Page 1

Single Phase Duplex

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing

this product. A qualified service person must install

and service this product according to applicable

electrical and plumbing codes.

EXPLOSION OR FIRE HAZARD

Do not use this product with flamable liquids

Do not install in hazardous locations as defined

by National Electrical Code, ANSI/NFPA 70.

Failure to follow these precautions could result in serious injury or death. Replace product immediately if switch cable becomes damaged

or severed. Keep these instructions with warranty after installation. This product must be installed in accordance with National Electric

Code, ANSI/NFPA 70 so as to prevent moisture from entering or accumulating within boxes, conduit bodies, fittings, float housing, or cable.

AE21L=3, AE21H=3, AE21L=4, AE21H=4

AE24L=3, AE24H=3, AE24L=4, and AE24H=4

Manufactured by SJE-Rhombus

Installation Instructions and Operation/Troubleshooting Manual

7000 Apple Tree Avenue

Bergen, New York 14416

Phone: 1-800-543-2550

Email: liberty@libertypumps.com

www.libertypumps.com

This control panel must be installed and serviced by a licensed electrician in accordance

with the National Electric Code NFPA-70, state and local electrical codes.

All conduit running from the sump or tank to the control panel must be sealed with conduit sealant

to prevent moisture or gases from entering the panel. NEMA 1 enclosures are for indoor use only,

primarily to provide a degree of protection against contact with enclosed equipment. Cable connectors

are not required to be liquid-tight in NEMA 1 enclosures. Do not use NEMA 1 enclosures if subjected

to rain, splashing water or hose-directed water. NEMA 4X enclosures are for indoor or outdoor

use, primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing

water and hose-directed water. Cable connectors must be liquid-tight in NEMA 4X enclosures.

®

Warranty void if panel is modifi ed.

Call factory with servicing questions:

7249000B

1-800-543-2550

Page 2

Installation Instructions

Most single phase duplex panels are designed to operate as

three or four fl oat systems. The three fl oat system is standard

performing the common pump stop, lead pump start, and lag

pump start/high level alarm functions. The four fl oat system

utilizes separate fl oats for lag pump start and high level alarm.

NOTE: Options ordered may affect the number of fl oats and

their functions. Please reference the schematic provided

with the control panel for proper installation.

Installation of Floats

CAUTION: If control switch cables are not wired and mounted in

the correct location, the pump system will not function properly .

WARNING: Turn off all power before installing fl oats in pump

chamber. Failure to do so could result in serious or fatal

electrical shock.

1. Use fl oat label kit to identify and label cables on both

fl oat and stripped ends (stop, lead, lag, alarm, etc.). See

schematic for fl oat options.

2. Determine your normal operating level, as illustrated in

Figures 1-2.

