NOTE:

Active links in this document

are outlined in blue.

LG Electronics Alabama, Inc.

Plasma One Point Repair 2004

Contents

. Visual repair Index

. Introduction to Plasma

. Service Adjustments

. Trouble shooting

1

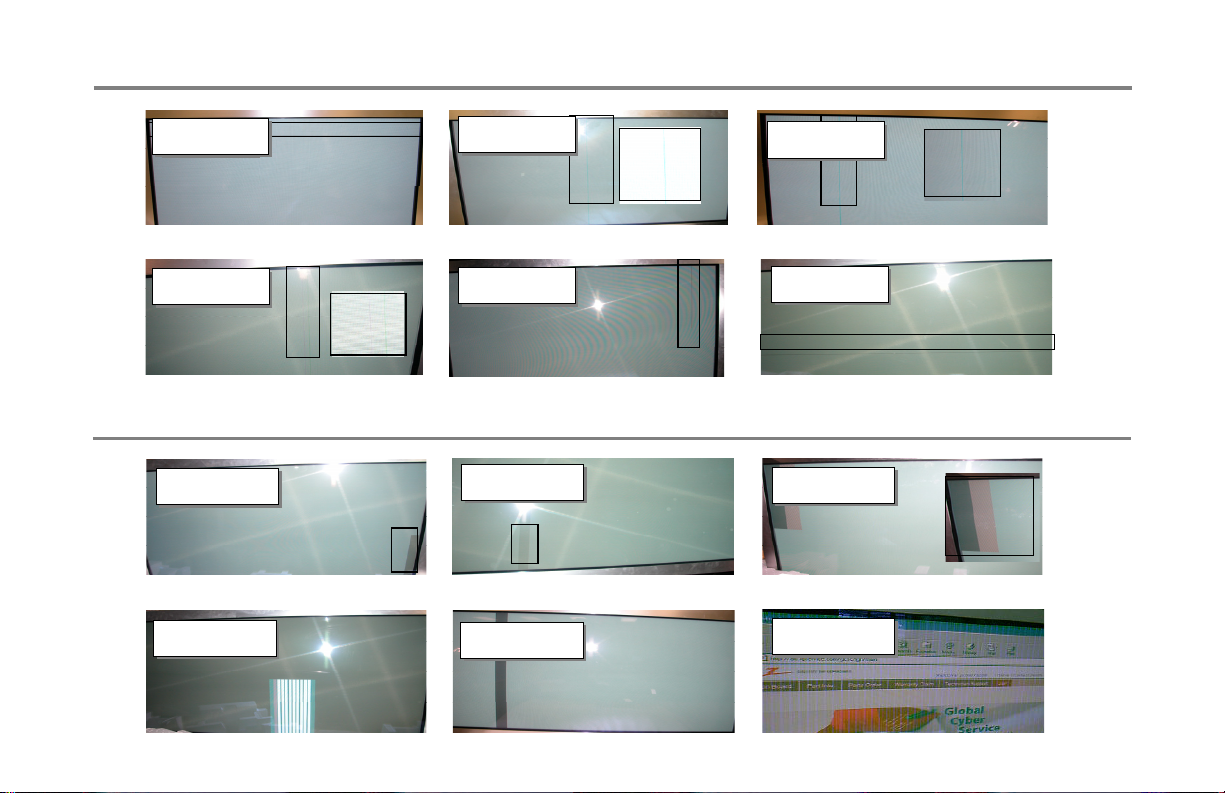

60’’ Known Visual problems with boards that fixed

Visual repair Index

Page # 37

Page # 37

Control Board & Y-Driver Amp

Page # 40

Page # 40

Y-Driver Top

Page # 38

Page # 38

Y- Amp

Page # 41

Page # 41

Control Board

60’’ Known Visual problems with boards that fixed

Page # 43

Page # 43

Y-Driver - Top

Page # 46

Page # 46

Page # 44

Page # 44

VSC- Board

Page # 47

Page # 47

Page # 39

Page # 39

Y-Driver Amp

Page # 42

Page # 42

X-Board upper right

Page # 45

Page # 45

Y-Driver - Top

Page # 48

Page # 48

VSC- Board

X- Board ( Top Right)

Y-Driver amp and X-Drive Top

2

50’’ Known Visual problems with boards that fixed

Visual repair Index

Page # 49

Fig # 13

Page # 49

Fig # 13

Y-Driver Amp upper

Page # 52

Page # 52

VSC Board

Page # 50

Page # 50

Control board

Page # 53

Page # 53

X-Board upper right

50’’ Known Visual problems with boards that fixed

Page # 56

Page # 55

Page # 55

X- Board ( Lower Right)

Page # 58

Page # 58

Page # 56

X- Board ( Lower Left)

Page # 59

Page # 59

Page # 51

Page # 51

Control Board

Page # 54

Page # 54

Y- Driver Amp bottom

X- Board ( Bottom Left)

Page # 57

Page # 57

Control Board

Page # 60

Page # 60

Y- Driver Bottom

Y- Driver Amp and X-Drive Top

Control Board

3

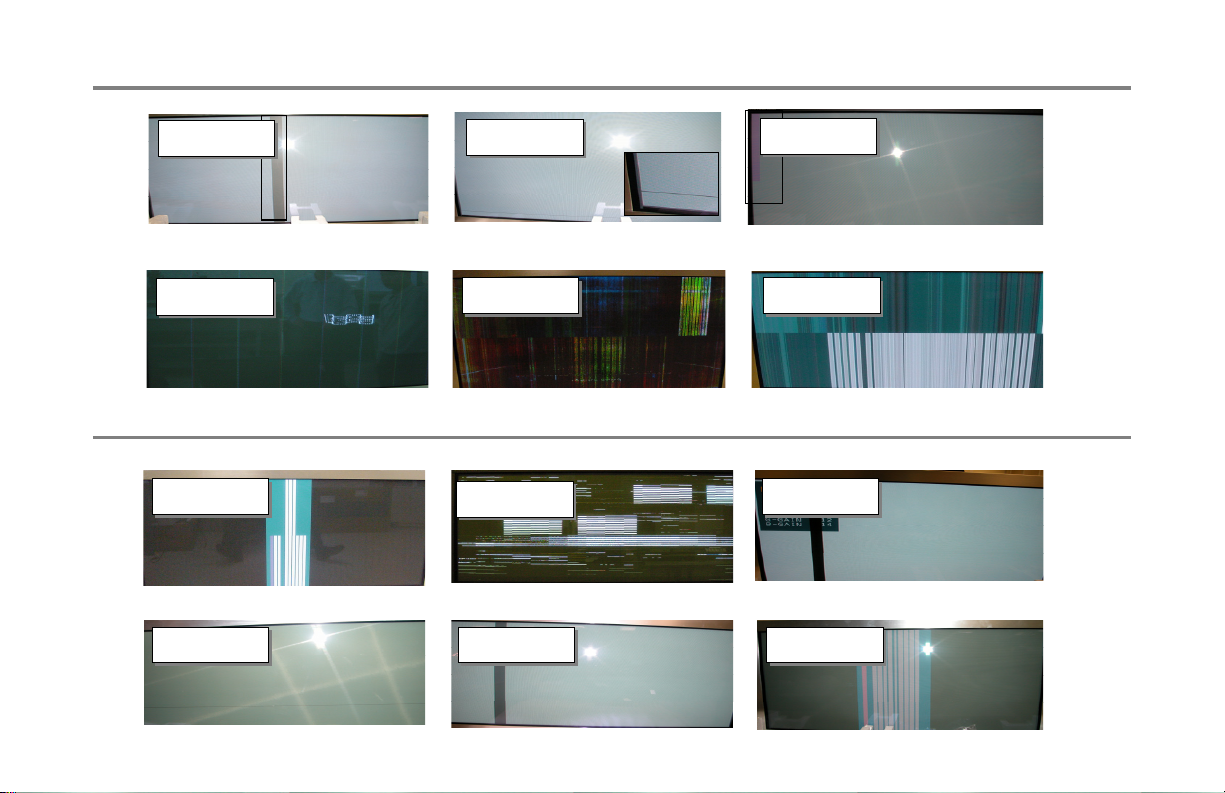

42’’ Known Visual problems with boards that fixed

Visual repair Index

Page # 61

Page # 61

Data @ X-Board – Yes/ tested for shorted

FOC IC – Ribbon shorted/ Defective Panel

Page # 64

Page # 64

Display’s waves - VSC

Page # 62

Page # 62

Installed Y- Driver Amp bottom no

Change/ Defective Panel

Page # 65

Page # 65

42’’ Known Visual problems with boards that fixed

Page # 67

Page # 67

Y-Driver - Top

Page # 70

Page # 70

Page # 68

Page # 68

VSC- Board

Page # 71

Page # 71

Page # 63

Page # 63

Data @ X-Board – Yes/ tested for shorted

FOC IC – Ribbon shorted/ Defective Panel

Page # 66

Page # 66

Y-Driver - TopY-Driver - Top

Page # 69

Page # 69

Y-Driver - Top

Page # 72

Page # 72

Y-Driver Amp upper

Control BoardControl board

4

8QGHUVWDQGLQJ0RGHO1XPEHUVIRU/*'LVSOD\’V

08– 3=9

352'8&77<3(

• 00RQLWRU

• '%,'LJLWDO7XQHU

• .%,'9'

• 5%,$QDORJ7XQHU

• 7%,395

5(*,21

• 81$PHULFD

• =(XURSH

• 71(8

• 36$PHULFD

• --DSDQ

• 1.RUHD

'LVSOD\6L]H

,QFKHV

63(&,$/237,21

',63/$<'(9,&(

33'3

//&'

))ODW&57

60LFUR'LVSOD\

$VSHFW5DWLR

• =<;…ZLGH

• $%&…

(QJLQHHULQJ7RRO

)RUPDQXIDFWXULQJ

SXUSRVHRQO\

++LJK$OWLWXGH

93LYRW9HUWLFDO'LVSOD\

0+LJK$OWLWXGH3LYRW

4+RPH6HFXULW\1HWZRUN

''/3

//&'

5

Introduction to Plasma

How the power supply works

Voltages for VS: Supplies support to the Y-Amplifier for

horizontal grid voltage. If the required voltage is not + or –

3% you may see the following in the picture: lines from side

to side or left to right, half picture top or bottom, intermittent

shutdown or dead.

Voltages for VA: Supplies support to the Z-Amplifier for

vertical grid voltage. If the required voltage is not + or – 3%

you may see the following in the picture: Comets, washout,

bleeding, intermittent shutdown or dead.

To start to understand plasma one must look for why this

voltage is not within specifications. In LG – Zenith line of

plasmas there are several power supply set-ups as follows:

60” plasma is made-up of a primary and secondary power

supply followed by a DC to DC converter. This is to support

the massive current that’s required to sustain picture

quality.

The 50” and 42” plasma power supplies are consolidated

into one board. In the 60” anyone of the three parts could

be out of adjustment. In the fifty and forty two the voltages

need to be still verified in chronological order. In most

cases if your facing a dead set scenario this is caused by

a shorted Y or X-driver board.

Testing for defective Y-drive boards can be done by looking

for a voltage drop if this is located in the Y-sustain

disconnect power and remove one Y-driver boards at a

time until Y-sustain voltage is accurate. If Y-sustain does

not respond with proper voltage supplied replace. Testing

for defective X-driver boards can be done by powering

down and disconnecting each X-driver and powering on

each quadrant at a time.

Pulse Frequency Coefficient: (PFC) adjustment is Located

the primary supply and is for aligning grid voltage. The

panels grid voltage averages 360 to 380 volts depending

on panel circuit.

