LG WM1814 Service Manual

100

WASHING MACHINE

SERVICE MANUAL

READ THIS MANUAL CAREFULLY TO DIAGNOSE

PROBLEMS CORRECTLY BEFORE SERVICING THE UNIT.

MODEL: WM1812CW/WM1814CW

CAUTION

Website: http: //www.LGEservice.com

E-mail: http: //www.LGEservice.com/techsup.html

!

101

JUN. 2004 PRINTED IN KOREA

P/No.:3828ER3027F

2

CONTENTS

1. SPECIFICATIONS .........................................................................................................................3

2. FEATURES & TECHNICAL EXPLANATION ................................................................................ 4

3. PARTS IDENTIFICATION ............................................................................................................ 7

4. INSTALLATION & TEST ............................................................................................................... 8

5. OPERATION ................................................................................................................................11

6. WIRING DIAGRAM/PROGRAM CHART.....................................................................................14

7. TROUBLESHOOTING.................................................................................................................16

7-1. BEFORE PERFORMING SERVICE ...................................................................................16

7-2. QC TEST MODE.................................................................................................................16

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY ......................................................16

7-4. ERROR DISPLAY ...............................................................................................................17

8. ERROR DIAGNOSIS AND CHECK LIST ....................................................................................19

8-1. DIAGNOSIS AND SOLUTION FOR ABNORMAL OPERATION ........................................19

8-2. FAULT DIAGNOSIS AND TROUBLESHOOTING ..............................................................22

9. DISASSEMBLY INSTRUCTIONS ...............................................................................................31

10. EXPLODED VIEW .....................................................................................................................40

10-1. CABINET & CONTROL PANEL ASSEMBLY ....................................................................40

10-2. DRUM & TUB ASSEMBLY................................................................................................41

10-3. DISPENSER ASSEMBLY .................................................................................................42

3

4

7

8

11

12

13

13

13

13

14

16

16

19

26

34

34

35

36

3

1. SPECIFICATIONS

ITEM WM1812CW/WM1814CW

COLOR BLUE WHITE

POWER SUPPLY AC 120 V, 60 Hz

PRODUCT WEIGHT 173 lbs. (78.5 kg)

WASHING 280 W

DRAIN MOTOR

80 W

WASH HEATER

–

WASH 46 rpm

SPIN

0-900 rpm

CYCLES 5

WASH/RINSE TEMPERATURES 5

SPIN SPEEDS 5

OPTIONS

Prewash, Quick Cycle, Extra Rinse, Rinse+Spin, Delay Wash

CUSTOM PROGRAM –

WATER CIRCULATION –

OPERATIONAL WATER PRESSURE 4.5

-

116 psi (800 kPa)

CONTROL TYPE Electronic

WASH CAPACITY 2.96 cu. ft (3.42 cu. ft. IEC)

DIMENSIONS 27” (W) X 301/32” (D) X 3811/16” (H), 5013/16” (D, door open)

DELAY WASH up to 9 hours

DOOR SWITCH TYPE PTC + Solenoid

WATER LEVEL 9 steps (by sensor)

LAUNDRY LOAD SENSING Incorporated

ERROR DIAGNOSIS Incorporated

AUTO POWER OFF Incorporated

CHILD LOCK Incorporated

ELECTRIC POWER

CONSUMTION

REVOLUTION SPEED

4

2. FEATURES & TECHNICAL EXPLANATION

2-1. FEATURES

■

Direct Drive System

The advanced Brushless DC motor directly drives the drum without

belt and pulley.

■

Tilted Drum and Large Door Opening

Tilted drum and large opening make it possible to load

and unload clothing more easily.

■

Time-Released Dispenser

Detergent, fabric softener and bleach are dispensed separately at

the right time during wash cycle.

■

Automatic Wash Load Detection

Automatically detects the load and optimizes the washing time.

■

Child Lock

The Child lock prevents children from pressing any button to

change the settings during operation.

