Page 1

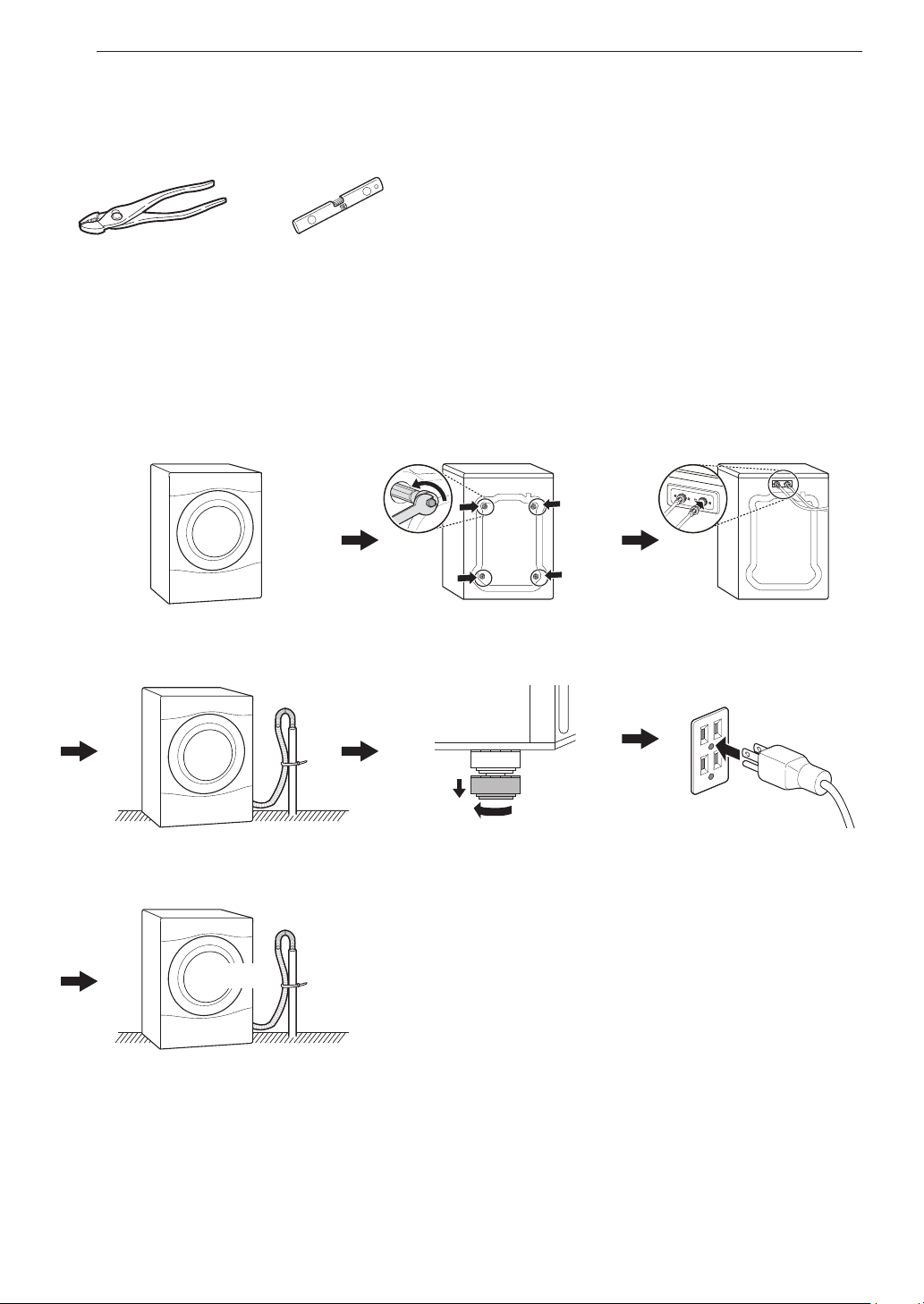

8 INSTALLATION

INSTALLATION

Tools Needed

Pliers

Level

Installation Overview

Please read the following installation instructions rst after purchasing this product or transporting it to another

location.