Known symptoms:

No Power

Intermittent Power

Picture dimming to bright during certain seines

Primary colors off, Hue or flesh tones

Colors bleeding

Left to Right picture is dark to bright

Introduction to Plasma

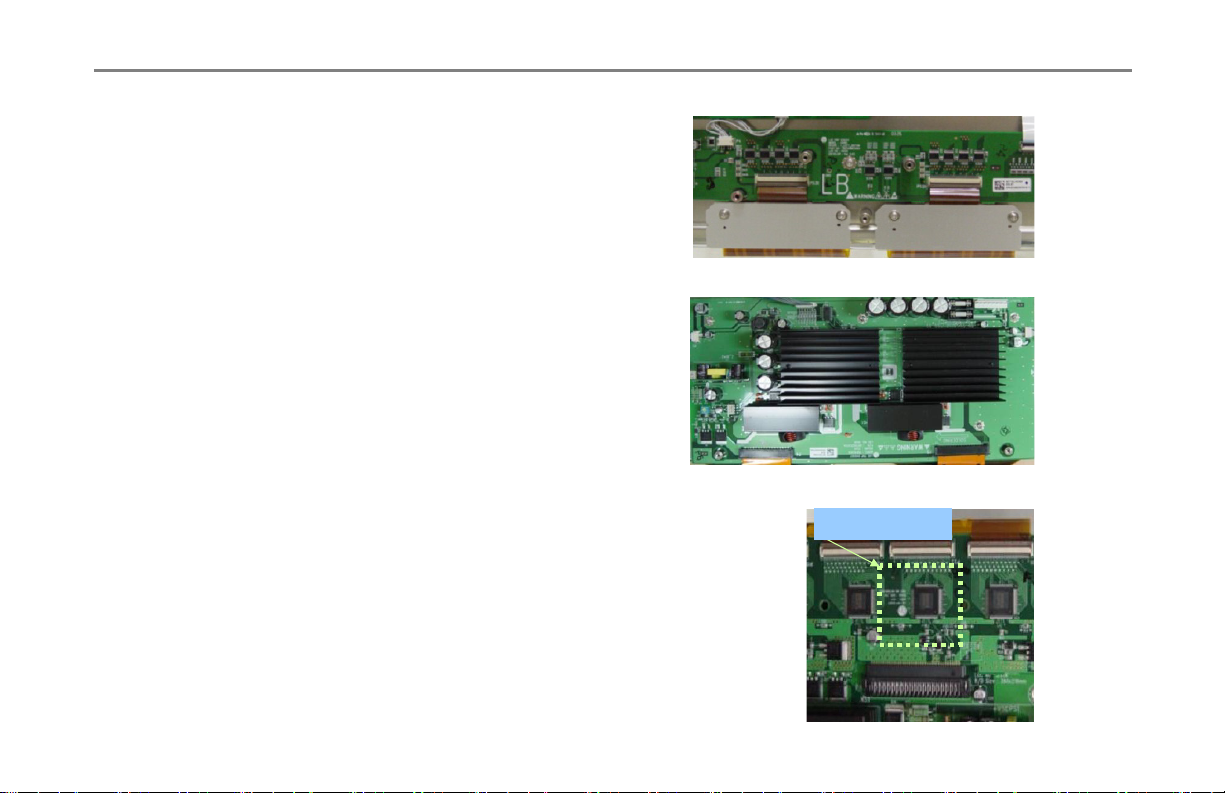

1. X B/D

Receiving LOGIC signal from CONTROL B/D to make ADDRESS

PULSE generating address discharge by an ON/OFF operation,

and supplies this waveform to COF IC (data) or ribbon IC.

X B/D

X B/D

2. Z sustain B/D

Responsible for making SUSTAIN PULSE and ERASE PULSE that

that generates SUSTAIN discharge in panel by receiving LOGIC

signals the CONTROL B/D.

The Sustain discharge waveform is supplied to panel through FPC (Z

B/D).

Composed of IPM,FET,DIODE, electrolytic capacitor, E/R coil.

3. Y drive B/D

1) This is a path to supply SUSTAIN ,RESET waveform which is made

from Y SUSTAIN B/D to panel through SCAN DRIVER IC.

2) Supplies the waveform that selects Horizontal pulse (Y SUSTAIN pulse) sequentially.

- Potential difference is 0V between GND and Vpp of DRIVER IC in SUSTAIN period.

- Generated potential difference between GND and Vpp only in SCAN period.

• E/R (Energy recovery)

• COF (Chip On Film)

• IPM (Intelligent Power Module)

Z B/D

Z B/D

Y SUB--

Y SUB

AMP B/D

AMP B/D

Scan drive IC

Introduction to Plasma

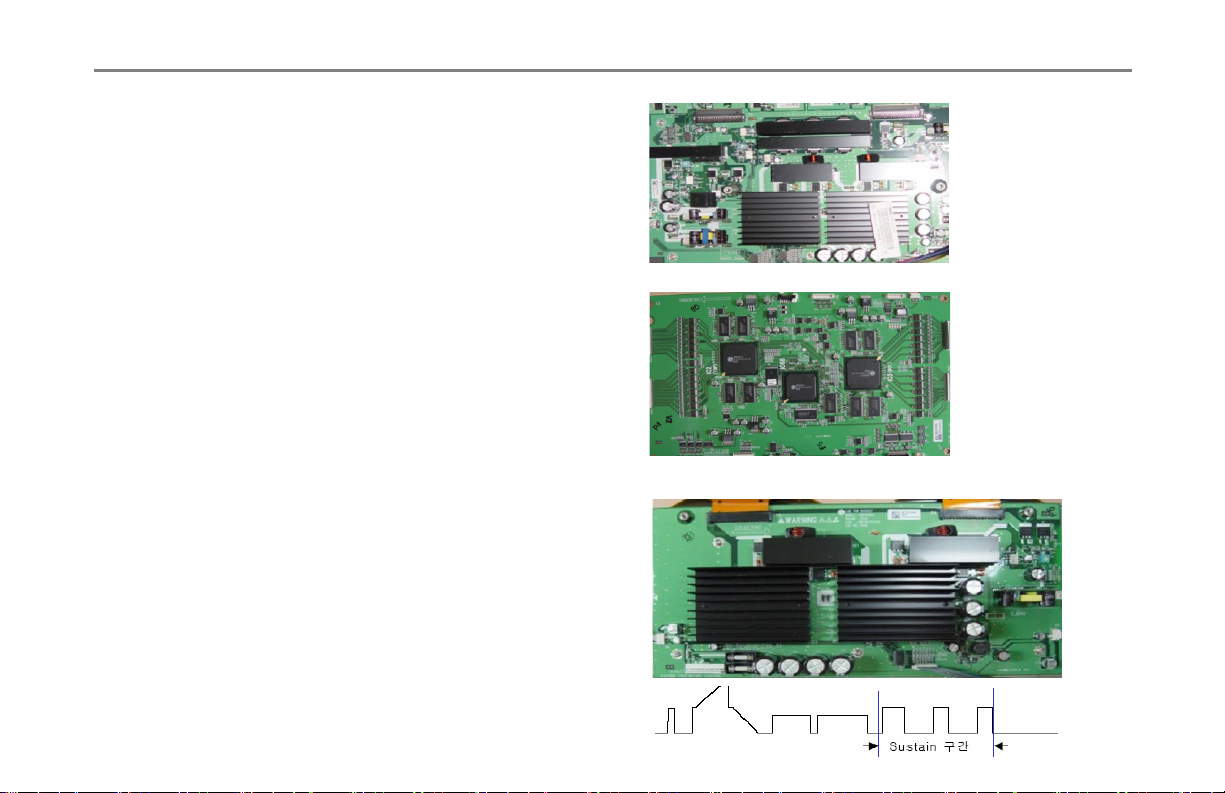

4. Y sustain B/D

Generates SUSTAIN, RESET waveform, VSC (SCAN) voltage

and supplies it to the Y DRIVER B/D.

Composed of IPM, DIODE, electrolytic capacitor, FET.

AMP B/D

YY--AMP B/D

5. Control (logic) Board

Creates signal processing (Contour noise, reduction ISM,..)

and an order of many FET switching IC’s on/ off of each

DRIVER B/D with R,G,B to each 8bit input COF ribbon IC.

Supply voltages 3.3V/ 5V.

6. IPM (Intelligent Power Module)

Connected to Z B/D and Y B/D, making Sustain waveform.

Sustaining and supplying a square wave to panel, creating video.

Composition

CAPACITORS/ DIODES/ IC LINEAR/ RESISTORS,

TRANSISTORS and FETS.

• E/R (Energy recovery)

• IPM (Intelligent Power Module)

