Page 1

Installation Manual

7264000G

8” Basin Extension for Pro-Series Systems

Models

X8

For P370 and P380 Systems

X8-D

For P680 Systems

Features

• 8” Molded Extension

• Rubber Gasket Seal

• Sixteen Stainless Steel Studs and Flange Nuts

• Discharge Pipe Extenders

P370 P380 P680

7000 Apple Tree Avenue

Bergen, NY 14416

ph: 800.543.2550

fax: 585.494.1839

www.libertypumps.com

Copyright © Liberty Pumps, Inc. 2018 All rights reserved.

Page 2

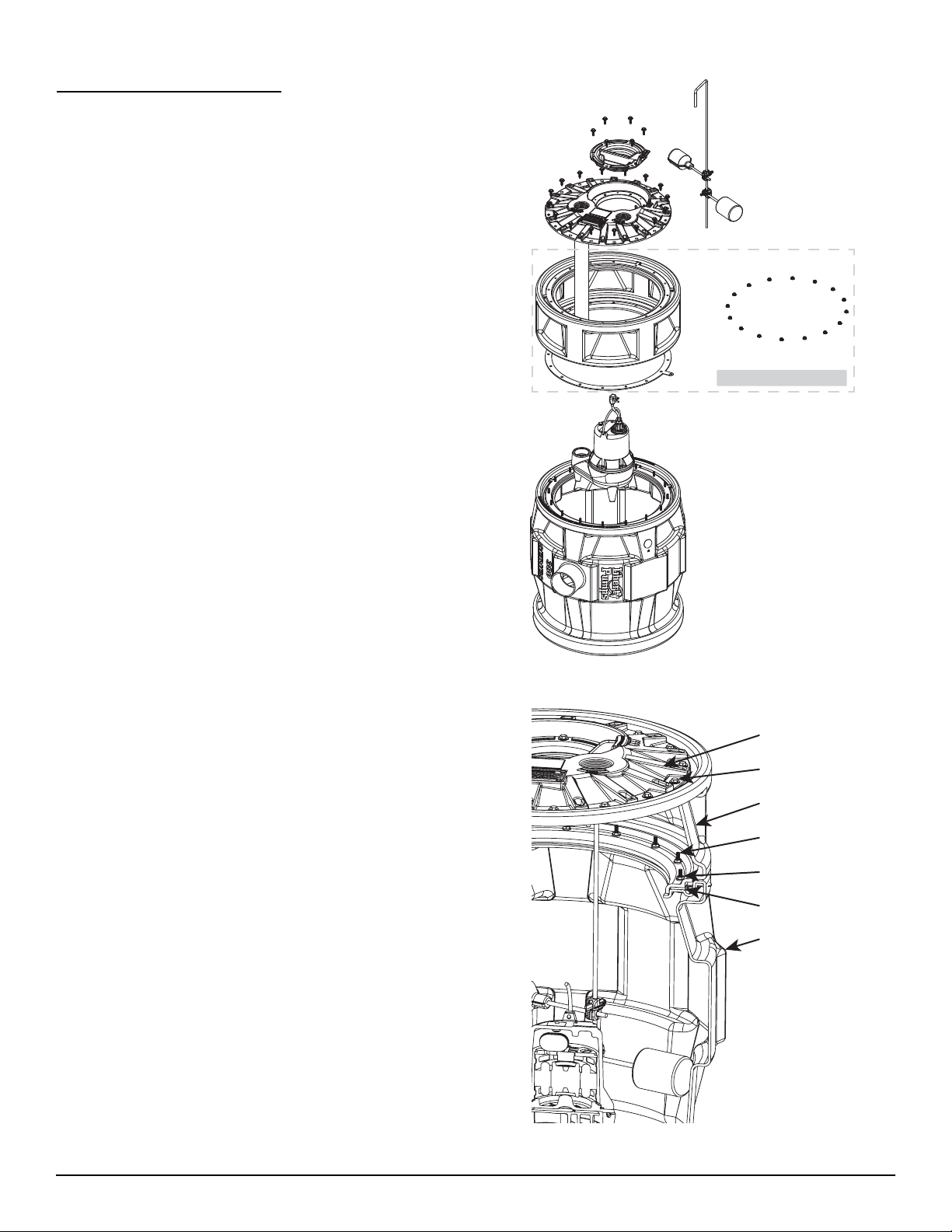

X8 and X8-D Extension Installation

WASHER HEAD SCREW

PRO EXTENSION

PRO COVER

FLANGE NUT

THREADED STUD

RUBBER GASKET SEAL

TANK

Included in Basin Extension

Before installing the X8 or X8-D basin extension, the pump and

cover must be removed from an assembled PRO system.

