Page 1

MODEL: HT303SU(SH33SU-S/W)/HT353SD(SH33SD-S/W)

SERVICE MANUAL

P/NO : AFN33723386 JANUARY, 2008

DVD/CD RECEIVER

SERVICE MANUAL

MODEL: HT303SU(SH33SU-S, SH33SU-W)/

HT353SD(SH33SD-S, SH33SD-W)

Website http://biz.lgservice.com

Internal Use Only

HT303SU

HT353SD

Page 2

1-1

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

[CONTENTS]

❍ SECTION 1. GENERAL

• SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

• ESD PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

• SERVICE INFORMATION FOR EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

•

HOW TO UPDATE AUDIO MICOM & DVD PROGRAMS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

• SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

❍ SECTION 2. ELECTRICAL PART

• TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

• DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING . . . . . . . . . . . . . . .2-13

• INTERNAL BLOCK DIAGRAM OF ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

• WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

• OVERALL BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

• CIRCUIT DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

• PRINTED CIRCUIT DIARGAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

❍ SECTION 3. EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

• CABINET AND MAIN FRAME SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

• DECK MECHANISM EXPLODED VIEW(DP-12TV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

• PACKING ACCESSORY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

• SPEAKER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

❍ SECTION 4. MECHANISM (DP-12TV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

❍ SECTION 5. REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Page 3

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1-2

SERVICING PRECAUTIONS

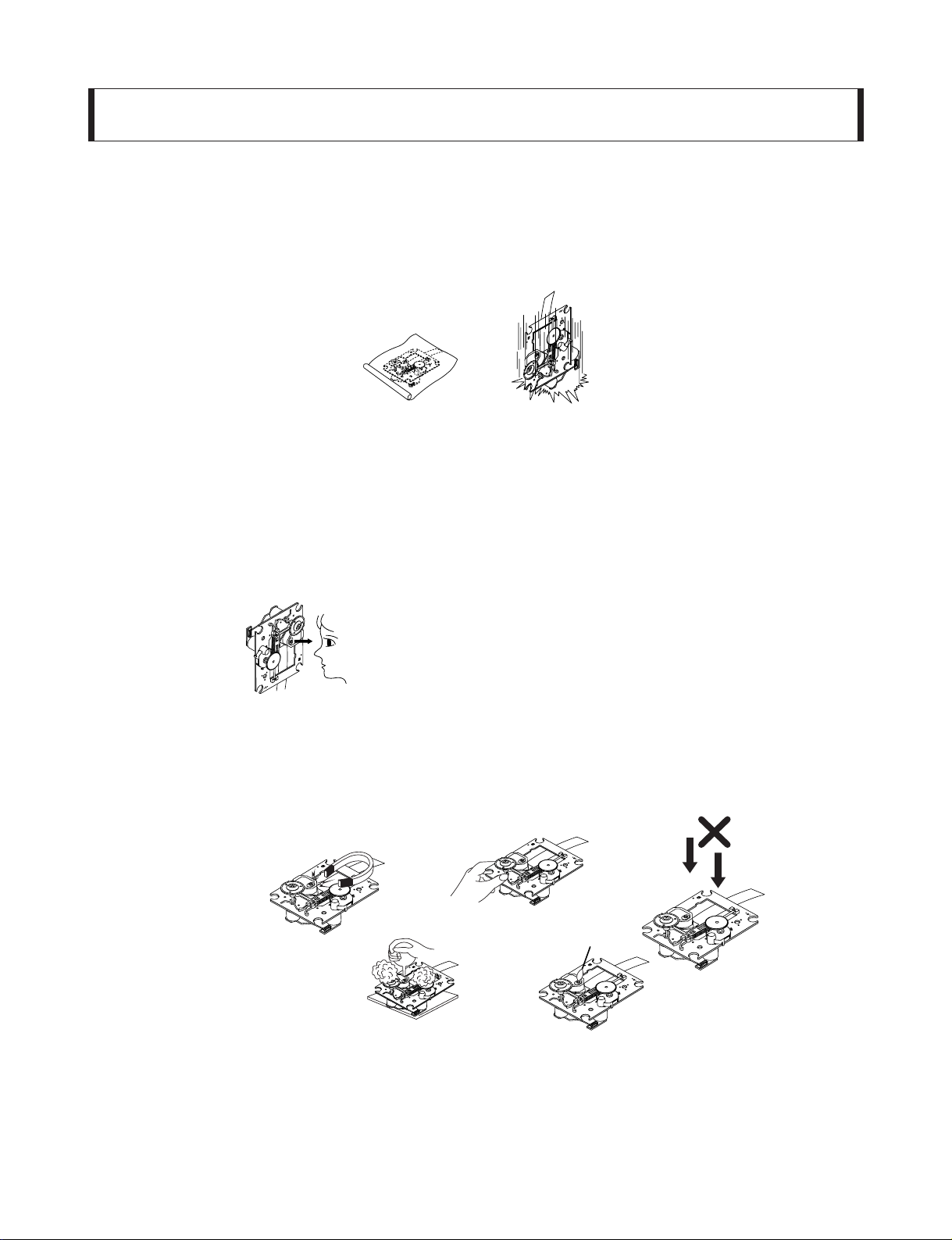

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton

swab should be used, taking care not to distort lens.

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

Magnet

How to hold the pick-up

Conductive Sheet

Cotton swab

Pressure

Pressure

SECTION 1. GENERAL

Page 4

1-3

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

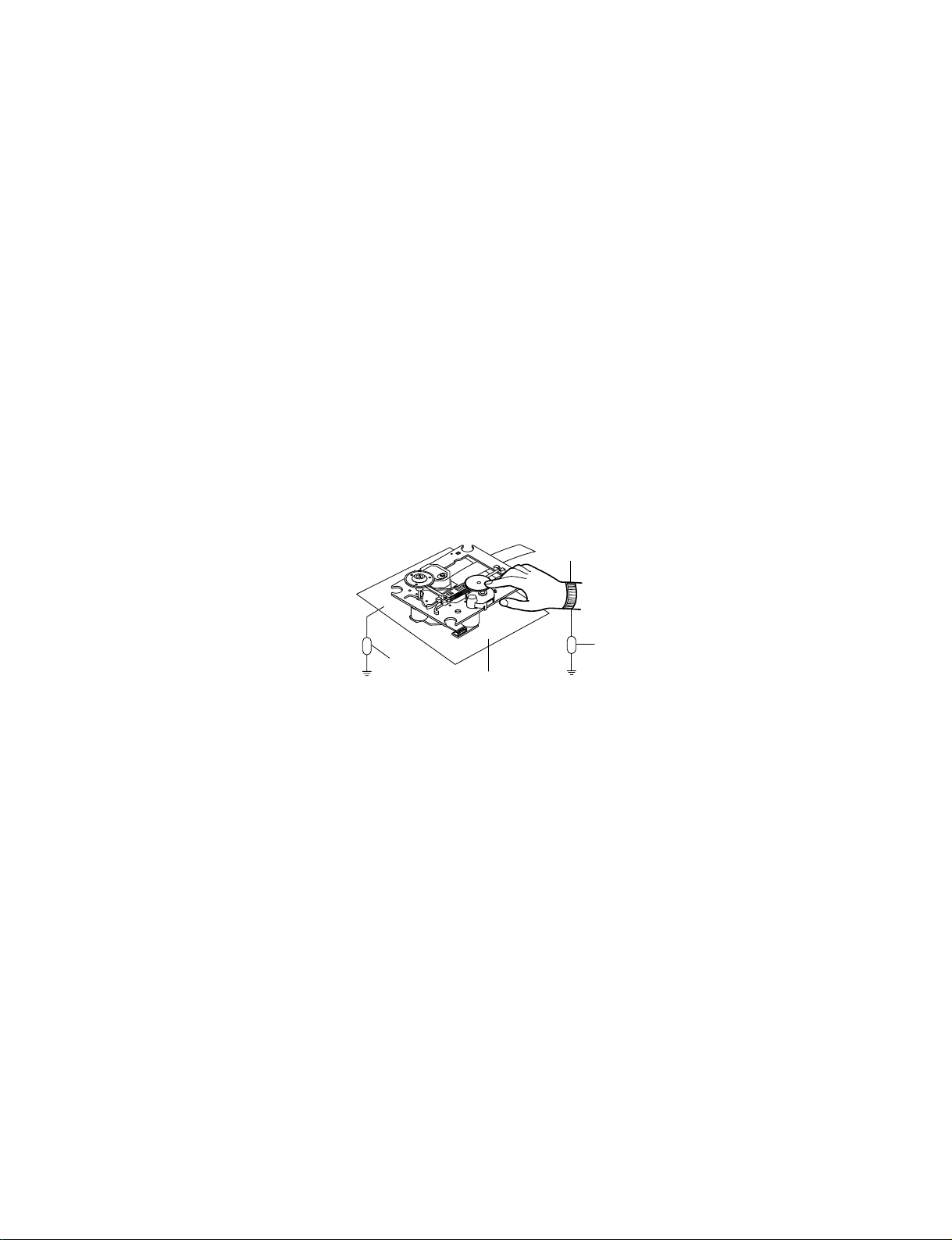

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M Ω)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Resistor

(1 Mohm)

Conductive

Sheet

Resistor

(1 Mohm)

Armband

Page 5

1-4

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 6

1-5

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

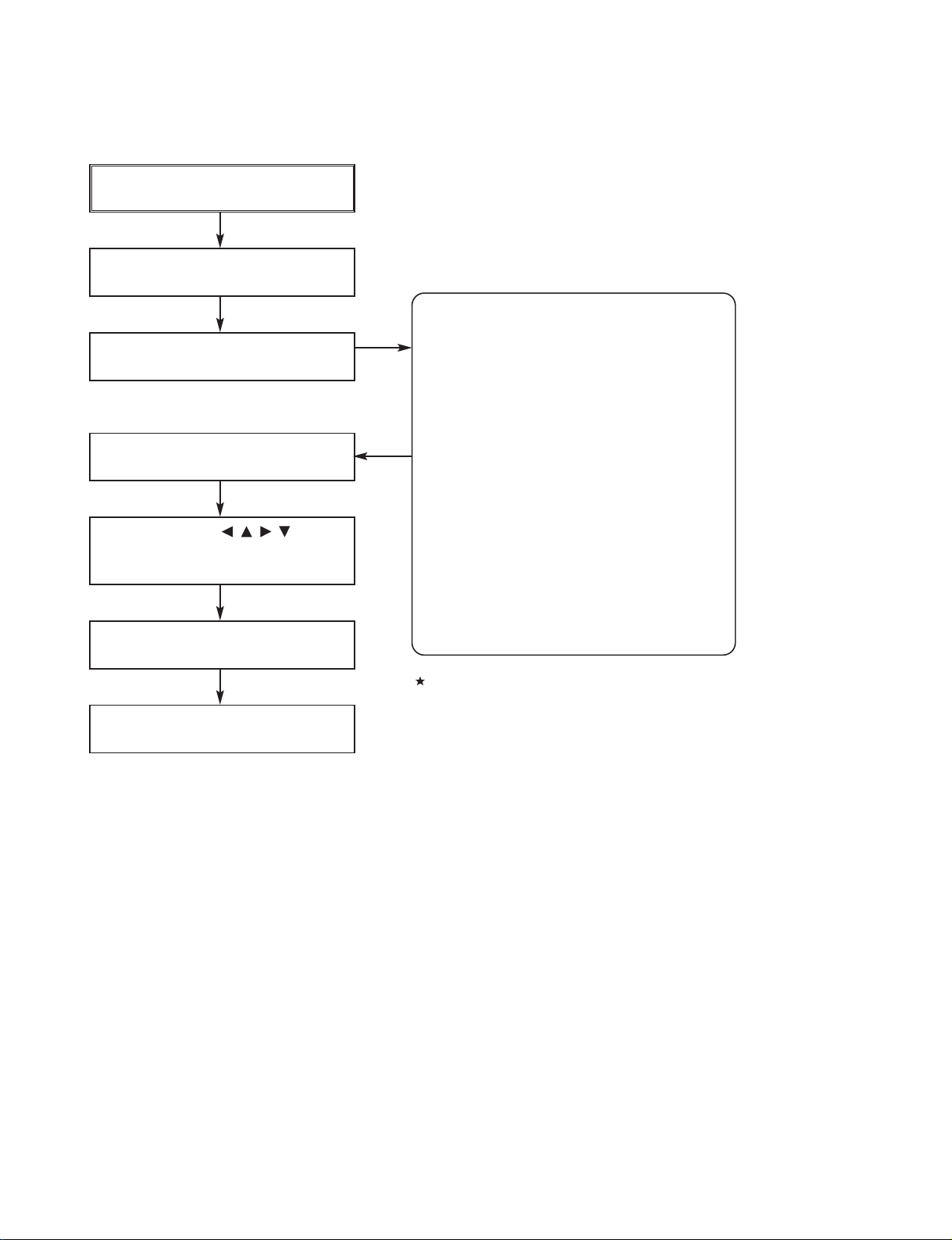

SERVICE INFORMATION FOR EEPROM (DVD PART)

POWER ON

DVD LOGO Status (NO Disk status)

Remote control

Pause key-->1-->4-->7-->2 in order.

Press number 0~9, Press character

A~F (1~6 for a while)

Use arrow key ( ) to

move to appropriate position and

make changes

Press pause key once

Change will be applied when power

OFF-->ON.

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

NAME

OPT 1

OPT 2

OPT 3

OPT 4

OPT 5

OPT 6

OPT 7

OPT 8

OPT 9

OPT A

OPT B

OPT C

OPT D

OPT E

OPT F

OPT G

HEX

44

45

30

FF

22

05

FC

32

AC

00

00

00

00

00

00

00

45

53

11

FF

22

05

FC

32

AC

00

00

00

00

00

00

00

48

55

20

FF

22

05

FC

32

AC

00

00

00

00

00

00

00

52

4F

20

FF

22

05

FC

32

AC

00

00

00

00

00

00

00

<A>

HEX

<B>

HEX

<C>

HEX

<D>

<A> Germany, Austria, Netherlands, France (LGEDG)

<B> Spain, Portugal, Greece, Italy (LGEES)

<C> Hungary, Czech Republic (LGEMK)

<D> Romania (LGERO)

Page 7

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1-6

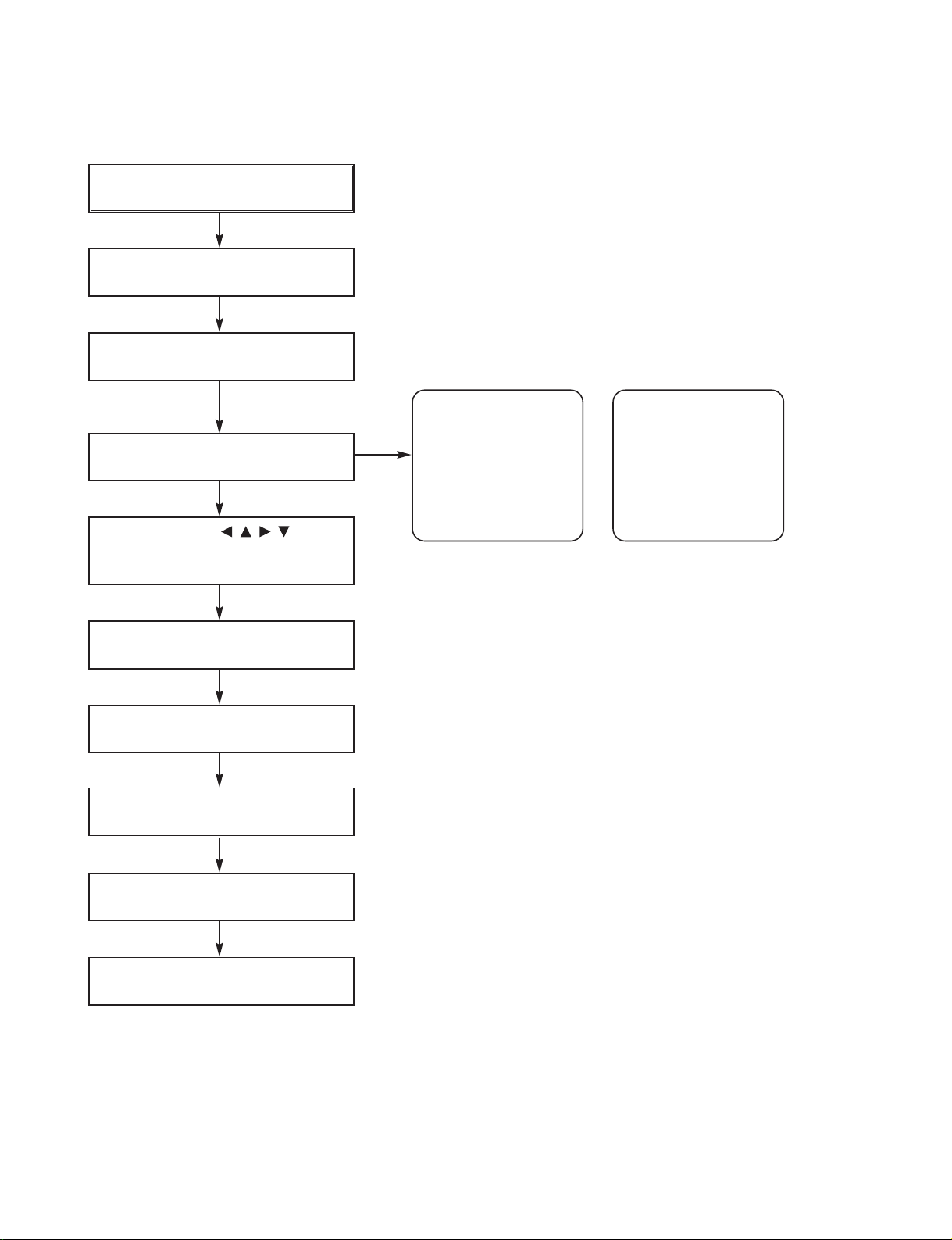

SERVICE INFORMATION FOR EEPROM (AMP PART)

POWER ON

FLD no disc status

Remote control ‘2’ + Front ‘STOP’

push same timing during 5s

FLD ‘OP-0….

Use arrow key ( ) move

to appropriate position and make

changes

Press ENTER key once

FLD ‘write ok’ or ‘up ok’

Remote control ‘2’ + Front ‘STOP’

push same timing

FLD display E2P CLR or EP CLR

Auto power off

MODEL : HT303

NAME HEX

OPT 1 82

OPT 2 CA

OPT 3 21

OPT 4 27

OPT 5 00

MODEL : HT353

NAME HEX

OPT 1 82

OPT 2 CA

OPT 3 20

OPT 4 27

OPT 5 00

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

Page 8

1-7

HOW TO UPDATE AUDIO MICOM & DVD PROGRAMS

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. How to update AUDIO MICOM program.