DIG CONTROL B/D

DIG CONTROL B/D

Z-APM B/D

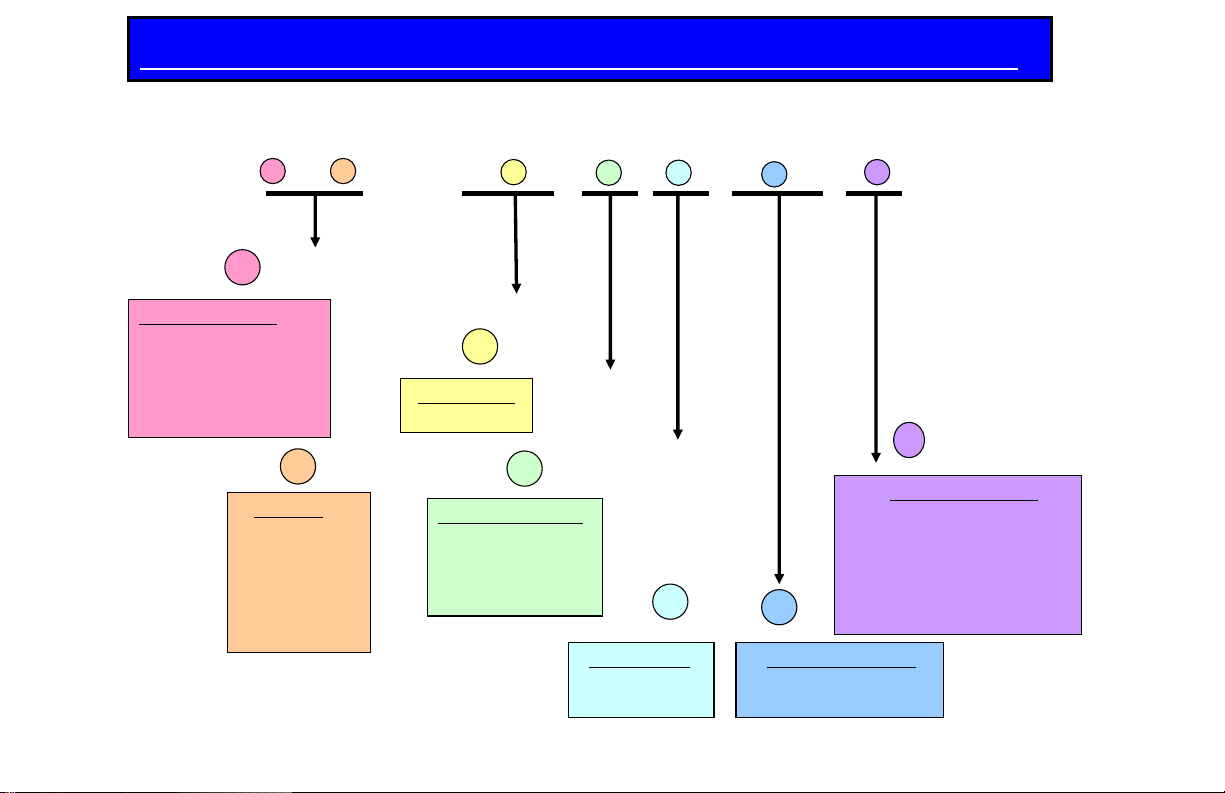

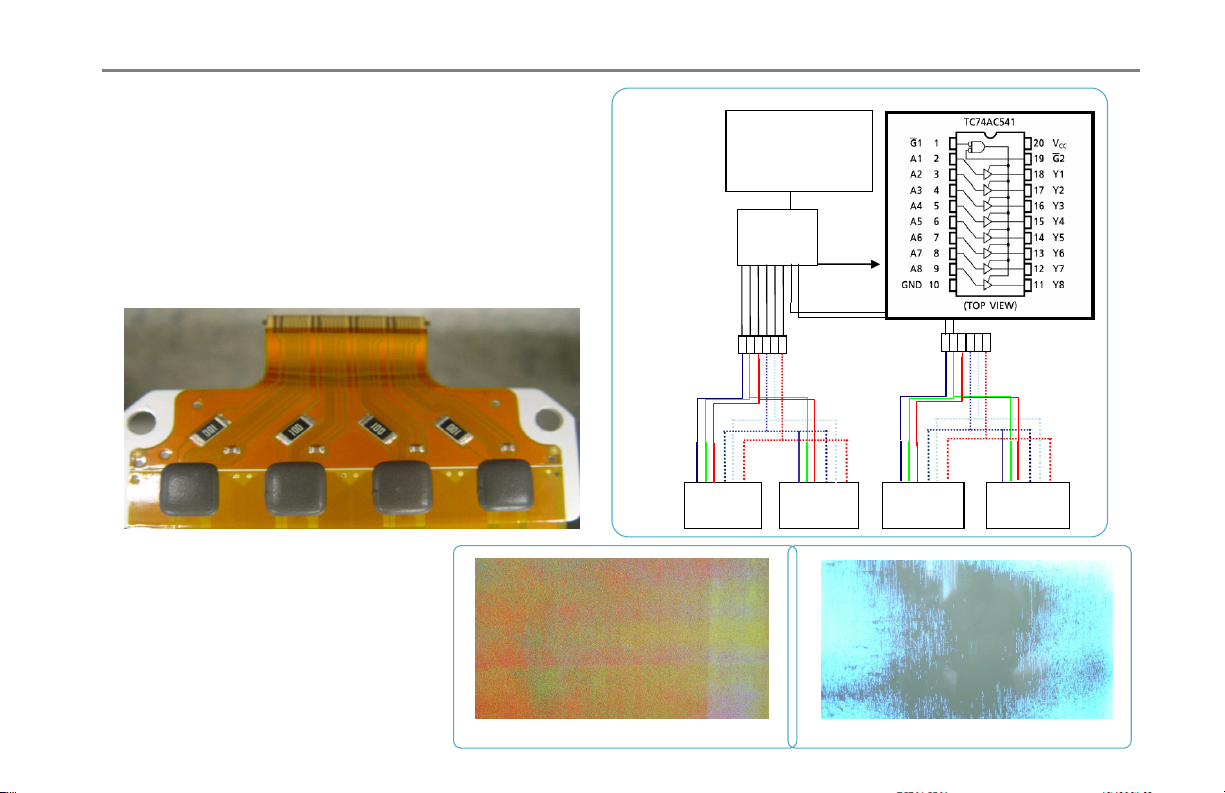

Introduction to Plasma

7. Ctrl B/D

CTRL B/D supplies video signal to COF. So if there is a

bar defect on panel this may be the ctrl b/d creating this

problem.

Flow, address signal

In the figure to the right shows data path to COF IC In this

description you can see how missing data can affect the

panel.

8. Checking order

1. Confirm Y, Z SUS signal cable.

2. Check Y DRV IC FAIL

3. Check Y sus b/d voltages (-Vy.Vscw)

4. Check Y ,Z-SUS IPM fail

5. Replace CTRL b/d

A. Mal-discharge problem Y-drive, Z -b/d.

<Diagram of ctrl b/d>

$6,&

Buffer

IC

$UUD\

UHVLVWRU

Each 16

lines

&2),& &2),& &2),& &2),&

B. Check VA and VS Voltage if occurred.

Introduction to Plasma

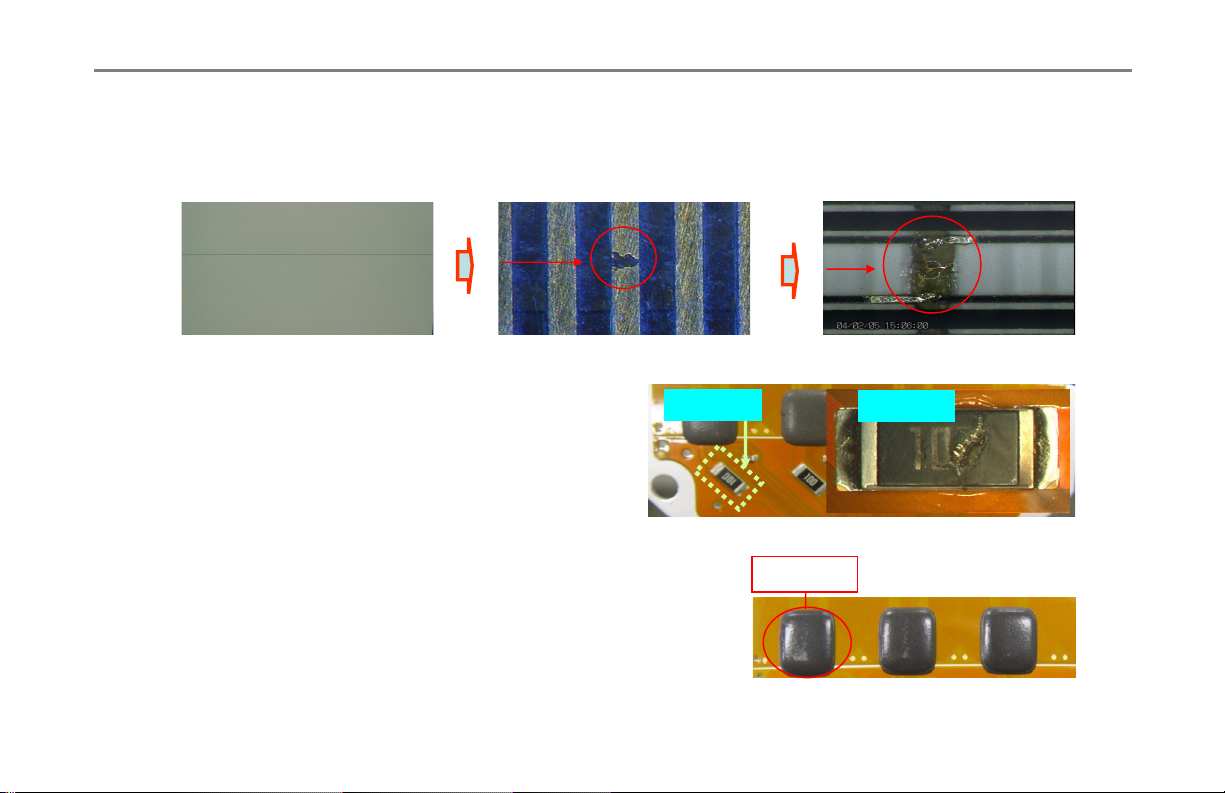

9. Check FPC

In case of horizontal 1 or more line, it is due to FPC or panel inside .ctrl b/d, Y b/d is just normal. First , clean the FPC

electrode with a cloth to clean off the ribbon connection removing particles.

Horizontal line.

COF ribbon to panel open Cell/ break down

10. Checking address COF input of resistor and IC

COF resistor check

Ⴇ

Check the both side of resistor With Digital multi meter(DMM) .

If the resistor is okay, the resistor value should be 10വif open

replace resistor.

Resistor

11. COF (Chip On Film)

Supplied with the X B/D waveform to the panel, controls grid & zones by

switching on or off the 96 pin COF IC.

the higher the resolution, the less spare space on the IC.

• E/R (Energy recovery)

• COF (Chip On Film)

• IPM (Intelligent Power Module)

Open

COF IC

Introduction to Plasma

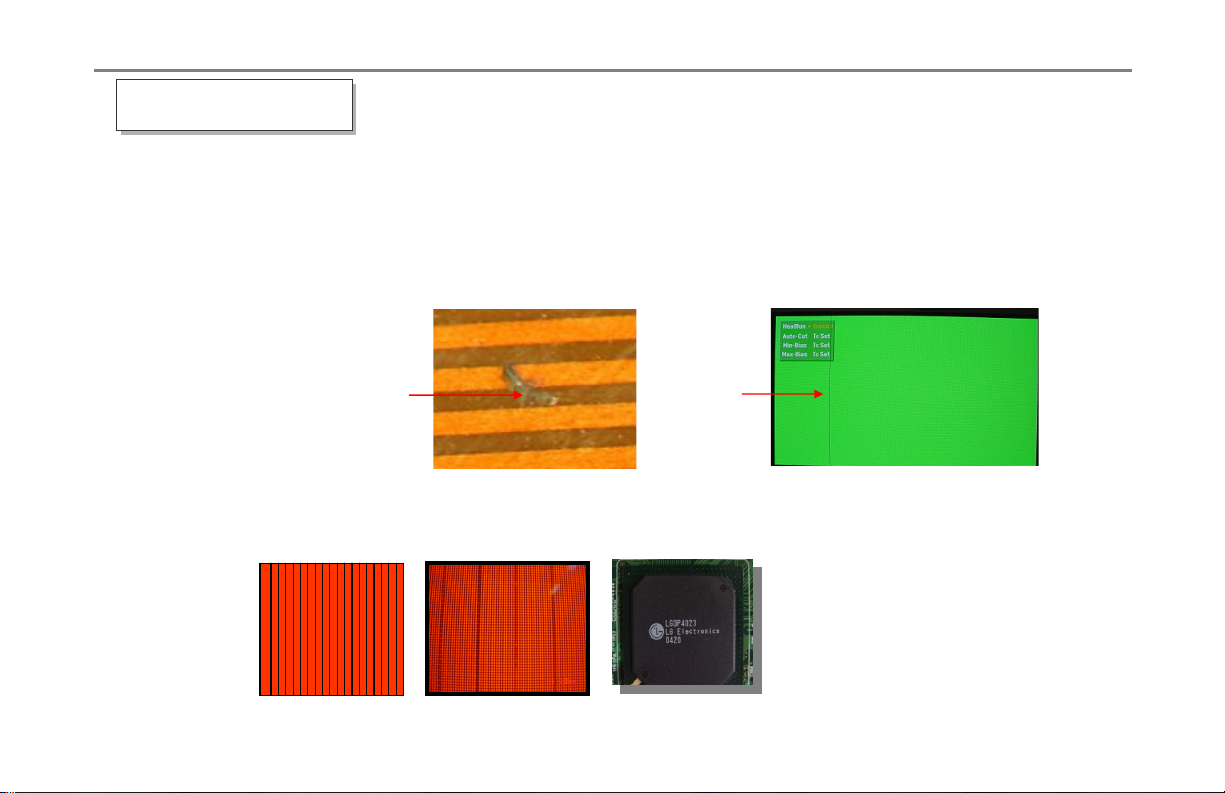

Vertical defect (line)

,QFDVHRIYHUWLFDOOLQHRUVKRUWFKHFNIRUIRUHLJQVXEVWDQFHVRQ&2)FRQQHFWRU

)LUVWFOHDQRIIWKHFRQQHFWRUZLWKFOHDQFORWKWRUHPRYHIRUHLJQ VXEVWDQFHV7HVWDJDLQWKHQLIWKHVDPH

OLQHDSSHDUVFKHFNIRUVKRUWHG,&6+257('UHSODFHSDQHO

1 line open or short

This phenomenon is due to COF IC inside short or adherence part of the Film and rear panel electrode

problem. In this case, replace the panel.

1 electrode open

Line open or short with same distance.

