LG OS9lOOD Service Manual

GolclStar

4B

LG

OSCILLOSCOPE

OS9lOOD

SERVICE MANUAL

Precision

Co.,Ltd.

Servicing_PPecautions

Please read all instructions in the service manual thoroughly

before servicing.

before opening the enclosure.

Instructions

1.

To maintain the precision and reliability of the product use

it in

centigrade and humidity

the

Disconnect power cord from power source

standard condi

45%~85%)

tions(

temperature

10”

-35O

2. After turning on power, please allow a

warm-up period before using.

3. Triple-line power cord is to be used for this product. But

when you are using doubleline power cord.

connect the earth ground terminal of the product to the

earth ground at the power source for safety

4. This product can be re-designed without prior notice for

quality

specifications.

Warranty

Warranty service covers a period of one year from the date of

original purchase.

In case of technical failure within a year, repair service will

be provided by our service

charge.

We charge for repairs after one year warranty period expires.

When the failure is a result of user’s neglect, natural

disaster or accident, we charge for repairs regardless of the

warranty period.

improvement ,

exterior

center

or sales outlet free of

15minute

make sure to

des i gn and

pre-heating

technical

Notice

This Service Manual describes the basic typical product of this

model.

manual and the servicing unit,

sales off ice in your area.

If there are any

L,G

Precision

speci fit

2

differences between this

please contact LG Precision

CO,. LAd,

CONTENTS

1.

GENERAL

2, SPECIFICATIONS

3,

ACCESSORIES

4. PREVENTIVE MAINTENANCE

5, CIRCUIT DESCRIPTION

6, CALIBRATION

6-l. Calibration Interval

6-2. Test Equipment Required

6-3. Preliminary Procedure

6-4.

Preliminary Control Settings

6-5. Initial Starting Procedure

6-6. Calibration Procedure

7, SEMICONDUCTOR LEAD CONFIGURATIONS

8, ELECTRICAL PARTS ARRANGEMENT ,’

.I. :

(WITH ADJUSTMENT LOCATIONS)

9, ELECTRICAL PARTS LIST

10,

11,

12,

13,

14,

BLOCK DIAGRAM

WIRING DIAGRAM

SCHEMATIC DIAGRAMS

MECHANICAL PARTS LIST

81

EXTERNAL VIEWS,

EXPLODED

VIEW

.

.a ,..

.

’

1. GENERAL

The

OS-9100D

is a 3 channel 6 trace oscilloscope with

1OOMHz

frequency

bandwidth. CH1 and CH2 vertical system provides calibrated deflection factors

from 5 V/division to 1

mV/division.

The stable sweep triggering is possible

over the full bandwidth capabilities of the vertical deflection system.

The horizontal deflection system provides calibrated sweep rates from 0.5

s/div

to 0.05

ys/div

along with delayed sweep features for accurate relative

time measurements.

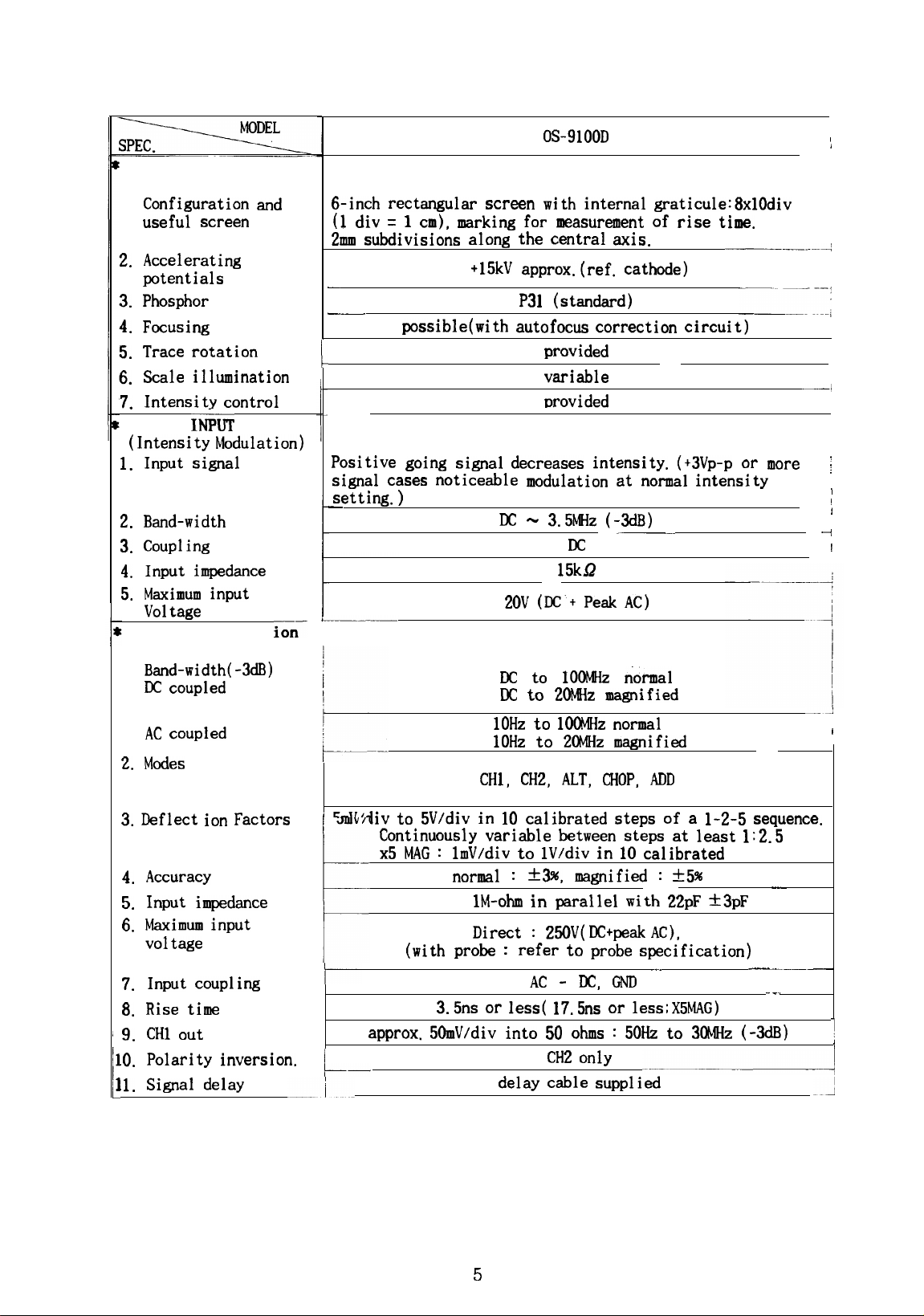

2, SPECIFICATIONS

CRT

1.

Configuration and

useful screen

Accelerating

2.

potentials

Phosphor

3.

4.

Focusing

Trace rotation

5.

Scale illumination

6.

Intensity control

7.

Z-AXIS

(Intensity Modulation)

1.

2.

3. Coup1 ing

4.

5.

Vertical Deflect

INPUT

Input signal

Band-width

Input impedance

Maximum input

Voltage

ion-

OS-9100D

6-inch rectangular screen with internal graticule:8xlOdiv

(1 div

2mm subdivisions along the central axis.

-

-__

c

Positive going signal decreases intensity. (+3Vp-p or more

signal cases noticeable modulation at normal intensity

setting. )

-

= 1 cm), marking for measurement of rise time.

----A

+15kV approx.(ref. cathode)

P31 (standard)

possible(with autofocus correction circuit)

provi ded

variable

provided

DC

- 3.5MHz (-3dB)

15kQ

2OV (DC’+ Peak AC)

-~

DC

,

1

-I

i

I

!

I

-I

!

1.

Band-width( -3dB)

DC coupled

AC coupled

Modes

2.

3. Deflect ion Factors

Accuracy

4.

Input impedance

5.

Maximum input

6.

voltage

7.

Input coupling

Rise time

8.

1

CH1 out

9.

Polarity inversion.

0.

1

Signal delay

1.

