Page 1

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contents

1.) General Information

2.) Safety Guidelines

3.) Installation

4.) Operation

5.) Maintenance and Troubleshooting

Installation and User Manual 7327000E

Model 331 Portable Transfer Pump

IMPORTANT:

Prior to installation, record Model,

Serial Number, and Code Number from

pump nameplate for future reference.

MODEL ___________________

SERIAL ___________________

CODE ___________________

©Copyright 2011 Liberty Pumps Inc. All rights reserved

Page 2

Length

25 ft

50 ft

100 ft

Wire Size

#16

#16

#14

2. Safety Guidelines

1. General Information

Before use, please read the following instructions carefully. Each Liberty Pump is individually factory tested to ensure proper

performance. Closely following these instructions will eliminate potential operating problems, providing years of trouble-free service.

This portable transfer pump is designed for such applications as emptying water heaters, swimming pool covers, livestock tanks, boats,

etc. When used for charging or servicing hydronic systems, the pump must be flushed with clear water afterwards to prevent corrosion.

It can also be used for an intermittent pressure boost for applications such as washing cars, cleaning driveways, etc. The motor is a

brush type air-cooled design.

Do not use under water or in wet areas. Pump is intended for dry locations only.

Do not use this pump with water over 140 F.

This manual contains information that is very important to know and understand. This information is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS.

Do not submerge motor or allow motor to be exposed to water. Personal injury and/or death could result.

Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, kerosene, etc. Do not use in a

flammable and/or explosive atmosphere. Personal injury and/or death could result.

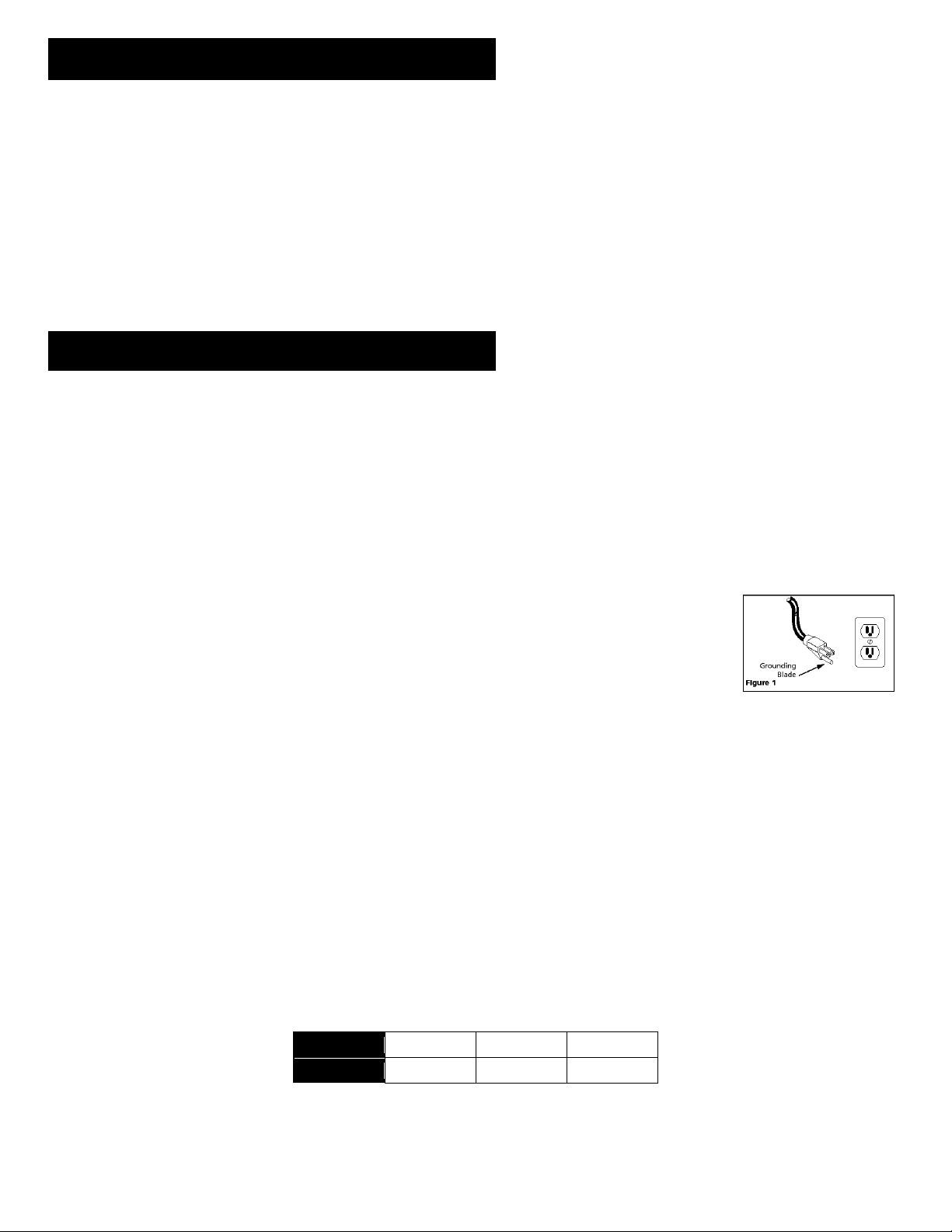

Risk of fatal electrical shock. Never remove the round grounding blade (see Fig. 1).

Cutting the cord or plug will void the warranty and make the pump inoperable.

Always disconnect the pump from power source before attempting to install or service the pump. Never

handle a pump with wet hands or when standing on a wet or damp surface or in water. Fatal electrical shock could occur.

The pump should be plugged into a properly fused electrical outlet with a ground fault circuit interrupter (GFCI) that conforms to

current National Electric codes (NEC) and local codes. All wiring must be performed by a qualified electrician.

This pump has been fitted with a 20’ power cord. Do not use an extension cord unless absolutely necessary. Follow the Extension

Cord Length Table for proper gauge of a 3-wire, grounding type extension cord.

Disconnect power and release all pressure within the system before servicing any component.

Drain all liquids from system before servicing.

Read all instructions before operation.

