Page 1

IMPORTANT:

Prior to installation, record Model, Serial Number, and

Code Number from pump nameplate for future reference.

MODEL ________________________

SERIAL ______________________

CODE ______________________

INSTALLATION

DATE _______________________

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contents

1.) General Information and Safety

Guidelines

2.) Installation

3.) Maintenance and Troubleshooting

Installation Manual 7212000D

Model 404 and 405 Automatic Drain Pump

MODEL 404 Residential

115 volt

MODEL 405 Commercial 115 volt

MODEL 405HV Commercial 230 volt

Contains Certified pump

©Copyright 2014 Liberty Pumps Inc. All rights reserved

Page 2

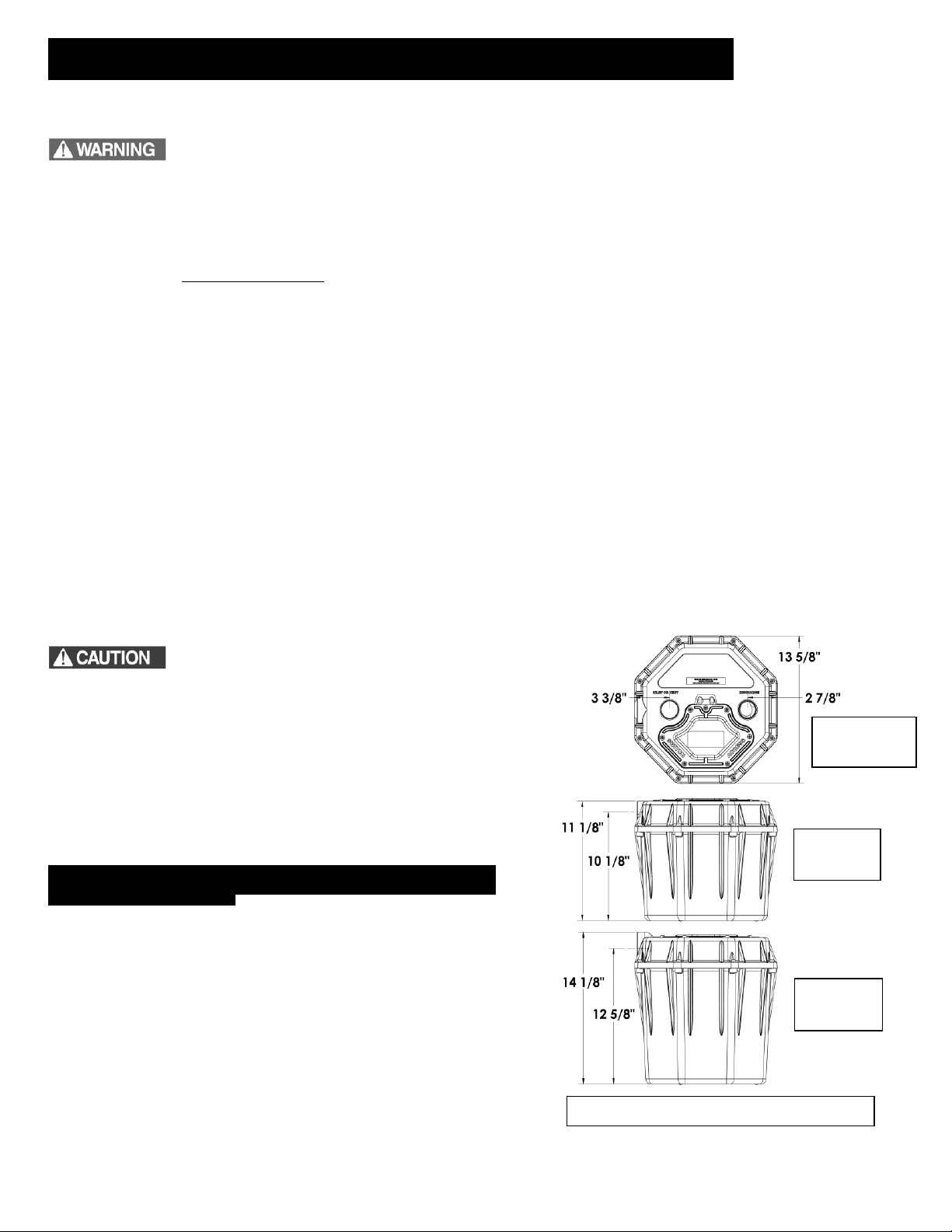

Side view

404

Side view

405

Top view

404 and 405

Dimensions are rounded to the nearest 1/8”

1. General Information and Safety Guidelines

2. Installation

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper

performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

Risk of electric shock. Always disconnect the pump from the power source before handling or making adjustments.

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

Explosion hazard during installation. PVC cleaners, primers, and cements can release explosive vapors. These heavier than

air vapors can accumulate in the tank. The heat of soldering or sweating copper or other metal pipe can ignite these vapors

causing a violent explosion. If the unit is to be connected to copper discharge or vent piping, all solvent welded PVC joints must be

allowed to cure a minimum of 24 hours. The access cover must be removed to allow the tank to be thoroughly ventilated prior to

sweating copper pipe near the unit.

This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric shock, be

certain that it is connected to a Ground Fault Circuit Interrupter (GFCI) receptacle that meets the latest requirements per UL 943

including End of Life Provision and protection from Reverse Line-Load Miswire.

Always wear rubber boots when water is on the floor and you must unplug the pump.

DO NOT bypass grounding wires or remove ground prong from attachment plugs. DO NOT use an extension cord.

This pump requires a separate, properly fused and grounded branch circuit. Make sure the power source is properly sized for the

voltage and amperage requirements of the pump, as noted on the nameplate.

The electrical outlet shall be within the length limitations of the pump power cord, and at least 4 feet above floor level to minimize

possible hazards from flood conditions.

The installation must be in accordance with the National Electric Code, Uniform Plumbing Code, International Plumbing Code, as

well as all applicable local codes and ordinances.

Keep clear of suction and discharge openings. To prevent injury, never insert fingers into pump while it is plugged in.

DO NOT use this product for flammable or corrosive liquid.

DO NOT use this product in applications where human contact with the pumped fluid is common (such as swimming pools,

fountains, etc.)

NEVER dispose of materials such as paint thinner or other chemicals down drains, as they can chemically attack and damage

pump components, potentially causing product malfunction or failure.

Model 404 Do not use this pump in water over 140

F.

Model 405 Do not use these pumps in water over 180°F

DO NOT DO NOT use pumps in mud, sand, cement, oil or chemicals.

DO NOT modify the pump in any way.

DO NOT lift or carry pump by power cord.

DO NOT remove any tags from pump or cords.

If pump is installed during construction before power is available, it

must be protected from the environment to prevent water from

entering through the cord plug end, etc.

