Page 1

OWNER'S MANUAL

LAUNDRY CENTER

Before beginning installation, read these instructions

carefully. This will simplify installation and ensure that the

product is installed correctly and safely. Leave these

instructions near the product after installation for future

reference.

ENGLISH

WK22**S6

MFL71728958

Rev.05_041421

www.lg.com

Copyright © 2020-2021 LG Electronics Inc. All Rights Reserved.

Page 2

TABLE OF CONTENTS

This manual may contain images or

content that may be different from the

model you purchased.

This manual is subject to revision by the

manufacturer.

SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE........................................................... 4

WARNING............................................................................................................ 6

INSTALLATION

Parts and Specifications ..................................................................................12

Installation Place Requirements ....................................................................15

Unpacking the Appliance ................................................................................17

Connecting Electric Dryer ...............................................................................18

Installing the Vent Kit of Dryer.......................................................................22

Venting the Dryer.............................................................................................23

Connecting Gas Dryer .....................................................................................24

Connecting the Water Supply Hose...............................................................26

Installing the Drain Hose ................................................................................28

Levelling the Appliance ...................................................................................29

Disassembly......................................................................................................32

OPERATION-WASHER

Operation Overview.........................................................................................34

Preparing the Wash Load ...............................................................................35

Adding Detergents and Softeners .................................................................36

Control Panel and Programme Table............................................................38

Extra Options and Functions ..........................................................................44

OPERATION-DRYER

Operation Overview.........................................................................................46

Preparing the Laundry ....................................................................................46

Control Panel and Programme Table............................................................48

Extra Options and Functions ..........................................................................53

SMART FUNCTIONS

Using LG ThinQ Application............................................................................56

Smart Diagnosis ...............................................................................................58

Page 3

MAINTENANCE

Washer ..............................................................................................................60

Dryer..................................................................................................................63

TROUBLESHOOTING

Washer ..............................................................................................................65

Dryer..................................................................................................................72

Common............................................................................................................78

Page 4

4

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

The following safety guidelines are intended to prevent unforeseen

risks or damage from unsafe or incorrect operation of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as

described below.

Safety Messages

This symbol is displayed to indicate matters and operations

that can cause risk. Read the part with this symbol carefully

and follow the instructions in order to avoid risk.

WARNING

This indicates that the failure to follow the instructions can

cause serious injury or death.

CAUTION

This indicates that the failure to follow the instructions can

cause the minor injury or damage to the product.

Safety for a Dryer

WARNING

Fire Hazard

Failure to follow safety warnings exactly could result in serious

injury, death or property damage.

Do not install a booster fan in the exhaust duct.

Install all clothes dryer in accordance with the installation

instructions of the manufacturer of dryer.

Page 5

SAFETY INSTRUCTIONS

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious

injury, death or property damage.

•

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

•

WHAT TO DO IF YOU SMELL GAS

-

Do not try to light any appliance.

-

Do not touch any electrical switch; do not use any phone in

your building.

-

Clear the room, building or area of all occupants.

-

Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

-

If you cannot reach your gas supplier, call the fire

department.

5

ENGLISH

•

Installation and service must be performed by a qualified

installer, service agency or your gas supplier.

Page 6

6

WARNING

SAFETY INSTRUCTIONS

WARNING - Risk of Fire

Install the clothes dryer according to the manufacturer’s

instructions and local codes.

•

Clothes dryer installation must be performed by a qualified

installer.

•

Do not install a clothes dryer with flexible plastic venting

materials. If flexible metal (foil type) duct is installed, it must

be of a specific type identified by the appliance manufacturer

as suitable for use with clothes dryers. Flexible venting

materials are known to collapse, be easily crushed, and trap

lint. These conditions will obstruct clothes dryer airflow and

increase the risk of fire.

•

To reduce the risk of severe injury or death, follow all

installation instructions.

WARNING

• To reduce the risk of explosion, fire, death, electric shock, injury or

scalding to persons when using this product, follow basic

precautions, including the following:

Technical Safety

• This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person

responsible for their safety.

• Children should be supervised to ensure that they do not play with

the appliance.

• The inlet water pressure must be between 50 kPa and 800 kPa.

Page 7

SAFETY INSTRUCTIONS

7

• Use a new hose or hose-set supplied with the appliance. Reusing old

hoses can cause a water leak and subsequent property damage.

• Ventilation openings must not be obstructed by a carpet.

• Do not dry unwashed items in the appliance.

• Fabric softeners, or similar products, should be used as specified by

the fabric softener instructions.

• Remove all objects from pockets such as lighters and matches.

• Never stop the appliance before the end of the drying cycle unless all

items are quickly removed and spread out so that the heat is

dissipated.

• The appliance is not to be used if industrial chemicals have been used

for cleaning.

• Items that have been soiled with substances such as cooking oil,

vegetable oil, acetone, alcohol, petroleum, kerosene, spot removers,

turpentine, waxes and wax removers should be washed in hot water

with an extra amount of detergent before being dried in the

appliance.

• Do not drink the condensed water. Failure to do so may result in foodborne illnesses.

• If the supply cord is damaged, it must be replaced by the

manufacturer or its service agents or similarly qualified person in

order to avoid a hazard.

ENGLISH

• The lint filter must be cleaned frequently.

• Lint must not to be allowed to accumulate around the appliance.

• Do not spray dry cleaning detergent directly onto the appliance or

use the appliance to dry clothes left with dry cleaning detergent.

• Do not dry clothes stained with oil substances. Oil substances

(including edible oils) stained on clothes cannot be completely

removed even after washing with water.

• The appliance must not be supplied through an external switching

device, such as a timer, or connected to a circuit that is regularly

switched on and off by a utility.

• Remove clothes from the product immediately when drying is

complete or the power is turned off during the drying process.

Page 8

8

SAFETY INSTRUCTIONS

Leaving clothes that has been dried in the appliance unattended

could result in fire. Clothes not removed from the appliance after

drying could result in fire. Remove clothes immediately after drying,

and then hang or lay the clothes flat to cool.

• This appliance is intended to be used in household only.

Maximum Capacity

The maximum capacity in some cycles for dry clothes to be used is

Wash : 22 kg, Dry : 11 kg (Dry Clothes) / 22 kg (Wet Clothes)

.

Installation

• Never attempt to operate the appliance if it is damaged,

malfunctioning, partially disassembled, or has missing or broken

parts, including a damaged cord or plug.

• This appliance should only be transported by two or more people

holding the appliance securely.

• Do not install the appliance in a damp and dusty place. Do not install

or store the appliance in any outdoor area, or any area that is subject

to weathering conditions such as direct sunlight, wind, rain, or

temperatures below freezing.

• Make sure the power plug is completely pushed into the power

outlet.

• Do not plug the appliance into multiple outlet sockets, power boards,

or an extension power cable.

• Do not modify the power plug provided with the appliance. If it does

not fit the power outlet, have a proper outlet installed by a qualified

electrician.

• This appliance is equipped with a power cord having an equipmentearthing / grounding conductor (earthing pin) and a grounding

power plug. The power plug must be plugged into an appropriate

outlet socket that is installed and earthed / grounded in accordance

with all local codes and ordinances.

• Improper connection of the equipment-grounding conductor can

result in risk of electric shock. Check with a qualified electrician or

Page 9

SAFETY INSTRUCTIONS

service personnel if you are in doubt as to whether the appliance is

properly grounded.

9

• This appliance must not be installed behind a lockable door, a sliding

door or a door with a hinge on the opposite side to that of the

appliance, in such a way that a full opening of the appliance door is

restricted.

• Tighten the drain hose to avoid separation.

• If the power cord is damaged or the hole of the socket outlet is loose,

do not use the power cord and contact an authorized service centre.

Operation

• To avoid breaking the door glass, do not push too hard on the door

when closing.

• Do not apply any sharp objects to the control panel in order to

operate the appliance.

• Do not attempt to separate any panels or disassemble the appliance.

• Do not repair or replace any part of the appliance. All repairs and

servicing must be performed by qualified service personnel unless

specifically recommended in this Owner's Manual. Use only

authorized factory parts.

• Do not push down the door excessively, when the appliance door is

open.

ENGLISH

• Do not put animals, such as pets into the appliance.

• Do not wash rugs, mats, shoes or pet blankets, stuffed toys, or any

other items other than clothes or sheets, in this machine.

• Keep the area underneath and around the appliance free of

combustible materials such as lint, paper, rags, chemicals, etc.

• Do not leave the appliance door open. Children may hang on the door

or crawl inside the appliance, causing damage or injury.

• Do not put in, wash or dry articles that have been cleaned in, washed

in, soaked in, or spotted with combustible or explosive substances

(such as waxes, wax removers, oil, paint, gasoline, degreasers,

drycleaning solvents, kerosene, petrol, spot removers, turpentine,

Page 10

10

SAFETY INSTRUCTIONS

vegetable oil, cooking oil, acetone, alcohol, etc.). Improper use can

cause fire or explosion.

• Do not use or store flammable or combustible substances (ether,

benzene, alcohol, chemical, LPG, combustible spray, gasoline,

thinner, petroleum, insecticide, air freshener, cosmetics, etc.) near

the appliance.

• Never reach into the appliance while it is operating. Wait until the

drum has completely stopped.

• Do not touch the door during a high temperature programme.

• In case of a water leak from the appliance or flood, disconnect the

power plug and contact the LG Electronics customer information

centre.

• Turn off water taps to relieve pressure on hoses and valves and to

minimize leakage if a break or rupture should occur. Check the

condition of the fill hoses; they should be replaced after 5 years.

• If there is a gas leakage (isobutane, propane, natural gas, etc.) within

the home, do not touch the appliance or power plug and ventilate the

area immediately.

• If the drain hose or inlet hose is frozen during winter, use it only after

thawing.

• Keep all washing detergents, softener and bleach away from

children.

• Do not touch the power plug or the appliance controls with wet

hands.

• Do not bend the power cable excessively or place a heavy object on it.

• Avoid touching any water that is drained from the appliance during

the wash.

• Make sure that drainage is working properly. If water is not drained

properly, your floor may get flooded.

• When the air temperature is high and the water temperature is low,

condensation may occur and thus wet the floor.

• Wipe off dirt or dust on the contacts of the power plug.

Page 11

SAFETY INSTRUCTIONS

11

Maintenance

• Disconnect the appliance from the power supply before cleaning the

appliance. Setting the controls to the OFF or stand by position does

not disconnect this appliance from the power supply.

• Securely plug the power plug in the outlet socket after completely

removing any moisture and dust.

• Do not spray water inside or outside the appliance to clean it.

• Never unplug the appliance by pulling on the power cable. Always

grip the power plug firmly and pull straight out from the outlet

socket.

• Only qualified service personnel from LG Electronics service centre

should disassemble, repair, or modify the appliance. Contact an LG

Electronics customer information centre if you move and install the

appliance in a different location.

Disposal

• Before discarding an old appliance, unplug it. Cut off the cable

directly behind the appliance to prevent misuse.

ENGLISH

• Dispose of all packaging materials (such as plastic bags and

styrofoam) away from children. The packaging materials can cause

suffocation.

• Remove the door before disposing of or discarding this appliance to

avoid the danger of children or small animals getting trapped inside.

