Page 1

DREAM RF RTU SYSTEM

GUIDE

Generations III, IV, IV.V

TALGIL COMPUTING & CONTROL LTD.

NAAMAN CENTER, HAIFA - ACCO ROAD

ISRAEL

P.O. BOX 775 KIRYAT MOTZKIN 26119

TEL: 972-4-9506051 , 9506052

FAX: 972-4-8775949

2014

Page 2

contents

1. SYSTEM OVERVIEW............................................................................................................ - 4 -

2. SETTING UP AN RF RTU SYSTEM .................................................................................... - 7 -

2.1 SETTINGS TO BE DONE AT THE HOST CONTROLLER .................................................. - 8 -

2.2 SETTING UP THE INTERFACE AND THE RF MASTER ................................................... - 9 -

2.3 SETTING UP THE RF SLAVE ............................................................................................ - 11 -

2.4 SETTING UP THE RF RTU BASE ...................................................................................... - 12 -

2.4.1 Setting the RTU address ............................................................................................ - 13 -

2.4.2 Defining the polling rate ............................................................................................ - 13 -

2.4.3 Setting the layer ......................................................................................................... - 13 -

2.4.4 Setting up a repeater .................................................................................................. - 14 -

2.4.5 Functions of the jumpers ........................................................................................... - 15 -

3. THE VARIOUS MODES OF OPERATION ...................................................................... - 15 -

3.1 START-UP MODE ......................................................................................................... - 15 -

3.2 NORMAL MODE ........................................................................................................... - 15 -

3.3 RF TEST MODE ............................................................................................................. - 15 -

3.4 WHEN LOOSING COMMUNICATION ......................................................................... - 16 -

3.5 TESTING INPUTS AND OUTPUTS ............................................................................. - 16 -

3.6 LOW BATTERY INDICATION ....................................................................................... - 17 -

4. READING ANALOG INPUTS BY RF RTUS .................................................................... - 18 -

4.1 SETTING THE INTERFACE FOR ANALOG INPUTS .................................................. - 18 -

4.2 SETTING THE RTU FOR ANALOG INPUTS ................................................................ - 18 -

4.3 SETTING THE DREAM FOR READING RF ANALOG INPUTS .................................. - 19 -

5. USING RFPROG FOR PROGRAMMING THE RTU ...................................................... - 20 -

5.1 ANALOG INPUTS PARAMETERS ............................................................................... - 21 -

5.2 THE SOLENOIDS ACTIVATION PULSE PARAMETERS ........................................... - 22 -

5.3 INPUTS PULSE DIVISION ........................................................................................... - 22 -

5.4 THE AUTO CLOSE PARAMETERS ............................................................................. - 22 -

6. SOUNDS and LED LIGHTS ................................................................................................ - 23 -

6.1 RTU+SLAVE during START UP .................................................................................... - 23 -

6.2 RTU BASE+SLAVE during normal communication ...................................................... - 23 -

6.3 BASE+SLAVE while losing communication ................................................................... - 23 -

6.4 BASE+SLAVE during RF test - COMMUNICATION OK .............................................. - 23 -

6.5 BASE+SLAVE during RF test – NOT RECEIVING ....................................................... - 24 -

6.6 No communication between BASE and SLAVE .............................................................. - 24 -

6.7 BASE during inputs test .................................................................................................. - 24 -

6.8 BASE during outputs test ................................................................................................ - 24 -

6.9 BASE when battery becomes low .................................................................................... - 25 -

- 2 -

Page 3

6.10 INTERFACE+MASTER during normal operation - RF OK .......................................... - 25 -

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his

own expense.

Changes or modifications not expressly approved by the

manufacturer could void the user’s authority to operate the

equipment

6.11 INTERFACE not communicating with the MASTER ...................................................... - 25 -

6.12 INTERFACE not communicating with the DREAM ....................................................... - 25 -

6.13 BASE ENTERING PROGRAMMING MODE ................................................................ - 25 -

6.14 SLAVE ADDRESS ZERO ............................................................................................... - 25 -

APPENDIX A - Decimal to binary conversion table .................................................................... - 26 -

APPENDIX B - WIRING..................................................................................................................... 27

Wiring between DREAM – RF INTERFACE (internal) and RF MASTER ....................................... 27

Wiring between DREAM – RF INTERFACE (internal) and RF MASTER ....................................... 27

Wiring between RTU BASE and RF SLAVE .................................................................................... 28

Wiring of Outputs and Inputs into the RTU BASE:............................................................................ 29

APPENDIX C – THE RF EAR............................................................................................................ 30

HOW TO USE THE RF EAR ? ......................................................................................................... 30

The system contains the transmitter module FCC ID: 2AC2T-RF-MODULE-45

- 3 -

Page 4

The RF module 4.5

complies with part 15 of the

FCC rules. Operation is

suitable to the following

conditions:

(1) this device may not

cause harmful interference .

(2) this device must accept

any interference received ,

including interference that

may cause undesired

operation.

1. SYSTEM OVERVIEW

The RF RTU system is designed to work in conjunction with the DREAM irrigation

control system, with the UNILINER, MINILINER and OASIS systems, enabling them

to reach remote Input and Output (I/O) devices by wireless means.

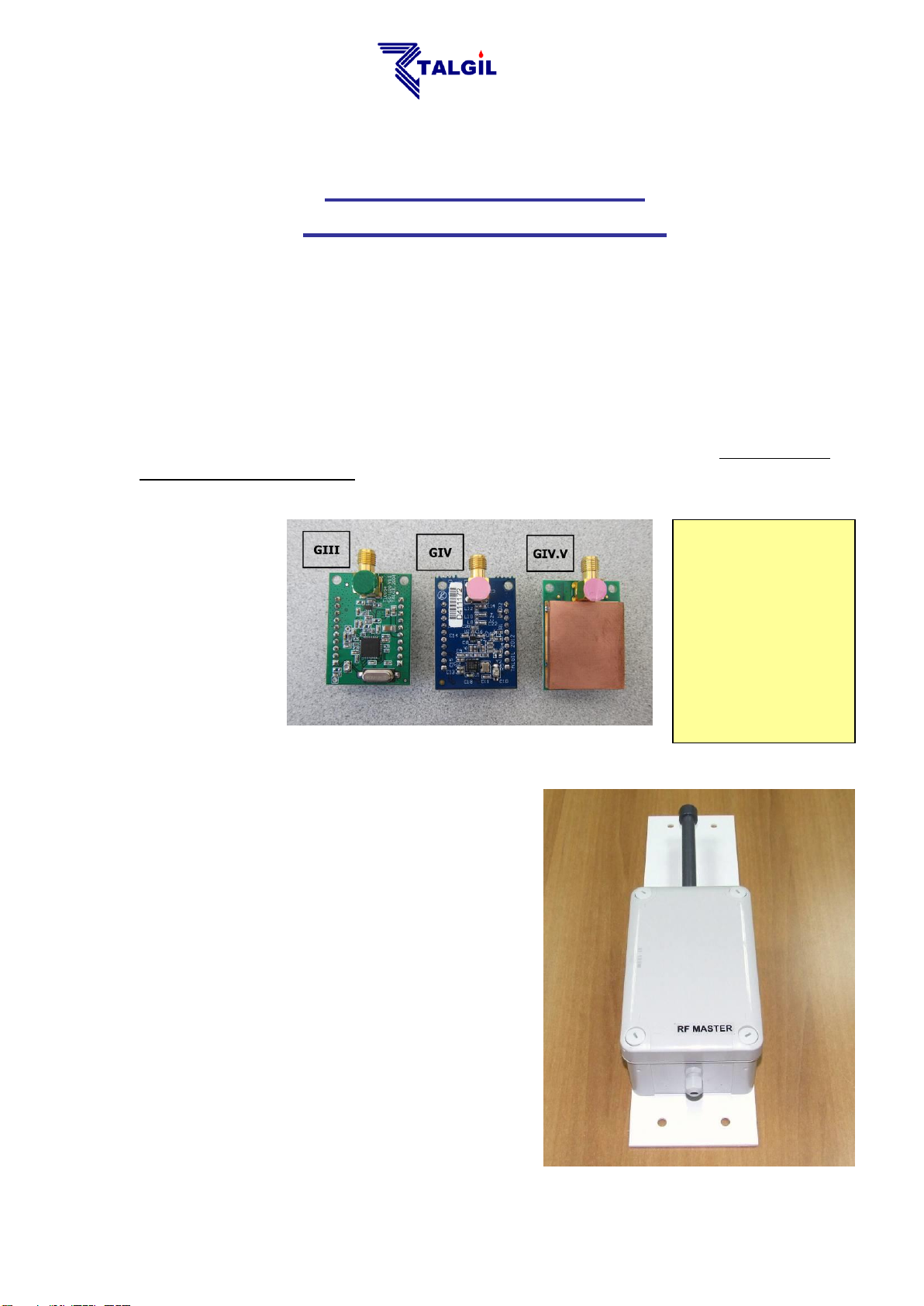

Generations GIV and GIV.V were developed after GIII in order to improve the

frequency separation ability and to cover different frequency ranges. GIII, GIV and

GIV.V are not compatible. The picture below shows the RF units of the three kinds.

Remember - in the same system all RF units must be of the same type:

The RF system consists of the following parts:

1. The RF MASTER – The central

THE RF RTU SYSTEM

GENERATION III, IV, IV.V

receiver/transmitter unit. Includes an RF

unit with antenna, should be installed on top

of a high pole located next to the host

controller.

All the communication with all the RTU

units on site, goes through the RF

MASTER, therefore it should be carefully

positioned at a place from where it may

have a clear line of sight to most of the RTU

units.

