LG LVN180HV4 Installation instructions

INSTALLATION MANUAL

AIR

CONDITIONER

ENGLISH FRANÇAIS ESPAÑOL

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring standards

by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

Vertical Air Handling Unit

www.lghvac.com

MFL67206512

Rev.01_032620

Copyright © 2016 - 2020 LG Electronics Inc. All Rights Reserved.

www.lg.com

IMPORTANT!

Please read this instruction sheet completely before installing the product.

This air conditioning system meets strict safety and operating standards. As the installer or service person,

it is an important part of your job to install or service the system so it operates safely and efficiently.

!

WARNING

• Installation or repairs made by unqualified persons can result in hazards to you and others.

Installation of all field wiring and components MUST conform with local building codes or, in the absence of local

codes, with the National Electrical Code 70 and the National Building Construction and Safety Code or Canadian

Electrical code and National Building Code of Canada.

• The information contained in the manual is intended for use by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property

damage, personal injury and/or death.

CAUTION

Safety Precautions

NOTE TO INSTALLING DEALER: The Owners Instructions and Warranty are to be given to the owner

:

Improper installation, adjustment, alteration, service or maintenance can void the warranty.

The weight of the condensing unit requires caution and proper handling procedures when lifting

or moving to avoid personal injury. Use care to avoid contact with sharp or pointed edges.

• Always wear safety eye wear and work gloves when installing equipment.

• Never assume electrical power is disconnected. Check with meter and equipment.

• Keep hands out of fan areas when power is connected to equipment.

• R-410A causes frostbite burns.

• R-410A is toxic when burned.

or prominently displayed near the indoor Furnace/Air Handler Unit.

!

When wiring:

Electrical shock can cause severe personal injury or death. Only a qualified,

experienced electrician should attempt to wire this system.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

•

•

The choice of materials and installations must comply with the applicable local/national or international standards.

When transporting:

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and

bend your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on

the air conditioner can cut your finger.

When installing...

... in a wall: Make sure the wall is strong enough to hold the unit's weight.

... in a room: Properly insulate any tubing run inside a room to prevent "sweating" that can cause

... in moist or uneven locatinons: Use a raised concrete pad or concrete blocks provide a solid,

... in an area with high winds: Securely anchor the outdoor unit down with bolts and a metal

... in a snowy area(for Heat Pump Model): Install the outdoor unit on a raised platform that is

When connecting refrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Check carefully for leaks before starting the test run.

When servicing

• Turn the power OFF at the main power box(mains) before opening the unit to check or repair

electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

It may be necessary to construct a strong wood or metal frame to provide added support.

dripping and water damage to wall and floors.

level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

frame. Provide a suitable air baffle.

higher than drifting snow. Provide snow vents.

SPECIAL WARNING

2 Vertical Air Handling Unit

Table of contents

TABLE OF CONTENTS

4 SAFETY INSTRUCTIONS

6 FEATURES

7 Duct Connection Dimensions

8 INSTALLATION

8 Selection of the best location

9 Upflow Installation

10 Downflow Installation

12 Horizontal-Right Installation

13 Duct work

14 Horizontal-left Installation

15 Combination indoor units (Multi Zone)

16 Flaring work

17 Connection of piping - Indoor, Outdoor, BD Unit

18 Plumbing materials and storage methods

19 Insulation

20 Condensate Drain

22 Wiring Connection

24 REMOTE CONTROLLER INSTALLATION

26 Wired remote controller installation

ENGLISH

27 3rd PARTY THERMOSTAT

28 INTERNAL ELECTRIC HEATER(ACCESSORY)

29 DIP SWITCH SETTING OF INDOOR UNIT PCB

30 PRODUCT DATA

30 External Static Pressure & Air Flow

31 Minimum airflow by heater capacity

31 Internal Electric Heater Static pressure drop factors

32 Air Filter (Field supply) Static pressure drop factors

32 Downflow (Field supply) Static pressure drop factors

33 Downflow - Air Filter (Field supply) Static pressure drop factors

33 Downflow -Internal Electric Heater Static pressure drop factors

Installation Manual 3

Safety Instructions

Safety Instructions

The following safety guidelines are intended to prevent unforeseen risks or damage from

unsafe or incorrect operation of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as described below.

