Page 1

SERVICE MANUAL

Product Type: LCD TV

Chassis: ZLD

Manual Series: CM153

Manual Part #: 923-03443R1

Model Line: D

Product Year: 2001

Model Series:

ZLD15A1

ZLD20A1

Printed in U.S.A.

ZLD20 CCI 2.5k

CONTENTS

General Info/Remotes .................................... 1

Installer’s Menu.............................................2

Servicing/Troublshooting...............................3

Module/Model Part Lists................................. 4

Exploded Views ............................................. 5

Schematics/PCB Layouts................................. 6

Published by Technical Publications

Zenith Electronics Corporation

P.O. Box 240007

Huntsville, Alabama 35824

Copyright ? April 2001 by Zenith Electronics Corporation

Page 2

A

0

d

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audiovisual service technicians. When servicing this product, under no

circumstances should the original design be modified or altered

without permission from Zenith Electronics Corporation. All

components should be replaced only with types identical to those

in the original circuit and their physical location, wiring, and lead

dress must conform to original layout upon completion of repairs. If

any fuse (or Fusible Resistor) in this TV receiver is blown, replace it

only with the factory specified fuse type and rating. When replacing

a high wattage resistor (Oxide Metal Film Resistor, over 1W), keep the

resistor 10mm away from PCB. Always keep wires away from high

voltage or high temperature parts.

Special components are also used to prevent x-radiation, shock, and

fire hazard. These components are indicated by the letter “x” included

in their component designators and are required to maintain safe

performance. No deviations are allowed without prior approval by

Zenith Electronics Corporation. Service work should be performed

only after you are thoroughly familiar with these safety checks and

servicing guidelines.

Circuit diagrams may occasionally differ from the actual circuit used.

This way, implementation of the latest safety and performance

improvement changes into the set is not delayed until the new

service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never

perform customized installations without manufacturer’s approval.

Unauthorized modifications will not only void the warranty, but

may lead to property damage or user injury.

GENERAL GUIDANCE

An lsolation Transformer should always be used during the servicing

of a receiver whose chassis is not isolated from the AC power line. Use

a transformer of adequate power rating to protect against personal

injury from electrical shocks. It will also protect the receiver and it’s

components from being damaged by accidental shorts of the circuitry

that may be inadvertently introduced during the service operation.

Before returning the receiver to the customer, always perform an AC

leakage current check on the exposed metallic parts of the cabinet,

such as antennas, terminals, etc., to be sure the set is safe to operate

without damage of electrical shock.

LEAKAGE CURRENT COLD CHECK (ANTENNA COLD CHECK)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC switch

in the on position, connect one lead of ohm-meter to the AC plug

prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone jacks,

etc. If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1M½ and 5.2M½. When the

exposed metal has no return path to the chassis the reading must be

infinite. Any other abnormality that exists must be corrected before

the receiver is returned to the customer.