[Update using CD]

1. Change the filename to download as “(MODEL NAME)_(Version).HEX”. Only upper cases are permitted.

ex) HT353 : “HT353_0709081.HEX”

2. Copy the file to the root folder of a CD and burn it.

3. Insert the CD to the SET, and move to the DVD function. Then the upgrade process will be started with

the upgrade information.

4. If the upgrade process is complete, the set will be rebooted with “Complete” message.

[Update using USB]

1. Change the filename to download as “(MODEL NAME)_(Version).HEX”. Only upper cases are permitted.

ex) HT353 : “HT353_0709081.HEX”

2. Copy the file to the root folder of USB storage.

3. Put the USB into the SET, and move to the USB function. Then the upgrade process will be started with

the upgrade information.

4. If the upgrade process is complete, the set will be rebooted with “Complete” message.

2. How to update DVD program.

[Update using CD]

1. Rename the filename to download as “TARGET.BIN” in upper cases.

2. Copy the file to “\MTK_UPG\” folder of CD, and burn it.

Ex) P:\MTK_UPG\TARGET.BIN

3. Insert the CD to the SET, then after a while the CD tray will be opened with upgrade information on the

screen.

4. Remove the CD, and press UP key in remote controller.

5. Remove and reconnect the power cable when it changes to logo screen from upgrade information. Then

the upgrade process is completed.

[Update using USB]

1. Rename the filename to download as “TARGET.BIN” in upper cases.

2. Copy the file to “\MTK_UPG\” folder of the formatted USB, and burn it.

Ex) P:\MTK_UPG\TARGET.BIN

3. Move to the USB function, and insert the USB to the set. The upgrade information will be shown on the

screen.

4. Remove the USB, press UP key of the remote control.

5. Remove and reconnect the power cable when it changes to logo screen from upgrade information. Then

the upgrade process is completed.

Page 9

1-8

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SPECIFICATIONS

(* Depending on the sound mode

settings and the source, there may

be no sound output.)

GENERAL

Power supply Refer to main label

Power consumption Refer to main label

Net Weight 2.5 kg

External dimensions (W x H x D) 360 x 62 x 305 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

AMPLIFIER

Output Power Front: 45W + 45W (Rated Output Power 30W, THD 10%)

Center*: 45W

Surround*: 45W + 45W (Rated Output Power 30W, 4 Ωat 1 kHz, THD 10%)

Subwoofer*: 75W (Rated Output Power 60W, 8 Ωat 30 Hz, THD 10%)

SPEAKERS (SH33SU)

Front/Rear/Center Speaker Passive Subwoofer

(SH33SU-S) (SH33SU-W)

Impedance 4Ω 8 Ω

Net Dimensions 99 x 114 x 86 mm 156 x 325 x 320 mm

(W x H x D)

Net Weight (1EA) 0.35 kg 3.5 kg

SPEAKERS (SH33SD)

Front/Rear/Center Speaker Passive Subwoofer

(SH33SD-S) (SH33SD-W)

Impedance 4Ω 8 Ω

Net Dimensions 99 x 114 x 86 mm 156 x 325 x 320 mm

(W x H x D)

Net Weight (1EA) 0.35 kg 3.5 kg

Designs and specifications are subject to change without notice.

Page 10

2-1

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

SECTION 2. ELECTRICAL PART

TROUBLESHOOTING GUIDE

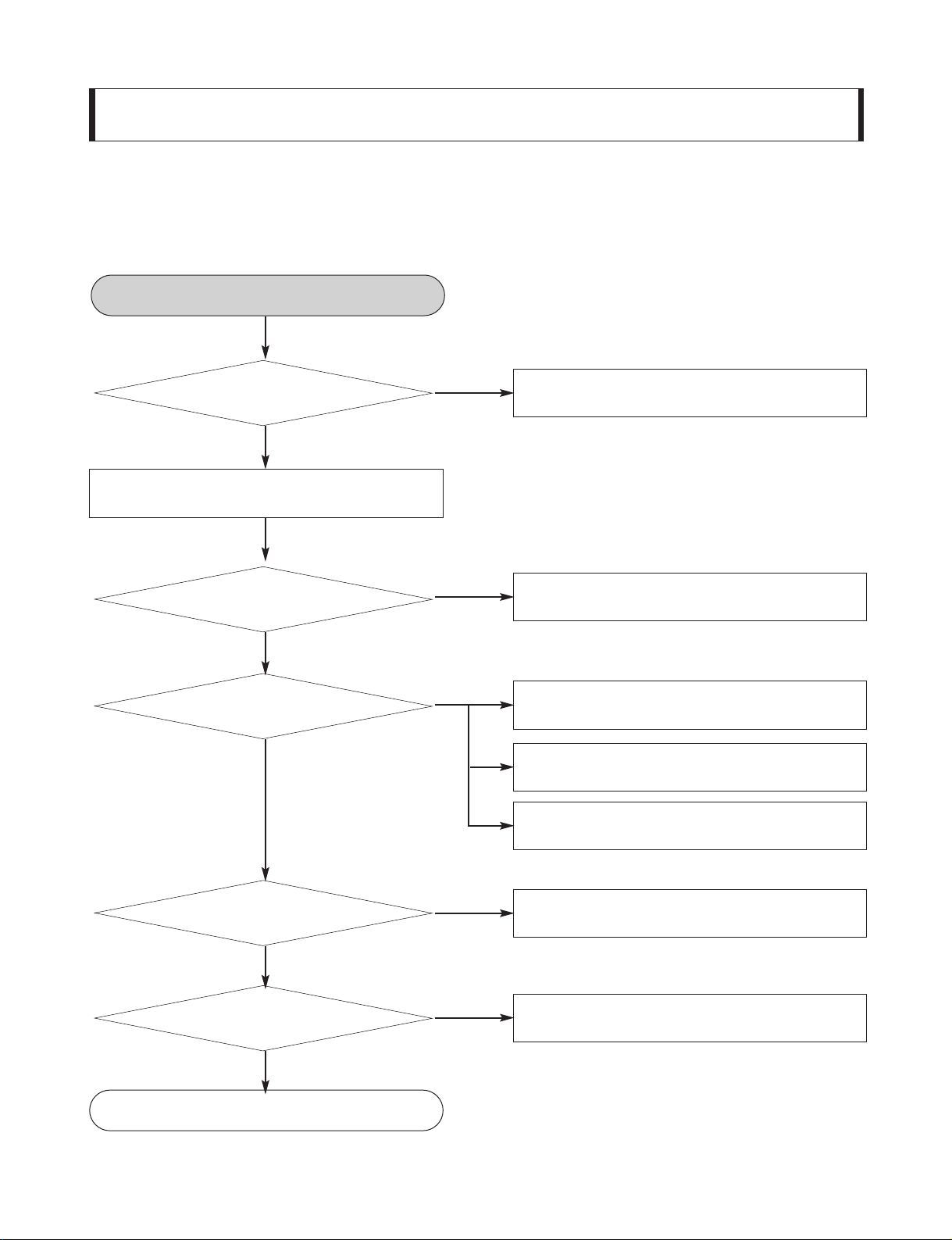

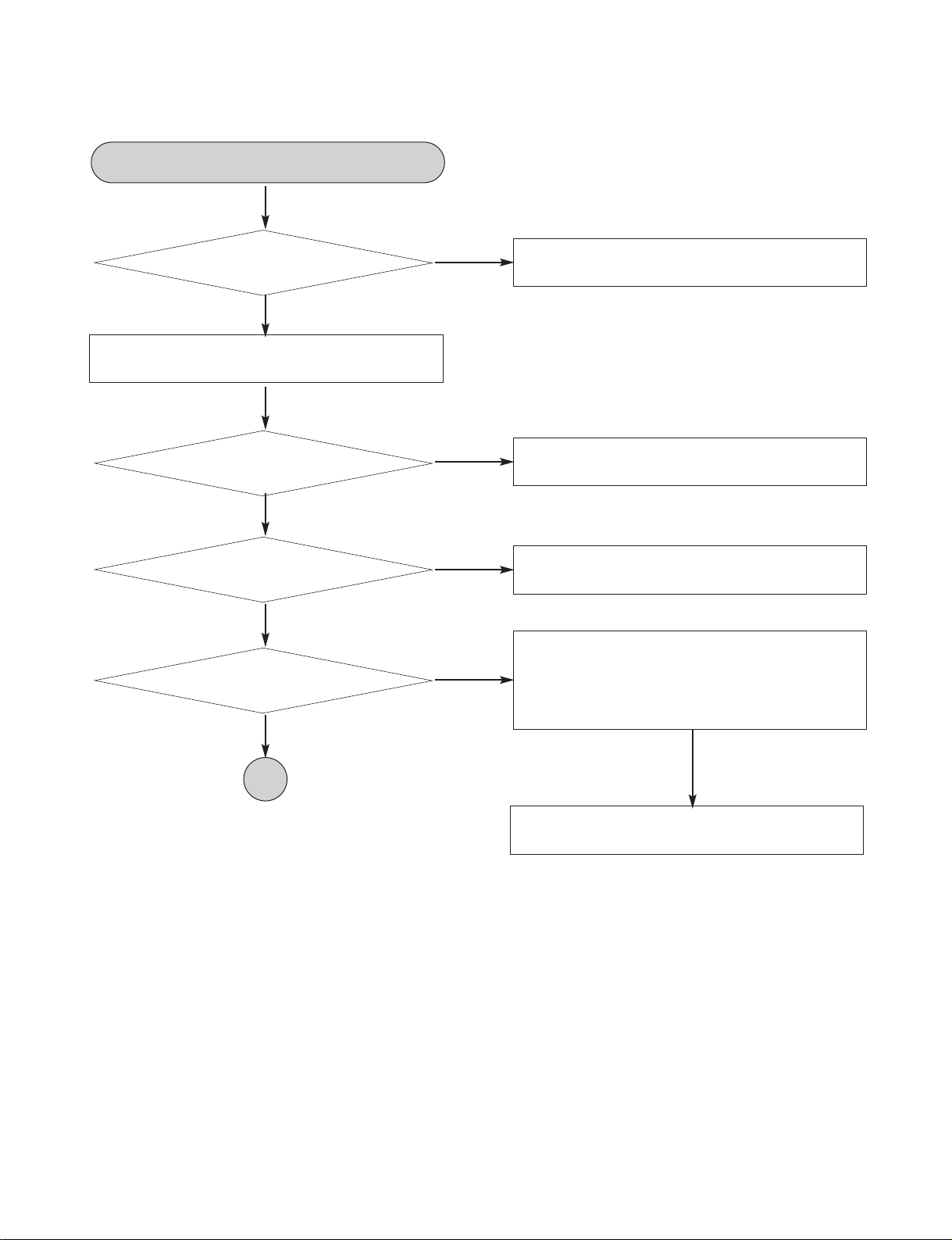

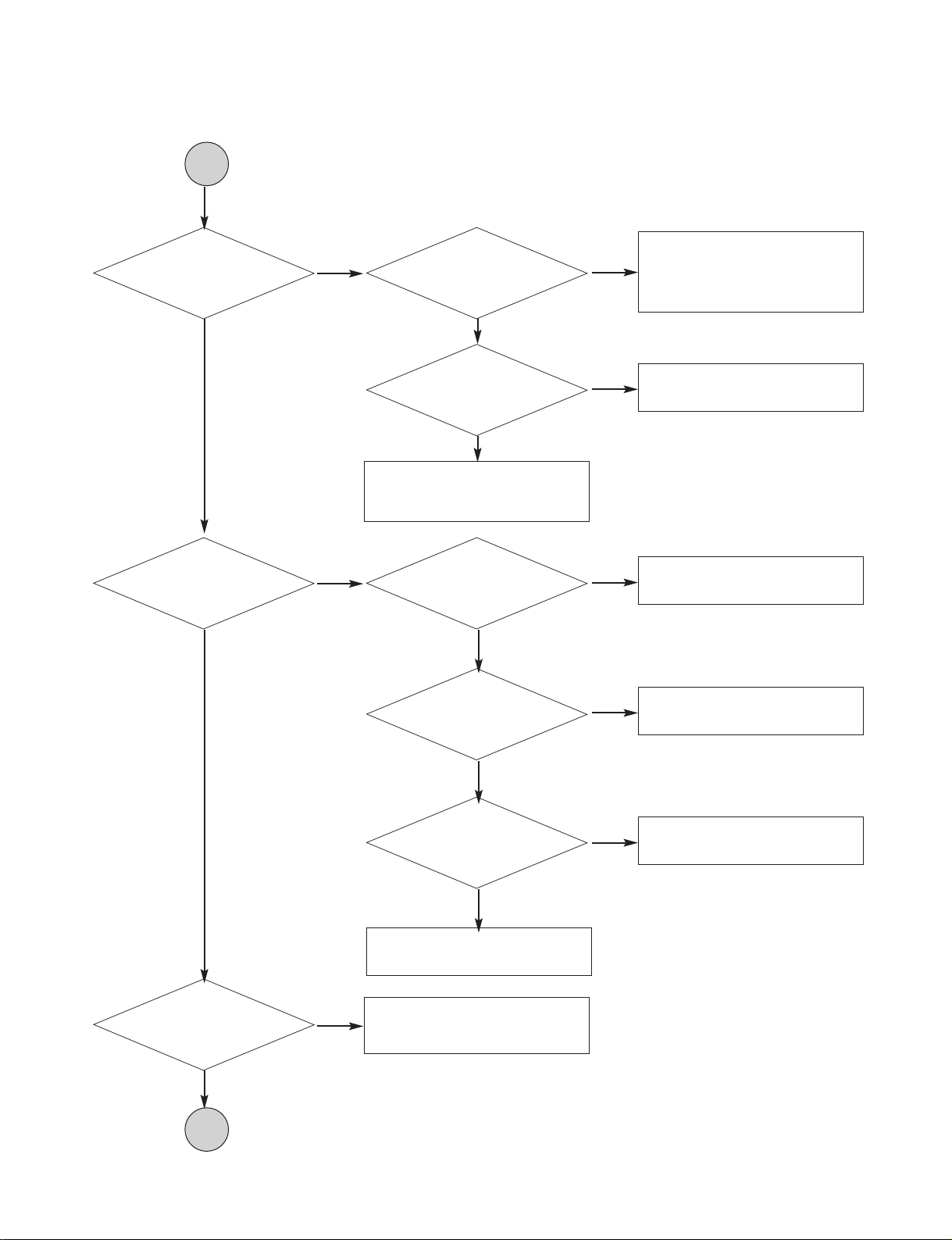

1. Power Supply Circuit

YES

NO

Check power plug and power

supply circuit.

NO

Check power supply circuit.

NO

Check laser circuit.

Check focus circuit.

Check disc.

NO

Check tracking servo circuit.

NO

Check audio circuit.

Does red power led

turn on?

YES

Is power on?

YES

Does red power led

turn on?

YES

Does it play?

YES

Does it output

audio?

YES

YES

Turn power on.

INSERT POWER CORD.

