Page 1

PLASMA MONITOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : NP-00KB

MODEL : MT/MZ-60PZ12/B

MODEL : MT/MZ-60PZ14/B

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

Contents ................................................................................................................. 2

Safety Precautions ............................................................................................3

Specifications ..................................................................................................... 4

Control Descriptions ........................................................................................ 5

Adjustment Instructions ............................................................................... 9

Trouble Shooting ............................................................................................... 11

Block Diagram .................................................................................................... 13

Exploded View .................................................................................................. 16

Exploded View Parts List ..............................................................................17

Replacement Parts List ................................................................................ 18

SVC. Sheet ................................................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

SPECIFICATIONS

Note : Specification and others are subject to change without notice for improvement.

O Video receiving system:

PAL

SECAM

NTSC-M

NTSC 4.43

O Input Voltage : AC 110~240V, 50/60Hz(MT-)

AC 200~240V, 50/60Hz(MZ-)

O Power consumption : Max 750W

Stand-By : 5W

O PDP Module : PDP60WXDP4

O Speaker Impedance : 8 ohm

O Feature : AV Input

Component Input

RGB Input

External SPK Out

RGB/ Control Input

S-Video Input

O Funtion : Auto Picture

DASP

AVL

PIP

SSC

O External Interface

Item

Video Input Level

Video Input Frequency Response

Video Input S/N

S Video Input Level(Y)

S Video Input Level(C-Burst)

Audio Input Level

Audio Input Frequency Response

Audio Input S/N

Audio Input Distortion

Audio Input Dynamic Range

Component Video Input Level

R/G/B Video Input Level

Min

0.9

5

40

0.85

0.143

0.3

0.08

40

2

0.6

0.6

Typ

1

1

0.4

0.7

0.7

Max

1.1

1.15

0.286

0.5

7

2

0.8

0.8

Unit

Vpp

Mhz

dB

Vpp

Vpp

Vrms

kHz

dB

%

V

Vpp

Vpp

REsolution

640*480

640*480

704*480

1280*720

1280*720

1920*1080

1920*1080

H-Freq(Khz)

15.73

15.63

31.47

45.00

44.96

33.75

33.72

V-Freq(hz)

60

50

59.94

60.00

59.94

60.00

59.94

Proposed

SDTV,DVD 480I

SDTV,DVD 480I

SDTV 480P

HDTV 720P

HDTV 720P

HDTV 1080I

HDTV 1080I

Component Video Input

RGB Input(PC/DTV)

PC

REsolution

640*350

640*350

720*400

720*400

640*480

640*480

640*480

640*480

640*480

640*480

640*480

640*480

800*600

800*600

800*600

800*600

800*600

800*600

800*600

832*624

1024*768

1024*768

1024*768

1024*768

1280*724

1152*864

1152*864

1152*864

1152*864

1152*870

1280*960

1280*960

1280*1024

1280*1024

H-Freq(hz)

31.469

37.861

31.469

37.927

31.469

35.000

37.861

37.500

43.269

45.913

53.011

64.062

35.156

37.879

48.077

46.875

53.674

56.000

64.016

49.725

48.363

56.476

60.023

68.677

52.400

54.348

63.995

67.500

77.487

68.681

60.000

75.000

63.981

79.976

V-Freq(hz)

70.09

85.08

70.08

85.03

59.94

66.66

72.80

75.00

85.00

90.03

100.04

120.00

56.25

60.31

72.18

75.00

85.06

90.00

100.00

74.55

60.00

70.06

75.02

84.99

69.98

60.05

70.01

75.00

85.05

75.06

60.00

75.00

60.02

75.02

Pixel clock

70.09

85.08

70.08

85.03

59.94

66.66

72.80

75.00

85.00

90.03

100.04

120.00

56.25

60.31

72.18

75.00

85.06

90.00

100.00

74.55

60.00

70.06

75.02

84.99

88.87

60.05

70.01

75.00

85.05

75.06

108.00

129.60

108.00

135.00

Proposed

EGA

EGA

DOS

DOS

VESA(VGA)

Macintosh

VESA(VGA)

VESA(VGA)

VESA(VGA)

VESA(VGA)

VESA(VGA)

VESA(VGA)

VESA(SVGA)

VESA(SVGA)

VESA(SVGA)

VESA(SVGA)

VESA(SVGA)

VESA(SVGA)

VESA(SVGA)

Macintosh

VESA(XGA)

VESA(XGA)

VESA(XGA)

VESA(XGA)

HD70Hz(Just scan)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

VESA(SXGA)

REsolution

704*480

1280*720

1280*720

1920*1080

1920*1080

H-Freq(Khz)

31.47

45.00

44.96

33.75

33.72

V-Freq(hz)

59.94

60.00

59.94

60.00

59.94

Pixel clock

Proposed

SDTV 480P

HDTV 720P

HDTV 720P

HDTV 1080I

HDTV 1080I

DTV

Page 5

- 5 -

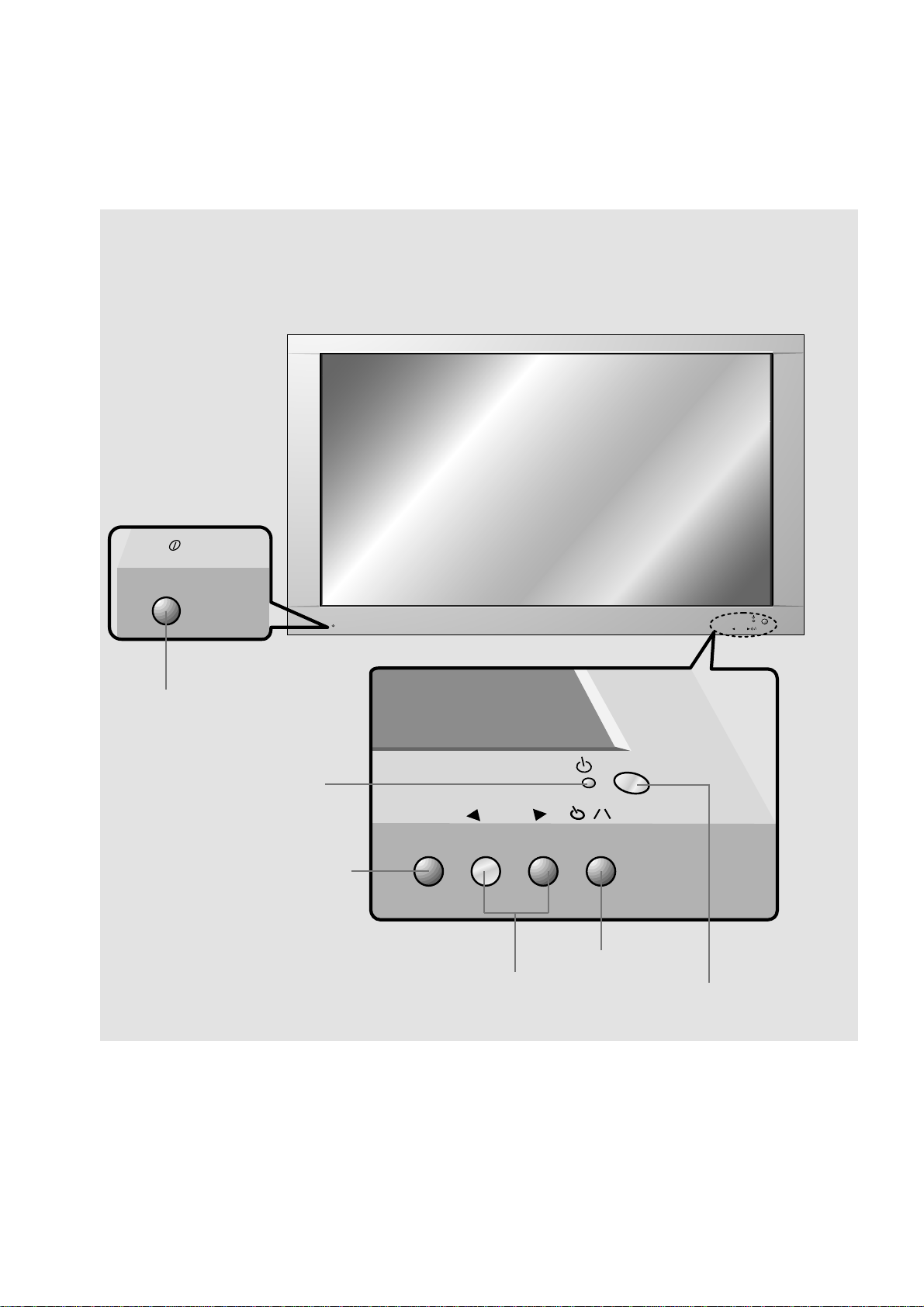

CONTROL DESCRIPTIONS

ON/OFF

ON/OFF

INPUT

SELECT

VOLUME

INPUT

SELECT

VOLUME

<Front Panel>

Main power button

INPUT SELECT button

Sub power button

VOLUME (FF,GG) buttons

Power standby indicator

Illuminates red in standby

Illuminates green when the

Monitor is switched on

Remote control sensor

Page 6

- 6 -

(+) ( ) (+)( )

(+)

( )

(+)( )

AUDIO

(MONO)

R L VIDEO Y P

B R

P

AV INPUT

AUDIO

R L

R

L

EXTERNAL SPEAKER (8Ω) AC INPUTAUDIO INPUT

RS-232CS-VIDEO

COMPONENT(480i/480p)

RGB-PC INPUT

(VGA/SVGA/XGA/SXGA)

AUDIO

(MONO)

R L

AV INPUT

S-VIDEO

COMPONENTI(480i/480p)

(DVD INPUT)

RGB-PC INPUT

R

AUDIO INPUT

EXTERNAL SPEAKER 8Ω

R L

AC INPUT

L

AUDIO

(VGA/SVGA/XGA/SXGA)

VIDEO

Y P

BPR

(DVD INPUT)

RS-232C

AV INPUT /

COMPONENT (480i/480p)

(DVD INPUT) SOCKETS

EXTERNAL SPEAKER

(8 ohm output)

RGB-PC INPUT (VGA/SVGA/XGA/SXGA)/

AUDIO INPUT/

RS-232C jacks

POWER INPUT

SOCKET

This Monitor operates

on an AC mains supply,

the voltage is as indicated as inside back cover

of this manual. Never

apply DC power to the

Monitor.

