LG TD-C7014 series Service Manual

CONDENSING DRYER

SERVICE MANUAL

READ THIS MANUAL CAREFULLY TO DIAGNOSE TROUBLE

CORRECTLY BEFORE OFFERING SERVICE.

CAUTION

MODEL : TD-C7014** Series

2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property

damage.The manufacturer or seller cannot be responsible for the interpretation of this information, nor can it assume any

liability in connection with its use.

To avoid personal injury, disconnect power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

WARNING !

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path to ground are

removed for service, they must be returned to their original position and properly fastened.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic control

assembly. The new control assembly may appear to work well after repair is finished, but

failure may occur at a later date due to ESD stress.

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or unpainted

metal in the appliance.

-OR -

Touch your finger repeatedly to a green ground connection point or unpainted metal in the

appliance.

Before removing the part from its package, touch the anti-static bag to a green ground connection point or

unpainted metal in the appliance.

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

When repackaging failed electronic control assembly in anti-static bag, observe above instructions.

3

CONTENTS

1. SPECIFICATIONS ...........................................................................................................................................................4

2. FEATURES AND LOOK ..................................................................................................................................................5

3. PART IDENTIFICATION ..................................................................................................................................................6

4. PROGRAM CYCLE .........................................................................................................................................................7

5. INSTALLATION INSTRUCTIONS ...................................................................................................................................10

6. MAINTENANCE INSTRUCTIONS ..................................................................................................................................12

7. COMPONENT TESTING TIPS ........................................................................................................................................15

8. CONTROL LAY-OUT.....................................................................................................................................................17

9. WIRING DIAGRAM .....................................................................................................................................................18

10. TROUBLESHOOTING..................................................................................................................................................19

11. DIAGOSTIC TEST........................................................................................................................................................21

12. DISASSEMBLY INSTRUCTIONS....................................................................................................................................28

13. EXPLODED VIEW .......................................................................................................................................................38