Page 12

12

NOTE

INSTALLATION

INSTALLATION

Parts and Specifications

• Appearance and specifications may change without notice to improve the quality of the appliance.

h

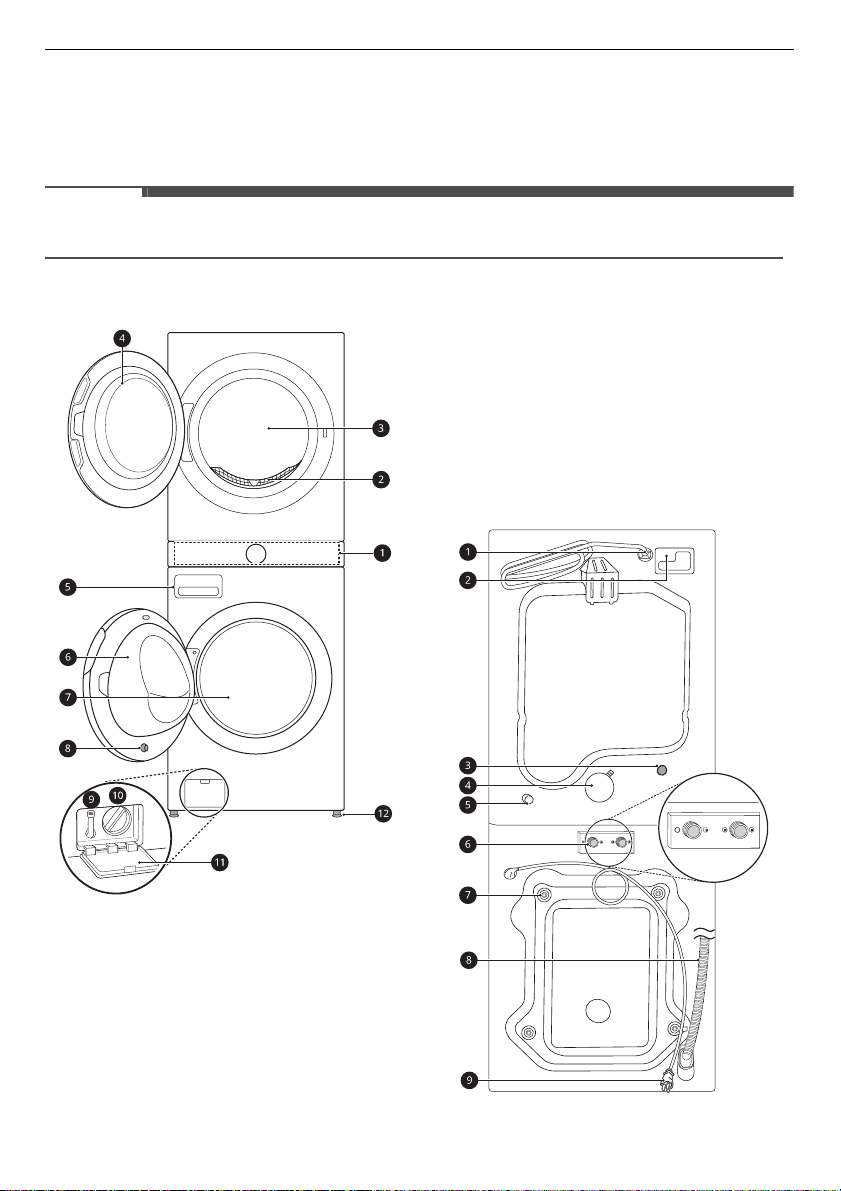

Front View

Washer Door Magnet

i

Drain Hose

j

Drain Pump Filter

k

Drain Pump Filter Cover

l

Leveling Feet

Rear View

a

Control Panel

b

Lint Filter

c

Dryer Drum

d

Dryer Door

e

Detergent Dispenser Drawer

f

Washer Door

g

Washer Drum

a

Power Cord (for Gas Models)

Page 13

INSTALLATION

WARNING

13

b

Terminal Block Access Panel (for Electric

Models)

c

Cold Water Inlet

d

Exhaust Duct Outlet

e

Gas connection (for Gas Models)

f

Hot and Cold Water Inlets

g

Shipping Bolts

h

Drain Hose

i

Power Cord (for Washer)

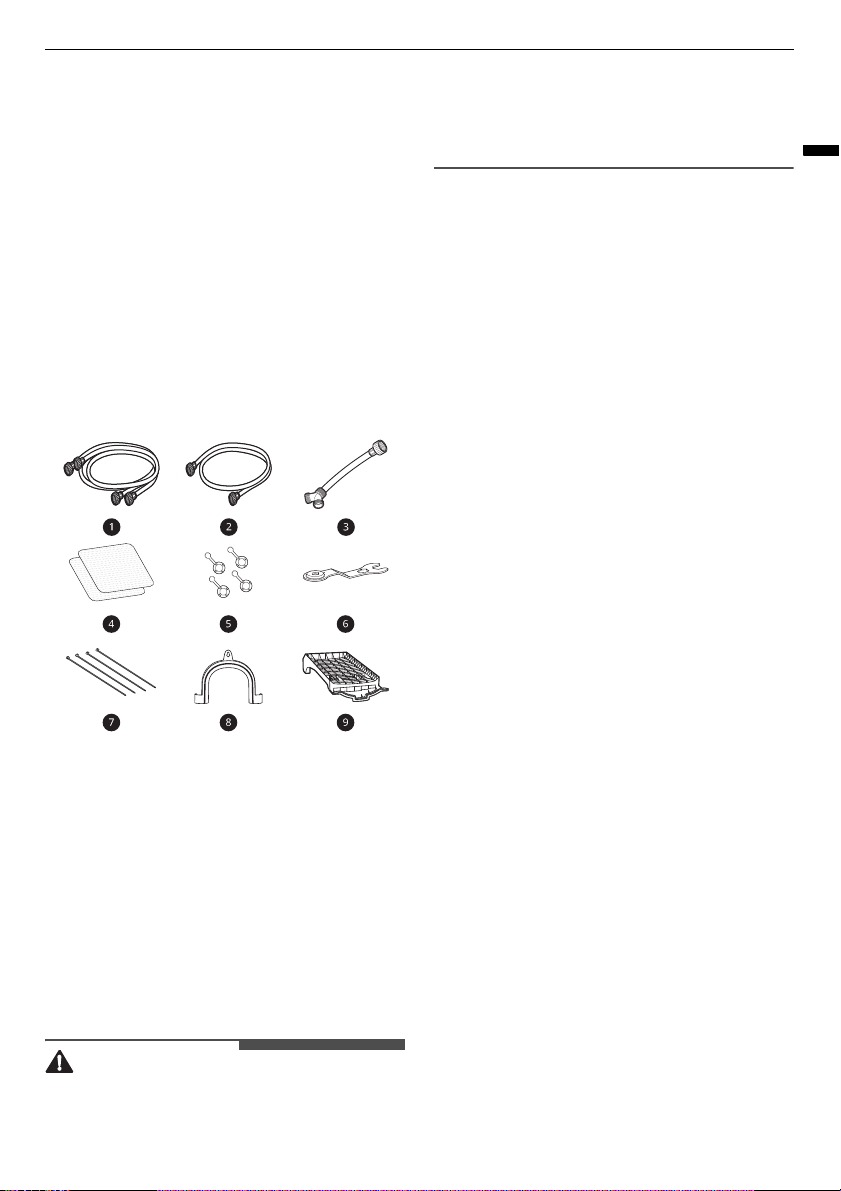

Accessories

malfunction, property damage or bodily injury

caused by the use of separately purchased

unauthorized components, parts, or non-LG

products.

ENGLISH

a

Hot and Cold Water Hoses (for Washer)

b

Cold Water Hose (for Dryer)

c

Connecting Supply Hose

d

Non-skid Pads

e

Hole Caps

f

Wrench

g

Tie Straps

h

Elbow Bracket (for securing drain hose)

i

Drying Rack

• For your safety and for extended product life,

use only authorized components. The

manufacturer is not responsible for product

Page 14

14

INSTALLATION

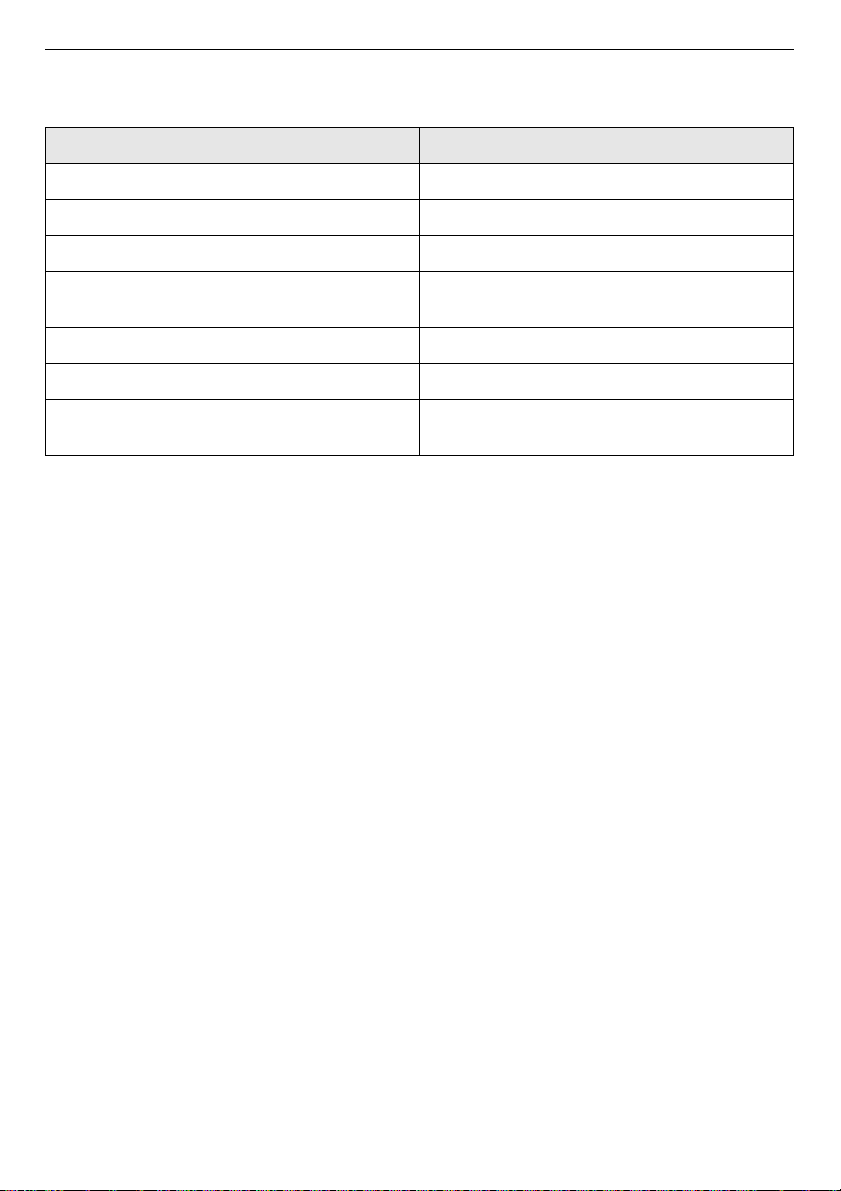

Specifications

Model WK22**S6

Power supply

Dimensions (Width X Depth X Height)

Product weight

Max. capacity

Maximum Power

Permissible Inlet Water pressure

Gas Requirements

120 V~ 60 Hz

700 mm X 770 mm X 1890 mm

142 kg

Washing : 22 kg

Drying : 11 kg (Dry Clothes) / 22 kg (Wet Clothes)

1320 W (washing) / 400 W (drying)

50 KPa ~ 800 KPa (0.5~8.0 kgf/cm²)

NG: 10.2 - 26.7 cm WC

LP: 20.4 - 33.1 cm WC

Page 15

INSTALLATION

E

15

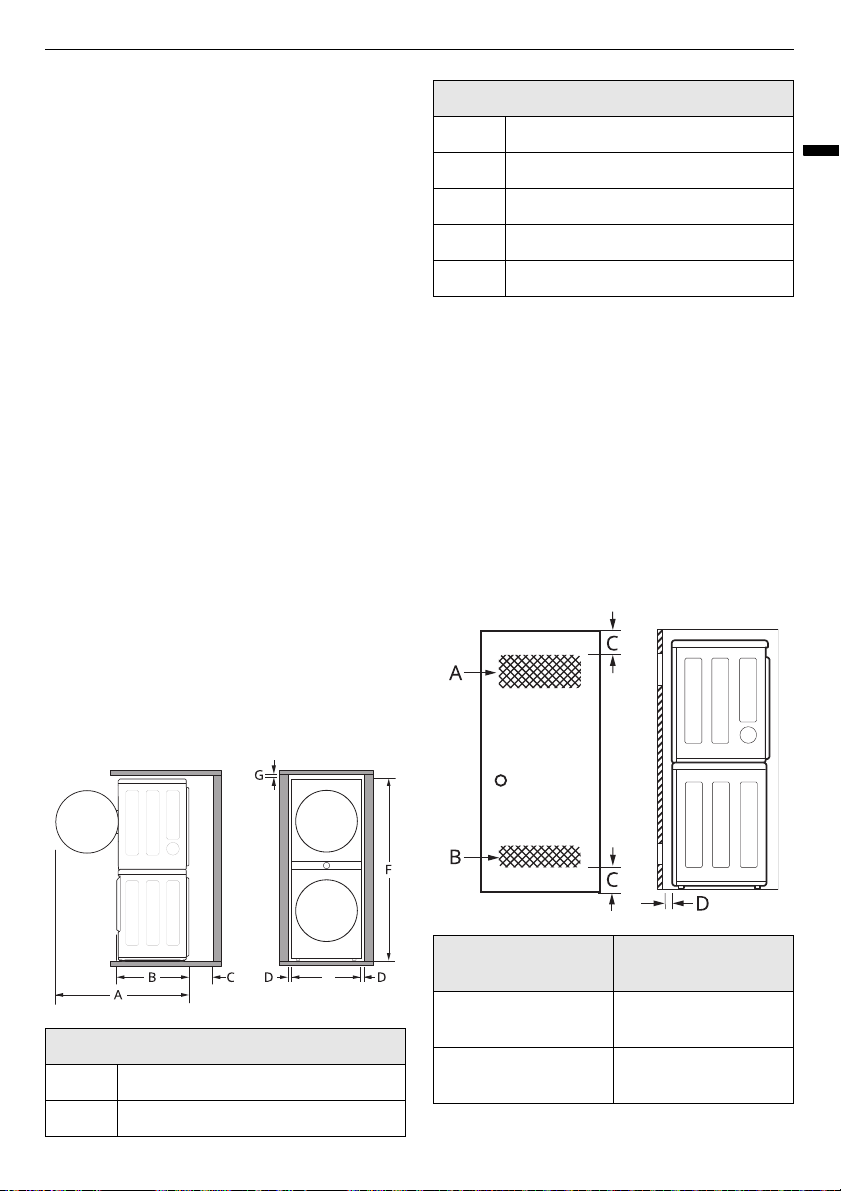

Installation Place Requirements

Before installing the appliance, check the following

information to make sure that the appliance

should be installed in a correct place.