1

I

DC to lOOMH2 normal

DC to 2OMHz magnified

1OHz to 1OoMHz normal

1OHz to 2OMHz magnified

CHl, CH2, ALT, CHOP, ADD

’ 5mV/div to 5V/div in 10 calibrated steps of a l-2-5 sequence.

Continuously variable between steps at least 1:2.5

x5 MAG :

1

t-

approx. 5OmV/div into 50 ohms : 5OHz to 3OMHz (-3dB)

I

t--

lmV/div to lV/div in 10 calibrated

normal :

approx.

(with probe :

lM-ohm in parallel with 22pF 23pF

Direct :

3.5ns or less( 17.5ns or 1ess:XSMAG)

f3%, magnified : +5%

25OV( DC+peak AC),

refer to probe specification)

AC - DC, GND ---

CH2 only

delay cable supplied

-----I

steps.

--____

-i

-

~-’

.-_1

I

1

I

5

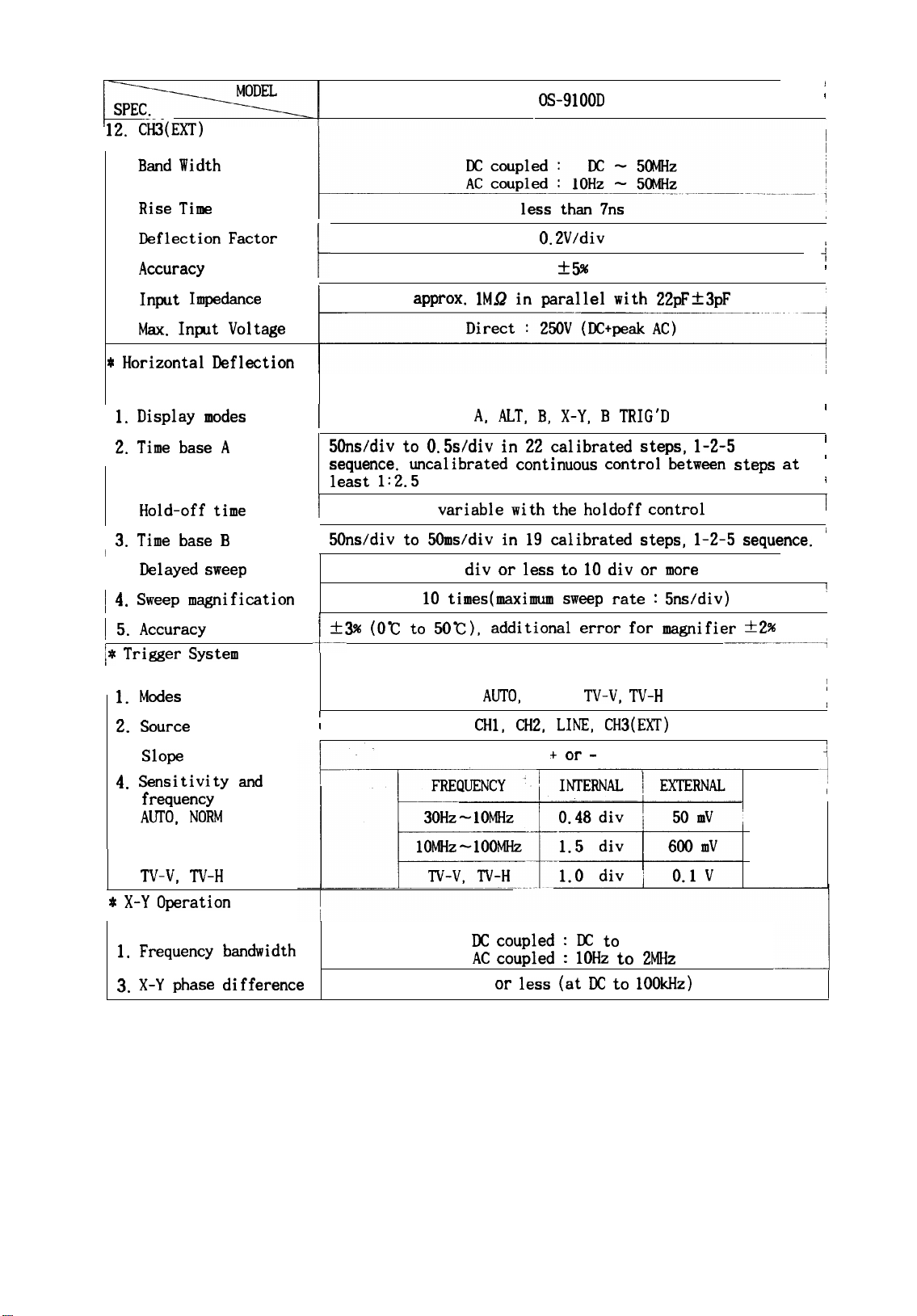

12. CH3(EXT)

Band Width

Rise Time

OS-9100D

1

I

Deflection Factor

Accuracy

Input Impedance

Max. Input Voltage

* Horizontal Deflection

1. Display modes

1 2.

Time base A

Hold-off time

1 3.

Time base B

I

Delayed sweep

/ 4. Sweep magnification

I

I 5. Accuracy

I* Trigger System

1. Modes

2. Source

3.

Slope

4. Sensitivity and

frequency

AUTO, NORM

0. ZV/div

t

+5%

approx. 1MlR in parallel with 22pF+3pF

I

A, ALT, B, X-Y, B TRIG’D

5Ons/div to 0.5s/div in 22 calibrated steps, l-2-5

sequence.

uncalibrated continuous control between steps at

least 1:2.5

I

variable with the holdoff control

5Ons/div to 5Oms/div in 19 calibrated steps, l-2-5 sequence.

1

div or less to 10 div or more

10 times(maximum sweep rate : 5ns/div)

j f3 (OC to 5O’c),

t-

I

I

additional error for magnifier +2%

--------

AUTO,

NORM,

TV-V, TV-H

CHl, CH2, LINE, CH3(EXT)

+ or -

i

,

I

I

’

I

I

/

I

i

j

/

TV-V, TV-H

* X-Y Operation

1. Frequency bandwidth

3. X-Y phase difference

DC coupled

AC coupled

3” or

6

: lx to

2MHz

: 1OHz to 2MHz

less (at DC to 1OOkHz)