This symbol is displayed to indicate matters and operations that can cause risk.

!

Read the part with this symbol carefully and follow the instructions in order to avoid risk.

!

WARNING

This indicates that the failure to follow the instructions can cause serious injury or death.

!

CAUTION

This indicates that the failure to follow the instructions can cause the minor injury or damage to the product.

!

WARNING

Installation

• Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized Service Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not let the air conditioner run for a long time when the humidity is very high and a door or a window is left open.

- Moisture may condense and wet or damage furniture.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins on the con-

denser and evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

4 Vertical Air Handling Unit

Safety Instructions

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property damage, product failure,

and personal injury.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress air

or Oxygen and do not use Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

Operation

• Do not store or use flammable gas or combustibles near the product.

- There is risk of fire or failure of product.

!

CAUTION

Installation

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children may not play with them. If chil-

dren play with a plastic bag which was not torn apart, they face the risk of suffocation.

ENGLISH

Installation Manual 5

Features

Features

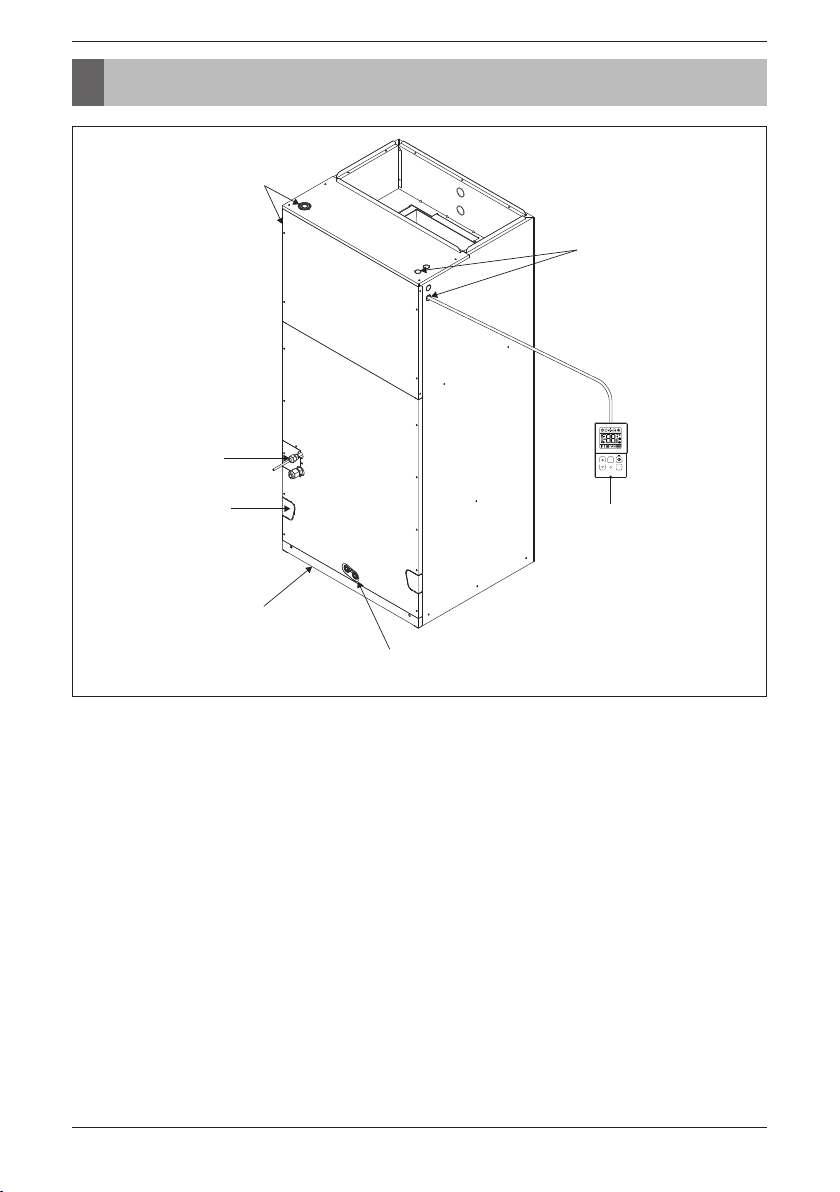

Wiring knockouts

for conduit

Wiring knockouts

for conduit

Refrigerant

connections

Drain connections

for horizontal

application

Filter access

Drain connections for

upflow application

FAN

SPEED

TEMP

OPER

MODE

Wired Remote

Controller

(Accessory)