Flooring

• To minimize noise and vibration, install the

washer on a level, solidly constructed floor

capable of supporting the appliance without

flexing or bouncing.

• The appliance must be installed on firm flooring

to minimize vibration during the spin cycle.

Concrete flooring is best, but a wood floor is

sufficient, provided it is built to FHA standards.

• The floor under the appliance must not slope

more than

side.

• Installing on carpeting and soft tile surfaces is

not recommended.

• Never install the appliance on a platform or

weakly supported structure.

Floor Installation

To ensure sufficient clearance for water inlet hoses,

drain hose and airflow, allow minimum clearances

of at least

appliance. Be sure to allow for wall, door, or floor

moldings that may increase the required

clearances.

2.5 cm

2.5 cm

at the sides and

from front to back or side to

10 cm

behind the

Dimensions and Clearances

C10 cm

D2.5 cm

E70 cm

F 189 cm

G2.5 cm

Clearances

The following clearances are recommended for the

appliance.

• Additional clearances should be considered for

ease of installation and servicing.

• Additional clearances should be considered on

all sides of the appliance to reduce noise

transfer.

Installation spacing for Recessed Area or Closet Installation

ENGLISH

Dimensions and Clearances

A 139.6 cm

B 77 cm

Description

A: Upper Ventilation

Opening

B: Lower Ventilation

Opening

Dimension/

Clearance

2

310 cm

2

155 cm

Page 16

16

NOTE

CAUTION

NOTE

INSTALLATION

Description

C: Distance to

Ventilation Opening

D: Front Clearance 10 cm

Closet Ventilation Requirements

Closets with doors must have both an upper and

lower vent to prevent heat and moisture buildup in

the closet. One upper vent opening with a

minimum opening of 310 cm

lower than 6 feet above the floor. One lower vent

opening with a minimum opening of 155 cm

be installed no more than one foot above the floor.

Install vent grills in the door or cut down the door

at the top and bottom to form openings. Louvered

doors with equivalent ventilation openings are also

acceptable.

• There should be at least a little space around the

appliance (or any other appliance) to eliminate

the transfer of vibration from one appliance to

another. If there is enough vibration, it could

cause appliances to make noise or come into

contact, causing paint damage and further

increasing noise.

• No other fuel-burning appliance can be installed

in the same closet as an appliance.

Dimension/

Clearance

7.6 cm

2

must be installed no

2

must

contribute to excessive vibration and unbalance,

errors and malfunction.

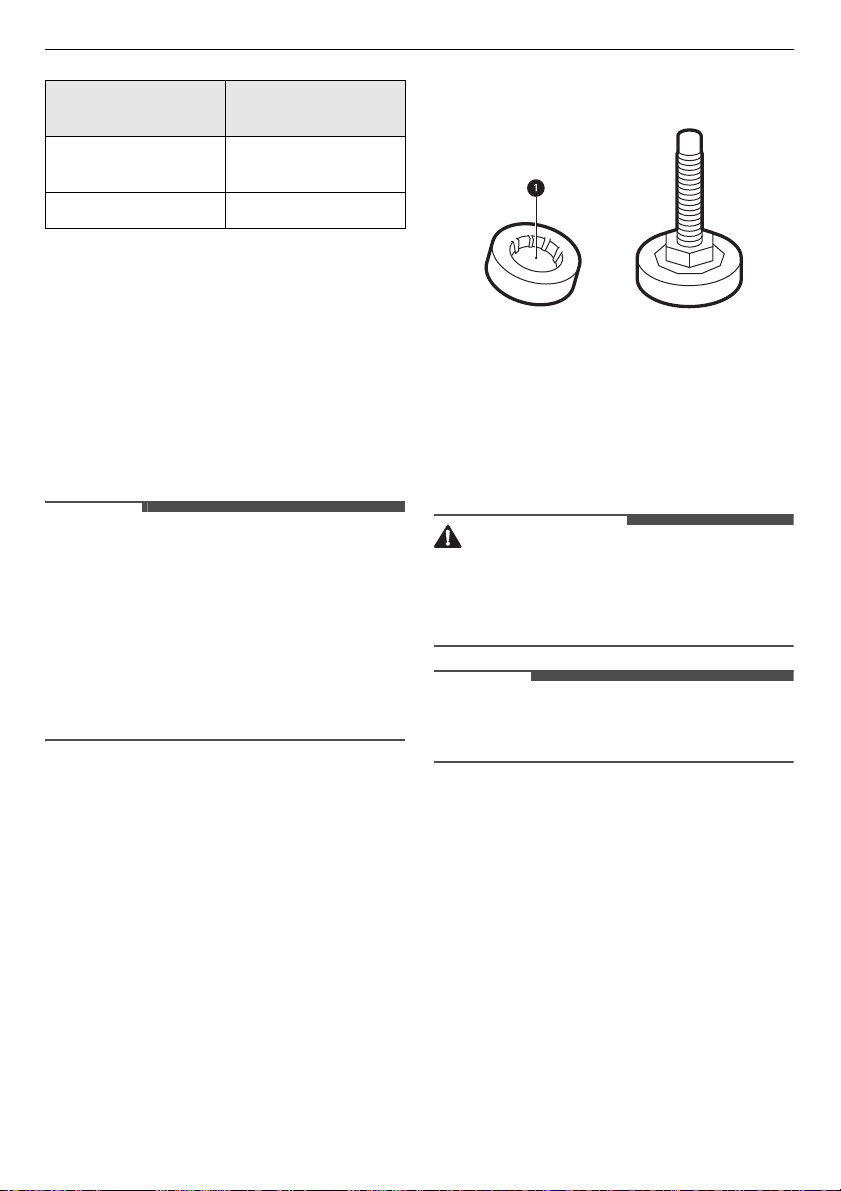

• To reduce vibration, we recommend placing at

least 15 mm thickness of rubber caps

each adjusting foot of the appliance, secured to

at least two floor beams with screws.

• If possible, install the appliance in one of the

corners of the room, where the floor is more

stable.

• Fit the rubber cups to reduce vibration.

• If the appliance is installed on the unstable floor

(e.g. wooden floor), the warranty does not cover

any damages and cost occurred due to the

installation on the unstable floor.

• You can purchase rubber cups (part No.

4620ER4002B

) from the LG service centre.

a

under

Wooden Floors (Suspended Floors)

When installing the appliance on wooden floors,

use rubber cups to reduce excessive vibration and

unbalance. Timber or suspended type flooring may

Electrical Connection

• Do not use an extension cord or double adapter.

• Always unplug the appliance and turn off the

water supply after use.

• Connect the appliance to an earthed socket in

accordance with current wiring regulations.

• The appliance must be positioned so that the

plug is easily accessible.

• Power outlet must be within 1 meter of either

side of the appliance.

Page 17

WARNING

• Repairs to the appliance must only be carried out

WARNING

NOTE

*

by qualified personnel. Repairs carried out by

inexperienced persons may cause injury or

serious malfunctioning. Contact your local

authorised LG repairer.

• The power plug must be plugged into an

appropriate outlet socket that is installed and

grounded/earthed in accordance with all local

codes and ordinances.

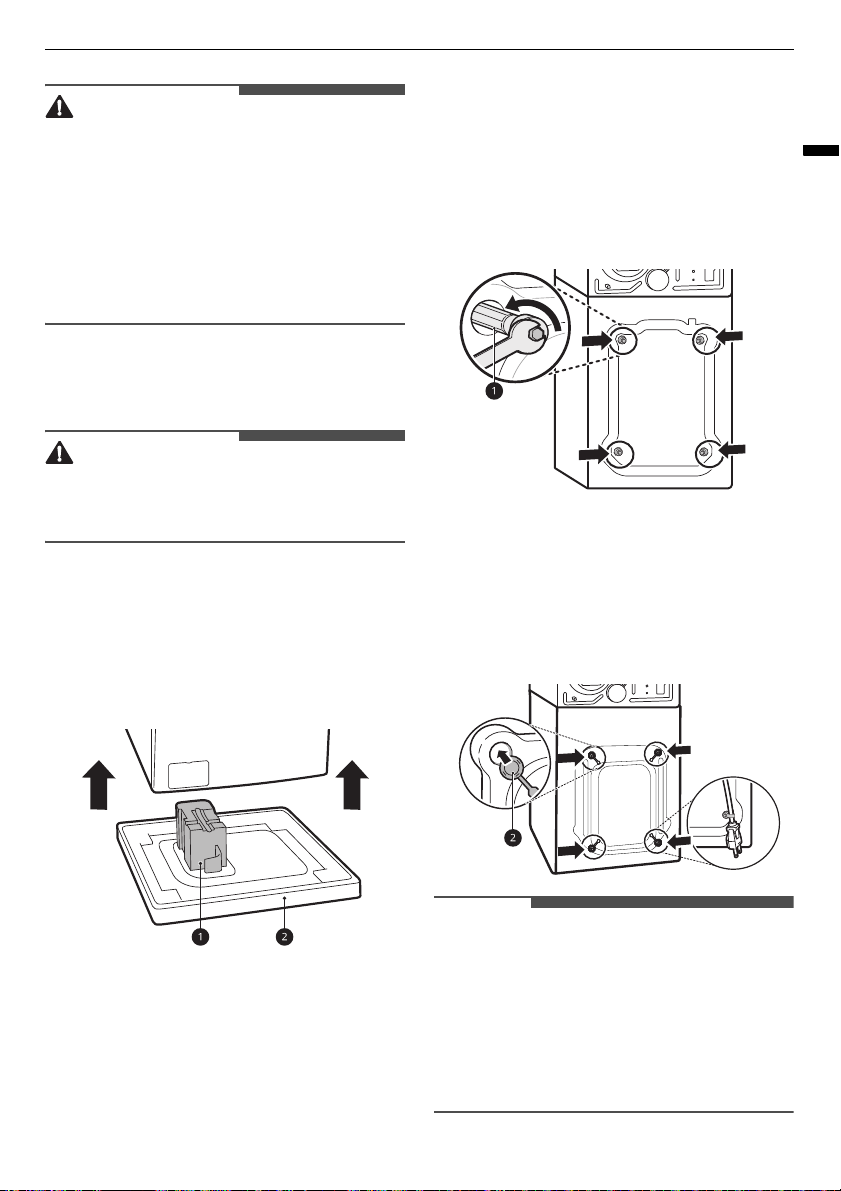

Unpacking the Appliance

• When installing this appliance, take adequate

measures to protect yourself, e.g. by wearing

protective gloves.

Lifting the Appliance Off the Foam Base

* This feature may vary depending on the model

purchased.

After removing the carton and shipping material,

lift the appliance off the foam base.

INSTALLATION

17

Removing the Transit Bolt Assemblies

To prevent the appliance from severe vibration and

breakage, remove transit bolts and retainers.

1

Starting with the bottom two transit bolts a,

use the spanner (included) to fully loosen all

transit bolts by turning them counterclockwise.

2

Remove the bolt assemblies by wiggling them

slightly while pulling them out.

3

Install the hole caps.

b

• Locate the hole caps

accessory pack or attached on the back.

included in the

ENGLISH

• Make sure the tub support

the base and is not stuck to the bottom of the

appliance.

• If you must lay the appliance down to remove

the carton base

appliance and lay it carefully on its side. Do not

lay the appliance on its front or back.

b

, always protect the side of the

a

* comes off with

• Save the transit bolts and retainers for future

use.

• To prevent damage to the appliance during

transport:

- Reinstall the transit bolts.

- Secure the power cord to the back of the

appliance.

Page 18

18

WARNING

WARNING

INSTALLATION

Connecting Electric Dryer

• To reduce the risk of fire or explosion, electric

shock, property damage, injury to persons, or

death when using this appliance, fulfill the

following requirements.

