P/NO : MFL50024804

www.lg.com

INSTALLATION MANUAL

AHU COMMUNICATION KIT

• Please read this installation manual completely before installing the product.

• Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

• Please retain this installation manual for future reference after reading it

thoroughly.

MODEL : PRDCA0

ENGLISH

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the equipment.

• Keep doors or windows closed tightly while you are operating the equipment.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your equipment more efficiently by referring to the instructions

below:

TIPS FOR SAVING ENERGY

TIPS FOR SAVING ENERGY

2

ENGLISH

3

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous situations and ensure peak

performance of your product

WARNING

It can result in serious injury or death when the directions are ignored

CAUTION

It can result in minor injury or product damage when the directions are ignored

WARNING

• Installation or repairs made by unqualified persons can result in hazards to you and others.

• Installation MUST conform with local building codes or, in the absence of local codes.

• The information contained in the manual is intended for use by a qualified service technician

familiar with safety procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property damage, personal injury and/or death.

Installation

• Always perform grounding.

- Otherwise, it may cause electrical shock.

• Don’t use a power cord, a plug or a loose socket that is damaged.

- Otherwise, it may cause fire or electrical shock.

• For installation of the product, always contact the service center or a professional installation

agency.

- Otherwise, it may cause fire, electrical shock, explosion or injury.

• Securely attach the electrical part cover to AHU Comm. Kit.

- If the electric part cover of AHU Comm. Kit is not attached securely, it could result in a fire or

electric shock due to dust, water, etc.

• Always install an air leakage breaker and a dedicated switching board.

- No installation may cause a fire and electrical shock.

• Do not keep or use flammable gases or combustibles near the equipment.

- Otherwise, it may cause a fire or the failure of product.

• Do not install, remove or reinstall the unit by yourself.

- Otherwise, it may cause a fire, electrical shock, explosion or injury.

• Do not disassemble or repair the product randomly.

- It will cause a fire or electrical shock.

• Do not install the product in a place where there is the concern of falling down.

- Otherwise, it may result in personal injury.

• Use caution when unpacking and installing.

- Sharp edges may cause injury.

!

!

!

IMPORTANT SAFETY INSTRUCTIONS

ENGLISH

Operation

• Do not share the outlet with other appliances.

- It will cause an electric shock or a fire due to heat generation.

• Do not use the damaged power cord.

- Otherwise, it may cause a fire or electrical shock.

• Do not modify or extend the power cord randomly.

- Otherwise, it may cause a fire or electrical shock.

• Take care so that the power cord may not be pulled during operation.

- Otherwise, it may cause a fire or electrical shock.

• Unplug the unit if strange sounds, smell, or smoke comes from it.

- Otherwise, it may cause electrical shock or a fire.

• Keep flames away.

- Otherwise, may occur a fire.

• Take the power plug out if necessary, holding the head of the plug and do not touch it with

wet hands.

- Otherwise, it may cause a fire or electrical shock.

• Do not use the power cord near the heating tools.

- Otherwise, it may cause a fire and electrical shock.

• Do not allow water to run into electrical parts.

- Otherwise, it may cause the failure of machine or electrical shock.

• Hold the plug by the head when taking it out.

- It may cause electric shock and damage.

• Be cautious that water could not enter the product.

- Otherwise, it may cause a fire electrical shock or product damage.

• Do not step on the indoor/outdoor unit and do not put anything on it.

- It may cause an injury through dropping of the unit or falling down.

• Do not place a heavy object on the power cord.

- Otherwise, it may cause a fire or electrical shock.

• When the product is submerged into water, always contact the service center.

- Otherwise, it may cause a fire or electrical shock.