Secure the discharge line before starting the pump. An unsecured discharge line under pressure may whip. Personal injury and/or

death could result.

Periodically inspect pump and system components, checking for weak and/or worn hoses. Be sure all connections are secure.

Protect electrical cord from sharp objects, hot surfaces, oil and chemicals. Avoid kinking the power cord.

Extension Cord Length Table:

©Copyright 2011 Liberty Pumps Inc. All rights reserved 2

Page 3

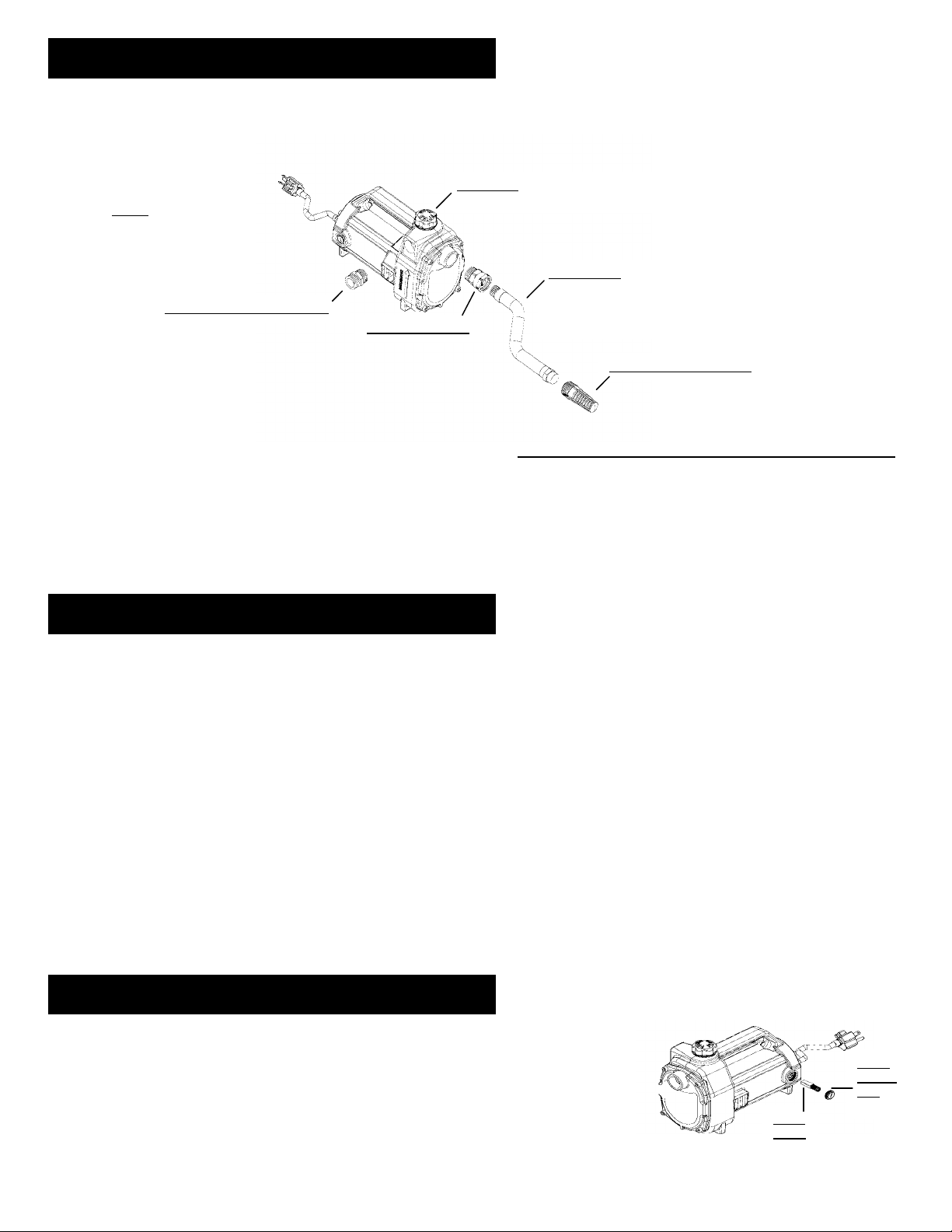

Brass male hose to male pipe

Prime plug – add water here prior to pump

operation.

Brass female hose

Suction hose (not included) - should not be

longer than needed (15’ maximum suction

lift). Use a high quality hose to prevent

collapsing.

Plastic male hose strainer

Motor

Brush

Brush

Access

Cap

3. Installation

4. Operation

5. Maintenance and Troubleshooting

Adapters are furnished with the pump. The inlet and discharge are threaded with a ¾” NPT. Standard water pipe can be threaded

directly into the casting. If a garden or other hose is to be used, the brass fittings must be installed. It is recommended that plumbing

tape or a pipe thread sealant when using the brass fittings. Liberty Pumps recommends that the swivel fitting be installed on the front of

the pump. NOTE: to reduce the possibility of hose collapse, use a high quality hose on the suction line (an ordinary garden hose may

collapse under suction pressure and should not be used).

Fig. 2

A strainer is furnished and should be used if pumping from a creek, pond, or source where foreign objects may be sucked into the

pump. The strainer helps prevent solids from entering the inlet line. This pump must be filled with water before operating.

Running the pump dry will cause damage to the shaft seal. This unit is not waterproof or weatherproof and should not be used in

showers, saunas, or other potentially wet locations. The motor is designed for use in a clean, dry location. The unit draws fresh air in

from the back and blows warm air out the sides, do not block air vents. Ambient temperatures around the motor should not exceed

104°F (40°C) in order to adequately cool motor. The motor is equipped with a thermal protector. If the motor temperature rises, the unit

will automatically turn-off. To reset the thermal switch simply unplug the unit or turn the electrical switch from on to off and allow unit to

cool. The switch must be in the off position in order for it to cool down. Please note that the water temperature should not exceed 140°

F.

1. IMPORTANT: Pump must be primed before operating to prevent shaft seal failure. To do this, remove the prime plug

(see Fig. 2) & fill the housing with water (approx. 2 cups). Replace the prime plug (hand-tighten only).