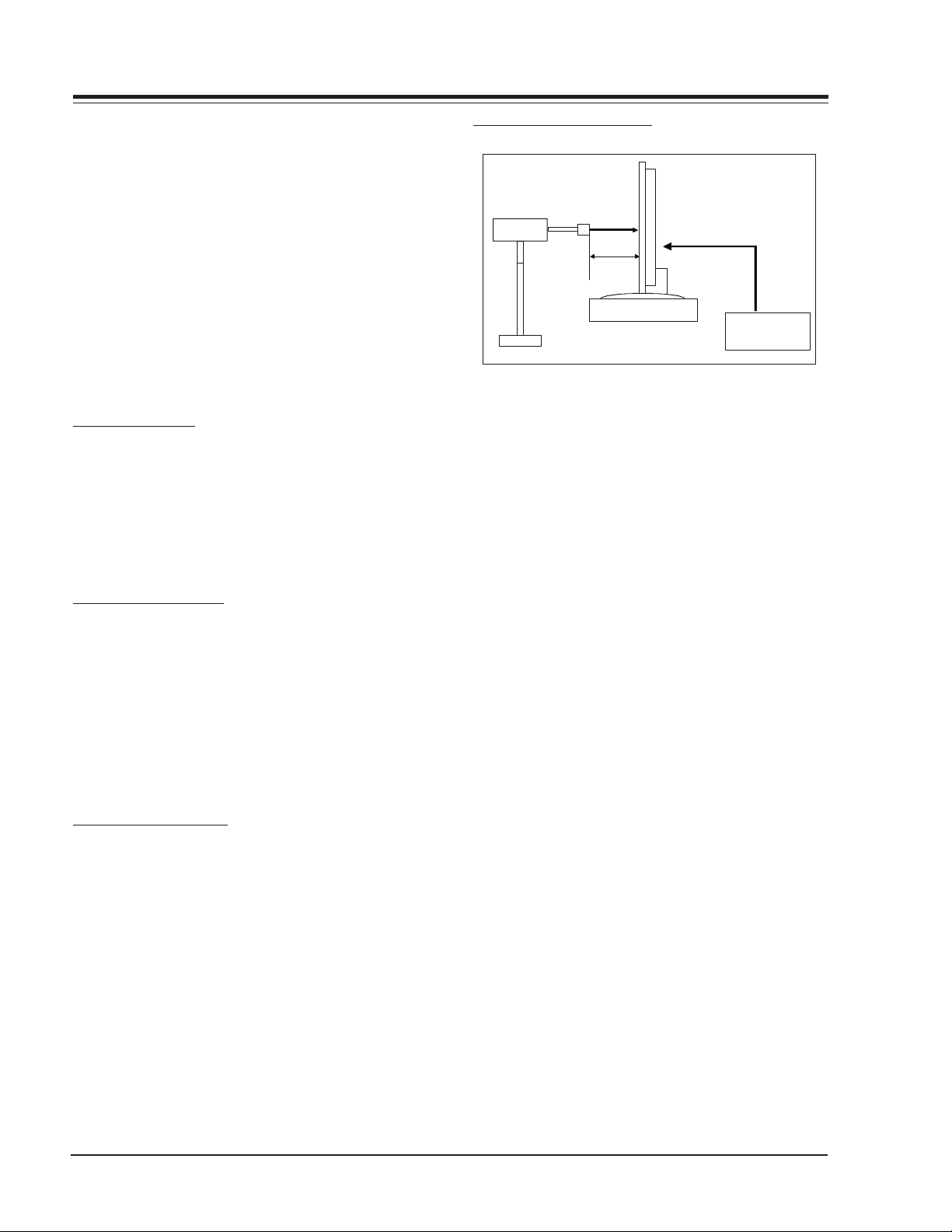

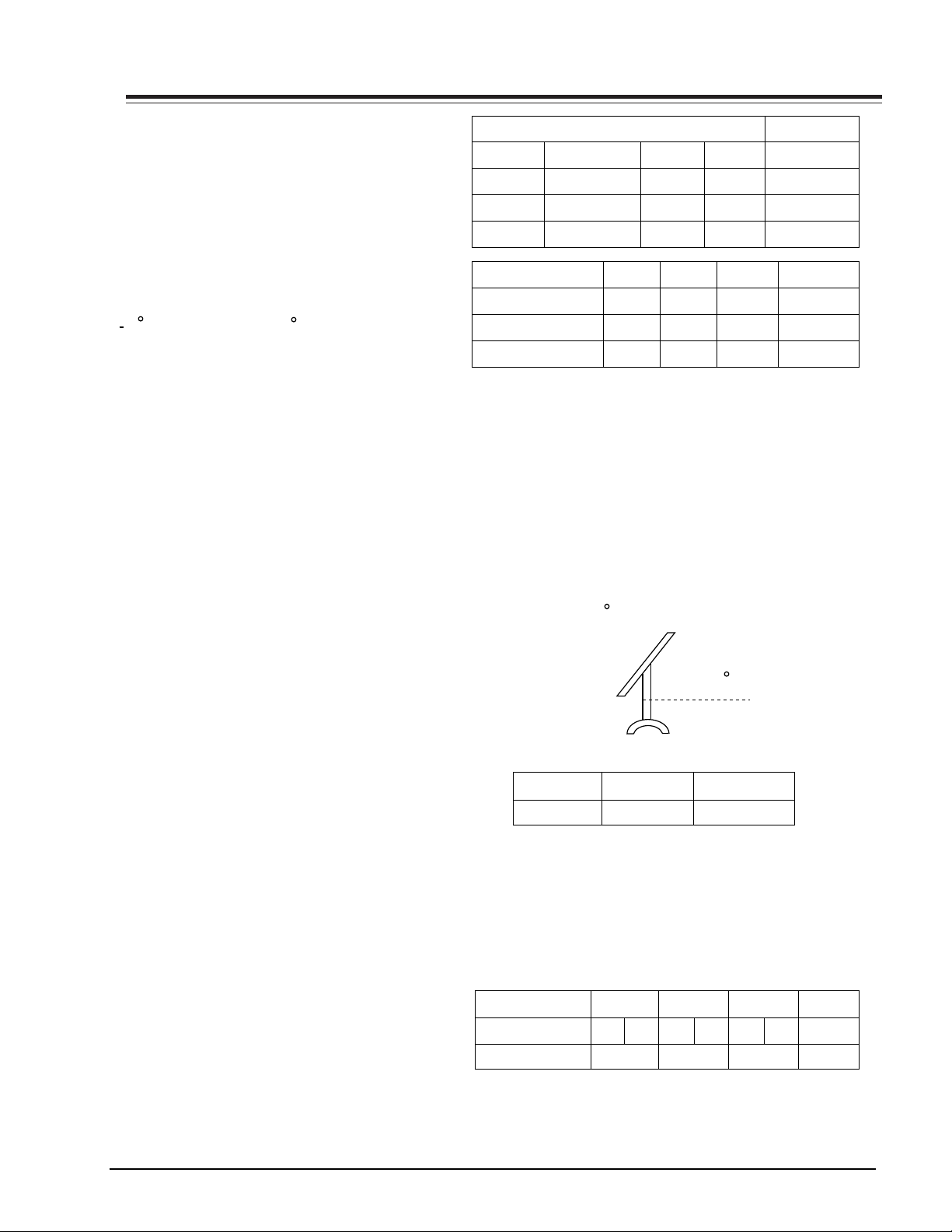

LEAKAGE CURRENT HOT CHECK (SEE BELOW FIGURE)