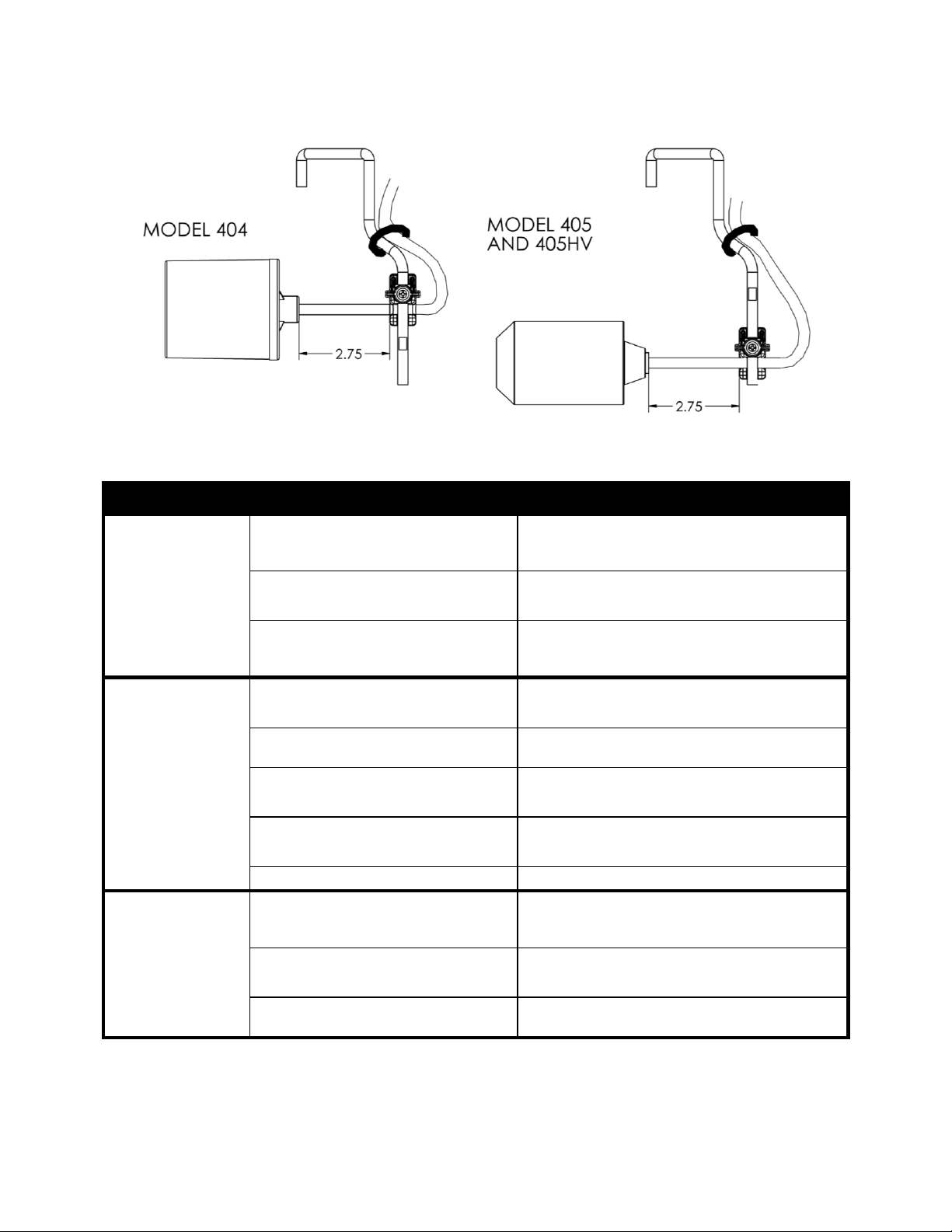

Fig. 1 – Typical Residential

Installation

This is a recommended

installation only.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 2

Page 3

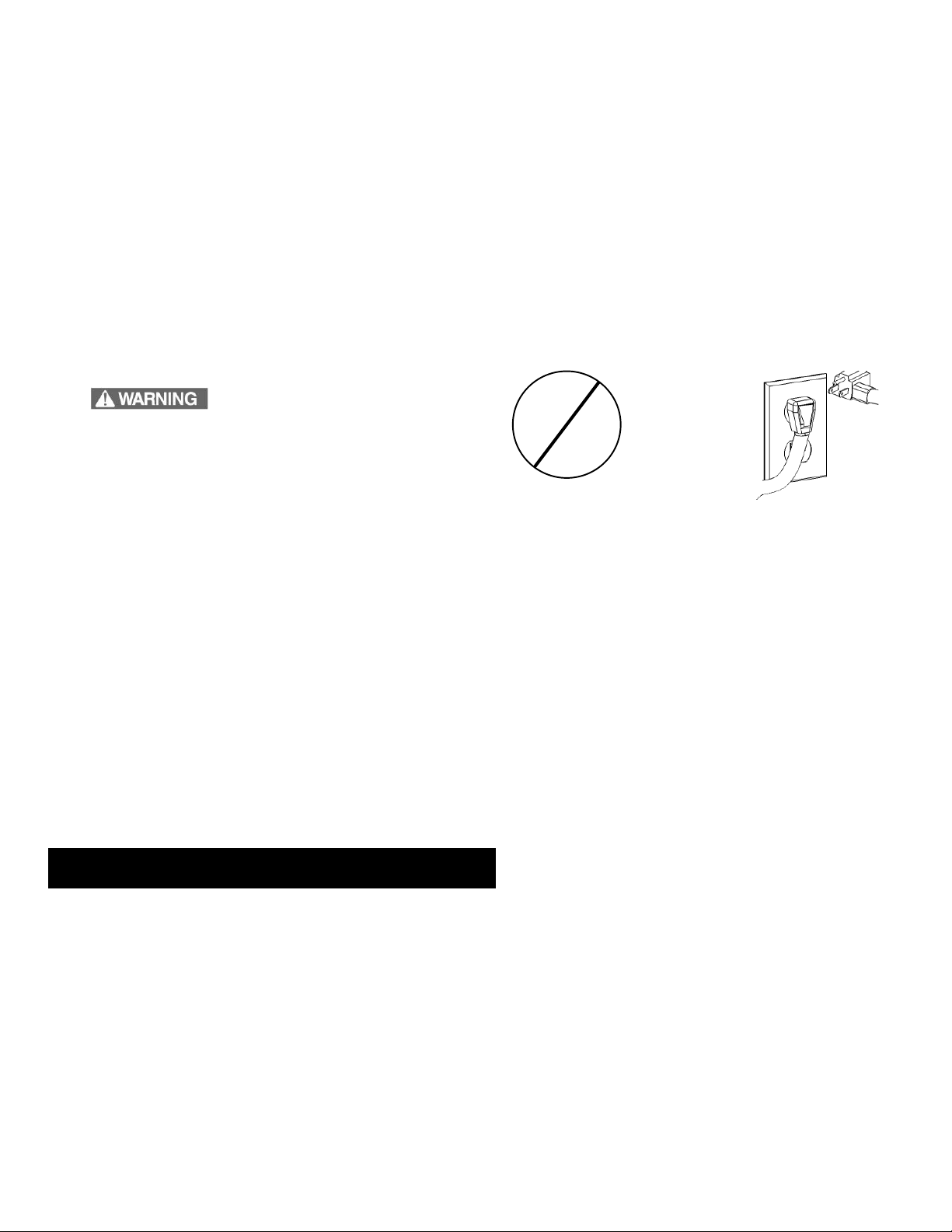

DON’T!

Fig. 1 Piggyback plug installation.

TEMPORARY

MANUAL

OPERATION

NORMAL

INLET: The pump has two ports: one on the top the other on the side, either can be used as a vent or inlet. Using the appropriate

3. Maintenance and Troubleshooting

piping (1-1/2” on the model 404 and 2” on models 405, 405HV) connect the fixture to the pump. Note: a trap shall be used between the

fixture and pump, a flange type is recommended. HAND-TIGHTEN TO PUMP. DO NOT OVERTIGHTEN OR CROSS-THREAD.

