Page 1

IMPORTANT:

Prior to installation, record Model, Serial Number, and

Code Number from pump nameplate for future reference.

MODEL ________________________

SERIAL ______________________

CODE ______________________

INSTALLATION

DATE _______________________

7000 Apple Tree Avenue

Bergen, NY 14416

Phone: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contents

1.) General Information

2.) Precautions/Pre-installation

3.) Installation

4.) Maintenance and Troubleshooting

Installation Manual 7386000I

2448-Series Simplex Grinder Systems

Features

24” diameter X 48” H fiberglass basin

LSG202M Grinder Pump- 2 HP, 208/230V

-orLSGX202M Grinder Pump- 2 HP, 208-230V

GR20 Guide Rail System

Plugger Box and Alarm

©Copyright 2011 Liberty Pumps Inc. All rights reserved

Page 2

GRINDER PUMP SPECIFICATIONS

Model

HP

Volts

Phase

Full Load

Amps

Locked

Rotor Amps

Discharge

Shut-off

Head

LSG202M

2

208/230

1

15

53

1¼”

108’

LSGX202M

2

208-230

1

15

53

1¼”

185’

1. General Information

2. Precautions/Pre-installation

Before installation, read the following instructions carefully. Each Liberty pump is individually factory tested to insure proper

performance. Closely following these instructions will eliminate potential operating problems, assuring years of trouble-free service.

Risk of electric shock. Always disconnect the pump from the power source before handling or making adjustments.

These pumps are not to be installed in locations classified as hazardous in accordance with the National Electric Code,

ANSI/NFPA 70.

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

This pump is supplied with a grounding conductor or a grounding-type attachment plug. To reduce the risk of electric shock, be

certain that the grounding conductor is connected only to a properly grounded control panel or, if equipped with a grounding-type

plug, that it is connected to a properly grounded, grounding-type receptacle.

Do not bypass grounding wires or remove ground prong from attachment plugs.

Do not remove cord and strain relief, and do not connect conduit to pump.

Do not use an extension cord.

This pump requires separate, properly fused and grounded branch circuit. Make sure the power source is properly sized for the

voltage and amperage requirements of the motor, as noted on the pump nameplate.

The installation must be in accordance with the National Electric Code and all applicable local codes and ordinances.

Sump and sewage pumps often handle materials which could cause illness or disease. Wear adequate protective clothing when

working on a used pump or piping.

Never enter a pump basin after it has been used. Sewage and effluent can emit several gases which are poisonous.

Do not use these pumps in water over 140 F.

The Uniform Plumbing Code (UPC) states that sewage systems shall have an audio and visual alarm that signals a malfunction of

the system, to reduce the potential for property damage.

IMPORTANT: The grinder pump and the plugger box are supplied with their own separate Installation/Operation/Maintenance

manuals. Ensure that you have received these manuals, and that you read and understand them prior to installing this unit. Your

familiarity with the grinder pump manual and the control panel manual is critical. This installation manual gives a brief overview of the

system, and deals mainly with inspection and installation of the basin, but it does not cover the specifics of the pump operation or the

control panel operation. If you have any questions, please call customer service at (800) 543-2550.

Risk of electric shock. Always disconnect the pump from the power source before handling or making

adjustments.

Pre-installation Checklist:

1. Inspect the system upon arrival to ensure that there is no shipping damage. Pay careful attention to the condition of the fiberglass

basin, control floats, pump guide rail brackets, and control panel. Notify the carrier immediately if there is any damage.

2. Read all instructions and familiarize yourself with the unit’s operation prior to proceeding with the installation.

3. A qualified licensed electrician should install and test all electrical circuits.

4. Check to ensure that your power source is adequate to handle the pump amperage as noted above and on the pump nameplate.

Ensure that the electrical supply circuit is equipped with fuses or breakers of the proper capacity.

5. A separate 115V branch circuit should be installed for the alarm. We do not recommend splitting the incoming pump power circuit

to power the control circuit. A separate 115V branch circuit is required for the alarm. Do not split the incoming pump power circuit

to power the control circuit.