2. Connect garden hoses, making sure each connection is tight. A pin hole leak in the suction hose will prevent the unit from priming.

If using a garden hose, be sure to use a new rubber gasket.

3. Plug the power cord into a properly fused and grounded GFCI electrical outlet. Turn the power switch to the “on” position. The

amount of time it takes the pump to prime depends on the suction line length and height. A maximum vertical suction lift of 15 feet

through a ¾” diameter garden hose could take up to 2 minutes to prime.

4. A check valve installed near the bottom of the suction hose (not included) is recommended for suction lifts of more than 10 feet

(this reduces the amount of time required to draw water).

5. Please note that this pump retains water after use. In areas that are prone to freezing temperatures, please

be sure to drain the pump before storing it.

6. When used to transfer materials other than clear water (such as glycol), the pump must be flushed with

water and drained before storage to prevent potential pump damage. Some chemicals used in hydronic

systems can result in corrosion of the aluminum pump housing.

The Model 331 operates with a brush-type motor. To remove brushes for replacement or

cleaning, disconnect the power cord from electrical supply. Remove the brush caps by

turning them with a screwdriver counterclockwise. The brushes are attached to coil

springs, which pull outward from the pump. If used brushes are to be reinserted, mark the

location of each brush (left or right) and reinstall on the same side, in the same orientation.

Brush replacement should be scheduled after approximately every 300 hours of use.

©Copyright 2011 Liberty Pumps Inc. All rights reserved 3

Page 4

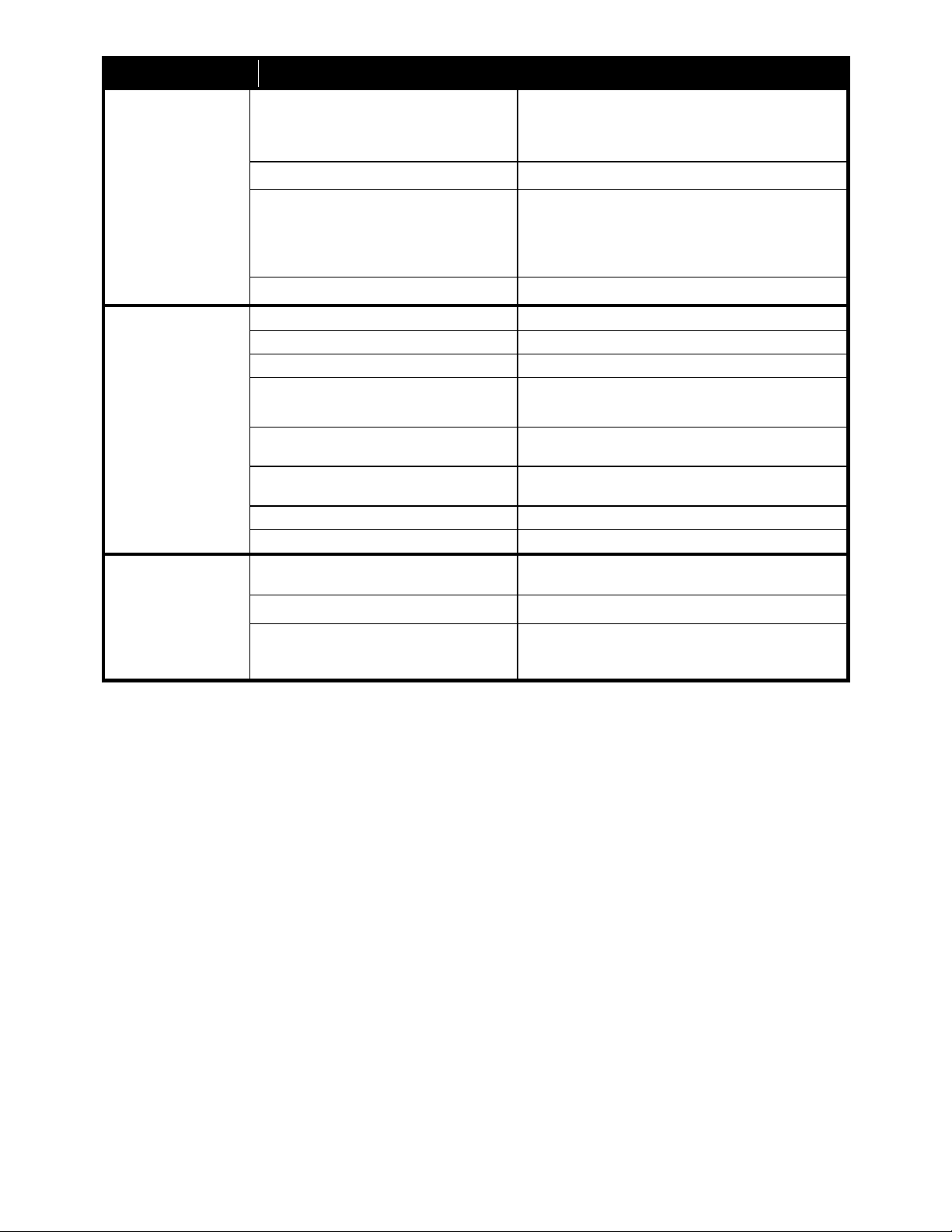

Problem

Cause

Correction

Pump will not run.

Blown fuse or other interruption of

power; improper voltage.

*If blown, replace with properly sized fuse or

reset breaker; if voltage is under 108V, check

wiring size. Remove extension cord if

connected or use one of a heavier gauge.

Worn motor brushes.

*Replace brushes

Impeller blockage.

*Remove blockage – this can be done by

removing the 4 screws that retain the impeller

plate or by removing the cap located at the

back of the unit and turning the shaft with a

flat screwdriver.

Defective motor or switch.

*Replace motor or switch – consult factory.

Pump will not prime

or retain prime after

operating.

Air leak in suction line.

Replace suction line.

Impeller blocked.

*Remove front plate and clean impeller area.

Impeller broken or worn.

*Replace impeller – contact factory.

Suction lift too high.

Lower pump or use a check valve near the

bottom of the suction line (maximum suction

lift 15’).