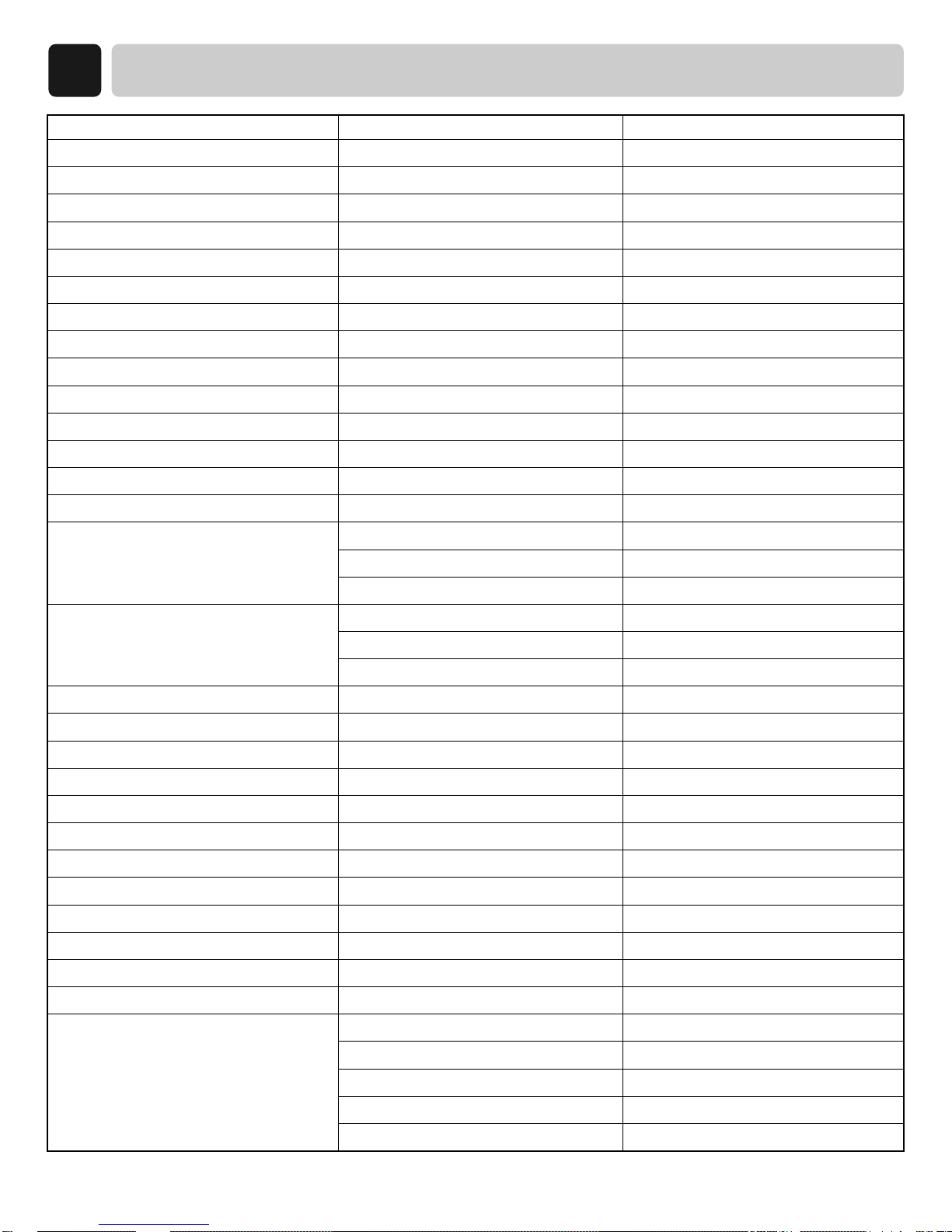

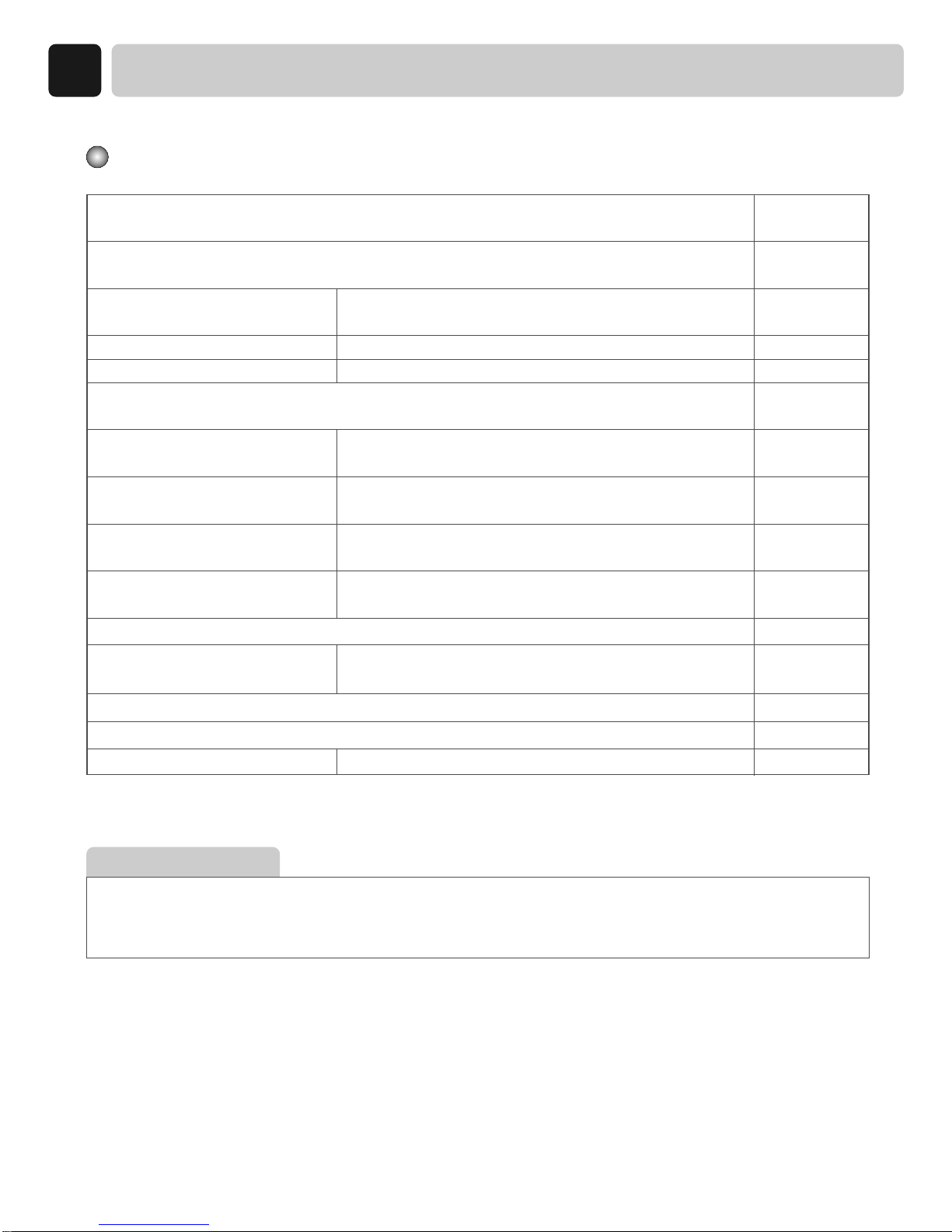

SPECIFICATIONS

1

4

ITEMS TD-C70140E REMARK

MATERIAL & FINISHES

DRYING TYPE Condensation

WEIGHT 40 kg (Gross : 46 kg)

DIMENSION 595(W) x 850(H) x 600(D)

STANDARD DRYING CAPACITY 7.0 kg

CONTROL TYPE Electronic Control

POWER SUPPLY AC 220~230V, 50Hz (16A) LGEUK : 13A, LGEAP : 10A

MOTOR 250W

HEATER 2500W(22.5) LGEUK : 2350W, LGEAP : 1900W

LAMP 15W(125mA)

DOOR SWITCH 250V(10A)

THERMOSTAT 240V(25A)

CONTROL TYPE Electronic

DRUM CAPACITY 116 Liter

SAFETY DEVICES Thermal Fuse (Motor)

Over current protect (Motor)

Thermostat

SENSING TYPE Micom electronic Control

1. Temperature : 2 thermistors

2. Humidity : Electrode Sensor

FILTER Removable (Double screen)

