Liberty Pumps AE34=3-131, AE34=3-141, AE34=3-171, AE34=3-191, AE34=3-511 Installation Manual

...Page 1

SF1

SF2

25K

5K

NC

150K

100K

125K50K

15K

SEAL FAIL

AUX

1-2 ALT 2-1

SF1

SEAL FAIL

SELECTOR

TB2

HOH

O

1-2 ALT 2-1

LEAD / LAG

SELECTOR

PUMP 1PUMP 1

STOP

TESTTEST

H

O

A

L1 N

ON OFF

TM

H

O

A

43

PUMP 1PUMP 1

STOP

TESTTEST

H

O

A

L1 N

ON OFF

TM

H

O

A

4

3

PUMP 1 PUMP 2PUMP 1 PUMP 2

AUX

CONTACTS

43

TB1

ON OFF

L1 N

1 2

AUX

NO C NC

SF1

SF2

25K

5K

NC

150K

100K

125K50K

15K

SEAL FAIL

AUX

AUX

CONTACTS

3

PUMP 1PUMP 1

STOP

TESTTEST

H

O

A

L1 N

TM

H

O

A

43

H

O

A

H

O

A

OFF ON

POWER

1

2

22650 County Highway 6

Detroit Lakes, MN 56501 USA

Tel: 218-847-1317

Email: sje@sjerhombus.com

Web: www.sjerhombus.com

H

O

A

H

O

A

H

O

A

H

O

A

1-2 ALT 2-1

SF1

SF2

SEAL FAIL

LEAD / LAG

SELECTOR

25K

5K

NC

150K

100K

125K50K

15K

PUMP 1 PUMP 2

PUMP 1 PUMP 2

f

H

H

O

O

A

A

i

LEAD / LAG

100K

125K50K

25K

15K

j

5K

150K

NC

SF2

k

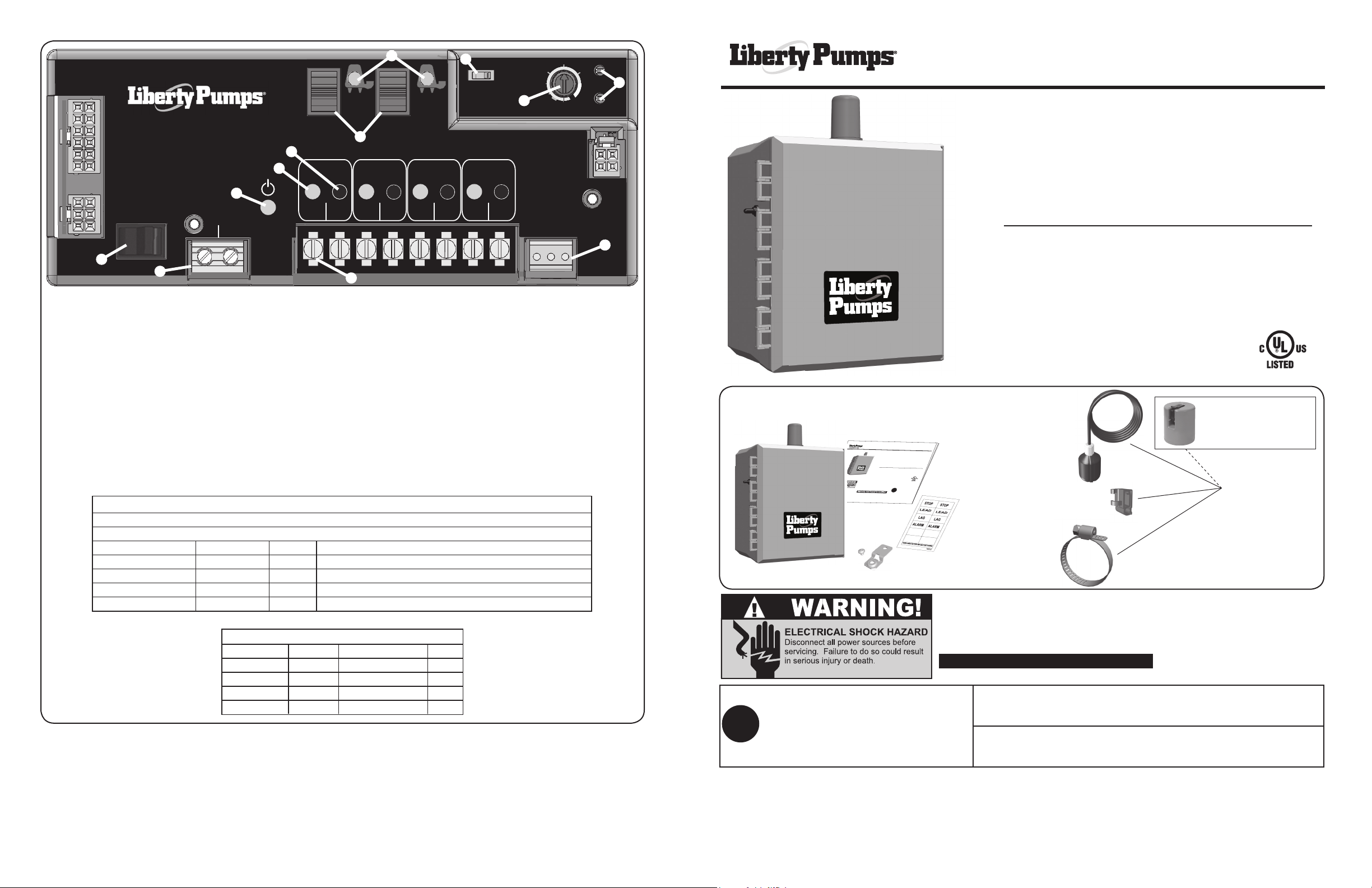

A Family and Employee Owned Company

Three Phase Duplex

d

g

e

STOP LEAD LAG ALARM

TEST TEST TEST TESTTEST TEST TEST

c

4 5 6 7 8 9 10

3

CONTACTS

AE34=3-131, AE34=3-141, AE34=3-171,

AE34=3-191, AE34=3-511, AE34=4-131,

AE34=4-141, AE34=4-171, AE34=4-191,

AE34=4-511, AE54=3-121, and AE54=4-121

a

b

h

Model shown contains optional Seal Fail circuitry.

COMPONENTS

a. ON/OFF Switch - Control/Alarm Power g. Simulate Float Buttons x4

b. 120V Incoming Power Terminals h. Float Terminals x8

c. Power LED - (Green) i. Lead/Lag Selecter Switch