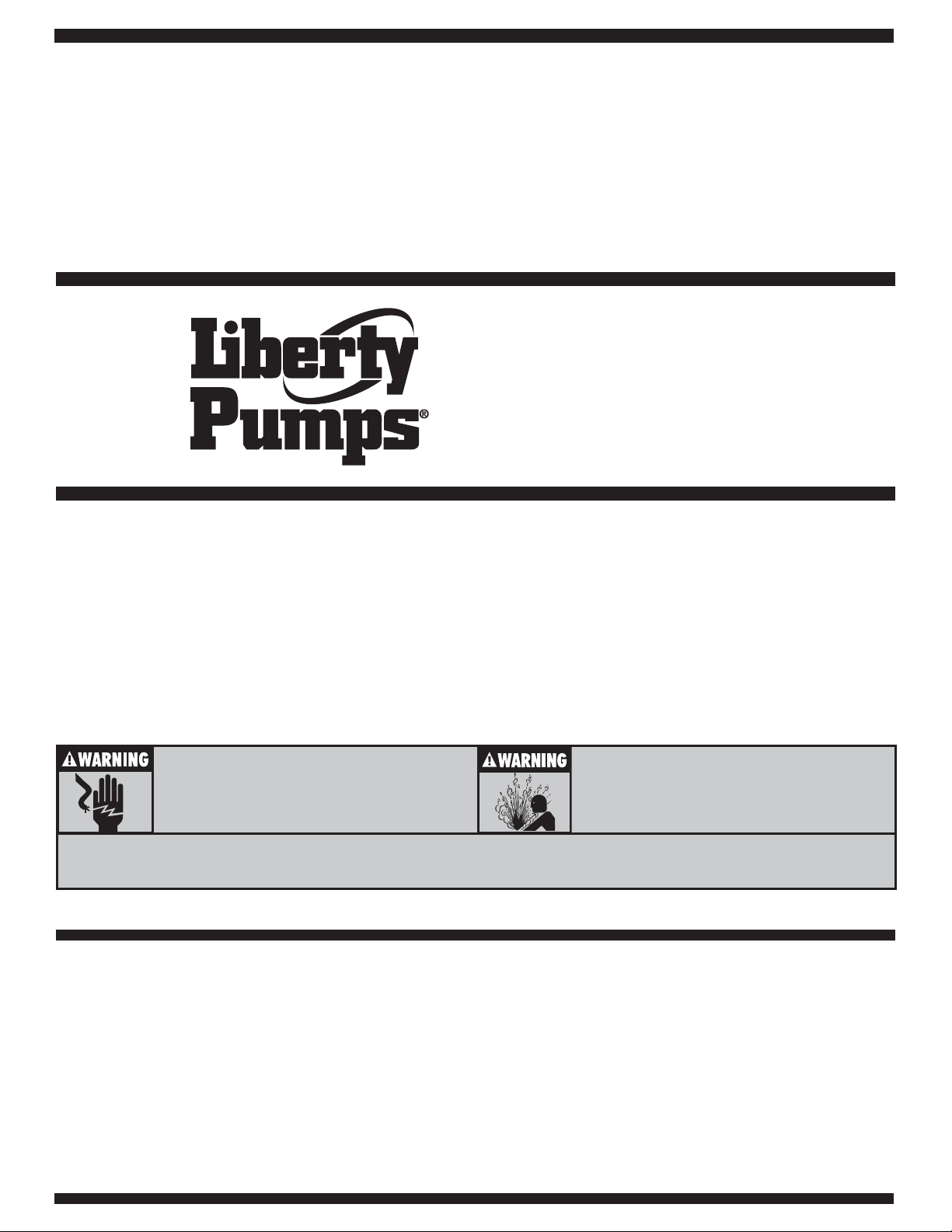

FIGURE 1: Three fl oat duplex

FIGURE 2: Four fl oat duplex

FIGURE 3: Internally weighted fl oat

3. Mount fl oat switches at appropriate levels as illustrated in

Figures 3-5. Be sure that fl oats have free range of motion

without touching each other, or other equipment in the basin.

If using the mounting clamp; follow steps 4-6.

4. Place the cord into the clamp as shown in Figure 5.

5. Locate the clamp at the desired activation level and secure

the clamp to the discharge pipe as shown in Figure 5.

NOTE: Do not install cord under hose clamp.

6. Tighten the hose clamp using a screwdriver . Over tightening

may result in damage to the plastic clamp. Make sure the

fl oat cable is not allowed to touch the excess hose clamp

band during operation.

NOTE: All hose clamp components are made of 18-8

stainless steel material. See your SJE-Rhombus® supplier

for replacements.

FIGURE 4: Float with cable weight

FIGURE 5: Mounting clamp detail

7249000B

- 2 -

Page 3

Installation Instructions

Mounting the control panel

1. Determine mounting location for panel. If

distance exceeds the length of either the fl oat

switch cables or the pump power cables,

splicing will be required. For outdoor or wet

installation, we recommend the use of a SJERhombus® liquid-tight junction box with liquidtight connectors to make required connections.

You must use conduit sealant to prevent

moisture or gases from entering the panel.

2. Mount control panel with mounting fl anges

furnished with control panel.

8. Run conduit to junction box. Drill proper size

holes for the type of conduit used. Attach liquidtight connectors to junction box.

9. Identify and label each wire before pulling

through conduit into control panel and junction

box. Pull pump power cables and control switch

cables through connectors into junction box.

Make wire splice connections at junction box.

10. Firmly tighten and seal all fi ttings on junction

box. Insure all cable connectors are liquid-tight

and sealed.

3. Determine conduit entrance locations on control

panel. Check local codes and schematic for

the number of power circuits required.

NOTE: Be sure the incoming power, voltage,

amperage, and phase meet the requirements

of the pump motors being installed. If in doubt,

see the pump identifi cation plate for electrical

requirements.

4. Drill proper size holes for type of connectors

being used.

NOTE: If using conduit, be sure that it is of

adequate size to pull the pump and switch

cables through. You must use conduit

sealant to prevent moisture or gases from

entering the panel.