Plug the AC cord directly into the AC outlet. Do not use a line

Isolation Transformer during this check. Connect 1.5K/10watt resistor

in parallel with a 0.15uF capacitor between a good earth ground

(Water Pipe, Conduit, etc.) and the exposed metallic parts. Measure

the AC voltage across the resistor using AC voltmeter with 1000

ohms/volt or more sensitivity. Reverse plug the AC cord into the AC

outlet and repeat AC voltage measurements for each exposed metallic

part. Any voltage measured must not exceed 0.75 volt RMS at 0.5mA.

In case any measurement is out of the limits specified, there is the

possibility of shock hazard and the set must be checked and repaired

before it is returned to the customer.

LEAKAGE CURRENT HOT CHECK CIRCUIT

.C. Voltmeter

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.15uF

1500 OHM

WATT

1

Place this probe

on each expose

metal part.

REGULATORY INFORMATION

This equipment, trade name Zenith, model number, IQD27D53T, has

been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when

the equipment is operated in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures: Reorient

or relocate the receiving antenna; Increase the separation between

the equipment and receiver; Connect the equipment into an outlet

on a circuit different from that to which the receiver is connected;

Consult the dealer or an experienced radio/TV technician for help.

The responsible party for this device compliance is:

Zenith Electronics Corporation

201 James Record Road

Huntsville, AL 35824, USA

Digital TV Hotline:

1-800-243-0000

Dolby Digital® Manufactured under license from Dolby Laboratories.

“Dolby” and the double-D symbol are trademarks of Dolby

Laboratories. Confidential Unpublished Works.

©1992-1997 Dolby Laboratories, Inc. All rights reserved.

The presence of the DTV certification mark indicates that this product

will successfully receive digital television transmissions that conform

to any and all of the video formats described in the ATSC Digital

Television Standard.

VCR Plus+, PlusCode and GUIDE Plus+ are trademarks of Gemstar

Development Corporation. The VCR Plus+ and GUIDE Plus+ systems

are manufactured under license from Gemstar Development

Corporation and VCR Index Systems B.V., respectively.

Gemstar is not in any way liable for the accuracy of the program

schedule information provided by the GUIDE Plus+ system. In no

event shall Gemstar be liable for any amounts representing loss of

profits, loss of business, or indirect, special, or consequential damages

in connection with the provision or use of any information,

equipment, or services relating to the GUIDE plus+ system.

923-03443R1 2 ZLDA1

Page 3

T ABLE OF CONTENTS

T ABLE OF CONTENTS ..............................................2

SERVICING PRECAUTIONS....................................... 3

ADJUSTMENTS ..................................................... 5

TROUBLE SHOOTING.............................................. 7

PARTS LIST .......................................................... 8

EXPLODED VIEW ...................................................14

BLOCK DIAGRAM ..................................................15

PCB MAIN (TOP VIEW) ..........................................16

PCB MAIN (BOTTOM VIEW)..................................... 17

PCB LAYOUT CONTROL & TUNER.............................. 18

SCHEMATIC ......................................................... 19

CM152 3 ZLDA1

Page 4

SERVICING

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow

the SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow

the safety precautions. Remember: Safety First.

GENERAL SERVICING PRECAUTIONS

1. Always unplug the receiver AC power cord from the

AC power source before performing the following.

a. Removing or reinstalling any component,

circuit board module or any other receiver

assembly.

b. Disconnecting or reconnecting any receiver

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with

an electrolytic capacitor in the receiver.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other voltage-measuring device (DVM, FETVOM, etc) equipped with a

suitable high voltage probe. Do not test high voltage by “drawing an arc”.

3. Discharge the picture tube anode only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield

at the point where the picture tube socket ground

lead is connected, and then (b) touch the other end

of the insulated clip lead to the picture tube anode

button, using an insulating handle to avoid personal

contact with high voltage.

4. Do not spray chemicals on or near this receiver or

any of its assemblies.

5. Unless specified otherwise in this service manual,

clean electrical contacts only by applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or comparable nonabrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture. Unless specified

otherwise in this service manual, lubrication of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks

with which receivers covered by this service manual

might be equipped.

7. Do not apply AC power to this instrument and/or any

of its electrical assemblies unless all solid-state device heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test

receiver positive lead. Always remove the test receiver

ground lead last.

9. Use with this receiver only the test fixtures specified

in this service manual.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this receiver.

ELECTROSTATIC SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatic Sensitive Devices.

