Page 1

Hiline Slim

Service Manual

Manuale di Assistenza

English

Italiano

cod. 272014 - rev. 12.01.2001

Issued by TDS

Page 2

Page 3

Caution

It is recommended that:

the manual is retained for the entire service life of the machine;

the user reads the manual carefully before carrying out any operations on the machine;

the machine is used exclusively for the purpose for which it is intended; incorrect use of the machine shall release

the manufacturer from any liability.

This manual has been prepared to enable the end-user to carry out only the operations that can made with the pan

els closed. Any operations that require the opening of doors or equipment panels must be carried out only by quali

fied personnel.

Each machine is equipped with an Electric Insulating device which allows the operator to work in conditions of

safety. This device must always be used to eliminate risks during maintenance (electric shocks, scalds, automatic

restarting, moving parts and remote control).

The panel key supplied with the unit must be kept by the person responsible for maintenance.

For identification of the unit (model and serial no.) in case of the necessity for assistance or spare parts, read the

identification label placed on the outside and inside of the unit.

IMPORTANT: this manual may be subject to modification; for complete and up-to-date information the user

should always consult the manual supplied with the machine.

Index

1 - Preliminary operations 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Foreword 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 - Operating limits 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 - Sound pressure levels 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 - Sealing the room 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 - Inspection 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 - Transport 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 - Positioning of air conditioner 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 - Service area 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 - Wall holes 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 - Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 - Electrical and kit connections 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 - Electrical connections 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 - Emergency cooling kit (optional) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 - Start-up 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 - First start-up (or after long halt) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 - Start-up with low outside temperature 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 - Starting and stopping 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 - Operation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 - Adjustment of the condenser fan speed 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 - Emergency cooling (optional) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 - Microprocessor controls 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 - Control logic 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 - Refrigerant R22 and oil charge 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 - Features of the refrigerating fluid R22 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 - Refrigerant charge 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 - Oil charge 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 - Calibrations 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 - Maintenance 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 - Dismantling the unit 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 - Fault finding / alarms 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 - Spare parts 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page 1

English

Page 4

1 - Preliminary operations

1.1 - Foreword

The following manual describes the installation, opera

tion and maintenance of Air Conditioners, series Hiline

Slim (see Fig. 1).

IMPORTANT:

Also consult the manual for the Microface microproces

sor control supplied with the machine (if installed).

1.2 - Operating limits

The units are designed to operate within working ranges

(see Tab. 1).

These limits are referred to new machines or for those

that have been correctly installed and serviced.

The warranty clauses are no longer valid for any damage

or malfunction that may occur during or due to opera

tion outside the application values.

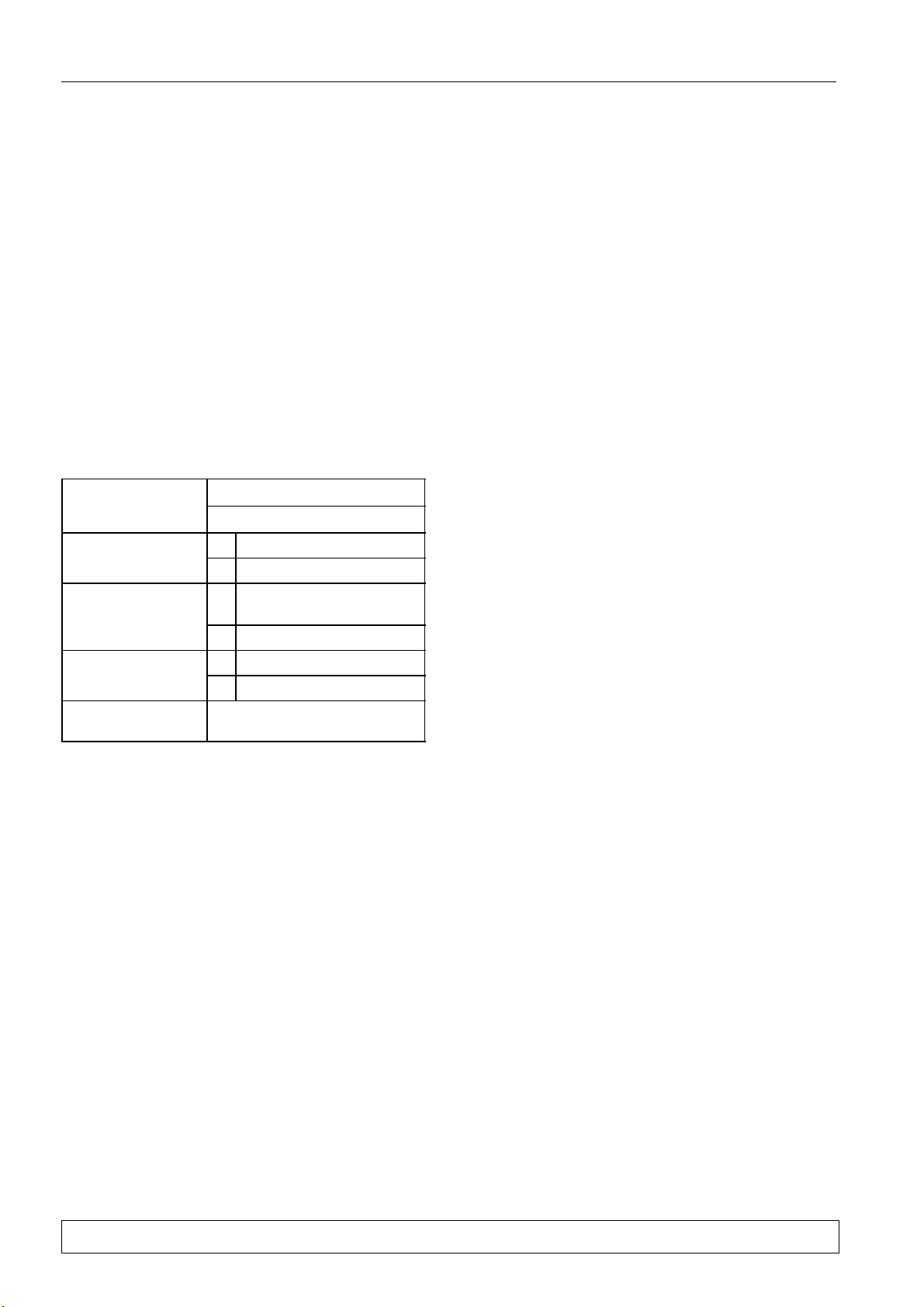

Tab. 1 - Operating limits

Power supply voltage

Outdoor conditions

Indoor conditions with

operating compressor

Storage conditions

External side protection

degree

230 V 10%/1/50 Hz

24/48 30% Vdc with INVERTER

da: -10C (-30C with VARIEX)

a: 43C

20C 30% R.H. e 20C 80%

da:

R.H.

a: 35C, 40% R.H.

da: -25C, 5% R.H.

a: 55C, 90% R.H.

IP 24

1.5 - Inspection

On receiving the equipment immediately inspect its

condition; report any damage to the transport company

at once.

1.6 - Transport

Always keep the unit vertically upright.

If possible transport the unit using a fork lift truck;

otherwise use a crane with belts or cables, avoiding

the exerting of pressure on the top edges of the pack

ing.

Unpack the unit as close as possible to its installation

position. Once unpacked, avoid stress being trans

mitted to its internal components.

1.7 - Positioning of air conditioner

The air conditioner can be installed in any indoor

location where it is not exposed to an aggressive

ambient.

Position the air conditioner so as to ensure optimum

air distribution within the area in which it is to oper

ate, preventing the creation of unconditioned zones.

For the correct positioning of the air conditioner see

Fig. 2 at the end of the manual.

1.8 - Service area

The unit must be provided with a suitable Service Area,

as follows (see Fig. 2):

All ordinary maintenance can be performed both

from the front side and from the rear side (external)

where a minimum area must be left free of obstruc

tions.

