Page 1

RS485 Option Board

for SV-iS5/iH Series

Read this manual carefully before using the RS485 OPTION BOARD

and follow the instructions exactly.

After reading this manual, keep it at handy for future reference.

LG Industrial Systems

User Manual

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 2

Thank you for purchase of LG RS 485 Option Board!

SAFETY PRECAUTIONS

Always follow safety precautions to prevent accidents and potential hazards from occurring.

Safety precautions are classified into “WARNING” and “CAUTION” in this manual.

WARNING

CAUTION

Throughout this manual we use the following two illustrations to make you aware of safety

considerations:

Identifies potential hazards.

Read the message and follow the instructions carefully.

Identifies shock hazards.

Particular attention should be directed because dangerous voltage may be present.

Keep this manual at handy for quick reference.

CAUTION

Do not touch the CMOS components unless the board is grounded.

ESD can cause break down of CMOS components.

Do not change the communication cable with the inverter power is applied.

Otherwise, there is a danger of connecting error and damage to the board.

Make sure to precisely insert the connector of inverter and option board

Otherwise, there is a danger of connecting error and damage to the board.

Check the parameter unit when setting the parameters.

Otherwise, there is a danger of connecting error and damage to the board.

Indicates a potentially hazardous situation which, if not avoided,

can result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided,

can result in minor to moderate injury, or serious damage to the

product.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 3

1

1. INTRODUCTION

By using a RS 485 OPTION BOARD, SV-iS5/iH inverter can be connected to a RS 485 network.

1.1. When you use the RS 485 Option Card …

Inverter can be controlled and monitored by the sequence program of the PLC or other master module.

Up to 31 drives or other slave devices may be connected in a multi-drop fashio n on the RS485 network and may be monitored or controlled by a single PLC or PC. Parameter setting and change

are available through PC.

1.1.1. Interface type of RS485 reference

- Allows the drive to communicate with any other co mputers.

- Allows connection of up to 31 drives with multi-drop link system.

- Noise-resistant interface

Users can use any kind of RS232-485 converters. The specifications of converters depend on the

manufacturers. Refer to the converter manual for detailed specifications.

1.1.2. Before Installation

Before installation and operation, this manual should be read thoroughly. If not, it can cause personal injury

or damage other equipment.

2. SPECIFICATION

2.1. Performance specification

Items Specifications

Communication method RS485 (Using RS232-485 Converter)

Transmission form Bus method, Multi-drop Link System

Applicable inverter IS5/iH series drive

Number of drives Maximum 31 drives connectable

Transmission distance Max. 1200m (Less than 700 m recommended)

Converter RS232-485, Use PC with RS232 card embedded

2.2. Hardware Specifications

Items Specifications

Installation Option connector on the inverter control board

Control B/D 5V dc supplied from inverter power supply

Power

Supply

Comm. B/D

Power supplied using 5V DC-DC converter on option

board

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 4

2

2.3. Communication Specification

Items Specifications

Communication speed 1200 /2400/4800/9600/19200 bps Selectable

Control procedure Asynchronous communication system

Communication system Half duplex system

Character system BINARY (8 bit)

Stop bit 1 bit

Error check (CRC16)