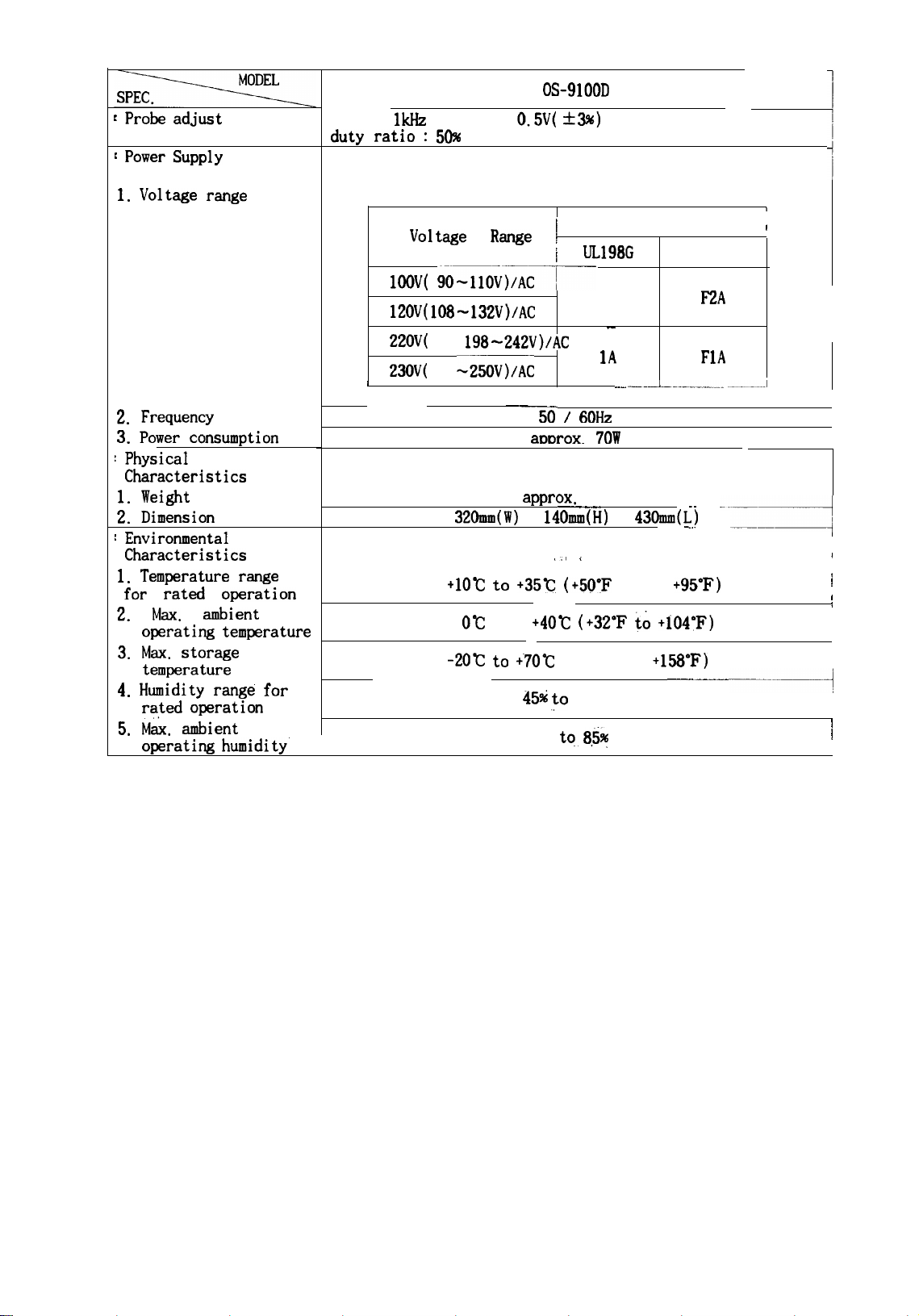

: Probe adjust

: Power Supply

-approx.

1kHz

frequency,

duty ratio : 50%

OS-9100D

0.5V( +396)

square wave

1. Voltage range

2. Frequency

3. Power consumption

: Physical

Characteristics

1. Weight

2. Dimension

I Environmental

Characteristics

1. Temperature range

for rated operation

2. Max. ambient

operating temperature

3. Maw. storage

temperature

4. Humidity range for

rated operation

5. Max. ambient

operating humidity.

Voltage Range 1

lOOV( 90-11oi~Ti~

12OV(108-132V)/AC

22OV( 198-242V)/AC

23OV(

207

/

--250V)/Ai

-___

32Omm(W)

t1Ot.z to +35’c (+5G’F

t1Ot.z to +35’c (+5G’F

OC

to

to

-2O’c to +7O’c

-2O’c to +7O’c

I

Fuse (250V)

/ UL198G

2A

-

1A

..-. --__I-------.-.e

50 / 60Hz

aDDrox.

approx.

x

+4O’c (+32”F tb +104”F)OC

+4O’c (+32”F tb +104”F)

7ow

9. Okg

__-

14Omm(H)

,.I ‘

(-4°F to

(-4°F to

x

to

to

43Omm(L)

__ -. .

+158’F)

+158’F)

__-

4598 !o

85% RH

4598 !o

85% RH

35% tq

85%

RH

IEC127

F2A

FlA

~~ .-.~--I

+95”F)

+95”F)

--I

---/

-+

b

1

’

I

I

!

I

/

/

I

1

I

1

1

I

3,

ACCESSORIES

(1) Operation Manual

(2) Probe (Option)

(3) Fuse(2A

(4) Power cable

for

1OOV

or 120V set or 1A for

22OV

and

23OV

set)

4,

PREVENTIVE MAINTENANCE

Preventive maintenance, when performed on a regular basis,

instrument breakdown and may improve the reliability of the oscilloscope.

The severity of environment to which this instrument is subjected will

determine the frequency of maintenance.

preventive maintenance is preceding recalibration of the instrument.

Disassembly

Remove the top cover and the bottom cover of the instrument. Most of the

internal parts of the instrument are now accessible, if access to the front

of the circuit board are necessary,

control shafts on the board.

Cleaning

The instrument should be cleaned as often as operating conditions require.

Accumulation of dirt in the instrument can cause component breakdown. The

covers provide protection against dust in the interior of the instrument,

Loose dust accumulated on these covers can be removed with a soft cloth or

small brush. Dirt that remains can be removed with a soft cloth dampened in

a mild detergent and water solution.

Cleaning the interior should only be occasionally necessary. The best way to

clean the interior is to blow off the dust with a dry, low-velocity stream

of air.

cleaning in narrow spaces or for cleaning more delicate components.

A soft-bristle brush or a cottontip applicator is useful for

remove the knobs from the external

abrasive cleaners should not be used.

A convenient time to perform

can prevent

Visual Inspection

The instrument should be inspected occasionally for such defects as broken

connections,

heatdamaged parts.

apparent

are found. Overheating usually indicates other trouble in the instrument

therefore,

recurrence of the damage.

improperly seated transistors,

The correct procedure for most visible defects is

;

however, particular care must be taken if heatdamaged components

correcting the cause of the overheating is important to prevent

damaged circuit boards, and

;

9

5,

CIRCUIT DESCRIPTION

The block diagram shows the overall relationship between all of the

circuit.

schematics diagrams.

circuit description for electrical values and relationship.

CH1 (CH2) INPUT AMPLIFIER

This circuit consists of the attenuator circuit and the input amplifier

circuit.

connector can be either AC coupled or DC coupled, or they can be

disconnected to the internal circuit when GND switch is push. Attenuation is

determined by the setting of

circuit, signal from the input attenuator circuit is connected to source

follower and amplified.

Complete schematics of each circuit are also given in section

Refer to these diagrams throughout the following

In the Attenuator circuit, input signal applied to the input

VOLT/DIV

CH1 (CH2) PREAMP & TRIGGER PICK OFF

switch. In the input amplifier

The

level. They also contain a stage to provide a sample of the input signal to

the trigger preamp circuit for internal triggering from the

signal only. And the trigger preamp of

the horizontal amplifier in the X-Y position of the HORIZ DISPLAY switch.

The trigger preamp circuit

level necessary to drive the trigger generator circuit.

of input signals to be connected to the vertical main amplifier.

signal combinations that can be displayed are selected by FLIP-FLOP that is

controlled by the vertical mode switches and the X-Y of the HORIZ DISPLAY

switch. In the ALT and CHOP modes,

on a shared time basis.

In the CH3 preamp,

provide the trigger amplifier circuit.

vertical deflection signal,

plates of the CRT. This circuit also provide control of vertical gain.

CHl(CH2)

VERTICAL SWITCHING

The vertical switching circuit determines the input signal or combination

The vertical main amplifier circuit provides the final amplification for the

preamp circuit provide control of vertical position and DC

CH1

or CH2

CH1

provides the

amplifies the internal trigger signal to the

&

CH3 PREAMP

both channels are alternately displayed

CH3 signal from horizontal circuit is amplified and

before it is applied to the vertical deflection

CH1

input signal to

Input

10

TRIGGER AMPLIFIER TRIGGER GENERATOR

The Trigger amplifier circuit amplifies the internal trigger signal to the

level necessary to drive the generator circuit. Input signal for the trigger

amplifier circuit is obtained by sampling the signal applied to CH1 or the

composite vertical signal from the vertical switching circuit.

This circuit also provides a signal to the horizontal amplifier for X-Y

operation,

The trigger generator circuit produces

generator circuit.

signal from the vertical deflection system,

the external

applied to the instrument.

This circuit consists of the trigger source, trigger mode switch, TV

syncronization circuit,

source is one of

HFR, LFR, DC. The trigger mode is one of AUTO, NORM, TV-V, TV-H. Sweep

signal A or B may be selected for the horizontal amplifier with the

This trigger pulses are derived from the internal trigger

CH3(EXT)

CHl,

input connector or a sample of the line voltage

horizontal control circuit and etc. The trigger

CH2, LINE,

CH3(EXT).

trigger pulse to start the sweep

an external signal connected to

The trigger couple is one of AC,

HORIZ

DISPLAY switch A or ALT and B or B TRIG’D. In X-Y operation, the signal

input to the vertical preamp for

amplifier via the trigger amplifier and the signal applied to CH2 input is

led to the horizontal amplifier. Thus, a Lissajous figure can be displayed

on the screen, by the signal applied to CH2 input(Y-axis display)

CH1

input is led to the horizontal

A AND

Sweep generator

integrator.

applied to the A sweep generator circuit and a sweep signal for horizontal

axis sweep is generated when the sweep gate opens.