추가선택, 예약,

5

5

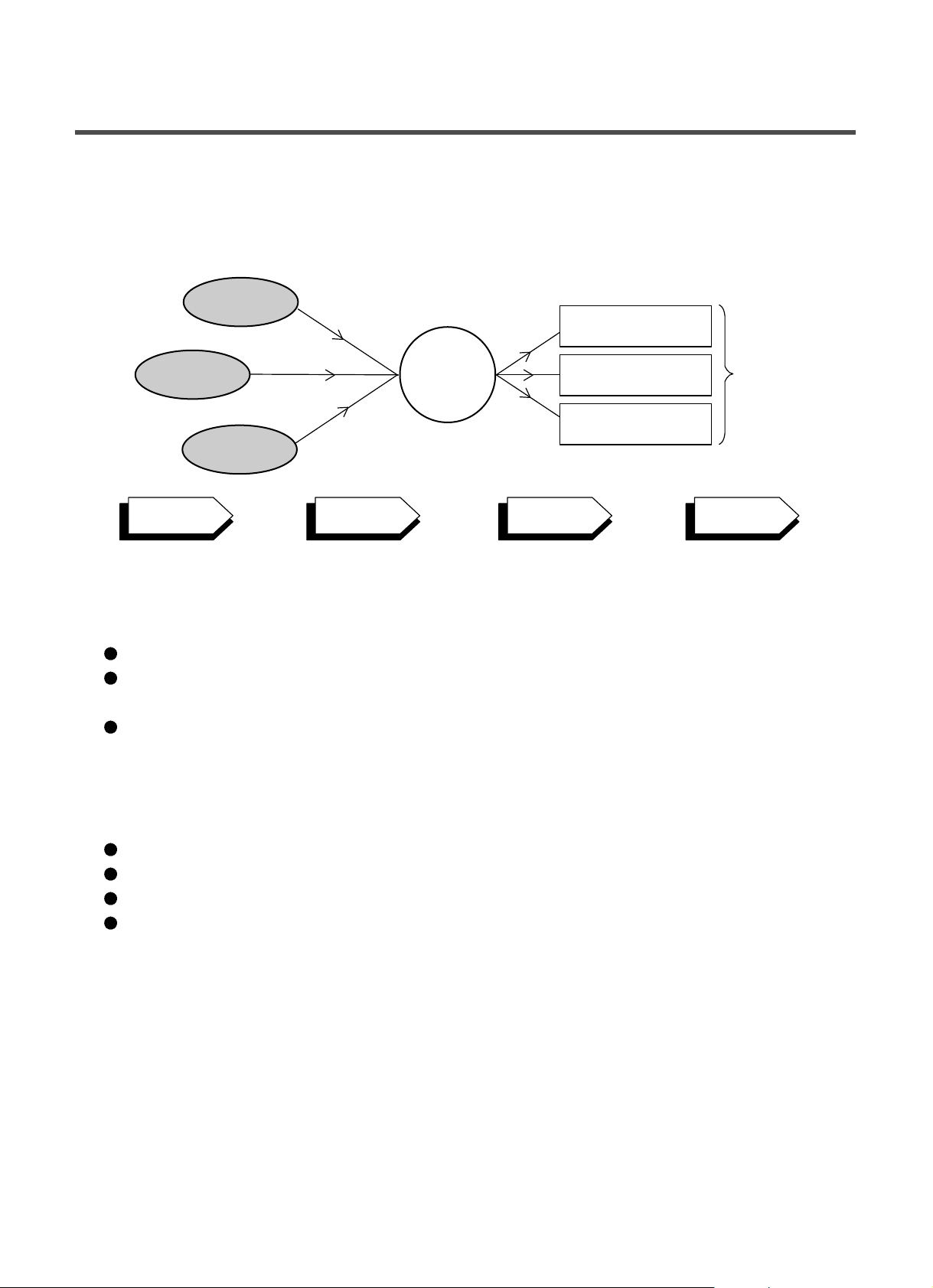

2-2. NEURO FUZZY WASHING TIME OPTIMIZATION

To get the best washing performance, optimal time is determined by the water temperature,

the selected washing temperature, and the size of the load.

2-3. WATER LEVEL CONTROL

This model incorporates a pressure sensor which can sense the water level in the tub.

The water supply is stopped when the water level reaches the preset level, the washing

program then proceeds.

Spinning does not proceed until the water in the tub drains to a certain level.

2-4. DOOR CONTROL

The door can be opened by pulling the door handle whenever washer is not in operation.

When the cycle is completed, the DOOR LOCKED light will turn off.

If a power failure has occurred while in operation, the door will unlock after 5 minutes.

Clicking sounds can be heard when the door is locked/unlocked.

NEURO-

FUZZY

load

size

selected

washing

temperature

water

temperature

washing time

rinsing time

spin rhythm, time

the best

washing

performance

SENSING

PROCESSING

DETERMINATION

EFFECT

6

2-5. THE DOOR CAN NOT BE OPENED

While program is operating

When a power failed and power plug is taken out in operation

While Door Lock lights turn on.

White the motor is in the process of intertial rotating, through the operation is paused.

2-6. DOOR LOCKED LAMP LIGHTS

When the frequency of water level is lower than 22.9 kHz

(It can be canceled when the frequency is more than 23.8 kHz)

When the temperature inside the tub is higher than 45 °C and water level is not 25.5 kHz

(It can be canceled when the water level is 25.5 kHz or the temperature inside the tub is lower than 40 °C)

2-7. CHILD LOCK

Use this option to prevent unwanted use of the washer. Press and hold OPTION button for 3 seconds to

lock/unlock control.

When Child lock is set, “ ” blinks and all buttons are disabled except the Power button. You can lock

the washer while it is operating.