6. All electrical connections should be tested to ensure that a proper ground has been established

©Copyright 2011 Liberty Pumps Inc. All rights reserved 2

Page 3

3. Installation

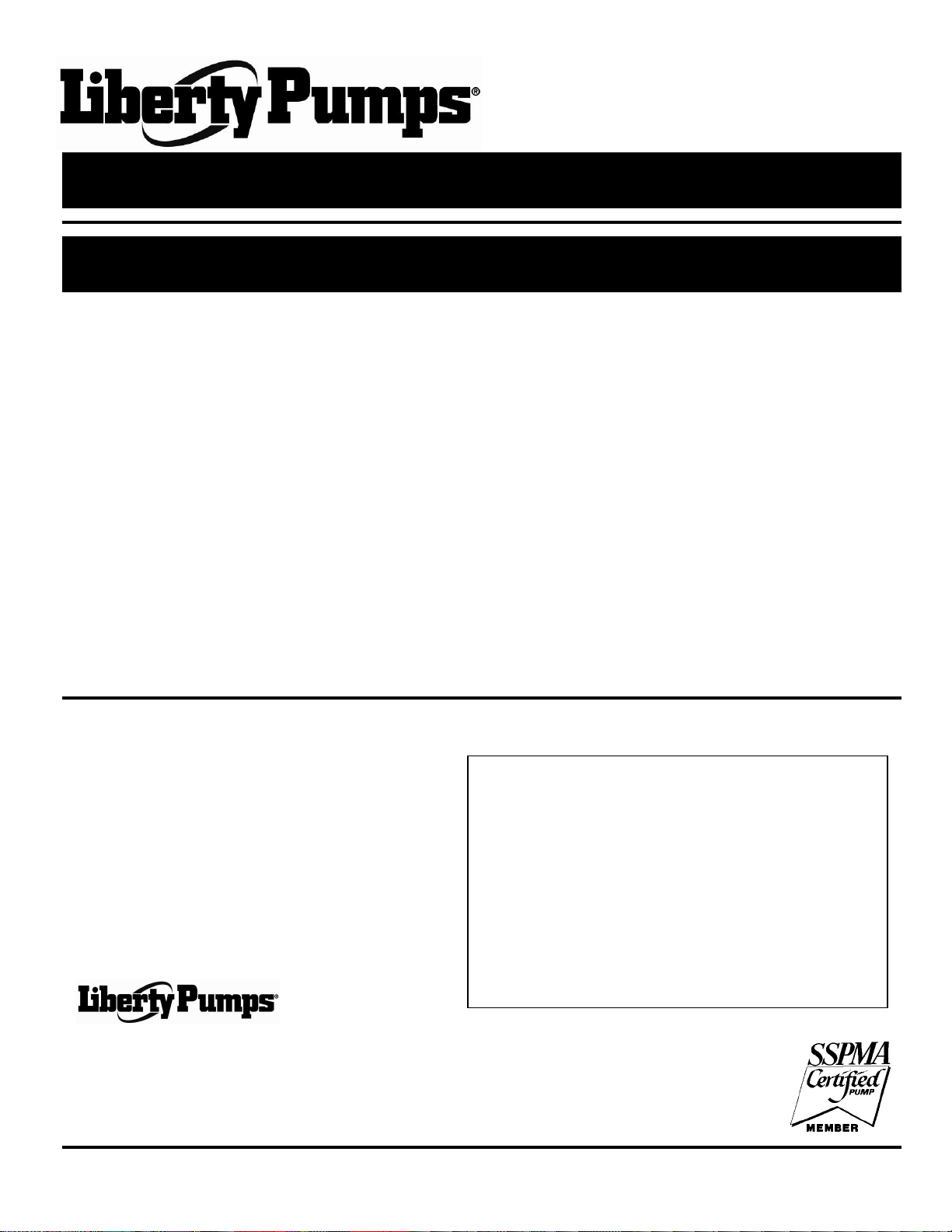

Fig. 1 – Inlet Venting

2448 System

A. Excavation: Excavate the hole for the basin as small as possible, with a minimum base diameter of 38”. Never place the basin in

direct contact with rocks or other sharp objects. Place enough fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone at

the bottom of the excavation to create a minimum of 12 inches stone or gravel after compaction. Do not use sand or native soil as

backfill*. Properly compact underneath the basin to provide a solid, level base that can support the weight of the filled basin. If a

concrete pad will be used under the basin, the compacted stone sub-base can be reduced to 6 inches.

B. Connections & Backfill: Pour enough concrete over and around the anti-floatation flange to anchor the basin and prevent

upward movement. Connect 1¼” schedule 80 PVC pipe to the pump discharge. Do not reduce the size of the discharge piping,

and do not increase the discharge piping to larger than 2”. The remainder of the discharge line should be as short as possible with

a minimum number of turns. Connect the inlet line to the 4” cast iron inlet hub using oakum and lead or with a rubber donut.

Connect the electrical coupling to 2” electrical conduit and run the power and float cords through the conduit to the control panel.

The remaining backfill should be only fine, 1/8" to 3/4" pea gravel or 1/8" to 1/2" washed, crushed stone. Do not use sand or native

soil as backfill*. *Other backfill options may be available – consult the factory for special instructions relative to your situation

Do not exert heavy pressure or run heavy equipment on the backfill material as this could cause the

tank to collapse.

C. Venting: The fiberglass basin provided with the 2448 must be completely sealed and properly vented in order to meet health and

plumbing code requirements. The 2448 is designed to be

vented through the inlet to an existing building vent stack. In

order to accomplish this, there must be no traps between the

2448 inlet and the nearest building vent stack connection. See

fig. 1 for an example. If this is not possible or desirable in your

application, a vent flange or grommet can be installed in a hole

cut into the solid fiberglass cover.

D. Alarm:

Risk of Electric shock: This pump is supplied with a

grounding conductor. To reduce the risk of electric shock,

be certain that it is connected only to a properly grounded

earth wire.

All electrical circuitry should be installed in accordance with

the National Electric Code (NEC) and all applicable local

codes or ordinances.

IMPORTANT: The alarm panel that is an integral part of this

complete unit is supplied with its own separate

Installation/Operation/Maintenance manual. Ensure that you

have received this manual, and that you read and understand it

prior to installing this unit. Your familiarity with the control panel

manual is critical.

A separate 115V branch circuit is required for the alarm circuit.

Do not split the incoming pump power circuit to power the

control circuit.

Connect the grinder pump leads and the float switch leads to

the control panel in accordance with the instructions included

with those units.

E. Float Switches: The float switch for the alarm is internally weighted and does not have to be clamped. The pump cycle is pre-set

at the factory at 12” (approximately 25 gallons). The pump cycle can be adjusted by loosening the cord grip and moving the “on”

float up or down. We do not recommend adjustments of more than 3” in either direction – please call the factory if you need to

adjust the pump cycle beyond this recommended level.