DRUM SPEED 56~57 rpm

REVERSIBLE DOOR Available

DRUM Stainless steel

DRYER RACK Available

CHILD LOCK Available

TEMPERTURE CONTROL Available (Quick/Gentle buttons) Default : ON

IRON-DRY BUZZER Available Default : OFF

ANTI-CREASE COURSE Available

TIME-ADDING Available 3~19 hours

TIME DELAY Available

DRUM INTERIOR LIGHT Available

LED DISPLAY TIME DISPLAY

RUNNING STATUS INDICATOR

EMPTY WATER

CLEAN FILTER

CHILD LOCK

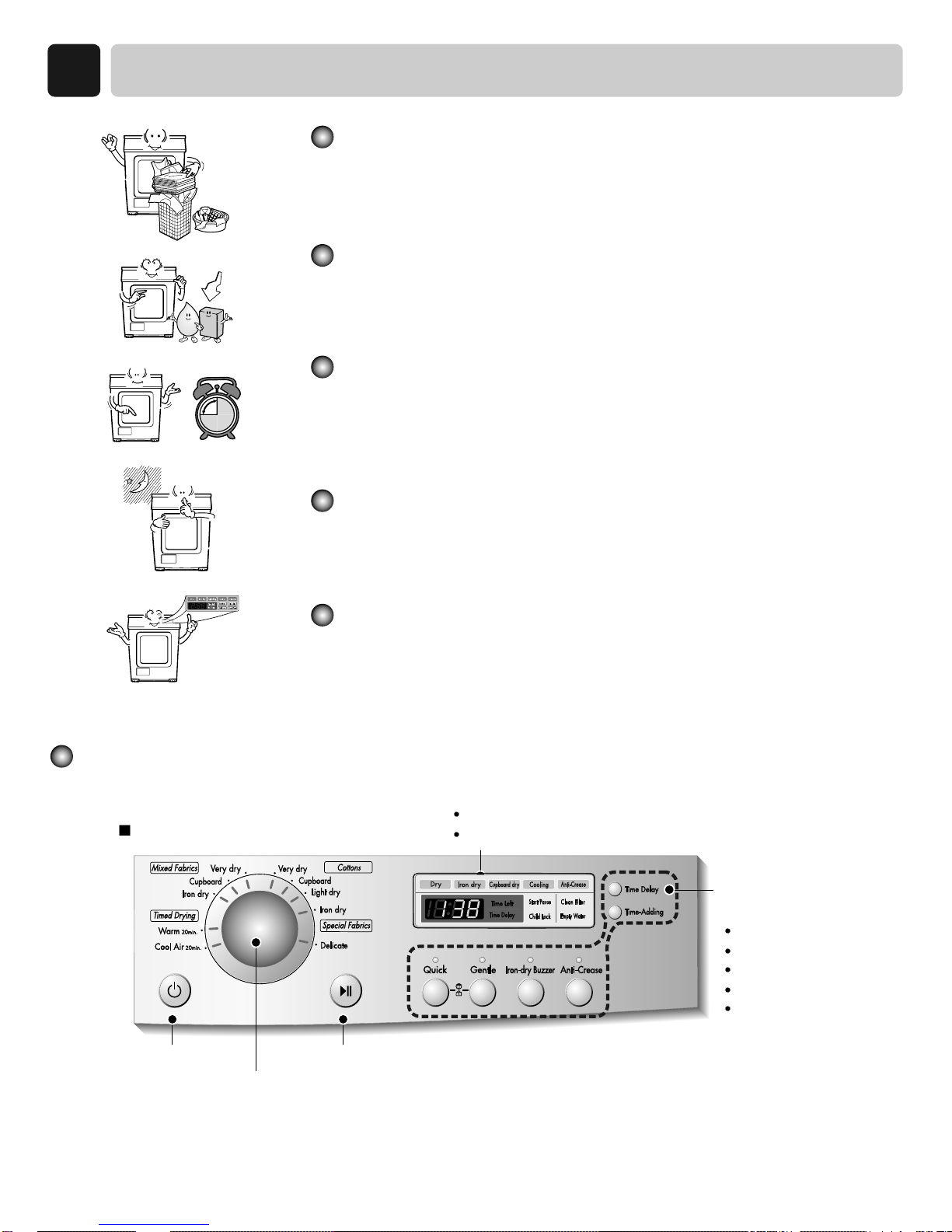

FEATURES AND LOOK

2

5

Energy

save

Ultra big Capacity Drum

LG Dryer has 7.0kg capacity which is the ultra big capacity.

Lower Energy Consumption

Energy is saved by Sirocco fan.

Reduced drying time

Drying time is shortened by efficient air flow mechanism and

optimized heater.

Innovative noise performance

Noise gets reduced by Noise-absorption & screening technology.

Easy of Use

Wide LED display using electric control.

