Page 1

SERVICE MANUAL

Model Series:

Product Type: Digital Rear Projection

Chassis: ZP26/28

Manual Series: PV154

Manual Part #: 923-03506

Model Line: E

Product Year: 2002

CONTENTS

General Info ................................................. 1

Service Menu ................................................ 2

Servicing ..................................................... 3

Part List ...................................................... 4

Diagrams / PCB Layouts .................................. 5

Schematics ................................................... 6

R50V26

R56W28

R60V26

R65W28

Printed in U.S.A.

Published August 2002

by Technical Publications

Zenith Electronics Corporation

201 James Record Road

Huntsville, Alabama 35824-1513

Copyright 2002 by Zenith Electronics Corporation

Page 2

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from Zenith Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by Zenith Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into

the set is not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage

or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended

to alert the service personnel to important safety information in

the service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ALL FUSES WITH THE SAME TYPE AND RATING AS MARKED

NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of

adjacent component shorts. This is especially important on items transported to and from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers,

shields, strain reliefs, power supply cords, and other hardware have been

reinstalled per the original design. Be sure that the safety purpose of the

polarized line plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign

particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a high current device or a resistor

rated at 1 watt or more. Lead tension around protruding metal surfaces

must be avoided.

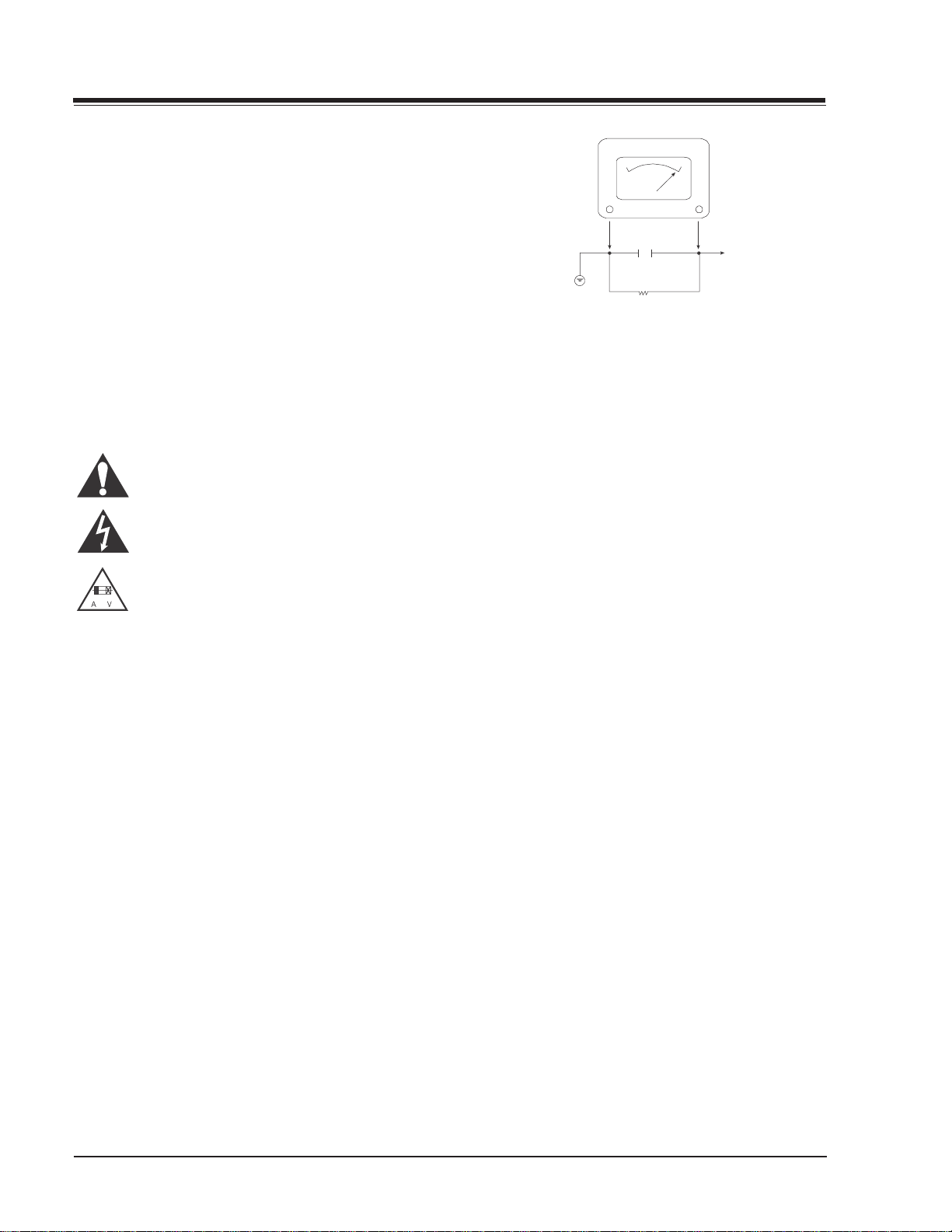

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in

the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by

a .15 mfd 150V AC type capacitor between a known good earth ground

water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part. Voltage

measured must not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp

AC. Any value exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

A.C. Voltmeter

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.15uF

1500 OHM

10 WATT

Place this probe

on each exposed

metal part.

X-RADIATION

1. Be sure procedures and instructions to all service personnel cover the

subject of x-radiation. The only potential source of x-rays in current TV

receivers is the picture tube. However, this tube does not emit x-rays when

the HV is at the factory-specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may cause a failure of

the picture tube or high-voltage supply and, under certain circumstances

may produce radiation in excess of desirable levels.

2. Only factory-specified CRT anode connectors must be used.

3. It is essential that the service personnel have available an accurate and

reliable high-voltage meter.

4. When the high-voltage circuitry is operating properly, there is no possibility

of an x-radiation problem. Every time a chassis is serviced, the brightness

should be run up and down while monitoring the high voltage with a

meter, to be certain that the high voltage does not exceed the specified

value and that it is regulating correctly.

5. When troubleshooting and making test measurements in a product with a

problem of excessively high voltage, avoid being unnecessarily close to

the picture tube and the high voltage power supply. Do not operate the

product longer than necessary to locate the cause of excessive voltage.

6. Refer to HV, B+, and shutdown adjustment procedures described in the

appropriate schematics and diagrams (where used).

IMPLOSION

1. All direct view picture tubes are equipped with an integral implosion

protection system; take care to avoid damage during installation.

2. Use only the recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely

fitting shelf space over, or close to, a heat duct, or in the path of heated

air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations

where dew is a factor, near steam radiators where steam leakage is a factor,

etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit

must follow the factory-approved mounting instructions. A product mounted

to a shelf or platform must retain its original feet (or the equivalent

thickness in spacers) to provide adequate air flow across the bottom. Bolts

or screws used for fasteners must not touch any parts or wiring. Perform

leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a

tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small

casters across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed

by Underwriters Laboratories, Inc. for use with its specific model of

television receiver or generically approved for use with TVs of the same or

larger screen size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

PV154 - 923-03506 ZP26/28 - SAFETY

i

Page 3

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

CRT ANODE HIGH VOLTAGE MEASUREMENT PROCEDURE

To prevent possible exposure to radiation caused by excessive CRT

Anode voltage, the High Voltage Shutdown circuit senses the level

of flyback pulse from “Flyback Transformer” representative of the

actual high voltage on the CRT anode. When this level exceeds a

predetermined voltage, the circuit shuts down the horizontal drive,

preventing further generation of anode voltage. In this condition,

the horizontal drive is “latched” off. The drive will remain off until

power (via remote control or front panel) is re-cycled from “Off” to

“On”.

Critical Safety components (designated with an “X” in the component designator) are designed to operate the CRT at a safe operating

Anode voltage and provide proper shutdown thresholds . If replacement of any of these components are deemed necessary, it is important to use original type Zenith replacement components. After

replacement is made, confirm proper Anode voltage using the following procedure.

Measurement of the CRT Anode voltage must be performed using a

high impedance high voltage meter, with no visible raster on the

screen, and operating at nominal horizontal scanning frequency.

Connect a strong broadcast signal (or TV signal generator operating

at 15.734kHz horizontal scanning rate) to the RF input.

After discharging the CRT, connect a high impedance high voltage

meter to the CRT anode. Turn the television “on” and confirm a good

signal is being displayed . Reduce Brightness and Contrast settings

until the picture is well extinguished. If the voltage reading is

higher than the maximum, verify circuit component values and

proper operation.

B+ VDC HV NOM HV MAX

(0 BEAM) KV KV

115 +/- 2% 30.2 30.5

SHUTDOWN TEST PROCEDURE

Equipment needed is a video generator, HV DC meter (0 to 40 KV,

high Z), and a external variable power supply (0V to 6VDC @ 5Amps

minimum).

To verify the Shutdown Circuit is operating properly, Supply +6V DC

to pin 1 of P1407 and ground to Heat sink of Q1413. If there is no

raster and set goes into Shutdown, then the Shutdown Circuit is

functional. If the set doesn’t go into Shutdown, then the Circuit is

defective.

ELECTROSTATICALLY SENSITIVE DEVICES

Some semiconductor (solid-state) devices can be damaged easily by

static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are

integrated circuits and some field-effect transistors and semiconductor “chip” components. The following techniques should be

used to help reduce the incidence of component damage caused by

static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic charge

on the body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices,

place the assembly on a conductive surface such as an ESD mat, to

prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static” can generate electrical

charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install t.(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil, or comparable conductive material.)

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to

the chassis or circuit assembly into which the device will be installed.

Caution: Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replace ment

ES devices. (Otherwise, seemingly harmless motion, such as the brushing together of your clothing or the lifting of your foot from a

carpeted floor, can generate static electricity sufficient to damage

an ES device.)

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the

following measures: Reorient or relocate the receiving antenna; Increase the separation between the equipment and receiver; Connect

the equipment into an outlet on a circuit different from that to

which the receiver is connected; Consult the dealer or an experienced radio/TV technician for help.

The presence of the DTV certification mark indicates that this product will successfully receive digital television transmissions that

conform to any and all of the video formats described in the ATSC

Digital Television Standard.

The responsible party for this device’s compliance is:

Zenith Electronics Corporation

201 James Record Road

Huntsville, AL 35824, USA

Digital TV Hotline: 1-800-243-0000

TRADEMARKS USED IN THIS MANUAL

Dolby Digital® Manufactured under license from Dolby Laboratories.

“Dolby” and the double-D symbol are trademarks of Dolby Laboratories. Confidential Unpublished Works. ©1992-1997 Dolby Laboratories, Inc. All rights reserved.

VCR Plus+, PlusCode and GUIDE Plus+ are trademarks of Gemstar

Development Corporation. The VCR Plus+ and GUIDE Plus+ systems

are manufactured under license from Gemstar Development Corporation and VCR Index Systems B.V., respectively.

Gemstar is not in any way liable for the accuracy of the program

schedule information provided by the GUIDE Plus+ system. In no

event shall Gemstar be liable for any amounts representing loss of

profits, loss of business, or indirect, special, or consequential damages in connection with the provision or use of any informaion,

equipment, or services relating to the GUIDE plus+ system.

SRS and the symbol are trademarks of SRS labs, Inc. SRS technology

is incorporated under license from SRS Labs, Inc.

Licensed by BBE Sound, Inc. under USP4638258 and 4482866. BBE

and the symbol are registered trademarks of BBE Sound, Inc.