The B sweep generator circuit generator circuit generates a sweep signal at

a preset time after the operation of the i\ sweep generator circuit. The

sweep by sweep B is called delayed sweep, As

are generated by opening and closing the sweep gate, and sweep gate signals

B SWEEP GENERATOR

circuit consists of sweep gate circuit and A miller

The pulse generated by the A trigger pulse shaping circuit is

descrived

above, sawtooth wave

A and B generated at that time are led the Z-Axis amplifier, The sweep gate

circuit produces an unblanking gate to unblank the during sweep time.

11

HORIZONTAL OUTPUT AMPLIFIER

This circuit provides the final signal amplification to drive the CRT

horizontal deflection plates. The horizontal output Amplifier has the

horizontal magnification

position of the

TIME/DIV

and the horizontal position functions, In all

select switch the input signal of the horizontal

output amplifier is the sawtooth signal from the sweep generator.

CRT CIRCUIT

The CRT circuit provides the voltage levels and control circuits to operate

the CRT. The circuit consists of the z-axis amplifier, high voltage

oscillator, high voltage regulator, high voltage rectifier and the CRT

controls. CRT control circuit consists of the probe adjust circuit and scale

i 1 luminate circuit. The probe adjust circuit produces a square wave output

signal with accurate amplitude and frequency. This output is available as a

square wave voltage at the PROBE ADJUST

0.5V (1kHz)

connector.

POWER SUPPLY

The low voltage power supply circuit

(-12vol

source

ts,

+5vol

(-18volts)

ts,

+12vol

ts,

+55vol

and two AC source (6.3,

ts

provides five regulated sources

and

+12Ovol ts),

one unregulated

24volts) used to operate the

vertical deflection system, horizontal deflection system and CRT driving

circuit,

12

6.

CALIBRATION

LG Precision provides complete instrument repair and calibration at our

oversea

or representative

6-l. Calibration interval

office and authorized dealer.

Contact your local LG Precision office

To maintain instrument accuracy, perform the calibration of the

unit at least every 1000 hours of operations or every six months if used

frequently.

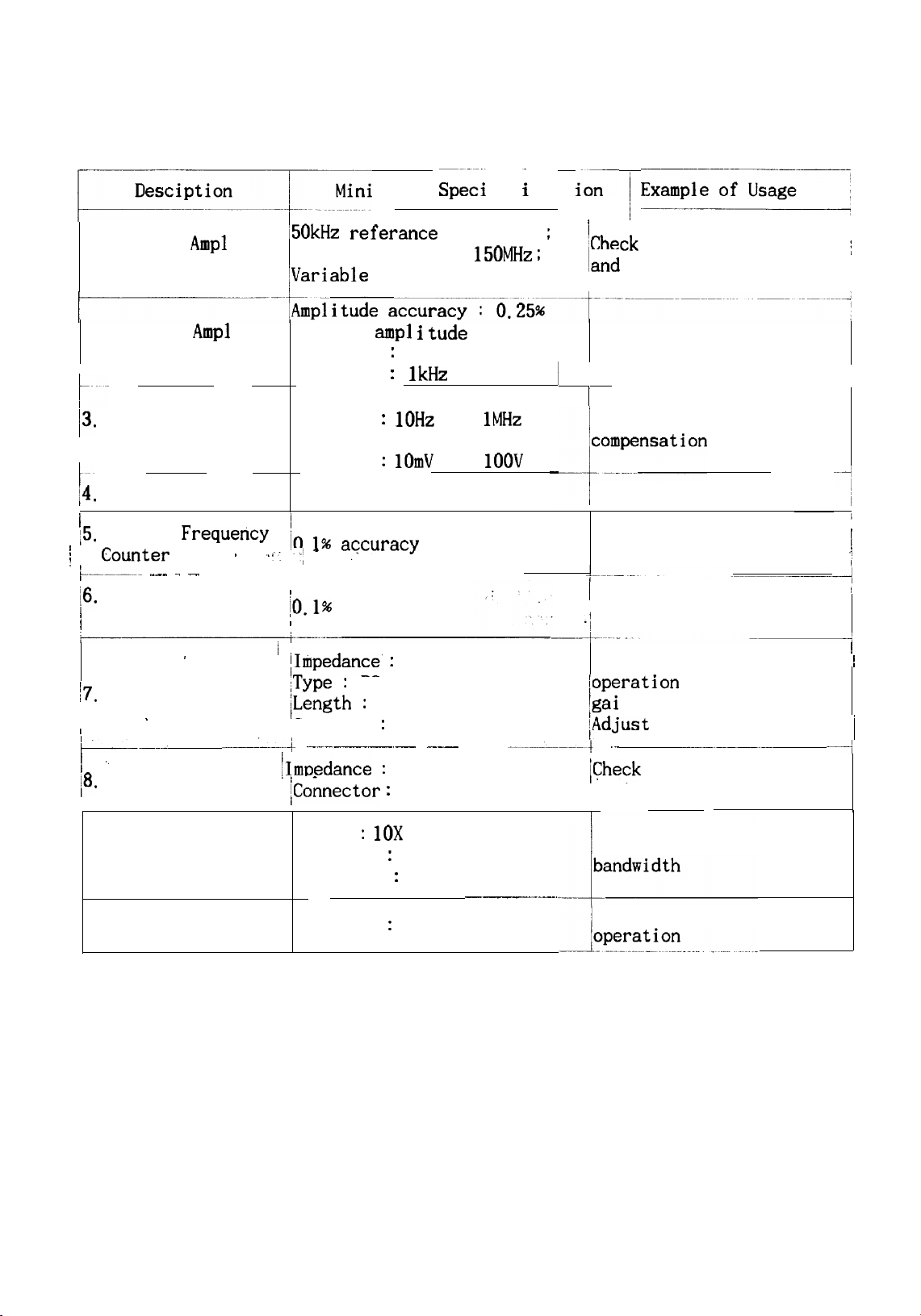

6-2. Test equipment required

The following test equipment {Table

are required for the complete calibration of the

specifications for the test equipment are the minimum necessary for accurate

calibration. Therefore,

meet or exceed the list specifications.

be correctly calibrated and operating within the listed specification.

Operating instructions

procedure. Refer to the instruction manual for the test equipment if more

information is needed.

6-3.

Preliminary procedure

This instrument should be calibrated under an ambient temperature or

oC(k5°C)

1. Connect the instrument to AC line voltage,

2. Set the instrument controls as given in the preliminary control

for best overall accuracy.

setting. Allow at least 30 minutes of warmup before proceeding,

the specifications of any test equipment used must

for the test equipment are not given in this

6-l)

and accessories, or equivalent,

OS-91OOP

All the test equipment is assumed to

50/6OHz

Units. The given

line source.

OS-9100D

+20

13

Table 6-l

--

TEST EQUIPMENT REQUIRED

!gni

1. Constant

Signal Generator

2. Standard

Calibrator

Amp1

i tude

Amp1

i tude Variable

I

I~--

13.

Square wave

generator

t--~

14.

Digital Multimeter 0.1% accuracy

I

15.iDigital

Counter

I------

16.

Time mark

/

Generator

!7.

Cable

I

I

IL---.

1 ‘.

18.

Termination

I

Frequericy

I

,

.--- ~. -

,

’

-i-.--.A-

‘50kHz referance

Maximum frequency

IVariable

Frequency

Variable frequency

Output amplitude

.

lo Ix accuracy

..“: -;j *

I

10.1%

I

/

IImpedance :

iType

iLength

Connector : BNC

.~-...---~-.~.~ ..---

IImpedance :

lConnector :

mum

amplitude

,‘.

accuracy

:

RG-58/U

:

42 inches

Speci

frequency

amp1 i tude

:

5mV to 40V

1kHz

:

: 1OHz

: 1OmV

50 ohm

50 ohm

BNC

square wave

to

to

f

150MHz ;

1MHz

1OOV

___

i

cat

----+

ion

~

ExarnpleoffUsege-!