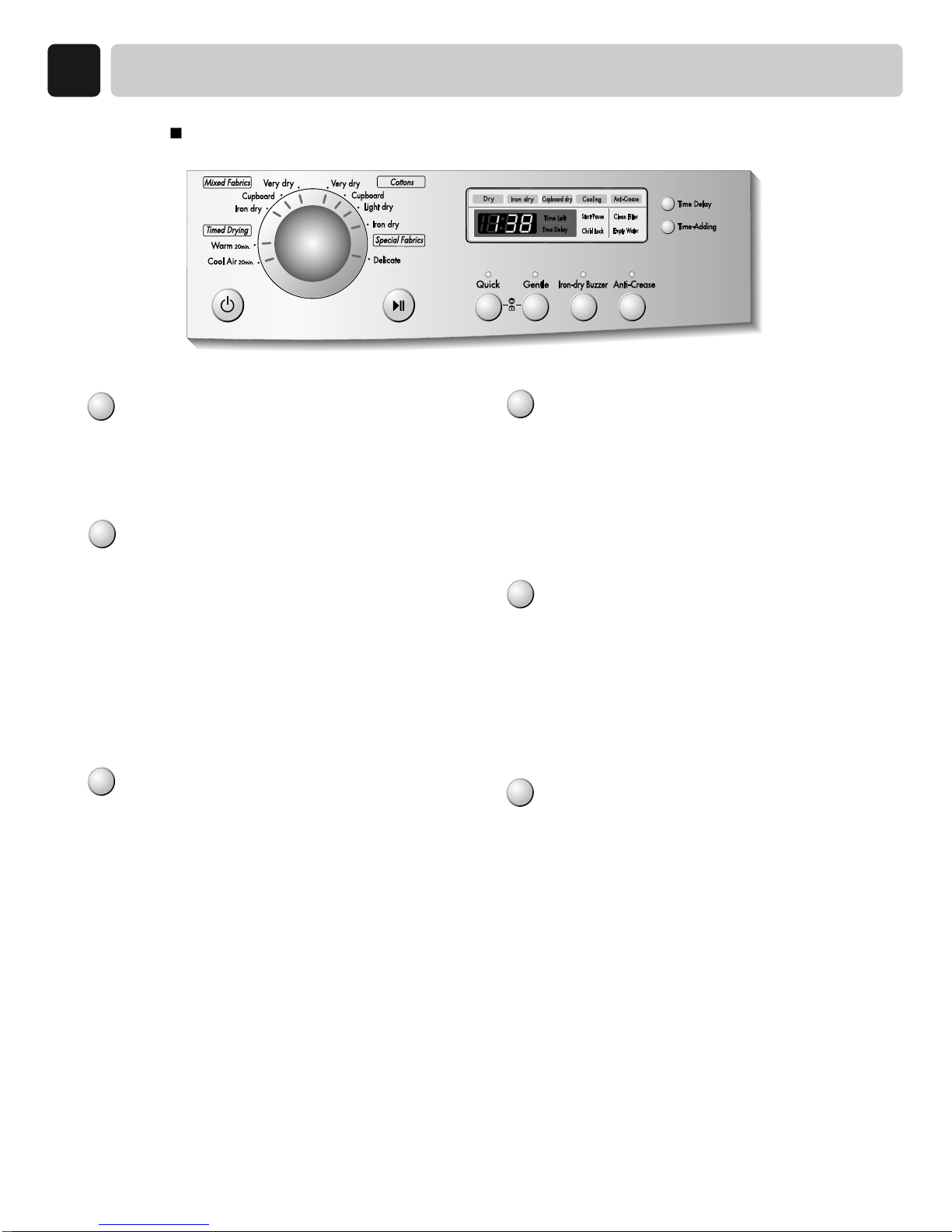

Control Panel

Program selector

Start/Pause

LED Display

Time Display

Indicator lamps

Additional function

buttons

Quick/Gentle

Iron-dry Buzzer

Anti-Crease

Time Delay

Time-Adding

TD-C70140E/145E

Power

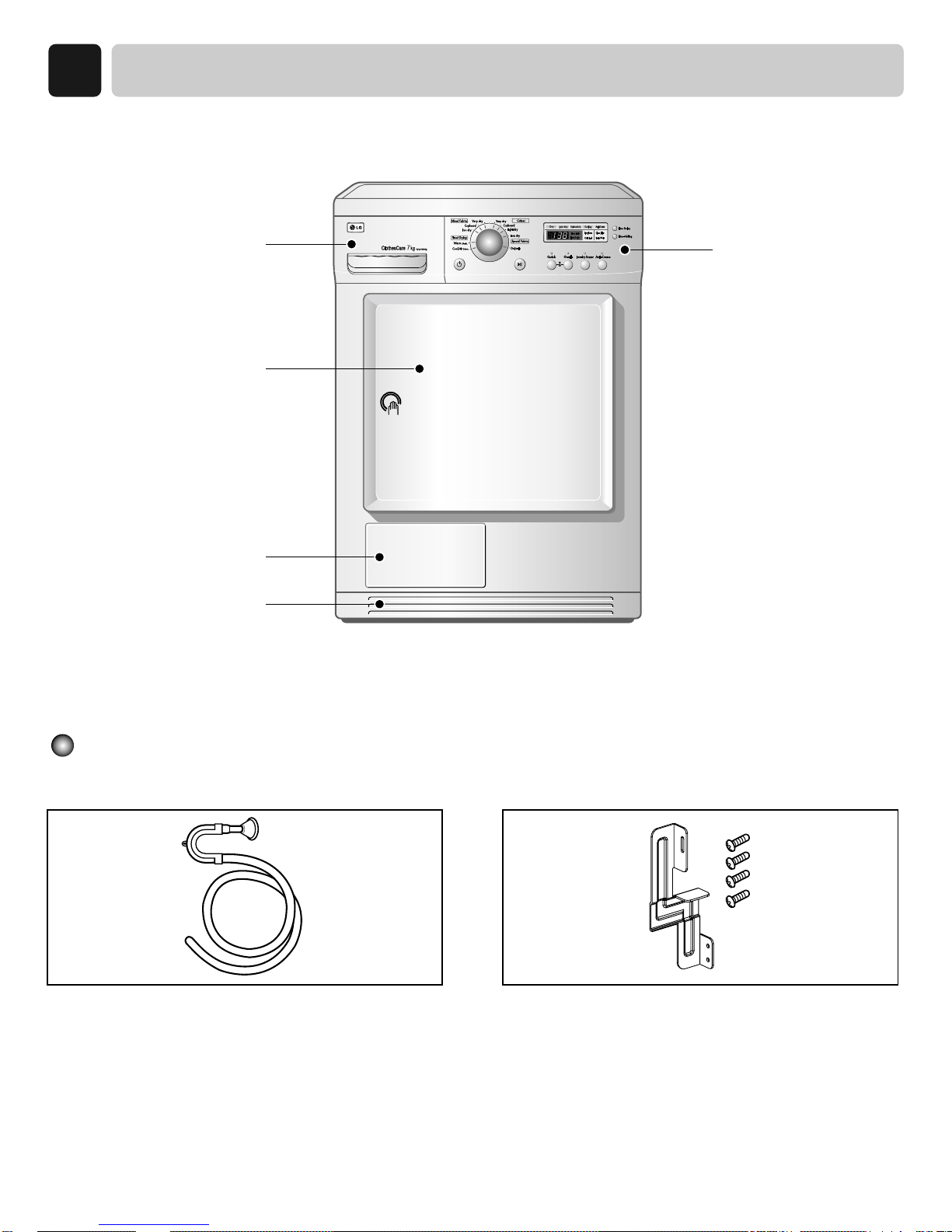

PART IDENTIFICATION

3

6

Accessories

1.Drain Hose Assembly (Purchased Separately) 2.Stacking kit Assembly (Purchased Separately)

P/No.:5001EL2001A

P/No.:5001EL2001C

Water container

Control panel

Door

Condenser Cover

Air ventilation grill

PROGRAM CYCLE

4

7

TD-C70140E/145E

Quick / Gentle

These are functioning to shorten or lengthen the

cycle time by increasing or decreasing

temperature.

Iron-dry Buzzer

Select Iron-dry Buzzer to alert you that your

clothes are approximately 80% dry.

This is useful when you want to remove

lightweight items in a mixed load to prevent

overdrying or remove partially dry items that

may need ironing.

NOTE : The Iron-dry Buzzer is only available

with the Cottons, Mixed Fabrics.

Time Delay

You can use the Time Delay function to delay

the finishing time of drying cycle.

Maximum Time Delay is 19 hours.

1. Turn the dryer on

2. Select cycle

3. Set time delay hour

4. Press Start/Pause button

Time-Adding

Press Time-Adding until the desired drying

time is displayed. Tap Time-Adding and the

time will change by 20 minute intervals.

NOTE : The Time-Adding function can be

used with Timed Drying.

Child-Lock

For the safety of your children, press “Quick”

and “Gentle” Buttons at the same time for

about 3 seconds.

You can see the “child lock” lamp is on, which

means this function is activated.

Anti-Crease

Anti-Crease is functioning to prevent creases

and rumples that are formed when the laundry

is not unloaded promptly at the end of drying

cycle. In this function, the dryer repeatedly

runs and pauses to the cycle end.

If the door is open during Anti-Crease process,

this function is cancelled. But in case of door

open during normal operation without

selecting Anti-Crease, this function will be

remembered and processed.

PROGRAM CYCLE

4

8

CAUTION!

If the load is less than 1kg, please use "Timed Drying Course"

Heat-sensitive fabrics including silk, underwears, lingerie should be used in delicates courses.

Otherwise, these clothes can cause undesirable drying results.

Standard

Program

Very Dry

Cupboard dry

Iron Dry

Very Dry

Cupboard dry

light Dry

Iron Dry

Warm (20min.)

Cool Air (20min.)

Delicates

Bed linen and table linen, tracksuits,

anorak, blankets

shirts, blouses and sportswear

Trousers, dressers, skirts, blouses

Terry toweling, tea towels, towel,

bed linen

Bath towels, tea towels,

underwear, cotton socks

T-shirts, trousers, underwear,

work clothes

Bed linen, table linen, towels, T-shirts

Polo shirts and work clothes

Bath towels, bath robes, dishcloths,

Quilted fabrics made of acrylic

All fabrics needing freshing, tumbles without heat

Silk, Women's thin clothes, lingerie

For thick and quilted fabrics which do not need to be ironed.

For fabrics which do not need to be ironed.

For fabrics which do need to be ironed.

For thick and quilted fabrics which do not need to be ironed.

For fabrics which do not need to be ironed.

For fabrics which do need to be ironed lightly, not completely.

For fabrics which do need to be ironed.

Small clothes & pre-dried laundry Normal

Normal fabrics using hot temperature for 20minutes

For fabrics which are heat-sensitive like synthetic fabrics.