6 Vertical Air Handling Unit

Features

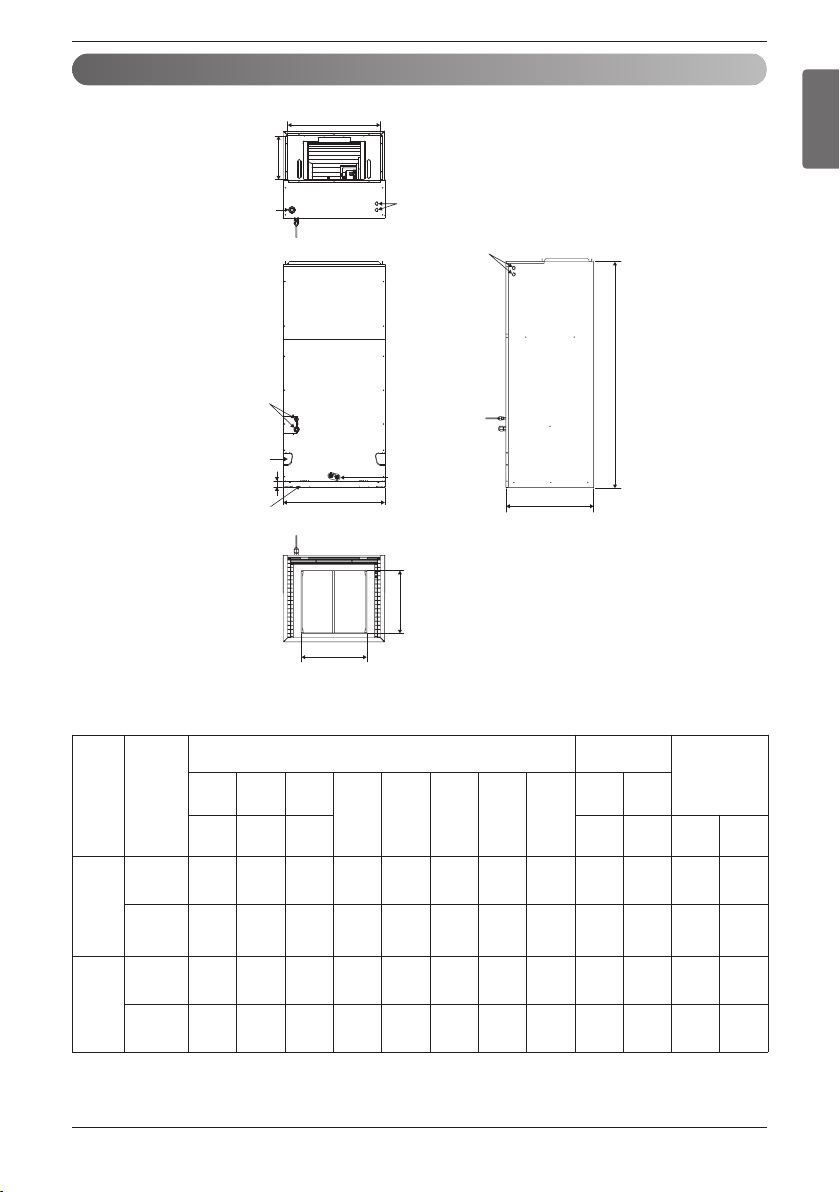

Duct Connection Dimensions

G

H

I

<Top>

Refrigerant

connections

Drain connections

for horizontal

application

D

Air filter cover

B

<Front>

E

<Bottom>

J

Drain

connections

for upflow

application

F

ENGLISH

J

A

C

<Side-right>

ODU

Single

Zone

Multi

Zone

Capacity

(kBtu/h)

182448-5/8

36

42

48

182448-5/8

36

Dimensions

A B C

Knock out

I J

D E F G H

Height Width Depth Power

21-1/4

1-9/16

(1236)18(457)

55-3/16

(1401)25(635)

(1236)18(457)

55-3/16

(1401)25(635)