F. Testing and Startup: Follow the testing and startup procedures found in the pump and control panel manuals.

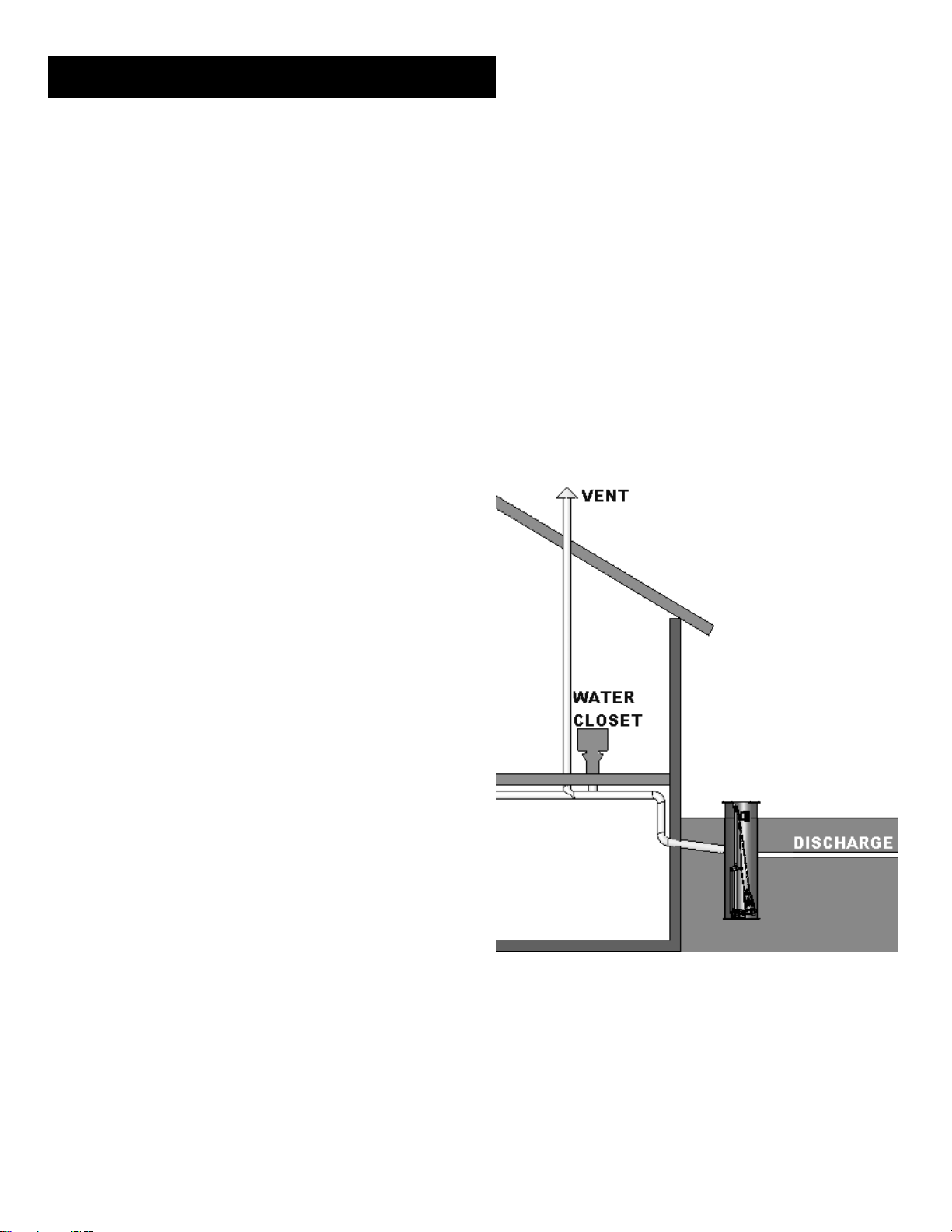

G. GR20 Assembly: The GR20 quick disconnect assembly provided with your grinder package system is designed to allow easy

installation and removal of the pump. Please ensure that installation is done as per the diagrams below.

©Copyright 2011 Liberty Pumps Inc. All rights reserved 3

Page 4

4. Maintenance and Troubleshooting

DISCONNECTED POSITION OPERATING POSITION

IMPORTANT: The grinder pump and control panel are supplied with their own separate Installation/Operation/Maintenance manuals.

Ensure that you have received these manuals, and that you read and understand them prior to installing this unit. Your familiarity with

the grinder pump manual and the control panel manual is critical. Please follow the Maintenance and Troubleshooting procedures

provided in those manuals

3 Year Limited Warranty Liberty Pumps, Inc. warrants that pumps of its manufacture are free from all factory defects in material

and workmanship for a period of 3 years from the date of purchase. The date of purchase shall be determined by a dated sales receipt

noting the model and serial number of the pump. The dated sales receipt must accompany the returned pump if the date of return is

more than 3 years from the "CODE" (date of manufacture) number noted on the pump nameplate. The manufacturer's obligation under

this Warranty shall be limited to the repair or replacement of any parts found by the manufacturer to be defective, provided the part or

assembly is returned freight prepaid to the manufacturer or its authorized service center, and provided that none of the fol lowing

warranty-voiding characteristics are evident: The manufacturer shall not be liable under this Warranty if the product has not been

properly installed; if it has been disassembled, modified, abused or tampered with; if the electrical cord has been damaged or

improperly spliced; if the pump discharge has been reduced in size; if the pump has been used in hot water or water containing sand,

lime, cement, gravel or other abrasives; if the product has been used to pump chemicals or hydrocarbons; if a non-submersible motor

has been subjected to excessive moisture; or if the label bearing the serial and code number has been removed. Liberty Pumps, Inc.

shall not be liable for any loss, damage or expenses resulting from installation or use of its products, or for consequential damages,

including costs of removal, reinstallation or transportation. There is no other express warranty. All implied warranties, including

those of merchantability and fitness for a particular purpose, are limited to three years from the date of purchase. This

Warranty contains the exclusive remedy of the purchaser, and, where permitted, liability for consequential or incidental damages under

any and all warranties are excluded.