d. Pump HOA Switches j. Dual Seal Fail Pot - (Optional)

e. Float LEDs - (Red) x4 k. Dual Seal Fail LEDs - (Red) - (Optional)

f. Pump LEDs

Pump Run - (Green)

Pump Fail - (Red)

PROGRAMMING INSTRUCTIONS

WITH POWER ON, HOAs OFF, FLOATS OFF OR DISCONNECTED, PRESS DESIRED FLOAT BUTTON RAPIDLY 4 TIMES AND HOLD

**PUMP LEDs WILL FLASH UPON SUCCESSFUL PROGRAMMING**

OPTIONS FLOAT BUTTON DEFAULT OPERATION

PUMP FAIL ALARM STOP ON ACTIVATES IF A PUMP CAUSES “LAG” 3 CYCLES IN A ROW

MANUAL ALARM RESET LEAD OFF LATCHES HIGH ALARM: CLEAR WITH EXTERNAL TEST SWITCH

SEAL FAIL HORN LAG OFF ACTIVATES HORN UPON SEAL FAIL

ALARM FLASHER ALARM OFF FLASHES BEACON UPON HIGH ALARM

ALARM CONDITIONS

ALARM BEACON CONTROLLER LED HORN

PUMP FAIL FLASHING RED PUMP LIGHT NO

SEAL FAIL FLASHING SF1, SF2 PROG

FLOAT FAIL FLASHING BAD FLOAT NOT LIT NO

HIGH ALARM SOLID ALARM FLOAT YES

l. Auxiliary Alarm Terminals

SJE RHOMBUS is a trademark of SJE, INC.

© 2019 SJE, Inc. All Rights Reserved.

PN 1038909E • Rev 08/19

l

Manufactured by SJE Rhombus

®

Installation and Operation Manual

Parts Included

Call factory with servicing questions:

?

1-800-543-2550

This control panel must be installed

in accordance with the National Electric

codes.

UL Type 4X enclosures are for indoor or

Three Phase

AE4=3-131, AE34=3-141, AE34=3-171,

AE34=3-191, AE34=3-511, AE34=4-131,

AE34=4-141, AE34=4-171, AE34=4-191,

AE34=4-511, AE54=3-121, and AE54=4-121

Manufactured by SJE Rhombus®

Installation

and Operation Manual

and serviced by a licensed electrician

Code NFPA-70, state and local electrical

outdoor use.

x4

?