Choosing the proper location

Unpacking and removing

shipping bolts

Connecting the water lines

Connecting the drain line

TEST!

Testing the washer

Leveling the washer Connecting to the power

supply

Page 2

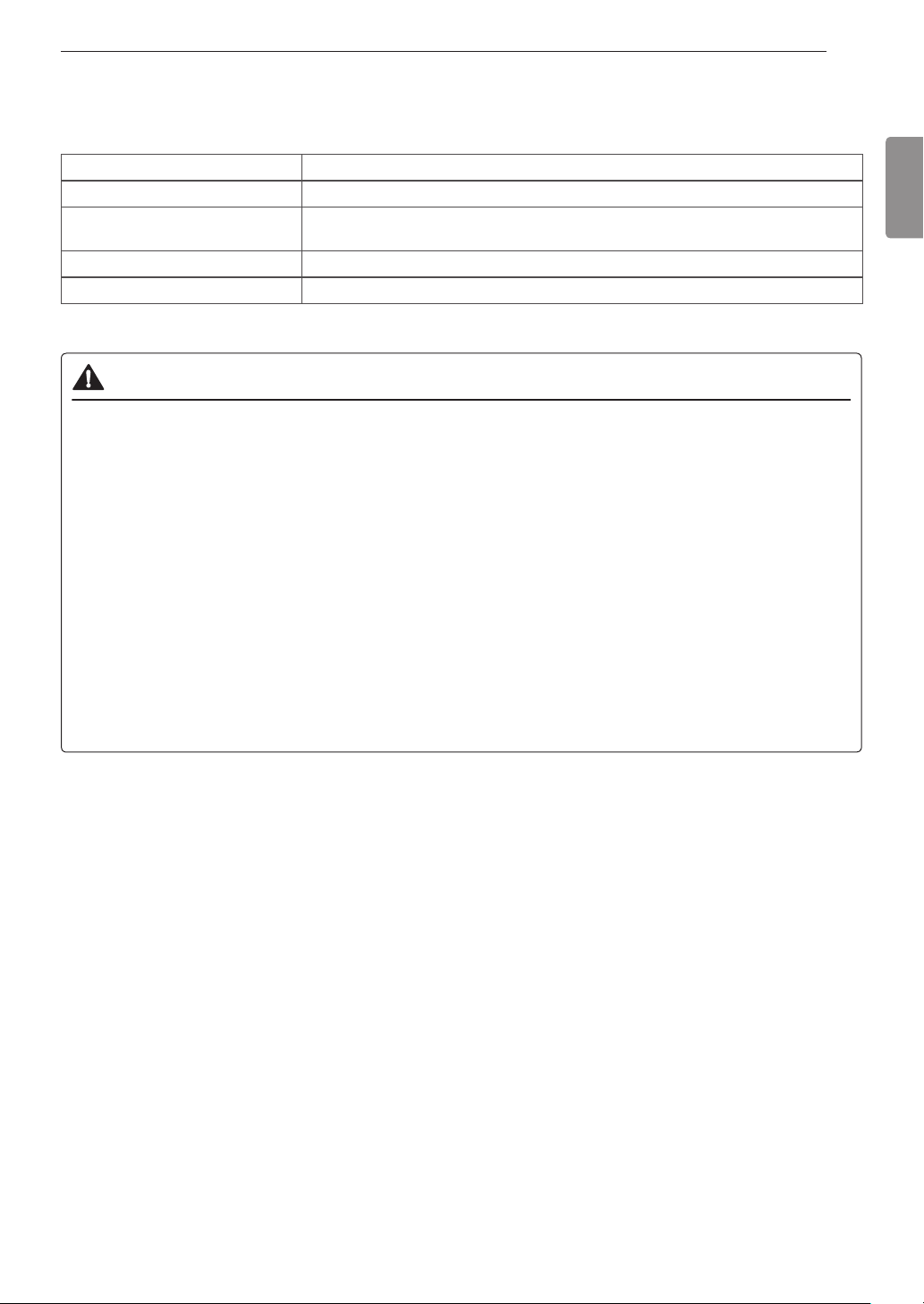

Product Specications

The appearance and specications listed in this manual may vary due to constant product improvements.

