Liberty Pumps 441-10A Installation Manual

Installation Manual

Battery Recommended

Model 441-10A Battery Back-up System

12 Volt Emergency Sump Pump System

Model

441-10A

Back-up Pump with 10A Charger

Features

• Advanced charging system automatically

recharges battery after use

2441000A

• Audible alarm and LED advises of

emergency pump operation

• Works with marine-type deep cycle

batteries

–StormCell® battery recommended

– Battery not included

Charger:

7000 Apple Tree Avenue

Bergen, NY 14416

ph: 1-800-543-2550

fax: 1-585-494-1839

www.LibertyPumps.com

Keep this manual handy for future reference.

For replacement manual, visit LibertyPumps.com,

or contact Liberty Pumps at 1-800-543-2550.

Retain dated sales receipt for warranty.

Installer: Manual must

remain with owner/operator.

Prior to installation, record information

from pump nameplate for future reference:

Model:

Serial:

Mfg Date:

Install Date:

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

Contents

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 | EN

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 | EN

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 | EN

Assembly Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 | EN

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 | EN

Back-up Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . 7 | EN

Charger Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 | EN

Charger Connection . . . . . . . . . . . . . . . . . . . . . . . . . . .11 | EN

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 | EN

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 | EN

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 | EN

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 | EN

Safety Guidelines

This safety alert symbol is used in the manual

and on the pump to alert of potential risk for

serious injury or death.

This safety alert symbol identifies risk of

electric shock. It is accompanied with an

instruction intended to minimize potential

risk of electric shock.

This safety alert symbol identifies risk of fire.

It is accompanied with an instruction

intended to minimize potential risk of fire.

This safety alert symbol identifies risk of

serious injury or death. It is accompanied

with an instruction intended to minimize

potential risk of injury or death.

This safety alert symbol identifies battery

hazards. It is accompanied with an instruction

intended to minimize potential risk from the

battery.

Warns of hazards which, if not avoided, will

result in serious injury or death.

Warns of hazards which, if not avoided, could

result in serious injury or death.

Warns of hazards which, if not avoided, could

result in minor or moderate injury.

Signals an important instruction related to

the pump. Failure to follow these instructions

could result in pump failure or property

damage.

Read every supplied manual before using

pump system. Follow all the safety instructions

in manual(s) and on the pump. Failure to do

so could result in serious injury or death.

Safety Precautions

Accidental contact with electrically live parts, items, fluid, or

water can cause serious injury or death.

Always disconnect pump(s) from power source(s) before

handling or making any adjustments to either the pump(s),

the pump system, or the control panel.

All installation and maintenance of pumps, controls,

protection devices, and general wiring shall be done by

qualified personnel.

The pump shall be plugged into a properly fused electrical

outlet with a ground fault circuit interrupter (GFCI) that

conforms to current National Electric Code (NEC) and all

applicable local codes. All wiring must be performed by

qualified personnel.

All electrical and safety practices shall be in accordance with

the National Electrical Code®, the Occupational Safety and

Health Administration, or applicable local codes and

ordinances.

Do not remove cord and strain relief, and do not connect

conduit to pump.

Pump shall be properly grounded using its supplied

grounding conductor. Do not bypass grounding wires or

remove ground prong from attachment plugs. Failure to

properly ground the pump system can cause all metal

portions of the pump and its surroundings to become

energized.

Do not handle or unplug the pump with wet hands, when

standing on damp surface, or in water unless wearing

Personal Protective Equipment.

Always wear dielectric rubber boots and other applicable

Personal Protective Equipment (PPE) when water is on the

floor and an energized pump system must be serviced, as

submerged electrical connections can energize the water. Do

not enter the water if the water level is higher than the PPE

protection or if the PPE is not watertight.

Do not lift or carry a pump or a float assembly by its power

cord. This will damage the power cord, and could expose the

electrically live wires inside the power cord.

The electrical power supply shall be located within the length

limitations of the pump power cord, and for below grade

installations it shall be at least 4 ft (1.22 m) above floor level.

Do not use this product in applications where human contact

with the pumped fluid is common (such as swimming pools,

fountains, marine areas, etc.).

Protect the power and control cords from the environment.

Unprotected power and control (switch) cords can allow water

to wick through ends into pump or switch housings, causing

surroundings to become energized.

Do not use metal or any other electrical conducting material

to raise the float or contact anything inside an electrically live

sump pit.

