Page 1

LIMBA ROMÂNĂ

ENGLISH

УКРАÏНСЬКА

中文

РУССКИЙ ЯЗЫК

ČEŠTINA

OWNER’S & INSTALLATION

MANUAL

AIR CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

WIRED REMOTE CONTROLLER

PREMTW101

MFL69312308

Rev.00_102119

DEUTSCH

ΕΛΛΗΝΙΚΆ

ESPAÑOL FRANÇAIS

ITALIANO

NEDERLANDS

POLSKI

www.lg.com

Copyright © 2019 LG Electronics Inc. All Rights Reserved.

Page 2

TIPS FOR SAVING ENERGY

2

SAFETY INSTRUCTIONS

3

ENGLISH

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

• Do not cool excessively indoors. This may consume more electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block

the air flow or reduce the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

SAFETY INSTRUCTIONS

The following safety guidelines are intended to prevent unforeseen risks or damage from unsafe

or incorrect operation of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as described below.

This symbol is displayed to indicate matters and operations that can cause risk.

Read the part with this symbol carefully and follow the instructions in order to avoid

!

risk.

WARNING

!

This indicates that the failure to follow the instructions can cause serious injury or death.

CAUTION

!

This indicates that the failure to follow the instructions can cause the minor injury or damage

to the product.

WARNING

!

Installation

• For electrical work, contact the dealer, seller, a qualified electrician, or an authorized service

Center.

- Do not disassemble or repair the product. There is risk of fire, electric shock, explosion,

equipment malfunction, or injury.

• Request to the service center or installation specialty store when reinstalling the installed

product.

- There is risk of fire, electric shock, explosion, equipment malfunction, or injury.

• Do not disassemble, fix, and modify products randomly.

- There is risk of fire, electric shock, explosion, equipment malfunction, or injury.

• The product shall be installed according to the national standards and local code.

• Apply totally enclosed noncombustible conduit in case of local building code requiring plenum.

• Use appropriate unit mounting procedures.

• Avoid direct sunlight.

• Avoid moist areas.

In-Use

• Do not place flammable objects close to the product.

- There is risk of fire, electric shock, explosion, equipment malfunction or injury.

• Do not allow product to get wet.

- There is risk of fire, electric shock, explosion, equipment malfunction or injury.

• Avoid dropping the product.

- There is risk of fire, electric shock, explosion, equipment malfunction or injury.

Page 3

SAFETY INSTRUCTIONS

4

• If product gets wet, contact your dealer or authorized service center.

- There is risk of fire, electric shock, explosion, equipment malfunction, or injury. If the

instructions are not followed, it may cause death or severe injury of the user.

• Do not use sharp or pointed objects on product.

- There is risk of fire, electric shock, explosion, equipment malfunction or injury.

• Do not touch or pull the lead wire with wet hands.

- There is risk of product breakdown or electric shock.

CAUTION

!

In-Use

• Do not clean using powerful detergents like solvent but use soft cloths.

There is risk of fire, electric shock, explosion, equipment malfunction or deformation.

• Do not press the screen using powerful pressure.

There is risk of product break-down or malfunction.

TABLE OF CONTENTS

2 TIPS FOR SAVING ENERGY

3 SAFETY INSTRUCTIONS

8 DESCRIPTION

8 Remote controller

9 DESCRIPTION OF THE OPERATION

9 Main screen

9 Menu screen

10 Setting screen

10 Popup screen

11 Monitoring

12 Returning to the screen

12 OPERATION SETTING

12 On / Off

12 Operation mode

13 Cooling operation

14 Heating operation

15 AI / Auto operation

16 TEMPERATURE SETTING

16 Controlling desired temperature

17 DHW heating operation

17 Quick DHW tank heating

18 View temperature

20 Zone target temperature

21 LOCK SETTING

21 How to enter Lock setting

22 Lock setting – all, on/off, mode, DHW lock

23 TIMER SETTING

23 Timer entrance and setting method

24 Simple Timer

25 Turn-On Reservation

26 Turn-Off Reservation

27 SCHEDULE SETTING

27 How to enter schedule

28 Daily schedule

29 Schedules & Edit

30 Schedules & Edit – Add schedule

31 Exception Day

TABLE OF CONTENTS

5

ENGLISH

Page 4

TABLE OF CONTENTS

32 INFORMATION OF METER INTERFACE

33 FUNCTION SETTING

33 How to enter function setting

34 Function setting

35 Low Noise Mode Time

36 Wi-Fi Pairing

37 Water Temperature Setting

38 3nd Party Boiler

39 USER SETTING

39 How to enter user setting

39 User Setting

40 Language

41 Temperature Unit

42 Screen Saver Timer

42 LCD Brightness In Idle

43 Date

44 Time

45 Summer Time

46 Password

47 Schedule Initialization

48 Theme

48 System Reboot

49 SERVICE SETTING

49 How to enter service setting

49 Service setting

50 Service Contact

51 Model Information

52 RMC Version lnformation

53 Open Source License

54 INSTALLATION

54 Installation of Remote Controller

56 Group control

59 INSTALLER SETTING

59 How to enter installer setting

60 Installer setting

63 Test Run

64 3 Minutes Delay

65 Select Temperature Sensor

66 Dry Contact Mode

67 Central Control Address

68 Override Master/Slave

69 Pump test run

70 Air cooling set temp

71 Water cooling set temp

72 Air heating set temp

73 Water heating set temp

74 DHW set temp

75 Cooling / Heating only mode

76 Screed drying

78 Heater on temperature

80 Water supply off temp. during cooling

82 Outdoor temp. for auto mode

83 Indoor air temp. for auto mode

84 LWT for auto mode

85 Tank disinfection setting 1, 2

86 Tank setting 1

87 Tank setting 2

89 Heater priority

90 DHW time setting

91 Use Heating Tank Heater

92 Pump frequency setting (LPM)

93 TH on/off Variable, heating air

94 TH on/off Variable, heating water

95 TH on/off Variable, cooling air

96 TH on/off Variable, cooling water

97 Heating temp. setting

98 Cooling temp. setting

99 Pump setting in heating

100 Pump setting. in cooling

101 Forced operation

102 CN_CC

103 Pump Capacity

104 Pump frequency setting (RPM)

105 Smart Grid(SG)

106 Seasonal auto temp

108 Modbus Address

109 Refrigerant Leak Sensor

110 IDU Address Verification

111 CN_EXT

112 ODU Function Master

113 Low Noise Mode Priority

114 Anti-freezing Temperature

115 Add Zone

116 Use External Pump

117 3rd Party Boiler

118 Meter Interface

119 Estimated energy display

120 Pump Prerun/Overrun

121 Solar Thermal System

123 Zone

125 Current flow rate

126 Data logging

127 Password Initialization

128 RMC master/slave

129

NOTICE

129 OPEN SOURCE SOFTWARE NOTICE INFORMATION

TABLE OF CONTENTS

76

ENGLISH

Page 5

DESCRIPTION

8

DESCRIPTION OF THE OPERATION

9

ENGLISH

DESCRIPTION

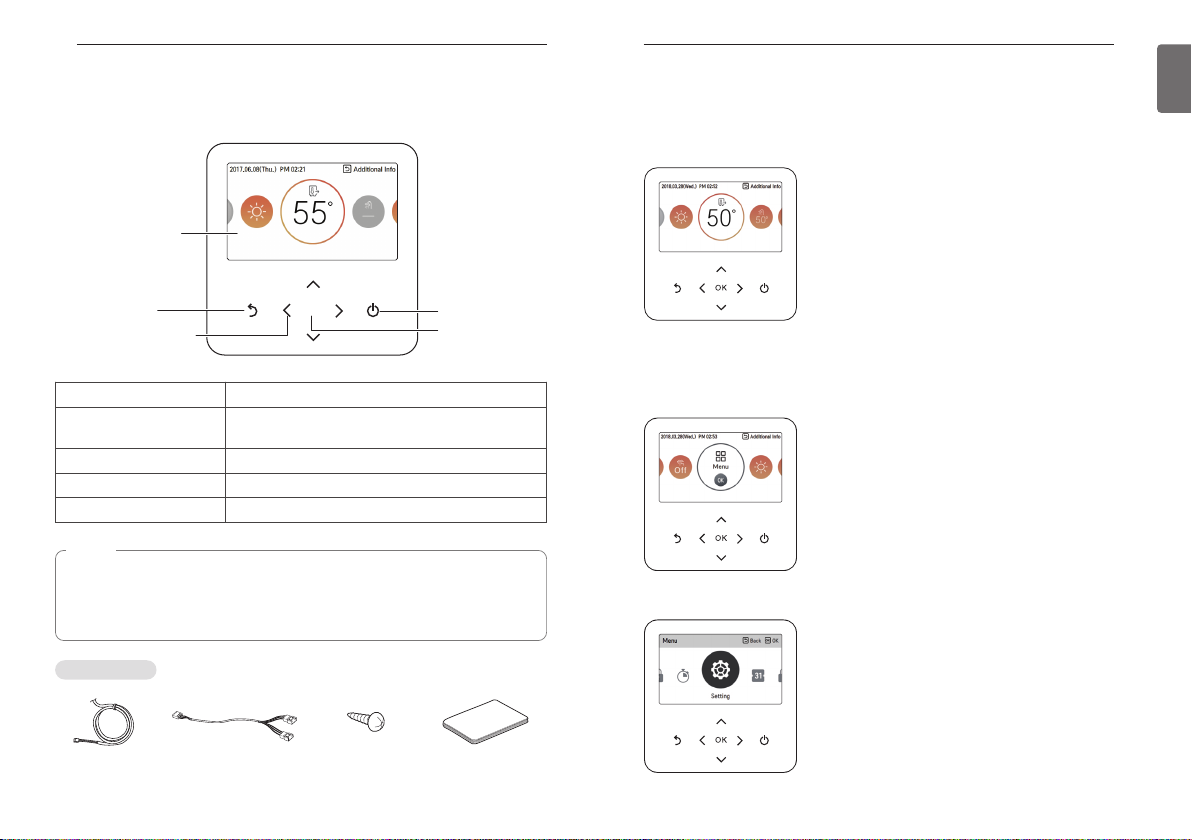

Remote controller

Operation display

window

Back button

Up/Down/Left/Right

button

Operation display window Operation and Settings status display

Back button

Up/down/left/right button

OK button

On/Off button When you turn ON/OFF the air conditioner

When you move to the previous stage from the menu’s

setting stage

When you change the menu’s setting value

When you save the menu’s setting value

NOTE

• Some functions may not be operated and displayed depending on the product type.

• The actual product can be different from above contents depending upon model type.

• When using simultaneous operation system, whenever press remote controller button,

system will approximately operate after 1~2 minutes.