PV154 - 923-03506 ZP26/28 - SAFETY

ii

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

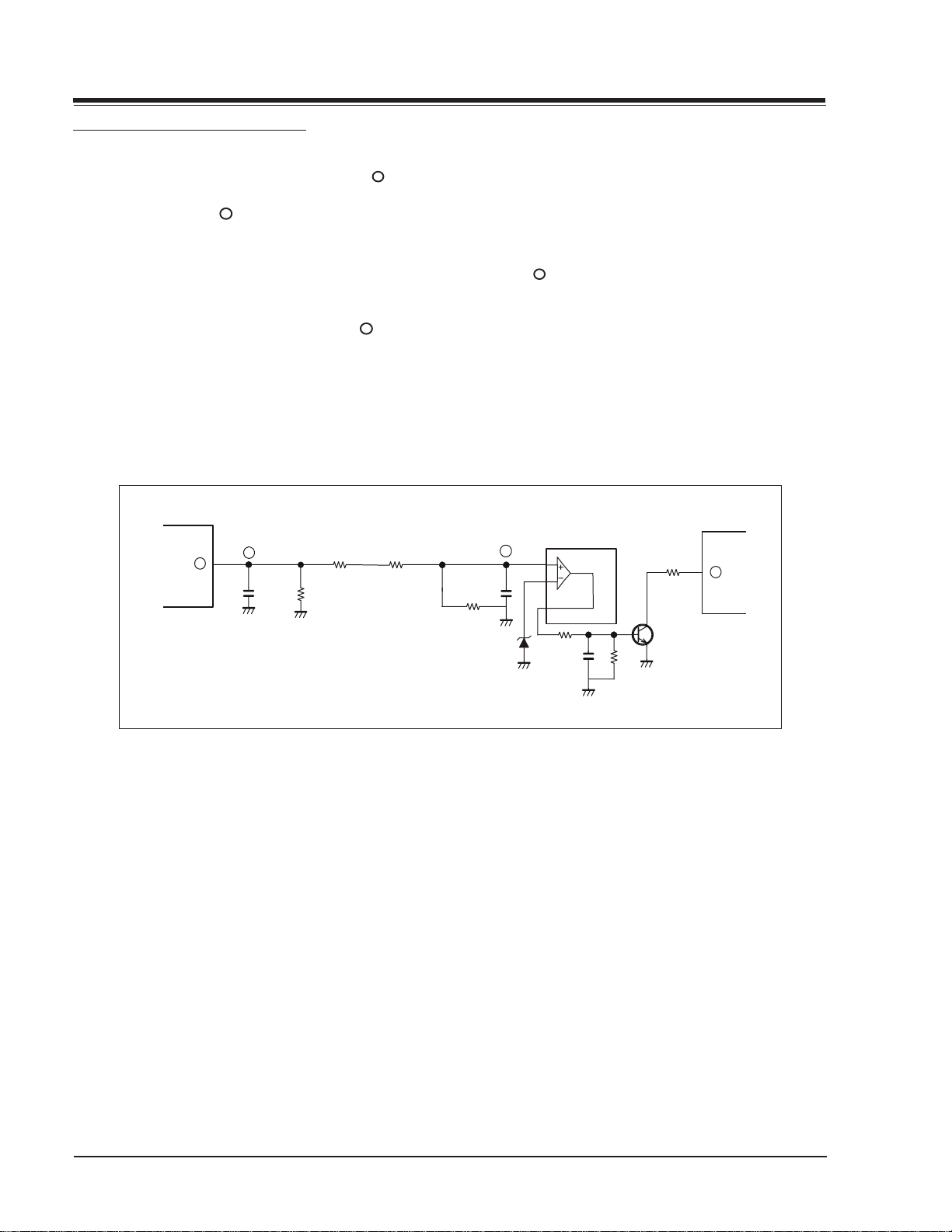

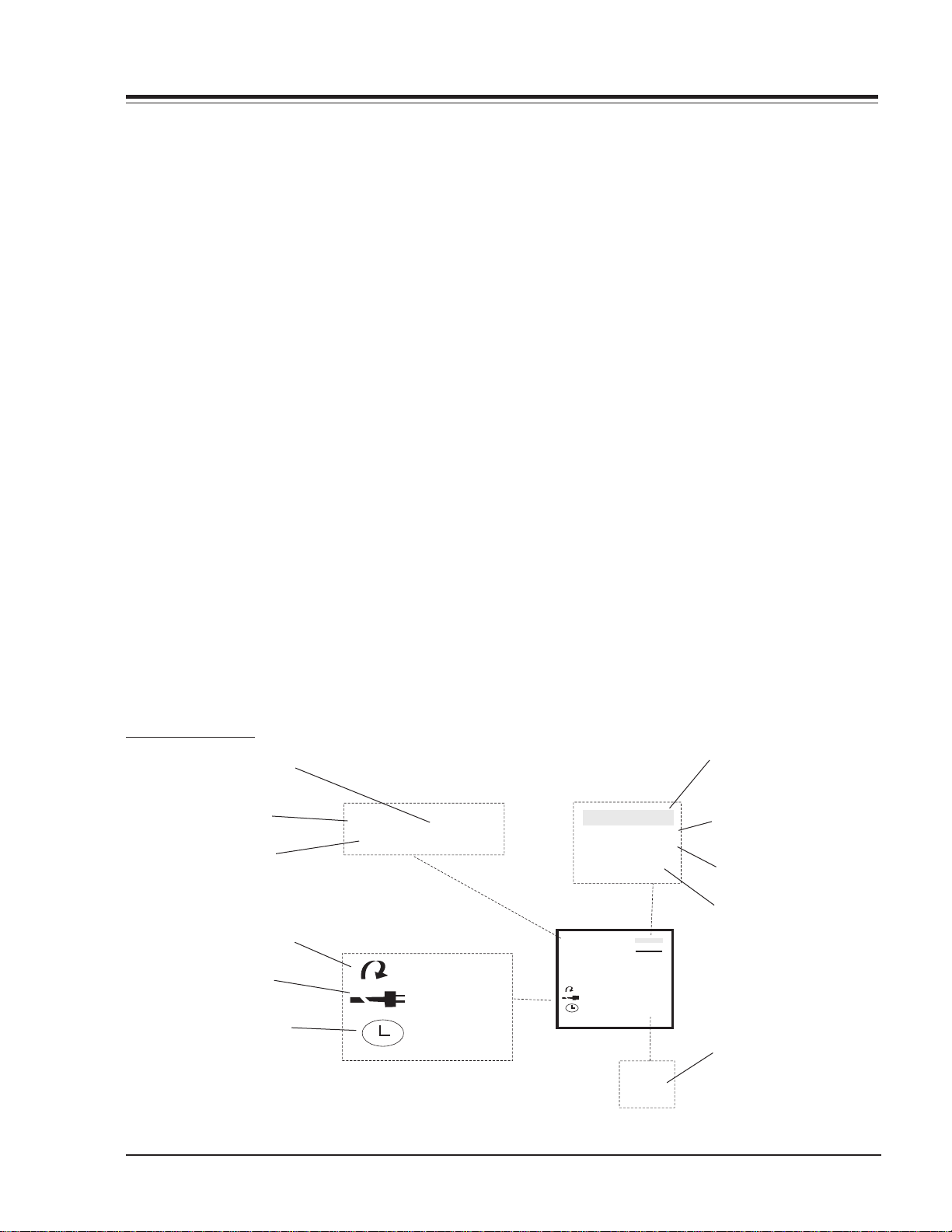

HOLD-DOWN CIRCUIT INFORMATION

NORMAL CONDITION

In normal condition, the DC voltage at point is ap-

a

proximately 4.88V through pin 1 of P1407 (HV Block).

The voltage at point is approximately 4.86V. The

b

voltage of pin 5 of IC404 is lower than the voltage of

pin 6 (5.1V). The voltage of pin 7 is 0V and the transistor Q403 is off.

ABNORMAL CONDITION

In abnormal condition, the voltage of point is much

b

higher than normal voltage. The voltage of pin 5 of IC404

is 24V and the transistor Q403 is on. Therefore, pin 1 of

IC401 receives a voltage causing the hold-down circuit

to be active. This results in the frequency of the horizontal oscillation and deflection to be stopped and then

the set goes into stand-by mode.

P1407 (H.V. Block)

1

a

C1439

R1435

R1455

R493

X-RAY PROTECTION

Check the X-Ray protection circuit using the following

steps. Turn the set on and input a color bar signal. Check

the B+ voltage to make sure it is correct. If B+ is 148 to

160 VDC, the power circuit is defective. To check the

operation of the hold-down circuit, apply DC 6V (+- 0.5)

to point . If there is no raster, the set is operating

a

properly and doesn’t need to be repaired.

IC401

5

6

7

R410

C455

IC404

R491

R411

Q403

1

HPROT

J8

C417

ZD406

(5.1V)