7

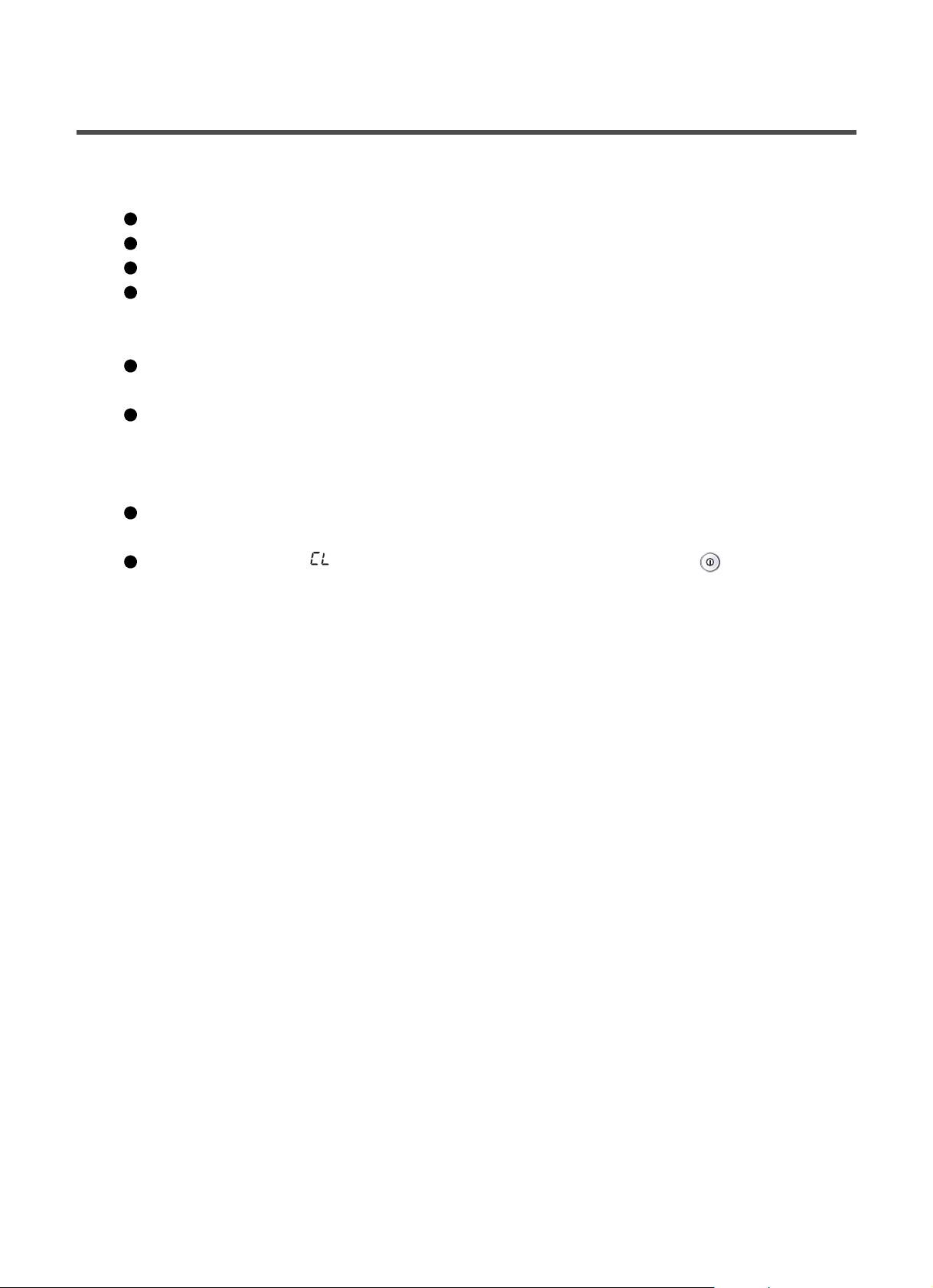

3. PARTS IDENTIFICATION

ACCESSORIES

울

란

제

리

란제리

8

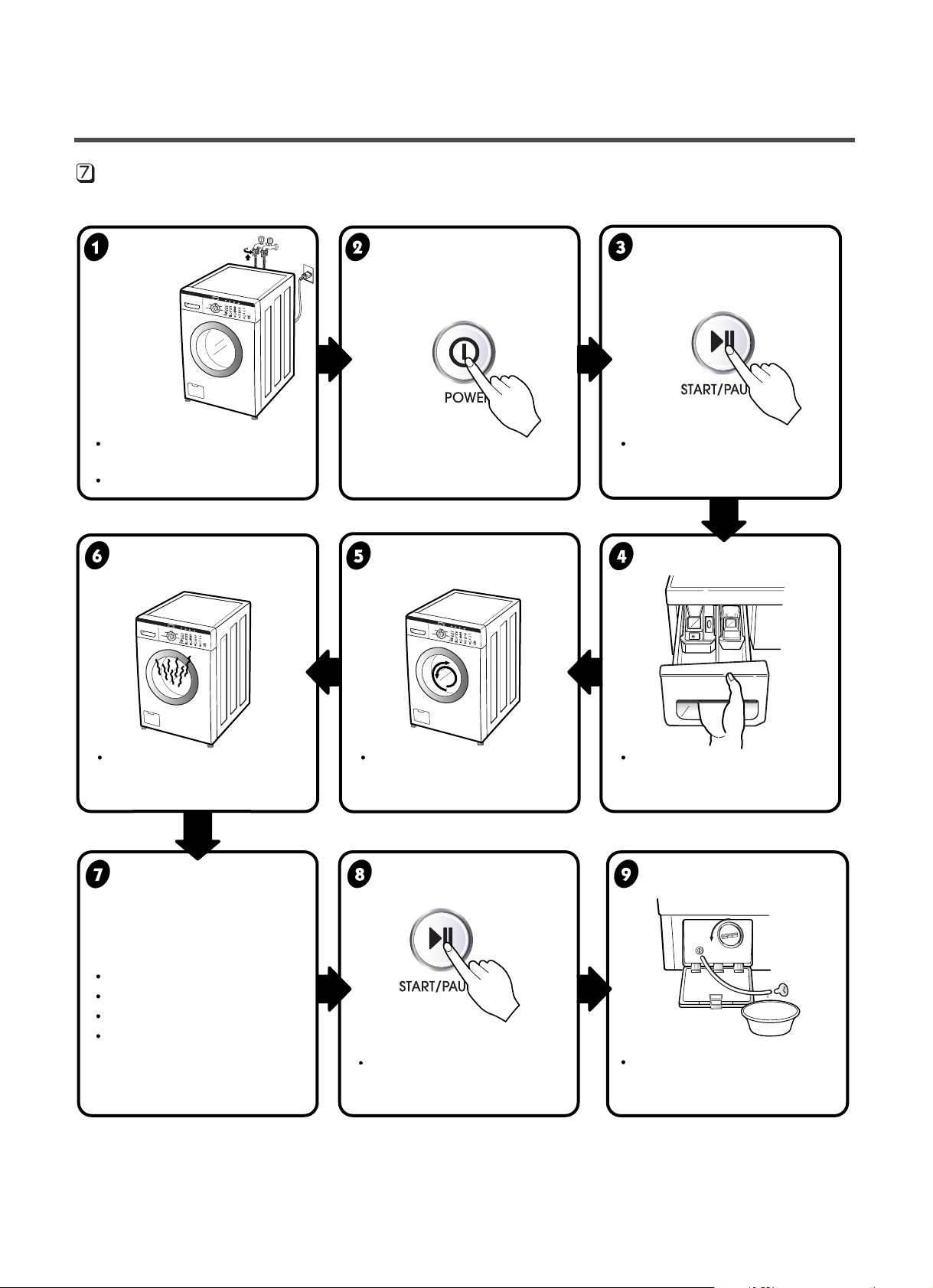

Before servicing, ask the customer what the trouble is.

Check the setup (power supply is 120 V AC, remove the transit bolts....).

Check with the troubleshooting guide.

Plan your service method by referring to the disassembly instructions.

Service the unit.

After servicing, operate the appliance to see whether it functions correctly.