A. DISCHARGE: HAND-TIGHTEN ONLY. Install a union just above the pump to facilitate removal if necessary for cleaning or

service. Install a check valve just above the union (as close to the pump as possible) to prevent the backflow of water after each

pump cycle.

B. VENT: Provision is made for a vent stack to allow extra volume for high suds conditions, and to ensure proper drainage of the

fixture. HAND-TIGHTEN ONLY. DO NOT CAP-OFF VENT. DO NOT use ONE-WAY QUICK-VENTS or AIR ADMITTENCE

VALVES as they will not guarantee proper fixture performance. The vent pipe should have a union to facilitate removal if required

and shall be connected directly to a building or house vent.

C. POWER CORD: The pump power cord is equipped with a grounding conductor and grounding-type 3-prong plug. It should be

connected to a separately fused, grounded, 3-wire grounding-type receptacle of 15-amp capacity with the proper voltage for your

model. Make sure all electrical wiring and connections are in accordance with the National Electric Code and all applicable local

codes.

MODEL 404 - 115 volts

MODEL 405 - 115 volts

MODEL 405HV - 230 volts

Risk of electric shock. Always disconnect the pump from

the power source before handling or making adjustments.

DO NOT remove the plug or ground prong.

DO NOT use an extension cord.

The 404 and 405-series pumps come factory-equipped with a float switch mounted within the tank. These models come with two

cords - one to the float switch and the other to the pump motor. The switch cord has a series (piggyback) plug enabling the pump cord

to be plugged into the back of it (see Fig. 4). The purpose of this design is to allow temporary manual operation of the pump.

For automatic operation using Liberty's supplied switch, the two cords should be interconnected and plugged into a separately fused,

grounded outlet of proper amp capacity for your selected pump model. (See the pump’s nameplate for electrical specifications of your

model.) Both cords are equipped with 3-prong plugs and must be plugged into a properly grounded 3-wire receptacle. DO NOT

REMOVE THE GROUND PRONGS.

For manual operation, or in the event of switch failure, the pump cord can be separated and plugged into the electrical outlet, directly

bypassing the switch. 208-230V single phase pumps should only be operated without the float switch by using the circuit breaker or

panel disconnect. Do not let the pump run dry for extended periods.

Application: The 404 and 405-series drain pumps are designed for use in gray wastewater applications. They will handle small debris

and solids such as laundry lint (up to 3/8”) associated with normal gray water drainage from a sink. Larger solids should be kept out of

the pump system. The 405-series is designed for commercial applications where higher temperature drain water (up to 180 degrees F.)

may be used.

Each unit is individually factory tested to ensure proper adjustment and operation. If the unit fails to operate properly, carefully re-read

the instructions to see that they have been followed correctly. Routine maintenance is not required on the pump itself, but associated

connections may require occasional attention. Lint and foreign objects should be removed from the trap periodically. The check valve

on the discharge should also be checked for freedom of operation at the same time.

The pump is automatically turned on and off by use of a float switch mounted within the tank. This switch can be easily removed and

checked for operation by removing the access cover located on top of the unit. Once the access cover has been removed a rubber plug

must be lifted to free up the switch cord. The switch is mounted to a rod which can be removed by lifting or pulling upward.

IMPORTANT: Do not adjust the tether length. If replacing the switch, make sure to maintain the correct tether length for your

model per the following diagram. (Tether length is the distance of cord measured between the clamp and top of float switch.)

©Copyright 2014 Liberty Pumps Inc. All rights reserved 3

Page 4

Problem

Cause

Correction

Pump will not turn

on or shut off.

Blown fuse or other interruption of

power; improper voltage.

Check that the unit is securely plugged in.

Have an electrician check all wiring for proper

connections and adequate capacity.

Plugged vent, or quick-vent in use.

Be sure that an unrestricted vent at least 1-¼”

in diameter is in use. Quick-vents shall not be

used.

Defective switch or build-up on tank

wall restricting free movement of

float switch.

*Remove access cover and check that float is

free to move. If build-up restricts float, clean

and reinstall. If defective, replace switch.

Pump runs or hums

but does not pump.

Discharge is blocked or restricted.

Check the discharge line for blockage,

including ice if the line passes through or into

cold areas.

Check valve is stuck closed or

installed wrong.

Remove and examine for freedom of

operation and proper installation.

Total lift height has been reached

(see Fig. 2)

Try routing pipe to a lower level. If not

possible, another pumping station may be

required at a level of roughly half the total lift.

Pump impeller is jammed.

*Disassemble the receiver and bottom base

of pump. Remove foreign material.

Reassemble.

Trap or inlet piping is clogged.

Check the trap and inlet piping for restrictions.

Pump short-cycles.

Plugged vent, or quick-vent in use.

Be sure that an unrestricted vent at least 1-¼”

in diameter is in use. Quick-vents shall not be

used.

Defective switch.

*Remove access cover and check that float is

free to move. If build-up restricts float, clean

and reinstall. If defective, replace switch.

Check valve was not installed, is

stuck open, or is leaking.

Remove and examine for freedom of

operation and proper installation.

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly beyond float removal in the field.

Disassembly, other than at Liberty Pumps or its authorized service centers, automatically voids warranty.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 4

Page 5

Pump runs

periodically when

fixtures are not in

use.

Check valve was not installed, is

stuck open, or is leaking.

Remove and examine for freedom of

operation and proper installation.

Faucets are dripping.

Repair faucets to eliminate dripping.

Water or soap suds

come out of vent

pipe.

Vent pipe is too short or too small in

diameter.

Be sure that an unrestricted vent at least 1-

¼” in diameter is in use.

Defective switch.

*Remove tank cover and check that float is

free to move. If build-up restricts float, clean

and reinstall. If defective, replace switch.

Rate of in-flow exceeds pump

output.

Use valve on the inlet to reduce rate of inflow.

Pump operates

noisily.

Foreign objects in impeller cavity.

*Disassemble the receiver and bottom base

of pump. Remove foreign material.

Reassemble.

Piping to house structure is too

rigid.

Replace a portion of the discharge pipe with

rubber hose to absorb noise.