OK

On/Off button

OK button

DESCRIPTION OF THE OPERATION

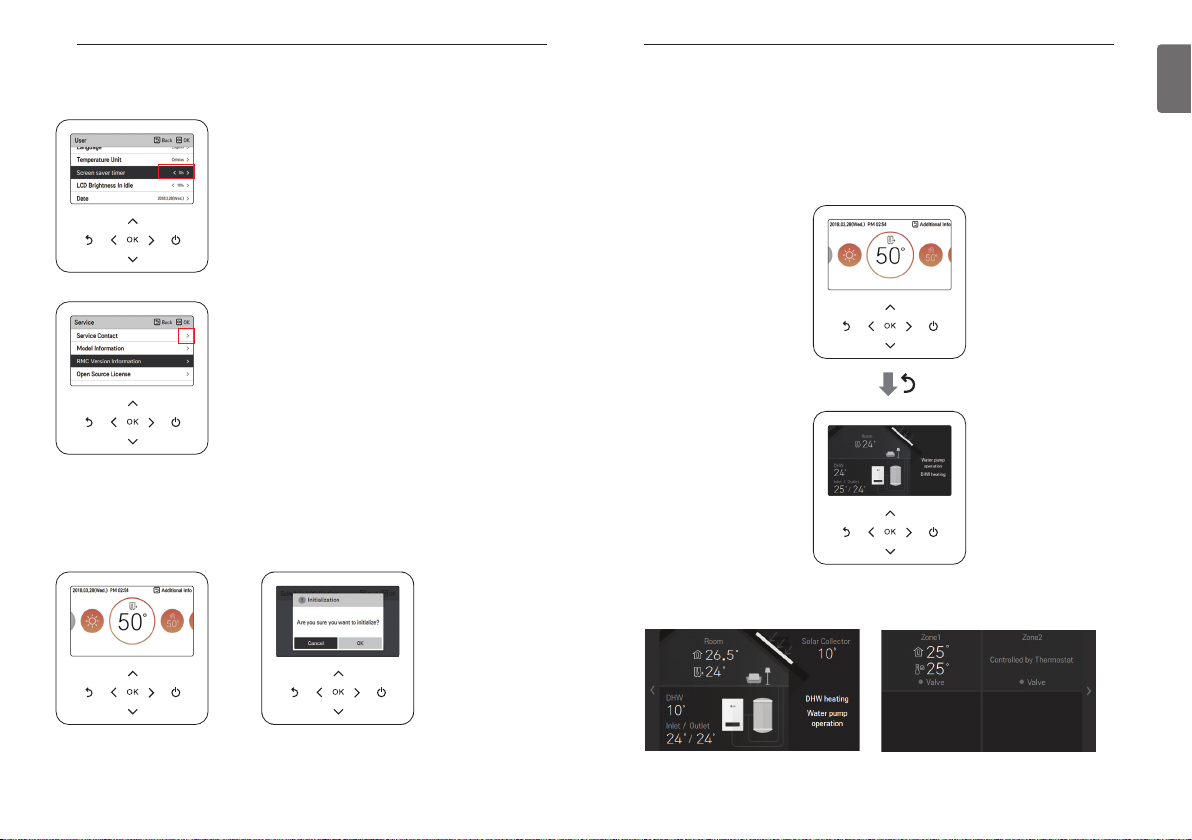

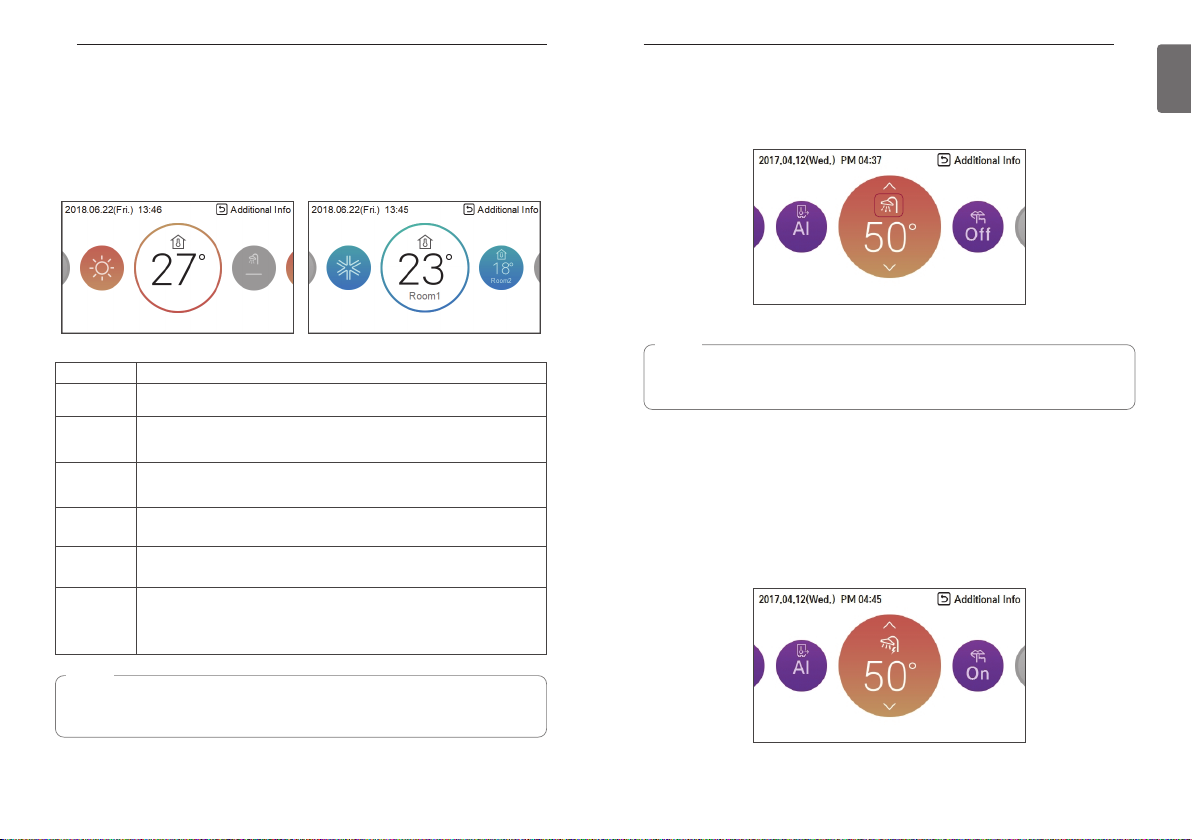

Main screen

In the main screen, press [<, >(left/right)] button to select the category to set, and you can

control by pressing [∧,∨ (up/down)] button.

Menu screen

In the main screen, press [<, >(left/right)] button to select the menu and press [OK] button to

move to menu screen.

In the menu screen, press [<, >(left/right)] button to select the category to set, and press [OK]

button to move to the detail screen.

Accessories

Connecting Cable 2-Remo cable Remote controller

fixing screws

(4 EA)

Quick Guide

Page 6

DESCRIPTION OF THE OPERATION

10

Setting screen

Select the category to set using [∧,∨(up/down)] button.

In each detail screen of the menu, as in the box in the left figure,

when “<,>” icons are displayed at the same time, you can

immediately apply the setting value by pressing [<, >(left/right)]

button.

※ For the values that can be set in each category, refer to the

detail manual for each function.

In each detail screen of the menu, as in the box in the left figure,

if only “>” icon is displayed, you can move to the detail setting

screen by pressing [>(right) or OK] button.

※ For the values that can be set in each category, refer to the

detail manual for each function.

Popup screen

The toast message is the message displayed at the bottom of the screen when an operation is

turned On/Off or if a function is set / cancelled.

The popup message is mainly displayed when an error occurred in the product.

DESCRIPTION OF THE OPERATION

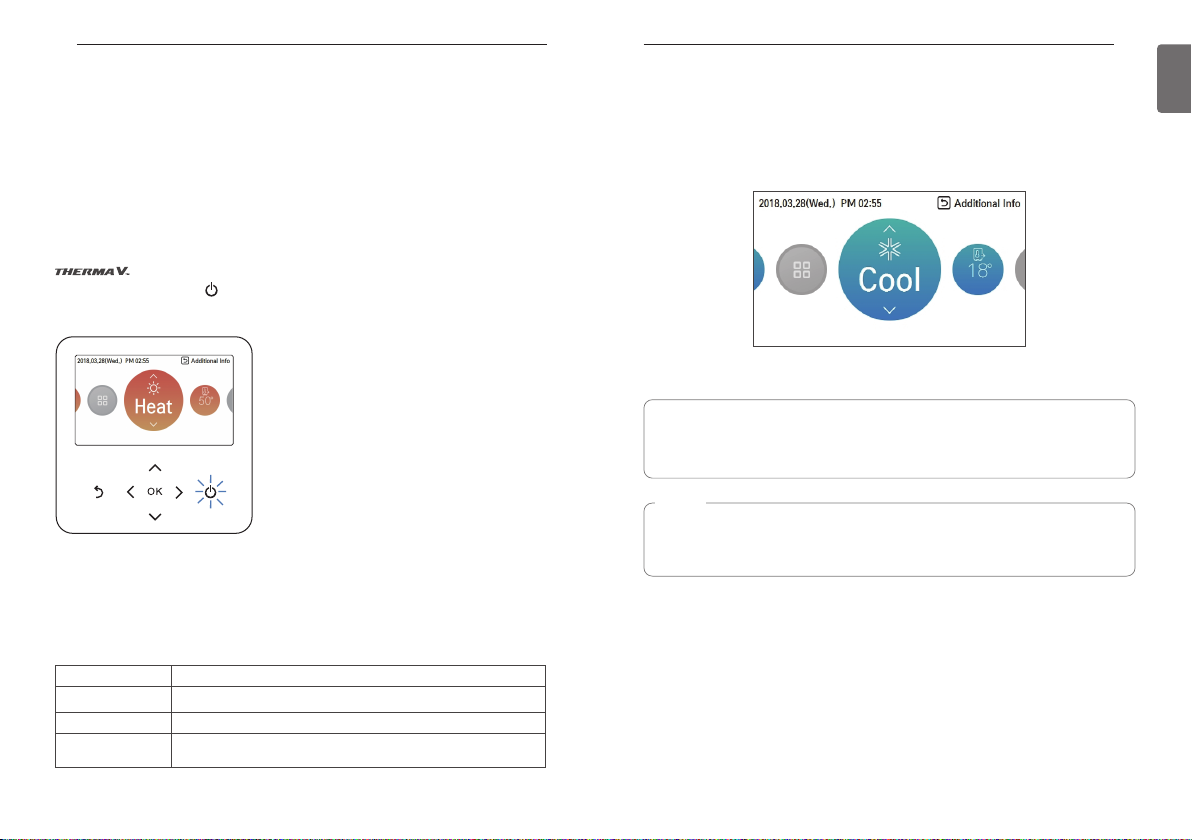

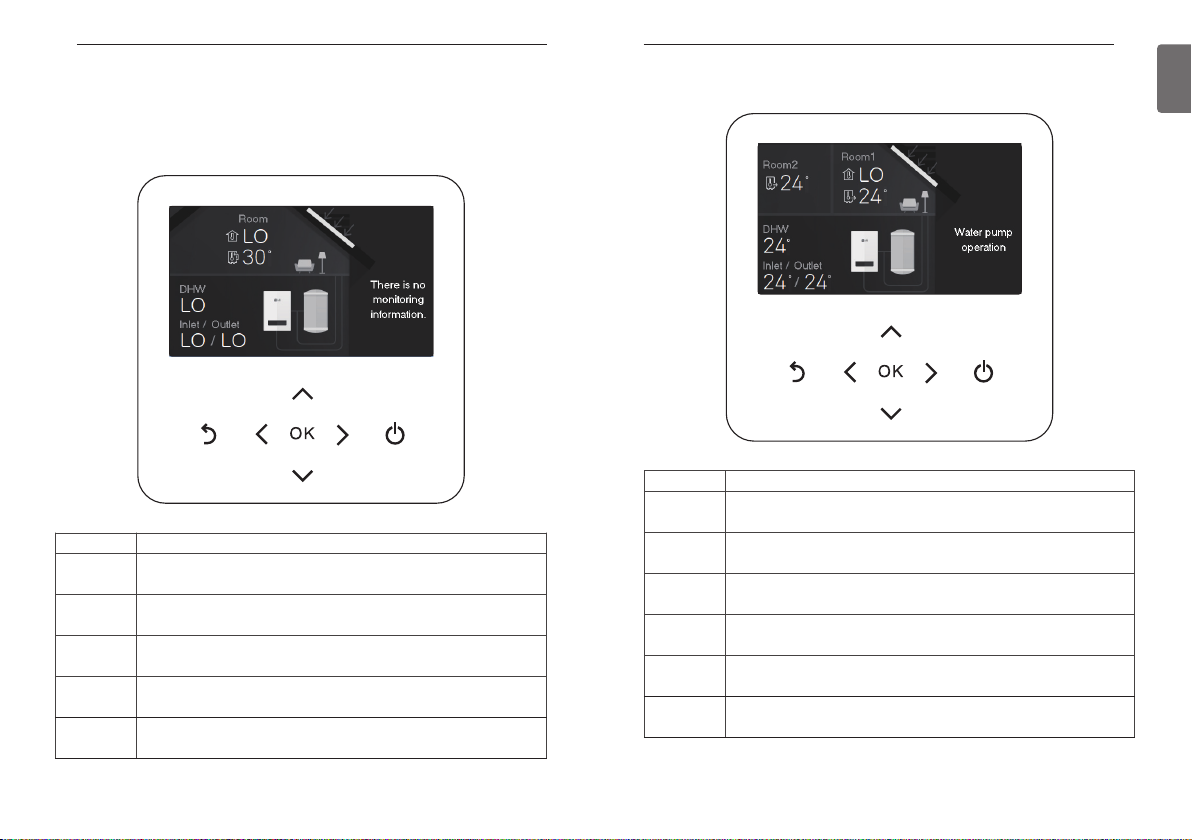

Monitoring

In the main screen, you can enter the monitoring screen by pressing [Back] button

In the monitoring screen, you can check the following information,

- The room temperature

- The water inlet / outlet temperature

- The water pump operation

- The zone status (when set the zone usage via installer setting)

When set the zone usage via installer setting.

11

ENGLISH

< Toast message > < Popup message >

Page 7

OPERATION SETTING

12

Returning to the screen

In the main screen, after moving to the category by pressing [<, >(left/right)] button, if there is no

remote controller operation, after 10 seconds, it returns to the main screen basic position. (basic

position: indoor temperature display part)

In the screens except the main screen, if there is no remote controller operation for 1 minute, it

moves to the main screen.

OPERATION SETTING

On / Off

Press the remote controller’s (On/Off) button.

- If the product is in operation, On/Off button will be illuminated.

If the product is in off, On/Off button backlight will be off.

Operation mode

You can easily control the desired operation mode.

In the main screen, press [<,>(left/right)] button to select the operation mode or home leave or

hold category, and press [∧,∨(up/down)] button to set the operation mode.

※Some products may not support some operation modes.

will be turned on or off.

Mode Description

Cool Cool the room to the desired temperature.

Heat Heats the room to the desired room temperature.

AI / Auto

The product automatically provides the appropriate fan speed based on

the temperature of the room.

OPERATION SETTING

Cooling operation

- Set the desired temperature lower than the water temperature.

- water temperature is displayed on the default screen of the remote controller.

- If the setpoint is set higher than the water temperature, then the unit will remain in the cool

mode but will not begin to cool the water temperature exceeds the setpoint.

- If your unit is operating in cooling mode and you press the [On/Off] button the cooling operation

will shut off.

What is 3 minute delay function?

After the cooling stops, when the product is started right away, the reason that the cold

water does not come out is that it is the function to protect the compressor.

The compressor starts after 3 minutes and the cold water comes out.

NOTE

The compressor starts after 3 minutes and the cold water comes out.

The favorable temperature difference between the water inlet temperature and outlet

temperature is 5 °C.

13

ENGLISH

Page 8

OPERATION SETTING

14

Heating operation

- Set the desired temperature higher than the water temperature.

- Water temperature is displayed on the default screen of the remote controller.

- When the desired temperature is set lower than the water temperature, warm water doesn't

come out.

- If your unit is operating in heating mode and you press the [On/Off] button the heatling

operation will shut off.

OPERATION SETTING

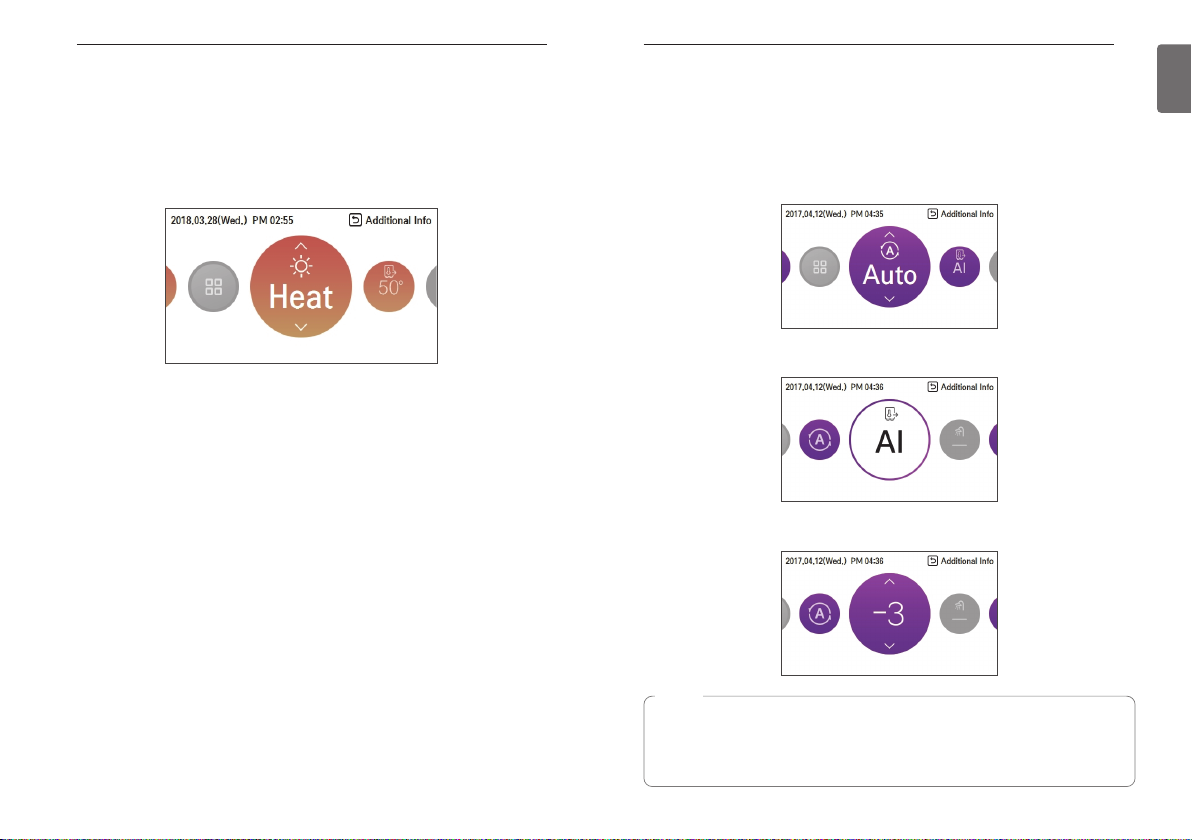

AI / Auto operation

This mode is only applied to heating.