<Back Panel>

Page 7

- 7 -

Optional Extras

AP-60WA20M series

(Tilt wall mounting bracket)

AP-60WA10 series

(Wall mounting bracket)

AP-60CA10 series

(Ceiling mounting bracket)

AP-60FA10 series

(Floor type stand)

AP-60DA10 series

(Desktop stand)

AP-60SA10 series

(Speakers)

AP-60SA10D series

(Speaker stand)

AP-60SA10F series

(Floor type speaker stand)

Video cables

Audio cables

P

B

Y

R

P

R L

AUDIO VIDEO

(MONO)

AV INPUT

S-VIDEO

(DVD INPUT)

COMPONENT (480i/480p)

AP-60EA21 (interface board)

- Optional extras can be changed or modified for quality improvement without any notification new

optional extras can be added.

- Contract your dealer for buying these items.

Page 8

- 8 -

Controls of the remote control

- When using the remote control aim it at the remote control sensor of the Monitor.

POWER

SLEEP INPUT SELECT

PSM SSM

ARC STILL

PIP TWIN PICTURE

PIP INPUT

MENU MUTE

OK

VOL

POWER STOP

PLAY FF

REC

REW

P/STILL

VOL

POSITION

POWER

SLEEP

PSM

ARC

PIP

PIP INPUT

MENU

OK

VCR BUTTONS

controls a LG video cassette

recorder.

VOLUME (FF, GG)

INPUT SELECT

SSM

STILL

POSITION

DD/ EE

selects a menu item.

MUTE

switches the sound on or off.

TWIN PICTURE

INPUT SELECT button on the

remote control

Each press of this button changes

the mode as below.

Component

Video

RGB

Page 9

- 9 -

1. Application Object

These instructions are applied to all of the PDP monitor, NP00KB.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 220V, 60Hz in

adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

¤ After receiving 100% white pattern(06CH), the receiver

must be operate prior to adjustment.(Or white condition

in HEAT-RUN mode)

¤ŁEnter into HEAT-RUN mode

- Select the 2.W/B by pressing ADJ button on Remote

Control for adjustment. And press the VOL + button.

- Press the VOL + button in HEAT-RUN.

(OSD display HEAT-RUN WHITE and screen display

100% full WHITE PATTERN)

¤ØSet is activated HEAT-RUN without signal generator in

this mode.

[ Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes, a

afterinage may be occur in the black level part of the

screen.

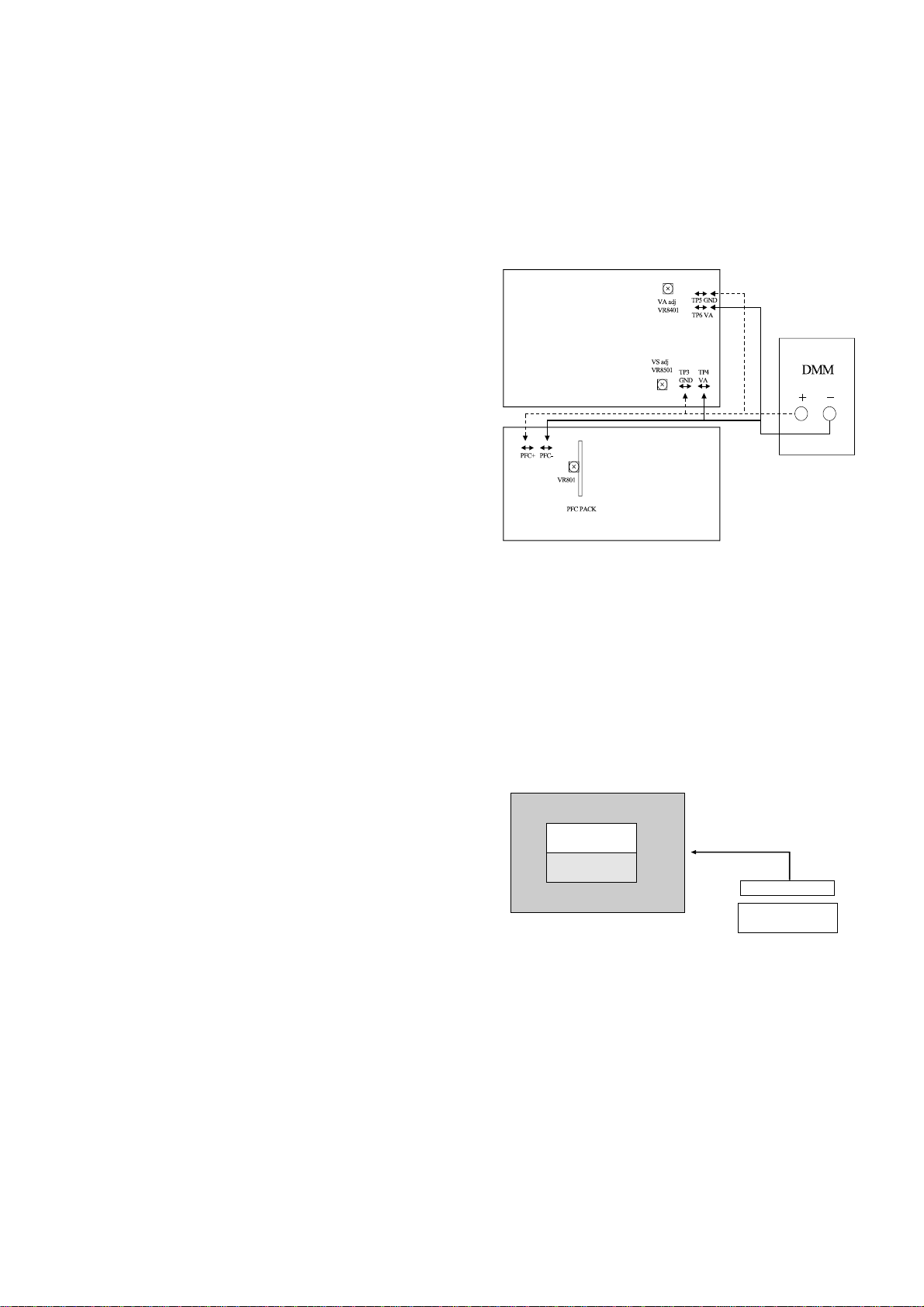

3. POWER PCB Assy Voltage Adjustment

[ Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

3-1. Test Equipment

D.M.M 1EA

3-2. Connection Diagram for Measuring

Refer to Fig 1.

3-3. Adjustment Method

(1) PFC Adjustment

¤ After receiving 100% white pattern, HEAT-RUN.

¤ŁConnect TP PFC+ and TP PFC-(GND) to D.M.M.

¤ØTurning VR801, adjustment is 380V(±1V).

(2) Va Adjusment

¤ Connect pin 1 of P814 to (+) jack of D.M.M.

¤ŁAfter turning the VR803(Va Adj), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel left/top.(Deviation : ±0.5V)

(3) Vs Adjustment

¤ Connect pin 9 of P803 to (+) jack of D.M.M.

¤ŁAfter turning the VR804(Vs Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel left/top.(Deviation : ±0.5V)

4. Adjustment White Balance

4-1. Required Equipment

Color analyzer(CA-100 or same production)

4-2. Connection Diagram of Equipment for

Measuring

[ After stop the Micom by pressing IN-START Key on Remote

Control, insert the P1002 with automatic adjustment of

connector.

After remove connector, move the Micom by pressing ENTER

Key.

ADJUSTMENT INSTRUCTIONS

<Fig 1> Connection Diagram of Power Adjustment for Measuring

COLOR

ANALYZER

TYPE; CA-100

Window

CVBS Signal Input

High Light

75±6cd/m2

Low Light

15±3cd/m2

PDP MONITOR

MSPG-2100 or

MSTG-5200

<Fig 2> Connection Diagram of Automatic Adjustment

Page 10

- 10 -

4-3. Adjustment of White Balance

• Operate the Zero-calibration of the CA—100, then stick

sensor to PDP module surface when you adjust.

• For manual adjustment, it is also possible by the following

sequence.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

ADJ button on Remote Control for adjustment then operate

HEAT RUN more than 15 minute.

(2) Supply 10 step gray scale bar signal in pattern generater.

(A/V Input)

(3) To adjust Low Light, stick sensor to 9th pattern(Dark),

select the W/B by pressing ADJ button on Remote Control

for adjustment and press the VOL + button enter

Adjustment Mode.