RISK OF ELECTRIC SHOCK

2 | EN Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 2441000A

Use PVC cement in a well-ventilated area away from fire or

flames. Follow the PVC cement and primer manufacturer’s

RISK OF FIRE

instructions.

Do not use an extension cord to power the product. Extension

cords can overload both the product and extension cord

supply wires. Overloaded wires will get very hot and can catch

on fire.

This product requires a separate, properly fused and

grounded branch circuit, sized for the voltage and amperage

requirements of the pump, as noted on the nameplate.

Overloaded branch circuit wires will get very hot and can

catch on fire. When used, electrical outlets shall be simplex of

the appropriate rating.

Do not use this product with or near flammable or explosive

fluids such as gasoline, fuel oil, kerosene, etc. If rotating

elements inside pump strike any foreign object, sparks may

occur. Sparks could ignite flammable liquids.

These pumps are not to be installed in locations classified as

hazardous in accordance with the National Electric Code

ANSI/NFPA 70.

®

Do not use to pump flammable or explosive fluids such as

gasoline, fuel oil, kerosene, etc. Do not use in flammable and/

or explosive atmosphere. Sparks could ignite flammable

liquids.

RISK OF SERIOUS INJURY OR DEATH

Do not modify the pump/pump system in any way.

Modifications may affect seals, change the electrical loading

of the pump, or damage the pump and its components.

All pump/pump system installations shall be in compliance

with all applicable Federal, State, and Local codes and

ordinances.

Do not allow children to play with the pump system.

Do not allow any person who is unqualified to have contact

with this pump system. Any person who is unaware of the

dangers of this pump system, or has not read this manual, can

easily be injured by the pump system.

Wear adequate Personal Protective Equipment when working

on pumps or piping that have been exposed to wastewater.

Sump and sewage pumps often handle materials that can

transmit illness or disease upon contact with skin and other

tissues.

Do not remove any tags or labels from the pump or its cord.

Keep clear of suction and discharge openings. To prevent

injury, never insert fingers into pump while it is connected to

a power source.

Do not use this product with flammable, explosive, or

corrosive fluids. Do not use in a flammable and/or explosive

atmosphere as serious injury or death could result.

This product contains chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm. www.p65warnings.ca.gov.

Battery voltage can cause serious or fatal electrical shock.

Follow the battery manufacturer’s recommendations for

BATTERY HAZARDS

maintenance and safe use of battery before using charger.

Battery acid is corrosive. Wear adequate Personal Protective

Equipment when working with the battery.

Never allow the battery DC terminals to touch each other. This

can cause severe burns and start a fire. For added safety,

protect the battery in provided battery box.

Only use 12 Volt lead acid batteries with this backup system.

Use of batteries with higher or lower output voltages can

damage the backup system, leak acid or explode.

Explosive gases develop during normal battery operation.

Keep battery in a well ventilated area, away from sparks and

open flames (such as pilot light). Never smoke in vicinity of

battery. Batteries generate flammable gases both charging

and discharging, which can explode or catch fire if ignited.

,

A check valve is required in the primary sump pump

discharge pipe to prevent water from recirculating back

into the pit.

Pump clear water only with this pump.

Do not dispose of materials such as paint thinner or other

chemicals down drains. Doing so could chemically attack and

damage pump system components and cause product

malfunction or failure.

Do not use pumps with fluid over 104°F (40°C). Operating the

pump in fluid above this temperature can overheat the pump,

resulting in pump failure.

Do not use pump system with mud, sand, cement,

hydrocarbons, grease, or chemicals. Pump and system

components can be damaged from these items causing

product malfunction or failure. Additionally, flooding can

occur if these items jam the impeller or piping.

Do not run dry.

Be prepared for water to leak from the coupling or piping

when disassembling or cutting the discharge pipe. Protect

system components, tools, and supplies from getting wet. Dry

any work areas that get wet immediately.

Do not position the pump float directly under the inlet from

drain tile or in the direct path of any incoming water.

Do not expose pump or discharge to freezing temperatures.

Maximum vertical pumping distance is 18 feet (5.5 m).

If a Carbon Monoxide (CO) sensor is installed, it must be at

least 15 feet away from the battery charger in order to avoid

nuisance CO alarms. Refer to the CO detector’s installation

guidelines for more information.

Locate charger as far away from battery as DC cables permit.

Never place charger directly above battery being charged as

gases from battery will corrode and damage charger.

Never allow battery acid to drip on charger when reading

gravity or filling battery.

