Page 1

www.lg.com

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

PRVC2

Original instruction

INSTALLATION MANUAL

LOW AMBIENT

CONTROL KIT

(For Multi V 5)

MFL42540252

Rev.01_010919

Copyright © 2017 - 2020 LG Electronics Inc. All Rights Reserved.

ENGLISH

Page 2

Table of contents

TABLE OF CONTENTS

3 SAFETY PRECAUTIONS

5 ACCESSORY PARTS

6 NAME OF EACH PART

7 INSTALLATION METHOD

7 IO Module Installation Method

10 Transformer, Terminal Block Installation Method

13 SETTING AND USING METHOD

13 Power source input

15 IO Module - Low Ambient Kit Function

16 IO Module - Other Function

19 Wiring for Damper Actuator

22 Setting of Outdoor Unit DIP Switch

23 INSTALLATION METHOD OF SNOW HOOD

AND AIR DAMPER

23 One Unit with Snow Hood and Air Damper

24 Two and Three Units with Snow Hood and Air Damper

25 Unit Placement and Clearances

2 Low Ambient Control Kit

Page 3

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

!

WARNING

!

CAUTION

n Meanings of symbols used in this manual are as shown below.

Installation

• Don’t touch with the hands while the power is on.

- Cause fire, electric shock, explosion or injury.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

!

WARNING

ENGLISH

• Product installation must be referred to a service center or installation

shop.

- Cause fire, electric shock, explosion or injury.

• Request installation from installation shop or service center when

reinstalling the product.

- Cause fire, electric shock, explosion or injury.

Do not install the product in the place where rain can get to the product.

•

- Cause product failure.

• Do not install the unit in humid locations.

- Cause product failure.

• Do not put the product closer to fire.

- Cause fire.

• Do not install in a place that cannot withstand the weight of the product.

- The product may get damaged or may break.

Installation manual 3

Page 4

Safety Precautions

• Do not install the product to a place that generates oil, steam, salt,

sulfuric gas, etc.

- Cause the product’s deformation or failure.

• Use standardized Product.

- Cause product failure.

Operation

• Do not change or extend power lines arbitrarily.

- Cause fire or electric shock.

• Do not give a shock to the product.

- If you give a shock to the product, it may cause the product’s failure.

• Do not use a heater near the power line.

- Cause fire or electric shock.

• Do notspill water inside of the product.

- Cause electric shock or breakdown.

• If the product has been inundated, you must refer to a service center or

installation shop.

- It can cause a fire.

• Children and elderly use the product under the guardian’s supervision.

- Cause accidents and product failures.

• Do not use for special purpose / place such as conserving flora and

fauna, precision instruments, art.

- Otherwise, it can cause property damage.

• Remove the power plug when cleaning.

- Cause fire or electric shock.

• Do not place heavy objects on the power line.

- Cause fire or electric shock.

• Do not disassemble, repair, or modify the product.

- Cause fire or electric shock.

• Do not touch with wet hands.

- Cause fire or electric shock.

4 Low Ambient Control Kit

Page 5

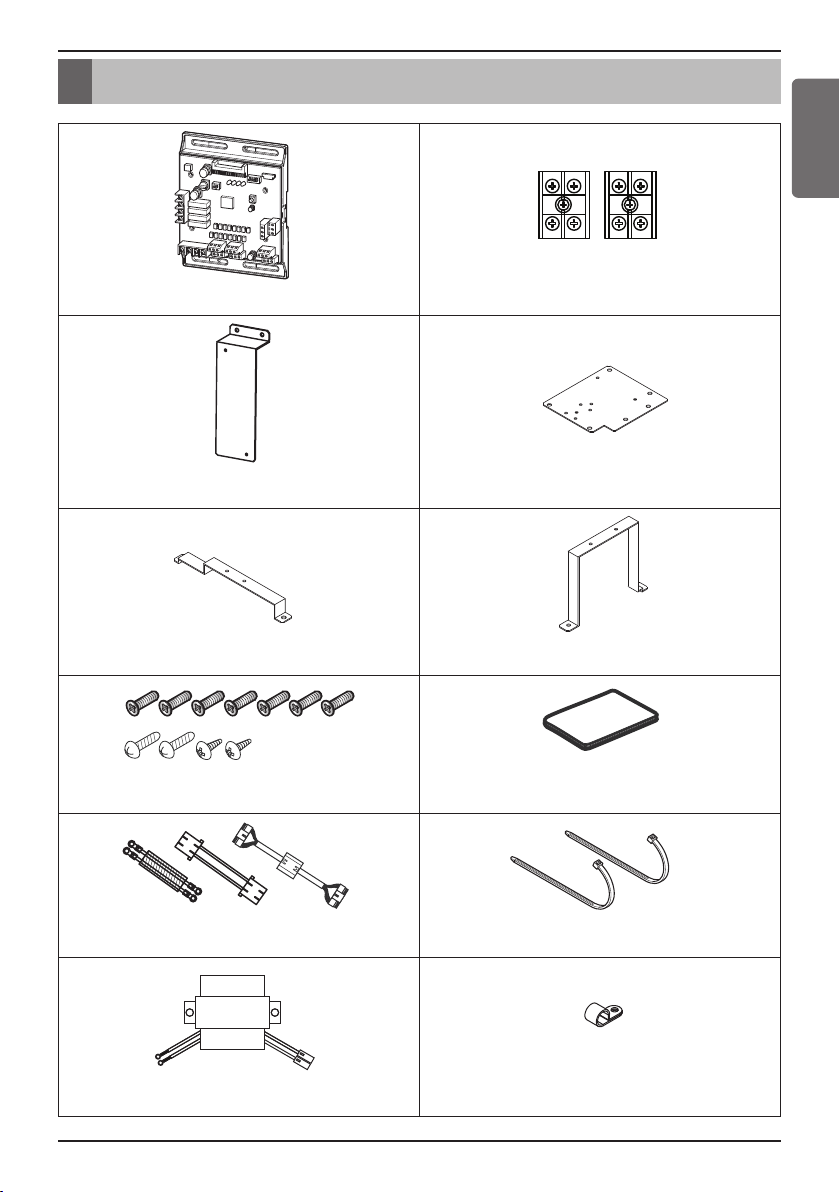

Accessory Parts

IO Module

Terminal Block (2 EA)

Bracket 1

Bracket 2

Bracket 3

Bracket 4

Screw (11 EA)

Manual

Cable (3 EA)

Tie (2 EA)