In order to save energy and to give highest comfort, setting temperature will follow outside

temperature. If outdoor temperature decreases, heating capacity for the house will increase

automatically in order to keep same room temperature. All parameters will be set by installer

during start-up procedure and will be adapted to the site characteristic.

1. Select AI / Auto mode.

2. Select the desired temperature category

3. Adjust the desired temperature level by press [∧,∨(up/down)] button.

15

ENGLISH

NOTE

Decreasing temperature profile by 3 °C (based on room air temperature)

<Temperature adjust step (unit : °C)>

-5, -4, -3, -2, -1, 0, 1, 2, 3, 4, 5

Cold Hot

Page 9

TEMPERATURE SETTING

16

TEMPERATURE SETTING

Controlling desired temperature

You can easily control to the desired temperature.

• In the main screen, press [<, > (left/right)] button to select the desired temperature category,

and press [∧,∨(up/down)] button to set the desired temperature.

- In the cooling, heating, and AI/auto mode, the desired temperature control is possible.

Mode Description

Room

temperature

Room 1 &

Room 2

temperature

Leaving water

temperature

DHW tank

temperature

Water inlet

temperature

Room

temperature +

Leaving water

temperature

Room temperature can be set by using remote sensor's internal temperature

sensor.

Temperature of Room 1 and Room 2 can be set respectively, when 2nd

circuit option is activated in installer mode.

If the desired temperature is lower than the water temperature, the heating

is not performed.

Set the desired temperature higher than the water temperature.

DHW tank temperature setting is available when DHW tank is installed.

This operation is changed to the temperature sensor only, the inlet

temperature sensor, and temperature control logic is the same as the leaving

water temperature operation.

Room temperature can be set by using remote sensor's internal temperature

sensor. If the desired temperature is lower than the water temperature, the

heating is not performed. Set the desired temperature higher than the water

temperature.

TEMPERATURE SETTING

DHW heating operation

Funtion to set whether or not to use a installed DHW tank

Press the [<] or [>] button to focus on the DHW icon, and press the ON / OFF button.

NOTE

• This function is not used when the DHW tank is not installed.

• If you want to know more information, refer function on installation information section.

Quick DHW tank heating

If there is urgent DHW heating demand, Quick DHW Tank Heating mode can be used to reduce

the time to reach target DHW tank temperature by forcibly turning on DHW tank heater.

After reaching target DHW tank temperature or by user’s input to stop, Quick DHW Tank Heating

mode will be finished.

1. Press down [Back] button for a second focused on DHW Heating Operation.

17

ENGLISH

NOTE

The function can be activated according to the installer setting.

Refer to the installer setting “Select temperature sensor”.

Page 10

TEMPERATURE SETTING

18

View temperature

General mode

You can check the current temperature.

• In the main screen, you can enter the monitoring screen by pressing [Back] button.

Mode Description

Room

temperature

temperature

Outlet

temperature

DHW

temperature

Solar heat

temperature

View room temperature

Inlet

View inlet temperature

View outlet temperature

View DHW temperature

(Only displayed when DHW heating mode)

View solar power temperature

(Only displayed when DHW water heating mode)

2ndcircuit mode

Mode Description

Room 1

temperature

Room 2

temperature

temperature

Outlet

temperature

DHW

temperature

Solar heat

temperature

View room 1 temperature

View room 2 temperature

Inlet

View inlet temperature

View outlet temperature

View DHW temperature

(Only displayed when DHW heating mode)

View solar power temperature

(Only displayed when DHW water heating mode)

TEMPERATURE SETTING

19

ENGLISH

Page 11

TEMPERATURE SETTING

20

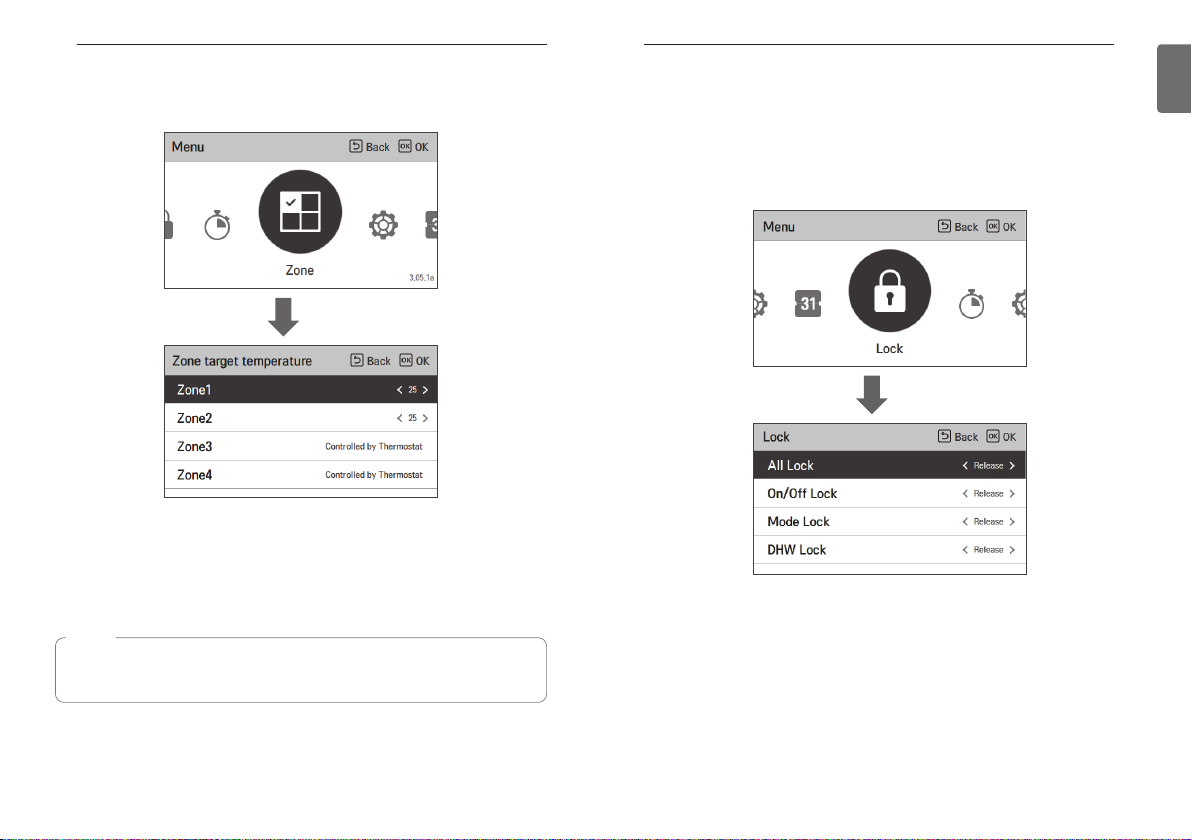

Zone target temperature

It is the function to set the target temperature for valve control by zone.

OK

• The number of zones set in the zone setup menu of installer setting is activated.

- For zone selected by sensor type: Set the target temperature (16 ~ 30 °C) or Open / Close

- For zones selected by thermostat: Display "Controlled by Thermostat"

(Temperature not controllable)

LOCK SETTING

LOCK SETTING

How to enter Lock setting

• In the menu screen, press [<,>(left/right)] button to select “lock setting” category, and press

[OK] button to move to the lock setting list screen.

• In the lock setting list, if you press [∧,∨(up/down)] button, you can turn on/off the

corresponding lock function.

OK

21

ENGLISH

NOTE

This function is not default.

It can be activated, after setting value in installer mode.

Page 12

LOCK SETTING

22

Lock setting – all, on/off, mode, DHW lock

• It is the function to lock the button operation of the remote controller so that children or other

persons cannot use it without permission.

•

It is the function to limit the desired temperature range that can be set in the wired remote controller.

Mode Description

All Lock It locks all button operation of the remote controller.

On/Off Lock It locks the On/Off button operation of the remote controller.

Mode Lock lock It locks the operation mode button operation of the remote controller

DHW Lock lock It locks the DHW On/Off button operation of the remote controller.

NOTE

• DHW lock is not used when the DHW tank is not installed.

• If you want to know more information, refer function on installation information section.

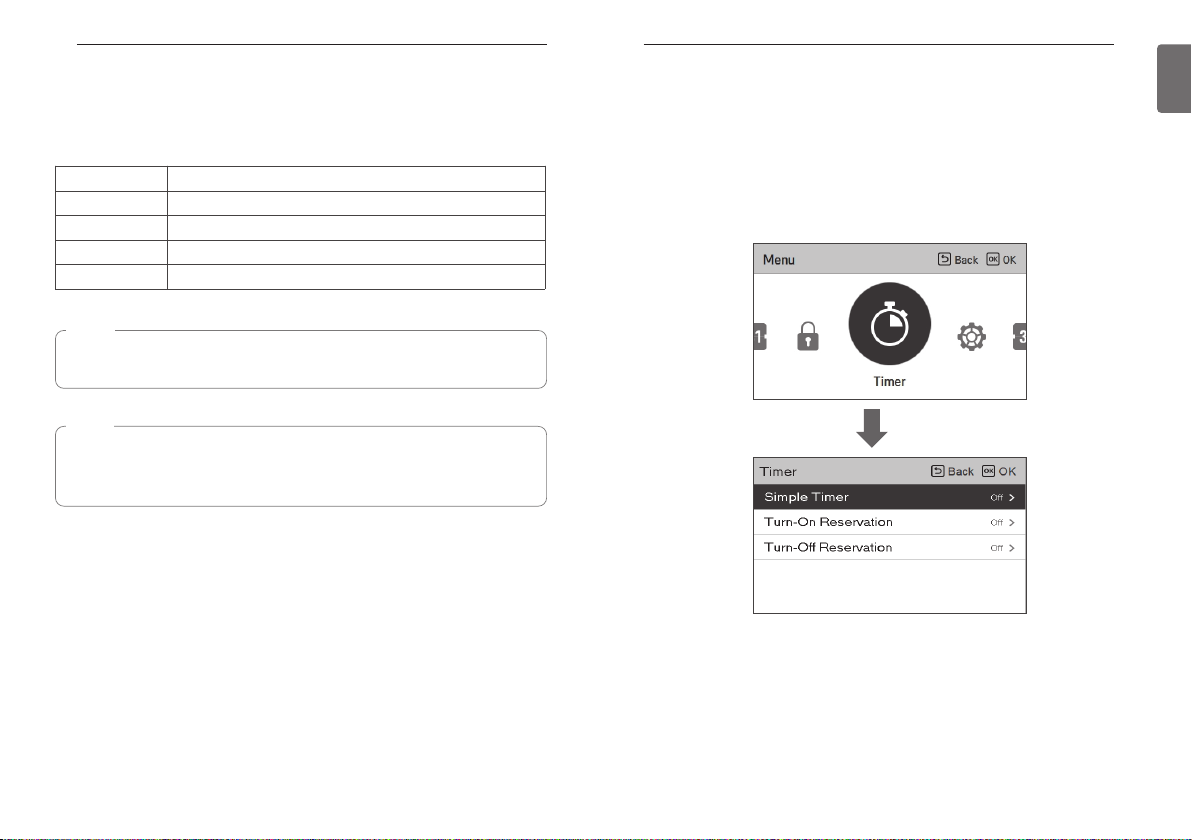

TIMER SETTING

TIMER SETTING

Timer entrance and setting method

• In the menu screen, press [<,>(left/right)] button to select the timer category, and press [OK]

button to move to the timer setting list screen.

• In the timer setting list screen, press [∧,∨(up/down)] button to select the timer to set, and

press [OK] button to move to the detail screen.

• After setting the value, when you press [OK] button, the timer is activated.

• After setting the value, if you press [Back] button, the changed value will not be applied.

23

ENGLISH

NOTE

In the central controller, when the central control temperature range lock is set, the wired

remote controller’s temperature lock setting is cleared.

The temperature change by external equipment is reflected regardless of the remote

controller temperature range lock.

OK

Page 13

TIMER SETTING

24

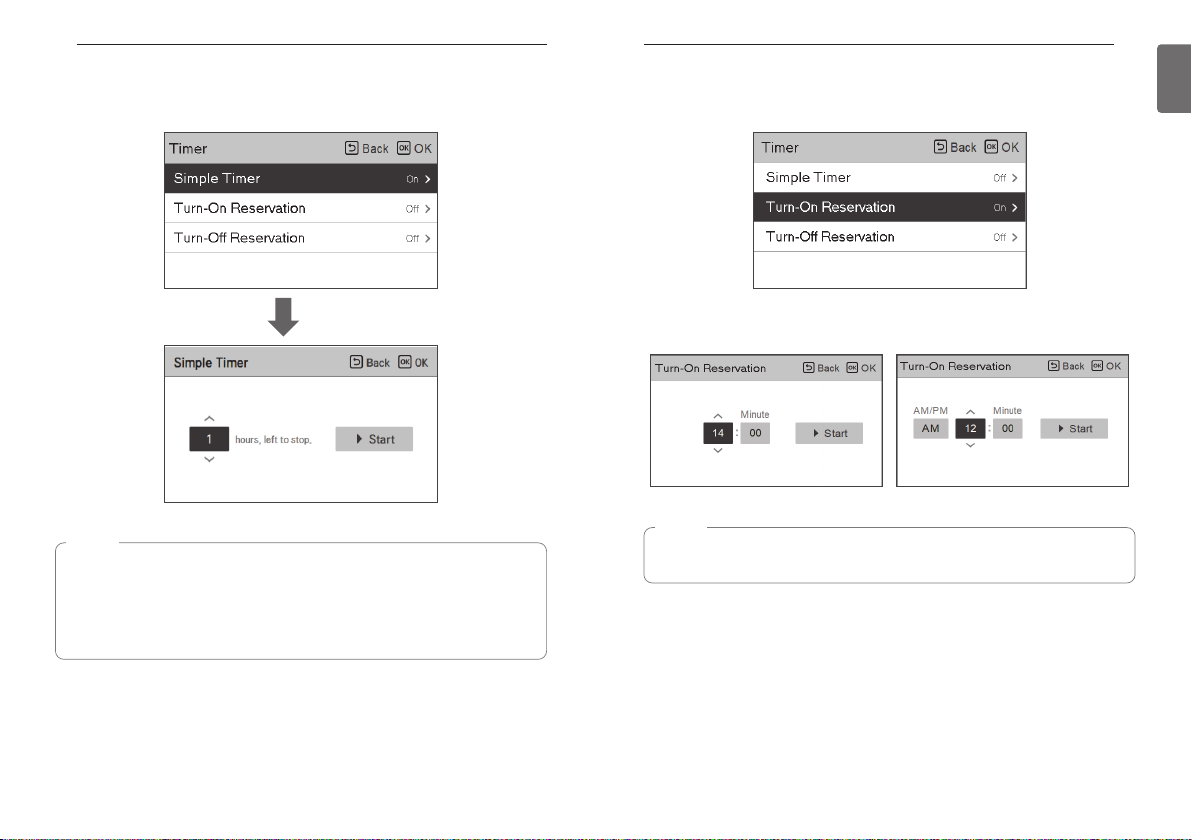

Simple Timer

You can easily set the timer in the range of 1~7 hours in the units of 1 hour.