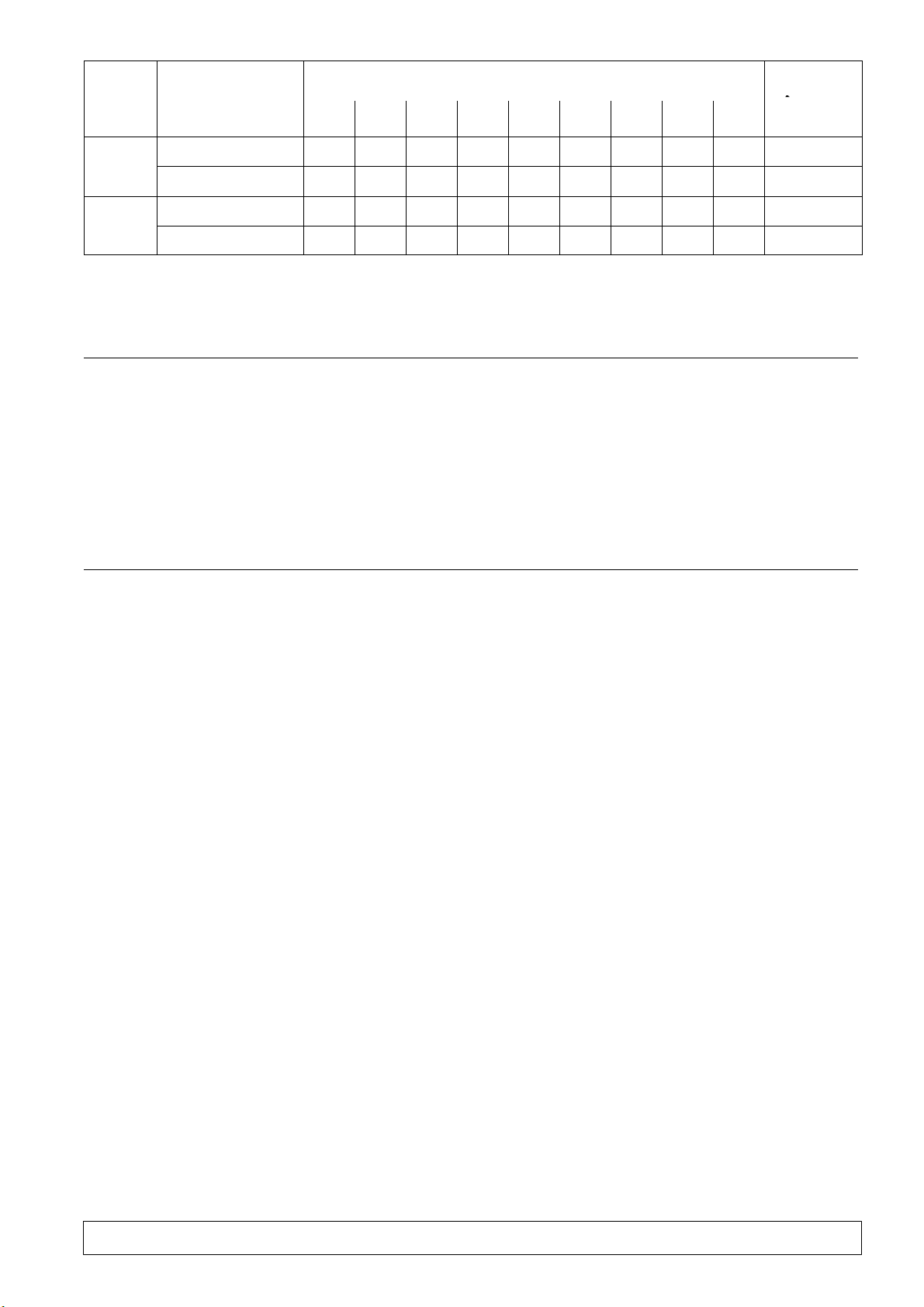

1.3 - Sound pressure levels

Tab. 2 shows, for the internal and the external side, the

maximum sound pressure levels of the units in standard

configuration, in continuous operation, at 2 m from the

front surface of the machine, at 1 m height in free field

conditions. The noise levels have the highest values at

the front of the unit, on the internal side.

1.4 - Sealing the room

To create stable indoor conditions make sure that the

room is airtight by sealing all gaps, cable entries, etc...

1.9 - Wall holes

Make the holes in the wall of the container next to the

unit's position (see Fig. 3).

English

page 2

272014 - 04.02.2000

Page 5

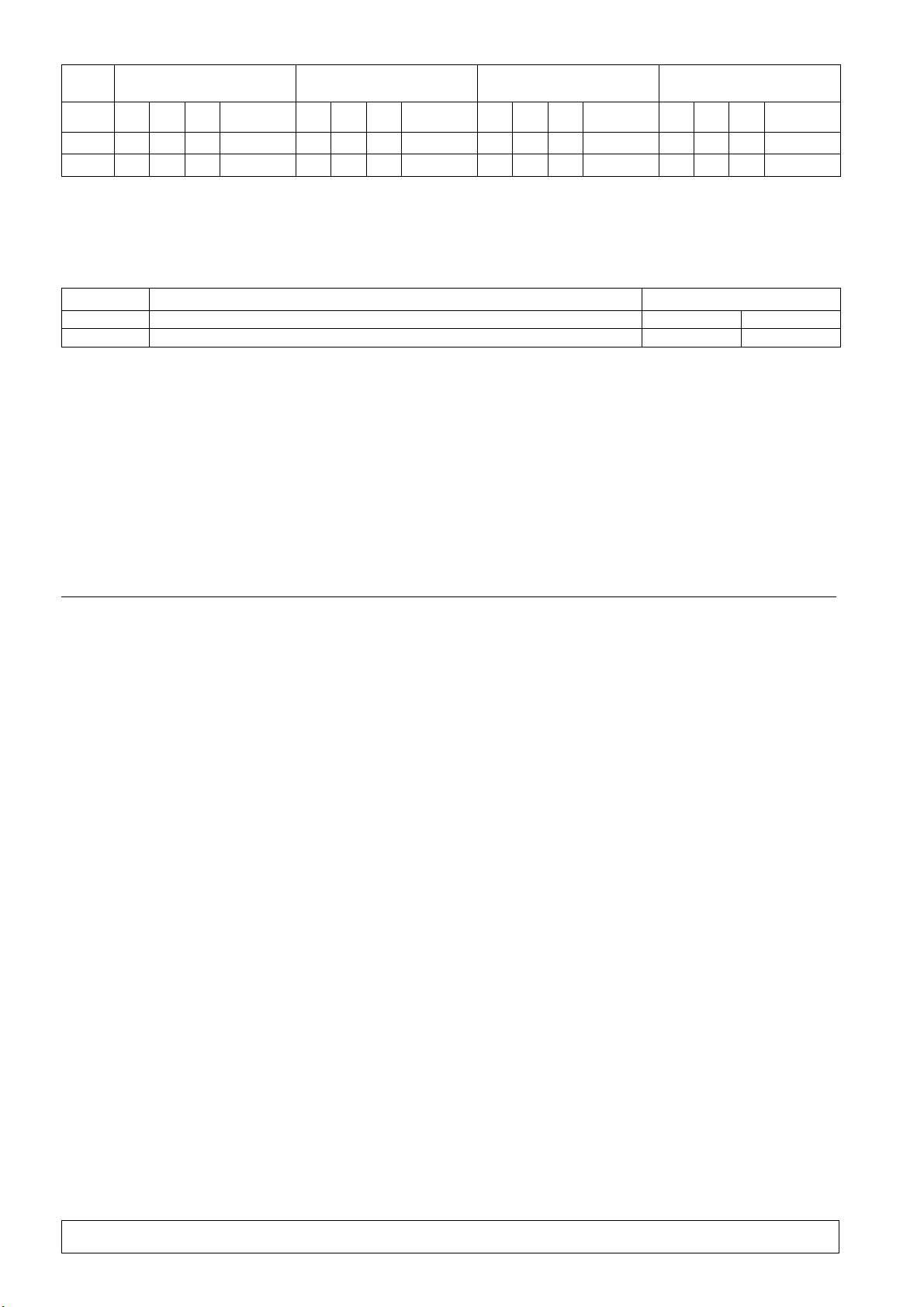

Tab. 2 - Sound pressure levels

Model

p

PKS3

PKS4

Indoor, free field at 2 m

in front of the unit

Outdoor, free field at

2 m in front of the unit

Indoor, free field at 2 m

in front of the unit

Outdoor, free field at

2 m in front of the unit

2 - Installation

Octave band frequency (Hz)

Sound

pressure

31.5 63 125 250 500 1000 2000 4000 8000

[dB(A)]

49 56 62 58 55 54 53 53 51 61

50 51 49 54 51 51 47 44 37 55

49 56 62 58 55 54 53 53 51 61

50 51 49 54 51 51 47 44 37 55

level

For a correct installation proceed as follows (Fig. 4):

Provide the unit with cornice protection elements

(these can be supplied as optional), using the proper

holes and the self-tapping screws with 3.5 mm diam

eter.

In order to avoid that water filters inside the contain

er, provide it with an adhesive rubber gasket.

3 - Electrical and kit connections

Before performing any operations on the electric parts,

make sure that:

all electrical components are undamaged;

all terminal screws are tight;

the supply voltage and frequency are as indicated on

the unit;

the switch QS1 is in open position (OFF);

the automatic switch QS2 on the outer clamps of the

inverter (if installed) are off;

there are no components under voltage.

3.1 - Electrical connections

(see the wiring diagram)

The electrical connections (power supply 230/1/50 and,

for emergency power supply (48 and 24 Vdc) will be car

ried out from the roof of the unit by means of some pro

per holes.

Let the electrical power supply cable (not supplied by

us), pass through the hole made on the unit roof.

Fix the cornice to the shelter wall by means of M4

screws with anchor.

Fix the lower cornice protection element by means of

two M4 screws with anchor.

Provide the unit roof with the fixing bracket to the

wall with two self-tapping screws with 3.5 mm diam

eter.

Note: For the power supply use a screened cable

(minimum section indicated in Tab. 4).

It is advisable to keep the mains power supply cable

as far as possible from the other cables coming out of

the inverter (optional).

Connect the 230V/1/50 Hz line to the main switch

QS1 placed inside the electrical panel.

Concerning the alarm contacts available in the differ

ent versions, these can be found on the terminal

board in the electrical panel.

For the alarm description see Chapter 6 and the

manual of the installed control.

To connect 2 or more units installed in the same con

tainer and provided with the MICROFACE control,

with HIROMATIC interface, use the HIROBUS

cable (supplied with the unit) by connecting it as

shown in the wiring diagram. See the Microface and

Hiromatic manual for the configuration of the

Stand-by units.

page 3

English

Page 6

Tab. 3 - Standard electrical features

S4

20A

4

2

4

2

Evaporator fan Condenser fan Compressor

OA FLA LRA Nom. power

PKS3

PKS4

(*) In the following conditions (ARI 520-78):

1 - - 200 1.5 - - 340 5.9 10 34 1370 - 13 - 3000

1 - - 200 1.5 - - 340 7.1 12 36.5 1700 - 13 - 3000

Condensing temperature 54.4C,

Ambient temp. 35C,

Evaporation temp. 7.2C,

Sub-cooling temp.: 8.3C

Overheating temp.: 11C

[W]

OA FLA LRA Nom. power

Tab. 4 - Protection switch and cable sizing

Protection switch with differential current In = 0.3A

PKS3-PK

Heater

(2 x unit)

OA

[W]

V230/1/50Hz 230 Vac 24/48Vdc

FLA LRA Nom. power

(*)

[W] (*)

OA FLA LRA Nom. power

Cable sizing

2

mm

mm

[W]

2

3.2 - Emergency cooling kit

(optional)

The emergency cooling kit consists of an inverter and a

single-phase transformer installed inside the electric

board.

Operating as shown in par. 3.1, supply power up to 48

(24) Vdc inside the electrical panel, by means of a

screened cable with a minimum section as shown in

4 - Start-up

4.1 - First start-up (or after a long halt)

Before starting the air conditioner do check if the power

supply voltage and frequency comply with those indi

cated on the identification plate of the unit.

After that, the conditioner can be started putting the

automatic switch QS1 to ON position. On the units pro

vided with this switch also press the ON-OFF push but

ton on the Hiromatic interface.