This is an ASIC of Ctrl b/d defect. ASIC defective, replace the ctrl b/d.

Will cause

1 line open

'$'DWD$UUDQJHU,&

No image in the specific area (see the screen location 2)

1) Check the related X-Board’s power connector.

2) Check the signal cable between Controller PCB & X-Board.

Fig # 01

Fig # 01

1

4

2

2

5

3

6

3) Replace X-Board

Correlation between screen & X Boards

Screen Location X Board

1) Top left 3/10 l X Top-right / Bottom-left B/D

2) Center top 2/5 l X Center Top B/D

3) Top right 3/10 l X Top-left / Bottom-right B/D

4) Bottom left 3/10 l X Top-left / Bottom-right B/D

5) Center bottom 2/5 l X Center Top B/D

6) Bottom right 3/10 l X Top-right / Bottom-left B/D

Visual Troubleshooting

2. Known Tips as to no data and partial display

No image/ Data COF IC.

1) Caused by X Board’s having no power or connections.

Data COF is totally or partially not displayed

2) Check the connector between COF IC & X-Board.

3) Data COF IC is defective, replace the related X-Boards.

12

Fig # 02

Fig # 02

Examples,

Non-image

Non Image white

Partially displayed

Regular vertical line with one or more Data COF IC

1) Check the related X Board’s power connector.

Fig # 03

Fig # 03

1

4

1) This is caused by X Board output IC being defective. When COF ICs have data this means the data transfer between the

Controller PCB and X Board is missing.

2) Check all related X Board connections.

3) Replace that X Board or CTRL PCB or both if needed.

Fig # 04

Fig # 04

2

5

3

6

Partial error or total error with One or more

ICs are defective.

2) Check the signal cable between Controller PCB & X-Board.

3) Replace X-Board

Correlation between screen & X Boards

Screen Location X Board

1) Top left 3/10 l X Top-right / Bottom-left B/D

2) Center top 2/5 l X Center Top B/D

3) Top right 3/10 l X Top-left / Bottom-right B/D

4) Bottom left 3/10 l X Top-left / Bottom-right B/D

5) Center bottom 2/5 l X Center Top B/D

6) Bottom right 3/10 l X Top-right / Bottom-left B/D

Visual Troubleshooting

13

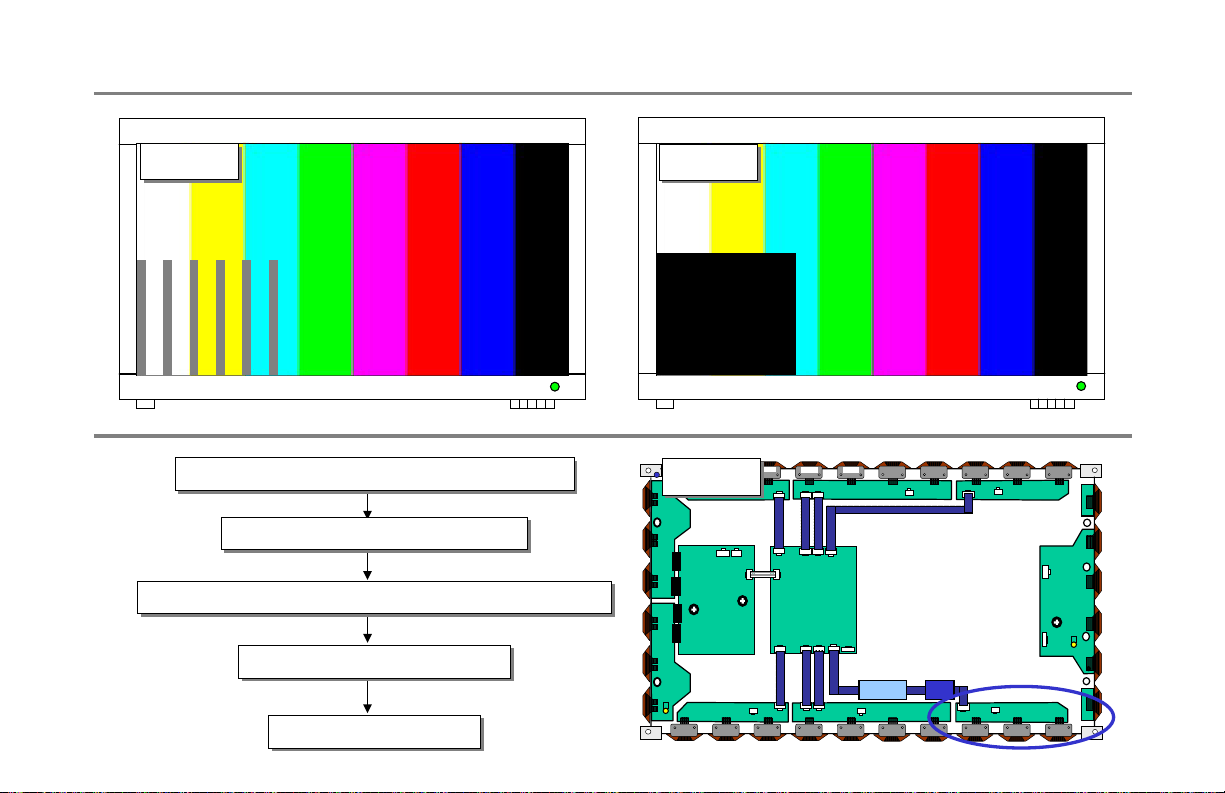

Address Bar ( Vertical ) & partial no-picture

Visual Troubleshooting

Fig # 05

Fig # 05

Related X-Board power supply voltage check

Related X-Board power supply voltage check

Related X-Board Connector check

Related X-Board Connector check

Related X-Board & Controller Board Connector check

Related X-Board & Controller Board Connector check

Related X-Board replacement

Related X-Board replacement

Module (Panel ) check

Module (Panel ) check

14

Fig # 06

Fig # 06

Bottom left 3/10 of the screen with no-pictureBottom left 3/10 of the screen with vertical bar

Fig # 07

Fig # 07

Y- Board

VR 424

B61 (TP;sus_up)

VR 301

Controller

Board

VSC

Board

P200

Side A/V L/F

Z- Board

VR 301

B61

(TP;sus_out)

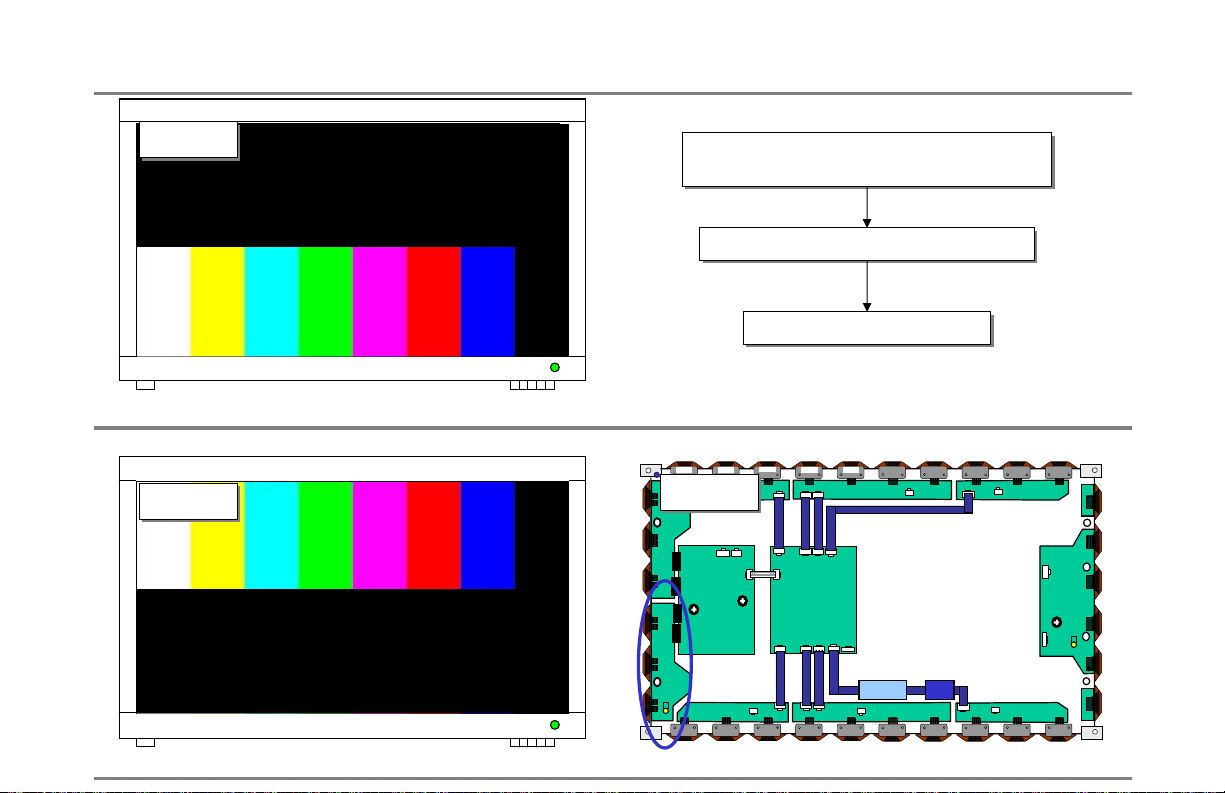

Bar (Horizontal) half -picture

Fig # 08

Fig # 08

2QO\ERWWRP,PDJHLV'LVSOD\LQJ

Fig # 09

Fig # 09

Visual Troubleshooting

<%RDUG<'ULYH%RDUG&RQQHFWRUFKHFN

<%RDUG<'ULYH%RDUG&RQQHFWRUFKHFN

Y-Drive Board ( Top ) Drive IC check

Y-Drive Board ( Top ) Drive IC check

Y-Drive Board replacement

Y-Drive Board replacement

Fig # 10

Fig # 10

Controller

Board

VSC

Board

P200

Y- Board

VR 424

VR 301

Z- Board

VR 301

B61

(TP;sus_out)

2QO\WRS,PDJHLV'LVSOD\LQJ

15

B61 (TP;sus_up)

Side A/V L/F

Vertical Lines

Visual Troubleshooting

6. One or more vertical lines in the screen.

1) Irregular vertical line is not related to Controller PCB or X Board.

2) It is mainly caused by the followings open (or short).

- Panel itself defect

- DATA COF FPC attached to panel is open or short.

- DATA COF attached to panel itself is defective

There can be several lines in ¼ inch wide area.

It can be seen on the both side, right and left.

The area is sometimes over ¼ inch wide.

7. One or more horizontal lines in the screen.

1) Irregular vertical line is not related to Controller PCB or Y Board.

2) It is mainly caused by the followings open (or short).

- Y FPC connector ය reinsertion

- Open because of Y Driver Board’s connector dry joint ය

Y DRV Board replacement

- Panel itself is defective, Y FPC attached to panel itself

is open or short

There can be several horizontal lines

8. Regular vertical lines in the whole screen. (mainly in one specific color, regular line is flicking)

1) This problem is related to CONTROL PCB.