- 4 -

Page 5

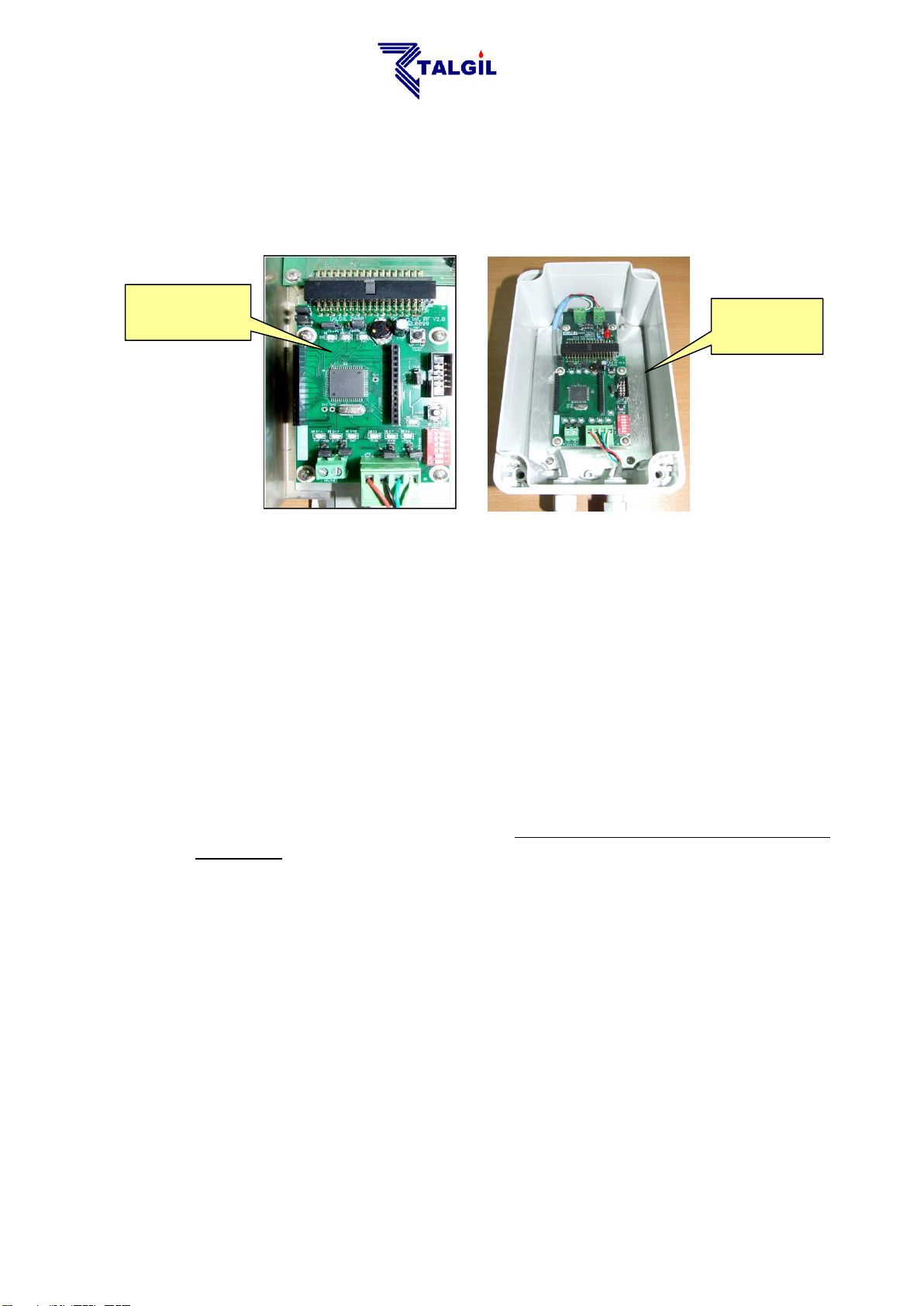

The RF interface

in a separate

enclosure

The RF interface

when located inside

the host enclosure

2. The RF INTERFACE – serves as a link between the RF MASTER and the host

controller. When possible, the RF INTEFACE will be placed inside the enclosure

of the host, otherwise it will have its own enclosure and then the interface will be

connected to the host by a shielded 4 wired cable that can be a few hundred

meters long. Similarly the communication to the RF MASTER uses also a

shielded 4 wired cable.

REMARK: The Oasis RF system does not use an interface.

3. The RF RTU – The RF RTU is the edge unit in the field, that communicates by

radio with the Master, receiving and carrying out commands to open/close

outputs, and reports back the status of inputs.

A single RF channel can handle as many as 60 RTUs.

There are 2 types of RTUs :

a) Modular – the modular RTU may have up to 8 outputs (in steps of 2,4,6,8),

4 digital inputs and up to 4 analog inputs. The outputs activate 2 wired DC

pulse latching solenoids. The ability of reading digital inputs can be added to

any of the 60 RF RTU units however analog inputs are limited to the first 8

RTUs only.

b) Economical– they come in two sizes – with 2 outputs and 2 digital inputs

(2/2), or with 1 output and 1 input (1/1).

The modular RTU consists of 2 parts: one is called the RF SLAVE and the other

is called the RF BASE. The 2 parts are connected by a shielded 4 wired cable

the length of which should not exceed 10 meters.

- 5 -

Page 6

3.1 The RF SLAVE is a

receiver/transmitter unit

including an antenna,

installed on top of a high

pole. The RF SLAVE is

the part of the RTU that

is in charge of the radio

communication between

the RF RTU and the

controller.

3.2 The RF RTU BASE

(EXECUTER) is in

charge of the output and

input activity of the RTU

executing output

commands and reading

the inputs. It is located at the lower part of the pole at a convenient height

for connecting the I/O devices to the unit.

In the Economical RF RTU the SLAVE and the BASE are combined into the same

board:

For practical reasons the Economical RF RTU cannot

be installed in a too high position, because then the

wiring of the outputs and inputs will be too difficult. On

the other hand if we install it in a low position we shall

sacrifice the height of the antenna. In order to solve

this problem we use an antenna extension kit:

- 6 -

Page 7

Connection to

the RF Master

Connection to

the host

Each RF RTU can act also as a REPEATER that can help reaching far RTUs or

help reaching those that are hidden by obstacles. Such a unit can function both as

an RTU and as a REPEATER at the same time.

NOTE : The upper part of the pole holding the RF MASTER and RF

SLAVE units must be made of nonmetallic material, otherwise the radio

signal may suffer some power attenuation. The construction of the

poles must include facilities that will enable easy lowering.

NOTE: Despite the resemblance between the MASTER and SLAVE

units, they are not interchangeable.

The RF RTU can be powered either by dry batteries or by rechargeable battery

charged by solar energy. When powered by dry batteries it will use 6v DC, supplied

by 4 x 1.5v “D” type standard alkaline batteries. When powered by solar energy, the

RF RTU will contain a 12v 1.0Ah rechargeable battery. Regular RTU will use a 2

Watt solar panel, and those who serve as repeaters will use a 5 Watt solar panel.

Assuming ideal conditions, in an area with no obstacles and no interferences, the

distance between the MASTER and a directly communicated RTU can reach about

2.5 -3km. By utilizing a REPEATER, the distance can be doubled.

2. SETTING UP AN RF RTU SYSTEM

The process of setting up an RF RTU system starts at the host controller (DREAM,

UNILINER, MINILINER, OASIS) where some necessary definitions have to be

made through which the controller is informed about the details of the RF system to

be controlled (see below).

An appropriate location should be found for locating the pole of the RF MASTER. It

should be not too far from the host controller and it should be as high as possible in

order to assure a clear line of sight to most of the RTUs in the field. Remember that

the upper part of the pole should be nonmetallic.