b

PV154 - 923-03506 ZP26/28 - SAFETY

- iii -

Page 5

TABLE OF CONTENTS

SECTION 1 .................... OVERVIEW

OVERVIEW ..................................................... 1-1

ON SCREEN DISPLAY .....................................1-3

REMOTE BUTTON DESCRIPTIONS .....................1-5

PROGRAMMING THE REMOTE .......................... 1-5

REMOTE BRAND CODES ..................................1-6

REMOTE CODES ............................................1-7

OPERATING MODE KEY FUNCTIONS ...................1-8

USER MENUS ..................................................1-9

USER MENUS ............................................ 1-10

SETUP ..................................................... 1-10

SPECIAL .................................................. 1-11

VIDEO MENU ............................................. 1-15

AUDIO MENU ............................................ 1-16

THEATER MENU ......................................... 1-17

POP-3 ..................................................... 1-17

SPLIT SCREEN ........................................... 1-17

SECTION 2 .............. SERVICE MENU

<PENDING>

SECTION 3 ....................SERVICING

CIRCUIT DESCRIPTIONS .................................... 3-1

POWER ON AND OFF .....................................3-1

POWER SUPPLY SHUTDOWN ........................... 3-1

STAND-BY MODE ..........................................3-1

HOT SHUT DOWN SENSING CIRCUITS................3-1

COLD SHUT DOWN SENSING CIRCUITS .............. 3-1

POWER SUPPLY SHUTDOWN CIRCUIT................3-2

SHUTDOWN DETECTION CIRCUITS ....................3-2

DEFLECTION SHUT DOWN CIRCUITS .................3-2

SHUT DOWN CIRCUIT DESCRIPTIONS................3-3

SUB POWER SUPPLY VISUAL LED ....................3-5

VOLTAGE LOSS OR EXCESSIVE LOAD DETECTION .. 3-5

B+ VOLTAGE TOO HIGH ................................. 3-5

SHUT DOWN CIRCUIT .................................... 3-5

B+ GENERATION FOR SUB POWER SUPPLY .........3-6

DEFLECTION POWER SUPPLY VISUAL LEDS ........ 3-6

DEFLECTION POWER DRIVER B+ GENERATION.....3-6

DEFELCTION GENERAL INFORMATION................ 3-7

MAIN MICROPROCESSOR .............................. 3-12

DAC1 I006 ............................................... 3-13

DAC3 I007 ............................................... 3-13

LEVEL SHIFT I004 ..................................... 3-13

3D Y/C I301 ............................................. 3-13

MAIN VIDEO CHROMA I501 (PREPARATION IC) 3-14

RAINFOREST IC01 (VIDEO/CHROMA PROCESSOR)3-14

A/V SELECTOR IX01 ................................... 3-14

SUB VIDEO CHROMA IX03 ........................... 3-14

MAIN Y PR/PB SELECTOR IX04 ..................... 3-14

SUB Y PR/PB SELECTOR IX04 ....................... 3-14

FRONT AUDIO CONTROL IC IA01 ................... 3-14

SRS AUDIO ............................................... 3-15

SERVICE ADJUSTMENTS .................................. 3-16

ZP-25 CHASSIS ADJUSTMENT ORDER ............. 3-16

CHASSIS PRE-HEAT RUN ADJUSTMENTS.......... 3-17

CHASSIS CUT-OFF (SCREENS) ADJUSTMENT ..... 3-17

CHASSIS PRE-FOCUS ADJUSTMENT ................ 3-17

DCU CROSSHATCH PHASE ADJUSTMENT .......... 3-17

CHASSIS HORIZONTAL PHASE ....................... 3-17

CHASSIS TILT (RASTER INCLINATION) ............ 3-18

CHASSIS BEAM ALIGNMENT ADJUSTMENT ....... 3-18

CHASSIS RED/BLUE RASTER OFFSET .............. 3-18

VERTICAL SIZE ADJUSTMENT ....................... 3-19

HORIZONTAL SIZE ADJUSTMENT.................... 3-19

BEAM FORM ADJUSTMENT ........................... 3-19

LENS FOCUS ADJUSTMENT ........................... 3-20

STATIC FOCUS ADJUSTMENT .........................3-20

BLUE DE-FOCUS ADJUSTMENT ...................... 3-20

WHITE BALANCE AND SUB BRIGHTNESS .......... 3-20

CHASSIS HORIZONTAL PHASE (FINE) ............. 3-21

CHASSIS INTELLISENSE “PATTERN SET UP” ...... 3-21

DIGITAL CONVERGENCE ALIGNMENT ...............3-22

SUB PICTURE AMPLITUDE ........................... 3-22

SECTION 4 ........................... PARTS

MODEL PARTS ............................................. 4-1

SECTION 5 .................... DIAGRAMS

ZP26/28 EXPLODED VIEW .................................5-1

50” WIRING DIAGRAM - BACK ........................... 5-2

60” WIRING DIAGRAM - BACK ........................... 5-3

50/60” WIRING DIAGRAM - FRONT .....................5-4

56” WIRING DIAGRAM - BACK ........................... 5-5

65” WIRING DIAGRAM - BACK ........................... 5-6

56/65” WIRING DIAGRAM - FRONT .....................5-7

ZP26/28 SRS PWB .......................................... 5-8

SECTION 6 .................. SCHEMATICS

CONVERGENCE CIRCUIT 1/2 ...............................6-1

CONVERGENCE CIRCUIT 2/2 ...............................6-2

MAGIC FOCUS CIRCUIT ..................................... 6-3

DEFLECTION POWER SUPPLY CIRCUIT .................. 6-4

DEFLECTION CIRCUIT ....................................... 6-5

POWER SUPPLY CIRCUIT ................................... 6-6

SIGNAL CIRCUIT 1/4 ....................................... 6-7

SIGNAL CIRCUIT 2/4 ....................................... 6-8

SIGNAL CIRCUIT 3/4 ....................................... 6-9

SIGNAL CIRCUIT 4/4 ..................................... 6-10

SRS CIRCUIT ................................................ 6-11

VELOCITY MODULATOR CIRCUIT ........................ 6-12

PV154 - 923-03506 ZP26/28 - TOC

TOC-1

Page 6

Page 7

SECTION 1

OVERVIEW

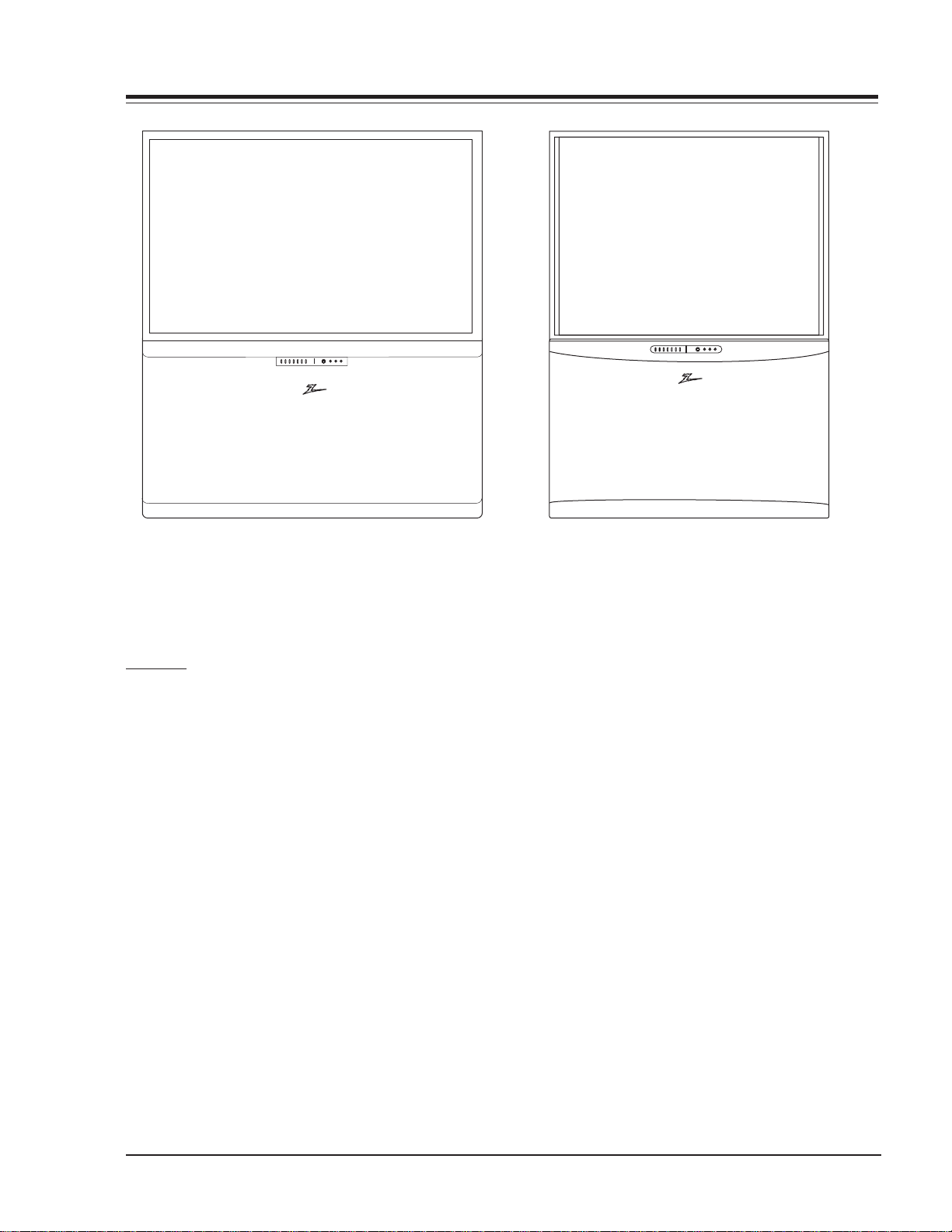

R56W28 & R65W28 R50V26 & R60V26

OVERVIEW

The R56/65W28 and R50/60V26 are HDTV Monitors. This means that most of the components of a HDTV are present

except for the ASTC tuner. An HDTV receiver or converter box is required to view an ASTC signal. The W28 models feature

a 16:9 aspect ratio screen. But, it can display video in several different aspect ratios, including 16:9 and 4:3. More

features and specifications are listed below.

Currently the ZP-26/28 chassis is module level repair only. Schematics and PCB layouts are provided to assist in

troubleshooting. Follow the normal procedures required for module level repair.

FEATURES

ENHANCED HD LENS SYSTEM

New 4 Element enhanced lens system improves brightness

and focus over the previous 25 series and provides a

more natural looking and true-to-life picture.

HD FOCUS (W28 MODELS)

Automatic system that eliminates the need to manually

adjust the picture. Simply select HD focus from the

onscreen set-up menu, and in approximately 8-10

seconds, over 8,000 points on the screen are adjusted,

for perfect center to edge focus of the image.

DIGITAL FOCUS ARRAY (V26 MODELS)

New advanced convergence technology is more accurate

than previous digital convergence, and is set at the

factory by a computer. The 9-Point system actually looks

at 117 points, since it interpolates between points,

yielding an image that is sharp from center to edge.

IMPROVED-HD DRIVER

Most HDTVs use upconversion of analog signals (line-

doubling) to simulate an HD picture, which introduces

artifacts that appear as pixilated scenes due to digital

conversion. Improved-HD dramatically improves this

process and produces images free rom picture artifacts

by increasing both vertical and horizontal resolution. True

HD signals are not affected by this process, leaving them

as true to life as possible.

IMPROVED PICTURE

Zenith’s 26 and 28 series projection televisions feature a

.52mm screen pitch, improved image scaling, and new 7"

CRTs yielding sharper images and finer detail. This

represents significant improvement compared to our

previous 94/95/25 series. The screen also features a

scratch resistant coating.

3:2 PULLDOWN DETECTION

Most movies are shot on film, and film operates at a frame

rate of 24fps (frames per second), compared to video

which operates at 30fps, 3:2 pulldown properly detects

and syncs film to video for smooth theater like pictures

at home.

PV154 - 923-03506 1-1 ZP26/28 - OVERVIEW

Page 8

OVERVIEW

R50/60V26 SPECIFICATIONS

VIDEO

Picture Tubes .......................................... 7" LFM

Resolution Display .......................... 540p or 1080i

Mirror ........................................ 1st Surface Glass

Lens System ..................................... Enhanced HD

Tuning System ....................... NTSC + Up Converter

Scan Velocity Modulation ................ Advanced SVM

Dynamic Focus ............................................... Yes

Digital Convergence ....................... 9-Point Digital

Color Temperature .......................... Cool/Warm/STD

Comb Filter .................................... Digital 3D Y/C

Horizontal Lines Resolution .......................... 1200

Picture In Picture (PIP) ........................... 2 Tuner

Advanced features .. Light Sentry, Detail Enhance, Su-

per Contrast, Gamma Correction, Auto Flesh Tone, Wide

Band Video Amp

AUDIO

Front Surround (SRS) ...................................... Yes

Mono/Stereo/MTS/SAP ............................ MTS/SAP

Bass/Treble/Balance (Tone Control) ................... Yes

Total Audio (Watts) ....................... 24W (2 x 12W)

Auto Noise Cancel .......................................... Yes

Audio Boost ......................................... Loudness

SPECIAL FEATURES

HD Monitor ................................... Digital Display

Displays Digital Signals at 540p

or 1080i (User Selects)

Tri-lingual Menus ............. English, Spanish, French

Other features .. Icon Menus, Source ID, Channel La-

bels, Parental Control with VChip, On/Off Timer, Flashback, CC,

CC When Mute, 2 Level Mute,

Channel Review, Channel Skip,

Power Resume, On/Off Speaker Selection, Date/Time/Channel

CABINET

Dimensions and weight:

R50V26: 43.5"w x 52"h x 23.5"d @177Lbs

R60V26: 51.5"w x 60.5"h x 26.5"d @226Lbs

Finish ............................................... Light Silver

Screen Protector .............................High Contrast

Swivel/Casters .......................................... Casters

Control Panel Escut. (Buttons) ........................... 8

REMOTE CONTROL

Transmitter Universal Remote w/Glow Channel & Vol-

ume

Model Number .......................................MBR5045

APPROVALS

UL, C-UL, NOM ....................................... UL, C-UL

UPC Code ............................. 50”:04464200642 6

60”:04464200632 7

SERVICE/LIMITED WARRANTY

Service Support Level.................. “M” Module Level

Warranty: Parts/CRT/Labor ...... 1 Year/2 Years/1 Year

R56/65W28 SPECIFICATIONS

VIDEO

Picture Tubes .......................................... 7" LFM

Resolution Display .......................... 540p or 1080i

Mirror ........................................ 1st Surface Glass

Lens System ..................................... Enhanced HD

Tuning System ....................... NTSC + Up Converter

Lens Elements .................................................. 4

Lens Filters......................Red & Green Color Purity

Screen w/Surface Diffuser ........ 160° Viewing Angle

Scan Velocity Modulation ................ Advanced SVM

Dynamic Focus ............................................... Yes

Digital Convergence ....................... 9-Point Digital

Picture In Picture (PIP) .................................. Yes

Picture Outside Picture (POP) .......... 3/Split Screen

Color Temperature .......................... Cool/Warm/STD

Black Level Exp./White Level Compression NTSC Fixed

Home Theater Mode TV, Movie, Sports, Music, Reset

Comb Filter .................................... Digital 3D Y/C

Horizontal Lines Resolution .......................... 1200

Picture In Picture (PIP) ........................... 2 Tuner

Aspect Ratio.......... Normal, Wide, Panoramic, Zoom

Advanced features .. Light Sentry, Detail Enhance, Su-

per Contrast, Gamma Correction, Auto Flesh Tone,

Wide Band Video Amp

AUDIO

Front Surround (SRS) ...................................... Yes

Mono/Stereo/MTS/SAP ............................ MTS/SAP

Bass/Treble/Balance (Tone Control) ................... Yes

Total Audio (Watts) ....................... 24W (2 x 12W)

Auto Noise Cancel .......................................... Yes

Audio Boost ......................................... Loudness

PV154 - 923-03506 1-2 ZP26/28 - OVERVIEW

Page 9

OVERVIEW

STEREO

ST/ SAP TV - PG DLSV

ANT 1 110

ABC

10:00AM

PIP ANT 1 14

SKIP ( C. S.)

OFF 10:05

AM

SLEEP 0:01

STEREO

ST / SAP TV - PG DLSV

ANT 1 110

ABC

10:00AM

May 14 2002

C. SKIP ( C. S. )

OFF 10:05 AM

SLEEP 0:01

TV

Normal

TV

Normal

MAIN PICTURE SOURCE

CHANNEL LABEL

TIME

Displays Main Picture Source

Active source highlighted).

Displays channel label you

have chosen.

Displays clock setting.

MONTH/DATE/YEAR

Shows current month, date,

and year.

PICTURE FORMAT

Shows current Theater mode

setting.

RATING BROADCAST

AUDIO BROADCAST

Displays the rating for the program

currently being broadcast.

Displays signal’s audio broadcast.

AUDIO SELECTED

CHANNEL SKIP

SECURITY TIMER

SLEEP TIMER SET

Displays signal’s audio setting.

Shows that Channel Skip is active.

Displays time that TV is set to

turn off.

Displays time left on Sleep Timer

before TV shut off.

SPECIAL FEATURES

HD Monitor Digital DisplayDisplays Digital Signals at

540p or 1080i (User Selects)

Tri-lingual Menus ............ English, Spanish, French

Other features .. Icon Menus, Source ID, Channel La-

bels, Parental Control with VChip, On/Off Timer, Flashback,

CC, CC When Mute, 2 Level Mute,

Channel Review, Channel Skip,

Power Resume, On/Off Speaker

Selection, Date/Time/Channel,

Energy Star®

CABINET DESCRIPTION

Dimensions and weight:

R56W28: 54.1"W x 52.21"H x 24.2"D

R65W28: 60.01"W x 62.01"H x 26.3"D

Finish ............................................... Light Silver

Screen Protector .............................High Contrast

Swivel/Casters .......................................... Casters

Control Panel Escut. (Buttons) ........................... 8

REMOTE CONTROL

Transmitter ..................... Universal Remote w/Glow

Model Number .......................................MBR5045

APPROVALS

UL, C-UL, NOM ....................................... UL, C-UL

UPC Code ............................ 56”:04464200622 8

65”:04464200612 9

SERVICE/LIMITED WARRANTY

Service Support Level..................... “M” Module Level

Warranty: Parts/CRT/Labor ......... 1 Year/2 Years/1 Year

ON SCREEN DISPLAY

PV154 - 923-03506 1-3 ZP26/28 - OVERVIEW

Page 10

OVERVIEW

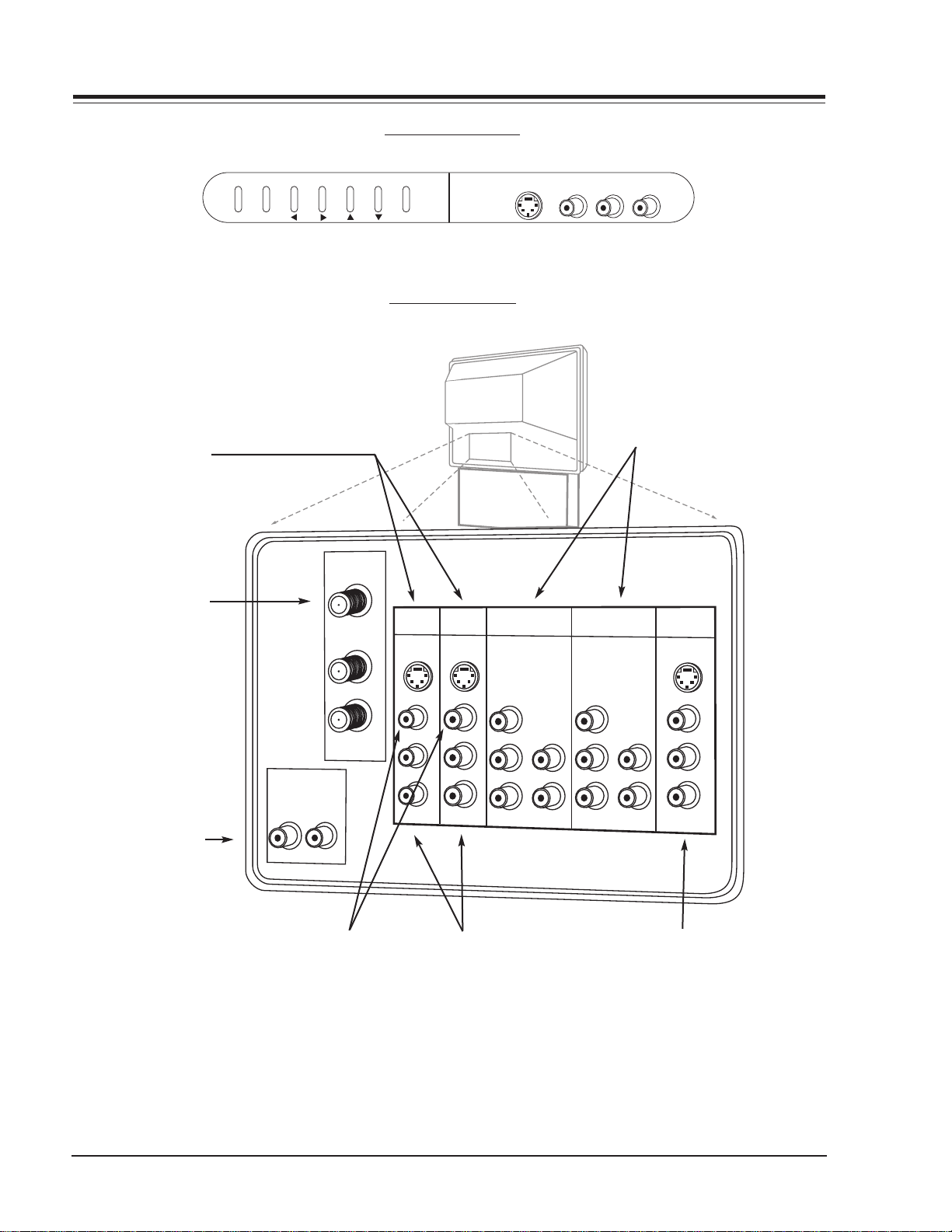

FRONT CONNECTIONS

S-Video Input 1 and 2

Connections available

for some high-end

equipment that provides

even better picture

quality.

