/A N/A 66 88 57 60 35

70% N/A N/A 56 72 48 50 30

80% N/A N/A 48 62 40 43 26

90% N/A N/A 41 52 35 36 22

100% N/A N/A 35 45 29 31 18

Internal Battery + 2 External Battery Cabinets (minutes)

Load% 700MT 1000MT 1000RT 1000RTE 500RT 2000RT 3000RT

10% N/A N/A 848 920 718 623 444

20% N/A N/A 425 505 365 345 236

30% N/A N/A 243 303 208 211 138

40% N/A N/A 196 238 164 156 100

50% N/A N/A 168 198 139 120 75

60% N/A N/A 133 155 112 94 59

70% N/A N/A 109 125 94 81 50

80% N/A N/A 89 103 78 70 43

90% N/A N/A 77 88 68 62 36

100% N/A N/A 66 76 58 54 31

Page 22

22

FUSE REPLACEMENT PROCEDURES

Insert flat blade

screwdriver into slot

Fuse Holder

Remove

Install

CAUTION: Before changing the input fuse, turn off the UPS, and unplug the

supply lead from the AC input supply and from the UPS. Replace the fuse with

the same type and rating.

and turn fuse holder

to remove / install

Input Fuse

1. Remove the fuse holder by inserting a flat blade screwdriver into the slot and

turning to remove as indicated in the figure above.

2. Remove the input fuse.

3. Locate the spare input fuse that is included with the UPS.

4. Insert the spare fuse into the fuse holder, and reinstall assembly into the

UPS. Using the screwdriver, rotate clockwise until fuse holder locks into

position.

5. Reconnect the input power lead to the UPS, and the input power lead to the

input AC supply.

6. Restart the UPS. The UPS is ready for normal operation.

NOTE: For 1500 VA, 2000 VA, and 3000 VA units, reset circuit protector.

AUDIBLE ALARM CONDITIONS

CONDITION ALARM

Battery mode

(utility failure)

Low battery

Output overload (bypass) One short beep every half second

Over temperature (bypass) One second beep every four seconds

DC Bus overvoltage (bypass) One second beep every four seconds

Control power supply failure (bypass)

PFC failure (bypass) One second beep every four seconds

Inverter failure One second beep every four seconds

Battery Test failure Two second beep every minute

One short beep every ten seconds; more

than two minutes of run time remaining

Two short beeps every five seconds; less

than two minutes of run time remaining

One second beep every four seconds

Page 23

23

TROUBLESHOOTING

BATTERY

Load / Battery

Level Indicators

The information below indicates various symptoms a user may encounter in the

event the UPStation GXT™ develops a problem. Use this information to

determine whether external factors cause the problem and how to remedy the

situation.

1. The fault indicator will illuminate indicating the UPS detected a problem.

2. An alarm will sound, alerting that the UPS requires attention.

3. One or more additional load/battery level LED indicators will be illuminated

to provide a diagnostic aid to the operator, as described below:

Fault

!

BYPASS

E

D

C

B

A

All. On bypass due to output overload (beep every half second)

A. On bypass due to over temperature condition (beep every 4 seconds)

B. On bypass due to DC bus overvoltage (beep every 4 seconds)

C. On bypass due to control power supply failure (beep every 4 seconds)

D. On bypass due to PFC failure (beep every 4 seconds)

E. On bypass due to inverter failure (beep every 4 seconds)

A&C. UPS failed battery test (long beep every minute)

C&E. UPS shutdown due to command from communication port (SNMP); no beep

The fault indicators will be illuminated indefinitely while battery charger is

operational, or for a maximum of 5 minutes while battery charger is not

operational. If a problem persists consult your dealer, or contact Liebert

Technical Support (LTS). World Wide Technical Support numbers are located at

the end of this section.

UPS

ON

AC

INPUT

Page 24

24

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

UPS fails to start when

on button is pressed

Battery indicator is

illuminated

UPS has reduced battery

time

Fault and Bypass

indicators and all load

level LEDs are

illuminated

Fault and Bypass

indicators and diagnostic

LED A are illuminated

Fault and Bypass

indicators and diagnostic

LED B are illuminated

Fault and Bypass

indicators and diagnostic

LED C are illuminated

Fault and Bypass

indicators and diagnostic

LED D are illuminated

Fault and Bypass

indicators and diagnostic

LED E are illuminated

Fault and Bypass

indicators and diagnostic

LED A & C are

illuminated

Fault and Bypass

indicators and diagnostic

LED C & E are

illuminated

UPS is short circuited or

overloaded

Internal fuse is blown,

indicating internal fault

UPS not plugged in UPS is operating from battery mode,

UPS input protection has

opened

Mains voltage out of UPS

input range.

