LG MZ-42PZ14, MZ-42PZ12, MT-42PZ14, MT-42PZ14B, MZ-42PZ14B Service Manual

...

PLASMA MONITOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : MP-00MC

MODEL : MT/MZ-42PZ12/B

MODEL : MT/MZ-42PZ14/B

MODEL : MT/MZ-42PZ24/B

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

March,2002

Printed in KoreaP/NO : 3828VD0113P

- 2 -

CONTENTS

Contents ................................................................................................................. 2

Safety Precautions ............................................................................................3

Specifications ..................................................................................................... 4

Control Descriptions ........................................................................................ 5

Adjustment Instructions ............................................................................... 8

Block Diagram .................................................................................................... 12

Exploded View ............................................................................................ 14,16

Exploded View Parts List.........................................................................15,17

Replacement Parts List ................................................................................ 18

SVC. Sheet ................................................................................................................

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

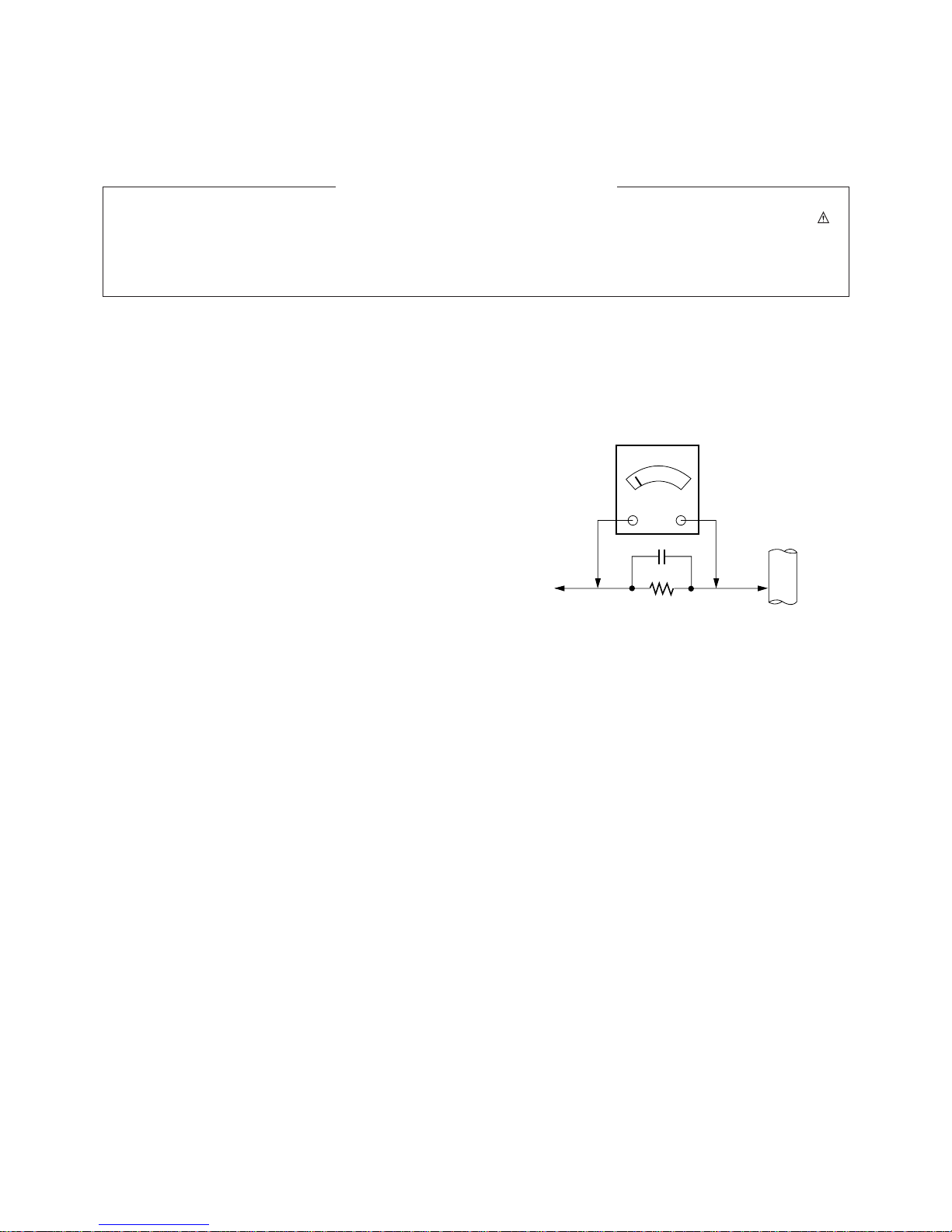

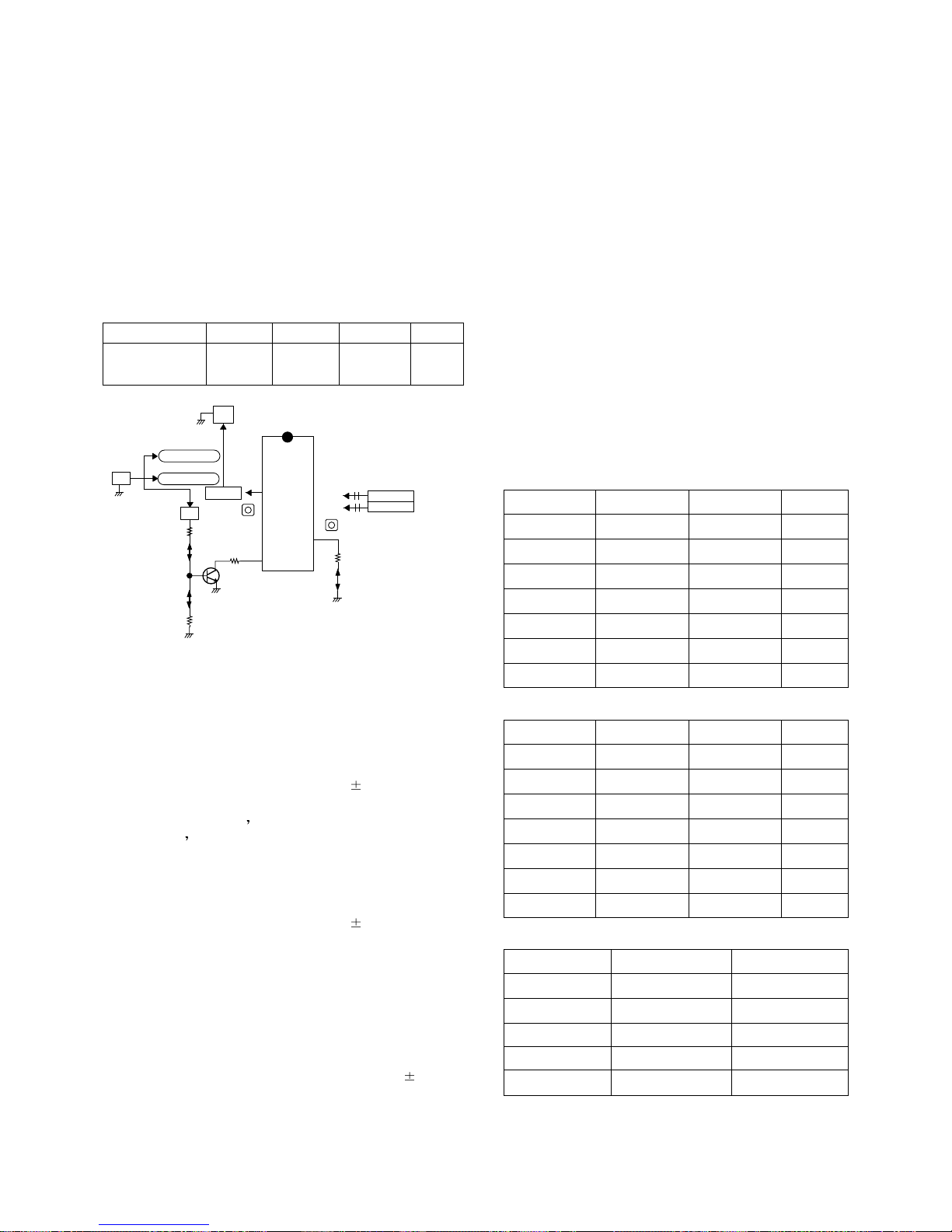

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

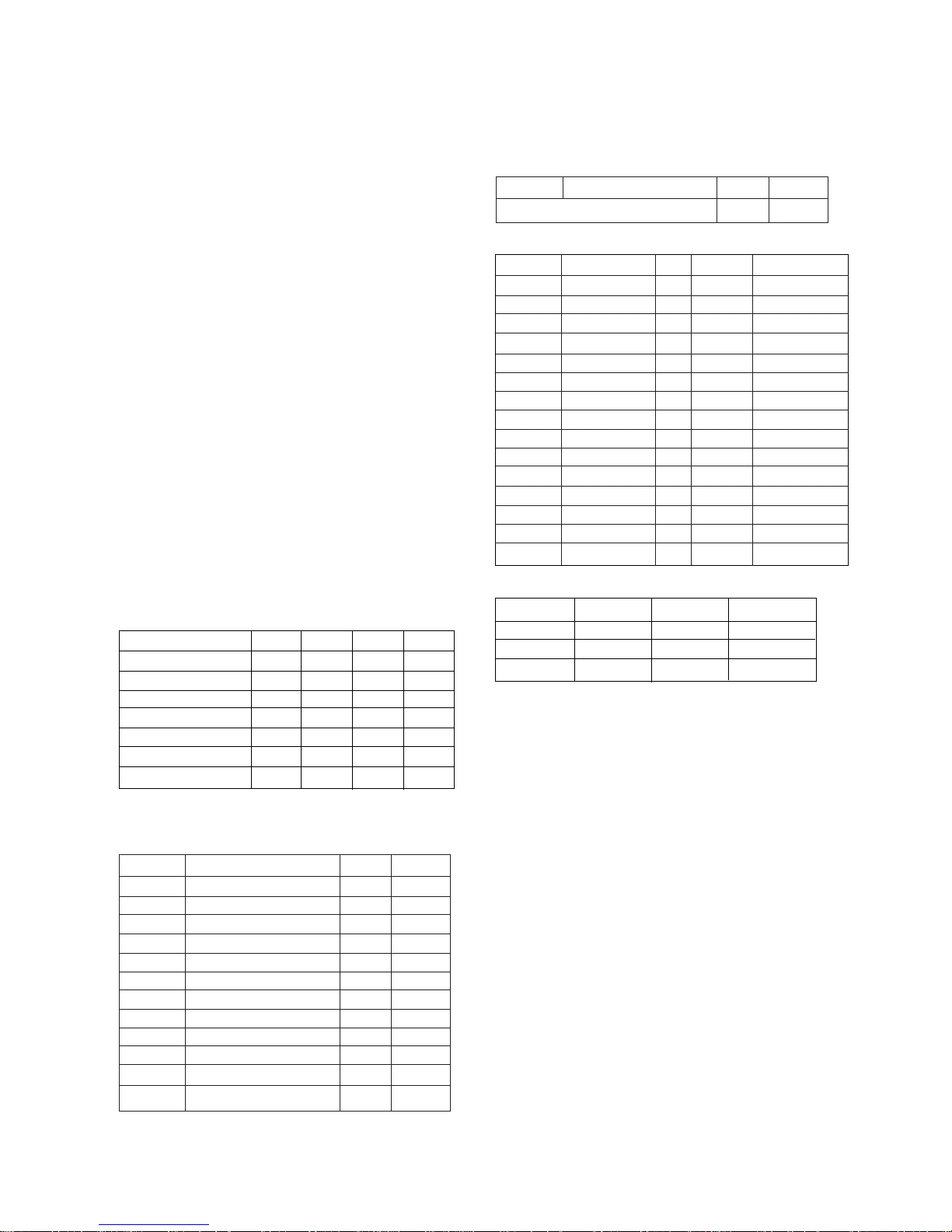

SPECIFICATIONS

Note : Specification and others are subject to change without notice for improvement.