A Group 27 battery will provide the same performance as a

Group 31 battery, but for a shorter length of time.

2441000A Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 3 | EN

Do not expose charger to rain, snow, or liquids.

2

1

4

5

3

7

6

10 amp

CHARGER

Silence

Alarm

Reset

Libertypumps.com | Bergen, NY

2031000

Battery Backup System

AC Power

Battery Full

Charging

Low Battery

Pump Run

Alarm Silenced

Alarm

Use charger only for charging a 12 V Lead Acid Battery. It is

not intended to supply power to a low voltage electrical

system as the battery may burst and cause injury and

property damage.

12V marine-type deep cycle battery recommended (Group 27

or Group 31 AGM or Wet Cell compatible).

Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way; take it to a

qualified service professional.

Never charge a frozen battery.

Never charge lithium ion batteries with charger.

To protect battery box from chipping and gouging, do not let

the battery box sit on a concrete floor. Install the battery box

on a shelf or a protective pad (plywood, 2x4s, etc.).

Always install the battery box in a dry location that is

protected from flooding.

Use of a standard automobile battery with this charger is not

recommended as an automobile battery may require

charging after only 1–2 hours of continuous use and the

repeated charging cycles may cause early plate failure in the

battery.

General Information

The Model 441-10A battery back-up sump pump system is not

a substitute for a primary sump pump. It is designed to

temporarily provide backup to a primary sump pump during a

power outage or other problem that prevents normal operation of

the primary pump.

Install this system during a time when the primary pump will not

be needed. If this is not possible and water will enter the sump pit

during the installation process, an additional pump may be

required to keep the pit dry.

The Model 441-10A back-up pump will activate when the sump

water triggers the back-up pump’s float switch. The system will

continue to operate automatically until the issue with the primary

pump is corrected, and for as long as the charge in the battery

installed with the system lasts.

