LG XA64 Service Manual

MODEL: XA64 (XAS64F)SERVICE MANUAL

9002 ,NOVEMBER97405237NFA : ON/P

Website http://biz.lgservice.com

Internal Use Only

MICRO Hi-Fi SYSTEM

SERVICE MANUAL

MODEL:

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

XA64 (XAS64F)

CONTENTS

SECTION 1 ........SUMMARY

SECTION 2 ........CABINET & MAIN CHASSIS

SECTION 3 ........ELECTRICAL

SECTION 4 ........REPLACEMENT PARTS LIST

1-1

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR A/V PRODUCTS................................... 1-3

SERVICING PRECAUTIONS ................................................................................................................... 1-4

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

SERVICE INFORMATION FOR EEPROM .......................................................................................... 1-5

PROGRAM UPDATE GUIDE ................................................................................................................... 1-6

SPECIFICATIONS ....................................................................................................................................... 1-7

1-2

PRODUCT SAFETY SERVICING GUIDELINES

FOR A/V PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from LG Corporation. All components should

be replaced only with types identical to those in the original circuit and their physical

location, wiring and lead dress must conform to original layout upon completion of

repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component designators and are required to maintain safe performance. No deviations are allowed

without prior approval by LG Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into the

set is not delayed until the new service literature is printed.

CAUTION : Do not attempt to modify this product in any way. Never perform cus-

tomized installations without manufacturer’s approval. Unauthorized modifications

will not only void the warranty, but may lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended to alert

the service personnel to important safety information in the service

literature.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the service personnel to the presence of noninsulated “dangerous voltage” that may be of sufficient magnitude to

constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral triangle is intended to convey to the service personnel the following fuse replacement caution notice:

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF

FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After

the original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items trans-ported to and from

the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields, strain

reliefs, power supply cords, and other hardware have been reinstalled per the

original design. Be sure that the safety purpose of the polarized line plug has not

been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components,

for frayed leads or damaged insulation (including the AC cord), and replace if

necessary.

5. No lead or component should touch a high current device or a resistor rated at 1

watt or more. Lead tension around protruding metal surfaces must be avoided.

