Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards

by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

VENTILATOR

Original instruction

INSTALLATION MANUAL

AIR

CONDITIONER

www.lg.com

Copyright © 2017 - 2019 LG Electronics Inc. All Rights Reserved.

MFL67855539

Rev.02_013019

ENGLISH

Table of contents

TABLE OF CONTENTS

3 SAFETY PRECAUTIONS

6 INTRODUCTION

6 Symbols used in this manual

6 Feature dimension diagram

10 INSTALLATION

10 Installation map

12 Installation of main body

12 Connection of duct

14 Method to connect power cord

15 How to connect remote controller(accessory)

16 Group control

17 Installer setting -How to enter installer setting mode

19 TEST RUNNING

19 Method to operate and select air volume – Interlinked operation with ventilation.

20 Method to operate and select air volume – Ventilation single operation

21 In case of finding a problem at a test running

21 Airborne noise emission

21 Available accessories

2 Ventilator

Safety precautions

Safety precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

ENGLISH

!

WARNING

!

CAUTION

Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

!

WARNING

Installation

• Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an authorized service center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not install, remove, or re-install the unit by yourself (customer).

- There is risk of fire, electric shock, explosion, or injury.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury.

• For installation, always contact the dealer or an authorized service center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

Installation manual 3

Safety precautions

• Do not let the product run for a long time when the humidity is very high and a door or a window is

left open.

- Moisture may condense and wet or damage furniture.

• For re-installation of the installed product, always contact the dealer or an authorized service center.

- There is risk of fire, electric shock, explosion or injury.

• Do not open the maintenance cover of the main body during operation.

- Otherwise, it may cause electrical shock.

• Use the outdoor air suction hole with the net installed to ensure that birds could not come in.

- Remove estrange things like the bird’s nest. Otherwise, it may cause scarcity of indoor oxygen.

• Install the air intake where polluted air can not be directly sucked in.

- It may cause various accidents, including suffocation, due to the suction of harmful gasses(CO,

etc.)

• Do not install this product in a refrigerated warehouse, heated swimming pool or other location

where the temperature and humidity are significantly different.

- There is risk of electrical shock, malfunctioning.

• Install this product in an environment where the temperature ranges from –10 °C to +45 °C and the

relative humidity is less than 80%. It condensation is expected to form, heat up the fresh outside air

using a duct heater etc.

• Install this product in and environments where the outside air intake meets the following conditions:

temperature range is between –15 °C and +40 °C and the relative humidity is 80 % or less.

• Use the designated electrical wires for the terminal board connections, and connect the wires

securely so that they will not become disconnected. (Failure to ensure proper connections may

cause fire.)

• When passing metal ducts through wooden buildings clad with metal laths, wire laths or metal, these

ducts must be installed in such a way that they will not make electrical contact with the metal laths,

wire laths or metal sheets. (Power leakage can cause ignition)

Operation

• Avoid fire equipment

- There is risk of fire.

• When the product is soaked (flooded or submerged), contact an authorized service center.

- There is risk of fire or eletric shock.

• Don't touch a dedicated circuit or breaker with wet hands.

- There is risk of electric shock.

• When the product is not be used for a long time, disconnect the power supply plug or turn off the

breaker.

- There is risk of product damage or failure, or unintended operation.

• When flammable gas leaks, turn off the gas and open a window for ventilation before turn the

product on.

- Do not use the telephone or turn switches on or off.

There is risk of explosion or fire.

• Be cautious that water could not enter the product.

- There is risk of fire, electric shock, or product damage.

• Turn the breaker off when cleaning or maintaining the product.

- There is risk of electric shock.

4 Ventilator

Safety precautions

• The outside ducts must be tilted at a gradient (1/30 or more) down toward the outdoor area from the

ventilator unit, and properly insulated. (The entry of rain water may cause power leaks, fire or

damage to household property.)

• Glove should be worn when doing the installation work. (There is risk of injury.)

!

CAUTION

Installation

• Don't connect the ground wire to the window frame or water cock.

- There is risk of electric shock.

• Do not install the product at a smoky and oily place like kitchen or factory.

- Otherwise. oil may adhere to the filter or heating exchanger and cause trouble.

• Install the product in an insulated space from outdoor air.

- In case of installing the product outside of the insulated layer, dewing occurs inside of the main

body in winter.And it causes electrical shock or falling of condensed water.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator

fins, could cause product malfunction or inefficient operation.