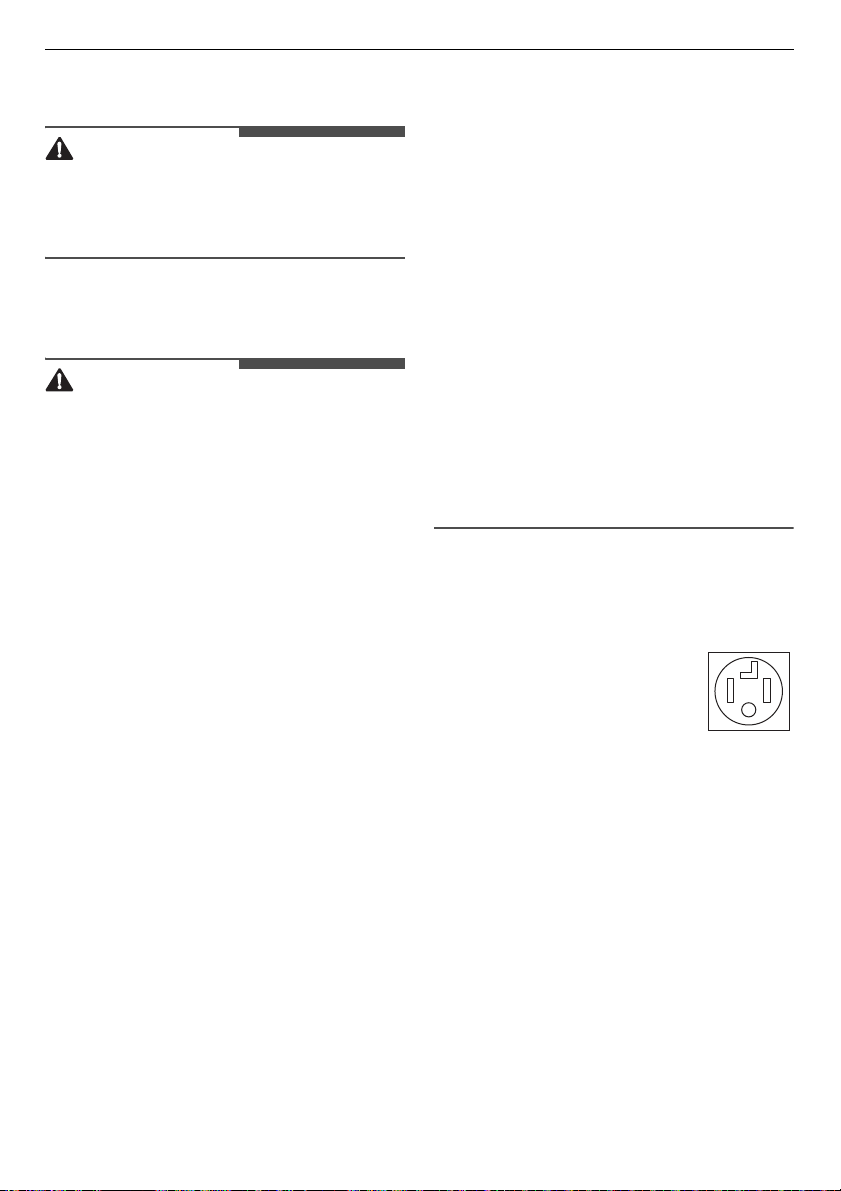

Electrical Requirements for Electric Models Only

• The wiring and grounding must conform to the

latest edition of the National Electrical Code,

ANSI/NFPA 70 and all applicable local

regulations. Please contact a qualified electrician

to check your home’s wiring and fuses to ensure

that your home has adequate electrical power to

operate the dryer.

• This dryer must be connected to a grounded

metal, permanent wiring system, or an

equipment-grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

dryer.

• The dryer has its own terminal block that must

be connected to a separate 240 VAC, 60-Hertz,

single-phase circuit, fused at 30 amperes (the

circuit must be fused on both sides of the line).

ELECTRICAL SERVICE FOR THE DRYER SHOULD

BE OF THE MAXIMUM RATE VOLTAGE LISTED ON

THE NAMEPLATE. DO NOT CONNECT THE DRYER

TO 110-, 115-, OR 120-VOLT CIRCUIT.

• If the branch circuit to dryer is 4.5 m or less in

length, use UL (Underwriters Laboratories) listed

No.-10 AWG wire (copper wire only), or as

required by local codes. If over 4.5 m, use ULlisted No.-8 AWG wire (copper wire only), or as

required by local codes. Allow sufficient slack in

wiring so the dryer can be moved from its

normal location when necessary.

• The power cord (pigtail) connection between the

wall receptacle and the dryer terminal block IS

NOT supplied with the dryer. Type of pigtail and

gauge of wire must conform to local codes and

with instructions on the following pages.

• Do not modify the plug and internal wire

provided with the dryer.

• The dryer should be connected to a 4-hole outlet.

• If the plug does not fit the outlet, a proper outlet

will need to be installed by a qualified electrician.

• Connect the power cord to the terminal block.

Each colored wire should be connected to the

same color screw. Wire color indicated on

manual is connected to the same color screw in

the block.

• Grounding through the neutral conductor is

prohibited for: (1) new branch-circuit

installations and (2) areas where local codes

prohibit grounding through the neutral

conductor.

• This dryer is supplied with the neutral wire

grounded. This white ground wire MUST BE

MOVED to the neutral terminal when a 4-wire

cord is to be used, or where grounding through

the neutral conductor is prohibited.

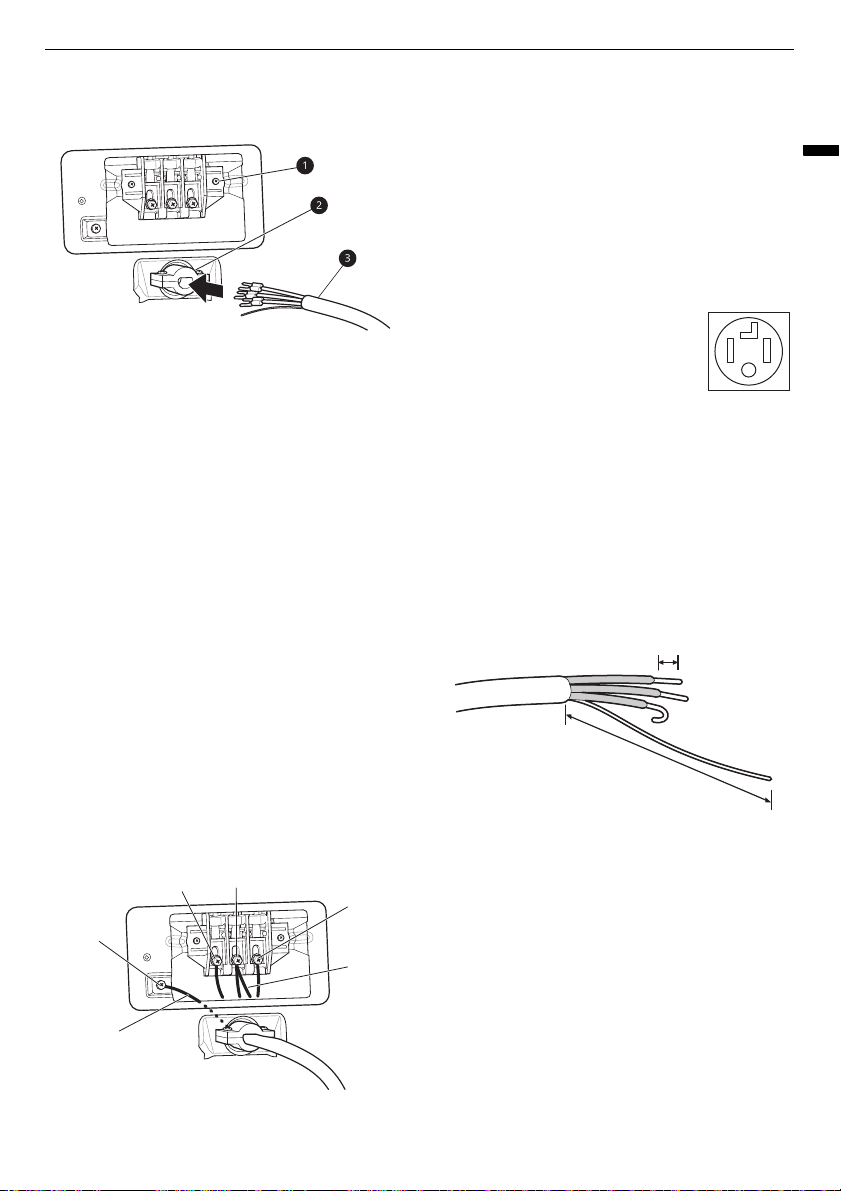

Four-Wire Power Cord

• A UL-listed strain relief is

required.

• Use a 30-amp, 240-volt, 4-wire, UL-listed

power cord with #10 AWG-minimum copper

conductor and closed loop or forked

terminals with upturned ends.

1

Remove the terminal block access cover on the

upper back of the appliance.

2

Install UL-listed strain relief into the power

cord through-hole.

Page 19

3

a

b

b

c

d

e

Thread a 30-amp, 240-volt, 4-wire, UL-listed

power cord with #10 AWG-minimum copper

conductor through the strain relief.

a

Terminal Block

b

UL-Listed Strain Relief

c

UL-Listed 4-Wire Power Cord

4

Transfer the appliance's ground wire from

behind the green ground screw to the center

screw of the terminal block.

5

Attach the two hot leads (black and red) of the

power cord to the outer terminal block screws.

6

Attach the neutral (white) wire to the center

screw of the terminal block

INSTALLATION

b

Hot Leads of Power Cord (Black and Red)

c

Neutral Wire (White)

d

Power Cord Ground Wire

e

Ground Screw (green)

Four-Wire Direct Wire

• A UL-listed strain relief is

required.

• Use UL-listed 4-wire #10 AWG minimum

copper conductor cable. Allow at least 1.5 m

of wire to allow for removal and reinstallation

of the dryer.

1

Remove 12.7 cm of the outer covering from the

wire and remove 12.7 cm of insulation from the

ground wire. Cut off approximately 3.8 cm

from the other three wires and strip 2.5 cm

insulation from each wire. Bend the ends of the

three shorter wires into a hook shape.

1’’ (2.5 cm)

19

ENGLISH

7

Attach the power cord ground wire to the

green ground screw.

8

Tighten all screws securely.

9

Reinstall the terminal block access cover.

a

White Wire moved from Ground Screw

5’’ (12.7 cm)

a

Ground Wire

2

Remove the terminal block access cover on the

upper back of the appliance.

3

Install UL-listed strain relief into the power

cord through-hole.

a

Page 20

20

a

b

c

a

b

b

c

d

e

INSTALLATION

4

Thread the 4-wire #10 AWG minimum copper

power cable prepared in step 1 through the

strain relief.

a

Terminal Block

b

UL-Listed Strain Relief

c

UL-Listed 4-Wire Power Cord

5

Transfer the appliance's ground wire from

behind the green ground screw to the center of

the terminal block.

6

Attach the two hot leads (black and red) of the

power cord to the outer terminal block screws.

7

Attach the neutral (white) wire to the center

screw of the terminal block.

8

Attach the power cord ground wire to the

green ground screw.

c

Neutral Wire (White)

d

Power Cord Ground Wire

e

Ground Screw (green)

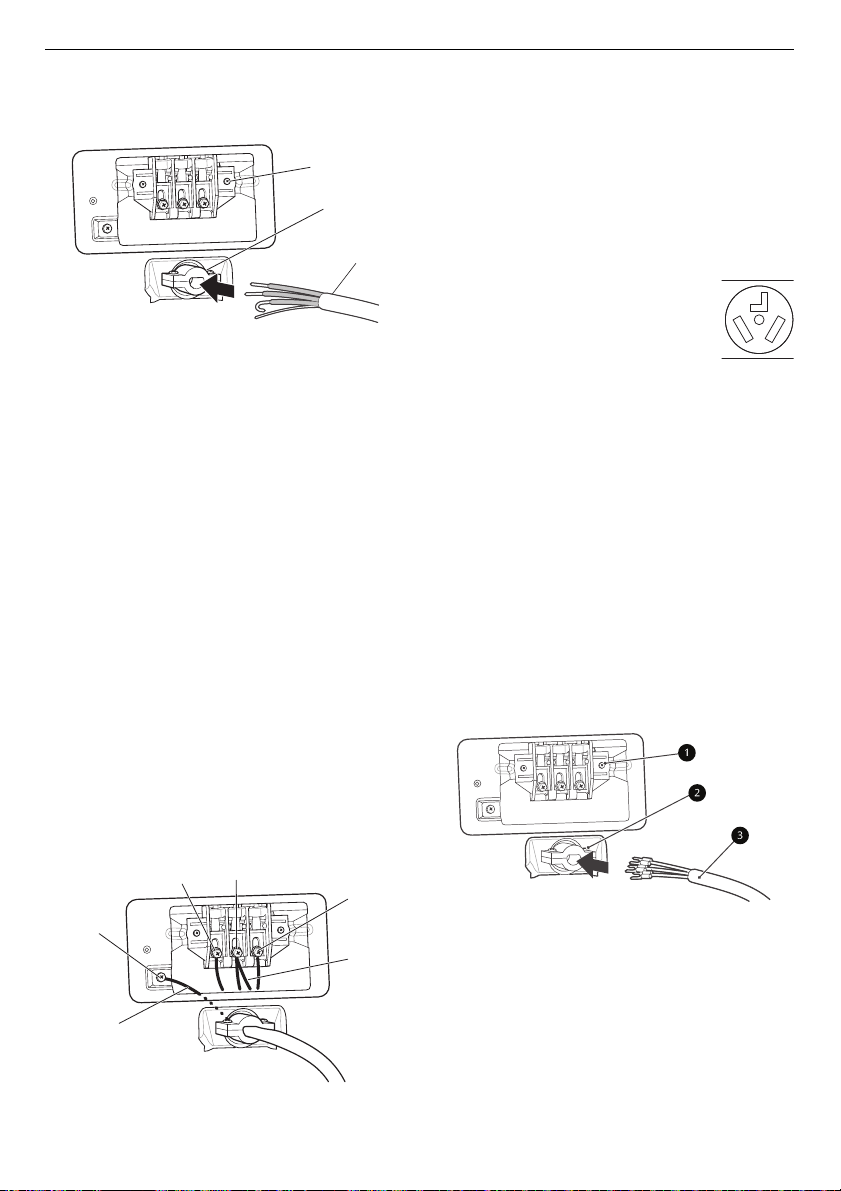

Three-Wire Power Cord

• A 3-wire connection is NOT

permitted on new construction

after January 1, 1996.