©Copyright 2011 Liberty Pumps Inc. All rights reserved 4

Page 5

IMPORTANTE:

Apunte el modelo, el número de serie y el código que

aparecen en la placa de la bomba antes de instalarla para

que le sirvan de referencia en el futuro.

MODELO _______________________

SERIE ______________________

CÓDIGO _____________________

FECHA DE

INSTALACIÓN____________________

7000 Apple Tree Avenue

Bergen, NY 14416 EUA

Teléfono: (800) 543-2550

Fax: (585) 494-1839

www.libertypumps.com

Contenido

1.) Información general

2.) Precauciones/Preinstalación

3.) Instalación

4.) Mantenimiento y diagnóstico de problemas

Características

Cubeta de fibra de vidrio con 121.92 cm (48 plg) de

altura y 60.95 cm (24 plg) de diámetro.

Bomba trituradora LSG202M de 208/230V con 2 HP de

potencia

-oBomba trituradora LSGX202M de 208-230V con 2 HP

de potencia

GR20 Sistema de guiaderas

Caja de conexiones y alarma

Manual de instalación 7386000I

Sistema Triturador Simple 2448

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados

Page 6

ESPECIFICACIONES DE LA BOMBA TRITURADORA

Modelo

HP

Voltios

Fase

Carga total

Amps

Corriente

con rotor bloqueado

Desagüe

Altura práctica

con válvula cerrada

LSG202M

2

208/230

1

15

53

3.18 cm ( 1¼ plg)

32.9 m (108 pies)

LSGX202M

2

208-230

1

15

53

3.18 cm ( 1¼ plg)

56.4 m (185 pies)

1. Información general

2. Precauciones/Preinstalación

Lea con atención estas instrucciones antes de instalar la bomba. Todas las bombas de Liberty se someten a prueba en fábrica como

garantía de su funcionamiento. Siga estas instrucciones al pie de la letra para prevenir problemas de funcionamiento y conseguir

muchos años de servicio satisfactorio.

Riesgo de electrocución. Desenchufe la bomba siempre que vaya a moverla o a realizar algún ajuste.

La bomba no se deberá instalar en un lugar clasificado como peligroso por el código eléctrico nacional (NEC) de Estados Unidos,

ANSI/NFPA 70.

Sólo personal calificado podrá encargarse de instalar las conexiones y cables eléctricos necesarios para montar la bomba.

Esta unidad lleva un conector a tierra y un enchufe tomacorriente con conexión a tierra. Para reducir el riesgo de electrocución, el

conector de puesta a tierra tiene que estar conectado a un panel de control a tierra o si lleva un enchufe a tierra tendrá que

enchufarse a un tomacorrientes conectado a tierra.

No derive los cables de puesta a tierra ni retire las espigas a tierra de los enchufes.

No quite el cable ni la protección contra tirones, y no conecte canal para cables a la bomba.

No use cables prolongadores.

Con esta bomba hay que utilizar un circuito derivado independiente conectado a tierra y fusibleado. La fuente de potencia tendrá

que tener suficiente capacidad para cumplir los requisitos de tensión e intensidad del motor, indicados en la placa de la bomba.

Se deberá instalar la unidad según las disposiciones del código eléctrico nacional (NEC) de Estados Unidos y todos los códigos y

regulaciones locales que correspondan.

Las bombas de drenaje y de alcantarillado a menudo manejan materiales capaces de provocar enfermedades. Use ropa

protectora adecuada cuando trabaje en una bomba o una tubería usada.

Nunca ingrese a una cubeta de bomba después que haya sido usada. Los sistemas de efluentes y de alcantarillado pueden emitir

diferentes tipos de gases tóxicos.

La bomba no se debe utilizar con agua por encima de los 60 C (140 ° F).

El código uniformado de fontanería (UPC) de Estados Unidos exige que todos los sistemas de saneamiento dispongan de una

alarma visual y sonora que indique averías del sistema con el fin de evitar daños a la propiedad.

IMPORTANTE: tanto la bomba trituradora como la caja de conexiones vienen con su propio manual de instalación, operación y

mantenimiento. Es importante que estos manuales vengan incluidos con el producto y que usted los lea detenidamente antes de

instalar la unidad. Es muy importante que usted conozca bien estos manuales. En este manual de instalación se incluye una breve

descripción del sistema y se trata principalmente la inspección e instalación de la cubeta, pero no las características especificas de la

operación de la bomba o del panel de control. Si tiene alguna pregunta, llame al servicio de atención al cliente al teléfono 1 800 543-

2550.

Riesgo de electrocución. Desenchufe la bomba siempre que vaya a moverla o a realizar algún ajuste.

Pasos preliminares a la instalación:

1. Inspeccione la sistema cuando la reciba para comprobar que no haya sufrido daños durante el transporte. Preste especial

atención al estado de la cubeta de fibra de vidrio, los flotadores de control, los soportes de las guiaderas y el panel de control. Si

encuentra algún desperfecto, notifique de inmediato a la empresa transportista.

2. Lea las instrucciones en su integridad y familiarícese con el funcionamiento de la unidad antes de instalarla.

3. La instalación y prueba de los circuitos eléctricos deberá estar a cargo de un electricista licenciado.

4. Verifique que la fuente de energía sea adecuada para el amperaje de la bomba según lo anteriormente indicado y como aparece

en la placa de la bomba. El circuito de suministro eléctrico tendrá que tener fusibles o interruptores automáticos de capacidad

suficiente.

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados

Page 7

Figura 1 – Ventilación

entrante

RESPIRADERO

SANITARIO

DESAGÜE

SISTEMA

3. Instalación

5. Se debe instalar un circuito de derivación de 115V exclusivamente para la alarma. No se recomienda dividir el circuito de

alimentación entrante de la bomba para alimentar el circuito de control. Se debe instalar un circuito de derivación de 115V

exclusivamente para la alarma. No divida el circuito de alimentación entrante de la bomba para alimentar el circuito de control.