ENGLISH

Operation

• Use a soft cloth to clean. Do not use harsh detergents, wax or thinner, etc.

- Otherwise, color or surface of the oroduct mav deteriorate.

• Clean the filter and the heat exchanger regularly and use the gloves for cleaning.

- Adhering to a mass of dust may cause the deterioration of air volume.

• Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a

consumer ventilator, not a precision refrigeration system.

- There is risk of damage or loss of property.

• Do not block the inlet or outlet of air flow.

- It may cause product failure.

• Do not step on or put anyting on the product.

- There is risk of personal injury and failure of product.

• Means for disconnection must be incorporated in the fixed wiring in accordance with the wiring rules.

Installation manual 5

Introduction

Introduction

Symbols used in this manual

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

product.

NOTICE

This symbol indicates special notes.

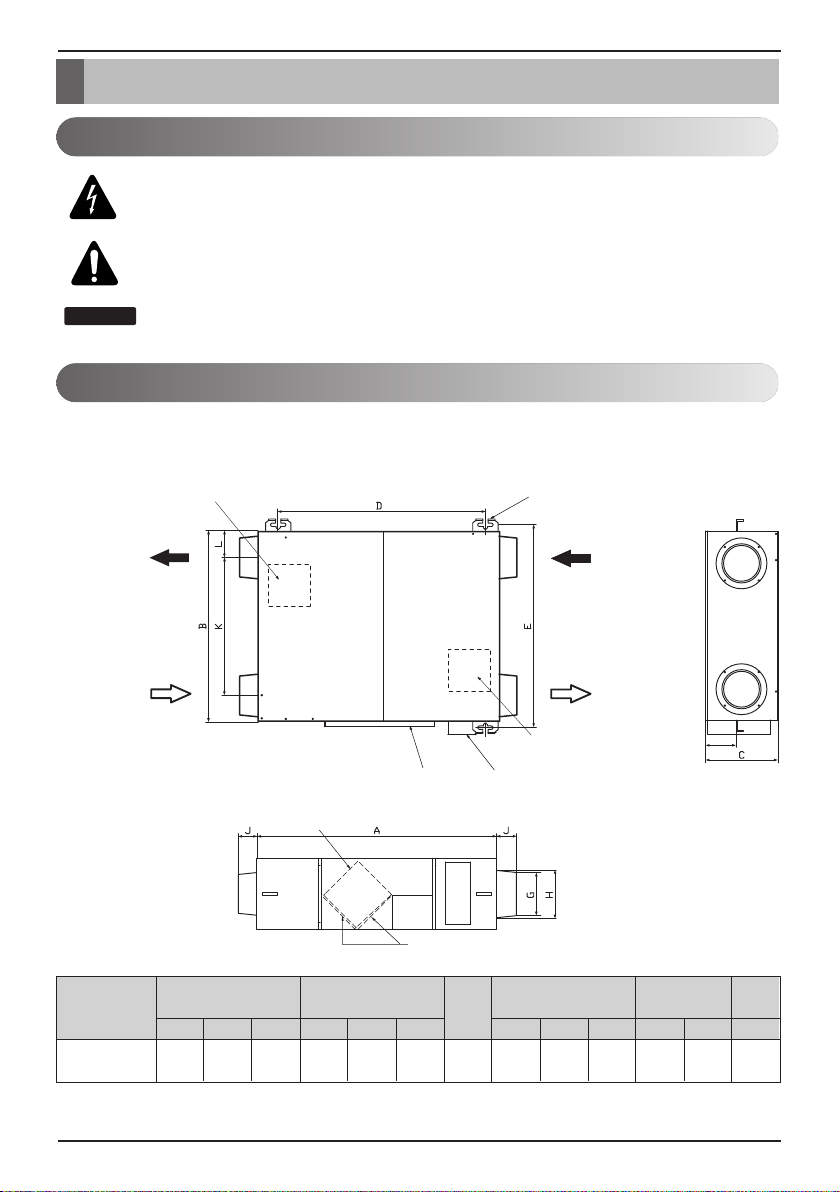

Feature dimension diagram

Model : 250 / 350 CMH

Blower for exhausting air

EA

(Exhaust Air)

OA

(Outdoor Air)

Maintenance cover

Total heat exchanger

Suspension fixture

Blower for supplying air

Control box

RA

(Return Air)

SA

(Supply Air )

F

Air filter

Model

250 CMH

350 CMH

h

It necessary to secure sufficient space for maintenance more than the dimensions described in the

Figure Duct pitch WeightPitch of suspension fixture Duct connection flange

A B C D E F G H J K L kg

1 014 988 273 939 1 025 135 200 194 252 96 590 198 44

Nominal

diameter

Unit : mm

product service.