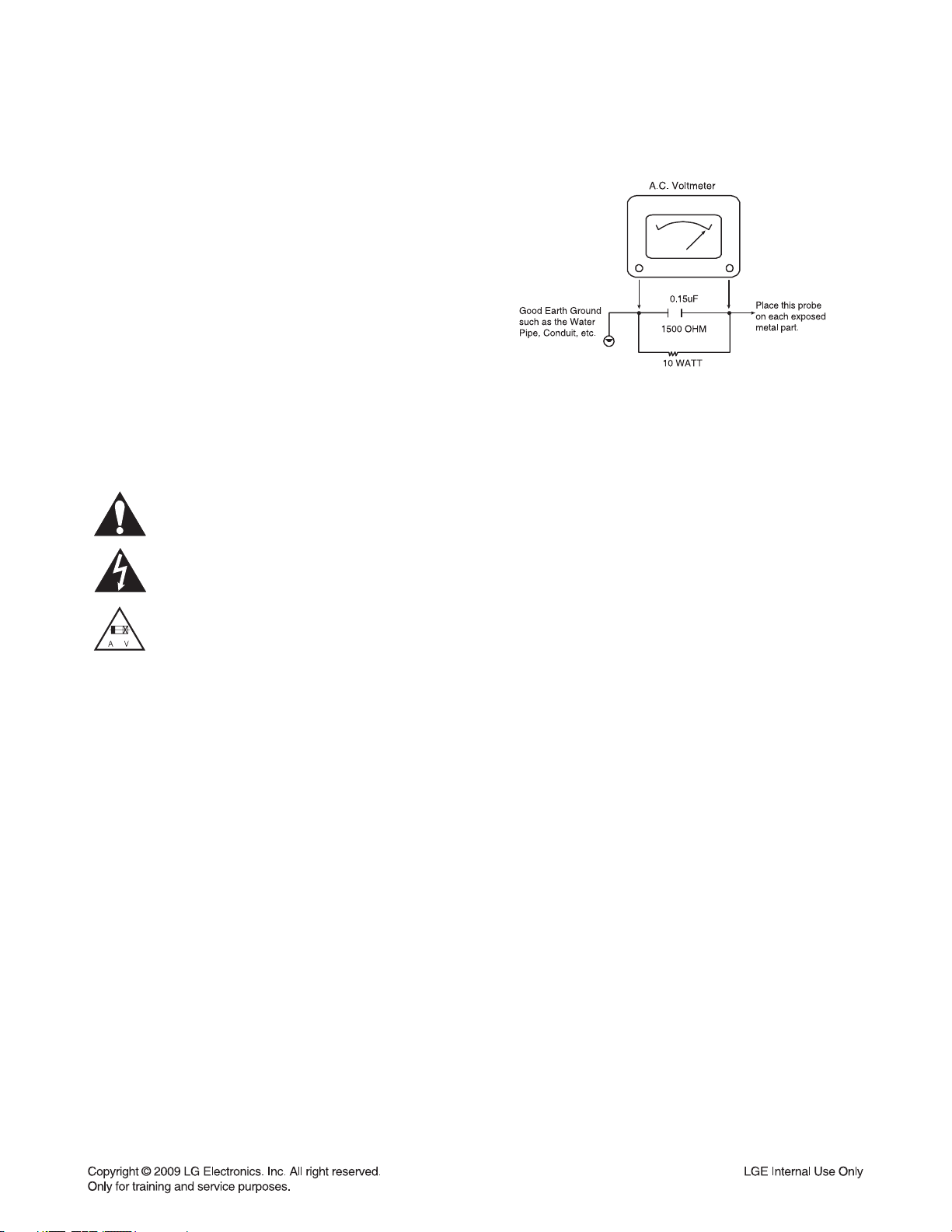

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the

following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by a .15 mfd

150V AC type capacitor between a known good earth ground water pipe, conduit,

etc.) and the exposed metallic parts, one at a time. Measure the AC voltage

across the combination of 1500 ohm resistor and .15 mfd capacitor. Reverse the

AC plug by using a non-polarized adaptor and repeat AC voltage measurements

for each exposed metallic part. Voltage measured must not exceed 0.75 volts

RMS. This corresponds to 0.5 milliamp AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew

is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should

also avoid the use of decorative scarves or other coverings that might obstruct

ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must follow

the factory-approved mounting instructions. A product mounted to a shelf or

platform must retain its original feet (or the equivalent thickness in spacers) to

provide adequate air flow across the bottom. Bolts or screws used for fasteners

must not touch any parts or wiring. Perform leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

1-3

SERVICING PRECAUTIONS

CAUTION: Before servicing the A/V products covered by this

service data and its supplements and addends, read and follow the SAFETY PRECAUTIONS.

NOTE: if unforeseen circumstances create conflict between

the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1. Always unplug the A/V products AC power cord from the

AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an electro-

lytic capacitor.

Caution : A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not spray chemicals on or near this A/V product or any

of its assemblies.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

3. Unless specified otherwise in this service data, clean electrical contacts by applying an appropriate contact cleaning

solution to the contacts with a pipe cleaner, cotton-tipped

swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this A/V product and / or any of

its electrical assemblies unless all solidstate device heat

sinks are correctly installed.

6. Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil,or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or cir-

cuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

1-4

SERVICE INFORMATION FOR EEPROM

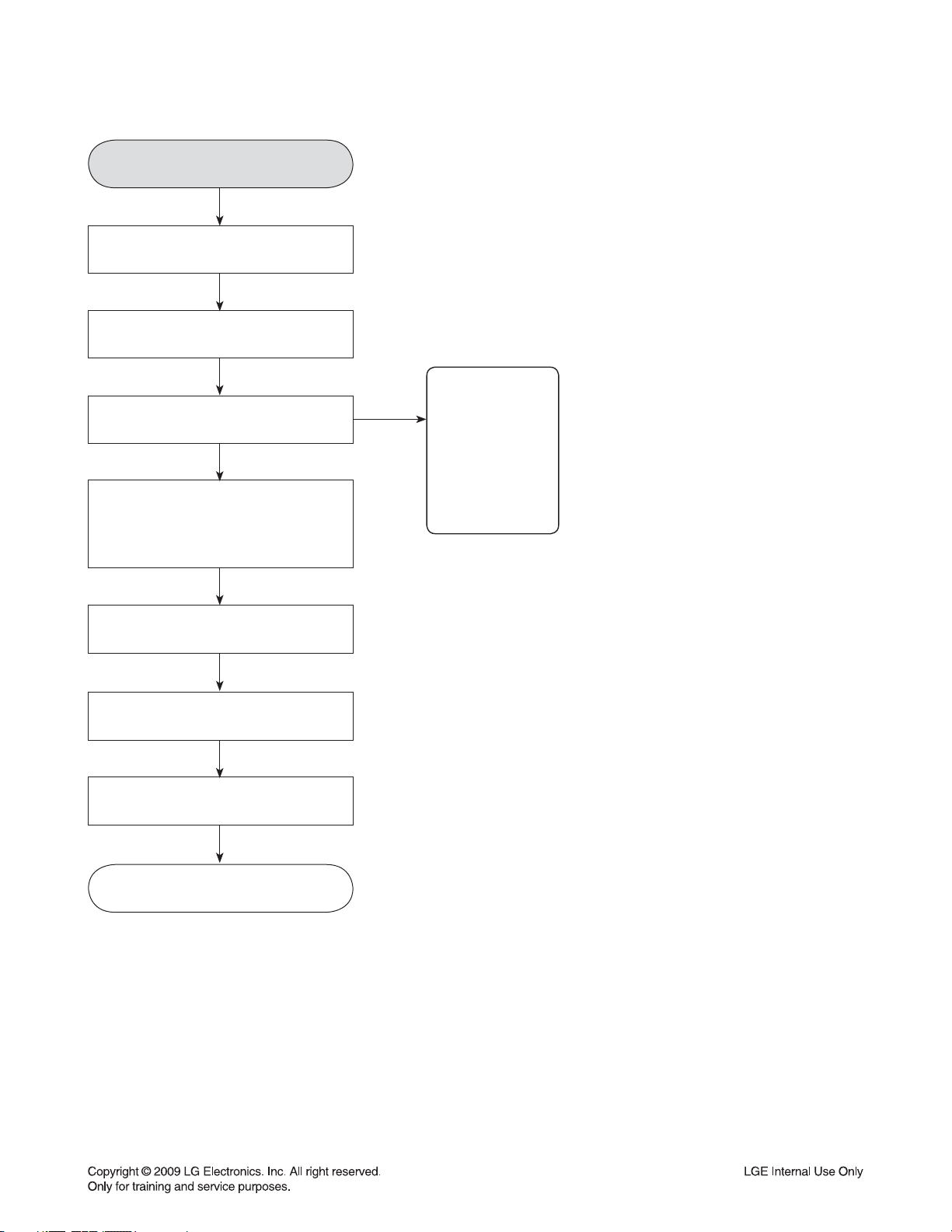

POWER ON

FLD no disc status

Front ‘STOP’ + Remote control ‘FWD

SKIP’ push same timing during 5s.

FLD ‘OP0-xx….

Move to appropriate position and

make changes with remote control

‘REPEAT / PLAY / BWD SKIP /

FWD SKIP’.

Press ‘STOP’ key.

FLD ‘write ok’

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

NAME HEX

OP0 xx

OP1 xx

OP2 xx

. .

. .

. .

Press ‘POWER’ key once.

Completed

1-5

PROGRAM UPDATE GUIDE

1. HOW TO UPDATE ESS PROGRAM

(1) Rename the file name to download as “LG_(MODEL NAME)_(Vresion).ROM” in upper cases.

ex) XA64 : “LG_XA64_0905180.ROM”

Refer to the Standard for naming of software.

(2) Copy the file to the formatted USB, and burn it.

(3) Move to the USB function, and insert the USB to the set.

The upgrade information will be shown on the screen.

(4) Remove the USB.

(5) Remove and reconnect the power cable when it changes to logo screen from upgrade information.

Then the upgrade process is completed.

2. HOW TO UPDATE SANYO PROGRAM

(1) Change the file name to download as “(MODEL NAME)_(Version).HEX”. in upper cases

ex) XA64: XA64_0809262.HEX

(2) Copy the file to the root folder of USB storage.

(3) Put the USB into the set.

Then the upgrade process will be started with the upgrade information.

(4) If the upgrade process is complete, the set will be rebooted with “Complete” message.

3. HOW TO UPDATE MCS PROGRAM

(1) Change the file name to download as “(MODEL NAME)_(Option)_(Version).MCS”.

ex) XA64_01010_07.HEX

(2) Copy the file to the root folder of USB storage.

(3) Put the USB into the set.

Then the upgrade process will be started with the upgrade information.

(4) If the upgrade process is complete, the set will be rebooted with “SUCCESS” message.