Electrical requirements 120 VAC @ 60 Hz

Min. / Max. water pressure 20 – 120 psi (138–827 kPa)

Dimensions

Net weight 187.4 lb (85 kg)

Max spin speed 1300 RPM

WARNING

• Moving or installation of the appliance requires two or more people. Failure to follow these instructions may

result in injury.

• Store and install the appliance where it will not be exposed to temperatures below freezing or exposed to

outdoor weather conditions. Failure to follow this warning can cause product or part failure, serious injury,

re, electric shock, or death.

• Properly ground the washer to conform with all governing codes and ordinances. Failure to follow this

warning can cause serious injury, re, electric shock, or death.

• To reduce the risk of electric shock, do not install the appliance in humid spaces. Failure to follow this

warning can cause serious injury, re, electric shock, or death.

• To ensure proper airow, do not block the large opening on the bottom of the washer with carpeting or other

materials.

• Do not remove the ground prong. Do not use an adapter or extension cord. Plug into a grounded 3-prong

outlet. Failure to follow this warning can cause serious injury, re, electric shock, or death.

• Certain internal parts are intentionally not grounded and may present a risk of electric shock only during

servicing. Service personnel - Do not contact the following parts while the appliance is energized: pump,

valve, motor, control board.

70 cm(W) X 77 cm(D) X 99 cm(H), 139.6 cm (D with door open)

27”(W) X 30 ¼”(D) X 39”(H), 55” (D with door open)