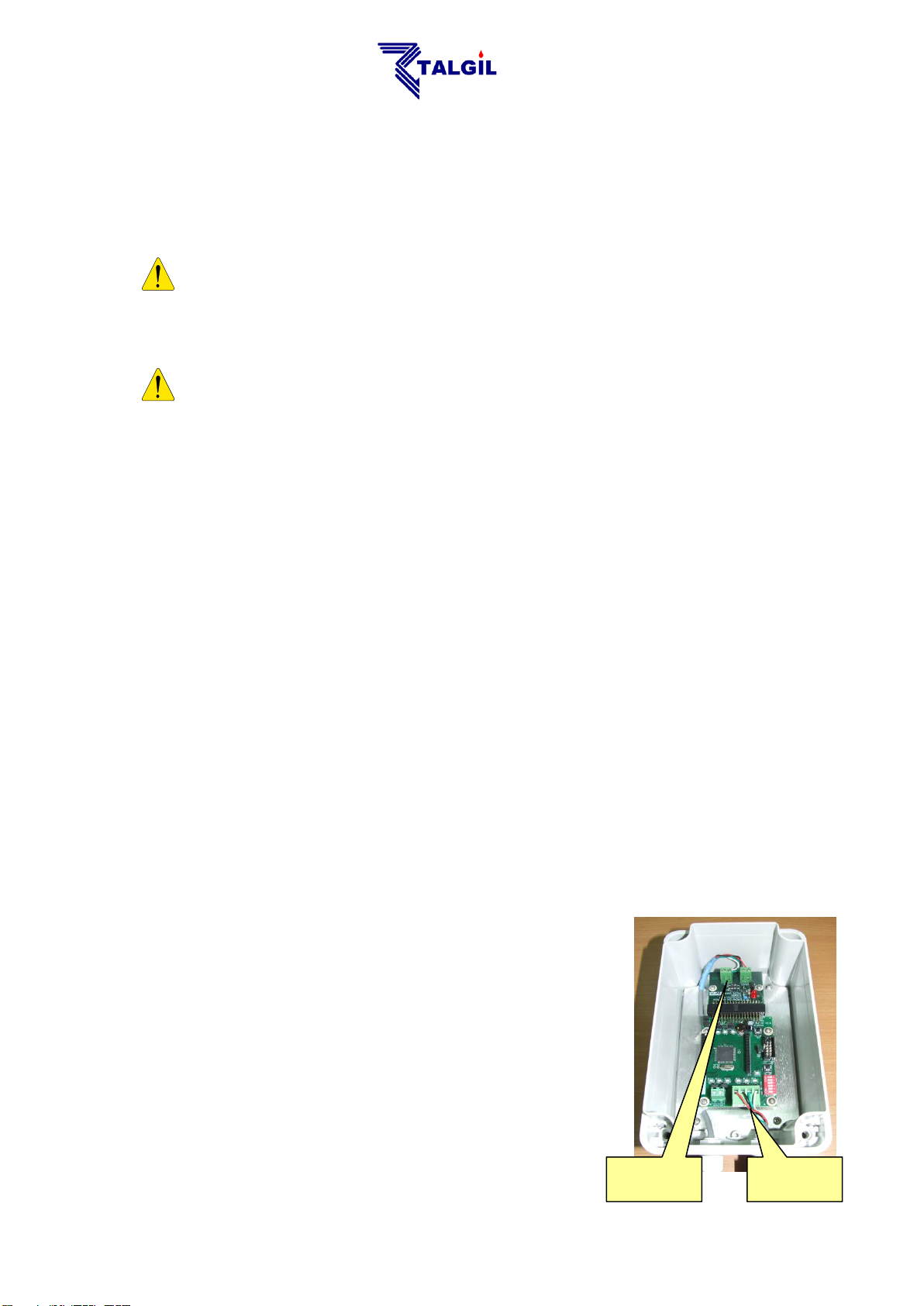

The RF INTERFACE that coordinates between the

MASTER and the host controller can be located inside the

host’s enclosure or externally. When external it will come

in a separate box and both sides of the interface the one

that is connected to the host and the one that is

connected to the Master will use a shielded 4 wired cable

for connection. The red and the black wires supply the

power (12v DC) and the green and white wires support

the communication; in both cases the polarity is important,

follow the directions below. The shield will be connected

together with the black wire.

- 7 -

Page 8

Declaring the

number of RF

interfaces

The address

of the RF

interface

The

scanning

rate 10 sec

Out in the field, each RTU BASE (EXECUTER)

and its RF SLAVE counterpart will also be installed

on a pole with the SLAVE unit on top of the pole

and the RTU BASE about 1 meter above ground.

Here again the upper part of the pole, where the

RF slave is located, should be of nonmetallic

material and here too the connection between the

SLAVE and the RTU BASE uses a shielded 4

wired cable.

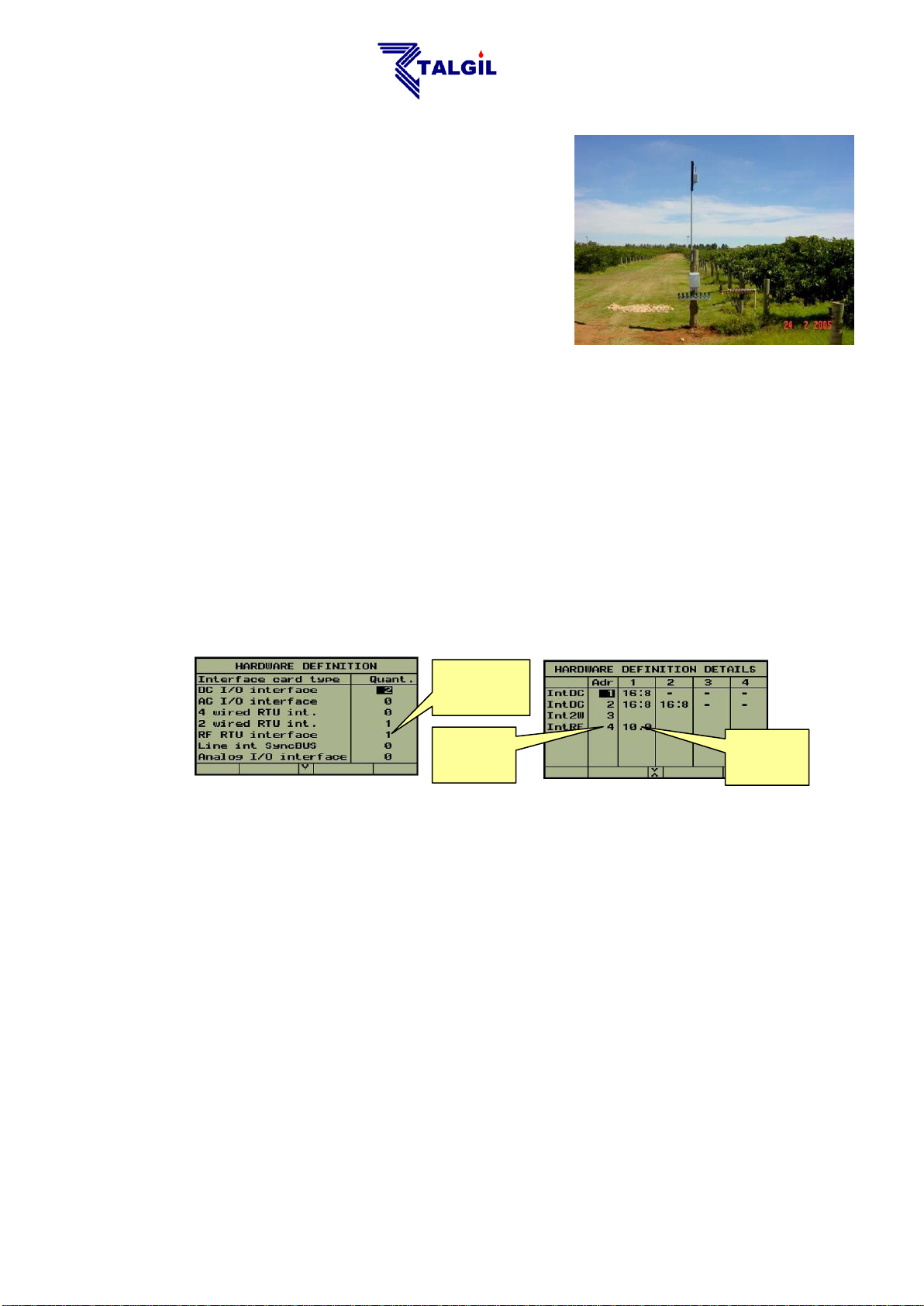

2.1 SETTINGS TO BE DONE AT THE HOST CONTROLLER

We shall use the DREAM controller for demonstration; however the same kind of

definitions should be done when the host is a UNILINER, MINILINER or OASIS.

The DREAM can handle several RF channels. Each channel will have its own

interface, its own RF MASTER and its own RTUs. The channels must use different

frequencies and they will be recognized by the address given to the RF

INTERFACE of the particular channel.

The screens below show the hardware definition to be made at the DREAM in order

to make the DREAM recognize the various interfaces included in the system.

Next to the address of the RF INTERFACE there is a definition of the scanning rate

by which the DREAM is exchanging information with the RTUs.

The following options exist: scanning every 10sec; 5sec; 2.5sec or 1.25 sec. For

energy saving purposes low scanning rate should be preferred, though too low

scanning rate may cause losing pulses of water meters and fertilizer meters having

high flow rates. Therefore the scanning interval should not be longer than the

shortest expected OPEN or CLOSED contact condition. When this condition cannot

be met, pulse dividers should be used (see explanation below). On the other hand,

the scanning rate cannot be decided without taking into consideration the

number of RTUs to be scanned. A scanning rate of 1.25 seconds will limit the

number of RTUs to 7, (the system will recognize RTUs with addresses from 1

to 7). With scanning rate of 2.5 sec, it will recognize RTUs 1 to 15, with

scanning rate of 5 sec, it will recognize RTUs 1 to 31 and with scanning rate

of 10 sec, it will recognize all the range of 60 RTUs.