OK

Page 11

2-2

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

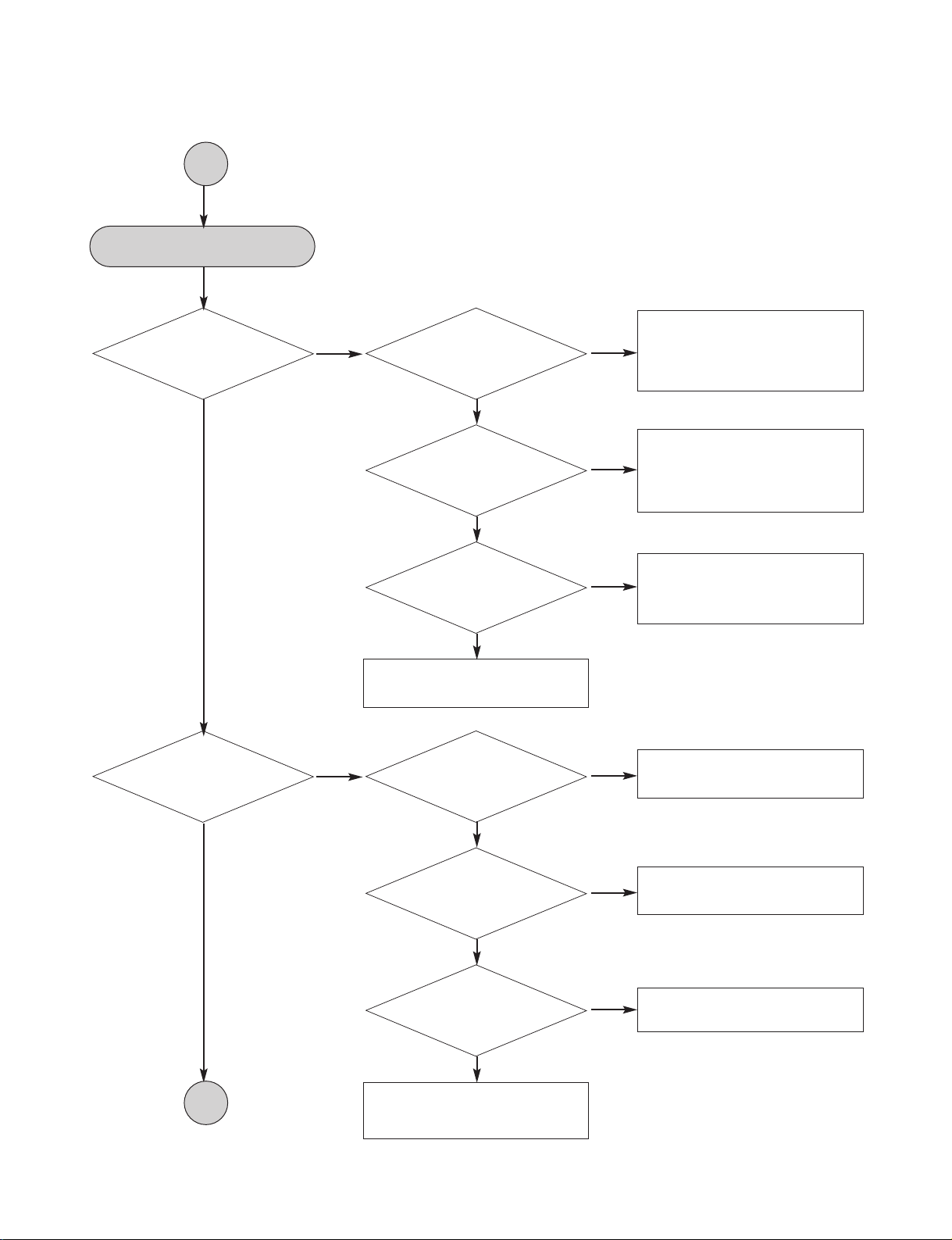

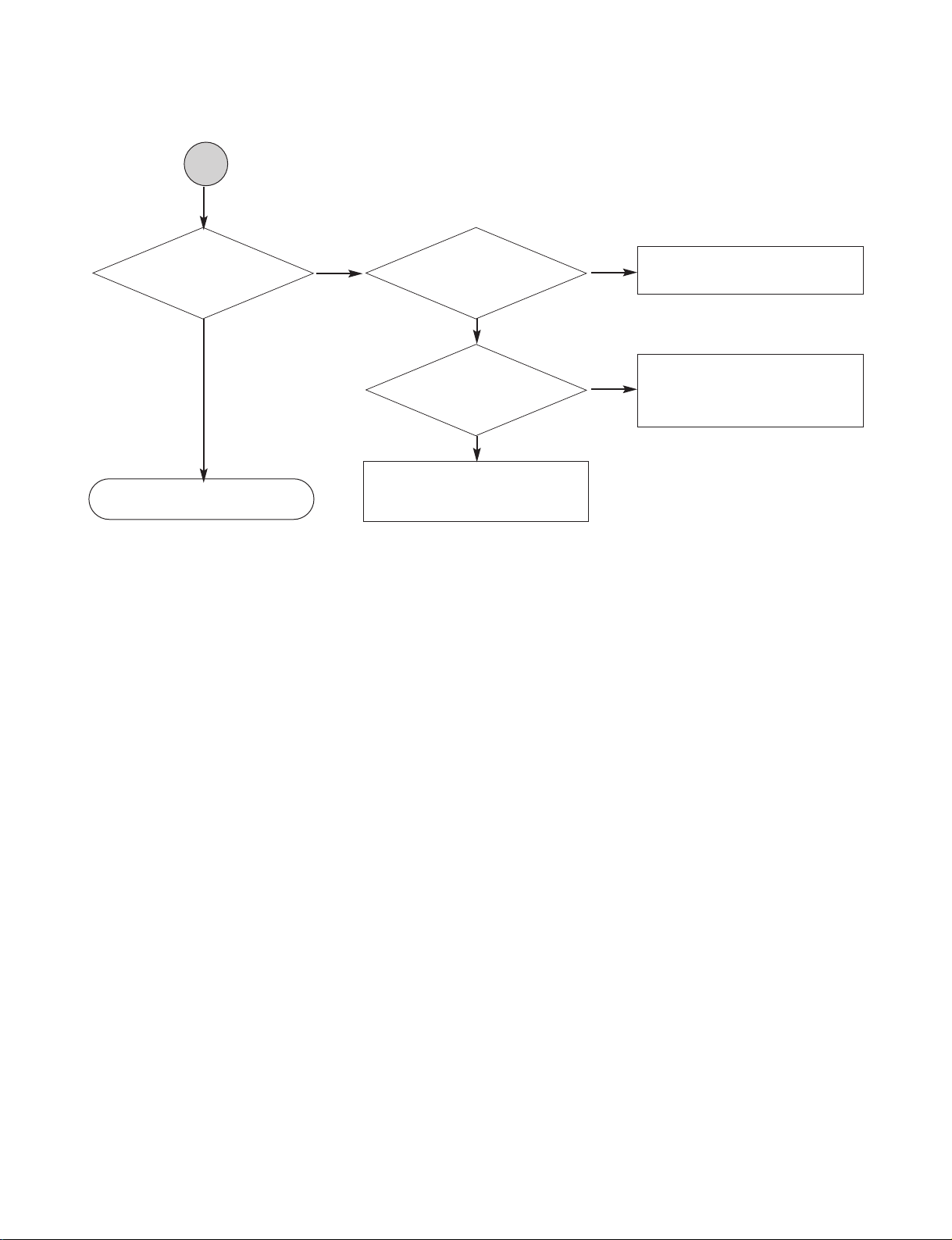

2. Front circuit (1/2)

NO NO

Reconnect it.

YES

YES YES

Check if

PN103 is ok?

Red LED turn off?

NO

NO

Refer to SMPS part.

YES

YES

Check if the front

power is ok?

Is the Digitron on

correctly?

NO NO

Check pattern and resoldering

YES

Check if

RC2 is ok?

Check if the remote

control is ok?

YES

Check if all

buttons are ok?

POWER ON.

Front B/D ok.

1

2

Page 12

2-3

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

3. Front circuit (2/2)

1

NO

Refer to power(SMPS).

NO

Replace R345 ~ R350.

Check if the

power part of the

front is ok?

YES

Check if

R345~R350

ok?

YES

Refer to MICOM circuit.

2

NO

Refer to power(SMPS).

NO

Check RM circuit

Check if the power

part of the front is ok?

YES

NO

Refer to MICOM circuit.

Check if the remote

control waveform of PN301

pin5 is ok?

YES

Check if RC2

voltage is ok(5V)?

YES

Resolder or Replace RC2.

Page 13

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-4

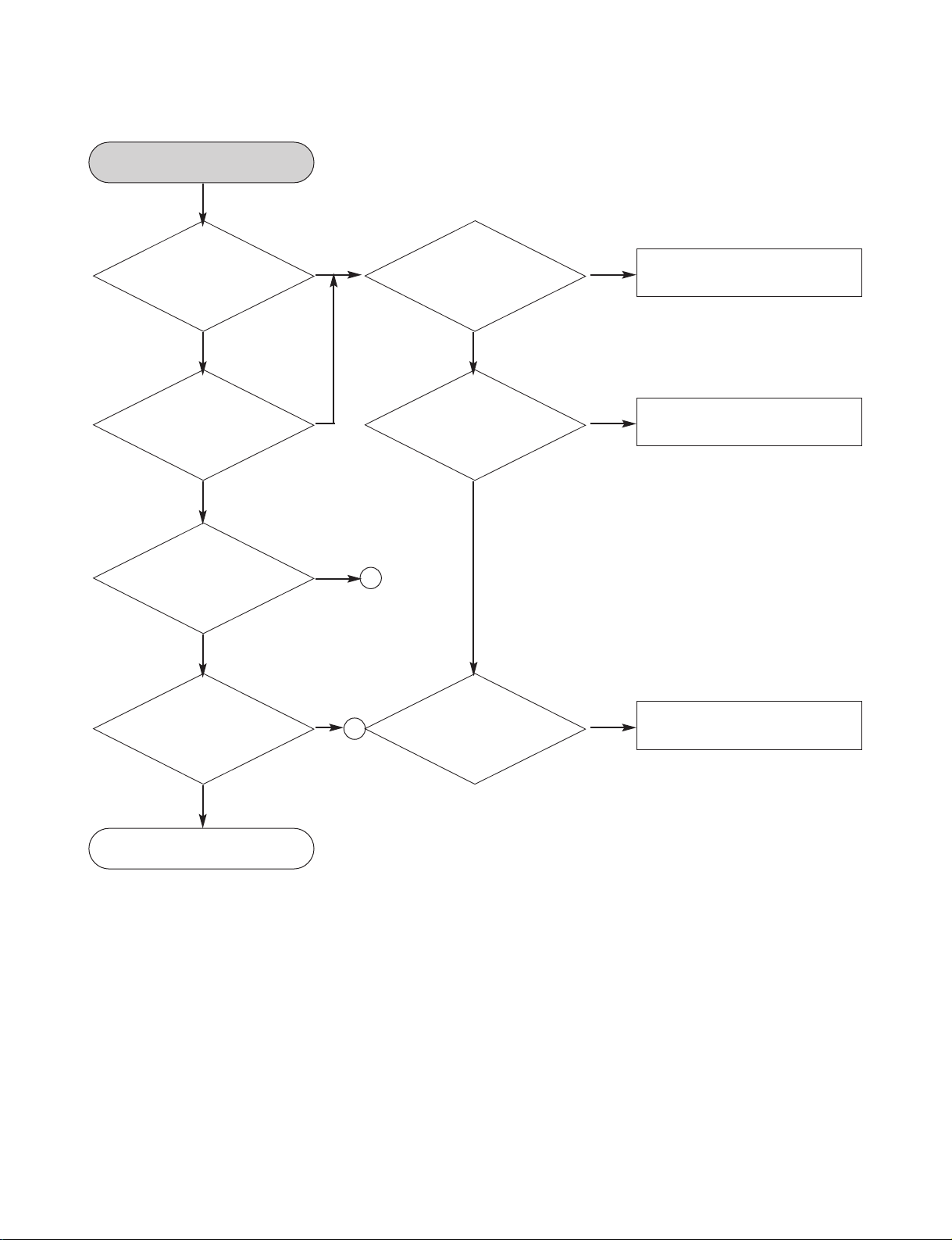

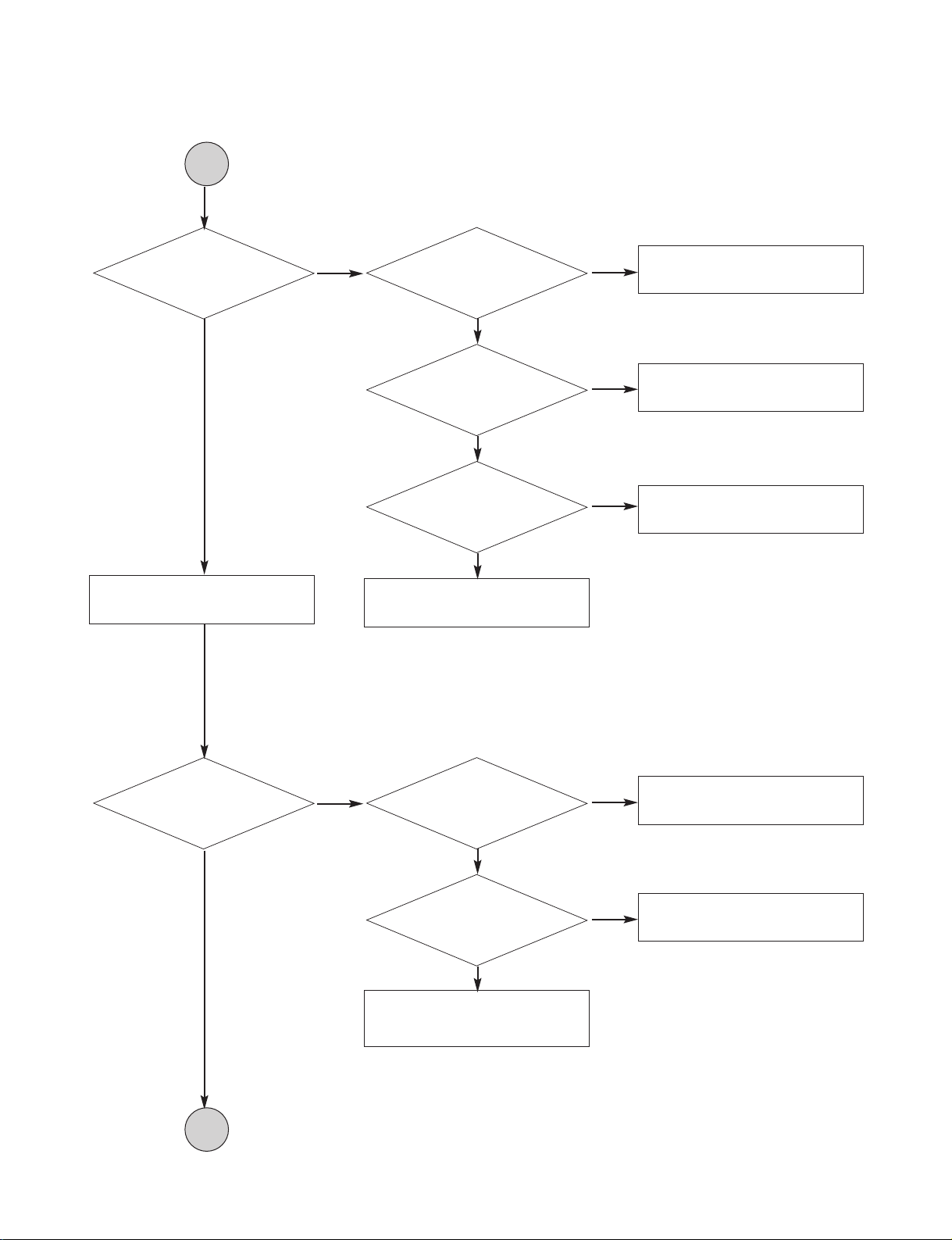

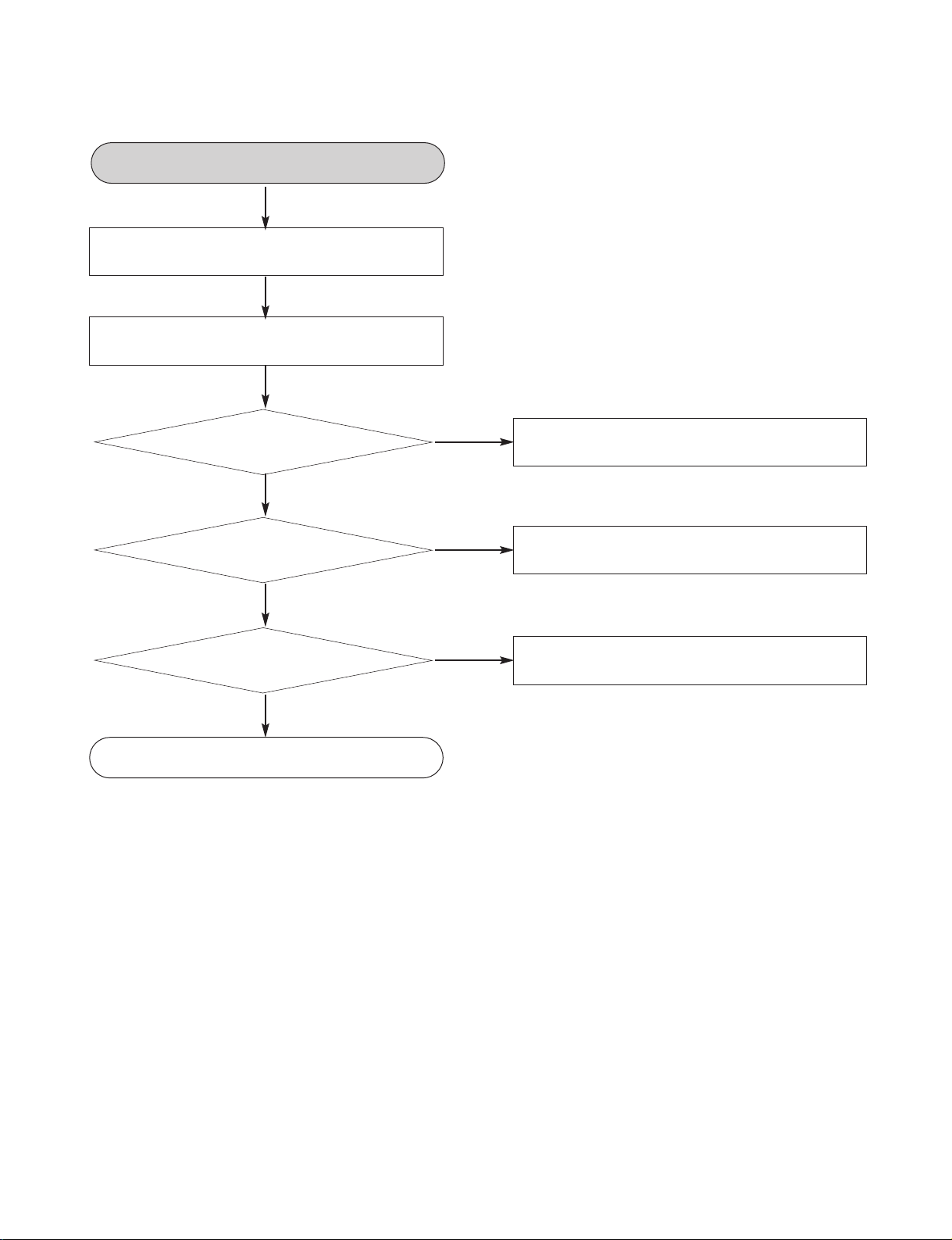

4. System operation flow

YES

YES

YES

Tray closed?

1. Initializes SERVO, DSP & RISC registers.

2. Write RISC code to SDRAM.

3. Reset RISC.

Show LOGO.

Tray close to closed position.

SLED at inner

side?

Recieve

OPEN/ CLOSE

Key?

Receive

CLOSE Key?

SLED moves to inner position.

1. Judge whether have disc and disc type.

2. Jump to related disc reading procedure.

1. Execute Pressed Key & IR Key.

2. System operation routine loop.

NO

NO

NO

NO

YES

1. Stop Playback & Open Tray.

2. Display tray open message & LOGO.

POWER ON.