Transformer

Clamp

Accessory Parts

ENGLISH

Installation manual 5

Page 6

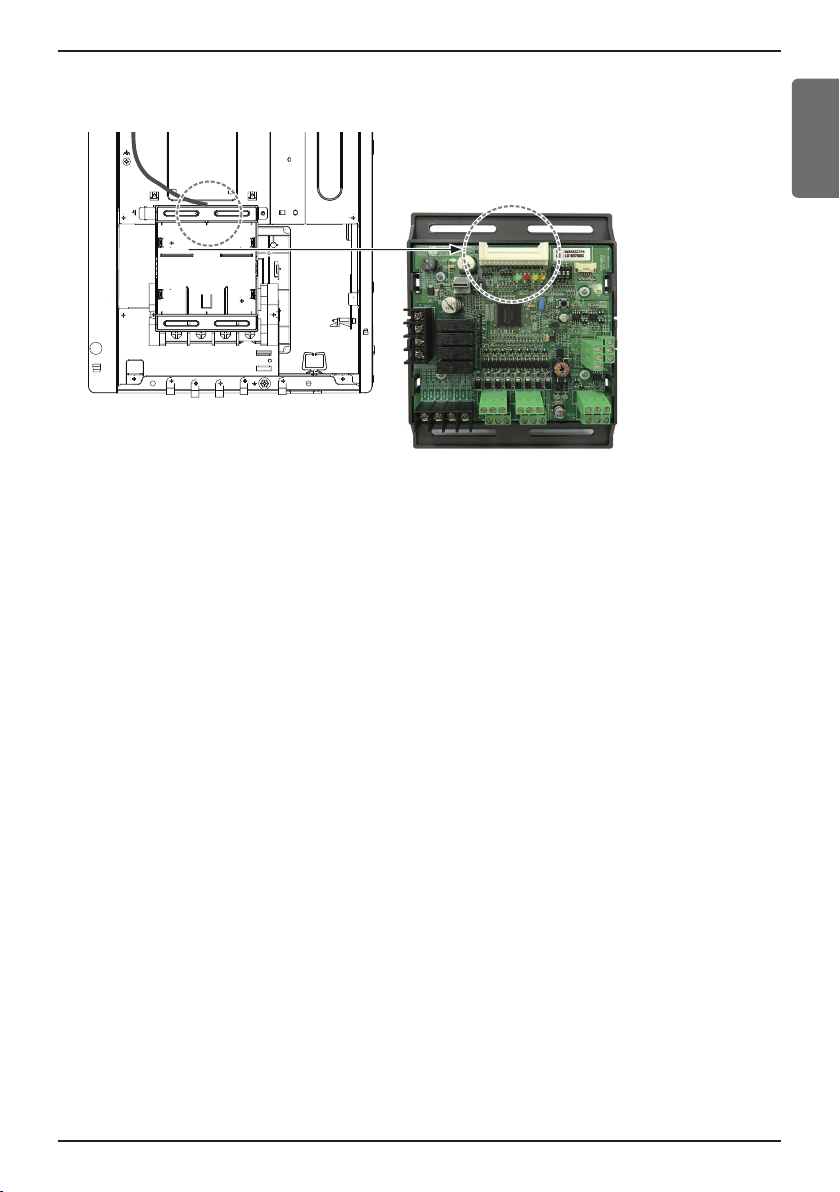

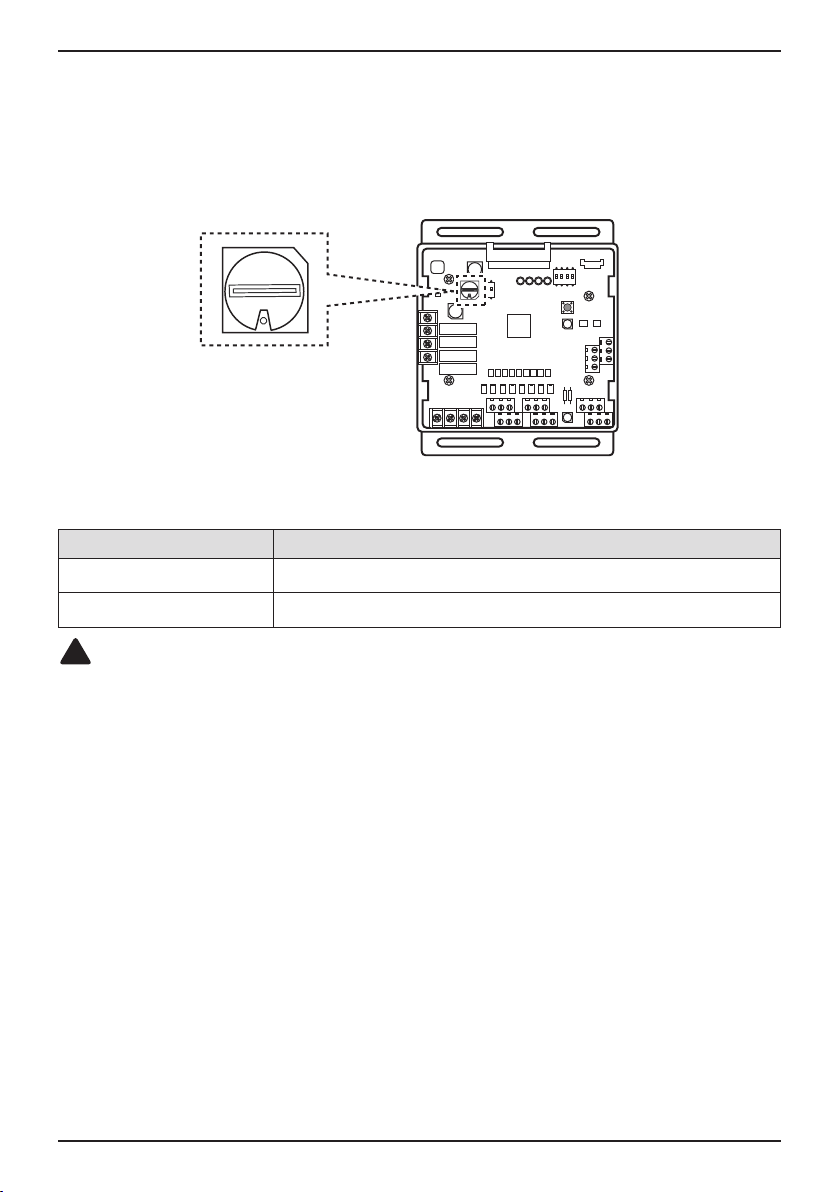

Name of each Part

Name of each Part

ڸ

ڹ

ں

ڻ

ڼڽ

① Main connector : Power input and communication connector with Outdoor unit

② SW102 : Switch for setting internal function

③ SW104 : Rotary Switch for setting Demand control step

④ Digital Output : Operating & Error status Relay output (250 V, 1 A)

Reserved Relay output (250 V, 1 A)

⑤ Digital Input : Dry contact input

ۀ

ڿ

ھ

⑥ Analog Input : DC 0 ~ 10 V Analog signal input

⑦ Analog Output : DC 0 ~ 10 V Analog signal output

⑧ SW103 : Reset Switch

⑨ SW101 : DIP Switch for setting operating function

6 Low Ambient Control Kit

Page 7

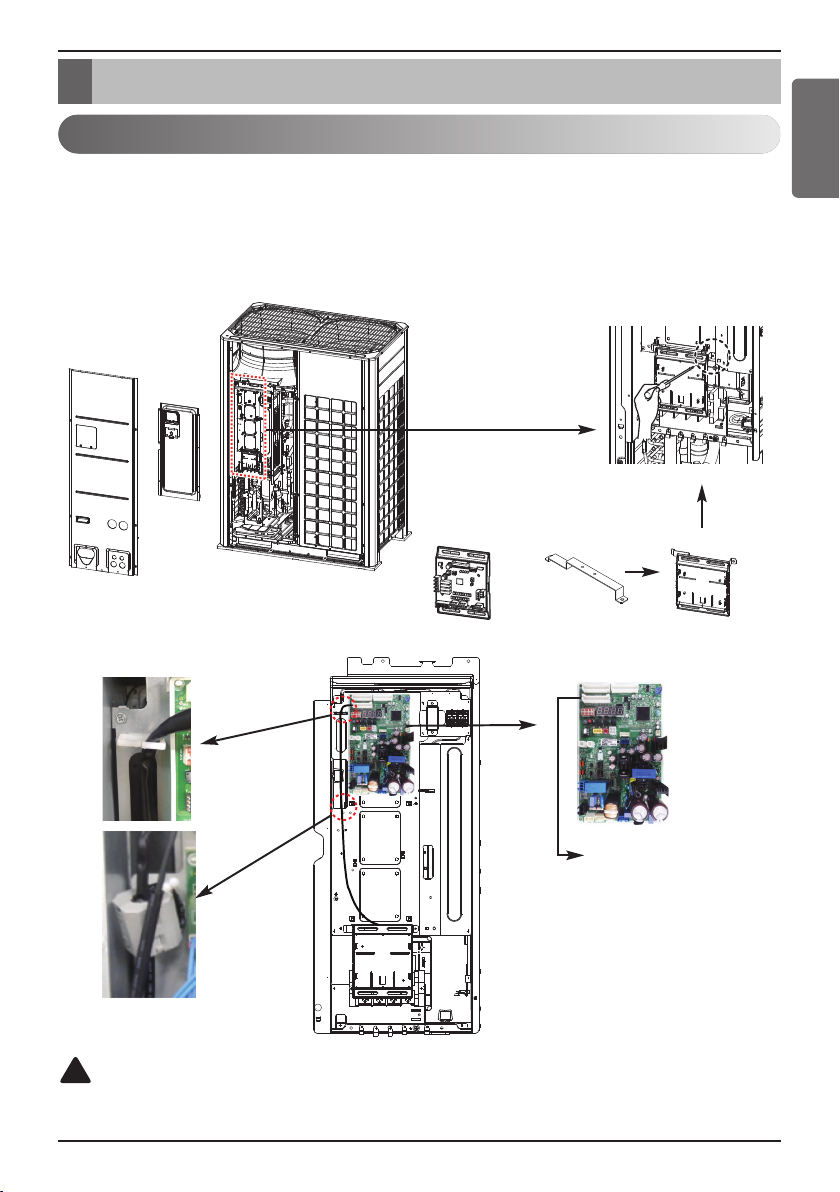

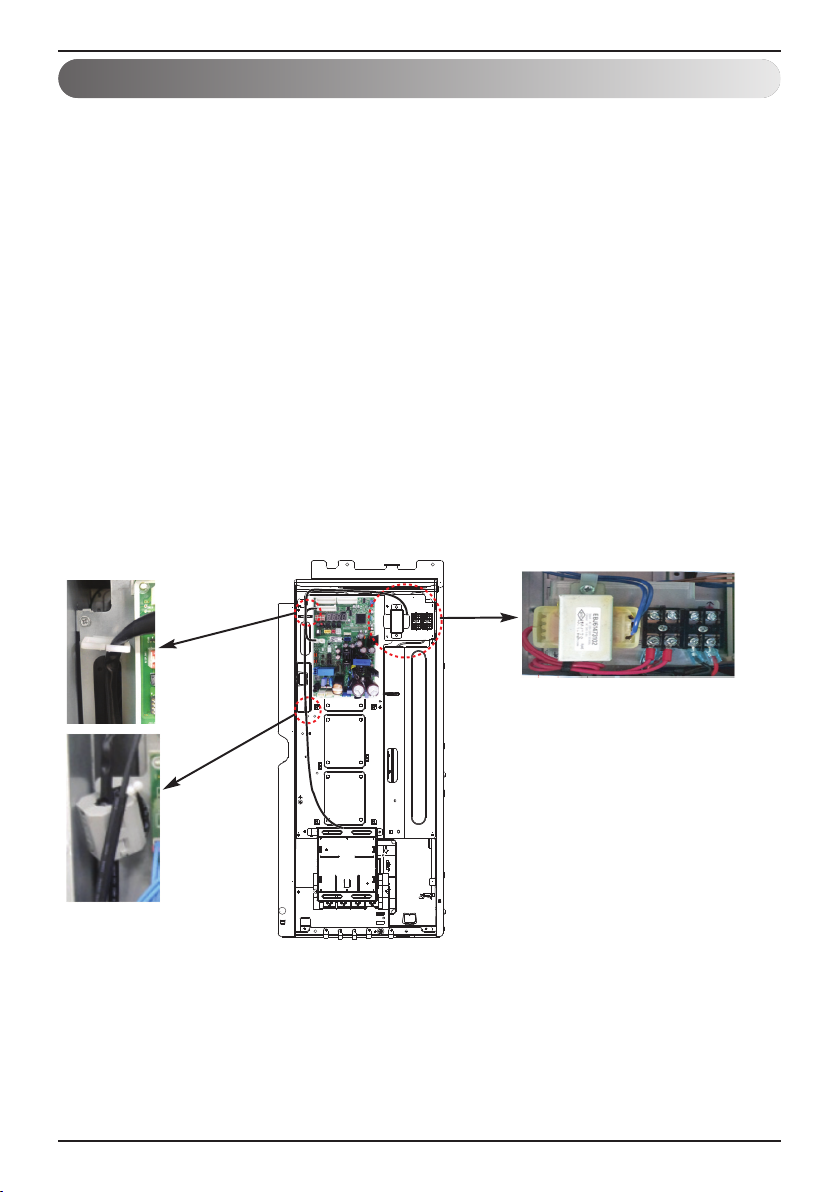

Installation Method

ڸ

ڹ

ں

Installation Method

IO Module Installation Method

① Separate front panel from outdoor unit.