- 8 -

Page 9

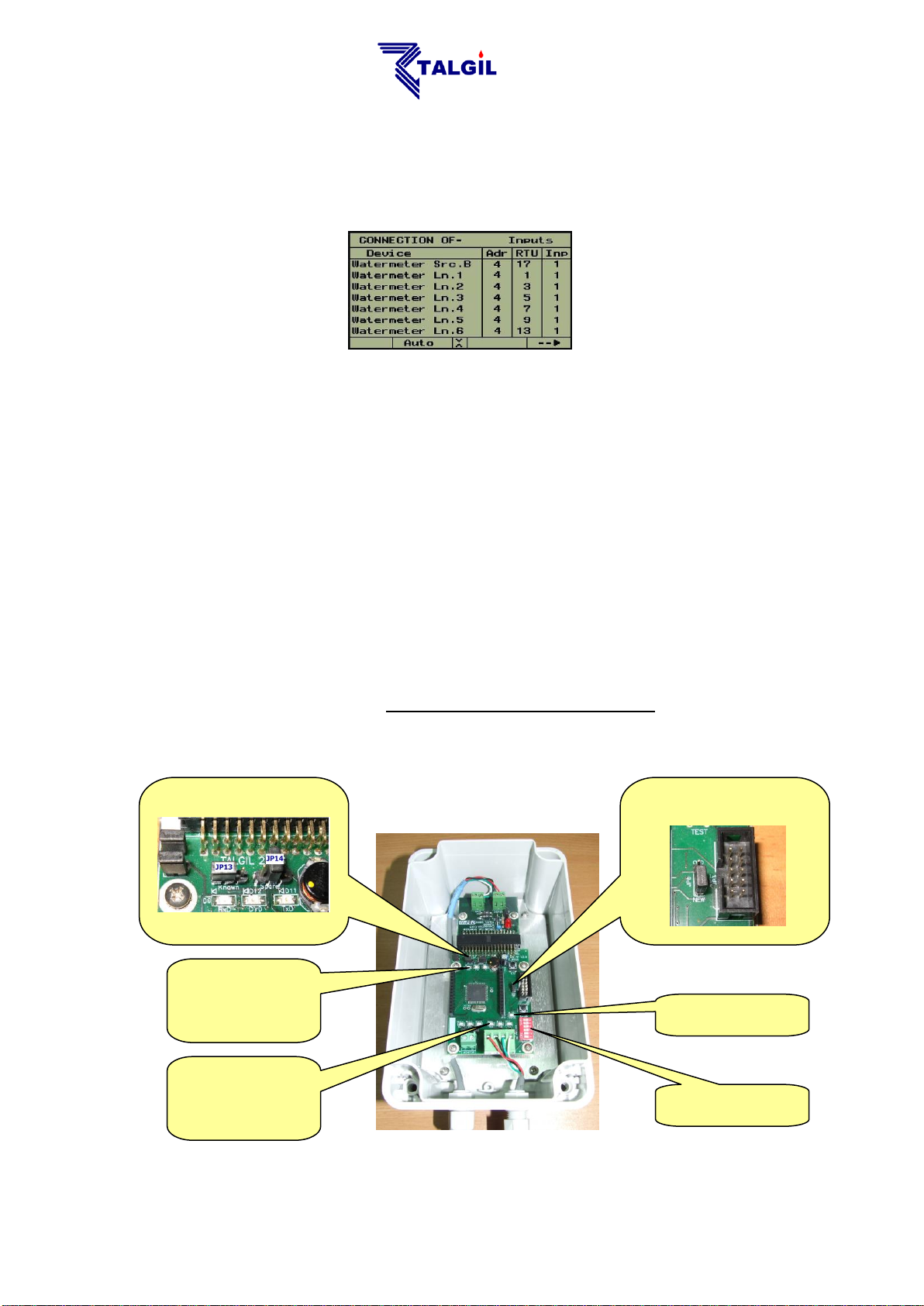

The next step is the definition of the connections table in which the physical

The address switch of

the RF INTERFACE

D5 the status indication

LED.

D3,D4,D7 the LEDs

indicating the

communication with

the MASTER

D9,D11,D12 the LEDs

indicating the

communication with

the DREAM

JP13 indicating analog inputs in

use . JP14 not in use.

JP6 the OLD-NEW selection

jumper

connection point of each I/O device is defined. During this procedure the host is

informed about the addresses of the RTUs existing on the particular channel, and

which I/O devices are connected to each.

2.2 SETTING UP THE INTERFACE AND THE RF MASTER

The RF INTERFACE has been designed to support the GIII and GIV versions, but it

can be compatible with older versions as well. When used with the previous

generation MASTER (up to version 7.8) jumper JP6 should be set to “OLD” position

and when used with a MASTER of version 7.9 or higher, JP6 should be in “NEW”

position (see picture below). Talking about compatibility it must be pointed out that

Master of version 7.9 or higher cannot work properly with interface of the old

generation, therefore if there is a need to replace a Master of version 7.8 or lower

with a Master of version 7.9 or higher it forces the replacement of the old RF

interface to the new one as well.

To indicate that the system contains analog inputs that are supposed to be read

through the RF RTU system, JP13 must be set in left position, leaving the right pin

free as in the picture below.

- 9 -

Page 10

Channel

number

DIP SWITCH S1

pos1

pos2

pos3

pos4

1

OFF

OFF

OFF

OFF 2 ON

OFF

OFF

OFF

3

OFF

ON

OFF

OFF 4 ON

ON

OFF

OFF

5

OFF

OFF

ON

OFF

6

ON

OFF

ON

OFF

7

OFF

ON

ON

OFF 8 ON

ON

ON

OFF

9

OFF

OFF

OFF

ON

10

ON

OFF

OFF

ON

11

OFF

ON

OFF

ON

12

ON

ON

OFF

ON

13

OFF

OFF

ON

ON

14

ON

OFF

ON

ON

15

OFF

ON

ON

ON

16

ON

ON

ON

ON

S1

Setting the channel address is done by use of the Address Dip Switches. The

address must be set according to the address defined at the DREAM (or other host)

controller. Make sure that there is no other interface with the same address. Notice

that the addressing uses binary coding. See “Appendix A” about the binary to

decimal conversion.

The interface board contains a status indication led D5 that supplies the following

information:

Lighting constantly – indicates having no configuration loaded from the

host which is a fault of course.

Blinking fast – indicates having no communication with the MASTER.

Blinking slowly – indicates a mistake in the definition of the analog inputs,

they are supposed to be allocated to a dummy analog interface whose

address must be one above the address of the RF INTERFACE itself.

Light off – indicates normal operation.

The LEDs D9,D11,D12 show the communication with the DREAM. They are

supposed to blink each second. The LEDs D3,D4,D7 show the communication with

the MASTER, when working with an old generation MASTER they will blink fast,

and when working with a new generation MASTER they will blink according to the

selected scanning rate.

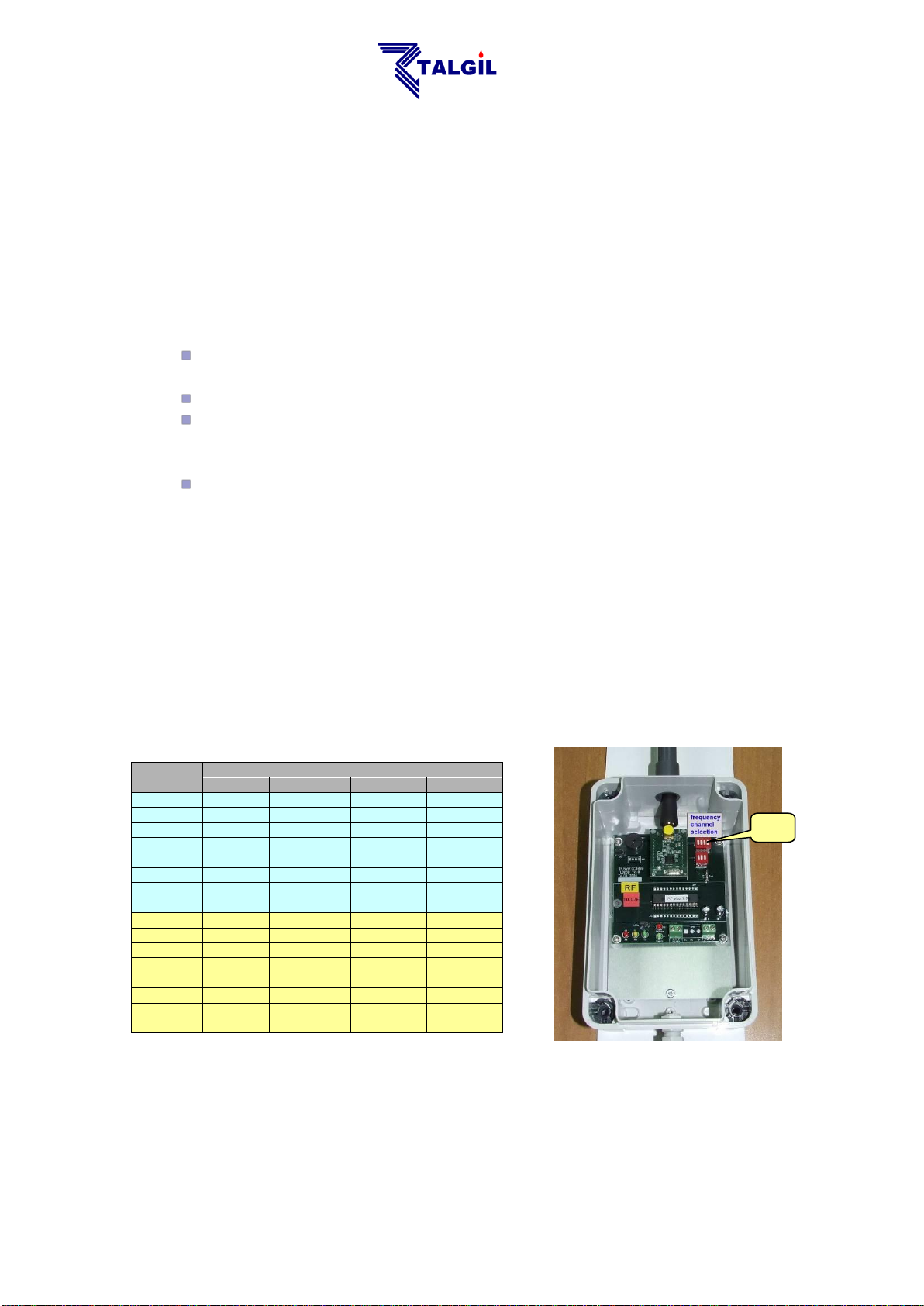

At the RF MASTER the only setting required is for selecting the RF FREQUENCY

to be used. There are 16 frequencies to choose from. The frequency selection must

take into consideration frequencies already being used by neighboring systems.

The selection of the RF frequency is done by the Dipswitch S1 (frequency).