Page 14

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-5

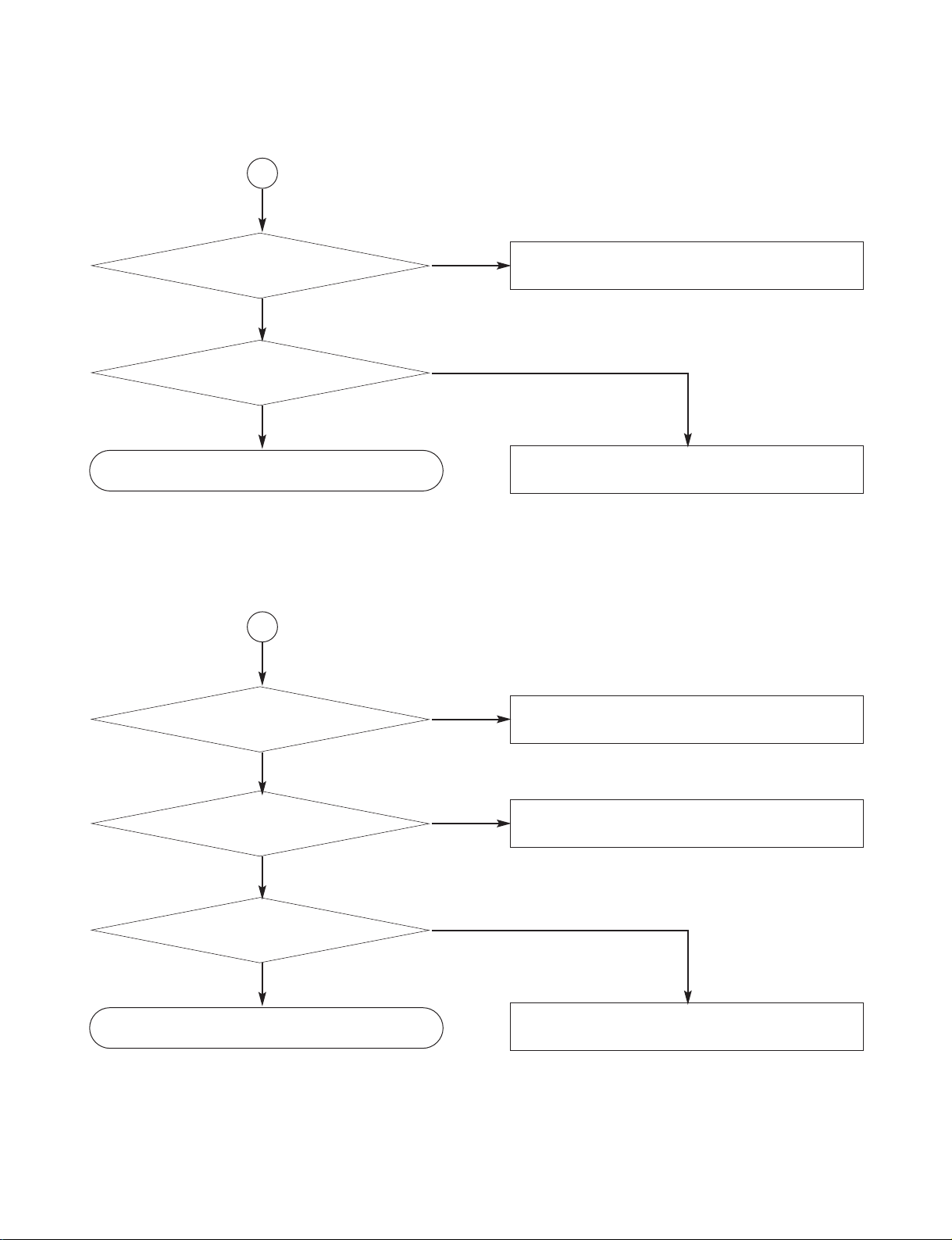

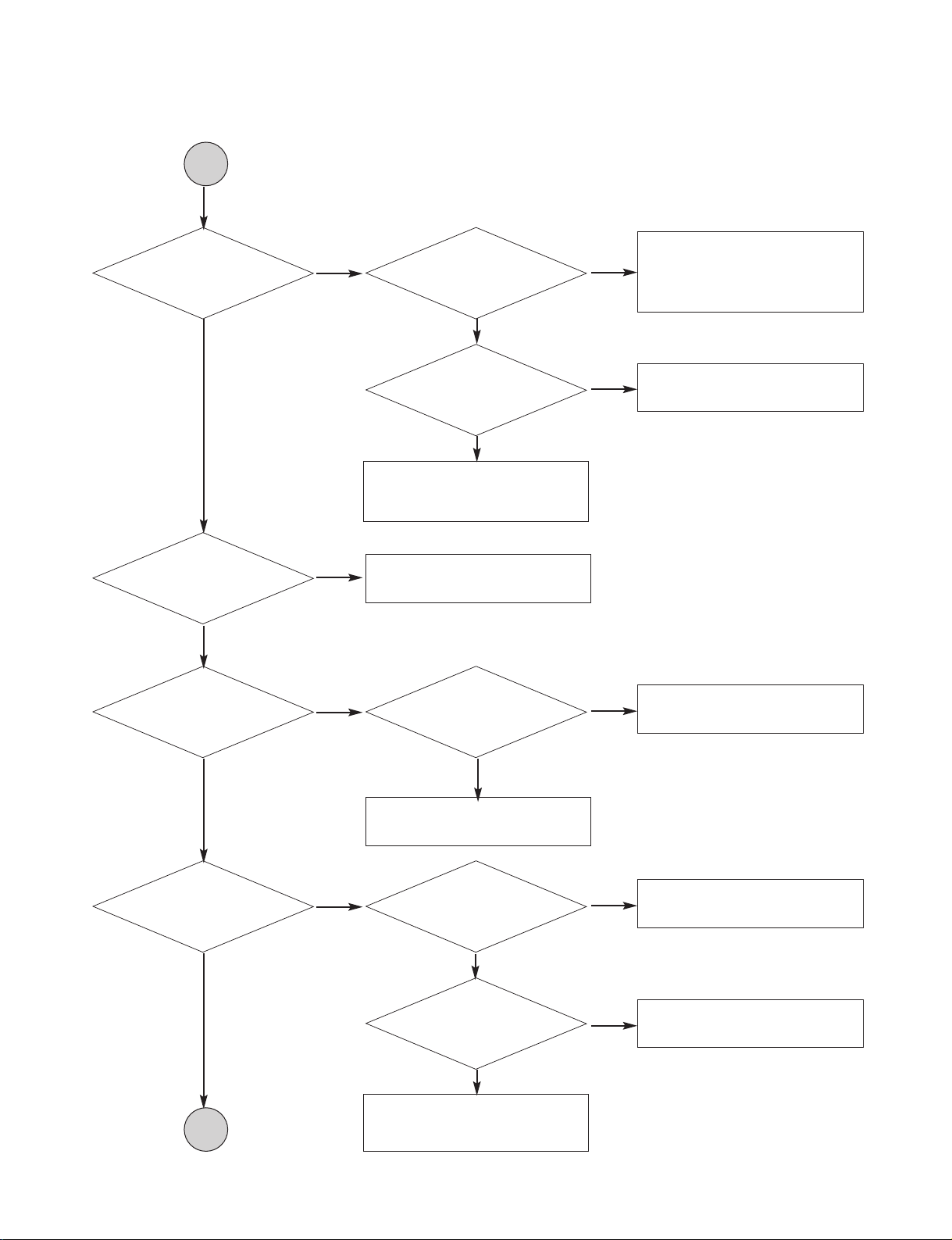

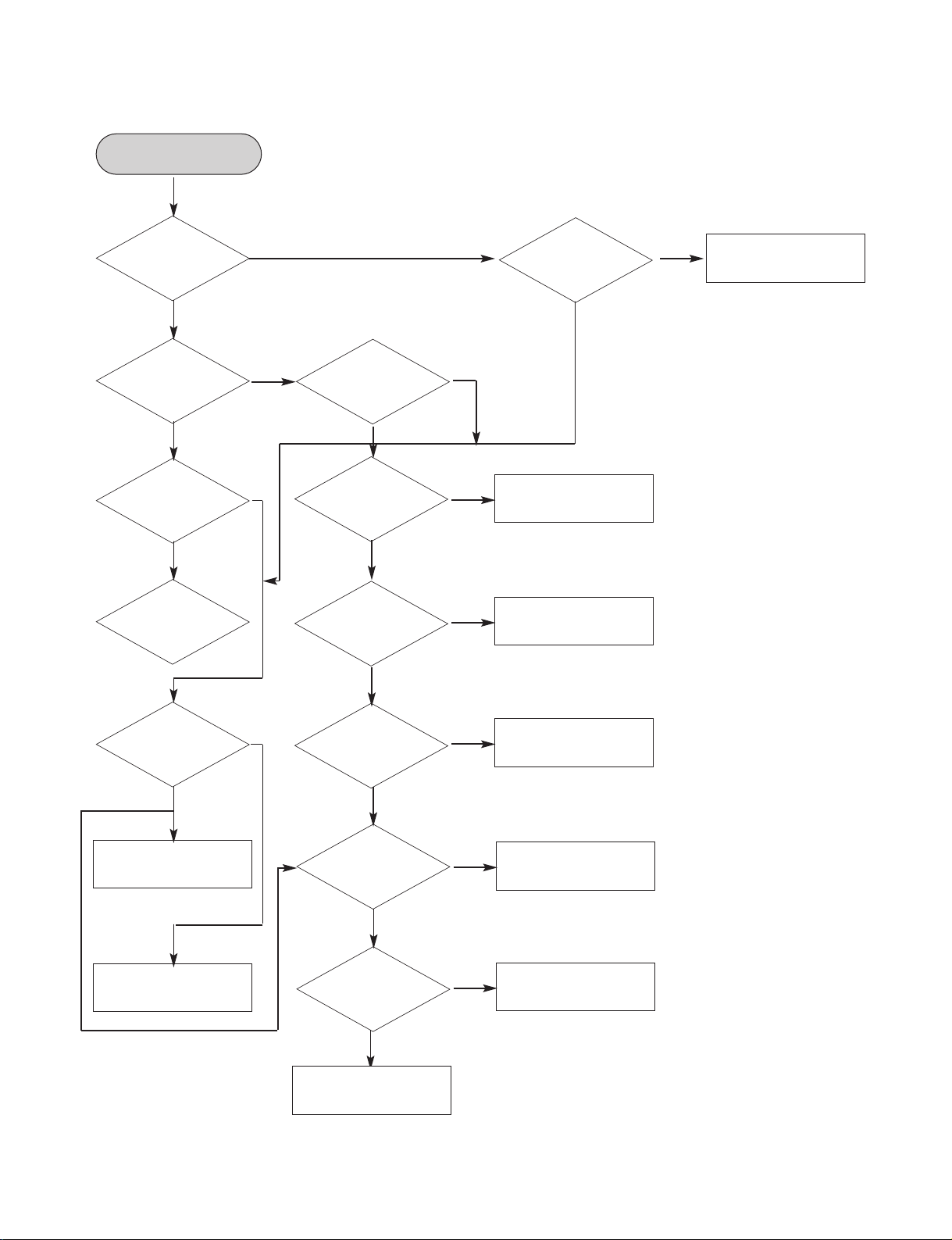

5. Test & debug flow

YES

NO

Check the POWER PART.

NO

Check the POWER PART.

Check the

AC voltage Power PCBA (110V

or 220V).

YES

NO

Check the regulators or diode.

NO

1. Check 27MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,

RWR.

4. Check FLASH Memory related circuit.

NO

Replace FLASH.

Are the

DC Voltage outputs OK? (12V, 5.6V,

3.5V, 5V,7V, 34V).

YES

Are 3.5V and

5V DC outputs normal on main

PCBA?

YES

YES

Update

FLASH successfully?

YES

Switch on the Power PCBA.

TEST.

A

Page 15

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-6

NO

NO

Check connection lines

between FLASH &MT1389/L

and the FLASH access time

whether is suitable or not.

YES

YES

YES

YES

Check AV cable

connection to TV set.

YES

YES

YES

Flash

Memory operates

properly?

NO

Check connection lines

between SDRAM(IC504) &

MT1389/L and the SDRAM

is damaged.

SDRAM

works properly?

NO

Check the related circuit of

MT1389/L IC501 Pins99, 102,

103, 104.

MT1389/L

VIDEO outputs

properly?

Show LOGO?

NO

NO

Check the load OPEN &

CLOSE switch.

Check AV cable connection

between main PCBA and

loader. (MECHA)

YES

YES

YES

Normal

OPEN_SW,

CLOSE_SW

signal?

NO

Check the Tray control IO pins

on MT1389/L.

Normal

IN_SW & OUT_SW

signal?

NO

Check the Tray control MOTOR

& SERVO circuit IC401.

Normal

LOAD+ & LOAD-signal?

Does

Tray move inside when it

is not at closed

position?

Power On.

A

B

Page 16

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-7

NO

NO

Check the connection line of

DRV_MUTE.

YES

YES

YES

Check the cable connection

with MECHA.

Do not put in disc

and close tray.

YES

YES

YES

Motor

Driver DRV_MUTE

pin is high?

NO

Check the related circuit of

SLEGN.

Motor

Driver DRV_MUTE

pin is High?

NO

Check the amp circuit on

motor driver.

SLED+ and

SLED- output

properly?

Does

the SLED move to inner

side when it is at outer

position?

NO

NO

Check Focus connection on

MT1389/L and motor driver.

Check cable connection with

pick-up head.

YES

YES

Proper Focus outputs

to motor dricer?

NO

Check the amp circuit on motor

driver.

Proper F+ & F- outputs?

Optical Lens

has movements for

searching Focus?

B

C

Page 17

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-8

NO

NO

NO

Check the laser power circuit

on MT1389/L and connecting

to power transistor.

(Q401, Q402).

YES

YES

YES

YES

YES

YES

Check cable connection

between transistor output and

pick-up head.

Laser off.

Check the RF connection

between AM5890 and MT1389/L.

YES

YES

DVDLD or

CDLD output

property?

NO

Check the related circuit on

laser power transistor.

Collector

voltage of power transistor

is OK?(Q401, Q402)

Laser turns on when

reading disc?

Put disc in?

NO

NO

Check the SPINDLE related

circuit on MT1389/L.

Check the cable connection

between spindle and main

PCB.

YES

YES

Proper

SPINDLE signal on

MT1389/L.

NO

Check the spindle control amp

circuit of motor driver.

SPNP

SPNN output

properly?

Does spindle rotate?

NO

NO

Check the related circuit on

MT1389/L RF signal.

Proper

RF signal on MT1389/L.

Disc ID is correct?

C

D

Page 18

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-9

NO

NO

Check connections between

MT1389/L and pick-up head.

YES

YES

YES

YES

YES

Check CD_DVDCT connection

between AM5890 and

MT1389/L.

Check cable connection

on pick-up head.

YES

YES

Proper

signals on A, B, C,

D of MT1389/L.

NO

Check the related circuit on

MT1389/L CD-DVDCT.

Proper

CD-DVDCT signal

on MT1389/L.

Focus on ok?

NO

Check RF signal waveform.

Disc Playback?

NO

NO

Check the related circuit on

MT1389/L.

NO

Check the TRACK connection

on MT1389/L and motor driver.

NO

Check the tracking control amp

circuit on motor driver.

Proper

CD-DVDCT signal

on MT1389/L.

YES

Proper

TRACK signal

on MT1389/L.

YES

TR+ & TR-output

properly?

Track On OK?

D

E

Page 19

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-10

NO

NO

Check connection between

IC704 BCK, LRCK, ADATAO.

YES

YES

Check Digital Amp circuit

(IC702, IC703).

YES

YES

PWM IC

received correct data

stream?

NO

Check the related circuit of

PWM.(Check Audio out

Pins 55, 59, 61, 62, 68, 71, 75).

Normal

PWM IC out?(IC704).

Normal Audio

output when disc

playback?

E

TEST END.

Page 20

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-11

6. AMP Protection

YES

NO

OK.

"PROTECTION"

appears continuously on the FLD.

YES

NO

Replace IC101.

Is the IC101 pin54

"LOW" signal(0V)?

YES

NO

Replace the Q701 and Q702.

Is the Q701 and Q702 normal?

YES

YES

After unplug power cord, connect again.

YES

Power on.

"PROTECTION" appears on the FLD.

Replace ST AMP IC(IC702 and IC703)

Page 21

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-12

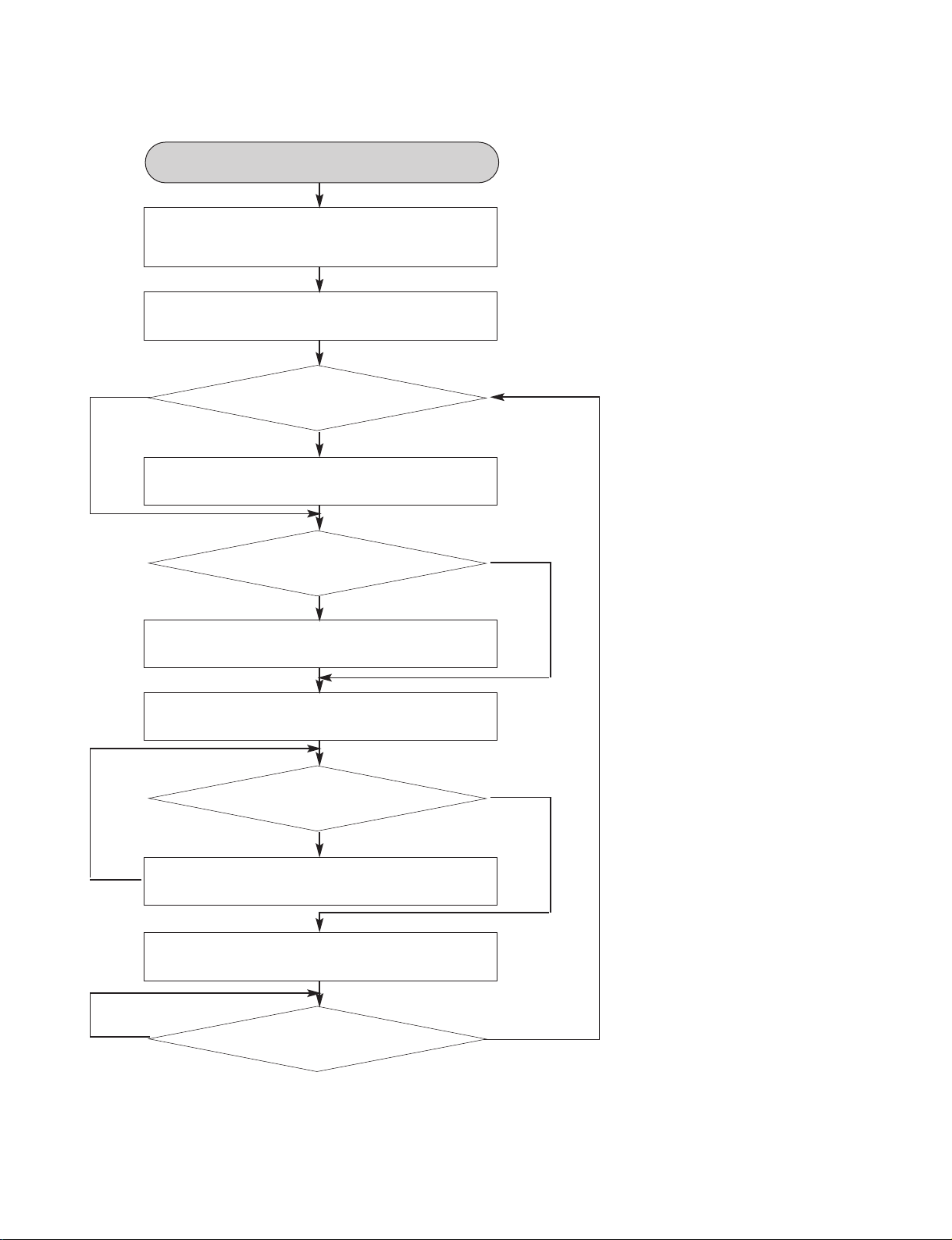

7. AUDIO µ-COM Circuit(DVD & AMP)

Check DVD Module.