Batteries not fully charged Keep UPS plugged in continuously at

UPS is overloaded Check load level display and reduce load

Batteries may not be able to

hold a full charge due to age

UPS overloaded or load

equipment is faulty

UPS internal fan has a

problem or UPS shutdown

due to temperature condition.

Load is on bypass power

UPS internal DC bus

overvoltage

UPS power control fault. UPS requires service. Contact your

UPS PFC fault. UPS requires service. Contact your

UPS inverter fault. UPS requires service. Contact your

UPS failed the battery test. Replace batteries. Contact your dealer

UPS shutdown due to a

command from the

communications port(s)

Ensure UPS is off. Disconnect all loads

and ensure nothing is lodged in output

sockets. Ensure loads are not defective

or shorted internally.

Do not attempt to open or service the

UPS. Contact your dealer or LTS.

make certain UPS is securely plugged

into the wall socket

UPS is operating from battery mode.

Save data and close applications.

Replace UPS input fuse or reset input

breaker, then restart UPS.

UPS is operating from battery mode.

Save data and close applications.

Ensure mains supply voltage is within

acceptable limits for UPS.

least 24 hours to recharge batteries

level

Replace batteries. Contact your dealer

or LTS for replacement battery kit

Check load level display and remove

non-essential loads. Recalculate load

VA and reduce number of loads

connected to UPS. Check load

equipment for faults.

Ensure UPS is not overloaded,

ventilation openings not blocked, or room

ambient temperature not excessive.

Wait 30 minutes to allow UPS to cool,

then restart UPS. IF it does not restart,

contact your dealer or LTS.

UPS requires service. Contact your

dealer or LTS.

dealer or LTS.

dealer or LTS.

dealer or LTS.

or LTS.

Your UPS has received a signal or

command from the attached computer. If

this was inadvertent, ensure the

communication cable used is correct for

your system. For assistance, contact

your dealer or LTS.

Page 25

25

SPECIFICATIONS

MODEL NUMBER GXT700MT-230 GXT1000MT-230

MODEL RATING VA/W 700 / 490 1000 / 700

DIMENSIONS: mm (in)

Unit

W x D x H

Shipping

W x D x H

WEIGHT: kg (lbs)

Unit 13.1 (28.8) 15.8 (34.8)

Shipping 15.0 (33.0) 17.7 (39.0)

INPUT AC PARAMETERS

Voltage Range (typical) 230 VAC nominal; variable based upon output load

100% - 70% Loading 160-163 VAC to 273-276 VAC

70% - 30% Loading 140-143 VAC to 273-276 VAC

30% - 0% Loading 120-122 VAC to 273-276 VAC

Frequency 48.1 - 51.9 Hz or 57.6 - 62.4 Hz; auto sensing

Input connector IEC320-10A IEC320-10A

OUTPUT AC PARAMETERS

Output Sockets (4) IEC320-10A (4) IEC320-10A

Voltage 208/220/230/240 (switch selectable) VAC; ±3%

Frequency 50 Hz or 60Hz

Waveform Sinewave

Main Mode Overload 200% for 8 cycles; 130% for 10 seconds with transfer to bypass

BATTERY PARAMETERS

Type Valve-regulated, nonspillable, lead acid

Qty. x Voltage x Rating 2 x 12V x7 or 7.2 AH 3 x 12V x 7 or 7.2 AH

Back-up Time See Typical Battery Discharge Curves

ENVIROMENTAL

Operating Temperature 0° C to +40° C (+32° F to +104° F)

Storage Temperature -15° C to +50° C (+5° F to +122 °F)