Hose kinked, looped, or collapsed.

Straighten hose or replace with heavier

reinforced hose.

Fittings not tight.

Tighten fittings. Use new rubber hose

gaskets.

Suction hose out of water.

Submerge suction hose and re-prime.

Clogged inlet.

*Clean inlet or suction screen at hose end.

Flow rate is too low.

Piping or hose is clogged or

damaged.

Replace hose or check hose for kinks.

Narrow piping or hose diameter.

Replace hose with ¾” reinforced hose.

Low line voltage.

*Check voltage. If under 108V, check wiring

size. Remove extension cord or use one with

a heavier gauge.

NOTE: Liberty Pumps, Inc. assumes no responsibility for damage or injury due to disassembly in the field. Disassembly, other than at

Liberty Pumps or its authorized service centers, automatically voids warranty. All electrical work should be done by a qualified

electrician.

3 Year Limited Warranty Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in

material and workmanship for a period of 3 years from the date of purchase. The date of purchase shall be determined by a

dated sales receipt noting the model and serial number of the pump. The dated sales receipt must accompany the returned

pump if the date of return is more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate.

The manufacturer's obligation under this Warranty shall be limited to the repair or replacement of any parts found by the

manufacturer to be defective, provided the part or assembly is returned freight prepaid to the manufacturer or its authorized

service center, and provided that none of the following warranty-voiding characteristics are evident.

The manufacturer shall not be liable under this Warranty if the product has not been properly installed; if it has been

disassembled, modified, abused or tampered with; if the electrical cord has been cut, damaged or spliced; if the pump

discharge has been reduced in size; if the pump has been used in water temperatures above the advertised rating, or water

containing sand, lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or hydrocarbons; if a

non-submersible motor has been subjected to excessive moisture; or if the label bearing the serial, model and code number

has been removed. Liberty Pumps, Inc. shall not be liable for any loss, damage or expenses resulting from installation or use of

its products, or for consequential damages, including costs of removal, reinstallation or transportation.

There is no other express warranty. All implied warranties, including those of merchantability and fitness for a particular

purpose, are limited to three years from the date of purchase.

©Copyright 2011 Liberty Pumps Inc. All rights reserved 4

This Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or incidental

damages under any and all warranties are excluded.

Page 5

7000 Apple Tree Avenue

Bergen, NY 14416 EUA

Teléfono: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contenido

1.) Información general

2.) Seguridad

3.) Instalación

4.) Operación

5.) Mantenimiento y diagnóstico de problemas

IMPORTANTE:

Apunte el modelo, el número de serie y

el código que aparecen en la placa de

la bomba antes de instalarla para que

le sirvan de referencia en el futuro.

MODELO ___________________

NÚM. SERIE ___________________

CÓDIGO ___________________

Manual de instalación y uso 7327000E

Bomba de Transferencia Portátil Modelo 331

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados

Page 6

Longitud

7.62 m

(25 pies)

15.24 m

(50 pies)

30.48 m

(100 pies)

Tamaño

del cable

#16

#16

#14

2. Seguridad

1. Información general

Figura 1

Patilla a

tierra

Lea con atención estas instrucciones antes de la bomba. Todas las bombas de Liberty se someten a prueba en fábrica como garantía

de su funcionamiento. Siga estas instrucciones al pie de la letra para prevenir problemas de funcionamiento y conseguir muchos años

de servicio satisfactorio.

Esta bomba de transferencia portátil sirve para vaciar calentadores, cubiertas de piscina, tanques de ganado, botes, etc. Cuando se

usa para la carga o mantenimiento de sistemas centrales térmicas, la bomba debe ser lavada con agua clara después para prevenir la

corrosion. También puede funcionar como facilitador de presión intermitente para lavar autos, limpiar patios, etc. Lleva un motor

refrigerado por aire.

No se debe usar sumergido ni en zonas húmedas. Sólo se deberá utilizar en lugares secos.

No use la bomba en temperaturas superiores a los 60 °C 140 F.

Es muy importante entender la información de este manual. Su objetivo es promover la SEGURIDAD y EVITAR PROBLEMAS

CON EL EQUIPO.

No se debe sumergir el motor ni dejarlo expuesto al agua. Esto podría producir daños personales y de la propiedad.

No utilice la bomba para bombear líquidos inflamables o explosivos, como gasolina, aceite combustible,

queroseno, etc. No la utilice en entornos inflamables o explosivos. Sólo se debe usar para bombear agua. De lo

contrario se podrían producir daños personales y de la propiedad.

Riesgo de electrocución fatal. No desmonte la patilla a tierra (vea la figura 1).

Si se corta el cable o el enchufe la garantía quedará anulada y la bomba no funcionará.

Desconecte la bomba de la fuente de alimentación antes de instalarla o mantenerla. No toque la bomba

con las manos mojadas o estando parado sobre una superficie mojada o húmeda o en agua. Podría sufrir una electrocución fatal.

Enchufe la bomba a un tomacorrientes fusibleado con un circuito de falla a tierra (GFCI) que cumpla el código eléctrico nacional

(NEC) de Estados Unidos y los códigos locales. El cableado deberá llevarlo a cabo un electricista calificado.

La bomba lleva un cable de potencia de 6.09 metros (20 pies). No utilice un cable alargador a no ser que sea absolutamente

necesario. La tabla de longitudes de cables alargadores le servirá para elegir un cable alargador trifilar con toma a tierra de la

clasificación correcta.

Desconecte la alimentación y deje escapar toda la presión del sistema antes de realizar cualquier tarea de mantenimiento.

Extraiga todo el líquido del sistema antes de realizar cualquier tarea de mantenimiento.

Lea todas las instrucciones antes de ponerlo en funcionamiento.

Sujete la línea de desagüe antes de poner la bomba en funcionamiento. Si no lo hace la presión puede hacer que se sacuda. Esto

podría producir daños personales y de la propiedad.

Inspeccione la bomba y demás componentes del sistema periódicamente; verifique que no haya ninguna manguera desgastada o

débil. Todas las conexiones deben estar bien apretadas.