Electronic Auto Dry Cycles

Mixed-Fabric cycles

(Note) press the "Gentle" button for heat-sensitive items

Cotton (Whites and coloreds)

(Note) press the "Gentle" button for heat-sensitive items

Time Cycles for selected length of time

Special Fabrics

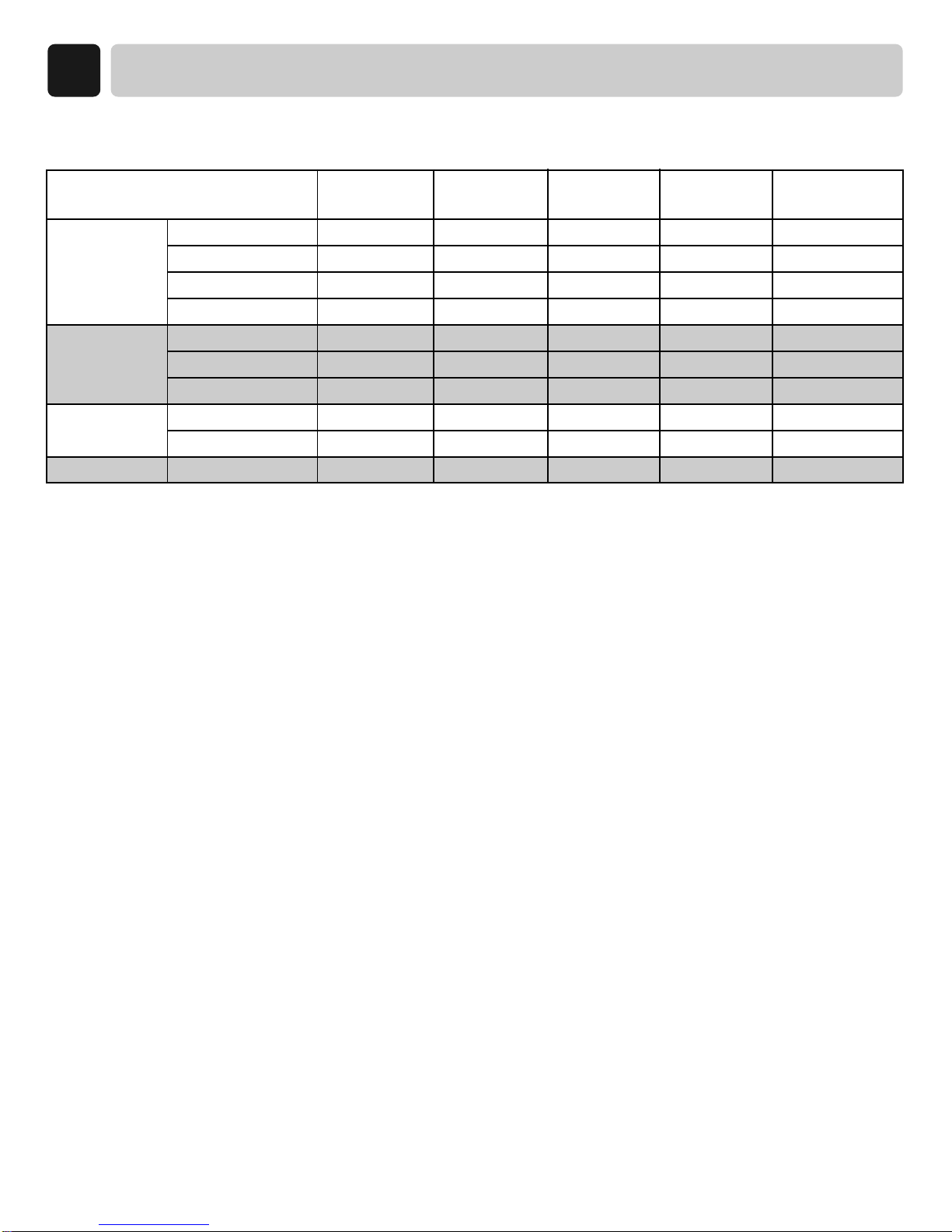

Cycle Selection Table

PROGRAM CYCLE

4

9

Course Quick Gentle

Iron-dry Buzzer

Anti-Crease Time left

Cottons Very dry O O O O 120

Cupboard dry O O O O 115

Light dry O O O O 103

Iron dry O O O O 97

Mixed Fabric Very dry O O O O 53

Cupboard dry O O O O 48

Iron dry O O O O 41

Timed Drying

Warm 20min. OOXO20

Cool Air 20min. XXXO20

Special Fabric

Delicate X X O O 69

INSTALLATION INSTRUCTIONS

5

10

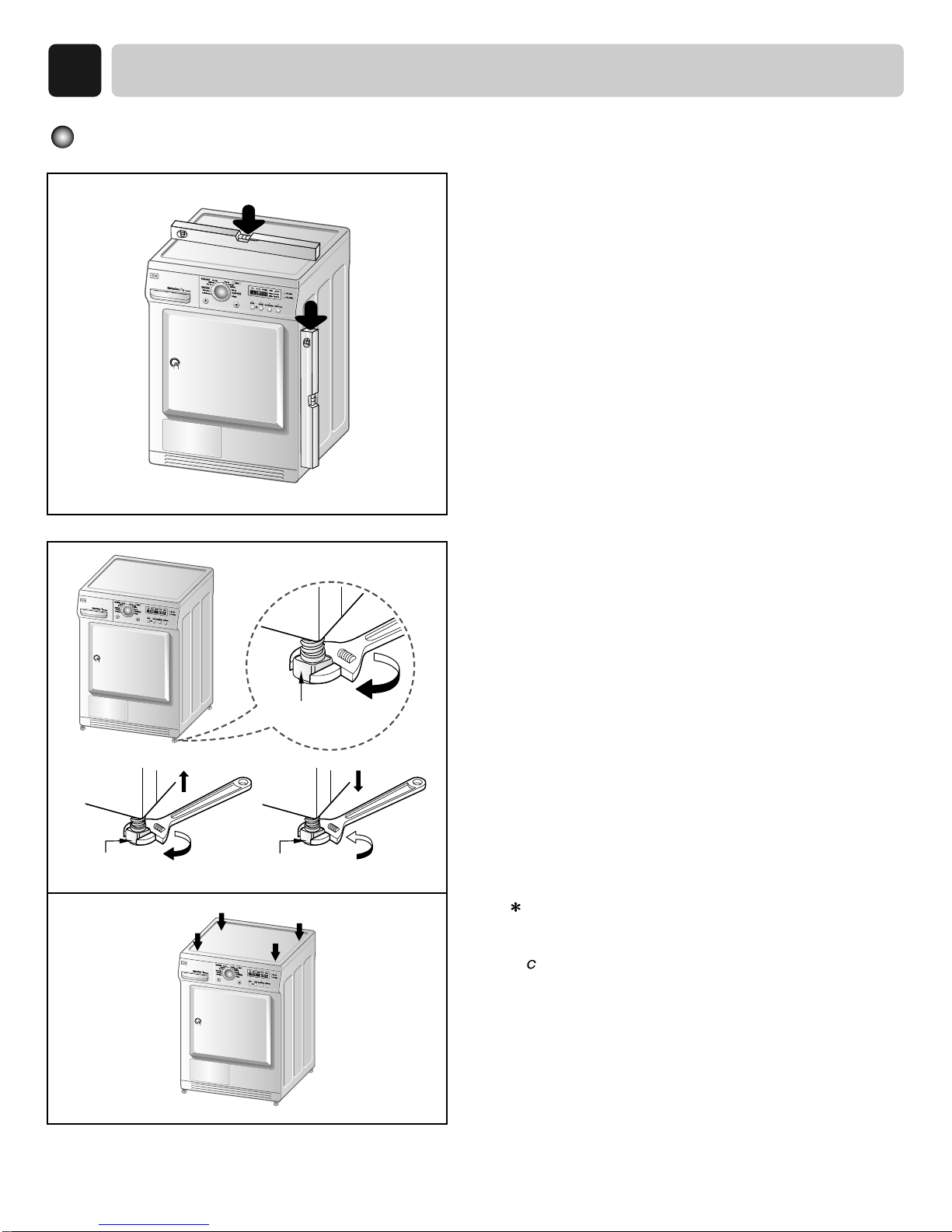

Level the dryer

Adjustable feet

Adjustable feetAdjustable feet

Raise Lower

1. Leveling the dryer is to prevent undesirable

noise and vibration.

When placing your dryer in an solid and level

area where water is not dripping and freezing,

flammable materials are not stored.

2. If the dryer is not properly level, adjust the front

leveling legs up and down as necessary.

Turn them clockwise to raise and

counterclockwise to lower until the dryer is not

wobbling both front-to-back and side-to-side.

Diagonal Check

When pushing down the edges of the washing machine,

the machine should not move up and down at all. (Please,

heck both of two directions)

If machine rocks when pushing the machine top plate