Check SMPS.

OK

YES

Power On.

Does

CD/DVD appear at

FLD?

YES

NO

Does

Loading appear

at FLD?

Does

it appear DVD Error

at FLD?

Does Aux,

Scart, opt and FM 87.5

appear at FLD.

YES

Does

no Disc or Time

appear at FLD?

YES

Check

if DVD an audio

micom insert is

OK.

Check Power.

YES

YES

YES

Replace IC101.

YESNO

NO

NO

NO

Refer to SMPS.

NO

Refer to oscillator circuit.

NO

Check IC101 reset

waveform.

NO

NO

YES

Check

power part of Main

B/D.

Check

oscillator o

X101.

Check

if IC101 Pin5

is high.

YES

YES

YES

Check 3.3V line.

NO

Check power section

circuit.

NO

Check

if IC101 Pin9,36,59 are

high(5V).

Check

if IC101 Pin49

is high.

YES

YES

Page 22

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-13

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

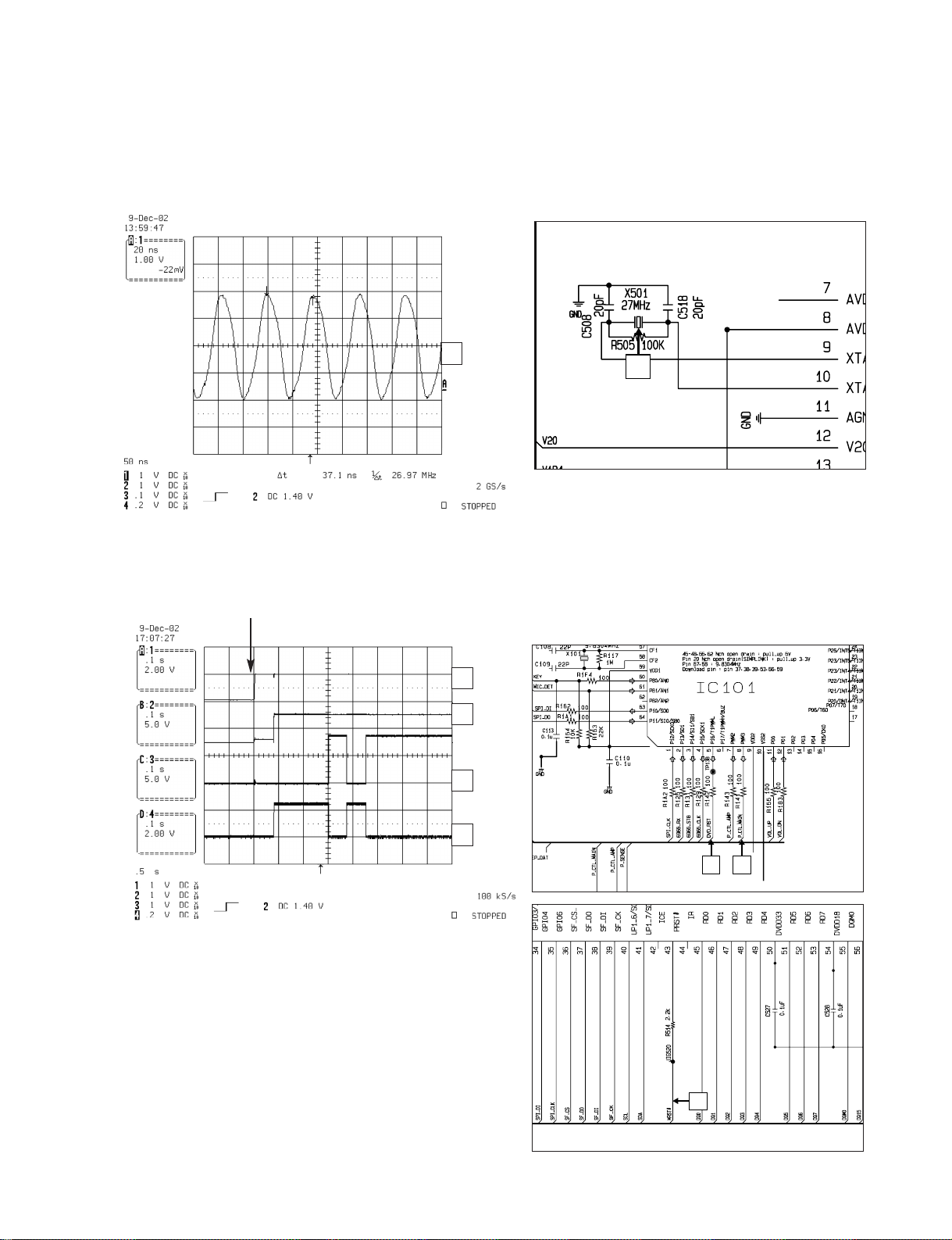

1. SYSTEM 27MHz CLOCK,RESET,FLASH R/W SIGNAL

1)

MT1389/L

main clock is at 27MHz(X501)

1

3 2

4

FIG 1-1

2)

MT1389/L

reset is high active.

Power Cord in

FIG 1-2

1

1

2

3

4

1

2

3

4

IC501

Page 23

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-14

2. SDRAM CLOCK

1)

MT1389/L

main clock is at 27MHz(X501)

DCLK = 93MHz, Vp-p=2.2, Vmax=2.7V

FIG 2-1

3) Flash R/W enable signal during download(Downloading)

FIG 1-4

1

2

1

1

2

1

Page 24

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-15

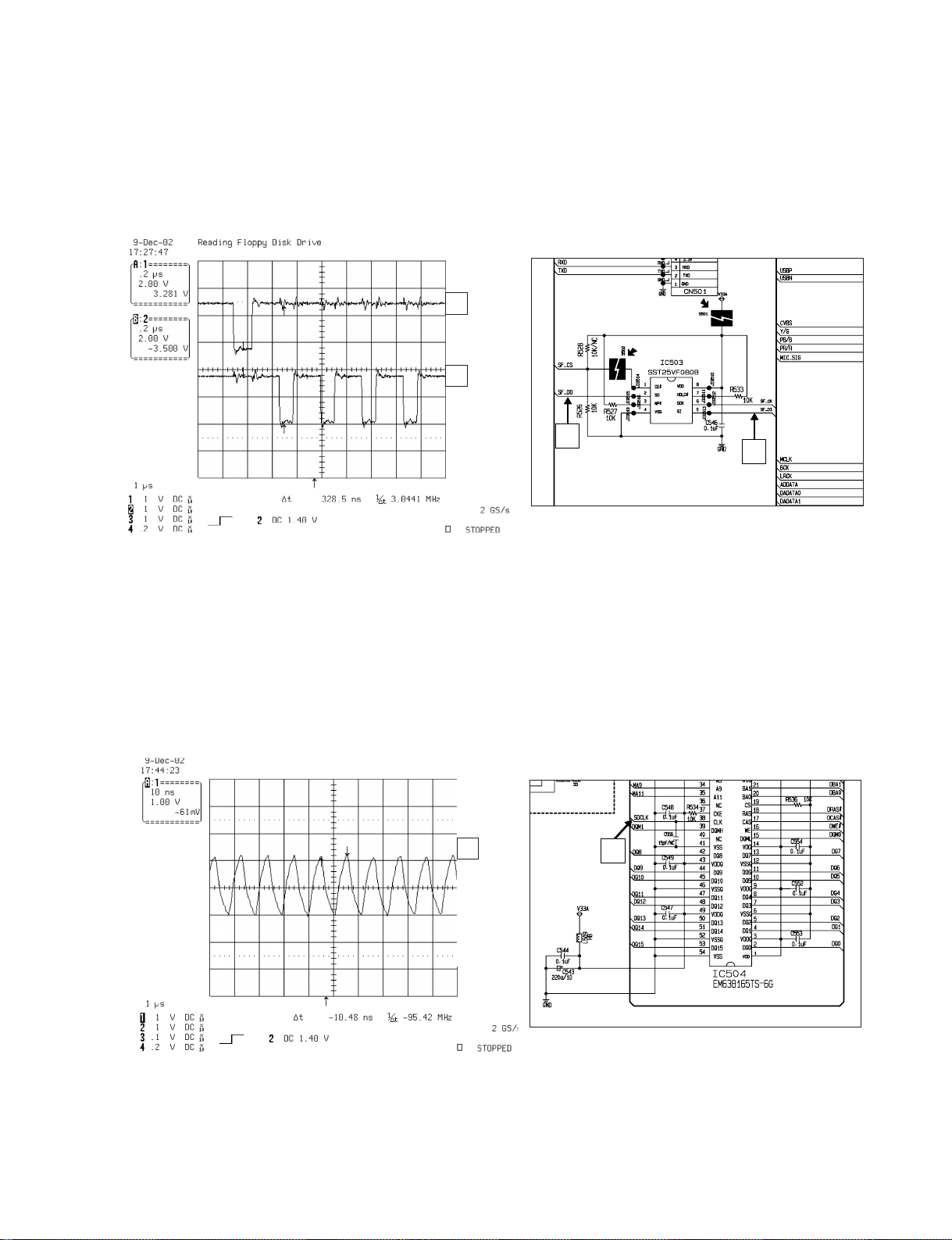

3) Tray open waveform

FIG 3-3

3. TRAY OPEN/CLOSE SIGNAL

1) Tray open/close waveform

FIG 3-1

2) Tray close waveform

FIG 3-2

2

1

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Page 25

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-16

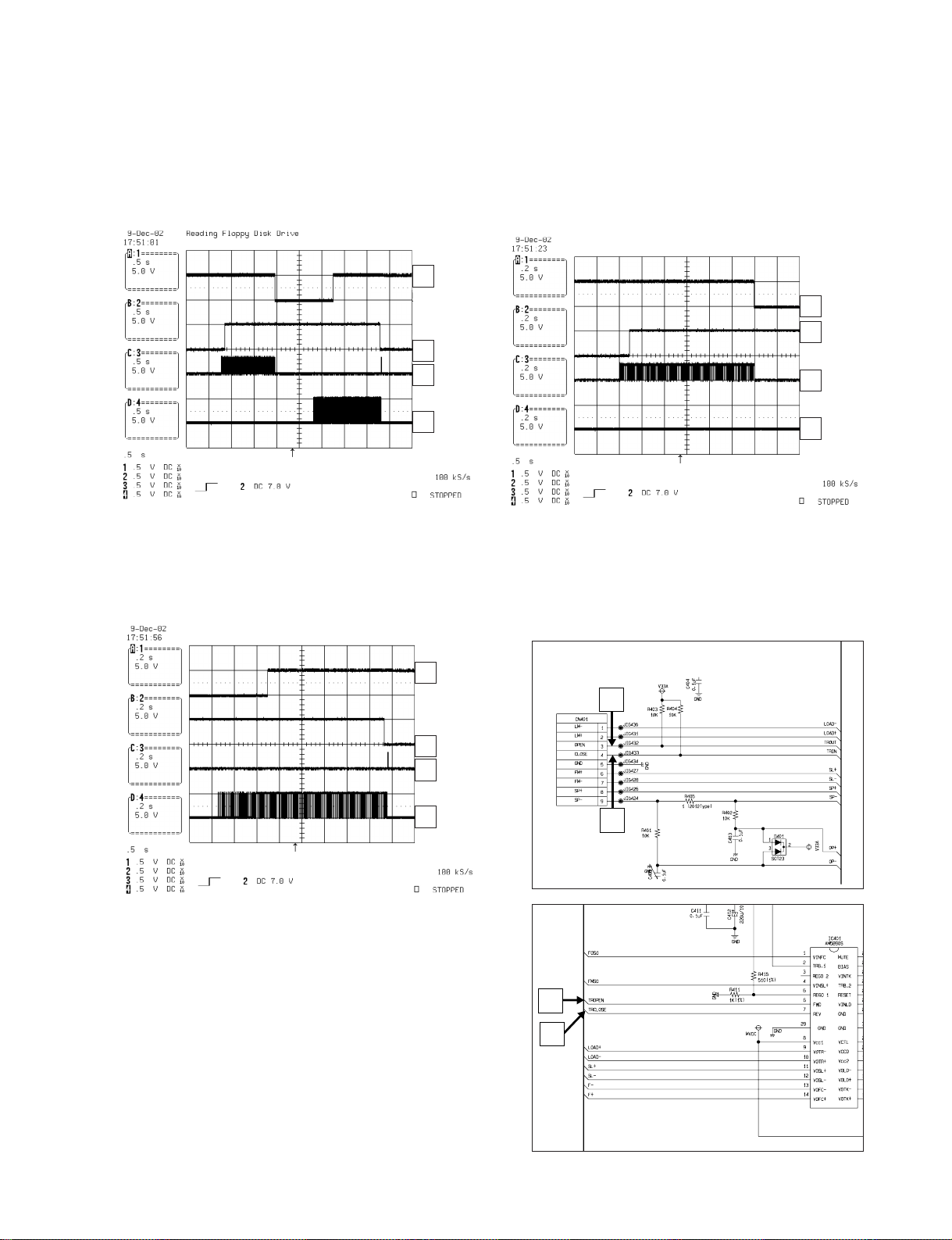

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

FIG 4-1

1

2

3

4

1

2

3

4

Page 26

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-17

6. LASER POWER CONTROL RELATED SIGNAL(NO DISC CONDITION)

FIG 6-1

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

FIG 5-1

1

3

2

1

3

2

1

2

3

1

2

3

Page 27

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-18

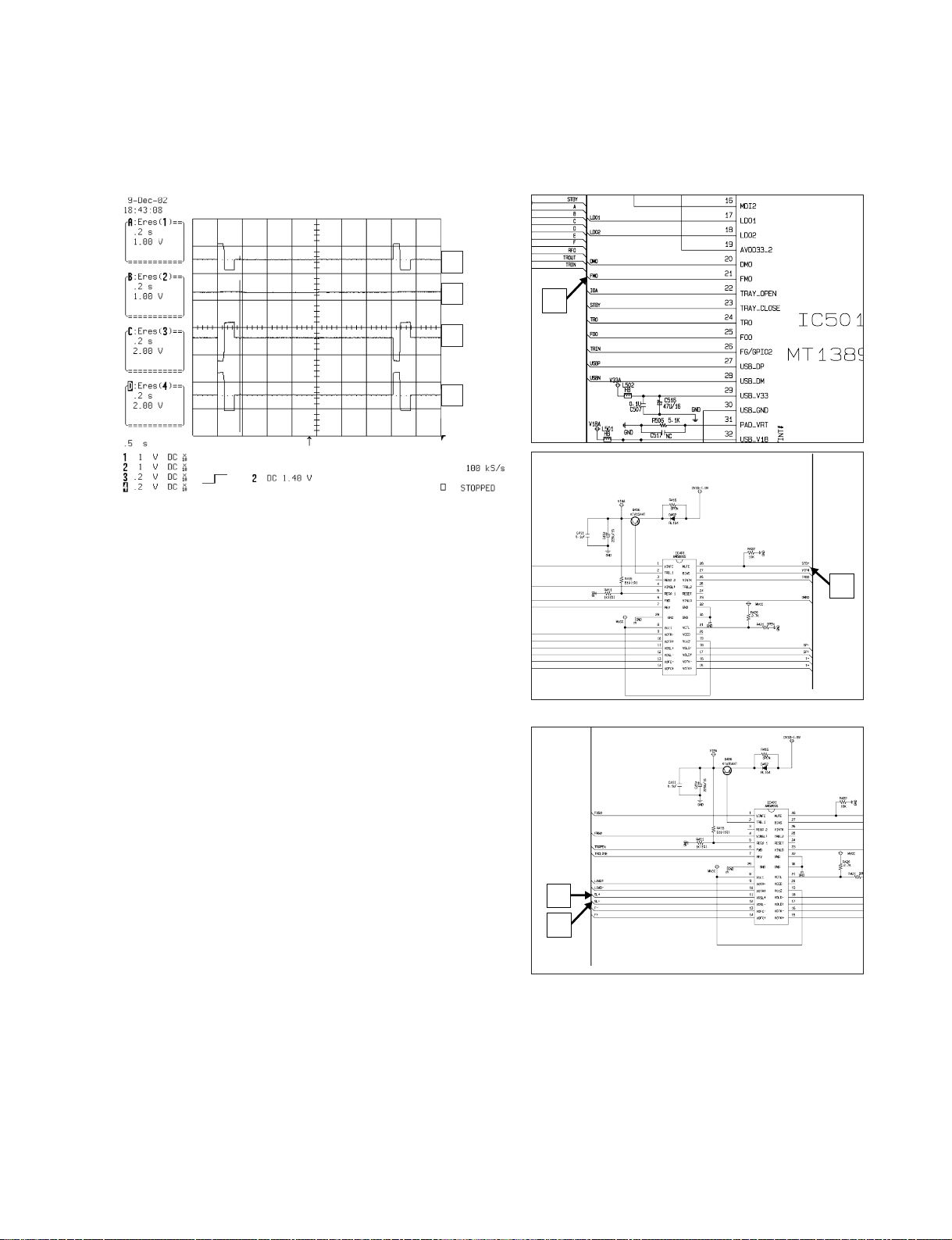

FIG 7-2 (DVD)

7. DISC TYPE JUDGEMENT WAVEFORMS

FIG 7-1 (DVD)

1

2

3

IC501

IC501

1

2

3

1

2

3

Page 28

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-19

FIG 7-4 (CD)

FIG 7-3 (CD)

1

2

3

IC501

IC501

1

2

3

1

2

3

Page 29

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-20

FIG 8-2 (CD)

8. FOCUS ON WAVEFORMS

FIG 8-1 (DVD)

1

2

3

1

2

3

4

4

1

2

4

3

IC501

Page 30

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-21

9. SPINDLE CONTROL WAVEFORMS (NO DISC CONDITION)

FIG 9-1

10. TRACKING CONTROL RELATED SIGNAL(System checking)

FIG 10-1(DVD)

1

2

3

1

1

2

3

1

2

3

4

IC501

Page 31

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-22

11.