2) Replace CONTROL PCB

Fig # 11

Fig # 11

Regular vertical lines in the whole screen

16

Vertical Lines

Visual Troubleshooting

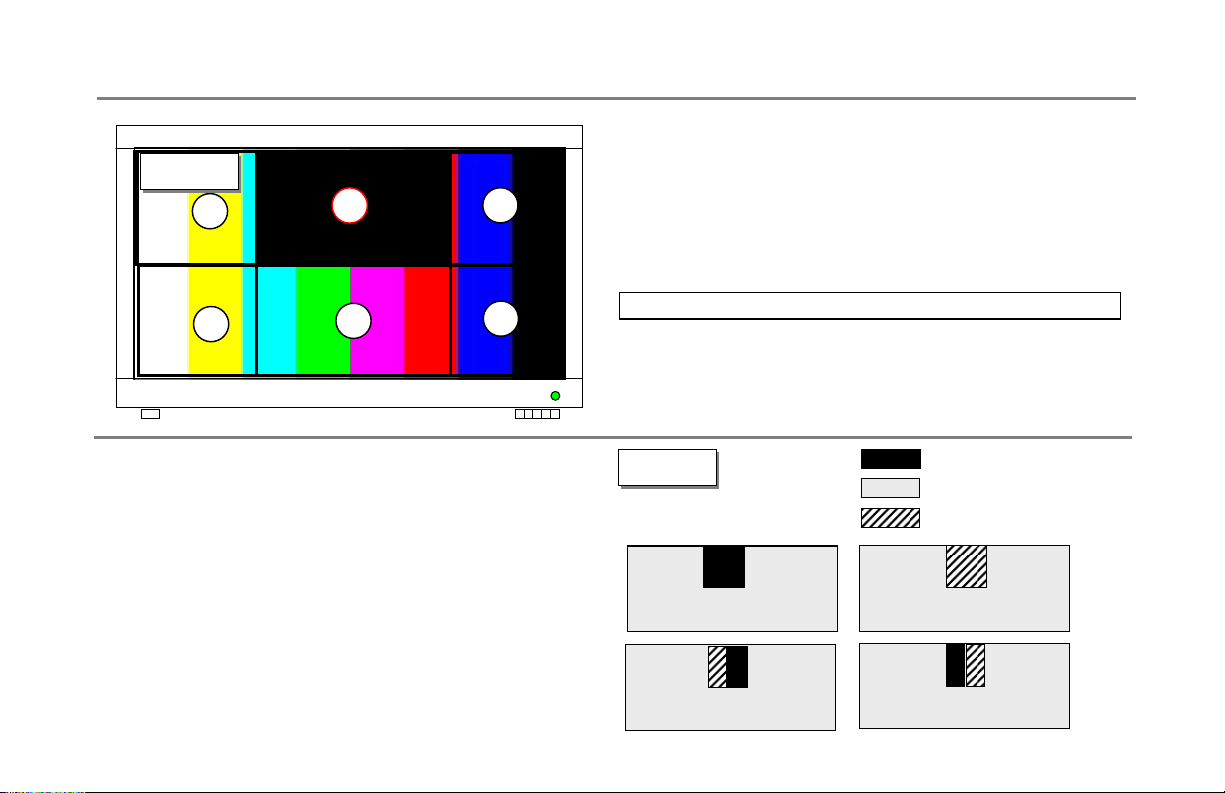

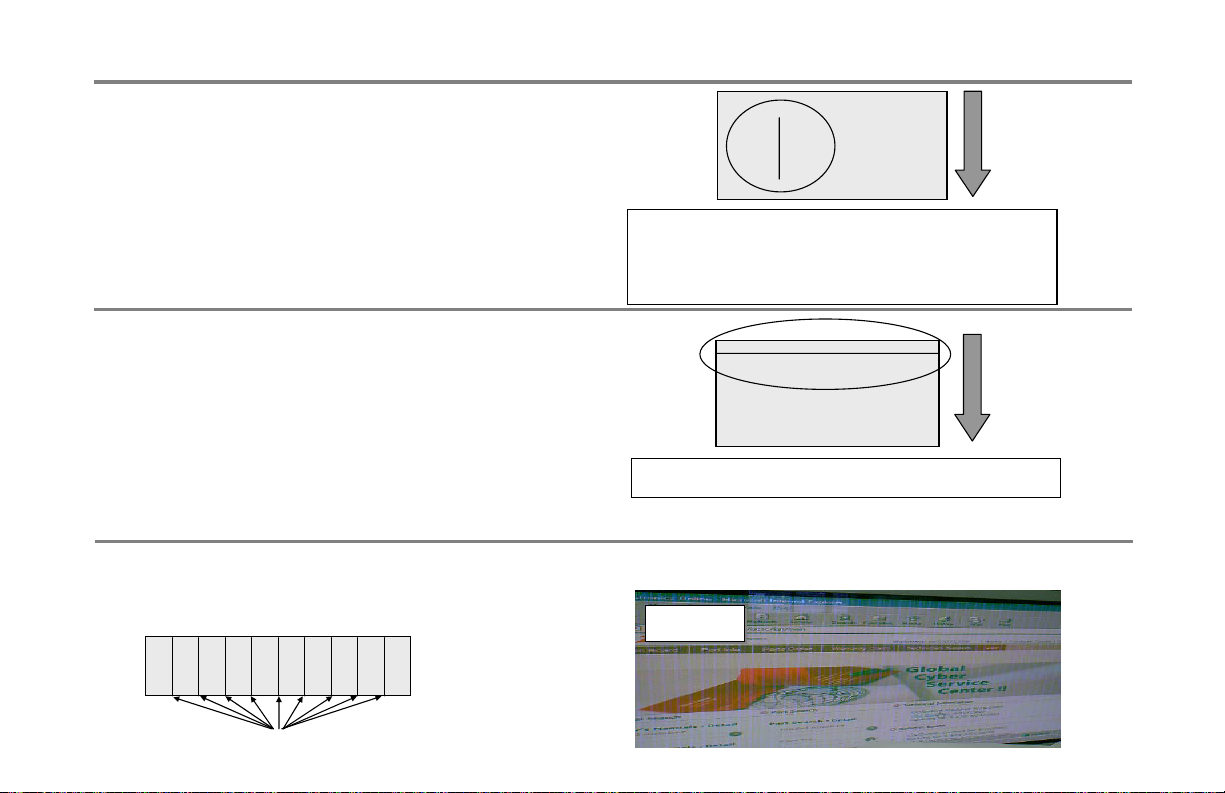

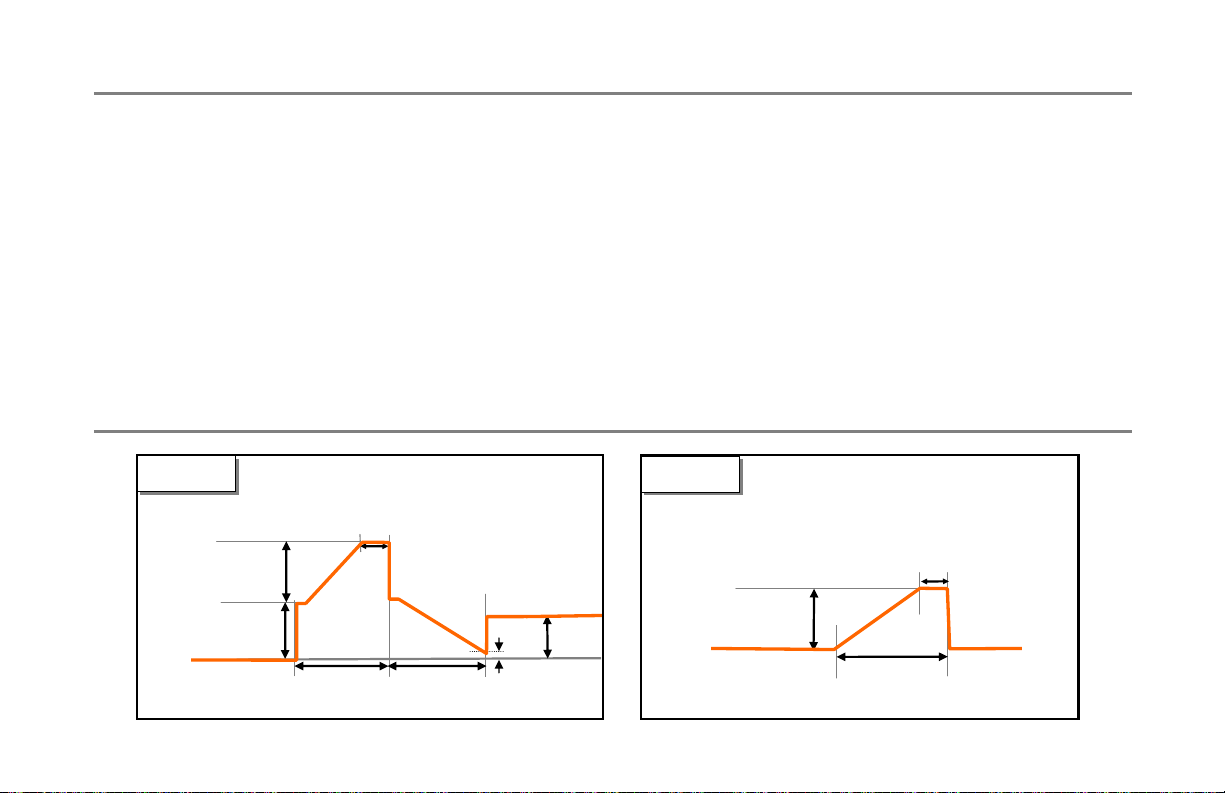

9. Vertical Data copy

1) This happens when scan wave is not reproduced properly.

2) Replace Y-Board

<case 1 : partial Top copy > <case2 : partial Bottom copy >

10. Grid X and Y Layout by screen size.

60’’

X

X

Y

X

Y

50’’

40’’42’’

Fig # 46

Fig # 46

X

X

Y

Y

17

Dark picture

Visual Troubleshooting

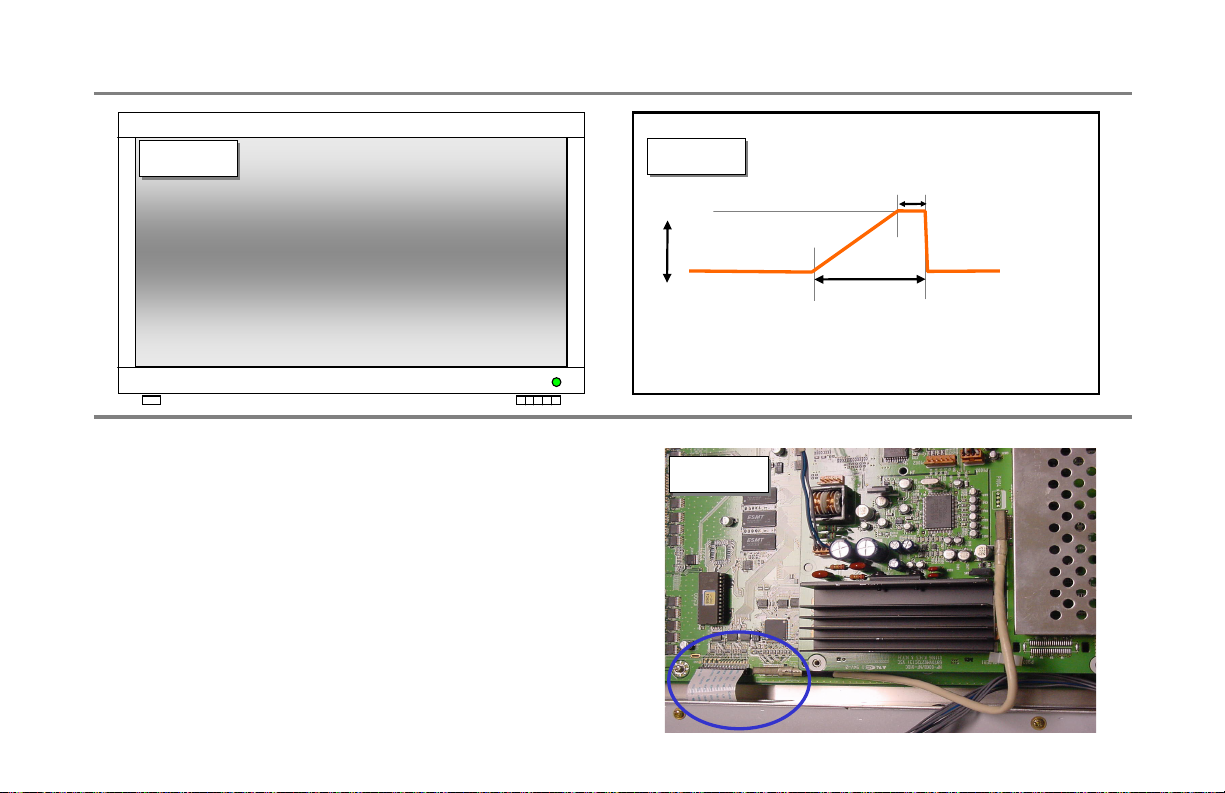

10. Input signal pattern is displayed but the screen is dark.

1) It happens when Z Board is not operating well.