O MONITOR

O Video receiving system:

PAL/SECAM/NTSC

VGA

SVGA

O Input Voltage : AC 200~240V, 50/60Hz(MZ-)

O Input Voltage : AC 110~240V, 50/60Hz(MT-)

O Power consumption : Max 400W

Stand-By : 5W

O PDP Module : PDP42WVSN3

O Speaker Impedance : 8 ohm

O Sound output : 10W max

O Feature : AV Input (Bottom)

Component Input (Bottom)

RGB Input (Bottom,D-Sub 15pin)

External SPK Out (Bottom,SPK Jack)

O Funtion : PSM /SSM/Child Lock

O External Interface

AV/COMPONENT Output

RGB/HV Control Signal In/Out Spec(

D-sub 25 pin Cable:PDP TV only)

O SET TOP BOX

O Video receiving system:

PAL-BG/DK/I

SECAM LL’

O Input Voltage : AC 110~240V, 50/60Hz

O Tuning System : FVS 100 Program

O Power consumption : Max 35W

Stand-By : 2W

O Available Channel : VHF : E2~E12(L/L’:B,C,D)

UHF : E21~E69

CATV : S1~S20(HYPER:S21~S41)

O Feature : AV In/out(Full Scart) : AV1(With RGB in/TV out)

AV In/out(Half Scart) : AV2(Monitor out)

V(Rear,CVBS)

S-Input

Y,Pb,Pr Input : Component(Rear,480I,480P)

RGB Input : RGB-PC(Rear,D-Sub 15pin)

Audio-Input : Component/RGB- PC

RGB out : RGB-PC(Rear,D-Sub 15pin)

RGB out/Control :

PDP MNT connection:RGB,Control

Woofer out :

Woofer Speaker

INPUT 25pin SPEC

Component Mode(Y,CB/PB,CR/PR)

- 4 -

ITEM

AV Video in

AV SYNC in

AV Burst in

AV Video in,L/R

AV Audio in,L/R

Component Video in

RGB/HV in

MIN

0.85

0.24

0.14

0.47

0.47

0.6

0.6

TYP

1.00

0.29

0.28

0.63

0.63

0.7

0.7

MAX

1.15

0.32

0.35

0.79

0.79

0.8

0.8

UNIT

Vpp

Vppz

Vpp

V

V

Vpp

Vpp

Resolution

640*480

640*480

704*480

H-Freq(Khz)

15.73

15.63

31.47

V-Freq(hz)

60

50

59.94

Proposed

SDTV,DVD 480I

SDTV,DVD 480I

SDTV 480P

PIn Name

R

G

B

GND

GND

GND

GND

GND

GND

GND

GND

GND

H Sync

V Sync

GND

Spec.

0.7Vpp

¡ 0.05

0.7Vpp¡ 0.05

0.7Vpp¡ 0.05

NC

Case Comon GND

R-return(shield)

G-return(shield)

B-return(shield)

NC

Case Comon GND

Case Comon GND

NC

4.0Vpp¡ 0.5

3.0Vpp¡ 0.5

NC

Pin

GND

STB-SDA

GND

STB-SCL

GND

GND

VSC-DET

GND

STB-DET

Spec.

Case Comon GND

SDA:3.0~4.5Vpp

Case Comon GND

SCL:3.0~4.5Vpp

NC

NC

NC

NC

High(STB)/Low

No.

1

2

3

4

5

6

7

8

9

Output 15-9 pin Spec

PIn Name

R

G

B

GND

H.Sync

V.Sync

STB-DET

STB-SDA

STB-SCL

HDSTBDET

VSCPWRON

PWR-KEY

Spec.

0.7Vpp¡ 0.05

0.7Vpp¡ 0.05

0.7Vpp¡ 0.05

Case Common

4.0Vpp¡ 0.5

3.0Vpp¡ 0.5

High(STB)/Low

3.0~4.5Vpp

3.0~4.5Vpp

NC

NC

NC

Pin

VSC-Det

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

No.

13

14

15

16

17

18

19

20

21

22

23

24

PIn Name

Spec.

Pin

GND

No.