/

;

iCheck

land

1

-

-1

horizontal, vertical

trigger bandwidth.

Check vertical gain.

I

Check probe and vertical

Check the power supply

Check frequency of Probe

Adjust terminal.

I

Check horizontal gain.

Check external trigger

/operation

jgai n.

iAdjust

..-

iCheck

/amplifier compensation.

and horizontal

horizontal gain.

-___~--~.-

and adjust vertical

/

~

i

I

I

-1

/

,

I

/

I

.

i

+

9. Attenuator

10. T-Connector

Ratio :

Connector : BNC

‘Impedance : 50 ohm

Connector : BNC

10X

14

-~

Check vertical amplifier

-._-..

Check external trigger

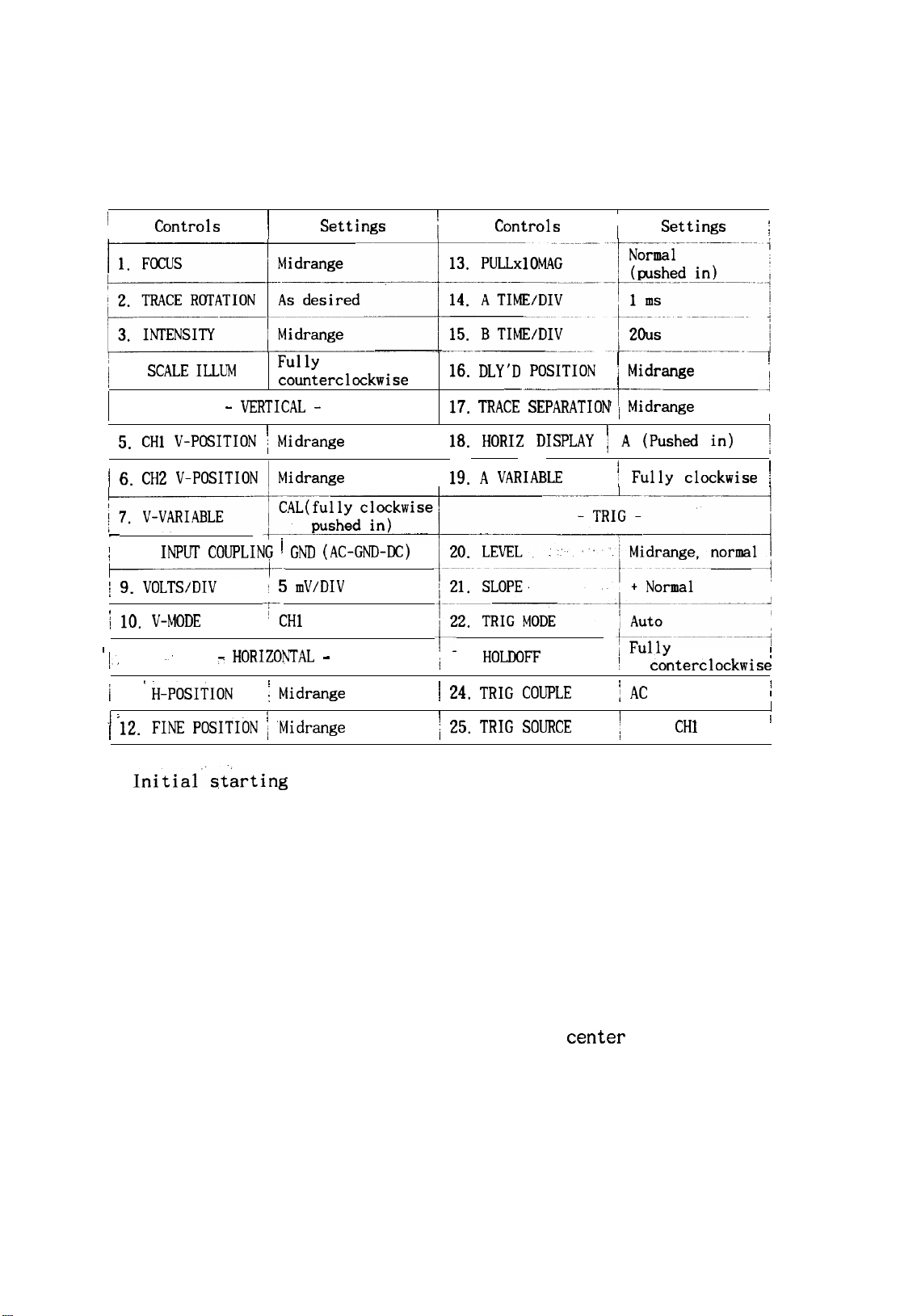

6-4. Preliminary control settings

Preset the instrument controls to the setting given below, when starting

the calibration procedures.

I

I

j

I

I

Controls Settings

4.

SCALE ILLUM

1

- VERTICAL -

Fully

counterclockwise

5. CH1 V-POSITION I Midrange

/ 6. CH2 V-POSITION

1

Midrange

-

;

8.

I-;-.

j 9. VOLTS/DIV

INPUT COUPLING I GND (AC-GND-DC)

: 5 mV/DIV

-r-

j 10. V-MODE

I

/,

~.

j

11. ’

i-I-POSITIONI

1 ;

1

12.

FINE POSITIGN / ‘Midrange

7

’ CH1

HORIZONTAL -

Midrange

I

I

Controls

16. DLY’D POSITION

I

Settings

I

1 Midrange

-__

17. TRACE SEPARATION / Midrange

I---

18. HORIZ DISPLAY 1 A (Pushed in)

19. A VARIABLE

I

I Fully clockwise j

---

j----~-----.-----i

e

j

23,

HOLDOFF

I 24. TRIG COUPLE

/ 25. TRIG SOURCE;

i Fully

I conterclockwise

j AC

CH1

i

1

i

I

I

I

I

I

I

I

6-5.

Initiallstarting

procedure

1. Push the POWER switch.

2. Wait a few seconds for the cathode ray tube (CRT) to warm up.

A trace should appear on the display of the CRT.

3. If the trace disappears,

increase (clockwise) the INTENSITY control

setting until the trace is easily observed.

4. Adjust FOCUS control for the best focused display.

5. Readjust POSITION controls if necessary, to

center

the trace.