Proteja el cable eléctrico de objetos afilados, superficies calientes, aceites y sustancias químicas. No deje que el cable se enrosque.

Tabla de longitudes del cable alargador:

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados - 2 -

Page 7

Manguera macho de latón a tubería macho

Tapón de cebado: añada agua antes de

encender la bomba.

Manguera hembra

Manguera de succión (no se incluye): no debe ser

más larga de lo necesario (altura de aspiración de

4.57 m (15 plg.) como máximo). Use una

manguera de calidad para que no colapse.

Tamiz de la manguera macho de plástico

Tapa de acceso

a las escobillas

Escobillas del motor

3. Instalación

4. Operación

5. Mantenimiento y diagnóstico de problemas

Se incluyen adaptadores con la bomba. La admisión y el desagüe llevan una rosca de 1.91 cm ( ¾ plg.) NPT. Se puede enroscar una

cañería directamente. Si se utiliza una manguera para regar o de otro tipo, habrá que instalar conexiones de latón. En este caso se

recomienda utilizar cinta de fontanería o sello para roscas. Liberty Pumps recomienda la instalación de un empalme giratorio en la

parte frontal de la bomba. NOTA: para reducir el riesgo de que la manguera colapse, utilice una manguera de calidad alta en la línea

de aspiración, ya que una manguera de jardín podría colapsar con la presión de aspiración.

Fig. 2

El tamiz que se incluye se debe usar cuando se bombea de un arroyo, una laguna u otros lugares donde la bomba podría aspirar

materia foránea. Este filtro evita que este tipo de material sólido entre en la línea de admisión. Llene la bomba de agua antes de

encenderla. Si funciona en seco podría dañarse la junta de eje rotatorio. La unidad no es impermeable ni estanca y no se debe utilizar

en duchas, saunas y otros lugares donde puede haber agua. El motor ha sido diseñado para su uso en lugares limpios y secos. La

unidad extrae aire por la parte posterior y lo expulsa en forma de aire caliente por los lados, por lo que es importante no bloquear los

respiraderos. La temperatura ambiente alrededor del motor nunca debe superar los 40° C (104° F) para que el motor se enfríe. El

motor lleva un protector térmico. Este dispositivo hace que se apague la unidad cuando la temperatura sube en exceso. Para

restablecer el interruptor térmico sólo hay que desenchufar la bomba o apagar el interruptor hasta que se enfríe. Para que esto ocurra

el interruptor tiene que estar en la posición de apagado. La temperatura del agua no puede superar los 60° C (140° F).

1. IMPORTANTE: hay que cebar la bomba antes de ponerla en funcionamiento para evitar dañar la junta de eje rotatorio. Para

hacerlo, retire el tapón de cebado (vea la figura 2) y llene el depósito de agua (medio litro aproximadamente). Vuelva a poner el

tapón (apriételo a mano).

2. Conecte y apriete las mangueras de regar. Si hay un agujero por muy pequeño que sea en la manguera de aspiración la unidad

no se cebará. Si va a usar una manguera de jardín, instale también una junta obturadora de caucho nueva.

3. Enchufe el cable de potencia en un tomacorrientes con interruptor de circuito de fallos de conexión a tierra. Ponga el interruptor en

la posición de encendido. El tiempo que la bomba tardará en cebarse dependerá de la longitud y altura de la línea de aspiración.

Una altura máxima de aspiración vertical de 4.57 metros (15 pies) a través de una manguera de jardín de 1.91 cm (¾ de plg.)

tarda 2 minutos en acabar de cebarse.

4. Se recomienda instalar una válvula de retención cerca del fondo de la manguera de aspiración (no se incluye) para alturas

superiores a los 3 metros (10 pies), ya que esto reduce el tiempo necesario para extraer el agua.

5. La bomba retiene agua después de su uso. Si reside en una zona con temperaturas bajo cero, vacíe la

bomba antes de almacenarla.

6. Cuando se utiliza para la transferencia de otros materiales que el agua clara (como el glicol), la bomba

debe lavar con agua y drenaje antes de su almacenamiento para evitar posibles daños a la bomba. Algunos

productos químicos utilizados en los sistemas de centrales térmicas puede dar lugar a la corrosión de la

carcasa de la bomba de aluminio.

El motor del Modelo 331 lleva escobillas. Si necesita desmontarlas para

reemplazarlas o limpiarlas, desconecte el cable de potencia de la alimentación. Gire

hacia la izquierda la tapa de la escobilla con un destornillador para retirarla. Las

escobillas están conectadas a resortes que presionan hacia afuera de la bomba. Si va

a volver a instalar las escobillas usadas, marque el emplazamiento de cada escobilla

(izquierda o derecha) y vuelva a instalarla en el mismo lado y con la misma

orientación. Reemplace las escobillas cada 300 horas de uso aproximadamente.

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados - 3 -

Page 8

Problema

Causa

Solución

La bomba no

funciona.

Se ha fundido un fusible o el flujo

eléctrico se ha visto interrumpido

de algún otro modo; tensión

incorrecta.

*Si se fundió un fusible, cámbielo por otro o

restablezca el disyuntor; si la tensión es inferior a

108V, verifique el tamaño de los cables. Si tiene

un cable alargador retírelo o use uno de calibre

superior.

Escobillas desgastadas.

*Reemplace las escobillas.

Bloqueo del rotor.

*Limpie el bloqueo. Para hacerlo, retire los 4

tornillos que sujetan la placa del rotor o la tapa

situada en la parte posterior de la unidad y gire el

eje con un destornillador plano.

Motor o interruptor defectuoso.

*Reemplace el motor o el interruptor. Consulte

con la fábrica.

La bomba no se

ceba o no se queda

cebada después de

funcionar.

Fuga de aire en la línea de

aspiración.

Reemplace la línea de aspiración.

Rotor bloqueado.

*Retire la placa frontal y limpie la zona del rotor.

Rotor roto o desgastado.

*Reemplace el rotor. Consulte con la fábrica.

La altura de aspiración es

demasiado alta.

Baje la bomba o use una válvula de retención

cerca de la parte inferior de la línea de aspiración

(altura de succión máxima 4.57 m/ 15 pies).