1. Remove the small access cover which is secured by 6

steners.

fa

®

2. Remove the QuickTree

by lifting the unit out of its holder.

3. Unscrew the fasteners securing the main cover to the tank. In

order to remove the main cover, it must be separated from

the PVC discharge pipe. This can be done by rotating the

cover back and forth while pulling upward.

Re-assembly:

1. The short length of pipe and the coupling must be “glued” to

current discharge pipe(s).

the

2. Place the pump(s) with pipe into the basin and position it

within the torque stops. (The torque stops are the three round

pockets located at the bottom of the basin.) Each leg of the

pump should be inside one of the pockets.

3. Install the threaded stainless steel studs in tank (finger-tight)

until they bottom out in the threaded inserts. Standard

systems use 8 studs; XL systems require 16 for proper sealing.

4. The rubber gasket seal can now be placed over the studs and

seated onto the tank’s rim.

4a. For 8 bolt systems, it is highly recommended that

the installer apply liberal amounts of sealant (such

as silicone) on both sides of the rubber gasket seal

surface to ensure proper sealing.

5. Lower the extension over the studs until it is firmly seated on

the rubber gasket seal.

6. Install the stainless steel flange nuts on the studs and torque

to 40 in-lbs. IMPORTANT: Do not over tighten.

7. Re-attach the main cover. To facilitate assembly, the PVC pipe

should be wetted with soapy water and inserted into the

rubber seal under the cover. The cover can be twisted back

and forth while pushing down until the cover meets the

extension. Re-attach the cover with the same screws that

were removed. Note: XL-systems will have 16 screws.

8. A new, longer QuickTree rod is provided with the X8/X8-D

extension. Remove the floats from the original QuickTree rod

by loosening the screw on the clamp. For systems with an

optional alarm, two floats need to be removed.

9. Re-attach the float(s) to the new, longer QuickTree

referencing Figure 3 or Figure 5 (according to system).

IMPORTANT: It is critical that the tether length remains the

same after re-installation. The tether length is the cord

distance from the clamp to the top of the float ball.

10. The QuickTree rod has four “flat” sections. The upper two are

used in a P380/680-Series system and the lower two positions

are used in a P370 system. The lowest float is the pump

control float; the highest is the alarm float (if system is

equipped with the alarm option).

(float rod and floats) from the basin

rod

Figure 1

Figure 2

– 2 – Copyright © Liberty Pumps, Inc. 2018 All rights reserved. 7264000G

Page 3

Pro380 and 680 Systems

(shorter)

3.5in.

[88.9mm]

Tether Length

3.5” alarm float

3.0” pump float

3.5in.

[88.9mm]

3.0in.

[76.20mm]

13.71in.

[348.29mm]

8.0in.

[203.2mm]

21.71in.

[551.49mm]

3.0in.

[76.20mm]

ALARM

FLOAT

ALARM

FLOAT

PUMP

CONTROL

FLOAT

PUMP

CONTROL

FLOAT

[644.53mm]

QuickTree (Float Tree) and Pipe Instructions

Original QuickTree

Replacement QuickTree

Figure 3

New Discharge Pipe Configuration

The new length of pipe required is 25-3/8", which is 8" longer than the one in the system. The Model X8/X8-D includes a coupling and

short length of pipe that must be “glued” to the existing discharge pipe; X8-D contains two extensions.

25.375in

Figure 4

7264000G Copyright © Liberty Pumps, Inc. 2018 All rights reserved. – 3 –

Page 4

Pro370 Systems

Original QuickTree

(shorter)

ALARM

FLOAT

ALARM

FLOAT

3.5in.

[88.9mm]

PUMP

CONTROL

FLOAT

PUMP

CONTROL

FLOAT

Tether Length

3.5” alarm float

3.5” pump float

Replacement QuickTree

3.5in.

[88.9mm]

3.5in.

[88.9mm]

3.5in.

[88.9mm]

18.46in.

[468.94mm]

8.0in.

[203.2mm]

8.0in.

[203.2mm]

12.46in.

[316.6mm]

20.46in.

[519.8mm]

26.46in.

[672.14mm]

31.625in

[803.28mm]

QuickTree (Float Tree) and Pipe Instructions

New Discharge Pipe Configuration

The new length of pipe required is 31-5/8”, which is 8” longer than the one in the system. The Model X8 includes a coupling and short

length of pipe that must be “glued” to the existing discharge pipe.

Figure 5

Figure 6

– 4 – Copyright © Liberty Pumps, Inc. 2018 All rights reserved. 7264000G

Loading...

Loading...