② Separate front cover of control box.

③ Assemble IO Module and Bracket3.

Connect the connection wires according to the instructions. (Please refer to Setting and Using Method)

④

UXB

+

ڻ

ENGLISH

!

CAUTION

Be sure to turn off outdoor unit power before installation.

Main board connector

Installation manual 7

Page 8

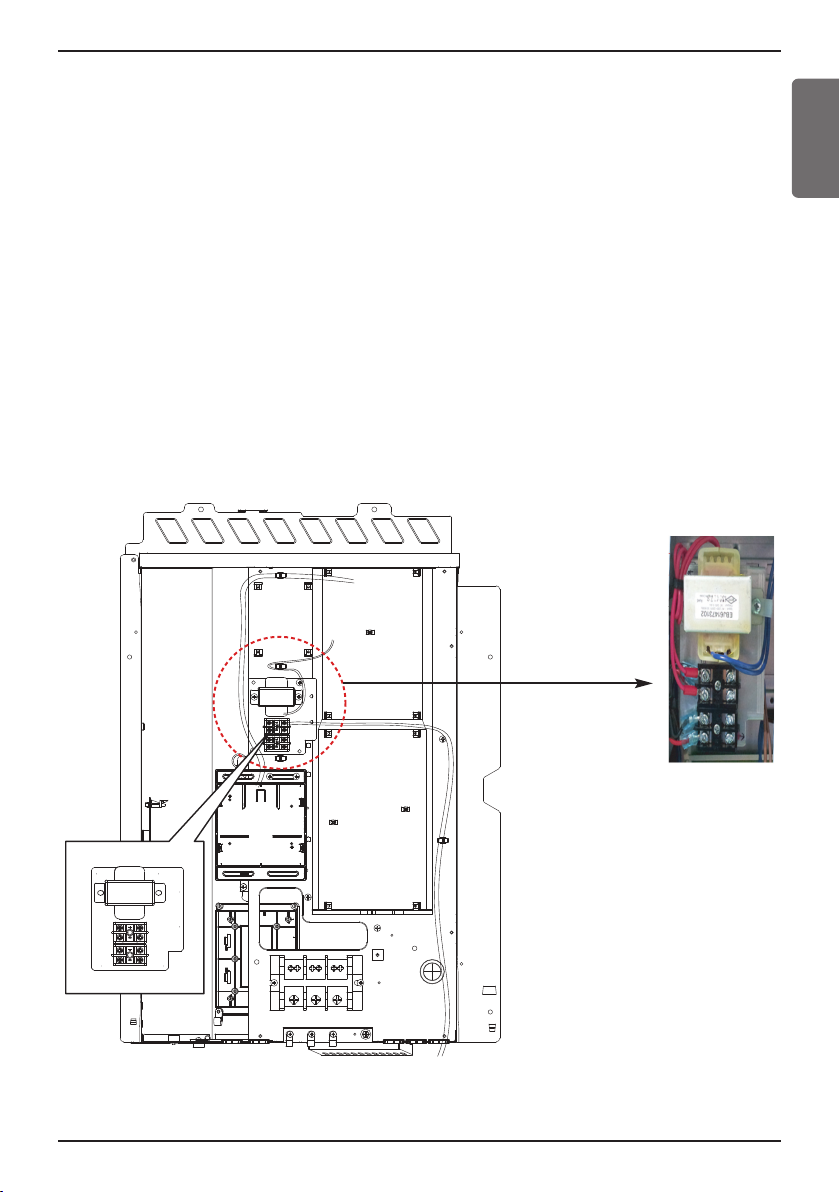

Installation Method

ڸ

ڹ

ں

ڻ

UXA

Main board connector

!

CAUTION

Be sure to turn off outdoor unit power before installation.

8 Low Ambient Control Kit

Page 9

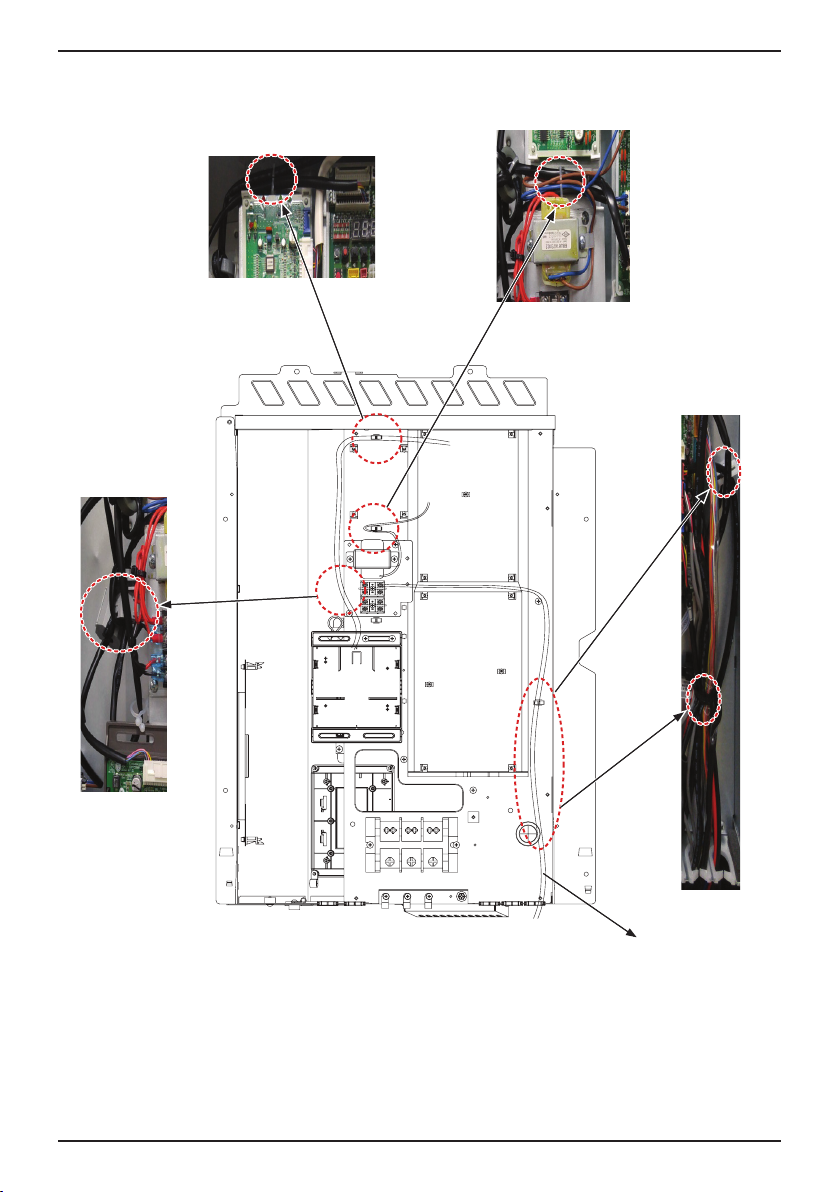

⑤ Fix and fasten components and cables.

⑥ Perform the switch setting according to the instructions.

Installation Method

ENGLISH

Installation manual 9

Page 10

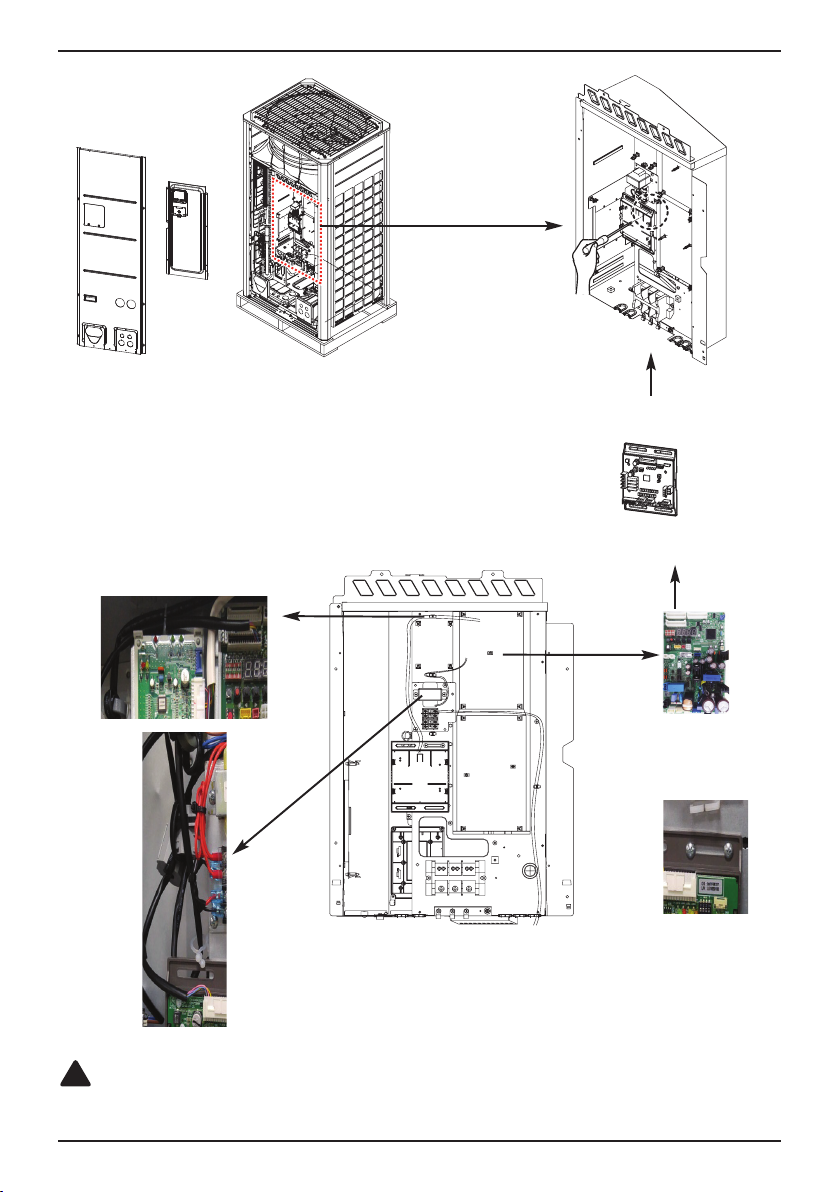

Installation Method

Transformer, Terminal Block Installation Method

UXB

① Shut off the main power of outdoor unit.