RF Connectors:

Antenna/Cable 1,

Antenna/Cable 2,

and Cable Box

Used to connect cable

service to the television,

either directly or

through your cable box.

menu source

exit

select

- volume + - channel +

ANTENNA/

CABLE 1

TO CABLE

BOX

power

REAR CONNECTIONS

INPUT 1 INPUT 2

VIDEO

S-VIDEO

VIDEO

Y/VIDEO

S-VIDEO

S-Video

INPUT 3

Video

L/Mono

INPUT 4

Y/VIDEO

R

Inputs 3 and 4

Y, P P

BR

, , and Audio L - R

Component Video

Some top-of-the-line DVD players use

what is called “component video,” for

extremely accurate picture reproduction.

Refer to your DVD manual for

further information.

MONITOR

OUT

S-VIDEO

VIDEO

MO NO/L

P

B

P

R

R

L

R

VARIABLE

ANTENNA/

CABLE 2

MO NO/LRMO NO/L

R

MO NO/L

P

B

P

R

R

AUDIO OUT

R

L

AUDIO

AU D IO

AUDIO

AUDIO

AUDIO

Variable Audio Out

Used to connect

either an external

amplifier or add a

sub-woofer to your

surround sound system.

Video1or2

Connects the video

signals from various

types of equipment.

Right/Left Audio

Used for stereo sound

from various types of

equipment.

Monitor Out

These jacks provide fixed

audio and video signals

which are used for recording.

Use S-Video Output

for high quality video output.

PV154 - 923-03506 1-4 ZP26/28 - OVERVIEW

Page 11

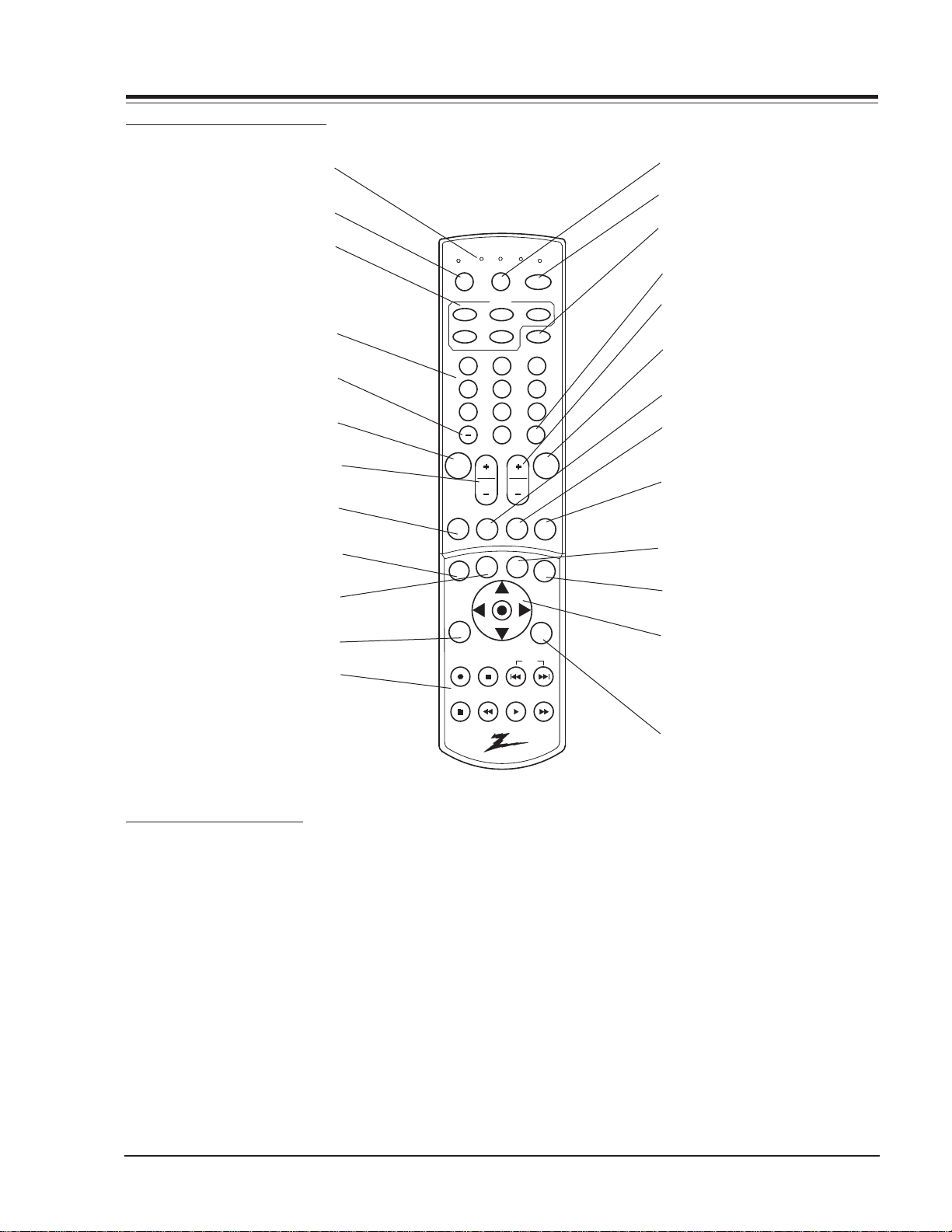

REMOTE BUTTON DESCRIPTIONS

REMOTE CONTROL

MODE INDICATOR LIGHTS

Light indicates mode when

keys are pressed.

Selects available TV sources.

TV, VCR, Cable, DVD, HD/STB

Switches remote operating mode

to control other devices. After pressing

a Mode switch key, wait2-3seconds

before pressing any other key.

NUMBER KEYPAD0-9

Selects channels directly and

enters numerical values.

DIGITAL MODE DASH

Use as the dash when selecting

digital channel numbers.

Press once for Soft Mute,

press again for full Mute.

VOL - (VOLUME) (+/-)

+ Increases the sound level.

- Decreases the sound level.

Turns the “Split Screen”

for the TV to turn off.

Turns On/Off Closed

Displays on-screen menus.

Record, Stop, Pause, REW (Rewind),

Play, FF (Fast Forward). These buttons

still operate the VCR while remote is

VCR FUNCTION KEYS

in TV operating mode.

SOURCE

MODES

MUTE

SPLIT

feature on and off.

SLEEP (TIMER)

Sets a preset time

CC

caption/text options.

MENU

Part Number

MBR6045A

924-10098

vcr

cable

tv

source

tv

dvd

dvd

light

mo de

vcr

hd/stb

123

456

789

0

mute

ch

vol

multi

CC

pip ch

fav ch

split

sleep

menu

record stop

pause rewffplay

skip

hd/stb

power

cable

aspect

display

theatr

flshbk

c skip

quit

LIGHT

Lights keys for five seconds.

POWER

Turns TV On and Off.

ASPECT

Selects different picture

proportion formats.

DISPLAY

Shows current on-screen settings.

CH - CHANNEL (+/ -)

Tunes to next higher/lower

available channel.

FLSHBK (FLASHBACK)

Returns to the previously

tuned channel.

MULTI

Turns “POP-3” feature on and off.

PIP CH

Channel tuning switch in Split

Screen mode. See Split Screen

section.

C SKIP

Channel Skip. Tunes to last channel

viewed. Tunes back to original

channel after 30, 60, 90, 120,

150, or 180 seconds.

FAVORITE CHANNEL

Select among 6 different channel

classifications.

QUIT

Leaves programming menus and

clears screen of displays

THUMBSTICK

(Menu Operation Directional

Arrows and Select key)

Up/Down arrows choose, and

Left/Right arrows adjust menu

options. Press the bulls eye Select

button in the center of the directional

arrows to confirm selection.

THEATER

Direct access to theater modes.

PROGRAMMING THE REMOTE

If you’re using Zenith products, the remote is already

programmed for most common codes. For other brands,

or if your remote fails to control your Zenith products,

4. Release the mode key. Point the remote at the device and press the POWER key. The device should

turn off. If not, try the other 3-number codes listed.

you’ll have to program the remote.

Make sure the batteries are installed and follow these

steps for each product:

1. Turn on the device to be operated.

NOTE: Use the CABLE device button for satellite receivers.

Use the DVD device button for home audio

components.

2. Press and hold the device button until the indicator

light turns on, continue holding down the device

button.

3. Now the remote control is ready to program the code

for the corresponding component. Enter the product’s

code number using the number buttons. Code numbers can be found on the following pages. The indicator light will flash three times and turn off if the

code was accepted.