After select the G cut and B cut, press the VOL +/- Key

and adjust it until color coordination becomes (R cut

fixation)

color coordination : X=0.283±0.005, Y=0.295±0.005

color temperature : 9,600

cK ± 500cK

(4) To adjust High Light, stick sensor to 2th pattern(White),

select the W/B by pressing ADJ button on Remote Control

for adjustment and press the VOL + button enter

Adjustment Mode.

After select the R GAIN and G GAIN, press the VOL +/Key and adjust it until color coordination becomes (B GAIN

fixation)

color coordination : X=0.283±0.005, Y=0.295±0.005

color temperature : 9,600cK ± 500cK

(5) Confirm the result of the High Light adjustment.

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(6) Exit adjustment mode using Enter button.

Page 11

- 11 -

TROUBLESHOOTING

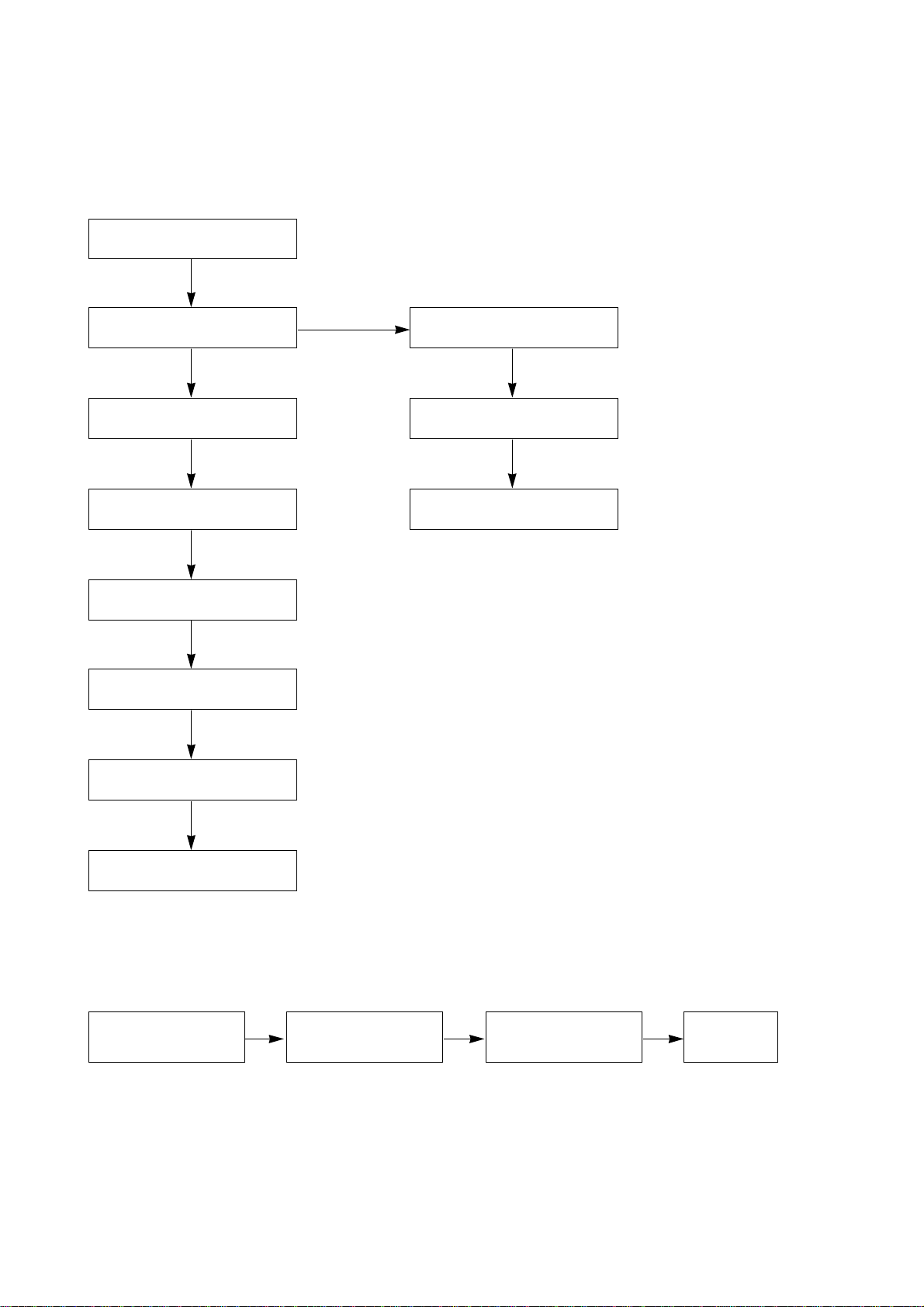

1. No Video

2. No Sound

Abnormal Picture

Input PC signal.

Normal

Abnormal

Check CXA2101

IC203

Normal

Check ADV7123

IC406

Check JAGASM

IC501

Check SII150

IC901

Check cable of pin 21

P901

Normal

Check FLI2220

IC404

Normal

Check FLI2200

IC403

Normal

Check VPC3230

IC201

Normal

Check Input jack & Connector.

Check connector

speaker to set.

Check MSP3401

IC601

Check LA4282

IC603

Check Input

Jack.

Page 12

- 12 -

3. No Video

4. No Sound

Nothing output of image.

Check Input of AC.

(85~225V)

Normal

Abnormal

Abnormal

Abnormal

Check ST-BY LED ON

Main S/W ON.

Normal

Check LED YELLOW

Sub S/W ON.

Connect plug with the set.

Check AC Line Fuse.

Check OPEN with PFC R8301,

R8302, R8303.

Abnormal

Replace R8301, R8302, R8303.

Abnormal

Check output of 5V MONI,

5V CTL.

Abnormal

Replace CTRL PACK.

Check operation of FAN.

Check CRTL Pack

VS On.

Normal

Normal

Check OPEN with

R8538, R8539, 8540.

Normal

Check normal operation

with VS, VA PACK.

Normal

Check a connective condition

and various connector.

Check a connective

condition of power cable.

Check voltage of sound

terminal.

Check Open with F8811

Fuse.

Check connection

line of speaker.

Page 13

- 13 -

BLOCK DIAGRAM

1. VSC Board

MICOM

EEPROM

X2416P

AUDIO

L

R

AUDIO AMP

LA4282

(L & R)

5

RGBHV

COLOR DECODER

(VPC3230D)

DEINTERLACE

(FLI2200)

MEMORY

(4M-BYTE)

ENHANCER

(FLI2220)

COLOR CONTROL

&

VIDEO SWITCH

(CXA2101Q)

3Y,Pb,Pr(MNT)

SCALER

(JAGASM)

MEMORY

(8M-BYTE)

EPLD

(GEN. CLAMP)

TMDS TX

(SII150)

H

V

Clamp

2H/V

H

5H/V/CLK/

HBLK/VBLK

4

H/V/DE/CLK

5

RGBHV

3RGB

AUDIO

SWITCH

(LA7222)

2

H/V

PORT EXP

(M62320X4)

ROM

(AT29C010)

(74HCT373)

YCbCr/

YPbPr

CVBS

Y/C

21P

8

4

H/V/

FIELD/

LLC1

2H/V

DAC

(ADV7123)

5

RGBHV

16

YUV

30

RGB

RGB

30

YUV

16

48

RGB

2

Rx,Tx

Control

(RS232C)

Digital Line

Analog Line

Page 14

- 14 -

2. POWER Board

EMI

FILTER

RECTIFIER

RECTIFIER

RUSH

CONTROL

POWER

CONTROL

PFC

INDUCTOR

Power

Switching

FET

PFC

380V

TINY

255P

Auxillary

Trans

TINY

255P

ST-BY

Trans

PFC Pack

UC 3854

HIGH POWER FACTOR

PREREGULATOR

St-by

5V

Aux.