6-6. Calibration procedure

15

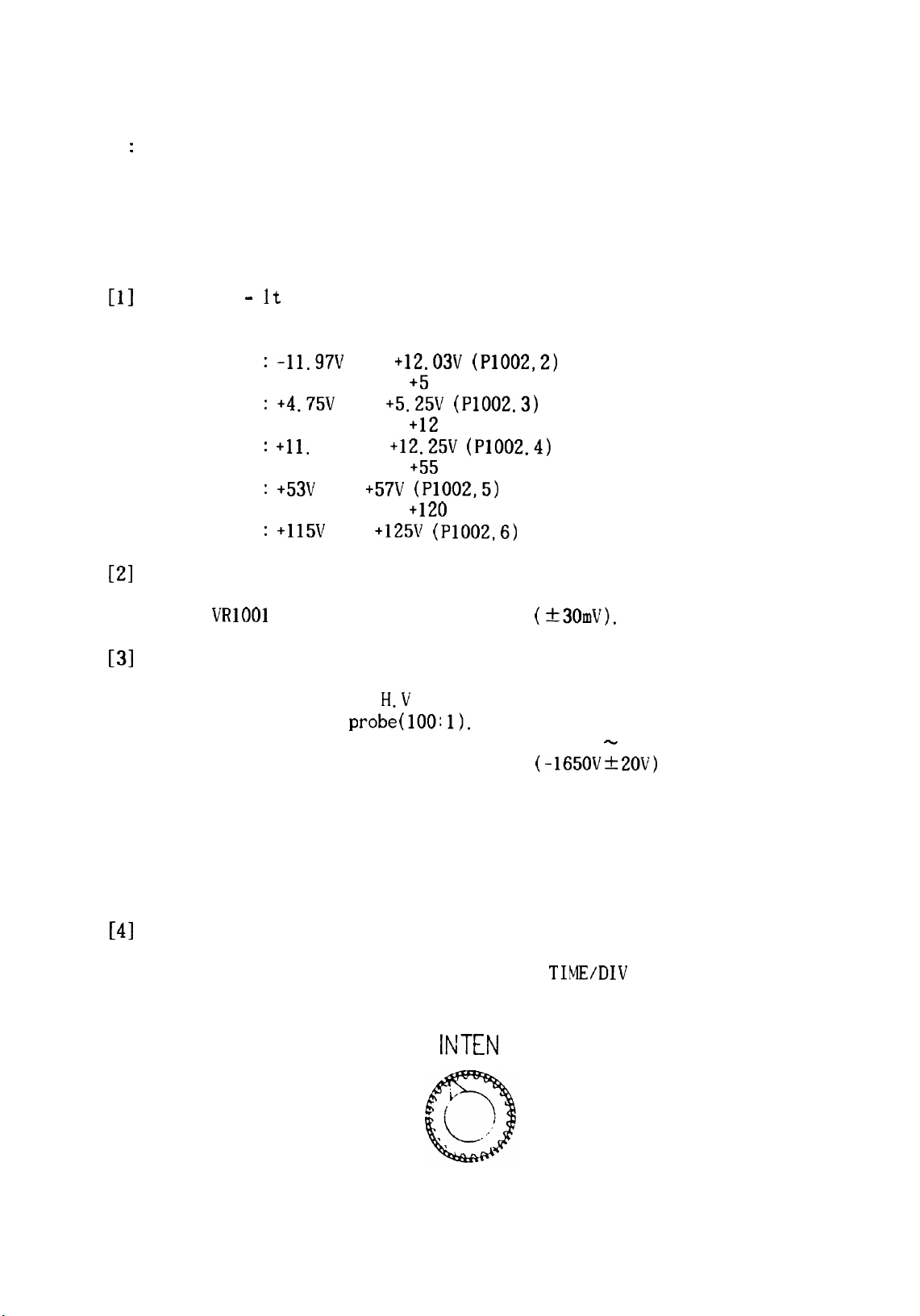

POWER SUPPLY SYSTEM

NOTE :Before you begin. see

LOCATIONS).

Control settings

Preset the controls as given in the Preliminary control settings.

[l]

Check Lo -

a. Connect the digital voltmeter (DVM) to the -12 volt line,

b. Connect the DVM to the +5 volt line.

c. Connect the DVM to the

d. Connect the DVM to the

e. Connect the DVM to the

[2]

Adjust L

It

w vo

ow-voltage supply.

age supply, if necessary.

: -11.97v

: +4,75V

: +ll.

75V to

: +53V

: +115V

to

to

8. ELECTRICAL PARTS ARRANGEMENT (WITH ADJUSTMENT

to

to

+12.03v (P1002,2)

+5.25V (P1002.3)

+12

volt line.

+12.25V (P1002.4)

+55

volt line.

+57V (P1002,5)

+120

volt line.

+125V (P1002,6)

Adjust

[3]

Adjust High-voltage supply.

a. Connect the DVM to the

b. Check the VR905 for a DVM reading as -1630 - -1670V

VRlOOl

with High-voltage

for a DVM reading of -12V

H.V

test point (CRT SOCKET BOARD)

probe(lOO:l).

(&30mV),

(-1650Vf20V)

DISPLAY

Control Setting

Preset the controls as given in the Preliminary control setting,

Check/Ad

[ 41

Display switch to the [A] position, and A

a. Set the INTENSITY to the direction of 10 o’clock as shown.

just

CRT Bias.

TIME/DIV

switch to the lms.

INTEN

16

b. Observe the trace on CRT.

c.

Adjust the CRT Bias Adjustment,

an appear.

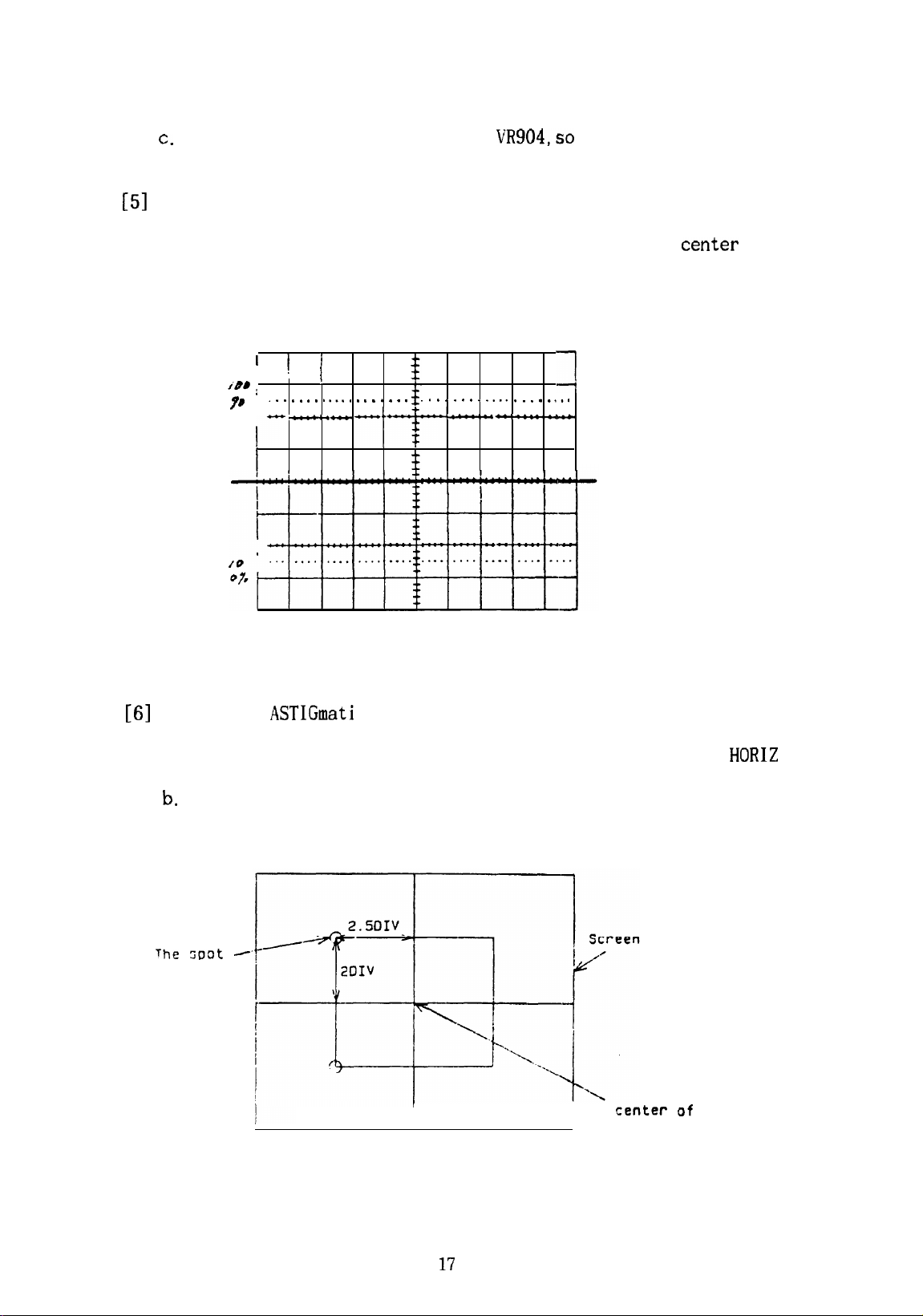

[5]

Check/Adjust Trace Rotation.

VR904,so

that the trace makes

a. Check that

b. Adjust the

horizontal

I

r’b@ :

p

. . . . . . . *... . . . . . . . .. . . . . . . .

y-

l

the trace is parallel to the horizontal

center

line.

TRACE ROTATION for a trace that is parallel with the

graticule lines.

I

!

!

-... . . . . .“..