25

Length:3m(-20,+50Cm,Audio(R/L):150

±10mm

- 5 -

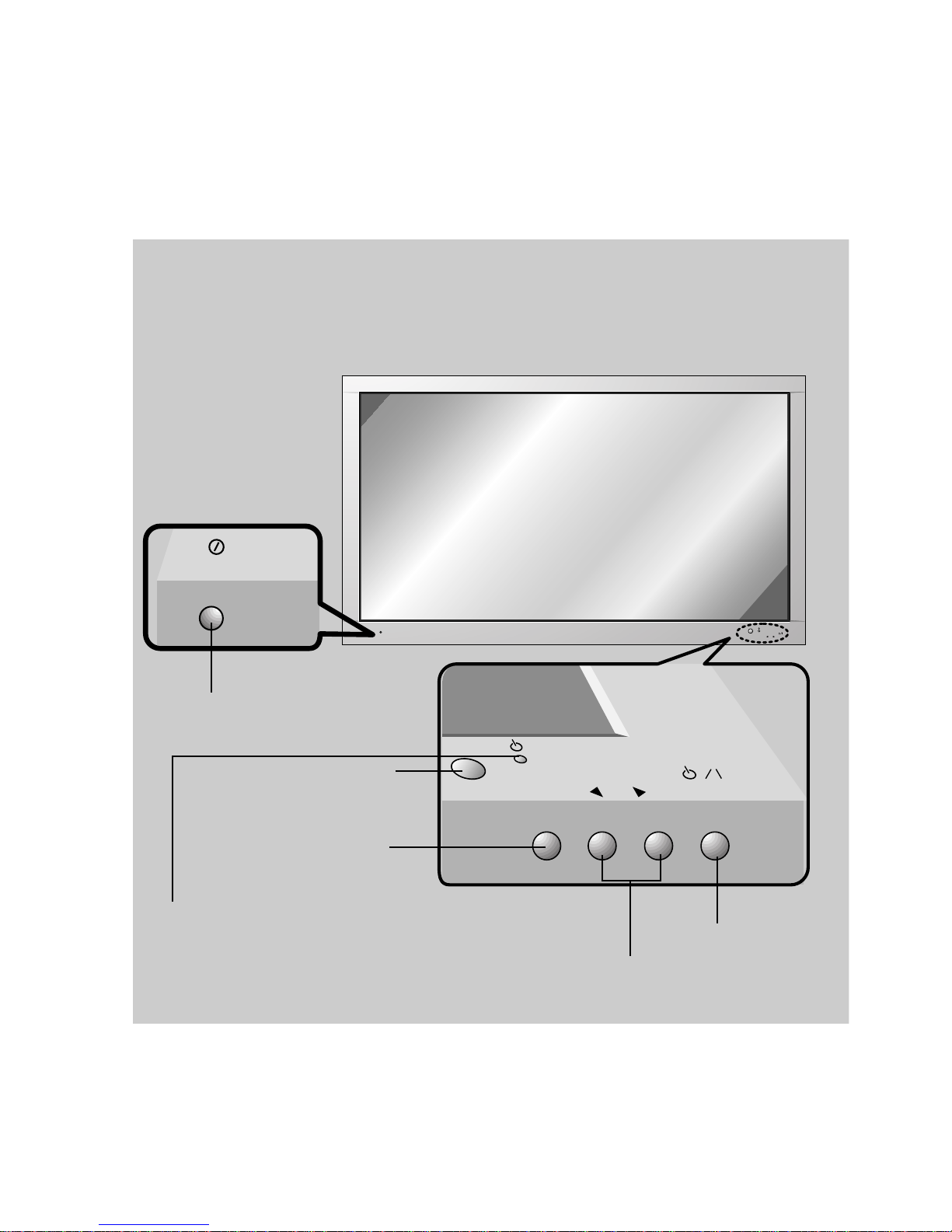

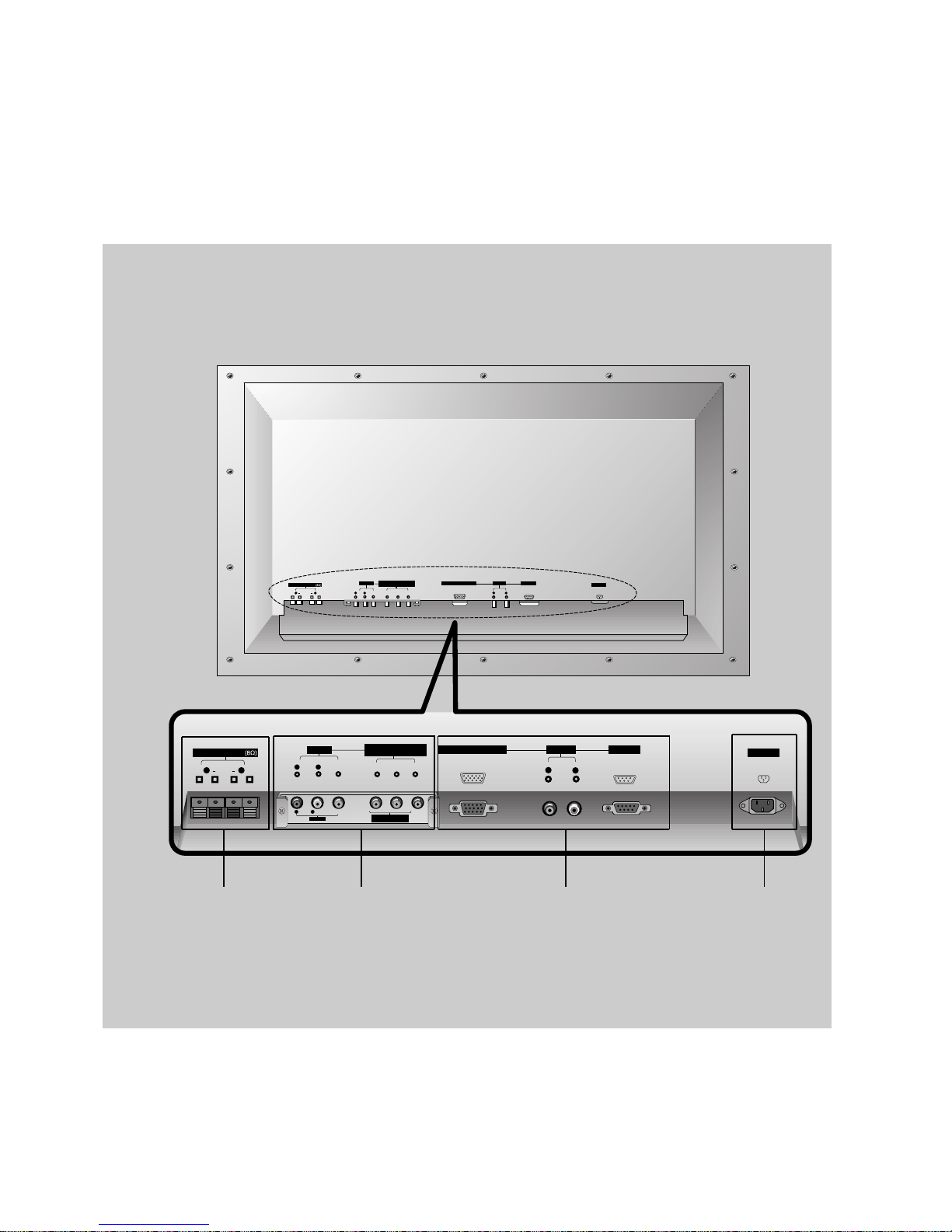

CONTROLS DESCRIPTION

ON/OFF

INPUT VOLUME

SELECT

ON/OFF

VOLUME

INPUT

SELECT

<Front Panel>

MAIN POWER BUTTON

INPUT SELECT BUTTON

REMOTE CONTROL SENSOR

POWER/STANDBY INDICATOR

Illuminates red in standby

Illuminates green when the Monitor is switched on

POWER BUTTON

VOLUME (FF,GG) BUTTON

- 6 -

AC INPUT

RGB INPUT(VGA/SVGA/XGA)

(+) ( ) (+)( )

EXTERNAL SPEAKER

R L

R

AUDIO INPUT

CONTROL

L

(+) ( ) (+)( )

AC INPUT

EXTERNAL SPEAKER

R L R

AUDIO INPUT

CONTROL

L

RGB INPUT(VGA/SVGA/XGA)

P

B R

Y P

AV INPUT

R L

AUDIO

<MONO>

VIDEO

COMPONENT (480i/480p)

(DVD INPUT)

PBY

R

P

AV INPUT

(DVD INPUT)

COMPONENT (480i/480p)

R L

AUDIO VIDEO

(MONO)

PBY

R

P

R L

AUDIO VIDEO

(MONO)

AV INPUT

(DVD INPUT)

COMPONENT (480i/480p)

<Back Panel>

EXTERNAL

SPEAKER (8Ω)

KNOBS

AV INPUT /

COMPONENT (480i/480p)

DVD INPUT SOCKETS

RGB INPUT (VGA/SVGA/XGA) /

AUDIO INPUT / CONTROL

SOCKET

POWER INPUT

SOCKET

This Monitor operates

on an AC mains supply,

the voltage is as indicated as inside back cover

of this manual. Never

apply DC power to the

Monitor.

