Page 1

Global LCD Panel Exchange Center

(◆) Preliminary Specification

()Final Specification

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

SPECIFICATION

FOR

APPROVAL

Title 19” SXGA TFT LCD

Customer

MODEL

APPROVED BY

/

/

SIGNATURE

SUPPLIER LG Display Co., Ltd.

*MODEL LB190E02

Suffix SL02

*When you obtain standard approval,

please use the above model name without suffix

APPROVED BY

Y. T. Woo / G.Manager

REVIEWED BY

K. H. Choi / Manager [C]

B. C. Lee / Manager [M]

SIGNATURE

J. K. Kim / Manager [P]

PREPARED BY

/

Please return 1 copy for your confirmation with

your signature and comments.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

B. Y. Ha / Engineer

Products Engineering Dept.

LG Display Co., Ltd

1 / 32

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

Contents

No ITEM

COVER

CONTENTS

RECORD OF REVISIONS

1 GENERAL DESCRIPTION

2 ABSOLUTE MAXIMUM RATINGS

3 ELECTRICAL SPECIFICATIONS

3-1 ELECTRICAL CHARACTREISTICS

3-2 INTERFACE CONNECTIONS

3-3 SIGNAL TIMING SPECIFICATIONS

3-4 SIGNAL TIMING WAVEFORMS

3-5 COLOR INPUT DATA REFERNECE

3-6 POWER SEQUENCE

Page

1

2

3

4

5

6

6

8

13

14

15

16

3-7 V

4 OPTICAL SFECIFICATIONS

5 MECHANICAL CHARACTERISTICS

6 RELIABLITY

7 INTERNATIONAL STANDARDS

7-1 SAFETY

7-2 EMC

7-3 ENVIRONMENT

8 PACKING

8-1 DESIGNATION OF LOT MARK

8-2 PACKING FORM

9 PRECAUTIONS 30

Power Dip Condition

LCD

17

18

24

27

28

28

28

28

29

30

29

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

2 / 32

Page 3

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

RECORD OF REVISIONS

Revision

No

0.0 Aug. 17. 2012 - First Draft, Preliminary Specifications

Revision

Date

Page Description

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

3 / 32

Page 4

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

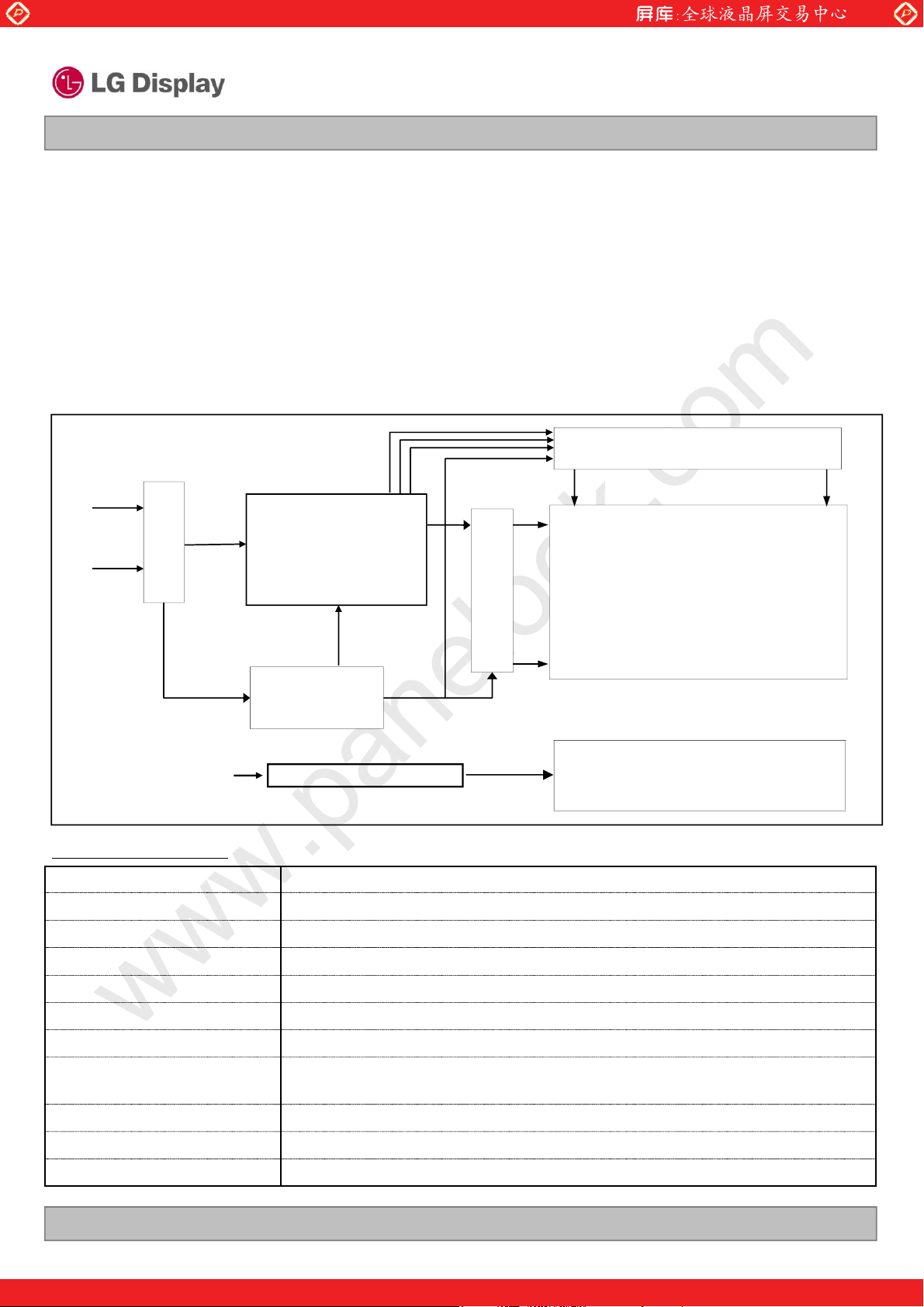

1. General Description

LB190E02 is a Color Active Matrix Liquid Crystal Display with a Light Emitting Diode ( White LED) backlight

system without LED driver. The matrix employs a-Si Thin Film Transistor as the active element.

It is a transmissive type display operating in the normally black mode. It has a 19.0 inch diagonally

measured active display area with SXGA resolution (1024 vertical by 1280 horizontal pixel array)

Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arranged in vertical stripes.

Gray scale or the brightness of the sub-pixel color is determined with a 8-bit gray scale signal for each dot,

thus, presenting a palette of more than 16,7M colors

It has been designed to apply the 8Bit 2 port LVDS interface.

It is intended to support displays where high brightness, super wide viewing angle,

high color saturation, and high color are important.

EPI (RGB)

RGB

Source Driver Circuit

LVDS

G1

2port

+5.0V

CN1

(30pin)

+5.0V

Timing

Controller

Power Circuit

Gate Driver Circuit

G1024

Block

V

LED

General Features

CN2 (6PIN)

[ Figure 1 ] Block diagram

Active Screen Size 19.0 inch (481.84mm) diagonal

Outline Dimension 396.0(H) x 324.0(V) x 13.2(D) mm(Typ.)

Pixel Pitch 0.294 mm x 0.294mm

S1 S1280

TFT - LCD Panel

(1280 × RGB × 1024 pixels)

Back light Assembly

(LED)

Pixel Format 1280 horiz. by 1024 vert. Pixels. RGB stripe arrangement

Color Depth 16,7M colors

2

Luminance, White 330 cd/m

( Center 1 Point, Typ.)