2) Check whether Z Board’s power connector is plugged properly.

3) Check whether the signal connector between Controller PCB & Z Board is plugged.

4) Replace Z Board or controller PCB.

11. Input signal is white pattern but other colors are displayed in spots, missing data.

1) Check the slope & waveform of Y Board set up, set down.

2) Check the slope of Z Board’s ramp waveform

3) Measure each Board’s output waveform by over 200MHz scope and reference Fig. 12 and 13.

it is possible to control Y Board’s setup slope by adjusting VR2 and Z Board’s ramp slope by adjusting VR1.

Fig # 12

Fig # 12

Fig # 13

Fig # 13

- Y B/D measurement point : B61 ( SUS_UP OUTPUT ) - Z B/D measurement point : B61 ( SUS_OUT )

V-set-up

( 200V~240V)

Vs (170 ~ 185V)

0V

140ᓪ

< Y Sustain voltage wave>

20s5ᓪ

170s5ᓪ

VCC ( 90~110V)

10V

Vs (170 ~ 185V)

0V

3ᓪs2ᓪ

23ᓪ

< Z Ramp voltage wave >

18

Dark picture at Top, Bottom or Center

Visual Troubleshooting

Fig # 14

Fig # 14

13. A specific brightness of one color is not clear.

1) Check CTRL Board’s input signal connector.

2) Replace CTRL Board.

14. With a full white pattern, the picture is darker toward

the center.

1) Dark picture will occur when the Z-board is missing its ramp

waveform/ see Fig # 15

2) Check the connection between CTRL PCB and the Z-board

signal cable.

3) If the signal cable is -OK- Replace the Z-Board.

Fig # 15

Fig # 15

Vs (170 ~ 185V)

Fig # 16

Fig # 16

3ᓪs2ᓪ

23ᓪ

< Z Ramp voltage wave >

19

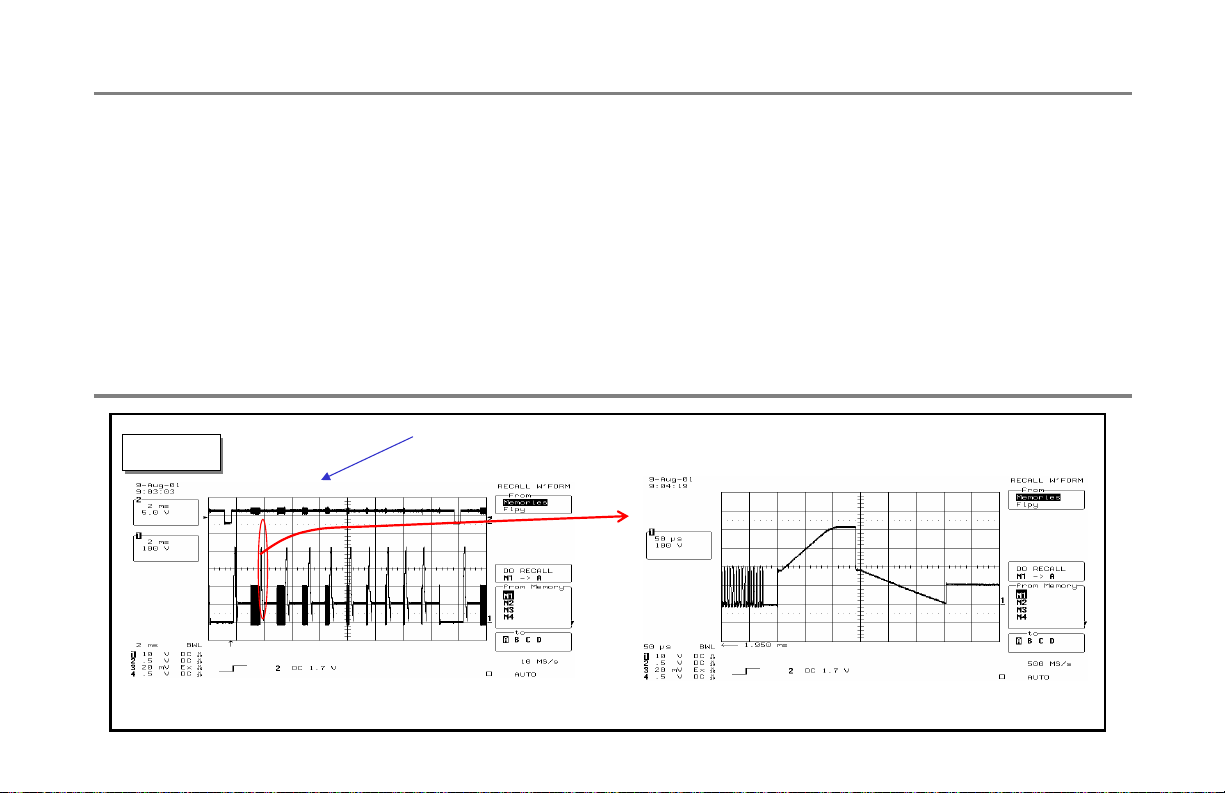

No picture

1) Check CTRL PCB’s LED (D1~ D4).

2) Check the power or signal cable inputting into CTRL PCB.

3) Check X Board, Y Board and Z Board’s power connector.

4) Check the connector between CTRL PCB, X Board, Y Board, and Z Board respectively.

5) Measure Y Board’s output waveform with over 200MHz oscilloscope and compare it to Fig 17 below.

- Y Board measurement point : ( SUS_UP OUTPUT )

- X Board measurement point : ( SUS_DN OUTPUT )

6) Test data X Board waveform @ COF IC See Fig 34 page 26.

7) No Signal - Replace Controller PCB

V_SYNC

Fig # 17

Fig # 17

amplified

Visual Troubleshooting

< Y Board output wave - 1 Frame > < Y Board output wave (amplified) - 1 SF >

20

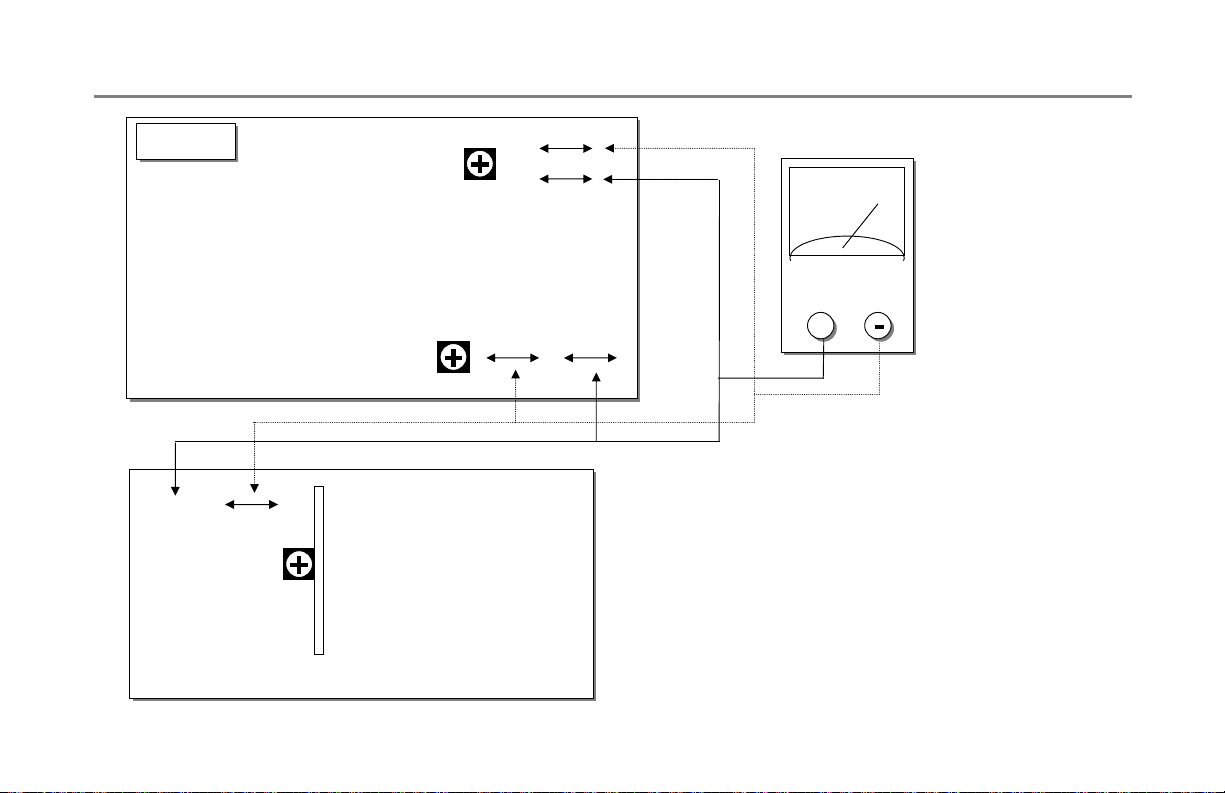

Voltage Adjustment

Fig # 18

Fig # 18

TP5 GND

Service Adjustment

When replacing power board,

Be sure to follow Power Assembly voltage Proc.