Check the electrical input of all components and

compare it with the data shown in the Tab. 3. Check that

there are no active alarms; wait until the system reaches

the standard operation and then make the following

checks:

check that the fans are working correctly;

make sure that the temperature is guaranteed and

the compressor and the heaters (optional) work

when required;

only on versions provided with the Variex option (speed

adjustment)make sure that the speed adjuster of the

fan of the condensing section is correctly calibrated

and controls the fan operation (see chapter 8).

Tab. 4. Connect the possible ground line to the positive

pole of the 48 Vdc power supply. Connect the cable

screening to the metal cable clamp and perform the con

nections following the wiring diagram carefully.

Attention: Connect the poles correctly.

As regards the units with emergency supply through

external Inverter, make the connections as specified in

the electrical diagram.

4.2 - Start-up with low outside temperature

In case of low outside temperature (<0C), the unit

start-up is helped by the delay time of the low pressure

alarm activation, within which the pressures in the refrig

erating circuit reach the standard operation values.

4.3 - Starting and stopping

For the units provided with HIROMATIC interface:

start the unit by pressing the ON-OFF push button

on the Hiromatic (confirmed by SYS.ON on the

display);

stop the unit by pressing the ON-OFF push button

on the Hiromatic (confirmed by SYS.OFF. on the

display).

Note: turn the main switch QS1 and the QS2 Inverter

switch off only if the unit is stopped for a long time.

For the units provided with the Microface control, you

can switch on/off using the main switch QS1, which is ac

cessible by opening the hinged higher panel acting on

quick lock system.

English

page 4

272014 - 04.02.2000

Page 7

5 - Operation

The unit operation is completely automatic.The below

sequence explains (with the assistance of Fig. 5 - Opera

tion diagram) how the unit operates (see also Fig. 6

Refrigerating circuit):

1) The temperature sensor, positioned inside the shel

ter, informs the control about the condition of the air

to be conditioned.

2) The control compares the received information with

the Set Point values (= min. indoor temperature

required) and Differential programmed values, pre

setting the air conditioner for the air conditioning

with the following modes:

Cooling (Fig. 5)

The compressor (9) and the fans (6) and (10) are started

up when the temperature of the room to be conditioned

exceeds the preset value. The intake air from the centrif

ugal fan (6) enters the unit through the lower gap (A),

goes immediately through the filter (1) and then the

evaporator (5).

The cool refrigerant flows through the evaporator (5),

thus cooling the air passing through it. The conditioned

air is conveyed into the conditioned room through the

discharge opening (B).

The heat taken from the room and the one generated by

the conditioner motor operation are disposed through

the condenser (11) placed in the lower part of the unit

and hit, thanks to the fan (11), by the outside air. The fan

operation is managed in ON - OFF mode (or with

Variex, see par. 5.1) as a function of the condensing pres

sure.

For the operation logics of the control see chapter 6.

Heating (optional)

The air heating is achieved by means of electric heaters

(7), located in the air flow and activated according to the

logics set on the control (see chapter 6).

The manual reset of the safety thermostat (15), placed

on the electrical heaters is carried out throught the front

after removing the grill panel.

Cooling in Freecooling (optional) - (Fig. 5)

When the outside air temperature is lower than the

inside air temperature by some degrees, it is possible to

use this difference to refresh the shelter inside part by

direct intake of the outside air, i.e. without using the

compressor. Thus it is possible to achieve a considerable

energy saving.

When the expected conditions occur, the servo-control

(2), managed by the Microface control, opens the mov

ing damper (12) separating the flows of the inside air and

outside air. In this way the outside air sucked by the fans

(6) flows inside the container and is discharged through

the openings of the condensing section. The air flows

present in this operation mode are shown in Fig. 5).

The opening degree of the damper is determined as a

function of the set point value to be kept and of the

intake air temperature (see chapter 6).

5.1 - Adjustment of the condenser fan speed

(compulsory for outside temperatures

-10 / -30C)

A sensor is positioned so as to detect constantly the con

densing pressure of the refrigeration gas. On the basis of

this information, an electronic device (Variex) adjusts

the fan rotation speed in order to keep the condensing

pressure within the allowed values. In this way, besides

optimizing the compressor operation, you can have a

remarkable reduction of the sound pressure level

(mainly during the night), an easier start-up of the com

pressor at low temperatures and some energy saving.

For the calibration of the speed adjuster refer to chapter

8.

5.2 - Emergency cooling

(optional)

This option is available for all those applications where it

is mostly important to guarantee air flow inside the shel

ter, even in the event of mains current drop. In this case,

by an inverter and a transformer, the units can be sup

plied by the emergency coils at 24 or 48 V dc (see Fig. 7).

The intervention mode of the emergency system

depends on the switch QS1 condition:

QS1 = ON

If the main power supply is not cut out, the emer

gency system remains inactive;

if there is no voltage on the main power supply line,

the inverter is automatically activated and, being sup

plied by the emergency coils at 24/48 V dc, by the

24/48 V / 230 V transformer it supplies the fan of the

evaporating section and the electronic control. So all

functions of the unit are still managed, allowing the

inside air to recirculate (or the outside air to come in,

if the unit is provided with freecooling) if the temper

ature inside the shelter is not within the permitted

range. In this operation mode, a relay contact (KM6)

signals the activation of the inverter system.

If the voltage of the emergency coils goes below the

safety value, the inverter system is automatically deactivated.

QS1 = OFF

In this abnormal condition occurring, for instance,

after a short-circuit in the unit the inverter is auto

matically de-activated.

CAUTION:

For safety reasons do disconnect the automatic switch

QS2 when you want to stop the unit.

page 5

English

Page 8

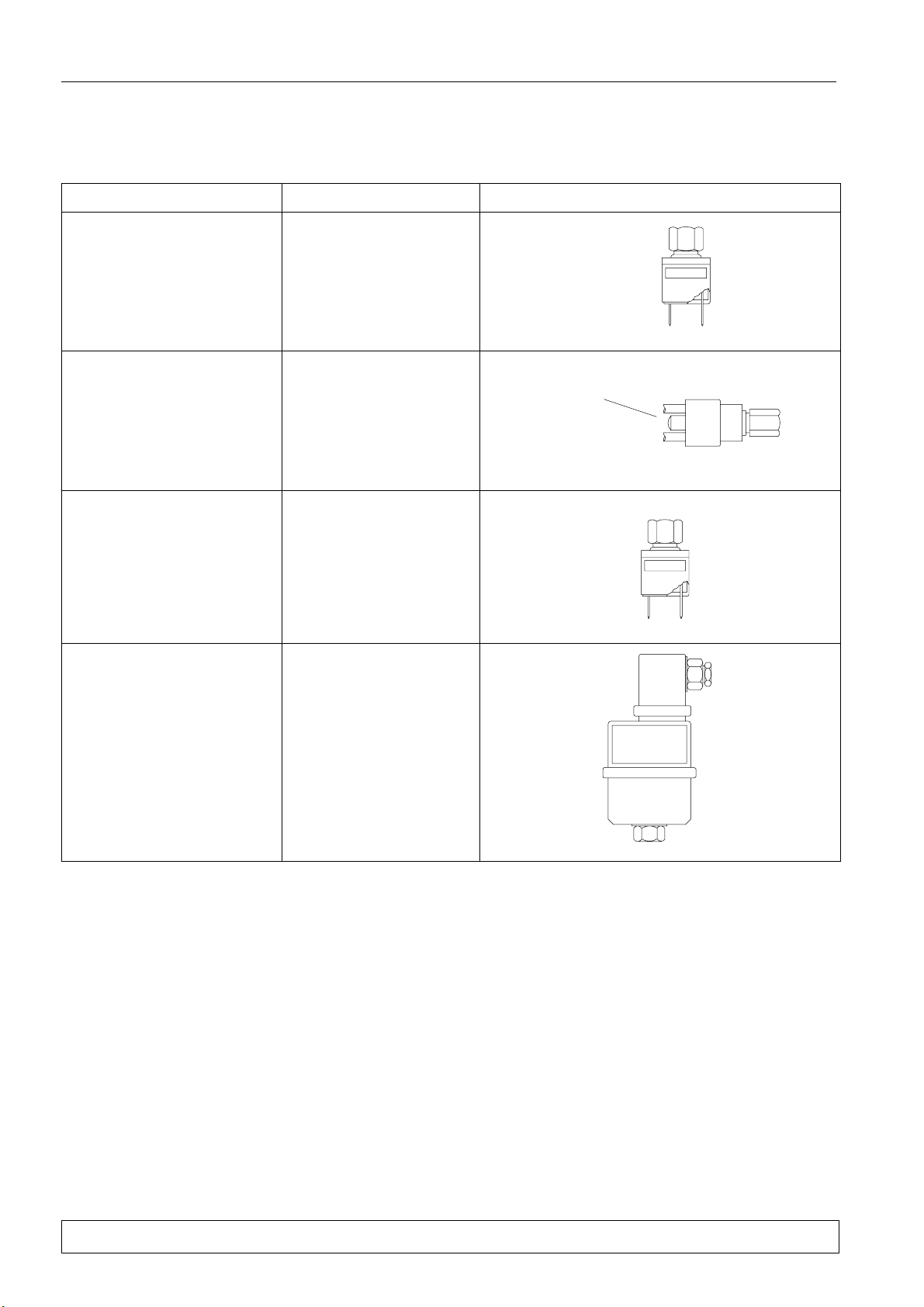

6 - Microprocessor controls

The machine is available in four different operating con

figurations:

1) chill unit only;

2) chill and hot unit;

3) unit with freecooling, chill only;

4) unit with freecooling, chill and hot.

All versions are equipped with the new Microface

microprocessor control.

6.1 - Control logic

These units are managed by the Microface microproces

sor control and may be combined with the Hiromatic

control for the complete monitoring of all unit operation

parameters (see enclosed manual).

The control algorithm is based on a single-stage adjust

ment for the heating and cooling with the compressor

and on an adjustment of the proportional-integrative

type for the cooling in the Freecooling mode, with setting

of the set point and proportional band (P) (Fig. d.)

The control manages all activation delays of the com

pressor, and minimum times, in order to guarantee the

proper operation and to extend its life as much as pos

sible.