6 Ventilator

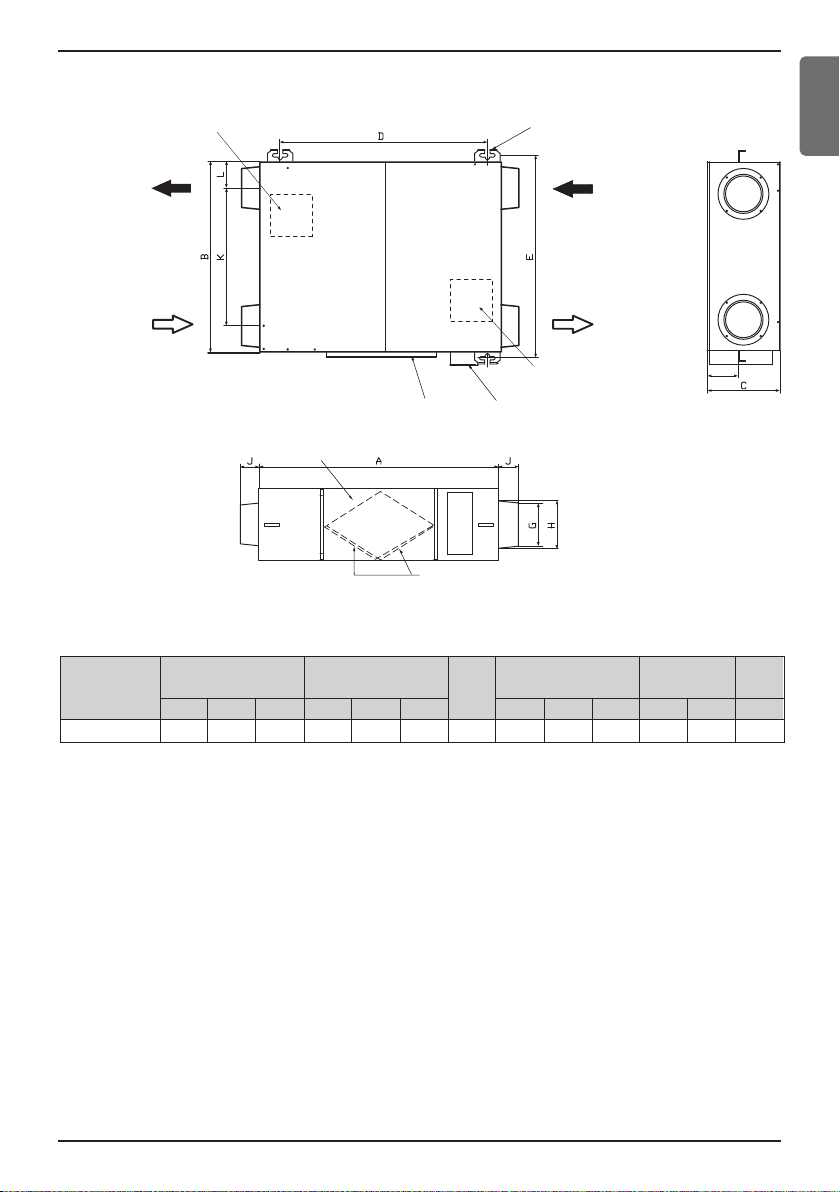

Model : 500 CMH

Introduction

ENGLISH

Blower for exhausting air

EA

(Exhaust Air)

OA

(Outdoor Air)

Maintenance cover

Total heat exchanger

Air filter

Suspension fixture

Blower for supplying air

Control box

RA

(Return Air)

SA

(Supply Air )

F

Unit : mm

Model

500 CMH

h

It necessary to secure sufficient space for maintenance more than the dimensions described in the

Figure Duct pitch WeightPitch of suspension fixture Duct connection flange

A B C D E F G H J K L kg

1 014 988 273 939 1 025 135 200 194 252 96 590 198 44

Nominal

diameter

product service.