Relative Humidity 0% to 95%, non-condensing

Operating Elevation Up to 3000 m (10,000 ft.) at 40° C without derating

Storage Elevation 15.000 m (50,000 ft.) maximum

Audible Noise <45 dBA, at 1 meter

AGENCY

Safety EN50091-1, TUV/GS Listed, CE Low Voltage Directive compliant

RFI/EMI EN55022, Class B; CE EMC Directive compliant

Immunity

162 x 430 x 225

(6.4 x 15.6 x 8.9)

280 x 502 x 362

(11.0 x 19.75 x 14.25)

IEC 801-2, Level 4 / IEC 801-3, Level 3 / IEC 801-4,

Level 4 / IEC801-5,Level 3

162 x 430 x 225

(6.4 x 15.6 x 8.9)

280 x 502 x 362

(11.0 x 19.75 x 14.25)

Page 26

26

SPECIFICATIONS

MODEL NUMBER GXT1000RT-230 GXT1000RTE-230

MODEL RATING VA/W 1000 / 700 1000 / 700

DIMENSIONS: mm (in)

Unit

W x D x H

Shipping

W x D x H

WEIGHT: kg (lbs)

Unit 23.6 (51.9) 31.1 (68.4)

Shipping 26.8 (59.0) 34.3 (75.5)

INPUT AC PARAMETERS

Voltage Range (typical) 230 VAC nominal; variable based upon output load

100% - 70% Loading 160-163 VAC to 273-276 VAC

70% - 30% Loading 140-143 VAC to 273-276 VAC

30% - 0% Loading 120-122 VAC to 273-276 VAC

Frequency 48.1 - 51.9 Hz or 57.6 - 62.4 Hz; auto sensing

Input connector IEC320-10A IEC320-10A

OUTPUT AC PARAMETERS

Output Sockets (4) IEC320-10A (4) IEC320-10A

Voltage 208/220/230/240 (switch selectable) VAC; ±3%

Frequency 50 Hz or 60Hz

Waveform Sinewave

Main Mode Overload 200% for 8 cycles; 130% for 10 seconds with transfer to bypass

BATTERY PARAMETERS

Type Valve-regulated, nonspillable, lead acid

Qty. x Voltage x Rating 3 x 12V x 7 or 7.2 AH 6 x 12V x 7 AH

Back-up Time See Typical Battery Discharge Curves

ENVIROMENTAL

Operating Temperature 0° C to +40° C (+32° F to +104° F)

Storage Temperature -15° C to +50° C (+5° F to +122 °F)

Relative Humidity 0% to 95%, non-condensing

Operating Elevation Up to 3000 m (10,000 ft.) at 40° C without derating

Storage Elevation 15.000 m (50,000 ft.) maximum

Audible Noise <50 dBA, at 1 meter

AGENCY

Safety EN50091-1, TUV/GS Listed, CE Low Voltage Directive compliant

RFI/EMI EN55022, Class B; CE EMC Directive compliant

Immunity

177 x 522 x 430

(7.0 x 19.3 x 16.9)

340 x 660 x 565

(13.38 x 26.0 x 22.25)

IEC 801-2, Level 4 / IEC 801-3, Level 3 / IEC 801-4, Level 4 / IEC801-

5,Level 3

177 x 522 x 430

(7.0 x 19.3 x 16.9)

340 x 660 x 565

(13.38 x 26.0 x 22.25)

Page 27

27

SPECIFICATIONS

MODEL NUMBER GXT1500RT-230 GXT2000RT-230 GXT3000RT-230

MODEL RATING VA/W 1500 / 1050 2000 / 1400 3000 / 2100

DIMENSIONS: mm (in)

Unit

W x D x H

Shipping

W x D x H

WEIGHT: kg (lbs)

Unit 27.7 (60.9) 36.8 (80.9) 39.0 (85.9)

Shipping 30.9 (68.0) 40.0 (88.0) 42.3 (93.0)

INPUT AC PARAMETERS

Voltage Range (typical) 230 VAC nominal; variable based upon output load

100% - 90% Loading 184-187 VAC to 273-276 VAC

90% - 70% Loading 160-163 VAC to 273-276 VAC

70% - 30% Loading 140-143 VAC to 273-276 VAC

30% - 0% Loading 120-122 VAC to 273-276 VAC

Frequency 48.1 - 51.9 Hz or 57.6 - 62.4 Hz; auto sensing

Input connector IEC320-10A IEC320-10A IEC320-16A

OUTPUT AC PARAMETERS

Output Sockets (4) IEC320-10A (4) IEC320-10A (4) IEC320-10A;