5. Attach cable connectors and/or conduit

connectors to control panel.

11. If a junction box is not required, connect

pump and fl oat wires to proper position on

terminals. See schematic inside control panel

for terminal layouts.

12. Connect control/alarm and pump power

conductors to proper position on terminals.

See schematic inside control panel for terminal

connections.

NOTE: It is the recommendation of the factory to

use separate pump and control/alarm power

sources.

VERIFY CORRECT OPERATION OF CONTROL

P ANEL AFTER INST ALLATION

IS COMPLETE.

FOR INSTALLATION REQUIRING A SPLICE,

FOLLOW STEPS 6-10;

FOR INSTALLATION WITHOUT A SPLICE,

GO TO STEP 11.

6. Determine location for mounting junction box

according to local code requirements. Do not

mount the junction box inside the sump or

basin.

7. Mount junction box to proper support.

7249000B

- 3 -

Page 4

Operations

Single phase duplex panels are designed to operate with three or four fl oats for pump sequencing.

The standard fl oat functions are common pump

stop, lead pump start, lag pump start/alarm (three

fl oats), or separate lag and alarm fl oats (four

fl oats).

Three Float Operation: As the liquid level rises

to the stop fl oat and tips it to the ON (closed)

position, the panel will remain inactive. As the

liquid level tips the lead fl oat, the lead pump will

start. If the liquid level tips the lag/alarm fl oat, the

lag pump will start and the audio/visual alarm will

activate. Both pumps and the alarm will remain

active until the liquid level drops and the lag fl oat

is in the OFF (open) position. At this time the alarm

will silence. Both pumps will remain on until the

liquid level drops to normal and all three fl oats

are in the OFF (open) position. When both pumps

have stopped running, the alternator will switch

the lead pump and lag pump operating functions

in the next sequence.

Four Float Operation: The alarm will activate

and remain on only if the alarm fl oat is tipped to

the ON (closed) position.

Control and Alarm Lights

Lights will illuminate when control/alarm power is

supplied.

Float Status Lights

Lights will illuminate when the respective fl oat is

in the closed position.

Circuit Breaker (optional)

The pump circuit has a thermal-magnetic circuit

breaker which provides pump disconnect and

branch circuit protection.

Dry Auxiliary Contacts

(standard feature)

Normally open - Contacts are open under normal conditions and closed when alarm condition

is present.

Normally closed - Contacts are closed under

normal conditions and open when alarm condition

is present. Both types automatically reset once

alarm condition is cleared.

Alarm System (Horn and Indicator standard)

When an alarm condition occurs, a red light and

a horn will be activated. If the test/normal/silence

switch is moved to the silence position, the horn

will be silenced. When the alarm condition is

cleared, the alarm system is reset. The alarm

system can be tested by moving the test/normal/

silence switch to the test position.

HOA Switch

A hand-off-automatic switch is provided for each

pump. In the hand mode, the pump will turn on

unless other safety features are employed. In

the automatic mode, the pump will turn on from

commands by the fl oat switch(es).

Pump Run Lights

The run light will be ON in either the hand or the

automatic mode when the pump is called to run.

NOTE: Some options ordered may not be included

in this manual. Certain options will require alternative circuitry not including fl oat status and control/

alarm indicators.

For information regarding the operations

of options not listed here or servicing

questions, please call a Liberty Pumps

customer service technician at

1-800-543-2550

Warranty void if panel is modifi ed.

Control and Alarm Fusing

The control circuit and alarm circuit are fused

separately.

7249000B

- 4 -

Page 5

Troubleshooting

Control/Alarm Circuit Board Power

If the green power status indicators are not

illuminated:

1. Check to see if the fuses on the circuit board

are blown.

2. Check to see if the incoming control/alarm

power is present at TB1-1 and TB1-2.

the alarm light. If the light does not activate, replace

with bulb of same type.

Float Controls

Check the floats during their entire range of

operation. Clean, adjust, or replace damaged fl oats.

Checking the float resistance - The float

resistance can be measured to determine if the

fl oat is operating correctly or is defective. Use the

following procedure to measure the fl oat resistance.

Warning: Disconnect all incoming power to

panel. Failure to do so could result in serious

or fatal electrical shock.

1. Isolate the fl oat by disconnecting one or both of

the fl oat leads from the fl oat terminals.