Installation manual 7

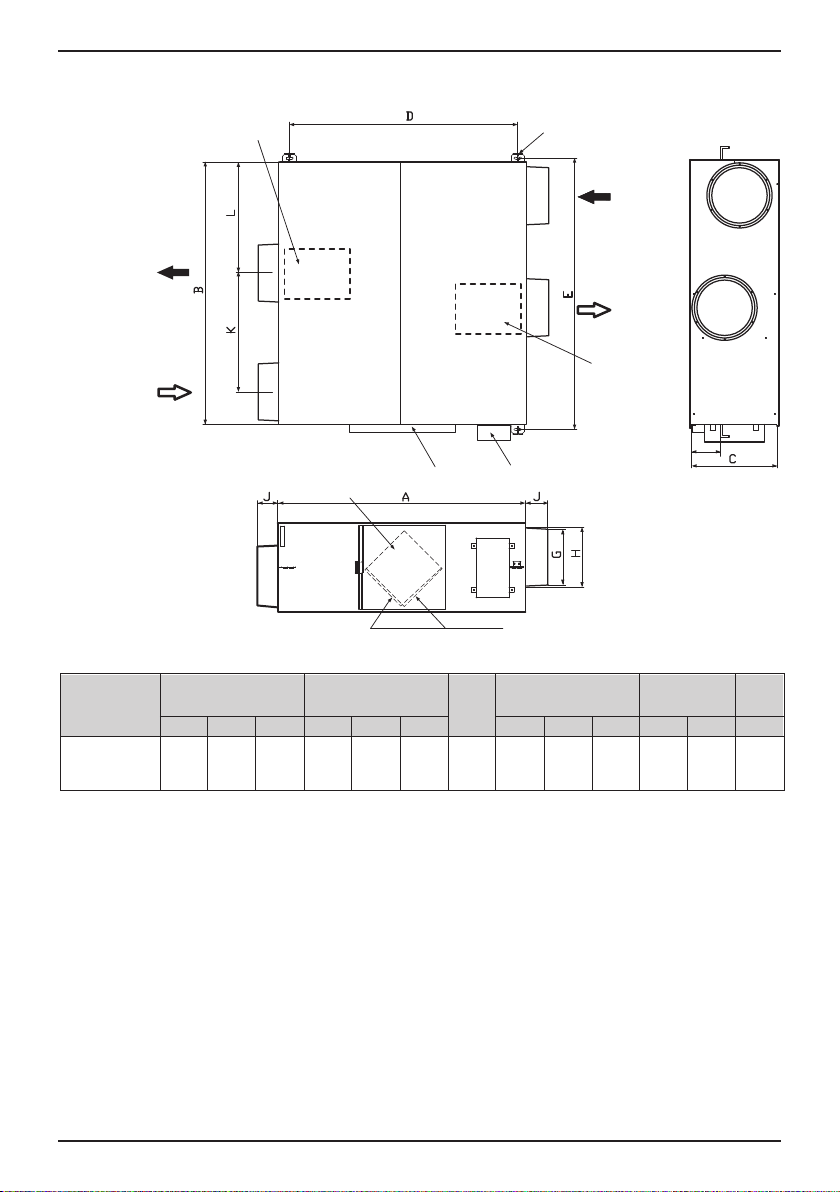

Introduction

Blower for exhausting air

Blower for

supplying air

Control box

Suspension fixture

Maintenance cover

Total heat exchanger

Air filter

F

RA

(Return Air)

SA

(Supply Air)

OA

(Outdoor Air)

EA

(Exhaust Air)

Model : 800 / 1 000 CMH

1 000 CMH

h

It necessary to secure sufficient space for maintenance more than the dimensions described in the

product service.

8 Ventilator

Model

A B C D E F G H J K L kg

800 CMH

1 062 1 140 365 987 1 176 180 250 242 253 98 513 481 62

Figure Duct pitch WeightPitch of suspension fixture Duct connection flange

Nominal

diameter

Unit : mm

Model : 1 500 / 2 000 CMH

Introduction

ENGLISH

D

QP

Model

1 500 CMH

2 000 CMH

O

RA

EA

B

N

E

SA

OA

Maintenance cover

A

C

L

K

Air filter

Control box

JM

G

Total heat exchanger

H

Unit : mm

Figure

A B C D E F G H J K L M N O P Q Kg

1 313

1 140

Pitch of suspension

fixture

738 987 1 176 339

Duct connection flange Duct pitch

242 253 98 340 350 130 410 482 233 271 140

F

Weight

h

It necessary to secure sufficient space for maintenance more than the dimensions described in the

product service.