Turn-On Reservation

The product is automatically turned On at the set timer time.

TIMER SETTING

25

ENGLISH

OK

NOTE

If the product operation is On, the easy timer turns off the operation after the corresponding

time.

If the product operation is Off, the easy timer turns on the operation after the corresponding

time.

If the easy timer operation is turned On/Off before the timer operation, the set timer will be

cleared.

It provides 2 Time formats, 12 Hours(AM/PM) or 24 Hours reference.

NOTE

Even if the Turn-on Reseravation operation is turned On/Off after the setting and before the

timer operation, the set timer is not cleared.

Page 14

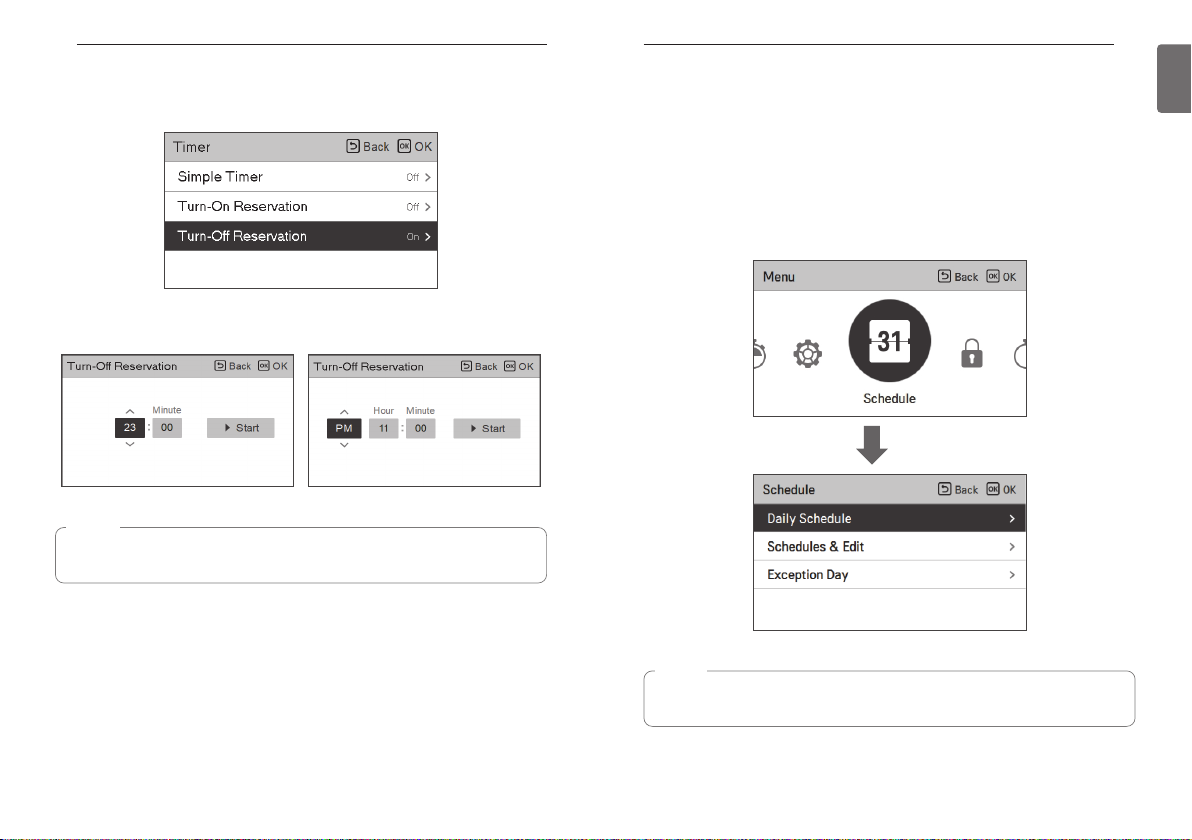

TIMER SETTING

26

Turn-Off Reservation

The product is automatically turned Off at the set timer time.

It provides 2 Time formats, 12 Hours(AM/PM) or 24 Hours reference.

NOTE

Even if the Turn-off Reservation operation is turned On/Off after the setting and before the

timer operation, the set timer is not cleared.

SCHEDULE SETTING

SCHEDULE SETTING

How to enter schedule

• In the menu screen, press [<,>(left/right)] button so select the schedule category, and press

[OK] button to move to the schedule setting list screen.

• In the schedule setting list screen, press [∧,∨(up/down)] button to select the menu to set, and

press [OK] button to move to the detail screen.

• There are 3 options in schedule formula, depending on product function.

- Room

- Hot water

- Heater of hot water tank

OK

27

ENGLISH

NOTE

Even though there is a heater of hot water tank schedule option, It cannot be activated in

case of sterilization operation.

Page 15

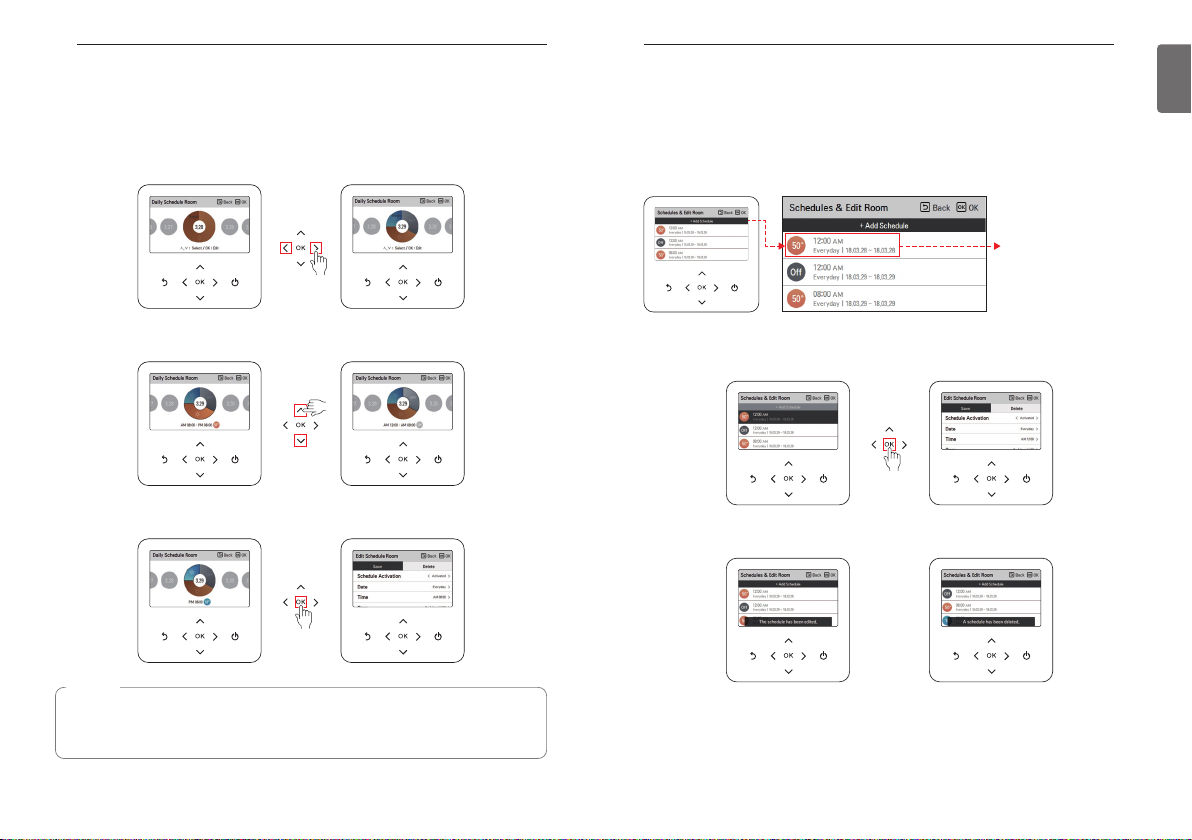

SCHEDULE SETTING

28

Daily schedule

It is the function that can check the status of the timer (schedule) saved in the remote controller.

• In the schedule list, select the daily schedule status category, and press [OK] button to move to

the detail daily schedule status screen.

• You can use the remote controller’s [<,>(left/right)] button to check the timer information of

other dates.

SCHEDULE SETTING

Schedules & Edit

It is the function that can check the status of the timer (schedule) saved in the remote controller.

• In the schedule list, select the daily schedule status category, and press [OK] button to move to

the daily schedule status detail screen.

• You can use the remote controller’s [<,>(left/right)] button to check other date’s timer

information.

You can check the set

timer’s operation

information (operation

On/Off, operation

mode, desired

temperature), timer

time, period, and day of

week.

29

ENGLISH

• You can use the remote controller’s [∧,∨(up/down)] button to check the corresponding date’s

other timer information.

• Select the timer information, and press [OK] button to move to the corresponding timer’s edit

screen.

NOTE

In the daily schedule status screen, even if the timer (schedule) is set, if the corresponding

date is designated as an exception date, the schedule will not be performed.

Less than 5 schedules per day is recommended.

• You can edit the saved schedule’s timer information.

- Select the schedule to edit using [∧,∨(up/down)] button, and press [OK] button to move to

the edit screen.

• Select the timer information, and press [OK] button to move to the corresponding timer’s edit

screen.

< If schedule is changed > < If schedule is deleted >

Page 16

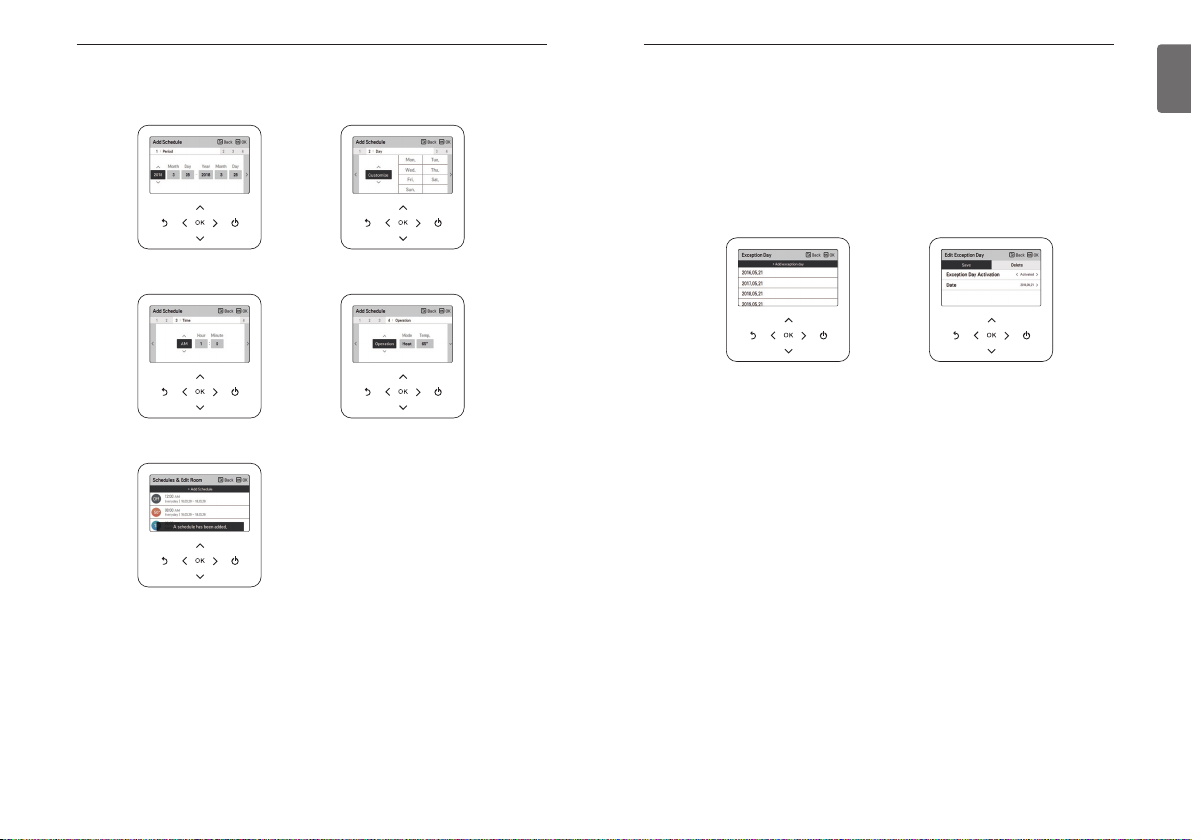

SCHEDULE SETTING

30

Schedules & Edit – Add schedule

Description of each stage in Add schedule

Stage 1. Period setting Stage 2. Day of week setting

Stage 3. Time setting Stage 4. Operation setting

Add schedule is completed

SCHEDULE SETTING

Exception Day

It is the function to automatically stop the operation on the set timer day.

• In the schedule list, select the exception day category, and press [OK] button to move to the

Exception day designation detail screen.

• In the exception day, you can check, and add/change/delete the exception day information

saved in the remote controller.

- To add an exception day, in the Exception day registration detail screen, designate

year/month/day, and press [OK] button to save the Exception day.