If voltage is present and fuse is not blown,

please call factory for assistance.

Circuit Breaker (optional)

Check each pole of the circuit breaker for proper

resistance reading using the following procedure:

Warning: Disconnect all incoming power to

control panel. Failure to do so could result in

serious or fatal electrical shock.

1. Isolate the circuit breaker by disconnecting

either the line side or load side wires.

2. Place the ohmmeter leads across the

corresponding line and load terminals of each

pole.

3. With the ohmmeter on the R X 1 scale and the

breaker in the OFF position, the reading should

be infinity (very high resistance). With the

breaker in the ON position, the reading should

be nearly zero ohms (very low resistance). If

the readings are not as stated, replace the

circuit breaker with one of the same ratings.

2. Place one ohmmeter lead on one of the fl oat

wires, and the other ohmmeter lead on the other

fl oat wire.

3. Place the ohmmeter dial to read ohms and

place on the R X 1 scale. With the fl oat in the

“off” position, the scale should read infi nity (high

resistance). Replace the fl oat if you do not get

this reading. With the fl oat in the ON position,

the scale should read nearly zero (very low

resistance). Replace the fl oat if you do not get

this reading.

NOTE: Readings may vary depending on the

length of wire and accuracy of the measuring

device.

Fuses

Check the continuity of each fuse. With power

OFF, pull the fuses out of the fuse blocks. With the

ohmmeter on the R X 1 scale, measure resistance.

A reading of infi nity indicates a blown fuse and must

be replaced. Replace fuse with same type, voltage

and amp rating.

Alarm Horn

Moving the test/normal/silence switch to the test

position or activating the alarm fl oat should turn on

the alarm horn. If the horn does not sound, replace

horn with same type.

Alarm Light

Moving the test/normal/silence switch to the test

position or activating the alarm fl oat should turn on

7249000B

Magnetic Contactor Coil

Warning: Disconnect all incoming power to

panel. Failure to do so could result in serious

or fatal electrical shock. Check the coil by

disconnecting one of the coil leads. Measure the

coil resistance by setting the ohmmeter on the R

X 1 scale. A defective coil will read zero or infi nity,

indicating a short or opened coil respectively.

Replace defective contactor with same type.

- 5 -

Page 6

Liberty Pumps Three-Year Limited Warranty

*

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly in the

fi eld. Disassembly, other than at Liberty Pumps or its authorized service centers, automatically voids

warranty.

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material

and workmanship for a period of 3 years from the date of purchase. The date of purchase shall be

determined by a dated sales receipt noting the model and serial number of the pump. The dated sales

receipt must accompany the returned pump if the date of return is more than 3 years from the “CODE”

(date of manufacture) number noted on the pump nameplate.

The manufacturer’s obligation under this Warranty shall be limited to the repair or replacement of any

parts found by the manufacturer to be defective, provided the part or assembly is returned freight prepaid

to the manufacturer or its authorized service center, and provided that none of the following warrantyvoiding characteristics are evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed;

if it has been disassembled, modifi ed, abused or tampered with; if the electrical cord has been cut,

damaged or spliced; if the pump discharge has been reduced in size; if the pump has been used in

water temperatures above the advertised rating, or water containing sand, lime, cement, gravel or other

abrasives; if the product has been used to pump chemicals or hydrocarbons; if a non-submersible motor

has been subjected to excessive moisture; or if the label bearing the serial, model and code number has

been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses resulting from

installation or use of its products, or for consequential damages, including costs of removal, reinstallation

or transportation.

There is no other express warranty . All implied warranties, including those of merchantability and fi tness

for a particular purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for

consequential or incidental damages under any and all warranties are excluded.

7000 Apple Tree Avenue

Bergen, New York 14416

Phone: 1-800-543-2550

Email: liberty@libertypumps.com

©SJE-Rhombus

Printed in USA

PN1025047B • Rev 06/12

7249000B

www.libertypumps.com

- 6 -

Page 7

Three Phase Duplex

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing

this product. A qualified service person must install

and service this product according to applicable

electrical and plumbing codes.

EXPLOSION OR FIRE HAZARD

Do not use this product with flamable liquids

Do not install in hazardous locations as defined

by National Electrical Code, ANSI/NFPA 70.