1-6

SPECIFICATIONS

• GENERAL

Power supply 200 ~ 240 V, 50/60 Hz

Power consumption 50 W

Net Weight 2.71 kg

External dimensions (W x H x D) 170 x 240 x 253 (mm)

Operating temperature 5°C ~ 35°C

Operating humidity 5 % ~ 85 %

• TUNER

FM Tuning Range 87.5 ~ 108.0 MHz

AM Tuning Range 522 ~ 1,620 KHz

• AMPLIFIER

Output Power 30 W + 30 W

T.H.D 0.5 %

Frequency Response 50 Hz ~ 20 KHz

Signal-to-noise ratio 70 dB

• CD

Frequency response 100 Hz ~ 18 KHz

Signal-to-noise ratio 70 dB

Dynamic range 55 dB

• SPEAKERS

Type 2 Way 2 Speaker

impedance 6 Ω

Rated Input Power 30 W

Max. Input Power 60 W

Net Dimensions (W x H x D) 150 x 243 x 180 (mm)

Net Weight 2.08 kg

Note : Design and specifications are subject to change prior notice.

1-7

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

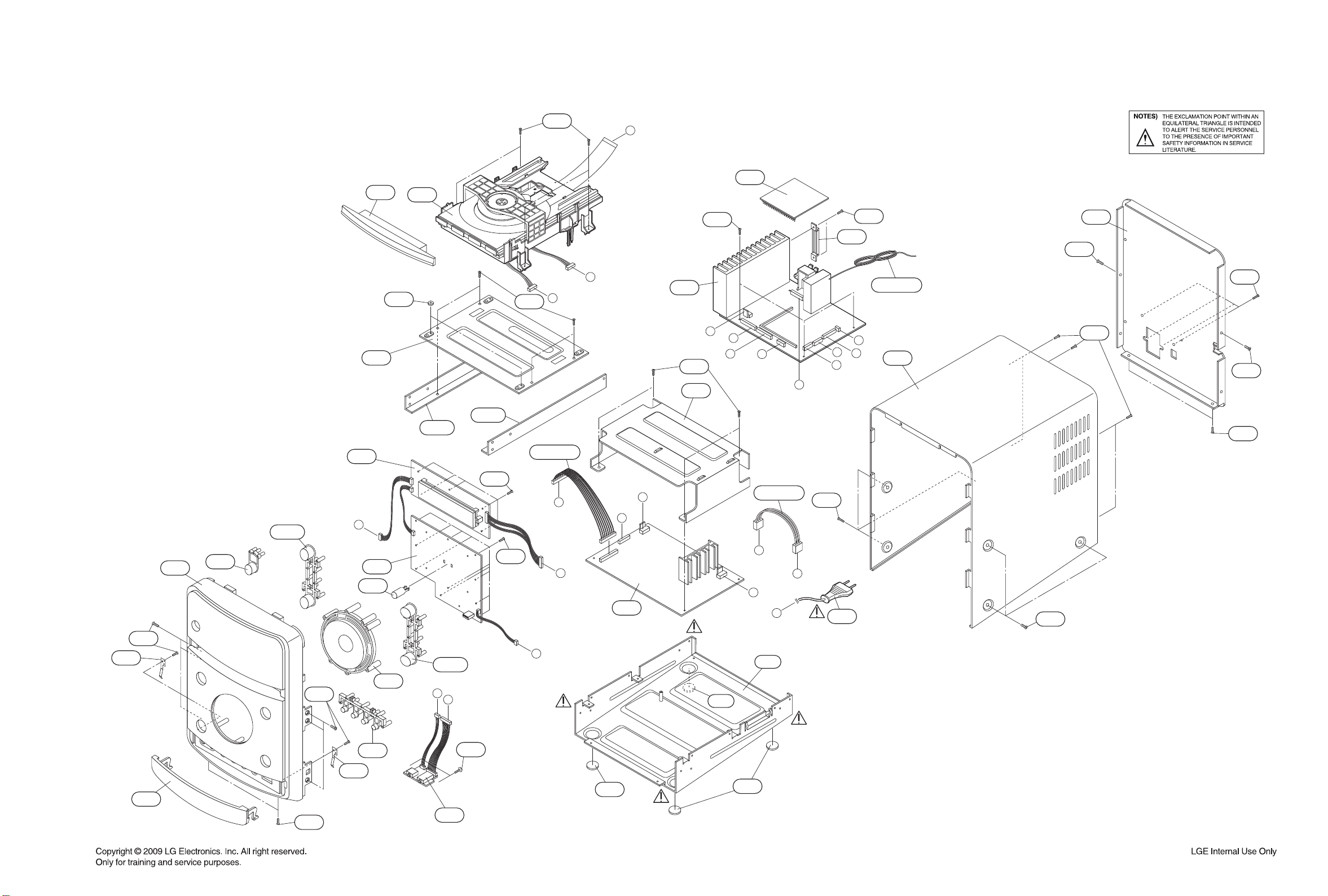

EXPLODED VIEWS ..................................................................................................................................... 2-3