Viewing Angle(CR>10) View Angle Free (R/L 178(Typ.), U/D 178(Typ.))

Power Consumption Total TBD Watt (Typ.) (TBD Watt

@VLCD, TBD Watt @W/O Driver)

Weight TBD g (typ.)

Display Operating Mode Transmissive mode, normally black

Surface Treatment Hard coating(3H), Anti-Glare treatment of the front polarizer

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

4 / 32

Page 5

Global LCD Panel Exchange Center

[ Storage ]

[ Operation ]

-10

10

20 30 40 50

60 700

Dry Bulb Temperature [℃]

10%

30%

60%

90%

0

10

20

30

40

50

60

Wet Bulb

Temperature [℃]

Humidity[(%)RH]

80%

80

-30

-20

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

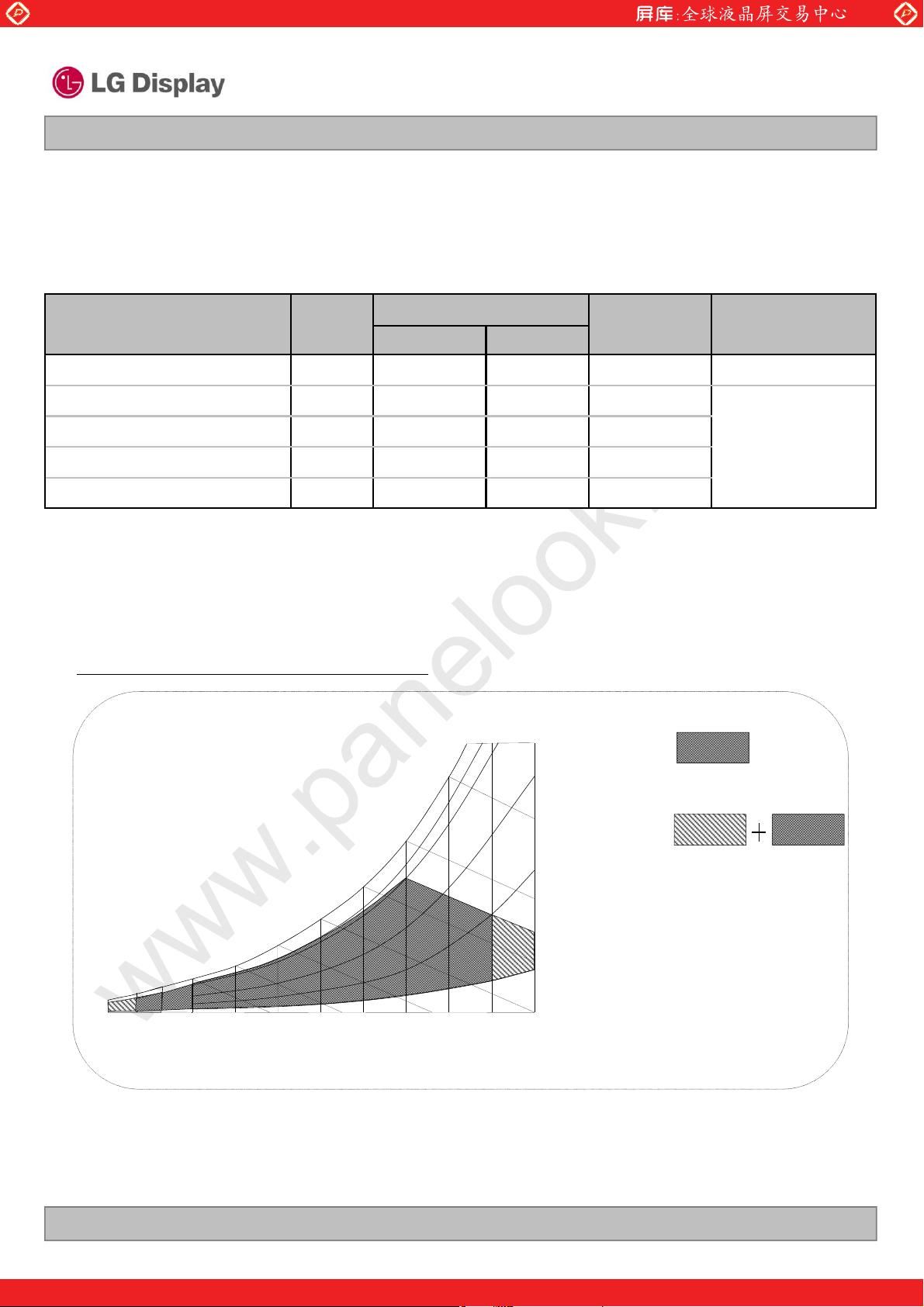

2. Absolute Maximum Ratings

The following are maximum values which, if exceeded, may cause faulty operation or damage to the unit.

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter Symbol

Power Input Voltage

Operating Temperature

Storage Temperature

Operating Ambient Humidity

Storage Humidity

VLCD -0.3 6.0 Vdc at 25 ! 2°C

TOP -10 70

TST -20 80

HOP 10 90 %RH

HST 10 90 %RH

Values

Units Notes

Min Max

°C

°C

Note : 1. Temperature and relative humidity range are shown in the figure below.

Wet bulb temperature should be 39 °C Max, and no condensation of water.

2. Maximum Storage Humidity is up to 40℃, 70% RH only for 4 corner light leakage Mura.

3. Storage condition is guaranteed under packing condition

FIG.2 Temperature and relative humidity

1, 2, 3

[

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

5 / 32

Page 6

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

3. Electrical Specifications

3-1. Electrical Characteristics

It requires two power inputs. One is employed to power the LCD electronics and to drive the TFT array and

liquid crystal. The second input power for the LED/Backlight, is typically generated by a LED Driver.

The LED Driver is an external unit to the LCDs.

Table 2-1. ELECTRICAL CHARACTERISTICS

Parameter Symbol

MODULE :

Power Supply Input Voltage V

Power Supply Input Current I

Power Consumption

Differential Impedance Zm 90 100 110 Ohm

Rush current I

LCD

LCD

P

c TYP -

P

c MAX -

RUSH - - 3.0 A 3

Min Typ Max

4.5 5.0 5.5

-

-

Values

TBD -

TBD -

TBD -

TBD -

Unit Notes

Watt 1

Watt 2

Note :