(540)

21-1/4

(540)

21-1/4

(540)

21-1/4

(540)

17-1/2

(40)

(445)20(530)17(432)

1-9/16

24-1/2

(40)

(623)20(530)24(610)

1-9/16

17-1/2

(40)

(445)20(530)17(432)

1-9/16

24-1/2

(40)

(623)20(530)24(610)

12-1/8

(308)

12-1/8

(308)

12-1/8

(308)

12-1/8

(308)

1-11/16

(43)

1-11/16

(43)

1-11/16

(43)

1-11/16

(43)

(Unit: inch(mm))

Wiring

Commu-

nication

7/8

(22)

7/8

(22)

7/8

(22)

7/8

(22)

Refrigerant

Connections

Pipe size

Liquid Gas

3/8

5/8

(9.52)

(15.88)

3/8

5/8

(9.52)

(15.88)

1/4

1/2

(6.35)

(12.7)

3/8

5/8

(9.52)

(15.88)

Installation Manual 7

Installation

Installation

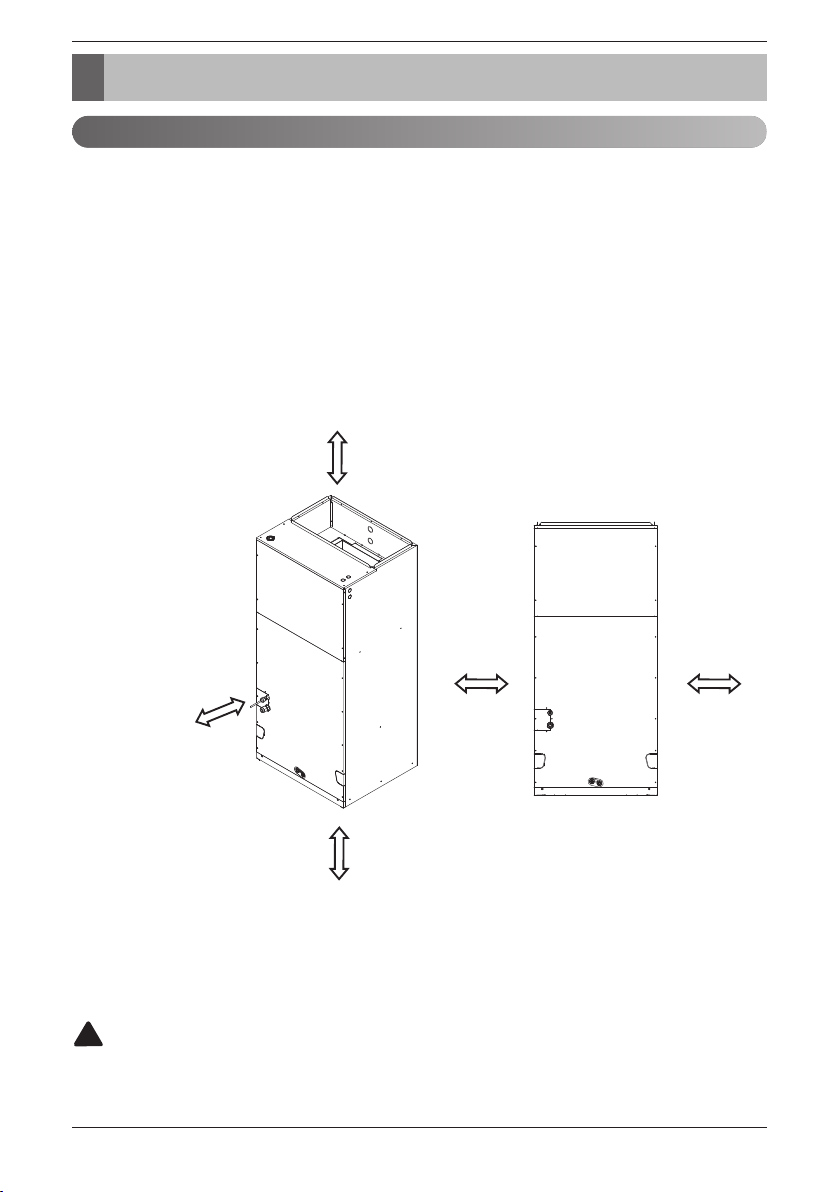

Selection of the best location

• Where optimum air distribution can be ensured.