② Install the IO Module in the C/Box by using screws.

③ Install the Bracket2 in the C/Box by using screws.

④ Install the transformer on the Bracket2 by using screws.

⑤ Install the terminal block on the Bracket2 by using screws.

⑥ Connect the Main PCB(CN10) to IO Module(CN101) by using the cable assembly.

⑦ Connect the blue cable of transformer to the Main PCB(JIG_N), brown cable of transformer to

the Main PCB(JIG_L).

⑧ Connect the red cable of transformer to the terminal block (2Pin Yellow terminal block).

⑨ Connect a power cable(DC 12 V) to CN101(12 V,GND) of IO Module.

⑩ Connect the black cable of Damper Actuator to the terminal block and connect the cable of

IO Module(CN1_A0(GND(A-)) to the black cable of Damper Actuator.

⑪ Connect the red cable of Damper Actuator to CN1_A0(A0_1(A+)) of IO Module.

⑫ Set up the main function DIP S/W of IO Module.

(SW101 : L1,L2=On and L3,L4=Off / SW102 : L1,L2=Off)

⑬ Set up the DIP S/W of Main Outdoor unit PCB. (Refer to page 21 for details)

⑭ Turn on the main power of outdoor unit.

⑮ Check the signal to CN1_A0(AO_01,GND) of IO Module and Air Damper.

10 Low Ambient Control Kit

Page 11

Installation Method

UXA

① Shut off the main power of outdoor unit.

② Install the IO Module in the C/Box by using screws.

③ Install the Bracket2 in the C/Box by using screws.

④ Install the transformer on the Bracket2 by using screws.

⑤ Install the terminal block on the Bracket2 by using screws.

⑥ Connect the Main PCB(CN10) to IO Module(CN101) by using the cable assembly.

⑦ Connect the blue cable of transformer to the Main PCB(JIG_N), brown cable of transformer to

the Main PCB(JIG_L).

⑧ Connect the red cable of transformer to the terminal block (2Pin Yellow terminal block).

⑨ Connect a power cable(DC 12 V) to CN101(12 V,GND) of IO Module.

⑩ Connect the black cable of Damper Actuator to the terminal block and connect the cable of

IO Module(CN1_A0(GND(A-)) to the black cable of Damper Actuator.

⑪ Connect the red cable of Damper Actuator to CN1_A0(A0_1(A+)) of IO Module.

⑫ Set up the main function DIP S/W of IO Module.

(SW101 : L1,L2=On and L3,L4=Off / SW102 : L1,L2=Off)

⑬ Set up the DIP S/W of Main Outdoor unit PCB. (Refer to page 21 for details)

⑭ Turn on the main power of outdoor unit.

⑮ Check the signal to CN1_A0(AO_01,GND) of IO Module and Air Damper.

ENGLISH

Installation manual 11

Page 12

Installation Method

Using the Clamp and Tie, fasten the Damper Actuator output cable and Trans output cable as

below.

12 Low Ambient Control Kit

Actuator Wire

Page 13

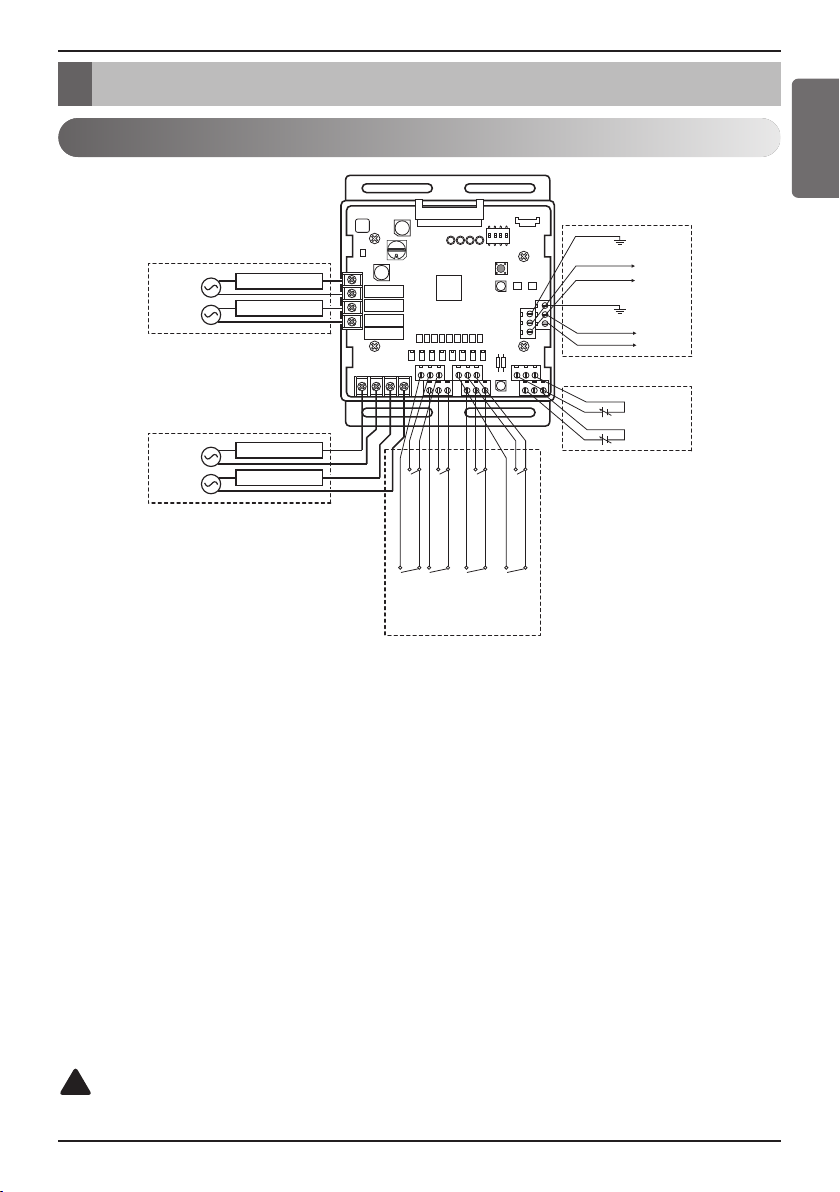

Setting and Using Method

Error Status

Input_3

Power

AC or DC

LG does not supply this

section (Field supply)

Status output Relay can

endure 250 VAC, 1 A.

Power

AC or DC

Operating Status

ڻ

ڻ

Reserved

Reserved

Power

AC or DC

Power

AC or DC

Reserved

Input_1Input_2

Input_LNO

Reserved

Input_7

Priority setting

AI_1

Reserved

ڹ

AO_4

AO_4 GND

AO_3 GND

AO_2 GND

AO_1 GND

AO_3

AO_2

AO_1

ں

ڸ

Setting and Using Method

Power source input

AI : Analog Input (DC 0~10 V)

AO : Analog Output ( DC 0~10 V, Max 20 mA)

Input_LNO : Low Noise Operation

ENGLISH

① Dry contact input part

Connect Non Voltage contact signal for demand control (3 step)

* Priority setting

Using ‘Priority setting’ contact signal, set the priority of command.

(External command from DDC Vs Command from LG central controller.)

② Analog input part

- Close : Central controller has priority to external signal.

- Open : External signal has priority to central controller.

Connect Analog input signal for demand control (10 step)

③ Analog output part

Connect Analog output signal for controlling third party devices.

Ex) Valve actuator for variable water flow. Damper actuator for Low Ambient Kit

④ Digital output part

Connect status display devices.

!

CAUTION

Power must be turned on after the product is wired completely.

Installation manual 13

Page 14

Setting and Using Method

n

Communication and Power Line

- If communication and power lines are run alongside each other then there is a strong likelihood of

operational faults developing due to interference in the signal wiring caused by electrostatic and

electromagnetic coupling. The tables below indicates our recommendation as to appropriate spacing

of communication and power lines where these are to be run side by side.

Current capacity of power line Spacing

10 A 11-13/16 in (300 mm)

100 V or more

Notes

If the power supply waveform continues to exhibit some distortion the recommended spacing in the

table should be increased.

• If the lines are laid inside conduits then the following point must also be taken into account when

grouping various lines together for introduction into the conduits.

• Power lines (including power supply to air conditioner) and signal lines must not be laid inside the

same.