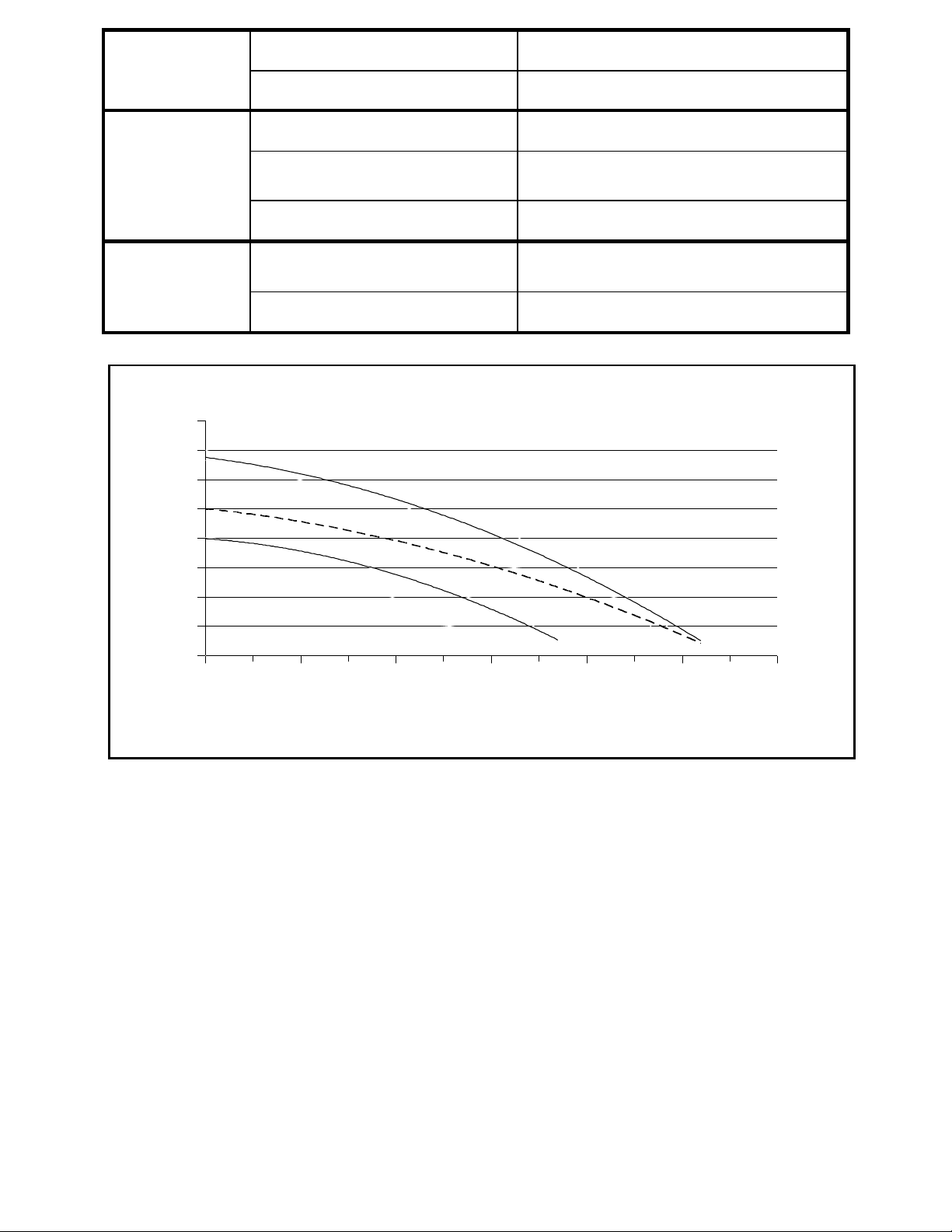

MODEL 404 AND 405

PERFORMANCE CURVES AT 80° F WATER TEMP

0

5

10

15

20

25

30

35

40

0 10 20 30 40 50 60

FLOW (GPM)

HEAD (FEET)

MODEL 404

MODEL 405

405 @ 180°F

Figure 2

3 Year Limited Warranty

Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material and workmanship

for a period of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt

noting the model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date

of return is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found by the

manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its

authorized service center, and provided that none of the following warranty-voiding characteristics are evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or

water containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or

hydrocarbons; if a non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial,

model and code number has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses

resulting from installation or use of its products, or for consequential damages, including costs of removal, reinstallation or

transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a particular

purpose, are limited to three years from the date of purchase.

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or

incidental damages under any and all warranties are excluded.

©Copyright 2014 Liberty Pumps Inc. All rights reserved 5

Page 6

7000 Apple Tree Avenue

Bergen, NY 14416

Teléfono: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contenido

1.) Información general y

recomendaciones de seguridad

2.) Instalación

3.) Mantenimiento y diagnóstico

de problemas

Manual de instalación 7212000D

Bomba de drenaje automática modelos 404 y 405

MODELO 404 residencial

de 115 voltios

MODELO 405 comercial de 115 voltios

MODELO 405HV comercial de 230 voltios

IMPORTANTE:

Apunte el modelo, el número de serie y el código que aparecen

en la placa de la bomba antes de instalarla para que le sirvan

de referencia en el futuro.

MODELO ________________________

SERIE ______________________

CÓDIGO ______________________

FECHA DE

INSTALACIÓN _________________

©Copyright 2014 Liberty Pumps Inc. Todos los derechos reservados

Page 7

Vista lateral

404

Vista lateral

405

Vista superior

404 y 405

Las dimensiones se han redondeado al octavo

de pulgada más cercano.

1. Información general y recomendaciones de seguridad

2. Instalación

Lea con atención estas instrucciones antes de instalar la bomba. Todas las bombas Liberty se someten a prueba en fábrica como

garantía de su funcionamiento. Siga estas instrucciones al pie de la letra para prevenir problemas de funcionamiento y conseguir

muchos años de servicio satisfactorio.

Riesgo de electrocución. Desconecte la bomba de la fuente de alimentación antes de moverla o realizar algún ajuste.

Sólo personal calificado podrá encargarse de instalar las conexiones y cables eléctricos necesarios para montar la bomba.

Riesgo de explosión durante la instalación. Los limpiadores, las pinturas base y los cementos de tubos de PVC pueden liberar

vapores explosivos. Estos vapores más densos que el aire se pueden acumular en el tanque. El calor emitido por soldadores de

cobre o por el proceso de soldar cobre u otros tubos de metal puede incendiar estos vapores y causar una explosión violenta. Si la

unidad se va a conectar a un desagüe de cobre o a una tubería de ventilación, todas las conexiones de los tubos de PVC unidas

por solvente se deben curar durante un mínimo de 24 horas. La tapa de acceso se debe extraer para permitir que el tanque se

ventile debidamente antes de soldar tubería de cobre cerca de la unidad.

Este producto se debe conectar a un interruptor de circuito de fallas a tierra (GFCI) o a un disyuntor.

Esta unidad lleva un conector a tierra y un enchufe tomacorriente con conexión a tierra. Enchufe la bomba a un tomacorriente

que esté debidamente conectado a tierra para evitar electrocuciones.

No pase por alto los cables de puesta a tierra ni retire las espigas a tierra de los enchufes.

Con esta bomba hay que utilizar un circuito derivado independiente conectado a tierra y con fusibles. La fuente de alimentación

tendrá que tener suficiente capacidad para cumplir con los requisitos de tensión e intensidad indicados en la placa de la bomba.

El tomacorriente deberá encontrarse al alcance del cable de alimentación de la bomba y a 1,2 metros como mínimo por encima

del piso para evitar problemas en caso de inundación.

Se deberá instalar la unidad según las disposiciones del Código eléctrico nacional (NEC) y los Códigos sobre fontanería de los

Estados Unidos, además de todos los códigos y regulaciones locales que correspondan.

Modelo 404 No use la bomba en aguas con temperaturas superiores a los 60°C (140° F).

Modelo 405 No use la bomba en aguas con temperaturas superiores a los 82°C (180°F).

NO utilice las bombas con lodo, arena, cemento, aceite o químicos.

NO modifique la bomba de ninguna manera.

NO levante ni transporte la bomba por medio del cable eléctrico.

NO retire ninguna etiqueta de la bomba o cables.