PV154 - 923-03506 1-5 ZP26/28 - REMOTES

Page 12

REMOTE BRAND CODES

TVs

REMOTE CONTROL

Daewoo . . . . . . . 149

Zenith . . . . . . . . 101 121 149 152

VCRs

Admiral . . . . . . . 261

Akai . . . . . . . . . . 292 717 718 719

720

Audio Dynamics . . 726

Bell & Howell . . . . 247

Broksonic . . . . . . 221 250 255 729

Candle . . . . . . . . 727

Canon . . . . . . . . . 704

Capeheart . . . . . . 728

Citizen . . . . . . . . 727

Craig . . . . . . . . . 212

Curtis Mathes . . . 259 266 725 727

Daewoo . . . . . . . 244 246 248 254

703 729

Daytron . . . . . . . 246

DBX . . . . . . . . . . 726

Electrochrome. . . . 730

Emerson . . . . . . . 203 221 243 250

293 721 722 729

730 731 732

Fisher . . . . . . . . . 211 212 213 247

265 274

TV/VCR Combination Codes

Adventura TV/VCR . 154

Daewoo TV/VCR . . 148

General Electric . . 216 220 266 282

701 702 725

Go Video . . . . . . . 256 262 263 700

Goldstar . . . . . . . 253

Harmon Kardon. . . 296

Hitachi . . . . . . . . 257 270 273 292

705 706 707 708

J.C. Penny . . . . . . 268 726

Jensen . . . . . . . . 292

JVC . . . . . . . . . . 224 225 258 268

292 299 726

Kenwood . . . . . . . 268 292 726 727

Magnavox . . . . . . 275

Marantz . . . . . . . 267 268 726 727

Memorex . . . . . . . 212 298

MGA . . . . . . . . . . 297 730

Mitsubishi . . . . . . 276 277 278 279

280 296 297 730

Montgomery Ward 216 219 249 291

730

MultiTech. . . . . . . 727

NEC . . . . . . . . . . 267 268 269 281

292 709 726

Funai TV/VCR. . . . 154

Goldstar TV/VCR . . 153 172

Symphonic TV/VCR 154

Orion . . . . . . . . . 250

Panasonic . . . . . . 245 251 259 713

714 715 716

Pentax . . . . . . . . 708 727

Philco . . . . . . . . . 275

Pioneer . . . . . . . 210 282 726

Portland . . . . . . . 246 727

ProScan . . . . . . . 216 260 266 282

725

Quasar . . . . . . . . 259 295

Radio Shack . . . . . 213 265 730

RCA . . . . . . . . . . 216 220 228 240

242 249 260 266

282 283 284 285

286 287 288 708

710 711 725

Realistic . . . . . . . 212 213 265 730

Saisho. . . . . . . . . 722

Salora . . . . . . . . . 297

Samsung . . . . . . . 220 230

Sansui . . . . . . . . 289 292 709 726

Sanyo . . . . . . . . 212 247 294

Scott . . . . . . . . . 243 290 729

Zenith TV/VCR . . . 150 152 153 154

172

Sears . . . . . . . . . 211 212 213 265

274

Sharp . . . . . . . . . 261 730

Signature 2000 . . . 216 219 249

Sony . . . . . . . . . 232 723 724

Sylvania . . . . . . . 275 297

Tatung . . . . . . . . 268 292

Teac . . . . . . . . . . 268

Teknika . . . . . . . . 272

Toshiba . . . . . . . . 213 274 290 297

Vector Research . . 726 727

Victor . . . . . . . . . 726

Video Concepts . . . 726 727

XR - 1000 . . . . . . 243

Yamaha . . . . . . . . 726

Zenith . . . . . . . . 201 224 225 229

Cable Boxes

Allegro . . . . . . . . 358 362

Allegro A-B Switch 361

Archer . . . . . . . . 325

Century . . . . . . . . 325

Citizen . . . . . . . . 325

Comtronic . . . . . . 326

Everquest. . . . . . . 379

Garrard . . . . . . . . 325

Gemini . . . . . . . . 305 331 338

General Electric. . . 367

General Instrument 304 305 306 307

308 309 310 318

923-03460 1-6 ZP26/28 - REMOTES

Hamlin . . . . . . . . 302 303 345 365

366

Jasco . . . . . . . . . 325

Jerrold . . . . . . . . 304 307 308 309

310 318 360 363

Kale Vision . . . . . 335

Macom . . . . . . . . 321

Magnavox . . . . . . 327 334

NSC . . . . . . . . . . 335 339 368 369

370

Oak . . . . . . . . . . 311 332 342

Panasonic . . . . . . 313 320

Philips . . . . . . . . 325 327 347 350

352 354 355

Pioneer . . . . . . . . 315 343

RCA . . . . . . . . . . 341

Regency . . . . . . . 329

Samsung . . . . . . . 326 335

Scientific Atlanta 316 323 336 337

364

Signal . . . . . . . . . 326

SL Marx . . . . . . . . 326

Sprucer . . . . . . . . 313

Standard Comp . . . 335

Stargate . . . . . . . 326 379

Teleview . . . . . . . 326

Texscan . . . . . . . 339 356 371

Tocom . . . . . . . . 317 318 346

Unika . . . . . . . . . 325 348 362

Universal . . . . . . 325 358 362

Vid Tech . . . . . . . 340

Video Way . . . . . . 349

Viewstar . . . . . . . 327 354 355 372

Zenith HT-2000. . . 353

Zenith PM . . . . . . 374

Page 13

REMOTE CODES

Satellite Receivers

REMOTE CONTROL

Alphastar. . . . . . . 516

Chaparral. . . . . . . 501 502

Cheyenne. . . . . . . 502

Dishnet . . . . . . . . 515

Drake . . . . . . . . . 503

General Electric. . . 510 517

General Instrument 504 505

Hitachi . . . . . . . . 519 520

DVD Players

JVC . . . . . . . . . . 965

Mitsubushi. . . . . . 964

Audio CD Players

ADC . . . . . . . . . . 940

ADO . . . . . . . . . . 939

Aiwa. . . . . . . . . . 938

Akai . . . . . . . . . . 937

Denon . . . . . . . . 935

Dynatech . . . . . . . 953

Emerson . . . . . . . 952

Fisher . . . . . . . . . 438 933 951

GE . . . . . . . . . . . 932

Goldstar . . . . . . . 460

Hitachi . . . . . . . . 950

Hughes Network . . 514

JVC . . . . . . . . . . 518

Macom . . . . . . . . 314

Magnavox . . . . . . 521

Phillips . . . . . . . . 521

PrimeStar. . . . . . . 513

ProScan. . . . . . . . 510 517

RCA DSS . . . . . . . 373

Pioneer . . . . . . . . 963

Sony. . . . . . . . . . 962

JVC . . . . . . . . . . 949 954

Kenwood . . . . . . 441 931 948

Luxman . . . . . . . . 930

Magnavox . . . . . . 421 422 433 434

Marantz. . . . . . . . 929 947

MCS . . . . . . . . . . 928

Mitsubishi . . . . . . 927

Nakamichi . . . . . . 925 926

Onkyo . . . . . . . . 923 924 946

Optimus . . . . . . . 920 921 922

Panasonic . . . . . . 431 432 945

RCA . . . . . . . . . . 510 517

Realistic . . . . . . . 506

Sierra I . . . . . . . . 502

Sierra II . . . . . . . 502

Sierra III . . . . . . . 502

Sony. . . . . . . . . . 511

STS1 . . . . . . . . . . 507

STS3 . . . . . . . . . . 508

Toshiba . . . . . . . . 961

Zenith. . . . . . . . . 960

Phillips . . . . . . . . 421 433 434

Pioneer . . . . . . . . 431 435 944

Quasar . . . . . . . . 432

Radio Shack . . . . . 431 441

RCA . . . . . . . . . . 437 943

Sanyo . . . . . . . . . 438 439

Sears . . . . . . . . . 936

Sharp . . . . . . . . . 441 442

Sherwood . . . . . . 449

Sony. . . . . . . . . . 420 443 444 445

934

Toshiba . . . . . . . . 509 512

Uniden . . . . . . . . 522

United . . . . . . . . 344

Zenith Drake. . . . . 312 330

Zenith Satellite . . 328 351 378 500

Soundesign . . . . . 461 498 901 902

Sylvania . . . . . . . 433

Teac . . . . . . . . . 418 419

Technics . . . . . . . 432

Toshiba . . . . . . . . 915

Yahama . . . . . . . . 414 941 942

Zenith . . . . . . . . 460 461 498 901

902

Zenith CD Recorder 415

Audio Tape Decks

Sony. . . . . . . . . . 452

Audio Tuners/Amps

Citizen . . . . . . . . 914

GE . . . . . . . . . . . 916

Goldstar . . . . . . . 460 474

Hitachi . . . . . . . . 919

JVC . . . . . . . . . . 908

Kenwood . . . . . . . 484

Luxman . . . . . . . . 467

Marantz. . . . . . . . 903 913

Memorex . . . . . . . 485

Nad . . . . . . . . . . 904

Nakamichi . . . . . . 493

Onkyo . . . . . . . . 471 906

Optimus . . . . . . . 905

Panasonic . . . . . . 912

Pioneer . . . . . . . . 470 485 907

Proton . . . . . . . . 910

Quasar . . . . . . . . 912

RCA . . . . . . . . . . 909

Sharp . . . . . . . . . 483 917 918

Sherwood . . . . . . 900

Sony. . . . . . . . . . 486 489 490

491 492

Soundesign . . . . . 461 498 901

Techniques. . . . . . 912

Toshiba . . . . . . . . 915

Victor . . . . . . . . . 908

Zenith . . . . . . . . 460 461 498

HD/Set Top Boxes

Echostar . . . . . . . 805

Hughes . . . . . . . . 803

PV154 - 923-03506 1-7 ZP26/28 - REMOTES

Philips . . . . . . . . 802

RCA . . . . . . . . . . 804

Sony. . . . . . . . . . 801

Zenith. . . . . . . . . 800

902

901 902

Page 14

REMOTE CONTROL

OPERATING MODE KEY FUNCTIONS

KEY NAME TV Mode VCR Mode Cable Mode DVD Mode HD/STB Mode

source TV Sources TV Sources TV Sources TV Sources TV Sources

light Lights Keys 5 Seconds Lights Keys 5 Sec Lights Keys 5 Sec Lights Keys 5 Sec Lights Keys 5 Sec

power TV On/Off VCR On/Off Cable Box On/Off DVD On/Off HD/STB On/Off

tv Selects TV Selects TV Selects TV Selects TV Selects TV

vcr Selects VCR Selects VCR Selects VCR Selects VCR Selects VCR

cable Selects Cable Selects Cable Selects Cable Selects Cable Selects Cable

dvd Selects DVD Selects DVD Selects DVD Selects DVD Selects DVD

hd/stb Selects HD/STB Selects HD/STB Selects HD/STB Selects HD/STB Selects

HD/STB/direcTV

aspect Selects Aspect Ratio N/A N/A N/A Selects Aspect Ratio

Formats Formats

1 TV Digit 1 VCR Digit 1 Cable Digit 1 DVD Digit 1 HD/STB Digit 1

2 TV Digit 2 VCR Digit 2 Cable Digit 2 DVD Digit 2 HD/STB Digit 2

3 TV Digit 3 VCR Digit 3 Cable Digit 3 DVD Digit 3 HD/STB Digit 3

4 TV Digit 4 VCR Digit 4 Cable Digit 4 DVD Digit 4 HD/STB Digit 4

5 TV Digit 5 VCR Digit 5 Cable Digit 5 DVD Digit 5 HD/STB Digit 5

6 TV Digit 6 VCR Digit 6 Cable Digit 6 DVD Digit 6 HD/STB Digit 6

7 TV Digit 7 VCR Digit 7 Cable Digit 7 DVD Digit 7 HD/STB Digit 7

8 TV Digit 8 VCR Digit 8 Cable Digit 8 DVD Digit 8 HD/STB Digit 8

9 TV Digit 9 VCR Digit 9 Cable Digit 9 DVD Digit 9 HD/STB Digit 9

0 TV Digit 0 VCR Digit 0 Cable Digit 0 DVD Digit 0 HD/STB Digit 0

- N/A N/A Cable/Satellite Dash DVD Zoom HD/STB Dash

display TV Display VCR Memory N/A DVD Display N/A

mute TV Mute TV Mute TV Mute TV Mute/Sound TV Mute

volume (up) TV Volume Up TV Volume Up TV Volume Up TV Volume Up TV Volume Up

volume (down) TV Volume Down TV Volume Down TV Volume Down TV Volume Down TV Volume Down

channel (up) TV Channel Up VCR Channel Up Cable Channel Up DVD Skip>> HD/STB Channel Up

channel (down) TV Channel Down VCR Channel Down Cable Channel Down DVD Skip << HD/STB Channel Down

flashbk TV Flashback TV Flashback Cable Flashback DVD Return HD/STB Flashback

split TV Split Screen On/Off VCR+ Cable/Sat Day Up DVD Marker N/A

multi TV POP-3 Multi On/Off VCR Search Cable/Sat Day Down DVD Repeat a-b N/A

pip ch TV Split Screen Channel VCR Display N/A DVD Marker Search STB Signal

Tuning Switch

c skip Channel Skip VCR am/pm N/A DVD Clear N/A

sleep TV Sleep Timer VCR Timer Cable/Sat Timer DVD Repeat Chap N/A

cc TV Closed Captions TV Closed Captions Cable/Sat Page Up DVD Sub Title N/A

923-03460 1-8 ZP26/28 - REMOTES

Page 15

USER MENUS

REMOTE CONTROL

KEY NAME TV Mode VCR Mode Cable Mode DVD Mode HD/STB Mode

fav ch (Channel) TV Favorite Channels VCR Channel Map Cable Page Down N/A N/A

quit TV Menu Quit VCR Quit Cable Quit DVD Resume HD/STB Quit

up arrow TV Select Up VCR Select Up Cable/Sat Up Arrow DVD Up Arrow HD/STB Up Arrow

down arrow TV Select Down VCR Select Down Cable/Sat Down Arrw DVD Down Arrow HD/STB Down arrow

left arrow TV Adjust Left VCR Tracking Down Cable/Sat Left Arrow DVD Left Arrow HD/STB Left arrow

Favorite Channels

right arrow TV Adjust Right VCR Tracking Up Cable/Sat Right Arrw DVD Right Arrow HD/STB Right arrow

Favorite Channels

Push “Select”

~ TV Menu Item Select VCR Enter Cable/Sat Enter DVD Enter HD/STB Enter

menu TV Menu VCR Menu Cable/Sat Menu DVD Menu HD/STB Menu

Disc Menu

theater TV Theater Modes N/A Cable/Sat Info DVD Open Close HD/STB Info

record VCR Record VCR Record Cable/Sat Buy DVD Angle N/A

stop VCR Stop VCR Stop VCR Stop DVD Stop/Eject VCR Stop

I<< skip DVD Skip I<< DVD Skip I<< DVD Skip I<< DVD Skip I<< DVD Skip I<<

skip >>I DVD Skip >>I DVD Skip >>I DVD Skip >>I DVD Skip >>I DVD Skip >>I

pause VCR Pause VCR Pause Cable/Sat Guide DVD Pause HD/STB Guide

rew (rewind) VCR Rewind VCR Rewind VCR Rewind DVD Scan << VCR Rewind

play VCR Play VCR Play VCR Play DVD Play VCR Play

ff VCR Fast Forward VCR Fast Forward VCR Fast Forward DVD Scan >> VCR Fast Forward

Reference: MBR6045, 924-10098

PV154 - 923-03506 1-9 ZP26/28 - REMOTES

Page 16

USER MENUS

USER MENUS

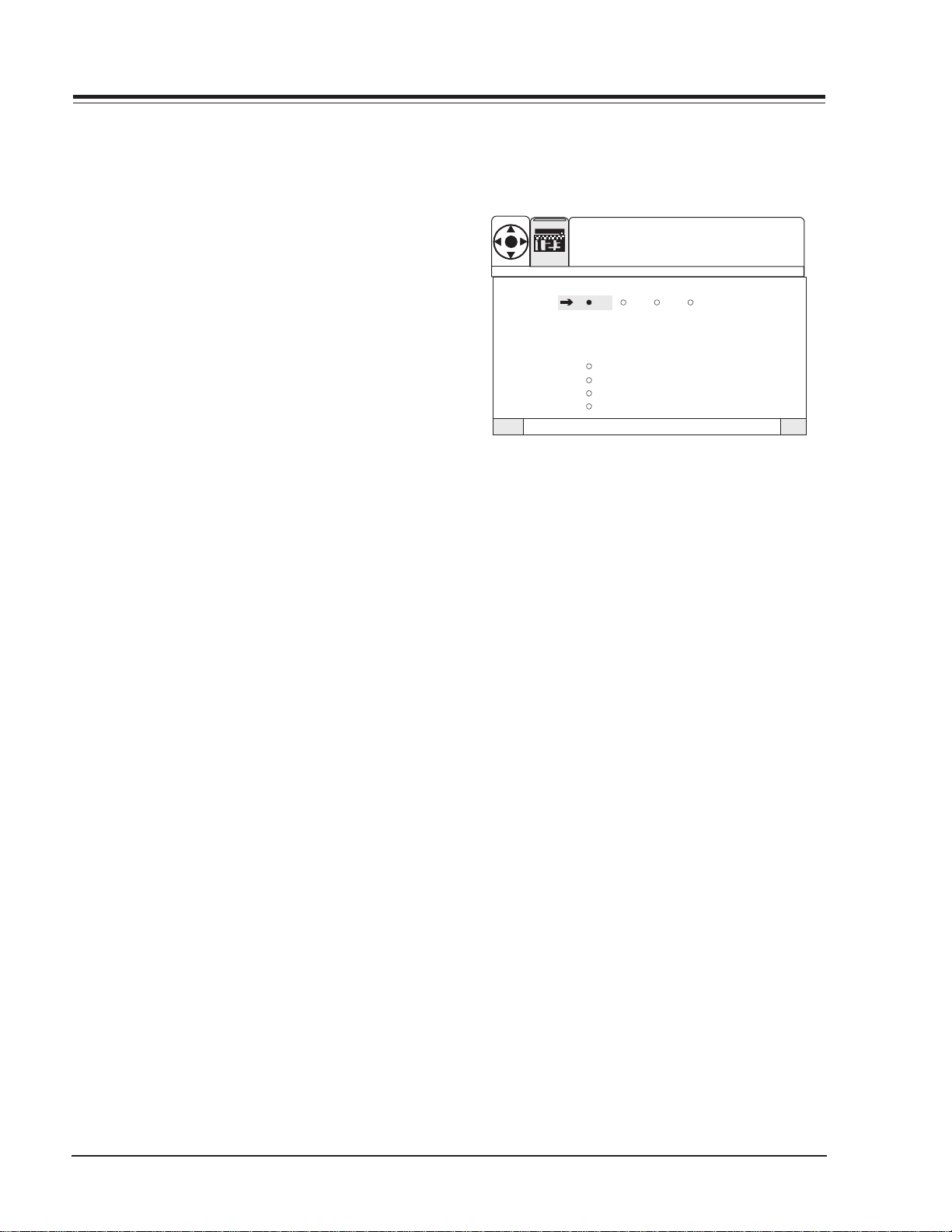

SETUP

TRILINGUAL MENUS

Press MENU to access the Setup menu. Use the DOWN

arrow to choose Trilingual. Press the RIGHT arrow

button to activate the Language menu option.