- Select the Exception day to edit using [∧,∨(up/down)] button, and press [OK] button to move

to the edit screen.

- In the exception day edit screen, you can check, delete/change the corresponding exception

day’s setting contents.

- When you change the exception day information, you need to save it after the change.

31

ENGLISH

In ‘Stage 1’, it sets the period to perform the timer.

In ‘Stage 2’, it sets the day of week to perform the timer.

- You can select ‘Everyday / Weekend / Weekdays / Individual selection’.

In ‘Stage 3’, it sets the start time for the timer.

In ‘Stage 4’, it sets the timer operation information.

- If ‘Stop’ is selected, you cannot set the mode / temperature

When stages 1~4 are completed, along with the message of ‘schedule is added’, it moves to

View and edit schedule screen.

Page 17

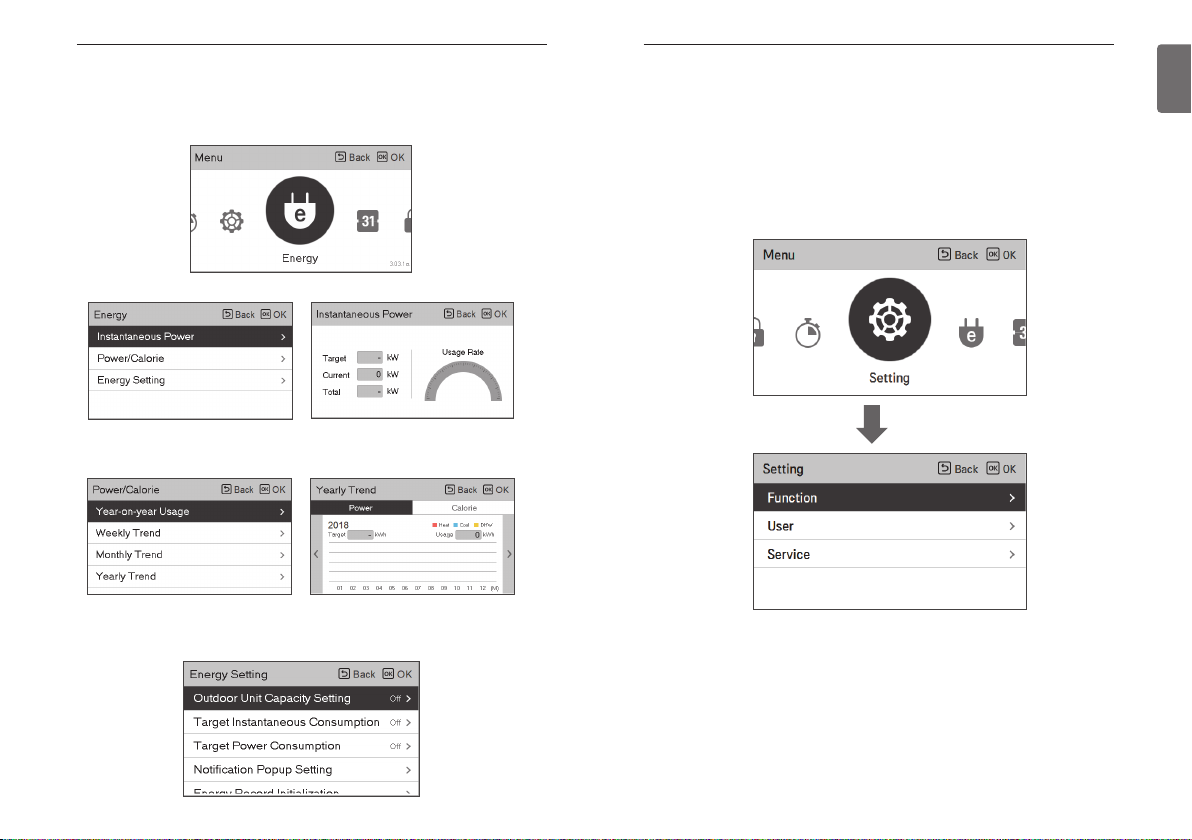

INFORMATION OF METER INTERFACE

32

FUNCTION SETTING

33

ENGLISH

INFORMATION OF METER INTERFACE

It provides useful information on the mount of energy and power during the week/month/year.

Opening “Energy “option, these are presented on screen. You can use this function only when

“Meter interface” is activated in installer setting.

Instantaneous Power

Power/Calorie

The information includes instantaneous power as well as power/calorie usage and up to annual

trend .

Energy Setting

In addition, various energy settings are possible as shown below.

Current value reaches to defined target value, It alerts to you on display

FUNCTION SETTING

How to enter function setting

To enter the menu displayed at the bottom, you need to enter the function setting menu as

follows.

• In the menu screen, press [<,>(left/right)] button to select the setting category, and press [OK]

button to move to the setting list.

• In the setting list, select the function setting category, and press [OK] button to move to the

function setting list.

OK

Page 18

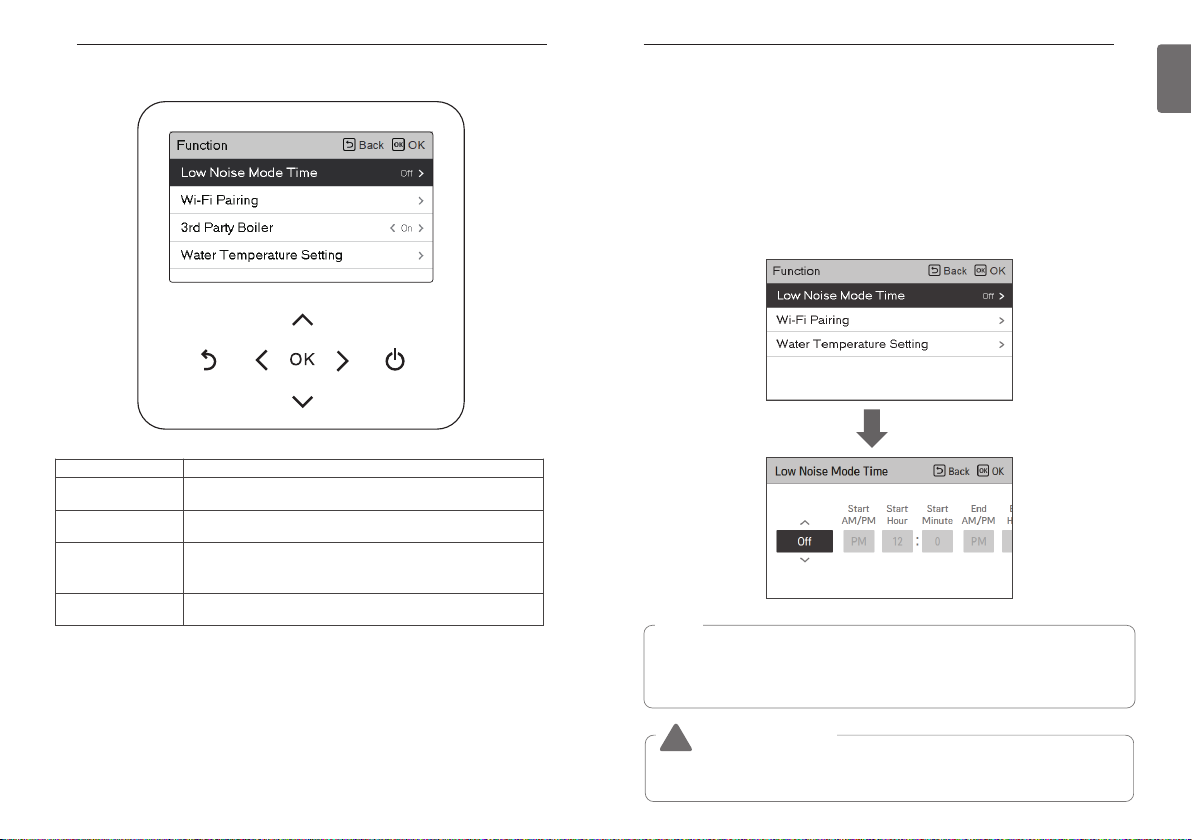

FUNCTION SETTING

34

Function setting

FUNCTION SETTING

Low Noise Mode Time

It is the function to set the start and end time of the outdoor unit’s low noise mode operation.

• In the function setting list, select the Low Noise Mode Time category, and press [OK] button to

move to the detail screen.

- After setting the start time and the end time, press [OK] button to move to the upper level

list.

- If the start time and the current time are the same, it enters the outdoor unit low noise

operation mode, and in the monitoring screen, ‘in outdoor unit low noise operation mode’

message is displayed.

- If the end time and the current time are the same, the outdoor unit low noise operation mode

is cleared.

OK

35

ENGLISH

Menu Description

Low Noise Mode Time

Wi-Fi Pairing It is the function to control remotely through network with indoor unit.

Water Temperature

Setting

3ndParty Boiler

It is the function to set the start and end time of the outdoor unit’s

low noise mode operation.

If you select (Air + Water) as the temperature control mode, This

option is activated on screen. It is the function to set target water

temperature.

It is the function to linkage the boiler of other companies. (this

function can be activated, after setting every value in installer mode.)

NOTE

In case that installed with Multi-V, Low noise mode time setting function can be set only

when the installer setting's outdoor unit function M/S setting is set to "Master" and low noise

mode priority function is set to "RMC".

Low noise mode time setting function is only available in some products.

CAUTION

!

If the function is not used, please set it to Off.

When you enter the low noise operation, the cooling capacity may be degraded.

Page 19

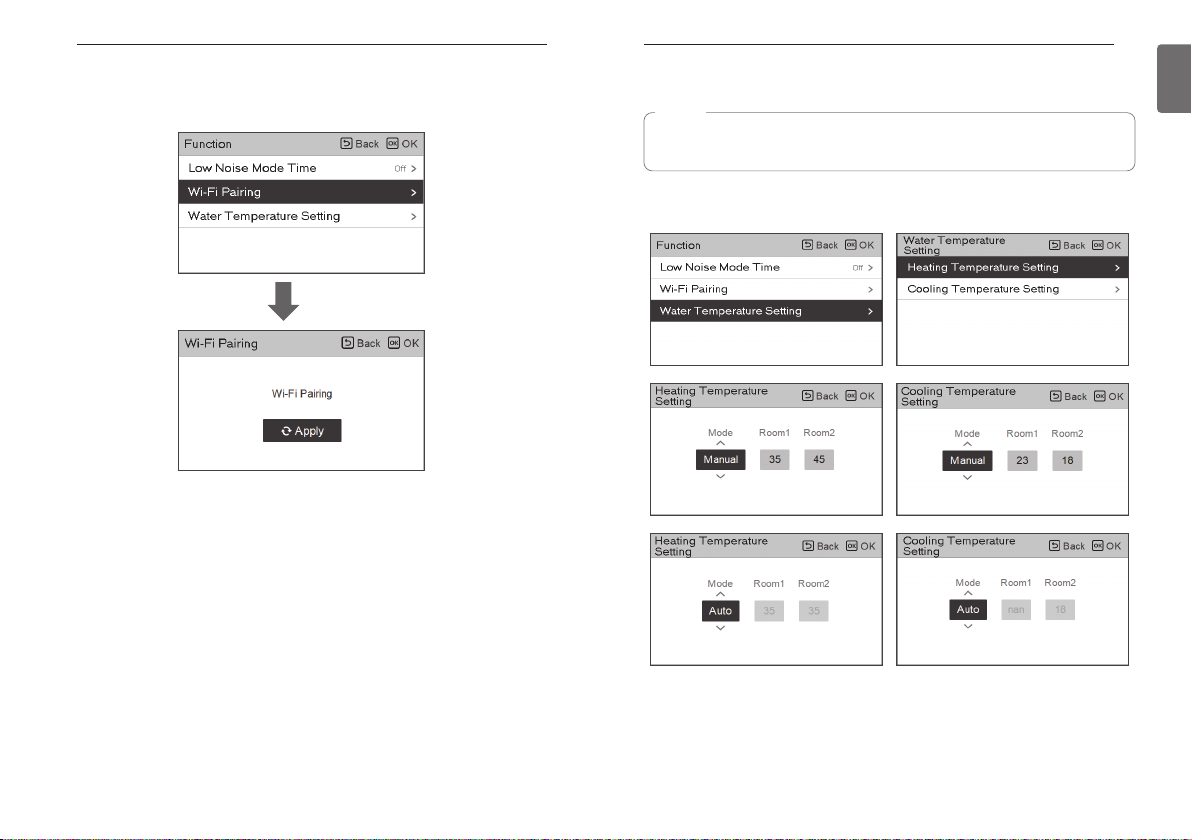

FUNCTION SETTING

36

Wi-Fi Pairing

It is the function to control remotely through network with indoor unit.

OK

FUNCTION SETTING

Water Temperature Setting

NOTE

This function is not default.

It can be activated, after setting value in installer mode.

If you choose air+water temperature control way, This option is listed-up on function setting

display. It is the function to set target water temperature.

37

ENGLISH

Page 20

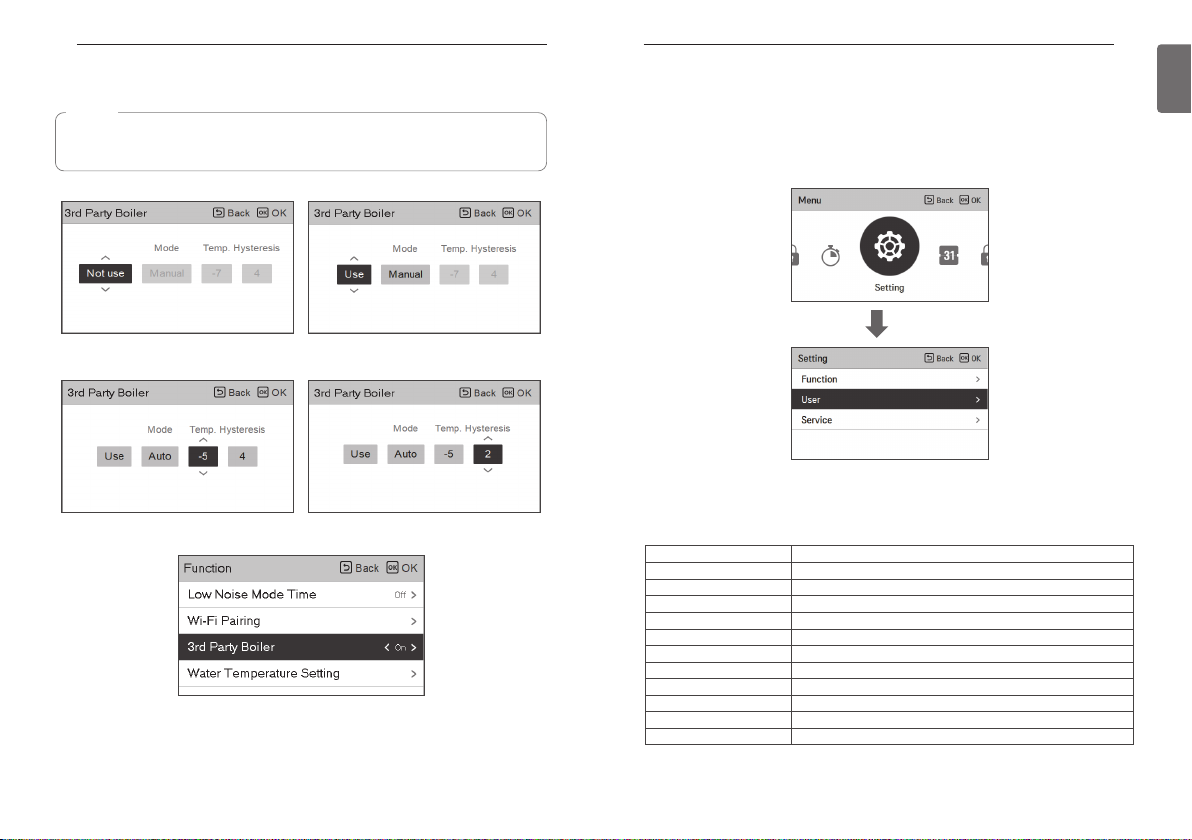

FUNCTION SETTING

38

3ndParty Boiler

NOTE

This function is not default.