IMPORTANT SAFETY INSTRUCTIONS

4

ENGLISH

5

2 TIPS FOR SAVING

ENERGY

3 IMPORTANT SAFETY

INSTRUCTIONS

6 INSTALLATION SCENE

7 SUPPLIES

8 OPTIONAL ACCES-

SORIES

9 PART DESCRIPTION

9 Communication Kit (PRDCA0)

10 BEFORE INSTALLATION

13 COMMUNICATION KIT

INSTALLATION

13 Mechanical installation

14 Electric Wiring Work

15 Electric Wiring Work

16 Electrical Work

17 Electric Wiring Work

18 Controller Setting Method

23 AHU KIT WIRING CON-

FIGURATION WITH DDC

23 Configuration concept

24 DI Wring concept

25 DO Wring concept

26 AI Wring concept

28 FAN Signal Wiring Concept

29 THERMISTORS INSTAL-

LATION

29 Pipe thermistors Installation

32 TROUBLESHOOTING

TABLE OF CONTENTS

TABLE OF CONTENTS

ENGLISH

6

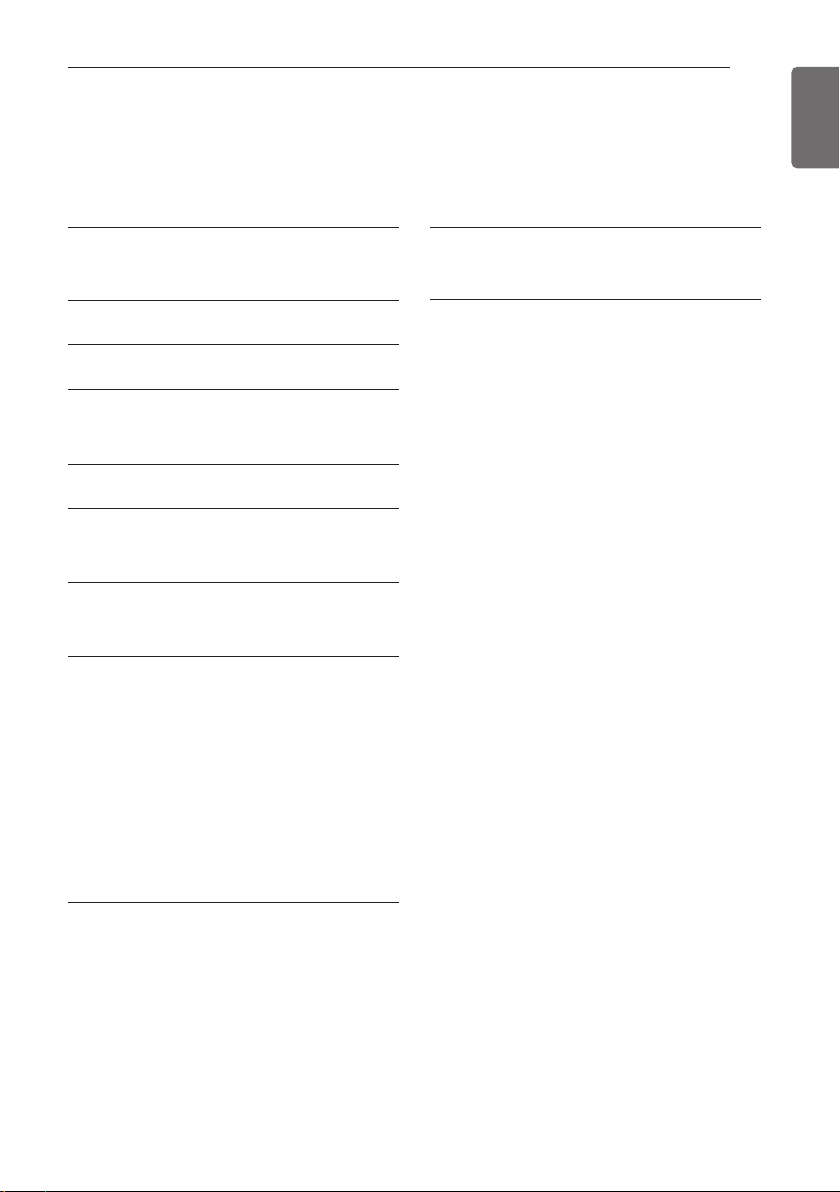

INSTALLATION SCENE

ENGLISH

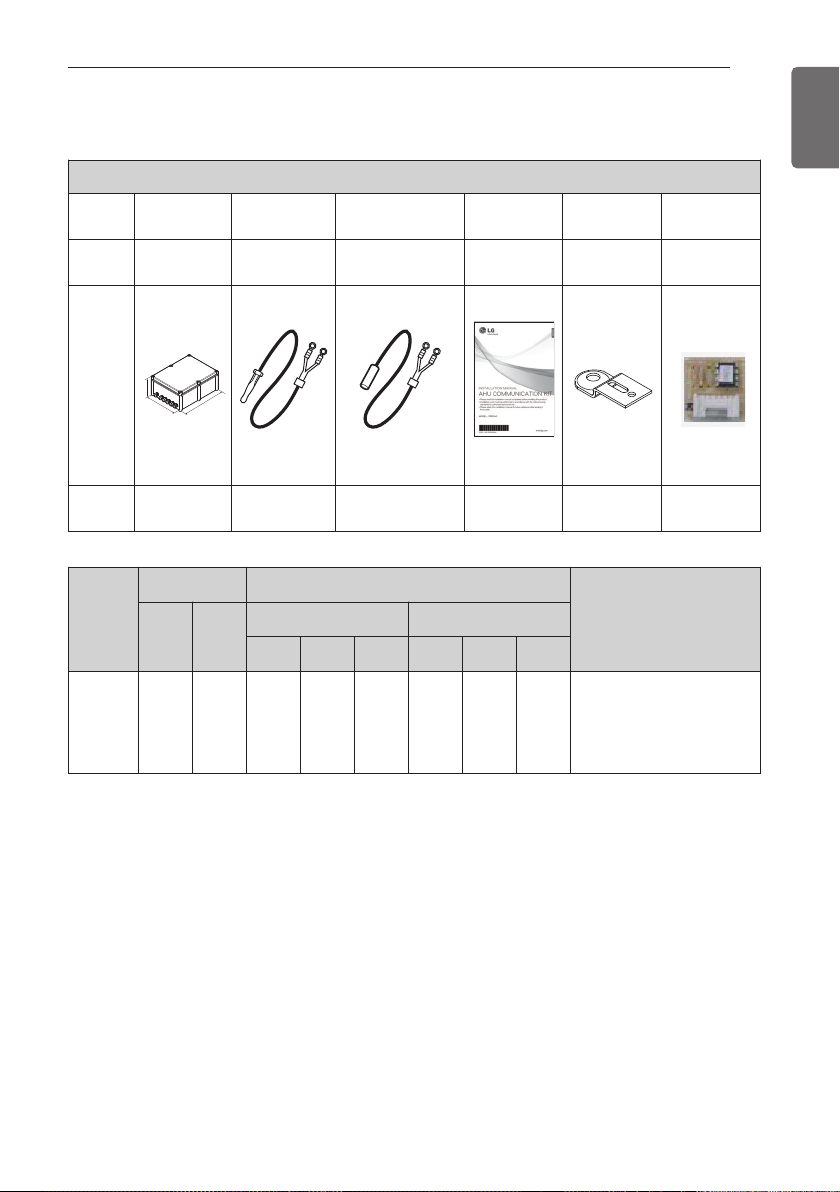

Parts and components

No. Name Remarks

1 Air Handling Unit Field supply

2 Outdoor Unit Multi V

3 AHU Communication Kit(PRDCA0) 4 AHU EEV Kit(PRLK048A0/PRLK096A0) 5 Field piping Field supply

Wiring connections

6 Communication Kit Wiring

Power supply and communication

between comm. kit and outdoor unit

7

Pipe thermistors

(EBG61287703/EBG61287704)

Evaporator (In/Out) control of Air Han-

dling Unit

8 Room thermistor (EBG61106821) Return air control

9

Remote controller(PQRCVSL0

/ PQRCVSL0QW)

Optional accessory

CAUTION

For Installation of Room thermistor (No. 8), always place it at the inlet of Heat Exchanger.

Otherwise, it might not operate properly.

!

INSTALLATION SCENE

Signal

Pipe

Thermistor

Air flow

Refrigerant flow

(Cooling)

Refrigerant flow

(Heating)

8

1

9

3

7

4

5

6

2

SUPPLIES

7

ENGLISH

PRDCA0

Compo-

nents

AHU Comm.