Installation manual 9

Installation

Installation

Installation map (250 / 350 / 500 / 800 / 1 000 CMH)

Plane figure

RA grille

EA

OA

Front view

Duct slope: More than 1/30(wall side)

obtaining of right distance

(Preventing penetration of rain water)

New type hood

(Preventing penetration of rain water)

EA

OA

Three dimension view

Ventilator

Maintenance space

Inspection hatch

Duct

Ventilator

1m or more 1m or more

Inspection hatch

Ceiling fixing bolt(Supplied by installer)

SA

SA grille

RA

RA grilleSA grille

Maintenance cover

Control box

SA grille

Installation of maintenance cover

EA

OA

More than 600

10 Ventilator

Ventilator

main body

Maintenance space

600x600

Inspection hatch

Installation map (1 500 / 2 000 CMH)

Maintenance cover

Control box

SA grille

Plane figure

RA grille

Installation

ENGLISH

EA

OA

Front view

Duct slope: More than 1/30(wall side)

obtaining of right distance

(Preventing penetration of rain water)

New type hood

(Preventing penetration

of rain water)

EA

OA

Three dimension view

Ventilator

1m or more

Inspection

hatch

Maintenance

space

Inspection

hatch

Ceiling fixing bolt(Supplied by installer)

1m or more

RA RA

RA grille

SA SA

SA grille

SA grille

Installation of maintenance cover

EA

OA

Ventilator

main body

More than 600

Maintenance space

600x600

Inspection hatch

Installation manual 11

Installation

Duct

Taping

Installation of main body

Assembly of washer, nut

Tighten the common washer and nut (more than 21

mm for the outside diameter of M10, to the commercial

ceiling fixing bolt (M10) as shown in the right figure.

• For the ceiling fixing bolt, perform work less than

50mm under the ceiling fixing bracket.

Ceiling fixing bolt

(M10)

Nut

Spring washer

Washer

Nut

Connection of duct

After securely connect the duct with the duct connection flange, wrap it with a commercial aluminium

tape so that air cannot be leaked.

Adjust the duct from the ceiling so that no force is applied to the main body of the ventilation system.

Always use two ducts at the outdoor with the heat insulating material for prevention of dewing.

12 Ventilator

Installation

Duct to OA

Main body

Heat insulating material

Aluminium

Duct connection flange

Rapid bending Excessive bending

Too close bending

to outlet

Rapid reduction of

duct diameter

!

CAUTION

• Check that there are no foreign materials

(paper, vinyl, etc) or cutoff powders in the

duct before connecting the duct.

• Take care so that shock may not be applied

to the damper plate within the main body

when performing the duct connection work.

• It is recommended to perform adiabatic

treatment even to the duct pipe at the indoor

side where ambient temperature is expected

higher than room temperature when the main

body of the ventilation system for cooling in

summer.

• Take care so that work may not be performed

as in the left figure. Otherwise, it may cause

reduction of air volume or abnormal noise.

!

CAUTION

•

In -10 ℃ below ambient temperature, when ventilation is installed the equivalent space in the

outdoor and outdoor, It may cause condensation, you must install drainage facilities(drain pan)

and MD(Motorized Damper) at SA/RA duct.

ENGLISH

Installation manual 13

Installation

Wiring specifications

Sheathed wire (should be complied with 60245 IEC 53 standard)

Size 0.75 - 1.25 mm

2

Length MAX. 100 m

External contact specifications Normally closed contact (Current tolerance 10 mA - 0.5 A)

Round pressure terminal

Power wire

Method to connect power cord

Release two screws and then open the

cover of the control box.

With reference to the below wiring diagram,

•

Cover of control box

Screw

accurately connect the main power cords into the

terminal block.

After inserting the power cord into the bushing, fully insert it into the

terminal block for connection.

• Fix the power cords with the clamp.

• Make sure that the power cords may not be removed by pulling them.

LZ-H025GBA4/LZ-H035GBA4/LZ-H050GBA4

LZ-H080GBA4/LZ-H100GBA4

GND Power M.D. M.D.

M.D.