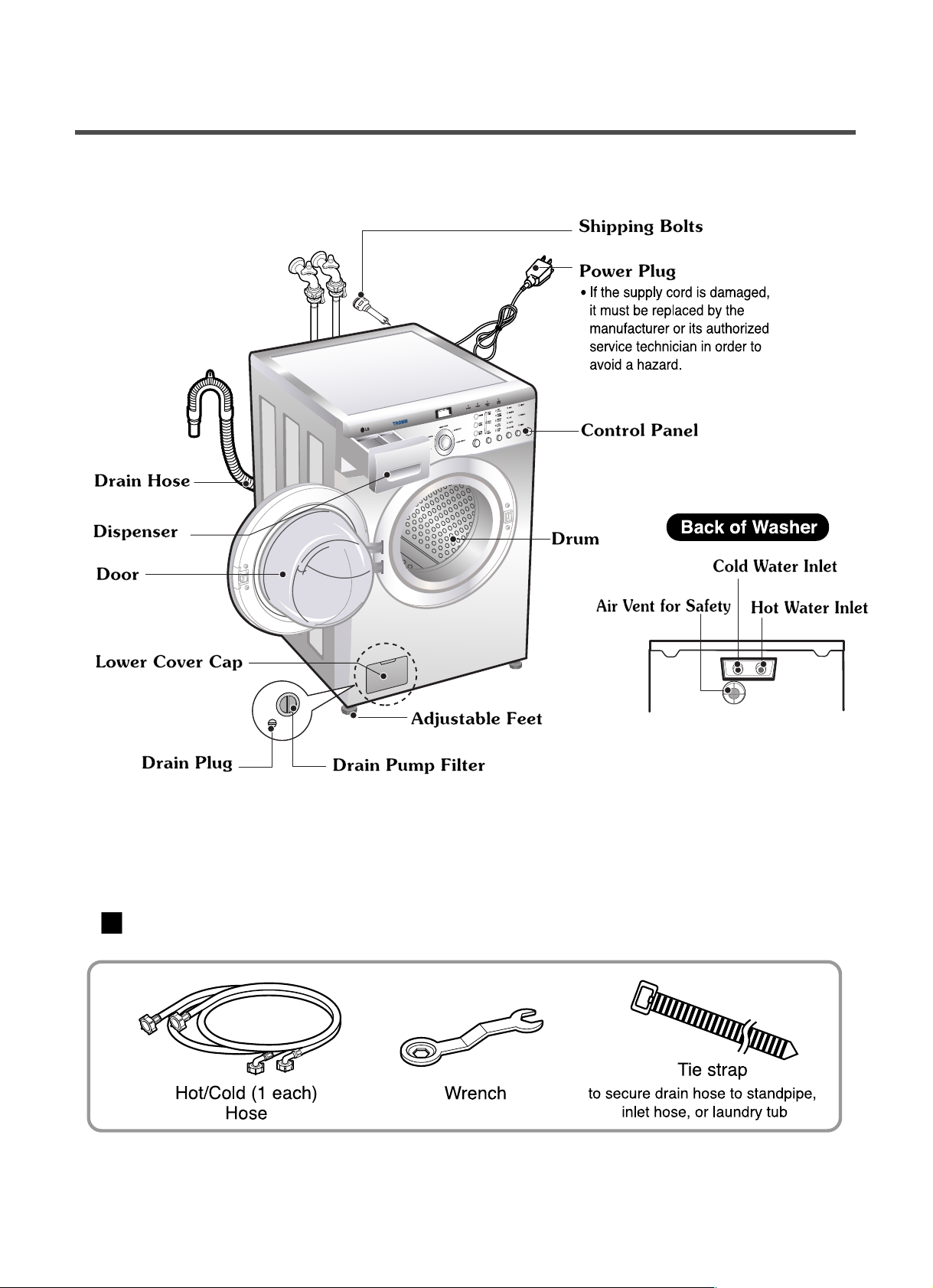

STANDARD INSTALLATION

The appliance should be installed as follows:

REMOVE THE SHIPPING INSTALL THE APPLIANCE ADJUST THE

BOLTS

ON A FLAT AND FIRM SURFACE

LEVELING

Remove the 4 shipping bolts Turn the leveling feet to adjust

with the supplied wrench. the appliance.

Do first lower side to remove easily.

Keep the shipping bolts and

spanner for future use.

Insert the 4 caps

(provided) into the hole.

Turn clockwise to raise;

counterclockwise to lower.