Kit

Room

thermistor

Pipe

thermistors

Installation

Manual

Bracket Option PCB

P/NO

AJT73857401 EBG61106821

EBG61287703(In)

EBG61287704(Out)

MFL50024804 MAZ49398901

EBR52358907

~17

Shape

Quanti-

ty(EA)

1 1 2(Each 1) 1 4 11(Each 1)

Model

Name

Weight (kg) Dimension (mm)

POWER

NET Gross

NET Gross

W H D W H D

PRDCA0 6.0 8.0 330 180 430 420 232 540

220-240 V~ 50 Hz

220 V~ 60 Hz

208/230 V~ 60 Hz

SUPPLIES

H

D

W

8

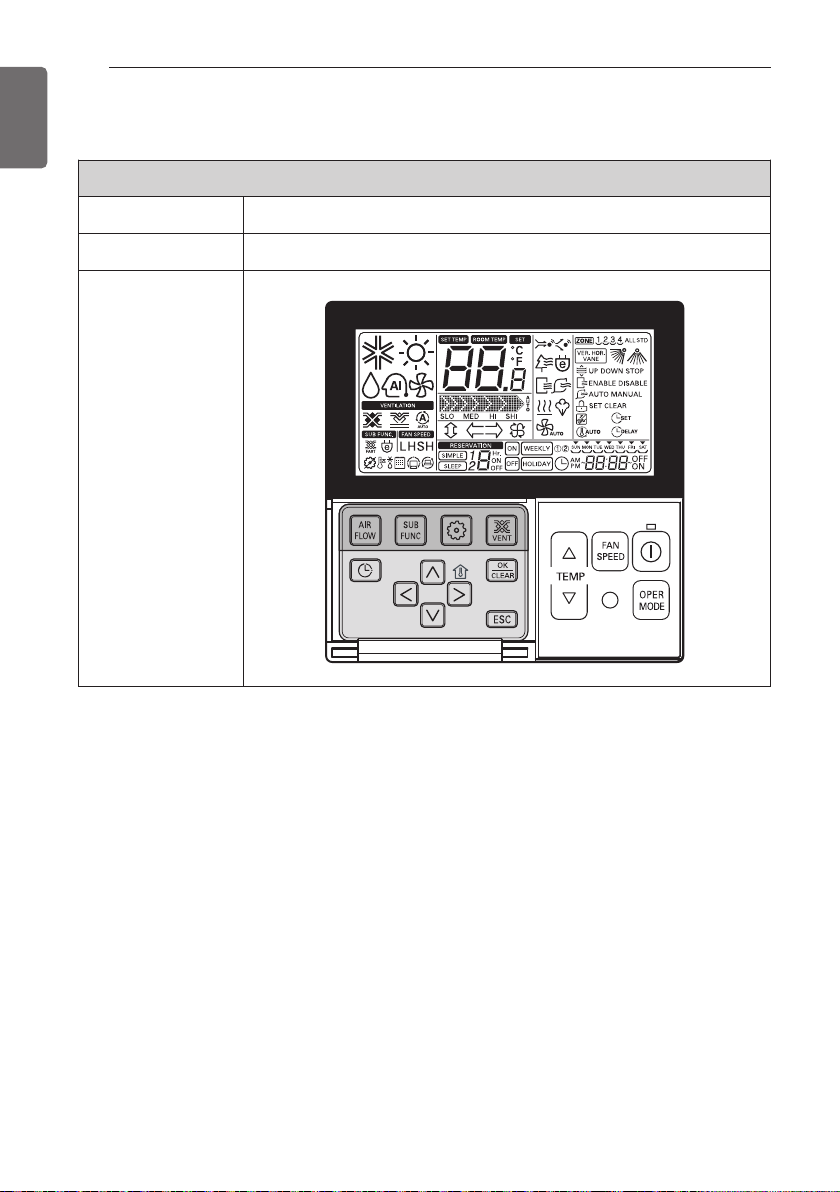

OPTIONAL ACCESSORIES

ENGLISH

* For further details of the accessories, refer to the manual provided at the time of purchasing

the accessories.

Accessories

Components Remote controller

Model name PQRCVSL0 / PQRCVSL0QW

Shape

OPTIONAL ACCESSORIES

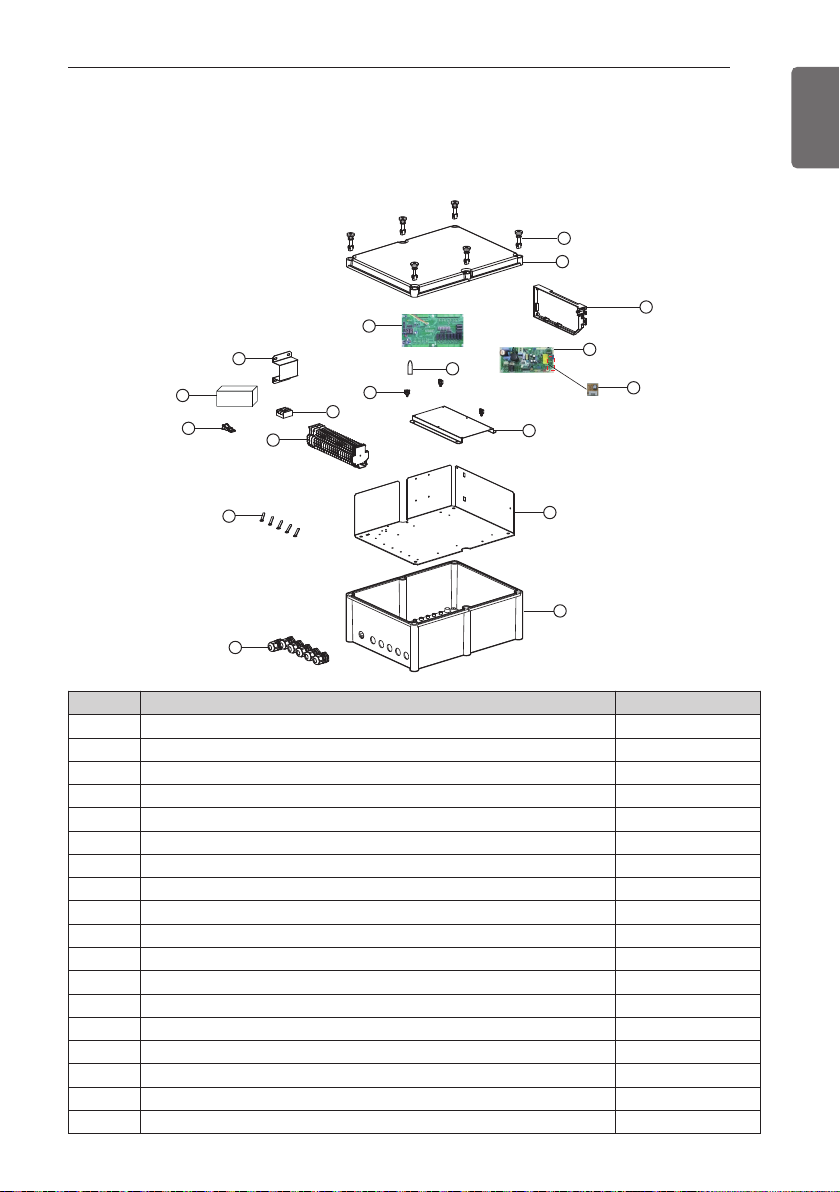

PART DESCRIPTION

9

ENGLISH

Communication Kit (PRDCA0)