Examples of typical ES devices are integrated circuits

and some field effect transistors and semiconductor “chip”

components. The following techniques should be used

to help reduce the incidence of component damage

caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and

wear a commercially available discharging wrist strap

device, which should be removed to prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static type solder removal device.

Some solder removal devices not classified as “antistatic” can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready

to install it. (Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric

or the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an

ES device.)

CM153 - 923-03443R1 4 ZLD20A1 - SERVICING

Page 5

SERVICING

GENERAL SOLDERING GUIDELINES

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range or 500cF to 600cF.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

mall wire bristle (0.5 inch, or 1.25cm) brush with a

metal handle. Do not use freon-propelled spray-on

cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal

temperature. (500cF to 600cF)

b. Heat the component lead until the solder

melts.

c. Quickly draw the melted solder with an anti-

static, suction-type solder removal device or

with solder braid. CAUTION: Work quickly to

avoid overheating the circuit board printed

foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500cF to 600cF)

b. First, hold the soldering iron tip and solder

the strand against the component lead until

the solder melts.

c. Quickly move the soldering iron tip to the

junction of the component lead and the

printed circuit foil, and hold it there only

until the solder flows onto and around both

the component lead and the foil.

CAUTION: Work quickly to avoid overheating

the circuit board printed foil.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wirebristle brush.

IC REMOVE/REPLACEMENT

Some chassis circuit boards have slotted holes (oblong)

through which the IC leads are inserted and then bent

flat against the circuit foil. When holes are the slotted

type, the following technique should be used to remove

and replace the IC. When working with boards using the

familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

REMOVAL

1. Desolder and straighten each IC lead in one operation by gently prying up on the lead with the soldering iron tip as the solder melts.

2. Draw away the melted solder with an anti-static suction-type solder removal device (or with solder braid)

before removing the IC.

REPLACEMENT

1. Carefully insert the replacement IC in the circuit

board.

2. Carefully bend each IC lead against the circuit foil

pad and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the

areas).

“SMALL-SIGNAL” DISCRETE TRANSISTOR

REMOVAL/REPLACEMENT

1. Remove the defective transistor by clipping its leads

as close as possible to the component body.

2. Bend into a “U” shape the end of each of three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor

leads.

4. Connect the replacement transistor leads to the corresponding leads extending from the circuit board

and crimp the “U” with long nose pliers to insure

metal to metal contact then solder each connection.

POWER OUTPUT, TRANSISTOR DEVICE

REMOVAL/REPLACEMENT

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of

the circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

DIODE REMOVAL/REPLACEMENT

1. Remove defective diode by clipping its leads as close

as possible to diode body.

2. Bend the two remaining leads perpendicular to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit

board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder

joints of the two “original” leads. If they are not

shiny, reheat them and if necessary, apply additional

solder.

FUSE AND CONVENTIONAL RESISTOR

REMOVAL/REPLACEMENT

1. Clip each fuse or resistor lead at top of the circuit

board hollow stake.

2. Securely crimp the leads of replacement component

around notch at stake top.

CM153 - 923-923-03443R1 5 ZLD20A1 - SERVICING

Page 6

SERVICING

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components

and the circuit board to prevent excessive

component temperatures.

CIRCUIT BOARD FOIL REPAIR

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the

foil to the circuit board causing the foil to separate

from or “lift-off” the board. The following guidelines

and procedures should be followed whenever this

condition is encountered.

AT IC CONNECTIONS

To repair a defective copper pattern at IC connections

use the following procedure to install a jumper wire on

the copper pattern side of the circuit board. (Use this

technique only on IC connections).

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper pattern.

3. Bend a small “U” in one end of a small gauge jumper

wire and carefully crimp it around the IC pin. Solder

the IC connection.

4. Route the jumper wire along the path of the out-

away copper pattern and let it overlap the previously

scraped end of the good copper pattern. Solder the

overlapped area and clip off any excess jumper wire.

AT OTHER CONNECTIONS

Use the following technique to repair the defective cop-

per pattern at connections other than IC Pins. This

technique involves the installation of a jumper wire

on the component side of the circuit board.

1. Remove the defective copper pattern with a sharp

knife. Remove at least ¼ inch of copper, to ensure

that a hazardous condition will not exist if the jumper

wire opens.

2. Trace along the copper pattern from both sides of

the pattern break and locate the nearest component

that is directly connected to the affected copper

pattern.

3. Connect insulated 20-gauge jumper wire from the lead

of the nearest component on one side of the pattern

break to the lead of the nearest component on the

other side. Carefully crimp and solder the connections. CAUTION: Be sure the insulated jumper wire is

dressed so the it does not touch components or sharp

edges.

CM153 - 923-03443R1 6 ZLD20A1 - SERVICING

Page 7

SECTION 1

OVERVIEW

SERVICING

ADJUSTMENTS

This set uses an adapter, so connect the adapter and the

set correctly before adjustment. The adjustment must

be performed under the correct sequence.