La manguera está liada, enrollada

o colapsada.

Enderece la manguera o reemplácela con una

manguera reforzada más gruesa.

El empalme está suelto.

Apriete el empalme. Use juntas obturadoras de

caucho nuevas.

La manguera de aspiración se salió

del agua.

Vuelva a sumergir la manguera y a cebar la

bomba.

Atasco en la admisión.

*Limpie la admisión o el filtro de la manguera.

El caudal es

insuficiente.

La tubería o manguera está

obturada o estropeada.

Reemplace la manguera o compruebe que no

esté torcida.

Tubería o manguera estrecha.

Reemplace la manguera con una reforzada de

1.91 cm ( ¾ de plg.).

Tensión baja.

*Verifique la tensión. Si está por debajo de los

108V, compruebe el tamaño de los cables. Retire

el cable alargador o use uno de calibre superior.

NOTA: Liberty Pumps, Inc. no asume ninguna responsabilidad por desperfectos o lesiones resultantes del desmontaje de la bomba sobre el terreno.

Si el desmontaje de la bomba no lo lleva a cabo Liberty Pumps o uno de sus centros de servicio autorizados, la garantía quedará anulada. Toda la

instalación eléctrica la deberá llevar a cabo un electricista calificado.

Garantía limitada de 3 años Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos de materiales y mano de obra

por un período de 3 años a partir de la fecha de compra. La fecha de compra se determinará con el recibo de compra fechado, que incluya el

modelo y el número de serie de la bomba. Este recibo deberá acompañar a la bomba si la fecha de devolución ocurre más de 3 años después

de la fecha de fabricación (código-CODE) indicada en la placa de la unidad.

Las obligaciones del fabricante bajo esta garantía se limitarán a la reparación o el reemplazo de las piezas que el fabricante determine que son

defectuosas, siempre que la pieza o el ensamblaje, se devuelva con el porte pagado al fabricante o a uno de sus centros de servicio

autorizados y que no se evidencie ninguna de las siguientes características, lo que supondría la anulación de la garantía.

El fabricante no tendrá obligación alguna bajo esta garantía si el producto no ha sido instalado correctamente;

si ha sido desmontado, modificado, abusado o forzado; si el cordón eléctrico se ha cortado, dañado o empalmado; si se redujo el tamaño de la

descarga de la bomba; si la bomba se usó con agua más caliente de la temperatura nominal, o agua con arena, cal, cemento, grava u otros

elementos abrasivos; si se utilizaron productos químicos para bombas o hidrocarburos; si un motor no sumergible fue sometido a un exceso de

humedad; o si se retiró

la etiqueta con el número de serie y de código. Liberty Pumps, Inc. no se hace responsable de pérdidas, daños

o gastos que resulten por la instalación o uso de sus productos, o por daños emergentes, incluidos los costos

de desmontar, reinstalar o transportar la unidad.

No se ofrece ninguna otra garantía expresa. Todas las garantías implícitas, incluidas las de comerciabilidad y adecuación para un propósito

determinado, están limitadas a un plazo de tres años a partir de la fecha de compra.

Esta garantía representa el único remedio del comprador y, siempre que se permita, se excluye toda responsabilidad por daños emergentes y

fortuitos bajo toda otra garantía.

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados - 4 -

Page 9

7000, avenue Apple Tree

Bergen (NY) 14416

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

Table des matières

1.) Renseignements généraux

2.) Directives de sécurité

3.) Installation

4.) Fonctionnement

5.) Entretien et dépannage

IMPORTANT :

Avant l’installation, noter les numéros

de modèle, de série et de code qui

figurent sur la plaque signalétique pour

éventuellement s’y référer.

MODÈLE ___________________

SÉRIE ___________________

CODE ___________________

Manuel d’installation et utilizer 7327000E

Pompe de transfert portative, modèle 331

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés

Page 10

Longueur

7,6 m (25 pi)

15,2 m (50 pi)

30,4 m (100 pi)

Dimension du câble

Nº 16

Nº 16

Nº 14

2. Consignes de sécurité

1. Renseignements généraux

Figura 1

Broche de mise

à la terre

Lire attentivement les directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en usine

pour assurer un bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de problèmes de fonctionnement et

assurera des années de service sans soucis.

Cette pompe de transfert portative est conçue pour des utilisations telles que vider les chauffe-eau, les toiles de piscine, les réservoirs

de pisciculture, les bateaux, etc. Lorsqu'il est utilisé pour transférer des matériaux autres que l'eau claire (comme le glycol), la pompe

doit être rincée avec de l'eau et égouttés avant le stockage pour éviter d'endommager la pompe potentiels. Certaines substances

chimiques utilisées dans les systèmes à eau chaude peut entraîner la corrosion du corps de pompe en aluminium. Elle peut également

fournir occasionnellement plus de pression pour laver les voitures et les entrées, etc. Elle est munie d’un moteur à balais refroidi à l’air.

Ne pas utiliser sous l’eau ou dans les endroits humides. Cette pompe est conçue pour être utilisée dans les

endroits secs seulement.

Ne pas utiliser cette pompe dans de l’eau dont la température est supérieure à 60 ºC (140 ºF).

Ce manuel renferme des renseignements qu’il est très important de connaître et de comprendre. Cette information est fournie pour la

SÉCURITÉ DE L’UTILISATEUR et pour PRÉVENIR LES PROBLÈMES DE FONCTIONNEMENT DU MATÉRIEL.

Ne pas immerger le moteur ni permettre qu’il soit exposé à l’eau. Cela pourrait causer des blessures corporelles

et/ou la mort.

Ne pas utiliser pour pomper des liquides inflammables ou explosifs comme de l’essence, de mazout, du kérosène,

etc. Ne pas utiliser en présence de gaz inflammable et/ou explosifs. Cette pompe ne doit pas servir à pomper autre

chose que de l’eau claire. Cela pourrait causer des blessures corporelles et/ou la mort.

Danger d’électrocution pouvant causer la mort. Ne jamais retirer la broche ronde de

mise à la terre de la fiche (voir fig. 1). Couper le cordon ou la fiche annulera la garantie et

nuira au fonctionnement de la pompe.