Use the UP/DOWN arrow button to choose your language

preference for the on-screen menus, press Select to

set and confirm. Press QUIT to exit and save your

choice.

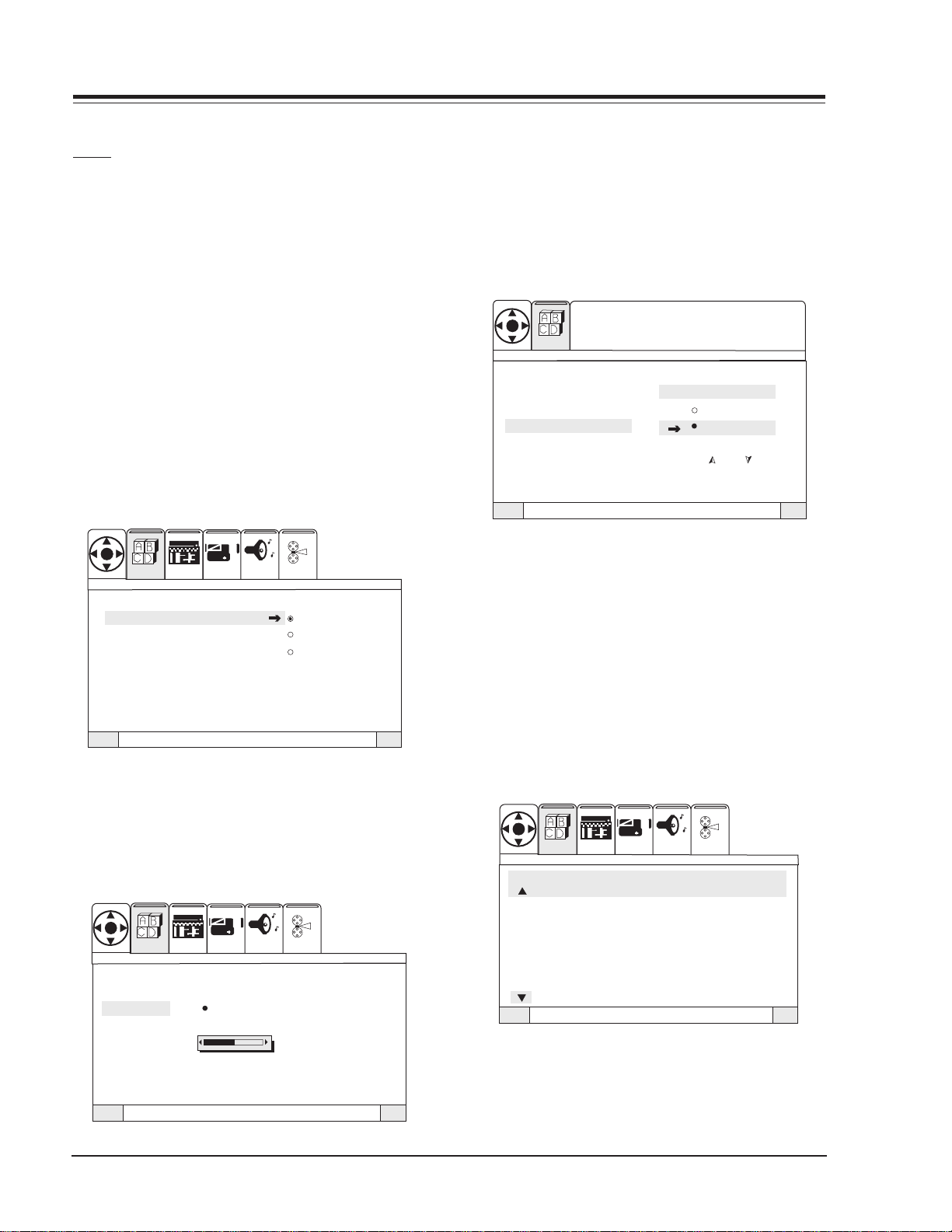

SIGNAL SOURCE

Select Signal using the DOWN arrow button. Activate

the Signal Menu option by pressing the RIGHT arrow

button. If your signal comes from an outdoor antenna,

leave set at ANTENNA. If your signal comes from a cable

TV service, select CATV 1 by pressing the DOWN arrow

button. Press “select” to set (confirm) your choice,

then press the MENU button to return to the Setup

Menu. Now scan for avaible channels.

SEL

VIDEOSETUP AUDIO THEATER

SPECIAL

Trilingual Menus

Signal Antenna

Scan CATV 1

Channel Add/Del CATV 2

Channel Review

Clock Set

HD Focus

Picture Formats

QuitTo ExitTo Menu BarMenu

SCAN

Choose Scan mode by pressing the DOWN arrow button

on your remote. Press the RIGHT arrow button to

choose Scan. Press the SELECT button on your remote

to begin Scan (the channel search).

SEL

VIDEOSETUP AUDIO THEATER

SPECIAL

Trilingual Menus

Signal

Scan

Channel Add/Del

Channel Review

Clock Set

HD Focus

Picture Formats

Installing

Channel 110

50% Complete

QuitTo ExitTo Menu BarMenu

If certain CATV channels are not received clearly in

CATV1 mode, set the source to CATV2 mode.

CHANNEL ADD/DEL (DELETE)

Customize your channel selection list: Add Channels

not found by Scan (Channel Search), Delete channels

you don’t watch. Channels will appear when using

Channel Up/Down Press the MENU button on your

remote to access the Setup menu.

SEL

SETUP

Trilingual Menus

Signal Channel 03

Scan Add

Channel Add/Del Erase

Channel Review Next Channel

Clock Set Ch Ch

HD Focus Or # Keys

Picture Formats

Press select to set

QuitTo ExitTo Menu BarMenu

Use the UP/DOWN arrow to choose Channel Add/Del.

Press the RIGHT arrow button to activate the Channel

Add/Del menu option. Use the UP/DOWN arrow button

to choose the Add or Erase option for the currently

chosen channel, press Select to set and confirm your

choice. Press QUIT to exit and save your choice or use

the Channel UP/DOWN buttons/numbers to choose

another channel to Add or Erase.

CHANNEL REVIEW

Use the UP/DOWN arrow to choose the Channel Review

option. Use the RIGHT arrow button to activate the

Channel Review menu option.

SEL

VIDEOSETUP AUDIO THEATER

SPECIAL

CHANNEL REVIEW Ant 1

Ch Id Scan Lock

1 **** ON ON

2 **** - - - -

3 **** - - - -

4 **** - - - -

5 **** - - - -

6 **** - - - -

7 **** - - - -

8 **** - - - -

QuitTo ExitTo Menu BarMenu

Use the UP/DOWN arrow button to cycle through your

channel list and review the settings. (Each press of

Up/Down arrows will display the next eight channels.)

Press QUIT to exit.

PV154 - 923-03506 1-10 ZP26/28 - MENUS

Page 17

USER MENUS

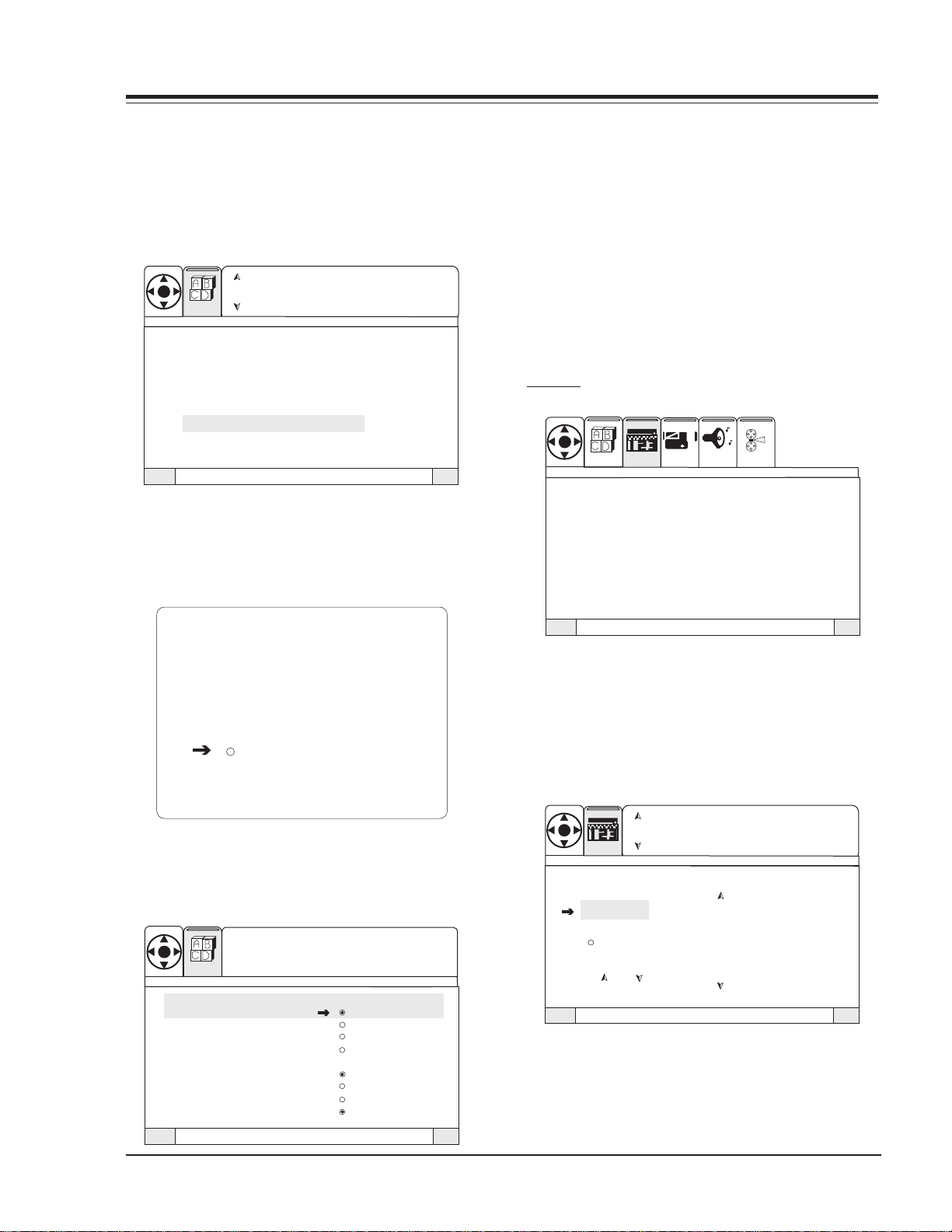

CLOCK SET

Use the UP/DOWN arrow to choose Clock Set. Use the

RIGHT arrow button to choose first the time option

and use the UP/DOWN arrow buttons to adjust time

options. Press the RIGHT arrow button and then use

the UP/DOWN arrow buttons to adjust month/date/

year options. Press QUIT to save and exit.

SEL

SETUP

Trilingual Menus

Signal

Scan

Channel Add/Del

Channel Review

Clock Set

HD Focus

Picture Formats

TO SET TIME

12 : 00 Am

May 02 2002

QuitTo ExitTo Menu BarMenu

HD FOCUS

Use the UP/DOWN arrow to choose HD Focus. Press the

RIGHT arrow button to go to the HD Focus option.

Press Select to adjust color convergence automatically.

Use the RIGHT arrow button to access the Picture

formats Menu. Choose and set the options based on

your equipment’s signal requirements for highdefinition or standard NTSC sources. Aspect Style:

Normal, Wide, Zoom, or Panorama. Vertical Position

sets the image’s vertical position on screen. Comp.

Color Type: HDTV or SDTV/DVD. Video Display: 1080i

or 540p. Press SELECT to set and confirm your settings.

Press QUIT to save and exit.

Note: 1080i signal source settings are fixed while other

signal source formats are adjustable

(1080i=1080i) (TV converts 720p to 540p, 480p

to 540p, 480i to 540p.).