<SMPS Board>

PFC +

PFC -

VR801

VS · 1V

PFC PACK

VA Adjust

VR8401

VS Adjust

VR8501

TP3

GND

TP6 VA

TP4

VS

21

DMM

+

+

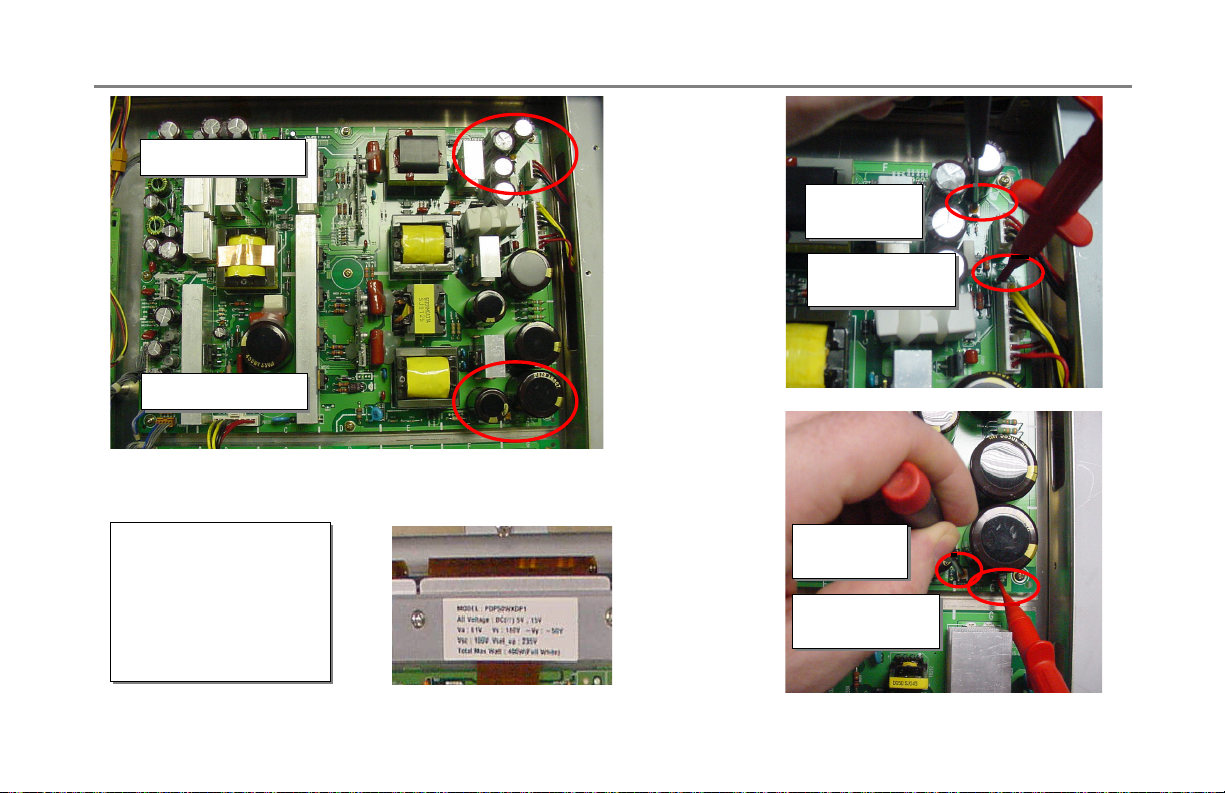

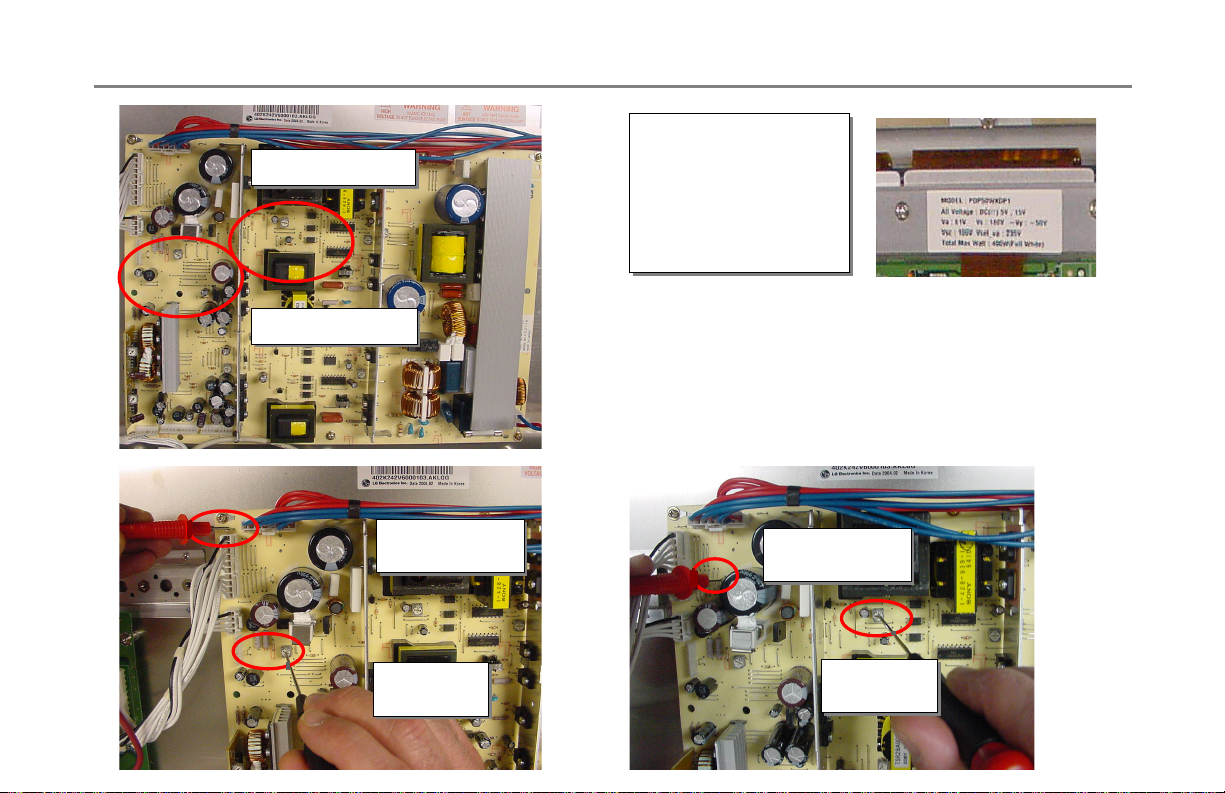

1. PFC adjustment

-. Select 100% White Pattern signal and Pre-Heat panel.

-. Connect DMM with TP PFC+ and TP PFC – (GND).

-. adjust VR801 to 380V (within ·1V ).

2. VA adjustment

-. Connect DMM + terminal with P814 #1 Pin.

-. Turn VR8401 (VA) to adjust the voltage on DMM to VA voltage

value marked on label @ bottom- right of panel. (allowable tolerance :

·0.5V )

3. VS adjustment

-. Connect DMM’s + terminal with P803 # 9 Pin.

-. Turn VR 8501 (VS)to adjust the voltage with DMM to Vs voltage

value marked on label @ bottom- right of panel.