9INSTALLATION

ENGLISH

Page 3

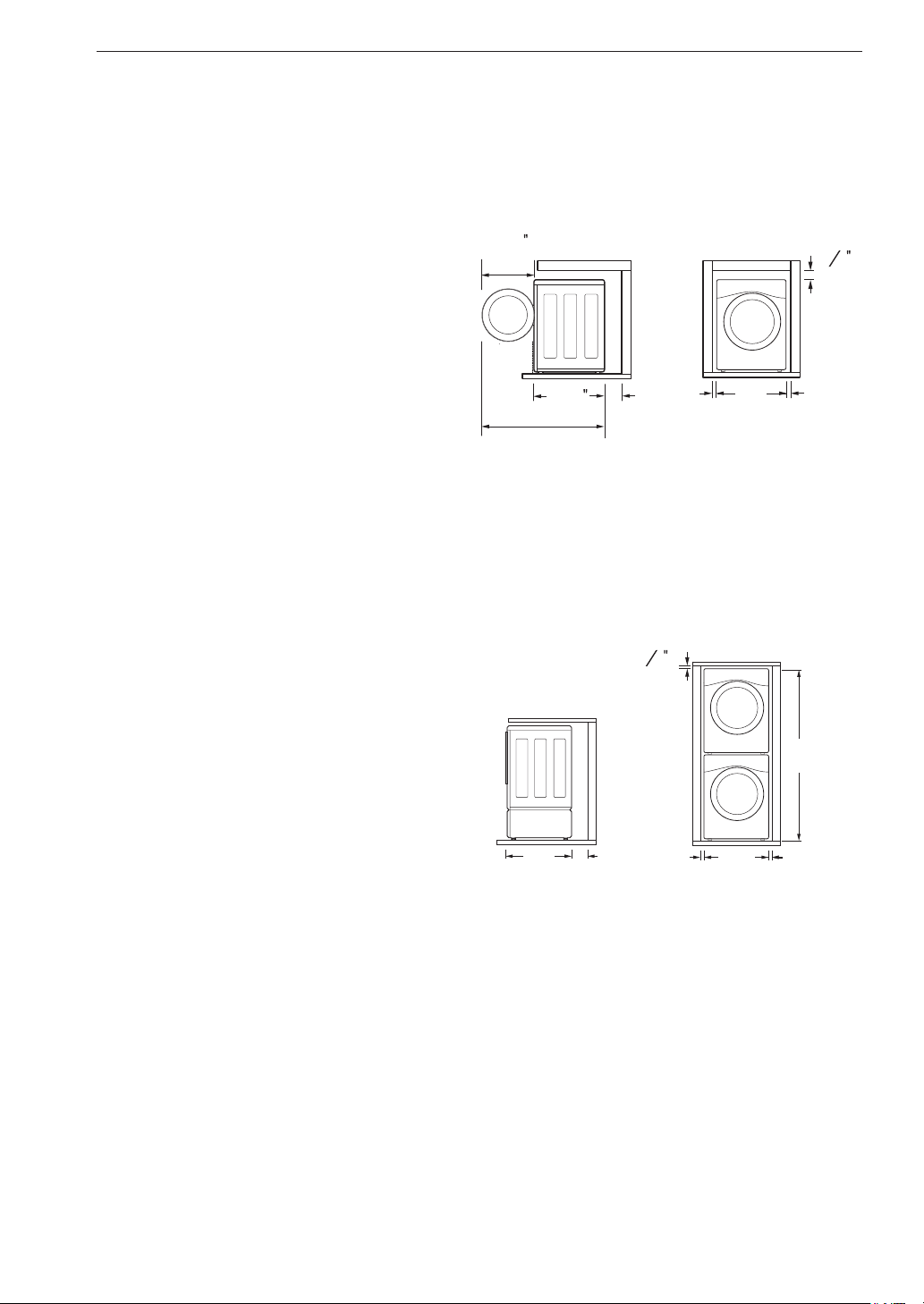

10 INSTALLATION

)

(139.6 cm)

24

¾

(77 cm)

(10 cm)

(70 cm)

(2.5 cm)

(2.5 cm)

(196.8 cm)

13

Choosing the Proper

Location

Install the washer on a solid oor that is strong and

rigid enough to support the weight of the washer,

even when fully loaded, without exing or bouncing.

If the oor has too much ex, you may need to

reinforce it to make it more rigid. If the oor is not

solid, it may cause severe vibration and noise.

NOTE

• Before installing the washer, make sure the oor

is clean, dry and free of dust, dirt, water and oil so

the washer feet cannot slide easily. Leveling feet

that can move or slide on the oor can contribute to

excess vibration and noise due to poor contact with

the oor.

• If a drip pan must be used, take extra care to follow

the instructions provided with the drip pan and make

sure the leveling feet are adjusted for rm and even

contact with the pan. Use of drip pans and failure to

properly level the machine may result in increased

vibration and noise during operation.

• Allow for sufcient space between the walls and the

washer for installation.

Power Outlet

• The power outlet must be within 60 inches (1.5 m)

of either side of the washer.

• The appliance and outlet must be positioned so that

the plug is easily accessible.

• Do not overload the outlet with more than one

appliance.

• The outlet must be grounded in accordance with

current electrical wiring codes and regulations.

• Use a time-delay fuse or circuit breaker.

NOTE

• The washer must be installed on rm ooring to

minimize vibration during the spin cycle. Concrete

ooring is best, but a wood oor is sufcient,

provided it is built to FHA standards.