2 byte

Parity check None

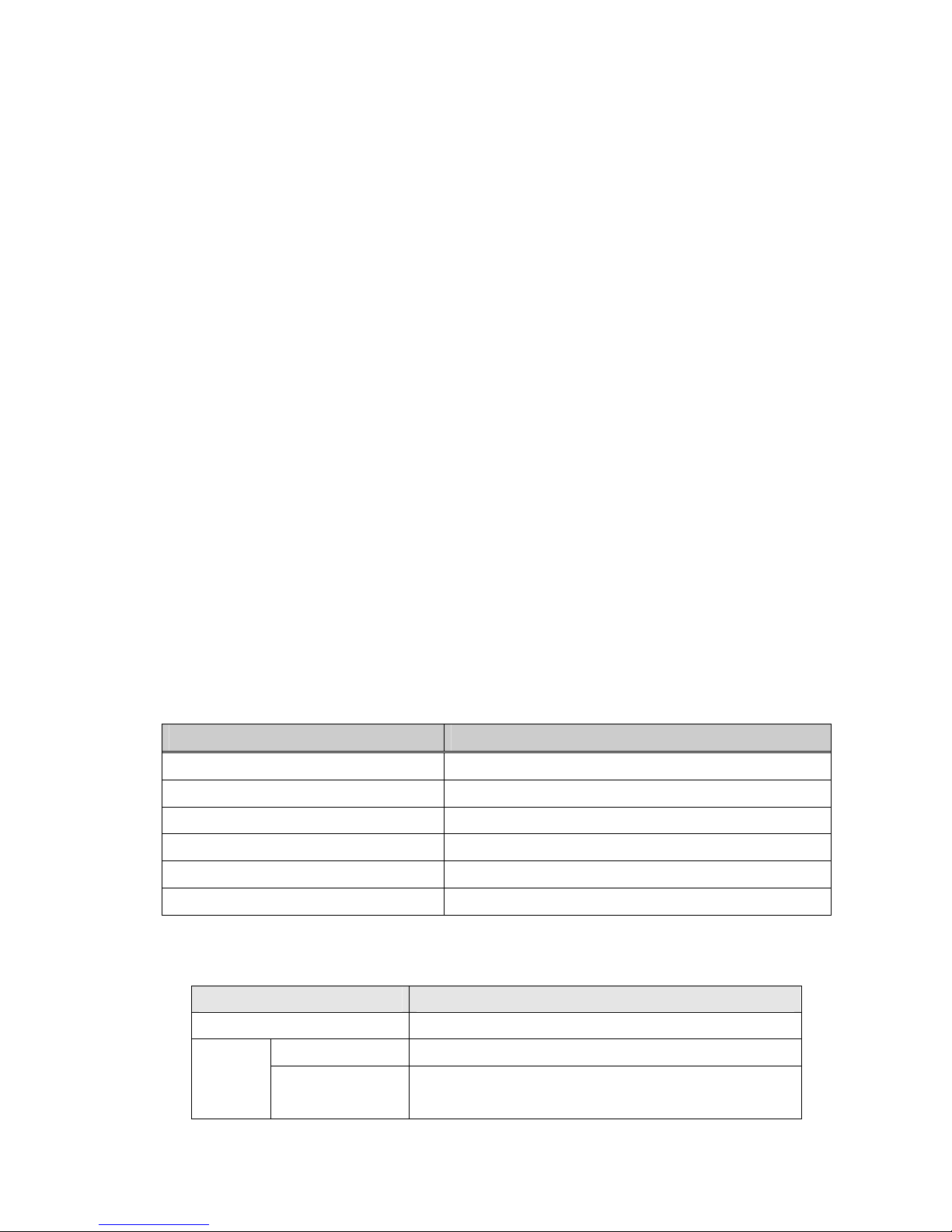

3. PRODUCT DETAIL

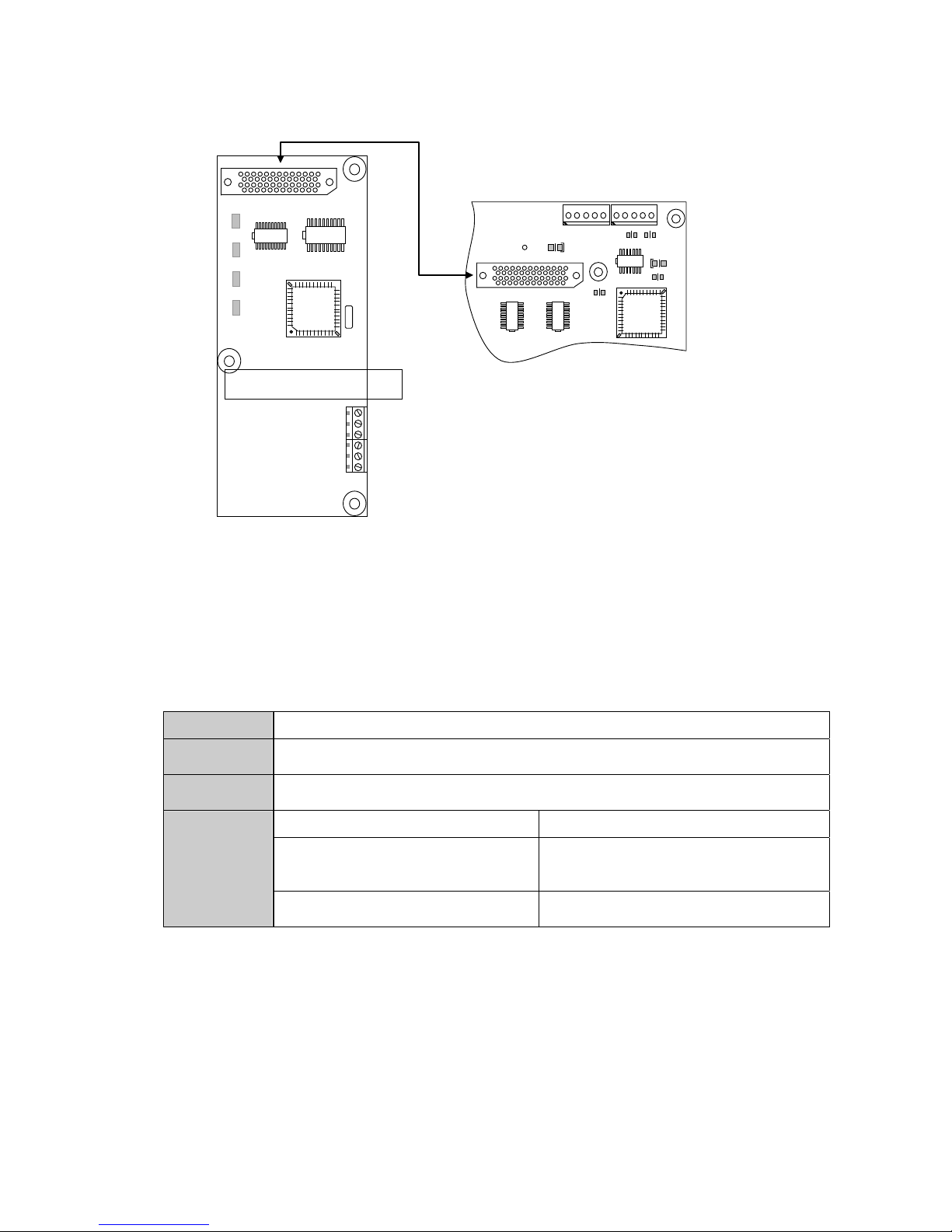

3.1. Layout and detail

Name Description

Connector Connector to inverter main PCB

P 485 signal - high

N 485 signal – low

G 485 Ground

S Shield

Signal

connection

terminal

Communication

signal connection

terminal

T1, T2 Connect a terminating resistor

Figure 1-1. Installating RS485 Option Card to SV-iS5

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 5

3

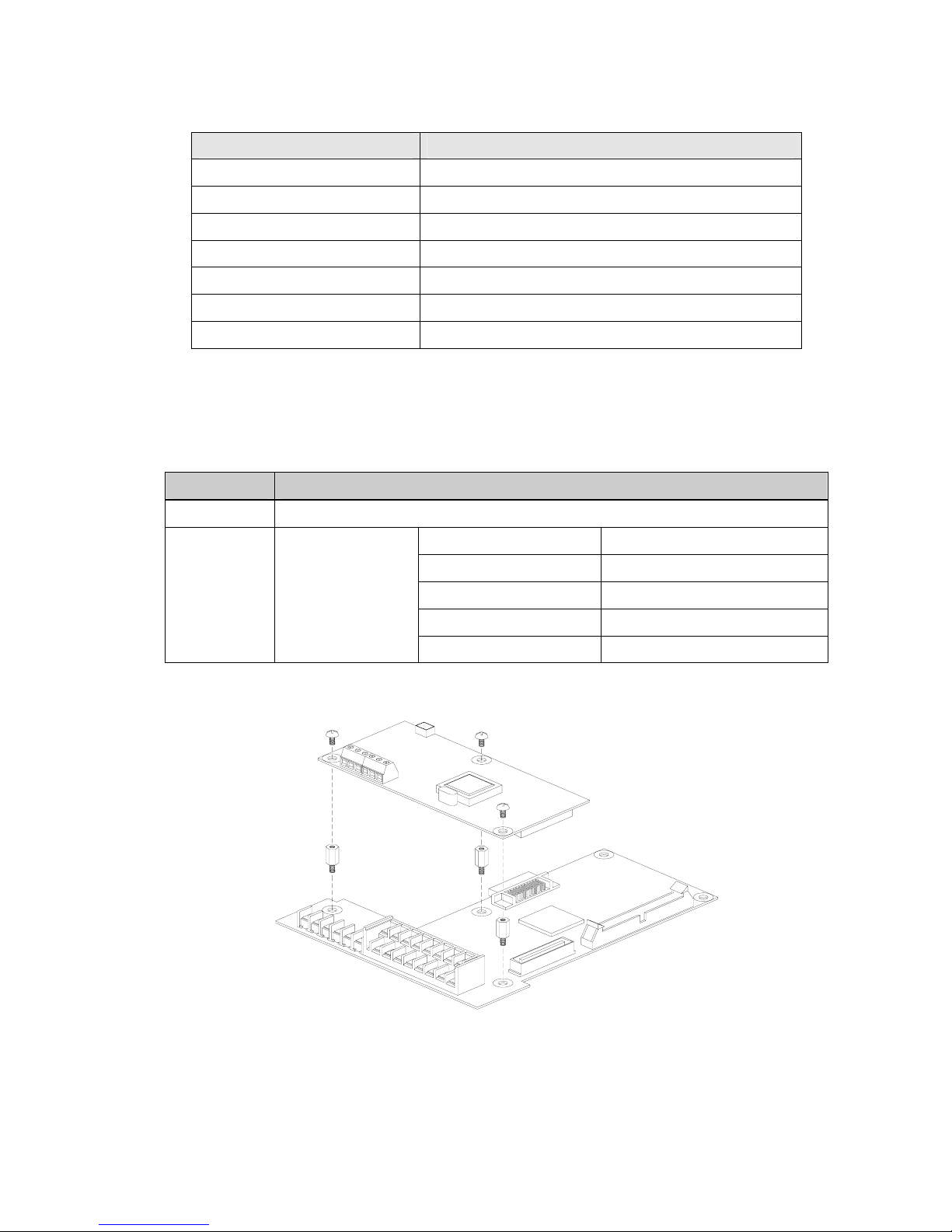

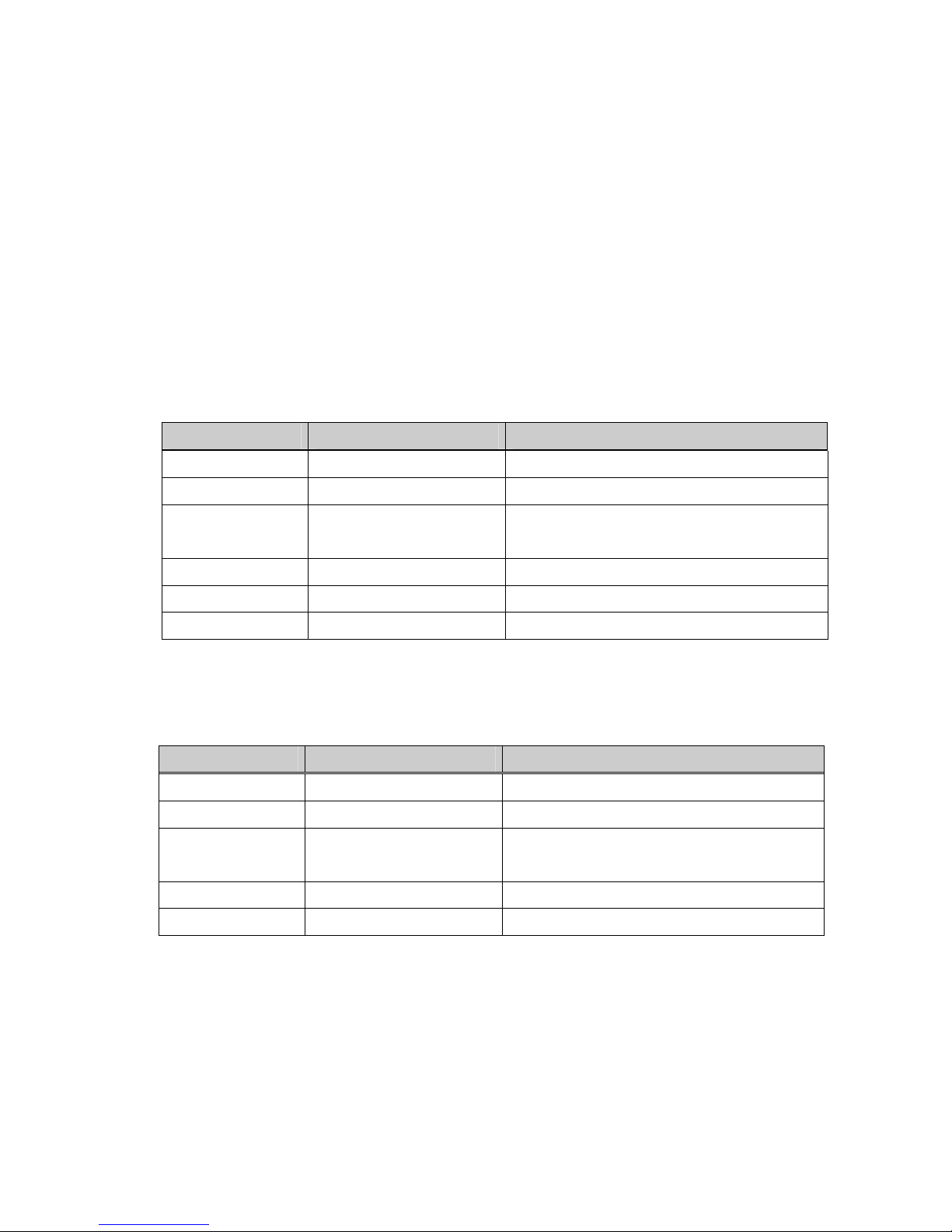

Figure 1-2. Installating RS485 Option Card to SV-iH

3.2. Status LED

CPU LED

Normal operation of the board

RXD LED

Receiving 485 signal

TXD LED

Responding to 485 signal

Intermittent blinking Wrong data received (normal)

Blingking with CPU LED

coincidentally

DPRAM Communication Error

ERR LED

Blinking after CPU LED blinks

Network Connection TimeOut

Connect CN1to CNC7

iH Control Board

RS485 Board

CPU

TX RX ERR

CN1

U1

U4

U3

X1

S

G T2 T1 N P

CNC3

G5 BC5

U6U7

U8

R

CNC7

U4

BC4

B7

iH

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 6

4

4. INSTALLATION

4.1. Option board installation guide

1. Remove the keypad on the inverter and connect the RS485 option board (See the Figure 1).

2. Double check the board is firmly installed to the board and then apply the inverter power.

3. When power ON, CPU LED is blinking per second after all LEDs blink one after another .

4. If “CPU LED” is not blinking, turn off the inverter power swiftly (if not, inverter and the board may get

damaged.) and check for the proper installation of the board. If the problem persists, contact LG

distributor.

5. Check I/O 47 is set to “RS485”.