1. CABINET AND MAIN FRAME SECTION ................................................................................................. 2-3

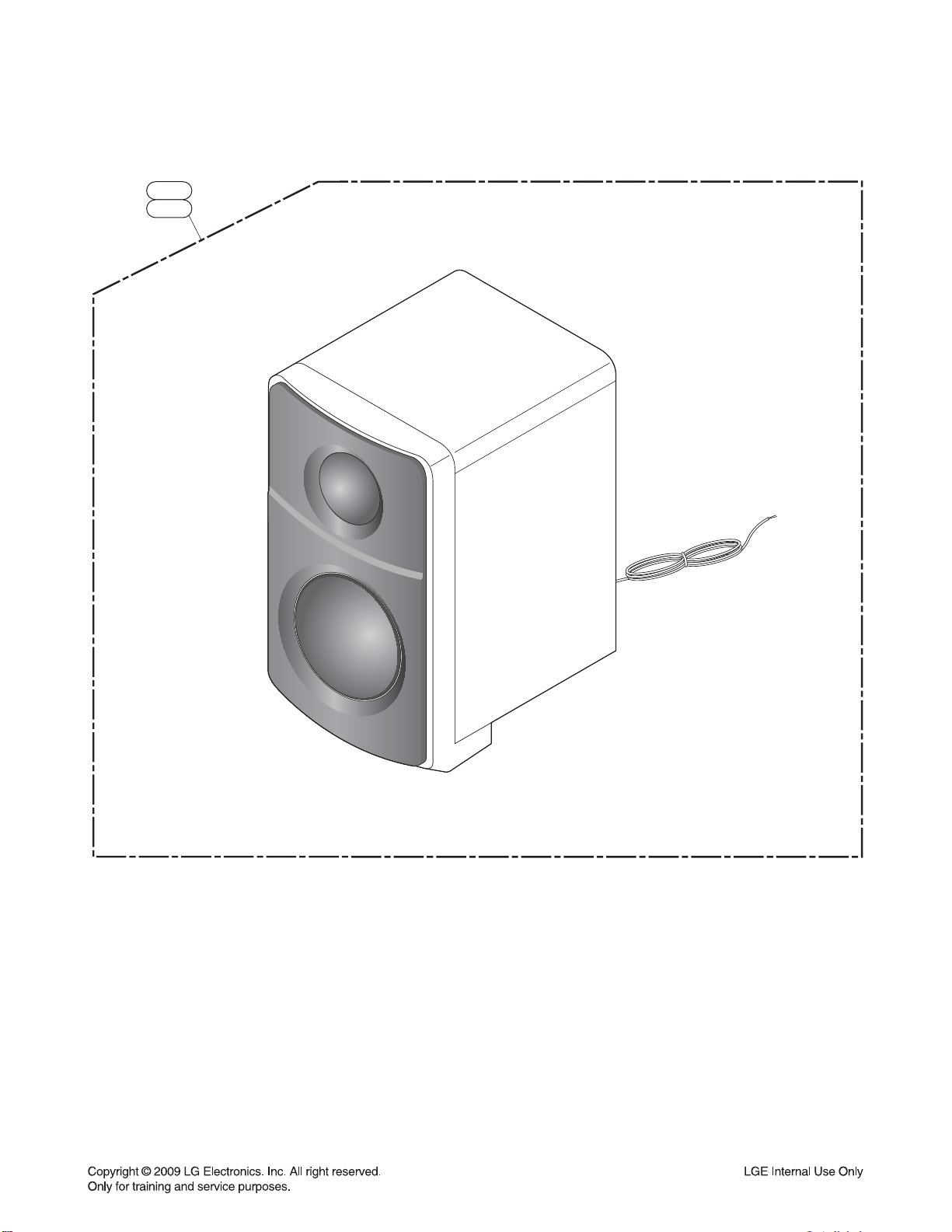

2. SPEAKER SECTION ................................................................................................................................ 2-7