Si la bomba se instala durante una construcción antes de que haya

energía eléctrica disponible, se deberá proteger de la intemperie para

evitar que el agua ingrese a través del enchufe, etc.

Fig. 1 –

Instalación

residencial

típica

Este es

solamente un

tipo

recomendado

de instalación.

©Copyright 2014 Liberty Pumps Inc. Todos los derechos reservados - 2 -

Page 8

3. Mantenimiento y diagnóstico de problemas

ADMISIÓN: la bomba tiene dos puertos: uno en la parte superior y otro en el lateral; ambos se pueden utilizar como respiradero

o como admisión. Conecte la máquina a la bomba con una tubería del tamaño apropiado (3,81 cm/1-1/2 pulgadas para el modelo 404

y 5,08 cm/2 pulgadas para los modelos 405 y 405HV). Nota: instale un purgador entre la máquina y la bomba; se recomienda uno con

brida. ENRÓSQUELO A LA BOMBA CON LA MANO. NO APRIETE EN EXCESO NI PASE LA ROSCA.

A. SALIDA: APRIETE LA CONEXIONES SÓLO CON LA MANO. De ser necesario, instale un empalme justo encima de la bomba

para facilitar su desmontaje para tareas de limpieza y mantenimiento. Instale una válvula de retención justo encima del empalme,

lo más cerca posible de la bomba, para evitar el contraflujo del agua después de cada ciclo de bombeo.

B. RESPIRADERO: la unidad tiene un respiradero para dar cabida al volumen extra del agua jabonosa y permitir el drenaje completo

de la unidad. APRIETE LA CONEXIÓN SÓLO CON LA MANO. NO TAPE EL RESPIRADERO. NO USE UNA MANERA RÁPIDA

VENTS o VÁLVULAS DE AIRE ADMITTENCE ya que no garantizan el rendimiento accesorio adecuado. No conecte un

respiradero de paso único directamente a la unidad. Siga las instrucciones de instalación del fabricante. El respiradero deberá

contar con una unión que facilite su desmontaje y deberá estar conectado a la tubería de ventilación del edificio o de la casa.

C. CABLE DE ALIMENTACIÓN: el cable de alimentación de la bomba lleva un conector a tierra y un enchufe de 3 espigas con

conexión a tierra. Se debe enchufar a un tomacorriente trifilar con fusibles independientes conectado a tierra y con capacidad para

15 amperios, con el voltaje apropiado para el modelo. Todos los cables y conexiones deberán cumplir con el código eléctrico

nacional NEC de los Estados Unidos y los códigos locales que correspondan.

MODELO 404 - 115 voltios

MODELO 405 - 115 voltios

MODELO 405HV - 230 voltios

Riesgo de electrocución. Siempre desconecte la bomba

de la fuente de alimentación cada vez que vaya a moverla

o a realizar algún ajuste.

NO desmonte el enchufe ni la espiga a tierra.

NO use cables prolongadores.

Las bombas de las series 404 y 405 vienen equipadas con un interruptor de flotador montado dentro del tanque. Estos modelos

llevan dos cables: uno al interruptor de flotador y el otro al motor. El cable del interruptor lleva un interruptor en serie (o cascada) en el

que se puede enchufar el cable de la bomba (vea la Fig. 4). Esto permite la operación manual de la bomba durante un tiempo limitado.

Si se quiere activar la operación automática con el interruptor de Liberty, se deberán interconectar los dos cables y enchufarse a un

tomacorriente con conexión a tierra, con fusible independiente y el amperaje apropiado para el modelo. (Consulte la placa de la bomba

para informarse de las especificaciones eléctricas del modelo.) Ambos cables llevan enchufes de 3 espigas y se deben enchufar en un

tomacorriente trifilar con conexión a tierra. NO DESMONTE LAS ESPIGAS A TIERRA.

Si se prefiere la operación manual, o falla el interruptor, el cable de la bomba se puede separar y enchufar en un tomacorriente,

pasando por alto de esta manera al interruptor. Las bombas monofásicas de 208-230V se deben operar solamente sin el flotador por

medio de un disyuntor o panel de desconexión. No deje que la bomba funcione en seco por períodos prolongados.

Aplicación: las bombas de drenaje de las series 404 y 405 se deben utilizar para bombear aguas residuales. Son capaces de admitir

residuos de tamaño reducido, como por ejemplo la pelusa de la colada (hasta 0,95 cm/3/8 plg.) que sale con el desagüe normal de un

fregadero. No permita que entren partículas sólidas de mayor tamaño en la bomba. La serie 405 ha sido diseñada para aplicaciones

comerciales y se puede utilizar agua de desagüe a temperaturas superiores (82°C/180°F como máximo).

Todas las bombas se someten a prueba en fábrica como garantía de su funcionamiento. Si la unidad no funciona correctamente,

vuelva a leer las instrucciones para asegurarse de que las siguió al pie de la letra. La bomba no necesita de mantenimiento periódico,

pero sus conexiones sí pueden requerir atención ocasionalmente. Limpie el purgador regularmente. También se deberá comprobar

que la válvula de retención en el desagüe funcione sin impedimentos.

El interruptor de flotador situado dentro del tanque apaga y enciende la bomba automáticamente. Este interruptor se puede desmontar

con facilidad para comprobar su funcionamiento. Para hacerlo, retire la tapa de acceso en la parte superior de la unidad.

A continuación, levante el tapón de goma para soltar el cable del interruptor. El interruptor está montado en una varilla: para retirarla

levántela o jale de ella hacia arriba. IMPORTANTE: no cambie la longitud del amarre. Si necesita reemplazar el interruptor,

compruebe que el amarre nuevo tenga la longitud indicada en este diagrama. (La longitud del amarre es la distancia que va

desde la abrazadera hasta la parte superior del interruptor de flotador.)

©Copyright 2014 Liberty Pumps Inc. Todos los derechos reservados - 3 -

Page 9

Problema

Causa

Solución

La bomba no

se puede

encender

o apagar.

Se ha fundido un fusible o el flujo

eléctrico se ha visto interrumpido de

algún otro modo; tensión incorrecta.

Compruebe que la bomba esté enchufada.

Haga que un electricista compruebe que

todos los cables estén correctamente

conectados y la capacidad sea la necesaria.

Respiradero atascado o respiradero

de paso único instalado.

Compruebe que haya un respiradero libre

de obstrucciones de 3,2 cm. (1-¼ plg.)

de diámetro como mínimo. Rápida-aire no se

utiliza.

Interruptor de flotador defectuoso

o acumulaciones en las paredes

del tanque que limitan el movimiento

del interruptor.

*Quite la tapa de acceso y verifique que el

flotador se pueda mover sin impedimentos. Si

el problema es que hay acumulaciones que

impiden el movimiento, limpie el tanque y

vuélvalo a instalar. Si el problema es que el

interruptor está estropeado, reemplácelo.

La bomba

funciona o zumba

pero no bombea.

El desagüe está atascado.

Compruebe que no haya atascos en la línea

de desagüe, como por ejemplo hielo si la

línea pasa por zonas frías.

Compruebe que la válvula no haya

quedado cerrada o esté mal instalada.

Desmóntela y revísela para asegurarse de que

funcione y que se haya instalado correctamente.

Se alcanzó la altura máxima

(vea la Fig. 2)

Intente llevar la tubería a un nivel más bajo.