6. When the above condition is met, set the communication parameters as shown below.

[For SV-iS5]

Parameter code Display Setting Value

< COM-01 > Opt B/D RS485 displayed automatically

< COM-02 > Opt mode Setting command to be controlled by option

< I/O- 46 > Inv. number

1~31

(Verify the assigned number is not duplicated.)

< I/O- 47 > Baud-rate

9600 bps (Factory default)

< I/O- 48 > Lost command (Note 1) User defined

< I/O- 49> Time.Out (Note 1) 0.1 sec (Factory default)

Note1) set for emergency stop of the inverter when inverter and master communication becomes

faulty. Activates when communcation has not been made during setting time. This means remote

controlling of inverter has not executed. Set these for safe use of the inverter.

[For SV-iH]

Parameter code Display Setting Value

< FUN-01 > Freq. set “Remote”

< FUN-02 > Run/stop set “Remote“

< I/O- 50 > Inv. number

1~31

(Verify the assigned number is not duplicated.)

< I/O- 51 > Baud-rate 9600 bps (Factory default)

< I/O- 52 > Comm.timeout(Note1) 10.0 (Factory default)

Note1) set for emergency stop of the inverter when inverter and master communication becomes

faulty. Activates when communcation has not been made during setting time. This means remote

controlling of inverter has not executed. Set these for safe use of the inverter.

If Comm. Timeout is set to “0”, inverter maintains its status without stopping at the event of

network communication disconnection.

7. Turn off the inverter power to connect the converter when step 6 is finished.

8. Connect the terminating resistor at the end of network (See the figure 3).

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 7

5

4.2. RS232-485 converter installation

See the converter manual for accurate installation.