6. Se deberá comprobar que todas las conexiones eléctricas tengan una buena toma a tierra.

A. Excavación: excave un hoyo tan pequeño como sea posible con un diámetro mínimo de 96.52 cm (38 plg) en su base. No

coloque la cubeta en contacto directo con rocas ni objetos cortantes. Coloque gravilla fina de 0.31-1.91 cm (1/8-3/4 plg) o piedra

pulverizada fina y lavada de 0.31-1.27 cm (1/8-1/2 plg) en el fondo de la excavación hasta que alcance una altura mínima de 30.48

cm (12 plg) después de haberla compactado. No utilice arena ni tierra del suelo como relleno*. Compacte la superficie sobre la

que se asentará la cubeta para que quede sólida y nivelada y pueda soportar el peso de la misma. Si se va a instalar una plancha

de hormigón armado debajo de la cubeta, la base de piedra compactada se puede reducir a 15.24 cm (6 plg).

B. Conexiones y relleno: vierta suficiente hormigón alrededor y por encima del borde antiflotamiento para que la cubeta quede bien

cimentada y no se pueda mover verticalmente. Conecte un tubo PVC 80 de 3.18 cm (1¼ plg) al desagüe de la bomba. No reduzca

el tamaño de la tubería de desagüe ni la alargue a más de 5.08 cm (2 plg). El resto del desagüe deberá ser tan corto como sea

posible con el mínimo número de giros. Use estopa o plomo para conectar la línea de admisión a la boca de admisión de hierro

fundido de 10.16 cm (4 plg); también podría usar una guarnición de caucho. Conecte el acoplamiento eléctrico a un conducto

eléctrico de 5.08 cm (2 plg) y pase por el conducto los cables de alimentación y de los flotadores hasta el panel de control. El

relleno restante solo puede ser de gravilla fina de 0.31-1.91 cm (1/8-3/4 plg) o de piedra pulverizada fina y lavada de 0.31-1.27 cm

(1/8-1/2 plg). No utilice arena ni tierra del suelo como relleno*. *Podrían haber otros rellenos opcionales disponibles. Comuníquese

con la fábrica para recibir instrucciones especiales para su caso.

No ejerza una presión excesiva ni trabaje con equipo pesado encima del material de relleno, ya que

esto podría hacer colapsar el tanque.

C. Ventilación: la cubeta de fibra de vidrio incluida con la 2448

debe quedar totalmente sellada y recibir la ventilación adecuada

para que cumpla con los requisitos de los códigos de fontanería y

sanitarios aplicables. La ventilación de la bomba 2448 se

consigue a través del punto de admisión del sistema de

ventilación existente en el edificio. Para que esto sea posible no

debe haber purgadores entre la 2448 y el sistema de ventilación

más cercano del edificio. Vea la figura 1 para ver un ejemplo. Si

esto no es posible o no es deseable para su aplicación

específica, se puede abrir un orificio en la tapa de fibra de vidrio

e instalar un collarín o arandela de ventilación.

D. Alarma:

Riesgo de electrocución: esta unidad lleva un conector a

tierra. Para reducir el riesgo de electrocución, este conector

tendrá que estar conectado a un hilo con puesta a tierra.

Todos los circuitos eléctricos deberán cumplir con el código

eléctrico nacional (NEC) de Estados Unidos y los códigos

locales que correspondan.

IMPORTANTE: el panel de alarma que forma parte integral de

esta unidad viene con su propio manual de instalación,

operación y mantenimiento. Es importante que estos manuales

vengan incluidos con el producto y que usted los lea

detenidamente antes de instalar la unidad. Es muy importante

que usted conozca bien estos manuales.

Se debe instalar un circuito de derivación de 115V exclusivamente para la alarma. No divida el circuito de alimentación entrante de la

bomba para alimentar el circuito de control.

Enchufe al panel de control el conectador de alimentación de la bomba y del interruptor de flotadores según las indicaciones

incluidas en estas unidades.

E. Interruptores de flotador: el interruptor de flotador para la alarma está compensado internamente y no necesita sujetarse con

una abrazadera. El ciclo de la bomba viene configurado de fábrica a 30.48 cm (12 plg) (aproximadamente 25 galones). El ciclo se

puede modificar aflojando la mordaza y moviendo el flotador activo hacia arriba o hacia abajo. No recomendamos ajustes de más

de 7.62 cm (3 plg) en ninguna dirección; comuníquese con la fábrica si desea modificar el ciclo de la bomba a un nivel por encima

del que aquí se recomienda.

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados

Page 8

4. Mantenimiento y diagnóstico de problemas

COMPRUEBE QUE LA ARANDELA

DE CAUCHO ESTÉ BIEN

INSTALADA EN ESTE PUNTO.

INSTALE AQUÍ PERNOS DE CABEZA

HEXAGONAL DE 0.95 X 40.64 CM

(3/8X16 PLG). APRIETE CON LA

MISMA FUERZA AMBOS LADOS PARA

QUE LA JUNTA OBTURADORA QUEDE

BIEN COMPRIMIDA.

POSICIÓN DE DESCONEXIÓN

POSICION DE OPERACION

COMPRUEBE QUE LA ARANDELA DE

CAUCHO ESTÉ BIEN INSTALADA EN

ESTE PUNTO.

F. Pruebas y puesta en marcha: siga los procedimientos de prueba y de puesta en marcha que se encuentran en el manual de la

bomba y del panel de control.

G. Ensamblaje de la GR20: el conjunto de desconexión GR20 que se incluye con el sistema de trituración está diseñado para

facilitar la instalación y el desmontaje de la bomba. Siga de cerca los diagramas a continuación para completar la instalación.