16V

STR-

F6668B

+

MULTI

TRANS

Fly

Wheel

DIODE

FLY BACK MODE

Panel

Ctl 5V

Panel

Drive 5V

Sound

30V

VSC

16V

VSC

12V

VSC

6V

Step down

Regulator

SI-8120S

Step down

Regulator

SI-8050S

PANEL

VIDEO SCAN CONVERTER

Zero Current Resonant Mode

Power

FET

2sk2837

UC 3863

Resonant power supply mode

IR 2113S

High speed power FET driver

UC 3863

Resonant power supply mode

IR 2113S

High speed power FET driver

Power

FET

2sk2837

VS

170-185

VA

72-80

SOUND

FAN VSC

ADRESS

SUSTAIN

DRIVE

LOGIC

P F C

DC-DC

~

VS Pack

VA Pack

EPROM

CTL Pack

5V moni

VS on

VS on

RL on

Rush CTL

Page 15

- 15 -

MEMO

Page 16

- 16 -

EXPLODED VIEW

310

550

620

560

101

331

400

401

520

540

301

302

306

303

304

330

590

201

202

203

204

205

206

213

214

207

208

209

210

211

212

600

610

530

580

630

300

305

640

200

Page 17

- 17 -

EXPLODED VIEW PARTS LIST

101 5900V08004A FAN,DC F8025L12B2-RG DONG YANG 80MM 1

200 6348Q-B032D PDP 60” 16:9 1280*720 FOR DND INTE

201 6871QRH015B PWB ASSY,DISPLAY XRRT ASSY 60HD4(X

202 6871QTH021A PWB ASSY,DISPLAY ZCNT ASSY 60HD4 2

203 6871QZH018B PWB ASSY,DISPLAY ZSUS ASSY 60HD4(Z_

204 6871QTH022A PWB ASSY,DISPLAY ZCNT ASSY 60HD4 2L

205 6871QRH014B PWB ASSY,DISPLAY XRRT ASSY 60HD4(X

206 6871QXH009B PWB ASSY,DISPLAY XRCT ASSY 60HD4 4L

207 6871QLH016B PWB ASSY,DISPLAY XRLT ASSY 60HD4(X

208 6871QDH028B PWB ASSY,DISPLAY YDRV ASSY 60HD4 4L

209 6871QYH017B PWB ASSY,DISPLAY YSUS ASSY 60HD4 4L

210 6871QDH027B PWB ASSY,DISPLAY YDRV ASSY 60HD4 (T

211 6871QLH017B PWB ASSY,DISPLAY XRLT ASSY 60HD4(X

212 6871QXH008B PWB ASSY,DISPLAY XRCT ASSY 4LAYER(T

213 6871QCH012B PWB ASSY,DISPLAY CTRL ASSY 60HD4 1C

214 6871QPH001B PWB ASSY,DISPLAY DCDC ASSY 60HD4

300 3091V00352A CABINET ASSEMBLY

301 4980V00142B SUPPORTER,FILTER TOP LEFT FD-60X3

302 4980V00142A SUPPORTER,FILTER TOP RIGHT FD-60X3

303 4980V00143B SUPPORTER,FILTER BOTTOM LEFT FD-60X3

304 4980V00143A SUPPORTER,FILTER BOTTOM RIGHT FD-60X3

305 3790V00267B WINDOW,H04PR-LGE60-02 FD60X3R FIBER M

306 4980V00141A SUPPORTER,FILTER R/LEFT FD-60X3

310 5020V00437A BUTTON 4KEY FD- 60X3

330 5020V00436A BUTTON FD- 60X3

331 3141VSN122B CHASSIS ASSY,POWER S/W

400 3809V00280C BACK COVER ASSEMBLY

401 3300V00067R PLATE,REAR A/V

3300V00067M PLATE,REAR A/V

520 6871VMM992B PWB ASSY,MAIN VER.2 VSC PAL

530 6871VPM992A PWB ASSY,POWER SMPS PFC V.2

540 6871VPM991A PWB ASSY,POWER SMPS POWER V.2

550 6871VSM677A PWB ASSY,CONTROL

560 3141VSN195A CHASSIS ASSY,LINE FILTER ASSY

580 6871VSMB46A PWB ASSY,NP-00KB VER.2 PFC PACK

590 6871VSM668A PWB ASSY,POWER VA M/I

600 6871VSM669A PWB ASSY,POWER VS M/I

610 6871VSM670A PWB ASSY,POWER CONTROL

620 6871VSM676B PWB ASSY,SIDE A/V

630 6871VSMC90A PWB ASSY,A/V NP-00KB VER2 INTERFACE BD

640 6871VSMB57A PWB ASSY,NP-00KA/B VER.2 FAN CONTRO

No.

Part No.

Description

Page 18

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

IC8104

IC8131

IC8201

IC8202

IC8204

IC8205

IC8602

IC8603

IC8604

IC8631

IC8801

IC8802

IC8803

IC8804

IC8806

IC8900

PC8201

PC8202

PC8401

PC8402

PC8403

PC8501

PC8502

PC8503

PC8504

PC8801

PC8802

D1

D101

D102

D103

D104

D105

D106

D250

D251

D252

D401

D402

D601

D602

D603

D604

D610

D801

D802

D802

0ISH121100D

0IUN386300B

0ISK615311B

0ISK615311B

0ISK005000A

0IKE781200P

0IIR121130A

0IRH103392A

0ISH121100D

0IUN386300B

0ISK666813A

0ISK005000A

0IFA754207A

0ISK805011A

0ISK812011A

0ISH817300B

0ILI817000G

0ILI817000G

0ILI817000G

0ILI817000G

0ILI817000G

0ILI817000G

0ISH851000A

0ILI817000G

0ILI817000G

0ILI817000G

0ILI817000G

0DD100009AM

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD226239AA

0DD184009AA

0DL233309AC

0DL233309AC

0DD184009AA

0DD184009AA

0DD184009AA

0DD226239AA

0DD226239AA

0DZ240009CG

0DD100009AM

0DZ910009AJ

IC,PQ12DZ1U 5 SMD R/TP REGULATOR

IC,UC3863DW 20PLCC R/TP PFZO CONT

IC,STR-G6153T(LF1101) 5PIN BK STR

IC,STR-G6153T(LF1101) 5PIN BK STR

IC,SE005N 3P TO-220 BK 5V ERROR A

IC,KIA7812API TO220 ST 3P 12V REG

IC,1R2113S 16SOP R/TP H/BRIDGE DR

IC,BA10339FV-E2 SSOP-B14PIN R/TP

IC,PQ12DZ1U 5 SMD R/TP REGULATOR

IC,UC3863DW 20PLCC R/TP PFZO CONT

IC,STR-F6668B(LF1352) 5PIN BK STR

IC,SE005N 3P TO-220 BK 5V ERROR A

IC,KA75420ZTA(KA7542ZTA) 3P,TO-92

IC,SI-8050S(LF1113) 5PIN BK 5V RE

IC,SI-8120S(LF1113) 5PIN BK 12V R

IC,PC817XF3 4D PHOTO COUPLER

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,PC851 4P,DIP BK HIGH VOLTAGE P

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

IC,LTV817M-VB 4P,DIP BK PHOTO COU

DIODE,RECTIFIERS EU1ZV(1) TP SANKEN

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING KDS184S CHIP 85V 300MA

LED,SAM2333 TP KWANG GREEN/RED GRE

LED,SAM2333 TP KWANG GREEN/RED GRE

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,ZENERS MTZJ24B TP ROHM-K DO34 24V