diagonally,adjust the feet again.

INSTALLATION INSTRUCTIONS

5

11

GROUNDING INSTRUCTION

This appliance must be grounded. In the event of

malfunction or breakdown, grounding will reduce

the risk of electric shock by providing a path of

least resistance for the electric current.

This appliance is equipped with a cord having an

equipment grounding conductor and a grounding

plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Additional Grounding Procedure

Some local codes may require a separate ground. In

such cases, the required accessory ground wire,

clamp and screw must be purchased separately.

Condensate Drain

The dryer can drain water without delivering to

water container. Water is directly pumped out of

the dryer.

Improper connection of the equipment

grounding conductor can result in a risk of

electric shock. Check with a qualified electrician

or a service person if you are in doubt as to

wether the dryer is properly grounded.

WARNING !

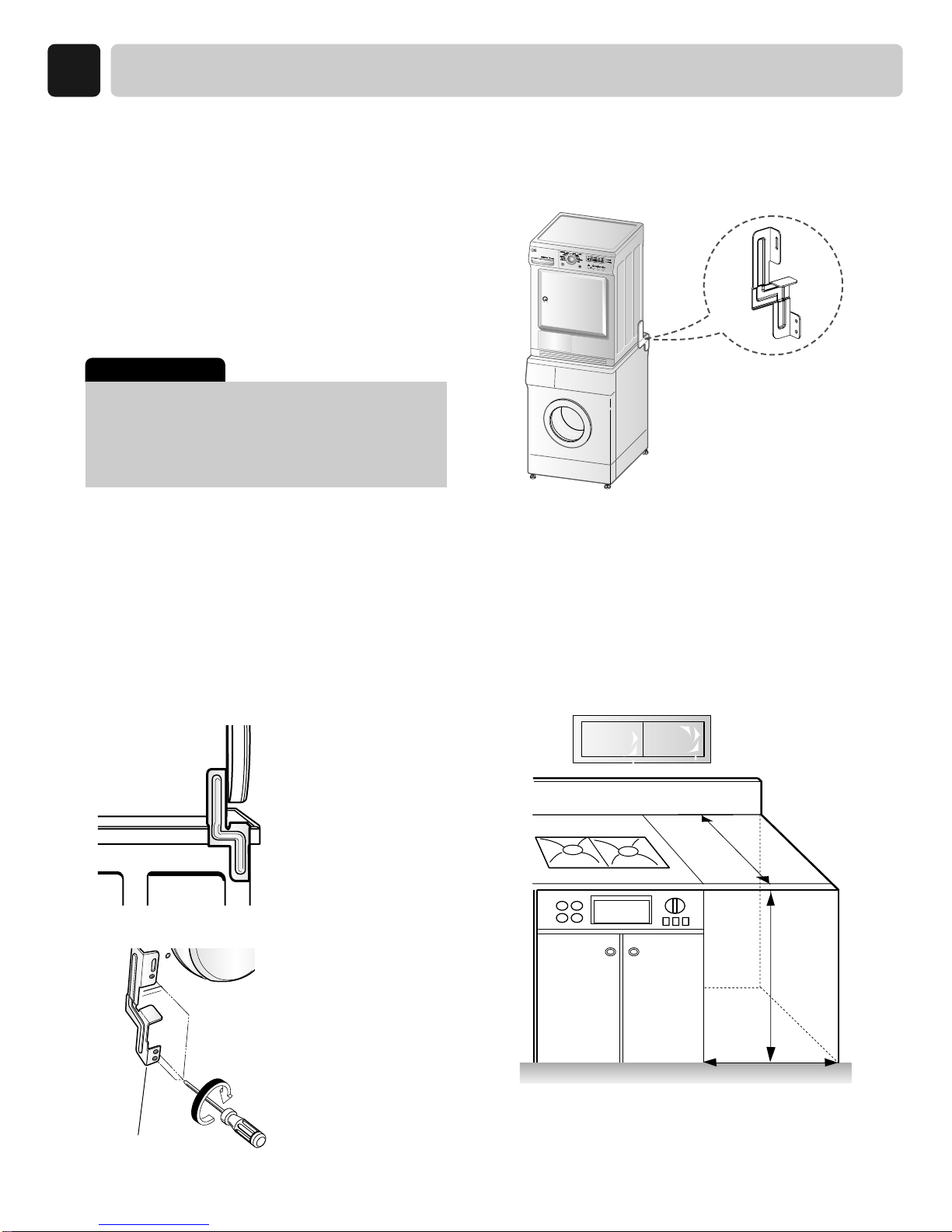

Installed Stacking kitside view

Installed Stacking kit rear view

Stacking Kit

In order to stack this dryer on a LG washing

machine, a stacking kit is needed.

Built-in Installation

Your dryer can be built-in. You can fit the dryer

under-counter in a kitcken cabinet opening.

Opening dimensions are shown as follows.

For your safety, metal cover must be tightly fitted.

This must be placed by an experienced service

person and installed under a continuous worktop.