Si esto no fuera posible, puede que haga falta

instalar otra bomba a la mitad de la altura total.

El rotor de la bomba está atascado.

*Desmonte el depósito y la base de la bomba.

Limpie la obstrucción. Vuelva a montar la bomba.

El purgador o la tubería de admisión

están atascados.

Compruebe que no haya obstrucciones en

el purgador ni en la tubería de admisión.

Ciclos cortos.

Respiradero atascado o respiradero

de paso único instalado.

Compruebe que haya un respiradero libre

de obstrucciones de 3,2 cm. (1-¼ plg.) de

diámetro como mínimo. Rápida-aire no se

utiliza.

Interruptor defectuoso.

*Quite la tapa de acceso y compruebe que el

flotador se pueda mover sin impedimentos. Si

el problema es que hay acumulaciones que

impiden el movimiento, limpie el tanque y

vuélvalo a instalar. Si el problema es que el

interruptor está estropeado, reemplácelo.

No se instaló la válvula de retención,

se queda abierta o tiene una fuga.

Desmóntela y revísela para asegurarse de

que funcione y que se haya instalado correctamente.

NOTA: Liberty Pumps, Inc. no asume ninguna responsabilidad por desperfectos o lesiones resultantes del desmontaje de la bomba

sobre el terreno, excepto si se trata de desmontar el flotador. Si el desmontaje de la bomba no lo lleva a cabo Liberty Pumps o uno de

sus centros de servicio autorizados, la garantía quedará anulada.

©Copyright 2014 Liberty Pumps Inc. Todos los derechos reservados - 4 -

Page 10

La bomba se

activa cuando

la maquinaria

no está en uso.

No se instaló la válvula de retención,

se queda abierta o tiene una fuga.

Desmóntela y revísela para asegurarse de que

funcione y que se haya instalado correctamente.

Los grifos gotean.

Repare los grifos.

Sale agua o jabón

por el respiradero.

La tubería es demasiado estrecha

o demasiado corta.

Compruebe que haya un respiradero libre

de obstrucciones de 3,2 cm. (1-¼ plg.)

de diámetro como mínimo.

Interruptor defectuoso.

*Quite la tapa del tanque y compruebe que el

flotador se pueda mover sin impedimentos. Si

el problema es que hay acumulaciones que

impiden el movimiento, limpie el tanque y

vuélvalo a instalar. Si el problema es que el

interruptor está estropeado, reemplácelo.

El caudal de entrada supera al caudal

de salida de la bomba.

Cierre el caudal de entrada con la válvula en

la admisión.

La bomba hace

demasiado ruido.

Material foráneo en la cavidad

del rotor.

*Desmonte el depósito y la base de la bomba.

Limpie la obstrucción. Vuelva a montar la bomba.

La tubería a la estructura es

excesivamente rígida.

Reemplace una porción de la tubería de

desagüe con un trozo de manguera de

caucho para que absorba el ruido.

Figure 2

Garantía limitada

Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos de materiales y mano de obra por un período de 3 años a partir de la fecha de

compra. La fecha de compra se determinará con el recibo de compra fechado, que incluya el modelo y el número de serie de la bomba. Este recibo deberá

acompañar a la bomba si la fecha de devolución ocurre más de 3 años después de la fecha de fabricación (código-CODE) indicada en la placa de la unidad.Las

obligaciones del fabricante bajo esta garantía se limitarán a la reparación o el reemplazo de las piezas que el fabricante determine que son defectuosas, siempre

que la pieza o el ensamblaje, se devuelva con el porte pagado al fabricante o a uno de sus centros de servicio autorizados y que no se evidencie ninguna de las

siguientes características, lo que supondría la anulación de la garantía.El fabricante no tendrá obligación alguna bajo esta garantía si el producto no ha sido

instalado correctamente; si ha sido desmontado, modificado, abusado o forzado; si el cordón eléctrico se ha cortado, dañado o empalmado; si se redujo el

tamaño de la descarga de la bomba; si la bomba se usó con agua más caliente de la temperatura nominal, o agua con arena, cal, cemento, grava u otros

elementos abrasivos; si se utilizaron productos químicos para bombas o hidrocarburos; si un motor no sumergible fue sometido a un exceso de humedad; o si se

retiró la etiqueta con el número de serie y de código. Liberty Pumps, Inc. no se hace responsable de pérdidas, daños o gastos que resulten por la instalación o

uso de sus productos, o por daños emergentes, incluidos los costos de desmontar, reinstalar o transportar la unidad. No se ofrece ninguna otra garantía

expresa. Todas las garantías implícitas, incluidas las de comerciabilidad y adecuación para un propósito determinado, están limitadas a un plazo de tres años a

partir de la fecha de compra. Esta garantía representa el único remedio del comprador y, siempre que se permita, se excluye toda responsabilidad por daños

emergentes y fortuitos bajo toda otra garantía.

©Copyright 2014 Liberty Pumps Inc. Todos los derechos reservados - 5 -

Page 11

7000 Apple Tree Avenue

Bergen (NY) 14416

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

Table des matières

1.) Renseignements généraux

et directives de sécurité

2.) Installation

3.) Entretien et dépannage

Manuel d'installation 7212000D

Pompe d'évacuation automatique, modèles 404 et 405

MODÈLE 404 résidentiel

115 volts

MODÈLE 405 commercial 115 volts

MODÈLE 405HV commercial 230 volts

IMPORTANT :

Avant l’installation, noter les numéros de modèle, de série et de code

qui figurent sur la plaque signalétique pour éventuellement s’y référer.

MODÈLE ____________________

SÉRIE ___________________

CODE ___________________

DATE

D'INSTALLATION _____________

Contient certifié pompe

©Copyright 2014 Liberty Pumps Inc. Tous droits réservés

Page 12

Vue latérale

404

Vue latérale

405

Vue du haut

404 et 405

Les dimensions sont arrondies à 3 mm (1/8 po) près.

1. Renseignements généraux et directives de sécurité

2. Installation

Lire attentivement ces directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en usine

pour assurer son bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de problèmes de fonctionnement

et assurera des années de service sans soucis.

Danger d’électrocution. Toujours couper l'alimentation électrique la pompe avant de la manipuler ou d'y effectuer des réglages.

Les raccords électriques et le câblage pour l’installation de la pompe ne devraient être effectués que par des professionnels qualifiés.

Danger d’explosion durant l’installation. Les nettoyants à PVC, les apprêts et les colles peuvent dégager des vapeurs explosives. Ces

émanations plus lourdes que l’air peuvent s’accumuler dans le réservoir. La chaleur dégagée lors du soudage des tuyaux en cuivre ou

autre métal peut allumer ces vapeurs et causer une violente explosion. Si l’appareil doit être raccordé à un tuyau d’évacuation ou à un

évent en cuivre, il faut laisser tous les joints en PVC collés sécher pendant au moins 24 heures. Il faut retirer le couvercle d’accès afin

de bien ventiler la pompe déchiqueteuse avant de souder les tuyaux en cuivre situés à proximité de l’appareil.

Ce produit doit être raccordé à un disjoncteur de fuite de terre (différentiel).

Cette pompe est fournie avec un conducteur de mise à la terre et une fiche de branchement de type mise à la terre. Afin de réduire

les dangers d'électrocution, s’assurer que celle-ci est raccordée seulement à une prise correctement mise à la terre.