Voltage 208/220/230/240 (switch selectable) VAC; ±3%

Frequency 50 Hz or 60Hz

Waveform Sinewave

Main Mode Overload 200% for 8 cycles; 130% for 10 seconds with transfer to bypass

BATTERY PARAMETERS

Type Valve-regulated, nonspillable, lead acid

Qty. x Voltage x Rating 4 x 12V x 7 or 7.2 AH 8 x 12V x 6.5 or 7.0 AH 8 x 12V x 7 or 7.2 AH

Back-up Time See Typical Battery Discharge Curves

ENVIROMENTAL

Operating Temperature 0° C to +40° C (+32° F to +104° F)

Storage Temperature -15° C to +50° C (+5° F to +122 °F)

Relative Humidity 0% to 95%, non-condensing

Operating Elevation Up to 3000 m (10,000 ft.) at 40° C without derating

Storage Elevation 15.000 m (50,000 ft.) maximum

Audible Noise <50 dBA, at 1 meter

AGENCY

Safety EN50091-1, TUV/GS Listed, CE Low Voltage Directive compliant

RFI/EMI EN55022, Class B; CE EMC Directive compliant

Immunity

177 x 522 x 430

(7.0 x 19.3 x 16.9)

340 x 660 x 565

(13.38 x 26.0 x 22.25)

IEC 801-2, Level 4 / IEC 801-3, Level 3 / IEC 801-4, Level 4 / IEC801-5,Level 3

177 x 522 x 430

(7.0 x 19.3 x 16.9)

340 x 660 x 565

(13.38 x 26.0 x 22.25)

177 x 522 x 430

(7.0 x 19.3 x 16.9)

340 x 660 x 565

(13.38 x 26.0 x 22.25)

(1) IEC320-16A

Page 28

28

BATTERY CABINET SPECIFICATIONS

MODEL NUMBER GXT36VBATT GXT48VBATT GXT96VBATT

Used w/ UPS Model 1000RT 1500RT

DIMENSIONS: in (mm)

Unit

W x D x H

Shipping

W x D x H

WEIGHT: lbs (kg)

Unit 61.3 (27.9) 71.6 (32.5) 71.6 (32.5)

Shipping 68.4 (31) 78.7 (35.7) 78.7 (35.7)

BATTERY PARAMETERS

Type Valve-regulated, nonspillable, lead acid

# of Strings x Qty/Str. x

Batt. Voltage x Batt. Rating

Batt. Mfg./ Part # CSB GP1270F2 or Panasonic LC-R127R2CH1

Back-up Time See Typical Battery Discharge Curves

Recharge Time 5 Hours to 95% capacity after full discharge into 100% load

ENVIROMENTAL

Operating Temperature +32° F to +104° F (0° C to +40° C)

Storage Temperature +5° F to +122 °F (-15° C to +50° C)

Relative Humidity 0% to 95%, non-condensing

Operating Elevation Up to 10,000 ft. (3000 m) at 40° C without derating

Storage Elevation 50,000 ft. (15.000 m) maximum

AGENCY

Safety UL 1778, c-UL Listed; TUV, CE LVD compliant

RFI/EMI FCC Part 15, Subpart B, Class A; EN5022 Class B; CE ECM compliant

Immunity

177 x 522 x 430

(7.0 x 19.3 x 16. 9)

13.38 x 26.0 x 22.25

(340 x 660 x 565)

2x3x12Vx7.0 or 7.2 AH 2x4x12Vx7.0 or 7.2 AH 1x8x12Vx7.0 or 7.2

IEEE 587 Category A; IEC 801-2, Level 4;

IEC801-3, Level 3 IEC801-4, Level 4 IEC801-5, Level 3

177 x 522 x 430

(7.0 x 19.3 x 16. 9)

13.38 x 26.0 x 22.25

(340 x 660 x 565)

2000RT/3000RT

177 x 522 x 430

(7.0 x 19.3 x 16. 9)

13.38 x 26.0 x 22.25

(340 x 660 x 565)

