Page 1

ALM-2 and ALM-2-1 Alarm System Installation Instructions

This alarm system monitors liquid levels in lift pump chambers, sump pump basins, holding tanks, sewage, agricultural, and other

water applications.

The ALM-2 and ALM-2-1 alarm systems can serve as a high or low level alarm depending on the fl oat switch model used. The alarm

horn sounds when a potentially threatening liquid level condition occurs. The horn can be turned off, but the alarm light remains on

until the condition is remedied. Once the condition is cleared the alarm will automatically reset. A green "power on" light indicates

120 VAC primary power to the alarm. Low battery chirp feature indicates when battery should be replaced.

FEATURES

120 VAC Model Voltage - (circuits not supervised) Primary: 120 VAC, 60 Hz, 2.4 watts maximum

(alarm condition) Operating Voltage: 9 VDC Double insulation.

NEMA 1 enclosure rated for indoor use.

Automatic alarm reset.

Red "alarm" light and green "power on" light, alarm "test" switch, and horn "silence" switch.

6 foot (1.8 meter) power cord.

Alarm horn sounds at 87 decibels at 10 feet (3 meters).

Can be used with any UL Listed switching mechanism rated to include 1 amp, 9 VDC load.

Maximum line impedance for initiating device: 5 ohms.

If primary power fails, the alarm system continues to work due to battery backup feature.

Battery Backup Power - (circuit not supervised) 9 VDC.

Complete package includes standard SJE SignalMaster® control switch with 10 (ALM-2-1) or

20 (ALM-2) feet of cable, mounting clamp, and cord bung.

Switching mechanism operates on low voltage and is isolated from the power line to reduce the

possibility of shock.

Low battery chirp.

External terminal block for easy fl oat switch installation.

Three-year limited warranty.

• Periodically inspect the product. Check that the cable has not become worn or that the housing has not been damaged so as to impair the protection of the

PREVENTATIVE MAINTENANCE

product. Replace the product immediately if any damage is found or suspected.

• Periodically check to see that the fl oat is free to move and operate the switch.

• Use only SJE-Rhombus

®

replacement parts.

LIBERTY PUMPS® THREE-YEAR LIMITED WARRANTY

Liberty Pumps, Inc. warrants that products of its manufacture

are free from all factory defects in material and workmanship for a

period of 3 years from the date of purchase. The date of purchase

shall be determined by a dated sales receipt noting the model

and serial number. The dated sales receipt must accompany the

returned product if the date of return is more than 3 years from

the date of manufacture noted on the product.

The manufacturer’s obligation under this Warranty shall be

limited to the repair or replacement of any parts found by the

manufacturer to be defective, provided the part or assembly is

returned freight prepaid to the manufacturer or its authorized

service center, and provided that none of the following warrantyvoiding characteristics are evident:

The manufacturer shall not be liable under this Warranty if

the product has not been properly installed; if it has been

disassembled, modifi ed, abused or tampered with; if the electrical

cord has been damaged or improperly spliced; if the pump

discharge has been reduced in size; if the pump has been used

in hot water or water containing sand, lime, cement, gravel, or

other abrasives; if the product has been used to pump chemicals

or hydrocarbons; if a non-submersible motor has be subject to

excessive moisture; or if the label bearing the serial and code

number has been removed.

Liberty Pumps, Inc. shall not be liable for any loss, damage or

expenses resulting from installation or use of its products, or for

consequential damages, including costs of removal, reinstallation

or transportation.

There is no other express warranty. All implied warranties,

including those of merchantability and fi tness for a particular

purpose, are limited to three years from date of purchase.

The Warranty contains the exclusive remedy of the purchaser,

and, where permitted, liability for consequential or incidental

damages under any and all warranties are excluded.

Page 2

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing this

product. A qualifi ed service person must install and

service this product according to applicable electrical

and plumbing codes.

Failure to follow these precautions could result in serious injury or death. Replace product immediately if switch cable becomes damaged

or severed. Keep these instructions with warranty after installation. This product must be installed in accordance with National Electric Code, ANSI/

NFPA 70 so as to prevent moisture from entering or accumulating within boxes, conduit bodies, fi ttings, fl oat housing, or cable.

EXPLOSION OR FIRE HAZARD

Do not use this product with fl ammable liquids.

Do not install in hazardous locations as defi ned by

National Electrical Code, ANSI/NFPA 70.

For detailed specifi cations on this product, or for the complete line of

Liberty Pumps

®

products, visit our web site at www.libertypumps.com.