It can be activated, after setting value in installer mode.

Function to set whether or not to use a installed 3rd Party function.

If the mode of this function is set to “Auto”, you can set temperature of the boiler and

hysteresis, respectively.

Only when the mode is set to "Manual", 3rd party boiler option is activated in function list.

On/off mode of this option are opened by pushing "<" or ">" button simply and easily.

USER SETTING

USER SETTING

How to enter user setting

To enter the menu displayed at the bottom, you need to enter the user setting menu as follows.

• Select the setting category, and press [OK] button to move to the setting list.

• Select the user setting category, and press [OK] button to move to the user setting list.

OK

User Setting

• You can set the product user functions.

• Some functions may not be available in some product types.

Menu Description

Language Set the language to be displayed on the remote controller.

Temperature Unit Set the temperature unit displayed on the remote controller.

Screen Saver Timer Adjust the screen Off time of the remote controller.

LCD Brightness In Idle Adjust the remote controller’s screen brightness.

Date Set the date displayed on the remote controller.

Time Set the time displayed on the remote controller.

Summer Time Set the summer time in the remote controller.

Password

Schedule Initialization Initialize all timer settings in the remote controller.

Theme Set the theme of the remote controller screen.

System Reboot Restart the remote controller.

Set the password to prevent unauthorized change to remote controller settings.

39

ENGLISH

Page 21

USER SETTING

40

Language

Set the language to be displayed on the remote controller.

• In the user setting list, select the language category, and press [OK] button to move to the

detail screen.

• After the setting, if you press [OK] button, the setting is saved and moves to the previous

screen.

OK

USER SETTING

Temperature Unit

Set the temperature unit displayed on the remote controller.

• In the user setting list, select the temperature unit setting category, and press [OK] button to

move to the detail screen.

OK

41

ENGLISH

Language

한국어

Deutsche Español Polski Čeština

ελληνικά Nederlands Românesc Português

Magyar

Українська

English Français Italiano

Hrvatski Srpski Türk

Български Slovenščina

中国

Value

CAUTION

!

The temperature unit function may not work or work differently in some products.

You cannot set the temperature unit in the slave wired remote controller.

Celsius

Fahrenheit

Page 22

USER SETTING

42

Screen Saver Timer

Adjust the screen Off time of the remote controller.

• Select the following setting values using [<,>(left/right)] button.

USER SETTING

Date

Set the date displayed on the remote controller.

• In the user setting list, select the date category, and press [OK] button to move to the detail

screen.

• After the setting, if you press [OK] button, the setting is saved and moves to the previous

screen.

43

ENGLISH

15 seconds 30 seconds (default) 1 min

CAUTION

!

Selecting longer stand by screen will decrease LCD lifespan.

Value

LCD Brightness In Idle

Adjust the remote controller’s screen brightness.

• Select the following setting values using [<,>(left/right)] button.

Value

0 %

CAUTION

!

Selecting brighter stand by screen will decrease LCD lifespan.

10 %

(default)

20 % 30 %

OK

Page 23

USER SETTING

44

Time

Set the time displayed on the remote controller.

• In the user setting list, select the time category, and press [OK] button to move to the detail

screen.

• After the setting, if you press [OK] button, the setting is saved and moves to the previous

screen.

• In the screen, Time display can be presented in the form of AM / PM or 24 hours standard.

USER SETTING

Summer Time

Set the daylight savings time dates in the remote controller.

• In the user setting list, select the summer time setting category, and press [OK] button to

move to the detail screen.

- Summer time: The system to advance the time by 1 hour from the spring when the day is

longer and return back in the fall when the day gets shorter.

- When it becomes AM 02:00 on the DST start date, the current time changes to AM 03:00,

and when it becomes AM 02:00 of the DST end date, the current time changes to AM 01:00.

45

ENGLISH

OK

OK

Page 24

USER SETTING

46

Password

Set the password to prevent unauthorized change to remote controller settings.

• Select the user password setting category, and press [OK] button to move to the detail screen.

- If the password is set, when you enter “menu – setting”, you need to input password to

enter the setting list.

- When you forgot the password, you can initialize the password using the installer setting’s

“password initialization”.

The initialized password is “0000”.

OK

USER SETTING

Schedule Initialization

Initialize all timer settings in the remote controller.

• In the user setting list, select the schedule initialization setting category, and press [OK] button

to move to the detail screen.

- Press the check button to initialize the sleep/simple timer, on/off timer, schedule and

exception date in the remote controller.

OK

47

ENGLISH

Page 25

USER SETTING

48

Theme

Set the theme of the remote controller screen.

• Select either white or black using [<,>(left/right)] button.

System Reboot

Restart the remote controller.

• In the user setting list, select the system restart setting category, and press [OK] button to

move to the detail screen.

- In the detail screen, when you press [OK] button, a popup message is displayed, press the

check button, to restart the system.

- For forced reset, press down [On/Off + Back] button for 5 seconds to restart the system.

SERVICE SETTING

SERVICE SETTING

How to enter service setting

To enter the menu displayed at the bottom, you need to enter the service setting menu as

follows.

• In the menu screen, press [<,>(left/right)] button to select the setting category, and press [OK]

button to move to the setting list.

• In the setting list, select the service setting category, and press [OK] button to move to the

service setting list.

OK

Service setting

• You can set the product service functions.

• Some functions may not be displayed/operated in some product types.

49

ENGLISH

OK

Menu Description

Service contact

Model information View product and capacity information

RMC Version Information Check the remote controller model name and software version.

Open Source License View the remote controller’s open source license.

Check and input the service center phone number that you can call

when there is service issue.

Page 26

SERVICE SETTING

50

Service Contact

Check and input the service center phone number that you can call when there is service issue.

• In the service setting list, select the service contact point and press [OK] button to move to the

detail screen.

• While “edit” button is selected, press [OK] button to move to the edit screen, change it, and

press [OK] button to change the service contact point.

OK

OK

SERVICE SETTING

Model Information

Check product and capacity information to which the remote controller is connected.

• In the service setting list, select model information category, and press [OK] button to move to

the detail screen.

• The unit capacity

- 1 kWh = 1 kBtu * 0.29307

kWh is the result calculated based on Btu, There may be a small difference between

calculated and actual capacity.

Ex) If the unit capacity is 18 kBtu, it is displayed as 5 kWh.

OK

51

ENGLISH

Page 27

SERVICE SETTING

52

RMC Version lnformation

View the remote controller software version.

• In the service setting list, select the RMC version information and press [OK] button to move to

the detail screen

SERVICE SETTING

Open Source License

View the remote controller’s open source license.

• In the service setting list, select the open source license category, and press [OK] button to

move to the detail screen.

53

ENGLISH

OK

OK

Page 28

INSTALLATION

ڹ Top side guide groove ڹ Top side guide groove

ڻRight side

guide

groove

ںLeft side

guide

groove

ڹ Top side guide groove

ںLeft side

guide

groove

ڻRight side

guide groove

ڸRear cable

entry

54

INSTALLATION

Installation of Remote Controller

• After fixing the remote controller installation plate on the desired location, fix it firmly with the

provided screws.

- If the installation plate is not flat on the surface, it may result in the controller being twisted

and cause a defect.

- If there is a mounting box, install the remote controller installation plate using the fixings holes

which suit, as in the below diagrams.

- Do not leave a gap with the wall or product loose after the installation.

• The wired remote controller cable can be installed in 4 directions. Install to the suitable

direction according to the installation environment.

- Installation direction: Rear entry, top side, right side, left side.

- When you install the remote controller cable at the top, right and left side, remove the remote

controller cable guide hole before the installation.

※ Use a long nose pliers to remove the guide hole.

• After removing the hole, trim the cut surface neatly.

INSTALLATION

• After fixing the remote controller top side on the installation plate attached to the wall as in the

following figure, press the bottom side to combine with the installation plate.

- Do not leave a gap in the top, bottom, left, and right side of the remote controller and the

installation plate after combining them.

- Before combining with the installation plate, arrange the cables to avoid interference with the

circuit parts.

<Order of Combining>

Wall Wall

•

When you remove the remote controller from the installation plate, insert a small flat head

screwdriver into the bottom side separation hole and turn clockwise to separate the remote

controller.

- There are 2 separation holes at the bottom part. Slowly separate one by one.

- Be careful not to damage the internal parts during the removal.

<Order of Separation>

Wall Side

• Use the connection cables to connect the indoor unit with the remote controller.

55

ENGLISH

•

When installing the remote control cable on the left side, be sure to install it in the following guide.

1. Make the cable to "ㄱ" shape as shown below.

2. Fit the bent "ㄱ" cable into the upper center piece of case.

3. Tighten the installation plate with preventing interference with the surrounding guide structure.

※ If the cable is assembled in a shape other than "ㄱ", it may not be fastened to the installation

plate due to interference with the structure of case.

Reference. the bent cable shape

The Upper center boss for fixing the bent cable

DC 12 V Red

Signal Yellow

GND Black

OK

Please check if connector is normally connected.

Connecting cable

Indoor

Unit side

• For the following cases, separately purchase and use the cables suitable for the situation.

- Do not install the cable over 50 m. (It may cause communication issues.)

- If the distance between the wired remote controller and the indoor unit is 10 m or more : 10

m extension cable (model name: PZCWRC1)

- If you control several indoor unit products with one wired remote controller : Group control

cable (model name: PZCWRCG3)

NOTE

During the wired remote controller installation, do not bury it in the wall. (It may cause

temperature sensor failure.)

Do not install the cable over 50 m. (It may cause communication defect.)

When you install the extension cable, carefully check the direction of the connectors on the

remote controller side and the product side before the installation.

Specification of extension cable: AWG 24, 3 conductor or above.

Page 29

INSTALLATION

RED(12V)

YELLOW(SIG)

BLACK(GND)

YELLOW(SIG)

BLACK(GND)

YELLOW(SIG)

BLACK(GND)

OK

Indoor unit Main PCB

Indoor unit 1 Indoor unit 2 Indoor unit 3

Master Slave Slave

1

2

No. 1 switch OFF: master (factory ship-out based)

No. 1 switch ON: slave

SlaveSlave

Master

Slave

GND

Signal

12 V

OK

Master

GND

DC 12 V

B Y R B Y R

Signal

GND

DC 12 V

Signal

OK

Master

OK

Slave

56

Group control

1. It is possible to connect 16 indoor units(Max) by one wired remote controller.

※Connect using the group control cable.

① Group control cable (PZCWRCG3): Connect to indoor unit’s wired remote controller connector

② Extension cable (PZCWRC1): Connect to No. ① cable and slave indoor unit’s wired remote

controller connector

While No. ① cable is connected, connect No. ② cable.

NOTE

• Connect only GND and signal cable to the indoor unit set as slave. (If power cable is also

connected, it may cause loss of communication)

• Inquiries related to the purchase of the cable shall be directed to the specialized company

and the service center.

• Change master/slave of the indoor unit.

- For Hydro Kit change the setting with the indoor unit PCB switch.

INSTALLATION

- After completing the master/slave setting in the indoor unit product, turn Off the power of the

indoor unit product, and turn On the power after 1 minute.

NOTE

• During the group control, set only 1 indoor unit as master.

• Indoor unit(Hydro Kit)’s group setting is possible which connected same outdoor unit.

• In case of Group Control, it is possible to use following functions.

- Selection of operation options (operation/stop/mode/set temperature)

- It is not possible at some functions.

• During the individual control, if the master indoor unit DIP switch is set to slave,

malfunction may occur.

2. You can use two wired remote controllers for one indoor unit.

• A dedicated cable must be used for the connection. If necessary, use an extension cable

additionally and install. (2-Remo cable : PZCWRC2, Extension cable : PZCWRC1)

• For normal operation, one should be set as master and the other as slave.

(Refer to the function "Installation setting - RMC master/slave")

• After completing the RMC master/slave setting, turn off the power of indoor unit, and turn

on the power after 1 minutes.

57

ENGLISH

Page 30

INSTALLATION

58

• If you set as Master-Master or Slave-slave for both remote controllers, the following pop-up is

displayed once within 10 minutes after power-on.

If you use the 2-remo function, through the master remote controller you can check the

temperature where the remote controller set as slave is installed.

The room temperature icon changes. This means that the value is detected by the slave remote

controller.

INSTALLER SETTING

INSTALLER SETTING

How to enter installer setting

CAUTION

!

The installer setting mode is the mode to set the remote controller’s detail function. If the

installer setting mode is incorrectly set, it may cause product failure, user’s injury, or property

damage. It must be set by the installation specialist with the installation license, and if it is

installed or changed without installation license, all problems caused will be the responsibility of

the installer, and may void the LG warrenty.

• In the menu screen, press [<,>(left/right)] button to select the setting category, and press

[∧(up)] button for 3 seconds to enter the password input screen for the installer setting.

• Input the password and press [OK] button to move to the installer setting list.

OK OK

※Installer setting password

Main screen → menu → setting → service → RMC version information → SW Version

Example) SW version : 1.00.1 a

In the above case, the password is 1001.