4.3. Computer, Converter and RS485 Option Card Configuration

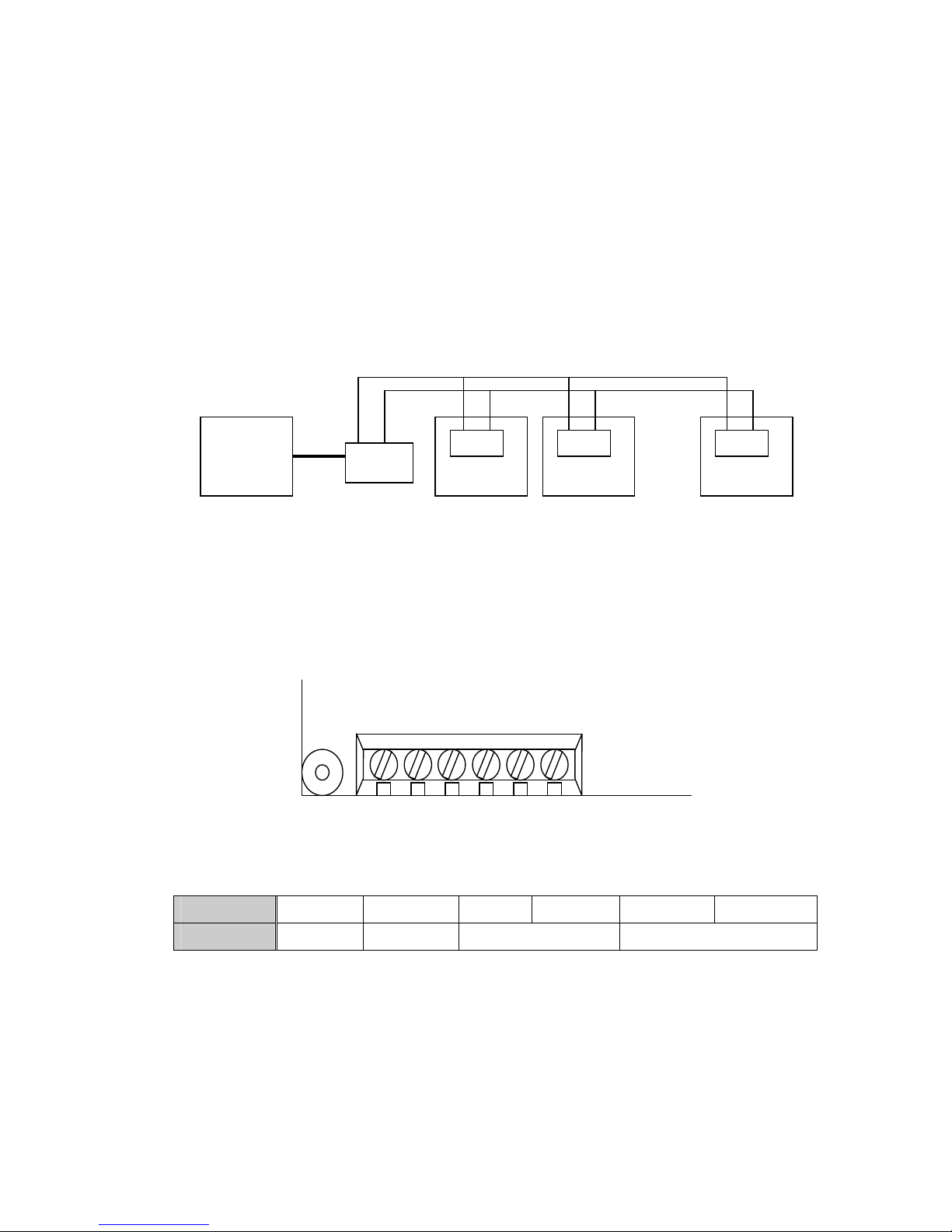

4.3.1. System configuration

Maximum cable length is 1200m but recommended length is within 700.

The number of connectable inverter is 31.

Figure 2. System configuration

4.3.2. Communication signal connection

Figure 3. Option card terminal layout

Pin S GND T1 T2 N P

Description Shield Ground Termination Signal

* S: Networkd line ground shoud be done only one point.

Connect it to screw near terminal shield when grounding through inverter.

* GND: Ground terminal for 485 communication

* T1, T2: Shorting these terminals connects a terminating resistor.

Computer

232/485

Converter

Option card

Option card

Option card

Inverter 1 Inverter 2 Inverter n

…

S GND

T1

T2 N P

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 8

6

5. COMMUNICATION PROTOCOL

Use LG RS485 protocol (Open protocol). Contact LG representatives.

Computer or other hosts can be Master and inverters Slave. Inverter responds to Read/Write

command from Master.

5.1. Supported command codes

Function Code Name

‘R’ Parameter Read

‘W’ Parameter Write

‘X’ Monitor Register

‘Y’ Monitor Execution

(Important: Use ASCII CODE (Capital Letter).)

5.2. BroadCast Function

Use it to send command to all inverters at the network.

All inverters respond when command is sent from Station # 255.

5.3. Error Code

Error Code Display Description

ILLEGAL

FUNCTION

IF Invalid command received.

ILLEGAL DATA

ADDRESS

IA

Invalid parameter address received.

Monitor executed without resistoring monitor.

ILLEGAL DATA

VALUE

ID Invalid data received.

WRITE MODE

ERROR

WM Read Only or not-programmable during run.

FRAME ERROR FE Frame size, internal Num or Sum is different.

TIME OUT

ERROR

TO DPRAM communication failed for the set time.

DPRAM OFF LINE DO DPRAM is Off-line.

INVALID ID

NUMBER

IN Different address received.

UNDEFINED

CONDITION

UC Undefined condition received.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 9

7

6. TROUBLESHOOTING

Refer to this section when communication error occurs.

CPU LED does not work properly.

Symptom

Inverter doesn’t work properly or connection between options of VFD is

not achieved correctly.

Solution

1. Check power source of Inverter.

2. Check connection status whether option card is correctly inserted into

the slot of inverter or not, if inverter works normally.

TXD LED and RXD LED do not work properly.

What to check Corrective action

Is the power provided to the converter? Provide electric power to the converter.

Are the connections between converter and

computer correct?

Refer to converter manual.

Is communication card installed into the

inverter correctly?

Install it correctly referring to

“4.Installation”

Is communication program running on the

computer?

Start communication program.

Is baud rate of computer and inverter correctly

set?

Set baud rate identically referring to “4.

Installation”

Is the format of user program* right? Correct user program.

Is the connection between converter and

communication card right?

Connect correctly referring to “4.

Installation”

* User program is User-made S/W for PC.

ERR LED is blinking.

Status Solution

Blinking intermittently

Normal operation. Wrong data is received due to noise and

other causes.

Blinking after CPU LED

blinks

Network communication is not made for TimeOut (I/O 49).

Check Master status.

Blinking with CPU LED at the

same time

Communication error between inverter and option card.

Cycle the inverter power (On/Off). If this problem persists,

contact LG representatives.

* Refer to COM group parameters for Freq/Run/Stop command setting.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 10

8

7. PARAMETER CODE (HEX)

<Common>: Area accessible regardless of inverter models (Note 2)

Parameter

Address

Parameter Name Unit Read/Write Data Value (Hex)

0000 Inverter model - R 4: SV-iS5 3:SV-IH

SV-iS5

0: 0.75 1:1.5 2:2.2 3: 3.7 4: 5.5

5: 7.5 6: 11 7: 15 8: 18.5 9: 22

A

: 30 B:37 C:45 D: 55 E: 75 F: 90

10: 110 11: 132 12: 160 13: 200 14: 220

15: 280 16:375 (Unit: kW)

0001 Inverter capacity - R

SV-IH

A: 30 B: 37 C: 45 D: 55 E: 75 F: 90

10: 110 11: 132 12: 160 14: 220

(Unit: kW)

0002 Inverter Input Voltage - R 0: 220V 1: 440V

0003 S/W Version - R

SV-iS5

0100: Ver. 1.00, 0101: Ver 1.01

SV-iH

0200 : Ver. 2.00, 0201: Ver. 2.01

0004 Parameter Lock - R/W

0: Lock (default)

1: Unlock

0005 Frequency Reference 0.01Hz R/W 0-60000

0006 Run Command - R/W

Bit 0: Stop

Bit 1: Forward Run

Bit 2: Reverse Run

Bit 3: Fault Reset

Bit 4: Emergency Stop

(Bit 0 also resets fault)

0007 Acceleration Time 0.1 sec R/W

0008 Deceleration Time 0.1 sec R/W

0009 Output Current 0.1 A R

000A Output Frequency 0.01 Hz R

000B Output Voltage 0.1 V R

000C DC Link Voltage 0.1 V R

000D Output Power 0.1 kW R

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 11

9

Parameter

Address

Parameter Name Unit Read/Write Data Value (Hex)

SV-iS5

Bit 0: Stop, Bit 1: Forward Running

Bit 2: Reverse Running Bit 3:Fault (Trip)

Bit 4: Accelerating Bit 5: Decelerating

Bit 6: Output Frequency Arrival

Bit 7:DC Braking, Bit 8: Stopping

Bit 9: Not used

Bit10: BrakeOpen

Bit 11: FWD Run Command ON,

Bit 12: REV Run command ON,

Bit13: Rem. Run/Stop

Bit14: Rem. Freq. Cmd

000E Sequence Monitor - R

SV-iH

BIT 0 : Stop

BIT 1 : Forward Run

BIT 2 : Reverse Run

BIT 3 : Fault (Trip)

BIT 4 : Accelerating

BIT 5 : Decelerating

BIT 6 : Output Frequency Arrival

BIT 7 : DC Braking

BIT 8 : Stopping

BIT13: Rem. Run/Stop

BIT 14: Rem. Freq. Cmd

000F Trip information - R

SV-iS5

Bit 0:OCT1,Bit 1: OV, Bit 2: EXT-A

Bit 3: BX, Bit 4:OCT2, Bit 5: GF,

Bit 6: OH,Bit 7: ETH, Bit 8: OLT, Bit 9:

HW-diag,Bit10:EXT-B,Bit11:FO

Bit12:OPT,Bit13:POBit,14:IOLT, Bit15:LV

SV-iH

Bit 0: OC Bit 1: OV Bit 2:EXT

Bit 3: BX Bit 4:LV Bit 5:FUSE OPEN Bit 6:

GF Bit 7: OH

Bit 8: ETH Bit 9:OLT Bit 10: MCF

Bit 12: SCT Bit 15: IOLT

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 12

10

Parameter

Address

Parameter Name Unit Read/Write Data Value (Hex)

0010 Input Terminal Status - R

SV-iS5

Bit 0: P1, Bit 1: P2, Bit 2: P3

Bit 3: P4, Bit 4: P5, Bit 5: P6,

Bit 6: RST, Bit 7: BX, Bit 8: JOG, Bit 9:

FX, Bit 10: RX

SV-iH

Bit 0: FX Bit 1:RX Bit 2:BX

Bit 3: RST Bit 8: P1 Bit 9: P2

Bit 10: P3 Bit 11: P4

Bit 12: P5 Bit 13: P6

0011 Output Terminal Status - R

Bit 0: Q1 (OC1) , Bit 1: Q2 (OC2)

Bit 2: Q3 (OC3)

SV-iS5

Bit 3: AUX Bit 4: 30AC

SV-iH

Bit 3: AUX1 Bit 4: AUX2

x0012 V1 - R

SV-iS5 0 – FFC0

SV-iH 0-FFFF

0x0013 V2 - R

SV-iS5 0 – FFC0

SV-iH 0-FFFF

0x0014 I - R

SV-iS5 0 – FFC0

SV-iH 0- FFFF

0x0015 RPM - R

(Note 2) The changed value in Common affects the current setting but returns to the previous setting when power is

cycled or Inverter is reset. However, changing value is immediately reflected in other parameter groups even in the case

of Reset or Power On/Off.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 13

11

SV-iS5

< DRV group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5100 DRV#00 Cmd. freq 0 MaxFreq 0 0.01Hz

5101 DRV#01 Acc. Time 100 6000 0 0.1sec

5102 DRV#02 Dec. Time 200 6000 0 0.1sec

5103 DRV#03 Drive mode 1 2 0

5104 DRV#04 Freq. mode 0 4 0

5105 DRV#05

Step freq - 1 1000 MaxFreq startFreq 0.01Hz

5106 DRV#06

Step freq - 2 2000 MaxFreq startFreq 0.01Hz

5107 DRV#07

Step freq - 3 3000 MaxFreq startFreq 0.01Hz

5108 DRV#08

Current - - - 0.1A

5109 DRV#09

Speed - - - 1rpm

510A DRV#10 DC Link Voltage - - V

< FU1 group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5203 FU1 #03 Run prohibit 0 2 0