No. m Part Name Quantity (EA)

1 Plastic (+) Bolt 6

2 Cover 1

3 Expansion I/O PCB 1

4 Supporter (Connect No. 3) 6

5 Main PCB case 1

6 Main PCB 1

7 Option PCB (192 kBtu/hr) 1

8 Bracket (For Adaptor) 1

9 AC/DC Convertor 1

10 Supporter (Fixing Wiring) 7

11 Terminal Block (Communication) 1

12 Terminal Block (POWER Supply) 1

13 Clamp Cord (For Power Wiring) 1

14 Clamp Cord 5

15 Panel 1

16 Control Box Case 1

17 Cable gland 6

18 Bracket (For Expansion I/O PCB) 1

PART DESCRIPTION

1

2

3

8

9

13

11

14

17

10

12

4

18

15

16

5

6

7

10

BEFORE INSTALLATION

ENGLISH

CAUTION

• Don't install or operate the unit in rooms mentioned below.

① Where mineral oil, like cutting oil is present.

② Where the air contains high levels of salt such as air near the ocean.

③ Where sulphurous gas is present such as that in areas of hot spring.

④ In vehicles or vessels.

⑤ Where voltage fluctuates a lot such as that in factories.

⑥ Where high concentration of vapor spray are present.

⑦ Where machines generating electromagnetic waves are present.

⑧ Where acidic or alkaline vapor is present.

⑨ The option boxes must be installed with entrances downward.

• Check the mentioned below, when you apply the AHU (Field supply).

① If the AHU (Field supply) provided in the field is exclusively for heating, you must not

change the operating mode to cooling on the remote controller. If not, it can cause

electric shock, injury or death. If you want to operate in cooling mode, AHU (Field supply) must comply with the following details.

(Following)

- The insulation level of AHU (Field supply) motor must be ‘F’ or above, and the protection level must satisfy ‘IP 54’.

- AHU (Field supply) must have the drain pan installed.

② Fan speed button on the wired remote controller (PQRCVSL0 /PQRCVSL0QW) is not

operated.

③ For refrigerant piping of outdoor unit, refer to the installation manual supplied with the

outdoor unit.

④ For installation of the wired remote controller (PQRCVSL0 /PQRCVSL0QW), refer to

the manual supplied with the wired remote controller.

⑤ For protecting the refrigerant cycle in heating, the inlet Air temperature to the Heat

Exchanger has to be over 5°C.

⑥ The EEV or TXV kit has to be installed on the AHU as close as possible to the Heat

Exchanger.

• AHU Communication Kit

① Thermistor cable and remote controller wire should be located at least 50mm away

from power supply wires and from wires to the controller. Not following this guideline

may result in malfunction due to electrical noise.

② Use only specified wires, and tightly connect wires to the terminals. Keep wiring in

neat order so that it does not obstruct other equipment. Incomplete connections could

result in overheating, and in worse case electric shock or fire.

!

BEFORE INSTALLATION

BEFORE INSTALLATION

11

ENGLISH

CAUTION

Selection of Evaporator(Air Handling Unit)

See table below for applicable units

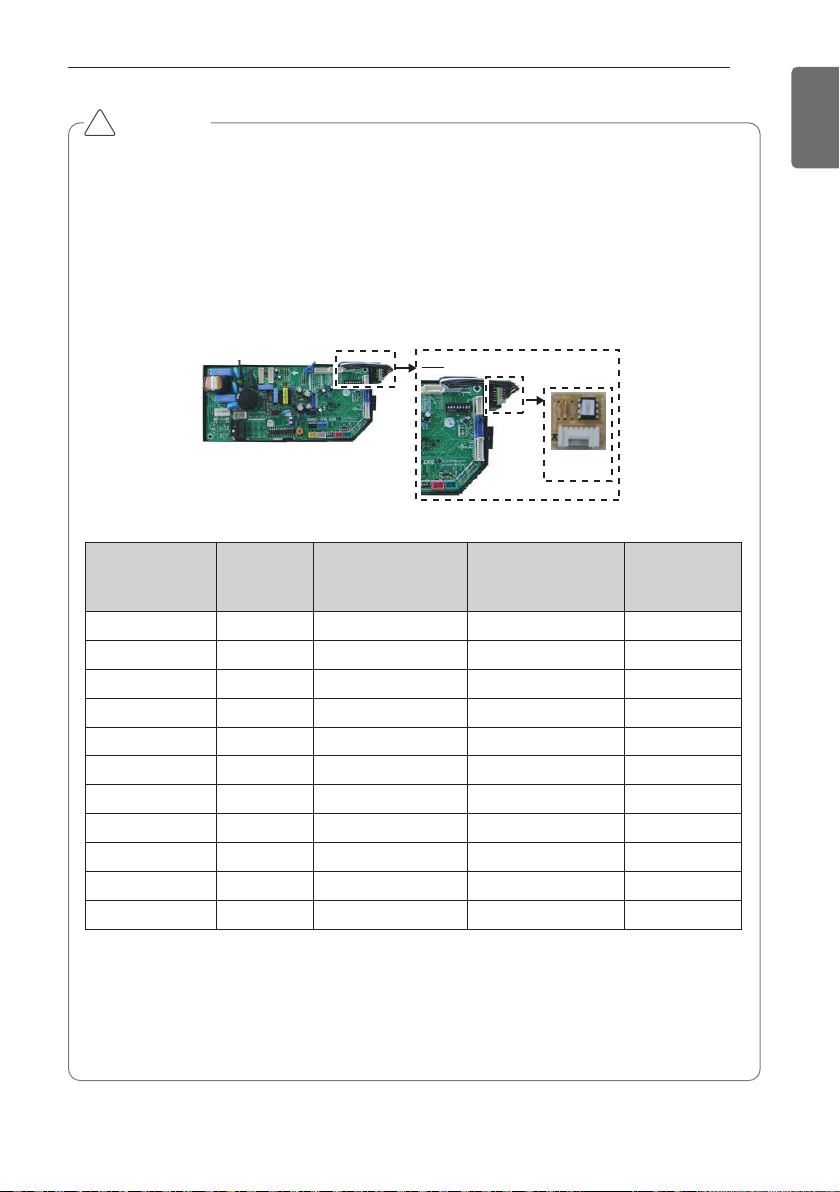

Selecting the capacity setting 'Option PCB'(Accessory) according to the capacity mentioned

below.