When there are DREAM RF systems in close vicinity, or when a DREAM system

utilizes several channels, one channel may disturb the operation of the others. To

- 01 -

Page 11

Two channels system Three channels system

First

channel

Options for the second channel

First channel

Second

channel

Options for the third

channel

1

07, 08, 09, 10, 12, 13, 14, 15, 16 1 7

13, 14, 15, 16 2 08, 09, 10, 11, 12, 13, 14, 15, 16 1 8

14, 15, 16

3

09, 10, 11, 12, 14, 15, 16 1 9

15, 16 4 10, 11, 12, 13, 14, 15, 16

1

10

16 5 11, 12, 13, 14, 15, 16

2 8 14, 15, 16

6

12, 13, 15, 16

2 9 15, 16

7

01, 13, 14, 15, 16

2

10

16 8 01, 02, 14, 15, 16

3 9 15, 16 9 01, 02, 03, 15, 16

3

10

16

10

01, 02, 03, 04, 16

4

10

16

11

02, 03, 04, 05

12

01, 02, 03, 04, 05, 06

13

01, 02, 04, 05, 06, 07

14

01, 02, 03, 04, 05, 07, 08

15

01, 02, 03, 04, 05, 06, 07, 08, 09 16

01, 02, 03, 04, 05, 06, 07, 08, 09, 10

S1Frequency

setting

eliminate disturbance between the systems the frequency selection should be

according to the following tables:

On the RF MASTER board, there are 5 LEDS. The three LEDS - D3; D4 and D5

indicate the communication with the RF INTERFACE and when the communication

functions properly, they blink fast. The red LED D2 blinks each time the RF

MASTER is calling any of the RTUs, so during each scanning cycle it will blink

several times according to the number of RTUs defined. Each time the RF

MASTER picks up a proper response of an RTU, it makes a short beep sound by its

buzzer , so during each scanning cycle when there are several RTUs responding

to the MASTER each in its turn, there will be a series of beep sounds

…..

2.3 SETTING UP THE RF SLAVE

The only setting required at the RF SLAVE is the

setting of Dipswitch S1 (frequency). The selected

frequency should be identical to the selected

frequency at the RF MASTER board (see

paragraph above).

REMARK: Starting from GIII the frequency

setting can be done at the RF Base instead of at

the RF SLAVE (see below), this feature enables

changing the frequency without lowering the pole

on which the slave is installed.

- 00 -

Page 12

Layer

RTU

Addres

Polling

rate

Number of RTUs

served by the repeater

Selecting I/O

for test

Buzzer

ON/OF

LED

On/Off

Test I/O

Reset

button

4 digital

inputs

plug-in

board

2 DC latch

outputs

plug-in

board

RF test

jumper

Frequency

selection

Frequency

source

Analog

input type

selection

TH/ other

RTU

Addres

Polling

rate

Frequency

selection

Layer

Number of RTUs

served by the repeater

Test I/O

Selecting I/O

for test

RF test

jumper

Reset

button

2 DC latch

outputs

2 digital

inputs

Buzzer

ON/OF

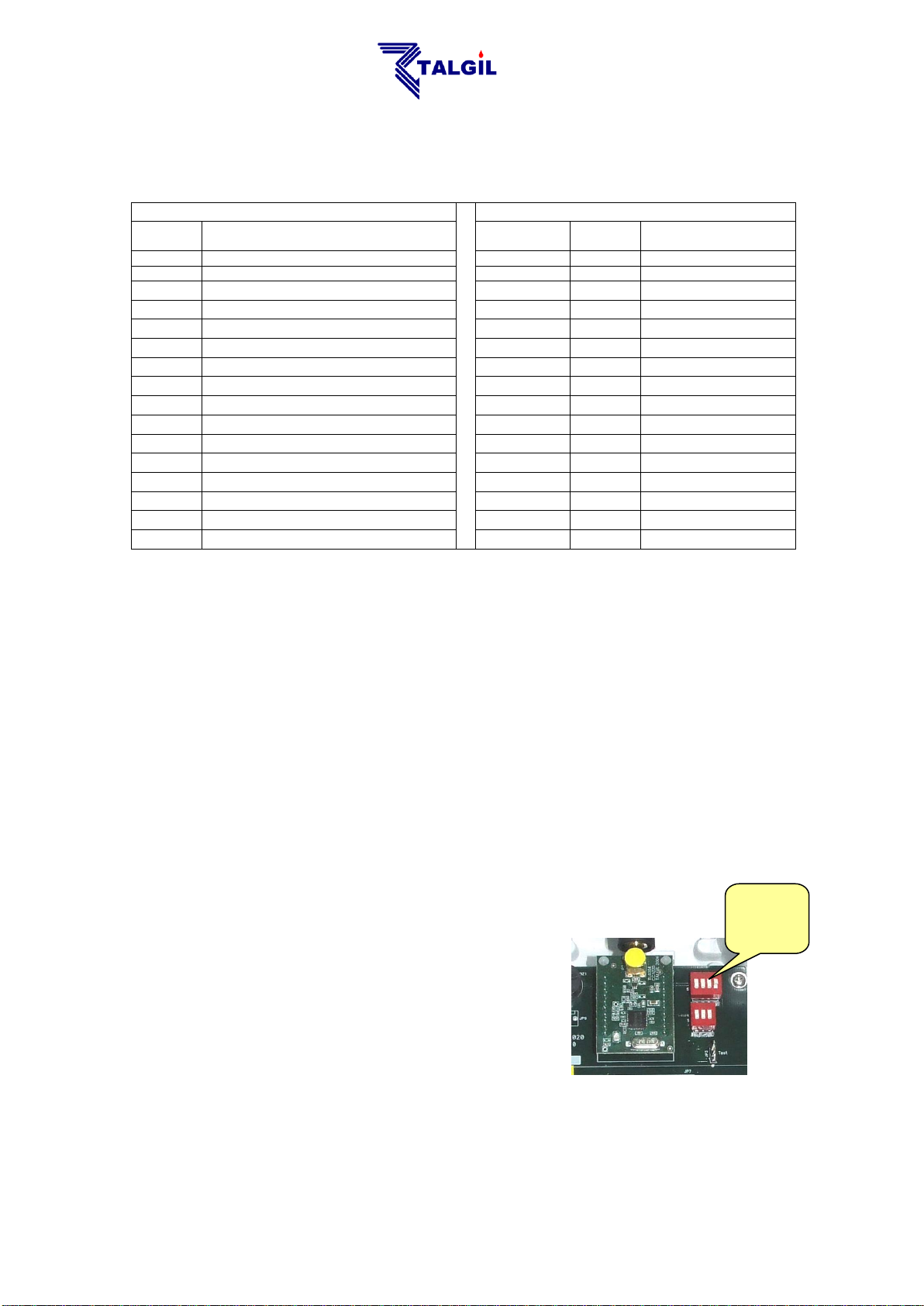

2.4 SETTING UP THE RF RTU BASE OR THE ECONOMICAL RTU

The following pictures describe the RF RTU base (executer) board, and the

ECONOMICAL RTU board.

The ECONOMICAL RF RTU includes all the functions of the MODULAR RF RTU

except for analog inputs and the ability of expanding the outputs.

- 02 -

Page 13

SW4 – pos 1 pos 2

The polling rate (sec)

Highest RTU address

0 0

10

60

1 0

5

31

0 1

2.5

15

1 1

1.25

7

Before being able to use the RTU there are some necessary settings to be done:

Setting the address of the RTU

Setting the polling rate by which the MASTER is communicating with

the RTUs

Setting the layer of the RTU. The layer defines whether the RTU

communicates directly with the MASTER or through a REPEATER.

(See below the explanation about repeaters).

For RTUs serving as repeaters, it is necessary to define the number of

RTUs that are serviced by the repeater.

Setting the communication frequency. In the old generation the

frequency setting could only be done at the SLAVE board. Starting

from GIII the frequency can be set at the BASE board as well,

therefore the source of frequency need to be selected.

2.4.1 Setting the RTU address

SW1- Defines the address of the specific RTU. The addressing uses binary notation

(see Appendix A about the binary to decimal conversion). Each RTU must have its

own unique address in the range 1 to 60. However the selection of the address

must obey some rules depending on the polling rate and the use of REPEATERS

as explained below.

2.4.2 Defining the polling rate

SW4- Defines the polling rate (known also as scanning rate) by which the MASTER

is communicating with the RTUs. The setting of the polling rate should be identical

in all RTUs and equal to what has been defined at the host controller. The selection

of the scanning rate is not totally free, it must take into consideration the total

number of RTUs that need to be scanned, or more accurately the highest address

to be scanned. The following table shows what will be the highest address

recognizable at any scanning rate selected, and the combination needed at SW4 for

selecting each polling rate.

2.4.3 Setting the layer

SW5- Defines the layer to which the specific RTU belongs. RTU that communicates

directly with the Master without going through a REPEATER is said to belong to

layer “0” and those that communicate through a REPEATER belong to layer “1”.

The directly communicating RTUs will have SW5 set to “00”, and RTUs that

communicate via a REPEATER will have SW5 set to “10”.

- 03 -

Page 14

DREAM

Layer 0

Layer 1

RTU

1

RTU

7

RTU

5

RTU

3

RTU

9

RTU

2

1

2

9

7

5

3

REPEATER

2.4.4 Setting up a repeater

When some RTUs have difficulty to communicate directly with the MASTER

because of a disturbing obstacle or too long distance, there is a necessity to use a

REPEATER. Both the RTU serving as a REPEATER and those using its services,

need to be informed about the arrangement. The following settings are required:

SW3- When SW3 is set to a nonzero value, the RTU becomes a REPEATER and

the value of SW3 represents the number of RTUs using the services of the

REPEATER. The number is expressed in binary notation (see Appendix A about

the binary to decimal conversion). For all the RTUs that are not repeaters, SW3

must be set to "0". In the example below, RTU No 2 is a repeater for 3 units

therefore switch SW3 of RTU No 2 should be set to 3.