IMPORTANTE: tanto la bomba trituradora como el panel de control vienen con su propio manual de instalación, operación y

mantenimiento. Es importante que estos manuales vengan incluidos con el producto y que usted los lea detenidamente antes de

instalar la unidad. Es muy importante que usted conozca bien estos manuales. Siga los procedimientos de mantenimiento y

diagnóstico de problemas incluidos en estos manuales

Garantía limitada de 3 años Liberty Pumps, Inc. garantiza que las bombas que fabrica están libres de defectos de material y

mano de obra por un período de 3 años desde la fecha de adquisición. La fecha de adquisición se determinará con el recibo de

compra fechado que incluye el modelo y el número de serie de la bomba. Este recibo deberá acompañar a la bomba si la fecha de

devolución es superior a 3 años de la fecha de fabricación (código-CODE) indicada en la placa de la unidad. Las obligaciones del

fabricante bajo esta garantía se limitarán a la reparación o reemplazo de las piezas que el fabricante determine que son defe ctuosas,

siempre que tal pieza o ensamblaje de piezas sea devuelta con el franqueo pagado al fabricante o a uno de sus centros autorizados, y

que no se evidencie ninguna de las características siguientes, lo que supondría la anulación de la garantía: el fabricante no tendrá

obligación alguna bajo esta garantía si el producto no ha sido instalado correctamente; si ha sido desmontado, modificado, abusado o

forzado; si el cable de potencia está dañado o tiene un empalme inapropiado; si se redujo el tamaño del desagüe de la bomba; si la

bomba se usó con agua caliente, o agua con arena, cal, cemento, grava u otros elementos abrasivos; si se utilizaron productos

químicos para bombas o hidrocarburos; si un motor no sumergible fue sometido a un exceso de humedad; o si se retiró la etiqueta con

el número de serie y de código. Liberty Pumps, Inc. no se hace responsable de pérdidas, daños o gastos que resulten de la instalación

o uso de sus productos, o por daños emergentes, como pueden ser los gastos de desmontar, reinstalar o transportar la unidad, entre

otros. No se ofrece ninguna otra garantía expresa. Todas las garantías implícitas, incluidas las de comerciabilidad o

adecuación a un propósito determinado, están limitadas a un plazo de tres años desde la fecha de adquisición. Esta garantía

representa el único remedio del comprador y, siempre que se permita, se rechaza toda responsabilidad por daños emergentes y

fortuitos bajo toda otra garantía.

©Copyright 2011 Liberty Pumps Inc. Todos los derechos reservados

Page 9

IMPORTANT :

Avant l’installation, noter les numéros de modèle, de série

et de code qui figurent sur la plaque signalétique pour

éventuellement s’y référer.

MODÈLE _____________________

SÉRIE _______________________

CODE ______________________

DATE

D'INSTALLATION _____________

7000, avenue Apple Tree

Bergen (NY) 14416

Téléphone : (800) 543-2550

Télécopieur : (585) 494-1839

www.libertypumps.com

Table des matières

1.) Renseignements généraux

2.) Précautions/préinstallation

3.) Installation

4.) Entretien et dépannage

Caractéristiques

Bassin de fibre de 61 cm x 123,2 cm

(24 po x 48½ po) de diamètre

LSG202M Pompe broyeuse - 2 HP, 208/230 V

-ouLSGX202M Pompe broyeuse - 2 HP, 208-230 V

GR20 Système de rail guide

Fouloir et alarme

Manuel d’installation 7386000I

Système de broyeur simple 2448

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés

Page 10

CARACTÉRISTIQUES DE LA POMPE BROYEUSE

Modèle

HP

Volts

Phase

Intensité

maximale

Intensité fixe

du rotor

Évacuation

Hauteur de chute

d’arrêt

LSG202M

2

208/230

1

15

53

1¼ po

33 m (108 pi)

LSGX202M

2

208-230

1

15

53

1¼ po

56 m (185 pi)

1. Renseignements généraux

2. Précautions/préinstallation

Lire attentivement les directives avant d’effectuer l’installation. Chaque pompe de marque Liberty est testée individuellement en usine

pour assurer un bon fonctionnement. Le fait de suivre ces directives à la lettre éliminera les risques de problèmes de fonctionnement et

assurera des années de service sans soucis.

Danger d’électrocution. Toujours débrancher la pompe de l’alimentation électrique avant de la manipuler ou d’y effectuer des

réglages.

Cette pompe ne doit pas être installée dans un endroit classé dangereux selon la norme ANSI/NFPA 70 du NEC.

Les raccords électriques et le câblage pour l’installation de la pompe ne devraient être effectués que par des professionnels

qualifiés.

Cette pompe est fournie avec un conducteur de mise à la terre et une fiche de branchement de type mise à la terre. Afin de réduire

les dangers d’électrocution, s’assurer que le conducteur de mise à la terre est raccordé seulement à un panneau de commande

correctement mis à la terre, ou, s’il est muni d’une fiche avec mise à la terre, qu’elle est correctement mise à la terre.

Ne pas dévier les fils de mise à la terre ou retirer la broche de mise à la terre des fiches de branchement.

Ne pas retirer le cordon ni le réducteur de tension, et ne pas raccorder la canalisation électrique à la pompe.

Ne pas utiliser de rallonge.

Cette pompe nécessite un circuit de dérivation à part correctement protégé par un fusible et mis à la terre. S’assurer que la source

d’alimentation électrique est suffisante pour répondre aux exigences de tension et d’intensité du courant électrique du moteur, tel

qu’indiqué sur la plaque signalétique de la pompe.

L’installation doit être faite en respectant le code national de l’électricité et tous les codes locaux et règlements en vigueur.