Voltage Adjustment

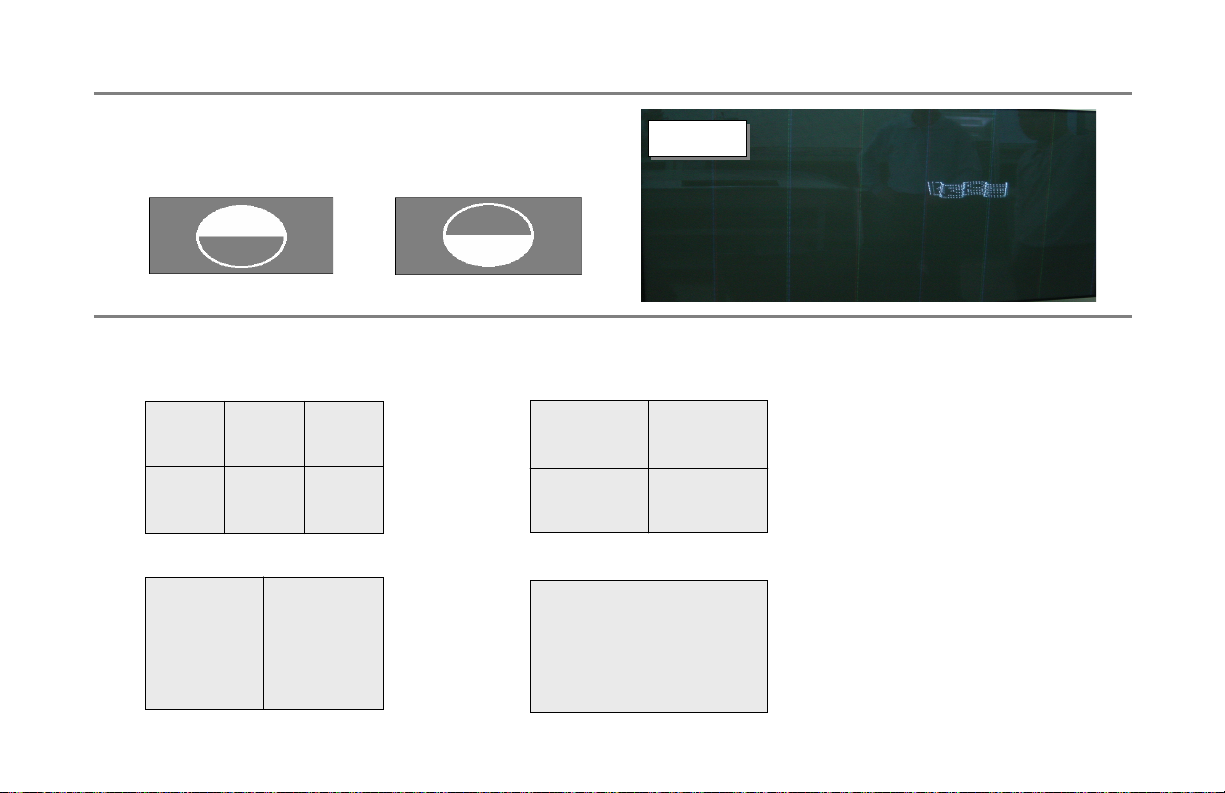

Service Adjustment

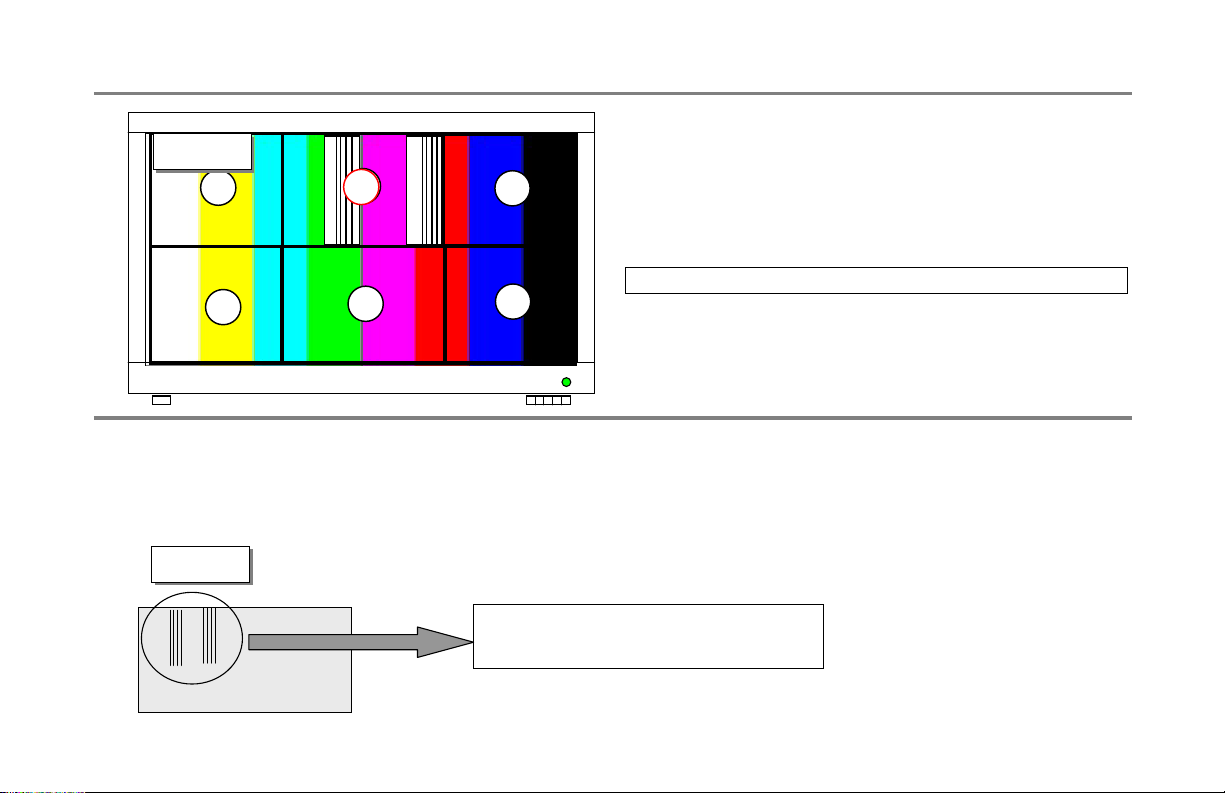

Fig #47

Fig #47

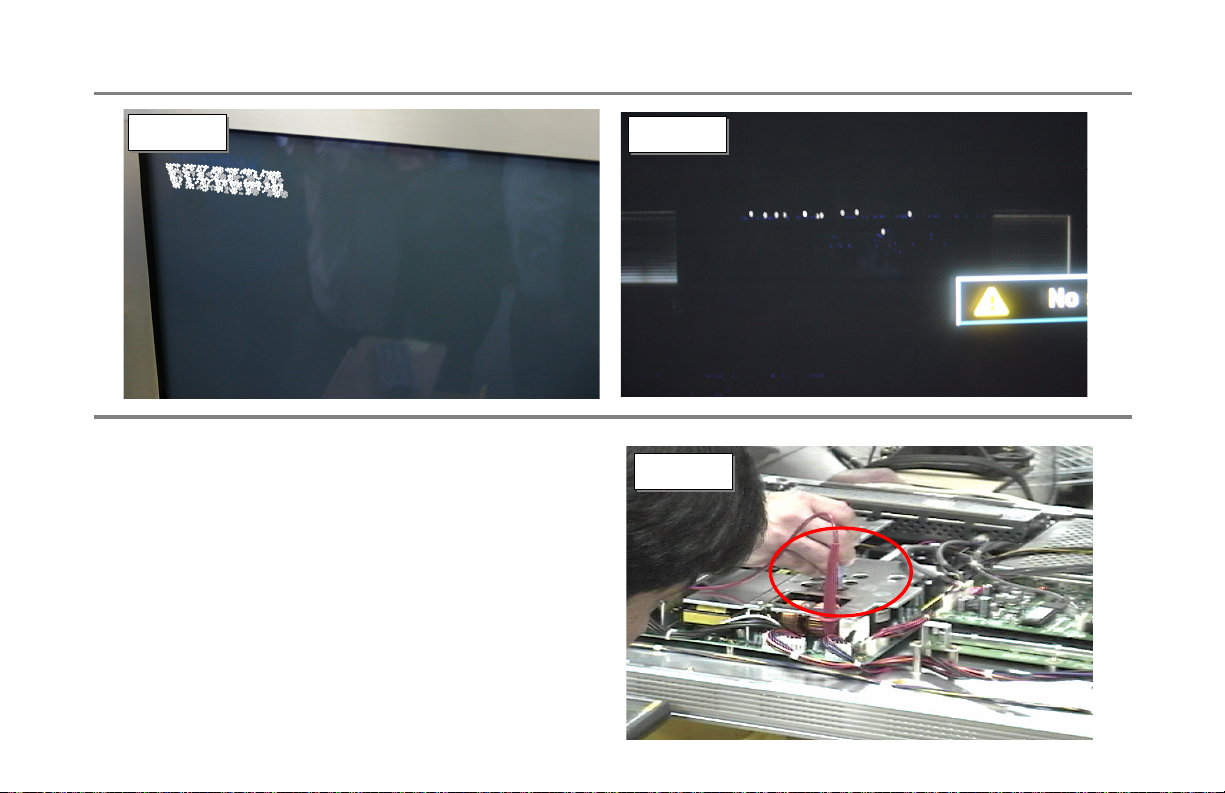

Problem: The picture above is an example of distorted

text.

Cure: VA & VS voltage adjustment is needed when

the following items are found:

• Distorted text

• Blocked text

• Pixilated picture

• Dots running from side to side

• Tearing in the picture

• Video smear

Fig # 48

Fig # 48

Fig # 49

Fig # 49

22

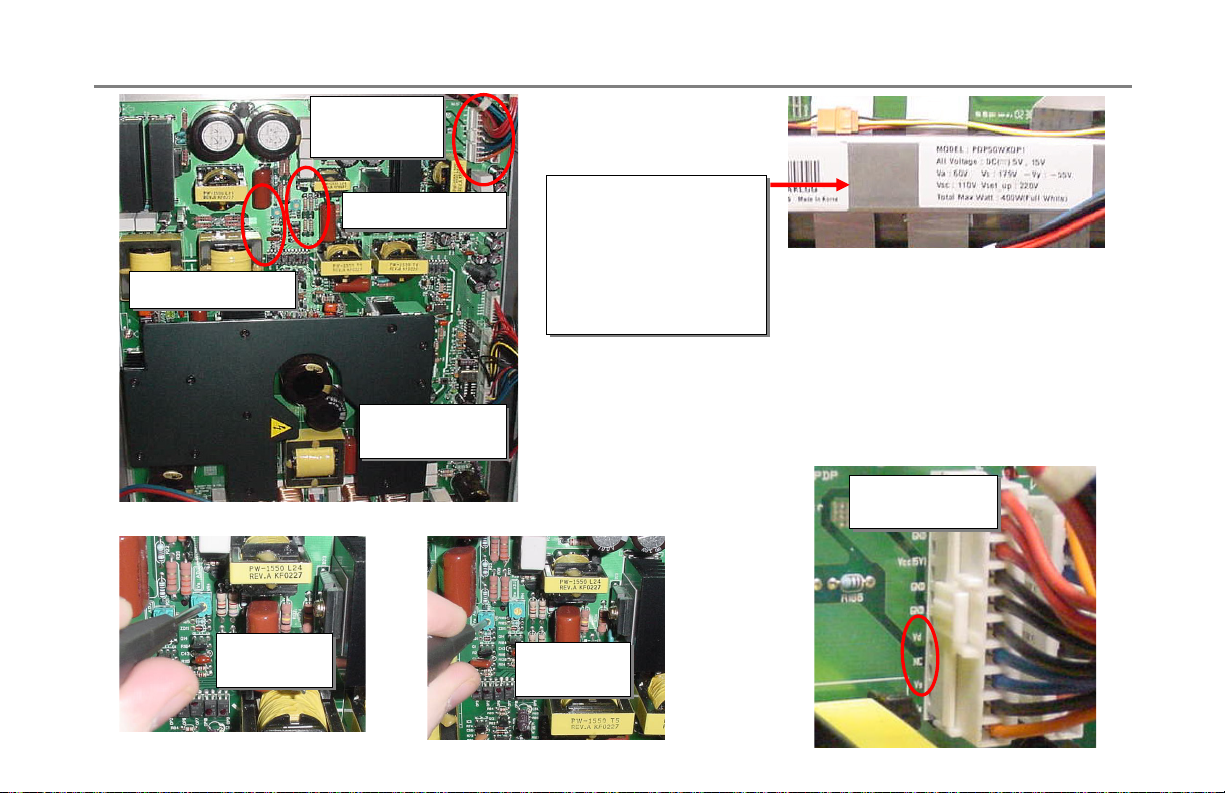

60’’ Test points and voltage adjustments.

VS adjustment

VS adjustment

VA adjustment

VA adjustment

Service Adjustment

VA adjust

VA adjust

VR8401

VR8401

VA test point

VA test point

TP-6

TP-6

The voltage settings

The voltage settings

change from model

change from model

to model and are

to model and are

labeled and located

labeled and located

at the top center of

at the top center of

the screen.

the screen.

23

VS adjust

VS adjust

VR8501

VR8501

VS test point

VS test point

TP-4

TP-4

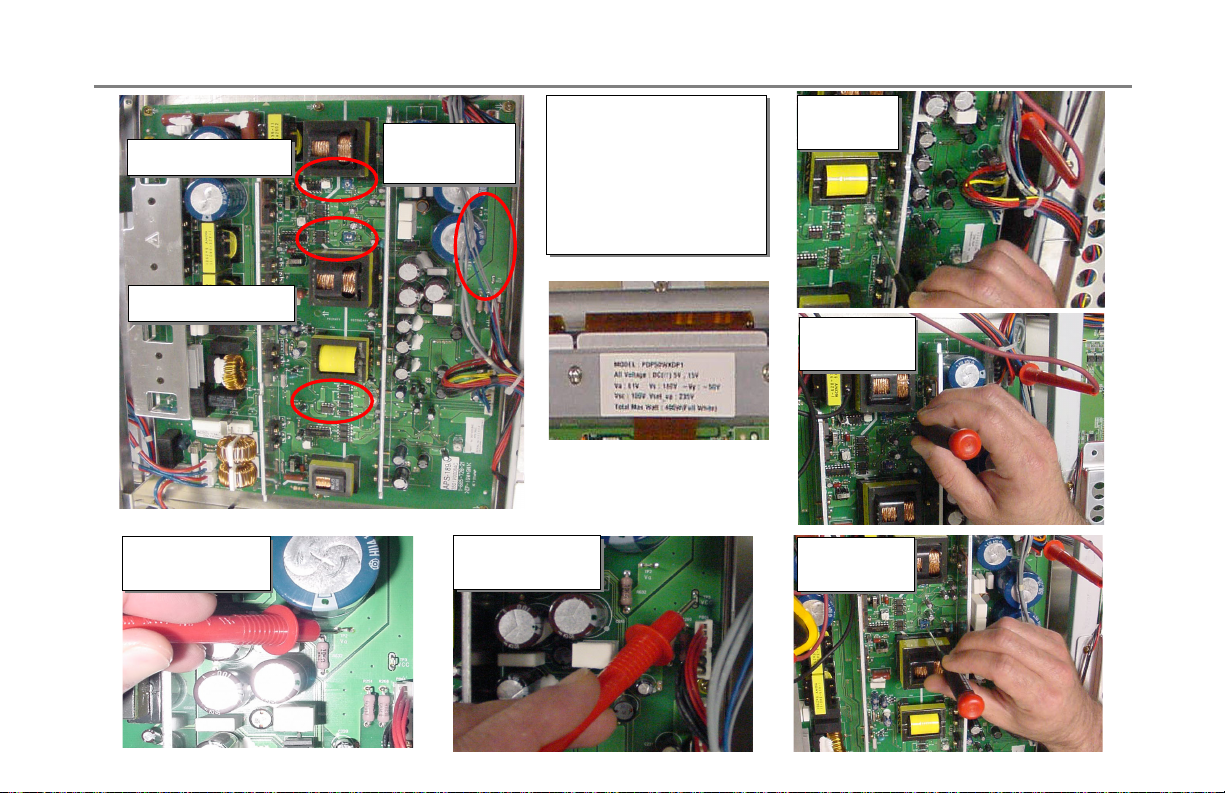

50’’- 26 series Test points and voltage adjustments.

VS/ VA

VS/ VA

Test Points

Test Points

The voltage settings

The voltage settings

change from model

change from model

to model and are

to model and are

labeled and located

labeled and located

at the top center of

at the top center of

VA adjustment

VA adjustment

VS adjustment

VS adjustment

the screen.

VS test point

VS test point

TP1

TP1

the screen.

Service Adjustment

VA test point

VA test point

VA adjust

VA adjust

RV601

RV601

VS adjust

VS adjust

RV401

RV401

24

50’’- 28 Series Test points and voltage adjustments.

Service Adjustment

VS adjustment

VS adjustment

VA adjustment

VA adjustment

VA test point

VA test point

TP2

TP2

VS/ VA

VS/ VA

Test Points

Test Points

VS test point

VS test point

TP1

TP1

The voltage settings

The voltage settings

change from model

change from model

to model and are

to model and are

labeled and located

labeled and located

at the top center of

at the top center of

the screen.

the screen.

Five B +

Five B +

RV203

RV203

VS adjust

VS adjust

RV401

RV401

VA adjust

VA adjust

RV601

RV601

25

42’’ with tuner test points and voltage adjustments.

VS adjustment

VS adjustment

VA adjustment

VA adjustment

VS test point

VS test point

TP-2

TP-2

Service Adjustment

The voltage settings

The voltage settings

change from model

change from model

to model and are

to model and are

labeled and located

labeled and located

at the top center of

at the top center of

the screen.

the screen.

VA test point

VA test point

TP-1

TP-1

VS adjust

VS adjust

RV601

RV601

26

VA adjust

VA adjust

RV401

RV401

Loading...

Loading...