Now the question is how does the REPEATER know exactly which RTUs it is

serving? The answer lies in the addresses of those RTUs. The first RTU must have

the address of the REPEATER +1, the second must have the address of the

REPEATER +3, the third will have the address of the REPEATER + 5 etc…

As mentioned above, all RTUs that are directly communicating with the MASTER,

without using a REPEATER, belong to layer "0". The RTUs that are functioning as

REPEATERS belong also to layer "0". Only the RTUs that are communicated via

REPEATERS are considered to belong to layer "1". Each of the units of layer "0"

occupy a single address, but those who belong to layer “1” occupy 2 addresses,

therefore the immediately following address of such RTUs must be skipped.

Therefore RTUs that are communicating via repeaters differ from regular RTUs by

two things: first they belong to layer “1” and second they occupy two addresses

instead of one.

Notice that the first RTU communicating through a repeater will get the

address immediately following the address of the REPEATER. The

other RTUs communicating via the REPEATER will have a gap of 1 from

the former RTU address.

There is no predefined limit to the number of REPEATERS that can be

used in an RF system. However the number of RTUs using the same

repeater is limited to 15.

EXAMPLE – The drawing shows a system

utilizing a repeater. There are 3 RTUs using

RTU No. 2 as a REPEATER, these units

belong to layer "1" while the REPEATER and

the other RTUs belong to layer “0”. The units

that communicate through the REPEATER

have the addresses "3", "5" and "7" and the

addresses "4", "6", "8" are skipped, they cannot

be used.

- 04 -

Page 15

2.4.5 Functions of the jumpers

JP5- When in the upper position, the buzzer is enabled.

JP15- When set to the upper position, a request for RF testing mode is sent to the

DREAM controller. (see paragraph 3.3 below about the RF test mode).

3. THE VARIOUS MODES OF OPERATION

3.1 START-UP MODE

Right after energizing the RTU or after pushing it's reset button there is an

initialization process that starts with a sequence of 3 short and one long beeps

after which the solenoids are closed one by one. Every 15 seconds 2

short beeps will be sounded and every 30 seconds the slave will try to acquire

communication with the MASTER. During the process of acquiring communication

the red LED of the SLAVE turns on indicating that the receiver is open and

listening. This takes about 10 seconds. If the communication is established, the

RTU goes into NORMAL MODE, otherwise it will keep trying to pick up the

communication signal every 30 seconds.

3.2 NORMAL MODE

During normal mode of operation, the RTUs are scanned by the host via the

MASTER one by one in a cyclic manner and in a constant rate. In each cycle, every

RTU is communicated within its allocated timeslot, which is dictated by its address.

During that timeslot, an information exchange takes place, the required state of the

outputs is sent from the host controller to the RTU, and the current state of inputs is

transmitted back to the host controller. The rate of scanning must be identically set

both at the host controller and at each RTU. When the MASTER initiates a

scanning cycle there will be a blink of the MASTER's LED and for each response

received correctly from any RTU, there will be a short beep sounded by the

MASTER's buzzer.

At the other end the RF SLAVE which is dormant between the scanning cycles,

wakes up at the right timeslot and prepares itself for receiving the transmission of

the MASTER. This state is indicated by a blink of the SLAVE's LED . Each time a

successful information exchange takes place there will be a short beep sound

made by the buzzers of both the RTU BASE and the RF SLAVE. If the RTU picks

up the signal from the MASTER but the call was not correctly addressed, it will

sound a double beep . For those who have difficulty hearing the buzzer, the

green LED blinks each time the buzzer sounds.

3.3 RF TEST MODE

The purpose of this test is to check the communication quality between a specific

RTU and the MASTER. Prior to initiating the TEST mode, it must be enabled at the

host controller. When enabled, the request for RF TEST is initiated from the RTU.

By setting JP15 to "RF test" (upper position) a test request signal is sent to the

Master. When the request is received by the MASTER, it is immediately granted

and the RF test starts. During RF TEST mode the regular scanning of all the RTUs

is stopped and the MASTER starts communicating solely with the RTU under test

- 05 -

Page 16

SW6

Input/ Output

under test

000

1

100

2

010

3

110

4

001

5

101

6

011

7

111

8

TE=Test Enabled

TR=Test Request

Signal strength of the RTU picked up by the Master

Signal strength of the Master picked up by the RTU

second by second. The red LED of the SLAVE is constantly ON . The rate of

communication becomes once per second. Each second the Master transmits to

the RTU the signal strength picked up by the Master from the RTU and the RTU

responds by transmitting to the Master the signal strength picked up by the RTU

from the Master. Listening (by the RF Ear) to the exchange of information between

the Master and the RTU under test, one can tell exactly how they hear each other.

00:09:59(097) M->X (15)01 01000010(66) TE AA RSSI=66

00:09:59(147) M<-X (15)01 01000001(65) TR OK RSSI=66

The MASTER will remain in TEST mode until receiving an END OF TEST signal

from the RTU (as a result of removing jumper 15) or until the RF TEST is disabled

by the user at the host controller.

3.4 WHEN LOOSING COMMUNICATION

The reaction of the RTU in case of losing communication with the host can be

initially programmed. The following options exist: 1) to leave the outputs as they are

2) to shut down the open outputs after a predefined delay (Autoclose). Every 30

seconds the unit will try seeking the communication signal of the MASTER. During

this process every 15-second a double beepwill sound, and every 30 seconds

the red LED of the SLAVE will turn on for 10 seconds indicating that the receiver

is open trying to pick up the communication signal. This will continue for 1 hour and

then for energy saving purposes the RTU instead of seeking communication every

30 seconds will start seeking communication only once every hour. When the

communication signal is regained, the RTU returns to its normal state.

Notice that if the MASTER was OFF for more than an hour, then when it

is turned ON again, the RTUs may not respond immediately to the calls

of the MASTER, because they are in energy saving mode. It may take

an hour before they start responding. They can be forced to exit energy

saving mode by pushing the RESET button of the RTU.

3.5 TESTING INPUTS AND OUTPUTS

During test mode the inputs and outputs are tested one by one. The input and

output to be tested is selected by dipswitch block SW6 as follows:

- 06 -

Page 17

INPUT TEST – The test begins by pushing the TEST button SW7. Each change of

state of the selected input will be indicated by a short beep of the buzzer, single

beep for closing the contact and double beep for opening.

OUTPUT TEST – While being in INPUT TEST, pushing SW7 again, will terminate

the INPUT TEST and will start the OUTPUT TEST. An "open" command will be

sent to the selected output followed by a single beep . Another push of SW7

generates a "close" command indicated by a double beep .

Each push of SW7 will switch the solenoid between "open" and "close" positions.

To exit test mode change the position of SW6 or wait 1 minute and it will exit

automatically.

3.6 LOW BATTERY INDICATION

When the battery of an RTU gets too low, there will be a LOW BATTERY indication

both at the RTU and at the host controller.

At the RTU, the low battery is indicated by a sound of 3 beeps sounded

every few seconds.

When is the battery considered low? The system decides on low battery situation by

two criterions: one is the voltage of the battery and the second is the time it takes to

recharge the capacitor after execution of an output command. For example, if the

powering voltage is 6v, then low battery starts to be signaled when the battery

drops to 4.8 volts or when the recharging time is longer than 5 seconds. At this

stage the normal operation continues but the user is informed that the battery

should be replaced. If the voltage drops further to 3.6v the beeping stops and all

outputs will be shut down, since the unit is no longer able to continue

communicating with the MASTER.

- 07 -

Page 18

JP13 indicates that analog inputs

are enabled.

JP6 the OLD-NEW selection

jumper set to NEW

4. READING ANALOG INPUTS BY RF RTUS

Starting from GENERATION III the RF RTU system is capable of reading analog

inputs. This ability is limited to the RTUs addressed 1 up to 8 only. Currently the

only host that recognizes the analog values is the DREAM controller. We shall now

describe the necessary settings and definitions for enabling analog inputs reading

through the RF RTU system.

4.1 SETTING THE INTERFACE FOR ANALOG INPUTS

To enable reading analog inputs the interface must be set as follows:

JP6 – must be set with upper pin free (NEW)

JP13 – must be set with right pin free (ANALOG ENABLED)

The RF MASTER needs no special setting but it must be version 7.9 or higher.

4.2 SETTING THE RTU FOR ANALOG INPUTS

To enable reading analog inputs the RTU must be equipped with a special

EXPANSION BOARD OF ANALOG INPUTS that can handle up to 4 analog inputs.

The analog inputs are additional to the 4 digital inputs that the RTU can read when

equipped with the appropriate plug in board.

The number of analog inputs that will really be used and the way the analog inputs

will be powered is defined by programming the RTU BASE board.

For that purpose a special communication interface and special software “RFProg”

are used.

During programming, the interface will be connected in place of the SLAVE

communication lines as demonstrated below. The PC software “RFProg”

communicates with the RTU through the interface and enables setting the desired

- 08 -

Page 19

Analog

sensor with

2 wires

Analog

sensor with

2 wires

Analog

sensor with

3 wires

Analog

sensor with

3 wires

Expansion

board of

analog inputs

RTU base board

Special

interface for

programming

Plug-in board

of 4 digital

inputs

Plug-in board

of 2 outputs

Internally energized

Externally energized

Connection of the

Special interface to

the RTU in place of

the SLAVE

Internally energized

Externally energized

parameters as explained below at the paragraph about “PROGRAMMING THE

RTU”.