Ne pas dévier les fils de mise à la terre ou retirer la broche de mise à la terre des fiches de branchement.

Ne pas utiliser de rallonge.

Cette pompe nécessite un circuit de dérivation dédié correctement protégé par un fusible et mis à la terre. S’assurer que la tension

et l’intensité du courant électrique de la source d’alimentation électrique sont suffisantes pour répondre aux exigences de la

pompe, telles qu’indiquées sur la plaque signalétique.

La prise électrique doit se trouver à la portée du cordon d’alimentation de la pompe et à au moins 1,2 m (4 pi) au-dessus du niveau

du plancher pour minimiser les dangers possibles pouvant être causés par une inondation.

L’installation doit être faite en respectant le code national de l’électricité et tous les codes locaux et règlements en vigueur.

Modèle 404 : ne pas utiliser cette pompe dans une eau dont la température est supérieure à 140 °F.

Modèle 405 : ne pas utiliser ces pompes dans une eau dont la température est supérieure à 180 °F.

NE PAS utiliser de pompes avec de la boue, du sable, du ciment, du

pétrole ou d'autres produits chimiques.

NE PAS modifier les pompes, de quelque manière que ce soit.

NE PAS soulever ou transporter la pompe par son cordon électrique.

NE PAS retirer les étiquettes de la pompe ou des cordons.

Si la pompe est installée durant la construction, avant que

l'alimentation électrique ne soit disponible, il est important de la

garder à l'abri afin d'empêcher que de l'eau ne pénètre par l'extrémité

du cordon électrique, etc.

Fig. 1 –

Installation

résidentielle

type

Il s’agit d’une

forme

d’installation

recommandée

fournie à titre

d’exemple.

©Copyright 2014 Liberty Pumps Inc. Tous droits réservés - 2 -

Page 13

3. Entretien et dépannage

ENTRÉE : La pompe est dotée de deux orifices : un sur le dessus et un sur le côté; ils peuvent tous deux être utilisés pour l'aération ou

l'entrée. Raccorder l'accessoire à la pompe à l'aide de la tuyauterie appropriée (1 1/2 po pour le modèle 404 et 2 po pour les modèles

405 et 405HV). Remarque : un conduit de type bride (recommandé) doit être utilisé entre l'accessoire et la pompe. RESSERRER À LA

MAIN SUR LA POMPE. NE PAS TROP SERRER NI FAUSSER LES FILETS.

A. ÉVACUATION : SERRÉ À LA MAIN SEULEMENT. Installer un raccord juste au-dessus de la pompe pour en faciliter le retrait s'il

devient nécessaire de la nettoyer ou de la réparer. Installer un clapet antiretour tout juste au-dessus du raccord (aussi près que

possible de la pompe) pour éviter le refoulement d'eau après chaque cycle de la pompe.

B. ÉVENT : Une colonne de ventilation secondaire est prévue pour permettre plus de volume en présence de grandes quantités de

mousse et assurer un écoulement adéquat de l’accessoire. RESSERRER À LA MAIN SEULEMENT. NE PAS REFERMER L’ÉVENT,

les méthodes de ventilation (ÉVENTS RAPIDES UNIDIRECTIONNELS) doivent se conformer aux codes nationaux et locaux. Les évents

rapides unidirectionnels ne doivent pas être vissés directement sur ce produit. Suivre les directives d'installation du fabricant. Le tuyau

d'évent doit être doté d'un raccord afin de faciliter son retrait (le cas échéant) et être raccordé au bâtiment ou à l'évent de la maison.

C. CORDON D’ALIMENTATION ÉLECTRIQUE : Le cordon d’alimentation électrique de la pompe est muni d’un conducteur de mise

à la terre et d’une fiche de branchement de type mise à la terre. Il devrait être branché à une prise à trois fils de 115 volts avec

fusibles indépendants et mise à la terre d'une intensité de 15 ampères dont la tension convient au modèle. S’assurer que tous les

câbles et raccordements électriques sont conformes au code national de l’électricité et aux codes locaux en vigueur.

MODÈLE 404 - 115 volts

MODÈLE 405 - 115 volts

MODÈLE 405HV - 230 volts

Danger d’électrocution. Toujours débrancher la pompe

de l'alimentation électrique avant de la manipuler ou

d'y effectuer des réglages.

NE PAS retirer la fiche ou la broche de mise à la terre.

NE PAS utiliser de cordon d’extension.

Les pompes de modèles 404 et 405 sont équipées en usine d'un interrupteur à flotteur sur la paroi du réservoir. Ces modèles sont

munis de deux cordons : l’un relié à l’interrupteur à flotteur et l’autre au moteur de la pompe. Le cordon de l’interrupteur est muni d’un

connecteur en série (siamois) permettant de brancher le cordon de la pompe sur son dos (voir Fig. 4). Ce système a pour but de

permettre le fonctionnement manuel temporaire de la pompe.

Pour un fonctionnement automatique, à l'aide de l'interrupteur fourni par Liberty, les deux cordons doivent être interconnectés et

branchés dans une prise d’une intensité en ampères suffisante pour le modèle de pompe choisi, avec fusibles indépendants et mise à

la terre. (Voir la plaque signalétique de la pompe pour connaître les caractéristiques électriques du modèle.) Les deux cordons sont

munis de fiches à trois broches et doivent être branchés dans une prise à trois ouvertures avec mise à la terre adéquate. NE PAS

RETIRER LA BROCHE DE MISE À LA TERRE.

Pour permettre le fonctionnement manuel, ou en cas de défaillance de l’interrupteur, le cordon de la pompe peut être séparé et

branché dans la prise électrique, en contournant directement l’interrupteur. On doit uniquement faire fonctionner les pompes 208-230 V

monophasées sans l’interrupteur à flotteur en utilisant le disjoncteur ou l’interrupteur du panneau. Ne pas laisser la pompe fonctionner

à sec pendant de longues périodes.

Utilisation : Les pompes d'évacuation des séries 404 et 405 sont conçues pour une utilisation dans les eaux usées. Elles peuvent

tolérer de petits débris et solides, tels les fibres de buanderie (jusqu'à 3/8 po) associés à l'évacuation normale des eaux usées d'un

évier. Les plus gros solides ne doivent pas pénétrer dans le système de la pompe. La série 405 est conçue pour une utilisation

commerciale avec des eaux d'évacuation d'une température supérieure (jusqu'à 180 degrés F).

Chaque appareil est testé individuellement en usine pour assurer un bon réglage et un fonctionnement adéquat. Si l’appareil ne

fonctionne pas correctement, relire attentivement les directives pour s'assurer qu'elles ont été correctement suivies. Il n’est pas

nécessaire d’effectuer des travaux réguliers d’entretien sur la pompe en elle-même, mais les raccordements peuvent

occasionnellement en nécessiter. Les charpies et les corps étrangers devraient être retirés régulièrement du collecteur. Une vérification

du clapet antiretour du tuyau d'évacuation devrait également être faite pour s’assurer de son libre fonctionnement.