Failure to follow these precautions could result in serious injury or death. Replace product immediately if switch cable becomes damaged

or severed. Keep these instructions with warranty after installation. This product must be installed in accordance with National Electric

Code, ANSI/NFPA 70 so as to prevent moisture from entering or accumulating within boxes, conduit bodies, fittings, float housing, or cable.

AE34=3-131, AE34=3-141, AE34=3-171, AE34=3-191,

AE34=3-511, AE34=4-131, AE34=4-141, AE34=4-171,

AE34=4-191, AE34=5-511, AE54=3-121, and AE54=4-121

Manufactured by SJE-Rhombus

®

Installation Instructions and Operation/Troubleshooting Manual

7000 Apple Tree Avenue

Bergen, New York 14416

Phone: 1-800-543-2550

Email: liberty@libertypumps.com

www.libertypumps.com

This control panel must be installed and serviced by a licensed electrician in accordance

with the National Electric Code NFPA-70, state and local electrical codes.

All conduit running from the sump or tank to the control panel must be sealed with conduit sealant

to prevent moisture or gases from entering the panel. NEMA 4X enclosures are for indoor or outdoor

use, primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing

water and hose-directed water. Cable connectors must be liquid-tight in NEMA 4X enclosures.

Warranty void if panel is modifi ed.

Call factory with servicing questions:

7228000B

1-800-543-2550

Page 8

Installation Instructions

3.5 inch (9 cm)

tether length

7"

5

5

suspended cable

4"

tether

length

CABLE

WEIGHT

approximate

activation level

Most three phase duplex panels are designed to operate with three

or four fl oat systems. The three fl oat system is standard, perform-

ing the common pump stop, lead pump start, and lag pump start/

high level alarm functions. The four fl oat system utilizes separate

fl oats for each function.

NOTE: Options ordered may affect the number of fl oats and

their functions. Please reference the schematic provided with

the control panel for proper installation.

Installation of Floats

CAUTION: If control switch cables are not wired and mounted in

the correct order, the pump system will not function properly.

WARNING: Turn off all power before installing fl oats in pump cham-

ber. Failure to do so could result in serious or fatal electrical shock.

1. Use fl oat label kit to identify and label cables on both fl oat and

stripped ends (stop, lead, lag, alarm, etc.). See schematic for

fl oat options.