Toujours débrancher la pompe de l’alimentation électrique avant de tenter de l’installer ou d’y effectuer des travaux d’entretien. Ne

jamais manipuler une pompe avec les mains mouillées ou en se tenant sur une surface mouillée ou humide, ou dans l ’eau. Cela

pourrait causer une électrocution fatale.

La pompe doit être branchée dans une prise électrique convenablement mise à la terre avec disjoncteur de fuite de terre qui est

conforme au code national de l’électricité et aux codes locaux en vigueur. Tout le câblage doit être effectué par un électricien

qualifié.

Cette pompe est munie d’un cordon électrique de 6 m (20 pi). Ne pas utiliser de rallonge à moins que cela ne soit absolument

nécessaire. Suivre les directives du tableau sur la longueur des rallonges pour connaître le calibre d’une rallonge à trois fils

assurant la mise à la terre qui convient.

Couper l’alimentation électrique et évacuer la pression de l’appareil avant d’effectuer des travaux d’entretien.

Évacuer tout liquide de l’appareil avant d’effectuer des travaux d’entretien.

Lire toutes les directives avant d’utiliser cet appareil.

Bien fixer la canalisation d’évacuation avant de démarrer la pompe. Une canalisation d’évacuation mal fixée mise sous pression

peut faire de mouvements de fouet. Cela pourrait causer des blessures corporelles et/ou la mort.

Examiner régulièrement tous les composants de la pompe et du système pour repérer les tuyaux affaiblis ou usés. S’assurer que

tous les raccordements sont solides.

Protéger les cordons électriques des objets pointus, des surfaces chaudes, de l’huile et des produits chimiques. Éviter de plier ou

tordre le cordon électrique.

Tableau des longueurs de rallonges :

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés - 2 -

Page 11

Balai du

moteur

Bouchon d’accès

aux balais

Bouchon d’amorçage – ajouter de l’eau ici avant

de mettre la pompe en marche

Raccordement du

boyau en laiton

femelle

Boyau d’aspiration (non compris) – ne doit pas

être plus long que nécessaire (maximum 4,5

m (15 pi) de hauteur géométrique

d'aspiration). Utiliser un boyau de grande

qualité afin de prévenir l’affaissement.

Filtre de boyau mâle en

plastique

Raccordement du boyau en

laiton mâle au tuyau mâle

3. Installation

4. Fonctionnement

5. Entretien et dépannage

Les adaptateurs sont fournis avec la pompe. Les orifices d’entrée et de sortie sont munis de raccordements ¾ po NPT. Des tuyaux

d’eau standard peuvent être vissés directement dans le moulage. Pour utiliser un boyau d’arrosage ou d’un autre type, il faut installer

les raccordements en laiton. Il est recommandé d’utiliser du tuyau de plomberie ou un agent d’étanchement de filets lors de l’utilisation

des raccordements en laiton. Liberty Pumps recommande d’installer le raccord tournant à l’avant de la pompe. REMARQUE : afin de

réduire les risques d’affaissement, utiliser un boyau de grande qualité comme tuyau d’aspiration (un boyau d’arrosage ordinaire peut

s’affaisser sous l’effet de la pression de succion et son usage est déconseillé).

Fig. 2

Un filtre est fourni et doit être utilisé lors du pompage dans un ruisseau, un étang ou une autre source où des corps étrangers risquent

d’être aspirés dans la pompe. Le filtre sert à empêcher les matières solides d’entrer dans la conduite d’arrivée d’eau. Cette pompe doit

être remplie d’eau avant sa mise en marche. Faire fonctionner la pompe à sec endommagera le joint de l’arbre d’entraînement. Cet

appareil n’est pas à l’épreuve de l’eau ou des intempéries, et ne doit pas être utilisé dans les douches, saunas ou autres endroits

potentiellement humides. Ce moteur est conçu pour être utilisé dans un endroit propre et sec. L’appareil tire de l’air frais de l’arrière et

expulse de l’air chaud des côtés. Ne pas bloquer les évents. La température ambiante autour du moteur ne devrait pas dépasser 40 °C

(104 °F) afin de permettre au moteur de se refroidir convenablement. Le moteur est muni d’un protecteur thermique. Si la température

du moteur s’élève trop, l’appareil s’éteint automatiquement. Pour réinitialiser l’interrupteur thermique, débrancher l’appareil ou éteindre

l’appareil pour le laisser refroidir L’interrupteur doit être en position d’arrêt pour que l’appareil refroidisse. Il est à noter que la

température de l’eau ne doit pas dépasser 40 °C (104 °F).

1. IMPORTANT : Il faut amorcer la pompe avant de la mettre en marche pour prévenir les dommages au joint de l’arbre. Pour ce

faire, retirer le bouchon d’amorçage (voir figure 2) et remplir le compartiment d’eau (environ 2 tasses). Remettre le bouchon en

place (resserrer à la main seulement).

2. Raccorder les boyaux d’arrosage, en s’assurant que chaque raccord est bien étanche. Un trou d’épingle dans le boyau d’aspiration

empêchera l’amorçage de la pompe. S’assurer d’utiliser une rondelle d’étanchéité neuve lors de l’utilisation d’un boyau d’arrosage

de jardin.

3. Brancher le cordon d’alimentation dans une prise électrique convenablement mise à la terre avec disjoncteur de fuite de terre.

Mettre le commutateur électrique en position de marche « On ». Le temps nécessaire à l’amorçage de la pompe dépend de la

longueur et de la hauteur du boyau d’aspiration. Une hauteur géométrique d’aspiration maximum de 4,5 m (15 pi) à travers un

boyau d’arrosage domestique de ¾ po de diamètre peut nécessiter 2 minutes de temps d’amorçage.

4. Il est recommandé d’installer un clapet antiretour près du bas du boyau d’aspiration (non compris) si la hauteur géométrique

d’aspiration dépasse 3 m (10 pi) (cela réduit la quantité de temps nécessaire pour aspirer l’eau).

5. Il est à noter que cette pompe retient l’eau après usage. Dans les régions où il y a risque de gel s’assurer de purger la pompe

avant de la ranger.