• A UL-listed strain relief is required.

• Use a 30-amp, 240-volt, 3-wire, UL-listed

power cord with #10 AWG-minimum copper

conductor and closed loop or forked

terminals with upturned ends.

1

Remove the terminal block access cover on the

upper back of the appliance.

2

Install the UL-listed strain relief into the power

cord through-hole.

3

Thread a 30-amp, 240 volt, 3-wire, UL-listed

power cord with #10 AWG-minimum copper

conductor through the strain relief.

9

Tighten all screws securely.

10

Reinstall the terminal block access cover.

a

White Wire moved from Ground Screw

b

Hot Leads of Power Cord (Black and Red)

a

Terminal Block

b

UL-Listed Strain Relief

c

UL-Listed 3-Wire Power Cord

4

Attach the two hot leads (black and red) of the

power cord to the outer terminal block screws.

Page 21

INSTALLATION

1’’ (2.5 cm)

21

5

Attach the neutral (white) wire to the center

terminal block screw.

6

Connect the external ground (if required by

local codes) to the green ground screw.

7

Tighten all screws securely.

8

Reinstall the terminal block access cover.

a

White Wire from Dryer harness

b

Hot Leads of Power Cord (Black and Red)

c

Neutral Wire (White)

d

External Ground Wire (If required by local

codes)

e

Ground Screw (green)

Bend the ends of the three wires into a hook

shape.

2

Remove the terminal block access cover on the

upper back of the appliance.

3

Install UL-listed strain relief into the power

cord through-hole.

4

Thread the 3-wire, #10 AWG minimum copper

conductor power cable prepared in step 1

through the strain relief.

a

Terminal block

b

UL-listed strain relief

c

UL-listed 3-wire power cord

ENGLISH

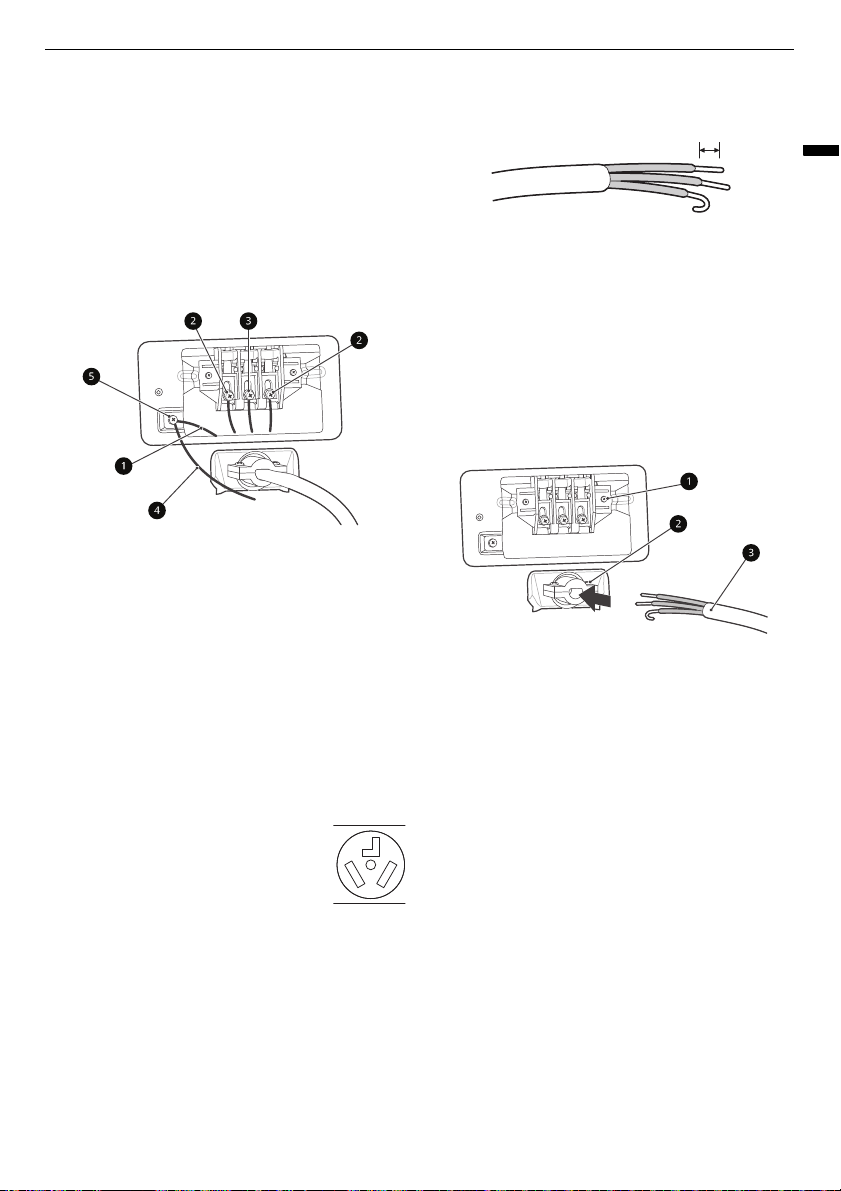

Three-Wire Direct Wire

• A 3-wire connection is NOT

permitted on new construction

after January 1, 1996.

• A UL-listed strain relief is required.

• Use UL-listed 3-wire, #10 AWG minimum

copper conductor cable. Allow at least 1.5 m

length to allow for removal and installation of

dryer.

1

Remove 8.9 cm of the outer covering from the

wire. Strip 2.5 cm insulation from each wire.

5

Attach the two hot leads (black and red) of the

power cord to the outer terminal block screws.

6

Attach the neutral (white) wire to the center

terminal block screw.

7

Connect the external ground (if required by

local codes) to the green ground screw.

8

Tighten all screws securely.

Page 22

22

WARNING

NOTE

a

b

c

d

f

e

INSTALLATION

9

Reinstall the terminal block access cover.

a

Hot lead (black and red)

b

Neutral wire (white)

c

External ground wire (if required by local

codes)

d

Wire from the appliance harness

e

Ground screw (green)

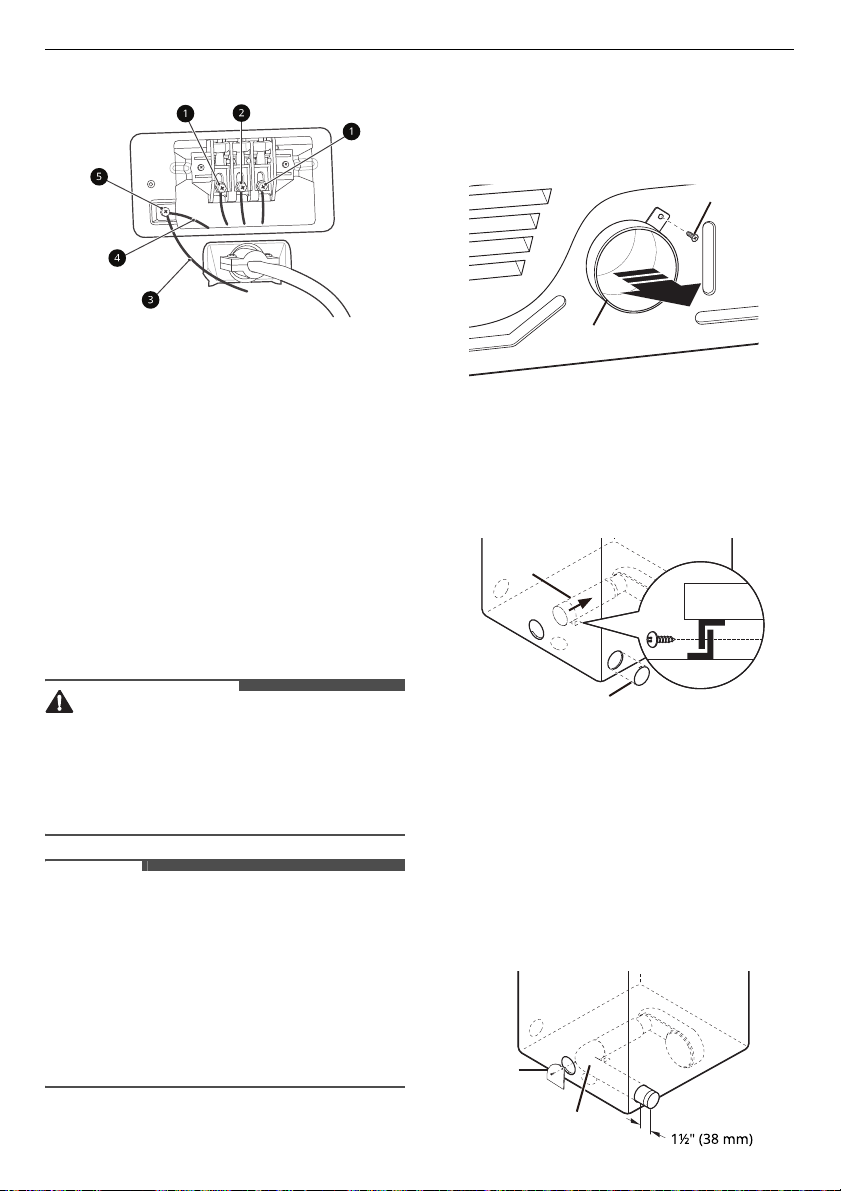

Installing the Vent Kit of Dryer

The appliance is configured to vent to the rear. It

can also vent to the side.

Side Venting

1

Remove the rear exhust duct retaining screw

a

and pull out the exhaust duct b.

2

Press the tabs on the knockout c and carefully

remove the knockout for the desired vent

opening. (Right-side venting is not available on

gas models.) Press the adapter duct

blower housing and secure to the base of the

dryer as shown.

d

onto the

• Use long-sleeved gloves and safety glasses.

• Use a heavy metal vent.

• Do not use plastic or thin foil ducts.

• Clean old ducts before installing the appliance.

• An adapter kit, part number 383EEL9001B, may

be purchased from your LG retailer. This kit

contains duct components necessary to change

the appliance vent location.

• Right-side venting is not available on gas

models.

• Bottom venting is not available on stacked or

integrated stacked models.

3

Preassemble a

cm

duct section, and secure all joints with duct

tape. Be sure that the male end of the elbow

faces AWAY from the dryer. Insert the elbow/

duct assembly through the side opening and

press it onto the adapter duct. Secure it in place

with duct tape. Be sure that the male end of the

duct protrudes

remaining ductwork. Attach the cover plate

to the back of the dryer with the included

screw.

10 cm

elbow e to the next

3.8 cm

to connect the

10

f

Page 23

INSTALLATION

WARNING

a

a

a: 4 ‘’ (10 cm)

b: 2 1/2 ‘’ (6.4 cm)

b

23

Venting the Dryer

• Gas dryers MUST exhaust to the outdoors.

• DO NOT use sheet metal screws or other

fasteners which extend into the duct that could

catch lint and reduce the efficiency of the

exhaust system. Secure all joints with duct tape.

• To reduce the risk of fire, combustion, or

accumulation of combustible gases, DO NOT

exhaust dryer air into an enclosed and

unventilated area, such as an attic, wall, ceiling,

crawl space, chimney, gas vent, or concealed

space of a building.