The activation of the Freecooling mode occurs as a func

tion of the difference (that can be set) between the inside

temperature and the outside temperature. This means

that if the difference between the 2 temperatures

increases beyond a certain value, the unit automatically

passes to the Freecooling function: the compressor is

de-activated and the analog output controls the

3-point servomotor of the damper. The damper open

ing is varied in order to maintain the inside temperature

equal to setpoint and as a function of the intake air tem

perature, which cannot be lower than a preset safety

value.

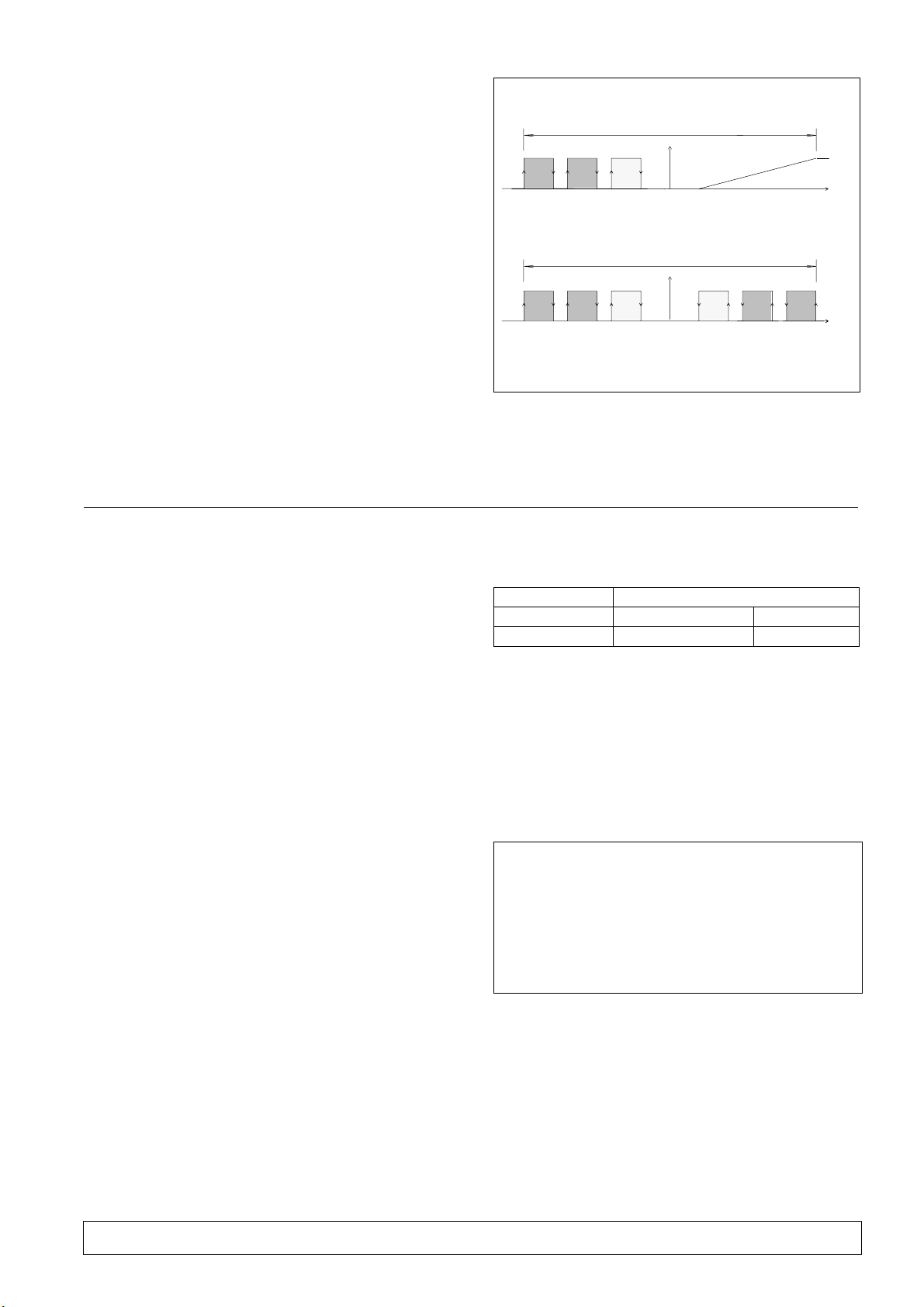

Fig. a Compressor, heater and damper opening opera

tion

P Band

Freecooling

mode

ing mode remains de-activated for 1/2 hour. If the inside

temperature exceeds the proportional band by more

than 50%, the Freecooling mode is immediately deactivated and remains in this condition for 1/2 hour and

the cooling by refrigerating compressor intervenes.

6.1.1 - Start-Stop

Altogether there are three ways for starting or stopping

the unit:

a) the isolator switch inside the electrical panel;

b) the digital input of the Microface card;

c) the ON-OFF push button on the Hiromatic interface

(optional).

Priority: a) b) c) must be considered as 3 series contacts;

only if all contacts are on, the unit can operate.

6.1.2 - Alarm control

The terminal board of the elertical panel is provided with

2 clean exchange contacts, on standard configuration,

used as follows:

1) General alarm:

compressor low pressure

compressor high pressure (reset on the pressure

switch)

sensor fault

memory fault

fan fault (with optional sensors)

2) General warning - signalling of various failure

conditions, among which:

high temperature

low temperature

heater thermostat (reset on the thermostat)

Notes:

both the alarm and the warning must be reset manu

ally on the Microface.

An alarm causes the unit to stop and the unit in

stand-by (if available) to intervene. If the unit is in

stand-alone, the high and low pressure alarms don't

stop the machine to allow the operation in Freecool

ing mode in the proper conditions.

The warning doesn't cause the unit to stop.

When the heater safety thermostat intervenes, the

reset will be carried out on the thermostat (15) acces

sibble by removing the internal fan side panel.

Set CoolingHeating C

P Band

Compressor

cooling mode

Set CoolingHeating C

If the inside temperature exceeds the proportional band

by more than 20% for longer than 10 minutes, the unit

passes to the cooling with compressor and the Freecool

English

page 6

6.1.3 - Optional alarm card

Besides the components described for the standard con

figuration, on the alarm card - which can be supplied as

optional - there are relay contacts to obtain the follow

ing alarms separated:

1) compressor high and low pressure

2) Clogged filter alarm

3) Fan fault

4) High temperature

5) Low temperature

These alarms cause the unit to stop in the same ways as

described in the previous paragraph.

For the detailed description of the alarms, see the Micro

face manual enclosed.

272014 - 04.02.2000

Page 9

6.1.4 - Unit in stand-by

The control of the unit in stand-by is completely auto

matic thanks to the possibility to connect the Microface

control.

A unit in stand-by starts in the event of an alarm which

stops the main unit; this occurs even if the main unit is

switched off or disappears from the system due to a fault

on the control connecting bus.

The rotation per hour of the units in stand-by occurs

automatically every 24 hours, so as to allow a homoge

neous wear of the system components.

If the system is connected to the Hiromatic interface, it is

possible to set a different rotation control.

If several units are simultaneously working with the same

set point, the temperature used for the control is the

average of the detected ones; further, in the operation

with compressor, the proportional band is divided in as

many parts as twice the number of units belonging to the

system, so as to shut the total available refrigerating

capacity.

The operation in Freecooling mode is homogeneous and

simultaneous on all units.

Fig. b, shown as an example, describes the operation of a

system consisting of 3 units.

7 - Refrigerant R22 and oil charge

Fig. b System with 2 units in stand-by -

Microface control

Freecooling mode

P Band

1

2

3

Set CCoolingHeating

Compressor cooling mode

P Band

3

1 = main unit

2 = unit in stand-by

3 = unit in stand-by

11

223

Set CCoolingHeating

THESE OPERATIONS MUST BE PERFORMED BY

AN EXPERIENCED REFRIGERATION TECHNI

CIAN.

7.1 - Features of the refrigerating fluid R22

At standard temperature and pressure it is a colourless gas

with low toxicity, non-flammable, and it has an allowed

exposure limit value (AEL/TLV) corresponding to 1000

ppm (average value measured on 8 hours/day). In the

event of leakage, air the room before use.

7.2 - Refrigerant charge

WHEN REPAIRING THE REFRIGERATION CIR

CUIT RECUPERATE ALL REFRIGERANT IN A CON

TAINER: DO NOT ALLOW IT TO ESCAPE.

1) Start the unit as described in par. 4.1.

2) Start the compressor manually.

3) Guarantee a constant condensation temperature

(preferably 42-45°C); if necessary, partially obstruct

the condenser coil surface or limit its ventilating

power to obtain these conditions.

4) Charge the unit with the quantity of refrigerant R22

as shown in Tab. 5 and wait until the operating condi

tions of the whole refrigeration circuit are normal.

5) Check that the overheating is 7-8°C.

Tab. 5 - Refrigerant charge

MODEL

PKS3 PKS4

Refrigerant charge (g)

1500 1700

7.3 - Oil charge

The oil to be used when topping up is SUNISO 3GS; if

SUNISO 3GS is unavailable use an oil with the same

characteristics (see Tab. 6).

NEVER MIX DIFFERENT OILS TOGETHER.

CLEAN THE PIPING COMPLETELY BEFORE

CHANGING THE TYPE OF OIL USED.

Tab. 6 - Suniso 3GS oil (standard)

approx. specific weight (at 15C)

flash point (C.O.C.)

pour point

ENGLER viscosity at 50 C

viscosity index

copper corrosion (100 C, 3 hours) ASTM D130

neutralization value

conradson carbon residue

dielectric strength

:

0.91 kg/l

:

170 C

:

-40 C

:

2.7 E

:

0

:

1

:

0.03 max.

:

0%

:

> 30 kV

page 7

English

Page 10

8 - Calibrations

The air conditioner has already been factory-tested

and calibrated as described below.

For the MICROFACE calibrations refer to the rele

vant manual (to avoid wrong operations do not use

COMPONENT Setting (LP) NOTES

Low pressure

switch (LP)

High pressure

switch (HP)

Fan

pressure switch

(SP)

STOP : 1.2 bar

START : 2 bar

(fixed settings)

STOP : 26 bar

START : 20 bar

(fixed settings)

START : 18 bar

DIFF : 4 bar

(STOP : 14 bar)

(fixed settings)

temperature and rel. humidity set points/propor

tional bands which differ excessively from the stan

dard settings).

automatic

reset

manual reset

pressing the

push button

Fan speed

adjuster

SET. : 16 bar

BAND P : 3.5 bar

(For the adjustment refer

to the instructions supplied

with the machine)

English

page 8

272014 - 04.02.2000

Page 11

9 - Maintenance

For safety reasons, clear the unit opening the switches

QS1 and QS2 before performing any maintenance

operations.