6. Lorsqu'il est utilisé pour transférer des matériaux autres que l'eau claire (comme le glycol), la pompe doit être rincée avec de l'eau

et égouttés avant le stockage pour éviter d'endommager la pompe potentiels. Certaines substances chimiques utilisées dans les

systèmes à eau chaude peut entraîner la corrosion du corps de pompe en aluminium.

Le modèle 331 est muni d’un moteur à balais. Afin de retirer les balais pour les nettoyer ou les

remplacer, couper l’alimentation de l’appareil en débranchant le cordon de la prise. Retirer les

bouchons qui protègent les balais en les tournant le sens inverse des aiguilles d’une montre à l’aide

d’un tournevis. Les balais sont fixés à des ressorts qui sont orientés vers l’extérieur de la pompe.

S’il faut remettre les balais en place, identifier l’emplacement de chacun (gauche ou droit) et

replacer du même côté, dans le même sens. Les balais doivent être remplacés environ à toutes les

300 heures de fonctionnement.

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés - 3 -

Page 12

Problème

Cause

Mesure correctrice

La pompe ne

fonctionne pas.

Fusible brûlé ou autre interruption

d’alimentation, tension inadéquate.

*Si le fusible est brûlé, remplacer par un fusible de

la bonne intensité ou réarmer le disjoncteur; si la

tension est inférieure à 108 V, vérifier la grosseur

des câbles. Retirer la rallonge qui est utilisée ou

remplacer par une de plus gros calibre.

Balais de moteur usés.

*Remplacer les balais.

* Rotor bloqué.

*Retirer ce qui le bloque – pour ce faire, dévisser les

4 vis qui retiennent la plaque du rotor ou retirer le

bouchon situé à l’arrière de l’appareil et faire tourner

l’arbre avec un tournevis plat.

Interrupteur ou moteur défectueux

*Remplacer l’interrupteur ou le moteur – consulter le

fabricant.

La pompe refuse de

s’amorcer ou ne

retient pas son

amorce après avoir

fonctionné.

Fuite d’air dans le boyau

d’aspiration.

Remplacer le boyau d’aspiration.

Rotor bloqué.

*Retirer la plaque avant et nettoyer la zone du rotor.

Rotor brisé ou usé.

*Remplacer le rotor – communiquer avec le fabricant.

Hauteur géométrique d’aspiration

trop importante.

Abaisser la pompe ou installer un clapet antiretour

près du bas du boyau d’aspiration; hauteur

géométrique d’aspiration maximum : 4,5 m (15 pi)

Boyau plié, tordu ou affaissé.

Redresser le boyau ou remplacer par un boyau

renforcé plus rigide.

Raccords pas assez étanches.

Resserrer les raccords. Utiliser des rondelles

d’étanchéité pour boyaux neuves.

Boyau d’aspiration vide.

Plonger le boyau dans l’eau pour le réamorcer.

Entrée obstruée.

*Nettoyer l’entrée ou le filtre d’aspiration à

l’extrémité du boyau.

Débit trop faible.

Tuyau ou boyau obstrué.

Remplacer le boyau ou vérifier s’il est plié.

Réduire le diamètre du tuyau ou

boyau.

Remplacer par un boyau renforcé plus rigide de

¾ po.

Tension d’alimentation faible.

*Vérifier la tension. Si la tension est inférieure à

108 V, vérifier la grosseur des câbles. Retirer la

rallonge ou remplacer par un de plus gros calibre.

REMARQUE : Liberty Pumps, Inc. n’est pas responsable des dommages ou blessures résultant d’un démontage sur le terrain. Le démontage effectué

ailleurs que chez Liberty Pumps à l’un de ces centres de services autorisés annule automatiquement la garantie. Tout le câblage doit être effectué par

un électricien qualifié.

Garantie limitée de 3 ans Liberty Pumps, Inc. garantit que les pompes sortant de son usine sont exemptes de tout défaut de matériau et de

fabrication pour une période de 3 ans à partir de la date d’achat. La date d'achat sera établie par une facture d’achat datée indiquant les

numéros de modèle et de série de la pompe. La pompe retournée doit être accompagnée de la facture d’achat datée si la date de retour se

situe à plus de 3 ans du numéro de « CODE » (date de fabrication) indiqué sur la plaque signalétique de la pompe.

L’obligation de garantie du fabricant se limite à la réparation ou au remplacement de toute pièce jugée défectueuse par le fabricant, à condition que la

pièce ou l’appareil soient retourné, franco de port, au fabricant ou à son centre d'entretien autorisé et à condition qu’il n’y ait aucune preuve que les

critères suivants annulant la garantie sont en cause.

Le fabricant ne peut en aucun cas être tenu responsable, selon les dispositions de cette garantie, si le produit n’a pas été correctement installé; s’il

a été démonté, modifié, soumis à un usage abusif ou endommagé; si le cordon électrique a été coupé, endommagé ou ligaturé; si la taille du tuyau

d’évacuation de la pompe a été réduite; si la pompe a été utilisée pour pomper de l’eau d'une température supérieure aux recommandations cidessus ou de l’eau contenant du sable, de la chaux, du ciment, du gravier ou autres matières abrasives; si le produit a été utilisé pour pomper des

produits chimiques ou des hydrocarbures; si un moteur non submersible a été exposé à de l’humidité excessive; ou si l’étiquette portant le numéro

de série, de modèle et de code a été retirée. Liberty Pumps, Inc. ne pourra être tenue responsable des pertes, dommages, frais attribuables à

l’installation ou l’utilisation de ses produits ni pour les dommages accessoires ou consécutifs, y compris les coûts de retrait, de réinstallation ou de

transport.

Il n’y a aucune autre garantie expresse. Toute garantie implicite, y compris celles de qualité marchande et d'aptitude à une fin particulière, est

limitée à trois ans à partir de la date d’achat.

Cette garantie contient le recours exclusif de l’acheteur et exclut, lorsque permis par la loi, toute responsabilité pour dommages consécutifs ou

accessoires en vertu de toutes autres garanties.

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés - 4 -

Loading...

Loading...