The adjustment must be performed in the circumstance

of 25+/-5cC of temperature 65+/-10% of relative

humidity if there is no specific designation. The input

voltage of the receiver must keep 220V, 60Hz in adjusting.

The set must be operated for 30 minutes preliminarily

before adjustment if there is no specific designation.

Note: Heat Run must be performed with the full white signal

or TV noise signal in the internal part of the set. The

time for Heat Run can be changed owing to production

plan.

DVCO ADJUSTMENT

Turn the TV on.

(2) Receive the Digital Pattern.

3-2. Adjustment

(1) Select DVCO ADJ by pressing ADJ Key(or SVC Key) of

Remote Control for Adjustment.

(2) Press the VOL + Key repeatly to appear ÒOKÓ.

USING METHOD FOR CA-110

CA110

Screen

30[cm]

LCD TV

Input signal of Video

NTSC 13 CH

AUTO RGB ADJUSTMENT

4-1. Preparation for Adjustment

(1) Adjust it after performing DVCO Adjustment.

(2) Receive the Digital Pattern.

4-2. Adjustment

(1) Select AUTO RGB ADJ by pressing ADJ Key(or SVC

Key)

of Remote Control for Adjustment.

(2) Press the VOL + Key repeatly to appear ÒOKÓ.

RGB LEVEL ADJUSTMENT

5-1. Using Equipment

(1) Pattern Generator(408NPS-READER) which 10 STEP

is possible.

(2) A Remote Control for Adjustment 5-2. Adjustment

(1) Select RGB LEVEL by pressing ADJ Key(or SVC Key) of

Remote Control for Adjustment.

(2) Select it by using VOL + Key.

(3) Adjust that until 9th and 10th STEP is

undistinguished by using VOL +/- Key in R-DRIVE item.

(4) Adjust G-DRIVE and B-DRIVE as same way.

(5) When adjustment is finished, escape it by pressing

ENTER Key.

CM153 - 923-03443R1 7 ZLD20A1 - SERVICING

Page 8

ADJUSTMENT INSTRUCTIONS ZLD15A1

1. Application Object

This instruction is for the application to the LCD TV.

2. Notes

(1) This set uses an adapter, so connect the adapter and the

set correctly before adjusting.

(2) The adjustment must be performed in the correct

sequence.

(3) The adjustments must be performed in the circumstance of

25+ 5 C of temperature and 65 10% of relative humidity

unless otherwise specified.

(4) The input voltage of the receiver must be 220V, 60Hz

during adjustment.

(5) The set must be operated for 30 minutes preliminarily

before adjustment unless otherwise specified.

* "Heat Run" must be performed with the full white signal or TV

noise signal in the internal part of the set.

3. TV Mode Adjustment

Before entering into the adjustment mode set the TV up with

the MENU button as below.

Contrast 85

Brightness 100

Saturation 50

Tint 0

Low Light(Black)

IC

VPC3230D

VPC3230D

VPC3230D

Brightness:[cd/m^2]

IIC Type

IIC 0x52/7:0/

IIC 0x30/11:0/

Fp 0xDC

x

y

Red

0.63

0.34

Name

BR

ACC_Sat

Tint

Green

0.30

0.60

Default

2930

0

0

Blue

0.14

0.10

Unit-Decimal

Adj. Mode

No.304

No.236~237

No.248

White

0.32

0.34

150[cd/m^2]

4. PC Input Mode Adjustment

4-1. Required Test Equipment

(1) A pattern generator being in proportion to VG819 ; Pattern

of 64 tones

(2) A remote control

4-2. Preparation for Adjustment

(1) Perform "Heat Run" for more than 30 minutes in white

pattern.

(2) Connect the signal of pattern generator to LCD TV.

(3) Lean the set 45 backward. (Adjustment is easy.)

45

3-1. White Balance Adjustment

3-1-1. Required Test Equipment

(1) A Remote Control

(2) A Color Analyzer for LCD : CA-110

(3) A TV Signal Generator : Pattern of 64 (128) tones or Ch. 13

in the company.

3-1-2. Preparation for Adjustment

(1) This adjustment should be performed 30 minutes later

after "Heat Run".

(2) This adjustment should be performed in a darkroom or in

the simmilar condition.

3-1-3. Low Light Adjustment

(1) Seletc Ch.13 .

(2) Enter into the adjustment mode with the ADJ button.

(3) Select the Sub-bright and stop adjusting at the moment

when Gray 0 and 1 are not distinguished.

CM153 8 ZLD15A1

(4) Set the PC mode menu as below.

Initial Value

Contrast

70

Brightness

100

4-3. White Adjustment

(1) Approve the signal of 64 tones of XGA(1024 * 768).

(2) Select all the gain of R, B and G with using ADJ of remote

control.

(3) After making 62 tones, 63 tones and 64 tones not

distinguished with using each signal of R, G and B, finish

adjusting at the moment when the signal 62, 63 and 64 is

distinguished.