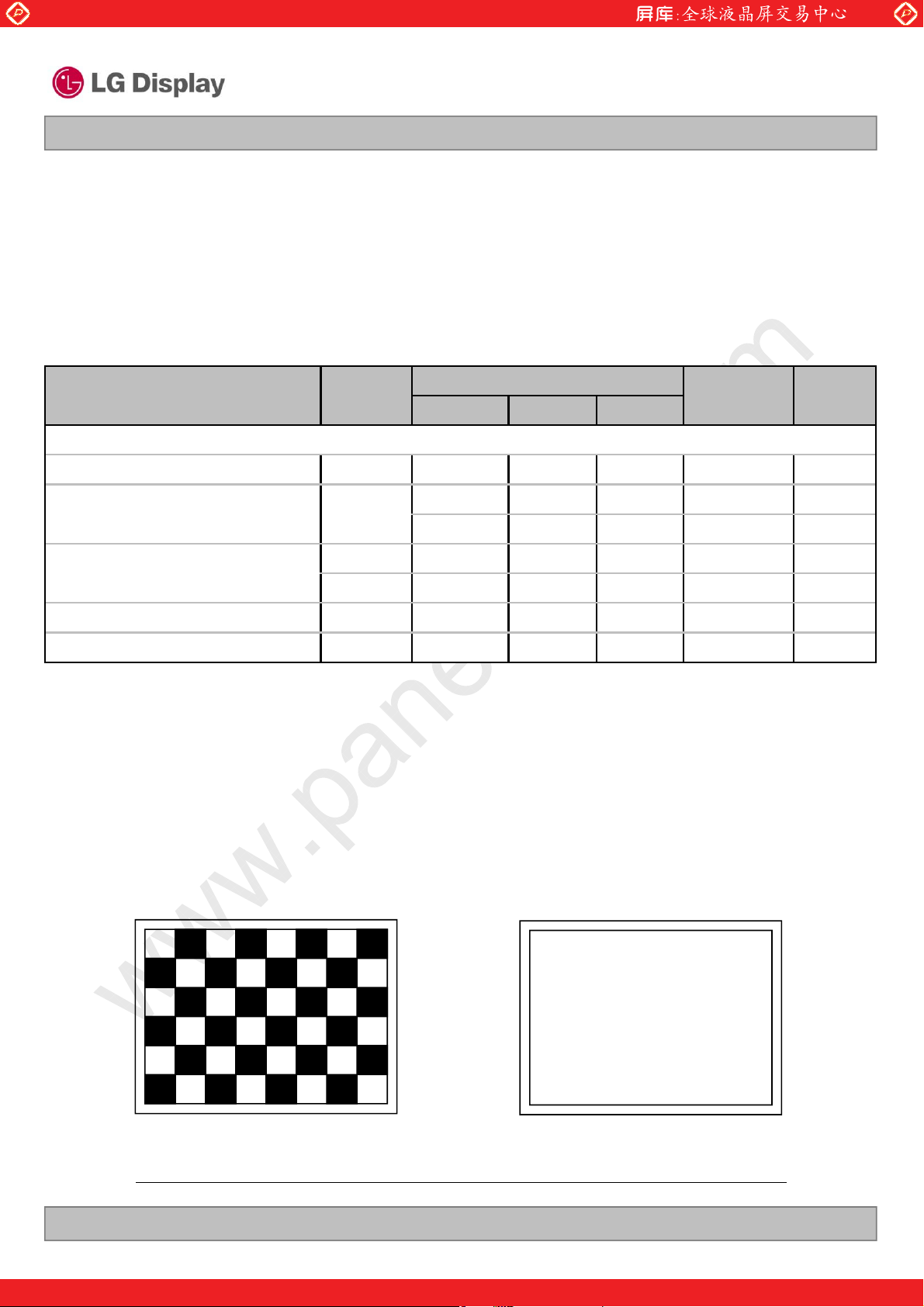

1. The specified current and power consumption are under the V

=5.0V, 25 ! 2°C,fV=60Hz condition

LCD

whereas Typical Power Pattern[Mosaic] shown in the [ Figure 3 ] is displayed.

2. The current is specified at the maximum current pattern.

Vdc

mA 1

mA 2

3. Maximum Condition of Inrush current :

The duration of rush current is about 5ms and rising time of power Input is 500us ! 20%.(min.).

Typical power Pattern

Maximum power Pattern

FIG.3 Mosaic pattern & White Pattern for power consumption measurement

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

6 / 32

Page 7

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

Table 2-2. LED Bar ELECTRICAL CHARACTERISTICS

LB190E02-SL02

Liquid Crystal Display

Parameter Symbol Condition

LED : 1,7

LED String Current Is - TBD - mA 2,7

LED String Voltage Vs - TBD - V 3,7

Power Consumption

LED Life Time LED_LT 50,000 - - Hrs 5,7

PBar - TBD - Watt 4,6,7

Min. Typ. Max.

Values

Unit Notes

LED driver design guide

1) The design of the LED driver must have specifications for the LED in LCD Assembly.

The performance of the LED in LCM, for example life time or brightness, is extremely influenced by

the characteristics of the LED driver.

So all the parameters of an LED driver should be carefully designed and output current should be

Constant current control.

Please control feedback current of each string individually to compensate the current variation

among the strings of LEDs.

When you design or order the LED driver, please make sure unwanted lighting caused by

the mismatch of the LED and the LED driver (no lighting, flicker, etc) never occurs.

When you confirm it, the LCD module should be operated in the same condition as installed in

your instrument.

2) LGD recommend that Dimming Control Signal (PWM Signal) should be synchronized

with Frame Frequency for Wavy Noise Free.

1. Specified values are for a single LED bar.

2. The specified current is input LED chip 100% duty current.

3. The specified voltage is input LED string and Bar voltage at typical 110 mA 100% duty current.

4. The specified power consumption is input LED bar power consumption at typical 110 mA 100% duty current.

5. The life is determined as the time at which luminance of the LED is 50% compared to that of initial

value at the typical LED current on condition of continuous operating at 25 ! 2°C.

6. The LED bar power consumption shown above does not include loss of external driver.

The used LED bar current is the LED typical current.