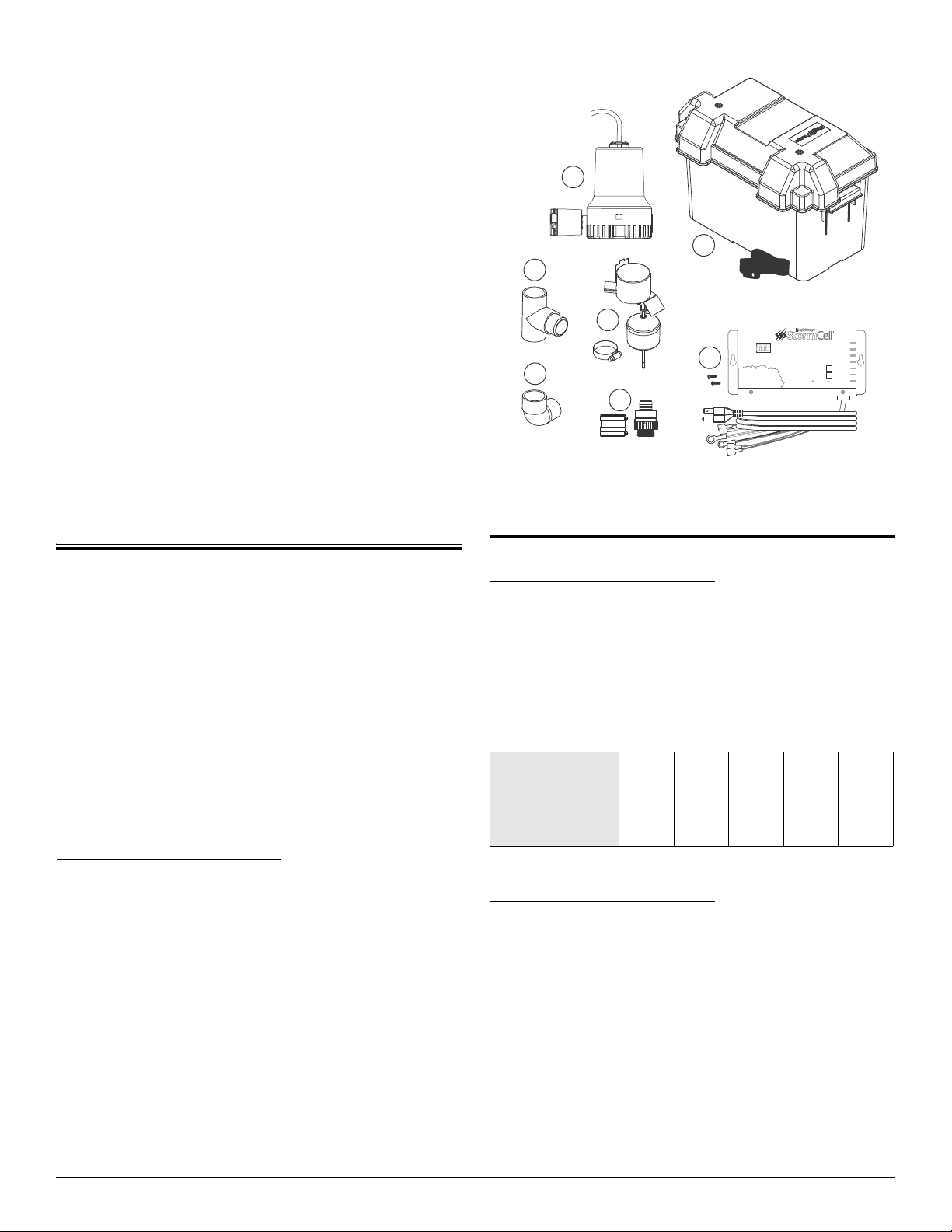

Included Parts

1. 12V Battery Back-up Pump

2. Tee

3. 1-1/2” Street Elbow

4. Back-up Float Switch with Hose Clamp

5. Primary Pump Check Valve/Coupler

6. Battery Box with Tie-down Strap

7. 10A Charger Kit

– Battery Charger

– Power and Control Leads

– Mounting Hardware and Fuse

8. Installation Manual

System Components

Battery Back-up Pump

The Model 441-10A back-up pump system flow rates are directly

tied to the voltage the battery supplies to the pump while it is

running. The flow rates shown in Table 1 were generated by

supplying the 441 pump with 12.1V at the battery terminals. When

the battery supplies the pump with more than 12.1V, the pump’s

flow rate will be greater than those shown; likewise, flow rates will

be less when the voltage is less than 12.1V.

Table 1. Back-up Pump Flow Rates

Vertical Pumping

Head (ft)

Gallons Per Hour 1500 1300 1050 450 0

Charger

The charger is designed to continuously charge, maintain peak

charge, and monitor battery health. With AC power applied, the

charger can be left unattended and will not overcharge or damage

the battery. It will also monitor and notify the user via an alarm

and horn if the battery is no longer suitable for use.

The time the charger takes to recharge a battery depends on the

battery’s reserve capacity and its current state of discharge. The

charger takes no longer than 19 hours to charge a healthy battery

to a maintenance charging point. For more detailed information,

refer to Charger Operation on page 10.

8 10121618

4 | EN Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 2441000A

Sump Pit

Diameter at

Base

µ?

Sump Pit

Diameter at

Base

µ?

Sump Pit

Depth

µ?

Sump Pit

Depth

µ?

Method A (recommended)

Method C

Method B

Battery Back-up

System may still

be installed but

the installation

may need to be

changed.

Consult Liberty

Pumps for

guidance.

Truly

Redundant

Back-up

System

Yes

No No

No

No

Yes

Yes

No

Yes

Yes

Check

Valve

Method C

Check

Valve

Check

Valve

Method A

(Recommended)

Battery

The total time the battery back-up can operate in standby while

the AC power is off greatly depends on the battery installed with

the system. Liberty Pumps recommends using a Liberty Pumps

StormCell® Group 27 or Group 31 Deep Cycle AGM or Wet Cell

lead acid battery with the 441 system. StormCell batteries have

been specifically designed to maximize reserve capacity time (the

time the battery can operate continuously before it needs to be

recharged). Additionally, StormCell batteries have been modified

to provide the highest resistance to battery plate degradation due

to repeated charging and continuous maintenance charging. With

a charged Group 27 or Group 31 deep cycle battery, this back-up

system can expect to operate for 4.25 hours continuously or up to

6 days cycling on 4 times an hour, moving 10 gallons of water at

10 feet of vertical head.

Note: In an emergency when the system’s deep cycle battery has

been depleted, any 12V automobile battery, or other lead acid

battery, may be used to keep the back-up pump operational. Be

sure to replace the deep cycle battery back into the system as

soon as possible. Automobile batteries have much lower reserve

capacities and require frequent, repeated charging that will result

in early battery failure.