Les pompes d'assèchement et de système d'égout traitent souvent des matières pouvant causer des maladies. Porter des

vêtements protecteurs adéquats pour manipuler une pompe ou de la tuyauterie ayant déjà servi.

Ne jamais pénétrer dans le réservoir de pompage après qu'il ait servi. Les égouts et effluents peuvent émettre des gaz toxiques

Ne pas utiliser ces pompes dans de l’eau dont la température est supérieure à 60 °C (140 F).

Le Uniform Plumbing Code (UPC, Code de plomberie universel) indique que les systèmes d’égout doivent être munis d’une

d’alarme sonore et visuelle qui signale tout mauvais fonctionnement du système, afin de réduire les risques de dommages à la

propriété.

IMPORTANT : La pompe broyeuse et le fouloir sont fournis avec leurs propres manuels d’installation/de

fonctionnement/d’entretien. S’assurer d’avoir ces manuels en main, de les lire et de les comprendre avant l’installer l’appareil. Il est essentiel

d’être familier avec les manuels de la pompe broyeuse et du panneau de commande. Ce manuel d’installation fournit un bref survol du

système, et porte surtout sur l’inspection et l’installation du bassin, mais il n’aborde pas les détails du fonctionnement de la pompe ni du

panneau de commande. Si vous avez des questions à ce sujet, veuillez communiquer avec le service à la clientèle au (800) 543-2550.

Danger d’électrocution. Toujours débrancher la pompe de l’alimentation électrique avant de la manipuler ou d’y

Aide-mémoire avant l’installation :

1. Inspecter le système dès réception pour s’assurer qu’il n’a subi aucun dommage lors du transport. Faire particulièrement attention

à l’état du bassin de fibre de verre, des flotteurs de commande, des supports du rail guide de la pompe et du panneau de

commande. Avertir immédiatement le service de livraison s’il semble y avoir des dommages.

2. Lire toutes les directives et se familiariser avec le fonctionnement de l’appareil avant de procéder à l’installation.

3. Un électricien autorisé qualifié doit installer et vérifier tous les circuits électriques.

4. S’assurer que la source d’alimentation électrique est suffisante pour convenir à l’intensité du courant électrique de la pompe, telle

qu’indiqué sur la plaque signalétique. S’assurer que le circuit d’alimentation électrique est muni de fusibles ou de coupe-circuit de

la bonne puissance.

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés 2

effectuer des réglages.

Page 11

3. Installation

Fig. 1 – Entrée

d’évent

ÉVENT

CUVETTE

ÉVACUATION

5. Un circuit de dérivation séparé de 115 V doit être installé pour l’alarme. Il n’est pas recommandé de diviser le circuit d’alimentation

de la pompe pour alimenter le circuit de commande. Un circuit de dérivation séparé de 115 V doit être installé pour l’alarme. Ne

pas diviser le circuit d’alimentation de la pompe pour alimenter le circuit de commande.

6. On doit vérifier tous les raccordements électriques pour s’assurer que la mise à la terre fonctionne bien.

A. Excavation : Creuser le trou le plus petit possible pour le bassin, avec un diamètre d’au moins 96,52 cm (38 po) à la base. Ne jamais

placer le bassin directement en contact avec des roches ou d’autres objets contondants. Placer au fond du trou suffisamment de

gravier 3 à 19 mm (1/8 à ¾ po) ou de concassé fin lavé de ou 3 à 13 mm (1/8 à ½ po) pour créer une base d’au moins 30,48 cm

(12 po) après compaction. Ne pas utiliser de sable ni de terre d’origine pour remplir le trou*. Compacter convenablement sous le

bassin afin de fournir une base solide et bien au niveau capable de supporter le poids du bassin, une fois rempli. Si on prévoit installer

une plaque de béton sous le bassin, l’épaisseur de la base de pierre compactée peut être réduite à 15,24 cm (6 po).

B. Raccordements et remplissage : Verser suffisamment de béton par-dessus et autour de la bride anti-flottaison pour ancrer le

bassin et prévenir les mouvements vers le haut. Raccorder un tuyau de PVC de nomenclature 80 de 1¼ po aux raccordements

d’évacuation de la pompe. Ne pas installer de tuyau d’évacuation d’un diamètre inférieur, et ne pas augmenter sa dimension audelà de 2 po. Le reste de la canalisation d’évacuation devrait être le plus court possible et comporter un nombre minimum de

virages. Raccorder la conduite d’arrivée d’eau à l’emboîtement d’entrée de 4 po à l’aide d’étoupe et de plomb ou d’un anneau de

caoutchouc. Brancher le raccordement électrique à la canalisation électrique de 2 po et faire passer les cordons électriques et du

flotteur à travers la canalisation vers le panneau de commande. Le concassé fin lavé de 3 à 19 mm (1/8 à ¾ po) ou 3 à 13 mm (1/8

à ½ po) est recommandé comme matériau de remplissage. Ne pas utiliser de sable ni de terre d’origine pour remplir le trou*.

*D’autres possibilités de matériau de remplissage peuvent exister

– consulter le fabricant pour obtenir des directives spéciales au

sujet de toute situation particulière.

Ne pas exercer de pression importante ni

C. Évent : Le bassin nécessaire fourni avec le 2448 doit être étanche et

ventilé adéquatement afin de respecter les normes des codes de

plomberie et de santé publique. Le modèle 2448 est conçu pour être

raccordé à une colonne de ventilation secondaire du bâtiment

existante. Pour ce faire, il ne doit pas y avoir de trappe entre l’entrée

du 2448 et le raccordement le plus près de colonne de ventilation

secondaire la plus proche. Voir l’exemple à la figure 1. Si cela n’est

pas possible ou souhaitable dans le cas d’une installation particulière,

on peut installer une bride de ventilation ou un œillet dans un orifice

découpé dans le couvercle de fibre de verre plein.