Min Power Consumption is calculated with PBar = Vs(Min.) x Is(Typ.) x Nstring

Max Power Consumption is calculated with PBar = Vs(Max.) x Is(Typ) x Nstring

7. LED operating DC Forward Current must not exceed LED Max Ratings at 25 ! 2°C

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

7 / 32

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Liquid Crystal Display

Product Specification

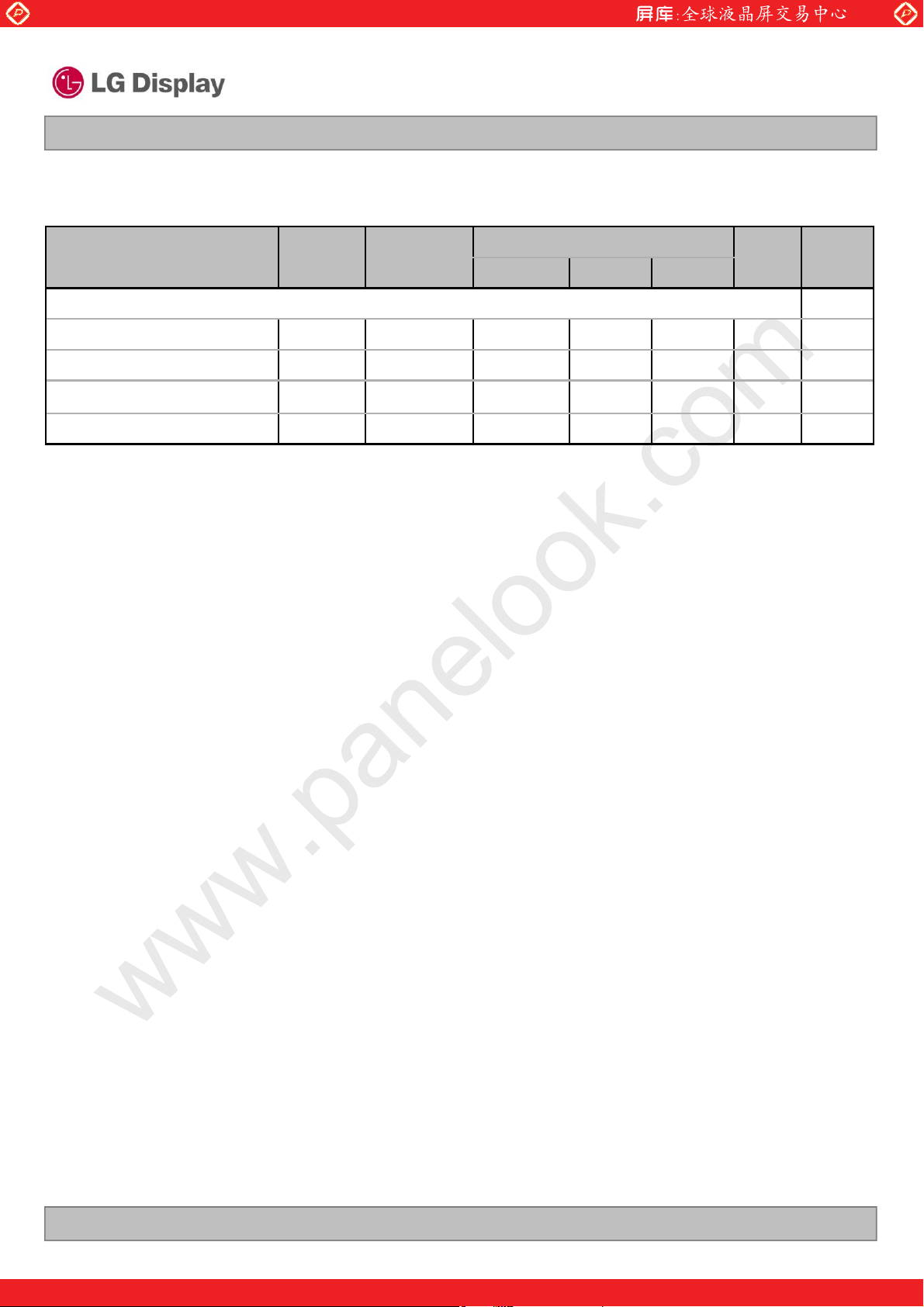

3-2. Interface Connections

3-2-1. LCD Module

- LCD Connector(CN1). : GT101-30S-H16 (LGC) , IN-30-BA10 (UJU)

- Mating Connector : FI-X30C2L (Manufactured by JAE) or Equivalent

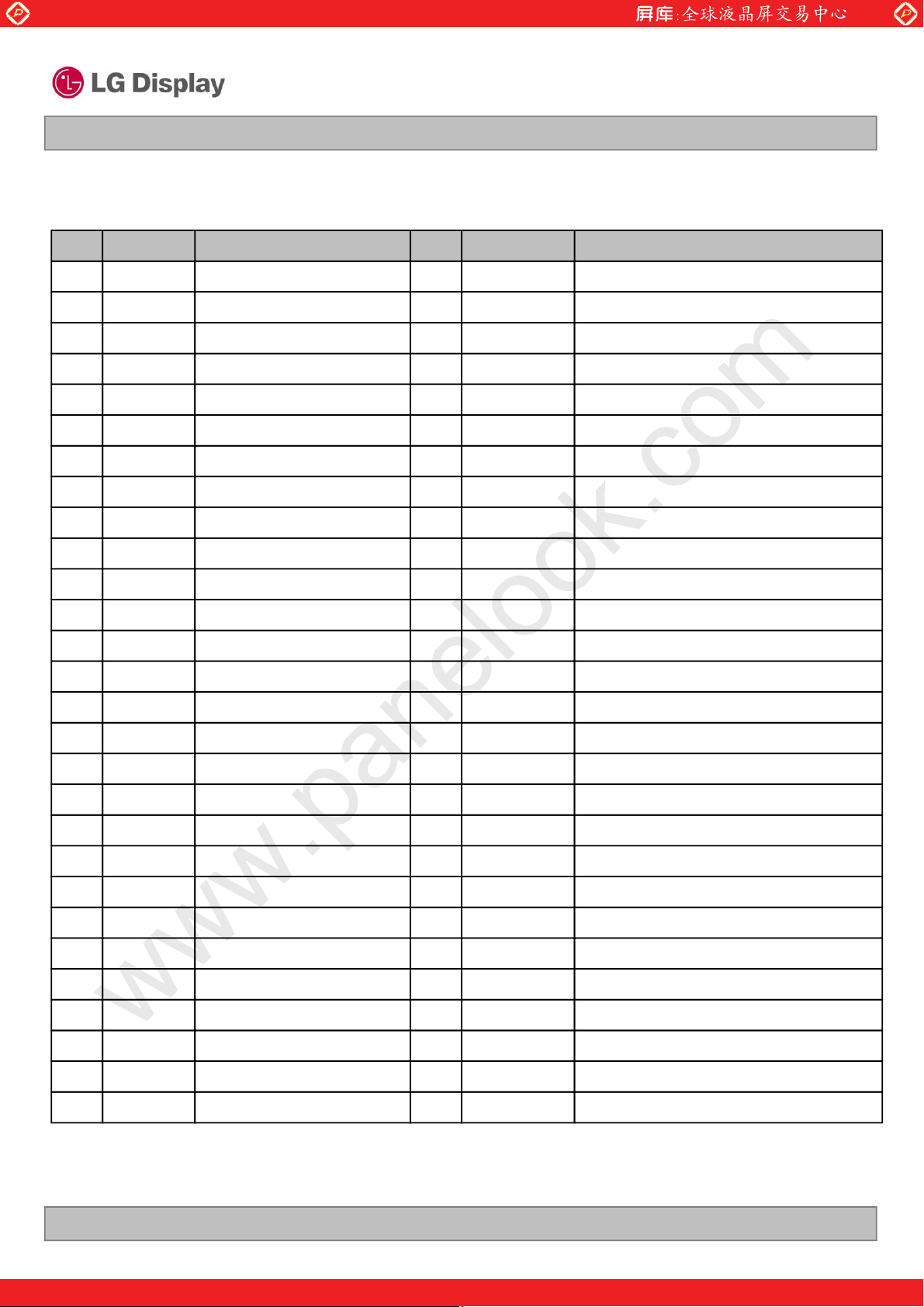

Table 3. MODULE CONNECTOR(CN1) PIN CONFIGURATION

No Symbol Description No Symbol Symbol

LB190E02-SL02

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

FR0M

FR0P

FR1M

FR1P

FR2M

FR2P

GND

FCLKINM

FCLKINP

FR3M

FR3P

SR0M

SR0P

GND

SR1M

Minus signal of odd channel 0 (LVDS)

Plus signal of odd channel 0 (LVDS)

Minus signal of odd channel 1 (LVDS)

Plus signal of odd channel 1 (LVDS)

Minus signal of odd channel 2 (LVDS)

Plus signal of odd channel 2 (LVDS)

Ground

Minus signal of odd clock channel (LVDS)

Plus signal of odd clock channel (LVDS)

Minus signal of odd channel 3 (LVDS)

Plus signal of odd channel 3 (LVDS)

Minus signal of even channel 0 (LVDS)

Plus signal of even channel 0 (LVDS)

Ground

Minus signal of even channel 1 (LVDS)

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

SR1P

GND

SR2M

SR2P

SCLKINM

SCLKINP

SR3M

SR3P

GND

NC

NC

NC

VLCD

VLCD

VLCD

Plus signal of even channel 1 (LVDS)

Ground

Minus signal of even channel 2 (LVDS)

Plus signal of even channel 2 (LVDS)

Minus signal of even clock channel (LVDS)

Plus signal of even clock channel (LVDS)

Minus signal of even channel 3 (LVDS)

Plus signal of even channel 3 (LVDS)

Ground

No Connection.(I2C Serial interface for LCM)

No Connection.(I2C Serial interface for LCM)

Groumd

Power Supply +5.0V

Power Supply +5.0V

Power Supply +5.0V

Note: 1. All GND(ground) pins should be connected together and to Vss which should also be connected to

the LCD’s metal frame.