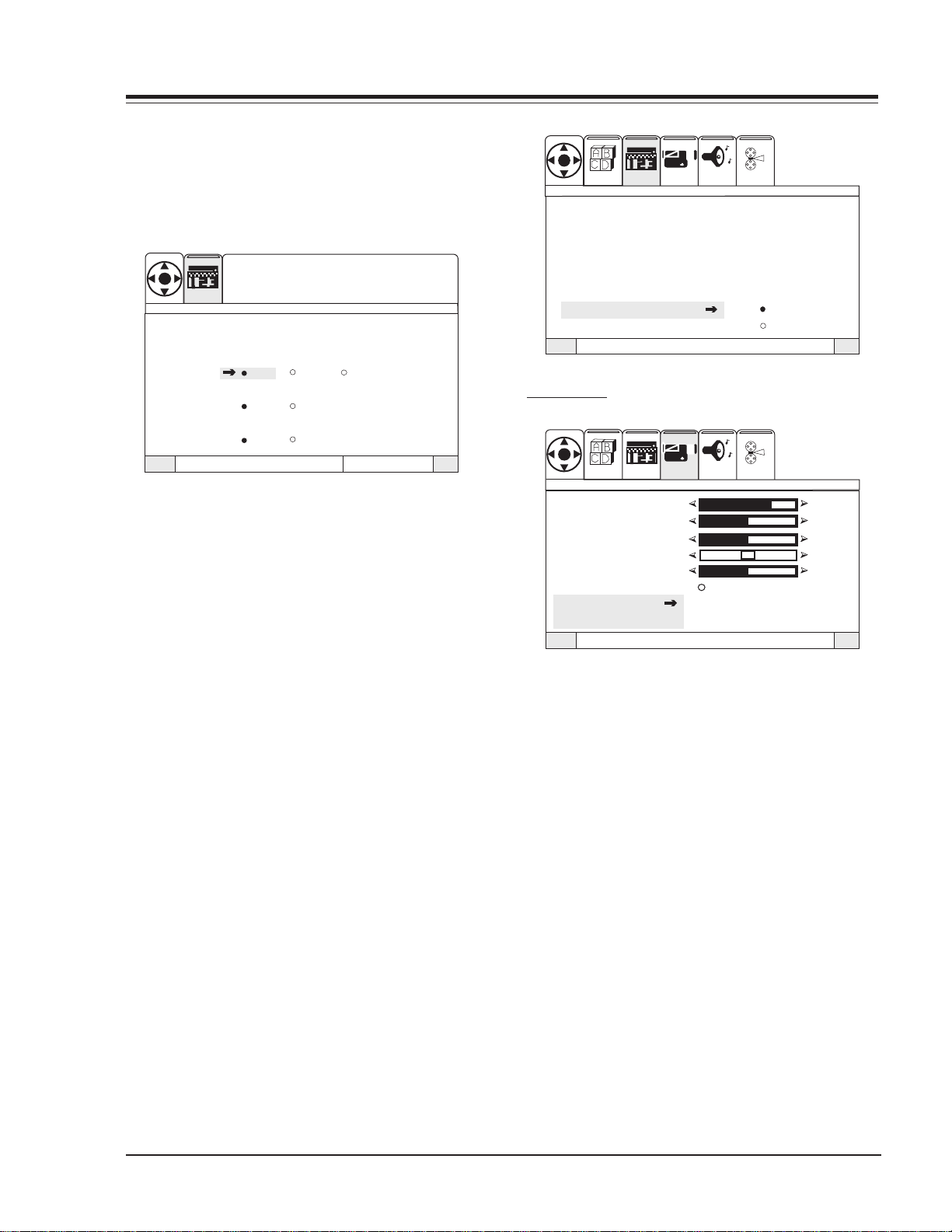

SPECIAL

SEL

SPECIAL

Channel Labels

Source I D

Favorite Channels

Parental Control

Security Timer

Caption/Text

Background

VIDEOSETUP AUDIO THEA

TER

Press the Select Button on

The Remote Control To Begin

The Alignment System

Begin

PICTURE FORMATS

Fine-tune High Definition and standard NTSC analog

signal source images.

SEL

SETUP

Picture Formats Ant 1 26

Aspect Style

V. Position +4

Comp. Color Type HDTV

Video Display 1080i

Press select to set

Normal

Wide

Zoom

Panorama

SDTV/DVD

540p

QuitTo ExitTo Menu BarMenu

QuitTo ExitTo Menu BarMenu

CHANNEL LABELS

Tune to a channel you want to label. Press MENU on

your remote and then use the RIGHT/LEFT arrow button

to access the Special Menu. Use the UP/DOWN arrow

to choose Channel Labels. Press the RIGHT arrow button

to activate the Channel Labels option.

SEL

SPECIAL

Channel Labels

Ch03 XXXX

Ch Labels

Custom

Reset

Next Ch

Ch Ch

Or #Keys

To Change Letter

ABC

CBS

ESPN

HBO

NBC

SHOW

QuitTo ExitTo Menu BarMenu QuitTo ExitTo Menu BarMenu

At this point you have three options:

• Select a pre-set channel label by choosing Ch Labels.

• Customize a channel label by choosing Custom Ch.

• Delete a channel label entirely by choosing Reset.

PV154 - 923-03506 1-11 ZP26/28 - MENUS

Use the UP/DOWN arrow to choose Picture Formats.

Page 18

USER MENUS

Use the UP/DOWN arrows to choose an option. If you

chose Ch Labels, press the RIGHT arrow button to access

the preset channel label list and scroll through this

list using the UP/DOWN arrow buttons. When you find

the appropriate label for the channel, press the SELECT

button.

If you select Custom Channel, press the RIGHT arrow

button once and then use the UP/DOWN arrow buttons

to select individual letters and LEFT/RIGHT arrow

buttons to choose placement of letters.

If you wish to delete a channel label, choose Reset

using the UP/DOWN arrow buttons and then press the

SELECT button on your remote. You will be asked “Are

You Sure?” press SELECT again if you are sure.

Use CHANNEL UP/DOWN buttons or the NUMBER KEYPAD

and choose another channel to label. Repeat steps for

all channels you wish to label. Press QUIT to save and

exit.

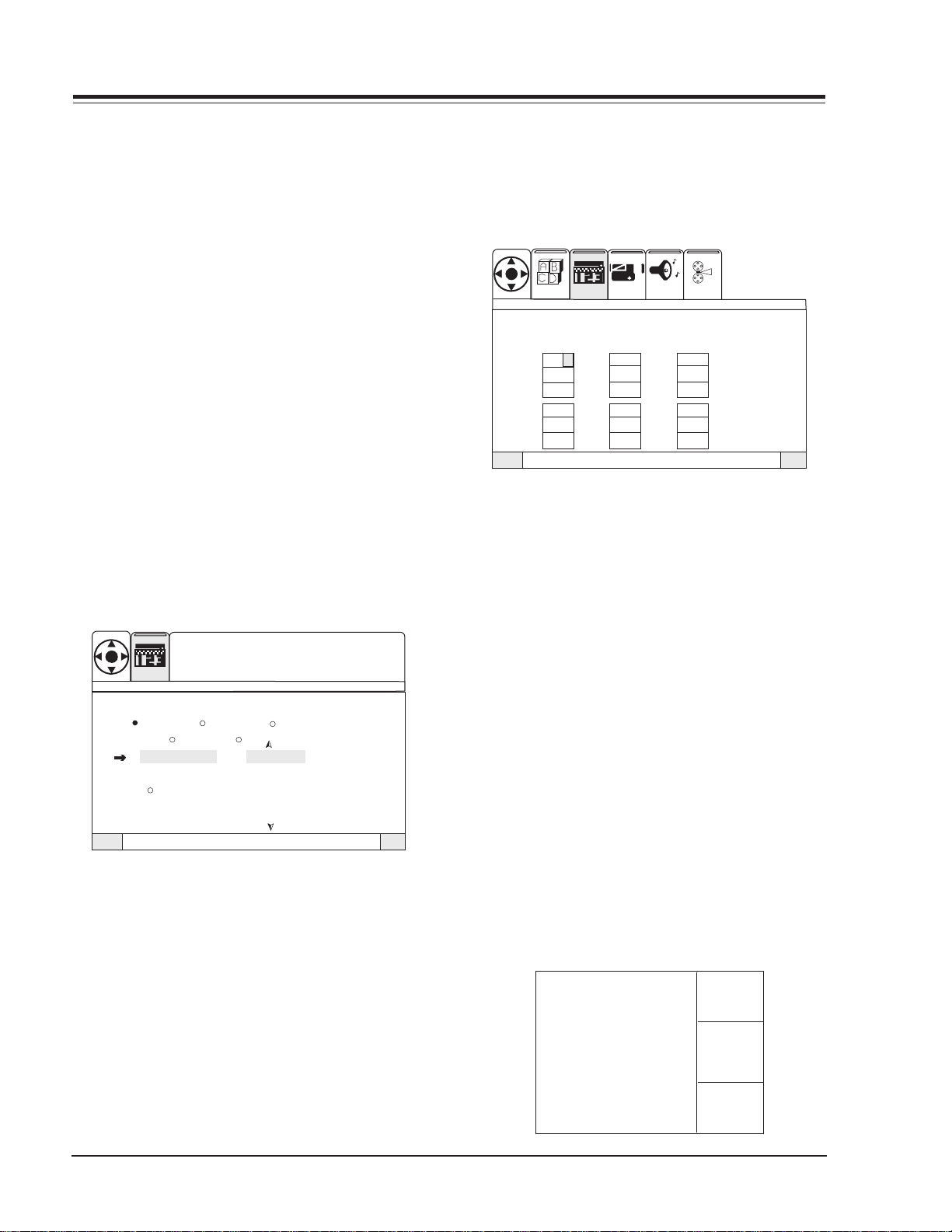

SOURCE ID

Choose preset names or create your own titles for

available picture/sound input sources. Use the UP/

DOWN arrow to select Source ID. Press the RIGHT arrow

button to activate the Source option. Use the RIGHT

arrow button to choose: In 1, In 2, 3, In 4, or In 5

(for front video jacks).

SEL

SPECIAL

Source I.D.

IN 1 IN 2 IN 5

Source List

Custom

Press select to set

IN 3 IN 4

VCR 1

CD

Reset

DVD

TAPE

LD

AUX

QuitTo ExitTo Menu BarMenu

Use the UP/DOWN arrow buttons to go to Source List

and choose a pre-set Source identification, Custom

to create your own label, or pick Reset to clear all

labels.

If you chose Source List, press the RIGHT arrow button

to access the list and then use the UP/DOWN arrow

buttons to pick an ID from the list. Press SELECT to

save your choice.

If you wish to customize your source ID, go to Custom

and press the RIGHT arrow button. Cycle through the

character choices using the UP/DOWN buttons and

cycle through the character slots using the RIGHT arrow

button. Press QUIT to save your choice and exit.

Note: Use * for blank spaces.

To delete a Source ID, select Reset, then press the

SELECT button. You will be asked “Are You Sure?” Press

SELECT again and then press QUIT to save and exit.

FAVORITE CHANNELS

SEL

VIDEOSETUP AUDIO THEATER

SPECIAL

Favorite Channels

MOVIES SPORTS NEWS

6

QuitTo ExitTo Menu BarMenu

Group your favorite channels into categories. Use the

UP/DOWN arrow to choose Favorite Channels. Press the

RIGHT arrow button to activate Favorite Channels

option. Use the RIGHT arrow button to choose a

Favorite Channels category such as Movies, Sports,

News, Sitcom, Music, Custom, or use Up/Down to

create your own category.

Once you have chosen a category, press the DOWN arrow

button to pick a slot for the Favorite Channel in that

category. Use the NUMBER keypad to enter the channel

number you want to include in that category. Wait

three seconds and the channel number will go into

the first inset to the right. Use the UP/DOWN arrow

buttons to choose the next channel number entry.

Repeat these steps for all categories.

To access your favorite channels categories press the

RIGHT arrow button repeatedly while watching TV. Use

the UP/DOWN arrow buttons to scroll through the

Favorite Channels you have set up. While in Favorite

Channels Mode, press the MENU button on your remote

and after a short time you will see three channel (Pop-

3) still frame insets representing three of the six

Favorite channels you have selected for that category

to the right of your viewing area.

3

Movies

3

6

8

10

14

22

6

8

PV154 - 923-03506 1-12 ZP26/28 - MENUS

Page 19

QuitTo ExitTo Menu BarMenu

**** Enter Secret Code

Channel 03

Video Lock

Quick Lock

Front Panel Lock

Movie Ratings

TV Ratings

Canadian Ratings (Eng)

Canadian Ratings (Frn)

Press select to set

SEL

SPECIAL

Parental Control

Notes

• Favorite Channels are only available on ANT 1 source.

• If Parental Control Ratings are locked, it will disable

multiple channel insets (including the Favorite

Channels POP-3 insets).

• When POP-3 favorite channel is on, Closed Caption

option will not appear.

• If Closed Caption is set to Auto and Mute is on,

Favorite Channels cannot be accessed.

PARENTAL CONTROL

Parental Control offers the user a wide variety of

options and settings that restrict or “block” the

programming that can appear on the TV. Parental

Control allows the user the capability of defining which

program rating they consider acceptable, to the

younger or more sensitive viewer. It can be preset and

turned either on or off by the user who specifies the

secret 4-number code, the password.

Viewer ratings are specified for both TV and the motion

picture industry; both rating systems should be used

for complete coverage. These ratings are based mainly

on children’s ages. See the Parental Control menu and

submenus example on the next page.

Things to Consider before Setting Up Parental Control

View or Block options:

• Determine which rating you consider acceptable

to the viewer. (For example, if you choose TV-PG,

all more restrictive ratings will be automatically

blocked; the viewer will not be able to see: TV-PG,

TV-14, or TV-MA rated programming.)

• Do you want to block individual channels or input

sources? (Blocks the signal sent by the equipment,

such as a VCR, connected to the TV Audio/Video

input jacks.) Or leave unblocked, then choose allowable ratings.

• Lock the front panel controls so they cannot be

used with the Front Panel Lock option.

• Select a secret password; in the Set Password option. Use the number keys on the remote. Don’t

forget the password, it is the only way you can

access the Parental Control menu and change rating selections, or turn Parental Control off.