R

Color Coordinates(x,y)

AD9884

0.63 0.34

0x02

G

0.30 0.60

0x03

B

0.14 0.10

0x04

+/-0.03

Register

Error

Page 9

4-4.Position of Mode Adjustment

Timing of Mode Table

Mode

H_Total

H_Display

H_Blanking

H_Sync

HPolarity

H_Bp

H_Fp

H-Freq[KHz]

/Clk[MHz]

V_Total

V_Display

V_Blanking

V_Sync

VPolarity

V_Bp

V_Fp

Mode

H_Total

H_Display

H_Blanking

H_Sync

HPolarity

H_Bp

H_Fp

H-Freq[KHz]

/Clk[MHz]

V_Total

V_Display

V_Blanking

V_Sync

VPolarity

V_Bp

V_Fp

VGA-60

800

640

160

96

NEG.

48

16

31.469

25.175

525

480

45

2

NEG

33

10

SVGA-75

1056

800

256

80

POS

160

16

46.875

49.5

625

600

25

3

POS

21

1

VGA-67

864

640

224

64

NEG.

96

64

35.0

30.24

525

480

45

3

NEG

39

3

SVGA-85

1048

800

248

64

POS

152

32

53.674

56.25

631

600

31

3

POS

27

1

VGA-72

832

656

176

40

NEG.

120

16

37.861

31.5

520

496

24

3

NEG

20

1

XGA-60

1344

1024

320

136

NEG

136

160

48.363

65.0

806

768

38

6

NEG

29

3

VGA-75

840

640

200

64

NEG.

120

16

37.5

31.5

500

480

20

3

NEG

16

1

XGA-70

1328

1024

304

136

NEG

144

24

56.476

75.0

806

768

38

6

NEG

29

3

VGA-85

832

640

192

56

NEG.

80

56

43.269

36.0

509

480

29

3

NEG

25

1

XGA-75

1312

1024

288

96

POS

176

16

60.23

78.75

800

768

32

3

POS

28

1

TEXT-70

900

720

180

108

NEG.

54

18

31.469

28.324

449

400

49

2

POS

34

13

MAC-75

1152

832

320

64

NEG

224

32

49.725

57.283

667

624

43

3

NWG

39

1

SVGA-56

1024

800

224

72

POS

128

24

35.156

36.0

625

600

25

2

POS

22

1

SVGA-60

1056

800

256

128

POS

88

40

37.879

40.0

628

600

28

4

POS

23

1

SVGA-72

1040

800

240

120

POS

64

56

48.077

50.0

666

600

66

6

POS

23

37

To gain access to the Service menu hold (Menu) key until the menu diappears

from the screen then press 9,8,7,6, (Enter).

Service Menu for ZLD15A1

DVCOAdjustAuto

AutoRGBAuto

ClampLevel44

RGBLevelAuto

VolumeCurve12345

Service Menu for ZLD20A1

0S-BRTTV107

1R-Gain33

2G-Gain34

3B-Gain29

4AL30016H14

5AL30019H84

6AL3001AH32

7AL30039H47

8AL3003CH115

9S-ConTV5

CM153 9 ZLD15A1

Page 10

TROUBLE SHOOTING

1. General Features

No.Problem Possible Cause Solution

1 Soft touch doesn't Defective speaker wire 1) Make some space between the speaker wire and

function properly and inverter wire the Soft touch Board by sticking the speaker wire

to the guide hole of the cabinet.

2) Arrange working state of A1. Tape in the inverter wire

and correct working state of the Shield case.

2 Soft touch doesn't 1) Broken components and 1) Check Soft touch with eyes

function soldering of them Check and repair soldering

2) P101 connector error 2) Check and repair the P101 connector

3 No screen Input error of inverter connector 1) Bend the pin legs of P802 connector -> recheck them

2) Check and repair the IC806 SI4925

P501 and Pin 41 connector 1) Check and fix P501 connector

slipped out 2) Check and fix the components at P501 LCD module

and at main board.

3) Check Pin41 and check and repair rubber packing

Cracked components and 1) Check and repair tuner board and main board

soldering at tuner board 2) Solder Q301, Q801 and R810

4 Dark screen 1) Defective LCD lamp 1) Replace the inverter

2) Defective inverter 2) Replace the LCD lamp

5 Broken OSD display Defective font rom of IC502 Replace IC502

2. PC Mode

No. Problem Possible Cause Solution

6 Screen noise Clock or phase being 1) Resettig is needed according to the video card of each

not able to be adjusted PC

2) Horizontal noise : adjust phase until no horizontal

noise occurres

3) Vertical noise : adjust clock in menu until no vertical

noise occurres

7 Screen position error Screen position error Adjust horizontal and vertical position until the screen

horizontally or vertically displayes normally

8 Color beat noise Soldering AD converter Recheck and repair

or making it short

3. TV and external input

No. Problem Possible Cause Solution

9 No sound Defective Reset IC of IC603 1) Check volume and speaker

- Speaker Defective MSP3400D of IC601 - Sound comes out only when being input into Audio

- Earphone L/R

2) Check after replacing IC603

3) Replace IC601

10 Video color beat noise Earphone shield case being touched

Soldering IC901 and IC501 Re-soldering

Check the mould of shield and JA401, Replace shield case

CM153 10 ZLD15A1

Page 11

PARTS LIST

COMPONENT PARTS

ZLD15A1

NOTE: This list will enable you to easily determine the parts used on each Model, Chassis, or Assembly.