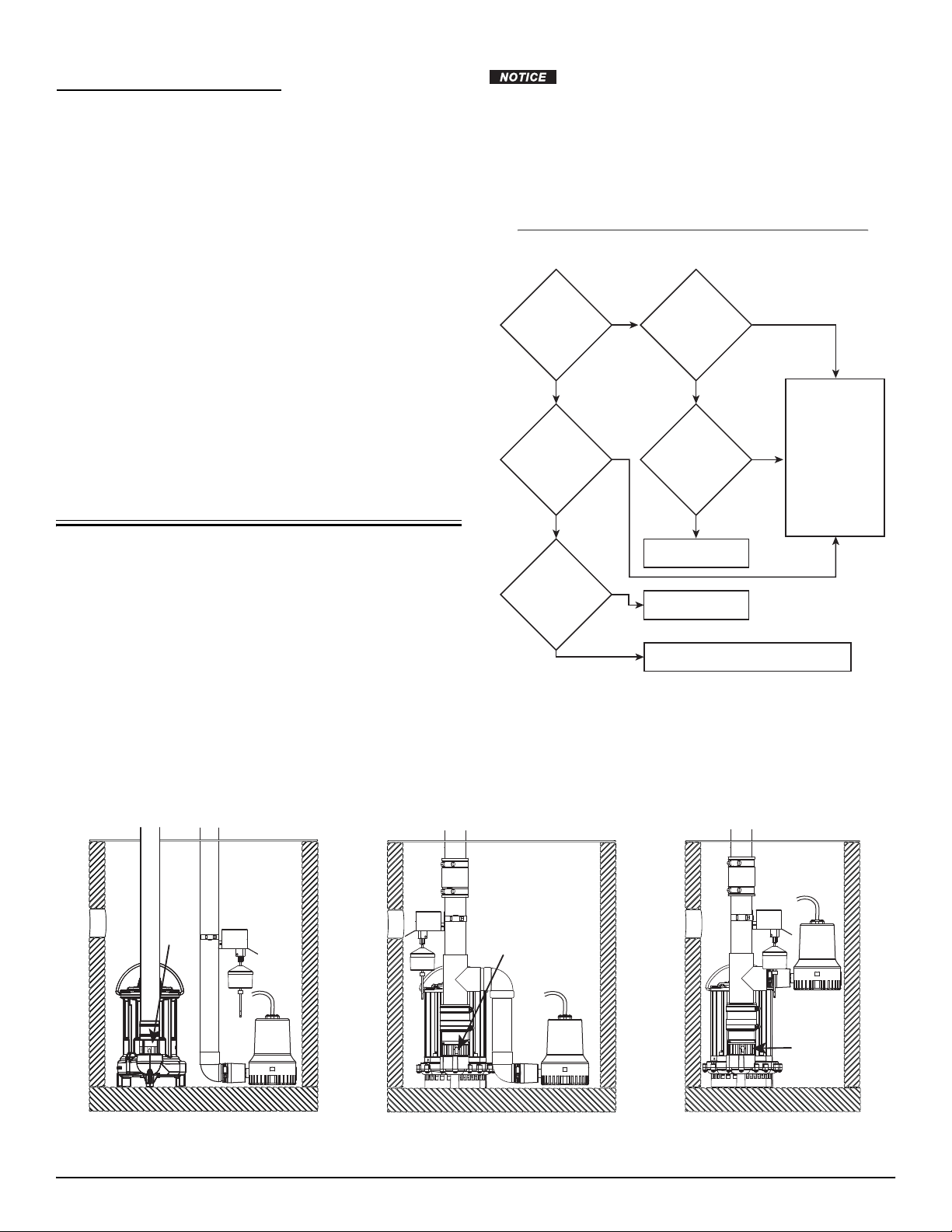

Assembly Methods

A check valve is required in the primary sump pump

discharge pipe to prevent water from recirculating back

into the pit.

Always install the back-up sump pump as close to the bottom

of the sump pit as possible.

All assembly methods require the back-up pump float switch

to have free movement.

There are three ways to assemble and install the battery back-up

pump, depending on sump pit diameter/depth and desire for a

truly redundant back-up system. Select appropriate method by

referring to Figure 1. Any method is acceptable, but Method A is

recommended. Examples are shown in Figure 2 as a visual aid.

Figure 1. Method Decision

Method B

2441000A Copyright © Liberty Pumps, Inc. 2021 All rights reserved. 5 | EN

Figure 2. Assembly Methods

Loading...

Loading...