-4-

-y

--cc--

--j

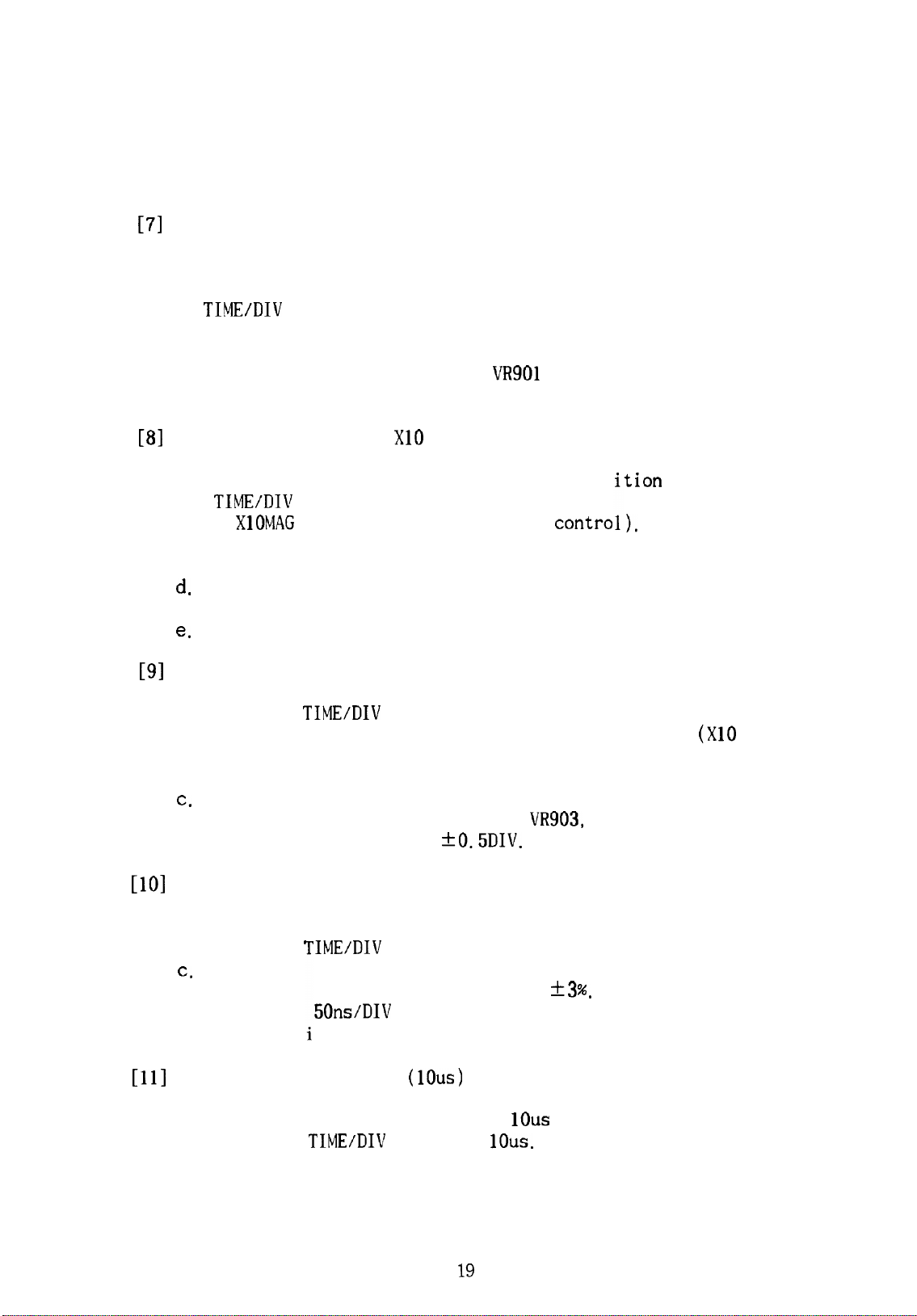

[6]

Check/Adjust

ASTIGmati

sm and FOCUS

a. Set Vertical Mode switch to the CH2 [X-Y] position, and

DISPLAY switch to the [X-Y] position, and AC-DC, GND to DC.

b.

Set the INTENSITY control for a small spot, as the following

figure, using position controls.

The soot --

The

I

center

Of

HORIZ

screen

17

c. Check that the spot is round.

d.

Adjust the FOCUS adjustment and

round spot.

ASTIG

adjustment

l/R402

for a

18

HORIZONTAL SYSTEM

Control settings

Preset the controls as given in the preliminary control settings.

[7]

Check/Adjust Horizontal A sweep Gain.

a. Set the input AC-DC, GND to DC.

b. Set the HORIZ. DISPLAY switch to the A position and A

TIME/DIV

c. Check that the time marks align with the graticule line over

the center eight divisions, within 3%.

d. Adjust the H GAIN adjustment

with the center eight graticule lines.

switch to lms.

VR901

so that

the time marks align

[8]

Check/Ad

a. Set the HORIZ. DISPLAY switch to the A pos

b. Set

c. Check that the one-cycle time marks align with the ten division

graticule lines, within 5%

d,

Adjust the MAG GAIN adjustment,

e.

Push in the A VARIABLE control after check and adjustment.

[9]

Check/Ad

a. Set the A

b. Being the A VARIABLE control is in pulled out state

c.

Observe the movement of the left end of the trace.

d. Adjust the MAG CENT adjustment,

[lo]

Check/Adjust high speed (50ns) A sweep accuracy.

just Horizontal

TIME/DIV

XlOMAG

time marks align with the ten division graticule lines.

the left end of the trace is brought to the center point and

then the A VARIABLE is depressed.

end of the trace within

switch to lms.

(Pull out the A VARIABLE

just

MAG CENT.

TIME/DIV

Xl0

MAG Gain.

switch to lms.

+0.5DIV.

ition

and A

contra

VR902, so that the one-cycle

VR903,

1).

(X10

for the movement of the

MAG),

a. Set the time mark generator for 50ns time marks.

b. Set the A

c,

Check that

the middle

d. Adjust the

coincide w

[ll]

Check/Adjust high speed

a. Set the time mark generator for

b. Set the A

c. Check that the time marks align with the graticule line over

IME/DIV

’

the time marks align with the graticule line over

eight divisions, within

50ns/DIV

th the middle eight graticule lines.

TIME/DIV

switch to 50ns.

t3%.

adjustment VC701 so that the time marks

(lOus)

switch to

A sweep accuracy.

lOus

time marks.

lOus.

19

the middle eight divisions, within

d. Adjust the

coincide with the middle eight graticule lines.

[12]

Check/Adjust Horizontal B Sweep Gain

lOus/DIV

adjustment VC702 so that the time marks

&3%.

a. Set the HORIZ DISPLAY switch to the B position. A

switch to the 2ms and B

b. Set the time mark generator for lms time marks.

c. Rotate the DLY’D POSITION C. C. W fully.

d. Check that the time marks align with the graticule line over

the middle eight divisions, within

e. Adjust the VR803 so that the time marks coincide with the

middle eight graticule lines.

[13]

Check/Adjust High speed (50ns) B sweep accuracy.

a. Set the time mark generator for 50ns time mark.

b. Set the A

50ns.

c.

Check that the time marks align with the graticule lines over

the middle eight divisions, within * 3%.

d.

Adjust the VC801 that the time marks coincide with middle eight

graticule lines.

[14]

Check/Adjust High

a. Set the time mark generator for

b.

Set the A

JOUS.

c. Check that the time marks align with the graticule lines over

the middle eight divisions, within

d,

Adjust VC802 that the time marks coincide with middle

graticule lines.

TIME/DIV

TIME/DIV

switch to 0. lus and B

speed(lOus)

switch to

TIME/DIV

B sweep accuracy.

switch to the lms.

+3%.

lOus

time mark.

20~s

and B

Ifr:

3%.

TIME/DIV

TIME/DIV

switch to

switch to

TIME/DIV

eig.ht

[15]

Check/Adjust A & B sweep start and stop.

a. Set the HORIZ DISPLAY switch to the ALT position. A

switch to the lms and B

b.

Set the time mark generator for lms time mark.

c. Rotate the DLY’D position to C. C. W fully,

d. Adjust the sweep start adjustment VR701 within

e.