59

ENGLISH

NOTE

Some categories of the installer setting menu may not be available depending on the

product function or the menu name may be different.

Page 31

INSTALLER SETTING

60

Installer setting

• You can set the product user functions.

• Some functions may not be displayed/operated in some product types.

Function Description

Test Run Test run operates Multi V in Cooling mode for max 18 minutes.

3 Minutes Delay Factory use only

Select Temperature Sensor

Dry Contact Mode setting

Central Control address

Override Master/Slave

Pump Test run Water pump test run

Air cooling set temp. setting Adjusting range of 'Setting Air Temperature' in cooling mode

Water cooling set temp.

setting

Air heating set temp. setting Adjusting range of 'Setting Air Temperature' in heating mode

Water heating set temp.

setting

DHW Set Temp.setting Setting DHW set temperature

Cooling / Heating only mode Setting the operation mode lock function.

Screed drying setting Setting for using Step 1 or 2 capacity of electric

Heater on temperature

Water supply off temp. during

cooling setting

Outdoor temp. for auto mode Setting outdoor Min/Max temperature for auto mode.

Indoor air temp. for auto

mode

LWT for auto mode Setting heating flow Min/Max temperature for auto mode

Selection for setting temperature as air temperature or leaving water

temperature or air+leaving water temperature

Dry contact function is the function that can be used only when the

dry contact devices is separately purchased and installed.

When connecting the central control, set the central control address

of the unit.

Override master/slave selection function is to prevent the unit’s

different mode operation. If the unit is set as the slave, it is blocked to

a change of opposite operating mode(cooling/heating).

Adjusting range of 'Setting Leaving Water Temperature' in cooling

mode

Adjusting range of 'Setting Heating Flow Temperature' in heating

mode

Setting outdoor air temperature where half capacity of electric heater

starts operation.

Determine leaving water temperature when the unit is turned off.

This function is used for preventing condensation on the floor in

cooling mode

Setting indoor Min/Max temperature for auto mode

INSTALLER SETTING

Function Description

Tank disinfection setting 1 Setting start/maintain time for pasteurisation

Tank disinfection setting 2 Setting pasteurisation temperature

Tank setting 1 Setting start temperature for operation

Tank setting 2 Setting maintain temperature for operation

Heater priority Determine electric heater and water heater on and off

DHW time setting

Use Heating Tank Heater

Pump frequency setting

(LPM)

TH on/off Variable, heating air

setting

TH on/off Variable, heating

Water setting

TH on/off Variable, cooling air

setting

TH on/off Variable, cooling

Water setting

Heating temp. setting

Cooling temp. setting

Pump setting in heating Set water pump on / off delay option in heating mode

Pump setting in cooling Set water pump on / off delay option in cooling mode

Forced operation

CN_CC setting

Pump Capacity Function to change Water Pump Capacity

Pump frequency setting(RPM) Function to change Water Pump RPM

Smart Grid(SG) setting

Seasonal auto temp setting Set the operating temperature in Seasonal Auto mode

Determine follow time duration : operation time of domestic hot water

tank heating, stop time of domestic hot water tank heating, and delay

time of DHW tank heater operating

It is the function to change the setting value of heating tank heater

operation such as use / non-use and heater delay time of heating tank

heater.

Setting for water flow rate in water piping.

Heating air temperature TH On / Off Type setting

Heating Water Outlet Temperature TH On / Off Type

Cooling air temperature TH On / Off Type setting

Cooling Water Outlet Temperature TH On / Off Type

At the leaving water control in heating mode, the control reference

water temperature position setting

At the leaving water control in cooling mode, the control reference

water temperature position setting

Water pump off After 20 consecutive hours, disable / enable the logic

that drives the water pump by itself

It is the function to set whether to install (use) Dry Contact. (It is not a

function for Dry Contact installation, but it is a function to set the

usage of the unit’s CN_CC port.)

Select whether to use or not use the SG Mode function of the

product, set the operation option value in SG1 step.

61

ENGLISH

Page 32

INSTALLER SETTING

62

Function Description

Modbus Address

Refrigerant Leak Sensor

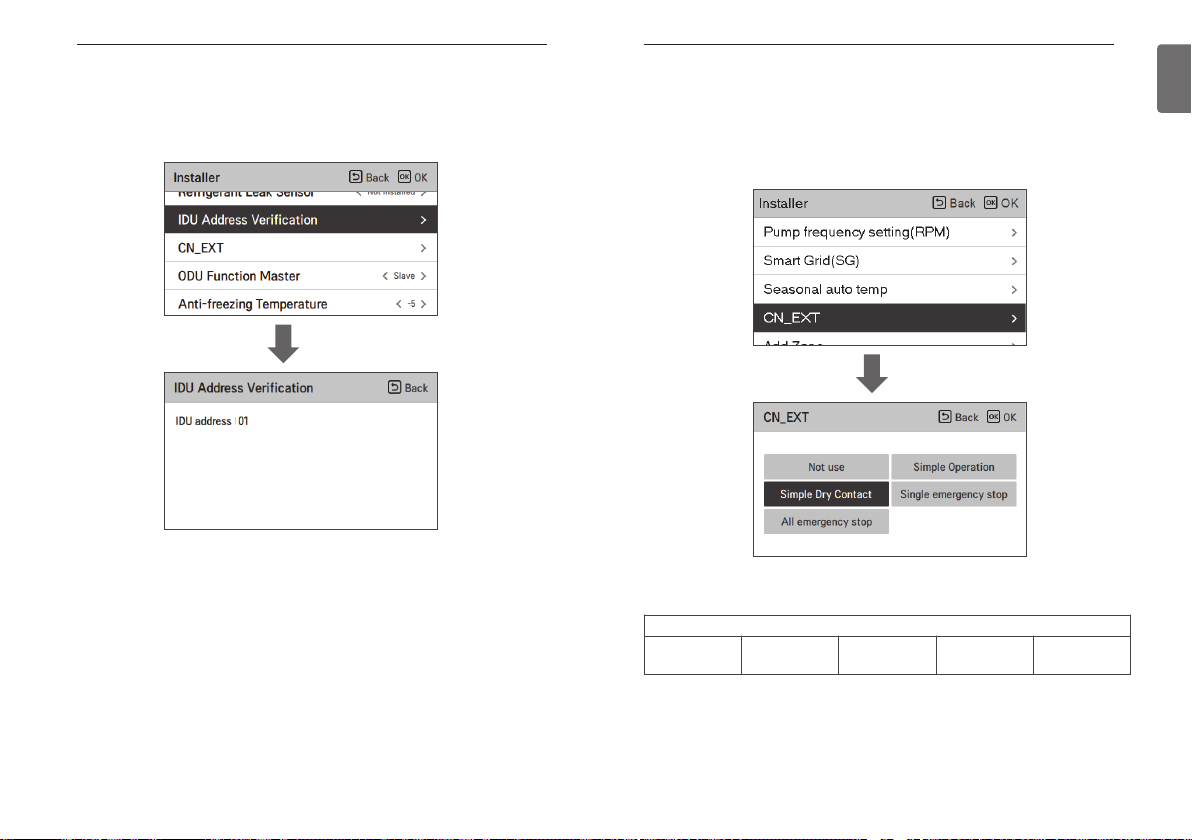

IDU Address Verification

CN_EXT

ODU Function Master Setting of outdoor function Setting function of Master / Slave.

Low Noise Mode Priority Function to set low noise mode control subject.

Anti-freezing Temperature This function prevents the product from freezing.

Add Zone Install additional valve in product to control additional operation area

Use External Pump Set up to control an external water pump

3rd Party Boiler Configuration to control 3rd party boiler

Meter Interface

Pump Prerun/Overrun

Estimated energy display

Zone Setting

Current flow rate Function to check the current flow rate.

RMC master/slave

Data logging setting Display error history of connected unit

Password Initialization setting

It is function to set the address of the Modbus device that is

externally linked to the product. Modbus address setting function is

available from indoor unit.

The installation of the flare coupling part and the welding part leakage

sensor of the indoor unit is set.

Check the result of Auto Addressing of outdoor unit with remote

control.

Function to set external input and output control according to DI / DO

set by customer using dry contact port of indoor unit. Determine the

use of the contact port (CN_EXT) mounted on the indoor unit PCB

When installing the meter interface to measure energy / calorie in the

product, set unit spec for each port

Set to reach the optimum flow rate by circulating the heating water

with the water pump before heat exchange. After the operation stop,

additional water pump is activated to circulate the heating water.

This function can set to display energy data which outdoor unit

estimated power consumption data without wattmeterd.

When using the zone module, it is the function to set the environment

necessary for control such as the number of use and address setting.

This function is to set master / slvae to use two remote controllers in

one indoor unit.

It is the function to initialize (0000) the password when you forgot the

password set in the remote controller.

INSTALLER SETTING

Test Run

Test run should be performed when charging the additional refrigerant is required. The unit must

be operated in Cooling mode when the refrigerant is being charged. Test run instantly makes the

unit operate in Cooling mode for 18 minutes.

NOTE

If you press any kind of button during this mode, Test Run mode will be finished.

• After the unit operates under Test run mode for 18 minutes, it will be turned off

automatically

OK

63

ENGLISH

Page 33

INSTALLER SETTING

64

3 Minutes Delay

Temporarily eliminates the 3-minute delay function of the outdoor unit Comp

- Factory use only

• In the installer setting list, select 3 Minutes Delay category, and press [OK] button to move to

the detail screen.

INSTALLER SETTING

Select Temperature Sensor

The product can be operated according to air temperature or leaving water temperature. The

selection for setting temperature as air temperature or leaving water temperature is determined.

• In the installer setting list, Select Temperature Sensor category, and press [OK] button to move

to the detail screen.

65

ENGLISH

OK

OK

Value

Water Air Air+Water

Page 34

INSTALLER SETTING

66

Dry Contact Mode

Dry contact function is the function that can be used only when the dry contact devices is

separately purchased and installed.

• Change setting values using [<,>(left/right)] button.

INSTALLER SETTING

Central Control Address

When connecting the central control, set the central control address of the unit.

• In the installer setting list, select Central Control Address category, and press [OK] button to

move to the detail screen.

67

ENGLISH

Value

Auto

manual

NOTE

For dry contact mode related detail functions, refer to the individual dry contact manual.

What is dry contact?

It means the contact point signal input when the hotel card key, human body detection

sensor, etc. are interfacing with the air conditioner.

Added system functionality by using external inputs (dry contacts and wet contacts).

OK

NOTE

Enter address code as hexadecimal value

Front: Central Control Gr. No.

Back side: Central control indoor the number

NOTE

This function is not available for monobloc

Page 35

INSTALLER SETTING

68

Override Master/Slave

Override master/slave selection function is to prevent the unit’s different mode operation. If the

unit is set as the slave, it is blocked to a change of opposite operating mode(cooling/heating).

• Change setting values using [<,>(left/right)] button.

INSTALLER SETTING

Pump test run

The pump test run is the function to test run by operating the water pump. This function can be

used for air vents / flow sensors and others.

• In the installer setting list, Pump Test run category, and press [OK] button to move to the detail

screen.

69

ENGLISH

M/S Description

Master Using group control, this master sets the mode of slave IDU’s.

Slave

If the unit is set as the slave, it blocks a change of opposite operating

mode(cooling/heating)

NOTE

Override M/S setting function is only available in some products.

OK

Page 36

INSTALLER SETTING

70

Air cooling set temp

Determine cooling setting temperature range when air temperature is selected as setting

temperature.

• In the installer setting list, select Air cooling set temp category, and press [OK] button to move

to the detail screen.

INSTALLER SETTING

Water cooling set temp

Determine cooling setting temperature range when leaving water temperature is selected as

setting temperature.

• In the installer setting list, select water cooling set temp category, and press [OK] button to

move to the detail screen.

71

ENGLISH

OK

NOTE

The setting range differs depending on the connected product.

OK

NOTE

Water condensation on the radiator

• While cooling operation, cold water may not flow to the radiator. If cold water enters to

the radiator, dew generation on the surface of the radiator can be occurred.

• The setting range differs depending on the connected product.

Page 37

INSTALLER SETTING

72

Air heating set temp

Determine heating setting temperature range when air temperature is selected as setting

temperature

• In the installer setting list, select Air heating set temp. category, and press [OK] button to move

to the detail screen.

INSTALLER SETTING

Water heating set temp

Determine heating setting temperature range when leaving water temperature is selected as

setting temperature

• In the installer setting list, select Water heating set temp. category, and press [OK] button to

move to the detail screen.

73

ENGLISH

OK

NOTE

The setting range differs depending on the connected product.

OK

NOTE

The setting range differs depending on the connected product.

Page 38

INSTALLER SETTING

74

DHW set temp

Determine heating setting temperature range when DHW temperature is selected as setting

temperature

• In the installer setting list, select DHW set temp. category, and press [OK] button to move to

the detail screen.

INSTALLER SETTING

Cooling / Heating only mode

Set the Operation mode lock when Multi V Indoor unit is used only cooling mode in summer and

Hydro Kit is used only heating in winter.

75

ENGLISH

OK

NOTE

The setting range differs depending on the connected product.

OK

Value1 Value2 (Oil Recovery)

Release -

Set

Type 0

Type 1

Page 39

INSTALLER SETTING

76

Screed drying

This function is a unique feature of AWHP that, when AWHP is installed in a new concrete

structure, controls the specific temperature floor heating out temperature for a certain period of

time to cure the floor cement.

• In the installer setting list, select Screed drying category, and press [OK] button to move to the

detail screen.

OK

How to display

Main Screen - Displays 'Screed drying' on the desired temperature display. The step in progress

at the bottom of the display is displayed.

Setting value

- Start-up step: 1~11

- Maximum temperature : 35 °C~55 °C

- Step 8 Holding time : 1 days~30 days

Function operation

- It is performed by the following procedure from the selected starting step.

- After all steps are completed, turn off the cement curing operation.

Step 1 2 3 4 5 6 7 8 9 10 11

Leaving Water

target

temperature[°C]

Duration

[hours]

25 Max.T Off 25 35 45 Max.T Max.T 45 35 25

72 96 72 24 24 24 24

Holding

time

72 72 72

INSTALLER SETTING

NOTE

• During Screed drying operation, button input except for installer function and temperature

display is restricted.

• When the power is applied again after a power outage during product operation, the

product operation state before power failure is remembered and the product is

automatically operated.

• Screed drying operation stops when an error occurs / When error is cleared, restart

cement Screed drying. (However, if the wired remote control is reset to the error

occurrence state, it is compensated in the unit of one day)

• Upon releasing after an error, Screed drying operation may take up to 1 minute of waiting

time after boot up. (The Screed drying operation status is judged as 1 minute cycle.)