4. INSTALLATION & TEST

9

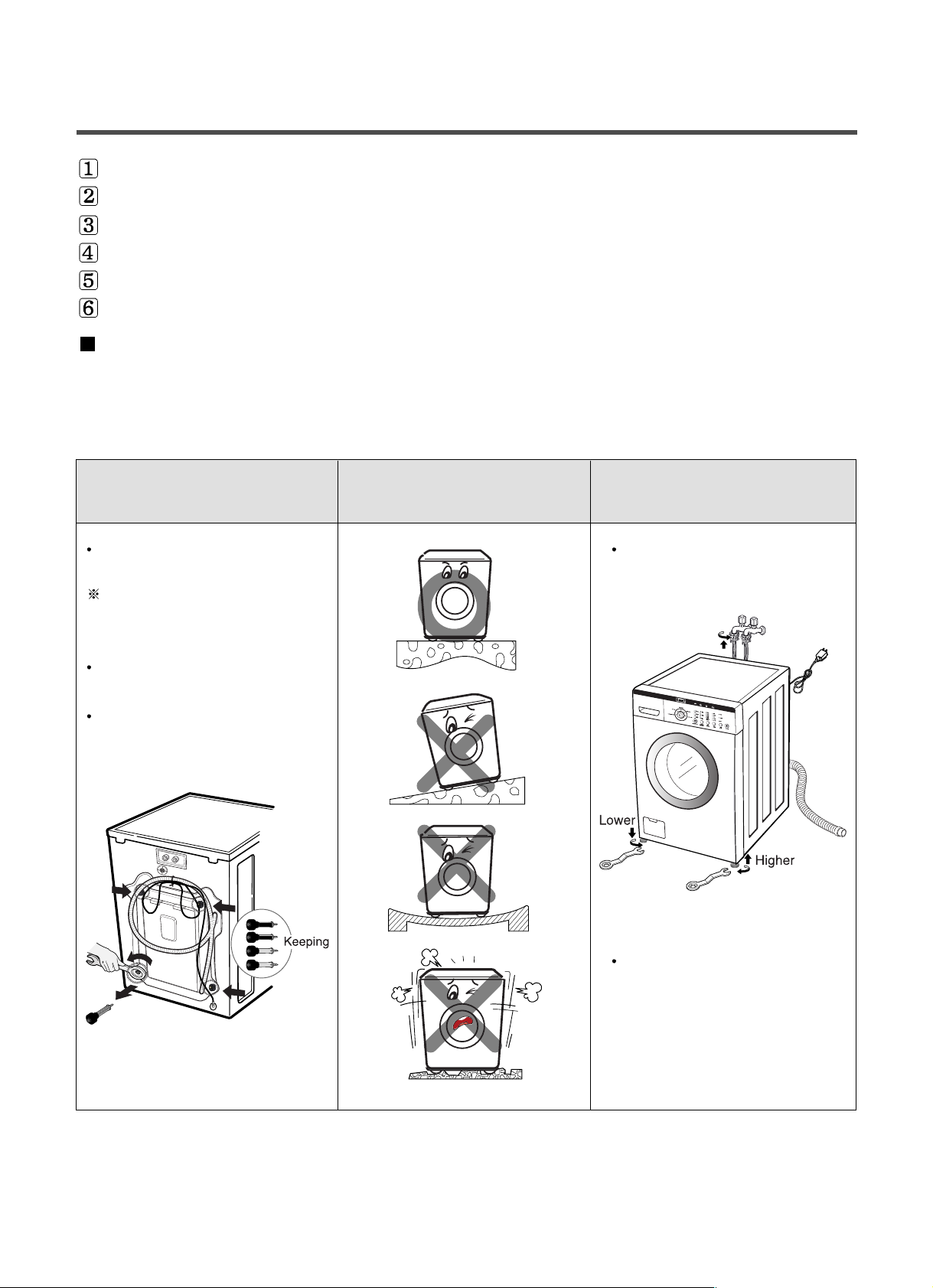

HOW TO CONNECT THE INLET HOSE

Verify that the rubber washer is inside of the

valve connector.

Tighten the inlet hose securely to prevent leaks.

CONNECT THE DRAIN HOSE

CONNECT POWER PLUG

The end of the drain hose should be placed less than 96”from the floor.