- The corresponding capacity setting 'Option PCB' needs to be selected depending on the

need capacity.

- After checking the need capacity, remove the 192 k Option PCB equipped in the main

PCB, and set up the Option PCB fitted the need capacity in the main PCB.

* Evaporator Saturated Temperature(SST) = 6 °C, SH (Superheat) 5K, Air Temperature =

27 °C DBT / 19 °C WBT

* Heat exchanger volume [m

3

] : Pipe cross-section × Tube length

-. Pipe cross-section [m

2

] = π × ID2/4

-. Tube length [m] = Tube length of 1 pipe × Tube step × Tube row

!

Option PCB

P/NO

Capacity

(Btu/h)

Standard heat

exchanger volume

(10-3× m3)

Maximum heat

exchanger capacity

(kW)

Air Flow rate

(CMM)

EBR52358907 28 k 2.7 8.6 22~26

EBR52358908 36 k 3.1 11 25~32

EBR52358909 42 k 3.4 13.8 31~35

EBR52358910 48 k 4.0 15.4 33~45

EBR52358911 76 k 5.4 22.2 50~64

EBR52358912 96 k 6.3 28.1 64~72

EBR52358914 115 k 7.3 33.7 72~88

EBR52358915 134 k 8.5 39.3 88~103

EBR52358916 153 k 9.5 45.4 103~116

EBR52358917 172 k 10.5 50.4 114~129

EBR52358913 192 k 11.2 56.2 121~137

Detail

Capacity setting

'Option PCB'

12

BEFORE INSTALLATION

ENGLISH

CAUTION

• AHU Operation range

- When installing Room thermistor, always place it to the inlet of Heat Exchanger. Otherwise, it may might not operate properly.

- Range of the inlet Air temperature to the Heat Exchanger is 18 ~ 40°C for cooling & 5 ~

30°C for heating. If the temperature is under 18°C for cooling & over 30°C for heating,

the system might operate ON and OFF because of protection logic system’s.

!

No Connection condition Combination

1

100% Fresh Air Intake

AHU only are connected

with outdoor units

1) The total capacity of 100% Fresh Air Intake AHU should be

50~100% of outdoor unit.

COMMUNICATION KIT INSTALLATION

13

ENGLISH

Mechanical installation

1 Remove the Comm. Kit box cover by unscrewing the plastic bolt (6EA)

2 Drill 4 holes on correct position and fix the Comm. Kit box securely with 4 screws

(Field supply) through the provided holes Ø4.5mm (Reference the length of the holes Ø4.5)

COMMUNICATION KIT INSTALLATION

Provided holes

Ø4.5 mm (4EA)

348 mm

332 mm

14

COMMUNICATION KIT INSTALLATION

ENGLISH

CAUTION

If you want to use Analogue Input signal for a variable capacity and a set temperature of

room, you have to connect the wiring of AI 10-2, AI 10-3, AI 10-4.

!

Circuit diagram

Electric Wiring Work

COMMUNICATION KIT INSTALLATION

15

ENGLISH

Terminal Block No. Connection Function Remark.

1(L) / 2(N) Power Supply

220-240 V~ 50 Hz

220 V~ 60 Hz

208/230 V~ 60 Hz

1-3 To AHU Fan Signal High/Mid/Low

4-9 To EEV Kit EEV Kit -

11-12 To AHU Communication Line Internet A, B

13-14

To Indoor Unit

Room Thermistor 15-16 Pipe In Thermistor 17-18 Pipe Out Thermistor 19-21 Remote Controller 23-24 To Outdoor Unit RS485 Communication -

25

Digital Input

DI 01-3 Operation ON/OFF

26 DI 01-1 Common Line

27 DI 23-3

Mode Change

28 DI 23-2

29 DI 23-1 Common Line

30 DI 45-3

Air Flow Rate

31 DI 45-2

33

Digital Output

DO 01-4 Running Status (ON/OFF)

34 DO 01-3 Common Line

35 DO 01-2 Comp. Status (ON/OFF)

36 DO 23-4

Running Mode

37 DO 23-2

38 DO 45-4

Air Flow Rate

39 DO 45-2

40 DO 67-4 Error Status

41 DO 67-1 Common Line

43

Analog Input

AI 10-2 Capacity Control

44 AI 10-3 Common Line

45 AI 10-4 Room Temperature Setting

CAUTION

If you want to use Analogue Input signal for a variable capacity and a set temperature of

room, you have to connect the wiring of AI 10-2, AI 10-3, AI 10-4.

!

Electric Wiring Work

16

COMMUNICATION KIT INSTALLATION

ENGLISH

1 For connection to outdoor unit and to controller (Field supply) :

Pull the wires inside through the cable gland and close the nut firmly in order to ensure a

good pull relieve and water protection.

2 The wires require an additional pull-relief. Strap the wire with the support tie wrap.

3 For the wired remote controller wire and outdoor unit communication wire, remove the

coating at the end of the wire to connect and use the ring type (Ø3) to connect to the terminal block.

t

Ring type (Ø3)

Connection of the wires

Electrical Work

Support

tie wrap

(Front View)

Detail

Nut of cable

gland

(Side view)

Cable Inser

COMMUNICATION KIT INSTALLATION

17

ENGLISH

CAUTION

• All field supplied parts and materials and electric works must be conform to local codes.

• Use copper wire only.

• All wiring must be performed by an authorized electrician.

• A main switch or other means for disconnection, having a contact separation in all poles,

must be incorporated in the fixed wiring in accordance to relevant local and national legislation.

• Refer to the installation manual attached to the outdoor unit for the size of power supply

electric wire connected to the outdoor unit, the capacity of the circuit breaker and switch,

wiring and wiring instructions.