D. Alarme :

Danger d’électrocution : Cette pompe est fournie avec un

conducteur de mise à la terre. Afin de réduire les dangers

d’électrocution, s’assurer que celle-ci est raccordée seulement à

un câble de mise la terre convenablement installé.

L’installation du circuit électrique doit être faite en respectant le

code national de l’électricité et tous les codes locaux et

règlements en vigueur.

IMPORTANT : La pompe broyeuse et le fouloir sont fournis avec

leurs propres manuels d’installation/de fonctionnement/d’entretien.

S’assurer d’avoir ces manuels en main, de les lire et de les comprendre avant d’installer l’appareil. Il est essentiel d’être familier

avec le panneau de commande.

Un circuit de dérivation séparé de 115 V doit être installé pour l’alarme. Ne pas diviser le circuit d’alimentation de la pompe pour

alimenter le circuit de commande.

Ne pas diviser le circuit d’alimentation de la pompe pour alimenter le circuit de commande.

E. Interrupteurs à flotteurs : L’interrupteur à flotteur pour l’alarme est muni d’une pesée interne et n’a pas besoin d’être attaché. Le

cycle de la pompe est réglé en usine à 30,48 cm (12 po), soit environ 95 litres (25 gallons É.-U.). On peut régler le cycle de la

pompe en relâchant l’attache du cordon et en déplaçant le dispositif de mise en marche à flotteur vers le haut ou le bas. Il n’est pas

recommandé de le déplacer de plus de 7,62 cm (3 po) dans l’une ou l’autre direction. Communiquer avec le fabricant s’il est

nécessaire de régler le cycle de la pompe au-delà du niveau recommandé.

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés 3

utiliser de matériel lourd sur le matériau de

remplissage, car cela pourrait causer

l’affaissement du réservoir.

Page 12

4. Entretien et dépannage

INSTALLER LES BOULONS

HEXAGONAUX 3/8 X 16 ICI.

RESSERRER UNIFORMÉMENT LES

DEUX CÔTÉS DE MANIÈRE À BIEN

COMPRIMER LE JOINT

D’ÉTANCHÉITÉ.

S’ASSURER QUE L’OEILLET DE

CAOUTCHOUC SOIT BIEN INSTALLÉ

ICI.

POSITION DE DÉCONNEXION

POSITION DE FONCTIONNEMENT

S’ASSURER QUE L’OEILLET

SONT BIEN INSTALLÉS ICI.

F. Essais et mise en marche : Suivre les procédures d’essais et de démarrage qui sont décrites dans les manuels du modèle et du

panneau de commande.

G. Montage : Le module de déconnexion rapide GR20 fourni avec le système de broyeur est conçu pour permettre d’installer et de

retirer facilement la pompe. Il est recommandé de s’assurer que l’installation est effectuée en respectant les schémas ci-dessous.

IMPORTANT : La pompe broyeuse et le panneau de commande sont fournis avec leurs propres manuels d’installation/de

fonctionnement/d’entretien. S’assurer d’avoir ces manuels en main, de les lire et de les comprendre avant ‘installer l’appareil. Il est

essentiel d’être familier avec les manuels de la pompe broyeuse et du panneau de commande. Suivre les méthodes d’entretien et de

dépannage fournies dans ces manuels.

Garantie limitée de 3 ans Liberty Pumps, Inc. garantit que les pompes sortant de son usine sont libres de tout défaut de matériau et

de fabrication pour une période de 3 ans à partir de la date d’achat. La date d’achat sera établie par une facture d’achat datée indiquant les

numéros de modèle et de série de la pompe. La pompe retournée doit être accompagnée de la facture d’achat datée si la date de retour

se situe plus de 3 ans du numéro de « CODE » (date de fabrication) indiqué sur la plaque signalétique de la pompe. L’obligation de

garantie du fabricant se limite à la réparation ou au remplacement de toute pièce jugée défectueuse par le fabricant, à condition que la

pièce ou l’appareil soient retournés franco de port au fabricant ou à son centre de service autorisé et à condition qu’il n’y ait aucune preuve

que les critères suivants annulant la garantie sont en cause. Le fabricant ne peut en aucun cas être tenu pour responsable, selon les

dispositions de cette garantie, si le produit n’a pas été correctement installé; s’il a été démonté, modifié, soumis à un usage abusif ou

endommagé; si le cordon électrique a été endommagé ou incorrectement ligaturé; si la taille du tuyau d’évacuation de la pompe a été

réduite; si la pompe a été utilisée dans de l’eau chaude ou de l’eau contenant du sable, de la chaux, du ciment, du gravier ou autres

matières abrasives; si le produit a été utilisé pour pomper des produits chimiques ou des hydrocarbures; si un moteur non submersible a

été exposé à de l’humidité excessive; ou si l’étiquette portant le numéro de série et le numéro de code a été retirée. Liberty Pumps, Inc. ne

pourra être tenue responsable des pertes, dommages, frais attribuables à l’installation ou l’utilisation de ses produits ou pour les

dommages accessoires ou consécutifs, y compris les coûts de retrait, de réinstallation ou de transport. Il n’y a aucune autre garantie

expresse. Toute garantie implicite, y compris celles de qualité marchande et d’aptitude à une fin particulière est limitée à trois

ans à partir de la date d’achat. Cette garantie contient le recours exclusif de l’acheteur et exclut, lorsque permis par la loi, toute

responsabilité pour dommages consécutifs ou accessoires en vertu de toutes autres garanties.

©Copyright 2011 Liberty Pumps Inc. Tous droits réservés 4

Loading...

Loading...