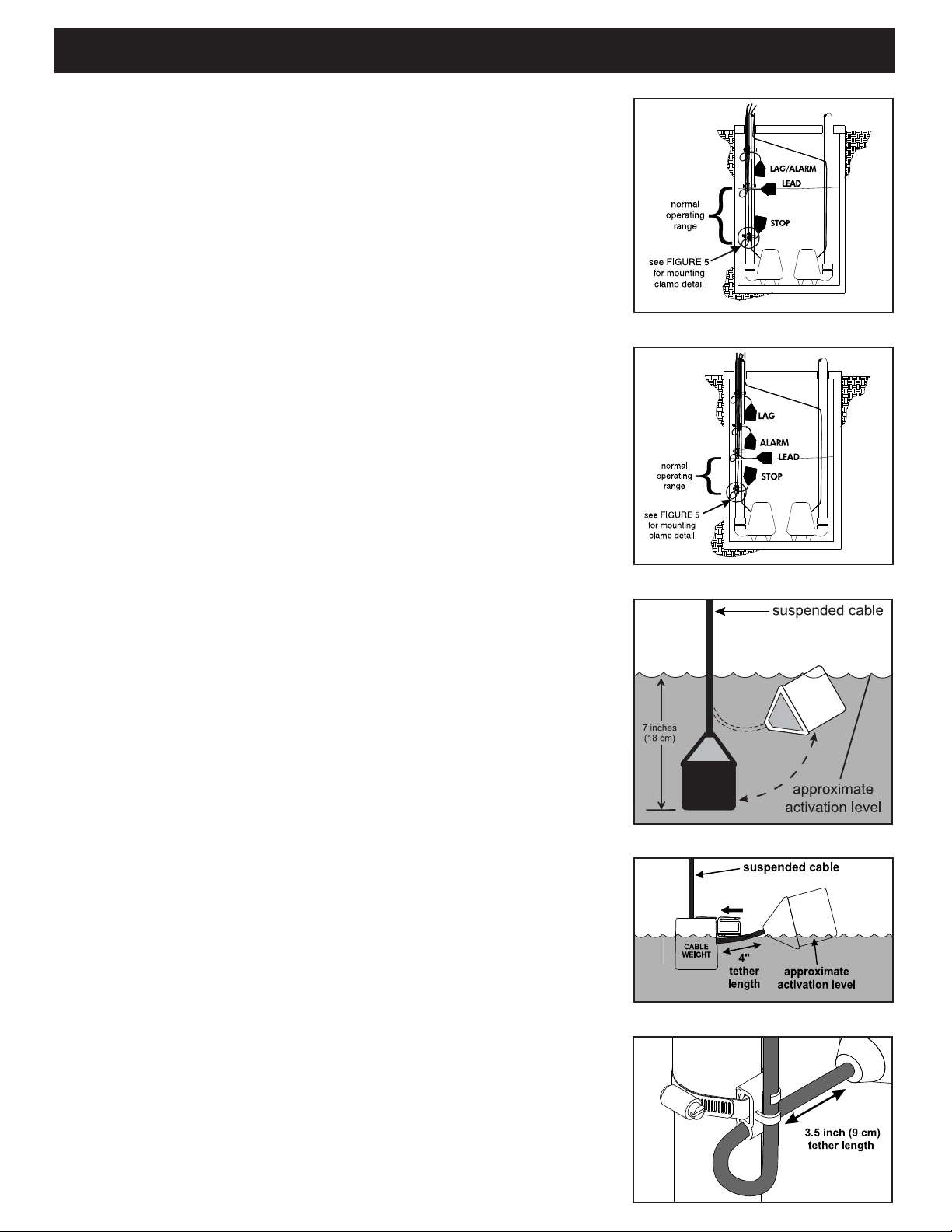

FIGURE 1: Three fl oat duplex

FIGURE 2: Four fl oat duplex

2. Determine your normal operating level, as illustrated in Figures

1 & 2.

3. Mount fl oat switches at appropriate levels as illustrated in Fig-

ures 3-5. Be sure that fl oats have free range of motion without

touching each other or other equipment in the basin.

If using the mounting clamp; follow steps 4-6.

4. Place the cord into the clamp as shown in Figure 5.

5. Locate the clamp at the desired activation level and secure the

clamp to the discharge pipe as shown in Figure 5.

NOTE: Do not install cord under hose clamp.

6. Tighten the hose clamp using a screwdriver. Over tightening

may result in damage to the plastic clamp. Make sure the fl oat

cable is not allowed to touch the excess hose clamp band

during operation.

FIGURE 3: Internally weighted fl oat

suspended cable

approximate

activation level

FIGURE 4: Float with cable weight

FIGURE 5: Mounting clamp detail

NOTE: All hose clamp components are made of 18-8

stainless steel material. See your SJE-Rhombus® supplier for

replacements.

- 2 -

7228000B

Page 9

Installation InstructionsInstallation InstructionsInstallation InstructionsInstallation InstructionsInstallation InstructionsInstallation InstructionsInstallation InstructionsInstallation InstructionsInstallation Instructions

Mounting the Control Panel

1. Determine mounting location for panel. If dis-

tance exceeds the length of either the fl oat

switch cables or the pump power cables,

splicing will be required. For outdoor or wet

installation, we recommend the use of an SJE-

®

Rhombus

tight connectors to make required connections.

You must use conduit sealant to prevent

moisture or gases from entering the panel.

2. Mount control panel with mounting devices

furnished.

3. Determine conduit entrance locations on control

panel.

NOTE: Be sure the incoming power, voltage,

amperage, and phase meet the requirements

of the pump motors being installed. If in doubt,

see the pump identifi cation plate for electrical

requirements.

4. Drill proper size holes for type of connectors

being used.

NOTE: If using conduit, be sure that it is of ad-

equate size to pull the pump and switch cables

through.

5. Attach cable connectors and/or conduit con-

nectors to control panel.

liquid-tight junction box with liquid-

8. Identify and label each wire before pulling

through conduit into control panel and junction

box. Make wire splice connections at junction

box.

9. Firmly tighten all fi ttings on junction box.

10. If a junction box is not required, pull cables

through conduit into control panel.

11. Set motor protective switches:

a) set the dials to match motor full load

amps.

b) turn dial on motor protective switch to the

ON position.

NOTE: Resetting the dial with power applied

to the motor protective switch could start

the motor.

12. Connect pump wires directly to the motor con-

tactors terminal positions T1, T2, and T3.

NOTE: Three-phase motors will run in either

direction. Check pump motor before installation

for proper rotation. To correct rotation, change

pump cable connections on any two terminals

T1-T2-T3.