MT1389/L

VIDEO OUTPUT WAVEFORMS

1) Full colorbar signal(COMPOSIT)

FIG 11-1

FIG 10-2(CD)

3

4

2

1

1

2

4

1

3

Page 32

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-23

ASDATA3

1) Audio related Signal

FIG 12-1

2) Y

FIG 11-2

12. AUDIO OUTPUT FROM mt1389/L

1

1 3 2

IC501

IC501

1

1

2

3

Page 33

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-24

1)

• R703 → TP704

2)

• R720 → TP711

3)

• R704 → TP707

or

R717

→ TP705

4)

• R709 → TP713

5)

• R707 → TP702

6)

• R701 → TP708

13. DVD & AMP WAVEFORMS

6

5

1

4

3

2

Page 34

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-25

GPIO13

DVDD18

GPIO9

XTALI

GPIO8

XTALO

GPIO7 / CKE

V20

V14

REXT

DVSS18

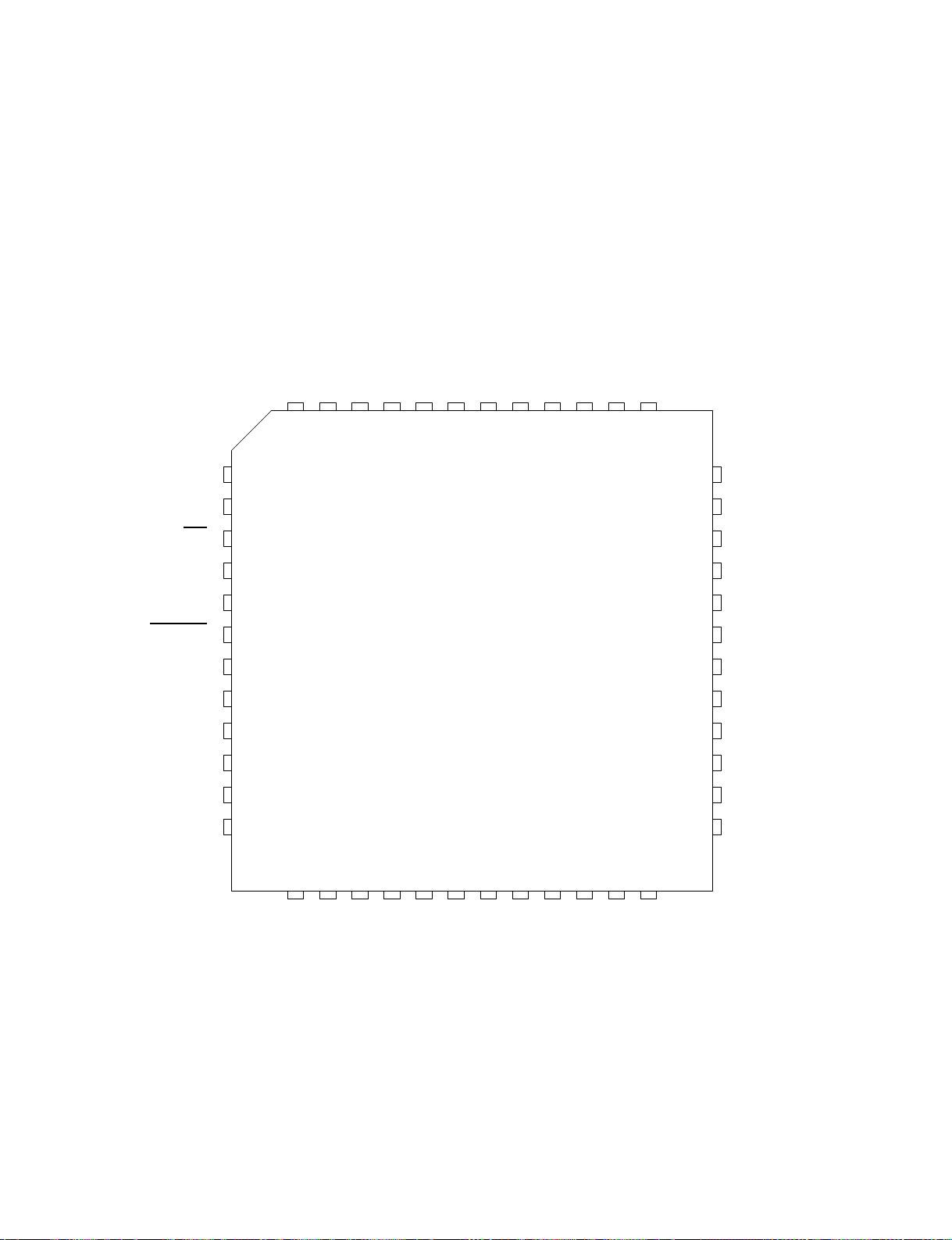

1. IC501 MPEG(MT1389L)

• PIN CONFIGURATION

INTERNAL BLOCK DIAGRAM OF ICs

AKIN1 / GPIO21 / Audio_mute

AKIN2 / GPIO19 / Audio_mute

ALF / CENTER / GPIO

ADVCM / GPIO20 /

DACVDDA

DACVDDB

100

DACVSSC

CVBS

FS

999897

64

APLLVDD

AADVDD

110

109

AADVSS

G

R

B

108

107

106

105

104

103

102

101

ARS / GPIO

AR / GPIO0

116

115

ARF / LFE / GPIO

ADACVSS1

ADACVSS2

APLLCAP

114

113

112

111

RFH / OPINN /

RFIN / OPOUT /

RFG / OPINP /

ADACVDD2

ADACVDD1

ALS / GPIO

AVDD18_1

AGND18

RFIP

128

127

126

125

124

123

122

121

1 96 VREF

RFA

2 95 DACVDDC

RFB

3 94

RFC

4

RFD

5

RFE

6 91

RFF

AVDD18_2

AVDD33_1

AGND33

AVDD33_2

TRAY

_OPEN

TRAY

_CLOSE

FG / GPIO2

USB_DP 27 70 RA8

USB_DM 28 69 RA9

VDD33_USB 29 68 DVDD33

VSS33_USB 30 67 RA11

PAD_VRT 31 66 RCLK

VDD18_USB 32 65 DQM1

7 90

8 89

9 88

10 87

11 86 RA3

12 85 RA2

13 84 DVDD33

14 83 RA1

15 82 RA0

MDI1

16 81 RA10

MDI2

17 80 BA1

LDO1

18

LDO2

19 78 BA0

20 77 RAS#

DMO

21 76 CAS#

FMO

22 75 RW E#

23 74 RA4

24 73 RA5

TRO

25 72 RA6

FOO

26 71 RA7

33343536373839404142434445464748495051525354555657585960616263

AL / GPIO1

AVCM

120

119

118

117

MT1389L

93 SPDIF / GPIO12

92

GPIO11

GPIO10

79

GPIO3 / INT#

GPIO4

GPIO6

SF_CS_

SF_DO

SF_DI

SF_CK

UP1_6 / SCL

UP1_7 / SDA

ICE

PRST#IRRD0

RD1

RD2

RD3

RD4

DVDD33

RD5

RD6

RD7

DVDD18

DQM0

RD15

RD14

RD13

RD12

DVSS33

RD11

RD10

RD9

RD8

Page 35

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-26

1. IC501 MPEG(MT1389L)

• BLOCK DIAGRAM

DVD

PUH

Module

Motor

Drive

FLASH

ROM

DRAM

GPIO

IR/VFD

RF Amplifier

Servo IO

Spindle

Control

Memory

Controller

System

CPU

Debug

Servo

Processor

Audio

DSP

System

Parser

CPPM/CPRM

DRM

32-bit

RISC

Po

rt

108MHz

TV Encoder

Video

Processor

Video DAC

De-

interlacer

MPEG-1/2/4

JPEG

Video Decoder

6ch Au

Internal

dio DACs

PCM output

Audio

Ouptut

CVBS, Y/C

Component

Vide

o

6ch Audio Analog

s

output

Audio

DAC

SDPIF

Audio Mic1

Internal

Audio A

DC

Audio Mic2

USB 2.0 High

Speed

controller

MS/SD/MMC

Card

Controller

USB 2.0 High

/ Full Speed

Devic

e

MS/SD/MMC

Flash Card

Page 36

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-27

1. IC501 MPEG(MT1389L)

• PIN DESCRIPTION

Pin Main Alt. Type Description

Analog I nterface (66)

125 RFIP Analog Input AC coupled DVD RF signal input RFIP

126 RFIN OPOUT Analog Input AC coupled DVD RF signal input RFIN

127 RFG OPINP Analog Input Main beam, RF AC input path

128 RFH OPINN Analog Input Main beam, RF AC input path

1 RFA Analog Input RF main beam input A

2 RFB Analog Input RF main beam input B

3 RFC Analog Input RF main beam input C

4 RFD Analog Input RF main beam input D

5 RFE Analog Input RF sub beam input E

6 RFF Analog Input RF sub beam input E

7 AVDD18_2 Analog power Analog 1.8V power

8 AVDD33_1 Analog power Analog 3.3V power

9 XTALI Input 27MHz crystal input

10 XTALO Output 27MHz crystal output

11 AGND33 Analog Ground Analog Ground

12 V20 Analog output Reference voltage 2.0V

13 V14 Analog output Reference voltage 1.4V

14 REXT Analog Input

Current reference input. It generates reference current for

RF path. Connect an external 15K resistor to this pin and

AVSS

15 MDI1 Analog Input Laser power monitor input

16 MDI2 Analog Input Laser power monitor input

17 LDO1 Analog Output Laser driver output

18 LDO2 Analog Output Laser driver output

19 AVDD33_2 Analog Power Analog 3.3V power

20 DMO Analog Output Disk motor control output. PWM output

21 FMO Analog Output Feed motor control. PWM output

22 TRAY_OPEN Analog Output Tray PWM output/Tray open output

23 TRAY_CLOSE Analog Output Tray PWM output/Tray close output

24 TRO Analog Output

Tracking servo output. PDM output of tracking servo

compensator

25 FOO Analog Output

Focus servo output. PDM output of focus servo

compensator

26 FG GPIO2 Analog

1) Motor Hall sensor input

2) GPIO

27 USB_DP Analog Input USB port DPLUS analog pin

28 USB_DM Analog Input USB port DMINUS analog pin

29 VDD33_USB USB Power USB Power pin 3.3V

30 VSS33_USB USB Ground USB ground pin

31 PAD_VRT Analog Inout USB generating reference current

32 VDD18_USB USB Power USB Power pin 1.8V

95 DACVDDC Power Power

96 VREF Analog Bandgap reference voltage

97 FS Analog Full scale adjustment (suggest to use 560 ohm)

98 DACVSSC Ground Ground pin for video DAC circuitry

99 CVBS Analog Analog composite output

• Abbreviations:

SR: Slew Rate

PU: Pull Up

PD: Pull Down

SMT: Schmitt Trigger

4mA~16mA: Output buffer driving strength.

Page 37

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-28

Pin Main Alt. Type Description

100 DACVDDB Power 3.3V power pin for video DAC circuitry

101 DACVDDA Power 3.3V power pin for video DAC circuitry

102 Y/G Analog Green, Y, SY, or CVBS

103 B/CB/PB Analog Blue, CB/PB, or SC

104 R/CR/PR Analog Red, CR/PR, CVBS, or SY

105 AADVSS Ground Ground pin for 2ch audio ADC circuitry

` 1) Audio ADC input 2

2) MS_CLK set B

3) MCDATA

106 AKIN2 Analog 4) Audio Mute

5) HSYN/VSYN output

6) C5

7) GPIO

1) 2ch audio ADC reference voltageC

107 ADVCM Analog 2) C6

3) GPIO

1) Audio ADC input 1

2) MS_D0 set B

3) Audio Mute

108 AKIN1 Analog

4) HSYN/VSYN output

5) C7

6) GPIO

109 AADVDD Power 3.3V power pin for 2ch audio ADC circuitry

110 APLLVDD3 Power 3.3V Power pin for audio clock circuitry

111 APLLCAP Analog InOut APLL external capacitance connection

112 ADACVSS2 Ground Ground pin for audio DAC circuitry

113 ADACVSS1 Ground Ground pin for audio DAC circuitry

114 ARF / LFE GPIO Analog Output

1) Audio DAC sub-woofer channel output

2) While internal audio DAC not used:

a. ACLK

b. GPIO

115 ARS GPIO Analog Output

1) Audio DAC right Surround channel output

2) While internal audio DAC not used:

a. ABCK

b. GPIO

1) Audio DAC right channel output

2) While internal audio DAC not used:

116 AR Analog Output a. SDATA2

b. GPIO

c. RXD2

117 AV CM Analog Audio DAC reference voltage

118 AL GPIO Analog Output

1) Audio DAC left channel output

2) While internal audio DAC not used:

a. SDATA1

b. GPIO

c. RXD1

119 ALS GPIO Analog Output

1) Audio DAC left Surround channel output

2) While internal audio DAC not used:

a. ALRCK

b. GPIO

120 ALF /CENTER GPIO Analog Output

1) Audio DAC center channel output

2) While internal audio DAC not used:

a. ASDATA0

b. GPIO

121 ADACVDD1 Analog Power 3.3V power pin for audio DAC circuitry

122 ADACVDD2 Analog Power 3.3V power pin for audio DAC circuitry

123 AVDD18_1 Analog Power Analog 1.8V power

124 AGND18 Analog Ground Analog Ground

General Power/ Ground (7)

54, 90 DVDD18 Power 1.8V power pin for internal digital circuitry

Page 38

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-29

Pin Main Alt. Type Description

79 DVSS18 Ground 1.8V Ground pin for internal digital circuitry

50, 68,84

DVDD33 Power 3.3V power pin for internal digital circuitry

60 DVSS Ground 3.3V Ground pin for internal digital circuitry

Micro Controller , Flash I nterface and GPIO(12)

33 GPIO3 INT#

InOut 1) General purpose IO 3

8mA, SR 2) Microcontroller external interrupt 1

PD, SMT

34 GPIO4

InOut

General purpose IO 4

4mA, PD

35 GPIO6

InOut

General purpose IO 6

4mA, PD

36 SF_CS_

InOut

8mA, SR Serial Flash Chip Select

PU, SMT

37 SF_DO

InOut

8mA, SR Serial Flash Dout

PD, SMT

38 SF_DI

InOut

8mA, SR Serial Flash Din

PU, SMT

39 SF_CK

InOut

8mA, SR Serial Flash Clock

PD, SMT

40 UP1_6 SCL

InOut 1) Microcontroller port 1-6

8mA, SR 2) I2C clock pin

PU, SMT

41 UP1_7 SDA

InOut 1) Microcontroller port 1-7

4mA, SR 2) I2C data pin

PU, SMT

42 ICE

Input

Microcontroller ICE mode enable

PD, SMT

43

PRST#

Input

Power on reset input, active low

PU, SMT

44 IR

Input

IR control signal input

SMT

Dram Interface (37) (Sorted by position)

45 RD0

InOut

DRAM data 0

4mA

46 RD1

InOut

DRAM data 1

4mA

47 RD2

InOut

DRAM data 2

4mA

48 RD3

InOut

DRAM data 3

4mA

49 RD4

InOut

DRAM data 4

4mA

51 RD5

InOut

DRAM data 5

4mA

52 RD6

InOut

DRAM data 6

4mA

53 RD7

InOut

DRAM data 7

4mA

55 DQM0

InOut

Data mask 0

4mA, PD

56 RD15

InOut

DRAM data 15

4mA

57 RD14

InOut

DRAM data 14

4mA

58 RD13

InOut

DRAM data 13

4mA

Page 39

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-30

Pin Main Alt. Type Description

59 RD12

InOut

DRAM data 12

4mA

61 RD11

InOut

DRAM data 11

4mA

62 RD10

InOut

DRAM data 10

4mA

63 RD9

InOut

DRAM data 9

4mA

64 RD8

InOut

DRAM data 8

4mA

65 DQM1

InOut

Data mask 1

4mA, PD

66 RCLK

InOut

Dram clock

4mA, PD

67 RA11

InOut

DRAM address bit 11

4mA, PD

69 RA9

InOut

DRAM address 9

4mA, PD

70 RA8

InOut

DRAM address 8

4mA, PD

71 RA7

InOut

DRAM address 7

4mA, PD

72 RA6

InOut

DRAM address 6

4mA, PD

73 RA5

InOut

DRAM address 5

4mA, PD

74 RA4

InOut

DRAM address 4

4mA, PD

75 RWE#

Output

DRAM Write enable, active low

4mA, PD

76 CAS#

Output

DRAM column address strobe, active low

4mA, PD

77 RAS#

Output

DRAM row address strobe, active low

4mA, PD

78 BA0

InOut

DRAM bank address 0

4mA, PD

80 BA1

InOut

DRAM bank address 1

4mA, PD

81 RA10

InOut

DRAM address 10

4mA, PD

82 RA0

InOut

DRAM address 0

4mA, PD

83 RA1

InOut

DRAM address 1

4mA, PD

85 RA2

InOut

DRAM address 2

4mA, PD

86 RA3

InOut

DRAM address 3

4mA, PD

1) GPIO 7

2) Dram Clock Enable

87 GPIO7 CKE

InOut 3) MS_CLK set A

4mA, PD 4) Audio Mute

5) HSYN/VSYN input

6) C0

GPIO (6)