• Where nothing blocks air passage and install the duct work.

• Where condensate can be properly drained.

• Where the ceiling is strong enough to bear the indoor unit weight.

• Where the false ceiling is not noticeably on an incline.

• Where sufficient clearance for maintenance and service can be ensured.

• Where piping between indoor and outdoor units is possible within the allowable limit. Refer to the installation manual for the outdoor unit.

• Vertical Air Handling Unit can be installed for upflow and horizontal-left positions.

More than 350

(13-25/32)

More than 600(23-5/8)

clearance from

access panels

for Service

More than 350

(13-25/32)

NOTE : The primary and secondary drain line must be trapped to allow proper drainage of condensate

water, If the secondary drain line is not used, it must be capped.

!

CAUTION

In the case of sea coast installation, salt residue may cause corrosion of cabinet and component parts.

Please take appropriate anti-corrosion measures.

8 Vertical Air Handling Unit

More than

250(9-27/32)

More than

250(9-27/32)

Unit : mm(inch)

Installation

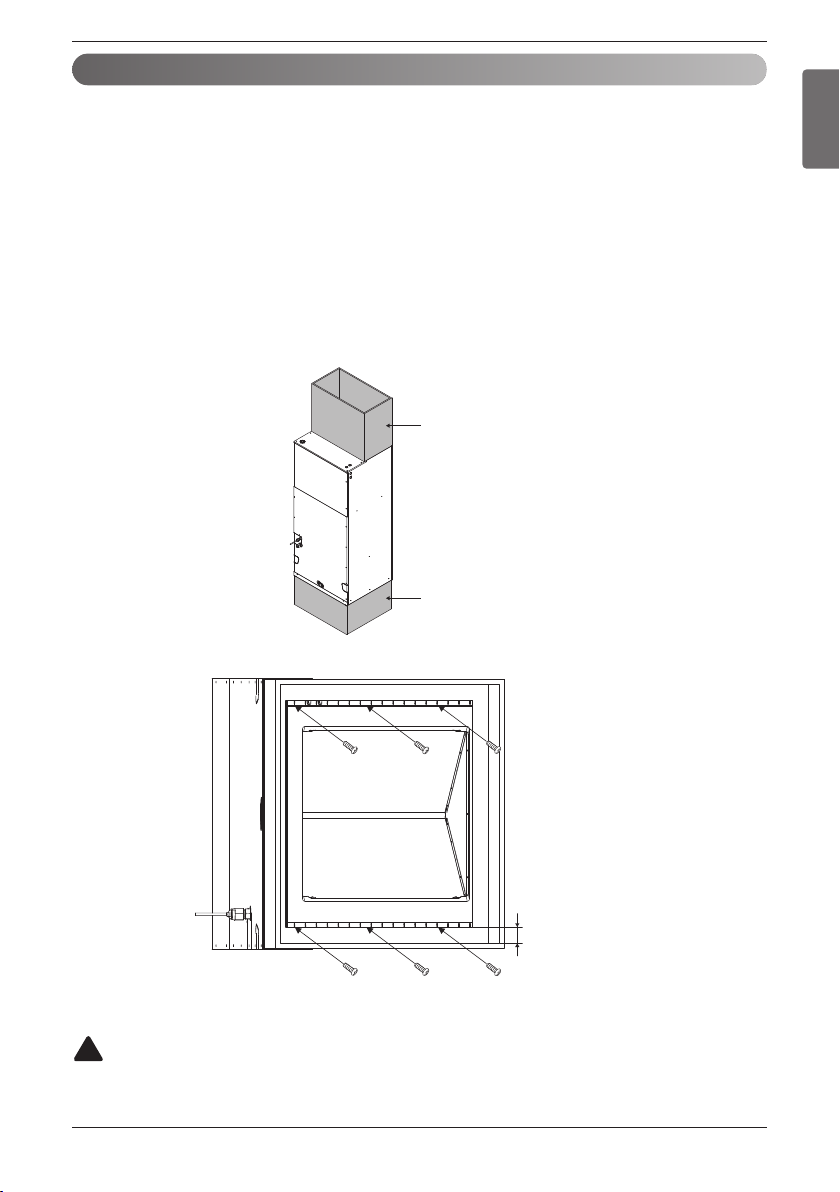

Upflow Installation

• Position unit for plenum installation.