Connect the power plug to the wall outlet.

Avoid connecting several electric devices, as

doing so may cause a fire.

Make sure that the hose is not twisted.

Avoid submerging the end of the hose.

10

SOFTENER

MAX

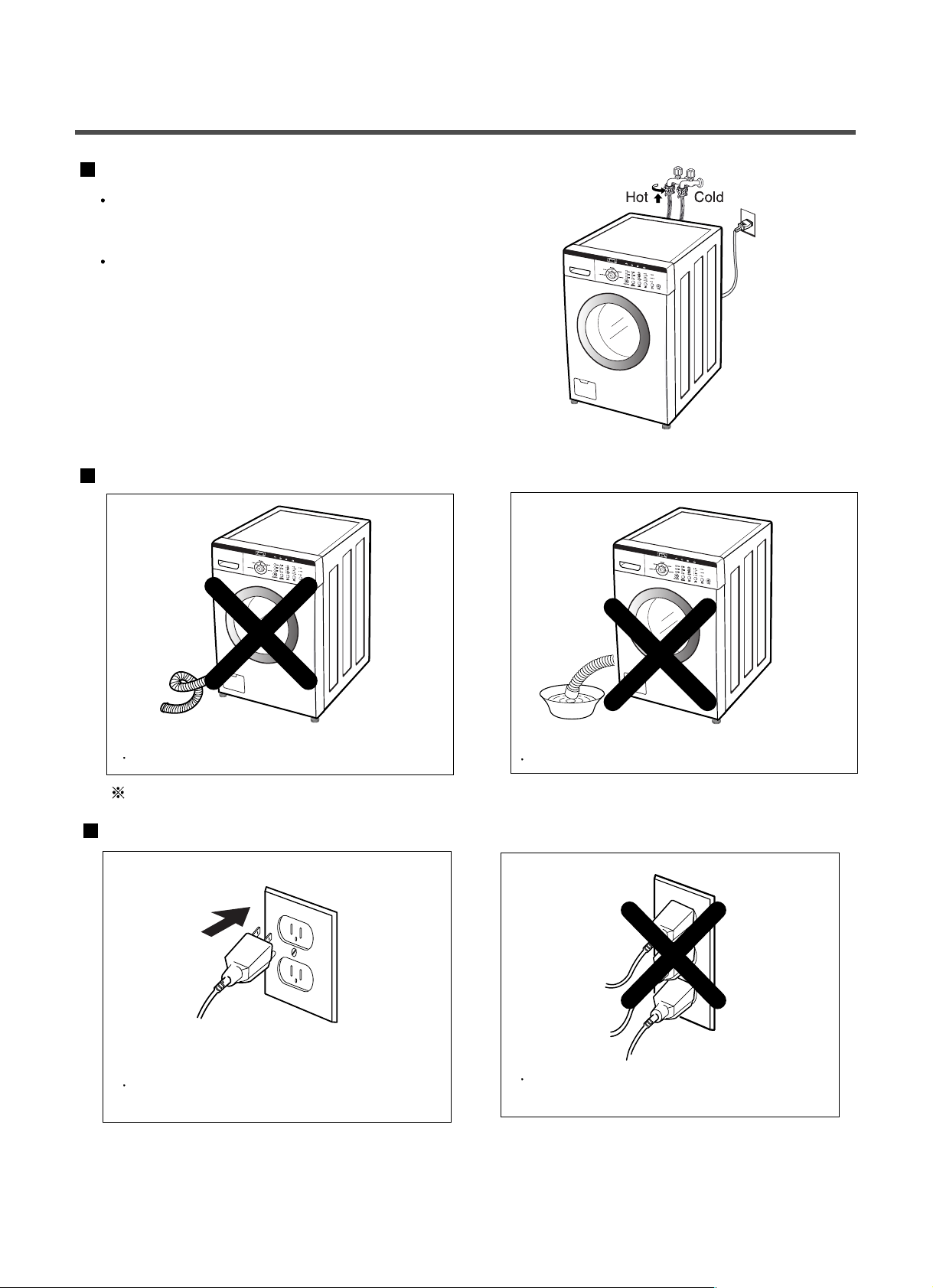

TEST OPERATION

Connect the power plug to

the outlet.