• In the same way, when grouping the lines power and signal lines should not be bunched together.

50 A 19-11/16 in (500 mm)

100 A 39-3/8 in (1 000 mm)

Exceed 100 A 59-3/64 in (1 500 mm)

14 Low Ambient Control Kit

Page 15

Setting and Using Method

SW102 SW101

L1

ON

2

3

4

L1

ON

2

ON

L1 2 3 4

ON

L1 2

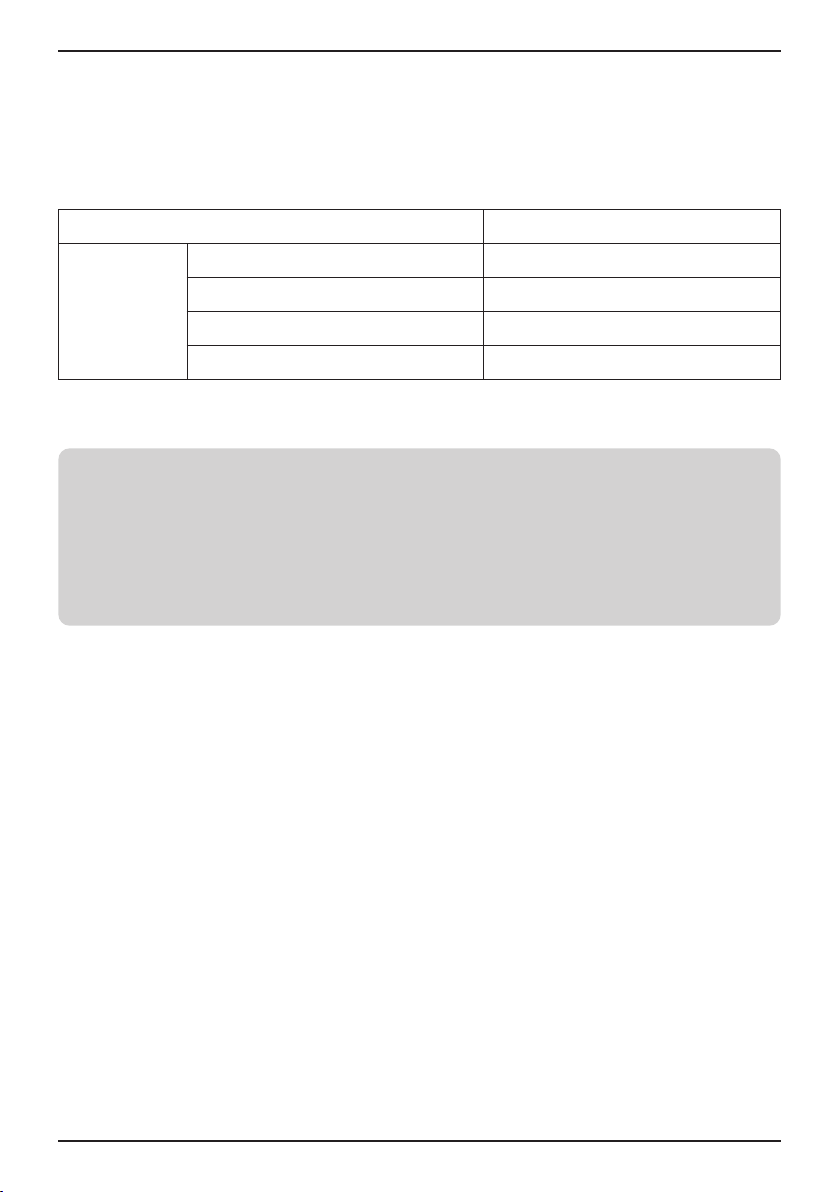

IO Module - Low Ambient Kit Function

Setting of DIP Switch

Using ‘SW101’, ‘SW102’, You can use Low Ambient Kit Mode

Notes

Default status is all off.

Set Low Ambient Kit Operation

ENGLISH

Position Setting of DIP Switch

SW101 - L1=ON

SW102 - L1=OFF

!

CAUTION

•

If the DIP SW is set , IO module System is operating preferentially than outdoor unit setting.

• After change DIP SW setting, press reset switch to reflect the setting.

L2=ON

L3=OFF

L4=OFF

L2=OFF

Installation manual 15

Page 16

Setting and Using Method

L1

ON

2

3

4

ON

L1 2 3 4

ON

L1 2 3 4

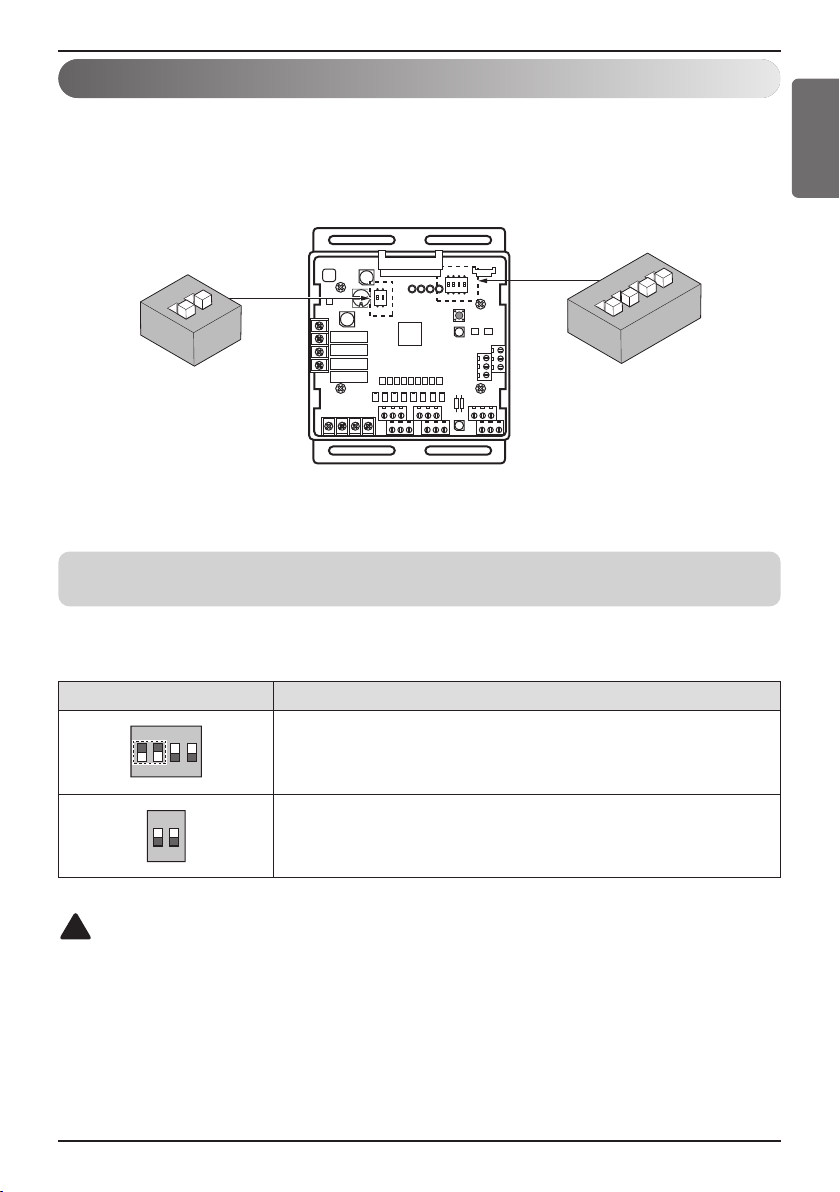

IO Module - Other Function

Setting of DIP Switch

Using ‘SW101’, select the option of control function as described below.

Notes

Default status is all off.

• L3 : Set Low Noise Operation

This is a function driving outdoor unit fan RPM to operate low speed for reducing fan noise

according to the input signal. To use this function, you should set Outdoor unit mode, Please

refer to PDB more detail.

Position Function

ON : Enable Low Noise Operation

OFF : Disable Low Noise Operation

!

CAUTION

If the DIP SW is set , IO module System is operating preferentially than outdoor unit setting.

• L4 : Set Operating status output

Position Function

!

CAUTION

After change DIP SW setting, press reset switch to reflect the setting.