2. All V

LCD (power input) pins should be connected together.

3. Input Level of LVDS signal is based on the IEA 664 Standard.

4. PWM_OUT signal controls the burst frequency of a inverter.

This signal is synchronized with vertical frequency.

It’s frequency is 3 times of vertical frequency, and it’s duty ratio is 50%.

If you don’t use this pin, it is no connection.

#1 #30

GT101-30S-H16(LGC) or

IN-30-BA 10 (UJU)

FIG.3 Connector diagram

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

#1 #30

Rear view of LCM

8 / 32

www.panelook.com

Page 9

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

Table 4. REQUIRED SIGNAL ASSIGNMENT FOR Flat Link (TI:SN75LVDS83) Transmitter

Pin # Require SignalPin Name Pin # Require SignalPin Name

1 Power Supply for TTL InputVCC 29 Ground pin for TTLGND

2 TTL Input (R7)D5 30 TTL Input (DE)D26

3 TTL Input (R5)D6 31 TTL Level clock InputTXCLKIN

4 TTL Input (G0)D7 32 Power Down InputPWR DWN

5 Ground pin for TTLGND 33 Ground pin for PLLPLL GND

6 TTL Input (G1)D8 34 Power Supply for PLLPLL VCC

7 TTL Input (G2)D9 35 Ground pin for PLLPLL GND

8 TTL Input (G6)D10 36 Ground pin for LVDSLVDS GND

9 Power Supply for TTL InputVCC 37 Positive LVDS differential data output 3

10 TTL Input (G7)D11 38 Negative LVDS differential data output 3

11 TTL Input (G3)D12 39 Positive LVDS differential clock output

12 TTL Input (G4)D13 40 Negative LVDS differential clock output

13 Ground pin for TTLGND 41 Positive LVDS differential data output 2

14 TTL Input (G5)D14 42 Negative LVDS differential data output 2

15 TTL Input (B0)D15 43 Ground pin for LVDSLVDS GND

16 TTL Input (B6)D16 44 Power Supply for LVDSLVDS VCC

17 Power Supply for TTL InputVCC 45 Positive LVDS differential data output 1

18 TTL Input (B7)D17

19 TTL Input (B1)D18

20 TTL Input (B2)D19

22 TTL Input (B3)D20

46 Negative LVDS differential data output 1

47 Positive LVDS differential data output 0

48 Negative LVDS differential data output 0

49 Ground pin for LVDSLVDS GND21 Ground pin for TTL InputGND

50 TTL Input (R6)D27

TxOUT3+

TxOUT3-

TXCLKOUT+

TXCLKOUT-

TXOUT2+

TXOUT2-

TXOUT1+

TXOUT1-

TXOUT0+

TXOUT0-

23 TTL Input (B4)D21

24 TTL Input (B5)D22

25 TTL Input (RSVD)D23

26 Power Supply for TTL InputVCC 54 TTL Input (R2)D2

51 TTL Input (R0)D0

52 TTL Input (R1)D1

53 Ground pin for TTLGND

55 TTL Input (R3)D327 TTL Input (HSYNC)D24

56 TTL Input (R4)D428 TTL Input (VSYNC)D25

Notes : 1. Refer to LVDS Transmitter Data Sheet for detail descriptions.

2. 7 means MSB and 0 means LSB at R,G,B pixel data

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

9 / 32

Page 10

Global LCD Panel Exchange Center

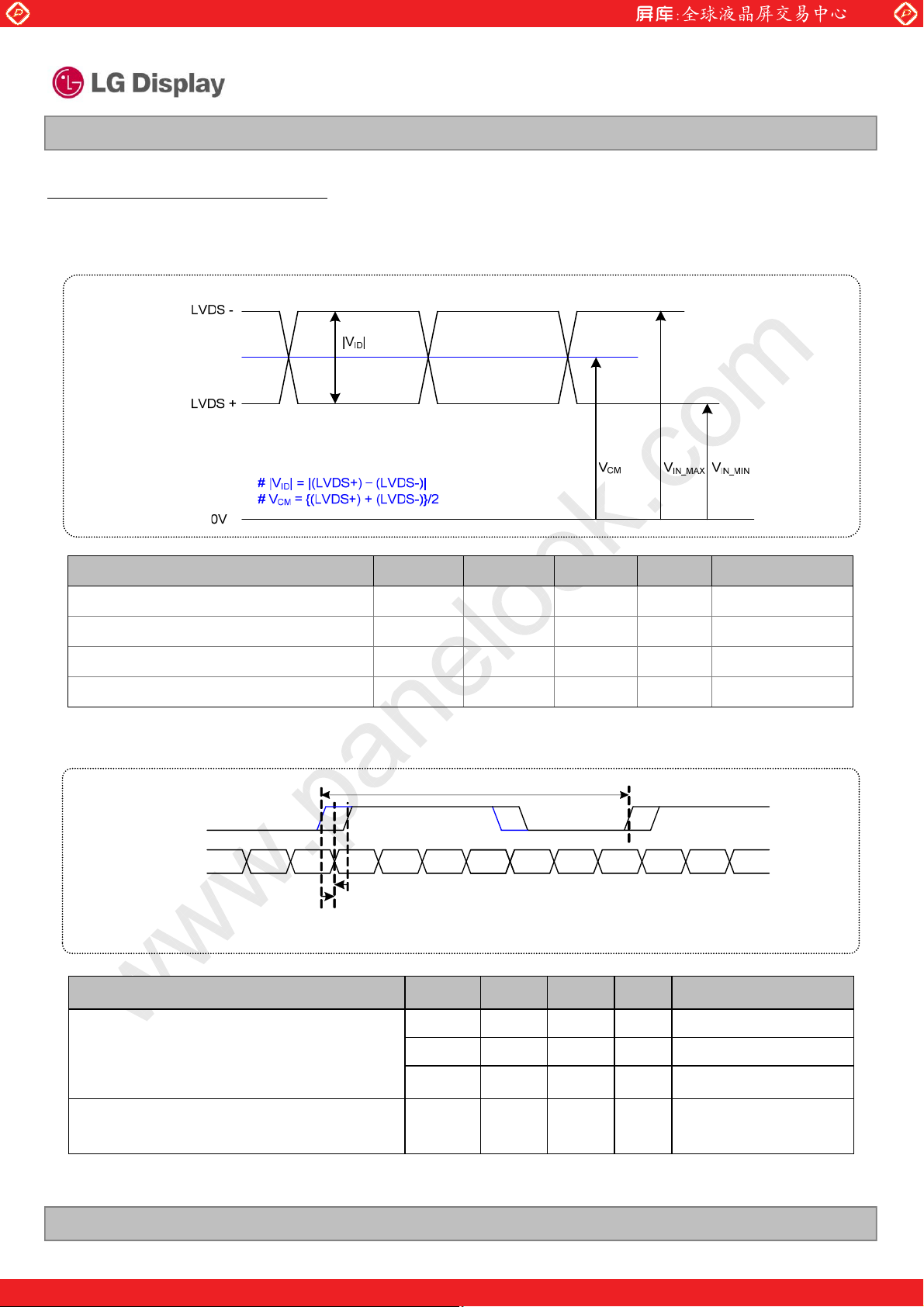

LVDS Input characteristics

1. DC Specification

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

Description Symbol Min Max Unit Notes

LVDS Differential Voltage |V

LVDS Common mode Voltage V

LVDS Input Voltage Range V

Change in common mode Voltage ΔV

2. AC Specification

LVDS Clock

LVDS Data

SKEW

t

Description Symbol Min Max Unit Notes

| 200 600 mV -

ID

CM

IN

CM - 250 mV -

SKEW (Fclk

t

= 1/T

1) 95 MHz > Fclk ≥85 MHz : - 300 ~ +300

2) 85 MHz > Fclk ≥65 MHz : - 400 ~ +400

3) 65 MHz > Fclk ≥30 MHz : - 600 ~ +600

1.0 1.5 V -

0.7 1.8 V -

clk

T

clk

)