• During Screed drying operation, installer function Screed drying operation is selectable.

• During Screed drying operation, starting operation, low noise mode off, low noise time

setting off, hot water off, solar heat off.

• During Screed drying operation, simple, sleep, on, off, weekly, holiday, heater does not

execute reservation operation.

Holding time

Leaving Water target temperature °C

Pre heating

Heating ready for tiling

Step

77

ENGLISH

※ If the upper limit setting value of the heating LW temperature is 55 °C or lower, it is set to

55 °C forcibly.

If the lower limit setting value of the heating LW temperature is 25 °C or higher, it is set to

25 °C forcibly.

Page 40

INSTALLER SETTING

78

Heater on temperature

Depending on local climatic conditions, it is necessary to change the temperature condition in

which electric heater turns on / off.

• In the installer setting list, Heater on temperature category, and press [OK] button to move to

the detail screen.

OK

NOTE

The setting range differs depending on the connected product.

INSTALLER SETTING

NOTE

• Heater on temperature

Using Half capacity of electric heater : when DIP Switch No. 6 and 7 is set as ‘OFF-ON’ :

- Example : If Heater on temperature is set as ‘-1’ and DIP switch No 6. and 7 is set as

‘OFF-ON’, then half capacity of electric heater will start operation when outdoor

air temperature is below -1 °C and current leaving water temperature or room

air temperature is much belower than target leaving water temperature or

target room air temperature.

Using Full capacity of electric heater : when DIP Switch No. 6 and 7 is set as ‘OFF-OFF’ :

- Example : If Heater on temperature is set as '-1' and DIP switch No 6. and 7 is set as

'OFF-OFF', then full capacity of electric heater will start operation when outdoor

air temperature is below -1 °C and current leaving water temperature or room

air temperature is much belower than target leaving water temperature or

target room air temperature.

79

ENGLISH

Page 41

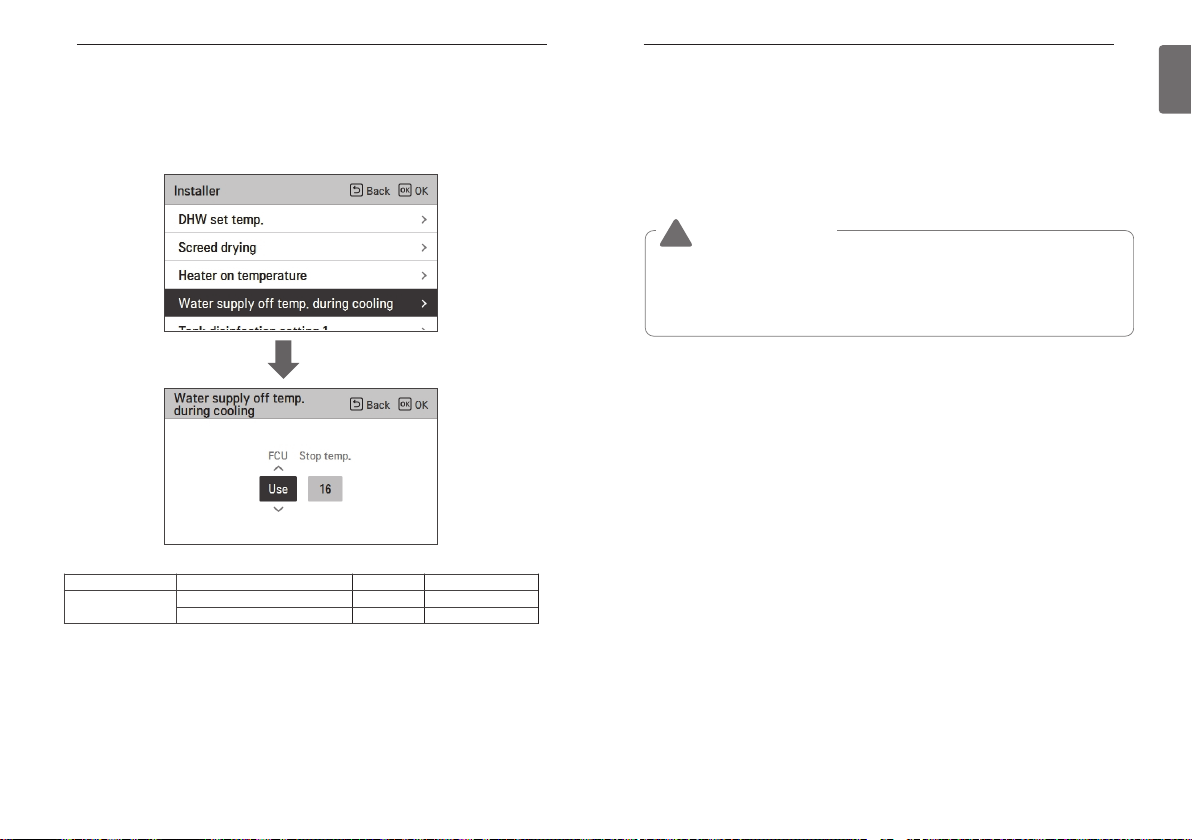

INSTALLER SETTING

80

Water supply off temp. during cooling

Determine leaving water temperature when the unit is turned off. This function is used for

preventing condensation on the floor in cooling mode

• In the installer setting list, select Water supply off temp. during cooling category, and press

[OK] button to move to the detail screen.

OK

INSTALLER SETTING

- Stop temp. : cut-off temperature. Stop temp. is valid when FCU is installed.

- FCU : determines if FCU is installed or not.

- Example : If Stop temp. is set as ‘10’ and FCU is ’Use’ and actually FCU is NOT installed in the

water loop, the unit stop operation in cooling mode when the leaving water

temperature is below 10 °C.

- Example : If Stop temp. is set as ‘10’ and FCU is ’Not use’ and actually FCU is installed in the

water loop, the Stop temp. is not used and the unit do NOT stop operation in cooling

mode when the leaving water temperature is below 10 °C.

CAUTION

!

FCU Installation

• If FCU is used, related 2way valve should be installed and connected to the unit PCB.

• If FCU is set as ‘Not use’ but FCU or 2way valve is NOT installed, the unit can do abnormal

operation.

81

ENGLISH

Function Value Default Setting Rang

cooling water

temperature

Water supply off temperature 16 25~16

FCU Use / not use use Use / Not Use

Page 42

INSTALLER SETTING

82

Outdoor temp. for auto mode

It is the function to set outdoor Min/Max temperature for auto mode.

Indoor air temp. for auto mode

It is the function to set indoor Min/Max temperature for auto mode.

INSTALLER SETTING

83

ENGLISH

OK

NOTE

The setting range differs depending on the connected product.

OK

NOTE

The setting range differs depending on the connected product.

Page 43

INSTALLER SETTING

Time

Start time

Max temp

Duration time

Water temperature

(Inside DHW)

Temperature profile

of Disinfection operation

84

LWT for auto mode

It is a function to set the heating flow Min/Max temperature for auto mode.

OK

NOTE

The setting range differs depending on the connected product.

INSTALLER SETTING

Tank disinfection setting 1, 2

• Disinfection operation is special DHW tank operation mode to kill and to prevent growth of

viruses inside the tank.

- Disinfection active : Selecting enable or disable of disinfection operation.

- Start date : Determining the date when the disinfection mode is running.

- Start time : Determining the time when the disinfection mode is running.

- Max temp. : Target temperature of disinfection mode.

- Duration time : Duration of disinfection mode.

OK

OK

85

ENGLISH

NOTE

DHW heating should be enable

• If Disinfection active is set as ’ Not use’, that is ‘disable disinfection mode’, Start date and

Start time is not used.

Page 44

INSTALLER SETTING

86

Tank setting 1

• In the installer setting list, select tank setting 1 category, and press [OK] button to move to the

detail screen.

INSTALLER SETTING

Tank setting 2

• In the installer setting list, select tank setting 2 category, and press [OK] button to move to the

detail screen.

87

ENGLISH

OK

NOTE

The setting range differs depending on the connected product.

OK

Value Range

Hysteresis 4~2

Heating priority Floor heating / DHW

Page 45

INSTALLER SETTING

88

• Tank setting 1, 2

Descriptions for each parameters are as following.

- Min temp. : temperature gap from Max outdoor temp.

- Max outdoor temp. : maximum temperature generated by AWHP compressor cycle.

- Example : If Min temp. is set as ‘5’ and Max outdoor temp. is set as ’48’, then Session A (see

the graph) will be started when the water tank temperature is below 45 °C…. If temperature is

above 48 °C…, then Session B will be started.

- Hysteresis : temperature gap from target DHW temperature. This value is required to frequent

On and Off of water tank heater.

- Heating priority : Determining heating demand priority between DHW tank heating and under

floor heating.

- Example : If user’s target temperature is set as ’70’ and Hysteresis is set as ‘3’, then the

water tank heater will be turned off when the water temperature is above 73 °C. The water

tank heater will be turned on when the water temperature is below 70 °C.

- Example : If Heating priority is set as ‘DHW’, that means heating priority is on DHW heating,

DHW is heated by AWHP compressor cycle and water heater. In this case the under floor can

not be heated while DHW heating. On the other hand, if the Heating priority is set as ‘Floor

heating’, that means heating priority is on under floor heating, DHW tank is ONLY heated by

water heater. In this case the under floor heating is not stopped while DHW is heated.

Water temperature

(Inside DHW water tank)

Water heater off

temperature

Target DHW

temperature (set by user)

Max outdoor temp.

Starting temperature

of DHW heating

Min temp.

Session A

Session A : Heating by AWHP compressor cycle and water heater

Session B : Heating by water heater

Session C : No heating (Water heater is Off)

Session D : Heating by water heater

Session B

Session C

Session D

Hysteresis

Time

INSTALLER SETTING

Heater priority

- Heater priority : determine electric heater and DHW tank heater on and off.

- Example : If Heater priority is set as ‘Main+Boost heater ON’, then electric heater and DHW

tank heater are on and off according to control logic. If Heater priority is set as ‘Boost heater

only ON’, then electric heater is never turned on and only DHW tank heater is on and off

according to control logic.

• In the installer setting list, heater priority category, and press [OK] button to move to the detail

screen.

OK

Value

Boost heater only ON Main+Boost heater ON

89

ENGLISH

NOTE

DHW heating does not operate when it is disabled.

Page 46

INSTALLER SETTING

90

DHW time setting

Determine following time duration : operation time of DHW tank heating, stop time of DHW tank

heating, and delay time of DHW tank heater operating.

- Active time : This time duration defines how long time DHW tank heating can be continued.

- Stop time : This time duration defines how long time DHW tank heating can be stopped. It is

also regarded as time gap between DHW tank heating cycle.

- Boost heater delay time : This time duration defines how long time DHW tank heater will not be

turned on in DHW heating operation.

- Example of timing chart :

1

DHW tank

is enabled

DHW tank

DHW tank

0

1

0

1

0

1

0

AS SS

BB

Time

heating is enabled

DHW tank heater

heating operation

heater operation

1=active / 0=not active

❈

A = Active time

❈

S = Stop time

❈

B = Boost heater delay time

❈

OK

INSTALLER SETTING

Use Heating Tank Heater

It is the function to change the setting value of heating tank heater operation such as use / nonuse and heater delay time of heating tank heater

• Change setting values using [<,>(left/right)] button.

OK

Value1 Value2 Value3

Use/Not Use Priority Delay time

Not use - -

Use disinfect - -

Use

Cycle

Heater / Cycle

10, 20, 30, 40, 50, 60,

90, 120, 1440

91

ENGLISH

Page 47

INSTALLER SETTING

92

Pump frequency setting (LPM)

It is a function to set for water flow rate in water piping.

OK

INSTALLER SETTING

TH on/off Variable, heating air

It is a function to adjust the heating air temperature Thermal On / Off temperature according to

the field environment in preparation for heating or heating claim.

• You can set the following setting values using [<,>(left/right)] button.

93

ENGLISH

Range

15 ~ 92 LPM

Value

Type0 -0.5 °C 1.5 °C

Type1 -1 °C 2 °C

Type2 -2 °C 3 °C

Type3 -3 °C 4 °C

Description

TH On TH Off

Page 48

INSTALLER SETTING

94

TH on/off Variable, heating water

It is a function to adjust the heating water temperature Thermal On / Off temperature according

to the field environment in preparation for heating or heating claim.

• You can set the following setting values using [<,>(left/right)] button.

INSTALLER SETTING

TH on/off Variable, cooling air

It is a function to adjust the cooling air temperature Thermal On / Off temperature according to

the field environment in preparation for cooling or cooling claim.

• You can set the following setting values using [<,>(left/right)] button.

95

ENGLISH

Value

Type0 -2 °C 2 °C

Type1 -3 °C 3 °C

Type2 -4 °C 4 °C

Type3 -1 °C 1 °C

Description

TH On TH Off

Value

Type0 0.5 °C -0.5 °C

Type1 1 °C -1 °C

Type2 2 °C -2 °C

Type3 3 °C -3 °C

Description

TH On TH Off

Page 49

INSTALLER SETTING

96

TH on/off Variable, cooling water

It is a function to adjust the cooling water temperature Thermal On / Off temperature according

to the field environment in preparation for cooling or cooling claim.

• You can set the following setting values using [<,>(left/right)] button.

INSTALLER SETTING

Heating temp. setting

• At the leaving water control in heating mode, the control reference water temperature position

setting

- If the air / leaving water temperature selection setting is set to leaving water temperature

• Change setting values using [<,>(left/right)] button

97

ENGLISH

Value

Type0 0.5 °C -0.5 °C

Type1 1 °C -1 °C

Type2 2 °C -2 °C

Type3 3 °C -3 °C

Description

TH On TH Off

Value

Outlet (Default) Inlet

Page 50

INSTALLER SETTING

98

Cooling temp. setting

• At the leaving water control in cooling mode, the control reference water temperature position

setting

- If the air / leaving water temperature selection setting is set to leaving water temperature

• Change setting values using [<,>(left/right)] button

INSTALLER SETTING

Pump setting in heating

• It is a function to help the water pump's mechanical life by putting the water pump's rest time

• Installer setting function to set water pump operation / delay time option in heating mode

• In the installer setting list, select Pump setting in heating category, and press [OK] button to

move to the detail screen.

99

ENGLISH

Value

Outlet (Default) Inlet

OK

Type Time setting Operation continue

On 1 Minute~60 minutes -

Off 1 Minute~60 minutes -

Page 51

INSTALLER SETTING

100

Pump setting. in cooling

• It is a function to help the water pump's mechanical life by putting the water pump's rest time