600

850

595

MAINTENANCE INSTRUCTIONS

6

12

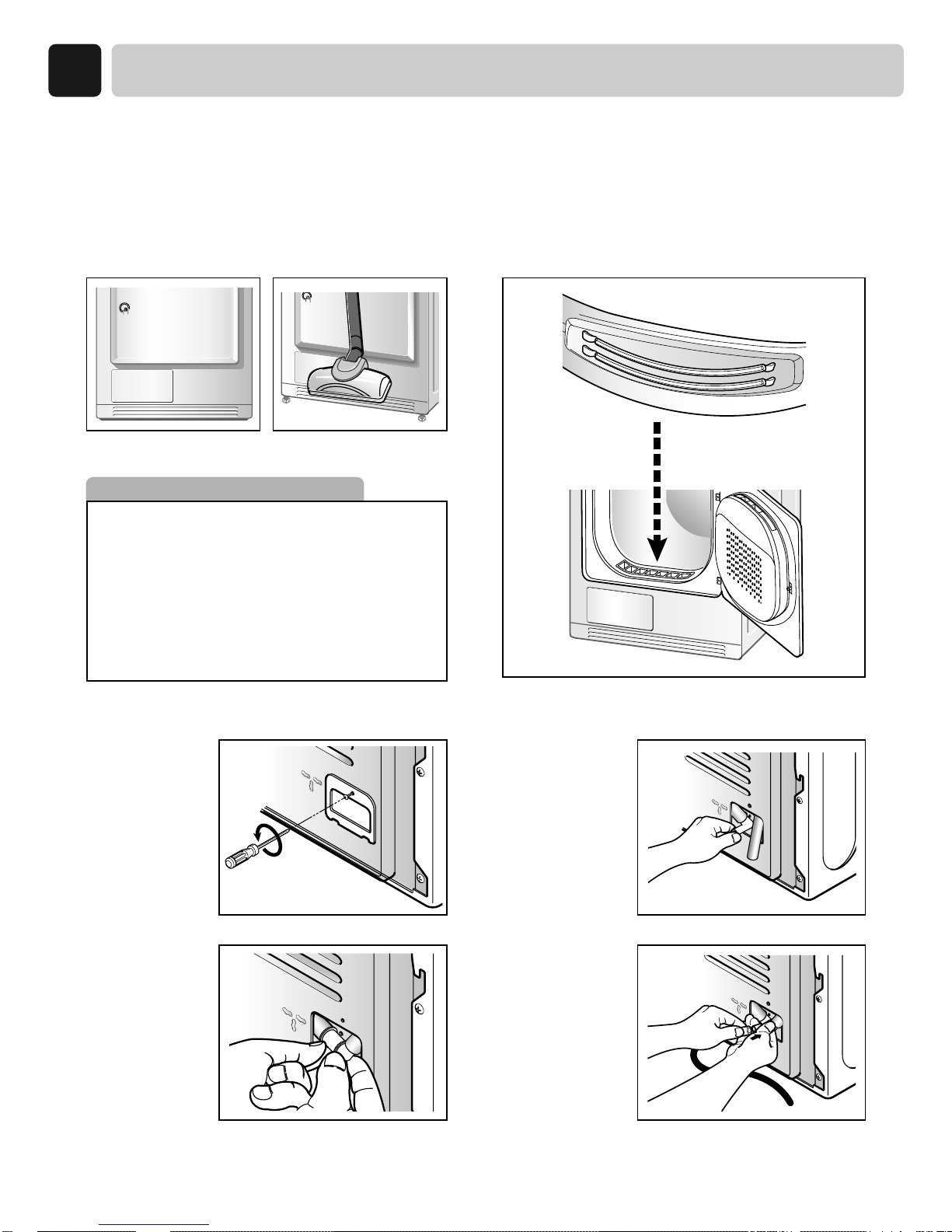

Front Ventilation Grille

Vacuum the front ventilation grill 3~4 time a year to

make sure there must be no build-up of lints or dirts

which cause improper intake air flow.

Normally, condensed water is pumped up to water

container where water is collected until emptied.

Not only using water container, but water can be drained

out directly to drain hose especially when dryer is stacked

on top of washing machine.

With connecting kit for drain hose, you can simply change

water path and water reroute to the drainage facility.

Please follow the below steps.

Condensed water Drain-out

Moisture Sensor?

This device functions to sense the moisture

remaining contents of the laundry during operation

which means it must be cleaned all the time. The

main reason of cleaning this part is to remove the

build-up of lime scale on the surface of sensor. Wipe

the sensors inside drum (Shown in the picture).

1.Unscrew

cover.

3. Separate water

container hose

from the kit.

2. Take

connecting kit

out.

4. Connect drain

hose to the kit.