• The plenum should be secured in order to support the installation of adapter callers accommodate the

installation of any duct work.

• Seal all duct work according to local codes to prevent air leakage. Ensure that filter access is unobstructed.

• The air handler support platform should be sturdy enough to support the cabinet plus any accessory

components including filter box.

• The minimum height clearance is 14 inches(350 mm) to maintain proper air flow.

• Vibration isolators (purchased locally) must be placed between the unit and the pedestal.

• An illustration showing an example of where a vibration isolator should be added would clarify what

the installing contractor should do to properly position the isolator.

Field Supplied

Supply Duct

Field

Supplied Return

Plenum

ENGLISH

More than

1 inch (25 mm)

More than 6 screws (M4*25L)

!

CAUTION

Do not connect the screws on Front and Rear side, it may cause the filter can not be mounted.

Installation Manual 9

Installation

Downflow Installation

Downflow installation requires various changes to the air handling unit from original configuration.

There are additional kits required in order to convert the air handling unit to the downflow configuration.

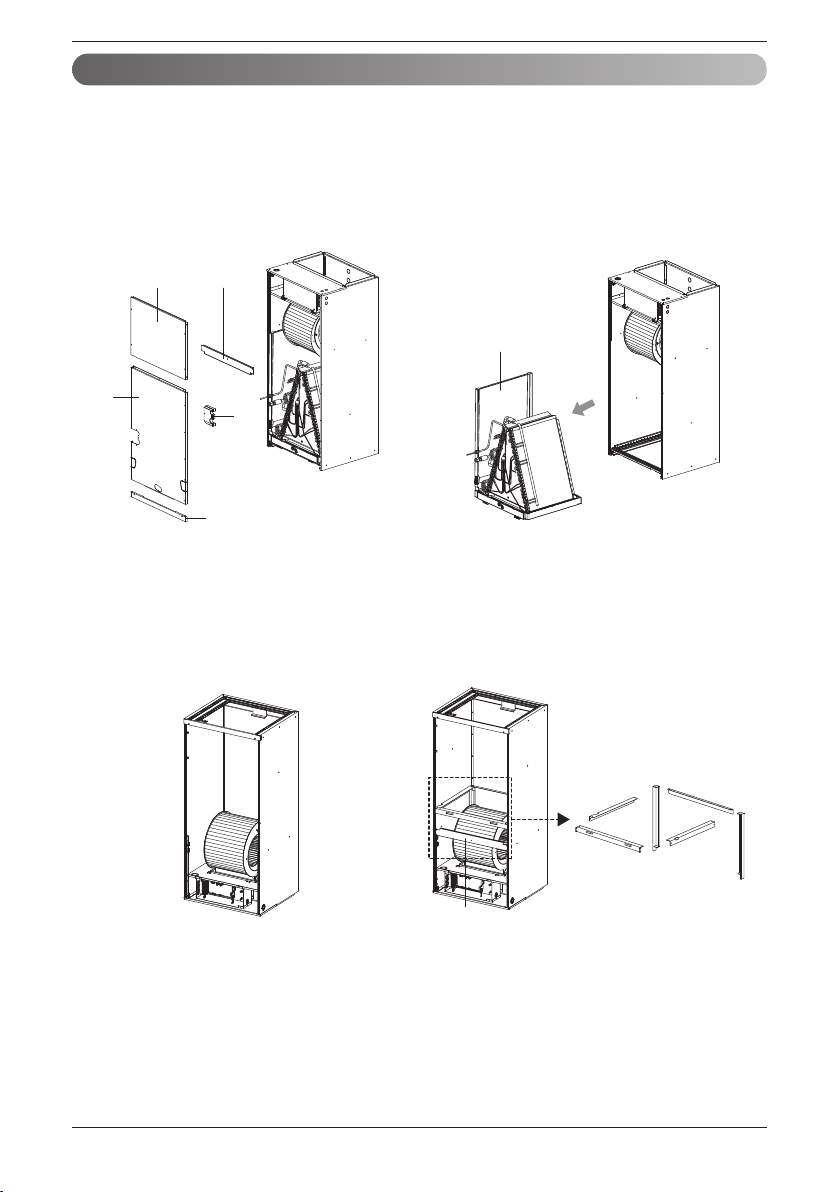

1) Please remove the panels and Brackets from

the unit.