- 7 -

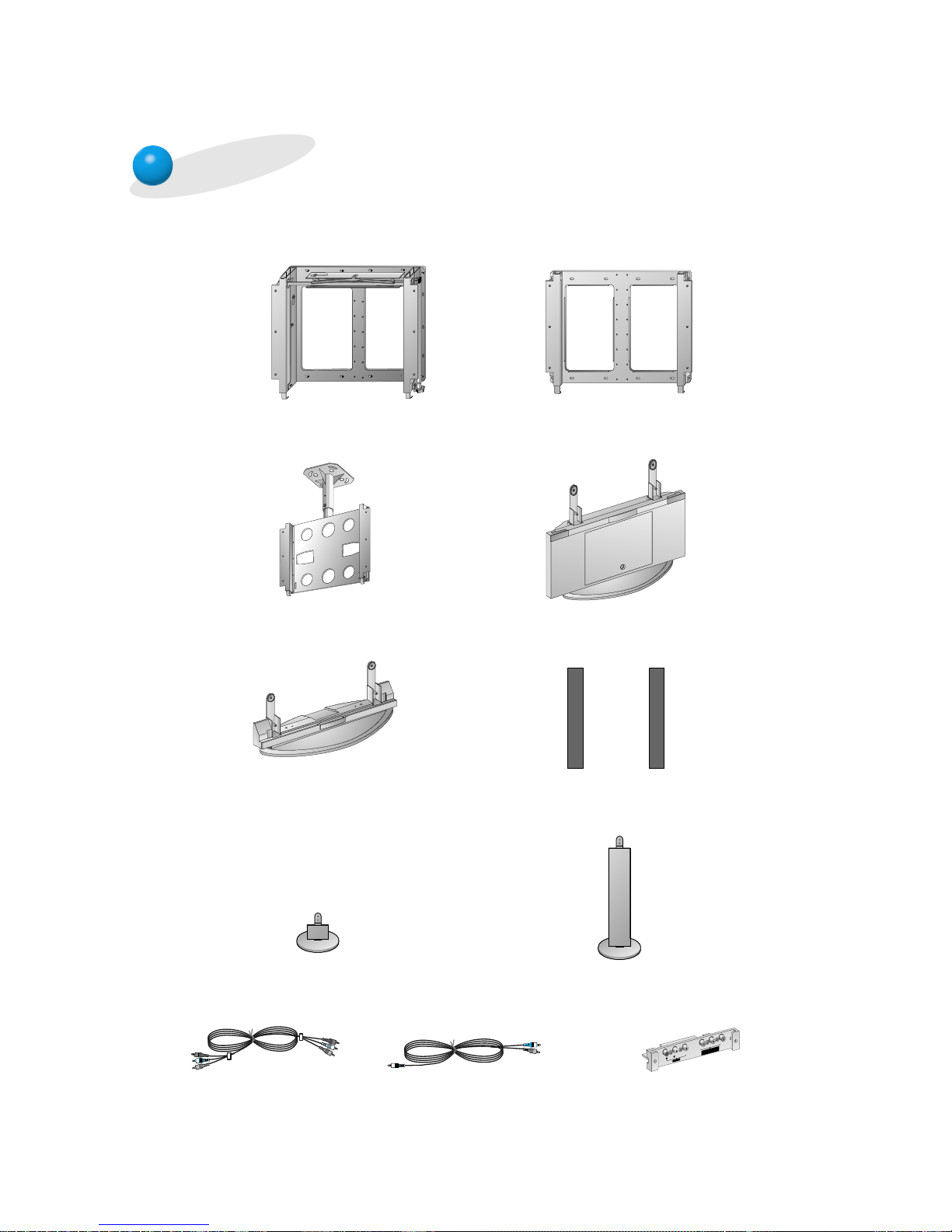

Optional Extras

AP-42WA20M series

(Tilt wall mounting bracket)

AP-42WA10 series

(Wall mounting bracket)

AP-42CA10 series

(Ceiling mounting bracket)

AP-42FA10 series

(Floor type stand)

AP-42DA10 series

(Desktop stand)

AP-42SA10 series

(Speakers)

AP-42SA10D series

(Speaker stand)

AP-42SA10F series

(Floor type speaker stand)

Video cables

Audio cables

P

B

Y

R

P

R L

AUDIO VIDEO

(MONO)

AV INPUT

(DVD INPUT)

COMPONENT (480i/480p)

AP-42EA20 (Interface board)

- Optional extras can be changed or modified for quality improvement without any notification new

optional extras can be added.

- Contract your dealer for buying these items.

- 8 -

1. Application Object

These instructions are applied to all of the PDP monitor, MP00MC.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

20±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 110/240V,

50/60Hz in adjusting.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

1) After receiving 100% white pattern, the receiver must be

operate prior to adjustment.(Or white condition in HEATRUN mode)

2) Enter into HEAT-RUN mode

- Select the HEAT-RUN OFF by pressing SVC button

on Remote Control for adjustment.

- Press the VOL + button in HEAT-RUN OFF.

(OSD display HEAT-RUN WHITE and screen display

100% full WHITE PATTERN)

3) Set is activated HEAT-RUN without SET TOP BOX or

signal generator in this mode.

[ Single color pattern of HEAT-RUN mode uses to check

PANEL.(RED/BLUE/GREEN)

[Caution] If you turn on a still screen more than 20 minutes, a

afterinage may be occur in the black level part of the

screen.