16 Low Ambient Control Kit

ON : Activate Digital Output according to Indoor Unit status

OFF : Activate Digital Output according to Outdoor Unit status

Page 17

Setting and Using Method

L1

ON

2

ON

L1 2

ON

L1 2

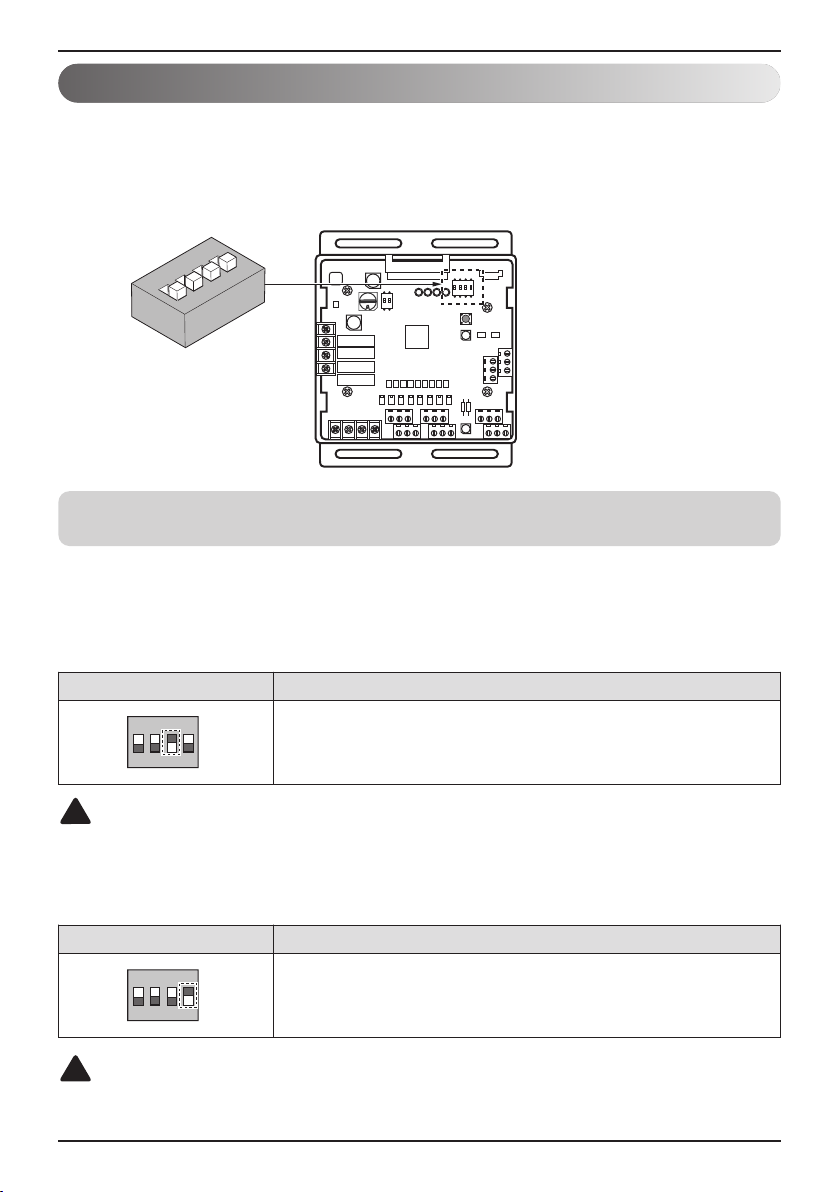

Using ‘SW102’, set the internal function as described below.

Notes

Default status is all off.

• L1 : Set Analog output default value when Communication Error will be occur (Module – ODU)

Position Function

ENGLISH

ON : Analog output 0 V

OFF : Analog output 10 V

• L2 : Set Analog output Range

Basically this module keeps a minimum Analog output voltage refer to L1,L2 setting of SW101 to

prevent unexpected accident. When you need to use 0~10V full range, L2 should be set as ON.

Position Function

ON : Ignore minimum Analog output value setting

(L1,L2 setting value of 4pin DIP SW)

OFF : Follow minimum Analog output value setting

(L1,L2 setting value of 4pin DIP SW)

!

CAUTION

After change DIP SW setting, press reset switch to reflect the setting.

Installation manual 17

Page 18

Setting and Using Method

Setting of Rotary Switch

Use the Rotary Switch to set a control step for contact signal input : The type of input signal and

control step can be set using ‘SW104’

This function is for demand control to reduce power consumption.

Set the control mode what you want according to the table as below.

- Type of input signal

SW_STEP

0, 1, 2, 3, 4, 5, 6, 7 Contact signal input

C, D, E Analog input signal

!

CAUTION

Do not change a command too quickly.

Keep the command 30 seconds at least, otherwise it will cause a damage to outdoor unit.

• Operation rate condition :

- Cooling : Outdoor 35 °C, Indoor 27 °C

- Heating : Outdoor 7 °C, Indoor 20 °C

• The tolerance of the operation rate can be cause by combination of outdoor unit, operating

condition, installation circumstance.

• When operation rate is 100 %, Target Evaporating Temp. and Target Condensing Temp. can be

changed by installation option. (Refer to product data book)

• Input_1 : 0 Έ OFF, Input_1 : 1 Έ ON

Input signal

18 Low Ambient Control Kit

Page 19

Setting and Using Method

Wiring for Damper Actuator

1 Unit

BRBL

AC 220 V

Transformer

RD

RD

Terminal

Block

IO Module

Damper

Actuator

ENGLISH

WH

GR

BK

RD

AC/DC 24 V

h BL : Blue, BR : Brown, RD : Red, BK : Black, WH : White, GR : Green

Notes

Damper Actuator can accept only DC 24 V power input.

Do not input AC power. Otherwise it will cause a serious damage.

The IO Module can control maximum three actuators.

Case of one valve, the slave signal connector must not use.

The power (AC/DC 24 V) and signal(DC 0~10 V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

DC 0~10 V

Control Signal

Installation manual 19

Page 20

Setting and Using Method

2 Unit

BL BR

Transformer

RD

RD

BK

AC 220 V

RD

Terminal

Block

IO Module

GR

GR

BK

RD

BK

RD

Damper

Actuator

WH

Damper

Actuator

WH

Notes

Damper Actuator can accept only DC 24 V power input.

Do not input AC power. Otherwise it will cause a serious damage.

The IO Module can control maximum three actuators.

Case of one valve, the slave signal connecter must not use.

The power (AC/DC 24 V) and signal(DC 0~10 V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

20 Low Ambient Control Kit

Page 21

Setting and Using Method

3 Unit

Transformer

RD

RD

BK

AC 220 V

RD

Terminal

Block

IO Module

GR

GR

GR

BK

RD

BK

RD

Damper

Actuator

WH

BK

RD

Damper

Actuator

WH

Damper

Actuator

WH

ENGLISH

Notes

Damper Actuator can accept only DC 24 V power input.

Do not input AC power. Otherwise it will cause a serious damage.

The IO Module can control maximum three actuators.

Case of one valve, the slave signal connecter must not use.

The power (AC/DC 24 V) and signal(DC 0~10 V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

Installation manual 21

Page 22

Setting and Using Method

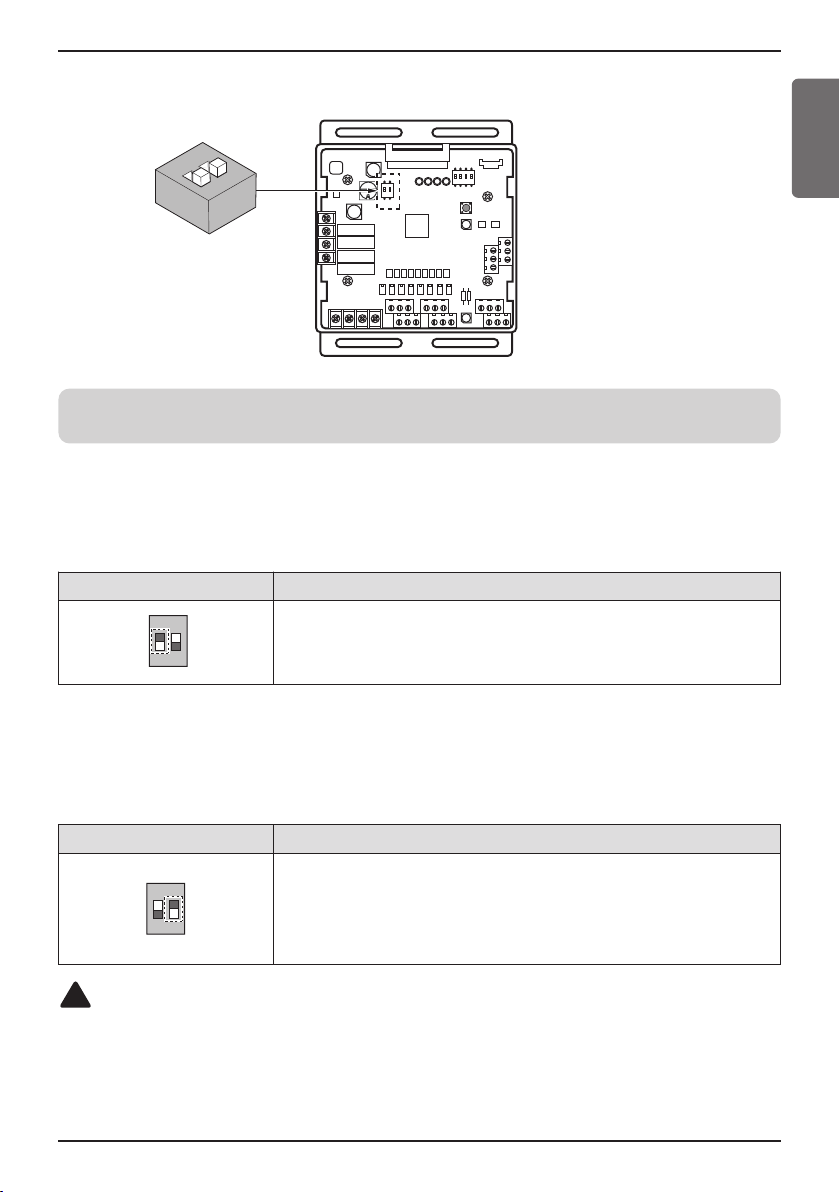

Setting of Outdoor Unit DIP Switch

Low Ambient Kit Mode

• Low Ambient Kit mode Setting method

Master unit PCB DIP switch on : No.5

Select the mode using ‘▶’, ‘◀’ Button :

“Func” Push the '●' (Confirm) button

Select the Function using ‘▶’, ‘◀’ Button :

DIP SWITCH 7-Segment

“Fn9” Push the '●' (Confirm) button

Select the Function using ‘▶’, ‘◀’ Button :

“On” Push the '●' (Confirm) button

Low Ambient Kit mode is set

h If you want to stop the Low Ambient Kit mode, refer to the following.