13. Connect “power-in” conductors to proper

locations: 208/240/480 VAC on the 3 position

terminal block. Install tagged factory wire to

appropriate transformer primary voltage tap.

FOR INSTALLATION WITHOUT A SPLICE,

GO TO STEP 10; FOR INSTALLATION RE-

QUIRING

A SPLICE, FOLLOW STEPS 6-9.

6. Determine location for mounting junction box

according to state and local code requirements.

Mount the junction box to proper support.

7. Run conduit to junction box. Drill proper size

holes for the type of conduit used. Attach connectors to junction box.

7228000B

VERIFY CORRECT OPERATION

OF CONTROL PANEL AFTER

INSTALLATION IS COMPLETE.

- 3 -

Page 10

Operations

Three phase duplex panels are designed to operate

with three or four fl oats for pump sequencing. The

standard fl oat functions are common pump stop,

lead pump start, lag pump start/alarm (three fl oats),

or separate lag and alarm fl oats (four fl oats). Other

fl oat options, such as redundant off, are available.

Three Float Operation: As the liquid level passes

the stop fl oat and tips it to the ON (closed) position,

the panel will remain inactive. As the liquid level

tips the lead fl oat, the lead pump will start. If the

liquid level tips the lag/alarm fl oat, the lag pump

will start and the audio/visual alarm will activate.

Both pumps and the alarm will remain active until

the liquid level drops and the lag fl oat is in the

OFF (open) position. At this time the alarm will

silence. Both pumps will remain on until the liquid

level drops to normal and all three fl oats are in

the OFF (open) position. When both pumps have

stopped running, the alternator will switch the lead

pump and lag pump operating functions in the next

sequence.

Four Float Operation: The alarm will activate and

remain on only if the alarm fl oat is tipped to the ON

(closed) position.

Alarm System (Horn and Indicator)

When an alarm condition occurs, a red light and

a horn will be activated. If the test/normal/silence

switch is moved to the silence position, the horn will

be silenced. When the alarm condition is cleared,

the alarm system is reset. The alarm system can

be tested by moving the test/normal/silence switch

to the test position.

Control/Alarm Switch

Allows the control/alarm power to be turned on

or off.

HOA Switch

A hand-off-automatic switch is provided for each

pump. In the hand mode, the pump will turn on

unless other safety features are employed. In

the automatic mode, the pump will turn on from

commands by the fl oat switches.

wired in series with the magnetic contactor coil so

that on an overload trip, the magnetic contactor

will be disabled. In the event of an overload trip,

the motor protective switch must be reset by fi rst

turning the selector handle counterclockwise to

the OFF position and then turning the handle 90

clockwise to the ON position.

o

Control/Alarm Light

The light will illuminate when the control ON/OFF

switch is in the ON position.

Pump Run Lights

Each pump has a run light. The run light will be ON

in either the hand or the automatic mode when the

pump is called to run.

Float Status Lights

Lights will illuminate when the respective fl oat is in

the closed position.

Dry Auxiliary Contacts (optional)

Normally open - Contacts are open under normal

conditions and closed when alarm condition is

present.

Normally closed - Contacts are closed under

normal conditions and open when alarm condition

is present.

Both types automatically reset once alarm condition

is cleared.

Seal Failure Circuit and Indicator Light

(optional)

The seal fail circuit has resistance sensitivity and

will sense the presence of water in the pump seal

chamber. Upon installation, turn the sensitivity

dial on the seal fail module to the point where the

light turns on, then dial back slowly until the light

turns off. If water enters the seal chamber at this

point, the seal fail circuit will sense the change in

resistance. After a short time delay, the indicator

light will turn on. When the condition is cleared, the

relay will de-energize and the indicator light will turn

off. The seal fail relay has a sensitivity adjustment

so that false readings may be tuned out.

Motor Protective Switch

A motor protective switch is supplied for each

pump to provide an adjustable overload, branch

circuit protection and disconnect. The overload

must be set in the fi eld. To set the overload, dial

the amp scale to the pump’s full load amp rating

(FLA). If the FLA’s are unknown, use a calibrated

amp meter to measure the pump amperage draw

under loaded conditions. An auxiliary contact is

7228000B

Thermal Cutout (optional)

The thermal cutout is wired in series with the

magnetic contactor coil. If the pump’s thermal

switch opens on high temperature, the contactor

will turn off and stop the pump. When the thermal

switch cools and closes, the magnetic contactor

will turn on if the pump is called to run.