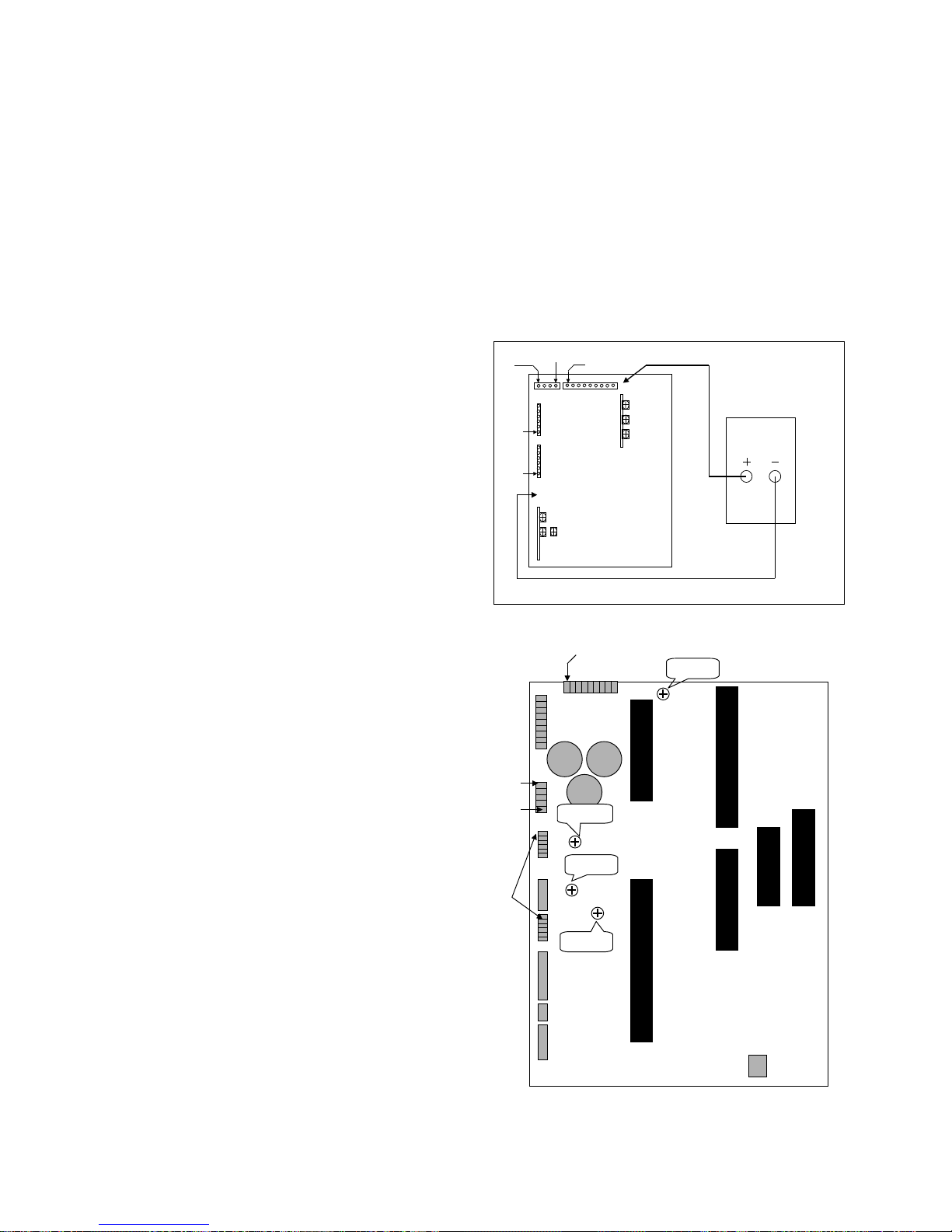

3. POWER PCB Assy Voltage Adjustment

[ Replace PDP Module or Power Board, adjust certainly Power

PCB Assy Voltage.

3-1. Test Equipment

D.M.M 1EA

3-2. Connection Diagram for Measuring

Refer to Fig 1.

3-3. Adjustment Method

(1) Va Adjustment(Address Voltage Adjustment)

1) Connect pin 1 of P806 or P811 to (+) jack of D.M.M.

2) After turning the VR351(Va Adj), voltage of D.M.M

adjustment as same as Va voltage which on label of

panel right/bottom.(Deviation : ±0.5V)

(2) Vs Adjustment

1) Connect pin 9 of P803 to (+) jack of D.M.M.

2) After turning the VR551(Vs Adj), voltage of D.M.M adjust

as same as Vs voltage which indicated on label of panel

right/bottom.(Deviation : ±0.5V)

(3) VSC Adjustment

1) Connect pin 4 of P802 to (+) jack of D.M.M.

2) After turning the VR751(VSC Adj), voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

(4) VSETUP Adjustment

1) Connect pin 1 of P802 to (+) jack of D.M.M.

2) After turning the VR651(VSETUP Adj),voltage of D.M.M

adjust as same as Vs voltage which indicated on label

of panel right/bottom.(Deviation : ±0.5V)

ADJUSTMENT INSTRUCTIONS

Vy

VR551

VR651

VR751

DMM

VSET UP

VA

VA

VS CTL

V

A CTL

VR351

GND

V

SETUP CTL

V

y CTL

V

S

<Fig 1> Connection Diagram of Power Adjustment for Measuring

- Vy

Vsetup

Vs

Va

Vsetup ADJ

VR8104

Va ADJ

VR8105

Vs ADJ

VR8102

- Vy ADJ

VR8103

<Fig 1> Connection Diagram of POWERWEL Power Adj. for Measuring

- 9 -

4. Adjustment of RGB Cut-off and

White Balance

4-1. Required Equipment

Color analyzer(CA-100 or same production)

4-2. Connection Diagram of Equipment for

Measuring

4-3. Adjustment of RGB CUT OFF

(1) Select A/C SRT (cut-off automatic adjustment ) by

pressing SVC button on Remote Control for adjustment.

(2) Press the VOL + or VOL - button.

(3) It displayed all of the black on the screen and then

adjustment is started.