DIODE,RECTIFIERSEU1ZV(1) TP SANKEN

DIODE,ZENERS MTZJ9.1B TP ROHM-K DO34 0.5W

LOCA. NO PART NO DESCRIPTION

IC1

IC2

IC3

IC4

IC5

IC102

IC103

IC104

IC201

IC202

IC203

IC204

IC205

IC301

IC402

IC403

IC404

IC406

IC501

IC502

IC503

IC601

IC602

IC603

IC604

IC605

IC701

IC702

IC703

IC704

IC706

IC707

IC708

IC709

IC710

IC801

IC802

IC803

IC804

IC806

IC807

IC808

IC901

IC1101

IC1102

IC8102

IC8103

0IDS162100B

0IPH743200A

0ISH052100A

0ISH092100A

0ISH122100B

0IDS232000A

0ISH052100C

0IFA741230A

0IIT323000C

0IKE704200J

0ISO210100B

0ISH092100A

0ISH052100C

0IMCRFA012A

0ISS464323A

0IMCRG2001A

0IMCRG2002A

0IMCRAD001A

0IMCRG2004A

0ISS464323A

0ISS464323A

0IMCRMN002A

0IKE704200J

0ISA428200A

0ISH052100C

0IKE780800A

0IMI623200B

0IMI623200B

0IMI623200B

0IAL241610A

0IMCRNS001A

0IPH740400G

0IPH806520A

0IZZVA0043B

0IPH743730E

0IUN385400B

0IMCRRH001A

0ILT176425A

0IMCRRH001A

0IMCRRH001A

0ILT176425A

0IPH743200A

0IS5150000A

0IMCRAT003A

0ISH052100C

0IIR121130A

0IRH103392A

IC,DS1621V 8P SOIC ST THERMOSTAT

IC,74HC32D 14SOP TP QUAD 2-INPUT

IC,PQ05RF21 4P(TO-220) 5V S/W REG

IC,PQ09RF21 4P 9V S/W REGULATOR -

IC,PQ12RD21 4SIP ST REGULATOR

IC,DS232AS 16P,SOP TP RS-232 DRIV

IC,PQ05RD21 4SIP ST REGULATOR

IC,DM74LS123MX 16SOP TP DUAL RETR

IC,VPC3230D-QA-B3 80P PQFP BK COM

IC,KIA7042AF SOT-89 TP 4.2V VOLTA

IC,CXA2101AQ 80P,QFP BK VIDEO SIG

IC,PQ09RF21 4P 9V S/W REGULATOR -

IC,PQ05RD21 4SIP ST REGULATOR

IC,DM74LS157MX FAIRCHILD 16P SOIC

IC,K4S643232E(C)-TC/L60(70) (KM43

IC,FLI2200 SAGE 176P,QFP TRAY VID

IC,FLI2220 SAGE 160P,QFP TRAY DIG

IC,ADV7123KSTC140 ANALOG DEVICE 4

IC,JAGASM SAGE 352BALL TRAY HIGHL

IC,K4S643232E(C)-TC/L60(70) (KM43

IC,K4S643232E(C)-TC/L60(70) (KM43

IC,MSP3400G QA B6 MICRONAS 80 QFP

IC,KIA7042AF SOT-89 TP 4.2V VOLTA

IC,LA4282 12S 2CHX10W AUDIO AMP

IC,PQ05RD21 4SIP ST REGULATOR

IC,KIA7808PI 3P(TO-220IS) 1A,8V -

IC,M62320FP,I/O EXPANDER 16P SOP

IC,M62320FP,I/O EXPANDER 16P SOP

IC,M62320FP,I/O EXPANDER 16P SOP

IC,AT24C16N-10SI 8P SOIC ST EEPRO

IC,LM810 NATIONAL SEMICONDUCTOR 3

IC,74HC04D HEX INVERTER 14P,SOP T

IC,80C652 40 PLCC ST 8-BIT MICROC

IC,AT27C020 32-PIN DIP ST NP-00

IC,74HCT373D 20SOP R/TP ADDRESS L

IC,UC3854BDW 20PLCC R/TP PFC CONT

IC,BA033FP ROHM 3P-SOP,TO252-3 R/

IC,LT1764EQ-2.5 5PIN Q PACKAGE R

IC,BA033FP ROHM 3P-SOP,TO252-3 R/

IC,BA033FP ROHM 3P-SOP,TO252-3 R/

IC,LT1764EQ-2.5 5PIN Q PACKAGE R

IC,74HC32D 14SOP TP QUAD 2-INPUT

IC,SII150 100QFP BK PANEL LINK TR

IC,EPM7064STC44-100 ALTERA 44P,QF

IC,PQ05RD21 4SIP ST REGULATOR

IC,1R2113S 16SOP R/TP H/BRIDGE DR

IC,BA10339FV-E2 SSOP-B14PIN R/TP

IC

- 18 -

DIODE

Page 19

- 19 -

LOCA. NO PART NO DESCRIPTION

D803

D804

D805

D807

D1101

D8101

D8102

D8104

D8105

D8201

D8202

D8203

D8204

D8205

D8206

D8208

D8209

D8210

D8211

D8212

D8213

D8214

D8215

D8216

D8217

D8301

D8302

D8303

D8304

D8305

D8306

D8307

D8311

D8311

D8312

D8319

D8401

D8402

D8403

D8404

D8405

D8406

D8407

D8408

D8409

D8411

D8412

D8414

D8418

D8419

D8501

D8502

0DZ750009AG

0DZ240009CG

0DD120000BB

0DZRM00178A

0DD226239AA

0DZ620009BB

0DR011009AA

0DD184009AA

0DD184009AA

0DD414809ED

0DD414809ED

0DD260000BB

0DD110009DB

0DD100009AP

0DD120000BB

0DR010009AA

0DD100009AM

0DZ160009BC

0DZ180009AG

0DR010009AA

0DD100009AP

0DD100009AM

0DZ300009BB

0DZ300009BB

0DZ750009AG

0DD414809ED

0DD414809ED

0DB250600AB

0DR310000BA

0DR310000BA

0DD410009AA

0DD410009AA

0DR360000BA

0DRFJ00041A

0DD100009AP

0DD410009AA

0DD100009AP

0DD414809ED

0DD414809ED

0DR240000BA

0DZ330009BA

0DZ330009BA

0DD100009AP

0DZ120009AF

0DZ680009BB

0DZ360009BC

0DZ330009BA

0DR220000CA

0DD414809ED

0DZ120009AF

0DD100009AP

0DZ610009AA

DIODE,ZENERS MTZJ7.5B TP ROHM-K DO34 0.5W

DIODE,ZENERS MTZJ24B TP ROHM-K DO34 24V

DIODE,RECTIFIERSFML-G12S

DIODE,ZENERS UDZS TE-17 5.1B ROHM

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,ZENERS MTZJ6.2B DO34 0.5W 6

DIODE,RECTIFIER EG01AV1 NON 600V 0.5

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,1N4148 TA

DIODE,1N4148 TA

DIODE,RECTIFIERS BRIDGE D2SBA60(STK)

DIODE,RECTIFIERS RM11CV(1) TP SANKEN

DIODE,RECTIFIERS EG1ZV(1) TP SANKEN

DIODE,RECTIFIERS FML-G12S

DIODE,RECTIFIERS EG01C 1000V 0.5A 1

DIODE,RECTIFIERS EU1ZV(1)

DIODE,ZENERS MTZJ16B TP ROHM-K DO34 0.5W

DIODE,ZENERS MTZJ18B TP ROHM-K DO34 18V

DIODE,RECTIFIERS EG01C TP 1000V 0.5A 1

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,RECTIFIERS EU1ZV(1) TP

DIODE,ZENERS MTZJ30B TP ROHM-K DO34 0.5W

DIODE,ZENERS MTZJ30B TP ROHM-K DO34 0.5W

DIODE,ZENERS MTZJ7.5B TP ROHM-K DO34 0.5W

DIODE,1N4148 TA

DIODE,1N4148 TA

DIODE,RECTIFIERS RBV-2506 600V 25A

DIODE,RECTIFIERS RM3A LF-U1 BK 600V

DIODE,RECTIFIERS RM3A LF-U1 BK 600V

DIODE,RECTIFIERS SCHOTTKY,BAT 41 TP

DIODE,RECTIFIERS SCHOTTKY,BAT 41 TP

DIODE,RECTIFIERS FMB-36M - 0.62V

DIODE,RECTIFIERS YG963S6R FUJI ST FTO220(4115)

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,RECTIFIERS SCHOTTKY,BAT 41 TP

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,1N4148 TA

DIODE,1N4148 TA

DIODE,RECTIFIERS FML-24S TO220 400V 1

DIODE,ZENER HZT33(TP) HITACHI

DIODE,ZENER HZT33(TP) HITACHI

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,ZENERS MTZJ12B TP DO34 - 12V 5

DIODE,ZENERS MTZJ6.8B TP DO34 0.5W 6

DIODE,ZENERS MTZJ3.6B TP DO34 0.5W 3

DIODE,ZENER HZT33(TP) HITACHI

DIODE,RECTIFIERS FMM-22S BK TO220 200V

DIODE,1N4148 TA

DIODE,ZENERS MTZJ12B TP ROHM-K DO34 12V 5

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,ZENERS P6KE100A TP G.I 1W 100V 1UA

LOCA. NO PART NO DESCRIPTION

D8503

D8504

D8505

D8506

D8507

D8508

D8509

D8510

D8511

D8515

D8601

D8602

D8604

D8605

D8801

D8802

D8803

D8804

D8811

D8814

D8815

D8816

D8818

D8819

D8820

D8821

D8822

D8900

D8901

D8903

D8904

D8907

LD001

LD801

LD802

LD803

ZD103

ZD104

ZD105

ZD8902

ZD8906

ZD8908

Q001

Q002

Q101

Q102

Q103

Q104

Q105

Q106

0DZ610009AA

0DD100009AP

0DR240000BA

0DD100009AP

0DD100009AP

0DZ120009AF

0DR240000BA

0DZ680009BB

0DZ610009AA

0DD414809ED

0DZ620009BB

0DR011009AA

0DD184009AA

0DD184009AA

0DD100009AM

0DD100009AM

0DD414809ED

0DD100009DK

0DR290000AA

0DZ910009AJ

0DD414809ED

0DR460009AA

0DR460009AA

0DZ150009AD

0DD100009AM

0DZ120009AF

0DZ750009AG

0DD184009AA

0DD184009AA

0DD226239AA

0DD226239AA

0DD226239AA

0DL200000CA

0DL233309AC

0DL233309AC

0DL233309AC

0DR050008AA

0DR050008AA

0DR050008AA

0DZRM00178A

0DZ750009AG

0DZRM00178A

0TR103009AD

0TR103009AD

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

DIODE,ZENERS P6KE100A TP G.I 1W 100V 1UA

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,RECTIFIERS FML-24S TO220 400V 1

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,RECTIFIERS EG1ZV(1) TP

DIODE,ZENERS MTZJ12B TP ROHM-K DO34 12V 5

DIODE,RECTIFIERS FML-24S TO220 400V 1

DIODE,ZENERS MTZJ6.8B TP ROHM-K DO34 0.5W

DIODE,ZENERS P6KE100A TP G.I 1W 100V 1UA

DIODE,1N4148 TA

DIODE,ZENERS MTZJ6.2B TP ROHM-K DO34 0.5W

DIODE,RECTIFIER EG01AV1 TP SANKEN NON 600V

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,RECTIFIERS EU1ZV(1) TP SANKEN

DIODE,RECTIFIERS EU1ZV(1) TP SANKEN

DIODE,1N4148 TA

DIODE,RECTIFIERS RU1P V(1) TP SANKEN

DIODE,RECTIFIERS FMB-29L TO220 90V 8A

DIODE,ZENERS MTZJ9.1B TP ROHM-K DO34 0.5W

DIODE,1N4148 TA

DIODE,RECTIFIERS RK46 TP SANKEN DO-214AC 60V

DIODE,RECTIFIERS RK46 TP SANKEN DO-214AC 60V

DIODE,ZENERS MTZJ15B TP ROHM-K DO34 500MW

DIODE,RECTIFIERS EU1ZV(1) TP SANKEN

DIODE,ZENERS MTZJ12B TP ROHM-K DO34 12V 5

DIODE,ZENERS MTZJ7.5B TP ROHM-K DO34 0.5W

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING KDS184S CHIP 85V 300MA

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

DIODE,SWITCHING CHIP KDS226 SOT-23

LED,SAM5670(DL-2LRG) BK Y-GREEN -

LED,SAM2333 TP KWANG GREEN/RED GRE

LED,SAM2333 TP KWANG GREEN/RED GRE

LED,SAM2333 TP KWANG GREEN/RED GRE

DIODE,RECTIFIERS SD05.TC R/TP SEMTECH SOD323 5V

DIODE,RECTIFIERS SD05.TC R/TP SEMTECH SOD323 5V

DIODE,RECTIFIERS SD05.TC R/TP SEMTECH SOD323 5V

DIODE,ZENERS UDZS TE-17 5.1B ROHM R/TP SMD

DIODE,ZENERS MTZJ7.5B TP ROHM-K DO34 0.5W 7

DIODE,ZENERS UDZS TE-17 5.1B ROHM R/TP SMD

TR,KRC103M(AT) TO-92M TP KEC

TR,KRC103M(AT) TO-92M TP KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TRANSISTOR