1(L)

2(N)

GND

GN/YL BR BL

3(L) 4(N)

Not

available

LZ-H150GBA4/LZ-H200GBA4

GNDPower

M.D.

1(L)

2(N)

3(L) 4(N)

Not

available

GND

GN/YLBR BL

Cord clamp

!

CAUTION

The power cord connected to the unit should be selected according to the following specifications .

!

WARNING

Indoor unit ground wires are required for preventing electrical shock accident during current leakage,

Communication disorder by noise effect and motor current leakage (without connection to pipe).

Wiring specifications

Precautions when laying power wiring

Use round pressure terminals for connections to the

power terminal block.

14 Ventilator

Installation

Please check if connector is normally connected.

Connecting cable

Indoor

Unit side

How to connect remote controller(accessory)

Please connect indoor unit and remote controller using connection cable.

Please use extension cable if the distance between wired remote controller and

indoor unit is more than 10 m.

!

CAUTION

When installing the wired remote controller, do not bury it in the wall.

(It can cause damage in the temperature sensor.)

Do not install the cable to be 50 m or above.

(It can cause communication error.)

• When installing the extension cable, check the connecting direction of the connector of the remote

controller side and the product side for correct installation.

• If you install the extension cable in the opposite direction, the connector will not be connected.

• Specification of extension cable: 2547 1007 22# 2 core 3 shield 5 or above.

ENGLISH

Installation manual 15

Installation

GND

GND

12V

Signal wire

Signal wire

GND

12V

B Y R B Y R

Master Slave

Signal wire

GND

12V

Signal wire

Group control

When installing more than 2

units of air conditioner to one

wired remote controller, please

connect as the right figure.

• If it is not event communication

indoor unit, set the unit as slave.

• Check for event communication

through the product manual.

When controlling multiple indoor units with event communication function with one remote

controller, you must change the master/slave setting from the indoor unit.

- Indoor units, the master/slave configuration of the product after completion of indoor unit power

‘Off’ and then ‘On’ the power after 1 minutes elapsed sign up.

- For ceiling type cassette and duct product group, change the switch setting of the indoor PCB.

12345678 12345678

#1 switch Off: Master

(Factory default setting)

- For wall-mount type and stand type product, change the master/slave setting with the wireless

remote controller. (Refer to wireless remote controller manual for detail)

h When installing 2 remote controllers to one indoor unit with event communication function, set

the master/slave of the remote controller. (Refer to remote controller master/slave selection)

When controlling the group, some functions excluding basic operation setting, fan level

min/mid/max, remote controller lock setting and time setting may be limited.

#1 switch On: Slave

When installing more than 2 wired remote

controllers to one air conditioner, please

connect as the right picture.

• When installing more than 2 units of wired

remote controller to one air conditioner, set

one wired remote controller as master and

the others all as slaves, as shown in the

right picture.

• You cannot control the group as shown in

the right for some products.

•

Refer to the product manual for more detail.

• When controlling in groups, set the master/slaver of the remote controller. Refer to

Installer setting section on how to set master/slave for more detail.

16 Ventilator

<When simultaneously connecting

2 sets of wired remote controller>

Installation

Installer setting -How to enter installer setting mode

!

CAUTION

Installer setting mode is to set the detail function of the remote controller.

If the installer setting mode is not set correctly, it can cause problems to the product, user injury or

property damage. This must be set by an certificated installer, and any installation or change that is

carried out by a non-certificated person should be responsible for the results. In this case, free service

cannot be provided.

If pressing button long for 3 seconds,

1

it enters into remote controller setter

setup mode.

- If pressing once shortly, it enters into

user setup mode. Please press more

than 3 seconds for sure.

When you enter the setting mode

2

initially, Function code is displayed on

the bottom of the LCD screen.

ENGLISH

Function code Value

•

Some categories of the menu may not be displayed according to the function of the

product, or the menu name may be different.

Installation manual 17

Installation

<Installer setting code table>

General ventilation product

No. Function Code Value

1 01 01 : Test run setup

Test run

2 02 00~FF : Address of central control

303

404

5 05

606

7 07

809

9 10 01 : Set

10 11

Address setting

SA(Supply Air) ESP

EA(Exhaust Air) ESP

Product direction

Quick refresh priority

Master setting

Dry contact

Release of 3 minute delay

Zone state test run

<ESP level> <ESP value> <Example>

01 : Low 0~255

02 : High

03 : Super high

01 : Normal

02 : Opposite

01 : Supply air first

02 : Exhaust air first

00 : Slave

01 : Master

00 : Auto-off

01 : Auto-on

01 : Variable

02 : Fixed

Function Code ESP valueESP step

h Some contents may not be displayed depending on the product function

18 Ventilator

Test running

ENGLISH

Test running

Method to operate and select air volume – Interlinked operation with ventilation.