PV154 - 923-03506 1-13 ZP26/28 - MENUS

USER MENUS

V-CHIP RATINGS

Most television programs and television movies can

be blocked by TV Rating and/or Individual Categories.

Movies that have been shown at the theaters or directto-video movies use the Movie Rating System(MPAA)

only.

Movies Ratings:

* Unblocked

* G - General audience

* PG - Parental guidance suggested

* PG-13 - 13 years and older

* R - Restricted

* NC-17 - 17 years and older

* X - Adult

General TV Ratings:

* Unblocked

* TV-G - General audience

* TV-PG - Parental guidance suggested

* TV-14 - 14 years and older

* TV-MA - Mature audience

Children TV Ratings:

* Unblocked

* TV-Y - youth

* TV-Y7 - youth, 7 years and older

Content Categories:

* Dialog - sexual dialogue (applies to TV-PG, TV-

14)

* Language - adult language (applies to TV-PG,

TV-14, TV-MA)

* Sex scenes - sexual situations (applies to TV-PG,

TV-14, TV-MA)

* Violence (applies to TV-PG, TV-14 and Above,

TV-MA)

* F Violence - fantasy violence (applies only to

TV-Y7)

* No Rating (blocks all viewing)

Page 20

USER MENUS

SETUP

Press MENU and then the RIGHT/LEFT arrow button

to access the Special Menu. Press the UP/DOWN arrow

to choose Parental Control and then press the RIGHT

arrow button to activate Parental Control. When

prompted, enter the default code 7777 from the

number keypad. If you wish to change the code, select

“Change Secret Code” and enter the new code through

the number keypad. If you forget your code, just

reenter “7777” to reset to factory preset code.

Use the UP/DOWN arrow button to choose your Block

options, press SELECT to confirm your choice:

• Channel: Selects the channel you wish to restrict.

• Video Lock: Selects the Video Inputs to be blocked.

• Quick Lock: Blocks CH3 and CH4 on ANT 1 and 2,

as well as all 3 video input jacks.

• Front Panel Lock: Blocks front panel controls from

being used. Only Power button will work when

this feature is active.

Now you will set the Ratings for the channel you

wish to block. Press the UP/DOWN arrows to select

the following rating formats and press the RIGHT arrow

button to activate each rating menu:

• Movie Ratings: Sets ratings based on MPAA ratings system.

• TV Ratings: Sets ratings based on the age of viewer

and content of programming.

• Canadian Ratings (Eng): Sets age ratings for Canadian broadcasting (Eng).

• Canadian Ratings (Frn): Sets age ratings for Canadian broadcasting (Frn).

For each rating menu, use the UP/DOWN arrow buttons

to choose the level of rating you wish to block. Use

the SELECT button to lock or unlock the rating

selection. Press QUIT to save and exit.

Notes

• Select the input source first in order to use Video

lock; press the source button repeatedly on the

remote until you select Input 1, Input 2, Input 3,

Input 4, or Input 5. The same applies to unlocking

the Video Lock.

• If Ant 1 and Ant 2 are set to the same signal source

mode if a channel is locked, it is locked on both Ant

1 and Ant 2 inputs.

• Be sure the TV’s internal clock is set before using

any Parental Control options.

• Text automatically appears on the screen to indicate

if Parental Control (Child Lock) is activate.

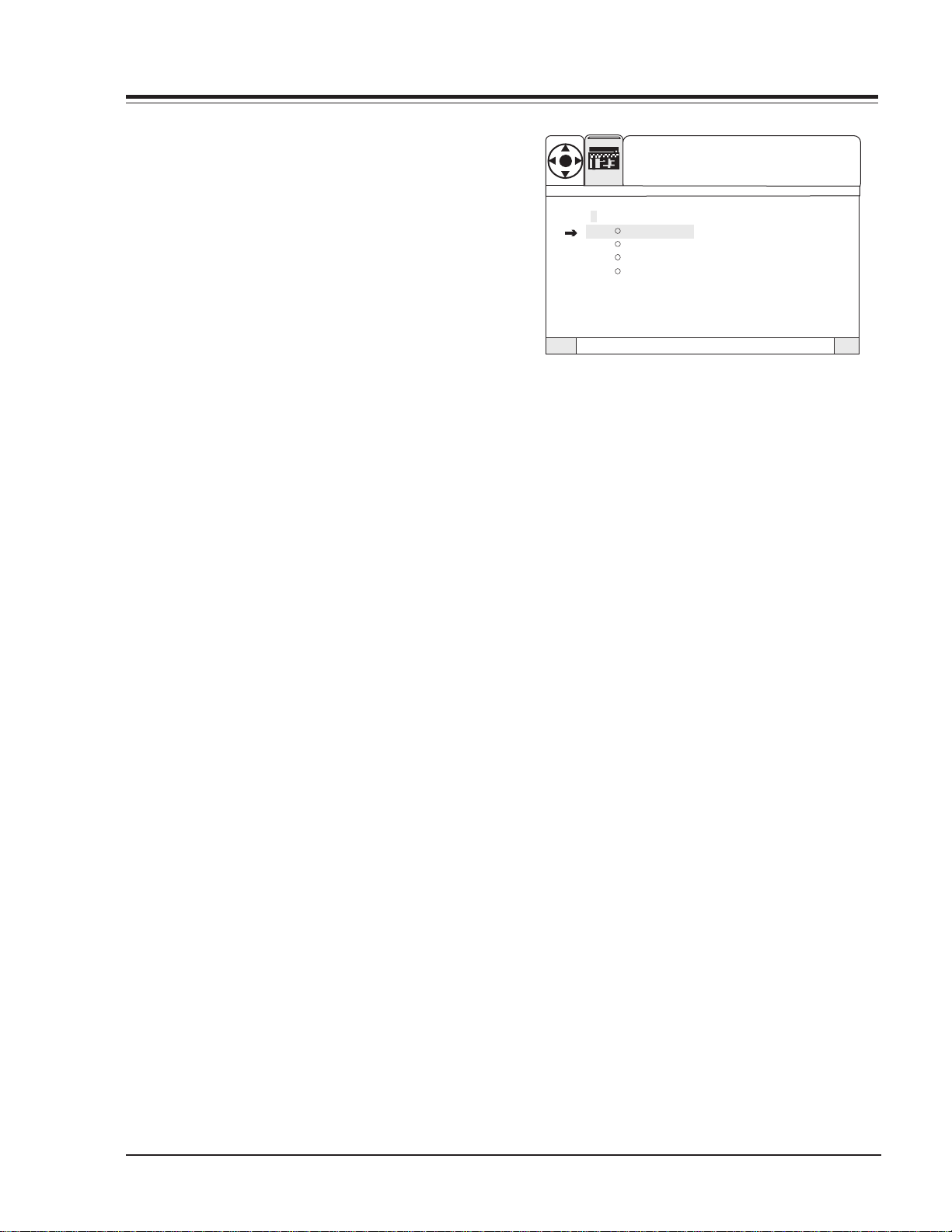

SECURITY TIMER

Use the Security Timer to program your TV to turn on,

tune to the preset channel, and then turn off

automatically at the times specified.

SEL

SPECIAL

Security Timer

Press select to set

1234

--:--AmTVOn

--:--

Am TV Off

Mon (Day of Week)

- - Channel

Once

Daily

Weekly

Off

QuitTo ExitTo Menu BarMenu

Press MENU and the RIGHT/LEFT arrow button to access

the Special Menu. Use the UP/DOWN arrow to choose

Security Timer. Press the RIGHT arrow button to go to

the Security Timer option. You may set up to four ON/

OFF times for your TV. Use the RIGHT arrow button to

choose 1-4, then press the DOWN arrow button to go

to the TV On time option. Press RIGHT arrow to Set On

time. Set time using the LEFT/RIGHT and UP/DOWN

arrow buttons (the same way you set the TV’s clock).

Press the LEFT arrow button repeatedly until the cursor

appears to the left of the current line item. Use the

DOWN arrow button to choose Day, press the RIGHT

arrow. Use the UP/DOWN arrow to choose which day of

the week (if necessary). Press the LEFT arrow button

repeatedly until the cursor appears to the left of the

current line item. Use the DOWN arrow to choose

Channel.

Set the channel for the TV to tune to by entering the

channel number using the number keypad. Press the

LEFT arrow button repeatedly until the cursor appears

to the left of the current line item. Use the UP/DOWN

arrow buttons to choose Once, Daily, Weekly or Off.

Press SELECT to confirm your selection. Repeat steps

3-8 for three more “events” or press QUIT to save and

exit.

Notes

• Security Timer is designed to program the TV to turn

on and off automatically. If the On Timer turned the

TV on and you change channels, the Off timer is

deactivated — then if no remote key is pressed, the

TV turns off automatically after three hours.

• For safety reasons, it is not recommended to use the

Security Timer feature to turn your TV on and off

while no one is at home.

PV154 - 923-03506 1-14 ZP26/28 - MENUS

Page 21

USER MENUS

QuitTo ExitTo Menu BarMenu

VIDEOSETUP AUDIO THEATER

SEL

SPECIAL

Channel Labels

Source I D

Favorite Channels

Parental Control

Security Timer

Captions

Background Solid

Shaded

CAPTIONS

Press MENU and the RIGHT/LEFT arrow button to access

the Special Menu. Use the UP/DOWN arrow to choose

Captions. Press the RIGHT arrow button to activate

Captions option. Use the LEFT/RIGHT arrow to choose

Display Off, On, or Auto option.

SEL

SPECIAL

Captions

Press Select to turn captions Display On, Off, or Auto.

On Caption/text option appears (if available on

program). Off Caption/text option does not appear.

Auto Caption/text option appears when sound is

muted. Press the DOWN arrow button to choose the

mode, C. C.” for Closed Captions or “Text” for Text. Use

the RIGHT arrow button to choose and press Select to

set.

Press select to set

Display

Off On Auto

Mode

C. C. Text

Channel

12

VIDEO MENU

QuitTo ExitTo Menu BarMenu

SEL

Contrast

Brightness

Color

Tint

Sharpness

Reset

Advanced

Settings

VIDEOSETUP AUDIO THEA

SPECIAL

TER

75 %

50%

50%

50%

QuitTo ExitTo Menu BarMenu

Press the DOWN arrow button to go to the Channel

option. Use the RIGHT arrow to specify caption/text

Channel 1 or Channel 2. (Usually this option is set to

Channel 1.) Press Select to set and confirm your choice.

Press QUIT to save and exit. If the POP-3 feature is

displayed on the screen, the selected Closed Caption

option will not appear.

BACKGROUND

Press MENU and use the RIGHT/LEFT arrow button to

access the Special Menu. Use the UP/DOWN arrow to

choose Background. Press the RIGHT arrow button to

activate the Background option. Use the UP/DOWN

arrow to choose Solid or Shaded. Solid Picture is not

visible. Shaded Picture is visible through translucent

menu. Press QUIT to save and exit.

PICTURE SETTINGS

Press MENU and the RIGHT/LEFT arrow button to show

the Video Menu. Use the UP/DOWN arrow to choose

one of the following options. Press the RIGHT/LEFT

arrow button to activate that option (For these items

only, the adjustment bar will drop to the bottom of

the screen, continue with normal operation.):

• Contrast: Changes the amount of difference between black levels and white levels in your picture.

• Brightness: Increases or decreases the amount of

white in your picture.

• Color: Adjust levels of all colors.

• Tint: Adjust the relative amounts of the color red

and green in your picture.

• Sharpness: Raise or lower the definition of the picture. The lower the level, the softer the image will

appear.

• Reset: To return setting to original levels.

PV154 - 923-03506 1-15 ZP26/28 - MENUS

Page 22

USER MENUS

RESET

Use the UP/DOWN arrow to choose Reset (Reset restores

the levels to their original settings). Press SELECT to

confirm your choice.

ADVANCED SETTINGS

Use the UP/DOWN arrow to choose Advanced Settings.

Press the RIGHT arrow button to activate the Advanced

Settings menu. Use the UP/DOWN arrow to choose from

the following options. Press SELECT to confirm your

choice:

• Light Sentry: Automatically monitors and adjusts

contrast depending on room lighting to produce

a more natural picture. Also adjusts Auto Flesh

Tone and Video Filter depending on signal.

• Auto Flesh: Automatically monitors and adjusts the

color to maintain constant color levels even after

a program or channel changes.

• Weak Signal: Automatically reduces conspicuous

noise in the picture without degrading picture

quality.

• Color Temperature: Set this to Warm for hotter colors such as red, set to Cool for less intense colors

with more blue, or Medium for normal color appearance.

Press QUIT to save and exit.

Notes

• It may be necessary to adjust TINT for optimum

picture quality, when viewing component video

sources (Y-PBPR) connected to Inputs 3/4.

• When viewing component video sources (Y-PBPR)

connected to Inputs 3/4, if the TINT and COLOR

in the picture appear to be abnormal, check to be

sure that the correct Component Color Type is selected for the Picture Formats option on the Setup

menu.

AUDIO MENU

SEL

VIDEOSETUP AUDIO THEATER

SPECIAL

Bass 75 %

Treble

Balance

Reset

Advanced

Settings

50%

50%

PICTURE SETTINGS

Press MENU and use the RIGHT/LEFT arrow button to

access the Audio Menu. Use the UP/DOWN arrow to

choose one of the following options. Use the RIGHT/

LEFT arrow buttons to adjust that option.

• Bass: Increase/decrease lower-end sounds.

• Treble: Increase/decrease higher-end sounds.

• Balance: Allows you to put the sound more to the

left or right channel.

RESET

Use the UP/DOWN arrow to choose Reset (Reset restores

the levels to their original settings). Press SELECT to

confirm your choice.

ADVANCED SETTINGS

Use the UP/DOWN arrow to choose Reset (Reset restores

the levels to their original settings). Press SELECT to

confirm your choice. Use the UP/DOWN arrow to choose

Advanced Settings. Press the RIGHT arrow button to