• To reduce the risk of fire, DO NOT exhaust the

dryer with plastic or thin foil ducting.

• Do not exceed the recommended duct length

limitations noted in the chart. Failure to follow

these instructions may result in extended drying

times, fire or death.

• Do not crush or collapse ductwork.

• Do not allow ductwork to rest on or contact

sharp objects.

Ductwork

• If connecting to existing ductwork, make sure it

is suitable and clean before installing the dryer.

• Venting must conform to local building codes.

• Use only 10 cm rigid, semi-rigid or flexible metal

ductwork inside the dryer cabinet and for

venting outside.

• The exhaust duct must be 10 cm in diameter with

no obstructions. The exhaust duct should be

kept as short as possible. Make sure to clean any

old ducts before installing your new dryer.

• Rigid, semi-rigid or flexible metal ducting is

recommended for use between the dryer and

the wall. All non-rigid metal transition duct must

be UL-listed. Use of other materials for transition

duct could affect drying time.

• Ductwork is not provided with the dryer. You

should obtain the necessary ductwork locally.

The vent hood should have hinged dampers to

prevent backdraft when the dryer is not in use.

• The total length of flexible metal duct must not

exceed 2.4 m.

ENGLISH

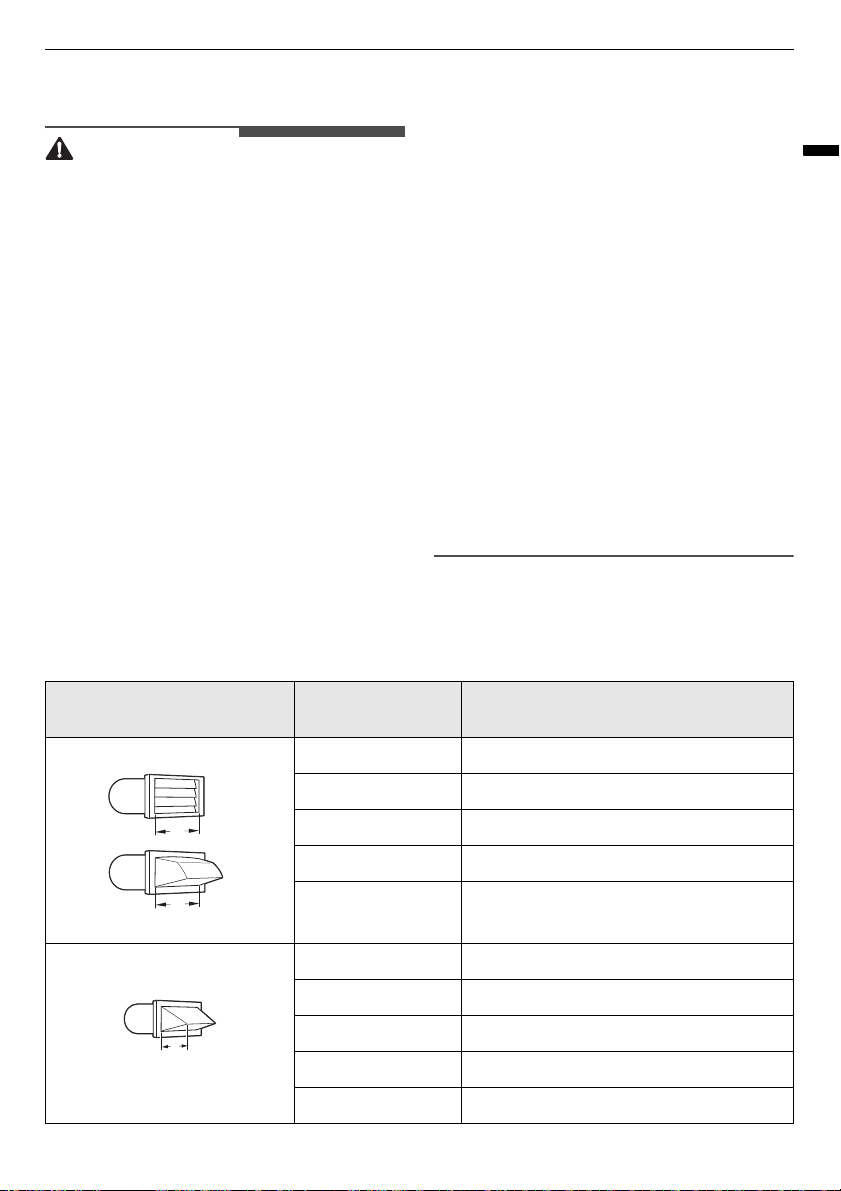

Wall Cap Type

Recommended 0 19.8 m

Use for only short run

installations

Number of 90°

Elbows

1 16.8 m

2 14.3 m

3 11.0 m

48.5 m

0 16.8 m

1 14.3 m

2 12.5 m

39.1 m

46.7 m

Maximum length of 10 cm diameter rigid

metal duct

Page 24

24

NOTE

WARNING

WARNING

WARNING

INSTALLATION

• Deduct 1.8 m for each additional elbow. Do not use more than four 90° elbows.

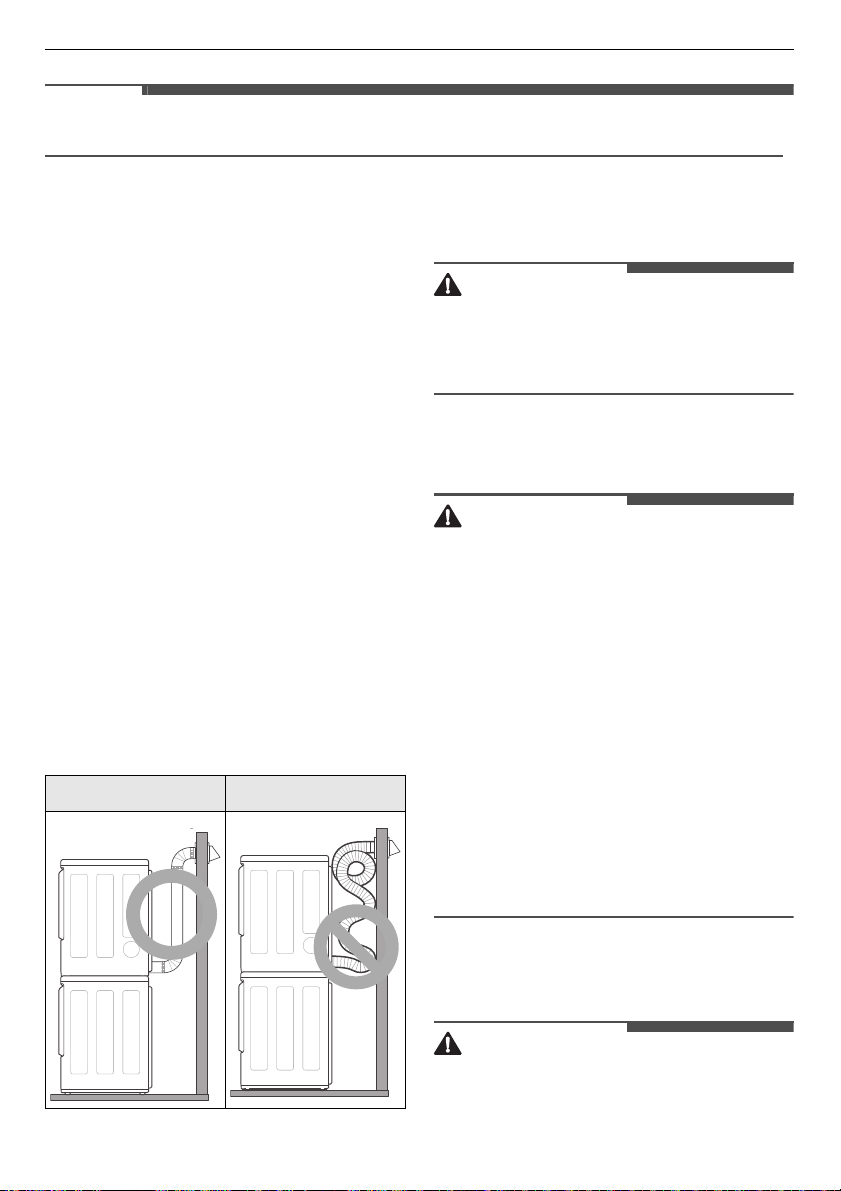

Routing and Connecting Ductwork

Follow the guidelines below to maximize drying

performance and reduce lint buildup and

condensation in the ductwork. Ductwork and

fittings are NOT included and must be purchased

separately.

• Use 10 cm diameter rigid, semi-rigid or flexible

metal ductwork.

• The exhaust duct run should be as short as

possible.

• Use as few elbow joints as possible.

• The male end of each section of exhaust duct

must point away from the dryer.

• Use duct tape on all duct joints.

• Insulate ductwork that runs through unheated

areas in order to reduce condensation and lint

buildup on duct surfaces.

• Incorrect or inadequate exhaust systems are not

covered by the dryer warranty. Dryer failures or

service required because of such exhaust

systems will not be covered by the dryer

warranty.

Correct Venting Incorrect Venting

Connecting Gas Dryer

• To reduce the risk of fire or explosion, electric

shock, property damage, injury to persons, or

death when using this appliance, follow

requirements including the following:

Electrical Requirments for Gas Models

• This dryer is equipped with a three-prong

grounding plug for protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle. Do

not cut or remove the grounding prong from this

plug.

• Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

• For personal safety, this dryer must be properly

grounded.

• This dryer must be plugged into a 120-VAC, 60Hz. grounded outlet protected by a 15-ampere

fuse or circuit breaker.

• Where a standard 2-prong wall outlet is

encountered, it is your personal responsibility

and obligation to have it replaced with a properly

grounded 3-prong wall outlet.

Gas Supply Requirements

• DO NOT attempt any disassembly of the dryer;

disassembly requires the attention and tools of

an authorized and qualified service technician or

company.

Page 25

• DO NOT use an open flame to inspect for gas

WARNING

NOTE

leaks. Use a noncorrosive leak detection fluid.

• Gas pressure must not exceed 20.4 cm water

column for NG, or 33.1 cm water column for LP.

• Isolate the dryer from the gas supply system by

closing its individual manual shutoff valve during

any pressure testing of the gas supply at

pressures greater than 3.5 kPa.

• Supply line requirements: Your laundry room

must have a rigid gas supply line to your dryer.

• If using a rigid pipe, the rigid pipe should be 0.5inch IPS. If acceptable under local codes and

ordinances and when acceptable to your gas

supplier, 3/8-inch approved tubing may be used

where lengths are less than 6.1 m. Larger tubing

should be used for lengths in excess of 6.1 m.

• To prevent contamination of the gas valve,

purge the gas supply of air and sediment before

connecting the gas supply to the dryer. Before

tightening the connection between the gas

supply and the dryer, purge remaining air until

the odor of gas is detected.

• Use only a new AGA- or CSA-certified gas supply

line (in compliance with the Standard for

Connectors for Gas Appliances, ANSI Z21.24 •

CSA 6.10) with flexible stainless steel connectors.

• Use Teflon tape or a pipe-joint compound that is

insoluble in propane (LP) gas on all pipe threads.

Connecting the Gas Supply

1

Make sure that the gas supply to the laundry

room is turned OFF and the dryer is unplugged.

Confirm that the type of gas available in your

laundry room is appropriate for the dryer.

2

Remove the shipping cap from the gas fitting at

the back of the dryer. Be careful not to damage

the threads of the gas connector when

removing the shipping cap.

3

Connect the dryer to your laundry room’s gas

supply using a new flexible stainless steel

connector with a 3/8-inch NPT fitting.

INSTALLATION

• DO NOT use old connectors.

4

Securely tighten all connections between the

dryer and your laundry room’s gas supply.

5

Turn on your laundry room’s gas supply.

6

Check all pipe connections (both internal and

external) for gas leaks with a noncorrosive

leak-detection fluid.

7

Proceed to Venting the Dryer.

a

3/8'' NPT Gas Connection

b

AGA/CSA-Certified Stainless Steel Flexible

Connector

c

1/8'' NPT Pipe Plug

d

Gas Supply Shutoff Valve

• Installation and service must be performed by a

qualified installer, service agency, or the gas

supplier.

• The dryer is configured for natural gas when

shipped from the factory. Make sure that the

dryer is equipped with the correct burner nozzle

for the type of gas being used (natural gas or

propane gas).

• Use only a new stainless steel flexible connector

and a new AGA-certified connector.

• A gas shutoff valve must be installed within 1.8 m

of the dryer.

25

ENGLISH

Page 26

26

NOTE

NOTE

INSTALLATION

• If ne cess ary, the corr ect nozz le (f or the LP nozz le

kit, order part number

installed by a qualified technician and the

change should be noted on the dryer.

• All connections must be in accordance with local

codes and regulations. Gas dryers MUST exhaust

to the outdoors.