Monday - Friday

7:00 AM to 6:00 PM EST

Technical support,

service questions:

1-800-543-2550

Duplex

This control panel must be installed and serviced by a licensed electrician in

accordance with the National Electric Code NFPA-70, state and local electrical codes.

UL Type 4X enclosures are for indoor or outdoor use.

Warranty void if panel is modied.

Liberty Pumps oers a three-year limited warranty.

For complete terms and conditions, please visit www.libertypumps.com.

Products returned must be cleaned, sanitized, or decontaminated as necessary

prior to shipment to ensure that employees will not be exposed to health

hazards in handling said material. All applicable laws and regulations shall apply.

Cable Weight available

separately. Order Liberty

Pumps Kit #001388

x3

or

x4

Control panel may be

ordered with or

without these items.

Copyright © Liberty Pumps, Inc. 2019 All rights reserved. Specications subject to change without notice. 7228000E P4

7000 Apple Tree Avenue Bergen, NY 14416 Phone 800-543-2550

Fax 585-494-1839

Email Liberty@LibertyPumps.com Web www.LibertyPumps.com

Copyright © Liberty Pumps, Inc. 2019 All rights reserved. Specications subject to change without notice. 7228000E P1

7000 Apple Tree Avenue Bergen, NY 14416 Phone 800-543-2550

Fax 585-494-1839

Email Liberty@LibertyPumps.com Web www.LibertyPumps.com

Page 2

Installing the Float Switches

CAUTION!

NOTE

3.5”

(9cm)

CAUTION!