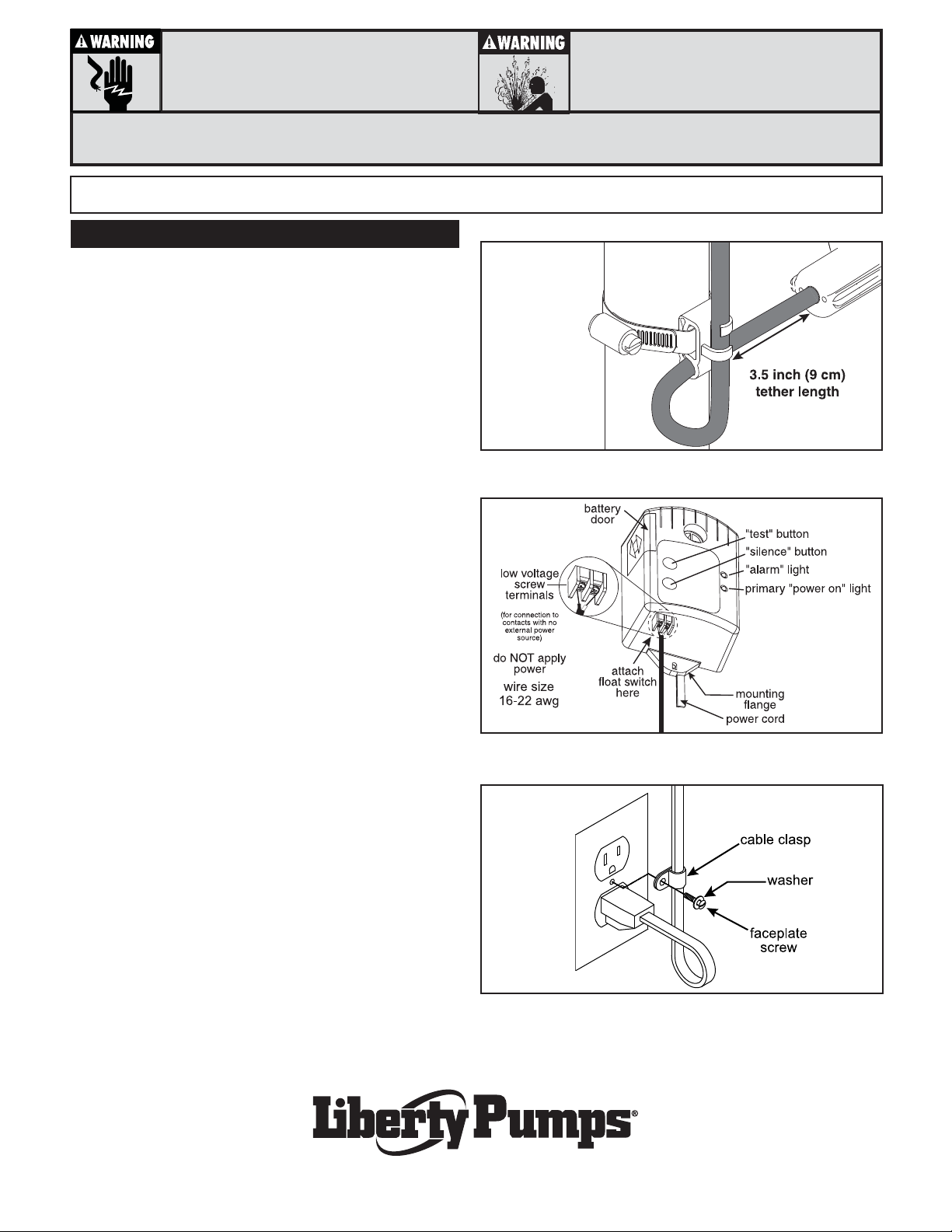

INSTALLING THE ALARM & FLOAT SWITCH

1. Determine indoor mounting location for alarm.

2. Insert screw (supplied) at desired wall location.

Note: Screw is to be located over wall stud or used with

a wall anchor sized for a #8 x 1.25" self tapping screw.

3. Hang alarm using keyhole on back of enclosure. Install

second screw in mounting fl ange located on bottom of

alarm.

4. Make sure power to alarm is disconnected.

5. Place the fl oat switch cord into the clamp as shown in

Figure A.

6. Locate the clamp at the desired activation level and secure

the clamp to the discharge pipe as shown in Figure A.

Note: Do not install cord under hose clamp.

7. T ighten the hose clamp using a screwdriver. Over tightening

may result in damage to the plastic clamp. Make sure the

fl oat cable is not allowed to touch the excess hose clamp

band during operation.

Note: All hose clamp components are made of 18-8

stainless steel material. See your Liberty Pumps

for replacements.

8. Bring cable leads back to alarm and wire according to

Figure B. A cord bung is included with the kit.

Note: When used with a pump application, connect alarm

to a circuit separate from the pump circuit. This allows the

alarm to operate if the pump circuit fails.

9. Open battery door and install 9 VDC alkaline battery (not

included). Battery must be installed for backup alarm

to function. Note: The green power on light does not

come on when unit is on battery power.

10. Plug the alarm in to apply primary power. Verify that the

green "power on" light illuminates.

1 1. Check installation by manually tipping the fl oat. The horn

will sound and the "alarm" light should come on.

12. Press "silence" button to silence the horn. The horn will

silence while the red "alarm" light stays on.

13. Tip fl oat back down and press "test" button. The "alarm"

light and horn will activate.

14. T est unit once a week. Replace battery every 12 months

and after each alarm condition to ensure proper

operation. If battery is low, low battery chirp feature will

cause the horn to chirp approximately once per minute.

Replace battery when this happens.

15. Using the provided cable clasp, secure cord to outlet as

shown in Figure C. Use existing receptacle faceplate screw

and supplied washer.

16. Test unit once per week to insure proper operation.

®

supplier

Figure A

Figure B

Figure C

7299000A

7000 Apple Tree Avenue

Bergen, New York 14416 USA Phone: 1-800-543-2550

www.libertypumps.com

©SJE-Rhombus 06/12

Instl. Instr. PN 1017740D

Model TAAB

Loading...

Loading...