AH

Page 29

29

LIMITED WARRANTY

Liebert Corporation extends the following LIMITED WARRANTY to the

purchaser and to its customer (collectively referred to as the "Purchaser"): the

enclosed Uninterruptible Power System (UPS) and components are free from

defects in materials and workmanship under normal use, service, and

maintenance FOR A PERIOD OF TWO YEARS FROM THE DATE OF

ORIGINAL PURCHASE from Liebert or the Liebert dealer or retailer. THE

FOREGOING WARRANTY IS THE ONLY WARRANTY GIVEN AND NO

OTHER WARANTY IS PROVIDED, EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMITATION, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Certain aspects of disclaimers are not applicable to

consumer products acquired by individuals and used for personal, family, or

household purposes (as distinguished from industrial or other purposes). Local

laws may not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you. This warranty gives you specific legal

rights, and you may have other rights which vary according to local law.

Certain repairs or services are the responsibility of the Purchaser and the

Purchaser is expected to pay for them. This warranty does not extend either to

products with removed or altered serial numbers or to any losses or damages

due to act of God or source external to the product, misuse, accident, abuse,

neglect, negligence, unauthorized modification, alteration, or repair, use beyond

rated capacity, or improper installation, maintenance, application or use,

including, without limitation, use in a manner contrary to the accompanying

instructions or applicable codes. WARNING: Warranty is void if the battery is

allowed to discharge below the minimum battery cutoff point. To prevent such

discharge DO NOT leave the unit power switch "ON" for more than two (2) days

without AC power being supplied to the UPS. The battery must be recharged

every four (4) to six (6) months when not in use.

If the UPS fails to conform with the above warranty within the two year warranty

period, Liebert will repair or replace the UPS, at Liebert's option. Repairs or

replacements are warranted for the remainder of the original warranty period.

Purchaser, to make a warranty claim, should call +44 (0)1793 553355 to obtain

a Returned Goods Authorization number and shipping instructions. Return

transportation costs to Liebert are the responsibility of the Purchaser.

This product is not recommended, and the Company will not knowingly sell this

“LIFE SUPPORT” POLICY

product, for use with life support and other designated "critical" devices. ANY

SUCH USE BY A USER AUTOMATICALLY VOIDS AND DISCLAIMS ANY

AND ALL WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY, IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, AND EXPRESS WARRANTIES THAT THIS

PRODUCT WILL CONFORM TO ANY AFFIRMATION OR PROMISE, FOR

THIS PRODUCT AND THE USER AGREES THAT IN NO EVENT SHALL THE

COMPANY BE LIABLE FOR CONSEQUENTIAL OR INDIRECT DAMAGES.

Page 30

30

R

UPStation GXT™

Technical

1050 Dearborn Drive Columbus, OH 43229 614-888-0246

700-3000 VA

230 V

Technical Support

Outside the U.S.A. 614-841-6755

U.S.A. 1-800-222-5877

U.K. +44 (0) 1793 553355

France +33 1 4 87 51 52

Germany +49 89 99 19 220

Italy +39 2 98250 1

Netherlands +00 31 475 503333

E-mail upstech@liebert.com

Web site http://www.liebert.com

Worldwide FAX tech support 614-841-5471

The Company Behind The Products

With more than 500,000 installations

around the globe, Liebert is the world

leader in computer protection systems.

Since its founding in 1965, Liebert has

developed a complete range of support

and protection systems for sensitive

electronics:

• Environmental systems: close-control air

conditioning from 1.5 to 60 tons.

• Power conditioning and UPS with power ranges

from 250 VA to more than 1000 kVA.

• Integrated systems that provide both

environmental and power protection in a single,

flexible package.

• Monitoring and control — on-site or remote —

from systems of any size or location.

• Service and support, through more than 100

service centers around the world, and a 24-hour

While every precaution has

been taken to ensure accuracy

and completeness in this

literature, Liebert Corporation

assumes no responsibility, and

disclaims all liability for

damages resulting from use of

this information or for any errors

or omissions.

©1998 Liebert Corporation All

rights reserved throughout the

world. Specifications subject to

change without notice.

® Liebert and the Liebert logo

are registered trademarks of

Liebert Corporation. All names

referred to are trademarks or

registered trademarks of their

respective owners.

SLI-23131 (4/98) Rev. 2.0

Loading...

Loading...