▷ DIP Switch No.5 On -> “Func” -> “Fn9” -> “Off”

SW04C ( X : cancel)

SW03C (

SW02C ( : backward)

SW01C ( : confirm)

SW01D (reset)

: forward)

ȯ

ȭ

Ɨ

22 Low Ambient Control Kit

Page 23

Installation Method of Snow Hood and Air Damper

Installation Method of Snow Hood and Air Damper

ENGLISH

One Unit with Snow Hood and Air Damper

One Unit with Snow Hood and Air Damper

Installation manual 23

Page 24

Installation Method of Snow Hood and Air Damper

Two and Three Units with Snow Hood and Air Damper

Two Units with Snow Hood and Air Damper

Three Units with Snow Hood and Air Damper

24 Low Ambient Control Kit

Page 25

Installation Method of Snow Hood and Air Damper

Top View

Prevailing wind

Building Wall

Outdoor Unit

H ≤ discharge

of air damper

Unit Placement and Clearances

1. Outdoor units should be located in an area protected from prevailing winds. (shown below)

In high wind locations it may be advisable to locate the units within a walled area.

2. If the units are surrounded by an enclosure, the discharge of the air damper must direct the air out and over the

enclosure walls to prevent air recirculation.

ENGLISH

Installation manual 25

Page 26

Installation Method of Snow Hood and Air Damper

3. When the distance is less than 7-7/8 in(200 mm) between outdoor units, do not necessary installation of side

Snow Hood as below.

7-7/8 in(200 mm)

26 Low Ambient Control Kit

7-7/8 in(200 mm)7-7/8 in(200 mm)

Page 27

Installation Method of Snow Hood and Air Damper

4. If units are placed further than 7-7/8 in(200 mm) apart, additional snow hoods may be required.

ENGLISH

Installation manual 27

Page 28

28 Low Ambient Control Kit

Page 29

ENGLISH

Installation manual 29

Page 30

30 Low Ambient Control Kit

Page 31

ENGLISH

Installation manual 31

Page 32

Representative (EU Only): LG Electronics Inc. EU Representative, Krijgsman 1, 1186 DM

Manufacturer: LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro, Seongsan-gu,

Changwon-si, Gyeongsangnam-do, KOREA

Amstelveen, The Netherlands

Page 33

❈ PRVC2 is available only for the Multi-V IV model

(PRVC2 can not be installed for the previous Multi-V IV model)

INSTALLATION MANUAL

Low Ambient

Control Kit

www.lg.com

PRVC2

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

MFL42540235

Rev.00_010319

Original instruction

Copyright © 2013 - 2018 LG Electronics Inc. All Rights Reserved.

ENGLISH

Page 34

Table of contents

TABLE OF CONTENTS

3 SAFETY PRECAUTIONS

5 ACCESSORY PARTS

6 NAME OF EACH PART

7 INSTALLATION METHOD

7 IO Module Installation Method

9 Transformer, Terminal Block Installation Method

11 SETTING AND USING METHOD

11 Power source input

13 IO Module – Low Ambient Kit Function

14 IO Module – Other Function

17 Wiring for Damper Actuator

20 Setting of Outdoor Unit DIP Switch

21 INSTALLATION METHOD OF SNOW HOOD AND AIR

DAMPER

21 One Unit with Snow Hood and Air Damper

22 Two and Three Units with Snow Hood and Air Damper

23 Unit Placement and Clearances

2 Low Ambient Control Kit

Page 35

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

ENGLISH

!

WARNING

!

CAUTION

n Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

!

WARNING

Installation

• Don’t touch with the hands while the power is on.

- Cause fire, electric shock, explosion or injury.

• Product installation must be referred to a service center or installation shop.

- Cause fire, electric shock, explosion or injury.

• Request installation from installation shop or service center when reinstalling the product.

- Cause fire, electric shock, explosion or injury.

• Do not install the product in the place where rain can get to the product.

- Cause product failure

• Do not install the unit in humid locations.

- Cause product failure

• Do not put the product closer to fire.

- Cause fire

• Do not install in a place that cannot withstand the weight of the product.

- The product may get damaged or may break.

• Do not install the product to a place that generates oil, steam, salt, sulfuric gas, etc.

- Cause the product’s deformation or failure.

• Use standardized Product.

- Cause product failure

Operation

• Do not change or extend power lines arbitrarily.

- Cause fire or electric shock.

• Do not give a shock to the product.

- If you give a shock to the product, it may cause the product’s failure.

Installation manual 3

Page 36

Safety Precautions

• Do not use a heater near the power line.

- Cause fire or electric shock.

• Do notspill water inside of the product.

- Cause electric shock or breakdown.

• If the product has been inundated, you must refer to a service center or installation shop.

- It can cause a fire.

• Children and elderly use the product under the guardian’s supervision.

- Cause accidents and product failures.

• Do not use for special purpose / place such as conserving flora and fauna, precision instruments, art.

- Otherwise, it can cause property damage.

• Remove the power plug when cleaning.

- Cause fire or electric shock.

• Do not place heavy objects on the power line.

- Cause fire or electric shock.

• Do not disassemble, repair, or modify the product.

- Cause fire or electric shock.

• Do not touch with wet hands.

- Cause fire or electric shock.

4 Low Ambient Control Kit

Page 37

Accessory Parts

IO Module

Terminal Block (2 EA)

Bracket 1

Bracket 2

Bracket 3

Bracket 4

Screw (11 EA)

Manual

Cable (3 EA)

Tie (2 EA)

Transformer

Clamp

Accessory Parts

ENGLISH

Installation manual 5

Page 38

Name of each Part

Name of each Part

ڸ

ڹ

ں

ڻ

ڼڽ

① Main connector : Power input and communication connector with Outdoor unit

② SW102 : Switch for setting internal function

③ SW104 : Rotary Switch for setting Demand control step

④ Digital Output : Operating & Error status Relay output (250 V, 1 A)

Reserved Relay output (250 V, 1 A)

⑤ Digital Input : Dry contact input

ۀ

ڿ

ھ

⑥ Analog Input : DC 0 ~ 10 V Analog signal input

⑦ Analog Output : DC 0 ~ 10 V Analog signal output

⑧ SW103 : Reset Switch

⑨ SW101 : DIP Switch for setting operating function

6 Low Ambient Control Kit

Page 39

Installation Method

ڸ

ڹ

ں

Installation Method

IO Module Installation Method

① Separate front panel from outdoor unit.

② Separate front cover of control box.

③ Assemble IO Module and bracket.

Connect the connection wires according to the instructions. (Please refer to Setting and Using Method)

④

+

ENGLISH

Main board connector

!

CAUTION

Be sure to turn off outdoor unit power before installation.

ڻ

Installation manual 7

Page 40

Installation Method

⑤ Fix and fasten components and cables.

⑥ Perform the switch setting according to the instructions.

8 Low Ambient Control Kit

Page 41

Installation Method

+

+

Transformer

Clamp

Bracket 2 and

Bracket 4

Terminal Block

Transformer, Terminal Block Installation Method

① Shut off the main power of outdoor unit.

② Install the IO Module in the C/Box by using screws.

③ Install the Bracket2 in the C/Box by using screws.

④ Install the transformer on the Bracket2 by using screws.

⑤ Install the terminal block on the Bracket2 by using screws.

⑥ Connect the Main PCB(CN10) to IO Module(CN101) by using the cable assembly.

⑦ Connect the blue cable of transformer to the Main PCB(JIG_N), brown cable of transformer to

the Main PCB(JIG_L).

⑧ Connect the red cable of transformer to the terminal block (2Pin Yellow terminal block).

⑨ Connect a power cable(DC 12 V) to CN101(12 V,GND) of IO Module.

⑩ Connect the black cable of Damper Actuator to the terminal block and connect the cable of

IO Module(CN1_A0(GND(A-)) to the black cable of Damper Actuator.

⑪ Connect the red cable of Damper Actuator to CN1_A0(A0_1(A+)) of IO Module.

⑫ Set up the main function DIP S/W of IO Module.

(SW101 : L1,L2=On and L3,L4=Off / SW102 : L1,L2=Off)

⑬ Set up the DIP S/W of Main Outdoor unit PCB. (Refer to page 21 for details)

⑭ Turn on the main power of outdoor unit.

⑮ Check the signal to CN1_A0(AO_01,GND) of IO Module and Air Damper.

ENGLISH

Installation manual 9

Page 42

Installation Method

Actuator Wire

Using the Clamp and Tie, fasten the Damper Actuator output cable and Trans output cable as

below.

10 Low Ambient Control Kit

Page 43

Setting and Using Method

Power source input

Setting and Using Method

ENGLISH

LG does not supply this

section (Field supply)

Power

AC or DC

ڻ

Power

AC or DC

Status output Relay can

endure 250 VAC, 1 A.

Power

AC or DC

ڻ

Power

AC or DC

Error Status

Operating Status

Reserved

Reserved

ڸ

Input_LNO

Input_1Input_2

Input_3

Reserved

Priority setting

Reserved

Input_7

AI : Analog Input (DC 0 ~ 10 V)

AO : Analog Output ( DC 0 ~ 10 V, Max 20 mA)

Input_LNO : Low Noise Operation

① Dry contact input part

Connect Non Voltage contact signal for demand control (3 step)

* Priority setting

Using ‘Priority setting’ contact signal, set the priority of command.

(External command from DDC Vs Command from LG central controller.)

- Close : Central controller has priority to external signal.

- Open : External signal has priority to central controller.

② Analog input part

Connect Analog input signal for demand control (10 step)

③ Analog output part

Connect Analog output signal for controlling third party devices.

Ex) Valve actuator for variable water flow. Damper actuator for Low Ambient Kit

④ Digital output part

Connect status display devices.

AO_4 GND

AO_3 GND

AO_4

AO_3

AO_2 GND

AO_1 GND

AO_2

AO_1

Reserved

AI_1

ں

ڹ

!

CAUTION

Power must be turned on after the product is wired completely.