Connect the inlet hoses.

Power off and the power on.

Press the SPIN SPEED button.

Press the START/PAUSE button.

Check the spin and drain

functions.

Listen for a click to determine

if the door is unlocking.

Listen for a click to determine if

the door has locked.

If SVC is needed during check,

remove the remaining water by

pulling out the hose cap.

Preparation for Press the POWER button. Press

the

Start/Pause

washing. button.

Press the WASH/RINSE button Check if the drum rotates Check if water is supplied

and the present temperature will

clockwise and counterclockwise.

through the detergent dispenser.

be displayed.

Check the water Check the automatic Check the water supply.

temperature. reverse rotation.

Check the drain and spin

Press the

Water removal

functions.

START/PAUSE button.

11

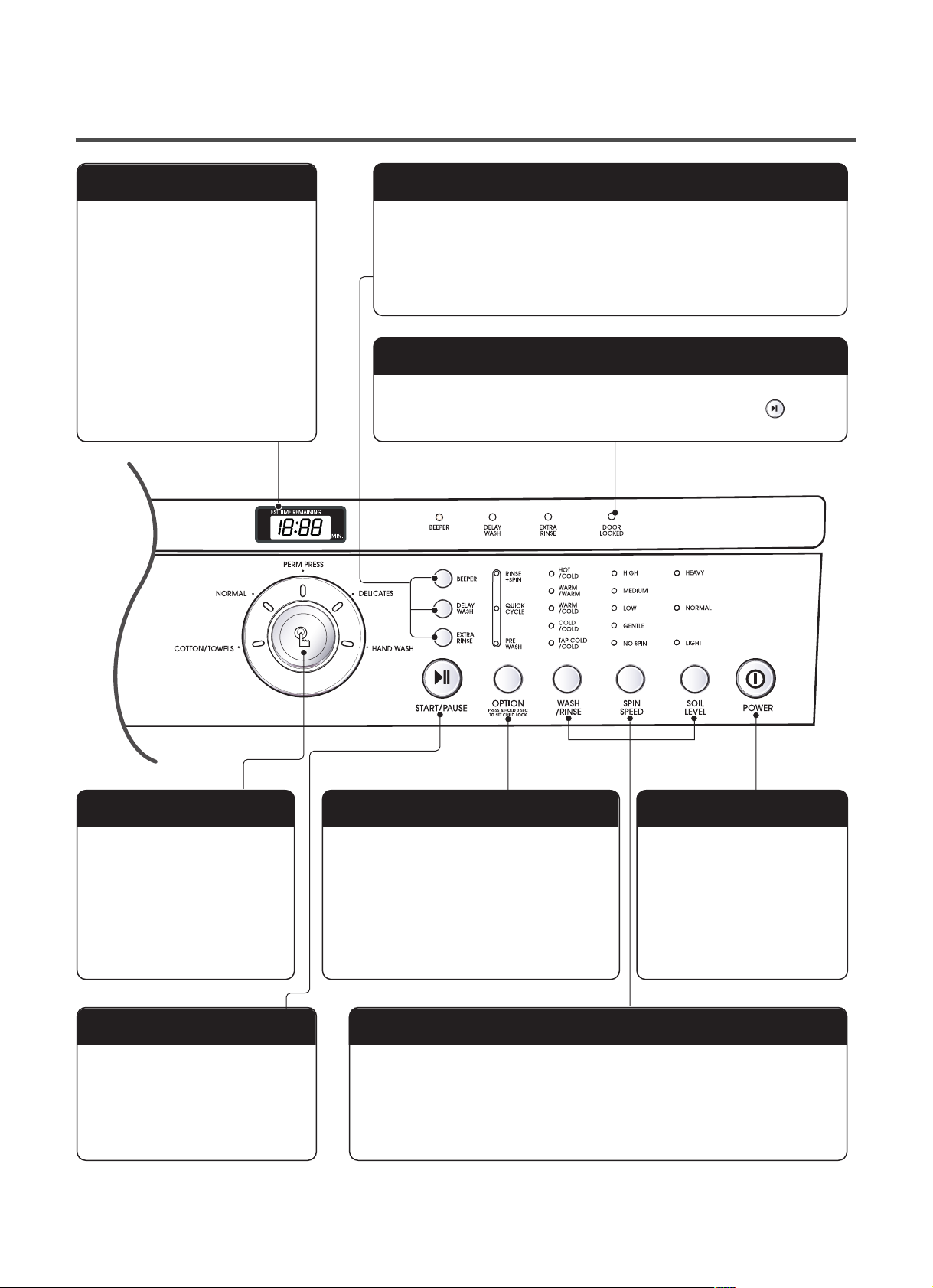

5. OPERATION

EST. TIME REMAINING

• This display shows:

a) the estimated time remaining

in the cycle when operation.

b) an error code when an error

has been detected.

CYCLE SELECTOR

• Press the Cycle selector to

select cycle designed for

different types of fabric and

soil levels.

START/PAUSE button

• Use this button to start/stop the

washer.