383EEL3002D

) should be

High-Altitude Installations

The BTU rating of this dryer is AGA-certified for

elevations below 3048 m.

If your gas dryer is being installed at an elevation

above 3048 m, it must be derated by a qualified

technician or gas supplier.

Connecting the Water Supply Hose

Note for Connection

that the curved end of the water supply hose is

connected to the appliance.

Connecting the Hose to the Water Tap

Connecting Screw-Type Hose to Tap with Thread

Screw the supply hose connector onto the water

supply tap.

• Water pressure must be between

800 kPa

(0.5 ‒ 8.0 kgf/cm²). If the water pressure

is more than

should be installed.

• Periodically check the condition of the water

supply hose and replace the water supply hose if

necessary.

• Do not overtighten the water supply hose or use

mechanical devices to tighten onto the inlet

valves.

• No further backflow protection required for

connection to the water inlet.

800 kPa

, a decompression device

Checking the Rubber Seal

Two rubber seals a are supplied with the water

supply hose. They are used for preventing water

leaks. Connection to taps is sufficiently tight.

• Do not use mechanical devices such as multi

grips to tighten the water supply hose. Ensure

50 kPa

and

Connecting Screw-Type Hose to Tap Without

Thread

1

Loose the 4 fixing screws a.

2

Remove the guide plate b if the tap is too large

to fit the adapter.

Page 27

INSTALLATION

NOTE

27

3

Push the adapter onto the end of the tap so

that the rubber seal is connected to be

watertight. Tighten the 4 fixing screws.

4

Push the inlet hose c vertically upwards so

that the rubber seal within the hose can adhere

completely to the tap and then tighten the

hose by screwing it to the right.

Connecting One Touch Type Hose to Tap

Without Thread

1

Unscrew the adapter ring plate d and loose

the 4 fixing screws.

watertight. Tighten the 4 fixing screws and the

adapter ring plate.

4

Pull the connector latch plate f down, push

the inlet hose onto the adapter, and release the

connector latch plate. Make sure the adapter

locks into place.

• After connecting the water inlet hose to the

water tap, turn on the water tap to flush out

foreign substances (dirt, sand, sawdust, and etc.)

in the water lines. Let the water drain into a

bucket, and check the water temperature.

ENGLISH

2

Remove the guide plate e if the tap is too large

to fit the adapter.

3

Push the adapter onto the end of the tap so

that the rubber seal is connected to be

Connecting the Hose to the Appliance

1

Connect the 2 blue hoses b to the Y connector

a

.

Page 28

28

4 "

(10 cm)

29.5 - 96 "

(75 - 244 cm)

29.5 - 96 "

(75 - 244 cm)

INSTALLATION

2

Attach the inlet hoses to the back of the

appliance and secure the cold water inlet hoses

with tie straps

For the Washer

• Attach the hot water inlet hose c to the hot

water inlet on the back of the washer. Attach

the cold water inlet hose

inlet on the back of the washer.

For the Dryer

• Attach the cold water inlet hose d to the

cold water inlet on the back of the dryer.

• Tighten the fittings securely. Turn on both

faucets all the way and check for leaks at

both ends of the hoses.

e

.

d

to the cold water

microorganisms could spread to the inside

of the washer.

2

Insert the end of the drain hose into the

standpipe.

3

Use the provided tie strap b to secure the

drain hose in place.

Installing the Drain Hose

Using a Standpipe to Drain

1

Clip the end of the hose into the elbow bracket.

• Connect the elbow bracket

of the end of the drain hose. If the drain hose

is extended more than

end of the elbow bracket, mold or

10 cm

a

within

beyond the

10 cm

4

If the water valves and drain are built into the

wall, fasten the drain hose to one of the water

hoses with the provided tie strap

side on inside).

c

(ribbed

Page 29

INSTALLATION

NOTE

4 "

(10 cm)

29

Using the Laundry Tub to Drain

1

Clip the end of the hose into the elbow bracket.

a

within

10 cm

• Connect the elbow bracket

of the end of the drain hose. If the drain hose

is extended more than

end of the elbow bracket, mold or

microorganisms could spread to the inside

of the washer.

2

Hang the end of the drain hose over the side of

the laundry tub.

10 cm

beyond the

Levelling the Appliance

Checking the Level

When pushing down the edges of the top plate

diagonally, the appliance should not move up and

down at all (check both directions).

• If the appliance rocks when pushing the top

plate of the appliance diagonally, adjust the feet

again.

• Check whether the appliance is perfectly level

after installation.

• Timber or suspended type flooring may

contribute to excessive vibration and unbalance.

Reinforcement or bracing of the timber floor

may need to be considered to stop or reduce

excessive noise and vibration.

Adjusting and Levelling the Feet

When installing the appliance, the appliance

should be aligned and perfectly level. If the

appliance is not aligned and level properly, the

appliance may be damaged or may not operate

properly.

ENGLISH

3

Use the provided tie strap to secure the drain

hose in place.

1

Turn the levelling feet as required if the floor is

uneven.

• Do not insert pieces of wood etc. under the

feet.

• Make sure that all four feet are stable and

resting on the floor.

Page 30

30

NOTE

NOTE

INSTALLATION

• Do not install the washing machine on a plinth,

stand or elevated surface unless it is

manufactured by LG Electronics for use with this

model.

2

Check if the appliance is perfectly level using a

spirit level

3

Secure the levelling feet with the lock nuts b

by turning anti-clockwise against the bottom of

the appliance.

a

.

• Do not let the feet of the appliance get wet.

Failure to do so may cause vibration or noise.

Using Anti-Slip Sheets

This feature may vary depending on the model

purchased.

If you install the appliance on a slippery surface, it

may move because of excessive vibration.

Incorrect levelling may cause malfunction through

noise and vibration. If this occurs, install the antislip sheets under the levelling feet and adjust the

level.

1

Clean the floor to attach the anti-slip sheets.

• Use a dry rag to remove and clean foreign

objects and moisture. If moisture remains,

the anti-slip sheets may slip.

2

Adjust the level after placing the appliance in

the installation area.

3

Place the adhesive side a of the anti-slip

sheets on the floor.

• The most effective way is to install the antislip sheets under the front feet. If it is

difficult to place the sheets under the front

feet of the appliance, attach them under the

rear feet.

4

Check if all lock nuts at the bottom of the

appliance are secured properly.

• Proper placement and levelling of the appliance

will ensure long, regular, and reliable operation.

• The appliance must be 100% horizontal and

stand firmly in position on a hard flat floor.

• It must not ‘Seesaw’ across corners under the

load.

4

Put the appliance on the anti-slip sheets.

• Do not attach the adhesive side

slip sheets to the feet of the appliance.

a

of anti-

Page 31

NOTE

• Additional anti-slip sheets are available at LG

Electronics service centre.

INSTALLATION

31

ENGLISH

Page 32

32

WARNING

NOTE

CAUTION

NOTE

INSTALLATION

Disassembly

Disassembling the Washer and Dryer

The washer and dryer cannot be disassembled and

installed for use side by side. If it is necessary to

disassemble the appliance in order to move or

reinstall it, follow these instructions.

• Protect your hands and arms from sharp edges.

To reduce the risk of injury to persons, adhere to

all industry recommended safety procedures

including the use of long-sleeved gloves and

safety glasses.

• Any damage resulting from improper

disassembly/assembly or installation of the

product is not covered by the product warranty.

1

Be sure to unplug the appliance.

4

Pull the control panel forward to remove it.

5

Disconnect the wire harnesses from the

washer

a

and dryer b to the control panel.

• Always ground yourself before touching the PCB

or wiring. Discharge of static electricity may

cause product malfunction.

2

Loosen screws assembled on the stack bracket

on the back of the appliance.

3

Push open the caps at the left and right sides of

the control panel on the front of the appliance.

Loosen the screws under the caps.

• Tuck the wire harnesses to the side to avoid

pinching them.

6

Unscrew the second screw from the top of the

four screws on the left and right.

Page 33

7

WARNING

NOTE

Lift the dryer and separate it from the washer.

• Protect your hands and arms from sharp edges

of the panel frame exposed on the top of the

washer.

• To avoid strain injuries, use 2 or more people to

lift the dryer.

INSTALLATION

33

ENGLISH

• When assembling the appliance, proceed in

reverse order.

Page 34

34

CAUTION

CAUTION

OPERATION-WASHER

OPERATION-WASHER

Operation Overview

Using the Washer

Before the first wash, select the

programme and add a half amount of the

detergent. Start the appliance without clothes. This

will remove possible residues and water from the

drum that may have been left during

manufacturing.

1

Sort clothes by fabric type, soil level, colour and

load size as needed.

2

Open the door and load items into the

appliance.

• Before closing the door, ensure that all clothes

and items are inside the tub and not

overhanging on the rubber door seal where they

will become caught when the door is closed.

Failing to do so will cause damage to the door

seal and the clothes.

Normal

wash

• Remove items from the flexible door seal gasket

to prevent clothing and door seal damage.

4

Add cleaning products or detergent and

softener.

• Add the proper amount of detergent to the

detergent dispenser. If desired, add bleach

or fabric softener to the appropriate areas of

the dispenser.

5

Press the

appliance.

6

Choose the desired cycle.

• Press the cycle button repeatedly or turn the

• Now select a wash temperature and spin

Power

button to turn on the

cycle selector knob until the desired cycle is

selected.

speed. Pay attention to the fabric care label

of your clothes.

3

Close the door.

7

Begin cycle.

• Press the

cycle. The appliance will agitate briefly

without water to measure the weight of the

load. If the

pressed within a certain time, the appliance

will shut off and all settings will be lost.

8

End of cycle.

Start/Pause

Start/Pause

button to begin the

button is not

Page 35

OPERATION-WASHER

NOTE

35

• When the cycle is finished, a melody will

sound. Immediately remove your clothing

from the appliance to reduce wrinkling.

Preparing the Wash Load

Sorting the Clothes

• For best washing results, sort your clothes

according to the care label stating fabric type

and washing temperature. Adjust the spin speed

or spin intensity in accordance to the fabric type.

• Soil level (Heavy, Normal, Light): Separate

clothes according to soil level. If possible, do not

wash heavily soiled items with lightly soiled

ones.

• Colour (White, Lights, Darks): Wash dark or dyed

clothes separately from whites or light colours.

Mixing dyed clothes with light clothes can result

in dye transfer or discolouration of lighter

clothes.

• Lint (Lint producers, Collectors): Wash separately

lint producing fabrics from lint collecting fabrics.

Lint producers can result in pilling and linting on

the lint collectors.

Symbol Wash / Fabric type

• Do not wash

ENGLISH

• The dashes under the symbol give you

information about the type of fabric and the

maximum allowance of mechanical stress.

Checking the Clothes before Loading

• Combine large and small items in a load. Load

large items first.

• Large items should not be more than half of the

total wash load. Do not wash single items. This

may cause an unbalanced load. Add one or two

similar items.

• Check all pockets to make sure that they are

empty. Items such as nails, hair clips, matches,

pens, coins and keys can damage both your

appliance and clothes.

Checking the Clothes Care Label

The symbols tell you about the fabric content of

your garment and how it should be washed.

Symbols on the Care Labels

Symbol Wash / Fabric type

• Normal Wash

• Cotton, Mixed Fabrics

• Easy Care

• Synthetic, Mixed Fabrics

• Special Delicate Wash

• Delicates

• Hand Wash Only

• Wool, Silk

• Wash delicates (stockings, underwired bras) in a

wash net.

• Close zippers, hooks and strings to make sure

that these items do not snag on other clothes.

• Pre-treat dirt and stains by brushing a small

amount of detergent dissolved water onto stains

to help lift dirt.

Page 36

36

NOTE

OPERATION-WASHER

Adding Detergents and Softeners

Detergent Dosage

• Detergent should be used according to the

instruction of the detergent manufacturer and

selected according to type, colour, soiling of the

fabric and the washing temperature. Use only

detergents that are suitable for Drum (front

load) type washers.

• If too many suds occur, reduce the detergent

amount.

• If too much detergent is used, too many suds

can occur and this will result in poor washing

results or cause heavy load to the motor.

• If you wish to use liquid detergent, follow the

guidelines provided by the detergent

manufacturer.

• You can pour liquid detergent directly into the

main detergent drawer if you are starting the

wash cycle immediately.

• Do not use liquid detergent if you have selected

Prelavado (Pre Wash)

dispense immediately and may harden in the

drawer or the tub.

• Detergent usage may need to be adjusted for

water temperature, water hardness, size and soil

level of the load. For best results, avoid

overdosing the detergent. Failing to do so will

cause oversudsing.

• Refer to the label of the clothes, before adding

the detergent and choosing the water

temperature.

• Use only suitable detergents for the respective

type of clothing:

- Liquid detergent is often designed for special

applications, e.g. for coloured fabric, wool,

delicate or dark clothes.