In case of sensor of 4-20 mA, a 221Ω resistor will be used as shown in the picture. Usually the board

will be supplied with the resistors included. In case of 0-5v the resistors should be removed.

+ -

Energy Energy

+ S + S

+ - + - + - + -

S= Signal

- -

- 09 -

Page 20

4.3 SETTING THE DREAM FOR READING RF ANALOG INPUTS

For being able to read analog inputs through the RF RTU system the DREAM host

controller must have the following definitions made:

1. At the NETWORK DEFINITION stage the number of analog inputs must be

declared.

2. At the HARDWARE DEFINITION stage a virtual ANALOG INTERFACE must

be declared and given an address that is higher by 1 than the address of the

RF INTERFACE through which the analog values will be transmitted.

3. At the CONNECTION DEFINITION stage the analog inputs must be defined

as connected to a virtual analog RTU belonging to the channel of the virtual

analog interface but with the same RTU number as the RF RTU to which the

analog input is really connected.

4. The RF RTU to which the analog input is connected must have at least 1

output and 1 digital input allocated to. If such allocation does not really exist,

a dummy output and a dummy digital input must be defined and allocated to

the specified RTU.

5. At the UTILITIES/ANALOG-SENSORS definition the type of each analog

sensor and its scale range should be defined.

The resolution of the analog inputs is 16 bits and they are transmitted

in nibbles of 4 bits per cycle, therefore it takes 4 cycles of

communication to transfer the value of a single analog input and if

there are 4 analog inputs connected to the same RTU it may take at

least 16 communication cycles to transfer 4 analog inputs. If a nibble

was not successfully received by the MASTER it will be requested

again on the next communication cycle.

5. USING RFPROG FOR PROGRAMMING THE RTU

By use of the RFProg (special software for programming the RF RTU) the following

parameters of the RF RTU can be set:

Parameters involved with the analog inputs

Parameters involved with the solenoids activation pulse

Parameters involved with the input pulses division

Parameters involved with the Auto-close in case of losing communication

To prepare for programming the RTU base must be energized by 6-12 volts and

must be put into “programming mode” by holding down the TEST button (SW7) and

then pushing the RESET button (SW2). Being in programming mode is indicated by

a single beep (and single blink ) every 6 seconds. Make sure that the RTU

address is set to a nonzero value. When programming a modular RF RTU the

connector of the cable between the Slave and the Executer must be pulled out.

- 21 -

Page 21

Selected

com port

Read

programmed

parameters

Write

programmed

parameters

Setting

default

parameters

Not in

use

Setting

analog inputs

parameters

Setting the

solenoids

pulse

parameters

Inputs pulses

division

factors

Auto close

cycle and

permission

checkbox

Enabled analog input checkbox

When checked indicates internally energizing

Delay between energizing and reading

Interval between cycles of reading in steps of 10 seconds

The voltage generated for reading

Number of samples used for obtaining the average value

Displaying

statuses of

digital and

analog inputs

Initially the software must be informed about the communication port of the PC to

which the special communication interface is connected. Notice that if the interface

is connected to a USB port, the CONTROL-PANEL/ SYSTEM/ HADWARE/

DEVICE MANAGER should be checked to find out which comport was the USB

serial output allocated to.

5.1 ANALOG INPUTS PARAMETERS

When the checkbox of an analog input is enabled, it indicates that the input is recognized by

the RTU. The input can be energized by external energy source or internally from the RF

RTU itself. When internally energized the energy to the sensor is generated inside the

EXPANSION BOARD OF ANALOG INPUTS and for energy saving purposes it is

supplied to the sensor, each time, only a short while before reading. The cycle of reading,

the voltage supplied and the delay between cycles of reading can be defined as shown

below.

- 20 -

Page 22

Pulse amplitude used for solenoids activation

Pulse width

Enable automatic close in case of communication loss

The period of continuous communication loss that will

cause auto-close of the outputs.

5.2 THE SOLENOIDS ACTIVATION PULSE PARAMETERS

For optimal solenoid activation and for energy optimizing the G III –GIV RF RTU

units enable defining the pulse amplitude and pulse width used for activating the

solenoids.

5.3 INPUTS PULSE DIVISION

Because the rate of pulses arriving to the digital inputs from water meters and

fertilizer meters may sometimes be higher than the scanning rate between the

MASTER and RTUs, it may be needed to count several pulses before transmitting

to the host. This is known as pulse division. The division factor can be set

individually per each input through the following table:

5.4 THE AUTO CLOSE PARAMETERS

It must be decided what will be the reaction in case of loosing communication

between the MASTER and an RTU. Sometimes we would like the outputs to be

closed and sometime we prefer to leave them unchanged. The desired action can

be decided in the following table:

- 22 -

Page 23

6. SOUNDS and LED LIGHTS

Longest beep - (500 msec)

Long beep - (100 msec)

Short beep - (50 msec)

A tick - (5 msec)

Long blink-

Short blink-

6.1 RTU+SLAVE during START UP

USER ACTION: connecting power or pushing the RESET button

RTU ACTION: closing all outputs

RTU BUZZER:

SLAVE LED:

lighting =<10 sec

30 sec

15 sec

15 sec

SLAVE ACTION:

30 sec

seeking communication

every 30 seconds

6.2 RTU BASE+SLAVE during normal communication

SLAVE LED:

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

…

BASE+SLAVE BUZZERS :

When incorrect RTU address

BASE+SLAVE BUZZERS :

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

…

…

6.3 BASE+SLAVE while losing communication

SLAVE LED:

BASE BUZZER:

15 sec

SLAVE ACTION:

30 sec

After 1 hour will go into energy saving mode and seek communication only once in an hour

lighting =<10 sec

30 sec

15 sec

seeking communication

6.4 BASE+SLAVE during RF test - COMMUNICATION OK

USER ACTION: JP15 to lower position (upper pin free)

SLAVE LED: lighting constantly

- 23 -

Page 24

BASE+SLAVE BUZZERS :

1 sec

1 sec

…

1 sec

6.5 BASE+SLAVE during RF test – NOT RECEIVING

USER ACTION: JP15 to lower position (upper pin free)

SLAVE LED: lighting constantly

BASE BUZZER :

SLAVE ACTION:

30 sec

…

30 sec

seeking communication

6.6 No communication between BASE and SLAVE

BASE BUZZER :

…

20 sec

6.7 BASE during inputs test

USER ACTION: selecting the desired input by SW6 and pushing TEST button

BASE BUZZER :

USER ACTION: closing the selected input contact

BASE BUZZER :

USER ACTION: opening the selected input contact

BASE BUZZER :

6.8 BASE during outputs test

USER ACTION: selecting the desired output by SW6 and pushing TEST button once for

entering test mode and again for opening the output

BASE ACTION: opens the selected output

BASE BUZZER :

USER ACTION: pushing TEST button again

BASE ACTION: closes the selected output

BASE BUZZER :

USER ACTION: keeps pushing repeatedly the TEST button for opening and closing the

output. For ending the test procedure the RESET button should be

pushed or else there will be an automatic exit after 1 minute of no

changes sensed.

- 24 -

Page 25

6.9 BASE when battery becomes low

BASE BUZZER : that follows any usual beep indicates low battery.

RTU ACTION: When the battery becomes very low closing all outputs one by one and

sounding without any other sounds.

6.10 INTERFACE+MASTER during normal operation - RF OK

INTERFACE D9,D11,D12:

1 sec

1 sec

1 sec

…

INTERFACE D3,D4,D7:

INTERFACE D3,D4,D7:

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

old generation master

new generation master

MASTER LED:

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

1 / 2.5 / 5 / 10 sec

…

MASTER BUZZER : …

… …

…

6.11 INTERFACE not communicating with the MASTER

INTERFACE D5:

blinking fast

…

6.12 INTERFACE not communicating with the DREAM

INTERFACE D9,D11,D12: no blinking

6.13 BASE ENTERING PROGRAMMING MODE

6 sec

6 sec

6 sec

6.14 SLAVE ADDRESS ZERO

1 sec

1 sec

…

- 25 -

Page 26

Decimal address

Binary value to be set by the Dip Switch

Positions: 1 2 3 4 5 6

1

1 0 0 0 0 0

2

0 1 0 0 0 0

3

1 1 0 0 0 0

4

0 0 1 0 0 0

5

1 0 1 0 0 0

6

0 1 1 0 0 0

7

1 1 1 0 0 0

8

0 0 0 1 0 0

9

1 0 0 1 0 0

10

0 1 0 1 0 0

11

1 1 0 1 0 0

12

0 0 1 1 0 0

13

1 0 1 1 0 0

14

0 1 1 1 0 0

15

1 1 1 1 0 0

16

0 0 0 0 1 0

17

1 0 0 0 1 0

18

0 1 0 0 1 0

19

1 1 0 0 1 0

20

0 0 1 0 1 0

21

1 0 1 0 1 0

22

0 1 1 0 1 0

23

1 1 1 0 1 0

24

0 0 0 1 1 0

25

1 0 0 1 1 0

26

0 1 0 1 1 0

27

1 1 0 1 1 0

28

0 0 1 1 1 0

29

1 0 1 1 1 0

30

0 1 1 1 1 0

31

1 1 1 1 1 0

32

0 0 0 0 0 1

33

1 0 0 0 0 1

34

0 1 0 0 0 1

35

1 1 0 0 0 1

36

0 0 1 0 0 1

37

1 0 1 0 0 1

38

0 1 1 0 0 1

39

1 1 1 0 0 1

40

0 0 0 1 0 1

41

1 0 0 1 0 1

42

0 1 0 1 0 1

43

1 1 0 1 0 1

44

0 0 1 1 0 1

45

1 0 1 1 0 1

46

0 1 1 1 0 1

47

1 1 1 1 0 1

48

0 0 0 0 1 1

49

1 0 0 0 1 1

50

0 1 0 0 1 1

51

1 1 0 0 1 1

52

0 0 1 0 1 1

53

1 0 1 0 1 1

54

0 1 1 0 1 1

55

1 1 1 0 1 1

56

0 0 0 1 1 1

57

1 0 0 1 1 1

58

0 1 0 1 1 1

59

1 1 0 1 1 1

60

0 0 1 1 1 1

APPENDIX A - Decimal to binary conversion table

- 26 -

Page 27

APPENDIX B - WIRING

The RF INTERFACE

4 wired shielded cable.