If installed:

AS THE HIROMATIC/MICROFACE FEATURES

AUTOMATIC RESTART (AFTER A SUPPLY

INTERRUPTION) IT IS ADVISED TO DISABLE

AUTORESTART AND OPEN THE SWITCH QS

WHEN PERFORMING ANY MAINTENANCE.

Maintenance program - Monthly check

Check that the fan motor rotates freely without any abnormal noise, and ensure

FANS

AIR FILTERS

HIROMATIC/MICROFACE

ELECTRICAL

CIRCUIT

REFRIGERATION

CIRCUIT

that the bearings are not running hot.

Also check the current absorption.

Check the filter conditions; if necessary clean or replace them.

How to replace:

remove the upper panel of the unit

extract the filter from its seat horizontally

introduce the spare part

close the panel

In very dusty environments perform this check more frequently.

Verify the operation of the HIROMATIC/MICROFACE's LEDs, display and

alarms.

Check the power supply on all phases.

Ensure that all electrical connections are tight.

Check the evaporating pressures (to be done by a refrigeration technician).

Check the compressor current absorption, its head temperature and the pres

ence of any unusual noise.

Ensure that there is no ice formation on the evaporator.

Every day check the Hiromatic/Microface readings for

temperature and, if shown, ambient relative humidity.

The Maintenance Programme described below

should be carried out by a skilled technician, prefer

ably working under a maintenance contract.

9.1 - Dismantling the unit

The machine has been designed and built to ensure con

tinuous operation.

The working life of some of the main components, such

as the fan and the compressor, depends on their mainte

nance.

If the unit has to be dismantled, this must be done by

skilled refrigerator technicians.

The refrigerating fluid and the lubricating oil in the cir

cuit must be disposed of in conformity with the laws in

force in your country.

page 9

English

Page 12

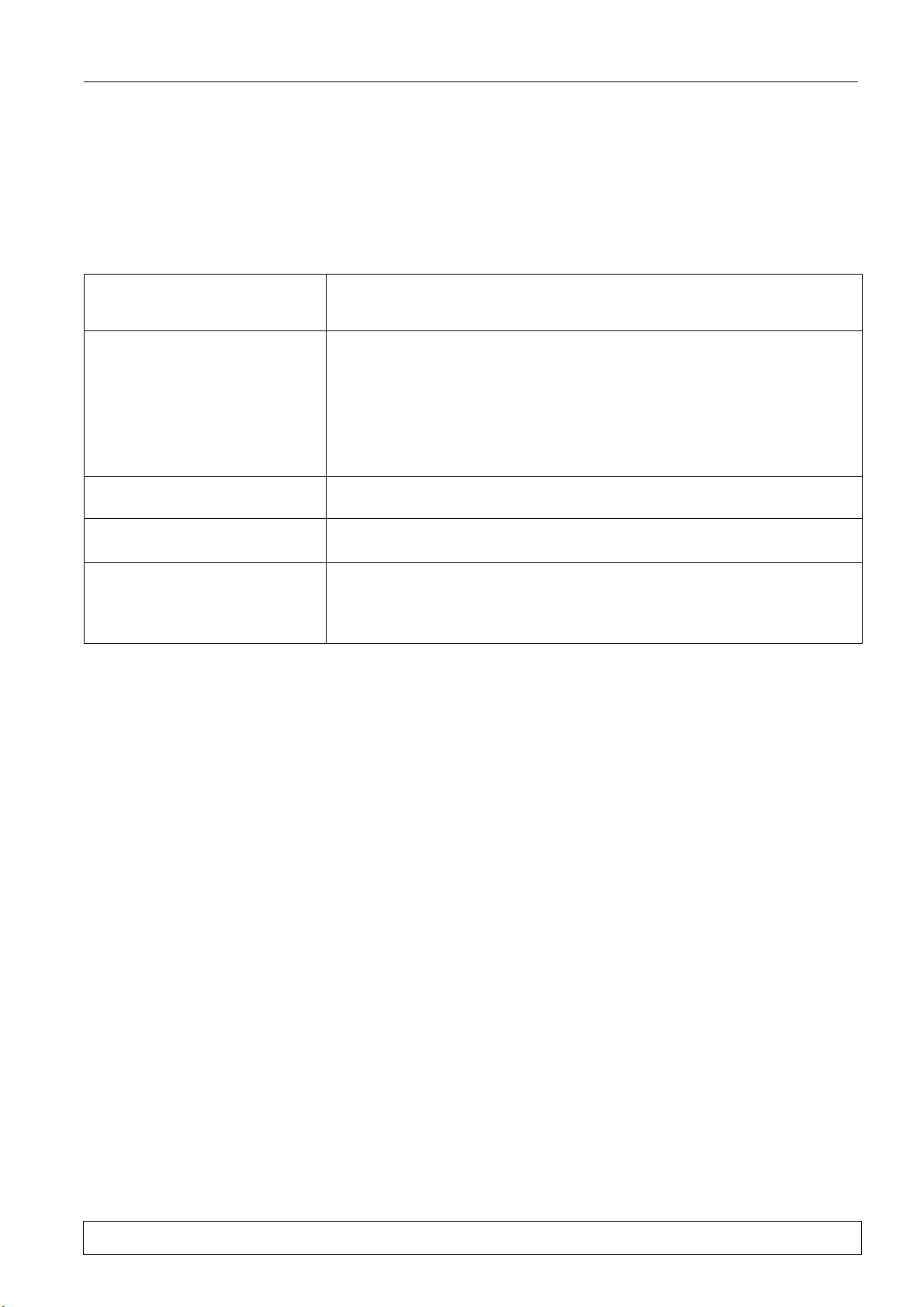

10 - Fault finding / alarms

Use the Fault Finding Guide on the right as follows:

Begin with "START" and follow the arrows marked both "YES" and

'NO' according to the type of fault.

The guide uses the following abbreviations:

Control of the HIR32 series

When an alarm occurs, the buzzer and the display indication can be reset manually pressing the

key PRG/mute. For the alarm code the reset is active only if the alarm cause has been removed.

The reset for the alarm contact is automatic. The reset of the adjuster operation occurs auto

matically when the alarm cause is removed.

For better information see the HIR32 manual.

Microface control

The alarms, shown in the guide, are reset as in

Fig. f.

Fig. c - How to reset an alarm

ALARM ON

(alarm LED

+ buzzer on)

read alarm

message

on display

START

check fan

operation plus

electrical circuit

check for high

air temperature

or low air flow

switch manual

operation off

reset conditioner

model

Ye s

Ye s

Ye s

No

No

air flow

lack

No

electric

heater

overheating

No

unit operating

in manual

Ye s

correct condi

tioner model on

Hiromatic/

Microface

No

is unit

operating

correctly?

press REPORT:

verify which alarm

has intervened

press HOME

press RESET

(mutes siren)

do you know

No

which alarm

has intervened?

rectify problem

using Fault

Finding Guide

press RESET

normal operation

(alarm LED off)

Ye s

fault

return to

rectified

fault not rectified

replace

HIROMATIC/

MICROFACE

No

is normal

operation

restored?

Ye s

continue

normal

operation

replace

interface

board

replace

EPROM

switch unit

main switch

off and then on

replace

sensor

verify state

of component:

continue if

everything is ok

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

No

faulty

interface

card

No

EPROM error

No

display board

failure

No

RAM/EPROM

error

No

sensor

failure alarms

No

working

hour

alarms

NOTES:

If several alarms intervene in sequence, only the last to inter

vene is displayed.

The STATUS REPORT lists all recent alarms (see Hiromatic/

Microface manual).

For further information see the Hiromatic manual.

English

page 10

272014 - 04.02.2000

Page 13

compressor HP

alarms

No

compressor LP

alarms

No

partially

frozen

evaporator

No

Ye s

Ye s

Ye s

high outside

temperature:

consult

supplier

low outside

temperature:

check

refrigerant charge

locked filter

dryer:

replace it

No No No

No Yes No

No No Yes

excessive

refrigerant charge:

reduce charge

No

low condensing

(temperature)

pressure

capillary locked:

replace

dirty

condenser:

clean

it

faulty

fan PV

pressure switch:

replace

No

reduced

air flow

burnt out fan

motor: replace

leak of refrigerant:

repair leak and

recharge

clogged filters

or locked air

flow: verify

pressure switch/

No No

t-stat/variex faulty

or capillary

locked: rectify

pressure switch/

t-stat/variex

miscalibrated:

recalibrate

compressor

overheating

high ambient

temperature

user alarms

smoke/fire alarm

(optional)

cold/noisy

compressor

Ye s

No

Ye s

No

Ye s

No No No

Ye s

No

Ye s N o

No

suction pipe

heats up when

compressor stops:

replace compressor

leak of refrigerant:

repair leak and

recharge

act as

necessary

act according to

local regulations

too much

refrigerant:

reduce charge

No Yes

No No No No

excessive

superheat

locked freecooling

damper: unlock

servocontrol

fault: replace

Ye s Ye s Yes

faulty external

sensor: replace

faulty room

sensor: replace

capillary fault:

replace

and control circuit

No

high room

temperature:

reduce temp.

Ye s

partially

frozen

evaporator

compressor not

under power:

check electrical

faulty compr.

substitute by

expert technician

Ye s

unit is not

cooling

is the compressor

faulty?

hot compressor

or klixon

intervention

leak of refrigerant:

repair leak and

recharge

No

excess current

absorption:

call expert

technician

No

noisy compressor:

substitute by

expert techncian

No

low ambient

temperature

Yes NoNoNoNo

unit is

cooling

unit in

dehumidification

wait for

temperature to rise

No

faulty room

sensor: replace

unit is not

heating

Ye sYe s

electrical

heaters are off

faulty control

circuit wiring:

check el. circuit

Ye s No

no power

arriving: check

electrical circuit

and safety T-stat

faulty control

function: replace

element burnt

out: replace

and check

electrical circuit

reduced

air flow

page 11

Ye s

English

clogged filters

or locked air

flow: verify

Page 14

11 - Spare parts

It is recommended the use of original spare parts.