!

Electric Wiring Work

18

COMMUNICATION KIT INSTALLATION

ENGLISH

CAUTION

- DI requires non-voltage contact

- DO provides relay output (max : 250Vac 1A)

- AI : 0Vdc ~ 10Vdc

- RS485 port : Connect to INTERNET A/B on ODU’s main PCB

!

ڸ

ڹ

ں

1 Analog Input : Actually only AHU controller controls or regulate SA temperature, we

only increase or decrease capacity of ODU and Comp. capacity of MULTI

_V.

2 Digital Input : Acquires the control value of AHU operation from DDC(Field supply).

3 Digital Output : Send the condition value of AHU operation to DDC (Field supply).

4 RS485 : Sends the On/Off signal taking from DDC to the indoor & outdoor unit and send the

condition value taking from indoor & outdoor unit to DDC with On/Off Output.

0

C

① Rotary S/W

Capacity controller

Controller Setting Method

Communication port

(1ch, RS485)

Reset

Button

Power(DC 12V)

Digital Input(5ch)

Analog Input(2ch)

Rotary S/W

(3EA)

Digital Output(7ch)

DIP S/W(SW03)

DIP S/W(SW01)

1

0

F

SW_GRP

3

2

E

D

SW_IO

4

C

SW_SPARE

This S/W is for setting up the address of

AHU Comm. Kit (00 ~ FF).

Example) AHU Comm. Kit address is ‘0C’ .

4

3

5

2

E

D

SW_GRP

6

7

8

9

A

B

C

1

0

F

SW_IO

5

6

7

8

9

A

B

SW_TYPE

This S/W is for setting up the

temperature from AHU Comm. Kit.

Detail information refer to the 20 page.

COMMUNICATION KIT INSTALLATION

19

ENGLISH

ྚ

② Dip S/W(SW03)

S/W

name

No

Item

On

Off

Note

SW03

_SW

1

RS485/IDU

RS485

Not available

-. RS485 : Connect to INTERNET A/B

on ODU unit

2 Master/Slave

Master

Slave

-. Master is default for single unit

installation

-. Master is only one among multiple

unit

3

Control enable /

disable

DI/DO

enable

DO only

enable

-. Enable : DI/DO are enable

-. Disable : DO only are enable

4

Room

Temperature

setting 1

AI

Rot.S/W

-. AI : Input as analog input

(Controlled through DDC)

-. Rot. S/W : manual setting

5

Air flow rate

High/Low

High/Mid/Low

-. On : Mid step is not available.

(Mid step is displayed as current

step)

6

Room

Temperature

setting 2

Default

AI / Rot. S/W

Room Temperature Default setting

-. On : Default(Cooling 18°C, Heating

30°C)

-. Off : Room air(or return air) temperature control using Al Signal and

Rotary S/W (Refer to the DIP S/W

No.4)

7

Not available

-

-

-

8

Flash Writing

Normal

On-boarding

-. Default : On

CAUTION

When the Dip S/W No. 6 is On, capacity control is possible and the value of Analogue input

signal for temperature control, Rotary S/W and Remote controller is ignored. In case of setting the temperature of room using Analogue input signal , Rotary S/W and Remote controller, Dip S/W No. 6 have to be Off certainly.

!

* Setting : Black

OFF

876 543 21

876 543 21

SW03_SW

[Default setting]

- . No 1/2/3/4/6/7/8 : On

- . No 5 : Off

20

COMMUNICATION KIT INSTALLATION

ENGLISH

ྛ

③ Dip S/W(SW01)

S/W name

No

Item

Setting Dip S/W

AI Function

1

2

3

SW01

_SW

1 ~3

ODU

Capacity

Option

Setting

Off Off Off Option #1

On Off Off Option #2

Off On Off Option #3

4~8 Not available - - - -

* Setting : Black

OFF

876 543 21

876 543 21

SW01_SW

[Default setting]

-. No 1/2/3/4/5/6/7/8 : Off

COMMUNICATION KIT INSTALLATION

21

ENGLISH

Rotary S/W

ڸ

ڹ

④ Room Temperature control from DDC or Rotary S/W

h

According to Dip S/W(SW03) Setting, you can set up the Function of Room Temperature control.

Dip S/W(② SW03)

Function

Setting

Dip S/W

No 1

ON RS485 Communication with MULTI V

OFF Not available

No 3

ON Possible to control Room Temperature Function (Default)

OFF Only Monitoring (DO Signal only is enable)

No 4

ON DDC Control (Wiring No. AI 10-4)

OFF Rotary S/W(SW_TYPE) Control

No 6

ON Room Temperature Default setting (Cooling 18°C, Heating 30°C)

OFF

Room Air(or return air) temperature control using Al signal and Rotary S/W

• Dip S/W(SW03) NO 4 : OFF

Rotary

S/W(①) Number

Room Temp.(°C) Cooling Room Temp.(°C) Heating

0 Not available Not available

1 18 16

2 18 17

3 18 18

4 19 19

5 20 20

6 21 21

7 22 22

8 23 23

9 24 24

A 25 25

B 26 26

C 27 27

D 28 28

E 29 29

F 30 30

ڹ

ڸ

Rotary S/W

Dip S/W(SW03)

22

COMMUNICATION KIT INSTALLATION

ENGLISH

• Dip S/W(SW03) NO 4 : ON

Example) 5.85~6.15 Voltage is recognized as 6.0V.

Analog Input 10-4 (VDC)

Room Temp.(°C)

Cooling

Room Temp.(°C)

Heating

Normal

Range

Min. Max.

0.5 0 1.15 Not available Not available

1.5 1.35 1.65 18 16

2 1.85 2.15 18 17

2.5 2.35 2.65 18 18

3 2.85 3.15 19 19

3.5 3.35 3.65 20 20

4 3.85 4.15 21 21

4.5 4.35 4.65 22 22

5 4.85 5.15 23 23

5.5 5.35 5.65 24 24

6 5.85 6.15 25 25

6.5 6.35 6.65 26 26

7 6.85 7.15 27 27

7.5 7.35 7.65 28 28

8 7.85 8.15 29 29

8.5 8.35 8.65 30 30

9.5 8.85 10 Not available Not available

CAUTION

If you want to control the Room Temperature using Remote controller, you have to be off

the Dip S/W 4 and Dip S/W 6, and setting the Rotary S/W to the ‘0’ .