Page 20

- 20 -

LOCA. NO PART NO DESCRIPTION

Q107

Q108

Q109

Q110

Q111

Q112

Q113

Q114

Q115

Q116

Q121

Q250

Q251

Q252

Q301

Q302

Q303

Q304

Q404

Q405

Q406

Q601

Q602

Q603

Q801

Q802

Q803

Q804

Q806

Q808

Q7105

Q7107

Q8101

Q8102

Q8104

Q8105

Q8106

Q8107

Q8108

Q8201

Q8203

Q8204

Q8205

Q8206

Q8207

Q8208

Q8210

Q8303

Q8304

Q8401

Q8402

Q8403

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR104009AF

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR150400BA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR176608AA

0TR387500AA

0TR118008AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR102009AG

0TR150400BA

0TR387500AA

0TR319809AA

0TR102009AB

0TR319809AA

0TR102009AB

0TR319809AA

0TR322709AA

0TR322709AA

0TR319809AA

0TFIR10001A

0TFIR10001A

0TF283700AA

0TF283700AA

0TR322709AA

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP KRC104S SOT-23 TP KEC - -

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,2SD1766Q R/TP ROHM KOREA SMD F

TR,CHIP 2SC3875S(ALY) KEC

TR,2SB1188Q R/TP ROHM KOREA SMD F

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP KRC102S SOT-23 TP KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,KTC3198 TP KEC - - -Y (KTC1815

TR,KRC102M,TP(KRC1202),KEC

TR,KTC3198 TP KEC - - -Y (KTC1815

TR,KRC102M,TP(KRC1202),KEC

TR,KTC3198 TP KEC - - -Y (KTC1815

TR,KTC3227-Y,TP(KTC1627A),KEC

TR,KTC3227-Y,TP(KTC1627A),KEC

TR,KTC3198 TP KEC - - -Y (KTC1815

TR,FETS INTERNATIONAL RECTIFIER IRFPS3

TR,FETS INTERNATIONAL RECTIFIER IRFPS3

TR,FETS 2SK2837 BK TOSHIBA 500V 20A TO

TR,FETS 2SK2837 BK TOSHIBA 500V 20A TO

TR,KTC3227-Y,TP(KTC1627A),KEC

LOCA. NO PART NO DESCRIPTION

Q8501

Q8502

Q8503

Q8505

Q8601

Q8602

Q8604

Q8605

Q8606

Q8607

Q8608

Q8801

Q8802

Q8803

Q8900

Q8901

Q8902

Q8903

Q8904

Q8905

Q8906

Q8907

Q8908

Q8909

C1

C001

C002

C2

C3

C5

C101

C102

C103

C104

C105

C109

C109

C110

C112

C112

C114

C115

C117

C118

C118

C120

C121

C123

C124

C125

0TF283700AA

0TF283700AA

0TF283700AA

0TR320709AA

0TR150400BA

0TR150400BA

0TR150400BA

0TR387500AA

0TR102009AG

0TR150400BA

0TR387500AA

0TR385200AA

0TR319809AA

0TR319809AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR102009AG

0TR102009AG

0TR387500AA

0TR150400BA

0TR102009AG

0CE107DD618

0CN1040K949

0CE476DD618

0CK104DK56A

0CE477DF618

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE107SF6DC

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE106SF6DC

TR,FETS 2SK2837 BK TOSHIBA 500V 20A TO

TR,FETS 2SK2837 BK TOSHIBA 500V 20A TO

TR,FETS 2SK2837 BK TOSHIBA 500V 20A TO

TR,KTC3207,TP(KTC2482),KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP KRC102S SOT-23 TP KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,2SC3852A SANKEN

TR,KTC3198 TP KEC - - -Y (KTC1815

TR,KTC3198 TP KEC - - -Y (KTC1815

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP KRC102S SOT-23 TP KEC

TR,CHIP KRC102S SOT-23 TP KEC

TR,CHIP 2SC3875S(ALY) KEC

TR,CHIP 2SA1504S(ASY) KEC

TR,CHIP KRC102S SOT-23 TP KEC

100UF STD 10V M FL TP5

0.1M 50V Z F TA52

47UF STD 10V 20% FL TP 5

0.1UF 2012 50V 10% R/TP X7R

470UF STD 16V 20% FL TP 5

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

CAPACITOR

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 21

- 21 -

LOCA. NO PART NO DESCRIPTION

C128

C129

C130

C135

C135

C136

C139

C159

C160

C161

C162

C163

C164

C166

C168

C170

C171

C173

C174

C202

C203

C205

C212

C214

C222

C224

C225

C227

C230

C232

C233

C242

C243

C244

C245

C246

C247

C255

C256

C257

C258

C267

C274

C275

C278

C281

C282

C283

C284

C285

C286

C288

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE476SF6DC

0CE107SF6DC

0CK104DK56A

0CE107SF6DC

0CE107SF6DC

0CK104DK56A

0CE106SF6DC

0CE107SF6DC

0CK224DF56A

0CK224DF56A

0CE106SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK224DF56A

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE106SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE105SK6DC

0CE107SF6DC

0CE107SF6DC

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE106SF6DC

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

220000PF 2012 16V 10% R/TP X7R

220000PF 2012 16V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

220000PF 2012 16V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

1UF MVG 50V M SMD R/TP

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

LOCA. NO PART NO DESCRIPTION

C290

C292

C293

C297

C299

C300

C310

C320

C373

C402

C404

C405

C407

C408

C410

C411

C413

C414

C418

C419

C420

C421

C422

C423

C424

C425

C426

C427

C428

C429

C430

C431

C432

C433

C434

C438

C439

C441

C442

C443

C444

C447

C448

C449

C450

C453

C454

C455

C456

C457

C458

C459

0CE106SF6DC

0CK104DK56A

0CE476SF6DC

0CE107SF6DC

0CK104DK56A

0CE107SF6DC

0CE476SF6DC

0CE476SF6DC

0CE1051K636

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE476SF6DC

0CE476SF6DC

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

1UF SM,SA 50V 20% FM5 BP(D) TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 22