t

SKEW

LVDS Clock to Data Skew Margin

LVDS Clock to Clock Skew Margin

(Even to Odd)

t

SKEW

t

SKEW

t

SKEW_EO

Ver. 0.0 Jun. 10. 2013

- 300 + 300 ps 95MHz > Fclk ≥ 85MHz

- 400 + 400 ps 85MHz > Fclk ≥ 65MHz

- 600 + 600 ps 65MHz > Fclk ≥ 30MHz

- 1/7 + 1/7 T

clk

-

10 / 32

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

3. Data Format

1) LVDS 2 Port

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

< Clock skew margin between channel >

< LVDS Data Format >

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

11 / 32

Page 12

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

Table 5. BACKLIGHT CONNECTOR PIN CONFIGURATION(CN2)

The LED interface connector is a model 05010HR-06C(G) manufactured by YEONHO.

The pin configuration for the connector is shown in the table below.

Pin Symbol Description Notes

1 FB1 Channel1 Current Feedback

2 FB2 Channel2 Current Feedback

LB190E02-SL02

Liquid Crystal Display

3 VLED LED Power Supply

4 VLED LED Power Supply

5 FB3 Channel3 Current Feedback

6 FB4 Channel4 Current Feedback

Insert

6

1

[ Figure 5 ] Backlight connector View

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

12 / 32

Page 13

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

3-3. Signal Timing Specifications

This is signal timing required at the input of the TMDS transmitter. All of the interface signal timing should be

satisfied with the following specifications for it’s proper operation.

Table 6. TIMING TABLE

ITEM Symbol Min Typ Max Unit Note

DCLK

Horizontal

Vertical

Period t

Frequency -

total t

Frequency fH

Blanking

valid tWH

total t

Frequency fV

Blanking

valid tWV

CLK

HP

VP

14.7 18.5 22.2

45.0 54.0 68.4

672 844 1022

53.3 64.0 82.1

32 204 382

640 640 640

1034 1066 1320

47 60 76

10 42 296

1024 1024 1024

ns

MHz

tCLK

KHz

tCLK

tCLK

tHP

Hz

tHP

tHP

Note:

1. DE Only mode operation. The input of Hsync & Vsync signal does not

have an effect on LCD normal operation.

2. The performance of the electro-optical characteristics may be influenced by variance of the

vertical refresh rates.

3. Horizontal period should be even.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

13 / 32

Page 14

Global LCD Panel Exchange Center

3-4. Signal Timing Waveforms

1. DCLK , DE, DATA waveforms

tCLK

DCLK

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

Valid data

First data

Second data

Invalid data

Invalid data

DE(Data Enable)

2. Horizontal waveform

DE(Data Enable)

Pixel 0,0

Valid data

Pixel 1,0

Pixel 2,0

Pixel 3,0

tHV

Invalid data

Invalid data

tHP

DE

3. Vertical waveform

t

VP

tVV

tHP

DE(Data Enable)

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

DE

14 / 32

Page 15

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

3-5. Color Input Data Reference

The Brightness of each primary color(red,green,blue) is based on the 8-bit gray scale data input for the color;

the higher the binary input, the brighter the color. The table below provides a reference for color versus data

input.

Table 7. COLOR DATA REFERENCE

Input Color Data

Basic

Color

RED

Color

MSB LSB

R7 R6 R5 R4 R3 R2 R1 R0 G7 G6 G5 G4 G3 G2 G1 G0 B7 B6 B5 B4 B3 B2 B1 B0

Black 000000000000000000000000

Red (255) 111111110000000000000000

Green (255) 000000001111111100000000

Blue (255) 000000000000000011111111

Cyan 000000001111111111111111

Magenta 111111110000000011111111

Yellow 111111111111111100000000

White 11111111111 1111111111111

RED (000) Dark 000000000000000000000000

RED (001) 000000010000000000000000

... ... ... ...

RED (254) 111111100000000000000000

RED (255) 111111110000000000000000

RED

MSB LSB

GREEN

BLUE

MSB LSB

GREEN (000) Dark 000000000000000000000000

GREEN (001) 000000000000000100000000

GREEN

GREEN (254) 000000001111111000000000

GREEN (255) 000000001111111100000000

BLUE (000) Dark 000000000000000000000000

BLUE (001) 000000000000000000000001

BLUE

BLUE (254) 000000000000000011111110

BLUE (255) 000000000000000011111111

Ver. 0.0 Jun. 10. 2013

... ... ... ...

... ... ... ...

15 / 32

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

3-6. Power Sequence

V

LCD

Power Supply, V

Interface Signal, Vi

(Digital RGB signal,

SCDT ,Vsync, Hsync,

DE, Clock to PanelLink

Transmitter)

LCD

0V

0V

www.panelook.com

Liquid Crystal Display

Product Specification

90%

10%

T1

T2 T5 T7

Valid Data

T3

T4

90%

10%

T6

LB190E02-SL02

Power Supply for

Backlight Inverter

Table 8. POWER SEQUENCE

Parameter

T1 0.5 - 10 ms

T2 0.01 - 50 ms

T3 500 - - ms

T4 200 - - ms

T5 0.01 - 50 ms

T7 1000 - ms

LED ONLED OFF

FIG.5 Power sequence

Values

Min Typ Max

LED OFF

Units

Notes : 1. Please avoid floating state of interface signal at invalid period.

2. When the interface signal is invalid, be sure to pull down the power supply for LCD V

LCD

to 0V.

3. LED power must be turn on after power supply for LCD and interface signal are valid.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

16 / 32

Page 17

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

3-7. V

Power Dip Condition

LCD

t

d

FIG.6 Power dip condition

3.5V

V

LCD

4.5V

1) Dip condition

3.5V ≤V

2) V

< 3.5V

LCD

V

-dip conditions should also follow the Power On/Off conditions for supply voltage.

LCD

< 4.5V , td≤20ms

LCD

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

17 / 32

Page 18

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

4. Optical Specifications

Optical characteristics are determined after the unit has been ‘ON’ for approximately 15 minutes

in a dark environment at 25±2°C. The values specified are at an approximate distance 50cm from the LCD

surface at a viewing angle of ∀ and # equal to 0 ° and aperture 1 degree.

FIG. 1 presents additional information concerning the measurement equipment and method.