When placing an order refer to Component List" enclo

sed with the machine and quote the unit model no. and

serial no.

English

page 12

272014 - 04.02.2000

Page 15

Avvertenze

Si raccomanda:

di conservare il manuale per tutto il periodo di vita della macchina;

di leggere con attenzione il manuale prima di qualsiasi operazione sulla macchina;

di impiegare la macchina esclusivamente per lo scopo per cui e' stata progettata; l'uso improprio dell'unita' eso

nera il costruttore da qualsiasi responsabilita'.

Il manuale e' rivolto all'utente finale per le sole operazioni eseguibili con pannelli chiusi.

Le operazioni che necessitano dell'apertura di porte o pannelli con attrezzi devono essere eseguite solo da personale

esperto.

Ogni macchina è munita di dispositivo Di Sezionamento Elettrico che consente all'operatore di intervenire in condi

zioni di sicurezza. Tale dispositivo deve essere sempre usato per eliminare i pericoli durante la manutenzione (scosse

elettriche, scottature, ripartenza automatica, parti in movimento e controllo remoto).

La chiave data in dotazione che permette la rimozione dei pannelli deve essere conservata dal personale addetto alla

manutenzione.

Per identificare la macchina (modello e numero di serie), in caso di richiesta di assistenza o di ricambi, leggere la

targhetta di identificazione posta esternamente ed internamente all'unita'.

ATTENZIONE: questo manuale e' suscettibile di modifiche; pertanto, ai fini di una completa e aggiornata informazione, l'utente

dovra' consultare il manuale a bordo della macchina.

Indice

1 - Operazioni preliminari 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 - Premessa 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 - Limiti di funzionamento 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 - Livello di pressione sonora 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 - Impermeabilità dell'ambiente 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 - Ispezione 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 - Trasporto 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 - Posizionamento del condizionatore 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 - Area di servizio 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 - Fori a parete 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 - Installazione 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 - Collegamenti elettrici e kit 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 - Collegamenti elettrici 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 - Kit Raffreddamento d'emergenza (optional) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 - Avviamento 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 - Primo avviamento (o dopo una lunga interruzione) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 - Avviamento con bassa temperatura esterna 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 - Avviamento e fermata 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 - Funzionamento 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 - Regolazione della velocità del ventilatore del condensatore 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 -Raffreddamento di emergenza (optional) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 - Controlli a microprocessore 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 - Logica di controllo 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 - Carica refrigerante R22 e olio 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 - Caratteristiche del fluido frigorigeno R22 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 - Carica refrigerante 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 - Carica olio 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 - Tarature 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 - Manutenzione 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 - Smantellamento dell'unità 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 - Ricerca guasti / allarmi 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 - Ricambi 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 1

Italiano

Page 16

1 - Operazioni preliminari

Condizioni di

1.1 - Premessa

Il seguente manuale descrive l'installazione, il funziona

mento e la manutenzione dei Condizionatori d'aria serie

Hiline Slim (ved. Fig. 1).

IMPORTANTE:

Consultare anche il manuale del controllo a micropro

cessore Microface e Hiromatic (se installato).

1.2 - Limiti di funzionamento

Le unità sono previste per funzionamento all'interno dei

campi di lavoro (ved. Tab. 1).

Tali limiti sono intesi per macchine nuove correttamente

installate o per le quali si sia effettuata una corretta

manutenzione.

Le clausole di garanzia non sono valide per ogni possibile

danneggiamento o malfunzionamento che puo' verifi

carsi durante od in conseguenza di operazioni al di fuori

dei valori di applicazione.

Tab. 1 - Limiti operativi

Tensione alimentazione

Condizioni esterne

Condizioni interne con

compressore funzionante

Condizioni di

immagazzinamento

Grado di protezione lato

esterno

230 V 10%/1/50 Hz

24/48 30% Vdc con INVERTER

da: -10C (-30C con VARIEX)

a: 43C

20C 30% R.H. e 20C 80%

da:

R.H.

a: 35C, 40% R.H.

da: -25C, 5% R.H.

a: 55C, 90% R.H.

IP 24

1.5 - Ispezione

Al ricevimento della macchina controllare immediata

mente il suo stato; contestare subito alla compagnia di

trasporto qualsiasi eventuale danno.

1.6 - Trasporto

Tenere sempre l'unita' in posizione verticale.

Se possibile trasportare la macchina usando un car

rello elevatore a forca; altrimenti usare una gru con

cinghie o funi, evitando di esercitare pressione sugli

angoli superiori dell'imballaggio.

Disimballare l'unita' il piu' vicino possibile al luogo

dell'installazione. Una volta disimballata evitare urti

che possono essere trasmessi ai componenti interni.

1.7 - Posizionamento del condizionatore

Il condizionatore d'aria puo' essere collocato in qual

siasi ambiente purche' questo non sia aggressivo.

Il condizionatore d'aria va posizionato in modo da

assicurare la migliore distribuzione d'aria nell'am

biente in cui esso deve operare, al fine di evitare zone

morte.

Per il corretto posizionamento del condizionatore ve

dere Fig. 2 in calce al manuale, che illustra l'installa

zione di due unità.

1.8 - Area di servizio

L'unità deve essere provvista di un'Area di Servizio

adatta (ved. Fig. 2):

Tutta la manutenzione ordinaria può essere realiz

zata dalla parte frontale e dalla parte posteriore

(esterna), dove uno spazio minimo deve essere

lasciato libero da ostruzioni.

1.3 - Livello di pressione sonora

Nella Tab. 2 vengono riportati, per il lato interno e per il

lato esterno, i valori di pressione sonora massimi per le

unita' in configurazione standard, in funzionamento

continuo, a 2 metri dalla superficie frontale della mac

china, a 1 metro di altezza, in condizione di campo libero.

I valori di rumorosita' piu' elevati si riscontrano frontal

mente all'unita', sul lato interno.

1.4 - Impermeabilita' dell'ambiente

Per creare stabili condizioni interne assicurarsi che la

stanza sia isolata dall'esterno sigillando le aperture, le

entrate dei cavi, ecc.

Italiano

1.9 - Fori a parete

Praticare i fori nella parete del container in corrispon

denza alla posizione del condizionatore (ved. Fig. 3).

pag. 2

Page 17

Tab. 2 - Livelli pressione sonora

Modell

p

PKS3

PKS4

Frequenza di banda d'ottava (Hz)

o

Ambiente interno, a 2 m

in fronte all'unità, campo

libero

Ambiente esterno, a 2 m

in fronte all'unità, campo

libero

Ambiente interno, a 2 m

in fronte all'unità, campo

libero

Ambiente esterno, a 2 m

in fronte all'unità, campo

libero

31.5 63 125 250 500 1000 2000 4000 8000

49 56 62 58 55 54 53 53 51 61

50 51 49 54 51 51 47 44 37 55

49 56 62 58 55 54 53 53 51 61

50 51 49 54 51 51 47 44 37 55

2 - Installazione

Per una corretta installazione procedere come segue

(Fig. 4):

Applicare all'unità gli elementi della cornice di prote

zione (fornibili come kit optional), utilizzando i fori

predisposti e viti autofilettanti di diametro 3.5 mm.

Per prevenire l'ingresso di acqua nel container, appli

care come guarnizione una striscia di gomma adesiva.

Livello di

pressione

sonora

[dB(A)]

Fissare la cornice alla parete dello shelter per mezzo

di viti M4 con tassello.

Applicare l'elemento inferiore della cornice di prote

zione con due viti M4 con tassello.

Applicare al tetto dell'unità la staffa di fissaggio alla

parete con due viti autofilettanti di diametro 3.5.

3 - Collegamenti elettrici e kit

Prima di eseguire qualunque operazione sulle parti elet

triche, assicurarsi che:

i componenti elettrici siano in buone condizioni;

tutte le viti terminali siano ben avvitate;

la tensione di alimentazione e la frequenza siano con

formi a quelle indicate sull'unità;

l'interruttore QS1 sia in posizione di aperto (OFF);

l'interruttore automatico QS2 sui morsetti d'uscita

dell'inverter (se installato) sia aperto (OFF);

non vi siano componenti sotto tensione.

3.1 - Collegamenti elettrici

(ved. schema elettrico)

I collegamenti elettrici (alimentazione 230/1/50 e, per

l'alimentazione d'emergenza (48 e 24 Vdc) si effettuano

dal tetto dell'unità dove sono stati predisposti alcuni fori

con pressacavi.

Far passare il cavo di alimentazione (non fornito da

noi), attraverso il foro praticato nel tetto dell'unità.

N.B.: Per l'alimentazione utilizzare un cavo scher

mato (sezione minima indicata in Tab. 4).

Si raccomanda di tenere il cavo di alimentazione dalla

rete il più lontano possibile dagli altri cavi uscenti

dall'inverter (opzionale).

Collegare la linea a 230V/1/ 50 all'interruttore QS1

posto nel quadro elettrico.

Per quanto concerne i contatti di allarme presenti

nelle varie versioni, questi sono disponibili su morset

tiera nel quadro elettrico.

Per la descrizione degli allarmi, consultare il Cap. 6 e

il manuale del controllo installato.

Per porre in comunicazione 2 o più unità installate

nello stesso container, e dotate del controllo

MICROFACE, con interfaccia HIROMATIC, utiliz

zare il cavo HIROBUS (fornito in dotazione) colle

gandolo come indicato nello schema elettrico. Con

sultare inoltre il manuale Microface e Hiromatic per

la configurazione delle unità in Stand-by.

pag. 3

Italiano

Page 18

Tab. 3 - Caratteristiche elettriche standard

S4

20A

4

2

4

2

Ventilatori evaporatore Ventilatori condensatore Compressore Resistenze riscaldamento

OA FLA LRA Potenza nom.