SF1

100K

SEAL FAIL

SELECTOR

1-2 ALT 2-1

SF1

SF2

25K

5K

NC

150K

100K

125K50K

15K

SEAL FAIL

LEAD / LAG

SELECTOR

H

O

A

1-2 ALT 2-1

SF1

SF2

SEAL FAIL

LEAD / LAG

SELECTOR

25K

5K

NC

150K

100K

125K50K

15K

SF1

SF2

150K

100K

TB2

H

O

A

H

O

A

1-2 ALT 2-1

LEAD / LAG

SELECTOR

AUX

CONTACTS

NO C NC

AUX

CONTACTS

NO C NC

SF1

SF2

150K

100K

TB2

NO C NC

TEST

TEST

PUMP 2

H

O

A

1-2 ALT 2-1

SEAL FAIL

LEAD / LAG

SELECTOR

25K

5K

100K

50K

15K

PUMP 2

H

O

A

PUMP 2

H

O

A

1-2 ALT 2-1

LEAD / LAG

SELECTOR

TEST TEST TEST TESTTEST TEST TEST

AUX

CONTACTS

NO C NC

4 5 6 7 8 9 10

AUX

CONTACTS

NO C NC

NO C NC

H

O

A

H

O

A

AUX

CONTACTS

NO C NC

1-2 ALT 2-1

SF2

SEAL FAIL

LEAD / LAG

SELECTOR

25K

5K

NC

150K

125K50K

15K

SF1

SEAL FAIL

SELECTOR

SF1

100K

TB2

O

A

TM

O

A

1-2 ALT 2-1

LEAD / LAG

SELECTOR

1 2

1 2

STOP LEAD LAG ALARM

AUX

CONTACTS

NO C NC

TB1

ON OFF

L1 N

1 2

TB1

AUX

NO C NC

SF1

100K

TB2

NO C NC

3

TB1

1 2

PUMP 1PUMP 1

H

O

A

H

O

A

1

2

PUMP 1 PUMP 2

H

O

A

PUMP 1

PUMP 2

H

O

A

STOP LEAD LAG ALARM

TEST TEST TEST TESTTEST TEST TEST

AUX

CONTACTS

H

O

A

L1 N

ON OFF

1 2

H

O

A

NO C NC

4 5 6 7 8 9 10

3

1-2 ALT 2-1

SF2

SEAL FAIL

LEAD / LAG

SELECTOR

25K

5K

NC

150K

125K50K

15K

TB1 TB2

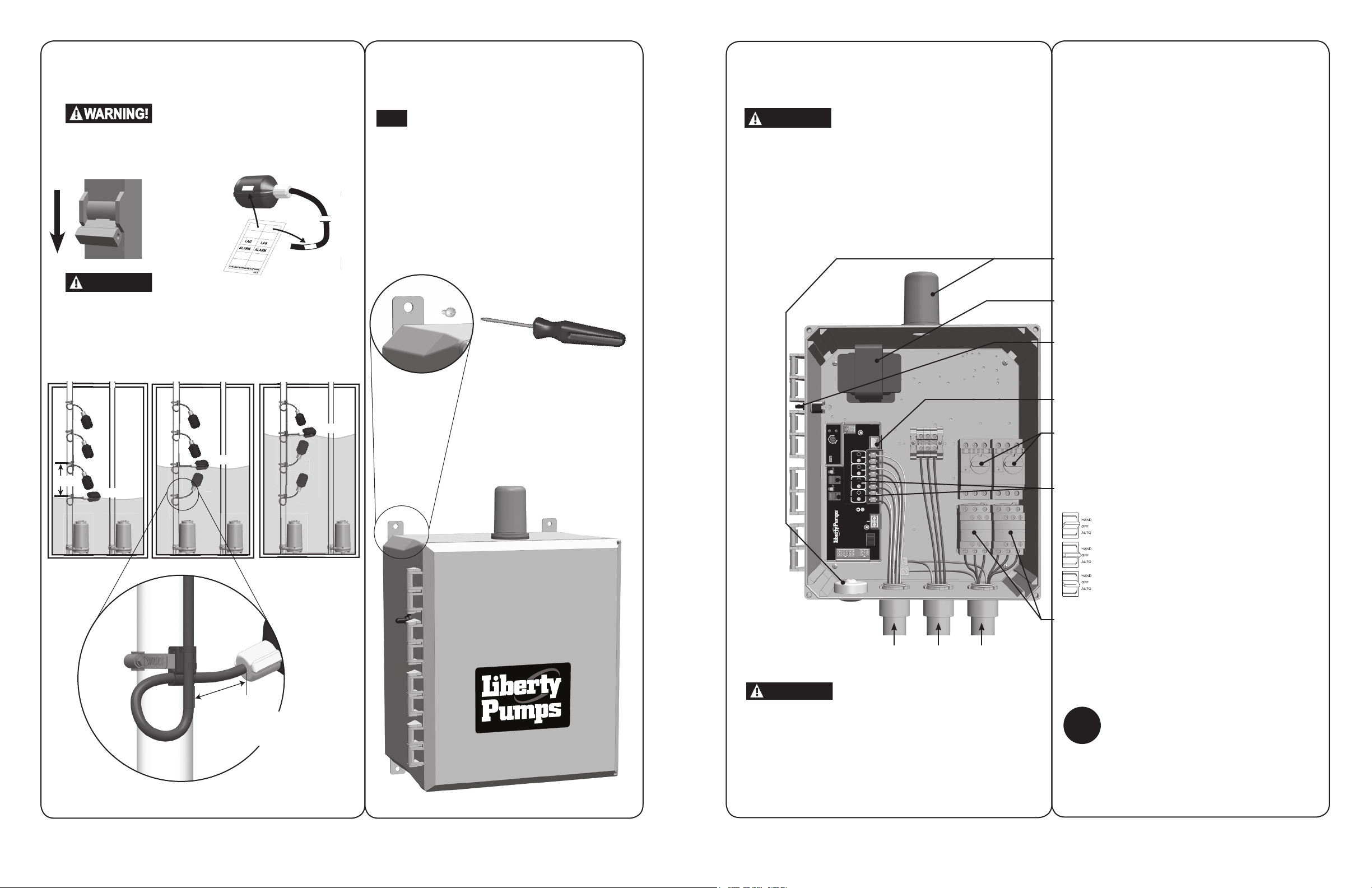

CAUTION!

The Three Phase Duplex control panel operates with fl oat switches

to activate pump STOP, LEAD pump START, LAG pump START and

high-level ALARM functions.

1

Ensure all power is turned OFF

before installing fl oats in tank.

Failure to do so could result in

serious or fatal shock.

3

If the fl oats are not properly mounted and connected in the correct

order, the pumps will not function properly.

Floats require free range of motion.

They must not touch each other or any equipment in the pump chamber.

Pipe Clamp Mounting

Label each fl oat and cord end

2

with the provided pairs of

STOP, LEAD, LAG, and ALARM

stickers.

STOP

LEAD

LEAD

STOP

Mounting the Control Panel

If the distance to the control panel exceeds the length of

the fl oat switch cords or the pump power cord, splicing

in a liquid-tight junction box will be required. For outdoor

or wet installation, we recommend a Liberty Pumps UL

Type 4X junction box.