!

AHU KIT WIRING CONFIGURATION WITH DDC

23

ENGLISH

AHU KIT WIRING CONFIGURATION WITH DDC

Configuration concept

1 Comm. Kit control capacity of the cooling/heating only according to the DDC’s control

signal (DC 0~10V)

2 Control signal from the DDC is decided by calculation logic with Td/Ti and setting tempera-

ture (Calculation logic depends on BMS program).

3 For Installation of Room thermistor, recommended to be installed to the inlet of Heat

Exchanger.

BMS

system

AHU

Comm. Kit

0~10V DC

(AI 10-2)

(Multi V)

0~10V DC

(AI 10-4)

DI/DO

Room

Temp. sensor

Target

pressure

Modulating

DDC

Discharge Temp. sensor

( DC 0~10V Output)

(AHU)

Ti : Inlet Temp.

Te : HEX. Temp.

Td : Discharge Temp.

TdTeTi

Field Su pp lyLG Supply

24

AHU KIT WIRING CONFIGURATION WITH DDC

ENGLISH

Wiring

No.

Input

Logic Conditions

Open Short

DI 01-3

Operation

Off

Operation

On

-. When short, the fan signal (FAN) is On

and ODU will start to run.

-. When open, ODU will off and FAN

changes to Off.

-. Operation mode

: DI 23-3/23-2

-. Fan mode

: DI 45-3/45-2

DI 23-3

FAN

Operation

Cooling or

Heating

-. When open, FAN is On but ODU will

not run.

-. When short, FAN is On and mode is

decided DI 23-2.

-. If no more cooling and heating is necessary, DI 23-3 is open and DI 01-3 is

On.

-. DI 01-3 : short

DI 23-2

Cooling

Operation

Heating

Operation

-. When open, mode is cooling

-. When short, mode is heating

-. DI 01-3 : short

-. DI 23-3 : short

DI 45-3

Low FAN

Mid FAN

-. When DI 45-3/45-2 are open : Low fan

mode and FAN is On.

-. When DI 45-3 is short : Mid fan and

FAN is On.

-. DI 01-3 : short

-. Operation mode

: DI 23-3/23-2

DI 45-2 High FAN

-. When DI 45-2 short : High fan and

FAN is On.

-. When DI 01-3 is open : FAN is Off, DI

45-3,/45-2 are neglected.

NOTE

!

Fan signal (FAN) can be delayed on heating mode start up despite of fan mode (DI 45-3/45-2)

because fan signal (FAN) will be On , if temperature of refrigerant pipe sensors (PIPE_IN,

PIPE_Out) are higher than 20°C to prevent cold air discharge.

DI Specification

: Non-Voltage Contact

DI Wring concept

Digital Input(5ch)

AHU KIT WIRING CONFIGURATION WITH DDC

25

ENGLISH

Digital Output(7ch)

NOTE

!

If AHU should have High/Mid/Low fan mode, Fan control in AHU should utilize DO 45-4 /45-2

(Non-Voltage Contact).

Wiring

No.

Output

Logic

Open Short

DO 01-4

OperationOnOperation

Off

-. When DI 01-3 is short, ODU and FAN are On.

-. When DI 01-3 is open, ODU and FAN are Off.

DO 01-2

Compressor

is Off

Compressor

is On

-. When ODU compressor is running, it is short.

-. When ODU compressor is off, it is open

DO 23-4

Cooling / Heating

Defrosting / FAN

-. When DO 23-4 / 23-2 are open, it is ventilation mode.

-. When DO 23-4 is open, DO 23-2 is short, it is defrosting

during heating. FAN can be OFF if PIPE_IN and

PIPE_OUT are less than 20°C.

-. When DO 23-4 is short, DO 23-2 is open, it is cooling.

-. When DO 23-4 is short, DO 23-2 is short, it is heating

-. Defrosting mode only works when it is connected with

ODU.

DO 23-2

DO 45-4

Low FAN

Mid FAN

-. When DO 45-4 / DO 45-2 are open, it is low fan mode.

-. When DO 45-4 is short and DO 45-2 is open , it is mid

fan mode.

DO 45-2 High FAN

-. When DO 45-2 is short, it is high fan mode (DO 45-4 is

neglected).

DO 67-4 No Error

Error

Occurred

-. When DO 67-4 is short, ODU has error and ODU stops

FAN is Off.

DO Specification

: AC 250V, DC 30V, 1A

DO Wring concept

26

AHU KIT WIRING CONFIGURATION WITH DDC

ENGLISH

Discharge Temperature Control through controlling of ODU capacity

AI Specification : DC 0~10V

AI

No.

Input

voltage

[Vdc]

Low

[Vdc]

High

[Vdc]

Capacity

of unit

[%]

Cooling

Heating

Control

Target

Low

Pressure

[kPa]

Tempera-

ture at

HEX [°C]

Target

High

Pressure

[kPa]

Tempera-

ture at

HEX [°C]

AI

10-2

0 0 0.4 No limit ----

DI should be

decided.

1 0.6 1.4 100 800 10.5 3,000 49.2

DI will determine

fan mode and

operation mode.

2 1.6 2.4 90 830 11.3 2,990 49.0

3 2.6 3.4 80 870 12.5 2,730 45.1

4 3.6 4.4 70 930 14 2,560 42.5

5 4.6 5.4 60 990 15.8 2,340 38.9

6 5.6 6.4 50 1,070 17.9 2,080 34.1

7 6.6 7.4 45 1,100 19 1,950 31.5

8 7.6 8.4 40 1,160 20.3 1,800 28.4

9 8.6 9.4

Comp.

off

----

If it is 9V, DO 01-4

is short, DO 01-2

is open.

10 9.6 10 All off ----

ODU and fan are

Off.

AI Wring concept

1. Option #1

Analog Input(2ch)

* Setting DIP S/W(SW01)

1.Option #1

OFF

876 543 21

876 543 21

2.Option #2

OFF

876 543 21

876 543 21

3.Option #3

OFF

876 543 21

876 543 21

AI

10-2

0 0 0.4

Comp.

off

---DO 01-4 is short,

DO 01-2 is open.