5205 FU1 #05 Acc. pattern 0 4 0

5206 FU1 #06 Dec. pattern 0 4 0

5207 FU1 #07 Stop mode 0 2 0

5208 FU1 #08 DcBr freq. 500 6000 startFreq 0.01Hz

5209 FU1 #09 DcBlk time 10 6000 0 0.01sec

520A FU1 #10 DcBr value 50 200 0 %

520B FU1 #11 DcBr time 10 600 0 0.1sec

520C FU1 #12 DcSt value 50 200 0 %

520D FU1 #13 DcSt time 0 600 0 0.1sec

5214 FU1 #20 Max freq. 6000 40000 4000 0.01Hz

5215 FU1 #21 Base freq. 6000 maxFreq 3000 0.01Hz

5216 FU1 #22 Start freq. 50 6000 1 0.01Hz

5217 FU1 #23 Freq limit 0 1 0

5218 FU1 #24 F-limit Lo. 50 highFreq startFreq 0.01Hz

5219 FU1 #25 F-limit Hi. 6000 maxFreq lowFreq 0.01Hz

521A FU1 #26 Torque boost 0 1 0

521B FU1 #27 Fwd boost 20 150 0 0.1%

521C FU1 #28 Rev boost 20 150 0 0.1%

521D FU1 #29 V/F pattern 0 2 0

521E FU1 #30 User freq. 1 1500 maxFreq 0 0.01Hz

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 14

12

Addr

ess

NO. Description Default Maximum Minimum Unit

521F FU1 #31 User volt. 1 25 100 0 %

5220 FU1 #32 User freq. 2 3000 maxFreq 0 0.01Hz

5221 FU1 #33 User volt. 2 50 100 0 %

5222 FU1 #34 User freq. 3 4500 maxFreq 0 0.01Hz

5223 FU1 #35 User volt. 3 75 100 0 %

5224 FU1 #36 User freq. 4 6000 maxFreq 0 0.01Hz

5225 FU1 #37 User volt. 4 100 100 0 %

5226 FU1 #38 Volt control 1000 1100 400 0.1%

5227 FU1 #39 Energy save 0 30 0 %

5232 FU1 #50 ETH select 0 1 0

5233 FU1 #51 ETH 1min 180 200 ETH Cont %

5234 FU1 #52 ETH Cont 100 150 50 %

5235 FU1 #53 Motor type 0 1 0

5236 FU1 #54 OL level 150 150 30 %

5237 FU1 #55 OL time 100 300 0 0.1sec

5238 FU1 #56 OLT select 1 1 0

5239 FU1 #57 OLT level 180 200 30 %

523A FU1 #58 OLT time 600 600 0 0.1sec

523B FU1 #59 Stall prev. 0 7 0

523C FU1 #60 Stall level 180 250 30 %

< FU2 group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5307 FU2 #07

Dwell freq 500 maxFreq StartFreq 0.01Hz

5308 FU1 #08 Dwell time 0 100 0 0.1sec

530A FU2 #10

Jump freq 0 1 0

530B FU2 #11

jump lo 1 1000 jump Hi [0] StartFreq 0.01Hz

530C FU2#12

jump Hi 1 1500 maxFreq jump Lo[0] 0.01Hz

530D FU2 #13

jump lo 2 2000 jump Hi [1] StartFreq 0.01Hz

530E FU2 #14

jump Hi 2 2500 maxFreq jump Lo[1] 0.01Hz

530F FU2 #15

jump lo 3 3000 jump Hi [2] StartFreq 0.01Hz

5310 FU2 #16

jump Hi 3 3500 maxFreq jump Lo[2] 0.01Hz

5311 FU2 #17 Start Curve 40 100 1 %

5312 FU2 #18 End Curve 40 100 1 %

5313 FU2 #19 Trip select 0 3 0 BIT

5314 FU2 #20

Power-on run 0 1 0

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 15

13

Addr

ess

NO. Description Default Maximum Minimum Unit

5315 FU2 #21

RST restart 0 1 0

5316 FU2 #22

Speed Search 0 15 0 BIT

5317 FU2 #23

SS Sup-Curr 100 200 80

5318 FU2 #24

SS P-gain 100 9999 0

5319 FU2 #25

SS I-gain 1000 9999 0

531A FU2 #26

Retry number 0 10 0

531B FU2 #27

Retry delay 10 600 0 0.1sec

531E FU2#30

Motor select 0 9 0

531F FU2#31

Pole number 4 12 2

5320 FU2 #32

Rated-Slip 200 1000 0 0.01Hz

5321 FU2 #33

Rated-Curr 36 2000 10 0.1A

5322 FU2 #34

Noload-Curr 7 2000 5 0.1A

5324 FU2 #36

Efficiency 72 100 70 %

5325 FU2 #37

Inertia rate 0 1 0

5327 FU2 #39

Carrier freq 50 150 10 0.1kHZ

5328 FU2 #40

Control mode 0 2 0

5329 FU2 #41

Auto tuning 0 1 0

532A FU2 #42

Rs (Note 4) (Note 3) 5000 0 0.001ohm

532B FU2 #43

Rr (Note 5) (Note 3) 5000 0 0.001ohm

532C FU2 #44

Lsigma (Note 6) (Note 3) MaxInduc 0 0.001mH

532D FU2 #45

SL P-gain 32767 32767 0

532E FU2 #46

SL I-gain 3276 32767 0

532F FU2 #47

proc PI mode 0 1 0

5330 FU2 #48

PID Ref 1 1 0

5331 FU2 #49

PID Ref Mode 0 5 0

5332 FU2 #50

PID Out Dir 1 1 0

5333 FU2 #51

PID F/B 0 2 0

5334 FU2 #52

PID P-gain 3000 9999 0 0.1%

5335 FU2 #53

PID I-time 300 320 0 0.1sec

5336 FU2 #54

PID D-time 0 9999 0 0.1msec

5337 FU2 #55

PID +limit 6000 maxFreq 0 0.01Hz

5338 FU2 #56

PID -limit 6000 maxFreq 0 0.01Hz

5339 FU2 #57

PID Out Inv 0 1 0

533A FU2 #58

PID OutScale 1000 9999 1 0.1%

533B FU2 #59

PID P2-gian 1000 9999 0 0.1%

533C FU2 #60

P-gain Scale 1000 1000 0 0.1%

5345 FU2 #69

Acc/Dec ch F 0 maxFreq 0 0.01Hz

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 16

14

Addr

ess

NO. Description Default Maximum Minimum Unit

5346 FU2 #70

Acc/Dec freq 0 1 0

5347 FU2 #71

Time scale 1 2 0

5348 FU2 #72

PowerOn disp 0 12 0

5349 FU2 #73

User disp 0 2 0

534A FU2 #74

RPM factor 100 1000 1 %

534B FU2 #75

DB mode 1 2 0

534C FU2 #76

DB %ED 10 30 0 %

534F FU2 #79

S/W Debug02 0 1 0

5351 FU2 #81

2nd Acc time 50 6000 0 0.1sec

5352 FU2 #82

2nd Dec time 100 6000 0 0.1sec

5353 FU2 #83

2nd BaseFreq 6000 maxFreq 3000 0.01Hz

5354 FU2 #84

2nd V/F 0 2 0

5355 FU2 #85

2nd F-boost 20 150 0 0.1%

5356 FU2 #86

2nd R-boost 20 150 0 0.1%

5357 FU2 #87

2nd Stall 150 150 30 %

5358 FU2 #88

2nd ETH 1min 150 200

2nd ETH

Cont

%

5359 FU2 #89

2nd ETH Cont. 100

2nd ETH

1min

50 %

535A FU2 #90

2nd R-Curr 36 2000 10 0.1A

538D FU2 #93

Para. Init 0 8 0

(Note 3,4,5,6) Value depends on motor capacity.

< I/O group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5401 I/O #01

V1 filter 10 9999 0 ms

5402 I/O #02

V1 volt x1 0 V1 vort x2 0 0.01V

5403 I/O #03

V1 freq y1 0 maxFreq 0 0.01Hz

5404 I/O #04

V1 volt x2 1000 1000 V1 volt x1 0.01V

5405 I/O #05

V1 freq y2 6000 maxFreq 0 0.01Hz

5406 I/O #06

I filter 10 9999 0 ms

5407 I/O #07

I curr x1 400 I curr x2 0 0.01mA

5408 I/O #08

I freq y1 0 maxFreq 0 0.01Hz

5409 I/O #09

I curr x2 2000 2000 I curr x1 0.01mA

540A I/O #10

I freq y2 6000 maxFreq 0 0.01Hz

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 17

15

Addr

ess

NO. Description Default Maximum Minimum Unit

540B I/O #11

Wire broken 0 2 0

540C I/O #12

P1 define 0 32 0

540D I/O #13

P2 define 1 32 0

540E I/O #14

P3 define 2 32 0

5411 I/O #17

Ti Filt Num 15 50 2

5414 I/O #20

Jog freq 1000 MaxFreq startFreq 0.01Hz

5415 I/O #21

Step freq - 4 4000 MaxFreq startFreq 0.01Hz

5416 I/O #22

Step freq - 5 5000 MaxFreq startFreq 0.01Hz

5417 I/O #23

Step freq - 6 4000 MaxFreq startFreq 0.01Hz

5418 I/O #24

Step freq - 7 3000 MaxFreq startFreq 0.01Hz

5419 I/O #25

Acc time– 1 200 6000 0 0.1sec

541A I/O #26

Dec time – 1 200 6000 0 0.1sec

541B I/O #27

Acc time – 2 300 6000 0 0.1sec

541C I/O #28

Dec time – 2 300 6000 0 0.1sec

541D I/O #29

Acc time – 3 400 6000 0 0.1sec

541E I/O #30

Dec time - 3 400 6000 0 0.1sec

541F I/O #31

Acc time – 4 500 6000 0 0.1sec

5420 I/O #32

Dec time – 4 500 6000 0 0.1sec

5421 I/O #33

Acc time – 5 400 6000 0 0.1sec

5422 I/O #34

Dec time – 5 400 6000 0 0.1sec

5423 I/O #35

Acc time – 6 300 6000 0 0.1sec

5424 I/O #36

Dec time – 6 300 6000 0 0.1sec

5425 I/O #37

Acc time – 7 200 6000 0 0.1sec

5426 I/O #38

Dec time – 7 200 6000 0 0.1sec

5428 I/O #40

FM mode 0 3 0

5429 I/O #41

FM adjust 100 200 10 %

542A I/O #42

FDT freq 3000 maxFreq 0 0.01Hz

542B I/O #43

FDT band 1000 maxFreq 0 0.01Hz

542C I/O #44

Aux mode 12 23 0

542D I/O #45

Relay mode 2 7 0 BIT3

542E I/O #46

Inv No. 1 31 1

542F I/O #47

Baud rate 3 4 0

5430 I/O #48

Lost command 0 2 0

5431 I/O #49

Time out 10 1200 1 0.1sec

* Contact LG representatives if address for Auto sequence operation parameters is needed.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 18