PR 880 or RD 80S

or PR650

Optical Stage(x,y)

LCD Module

50cm

FIG.7 Optical Characteristic Measurement Equipment and Method

Table 9. OPTICAL CHARACTERISTICS

Parameter Symbol

Contrast Ratio CR 600 900 - 1

Surface Luminance, white L

Luminance Variation

Response Time

Rise Time

Decay Time

RED Rx

GREEN Gx TBD

Color Coordinates

[CIE1931]

(By PR650)

Color Shift

(Avg. Δu’v’ < 0.02))

Viewing Angle (CR>10)

General

GSR @ 60dgree

(Gamma shift rate)

Gray Scale - 2.2 7

BLUE Bx TBD

WHITE Wx TBD

Horizontal

Vertical

Horizontal

Vertical

Horizontal

Vertical

WH

∃

WHITE

Tr

R

Tr

D

Ry TBD

Gy TBD

By TBD

Wy TBD

#

CST_H

#

CST_V

#

H

#

V

∃

Gamma_H

∃

Gamma_V

(Ta=25 °C, V

=5V, fV=60Hz Dclk=54MHz, Is=TBDmA)

LCD

Values

Min Typ Max

260 330 - cd/m

Units Notes

2

- - 1.33 % 3

-712

11 18

ms

TBD

Typ

-0.03

Typ

+0.03

- 178 Degree 4

- 178 -

170 178 -

170 178 -

Degree 5

--20

%6

--20

2

Ver. 0.0 Jun. 10. 2013

18 / 32

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

Notes 1. Contrast Ratio(CR) is defined mathematically as :

RatioContrast ∋

It is measured at center point(Location P1)

2. Surface luminance(L

from the surface with all pixels displaying white. For more information see FIG.8 (By PR880)

3. The variation in surface luminance , ∃ WHITE is defined as :

Where L1 to L9 are the luminance with all pixels displaying white at 9 locations.

For more information see FIG.8

4. Color shift is the angle at which the average color difference for all Macbeth is lower than 0.02.

For more information see FIG.9

- Color difference (Δu’v’)

'

∋

u

WH)is luminance value at Center 1 point(P1) across the LCD surface 50cm

WHITE

3122

∋

(By EZ Contrast)

9

'

∋

v

y

∃

4

x

%%&

yx

(By PR880)

)

P9P2P1

P9P2P1

3122

%%&

yx

pixels whiteall with LuminanceSurface

pixelsblack all with LuminanceSurface

(By PR880)

)L..,L,Maximum(L

)L....,L,(LMinimum

2

21

2

)''()''('' vvuuvu &%&∋(

21

24

)''(

(

∗

1

∋

i

)''(

∋(

vuAvg

ivu

24

- Pattern size : 25% Box size

- Viewing angle direction of color shift : Horizontal, Vertical

5. Viewing angle is the angle at which the contrast ratio is greater than 10. The angles are

determined for the horizontal or x axis and the vertical or y axis with respect to the z axis which

is normal to the LCD surface. For more information see FIG.10

6. GSR is the rate of gamma shift at up, down, left and right 60 degree viewing angle compare with

center gamma. For more information see FIG.11 and FIG.12

- GSR (∃

.

7. Gamma Value is approximately 2.2. For more information see Table 11.

) is defined as :

Gamma

1

/

1 +

&∋GSR

/

0

u’1, v’1 : u’v’ value at viewing angle direction

u’2, v’2 : u’v’ value at front (θ=0)

i : Macbeth chart number (Define 23 page)

(By PR880)

(By EZ Contrast)

Degree)60Light Reft,Down,(Up,ValueGammaangleView

Degree)(0ValueGammaCenter

.

,

100

,

−

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

19 / 32

Page 20

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

Measuring point for surface luminance & measuring point for luminance variation.

H

LB190E02-SL02

Liquid Crystal Display

H/2

●

●

P2

P5

V/2

V

●

V/10

P7

●

P3

●

P1

●

P8

●

●

●

H/10

P4

P6

P9

FIG.8 Measure Point for Luminance

Response time is defined as the following figure and shall be measured by switching the input signal for

“Black” and “White”.

Tr

R

Tr

D

100

90

Optical

Response

10

0

Black

White

White

Black

N = 0(Black)~255(White)

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

20 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

Color shift is defined as the following test pattern and color.

FIG.9 Color Shift Test Pattern

LB190E02-SL02

Liquid Crystal Display

25% Box size

Average RGB values in Bruce RGB for Macbeth Chart

Dark skin (i=1) Light skin Blue sky Foliage Blue flower Bluish green

R 98 206 85 77 129 114

G 56 142 112 102 118 199

B 45 123 161 46 185 178

Orange Purplish blue Moderate red Purple Yellow green Orange yellow

R 219 56 211 76 160 230

G 104 69 67 39 193 162

B 24 174 87 86 58 29

Blue Green Red Yellow Magenta Cyan

R 26 72 197 241 207 35

G 32 148 27 212 62 126

B 145 65 37 36 151 172

White Neutral 8 Neutral 6.5 Neutral 5 Neutral 3.5 Black

R 240 206 155 110 63 22

G 240 206 155 110 63 22

B 240 206 155 110 63 22

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

21 / 32

Page 22

Global LCD Panel Exchange Center

Dimension of viewing angle range.

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

2

= 1803, Left

2

= 2703, Down

Normal

E

#

2

FIG.10 Viewing angle

Y

2

= 903, Up

2

= 03, Right

FIG.11 Sample Luminance vs. gray scale

(using a 256 bit gray scale)

r

LaVL %∋

b

FIG.12 Sample Log-log plot of luminance

vs. gray scale

b

%∋&

)log()log()log( aVrLL

Here the Parameter α and γ relate the signal level V to the luminance L.

The GAMMA we calculate from the log-log representation (FIG.11)

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

22 / 32

Page 23

Global LCD Panel Exchange Center

Table 11. Gray Scale Specification

Gray Level Relative Luminance [%] (Typ.)

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

0

31 (1.08)

63 (4.72)

95 (11.49)

127 (21.66)

159 (35.45)

191 (53.00)

223 (74.48)

255 (100)

(0.11)

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

23 / 32

Page 24

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

5. Mechanical Characteristics

The contents provide general mechanical characteristics. In addition the figures in the next page are detailed

mechanical drawing of the LCD.

Horizontal 396.0mm

Outline Dimension

Bezel Area

Active Display Area

Weight(approximate) TBD

Surface Treatment

Vertical 324.0mm

Depth 13.2mm

Horizontal 379.8mm

Vertical 304.5mm

Horizontal 376.32mm

Vertical 301.06mm

Hard coating(3H)

Anti-Glare treatment of the front polarizer

Notes : Please refer to a mechanic drawing in terms of tolerance at the next page.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

24 / 32

Page 25

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

<FRONT VIEW>

Note) Unit:[mm], General tolerance:

! 0.5mm

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

25 / 32

Page 26

Global LCD Panel Exchange Center

<REAR VIEW>

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

LGD Highly recommendation :

As The IPS panel is sensitive & slim, please recommend the metal frame of the system supports the panel

by the double side-mount.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

26 / 32

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

6. Reliability

Environment test condition

No Test Item Condition

LB190E02-SL02

Liquid Crystal Display

1 High temperature storage test

2 Low temperature storage test

3 High temperature operation test

4 Low temperature operation test

5

6

7 Humidity condition Operation

8

Vibration test

(non-operating)

Shock test

(non-operating)

Altitude

operating

storage / shipment

Ta= 80°C 240h

Ta= -20°C 240h

Ta= 70°C 240h

Ta= -10°C 240h

Wave form : random

Vibration level : 1.00G RMS

Bandwidth : 10-300Hz

Duration : X, Y, Z, 10 min

One time each direction

Shock level : 100G

Waveform : half sine wave, 2ms

Direction : ±X, ±Y, ±Z

One time each direction

50 °C ,80%RH

Ta=

0 - 16,000 feet(4,876m)

0 - 40,000 feet(12,192m)

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

27 / 32

Page 28

Global LCD Panel Exchange Center

www.panelook.com

Product Specification

7. International Standards

7-1. Safety

a) UL 60950-1, Underwriters Laboratories Inc.