Floor Installation

(62.6 cm)

1" 1"

(77 cm)

55"

30

¼

4"

(10 cm)

27"

(70 cm)(2.5 cm) (2.5 cm)

To ensure sufcient clearance for water lines, the

drain line and airow, allow minimum clearances of

at least 1 inch (2.5 cm) at the sides and 4 inches (10

cm) behind the unit. Be sure to allow for wall, door,

or oor moldings that may increase the required

clearances.

13

64

(0.5 cm

Stacked or Pedestal Installation

64

(0.5 cm)

77 ½"

NOTE

• It is the personal responsibility and obligation of the

product owner to have a proper outlet installed by

qualied service personnel.

Flooring

• To minimize noise and vibration, the washer must

be installed on a solidly constructed oor.

• Allowable slope under the entire washer is a

maximum 1 inch (2.5 cm) difference from side to

side or from front to back.

• Installing on carpeting and soft tile surfaces is not

recommended.

• Never install the washer on a platform or weakly

supported structure.

30 ¼"

4"

1"

27"

1"

NOTE

• Refer to the instructions packaged with the optional

pedestal kit before installing with a pedestal kit.

• Do not use a drip pan with a pedestal or pedestal

washer installation as it can block the drawer. Using

a drip pan may result in increased vibration and

noise during operation.

Page 4

11INSTALLATION

Unpacking and Removing

Shipping Bolts

Unpack all shipping materials from the washer for

proper operation and inspect it for shipping damage.

CAUTION

• Failure to remove shipping materials can cause

excessive noise and vibration.

Lift the washer off the foam base.

1

After removing the carton and shipping material,

lift the washer off the foam base. Make sure the

plastic tub support comes off with the base and is

not stuck to the bottom of the washer.

If you must lay the washer down to remove the

base packaging materials, always protect the side

of the washer and lay it carefully on its side. Do

not lay the washer on its front or back.

Install the hole caps.

3

Locate the four hole caps included in the

accessory pack and install them in the shipping

bolt holes.

Cap

NOTE

• Save the bolt assemblies for future use. To prevent

damage to internal components, do not transport

the washer without reinstalling the shipping bolts.

• Failure to remove shipping bolts and retainers may

cause severe vibration and noise, which can lead

to permanent damage to the washer. The cord is

secured to the back of the washer with a shipping

bolt to help prevent operation with shipping bolts in

place.

ENGLISH

Foam tub

support

Remove the bolt assemblies.

2

Starting with the bottom two shipping bolts, use

the wrench (included) to fully loosen all four

shipping bolts by turning them counterclockwise.

Remove the bolt assemblies by wiggling them

slightly while pulling them out.

Shipping

bolt

Carton base

Retainer

Page 5

12 INSTALLATION

Connecting the Water Lines

To avoid the risk of costly water damage, purchase

and install new inlet hoses when installing the

washer.

Check the ttings and seals.

1

Inspect the threaded tting on each hose and

make sure there is a rubber seal in place in both

ends of each hose to prevent leaking.

Rubber seal Rubber seal

Water hose (to water

inlet on washer)

Connect the water supply hoses.

2

Connect the water supply hoses to the hot and

cold water faucets tightly by hand and then

tighten another 2/3 turn with pliers. Connect the

blue hose to a cold water faucet and the red hose

to a hot water faucet.

Water hose (to tap)

Attach the water lines to the back of the

4

washer.

Attach the hot water line to the hot water inlet on

the back of the washer. Attach the cold water line

to the cold water inlet on the back of the washer.

Tighten the ttings securely. Turn ON both faucets

all the way and check for leaks at both ends of the

hoses.

Cold

water

inlet

Hot water

inlet

WARNING

• Do not overtighten the hoses or cross-thread the

hose ttings. Overtightening or cross-threading

can damage the valves or couplings, resulting in

leaking and property damage.

• Do not reuse old hoses. Use only new hoses

when installing the washer. Old hoses could leak

or burst causing ooding and property damage.

Contact an LG Customer Information Center for

assistance in buying hoses.

Flush out the inlet hoses.