- Powdered detergent is suitable for all types of

fabric.

- For better washing results of white and pale

garments, use powdered detergent with

bleach.

- Detergent is flushed from the dispenser at the

beginning of the wash cycle.

option, as the liquid will

• Do not let the detergent harden. Doing so may

lead to blockages, poor rinse performance or

odour.

• Full load: According to manufacturer’s

recommendation.

• Part load: 1/2 of the normal amount.

• Minimum load: 1/3 of full load.

Using the Dispenser

To add detergent dosage to the dispenser:

1

Open the dispenser drawer.

2

Add the detergent and softener into the

appropriate compartments.

a

Main wash detergent compartment

b

Pre-wash detergent compartment

c

Liquid fabric softener compartment

d

Liquid bleach compartment

3

Gently close the detergent dispenser drawer

before starting the cycle.

• Slamming the drawer closed may result in

the detergent overflowing into another

compartment or dispensing into the drum

earlier than programmed.

• Be careful not to get a hand caught in the

drawer while closing.

• It is normal for a small amount of water to

remain in the dispenser compartments at

the end of the cycle.

Page 37

OPERATION-WASHER

NOTE

NOTE

37

Fabric Softener Compartment

This compartment holds liquid fabric softener,

which is automatically dispensed during the final

rinse cycle. Either powdered or liquid fabric

softener may be used.

• Pour fabric softer to the maximum fill line.

Pouring excessive fabric softener over the

maximum fill line can cause it to dispense too

early, which may stain the clothes.

• Do not pour fabric softener directly onto the

clothes in the wash drum, doing so will cause

dark staining on the clothes that will be difficult

to remove.

• Do not leave the fabric softener in the detergent

drawer for more than 1 day. Fabric softener may

harden. Softener may remain in the dispenser if

it is too thick. The softener should be diluted if

the consistency is too thick so that it can flow

easily.

• Do not open the drawer when water is being

supplied during the wash.

• Solvents (benzene, etc.) must never be used.

Adding Detergent Tablets

Detergent tablets can also be used when washing.

1

Open the door and put detergent tablets into

the drum before loading the clothes.

2

Load the clothes into the drum and close the

door.

• Do not put tablets into the dispenser.

ENGLISH

Adding Water Softener

A water softener, such as anti-limescale can be

used to cut down on the use of detergent in areas

with high water hardness level.

• First add detergent, and then the water softener.

Dispense according to the amount specified on

the packaging.

Page 38

38

OPERATION-WASHER

Control Panel and Programme Table

Control Panel Features

Description

Power On/Off Button

a

• Press this button to turn the washing machine on.

Programme Buttons

b

• Programmes are available according to the clothes type.

• The lamp will light up to indicate the selected programme.

Start/Pause Button

c

• This button is used to start the wash programme or pause the wash programme.

• If a temporary stop of the wash programme is needed, press this button.

Customizing Washing Programme Buttons / Extra Options and Functions

d

• Use these buttons to select the desired options for the selected programme. Not all options

are available in each programme.

• To use the extra functions, press and hold the corresponding button for 3 seconds. The

corresponding symbol lights up in the display.

Remote Start

With the

• In order to use this function, refer to

Wi-Fi

Press and hold the

LG ThinQ

LG ThinQ

application.

app, you can use a smartphone to control your appliance remotely.

SMART FUNCTIONS

Temp.

button for 3 seconds to initiate the connection of the appliance to the

.

Page 39

OPERATION-WASHER

Description

Time and Status Display

e

• The display shows the settings, estimated remaining time, options, and status messages.

When the appliance is turned on, the default settings in the display will illuminate.

• While the load weight is sensed automatically, the display on the control panel blinks.

Time and Status Display

Description

a

f

lights up when the appliance is connected to Wi-Fi network at home.

b

w

lights up when the remote control feature is activated.

c

H

lights up when the programme starts and the door is locked.

39

ENGLISH

d

m

li ghts u p wh en the bee p is on. Be ep s ound c an b e turn ed o n or off only t hro ugh the

application.

Estimated Time Remaining

e

• When a washing programme is selected, the default time for that programme is displayed.

This time will change as options are selected.

• If the display shows

the load size. This is normal.

• The time shown is only an estimate. This time is based on normal operating conditions.

Several external factors (load weight, room temperature, incoming water temperature, etc.)

can affect the actual time.

AI DD

f

•

AI DD

M provides the appropriate drum rotation actions after load sensing is completed.

• M is activated when the

Programme Status Indicators

g

• When a washing programme is running, LED for the active stage will blink, and the LEDs for

the remaining stages will remain steady. Once a stage is complete, the LED will turn off. If a

cycle is paused, the active stage LED will stop blinking.

---

, then the time will be displayed after the load sensing has detected

Normal

programmes are selected and operated.

LG ThinQ

Page 40

40

NOTE

OPERATION-WASHER

Washing Programme

Turn the knob or press the button to select the desired cycle. When you select a wash cycle, the light for

the corresponding wash cycle will turn on.

• Whenever load weights are mentioned, assume

•

Temperature: Fría (Cold)

•

Spin: No Cent. (No Spin)

Spin)

•

Soil: Ligero (Light)

(Heavy)

Cycle Normal

Description

Wash Temp.

Spin Speed

Soil Level

Cycle Ropa de Cama (Bedding)

Description

Use to wash all normal items such as cotton, linen, shirts, jeans or mixed loads,

except delicate fabrics such as wool or silk.

• Pressing the

cycle to begin immediately, using the default settings.

Default:

Default:

Default:

Suitable for washing blankets or bulky items which have difficulty absorbing water,

such as pillows, blankets, comforters, sheets or pet bedding.

• Do not use this cycle to wash a mixed load of bedding and non-bedding items.

• Do not mix large/bulky items with smaller articles of clothing.

• Do not wash excessively large items. If large/bulky items do not fit easily into the

tub, there may not be enough room for them to move during washing.

Start/Pause

Warm

Medium High

Normal

1 lb (0.45 kg)

>

Cool

>

Low

>

Medium Light

button without selecting a cycle will cause the

= 1 thick bath towel (dry).

>

Warm

>

Very Warm

>

Medium

>

>

Normal

Available: All

Available:

High

Available: All

Fuerte (High Spin), Medium

,

Medium, Low

Medium High

>

Medium Heavy

>

Caliente (Hot)

>

Fuerte (High

>

Normal

Sucia

Wash Temp.

Spin Speed

Soil Level

Default:

Default:

Default:

Warm

Medium

Normal

Available:

(Cold)

Available:

Spin)

Available: All

Very Warm, Warm, Cool, Fría

Medium, Low, No Cent. (No

Page 41

OPERATION-WASHER

Cycle Delicados (Delicates)

41

Description

Wash Temp.

Spin Speed

Soil Level

Cycle Carga Pesada (Heavy Duty)

Description

Wash Temp.

Spin Speed

Soil Level

Cycle Lavado Rápido (Speed Wash)

Description

Suitable for washing dress shirts/blouses, nylons, lingerie, or sheer and lacy clothes

which can easily be damaged.

Default:

Cool

Default:

Medium

Default:

Normal

Suitable for washing heavily soiled laundry, such as cotton fabrics, using more

powerful wash motions.

• When washing large loads, there will be brief periods of

without agitation. These soak periods are part of the cycle’s design, and are

normal.

Default:

Warm

Default:

Fuerte (High Spin)

Default:

Sucia (Heavy)

Quickly washes lightly soiled clothing and small loads. For high wash and rinse

efficiency, wash small loads of 2-3 lightly soiled garments.

• Use very little detergent in this cycle. To add an extra rinse, use the

Extra (Extra Rinse)

option.

(less than 8 lb (3.63 kg))

Available:

Available:

Spin)

Available: All

Available: All

Available:

High

Available: All

Warm, Cool, Fría (Cold)

Medium, Low, No Cent. (No

2 minutes

Fuerte (High Spin), Medium

,

Medium, Low

(less than 3 lb (1.36 kg))

or more

Enjuague

ENGLISH

Wash Temp.

Spin Speed

Soil Level

Cycle Ciclo Descargado (Enjuague+Centrifugado) (Downloaded (Rinse+Spin))

Description

Wash Temp.

Spin Speed

Default:

Very Warm

Default:

Fuerte (High Spin)

Default:

Ligero (Light)

Use a smartphone to download a specialized cycle to this cycle position.

• The default cycle is

available for download.

• Refer to the

Default:

Cool

Default:

Medium High

Enjuague+Centrifugado (Rinse+Spin)

LG ThinQ

application to see the cycles available for download.

Available:

(Cold)

Available: All

Available: All

Available:

Available: All

Very Warm, Warm, Cool, Fría

Cool

. This cycle is also

Page 42

42

OPERATION-WASHER

Cycle Ciclo Descargado (Enjuague+Centrifugado) (Downloaded (Rinse+Spin))

Soil Level

Default: - Available: -

Page 43

OPERATION-WASHER

NOTE

Selectable Washing Options

*1 This option is automatically included in the cycle and cannot be deselected.

• If the

Turbo Wash

option is on, you cannot set the spin level to

No Cent. (No Spin)

43

ENGLISH

.

Cycle Steam Turbo Wash

Normal

Ropa de Cama

(Bedding)

Delicados

(Delicates)

Carga Pesada

(Heavy Duty)

Lavado Rápido

(Speed Wash)

Ciclo Descargado

(Downloaded)

default:

Enjuague+Centri

fugado

(Rinse+Spin)

#

####

#

Enjuague Extra

(Extra Rinse)

*1

#

##

Prelavado (Pre

Wash)

##

*1

#

##

##

#

Page 44

44

WARNING

OPERATION-WASHER

Extra Options and Functions

Customizing a Washing Programme

4

Select a washing programme.

5

Customize the washing programme (

Centrifugado (Spin)

necessary.

, and

Suciedad (Soil)

Temp.

) as

,

Each programme has default settings that are

selected automatically. You may also customize

these settings using these buttons.

Temp.

This button selects the wash temperature for the

selected programme.

Temp.

Press the

lit.

• Select the water temperature suitable for the

type of load you are washing. Follow the

garment fabric care labels for best results.

Centrifugado (Spin)

The spin intensity level can be selected by pressing

this button repeatedly.

Press the

speed.

Suciedad (Soil)

Press the

the desired soil level is selected.

• The

Sucia (Heavy)

times. The

decrease cycle times.

button until the desired setting is

Centrifugado (Spin)

Suciedad (Soil)

soil setting may increase cycle

Ligero (Light)

button to select spin

button repeatedly until

soil setting may

Follow the next steps to customize a washing programme:

6

Press the

Start/Pause

button.

Using Special Options

You can customize the programmes by using the

following special options:

Steam

Adding this option to a wash cycle helps provide

superior cleaning performance. Using steam gives

fabrics the cleaning benefits of a very hot wash.

• Steam may not be clearly visible during steam

cycles. This is normal. Too much steam could

damage clothing.

• Do not use steam with delicate fabrics such as

wool and silk, or easily discolored fabrics.

• Do not touch the door during steam cycles. The

door surface can become very hot and can cause

severe burns. Allow the door lock to release

before opening the door.

• Do not attempt to override the door lock

mechanism or reach into the washer during a

steam cycle. Steam can cause severe burns.

Turbo Wash

Adding this option reduces the programme time

but the similar washing results will be provided.

• This option cannot be used with all cycles.

• This option defaults to on for

Pesada (Heavy Duty)

Normal

wash cycles.

and

Carga

1

Prepare the clothes and load the drum.

2

Press the

3

Add detergent.

Power

button.

Follow the next steps to use a special option.

1

Press the

2

Select a washing programme.

Power

button.

Page 45

3

NOTE

NOTE

Change the washing programme (

Centrifugado (Spin)

necessary.

4

Press the

5

Press the

Steam

Start/Pause

or

Suciedad (Soil)

or

Turbo Wash

button.

Special Cycles

Sanitario (Sanitary)

This cycle washes clothes at a high temperature.

Limpieza de Tina (Tub Clean)

This is a special cycle designed to clean the inside

of the washer.

Using Basic Options

You can customize the programmes by using the

following basic options:

Enjuague Extra (Extra Rinse)

This option adds an extra rinse to the selected

cycle. Use this option to help ensure the removal of

detergent or bleach residue from fabrics.

• Press the

to add additional rinses to the cycle.

Prelavado (Pre Wash)

This option adds a pre-wash (for about

minutes

stained clothing.

• Press the

you start a washing programme.

• If you select

the detergent directly in the drum, the detergent

may be washed away, reducing the washing

performance.

Enjuague Extra (Extra Rinse)

) for improved cleaning of heavily soiled or

Prelavado (Pre Wash)

Prelavado (Pre Wash)

button before

Settings

Bloqueo infantil (Child Lock)

Use this option to disable the controls. This