And then, rotate the DLY’D position to C. W fully.

f. Adjust the sweep stop adjustment VR702 over the

[lS]

Check/Adjust B sweep start.

a. Set the A and B

b. Rotate the DLY ‘D POSITION to C. C. W fully.

c.

Adjust the B sweep start adjustment

same A sweep start,

TIME/DIV

TIME/DIV

switch to

20

switch to the

lOus.

VR803A

TIME/DIV

lOus.

0.5div

1Odiv.

for B sweep start

VERTICAL SYSTEM

Control settings

Preset the controls as given in the Preliminary control settings.

[17]

Check/Adjust DC Balance (Step attenuator balance),

a. Set the

VOLTS/DIV

switch to 5mV position.

b. Position the trace to the horizontal center line.

c.

Change the

VOLTWDIV

switch to the

1OmV

position.

d. Check that the trace is within t 0.4 division of the

horizontal center line.

e.

Adjust the CHl(CH2) DC BAL adjustment,

VRlOl(VR201)

at the horizontal center line.

f.

Repeat part (a) through

shift is noted when changing the

[ 181

Check ADD BALANCE.

a. Set the A

DISPLAY switch to A position.

b.

Set the

c,

Set the V-MODE switch to ALT or CHOP.

CH1

and CH2 AC-DC, GND switches to GND.

TIME/DIV

switch to the lms position, and the

(e)

until less than t 0.05 division

VOLTS/DIV

setting.

.:

d. Next, Adjust the vertical Position control so that the trace is

identical with the horizontal center graticule line.

e. Set

the V-MODE switch to ADD.

f. Check that the trace is identical with the horizontal center

graticule line within fl division.

for a trace

HORIZ.

[19]

Check/Adjust vertical position center

a. Confirm the vertical POSITION control is at midrange.

b,

Check that the trace is 0 division of the horizontal center

1 ine.

c. Adjust the

CHl(CH2)

Position Center adjustment

a trace at the horizontal center line.

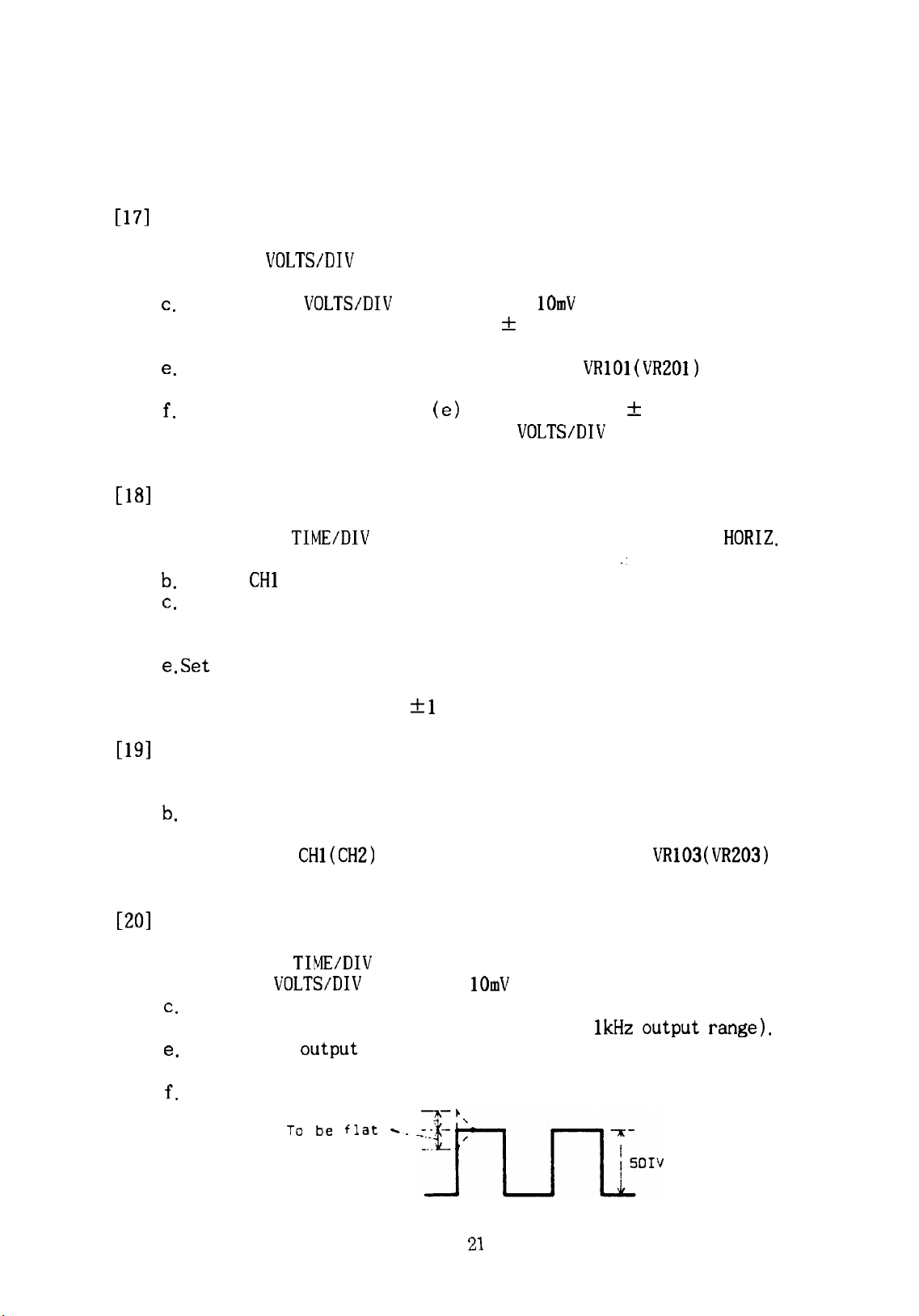

[20] Check/Adjust Xl AC GAIN

a. Set the A

b. Set the

c.

Set the AC-DC, GND switch to DC.

TIME/DIV

VOLTS/DIV

switch to

switch to lms position.

1OmV

position.

d. Connect the square-wave generator (using

e.

Adjust the

output

amplitude of the generator for 5 division

deflection of screen.

f.

Check that the high-voltage level of pulse is flat,

To be flat --

VR103(VR203)

1kHz output range),

for

21

g.

Adjust the

flat level.

[21]

Check/Adjust Vertical Gain

CHl(CH2)

Xl AC GAIN adjustment

VR102(VR202)

for a

a. Set the

switch to DC.

b. Connect the standard amplitude

connector.

c. Set the standard amplitude calibrator for a

d. Check for a display of five divisions.

e.

Adjust the CHl(CH2) GAIN adjustment

of 5 divisions, within 3%

f.

Check all the

[22]

Check/Adjust Input Capacity {ATT :

a. Set the

b. Set the AC-DC, GND switch to DC.

c. Connect the L-C meter to the input terminals.

d. Check that the input capacity is approximately 22pF.

[23]

Check/Adjust Vertical Step Response.

a. Set the

b.

Set the A

c.--

Connect the fast-rise, positive output

square-wave generator to the input. Use a

cable.

d. Set the square-wave generator to

generator output for a 5 divisions display.

e.

CH1 :

CH2: Adjust the VC202 for over-shoot that is

VOLTS/DIV

VOLTS/DIV

VOLTS/DIV

TIME/DIV swich

Adjust

to.

20mWdiv

to.

20mV/div

VC401, VC402, VC403,

35division at

of

35division at

of

switch to the

VOLTWDIV

switch to the 20mV position.

switch to

VOLTS/DIV

VOLTS/DIV

switch settings.

to 50ns position.

5mV/div, lOmV/div, fO.5division

5mV/div, lOmV/div, +O. Cidivision

1OmV

calibratior

1OmV

VC404 for over-shoot that is

switch.

switch.

pisition and AC-DC, GND

VR401(VR205)

tl)

position.

(50mV, 1MHz)

1MHz.

Adjust the square-wave

to the input

50mVp-p

5OQ

termination and

+0.25DIV.

signal.

for a display

of the

at

at

22

Loading...

Loading...