- 22 -

LOCA. NO PART NO DESCRIPTION

C460

C461

C462

C463

C464

C465

C466

C467

C468

C469

C470

C471

C476

C477

C479

C487

C503

C506

C509

C512

C515

C516

C518

C519

C521

C522

C524

C525

C526

C527

C528

C529

C530

C531

C532

C533

C534

C535

C536

C537

C538

C539

C540

C541

C542

C543

C544

C545

C546

C547

C548

C549

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE106SF6DC

0CE106SF6DC

0CK104DK56A

0CE476SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CE106SF6DC

0CK104DK56A

0CE106SF6DC

0CK104DK56A

0CE106SF6DC

0CK104DK56A

0CE106SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

LOCA. NO PART NO DESCRIPTION

C550

C551

C554

C601

C602

C604

C609

C610

C611

C612

C614

C616

C625

C626

C627

C630

C631

C640

C641

C643

C644

C645

C647

C648

C651

C652

C653

C653

C654

C654

C655

C655

C656

C656

C658

C659

C659

C660

C660

C661

C662

C699

C703

C707

C709

C711

C715

C716

C717

C718

C720

C721

0CK104DK56A

0CK104DK56A

0CE106SF6DC

0CE476SF6DC

0CE476SF6DC

0CE106SF6DC

0CE107SF6DC

0CE106SF6DC

0CE106SF6DC

0CE335SK6DC

0CE106SF6DC

0CE106SF6DC

0CK104DK56A

0CE107SF6DC

0CE107SF6DC

0CE477DK618

0CE477DK618

0CE474SK6DC

0CE474SK6DC

0CE474SK6DC

0CE474SK6DC

0CK104DK56A

0CE107SF6DC

0CK104DK56A

0CE227VF6DC

0CE105SK6DC

0CE107DH618

0CE477DK618

0CE106SF6DC

0CE477DK618

0CE107DH618

0CE477DK618

0CE107DH618

0CE477DK618

0CQ6821N509

0CE106SF6DC

181-120K

0CQ6821N509

181-120K

0CQ1041N509

0CQ1041N509

0CE227VF6DC

0CK104DK56A

0CK104DK56A

0CE476SF6DC

0CE106SF6DC

0CE106SF6DC

0CK104DK56A

0CE106SF6DC

0CE106SF6DC

0CE105SK6DC

0CK104DK56A

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

100UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

3.3UF MVG 50V 20% SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

100UF MVG 16V M SMD R/TP

470UF STD 50V 20% FL TP 5

470UF STD 50V 20% FL TP 5

0.47UF MVG 50V M SMD R/TP

0.47UF MVG 50V M SMD R/TP

0.47UF MVG 50V M SMD R/TP

0.47UF MVG 50V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

220UF MV 16V 20% R/TP(SMD) SMD

1UF MVG 50V M SMD R/TP

100UF STD 25V M FL TP5

470UF STD 50V 20% FL TP 5

10UF MVG 16V 20% R/TP(SMD) SMD

470UF STD 50V 20% FL TP 5

100UF STD 25V M FL TP5

470UF STD 50V 20% FL TP 5

100UF STD 25V M FL TP5

470UF STD 50V 20% FL TP 5

0.0068U 100V K POLY TP

10UF MVG 16V 20% R/TP(SMD) SMD

2200PF 4KV M E FMTW LEAD 4.5

0.0068U 100V K POLY TP

2200PF 4KV M E FMTW LEAD 4.5

0.1U 100V K POLY TP

0.1U 100V K POLY TP

220UF MV 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

1UF MVG 50V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 23

- 23 -

LOCA. NO PART NO DESCRIPTION

C722

C723

C726

C801

C801

C802

C804

C804

C806

C806

C809

C810

C810

C811

C811

C812

C813

C814

C815

C816

C818

C818

C819

C820

C820

C821

C822

C824

C825

C826

C828

C829

C830

C832

C834

C843

C844

C847

C849

C850

C851

C853

C855

C856

C857

C859

C861

C863

C864

C866

C868

C869

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE106WH6DC

0CK104DK56A

0CE227VF6DC

0CE105WK6DC

0CK104DK56A

0CE227VF6DC

0CQ2221N509

0CE105WK6DC

0CE227VF6DC

0CK104DK56A

0CE106WH6DC

0CK104DK56A

0CK104DK56A

0CE106WH6DC

0CE476SF6DC

0CE476SF6DC

0CK104DK56A

0CE106WH6DC

0CE227VF6DC

0CK104DK56A

0CE105WK6DC

0CK104DK56A

0CE107SF6DC

0CK104DK56A

0CE227VF6DC

0CE106SF6DC

0CE476SF6DC

0CE106SF6DC

0CE106SF6DC

0CK104DK56A

0CE476SF6DC

0CE106SF6DC

0CE227VF6DC

0CE227VF6DC

0CE227VF6DC

0CE476SF6DC

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CE476SF6DC

0CE476SF6DC

0CK104DK56A

0CK104DK56A

0CE106SF6DC

0CE477BF618

0CE477BF618

0CK104DK56A

0CK104DK56A

0CE108DF618

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

220UF MV 16V 20% R/TP(SMD) SMD

1UF MVK 50V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

220UF MV 16V 20% R/TP(SMD) SMD

0.0022U 100V K POLY TP

1UF MVK 50V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

1UF MVK 50V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

220UF MV 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

220UF MV 16V 20% R/TP(SMD) SMD

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

47UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

470UF KME 16V M FL TP5

470UF KME 16V M FL TP5

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

1000UF STD 16V M FL TP5

LOCA. NO PART NO DESCRIPTION

C870

C871

C873

C874

C876

C877

C903

C906

C909

C922

C924

C925

C926

C1101

C1103

C1104

C1105

C1106

C1107

C1108

C1110

C1111

C1113

C1720

C1721

C7116

C8101

C8102

C8105

C8106

C8107

C8110

C8111

C8202

C8203

C8204

C8205

C8206

C8207

C8209

C8210

C8211

C8212

C8213

C8214

C8215

C8216

C8217

C8218

C8219

C8220

C8221

0CE477BF618

0CE107SF6DC

0CK104DK56A

0CE227VF6DC

0CE106SF6DC

0CE106SF6DC

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CK104DK56A

0CE106SF6DC

0CK104DK56A

0CK104DK56A

0CE107SF6DC

0CK104DK56A

0CK104DK56A

0CE107SF6DC

0CK104DK56A

0CE476SF6DC

0CE106SF6DC

0CK104DK56A

0CE475WJ6DC

0CE106WH6DC

0CK104DK56A

0CE106WH6DC

0CE106WH6DC

0CK104DK56A

0CE106WH6DC

0CK104DK56A

0CQ1031N509

0CE105BK618

0CE226BV611

0CE477BJ618

181-010K

0CE226BV611

181-010K

0CE477BH618

0CK1040K945

0CE108BF618

181-091P

181-091P

181-033E

0CE108BF618

181-091P

0CE474QV618

0CE474QV618

0CE107BJ618

0CK1040K945

470UF KME 16V M FL TP5

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

220UF MV 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

0.1UF 2012 50V 10% R/TP X7R

100UF MVG 16V M SMD R/TP

0.1UF 2012 50V 10% R/TP X7R

47UF MVG 16V M SMD R/TP

10UF MVG 16V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

4.7UF MVK 35V 20% R/TP(SMD) SM

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

0.01U 100V K POLY TP

1UF KME 50V M FL TP5

22UF KME TYPE 450V M FL BK7.5

470UF KME TYPE 35V 20% FL TP 5

PP 0.01UF 630V 5% FM 7.5MM

22UF KME TYPE 450V M FL BK7.5

PP 0.01UF 630V 5% FM 7.5MM

470UF KME TYPE 25V 20% FL TP 5

0.1UF 50V Z F TR

1000UF KME 16V M FL TP5

SL 270PF 1KV 10%,-10% R/TP TP5

SL 270PF 1KV 10%,-10% R/TP TP5

CK 2200PF 1KV 10% TR 7.5MM

1000UF KME 16V M FL TP5

SL 270PF 1KV 10%,-10% R/TP TP5

0.47UF SMS,SG(HR) 450V 20% TP

0.47UF SMS,SG(HR) 450V 20% TP

100UF KME 35V M FL TP5

0.1UF 50V Z F TR

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

Page 24

- 24 -

LOCA. NO PART NO DESCRIPTION

C8222

C8223

C8225

C8301

C8302

C8303

C8304

C8305

C8306

C8307

C8308

C8309

C8311

C8312

C8313

C8314

C8315

C8316

C8317

C8318

C8319

C8320

C8321

C8322

C8327

C8328

C8329

C8330

C8331

C8332

C8333

C8336

C8401

C8402

C8404

C8407

C8409

C8410

C8411

C8412

C8413

C8414

C8416

C8504

C8506

C8507

C8508

C8510

C8511

C8512

C8513

C8514

0CE227BH618

0CE476BK618

0CQ1041N509

0CQZVBK002D

0CQZVBK002D

0CQZVBK002D

181-120K

181-120K

0CQZVBK002D

0CB8241Y474

0CB8241Y474

181-035N

0CE337RV6A0

0CE337RV6A0

181-035N

0CE337RV6A0

181-091D

181-033E

181-091D

181-091G

181-091G

0CE477BH618

0CQZVBK002D

0CQZVBK002B

181-033E

181-033E

181-033E

181-033E

181-091G

181-120K

181-120K

0CF1050W470

181-091R

0CC47001505

0CC47001505

0CBZVBK001A

0CC47001505

0CQ2231N509

0CE337RV6A0

0CE227BP650

0CE227BP650

0CE227BP650

0CQ1041N509

181-091R

0CBZVBK001B

181-033T

0CBZVBK001B

0CC47001505

0CE687RP6A0

0CC47001505

0CC47001505

0CC47001505

220UF KME 25V M FL TP5

47UF KME 50V M FL TP5

0.1U 100V K POLY TP

A.C 275V 0.47UF K (S=22.5)

A.C 275V 0.47UF K (S=22.5)

A.C 275V 0.47UF K (S=22.5)

2200PF 4KV M E FMTW LEAD 4.5

2200PF 4KV M E FMTW LEAD 4.5

A.C 275V 0.47UF K (S=22.5)

0.82UF D 630V J M/PP NI FM20

0.82UF D 630V J M/PP NI FM20

DE1010 B KD 471M

330UF KMH 450V M VNSN BULK

330UF KMH 450V M VNSN BULK

DE1010 B KD 471M

330UF KMH 450V M VNSN BULK

DEHR33A102KN2A 1000PF 1KV 10%,

CK 2200PF 1KV 10% TR 7.5MM

DEHR33A102KN2A 1000PF 1KV 10%,

DEHR33D471KN3A 470PF 2KV 10%,-

DEHR33D471KN3A 470PF 2KV 10%,-

470UF KME TYPE 25V 20% FL TP 5

A.C 275V 0.47UF K (S=22.5)

A.C 275V 0.15UF K (S=22.5)