WASH,RINSE temp., SPIN SPEED, SOIL LEVEL button

• Select a water temperature based on the type of load you are washing.

• To change the spin speed, press the Spin Speed button repeatedly

to cycle through available options.

• To change the soil level, press the Soil Level button repeatedly until

the desired setting is on.

OPTION button

• Prewash : Use this option for

loads that need pretreatment.

It adds 16 minutes prewash and drain.

POWER button

• Use this button to turn

power On/Off.

• Quick Cycle : The Quick offers a quick

cycle time.

• Rinse+Spin : Use this option to rinse

and then spin.

BEEPER, DELAY WASH, EXTRA RINSE button

• Use the Beeper button to turn the Beeper On/Off.

• Delay Wash allows the start of any cycle to be delayed for 1~9

hours.

• Extra Rinse provides an additional rinse.

DOOR LOCKED lamp

• Light whenever the door of the washer is locked.

• The door can be unlocked by pressing the Start/Pause

button to stop the washer.

**

Cool-down

**Approx.

(Minutes)

* Wash time is in minutes.

** The total working time will vary with the load size,

water temperature and ambient temperature.

12

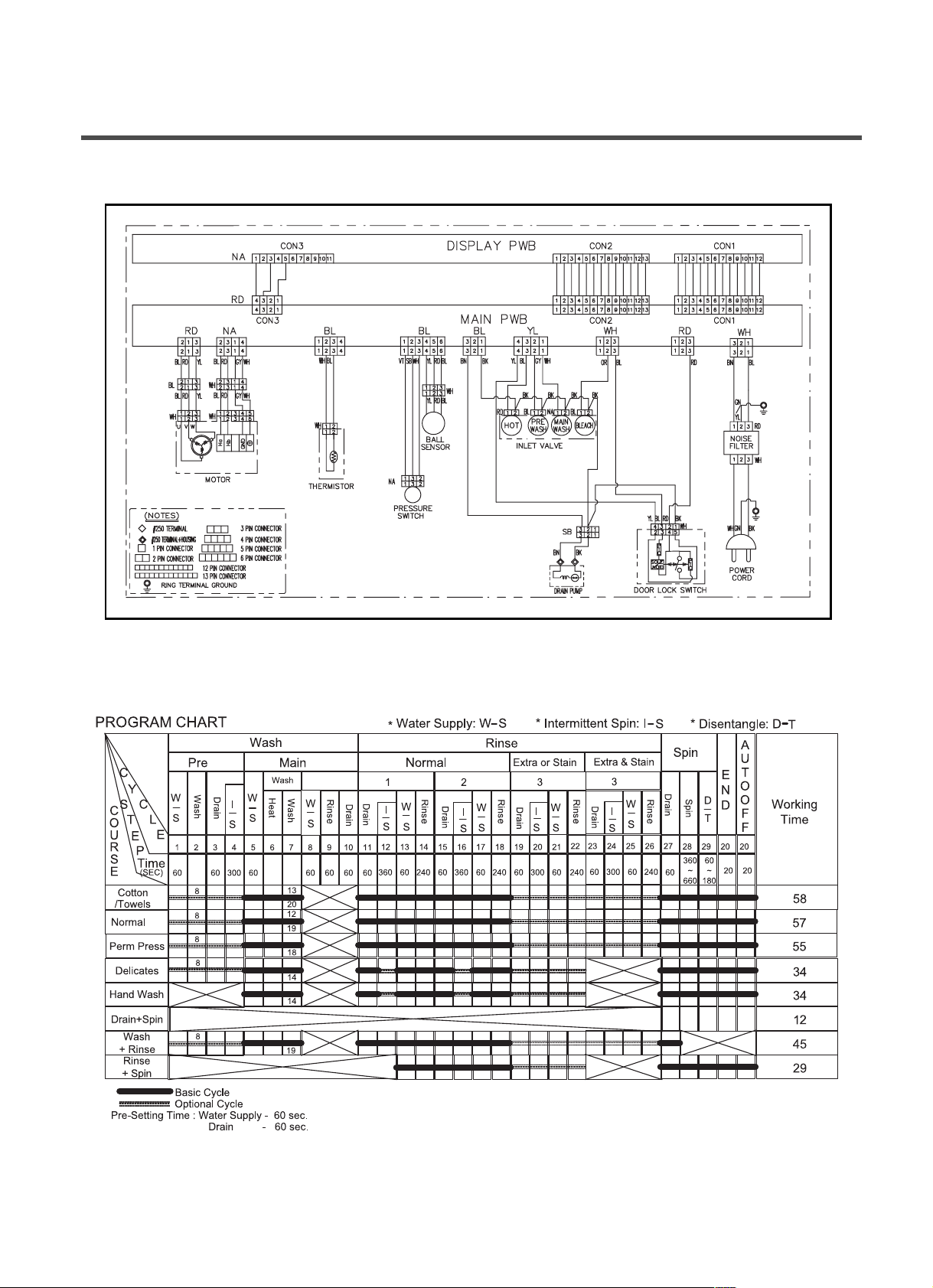

6. WIRING DIAGRAM/PROGRAM CHART

Loading...

Loading...