PKS3

PKS4

(*) Nelle seguenti condizioni (ARI 520-78):

1 - - 200 1.5 - - 340 5.9 10 34 1370 - 13 - 3000

1 - - 200 1.5 - - 340 7.1 12 36.5 1700 - 13 - 3000

Temp. condensazione: 54.4C

Temp. ambiente: 35C

Temp. evaporazione: 7.2C

Temp. sottoraffreddamento: 8.3C

Temp. surriscaldamento: 11C

[W]

OA FLA LRA Potenza nom.

[W]

Tab. 4 - Interruttore di protezione e dimensionamento cavo

Interruttore di protezione a corrente differenziale In = 0.3A

V230/1/50Hz 230 Vac 24/48Vdc

PKS3-PK

OA

FLA LRA Potenza nom.

(*)

[W] (*)

OA FLA LRA Potenza nom.

Dimensionamento cavo

2

mm

mm

[W]

2

3.2 - Kit Raffreddamento d'emergenza

(optional)

Il Kit Raffreddamento d'emergenza è costituito da un in

verter e da un trasformatore monofase, installati all'in

terno del quadro elettrico.

Agendo come illustrato nel par. 3.1, portare l'alimenta

zione a 48 (24) Vdc all'interno del quadro elettrico, per

mezzo di un cavo schermato di sezione minima riportato

in Tab. 4. Collegare l'eventuale linea di terra al morsetto

4 - Avviamento

4.1 - Primo avviamento (o dopo una lunga

interruzione)

Prima di avviare il condizionatore si raccomanda nuova

mente di verificare che la tensione e la frequenza d'ali

mentazione siano conformi a quelle indicate sulla tar

ghetta identificativa dell'unità.

Fatto ciò, è possibile avviare il condizionatore portando

l'interruttore QS1 nella posizione ON. Sulle unità che ne

sono equipaggiate, premere anche il pulsante ON- OFF

sull'interfaccia Hiromatic.

Controllare l'assorbimento elettrico di tutti i componen

ti e confrontare con i dati riportati nella Tab. 3. Verifi

care che non vi siano allarmi attivi; attendere che il siste

ma si porti a regime ed effettuare i seguenti controlli:

verificare che i ventilatori stiano funzionando corret

tamente;

assicurarsi che la temperatura sia garantita e che il

compressore e le resistenze di riscaldamento (optio

nal) funzionino quando richiesto;

solo su versioni dotate di opzione Variex (regolazione di

velocità) assicurarsi che il regolatore di velocità del

ventilatore della sezione condensante sia tarato cor

rettamente e che controlli il funzionamento del venti

latore (ved. Cap. 8).

di terra (PE). Collegare la schermatura del cavo al mor

setto giallo-verde ed eseguire i collegamenti seguendo

scrupolosamente lo schema elettrico.

N.B.: Collegare correttamente la polarità.

Per quanto riguarda le unità predisposte per ali

mentazione d'emergenza da Inverter esterno, ese

guire i collegamenti come specificato nello

schema elettrico.

4.2 - Avviamento con bassa temperatura

esterna

In caso di bassa temperatura esterna (<0C), la partenza

dell'unità è agevolata dal tempo di ritardo di attivazione

dell'allarme di bassa pressione), entro il quale le pressio

ni nel circuito frigorifero raggiungono i valori normali di

funzionamento.

4.3 - Avviamento e fermata

Per le unità dotate di interfaccia HIROMATIC:

avviare l'unità premendo il pulsante ON-OFF

sull'Hiromatic (confermato da SYS.ON sul display);

fermare l'unità premendo il pulsante ON-OFF

sull'Hiromatic (confermato da SYS.OFF. sul display).

N.B.: Spegnere l'interruttore principale QS1 e l'inter

ruttore Inverter QS2 (o aprire i fusibili FU4) solo

se l'unità viene fermata per un lungo periodo di

tempo.

Per le unità dotate del controllo Microface, l'accensione

e lo spegnimento si ottengono agendo sull'interruttore

principale QS1, al quale si accede aprendo il pannello su

periore incernierato agendo sul sistema di apertura rapi

da.

Italiano

pag. 4

Page 19

5 - Funzionamento

Il funzionamento dell'unità è completamente automati

co. La sequenza che segue spiega (con l'aiuto della Fig. 5

- Schema di funzionamento) come funziona l'unità (ve

dere anche la Fig. 6 - Circuito frigorifero):

6) Il sensore di temperatura, posizionato all'interno del

lo shelter, fornisce al controllo l'informazione relati

va alla condizione dell'aria da trattare .

7) Il controllo confronta l'informazione ricevuta con i

valori di Set Point (= temperatura interna minima

desiderata) e Differenziale programmati, predispo

nendo il condizionatore al trattamento dell'aria, con

le seguenti modalità:

Raffreddamento (Fig. 5)

Il compressore (9) e i ventilatori (6) e (10) vengono

avviati quando la temperatura dell'ambiente da condi

zionare supera il valore prefissato. L'aria aspirata dai

ventilatori assiali (6) entra nell'unità tramite l'accesso

superiore (A), attraversa immediatamente il filtro (1) e

quindi l'evaporatore (5).

Il refrigerante freddo fluisce attraverso l'evaporatore

(5), raffreddando così l'aria che l'attraversa. L'aria trat

tata viene convogliata nell'ambiente condizionato attra

verso l'apertura di mandata (B).

Il calore sottratto all'ambiente e quello generato dal fun

zionamento dei motori del condizionatore vengono

smaltiti attraverso il condensatore (11), posto nella parte

dell'unità a contatto con l'esterno e investito, grazie ai

ventilatori (10), dall'aria esterna. Il funzionamento dei

ventilatori viene gestito in modo ON - OFF (o con

Variex, ved. par. 5.1) in funzione della pressione di con

densazione.

Per la logica di funzionamento del controllo ved. Cap. 6.

Riscaldamento (optional)

Il riscaldamento dell'aria si ottiene per mezzo di resisten

ze elettriche (7), poste nel flusso d'aria e azionate secon

do la logica impostata sul controllo (ved. Cap. 6).

Il reset manuale del termostato di sicurezza (15), posto

sulle resistenze, va effettuato accedendo dalla parte

frontale, dopo aver rimosso il pannello grigliato.

Raffreddamento in Freecooling (optional) - (Fig. 5)

Quando la temperatura dell'aria esterna è inferiore alla

temperatura dell'aria interna di qualche grado, è possibi

le sfruttare questa differenza per rinfrescare l'interno

dello shelter mediante l'immissione diretta di aria ester

na, senza cioè l'uso del compressore. E' possibile ottene

re così un sensibile risparmio di energia elettrica.

Al verificarsi delle condizioni previste, il servocomando

(2), gestito dal controllo Microface, apre la serranda mo

bile (12) che separa la circolazione dei due flussi d'aria

interna ed esterna. In questo modo l'aria esterna, aspira

ta dai ventilatori (6), affluisce all'interno del container e

ne fuoriesce attraverso le aperture praticate nella se

zione condensante. I flussi d'aria presenti in questo

modo di funzionamento sono indicati nella Fig. 5.

Il grado di apertura della serranda viene determinato in

funzione del valore di Set Point da mantenere e della

temperatura dell'aria immessa (ved. Cap. 6).

5.1 - Regolazione della velocità del ventila

tore del condensatore (obbligatorio per

temp. esterne -10 / -30C)

Un sensore è posizionato in maniera tale da rilevare co

stantemente la pressione di condensazione del gas refri

gerante. In base a questa informazione, un'apparecchia

tura elettronica (Variex) regola la velocità di rotazione

del ventilatore al fine di mantenere la pressione di con

densazione entro i valori consentiti. In questo modo, ol

tre ad ottimizzare il funzionamento del compressore, si

ottiene una sensibile riduzione del livello di emissione

sonora (specialmente durante le ore notturne), si facilita

la partenza del compressore alle basse temperature e si

ottiene un risparmio di energia elettrica.

Per quanto riguarda la taratura del regolatore di velocità,

ved. il Cap. 8.

5.2 - Raffreddamento di emergenza

(optional)

Questa opzione è disponibile per tutte quelle applica

zioni in cui è importante garantire la circolazione

dell'aria all'interno dello shelter, anche quando vi è

un'interruzione dell'alimentazione elettrica dalla rete.

In questo caso, tramite un inverter e un trasformatore, le

unità possono essere alimentate con le batterie d'emer

genza a 24 oppure a 48 Vdc (ved. Fig. 7).

La modalità di intervento del sistema di emergenza

dipende dallo stato dell'interruttore QS1:

QS1 = ON

Se non ci sono interruzioni sull'alimentazione princi

pale il sistema di emergenza resta inattivo;

se viene a mancare tensione sulla linea di alimenta

zione principale, automaticamente l'inverter si attiva

e, prelevando energia dalle batteria d'emergenza a

24/48 Vdc, tramite il trasformatore 24/48 V / 230 V

alimenta il ventilatore della sezione evaporante e il

controllo elettronico. In questo modo tutte le funzio

ni dell'unità continuano ad essere gestite, consenten

do il ricircolo dell'aria interna (o l'afflusso di aria es

terna, se l'unità è dotata del sistema Freecooling) nel

caso in cui la temperatura all'interno dello shelter

esca dal range consentito. In questa modalità di fun

zionamento un contatto del relè (KM6) segnala l'atti

vazione del sistema inverter.

Se il voltaggio delle batterie d'emergenza scende al di

sotto del valore di sicurezza, il sistema inverter si

disattiva automaticamente.

QS1 = OFF

In questa condizione anomala, che si presenta ad

esempio dopo un corto circuito nell'unità, l'inverter

è automaticamente disattivato.

ATTENZIONE:

Per ragioni di sicurezza si raccomanda di disconnettere

l'interruttore automatico QS2 quando si desidera fer

mare l'unità.

pag. 5

Italiano

Page 20

6 - Controlli a microprocessore

La macchina è disponibile in quatttro diverse configura

zioni di funzionamento:

1) unità solo freddo;

2) unità freddo e caldo;

3) unità con freecooling, solo freddo;

4) unità con freecooling, freddo e caldo.

Tutte le versioni sono dotate del nuovo controllo a micro

processore Microface.

6.1 - Logica di controllo

Le unità sono gestite dal controllo a microprocessore Mi

croface, eventualmente abbinato al controllo Hiromatic

per il monitoraggio completo di tutti i parametri di fun

zionamento dell'unità (ved. manuale allegato).