3

After connecting the inlet hoses to the water

faucets, turn on the water faucets to ush out

foreign substances (dirt, sand or sawdust) in the

water lines. Let water drain into a bucket, and

check the water temperature to make sure you've

connected the hoses to the correct faucets.

NOTE

• Periodically check the hoses for cracks, leaks, and

wear, and replace the hoses every ve years. Do

not stretch the water hoses intentionally, and make

sure that they are not pinched, crushed or kinked by

other objects.

• Water supply pressure must be between 20 psi

and 120 psi (138 – 827 kPa). If the water supply

pressure is more than 120 psi, a pressure reducing

valve must be installed.

• To provide optimum washing performance, the hot

water temperature should be set at 120 – 130 °F

(48 – 54 °C) and the cold at 60 °F (15 °C).

• The washer should never be installed or stored in a

location subject to freezing temperatures. Damage

to the water lines and internal mechanisms of the

washer can result. If the washer was exposed to

freezing temperatures prior to installation, allow it to

stand at room temperature for several hours before

use and check for leaks prior to operation.

• Do not use ood-preventing hoses with auto shutoff

devices. The devices can be tripped during ll and

prevent the machine from lling properly.

Page 6

13INSTALLATION

Connecting the Drain Hose

Connect the drain hose to either a standpipe or

laundry tub.

NOTE

• The drain hose should always be properly secured.

Failure to properly secure the drain hose can result

in ooding and property damage.

• The drain must be installed in accordance with any

applicable local codes and regulations.

• Make sure that the drain hose is not stretched,

pinched, crushed, or kinked.

• Do not install the drain hose with the end lower than

29.5 inches (0.7 m) or higher than 96 inches

(2.4 m) above the bottom of the washer or more

than 60 inches (1.5 m) away from the washer.

• Never create an airtight seal between the hose and

the drain with tape or other means. If no air gap

is present, water can be siphoned out of the tub

resulting in poor wash/rinse performance or clothing

damage.

Option 1: Standpipe

Clip the end of the hose into the elbow

1

bracket.

Connect the elbow bracket within 4 inches

(10 cm) of the end of the drain hose. If the drain

hose is extended more than 4 inches (10 cm)

beyond the end of the elbow bracket, mold or

microorganisms could spread to the inside of the

washer.

Option 2: Laundry Tub

Clip the end of the hose into the elbow

1

bracket.

Connect the elbow bracket within 4 inches

(10 cm) of the end of the drain hose. If the drain

hose is extended more than 4 inches (10 cm)

beyond the end of the elbow bracket, mold or

microorganisms could spread to the inside of the

washer.

No more than

4 inches (10 cm)

Elbow bracket

Hang the end of the drain hose over the side

2

of the laundry tub.

Elbow bracket

Drain hose

Use a tie strap to secure the drain hose in

3

place.

ENGLISH

No more than

4 inches (10 cm)

Elbow bracket

Insert the end of the drain hose into the

2

standpipe.

Drain hose

Use a tie strap to secure the drain hose in

3

place.

Elbow bracket

Page 7

14 INSTALLATION

Leveling the Washer

The drum of your new washer spins at very high

speeds. To minimize vibration, noise, and unwanted

movement, the oor must be a level, solid surface.

NOTE

• Adjust the leveling feet only as far as necessary to

level the washer. Extending the leveling feet more

than necessary can cause the washer to vibrate.

• Before installing the washer, make sure that the

oor is clean, dry and free of dust, dirt, water and

oil so the washer feet cannot slide easily. Feet

that move or slide on the oor can contribute to

excessive vibration and noise due to poor contact

with the oor.

Position the washer in its nal location.

1

Take special care not to pinch, strain, or crush the

water and drain lines. If you have a carpenter's

level, you can place it across the top of the

washer. The slope beneath the washer should not

exceed 1 inch, and all four leveling feet must rest

rmly on the oor.

Level

Recheck the washer’s levelness.