MAINTENANCE INSTRUCTIONS

6

13

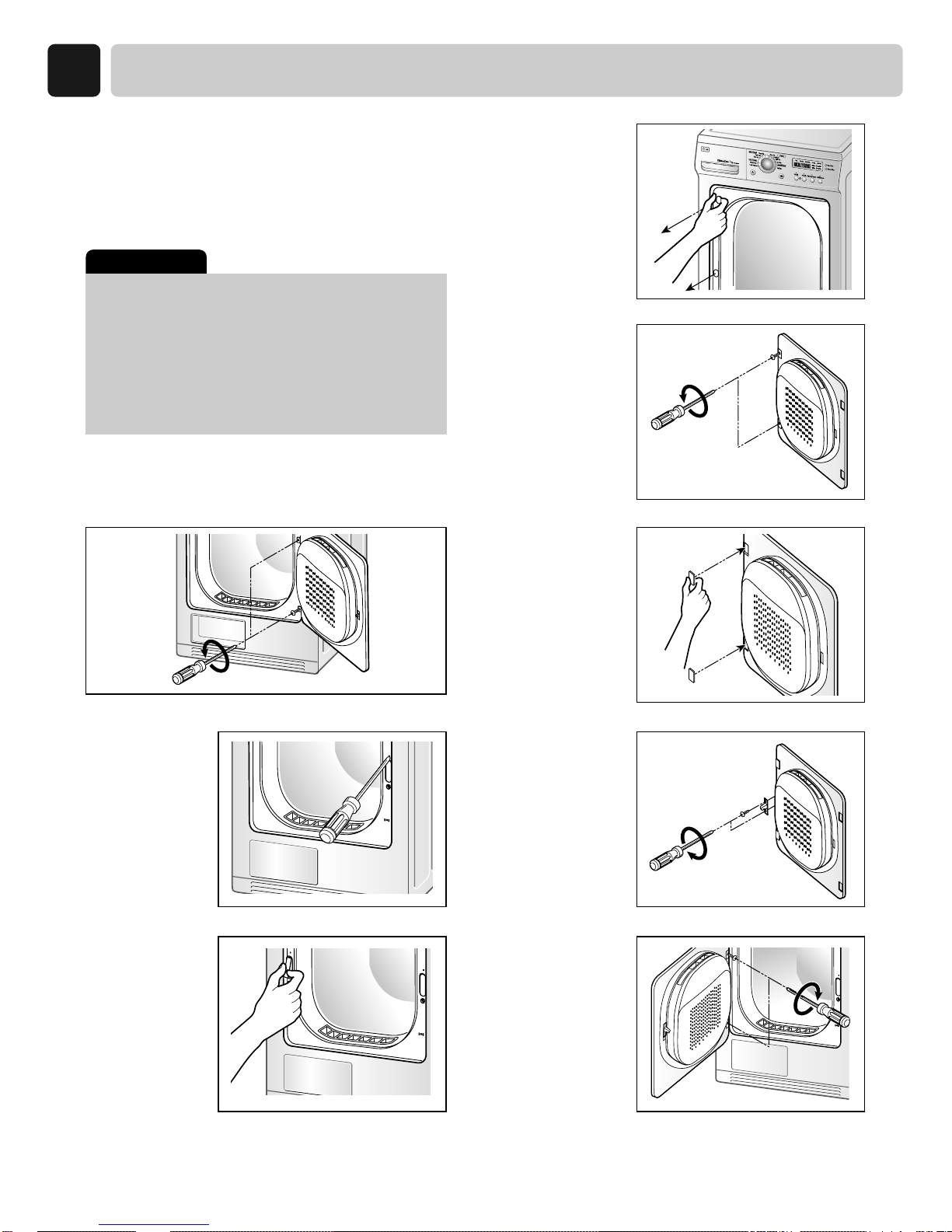

Reverse the door

The door can be reversed to fit to your own

installation conditions. From the factory, the door

hinge is located on the right side.

1. This work may cause the injury of your

hands so you must be careful to handle

some sharp devices like torque screwdriver or

slotted screwdriver.

2. When the door is revered, the hand sticker

on the door also must be replaced.

Do not use a machine screwdriver.

Caution !

1. Unscrew the bottom hinge of the door first

and top hinge. And then place on the blanket

to prevent scratches.

2. Remove the

door lock

cover.

3. Remove the

door lock and

replace where

door lock

cover is

4. Detach both

hinge point

covers.

5. Unscrew two

door hinges.

6. Replace both

hinge point

covers where

door hinge is

located.

7. Replace the

door catch to

the reverse

location.

8. Screw the

door hinges.

MAINTENANCE INSTRUCTIONS

6

14

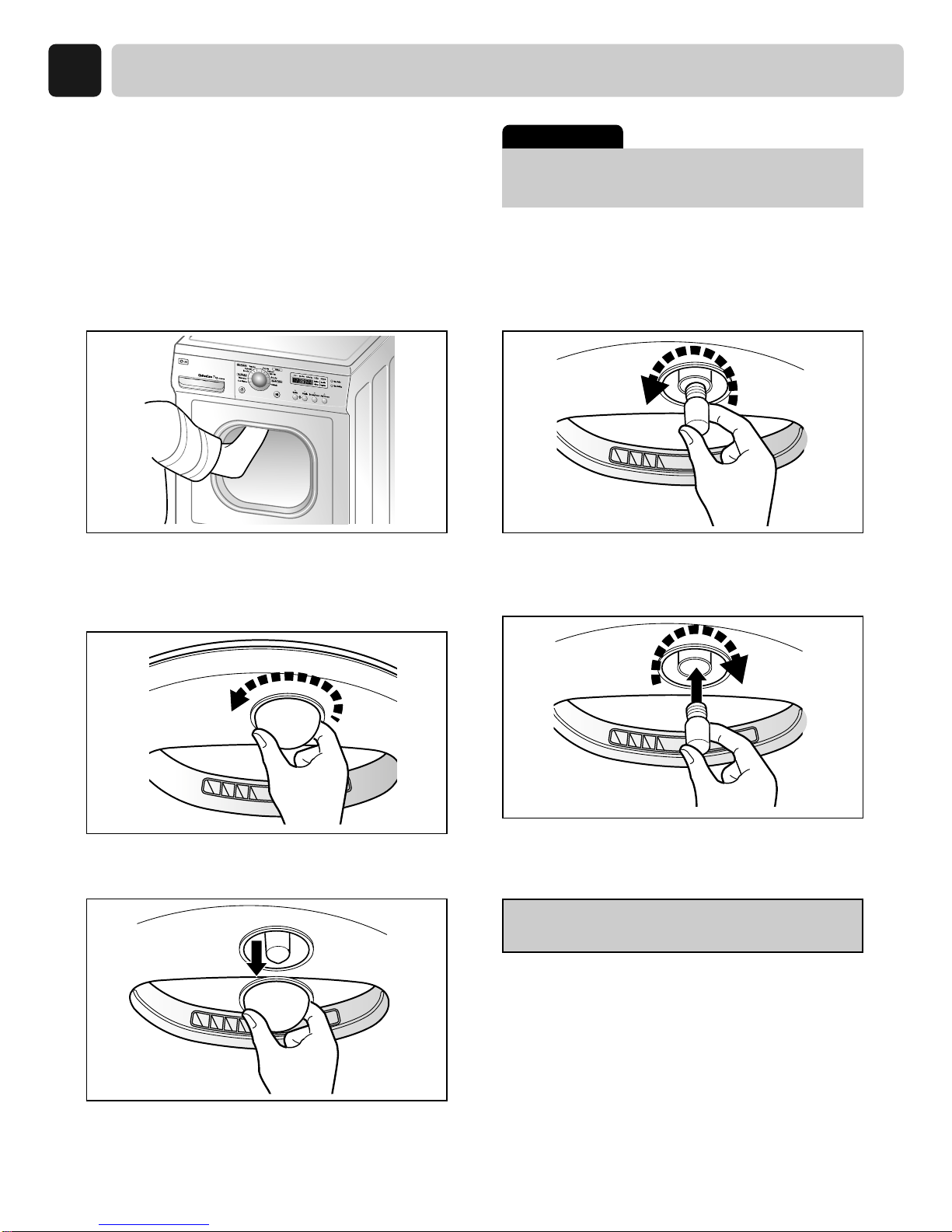

Change the Bulb

The bulb itself could be very hot when the dryer just

finishes its operation. So before changing the bulb,

be sure that the inside of the drum is cool down.

1. Open the door, put a hand into the drum and

grasp a bulb cover.

2. With bulb held by a hand, turn the bulb to the

clockwise direction with a certain amount of

force.

3. Separate bulb cover from the socket housing.

Power cord must be unplugged before this

work to avoid danger of electric shock.

Caution !

4. Remove the current bulb turning it to Counter

clockwise direction.

Be careful that it does not fall off.

5. Screw in the new bulb in the reverse

unscrewing direction.

Do not need any special tool for this work.

All steps can be done manually.

Loading...

Loading...