Can be hundreds of meters long.

+12v DC –RED

-12v DC – BLACK

Positive RS485 Communication - GREEN

Negative RS485 Communication -WHITE

Shield – YELLOW GRREN

The RF MASTER

The RF INTERFACE

The RF MASTER

4 wired shielded cable. Can be hundreds of

meters long.

+12v DC –RED

-12v DC – BLACK

Positive RS485 Communication - GREEN

Negativee RS485 Communication -WHITE

Shield – YELLOW GRREN

4 wired shielded cable. Can be hundreds of

meters long.

+12v DC –RED

-12v DC – BLACK

Positive RS485 Communication - GREEN

Negative RS485 Communication -WHITE

Shield – YELLOW GRREN

Wiring between DREAM – RF INTERFACE (internal) and RF MASTER

Wiring between DREAM – RF INTERFACE (internal) and RF MASTER

27

Page 28

4 wired shielded

cable. Maximum

10m long

Shield:

Yellow/ green

6v to SLAVE:

RED = +

BLACK= -

communication to

SLAVE:

GREEN = P

White = N

RTU Base

Wiring between RTU BASE and RF SLAVE

28

Page 29

Wiring of Outputs and Inputs into the RTU BASE:

Plug-in unit of 2 outputs

Plug-in unit of 4 inputs

Locations for more

Output Plug-in units

Locations for more

Output Plug-in units

Locations for more

Output Plug-in units

Each output is 12v 2

wired latching . For

normally open valves

the RED wire goes to

“Out-X” and the

BLACK wire goes to

“C” . For normally

closed valves,

exchange between the

two wires

Each input is

connected by 2 wires .

One wire goes to

“In.X” and the other to

“G” which is common

to all the inputs. The

polarity is of no

importance

Each output is 12v 2

wired latching . For

normally open valves

the RED wire goes to

“Out-X” and the

BLACK wire goes to

“C” . For normally

closed valves,

exchange between the

two wires

Each input is

connected by 2 wires .

One wire goes to

“In.X” and the other to

“G” which is common

to all the inputs. The

polarity is of no

importance. Bottom

row is for inputs 1,3

and upper row inputs

29

Page 30

S1- Selects

frequency

Not

in use

APPENDIX C – THE RF EAR

The RF EAR is a very efficient monitoring tool that supplies valuable

information about the communication between the RF MASTER and the

SLAVES of a particular system to which it is tuned.

The RF EAR contains an RF receiver/transmitter, which resembles the RF

MASTER but functions in a totally different way – it does not transmit anything

but it is continuously open for reception of any transmissions made by the

members of the system. The RF EAR picks up only data transfer using the

communication protocol utilized by Talgil RF systems and only if it is in the

selected frequency. Therefore, the collected information shows the behavior

of the particular system being tested, the information is displayed at a real

time basis on the screen of a mobile PC and it is continuously recorded for

later inspection.

By moving around with the RF EAR and recording the reception quality at the

various RTU locations and at the center, one can identify the weak points of

the system and decide about the solutions.

Usually the receiver/transmitter unit of the RF EAR will be installed on a long

PVC pole that enables raising it high at the places being checked.

HOW TO USE THE RF EAR ?

1. Set the frequency channel of the RF EAR to

the same frequency of the system being

checked.

2. Turn on the power switch of the RF EAR. The unit will start sounding

sequences of short beeps repeated in an interval of the scanning rate.

Each short beep indicates a communication picked up by the unit.

31

Page 31

3. Turn on the laptop and activate the RF EAR software. The following

window will appear:

4. Connect the communication cable of the RF EAR to a serial port of the

laptop, and set the “Comm. Port” of the software accordingly. For those

laptops having no serial port, a USB port with a converter from USB to

RS232 can be used. For GIII the Baud rate setting should be 9600

while for GIV and GIV.V it should be set to 19200.

5. Click on the START button, and the information received by the RF

EAR will start to be displayed as shown in the following screen.

30

Page 32

The time at which

the communication

took place..

The brackets

contain

milliseconds.

M – > X indicates

a call from the

MASTER to

SLAVE - X

The number of the

SLAVE -X is 2.

The number in

brackets is the

selected frequency

channel.

The status of the

outputs-each bit

represents 1 out of

8 outputs. “0”

means closed, “1”

means open.

The RSSI indicates

the strength of the

MASTER’S signal:

For GIII:

41-73 = Strong

34-40 = Medium

20-33 = Low

M <– X indicates

the response from

SLAVE - X to the

MASTER.

The status of the

inputs-each bit

represents 1 out of

4 outputs.

“0” means open

contact, “1” means

closed contact.

The RSSI indicates

the strength of the

SLAVE’S signal:

For GIII:

41-73 = Strong

34-40 = Medium

20-33 = Low

The display is refreshed each scanning cycle.

The drawings of the LEDS on the left side indicate the status of

communication with each of the RF SLAVES (or with each RTU). An RTU,

which responds properly, will be indicated by a LED lighting constantly. An

RTU that did not respond the call of the MASTER will be indicated by a

blinking LED. The RTUs that were not called by the MASTER either because

they are undefined or because the call of the MASTER was not received

remain dark.

On the right side of the window appear rows of characters that describe the

information transmitted either by the MASTER or by one of the SLAVES. The

rows are shifted downward with each new row received by the RF EAR.

The following row contains information about the MASTER’s transmission :

00:01:05(852) M->X (04)02 00000000(00) TD AA RSSI=66

The response of the slave has the following format:

00:01:05(901) M<-X (04)02 00000010(02) NT OK RSSI=66

Notice that in the 8 bits string containing the status of the outputs or the inputs

the rightmost digit represents the lower Output/Input bit.

When an RTU is defined to communicate through a REPEATER, there will be

4 rows describing the process: 1) the call of the MASTER; 2) the transfer of

the call to the SLAVE by the REPEATER; 3) the response of the SLAVE and

4) the transfer of the response to the MASTER by the REPEATER.

32

Page 33

1) MASTER

calling SLAVE 23

2) REPEATER

transfers the call to

SLAVE 23

3) SLAVE 23

responds to the

REPEATER

4) REPEATER

transfers the

response to the

MASTER

In the following example the MASTER is calling RTU 3 which communicates

through a REPEATER:

06:51:48(912) M->X (01)23 00000000(00) TD AA RSSI=39

06:51:48(952) R->S (01)23 00000000(00) TD AA RSSI=53

06:51:49(001) R<-S (01)23 00000000(00) NT OK RSSI=46

06:51:49(041) M<-X (01)23 00000000(00) NT OK RSSI=54

6. The recorded results are stored in text files called rfd0000.txt,

rfd0001.txt, rfd0002.txt etc…Each time we exit and restart the RF EAR

software a new file with a higher index is generated, thus eliminating

the erasure of the previously recorded information. The following rows

are taken from a file of recorded information. Notice that the first row

shows the earliest record and there is exactly 100 milisec between the

calls of the Master to the next RTU.

New loop: 12:47:18

00:00:34(629) M->X (01)01 00000001(01) TD AA RSSI=66

00:00:34(678) M<-X (01)01 00000000(00) NT OK RSSI=66

00:00:34(729) M->X (01)02 00000010(02) TD AA RSSI=66

00:00:34(778) M<-X (01)02 00000000(00) NT OK RSSI=66

00:00:34(829) M->X (01)03 00000100(04) TD AA RSSI=66

00:00:34(880) M<-X (01)03 00000000(00) NT OK RSSI=66

00:00:34(929) M->X (01)04 00000000(00) TD AA RSSI=66

00:00:34(981) M<-X (01)04 00000000(00) NT OK RSSI=66

********

Each asterisk (*) that follows a communication cycle indicates an

additional cycle which ended with identical results to the previous one.

33

Page 34

DIFFERENCES BETWEEN NEW/OLD RTU RF BASE BOARDS

Old RF Base board

New RF Base board GIII

SW3 – in case of

REPEATER, indicates

the number of RTUs

served by the repeater

SW5 –

indicates the

layer the RTU

belongs to

Selecting I/O

for test

Test I/O

button

SW1-Setting

RTU address

SW4-Setting

Polling Rate

Setting the

frequency -**

Selecting

frequency

source: Slave

or RTU-**

Test I/O

button

Selecting I/O

for test

SW1-Setting

RTU address

SW5 –

indicates the

layer the RTU

belongs to

SW4-Setting

Polling Rate

SW3 – in case of

REPEATER, indicates

the number of RTUs

served by the repeater

RF

test

RF

test

LED Enable/

Disable

Selecting between

Analog card or Temp/

Humidity sensor

**- actual from Slave version 7.12 or higher

LED Enable/

Disable

APPENDIX D –

34

Loading...

Loading...