16

< EXT group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5501 EXT #01

Sub B/D

5502 EXT #02

P4 define 3 32 0

5503 EXT #03

P5 define 4 32 0

5504 EXT #04

P6 define 5 32 0

5505 EXT #05

V2 mode 0 2 0

5506 EXT #06

V2 filter 10 9999 0 msec

5507 EXT #07

V2 volt x1 0 V2 volt x2 0 0.01V

5508 EXT #08

V2 freq y1 0 maxFreq 0 0.01Hz

5509 EXT #09

V2 volt x2 1000 1000 V2 volt x1 0.01V

550A EXT #10

V2 freq y2 6000 maxFreq 0 0.01Hz

550E EXT #14

F mode 0 2 0

550F EXT #15

F pulse set 0 1 0

5510 EXT #16

F pulse num 1024 4096 360

5511 EXT #17

F filter 10 9999 0 msec

5512 EXT #18

F pulse x1 0 F pulse x2 0 0.1kHz

5512 EXT #18

F pulse x1 0 F pulse x2 0 0.1kHz

5513 EXT #19

F freq y1 0 maxFreq 0 0.01Hz

5514 EXT #20

F pulse x2 100 1000 F pulse x1 0.1kHz

5515 EXT #21

F freq y2 6000 maxFreq 0 0.01Hz

5516 EXT #22

PG P-gain 3000 9999 0

5517 EXT #23

PG I-gain 300 9999 0

5518 EXT #24

PG Slip Freq 100 200 0 %

551E EXT #30

Q1 define 0 23 0

551F EXT #31

Q2 define 1 23 0

5520 EXT #32

Q3 define 2 23 0

5522 EXT #34

LM mode 1 3 0

5523 EXT #35

LM adjust 100 200 10 %

5528 EXT #40

AM1 mode 0 3 0

5529 EXT #41

AM1 adjust 100 200 10 %

552A EXT #42

AM2 mode 3 3 0

552B EXT #43

AM2 adjust 100 200 10 %

553C EXT #60

SPD P-Gain 10 500 1

553D EXT #61

SPD I-Gain 10 500 1

553E EXT #62

POS P-gain 10 500 1

553F EXT #63

POS I-gain 10 500 1

5540 EXT #64

Slip limit 500 500 0 0.01Hz

5541 EXT #65

Oper mode 1 4 0

5542 EXT #66

Enc 0pulse 1000 2000 1000

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 19

17

Addr

ess

NO. Description Default Maximum Minimum Unit

5543 EXT #67

Enc 1pulse 1000 2000 1000

5544 EXT #67

ROT ratio 10 100 1

5545 EXT #68

STBY ROT 0 1000 0

5546 EXT #69

STBY SPD 0 4000 0

5547 EXT #70

POS Sync

10 100 1

5548 EXT #71

SPD sync 10 20 1

5549 EXT #72

POS offset 0 9999 0

554A EXT #73

User dir 0 1 0

554B EXT #74

Max speed 1800 9999 1000

554C EXT #75

Motor pulse 1000 2000 500

554D EXT #76

DAC0 set 12 99 10

554E EXT #77

DAC1 set 24 99 10

555A EXT #89

Station ID 1 63 0

< COM group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5601 COM #01

Opt B/D

5602 COM #02

Opt mode 0 3 0

5603 COM #03

Opt version 1.00

5604 COM #04

D-in mode 0 6 0

5605 COM #05

Digital Ftr 15 50 2

560A COM #10

MAC ID 63 63 0

560B COM #11

Baud rate 0 2 0

560C COM #12

Out instance 0 3 0

560D COM #13

In instance 0 3 0

5611 COM #17

Station ID 1 63 0

5614 COM #20

Profi MAC ID 1 127 1

561E COM #30

Output Num 3 8 0

561F COM #31

Output 1 10 22527 0

5620 COM #32

Output 2 14 22527 0

5621 COM #33

Output 3 15 22527 0

5622 COM #34

Output 4 0 22527 0

5623 COM #35

Output 5 0 22527 0

5624 COM #36

Output 6 0 22527 0

5625 COM #37

Output 7 0 22527 0

5626 COM #38

Output 8 0 22527 0

5628 COM #40

Input Num 2 8 0

5629 COM #41

Input 1 5 22527 0

562A COM #42

Input 2 6 22527 0

562B COM #43

Input 3 0 22527 0

562C COM #44

Input 4 0 22527 0

562D COM #45

Input 5 0 22527 0

562E COM #46

Input 6 0 22527 0

562F COM #47

Input 7 0 22527 0

5630 COM #48

Input 8 0 22527 0

5634 COM #52

Modbus Mode 0 0 0

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 20

18

* I/O-46, 47: station number and baud rate setting

COM-01 [Opt B/D]

Displays option board installed.

Automatically set when board is installed.

COM-02 [Opt Mode]

Run/Stop/Frequency Reference setting via Option Board

Value Display Description

0 None Disabled

1 Command Run/Stop command via Option

2 Freq Frequency command via Option

3 Cmd + Freq Run/Stop/Frequency command via Option

Use Common area #0x0005 for Frequency command via Option.

Use Common area #0x0006 for Run/Stop command via Option.

COM-03 [Opt Version]

Displays option card’s version.