(4) If adjustment is finished, exit from adjustment mode by

pressing A/V button.

4-4. Adjustment of White Balance

• White Balance should be done after RGB cut-off become

adjustment.

• Operate the Zero-calibration of the CA—100, then stick

sensor to PDP module surface when you adjust.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

SVC button on Remote Control for adjustment then

operate HEAT RUN more than 15 minute.

(2) Supply window Signal in pattern generater.

[ When adjustment is operated manually, operate process (3)

to (6) regular sequence, when adjustment is operated

automatically operate process (1)~(2).

(3) To adjust Low Light, stick sensor to pattern(Dark), select

the R cut/B cuby pressing SVC button on Remote Control

for adjustment and adjust it until color coordination

becomes X=0.280±0.003, Y=0.310±0.003 and color

temperature becomes 8.800

cK ± 500cK by pressing VOL+,

- button. (G-cut fixation)

(4) To adjust High Light, stick sensor to pattern(White).

Select the R Gain/G Gain(adjustment 6) by pressing SVC

button on Remote Control for adjustment and adjust R

Gain/G Gain until color coordination becomes

X=0.280±0.003, Y=0.310±0.003 and color temperature

becomes 8.800cK ± 500cK.(B-Gain fixation)

(5) Confirm the result of the High Light adjustment.

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(6) Exit adjustment mode using AV button.

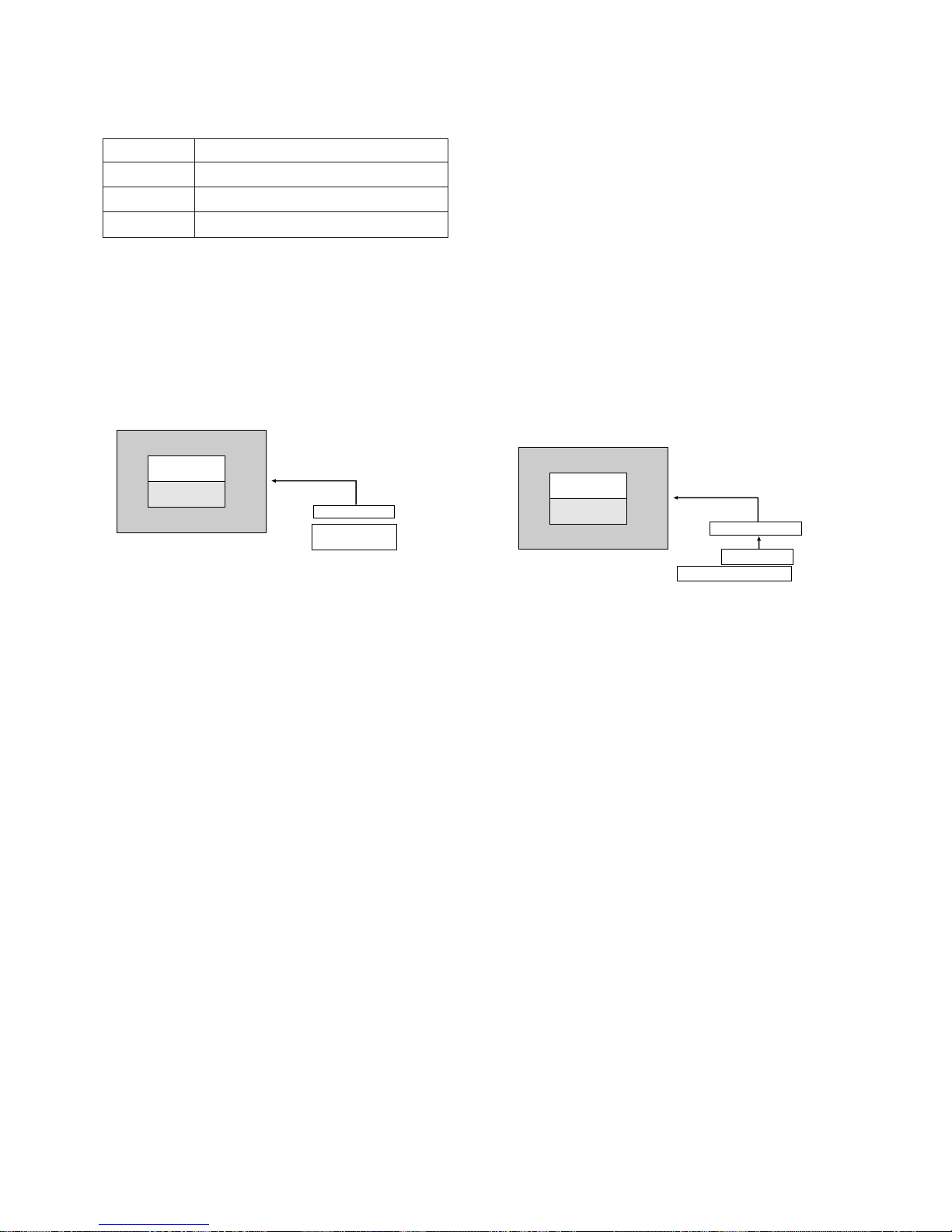

5. Color Temperature of STB

White Balance Adjustment

5-1. Required Equipment

Color Analyzer(CA-110, CA-100 or same production)

5-2. Connection diagram of equipment for

measuring

(1) To adjust the deviation of the STB signal output.

(2) Use regular PDP Monitor(JIG).

5-3. Adjustment Method

• Connect the STB to regular PDP Monitor.

• Operate the zero-calibration of the CA-100, then stick

sensor to surface of PDP module when you adjust.

(1) Select WHITE PATTERN of HEAT RUN mode by pressing

SVC button on Remote Control for adjustment, then

operate HEAT RUN more than 15 minute.

(Operate the HEAT RUN to adjust the STB at first, then if

OFF hour don’t keep more than 3 minutes, operate next

adjustment of the STB without HEAT RUN.)

(2) Supply window Signal to RZ-BA10 in pattern generator.

[ When adjustment is operated manually, operate process (3)

to (7) regular sequence, when adjustment is operated

automatically operate process (1) to (2).

(3) Select STB CXA2101 by pressing SVC,ADJUST button on

Remote Control for adjustment.