Installation manual 11

Page 44

Setting and Using Method

n

Communication and Power Line

- If communication and power lines are run alongside each other then there is a strong likelihood of

operational faults developing due to interference in the signal wiring caused by electrostatic and

electromagnetic coupling. The tables below indicates our recommendation as to appropriate spacing

of communication and power lines where these are to be run side by side.

Current capacity of power line Spacing

10 A 11-13/16 in (300 mm)

100 V or more

Notes

If the power supply waveform continues to exhibit some distortion the recommended spacing in the

table should be increased.

• If the lines are laid inside conduits then the following point must also be taken into account when

grouping various lines together for introduction into the conduits.

• Power lines (including power supply to air conditioner) and signal lines must not be laid inside the

same.

• In the same way, when grouping the lines power and signal lines should not be bunched together.

50 A 19-11/16 in (500 mm)

100 A 39-3/8 in (1 000 mm)

Exceed 100 A 59-3/64 in (1 500 mm)

12 Low Ambient Control Kit

Page 45

Setting and Using Method

ON

L1 2 3 4

ON

L1 2

IO Module – Low Ambient Kit Function

Setting of DIP Switch

Using ‘SW101’, ‘SW102’, You can use Low Ambient Kit Mode

ON

ON

4

3

2

L1

2

L1

ENGLISH

Notes

Default status is all off.

Set Low Ambient Kit Operation

Position Setting of DIP Switch

SW101 - L1=ON

SW102 - L1=OFF

!

CAUTION

•

If the DIP SW is set , IO module System is operating preferentially than outdoor unit setting.

• After change DIP SW setting, press reset switch to reflect the setting.

L2=ON

L3=OFF

L4=OFF

L2=OFF

Installation manual 13

Page 46

Setting and Using Method

ON

L1 2 3 4

ON

L1 2 3 4

IO Module – Other Function

Setting of DIP Switch

Using ‘SW101’, select the option of control function as described below.

ON

Notes

Default status is all off.

• L3 : Set Low Noise Operation

This is a function driving outdoor unit fan RPM to operate low speed for reducing fan noise

according to the input signal. To use this function, you should set Outdoor unit mode, Please

refer to PDB more detail.

Position Function

!

CAUTION

If the DIP SW is set , IO module System is operating preferentially than outdoor unit setting.

4

3

2

L1

ON : Enable Low Noise Operation

OFF : Disable Low Noise Operation

• L4 : Set Operating status output

Position Function

ON : Activate Digital Output according to Indoor Unit status

OFF : Activate Digital Output according to Outdoor Unit status

!

CAUTION

After change DIP SW setting, press reset switch to reflect the setting.

14 Low Ambient Control Kit

Page 47

Setting and Using Method

ON

L1 2

ON

L1 2

Using ‘SW102’, set the internal function as described below.

ON

2

L1

Notes

Default status is all off.

• L1 : Set Analog output default value when Communication Error will be occur (Module – ODU)

Position Function

ON : Analog output 0 V

OFF : Analog output 10 V

ENGLISH

• L2 : Set Analog output Range

Basically this module keeps a minimum Analog output voltage refer to L1,L2 setting of SW101 to

prevent unexpected accident. When you need to use 0~10 V full range, L2 should be set as ON.

Position Function

ON : Ignore minimum Analog output value setting

(L1,L2 setting value of 4pin DIP SW)

OFF : Follow minimum Analog output value setting

(L1,L2 setting value of 4pin DIP SW)

!

CAUTION

After change DIP SW setting, press reset switch to reflect the setting.

Installation manual 15

Page 48

Setting and Using Method

Setting of Rotary Switch

Use the Rotary Switch to set a control step for contact signal input : The type of input signal and

control step can be set using ‘SW104’

This function is for demand control to reduce power consumption.

Set the control mode what you want according to the table as below.

- Type of input signal

SW_STEP

0, 1, 2, 3, 4, 5, 6, 7 Contact signal input

C, D, E Analog input signal

!

CAUTION

Do not change a command too quickly.

Keep the command 30 seconds at least, otherwise it will cause a damage to outdoor unit.

• Operation rate condition :

- Cooling : Outdoor 35 °C, Indoor 27 °C

- Heating : Outdoor 7 °C, Indoor 20 °C

• The tolerance of the operation rate can be cause by combination of outdoor unit, operating

condition, installation circumstance.

• When operation rate is 100 %, Target Evaporating Temp. and Target Condensing Temp. can be

changed by installation option. (Refer to product data book)

• Input_1 : 0 Έ OFF, Input_1 : 1 Έ ON

Input signal

16 Low Ambient Control Kit

Page 49

Setting and Using Method

Wiring for Damper Actuator

1 Unit

Transformer

RD

AC 220 V

RD

Terminal

Block

BL

BR

IO Module

Main PCB Power Module

Damper

Actuator

ENGLISH

WH

GR

BK

RD

AC/DC 24 V

DC 0~10 V

Control Signal

h BL : Blue, BR : Brown, RD : Red, BK : Black, WH : White, GR : Green

Notes

Damper Actuator can accept only DC 24 V power input.

Do not input AC power. Otherwise it will cause a serious damage.

The IO Module can control maximum three actuators.

Case of one valve, the slave signal connector must not use.

The power (AC/DC 24 V) and signal(DC 0~10 V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

Installation manual 17

Page 50

Setting and Using Method

2 Unit

BL

Main PCB Power Module

BR

Transformer

RD

RD

BK

AC 220 V

RD

Terminal

Block

IO Module

GR

GR

BK

RD

BK

RD

Damper

Actuator

WH

Damper

Actuator

WH

Notes

Damper Actuator can accept only DC 24 V power input.

Do not input AC power. Otherwise it will cause a serious damage.

The IO Module can control maximum three actuators.

Case of one valve, the slave signal connecter must not use.

The power (AC/DC 24 V) and signal(DC 0~10 V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

18 Low Ambient Control Kit

Page 51

Setting and Using Method

3 Unit

Transformer

RD

RD

BK

BL

AC 220 V

RD

Terminal

Block

BR

IO Module

GR

GR

GR

BK

RD

BK

RD

Main PCB Power Module

Damper

Actuator

WH

BK

RD

Damper

Actuator

WH

Damper

Actuator

WH

ENGLISH

Notes

Damper Actuator can accept only DC 24 V power input.

Do not input AC power. Otherwise it will cause a serious damage.

The IO Module can control maximum three actuators.

Case of one valve, the slave signal connecter must not use.

The power (AC/DC 24 V) and signal(DC 0~10 V) line is recommended by AWG22(1/32 in, (0.644 mm),

0.016 Ω/ft (0.053 Ω/m)).

Installation manual 19

Page 52

Setting and Using Method

Setting of Outdoor Unit DIP Switch

Low Ambient Kit Mode

• Low Ambient Kit mode Setting method

Master unit PCB DIP switch on : No.5

Select the mode using ‘▶’, ‘◀’ Button :

“Func” Push the '●' (Confirm) button

Select the Function using ‘▶’, ‘◀’ Button :

DIP SWITCH 7-Segment

“Fn10 or Fn11” Push the '●' (Confirm) button

Select the Function using ‘▶’, ‘◀’ Button :

“On” Push the '●' (Confirm) button

Low Ambient Kit mode is set

h If you want to stop the Low Ambient Kit mode, refer to the following.

▷ DIP Switch No.5 On -> “Func” -> “Fn10” -> “Off”

h Fn10 Model : ARUB***BTE4

ARUB***DTE4

ARUB***LTE4

Fn11 Model : ARUN***BTE4

ARUN***DTE4

ARUN***LTE4

ARUN***LTS4

SW04C ( X : cancel)

SW03C (

SW02C ( : backward)

SW01C ( : confirm)

SW01D (reset)

: forward)

ȯ

ȭ

Ɨ

20 Low Ambient Control Kit

Page 53

Installation Method of Snow Hood and Air Damper

ENGLISH

Installation Method of Snow Hood and Air Damper

One Unit with Snow Hood and Air Damper

One Unit with Snow Hood and Air Damper

Installation manual 21

Page 54

Installation Method of Snow Hood and Air Damper

Two and Three Units with Snow Hood and Air Damper

Two Units with Snow Hood and Air Damper

Three Units with Snow Hood and Air Damper

22 Low Ambient Control Kit

Page 55

Installation Method of Snow Hood and Air Damper

Top View

Prevailing wind

Building Wall

Outdoor Unit

H ≤ discharge

of air damper

Unit Placement and Clearances

1. Outdoor units should be located in an area protected from prevailing winds. (shown below)

In high wind locations it may be advisable to locate the units within a walled area.

ENGLISH

2. If the units are surrounded by an enclosure, the discharge of the air damper must direct the air out and over the

enclosure walls to prevent air recirculation.

Installation manual 23

Page 56

Installation Method of Snow Hood and Air Damper

3. When the distance is less than 7-7/8 in(200 mm) between outdoor units, do not necessary installation of side

Snow Hood as below.

7-7/8 in(200 mm)

7-7/8 in(200 mm)7-7/8 in(200 mm)

24 Low Ambient Control Kit

Page 57

Installation Method of Snow Hood and Air Damper

4. If units are placed further than 7-7/8 in(200 mm) apart, additional snow hoods may be required.

ENGLISH

Installation manual 25

Page 58

26 Low Ambient Control Kit

Page 59

ENGLISH

Installation manual 27

Page 60

Representative: LG Electronics Inc. EU Representative, Krijgsman 1, 1186 DM

Manufacturer: LG Electronics Inc. Changwon 2nd factory, 84, Wanam-ro,

Amstelveen, The Netherlands

Seongsan-gu, Changwon-si, Gyeongsangnam-do, KOREA

Loading...

Loading...