NOTE: Some options ordered may not be included

in this manual.

- 4 -

Page 11

Troubleshooting

Alarm Horn

Pressing the alarm test/normal/silence switch to

the test position or activating the alarm fl oat should

turn on the alarm horn. If the horn does not sound,

replace with horn of same type.

Alarm Light

Pressing the alarm test/normal/silence switch to

the test position or activating the alarm fl oat should

turn on the alarm light. If the light does not activate,

replace with bulb of same type.

3. Place the ohmmeter dial to read ohms and

place on the R X 1 scale. With the fl oat in the

“off” position, the scale should read infi nity

(high resistance). Replace the fl oat if you do

not get this reading. With the fl oat in the ON

position, the scale should read nearly zero

(very low resistance). Replace the fl oat if you

do not get this reading.

NOTE: Readings may vary depending on the

length of wire and accuracy of the measuring

device.

Fuses

Check the continuity of the fuse. Pull the fuse out

of the fuse block. With the ohmmeter on the R X

1 scale, measure resistance. A reading of infi nity

indicates a blown fuse and must be replaced.

Replace fuse with same type, voltage and amp

rating.

Alternating Relay or Device

The alternation can be sequenced by lifting the

fl oat switches or making jumper wires to simulate

the fl oats closing. If the alternator fails during

testing, replace with same type. Consult factory

at 1-800-RHOMBUS (1-800-746-6287) when in

doubt about testing procedures or results.

Float Controls

Check the fl oats through their entire range of

operation. Clean, adjust, or replace damaged

fl oats.

Checking the float resistance - The float

resistance can be measured to determine if the

fl oat is operating correctly or is defective. Use

the following procedure to measure the float

resistance:

1. Isolate the fl oat by disconnecting one or both

of the fl oat leads from the fl oat terminals.

Magnetic Contactor

Contacts - Check the contacts for severely burnt

or welded contacts. The contactor arm should

move freely.

Coil - Measure the coil by disconnecting one of the

coil leads. Measure the coil resistance by setting

the ohmmeter on the R X 1 scale. A defective

coil will read zero or infi nity, indicating a short or

opened coil respectively . If contactor is defective,

replace with same type.

NOTE: Readings may vary slightly depending on

the and accuracy of the measuring device.

Motor Protective Switch

T est by inserting a paper clip or other small device

into the test hole and push to the left. The relay

should trip.

2. Place one ohmmeter lead on one of the fl oat

wires, and the other ohmmeter lead on the

other fl oat wire.

7228000B

- 5 -

Page 12

Liberty Pumps Three-Year Limited Warranty

*

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly in the

fi eld. Disassembly, other than at Liberty Pumps or its authorized service centers, automatically voids

warranty.

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material

and workmanship for a period of 3 years from the date of purchase. The date of purchase shall be

determined by a dated sales receipt noting the model and serial number of the pump. The dated sales

receipt must accompany the returned pump if the date of return is more than 3 years from the “CODE”

(date of manufacture) number noted on the pump nameplate.

The manufacturer’s obligation under this Warranty shall be limited to the repair or replacement of any

parts found by the manufacturer to be defective, provided the part or assembly is returned freight prepaid

to the manufacturer or its authorized service center, and provided that none of the following warrantyvoiding characteristics are evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed;

if it has been disassembled, modifi ed, abused or tampered with; if the electrical cord has been cut,

damaged or spliced; if the pump discharge has been reduced in size; if the pump has been used in

water temperatures above the advertised rating, or water containing sand, lime, cement, gravel or other

abrasives; if the product has been used to pump chemicals or hydrocarbons; if a non-submersible motor

has been subjected to excessive moisture; or if the label bearing the serial, model and code number has

been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses resulting from

installation or use of its products, or for consequential damages, including costs of removal, reinstallation

or transportation.

There is no other express warranty . All implied warranties, including those of merchantability and fi tness

for a particular purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for

consequential or incidental damages under any and all warranties are excluded.

7000 Apple Tree Avenue

Bergen, New York 14416

Phone: 1-800-543-2550

Email: liberty@libertypumps.com

©SJE-Rhombus

Printed in USA

PN1025048B • Rev 06/12

7228000B

www.libertypumps.com

- 6 -

Loading...

Loading...