88 GPIO8

1) GPIO8

2) MS_BS set A

InOut 3) SD_CLK set A

4mA, PD 4) ASDATA2

5) ACLK

Page 40

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-31

Pin Main Alt. Type Description

6) Audio Mute

7) HSYN/VSYN input

8) C1

1) GPIO9

2) MS_D0 set A

89 GPIO9

InOut 3) SD_CMD set A

4mA, PD 4) ASDATA1

5) ABCK

6) C2

7) RXD1

1) GPIO10

2) SD_CLK set B

3) SD_D0 set A

91 GPIO10

InOut 4) ASDATA0

4mA, PD 5) ALRCK

6) HSYN/VSYN output

7) C3

8) TXD1

1) GPIO11

2) SD_CMD set B

92 GPIO11

InOut 3) MS_BS set B

4mA, PD 4) Audio Mute

5) HSYN/VSYN output

6) C4

93 SPDIF GPIO12

InOut 1) SPDIF output

2mA, PD 2) GPIO12

1) GPIO13

94 GPIO13

InOut 2) SD_D0 set B

4mA, PD 3) ALRCK

4) Audio Mute

5) YUVCLK

Page 41

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-32

2. IC401 MOTOR DRIVER

• PIN CONFIGURATION

• BLOCK DIAGRAM

Page 42

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-33

1. IC501 MPEG(MT1389L)

• PIN DESCRIPTION

Page 43

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-34

3. IC101 MICOM1389L)

• PIN CONFIGURATION

8

33

3435363738

3940

5

6

P83/AN3

P84/AN4

P85/AN5

P86/AN6

PC0

PC1

PC2

PC3

PC4

PC5/DBGP0

3

PC6DBGP1

DD

PC7/DBGP2

V

3

V

SS

P30

P31

P70/INT0/T0LCP/AN8

P71/INT1/T0HCP/AN9

P72/INT2/T0IN/NKIN

P73/INT3/T0IN

RES

XT1/AN10

XT2/AN11

VSS1

CF1

CF2

VDD1

P80/AN0

P81/AN1

P82/AN2

P10/SO0

P11/SI0/SB0

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

4

47 4

4243444

41

LC87F5M64A

7654123

32

P32/UTX1

31

P33/URX1

30

P34/UTX2

29

P35/URX2

28

P36

27

P37

26

P27/INT5/T1IN

25

P26/INT5/T1IN

24

P25/INT5/T1IN

23

P24/INT5/T1IN/INT7

22

P23INT4/T1IN

21

P22/INT4/T1IN

20

P21/INT4/T1IN

19

P20/INT4/T1IN/INT6

18

P07/T7O

17

P06/T6O

15

141312111098

16

2

2

P00

P01

P02

P03

PWM3

V

P13/SO1

P12/SCK0

P15/SCK1

P14/SI1/SB1

P16/T1PWML

PWM2

P17/T1PWMH/BUZ

SS

DD

V

P04

P05/CKO

Top view

Page 44

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-35

• BLOCK DIAGRAM

SIO

0

SIO

1

Timer 0

Timer 1

Interrupt control

Standby

CF

RC

X’tal

MRC

control

r

Clock

generato

Bus interface

Port 0

Port 1

Port 2

IR PLA

ROM correct

Flash ROM

PC

ACC

B register

C register

Timer 4

Timer 5

Timer 6

Timer 7

Base timer

PWM2/3

Port 7

Port 8

ADC

INT0 to INT7

Noise filter

Port 3

Port C

UART1

UART2

ALU

PSW

RAR

RAM

Stack pointer

Watchdog timer

On-chip Debugger

Page 45

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-36

3. IC101 MICOM

• PIN DESCRIPTION

Pin Name I/O Description Option

VSS1, VSS2

VSS3

VDD1, VDD2

VDD3

Port 0

P00 to P07

Port 1

P10 to P17

Port 2 • 8-bit I/O port

P20 to P27

- - Power supply pin

- + Power supply pin

I/O • 8-bit I/O port

• I/O specifiable in 4-bit units

• Pull-up resistor can be turned on and off in 4-bit units

• HOLD release input

• Port 0 interrupt input

• Shared Pins

P05 : Clock output (system clock / can selected from sub clock)

P06 : Timer 6 toggle output

P07 : Timer 7 toggle output

I/O • 8-bit I/O port

• I/O specifiable in 1-bit units

• Pull-up resistor can be turned on and off in 1-bit units

• Pin functions

P10 : SIO0 data output

P11 : SIO0 data input/bus I/O

P12 : SIO0 clock I/O

P13 : SIO1 data output

P14 : SIO1 data input/bus I/O

P15 : SIO1 clock I/O

P16 : Timer 1 PWML output

P17 : Timer 1 PWMH output/beeper output

I/O Ye

• I/O specifiable in 1-bit units

• Pull-up resistor can be turned on and off in 1-bit units

• Other functions

P20: INT4 input/HOLD reset input/timer 1 event input/timer 0L capture input/

timer 0H capture input/INT6 input/timer 0L capture 1 input

P21 to P23 : INT4 input/HOLD reset input/timer 1 event input/timer 0L capture input/

timer 0H capture input

P24: INT5 input/HOLD reset input/timer 1 event input/timer 0L capture input/

timer 0H capture input/INT7 input/timer 0H capture 1 input

P25 to P27: INT5 input/HOLD reset input/timer 1 event input/timer 0L capture input/

timer 0H capture input

• Interrupt acknowledge ty

INT4

INT5

INT6

INT7

pe

Rising Falling

enable

enable

enable

enable

enable

enable

enable

enable

Rising/

Falling

enable

enable

enable

enable

H level L lev

disable

disable

disable

disable

disable

disable

disable

disable

el

No

No

Yes

Ye

s

s

Page 46

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-37

Pin Name I/O Description Option

Port 7 • 4-bit I/O port

P70 to P73

I/O

• I/O specifiable in 1-bit units

• Pull-up resistor can be turned on and off in 1-bit units

• Shared pins

P70 : INT0 input/HOLD reset input/timer 0L capture input/watchdog timer output

P71 : INT1 input/HOLD reset input/timer 0H capture input

P72 : INT2 input/HOLD reset input/timer 0 event input/timer 0L capture input/

high speed clock counter input

P73 : INT3 input (with noise filter)/timer 0 event input/timer 0H capture input

AD converter input port: AN8 (P70), AN9 (P71)

• Interrupt acknowledge ty

INT0 enable enable disable enable

INT1 enable enable disable enable

INT2 enable enable enable disable

INT3 enable enable enable disable

pe

Rising Falling

Rising/

Falling

H level L lev

enable

enable

disable

disable

el

No

Port 8

P80 to P86

PWM2

PWM3

Port 3

P30 to P37

Port C

PC0 to PC7

RES

XT1 Input • 32.768kHz crystal oscillator input pin

XT2 I/O • 32.768kHz crystal oscillator output pin

CF1 Input Ceramic resonator input pin

CF2 Output Ceramic resonator output pin

I/O • 7-bit I/O port

• I/O specifiable in 1-bit units

• Shared pins

AD converter input port : AN0 (P80) to AN6 (P86)

I/O • PWM2 and PWM3 output ports

• General-purpose I/O available

I/O • 8-bit I/O port

• I/O specifiable in 1-bit units

• Pull-up resistor can be turned on and off in 1-bit units

• Pin functions

P32: UART1 transmit

P33: UART1 receive

P34: UART2 transmit

P35: UART2 receive

I/O • 8-bit I/O port

• I/O specifiable in 1-bit units

• Pull-up resistor can be turned on and off in 1-bit units

• Pin functions

PC5 to PC7: On-chip Debugger

Input Reset pin

• Shared pins

General-purpose input port

AD converter input port : AN10

Must be connected to VDD1 if not to be used.

• Shared pins

General-purpose I/O port

AD converter input port : AN11

Must be set for oscillation and kept open if not to be used.

No

No

Ye

Ye

No

No

No

No

No

s

s

Page 47

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-38

4. IC201 ADC(CS5345)

• PIN CONFIGURATION

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

48 47 46 45 44 43 42 41 40 39 38 37

36

35

34

33

32

31

30

29

28

27

26

25

VLSSDA/CDOUT

AGND

OVFL

SCL/CCLK

AD0/CS

AD1/CDIN

VLC

RESE

T

AIN3A

AIN3B

AIN2A

AIN2B

AIN1A

AIN1B

VA

AFILTB

VQ

TSTO

FILT+

TSTO

AIN4A/MICIN1

AIN4B/MICIN2

AIN5A

AIN5B

AFILTA

TSTO

NC

NC

AGND

AGND

VA

PGAOUTB

PGAOUTA

AIN6B

AIN6A

MICBIAS

INT

VD

DGND

MCLK

LRCK

SCLK

SDOUTNCNC

NC

TSTI

CS5345

Page 48

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-39

4. IC201 ADC(CS5345)

• BLOCK DIAGRAM

.3V to +5V

+3

10

µF

0.1 µF

0.1 µF

0.1 µF

10

µF

+3.3V to +5V

+1.8V

to +

+1.8V

to +

5V

5V

Digital Audio

Capture

Micro-

Controller

See Note 1

2 k

VA

PGAOUT

PGAOUT

AIN1A

AIN1B

AIN2A

A

3.3 µF

B

3.3 µF

1800 pF

1800 pF

1800 pF

100

10 µF

*

*

10 µF

100

100

10 µF

*

Left Analog Inpu

100 k

100 k

Right Analog Inpu

Left Analog Inpu

100 k

t 1

t 1

t 2

0.1 µF

VLS

MCLK

SCLK

LRCK

SDOUT

T

IN

OVFL

VD

VA

RESET

*

SCL/CCLK

SDA/CDOUT

AD1/CDIN

AIN2B

AIN3A

1800 pF

1800 pF

AD0/CS

2 k

C

VL

AIN3B

AIN4A/MICIN1

0.1 µF

AIN4B/MICIN2

1800 pF

1800 pF

1800 pF

10 µF

100

100

10 µF

*

*

10 µF

100

100

10 µF

*

*

10 µF

100

100 k

Right Analog Inpu

Left Analog Inpu

100 k

100 k

Right Analog Inpu

Left Analog Inpu

100 k

100 k

Right Analog Inpu

t 2

t 3

t 3

t 4

t 4

Note 1: Resistors are required

for IC control port operation

NC

NC

NC

NC

NC

Note 2 The value of R

dictated by the microphone

carteridge.

is

L

TSTI

TSTO

TSTO

TST

VQ

FILT+

10 µF

0.1

µF

47 µF

0.1

µF

AG

ND

AIN5A

AIN5B

AINA

O

AIN6B

1800 pF

1800 pF

1800 pF

1800 pF

*

*

*

*

MICBIAS

AGN

D

AGND

**

AFILTA

10 µF

10 µF

10 µF

10 µF

47 µF

2.2nF

100

100

100

100

See Note 2

R

L

2.2nF

Left Analog Inpu

100 k

100 k

Right Analog Inpu

Left Analog Inpu

100 k

100 k

Right Analog Inpu

t 5

t 5

t ;

t 6

AFILTB

DGND

* Capacitors must be C0G or equivalent

Page 49

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-40

Pin Name # Pin Descr iptio n

SDA/CDOUT 1

Serial Control Data (Input/Output) - SDA is a data I/O in IC

®

Mode. CDOUT is the output data line for

the control port interface in SPI

TM

Mode.

SCL/CCLK 2 Serial Control Port Clock (Input) - Serial clock for the serial control port.

AD0/CS 3

Address Bit 0 (IC) / Co ntrol Por t Chip Select (SPI) (Input) - AD0 is a chip address pin in IC Mode;

CS is the chip-select signal for SPI format.

AD1/CDIN 4

Address Bit 1 (IC) / Ser i al Control Dat a Input (SPI) (Input) - AD1 is a chip address pin in IC Mode;

CDIN is the input data line for the control port interface in SPI Mode.

VLC 5

Control Port Power (Input) - Determines the required signal level for the control port interface. Refer

to the Recommended Operating Conditions for appropriate voltages.

RESET 6 Res et (Input) - The device enters a low-power mode when this pin is driven low.

AIN3A

AIN3B

78Stereo Analog Input 3 (Input) - The full-scale level is specified in the ADC Analog Characteristics

specification table.

AIN2A

AIN2B

910Stereo Analog Input 2 (Input) - The full-scale level is specified in the ADC Analog Characteristics

specification table.

• PIN DESCRIPTION

AIN1A

AIN1B

AGND 13 Analog Ground (Input) - Ground reference for the internal analog section.

VA 1 4 Analog Power (Input) - Positive power for the internal analog section.

AFILTA 15 Antialias Filter Connection (Output) - Antialias filter connection for the channel A ADC input.

AFILTB 16 Antialias Filter Connection (Output) - Antialias filter connection for the channel B ADC input.

VQ 17 Quiescent Voltage (Output) - Filter connection for the internal quiescent reference voltage.

TSTO 18 Test Pin (Output) - This pin must be left unconnected.

FILT+ 19 Positive Voltage Reference (Output) - Positive reference voltage for the internal sampling circuits.

TSTO 20 Test Pin - This pin must be left unconnected.

AIN4A/MICIN1

AIN4B/MICIN22122

AIN5A

AIN5B

MICBIAS 25

AIN6A

AIN6B

PGAOUTA

PGAOUTB

VA 3 0 Analog Power (Input) - Positive power for the internal analog section.

AGND

NC

TSTO 35 Test Pin (Output) - This pin must be left unconnected.

VLS 36

TSTI 37 Test Pin (Input) - This pin must be connected to ground.

NC

SDOUT 41 Serial Audio Data Output (Output) - Output for two’s complement serial audio data.

SCLK 42 Serial Clock (Input/Output)

LRCK 43

MCLK 44 Master Clock (Input/Output) - Clock source for the ADC’s delta-sigma modulators.

DGND 45 Digital Ground (Input) - Ground reference for the internal digital section.

VD 46 Digital Power (Input) - Positive power for the internal digital section.

INT 47 Interrupt (Output) - Indicates an interrupt condition has occurred.

OVFL 48 Overflow (Output) - I

1112Stereo Analog Input 1 (Input) - The full-scale level is specified in the ADC Analog Characteristics

specification table.

Stereo Analog Input 4 / Microphone Inp ut 1 & 2 (Input) - The full-scale level is specified in the ADC

Analog Characteristics specification table.

2324Stereo Analog Inpu t 5 (Input) - The full-scale level is specified in the ADC Analog Characteristics

specification table.

Microphone Bias Supply

teristics are specified in the DC Electrical Characteristics specification table.

2627Stereo Analog Input 6 (Input) - The full-scale level is specified in the ADC Analog Characteristics

specification table.

2829PGA Analog Audio Output (Output) - Either an analog output from the PGA block or high impedance.

31

Analog Ground (Input) - Ground reference for the internal analog section.

32

3334No Connect - These pins are not connected internally and should be tied to ground to minimize any

potential coupling effects.

Serial Audio Interface Power (Input) - Determines the required signal level for the serial audio interface. Refer to the Recommended Operating Conditions for appropriate voltages.

38,

No Connect - These pins are not connected internally and should be tied to ground to minimize any

39,

potential coupling effects.

40

Left Right Clock (Input/Output) - Determines which channel, Left or Right, is currently active on the

serial audio data line.

(Output) - Low-noise bias supply for external microphone. Electrical charac-

- Serial clock for the serial audio interface.

ndicates an ADC overflow condition is present.

Page 50

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-41

5. IC704 PWM

• PIN CONFIGURATION

• BLOCK DIAGRAM

/

OVERLOAD

EPD_ENA

SO/SDA

SCK/SCL

DVDD

DVSS

SI/I2C_AD0

/CS/I2C_AD2

SPI/I2C

IO_VSS

XOUT

DMIX_LRCK

DMIX_BCK

DMIX_SDOUT

DVDD

DVSS

DMIX_MCL

IO_VDD

IO_VSS

/RESET

TEST_MODE1

TEST_MODE2

SCAN_ENA

TEST_MODE3

7

7

7

7

8

8

8

8

8

8

XIN

8

8

8

8

9

9

9

K

9

9

9

9

9

9

9

1

IO_VSS

PWM8_P

PWM8_M

IO_VDD

72

73

74

75

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

0

1234567

IO_VSS

IO_VDD

PLL_DVSS

PLL_DVDD

PWM6_P

PWM6_M

IO_VSS

PWM7_P

PWM7_M

71

68

69

70

IO_VSS

IO_VDD

DVSS

DVDD

63

64

65

66

67

PWM4_P

IO_VSS

PWM5_P

PWM5_M

61

62

59

60

PULSUS

9101112131415

8

MBCK

MLRCK

IO_VSS

IO_VSS

IO_VDD

IO_VSS

PLL_AVSS

PLL_AVDD

DVDD

DVSS

16

MSDIN1

MSDIN0

171819

MSDIN2

IO_VSS

PWM4_M

57

58

SBCK

MSDIN3

PWM3_P

PWM3_M

IO_VDD

54

55

56

20

2122232425

SLRCK

IO_VSS

IO_VDD

IO_VSS

53

SSDIN0

PWM2_P

52

SSDIN1

PWM2_M

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

SSDIN2

IO_VSS

PWM1_P

PWM1_M

IO_VDD

PWM_HP_L_P

PWM_HP_L_M

IO_VSS

DVSS

DVDD

PWM_HP_R_P

PWM_HP_R_M

IO_VDD

IO_VSS

PWM_SWL_P

PWM_SWL_M

DVSS

DVDD

MIC_SDIN

MIC_LRCK

MIC_BCK

MIC_MCLK

IO_VDD

IO_VSS

EXT_MUTE

SSDIN3

MBCK

MLRCK

MSDIN[0:3]

SBCK

SLRCK

SSDIN[0:3]

MIC_MC

LK

MIC_BCK

MIC_LRCK

MIC_SDIN

SPI/I2C

SO/SDA

SCK/SCL

SI/I2C_AD0

CS/I2C_AD2

EXT_MUTE

Input

&

Output

MUX

Sample

Rate

Converte

Input

Mapper

Mic.

Input

Processo

Host

Interface

2

C, SPI)

(I

r

r

Internal Controls

Down

Mixe

Mixe

Crystal

Oscillator

XIN

Serial Audio

Output

interfac

e

Serial

Audio

r

Automatic

Gain

Limiter

e

Power Supply

PLL_AVSS

PLL_DVSS

PLL_AVDD

DVDD

Trim

Volume

DVSS

SS

IO_V

IO_VDD

Internal Reset

wer Down

Bass

Manager

EQ

r

Internal Clock

Reset & Po

Main

Volum

PLL

UT

XO

/RESET

PLL_DVDD

Output

inter

face

Output Mapper

PWM

Modulator

POP

NR

DMIX_MCLK

OLRCK

OBCK

DOUT

DMIX_S

PWM1_P/M

PWM2_P/M

PWM3_P/M

PWM4_P/M

PWM5_P/M

PWM6_P

/M

PWM7_P/M

PWM8_P/M

PWM_HP_L_P/M

PWM_HP_R_P/M

PWM_

SWL_P/M

EPD_ENA

OVERLOAD

Page 51

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-42

5. IC704 PWM

• PIN DESCRIPTION

SLRCK 20 I/O PCM word clock (left-right clock) input/output of sub 8-channel

audio. User can select the master/slave mode of this signal.

Schmitt-Trigger i

nput.

SSDIN [3:0] 23, 24, 25, 26 I/O PCM serial data input of sub-channel audio.

User can set this sub-channel data input pins to PCM serial data

output pins. See the Control Register Description part.

Schmitt-Trigger i

nput

Name Pin NO. Ty pe Description

PLL_AVDD 6 Analog

PLL_AVSS 8 Analog

PLL_DVDD 3 PLL

PLL_DVSS 2 PLL

DVDD 13, 34, 42,

DVSS 14, 35, 43,

IO_VDD 4,

IO_VSS 1, 5, 7, 9, 21,

/RESET 96 I H/W reset signal. Active Low Schmitt-Trigger input.

XIN 86 Analog Cryst

XOUT 87 Analog Cryst

MBCK 11 I/O PCM bit clock input/output of main 8-channel audio.

MLRCK 12 I/O PCM Word clock (left-right clock) input/output of main 8-channel

MSDIN [3:0] 15, 16, 17, 18 I PCM serial data input of main 8-channel audio.

SBCK 19 I/O PCM bit clock input/output of 8-channel audio.