4

Push or rock the top edges of the washer gently

to make sure the washer does not rock. If the

washer rocks, repeat steps 1-3.

CAUTION

• Using the washer without leveling it may cause

excess vibration and noise, leading to a machine

malfunction.

• Extend the leveling feet only to level the washer.

If you extend the leveling feet unnecessarily, it

may cause abnormal vibration of the washer.

Using Non-Skid Pads

If you install the washer on a slippery surface, it

may move because of excessive vibration. Incorrect

leveling may cause malfunction through noise and

vibration. If this occurs, install the non-skid pads

under the leveling feet and adjust the level.

Clean the oor to attach the non-skid pads.

1

Use a dry rag to remove and clean foreign objects

or moisture. If moisture remains, the non-skid

pads may slip.

Adjust the lower leveling feet.

2

Turn in one direction to raise the washer or the

other direction to lower it.

Raise Lower

Tighten the locknuts.

3

Turn the locknuts counter-clockwise and tighten

them when the washer is level.

Lock nut

Tighten all 4 lock

nuts securely

Adjust the level after placing the washer in the

2

1"

installation area.

Place the adhesive side of the non-skid pad

3

on the oor.

It is most effective to install the non-skid pads

under the front leveling feet. If it is hard to place

the pads under the front leveling feet, place them

under the back leveling feet.

This side up

Adhesive

side

Remove backing

Recheck the washer’s levelness.

4

Push or rock the top edges of the washer gently

to make sure that the washer does not rock. If the

washer rocks, level the washer again.

Page 8

15INSTALLATION

Connecting to the Power

Supply

The washer should be plugged into a 120-VAC, 60

Hz grounded 3-prong outlet. Plug in the washer.

WARNING

• Do not use a worn or damaged power cord or

power plug. Replace or repair it immediately.

Failure to do so may result in death, re, electric

shock, or malfunction.

• Do not modify the power cord and plug provided

with the appliance. Take care not to damage it

when installing or moving the washer. Failure to

do so may result in death, re, electric shock, or

malfunction.

• Make sure that the washer is grounded.

• Connect this washer to a grounded outlet

conforming to the rating prior to use. Failure

to do so may result in re, electric shock, or

malfunction.

• Do not damage or cut off the ground prong of

the power cord. Doing so may cause death, re,

electric shock, or product malfunction.

• Improper connection of the equipment-grounding

conductor can result in risk of electric shock.

Check with a qualied electrician or service

technician if you are in doubt as to whether the

appliance is properly grounded. If it does not t

the outlet, have a proper outlet installed by a

qualied electrician

• The appliance and outlet must be positioned so

that the plug is easily accessible.

• Do not use adapters or extension cords. Doing

so may result in serious injury, re, electric

shock, or death.

• For best performance, plug the washer into

its own individual outlet. This helps prevent

overloading house wiring circuits which could

cause a re hazard from overheated wires.

• If necessary, use a new, UL-listed 3-prong

adapter or 3-wire extension cord with a 3-prong

(grounding) plug rated at no less than the branch

circuit. Do not use an extension cord longer

than 3 feet. Failure to follow these warnings may

result in serious injury, re, electric shock, or

death.

Testing the Washer

Check if the washer is properly installed and run a

test cycle.

Load the washer with 6 pounds of laundry

1

(approximately 6 thick bath towels).

Press the Power button.

2

Press the Rinse+Spin button.

3

Press the Start/Pause button.

4

The wash cycle starts.

Check if water is supplied, that the machine does

5

not rock or vibrate excessively, and that it drains

well during the spin cycle.

NOTE

• If water leaks during water supply, see Connecting

the Water Lines to connect them properly.

• If the washer rocks and vibrates excessively, see

Leveling the Washer to level it again.

• If the drain does not work, see Connecting the Drain

Hose to install the hose properly.

ENGLISH

Loading...

Loading...