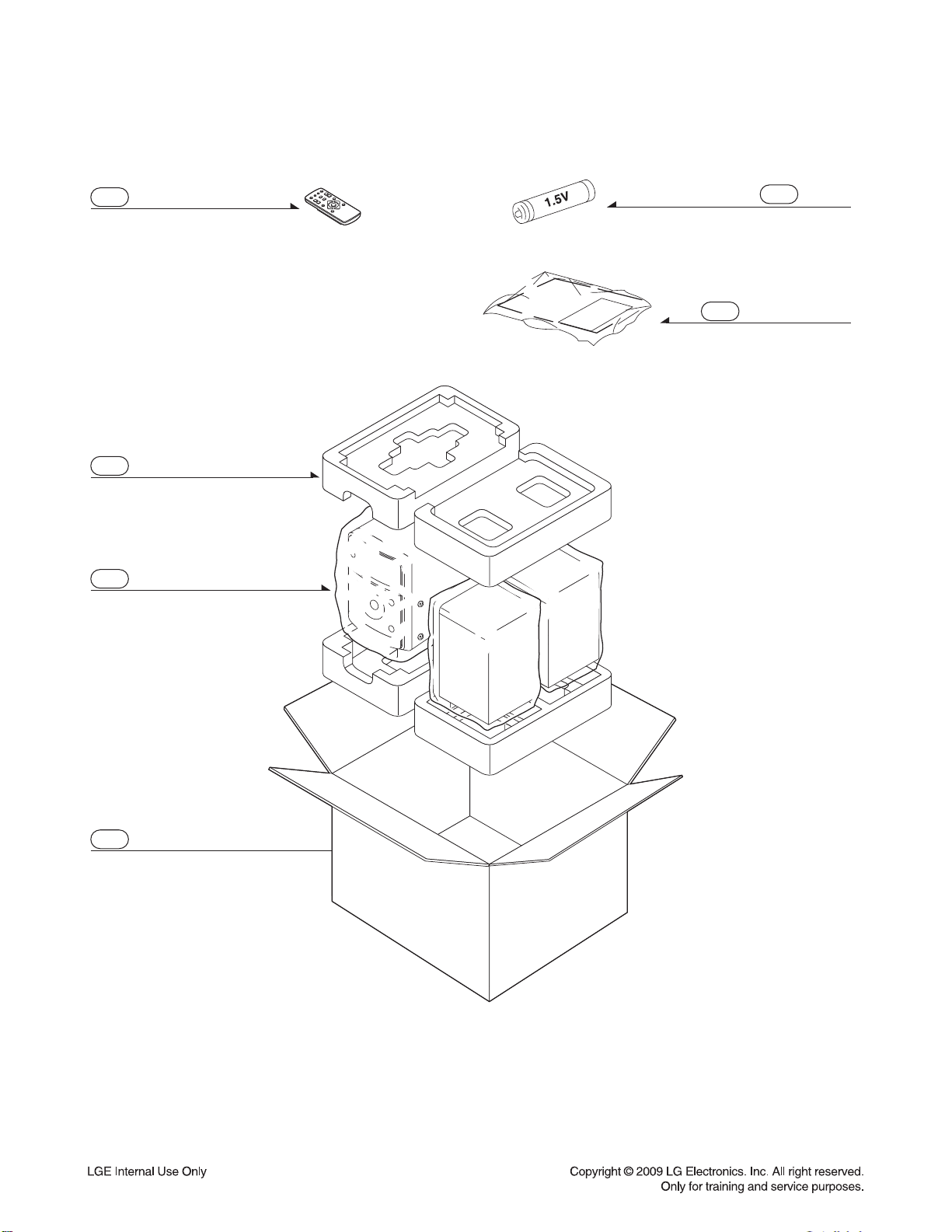

3. PACKING ACCESSORY SECTION ......................................................................................................... 2-8

2-1

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

A43

261

258

260

A26

259L

259R

453

CABLE1

453

F

H

A45

MCU

453

453

267

264

452

G

263

CABLE3

453

MAIN

453

262

A

B

C

D

E

I

G

H

F

268

451

452

453

252

452

251

250

254

255L

452

452

252

K

A41

257

253

256

USB

DISPLAY

KEY

255R

I

E

455

A42

454

454

B

J

K

CABLE2

J

451

SMPS

C

L

A47

D

266

266

265

266

A

L

300

451

2-3 2-4

2. SPEAKER SECTION

A60L

A60R

2-7

3. PACKING ACCESSORY SECTION

Remote controller900

Instruction Ass'y801

Packing803

Bag804

Battery808

Box802

2-8

Loading...

Loading...