(4) To adjust Low Light, stick sensor to 9th pattern(Dark).

Select the B Cut/R Cut, then adjust the B Cut/R Cut until

color coordination becomes X=0.280±0.003,

Y=0.310±0.003 and color temperature becomes 8.800cK

± 500cK by pressing VOL+, - button. (Adjust in B Cut

10±1, R Cut 6±1)

(5) To adjust High Light, stick sensor to 2th pattern(White).

Select the R Gain/G Gain, then adjust the R Gain/G Gain

until color coordination becomes X=0.280±0.003,

Y=0.310±0.003 and color temperature becomes 8.800cK

± 500cK. (B-Gain fixation)

(6) Confirm the result of the High Light adjustment.

COLOR

ANALYZER

TYPE; CA-100

CVBS Signal Input

PDP MONITOR

RZ-BA10(STB)

Window Pattern

MSPG-2100 or MSTG-5200

High Light

90±5cd/m2

Low Light

6±1cd/m2

<Fig 3> Connection Diagram of STB Automatic Adjustment

COLOR

ANALYZER

TYPE; CA-100

Window Pattern

CVBS Signal Input

High Light

90±5cd/m2

Low Light

6±1cd/m2

PDP MONITOR

MSPG-2100 or

MSTG-5200

<Fig 2> Connection Diagram of Automatic Adjustment

Refer to Typical Voltage

Va

Vs

Vy

Vsetup

60 ~ 75V

170 ~ 185V

-60 ~ -90V

210 ~ 240V

If the deviation of High Light occur, operate the adjustment

of Low Light and High Light again.

(Expectation average adjustment data : B-Cut & RCut=6±2, R-Gain/G-Gain=25±3)

(7) Exit adjustment mode using A/V button.

6. Adjustment of AFT-VCO COIL

6-1. Preparation for Adjustment

(1) Connect the equipment for measuring as below.

(2) Setting equipment for measuring.

RF Signal generator

* Output of Power Supply = DC 5V

* Oscilloscope range = set 0.5V/div., 5msec/Div.(using scope)

6-2. Adjustment 38.9MHz IF(B/G, D/K, I, L, M)

(1) Input the signal of the signal generater(38.9MHz) to

TP105(IC102 pin 7) through 0.01uF(103) capacitor.

(2) S1 : OFF, S2 : ON, S3 : OFF

(3) Adjust voltage of the TP103 to 2.5

0.1V by adjusting

X106.

6-3 Adjustment L VCO(Adjustment

SECAM-L ) --> Only SECAM L model

(1) After changing the signal of the signal generater to

34.25MHz, input the signal to TP102(IC102 pin 11) through

0.01uF(103) capacitor.

(2) S1 : ON, S2 : OFF, S3 : ON

(3) Adjust voltage of the TP103 to 2.5

0.1V by adjusting

VR101.

7. Adjustment AGC

7-1 Preparation for Adjustment

(1) Connect the signal of PAL-B/G 05ch. to Antenna jack.

(2) Connect Multi meter to point(J150) of AGC adjustment.

7-2 Adjustment

Adjustment the voltage of Multi meter to 2.4 0.1V by

changing VR102.

8. OPTION TABLE

8-1 Funtion of Line Service

(1) • Enter to SVC mode by using SVC button on the remote

control.

•To enter to the SVC mode,press the “OK” button on RZBA10 local key ond “OK” button on the remote control

simultaneously.

• In MZ-42PZ10 only,press the “INPUT” button and “OK”

button on remote control to enter to SVC mode.

(2) Select the item by using the Quick View(Yellow) button.

(3) After adjusting,restore adjusted item in EEPROM by using

“OK” button and use the CYAN button to cancel the

adjusted condition.

(4) Select the program directly and input the data of option by

using the number button.

(5) Line SVC-0(Hitrun&W/B Adj.mode)=> VSC EEPROM

• H/T RUN:OFF,WHITE,RED,GREEN,BLUE,OFF

• A/C SRT:Auto Cutoff

• R/G/B Fine 16,R/G/B Gain 3,R/G/B Cutoff 100

(6) Line SVC-1(Phase&Position Adj.mode)=> VSC EEPROM

• Phase 15,H-Pos 32,V-Pos 32,Auto Position

(7) VSC CXA2101 Adj.mode)=> VSC EEPROM

(8) STB CXA2101 Adj.mode)=> STB EEPROM

(9) SOUND Adj.mode => VSC EEPROM

- 10 -

IC102

TDA4474

TP103

ST-BY 5V:P001

24

7

13

15

1

0.01uF

TP105

X106

(VCO)

5V

PowerSupply

V Multimeter or Oscilloscope

TP110

38.9MHz

34.25MHz

(B/G,D/K,I,L)

(SECAM-L')

100 ohm

S1

5V

4.7 Kohm

S3

Q110

VR101

16

TP112(IF VCC)

S2

TP111

100 ohm

11 TP102

VR102(AGC)

(STB MAIN)

BC 7

RC 7

RG 10

GG 10

BG 10

SUB-CON 3

SUB-BRI 49

SUB-COL 15

ST 7

SUB-SHP 1

CTI 0

RYR 6

GYR 10

RYB 9

GYB 5

GMM 5

BLK 15

PRE 1

DCT 1

DPI 2

VTC 2

HWI 2

DCO 1

HDT 0

SFO 1

BC 7

RC 7

RG 31

GG 31

BG 31

SUB-CON 3

SUB-BRI 50

SUB-COL 0

SUB-HUE 14

SUB-SHP 0

CTI 1

RYR 6

GYR 10

RYB 9

GYB 5

GMM 0

BLK 15

PRE 1

DCT 0

DPI 0

VTC 2

HWI 2

DCO 0

HDT 0

SFO 1

CON 23

BRI 31

COL 31

HUE 31

SHP 35

FP

NP

SP

SC VOL

TB VOL

MT-42PZ12

14

80

25

83

118

MZ-42PZ12

28

120

25

68

115

ADJ.Point

X106

VR101

System

B/G,D/K/I,SECAM-L

SECAM-L’

Frequency

38.9

34.25

Modulation

OFF

OFF

Level

80dBuV

80dBuV

Loading...

Loading...