< APP group >

Addr

ess

NO. Description Default Maximum Minimum Unit

5701 APP #01

APP mode 0 3 0

5702 APP #02

Trv. Amp[%] 0 200 0 0.1%

5703 APP #03

Trv. Scr 0 500 0 0.1%

5704 APP #04

Trv Acc Time 20 6000 1 0.1sec

5705 APP #05

Trv Dec Time 30 6000 1 0.1sec

5706 APP #06

Trv Off Hi 0 200 0 0.1%

5707 APP #07

Trv Off Lo 0 200 0 0.1%

5708 APP #08

Aux Mot Run 0 4 0

5709 APP #09

Starting Aux 1 4 1

570A APP #10

Auto Op Time 0 5940 0

570B APP #11

Start freq1 4999 maxFreq 0 0.01Hz

570C APP #12

Start freq2 4999 maxFreq 0 0.01Hz

570D APP #13

Start freq3 4999 maxFreq 0 0.01Hz

570E APP #14

Start freq4 4999 maxFreq 0 0.01Hz

570F APP #15

Stop freq1 1500 maxFreq 0 0.01Hz

5710 APP #16

Stop freq2 1500 maxFreq 0 0.01Hz

5711 APP #17

Stop freq3 1500 maxFreq 0 0.01Hz

5712 APP #18

Stop freq4 1500 maxFreq 0 0.01Hz

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 21

19

Addr

ess

NO. Description Default Maximum Minimum Unit

5713 APP #19

Aux start DT 600 9999 0 0.1sec

5714 APP #20

Aux stop DT 600 9999 0 0.1sec

5715 APP #21

Nbr Aux’ 4 4 0

5716 APP #22

Regul Bypass 0 1 0

5717 APP #23

Sleep Delay 600 9999 0 0.1sec

5718 APP #24

Sleep Freq 19 maxFr eq 0 0.01Hz

5719 APP #25

WakeUp level 35 100 0 1%

571A APP #26

AutoCh_Mode 1 2 0

571B APP #27

AutoEx intv 4320 5940 0 0.1sec

571C APP #28

AutoEx level 20 100 0 1%

571D APP #29

Inter-lock 0 1 0

571E APP #30

Actual Value 0 maxFreq 0 0.01Hz

571F APP #31

Actual Perc 0 100 0 1%

5720 APP #32

Draw mode 0 3 0

5721 APP #33

DrawPerc 100 150 0 1%

SV-iH

< DRV group >

Addr

ess

NO. Description Default Maximum Minimum Unit

4001 DRV#01 Acc. time 300 60000 0 0.1sec

4002 DRV#02 Dec. time 600 60000 0 0.1sec

4003 DRV#03 Current 0 1 0 0.1 A

4004 DRV#04 Speed 0 1 0 1 rpm

4005 DRV#05 Power 0 5000 0 0.1kW

< FUN group >

Addr

ess

NO. Description Default Maximum Minimum Unit

4101 FU1 #01 Freq. Set 0 2 0

4102 FU1 #02 Run/stop set 0 3 0

4103 FU1 #03 Run prohibit 0 2 0

4104 FU1 #04 Freq. Max 6000 40000 4000 0.01Hz

4105 FU1 #05 Freq. base 6000 Freq. max 4000 0.01Hz

4106 FU1 #06 Freq. start 50 500 50 0.01Hz

4107 FU1 #07 Hold time 0 100 0 0.1sec

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 22

20

Addr

ess

NO. Description Default Maximum Minimum Unit

4108 FU1 #08 V/F pattern 0 3 0

4109 FU1 #09 Fwd boost 2 20 0 1 %

410A FU1 #10 Rev boost 2 20 0 1 %

410B FU1 #11 Acc. pattern 0 2 0

410C FU1 #12 Dec. pattern 0 2 0

410D FU1 #13 Volt control 100 110 40 1 %

410E FU1 #14 Energy save 100 100 70 1 %

410F FU1 #15 Stop mode 0 2 0

4110 FU1 #16 User-1f 1000 User-2f 0 0.01Hz

4111 FU1 #17 User-1v 15 User-2v 0 1 %

4112 FU1 #18 User-2f 3000 Freq. max User-1f 0.01Hz

4113 FU1 #19 User-2v 50 100 User-1v 1 %

4114 FU1 #20 V-I mode 0 3 0

4115 FU1 #21 Filter gain 25 100 1 1 %

4116 FU1 #22 Analog gain 1000 2500 500 0.1 %

4117 FU1 #23 Analog bias 1000 2000 0 0.1 %

4118 FU1 #24 Analog dir 0 1 0

4119 FU1 #25 Freq. limit 0 1 0

411A FU1 #26 F-limit high 6000 Freq. max F_limit low 0.01Hz

411B FU1 #27 F-limit low 0 F-limit high 0 0.01Hz

411C FU1 #28 Freq. jump 0 1 0

411D FU1 #29 Freq-jump 1f 1000 Freq. max 0 0.01Hz

411E FU1 #30 Freq-jump 2f 2000 Freq. max 0 0.01Hz

411F FU1 #31 Freq-jump 3f 3000 Freq. max 0 0.01Hz

4120 FU1 #32 Freq. band 500 3000 0 0.01Hz

4121 FU1 #33 DC-br freq. 50 6000 0 0.01Hz

4122 FU1 #34 DC-br block 20 50 5 0.1sec

4123 FU1 #35 DC-br time 5 250 1 0.1sec

4124 FU1 #36 DC-br value 1 20 1 1 %

4125 FU1 #37 Slip compen. 0 1 0

4126 FU1 #38 Rated slip 0 500 0 0.01Hz

4127 FU1 #39 M-rated cur. 1 9990 1 0.1 A

4128 FU1 #40 No-load cur. 1 3000 1 0.1 A

4129 FU1 #41 Inv capacity 0 15 0

412A FU1 #42 Retry number 0 10 0

412B FU1 #43 Retry time 10 100 0 0.1sec

412C FU1 #44 Relay mode 0 3 0

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 23

21

Addr

ess

NO. Description Default Maximum Minimum Unit

412D FU1 #45 Stall mode 0 7 0

412E FU1 #46 Stall level 150 150 30 1 %

412F FU1 #47 OL level 150 150 30 1 %

4130 FU1 #48 OL time 100 300 10 0.1sec

4131 FU1 #49 OC lim. level 160 200 30 1 %

4132 FU1 #50 OC lim. time 600 600 0 0.1sec

4133 FU1 #51 ETH select 0 1 0

4134 FU1 #52 ETH level 150 150 110 1 %

4135 FU1 #53 Motor type 0 1 0

4136 FU1 #54 Pole number 4 12 2

4137 FU1 #55 IPF select 0 1 0

4138 FU1 #56 SS acc. time 50 6000 1 0.1sec

4139 FU1 #57 SS dec. time 100 6000 1 0.1sec

413A FU1 #58 SS gain 100 200 0 1 %

413B FU1 #59 RST-restart 0 1 0

413C FU1 #60 Power on st 0 1 0

413D FU1 #61 Carrier freq 6

Carrier_ma

x

2 1 kHz

413E FU1 #62 PI-control 0 1 0

413F FU1 #63 P-gain 10 30000 1

4140 FU1 #64 I-gain 50 30000 1

4141 FU1 #65 PI-fb select 0 2 0

4142 FU1 #66 PI-fb flt G. 25 100 1 1 %

4143 FU1 #67 PI-fb gain 1000 2500 500 0.1 %

4144 FU1 #68 PI-fb bias 1000 2000 0 0.1 %

4145 FU1 #69 PI-fb dir 0 1 0

4146 FU1 #70 I_term scale 100 100 1 1 %

4147 FU1 #71 PI error invert 0 1 0

4148 FU1 #72 Regul bypass 0 1 0

415E FU1 #94 CT/VT 0 1 0

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 24

22

< I/O group >

Addr

ess

NO. Description Default Maximum Minimum Unit

4201 I/O #01 P1 input 0 14 0

4202 I/O #02 P2 input 1 14 0

4203 I/O #03 P3 input 2 14 0

4204 I/O #04 P4 input 3 14 0

4205 I/O #05 P5 input 4 14 0

4206 I/O #06 P6 input 5 14 0

4207 I/O #07 OC1 output 11 12 0

4208 I/O #08 OC2 output 12 12 0

4209 I/O #09 OC3 output 13 12 0

420A I/O #10 AUX1 output 10 12 0

420B I/O #11 AUX2 output 10 12 0

420C I/O #12 Jog freq. 3000 Freq. max 0 0.01 Hz

420D I/O #13 Step freq-1 1000 Freq. max 0 0.01 Hz

420E I/O #14 Step freq-2 2000 Freq. max 0 0.01 Hz

420F I/O #15 Step freq-3 3000 Freq. max 0 0.01 Hz

4210 I/O #16 Step freq-4 4000 Freq. max 0 0.01 Hz

4211 I/O #17 Step freq-5 5000 Freq. max 0 0.01 Hz

4212 I/O #18 Step freq-6 4600 Freq. max 0 0.01 Hz

4213 I/O #19 Step freq-7 3700 Freq. max 0 0.01 Hz

4214 I/O #20 Acc time-1 10 60000 0 0.01 Hz

4215 I/O #21 Dec time- 1 10 60000 0 0.01 Hz

4216 I/O #22 Acc time-2 20 60000 0 0.01 Hz

4217 I/O #23 Dec time- 2 20 60000 0 0.01 Hz

4218 I/O #24 Acc time-3 30 60000 0 0.01 Hz

4219 I/O #25 Dec time- 3 30 60000 0 0.01 Hz

421A I/O #26 Acc time-4 40 60000 0 0.01 Hz

421B I/O #27 Dec time-4 40 60000 0 0.01 Hz

421C I/O #28 Acc time-5 50 60000 0 0.01 Hz

421D I/O #29 Dec time-5 50 60000 0 0.01 Hz

421E I/O #30 Acc time- 6 60 60000 0 0.01 Hz

421F I/O #31 Dec time-6 60 60000 0 0.01 Hz

4220 I/O #32 Acc time-7 70 60000 0 0.01 Hz

4221 I/O #33 Dec time- 7 70 60000 0 0.01 Hz

4222 I/O #34 LM meter 0 1 0

4223 I/O #35 LM adj. 100 120 0 1 %

4224 I/O #36 FM adj. 100 120 0 1 %

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 25

23

Addr

ess

NO. Description Default Maximum Minimum Unit

4225 I/O #37 Io adj 100 120 0 1 %

4226 I/O #38 FST-freq. 50 Freq. max 50 0.01 Hz

4227 I/O #39 FDT-freq. 6000 Freq. max 50 0.01 Hz

4228 I/O #40 FDT-band 100 3000 0 0.01 Hz

4229 I/O #41 Mul. factor 100 999 0

422A I/O #42 Div. factor 100 999 1

4232 I/O #50 Inv. Number 1 31 1

4233 I/O #51 Baud-rate 3 4 0

4234 I/O #52 Comm. timeout 10 600 0 0.1 sec

423A I/O #58 DI mode 1 2 0

423B I/O #59 DA mode 0 2 0

423C I/O #60 DA adj. 100 120 80 1 %

423D I/O #61 FN : St. ID 1 63 1

423E I/O #62 DN : MAC ID 1 63 0

423F I/O #63 DN : BaudRate 0 2 0

4240 I/O #64 DN : Out Inst 0 3 0

4241 I/O #65 DN : In Inst 0 3 0

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Page 26

1

LG

LG Industrial Systems Co., Ltd.

LGIS constantly endeavors to improve its product so that

information in this manual is subject to change without notice.

Visit Our Website: http://www.lgis.com/

December 23, 2002

Publication #: 10310000414

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu

Loading...

Loading...