REF PART# DESCRIPTION REF PART# DESCRIPTION

112 900-10048 LCD(LIQUID CRYSTAL D 151X2-C2TH 151" LGP

120 849-10036 SPEAKER, GENERAL T401SX-095K14 LG C&D

121 812-10136 METAL HOLDER SPK SBHG

174 811-10039 POWER CORD PS204-001 VOLEX UL/C

300 857-10335 CABINET ASSY ZLD15A10 ZENITH

310 959-10102 BUTTON CONTROL 8KEY ABS

400 814-10159 BACK COVER ASSY ZLD15A1

420 812-10137 METAL STAND SECC

430 812-10138 HOLDER STAND ABS AF-303S(04

450 812-10139 COVER STAND ASSY ZLD15A1

500 809-10540 PWB(PCB) ASSY MAIN NF99LA US

521 926-10055 METAL MAIN FRAME SBHG

540 895-10117 INVERTER ASSY 12VOLT 500VOLT KS

541 926-10054 SHIELD CASE INVERTER ET-C

550 809-10541 PWB(PCB) ASSY, SUB CTL NF99LA ZLD15A1

A1 206-03652 MANUAL, OWNERS NF99LA ZLD15A1

A2 924-10091 REMOTE CONTROLLER NF99LA ZLD15A1

A3 895-10118 ADAPTER, AC-DC AC110VOLT DC12VOLT

A4 812-10090 ADAPTER ANT RF

Critical safety components are identified by

shading. Replace only with part numbers

specified.

CM153 11 ZLD15A1 - PARTS

Page 12

521

521

943

943

400

400

ZLD15A1 EXPLODED VIEW

410

410

541

541

540

540

420

420

430

430

500

500

121

121

120

120

300

300

112

112

550

550

310

310

CM153 12

ZLD15A1

Page 13

MODEL PARTS

ZLD20A1 PARTS

ZLD20A1

Location Part Number Description

1 804-10107 CASE,SPEAKER

2 849-10045 SPEAKER, GENERAL

2 809-10661 LEFT SPKR BRD

3 814-10196 SPEAKER REAR PANEL (L)

4 849-10048 SPEAKER W/CASE ASSY

5 895-10137 AC DC ADAPTER

6 811-10044 POWER CORD

7 836-10003 HANDLE ASSY ZLD20A1

8 857-10362 PANEL ASSY, FRONT

9 836-10002 HANDLE ASSY ZLD20A1

10 959-10110 BUTTON, CONTROL

11 809-10659 CONTROL BRD ASSY

12 900-10059 LCD 20 INCH

13 895-10136 INVERTER ASSY 15V

14 809-10658 SUB MODULE ASSY ZLD20A1

15 809-10657 MAIN MODULE ZLD20A1

16 804-10106 CASE,SPEAKER

17 849-10046 SPEAKER, TWEETER

19 809-10660 RIGHT SPKR BRD

20 814-10195 SPEAKER REAR PANEL (R)

21 849-10047 SPEAKER W/CASE ASSY

22 Part of 28 BRACKET FRONT LEFT

23 Part of 28 BRACKET FRONT RIGHT

24 Part of 28 METAL STAND BASE

25 Part of 28 METAL SHFT GUIDE SCP1

26 Part of 28 BRACKET STAND READ

27 Part of 28 METAL STAND

28 812-10155 STAND ASSY

29 814-10197 REAR CABINET MAIN

CM153 - 923-03443R1 13 ZLD20A1 - PARTS

Page 14

EXPLODED VIEW

ZLD20A1 DIAGRAMS

13

5

1

2

3

4

7

8

11

6

12

21

16

17

20

14

15

29

22

10

9

24

19

25

18

28

26

27

23

CM153 - 923-03443R1 14 ZLD20A1 - DIAGRAMS

Page 15

ZLD20A1 DIAGRAMS

WIRING DIAGRAM

MAIN P201B

CN1

P803B

SC801

CONTROL, POWER

SPEAK ER LEAD

HOLDER

S/P LEAD

HOLDER

B

1

0

0

P

S/P LEAD TIES

BAND

CN1

B

1

0

0

P

CM153 - 923-03443R1 15 ZLD20A1 - DIAGRAMS

Page 16

ZLD15A1 DIAGRAMS

BLOCK DIAGRAM

Tuner & IF

- 6700VNF003C

Ext- L

Ext- R

Audio-Amp

TDA7052A

Audio-Amp

CVBS

SIF

Processor

- MSP3400C

Audio

L

R

For TV

. Contrast

. Brightness

. Color

. Tint

Ext_Video

Video

Decorder

- VPC3230D

OSD FB/R/G/B

A to D Converter

Ext_Y/C

- AD9884

1H/1V

DVD Y/Pb/Pr

EPROM

For OSD

Video Scaler

- AL300

LM151X2

< 6-bits >

D-R/G/B,

H / V -Sync,

Den, Clock

From

Computer

TDA7052A

Computer

Signal

- D-Sub

For MNT Application

R/G/B

H/V

For PC Input

- Contrast

- Brightness

- Color

LCD

Micro-Controller

- M 37274

CVBS For Caption

For MNT Application

CM153 - 923-03443R1 16 ZLD15A1 - DIAGRAMS

Page 17

ZLD15A1 PCB Main (Top)