La pompe est automatiquement actionnée et éteinte grâce à un interrupteur à flotteur situé à l'intérieur du réservoir. L'interrupteur peut

facilement être retiré et son fonctionnement vérifié en retirant le couvercle d'accès situé sur le dessus de l'appareil. Une fois le

couvercle d'accès retiré, un bouchon de caoutchouc doit être soulevé afin de libérer le cordon de l'interrupteur. L'interrupteur est monté

sur une tige qui peut être retirée en soulevant ou en tirant vers l'avant. IMPORTANT : Ne pas modifier la longueur de la sangle. S'il

©Copyright 2014 Liberty Pumps Inc. Tous droits réservés - 3 -

Page 14

Problème

Cause

Correction

La pompe refuse

de s’allumer ou

s’éteindre.

Fusible brûlé ou autre interruption

d'alimentation, tension inadéquate.

S’assurer que le branchement de l’appareil

est sécuritaire. Demander à un électricien de

vérifier tous les câbles au niveau des branchements

et de s’assurer que la capacité est adéquate.

Évent bouché ou évent rapide

en utilisation.

S’assurer qu’un évent dégagé d'un diamètre

d'au moins 32 mm (1¼ po) est utilisé. Quickvent ne doit pas être utilisé.

Interrupteur défectueux ou

accumulation sur la paroi du réservoir

restreignant le mouvement libre

de l'interrupteur à flotteur.

*Retirer le couvercle du réservoir et vérifier si

le flotteur bouge librement. Si une accumulation

limite les mouvements du flotteur, nettoyer et

réinstaller. Remplacer l’interrupteur s’il est défectueux.

La pompe tourne

ou gronde, mais

ne pompe pas.

Conduits d’évacuation bloqués

entièrement ou partiellement.

Vérifier la canalisation d’évacuation pour

s'assurer qu’il n’y a pas de blocage, y compris

la formation de glace si la canalisation se

trouve dans des zones froides ou les traverse.

Clapet antiretour bloqué en position

fermée ou incorrectement installé.

Retirer et vérifier qu’il fonctionne librement

et qu’il est bien installé.

Capacité de charge ascensionnelle

totale atteinte (voir fig. 2)

Essayer de rediriger le tuyau à un niveau

inférieur. Si ce n’est pas possible, une autre

station de pompage pourrait être nécessaire à

environ la moitié de la charge ascensionnelle.

Rotor de la pompe bloqué.

*Démonter le contenant et la base de la

pompe. Retirer les corps étrangers. Remonter.

Tuyau ou conduit d'entrée bloqué.

Vérifier le conduit et le tuyau d’entrée pour

voir ce qui cause le blocage.

Cycles courts de

la pompe.

Évent bouché ou évent rapide

en utilisation.

S’assurer qu’un évent dégagé d'un diamètre

d'au moins 32 mm (1¼ po) est utilisé. .

Quick-vent ne doit pas être utilisé.

Interrupteur défectueux.

*Retirer le couvercle du réservoir et vérifier si le

flotteur bouge librement. Si une accumulation

limite les mouvements du flotteur, nettoyer et

réinstaller. Remplacer l’interrupteur s’il est défectueux.

Clapet antiretour non installé, bloqué

en position ouverte ou qui fuit.

Retirer et vérifier qu’il fonctionne librement

et qu’il est bien installé.

est nécessaire de remplacer l'interrupteur, veiller à ce que la longueur de la sangle demeure adéquate pour le modèle, en

consultant le schéma suivant. (La longueur de la sangle représente la longueur de cordon entre la pince et le flotteur.)

REMARQUE : Liberty Pumps, Inc. n’est pas responsable des dommages ou blessures résultant d’un démontage sur place, au-delà

du retrait du flotteur. Le démontage effectué ailleurs que chez Liberty Pumps ou à l’un de ses centres de services autorisés annule

automatiquement la garantie.

©Copyright 2014 Liberty Pumps Inc. Tous droits réservés - 4 -

Page 15

La pompe tourne

périodiquement

lorsque les

accessoires ne

sont pas utilisés.

Clapet antiretour non installé, bloqué

en position ouverte ou qui fuit.

Retirer et vérifier qu’il fonctionne librement

et qu’il est bien installé.

Robinets qui fuient.

Réparer les robinets pour éliminer les fuites.

De l’eau ou de la

mousse sort du

tuyau d’évent.

Tuyau d’évent trop court ou de

diamètre trop petit.

S’assurer qu’un évent dégagé d'un diamètre

d'au moins 32 mm (1¼ po) est utilisé.

Interrupteur défectueux.

*Retirer le couvercle du réservoir et vérifier si le

flotteur bouge librement. Si une accumulation

limite les mouvements du flotteur, nettoyer et

réinstaller. Remplacer l’interrupteur s’il est défectueux.

Débit entrant qui dépasse la capacité

d'évacuation de la pompe.

Utiliser la soupape de l'orifice d'entrée pour

diminuer le débit entrant.

La pompe fait

du bruit.

Corps étrangers dans les cavités

du rotor.

*Démonter le contenant et la base de la

pompe. Retirer les corps étrangers. Remonter.

Tuyau trop rigide raccordé à la

structure de la maison.

Remplacer une partie du tuyau d’évacuation par

un boyau de caoutchouc pour absorber le bruit.

Figure 2

Garantie limitée de 3 ans Liberty Pumps, Inc. garantit que les pompes sortant de son usine sont exemptes de tout défaut

de matériau et de fabrication pour une période de 3 ans à partir de la date d’achat. La date d'achat sera établie par une facture

d’achat datée indiquant les numéros de modèle et de série de la pompe. La pompe retournée doit être accompagnée de la

facture d’achat datée si la date de retour se situe à plus de 3 ans du numéro de « CODE » (date de fabrication) indiqué sur la

plaque signalétique de la pompe. L’obligation de garantie du fabricant se limite à la réparation ou au remplacement de toute pièce

jugée défectueuse par le fabricant, à condition que la pièce ou l’appareil soient retourné, franco de port, au fabricant ou à son centre

d'entretien autorisé et à condition qu’il n’y ait aucune preuve que les critères suivants annulant la garantie sont en cause. Le fabricant

ne peut en aucun cas être tenu responsable, selon les dispositions de cette garantie, si le produit n’a pas été correctement installé;

s’il a été démonté, modifié, soumis à un usage abusif ou endommagé; si le cordon électrique a été coupé, endommagé ou ligaturé;

si la taille du tuyau d’évacuation de la pompe a été réduite; si la pompe a été utilisée pour pomper de l’eau d'une température

supérieure aux recommandations ci-dessus ou de l’eau contenant du sable, de la chaux, du ciment, du gravier ou autres matières

abrasives; si le produit a été utilisé pour pomper des produits chimiques ou des hydrocarbures; si un moteur non submersible a été

exposé à de l’humidité excessive; ou si l’étiquette portant le numéro de série, de modèle et de code a été retirée. Liberty Pumps,

Inc. ne pourra être tenue responsable des pertes, dommages, frais attribuables à l’installation ou l’utilisation de ses produits ni pour

les dommages accessoires ou consécutifs, y compris les coûts de retrait, de réinstallation ou de transport. Il n’y a aucune autre

garantie expresse. Toute garantie implicite, y compris celles de qualité marchande et d'aptitude à une fin particulière, est limitée à

trois ans à partir de la date d’achat. Cette garantie contient le recours exclusif de l’acheteur et exclut, lorsque permis par la loi,

toute responsabilité pour dommages consécutifs ou accessoires en vertu de toutes autres garanties.

©Copyright 2014 Liberty Pumps Inc. Tous droits réservés - 5 -

Loading...

Loading...