1 0.6 1.4

Comp.

off

----

2 1.6 2.4 40 1,160 20.3 1,800 28.4

DI will determine

fan mode and

opeation mode

3 2.6 3.4 45 1,100 19.0 1,950 31.5

4 3.6 4.4 50 1,070 17.9 2,080 34.1

5 4.6 5.4 60 990 15.8 2,340 38.9

6 5.6 6.4 70 930 14.0 2,560 42.5

7 6.6 7.4 80 870 12.5 2,730 45.1

8 7.6 8.4 90 830 11.3 2,990 49.0

9 8.6 9.4 100 800 10.5 3,000 49.2

10 9.6 10 100 800 10.5 3,000 49.2

AHU KIT WIRING CONFIGURATION WITH DDC

27

ENGLISH

AI

No.

Input

voltage

[Vdc]

Low

[Vdc]

High

[Vdc]

Capacity

of unit

[%]

Cooling

Heating

Control

Target

Low

Pressure

[kPa]

Tempera-

ture at

HEX [°C]

Target

High

Pressure

[kPa]

Tempera-

ture at

HEX [°C]

AI

No.

Input

voltage

[Vdc]

Low

[Vdc]

High

[Vdc]

Capacity

of unit

[%]

Cooling

Heating

Control

Target

Low

Pressure

[kPa]

Tempera-

ture at

HEX [°C]

Target

High

Pressure

[kPa]

Tempera-

ture at

HEX [°C]

2. Option #2

3. Option #3

AI

10-2

0 0 0.4

Comp.

off

----

DO 01-4 is short,

DO 01-2 is open.

1 0.6 1.4 40 1160 20.3 1800 28.4

DI will determine

fan mode and

opeation mode

2 1.6 2.4 45 1100 19.0 1950 31.5

3 2.6 3.4 50 1070 17.9 2080 34.1

4 3.6 4.4 60 990 15.8 2340 38.9

5 4.6 5.4 70 930 14.0 2560 42.5

6 5.6 6.4 80 870 12.5 2730 45.1

7 6.6 7.4 90 830 11.3 2990 49.0

8 7.6 8.4 100 800 10.5 3000 49.2

9 8.6 9.4 100 800 10.5 3000 49.2

10 9.6 10 100 800 10.5 3000 49.2

28

AHU KIT WIRING CONFIGURATION WITH DDC

ENGLISH

HEX

M

M

h If the motor is On/Off type, HI/MED/LOW wire have to connect as common.

For example, If you just connect HI wire to the motor(On/Off), motor is not operating according

to our control logic.

FAN Signal Wiring Concept

ſſ

1(L) 2(N)

ſſ

[AHU]

N

R-LOW

Motor

Relay

Field Wiring

Factory Wiring

[AHU Comm. Kit]

HI(L)

MED(L)

LOW(L)

LOW

MED

HI

R-HI R-MED

ƖƖ

12

ƖƖ

Ɩ

3

Ɩ

ƖƖ

1(L) 2(N)

ƖƖ

(MCC Panel )

Motor operating power

220-240 V~ 50 Hz

220 V~ 60 Hz

208/230 V~ 60 Hz

Control power

220-240 V~ 50 Hz

220 V~ 60 Hz

208/230 V~ 60 Hz

Cable : Over CV 1.5mm

2

THERMISTORS INSTALLATION

29

ENGLISH

Pipe thermistors Installation

Location of the pipe thermistors

A correct installation of the thermistors is required to ensure a good operation :

1 Pipe_In(EBG61287703)

: Install the thermistor behind the distributor on the coldest pass the heat exchanger

(contact your heat exchanger dealer).

2 Pipe_Out(EBG61287704)

: Install the thermistor at the outlet of the heat exchanger as close as possible to the heat

exchanger.

Evaluation must be done to check if the evaporator is protected against freeze-up.

Execute test operation and check for freeze-up.

1 Pipe_In(Suction pipe)

2 Pipe_Out(Discharge pipe)

(Air Handling Unit)

THERMISTORS INSTALLATION

1

2

30

THERMISTORS INSTALLATION

ENGLISH

Installation of the pipe thermistor cable

1 Put the thermistor cable in a separate protective tube.

2 Always add a pull-relief to the thermistor cable to avoid strain on the thermistor cable and

loosening of the thermistor. Strain on the thermistor cable or loosening of the thermistor may

result in bad contact and incorrect temperature measurement.

Fixation of the pipe thermistors (Field work)

1 Fix the thermistor with insulating aluminum tape (Field supply) in order to ensure a good heat

transfer.

2 Put the supplied piece of rubber around the thermistor (EBG61287703/04) in order to avoid

loosening of the thermistor after some years.

3 Fasten the thermistor with 2 tie wraps (Field Supply)

4 Insulate the thermistor with insulation sheet(Over 5t, Field Supply)

123 4

Tie wrap

1

45°

2

Thermistor

THERMISTORS INSTALLATION

31

ENGLISH

INSTRUCTION

!

• Put the thermistor wire slightly top to above water accumulation on down of the thermistor.

• For sensing the evaporator’s temp. in thermistor, Put the upper port the thermistors on the

evaporator, this is the most sensitive point of the thermistor.

1 Most sensitive point of the thermistor

2 Maximize the contact

Water

2

1

45 °

32

TROUBLESHOOTING

ENGLISH

[Error Code]

Display Number Error Item Cause of Error

CH 01 Room Temperature

Temperature sensor disconnection or

short circuit on Room or RA of AHU

CH 02

Pipe In Temperature sensor

error

Temperature sensor disconnection or

short circuit on pipe inlet of AHU

CH 03

Communication error between

wired remote controller and

Comm. Kit

No communication signal for more

than 3 minutes from wired remote

controller to the Comm. Kit

CH 05

Communication error between

Comm.

Kit and Outdoor Unit

No communication signal for 5 minutes

continuously from Comm. Kit to Outdoor Unit

CH 06

Pipe Out Temperature sensor

error

Temperature sensor disconnection or

short circuit on pipe outlet of AHU

CH 09 Option PCB EEPROM error

No reading signal for 5 times continuously from EEPROM to Comm. Kit

Problem Cause Remedy

AHU Communication Kit

does not work

No power supply

Check the electrical connection and voltage

of the power supply.

Wiring is wrong

Check the electrical connection of the

Communication Kit (Refer to the circuit diagram of the Communication Kit)

AHU Communication Kit

is broken

Check the electrical and mechanical part.

TROUBLESHOOTING

33

ENGLISH

34

ENGLISH

Loading...

Loading...