Information Technology Equipment - Safety - Part 1 : General Requirements.

b) CAN/CSA C22.2 No.60950-1-07, Canadian Standards Association.

Information Technology Equipment - Safety - Part 1 : General Requirements.

c) EN 60950-1, European Committee for Electrotechnical Standardization (CENELEC).

Information Technology Equipment - Safety - Part 1 : General Requirements.

d) IEC 60950-1, The International Electrotechnical Commission (IEC).

Information Technology Equipment - Safety - Part 1 : General Requirements.

LB190E02-SL02

Liquid Crystal Display

7-2. EMC

a) ANSI C63.4 “American National Standard for Methods of Measurement of Radio-Noise

Emissions from Low-Voltage Electrical and Electronic Equipment in the Range of 9 kHz to 40 GHz.”

American National Standards Institute (ANSI), 2003.

b) CISPR 22 “Information technology equipment – Radio disturbance characteristics – Limit and

methods of measurement." International Special Committee on Radio Interference

(CISPR), 2005.

c) CISPR 13 “Sound and television broadcast receivers and associated equipment – Radio disturbance

characteristics – Limits and method of measurement." International Special Committee on Radio

Interference (CISPR), 2006.

7-3. Environment

a) RoHS. Directive 2002/95/EC of the European Parliament and of the Council on the reduction of the

use of certain hazardous substances in electrical and electronic equipment. January 2003

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

28 / 32

Page 29

Global LCD Panel Exchange Center

8. Packing

8-1. Designation of Lot Mark

a) Lot Mark

ABCDEFGHI JKLM

A,B,C : SIZE(INCH) D : YEAR

E : MONTH F ~ M : SERIAL NO.

Note

1. YEAR

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

Year

Mark

2. MONTH

Month

Mark

b) Location of Lot Mark

Serial No. is printed on the label. The label is attached to the backside of the LCD module.

This is subject to change without prior notice.

8-2. Packing Form

a) Package quantity in one box : 12 pcs

b) Box Size : 408 X 355 X 474mm

2016G2017H2018J2019

F

Jun

6

Jul

7

Aug9Sep

8

CBA

2014E2015

D

Apr5May

4

201320122011

2020

K

Oct

A

Nov

B

DecMarFebJan

C321

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

29 / 32

Page 30

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

9. PRECAUTIONS

Please pay attention to the followings when you use this TFT LCD module.

9-1. MOUNTING PRECAUTIONS

(1) You must mount a module using holes arranged in four corners or four sides.

(2) You should consider the mounting structure so that uneven force (ex. Twisted stress) is not applied to the

module. And the case on which a module is mounted should have sufficient strength so that external

force is not transmitted directly to the module.

(3) Please attach the surface transparent protective plate to the surface in order to protect the polarizer.

Transparent protective plate should have sufficient strength in order to the resist external force.

(4) You should adopt radiation structure to satisfy the temperature specification.

(5) Acetic acid type and chlorine type materials for the cover case are not desirable because the former

generates corrosive gas of attacking the polarizer at high temperature and the latter causes circuit break

by electro-chemical reaction.

(6) Do not touch, push or rub the exposed polarizers with glass, tweezers or anything harder than HB

pencil lead. And please do not rub with dust clothes with chemical treatment.

Do not touch the surface of polarizer for bare hand or greasy cloth.(Some cosmetics are detrimental

to the polarizer.)

(7) When the surface becomes dusty, please wipe gently with absorbent cotton or other soft materials like

chamois soaks with petroleum benzene. Normal-hexane is recommended for cleaning the adhesives

used to attach front / rear polarizers. Do not use acetone, toluene and alcohol because they cause

chemical damage to the polarizer.

(8) Wipe off saliva or water drops as soon as possible. Their long time contact with polarizer causes

deformations and color fading.

(9) Do not open the case because inside circuits do not have sufficient strength.

(10) As The IPS panel is sensitive & slim, please recommend the metal frame of the system supports the panel

by the double side-mount.

9-2. OPERATING PRECAUTIONS

(1) The spike noise causes the mis-operation of circuits. It should be lower than following voltage :

V=±200mV(Over and under shoot voltage)

(2) Response time depends on the temperature.(In lower temperature, it becomes longer.)

(3) Brightness depends on the temperature. (In lower temperature, it becomes lower.)

And in lower temperature, response time(required time that brightness is stable after turned on) becomes

longer.

(4) Be careful for condensation at sudden temperature change. Condensation makes damage to polarizer or

electrical contacted parts. And after fading condensation, smear or spot will occur.

(5) When fixed patterns are displayed for a long time, remnant image is likely to occur.

(6) Module has high frequency circuits. Sufficient suppression to the electromagnetic interference shall be

done by system manufacturers. Grounding and shielding methods may be important to minimized the

interference.

(7) Please do not give any mechanical and/or acoustical impact to LCM. Otherwise, LCM can’t be operated

its full characteristics perfectly.

(8) A screw which is fastened up the steels should be a machine screw.

(if not, it causes metallic foreign material and deal LCM a fatal blow)

(9) Please do not set LCD on its edge.

(10) When LCMs are used for public display defects such as Yogure, image sticking can not be guarantee.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

30 / 32

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

LB190E02-SL02

Liquid Crystal Display

Product Specification

9-3. ELECTROSTATIC DISCHARGE CONTROL

Since a module is composed of electronic circuits, it is not strong to electrostatic discharge. Make certain that

treatment persons are connected to ground through wrist band etc. And don’t touch interface pin directly.

9-4. PRECAUTIONS FOR STRONG LIGHT EXPOSURE

Strong light exposure causes degradation of polarizer and color filter.

9-5. STORAGE

When storing modules as spares for a long time, the following precautions are necessary.

(1) Store them in a dark place. Do not expose the module to sunlight or fluorescent light. Keep the temperature

between 5°C and 35°C at normal humidity.

(2) The polarizer surface should not come in contact with any other object.

It is recommended that they be stored in the container in which they were shipped.

9-6. HANDLING PRECAUTIONS FOR PROTECTION FILM

(1) The protection film is attached to the bezel with a small masking tape.

When the protection film is peeled off, static electricity is generated between the film and polarizer.

This should be peeled off slowly and carefully by people who are electrically grounded and with well ionblown equipment or in such a condition, etc.

(2) When the module with protection film attached is stored for a long time, sometimes there remains a very

small amount of glue still on the bezel after the protection film is peeled off.

(3) You can remove the glue easily. When the glue remains on the bezel surface or its vestige is recognized,

please wipe them off with absorbent cotton waste or other soft material like chamois soaked with normalhexane.

Ver. 0.0 Jun. 10. 2013

Note : This document is preliminary version. The latest version must be checked from LG Display before detail design.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

31 / 32

Loading...

Loading...