Wiring the Control Panel

1

Determine conduit entrance locations on control panel as shown.

Check local codes and schematic on the inside cover of the panel

for the number of power circuits required.

Be sure the pump power voltage and phase are the same as the

pump motor being installed.

2

Connect the following wires to the proper terminal positions:

• incoming power

• pump 1

• pump 2

• fl oat switches

See schematic on inside cover of the control panel for details.

Operation

Liberty Pumps Three Phase Duplex control panel operates

with fl oat switches. When all fl oats are in the open or OFF

position, the panel is inactive. As the liquid level rises and

closes the STOP fl oat, the panel remains inactive until the

LEAD fl oat closes. At this point the LEAD pump will turn

ON (if the Hand-O -Auto switch is in the AUTO mode and

the power is ON). The pump will remain ON until both the

STOP and LEAD fl oats return to their OFF positions. If the

liquid level rises beyond both the STOP and LEAD fl oats to

reach the LAG fl oat, the lag pump will turn ON (if the HandO -Auto switch is in the AUTO mode and the power is ON).

Both pumps will remain ON until the STOP, LEAD, and LAG

fl oats return to their OFF positions. If the liquid level rises

to reach the ALARM fl oat, the alarm will be activated.

Alarm System (Indicator Light and Horn)

When an alarm condition occurs, the red light and horn will

be activated.

Transformer

The transformer converts incoming three phase power to

120V to be used for control and alarm.

If the TEST/NORMAL/SILENCE switch is moved to the

SILENCE position and released, the horn will be silenced.

When the alarm condition is cleared, the alarm system is

reset.

Copyright © Liberty Pumps, Inc. 2019 All rights reserved. Speci cations subject to change without notice. 7228000E P2

7000 Apple Tree Avenue Bergen, NY 14416

Lag

Alarm

Operating

range

Lead

Stop

Tighten

the

clamp.

Hose clamp is 18-8

stainless steel.

Lag

Alarm

Lead

Stop

Make sure hose clamp

band does not interfere

with fl oat operation.

Do not install cord under

hose clamp.

Phone 800-543-2550

Lag

Alarm

Lead

Stop

Fax 585-494-1839

Email Liberty@LibertyPumps.com Web www.LibertyPumps.com

Auxiliary Contact

Form C - Can be wired normally open or normally closed.

SF2

SF2

150K

150K

125K50K

125K50K

NC

NC

100K

5K

5K

15K

AUX

15K

25K

25K

1-2 ALT 2-1

1-2 ALT 2-1

H

O

H

H

H

H

H

O

LEAD / LAG

LEAD / LAG

A

A

A

O

O

PUMP 2

PUMP 2

PUMP 2

PUMP 1

PUMP 1

PUMP 1

A

Tel: 218-847-1317

22650 County Highway 6

Email: sje@sjerhombus.com

Detroit Lakes, MN 56501 USA

Web: www.sjerhombus.com

STOP LEAD LAG ALARM

NO C NC

CONTACTS

10

9

8

7

6

TEST TEST TEST

5

4

4 5 6 7 8 9 10

TEST

TEST TEST TEST TESTTEST TEST TEST

3

3

2

1

POWER

OFF ON

Typical Layout

(May vary with

options ordered).

Float

Switches

Incoming

Power

Pumps

You must use conduit sealant to prevent

moisture or gases from entering the panel.

Type 4X conduit must be used to maintain a Type 4X rating of

the control panel.

3

Verify correct operation of control panel after installation is

complete.

Copyright © Liberty Pumps, Inc. 2019 All rights reserved. Speci cations subject to change without notice. 7228000E P3

7000 Apple Tree Avenue Bergen, NY 14416

Phone 800-543-2550

Fax 585-494-1839

Motor Protective Switches

Each pump circuit has motor protective switches that

provides pump disconnect, overload, and branch circuit

protection. Adjust overload to pump FLA.

Hand-Off -Auto (HOA) Switches

The HOA 3-way switches control pump functions.

In HAND mode, the pump will turn ON.

OFF turns the pump OFF.

In AUTO mode, commands from the fl oat switches

turn each pump ON and OFF.

Motor Contactors

Motor contactors control pumps by switching electrical lines.

Technical support,

?

service questions:

1-800-543-2550

Monday - Friday

7:00 AM to 6:00 PM Eastern Time

Email Liberty@LibertyPumps.com Web www.LibertyPumps.com

Loading...

Loading...