A

B

D

E

C

2) Please remove the thermistor from a coil. Also

remove a coil and Drain pan from the unit

Deletion

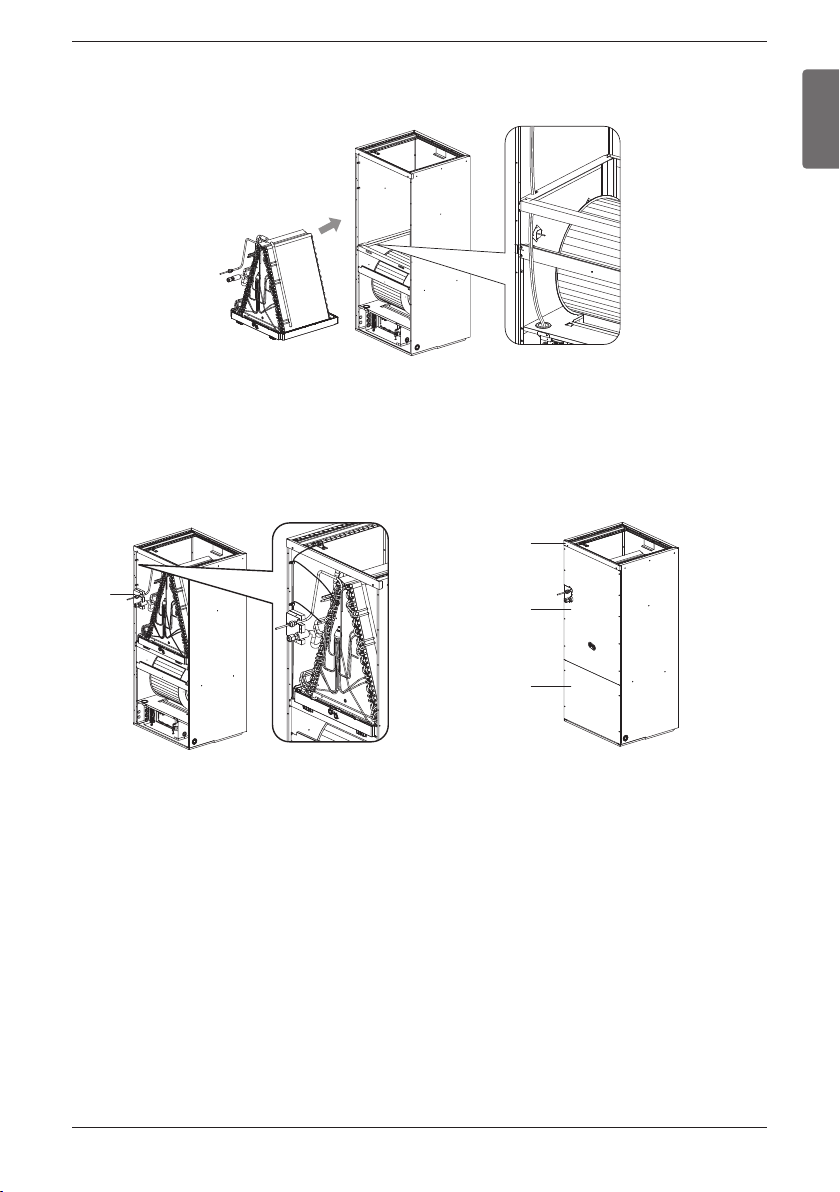

3) Rotate the cabinet. 4) Please assemble the downflow bracket as

below. Install the bracket in the order shown

and fix with screw.

10 Vertical Air Handling Unit

Bracket Installation

ڼ

ڸ

ڻ

D

ں

ڽ

ڹ

5) Reinsert the coil back to the cabinet.

Eva In

Before this action, please route the thermistor wires into the downflow Bracket

6) The brackets are required to be reattached. 7) Reinstall the new panel.

Installation

ENGLISH

Room

Eva In

Eva In

E

Eva

Out

C

New

A

Installation Manual 11

Loading...

Loading...