66, 80, 91

63, 81, 92

10, 22, 29, 39, 47,

56, 65, 72, 94

28, 38, 44, 50,

53, 57, 60, 64,

69, 73, 85, 95

Power and Ground

Power

Ground

Power

Ground

Power Core power supply

Ground Core digit

Power I/O power supply. 3.3V Digital power supply.

Ground I/O digital ground.

PCM Audio Input/Output Interface

PLL analog power supply.

analog ground.

PLL

PLL digital power supply.

PLL digit

Reset and Clock

The Schmitt-Trigger input allows a slowly rising input to reset the

chip reliably. The RESET signal must be asserted ‘Low’ during

power up. De-assert ‘High’ for normal operation.

User can select the master/slave mode of this signal.

Schmitt-Trigger i

audio. User can select the master/slave mode of this signal.

Schmitt-Trigger i

Schmitt-Trigger i

User can select the master/slave mode of this signal.

Schmitt-Trigger i

al ground.

al ground.

al Oscillator input pin.

al Oscillator output pin.

.

nput.

nput.

nput.

nput.

Page 52

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-43

MIC_MCLK 30 O Main clock for external microphone input A/DC.

Clock frequency can be selected between 6.144MHz,

12.288MHz, and 24.576MHz.

MIC_BCK 31 I/O PCM bit clock input/output of external microphone.

Bit clock frequency

is 3.072MHz (48kHz x 64, fixed)

MIC_LRCK 32 I/O PCM Word clock (left-right clock) input/output of external

microphone. Word clock rate is 48

kHz (fixed).

MIC_SDIN 33 I PCM serial data input of external microphone.

Schmitt-Trigger i

nput.

DMIX_MCLK 93 O Main clock for external down-mix line output D/AC.

DMIX_BCK 89 O PCM bit clock output of down-mix signal.

Bit clock frequency

is 6.144MHz (96kHz x 64, fixed)

DMIX_LRCK 88 O PCM Word clock (left-right clock) output of down-mix signal.

Word clock rate is 96kHz (fixed).

DMIX_SDOUT 90 O PCM serial dat

a output of down-mix signal.

PWM Audio Output

PWM1_P 49 O Positive PWM output of channel 1.

PWM1_M 48 O

Negative PWM output of channel 1.

PWM2_P 52 O Positive PWM output of channel 2.

PWM2_M 51 O

Negative PWM output of channel 2.

PWM3_P 55 O Positive PWM output of channel 3.

PWM3_M 54 O

Negative PWM output of channel 3.

PWM4_P 59 O Positive PWM output of channel 4.

PWM4_M 58 O

Negative PWM output of channel 4.

PWM5_P 62 O Positive PWM output of channel 5.

PWM5_M 61 O

Negative PWM output of channel 5.

PWM6_P 68 O Positive PWM output of channel 6.

PWM6_M 67 O

Negative PWM output of channel 6.

PWM7_P 71 O Positive PWM output of channel 7.

PWM7_M 70 O

Negative PWM output of channel 7.

PWM8_P 75 O Positive PWM output of channel 8.

PWM8_M 74 O

Negative PWM output of channel 8.

PWM_HP_L_P 46 O Positive PWM output of headphone lef

t channel.

PWM_HP_L_M 45 O Negative PWM output of headphone lef

t channel.

PWM_HP_R_P 41 O Positive PWM output of headphone right channel.

PWM_HP_R_M 40 O Negative PWM output of headphone right channel.

PWM_SWL_P 37 O

Positive PWM output of subwoofer line output.

PWM_SWL_M 36 O

Negative PWM output of subwoofer line output.

System Control Interface

SPI/I2C 84 I Host interface mode (SPI or I2C) selector.

Assert ‘HIGH’ for SPI mode. De-assert ‘LOW’ for I2C mode.

Internal pull-down resistor

.

SO/SDA 78 I/O SO for SPI mode or SDA

for I2C mode.

Page 53

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-44

SCK/SCL 79 I SCK for SPI mode or SCL for I2C mode.

Schmitt-Tr

igger input.

SI/I2C_AD0 82 I SI for SPI mode or Slave Address 0 for I2C mode.

Schmitt-Trigger input.

Internal pull-down resistor

.

/CS/I2C_AD2 83 I Chip selector (CS) for SPI mode or Slave Address 2 for I2C

mode.

Schmitt-Trigger input.

Internal pull-down resistor

.

Special Control Interface

EXT_MUTE 27 I External mute control input. Active High.

Assert ‘HIGH’ to mute audio output.

Internal pull-down resistor

.

OVERLOAD 76 I Power stage overload indication input.

Polarity is programmable. Schmitt-Trigger input.

When OVERLOAD is asserted, all PWM audio outputs go to

“LOW”. That shutdown process is programmable.

Internal pull-down resistor

.

EPD_ENA 77 O External amplifier power device enable output.

Active High.

Test Mode

TEST_MODE1 97 I Test mode selection pin 1.

In normal operation, it should be “LOW” or not connected.

Internal pull-down resistor

.

TEST_MODE2 98 I Test mode selection pin 2.

In normal operation, it should be “LOW” or not connected.

Internal pull-down resistor

.

SCAN_ENA 99 I Scan enable. Active High.

In normal operation, it should be “LOW” or not connected.

Internal pull-down resistor

.

TEST_MODE3 100 I Test mode selection pin 3.

In normal operation, it should be “LOW” or not connected.

Internal pull-down resistor

.

All inputs and bi-directional inputs are 5 Volt tolerant. The corresponding pins can be connected to the buses that can

swing between 0V and 5V. The output-only pins are not 5V tolerant and the buses they are connected to can swing only

between 0V and 3.3V.

Page 54

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-45 2-46

WIRING DIAGRAM

2007. 11. 30

PN202

CABLE1

Page 55

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-47 2-48

OVERALL BLOCK DIAGRAM

2007. 11. 30

Page 56

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2007. 11. 30

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

NOTES) Symbol denotes DC chassis ground.

NOTE) Warning

NOTE) Parts that are shaded are critical

NOTE) With respect to risk of fire or

NOTE) electricial shock.

2-49 2-50

CIRCUIT DIAGRAMS

1. SMPS(POWER) CIRCUIT DIAGRAM

IMPORTANT SAFETY NOTICE

WHEN SERVICING THIS CHASSIS, UNDER NO CIRCUMSTANCES SHOULD THE ORIGINAL DESIGN BE

MODIFIED OR ALTERED WITHOUT PERMISSION

FROM THE LG CORPORATION. ALL COMPONENTS

SHOULD BE REPLACED ONLY WITH TYPES IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT. SPECIAL

COMPONENTS ARE SHADED ON THE SCHEMATIC

FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY DIFFER FROM THE ACTUAL CIRCUIT USED. THIS WAY,

IMPLEMENTATION OF THE LATEST SAFETY AND

PERFORMANCE IMPROVEMENT CHANGES INTO

THE SET IS NOT DELAYED UNTIL THE NEW SERVICE

LITERATURE IS PRINTED.

NOTE :

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

Page 57

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-51 2-52

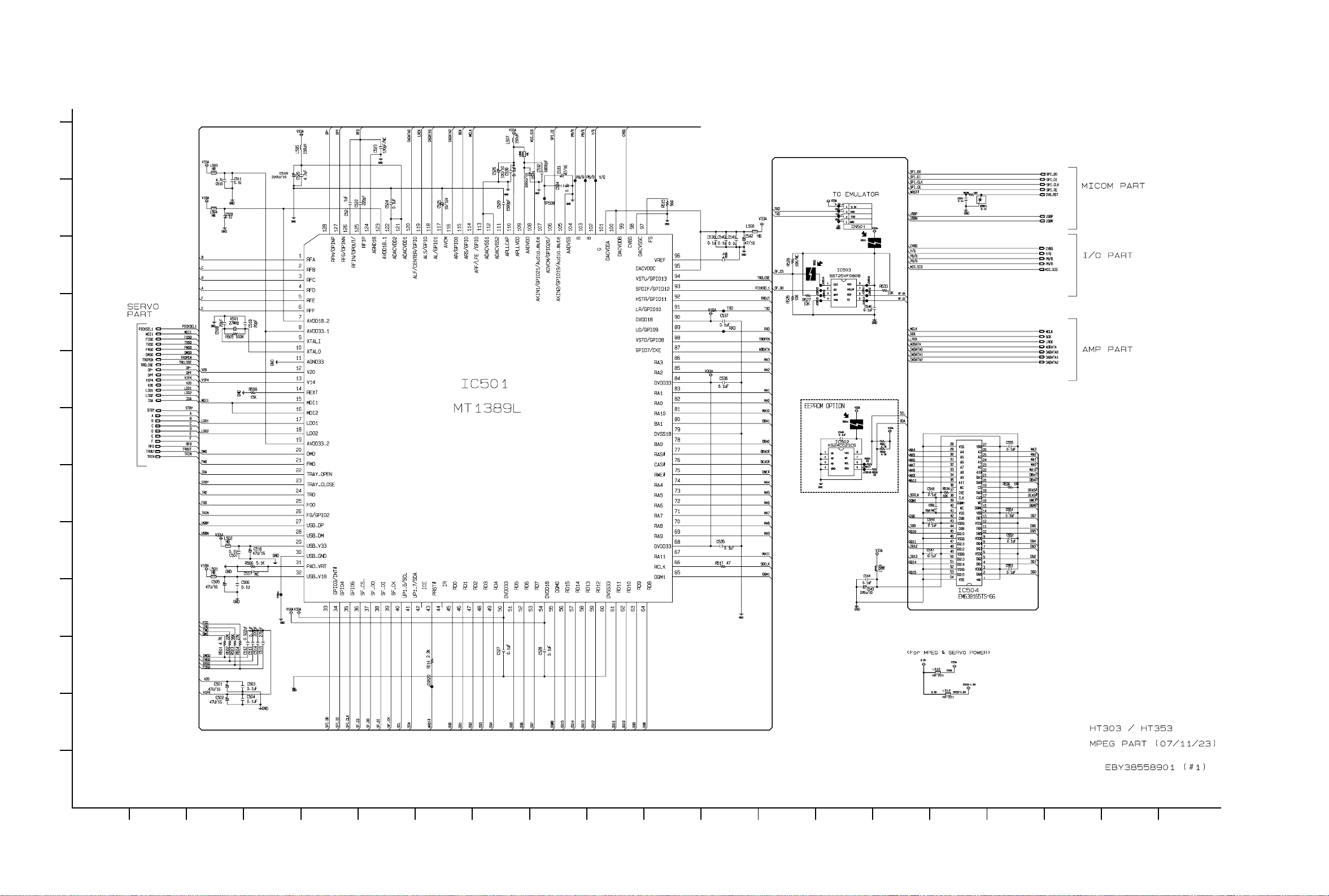

2. MPEG CIRCUIT DIAGRAM

2007. 11. 30

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 58

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-53 2-54

3. SERVO CIRCUIT DIAGRAM

2007. 11. 30

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 59

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-55 2-56

4. MICOM CIRCUIT DIAGRAM

2007. 11. 30

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 60

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-57 2-58

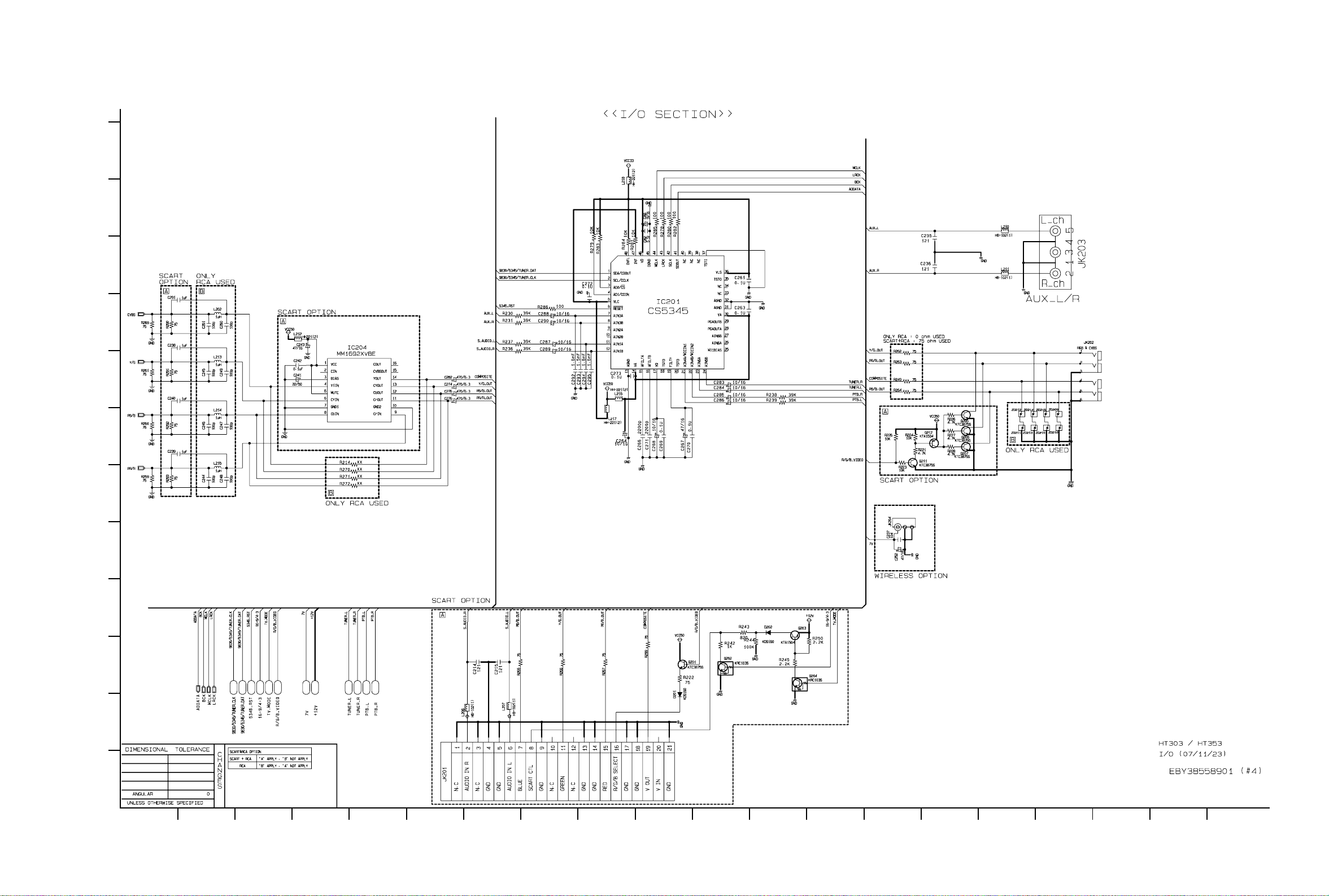

5. I/O CIRCUIT DIAGRAM

2007. 11. 30

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

Page 61

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2-59 2-60

6. AMP CIRCUIT DIAGRAM

2007. 11. 30

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

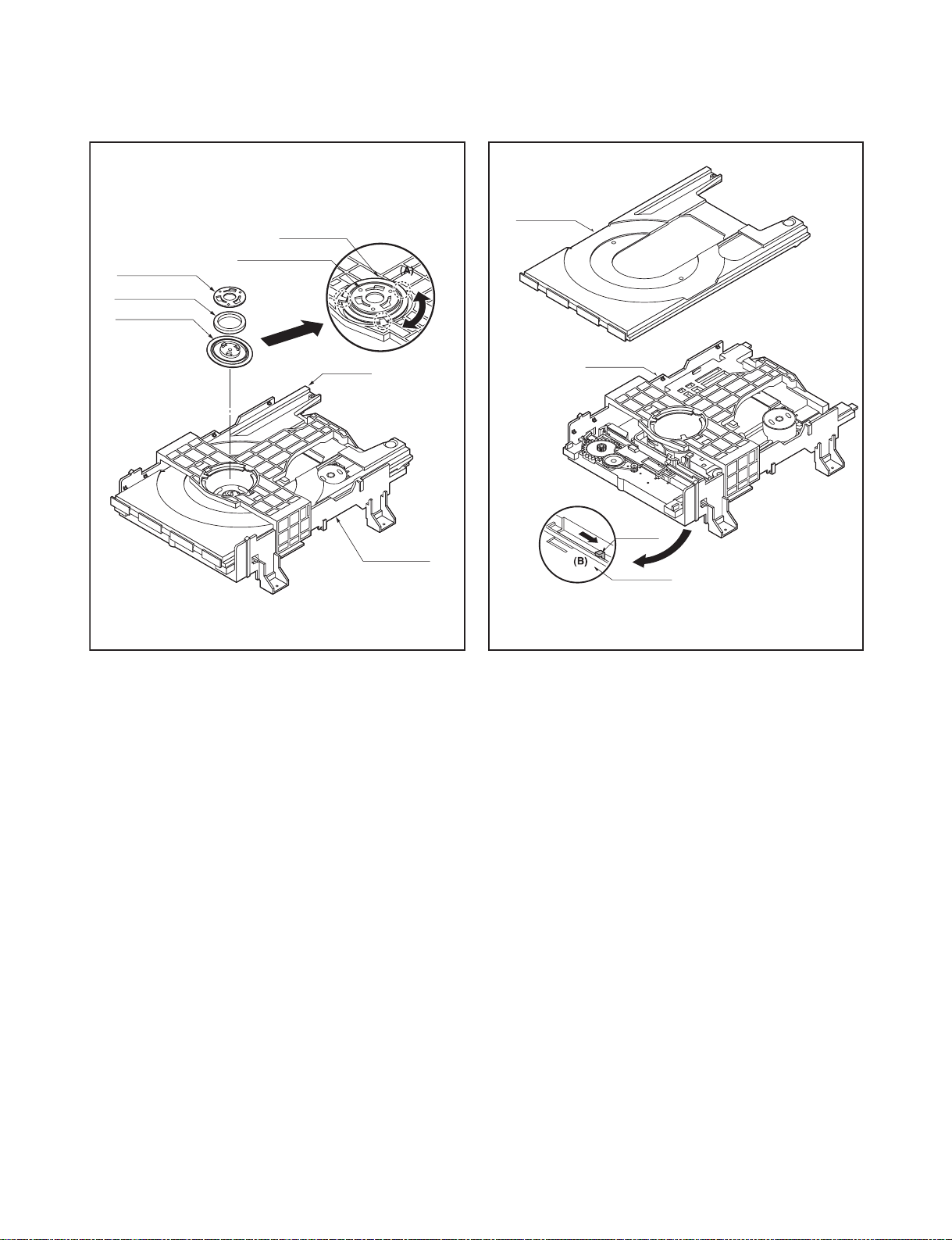

Page 62