It is used when air conditioner is interlinked with ventilation product.

It is a function that cools and refreshes indoor air using the ventilation product at the same time

operating the air conditioning function.

Ventilation interlinked operation

Press button on the remote

1

controller control panel.

- It is only used when air conditioner

and general ventilation is

interlinked.(‘Interlinked operation’ displayed

on the remote controller display)

Pressing 'Start/Stop' button at ventilation

2

mode will start ventilation.

Pressing button will change the

3

ventilation operation mode.

Pressing operation selection button

will change the mode in the order of

'heat exchange → normal → automatic'

❈ It only displays on the remote controller

display when it is in ventilation mode, and it

displays the desired temperature when it

returns to air condition mode.

Pressing button in general

4

ventilation mode will change airflow

speed.

Pressing airflow speed button will

change the mode in the order of 'weak → strong

→ very strong'.

2 sensor is installed, it can select from 'weak

If CO

→ strong → very strong → automatic'.

Changing back to air conditioner mode

5

1)Automatic conversion : when no button is

pressed for 15 seconds or longer, it

automatically converts back to air

conditioner mode.

2) Manual conversion : pressing button in

ventilation mode will manually convert.

Installation manual 19

Test running

Method to operate and select air volume – Ventilation single operation

It is a function to cool and refresh the indoor air using general ventilation product..

Ventilation single operation

Press button on the remote

1

controller.

Pressing button will change

2

the ventilation mode.

Ventilation

Remote controller

mode

Heat

exchange

Normal

Automatic

In the case of heat exchange mode, the display is

shown as below.

3

display

Circulate indoor air without loss of heat

Directly circulate indoor air without going

through heat exchanger

Circulate indoor air with automatically

comparing indoor and outdoor air

→→→ →→→→

Pressing button will change

the strength of the wind

- Pressing the button can select

from 'weak

strong'.

- If CO2 sensor is installed, it can select from

'weak → strong → very strong → automatic'.

→

strong → very

Contents

20 Ventilator

In case of finding a problem at a test running

Symptom Check item Counter-measure

The product doesn't work Is power not supplied? Supply power

Is the indoor temperature less

than 15 ℃ (59 ℉) or more than

40 ℃ (104 ℉)?

The product doesn't work through

you press the 'On' switch

Is air filtecr, total heat exchanger

clogged severely?

It's standby mode for protecting

total heat exchanger.

Follow cleaning and changing

method.

Test running

ENGLISH

The fan doesn't run

Even though you push the

button of remote controller, any

function doesn't work.

Are the PCB and remote

controller rightly connected?

"Is the outdoor temperature the

limit temperature?

(Less than -10 °C (14 °F), more

than 45 °C (113 °F))"

Is the icon " " displaying on

remote controller?

Connect rightly PCB and remote

controller.

Switch on Option No. 5.

Repower the product and check

whether it works or not.

Switch off Option No. 5. and

repower the product once again.

It's child lock mode.

Refer to remote controller.

Airborne noise emission

The A-weighted sound pressure emitted by this product is below 70 dB.

** The noise level can vary depending on the site.

The figures quoted are emission level and are not necessarily safe working levels. Whilst there is a

correlation between the emission and exposure levels, this cannot be used reliably to determine

whether or not further precautions are required. Factor that influence the actual level of exposure of

the workforce include the characteristics of the work room and the other sources of noise, i.e. the

number of equipment and other adjacent processes and the length of time for which an operator

exposed to the noise. Also, the permissible exposure level can vary from country to country. This

information, however, will enable the user of the equipment to make a better evaluation of the hazard

and risk.

Available accessories

Remote controller (PQRCVSL0/PQRCVSL0QW)

F7 filter (AHFT035H0/AHFT050H0/AHFT100H0)

sensor (AHCS100H0)

CO

2

PI485 gateway

Installation manual 21

22 Ventilator

ENGLISH

Installation manual 23

Loading...

Loading...