MAIN(T

OP)

CM153 - 923-03443R1 17 ZLD15A1 - DIAGRAMS

Page 18

CTL(TOP)

ZLD15A1 PCB Control & Tuner

CTL(BOTT

OM)

TUNER(TOP)

TUNER(BOTTOM)

CM153 - 923-03443R1 18 ZLD15A1 - DIAGRAMS

Page 19

LCD PANNEL

L

C

2

0

1

V

1

A

3

DC

(12V)

3.3V

VIDEO RAM

2M

R / G / B

8 /8 /8bit

15V

Dual Aud io AMP

LA4282

PC

ZLD20A1 DIAGRAMS

BLOCK DIAGRAM

3.3V 5V(FOR RESET IC 3,3V)

SCALER(Format Converter)

MX88L-284FC-V

14.318MHz

8.0V

Audio Processor

MSP-34XX

RF : 2, SCART : 4

MONO : 1

I2S : 2

------18.432MHz--L-SPK/WOOFER

H/P, I2S

SCART OUT : 2

R/G/B

24

5.0V

RESET 4.2V

SCL/S DA

R/G/B/FB L /Ri n TV/L/R out

Y/U/V in

Y PB PR L R V L R

SCART JACK

DVD/DT V

(480I/480P)

3.3V

Analog

R/G/B/H/V

Y/U/V

(480P)

0.5-0.7

IC302

SDA-9410

27.0MHz

SCL/S DA

SCL/SD A

. .

..

AD Converter

THS8083

9V

Multi-Component

Proces sor(BBVSP)

CXA 2101AQ

YCrCb : 2 / 4

RGB : 4 / 2

OUT RGB :1, TUV : 1

Y/U/V

(480P)

3.3V 3.3V

SCAN Converter

H/P S -

SCL/SDA

Y/U/V

4:2:2

H/V

(2H)

R/G/B

OSD

IC301

H- FILTER

(DRP Pr ocesso r )

LGTV-1001

SCART(R/G/B/FB)

YUV IN(VIN4 : H-CH E C K)480I

S-VHS (VIN1 : Y/C) )

A/V2(VIN 2 : CVBS)

EEP

EEP

ROM

ROM

SCL/SDA

.

3.3V

SCL1/SDA1

MICOM / TXT

6.0MHz

Color Decoder/

A/D Con v erter

VPC-3230D

. COMB/FIL : 4H

INPUT . 4 CVBS . 1 S-VHS

. 2 RGB /YCrCb

. 1 F/B

. 1 CVBS OUTPUT

. Y/Cr/Cb OUTPUT

M/O(CVBS)

V L R

VIDEO

IC1

IC201

480I/P

ÆÇ´ Ü

H-Sync.

SEP

RF(VIN3 : CVBS)

15V

X2

POWER

5V

DC to DC Convert er

3.3V

(SI786,SI4808DY,T801)

TO MI C O M

TO MICOM

TUNER

TUNER

ANT (RF )

15V

15V

R-SPK

L-SPK

33V

DC to AC

INVEERTER

BRI-AD J

POWER-ON/OF F

5V

3.3V

30V

5V

20.25MHz

SCL/SDA

DC

(12V)

SCL

SDA

CVBS

SIF

IF AGC

5V

Caption

Processor

VIDE O H/V

CAPTI ON

R/G/B

SCL/SD A

H-sync

CLK

Y/U/V

4:2:2

CM153 - 923-03443R1 19 ZLD20A1 - DIAGRAMS

Page 20

CM153 - 923-03443R1 20 ZLD20A1 - PCBS

ZLD20A1 PCB LAYOUTS

MAIN

PCB

LA

YOUT

Page 21

CM153 - 923-03443R1 21 ZLD20A1 - PCBS

ZLD20A1 PCB LAYOUTS

MX

PCB

LA

YOUT

MX(TOP

)

MX(BOTTOM)

Page 22

CM153 - 923-03443R1 22 ZLD20A1 - PCBS

ZLD20A1 PCB LAYOUTS

CONTROL PANEL

PCB

LA

YOUT

CONTROL(TOP)

CONTROL(BOTTOM)

SPEAKER(TOP)

SPEAKER(BOTTOM)

SPEAKER

CONNECT

PCB LA

YOUT

Page 23

Page 24

Page 25

Loading...

Loading...