L'algoritmo di controllo si basa su una regolazione a 1

gradino per il riscaldamento e il raffreddamento con

compressore e su una regolazione di tipo Proporzionale

- Integrativo per il raffreddamento in modalità Free

cooling, con impostazione del Set Point e della banda

proporzionale (P) (Fig. d.)

Il controllo gestisce tutti i ritardi di attivazione del com

pressore, e i tempi minimi, al fine di garantirne il corretto

funzionamento e allungarne il più possibile la vita opera

tiva.

L'attivazione della modalità Freecooling avviene in fun

zione della differenza (impostabile) fra la temperatura

interna e quella esterna. Ciò significa che se la differenza

fra le 2 temperature aumenta oltre un certo valore, auto

maticamente l'unità passa alla funzione Freecooling: il

compressore viene disattivato e l'uscita analogica con

trolla il servomotore a 3 punti della serranda. Il grado di

apertura della serranda viene variato al fine di mantene

re la temperatura interna uguale al setpoint impostato e

in funzione della temperatura dell'aria immessa in

ambiente, che non può essere inferiore ad un prefissato

valore di sicurezza.

Fig. d Funzionamento compressore, resistenze e aper

tura serranda

P Band

Freecooling

mode

ora e si passa al raffreddamento mediante il compressore

frigorifero.

6.1.1 - Start-Stop

In totale ci sono 3 modi per avviare o arrestare l'unità:

a) l'interruttore sezionatore all'interno del quadro elet

trico;

b) l'ingresso digitale della scheda Microface;

c) il pulsante ON-OFF sull'interfaccia Hiromatic (op

zionale).

Priorità: a) b) c) devono essere considerati come 3 con

tatti in serie; solo se tutti i contatti sono in On, l'unità può

operare.

6.1.2 - Gestione allarmi

Nella configurazione standard sono disponibili sulla

morsettiera del quadro elettrico 2 contatti puliti in scam

bio, così utilizzati:

1) Allarme generale:

bassa pressione compressore

alta pressione compressore (reset sul pressostato)

guasto sensore

guasto memoria

guasto ventilatore (con sonde opzionali)

2) Avviso generale - segnalazione di varie condizioni

anomale, fra cui:

alta temperatura

bassa temperatura

termostato resistenza (reset sul termostato)

Note:

Sia l'Allarme che l'Avviso devono essere resettati

manualmente sulla Microface.

Un allarme ferma l'unità e fa intervenire quella in

stand-by (se presente). Se l'unità è in stand alone, gli

allarmi di alta e di bassa pressione non fermano la

macchina per permettere il funzionamento in moda

lità Freecooling quando le condizioni esterne lo con

sentono.

L'avviso non ferma l'unità.

In caso di intervento del termostato di sicurezza resi

stenze, il reset deve essere effettuato sul termostato

(15) accessibile rimuovendo il pannello ventilatori la

to interno.

Set CoolingHeating

P Band

Set CoolingHeating

C

Compressor

cooling mode

C

Se la temperatura interna eccede la banda proporziona

le per oltre il 20% per più di 10 minuti, l'unità passa al

raffreddamento con compressore e la modalità Freecoo

ling è disabilitata per 1/2 ora. Se la temperatura interna

eccede la banda proporzionale per oltre il 50% per più di

2 minuti, la modalità Freecooling viene disattivata per 1/

Italiano

pag. 6

6.1.3 - Scheda allarmi opzionale

Oltre a quanto visto per la configurazione standard, sulla

scheda allarmi fornibile come optional sono presenti

contatti di relè per avere i seguenti allarmi separati:

1) Alta pressione e bassa pressione compressore

2) Allarme filtro sporco

3) Guasto ventilatore

4) Alta temperatura

5) Bassa temperatura

Questi allarmi provocano la fermata dell'unità con le

stesse modalità viste nel paragrafo precedente.

Per la completa descrizione degli allarmi ved. manuale

Microface allegato.

2

Page 21

6.1.4 - Unità in stand-by

La gestione delle unità in stand-by è completamente

automatica grazie alla possibilità di connessione del con

trollo Microface.

Un'unità in stand-by parte in caso di un allarme che

blocca quella principale; questo avviene anche se l'unità

principale viene spenta o scompare dal sistema per un

guasto sul bus di collegamento dei controlli.

La rotazione oraria delle unità in stand-by avviene au

tomaticamente ogni 24 ore, in modo da consentire un'o

mogenea usura dei componenti del sistema.

Se il sistema è connesso all'interfaccia Hiromatic, è pos

sibile impostare una diversa gestione della rotazione.

Se più unità sono contemporaneamente in funzione con

lo stesso Set Point, la temperatura usata per il controllo è

la media di quelle rilevate; inoltre, nel funzionamento

con compressore, la banda proporzionale è divisa in

tante parti pari al doppio del numero di unità che fanno

parte del sistema, in modo da parzializzare la potenza

frigorifera totale disponibile.

Il funzionamento in modalità Freecooling è omogeneo e

contemporaneo su tutte le unità.

La Fig. e, riportata come esempio, rappresenta il funzio

namento di un sistema composto da 3 unità.

7 - Carica refrigerante R22 e olio

Fig. e Sistema con 2 unità in stand-by -

Controllo Microface

Freecooling mode

P Band

1

2

3

Set CCoolingHeating

Compressor cooling mode

P Band

3

1 = unità principale

2 = unità in stand-by

3 = unità in stand-by

11

223

Set CCoolingHeating

QUESTE OPERAZIONI DEVONO ESSERE ESE

GUITE DA UN FRIGORISTA ESPERTO.

7.1 - Caratteristiche del fluido frigorigeno R22

A temperatura e pressione normale è un gas incolore che

presenta una bassa tossicità, non è infiammabile, ha un

valore limite di esposizione permesso (AEL/TLV) pari a

1000 ppm (valore medio ponderato su 8 ore giorno).

In caso di fuga aerare il locale prima di soggiornarvi.

7.2 - Carica refrigerante

QUANDO SI RIPARA IL CIRCUITO FRIGORIFERO

RECUPERARE TUTTO IL REFRIGERANTE IN UN

CONTENITORE: NON DISPERDERLO NELL'AM

BIENTE.

1) Avviare l'unita' come descritto in par. 4.1.

2) Avviare manualmente il compressore.

3) Garantire una temperatura di condensazione

costante (preferibilmente 42-45 C); se necessario

ostruire parzialmente la superficie di scambio del

condensatore o limitare la potenza ventilante per

ottenere queste condizioni.

4) Caricare l'unita' con la quantità di refrigerante R22

riportata in Tab. 5 e attendere che le condizioni di

funzionamento dell'intero circuito frigorifero risul

tino normali.

5) Verificare che il surriscaldamento sia di 3-5 °C.

Tab. 5 - Carica refrigerante

MODELLO

PKS3 PKS4

Carica refrigerante (g)

1500 1700

7.3 - Carica olio

L'olio da usare per il rabbocco e' il SUNISO 3GS; se non

e' disponibile SUNISO 3GS usare un olio con le stesse

caratteristiche (ved. Tab. 6).

NON MISCELARE MAI OLII INCOMPATIBILI.

DRENARE E PULIRE LA TUBAZIONE PRIMA DI

CAMBIARE IL TIPO DI OLIO USATO.

Tab. 6 - Olio Suniso 3GS (standard)

peso specifico approssimativo (a 15 C)

punto di infiammabilita' (C.O.C.)

punto di versamento

viscosita' ENGLER a 50 C

indice di viscosita'

corrosione su rame (100 C, 3 ore) ASTM D130

valore di neutralizzazione

residuo carbonico conradson

rigidita' dielettrica

:

0.91 kg/l

:

170 C

:

-40 C

:

2.7 E

:

0

:

1

:

0.03 max.

:

0%

:

> 30kV

pag. 7

Italiano

Page 22

8 - Tarature

Il condizionatore d'aria e' gia' stato collaudato e

tarato in fabbrica come sotto riportato.

Per le tarature della MICROFACE riferirsi al rispet

tivo manuale (per evitare operazioni sbagliate non

COMPONENTE TARATURA NOTE

Pressostato di bassa

pressione (LP)

Pressostato di alta

pressione (HP)

Pressostato

ventilatore

(SP)

STOP : 1, 2 bar

START : 2 bar

(tarature fisse)

STOP : 26 bar

START : 20 bar

(tarature fisse)

START : 18 bar

DIFF : 4 bar

(STOP : 14 bar)

(tarature fisse)

usare set points di temperatura e umidita' rel./bande

proporzionali molto differenti dai Settaggi Stan

dard).

reset

automatico

reset manuale

premendo il

pulsante

Regolatore di velocità

ventilatore

SET. : 16 bar

BANDA P : 3.5 bar

(Per la regolazione vedere

istruzioni allegate a bordo

macchina)

Italiano

pag. 8

Page 23

9 - Manutenzione

Per ragioni di sicurezza, togliere tensione all'unità

aprendo gli interruttori QS1 e QS2 prima di effettuare

qualsiasi manutenzione.

Se installato:

POICHE' L'HIROMATIC/MICROFACE DISPONE

DI RIPARTENZA AUTOMATICA (DOPO INTER

RUZIONE DELL'ALIMENTAZIONE) SI CONSI

GLIA DI DISABILITARE LA RIPARTENZA AUTO

MATICA E APRIRE L'INTERRUTTORE QS1 E QS2

QUANDO SI COMPIE QUALSIASI MANUTEN

ZIONE.

Programma di manutenzione - Controllo mensile

Controllare che il motore del ventilatore ruoti liberamente e senza rumori ano

VENTILATORI

FILTRI ARIA

HIROMATIC/MICROFACE

CIRCUITO

ELETTRICO

CIRCUITO

FRIGORIFERO

mali, e assicurarsi che i cuscinetti non si riscaldino.

Controllare anche l'assorbimento di corrente.

Verificare lo stato dei filtri; se necessario pulirli o sostituirli.

Per la sostituzione:

rimuovere il pannello superiore dell'unità (filtro interno) o la griglia superiore

esterna (filtro freecooling)

sfilare orizzontalmente il filtro dalla propria sede

inserire il ricambio

richiudere il pannello e la griglia