CK 2200PF 1KV 10% TR 7.5MM

CK 2200PF 1KV 10% TR 7.5MM

CK 2200PF 1KV 10% TR 7.5MM

CK 2200PF 1KV 10% TR 7.5MM

DEHR33D471KN3A 470PF 2KV 10%,-

2200PF 4KV M E FMTW LEAD 4.5

2200PF 4KV M E FMTW LEAD 4.5

1UF 0 500V 5% BULK M/PP NI

R 1000PF 1KV 10%,-10% R/TP TP5

47PF 1KV K SL TR

47PF 1KV K SL TR

M/PP NI 0.039UF 800V 5% FM 20M

47PF 1KV K SL TR

0.022U 100V K POLY TP

330UF KMH 450V M VNSN BULK

220UF KME TYPE 160V 20% FM7.5

220UF KME TYPE 160V 20% FM7.5

220UF KME TYPE 160V 20% FM7.5

0.1U 100V K POLY TP

R 1000PF 1KV 10%,-10% R/TP TP5

0.056UF 800V J M/PP NI FM20

2KV B 222K TP7.5

0.056UF 800V J M/PP NI FM20

47PF 1KV K SL TR

680UF KMH 160V M VNSN BULK

47PF 1KV K SL TR

47PF 1KV K SL TR

47PF 1KV K SL TR

LOCA. NO PART NO DESCRIPTION

C8515

C8517

C8518

C8519

C8520

C8521

C8522

C8523

C8524

C8525

C8601

C8602

C8605

C8606

C8607

C8610

C8611

C8802

C8803

C8804

C8805

C8807

C8808

C8811

C8812

C8813

C8815

C8817

C8818

C8819

C8820

C8821

C8822

C8824

C8825

C8834

C8835

C8836

C8839

C8841

C8900

C8901

C8903

C8905

C8907

L001

L801

L804

L808

L813

0CC47001505

0CE687RP6A0

0CE827RR6A0

0CE827RR6A0

0CE827RR6A0

0CQ1031N509

181-007H

181-120K

0CE476BK618

0CQ4731N509

0CE106WH6DC

0CK104DK56A

0CE106WH6DC

0CE106WH6DC

0CK104DK56A

0CE106WH6DC

0CK104DK56A

0CE227BK618

0CK8210K515

181-011B

0CK8210K515

181-010P

181-033T

181-007T

0CE478BH650

0CE478BH650

0CE478BH650

0CE478BH650

0CE475BK618

0CE228EJ61A

0CQ1041N509

0CQ1041N509

0CE108BJ618

0CE108BK61A

0CE108BK61A

0CE228BF618

0CE228BF618

0CE228BF618

0CE228BF618

0CQ1041N509

0CE107BH618

0CE226BK618

0CE106DK618

0CE107BH618

0CE336DH618

0LA0102K119

6140VB0004B

6140VB0004B

6140VB0004B

6140VB0004B

47PF 1KV K SL TR

680UF KMH 160V M VNSN BULK

820UF KMH 250V M VNSN BULK

820UF KMH 250V M VNSN BULK

820UF KMH 250V M VNSN BULK

0.01U 100V K POLY TP

MPE ECQ-V1H474JL3(TR), 50V 0.4

2200PF 4KV M E FMTW LEAD 4.5

47UF KME 50V M FL TP5

0.047U 100V K POLY TP

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

10UF MVK 25V 20% R/TP(SMD) SMD

0.1UF 2012 50V 10% R/TP X7R

220UF KME 50V M FL TP5

820P 50V K B TS

0.001UF D 1.6KV J M/PP NI FM20

820P 50V K B TS

PP 630V 0.068UF J

2KV B 222K TP7.5

MPE ECQ-V1H105JL3(TR), 50V 1.0

4700UF KME 25V M FM7.5 BULK

4700UF KME 25V M FM7.5 BULK

4700UF KME 25V M FM7.5 BULK

4700UF KME 25V M FM7.5 BULK

4.7UF KME TYPE 50V 20% FL TP 5

2200UF KMG 35V M FL TP 7.5

0.1U 100V K POLY TP

0.1U 100V K POLY TP

1000UF KME 35V M FL TP5

1000UF KME 50V M FL TP7.5

1000UF KME 50V M FL TP7.5

2200UF KME 16V M FL TP5

2200UF KME 16V M FL TP5

2200UF KME 16V M FL TP5

2200UF KME 16V M FL TP5

0.1U 100V K POLY TP

100UF KME 25V M FL TP5

22UF KME 50V M FL TP5

10UF STD 50V M FL TP5

100UF KME 25V M FL TP5

33UF STD 25V 20% FL TP 5

INDUCTOR,10UH K 2.3*3.4 TP

COIL,CHOKE 26UH 1UEWPHY 22.5TURN YL-9N

COIL,CHOKE 26UH 1UEWPHY 22.5TURN YL-9N

COIL,CHOKE 26UH 1UEWPHY 22.5TURN YL-9N

COIL,CHOKE 26UH 1UEWPHY 22.5TURN YL-9N

For Capacitor & Resistors,

the charactors at 2nd and 3rd

digit in the P/No. means as

follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

COIL & TRANSFORMER

Page 25

- 25 -

LOCA. NO PART NO DESCRIPTION

L816

L8810

L8812

L8814

L8815

L8816

L8819

L8820

T8201

T8202

T8301

T8302

T8401

T8501

T8502

T8503

T8801

JAC201

P101

P102

P103

P201B

P001B

P003A

P101

P102

P801

P803A

P803B

P804B

P804A

P805A

P806A

P807A

P808B

P808A

P830A

P840A

P1001

P1003B

P1807

P8011

P8012

P8013

P8601A

P8602A

P8900A

150-C02F

150-C04J

150-C04J

150-C02F

150-C02F

6170VZ0005B

6170VZ0005B

150-C02F

6170VS0002A

6170VS0002A

6170VG0002A

6170VG0002A

6170VMCA21E

151-A10K

151-A10K

6170VMCA37A

151-A10H

6612VLH002A

380-389N

380-389P

380-363J

6612VJH018A

387-B04H

387-A10L

6630VGA001C

6630GL00181

6602V00012A

6602V39001F

6602V39001F

366-921D

387-A05A

387-A07A

387-A05F

387-A15A

366-921C

387-A04A

6602V39002B

6602V39002B

6630VGA004B

387-A04K

387-A03K

6602V39001B

6602V39001H

366-921G

6602V25007A

6602V25007B

6602V25007C

COIL,CHOKE 82UH PHY TURN

COIL,CHOKE 3.8UH 0.65PHY 8.5TURN 10X10

COIL,CHOKE 3.8UH 0.65PHY 8.5TURN 10X10

COIL,CHOKE 82UH PHY TURN

COIL,CHOKE 82UH PHY TURN

TRANSFORMER,H-DRIVER IRON-15 150UH SI-8150S

TRANSFORMER,H-DRIVER IRON-15 150UH SI-8150S

COIL,CHOKE 82UH PHY TURN

TRANSFORMER,STAND-BY EE1927 1300UH 12V/5V INOUT

TRANSFORMER,STAND-BY EE1927 1300UH 12V/5V INOUT

TRANSFORMER,POWER CH400125 1400UH 1.3PHY,64TURNS

TRANSFORMER,POWER CH400125 1400UH 1.3PHY,64TURNS

TRANSFORMER,SMPS EER4244 500UH UC3863DW

TRANSFORMER,SMPS EER4445(HORIZONTAL) 270UH 11TU

TRANSFORMER,SMPS EER4445(HORIZONTAL) 270UH 11TU

TRANSFORMER,SMPS PQ3535 40UH UC3863DW LEAKAGE

TRANSFORMER,SMPS EER4445(HORIZONTAL) 550UH

JACK,RCA SP026B 4P RD/BK/BK/R

JACK,RCA S-456S-N A/V 3P RD-W

JACK,RCA S-456S-P A/V 3P GR-B

JACK,DIN PJ6046F H=8.0 W/O S/W

JACK,RCA PJ6058C-A A/V 2P MON

CONNECTOR ASSY,4P SHIELD WIRE(L=450)

CONNECTOR ASSY,10P (L=700)

CONNECTOR,68114-1521 MOLEX 15PIN 2.29MM

CONNECTOR,WSB036A1A3B1B MTS-KOREA 36P 2.

CONNECTOR,ETC 2P 641964-1 AMP 6.35MM

CONNECTOR,3.96MM 8P GP390-*P LG PDP

CONNECTOR,3.96MM 8P GP390-*P LG PDP

CONNECTOR,2.5MM 5P GIL-G LG CABLE .

CONNECTOR ASSY,5P (L=100)

CONNECTOR ASSY,7P (L=100)

CONNECTOR ASSY,5P (L=350)

CONNECTOR ASSY,12P(L=100)

CONNECTOR,2.5MM 4P GIL-G

CONNECTOR ASSY,4P (L=100)

CONNECTOR,YW396 YEONHO 4P 3.96MM

CONNECTOR,YW396 YEONHO 4P 3.96MM

CONNECTOR,69107-0921 MOLEX 9P 2.77MM FOR

CONNECTOR ASSY,4P (L=600)

CONNECTOR ASSY,3P (L=600)

CONNECTOR,3.96MM 4P GP390-*P LG PDP

CONNECTOR,3.96MM 10P GP390-*P LG PDP

CONNECTOR,2.5MM 8P GIL-G

CONNECTOR,2.5MM 6P 35772-0621

CONNECTOR,2.5MM 8P 35772-0821

CONNECTOR,2.5MM 12P 35772-1221

LOCA. NO PART NO DESCRIPTION

AR201

AR202

AR203

AR204

AR401

AR402

AR403

AR404

AR405

AR406

AR407

AR408

AR409

AR410

AR411

AR412

AR413

AR414

AR415

AR416

AR417

AR418

AR419

AR420

AR421

AR422

AR423

AR424

AR425

AR426

AR427

AR428

AR501

AR502

AR503

AR504

AR505

AR506

AR507

AR508

AR509

AR510

AR511

AR512

AR513

AR514

AR515

AR516

AR517

AR518

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A

0RRZVTA001A