LG LS-L1262CL, LS-L1261CLCM, LS-L1262CM, LS-L1262CN, LS-L1262CD Service Manual

...

SERVICE MANUAL

Room Air Conditioner

CAUTION

-BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

-ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL : LS-L1261CL/CM/CN/CD/CS

LS-L1262CL/CM/CN/CD/CS

LS-L1263DL

LS-L1261EL/HL/HM/HN/HD/HS

LS-L1262HL/HM/HN/HD/HS

LS-L1220HL/HM/HN/HD/HS

website http://biz.LGservice.com

e-mail http://www.LGEservice.com/techsup.html

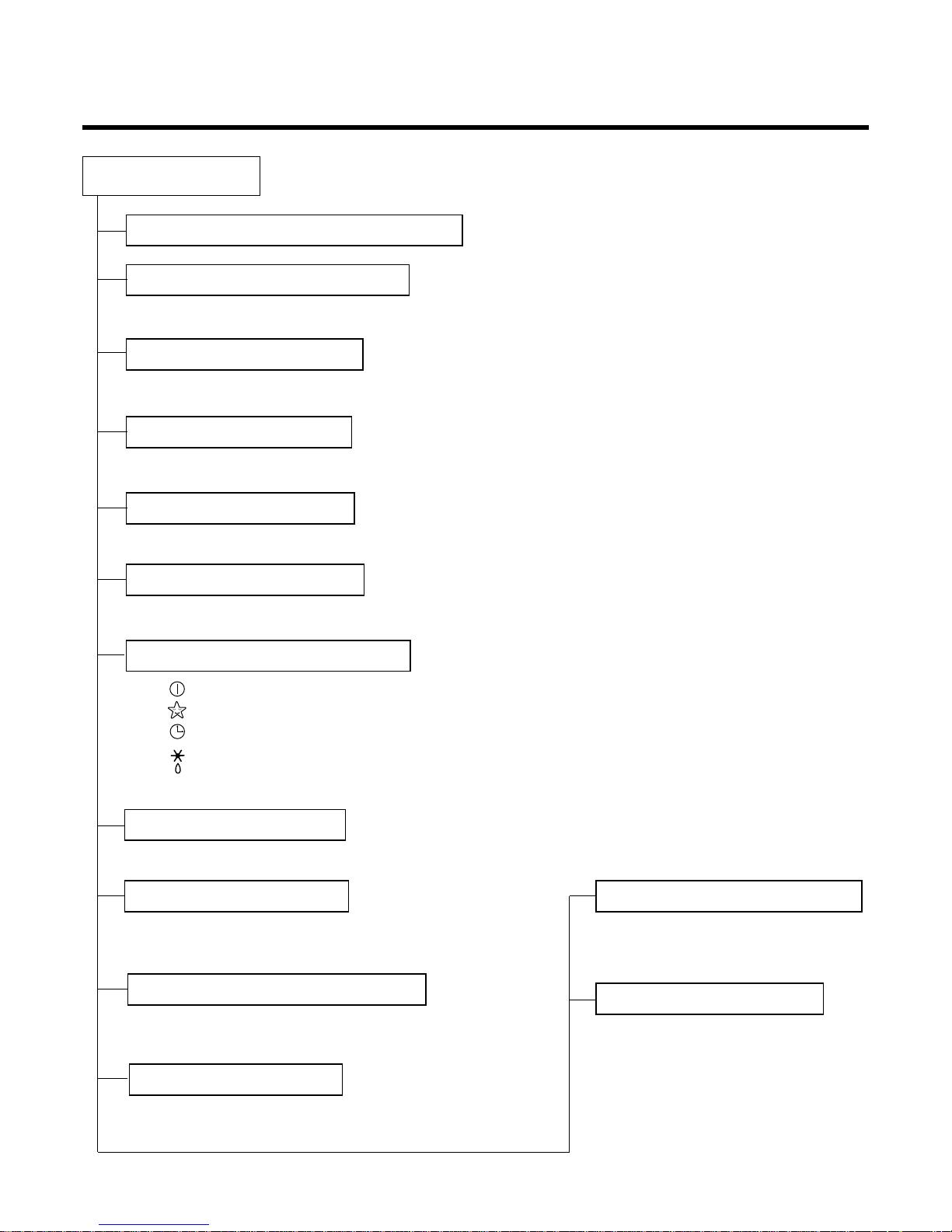

Contents

Functions

................................................................................................................................

3

Product Specifications

.........................................................................................................

5

Dimensions

.............................................................................................................................

6

Refrigeration Cycle Diagram

.................................................................................................

8

Wiring Diagram

.......................................................................................................................

9

Operation Details

.................................................................................................................

10

Display Function

..................................................................................................................

17

Self-diagnosis Function

.......................................................................................................

17

Installation

............................................................................................................................

18

Operation

..............................................................................................................................

34

Disassembly of the parts (Indoor Unit)

..............................................................................

36

2-way, 3-way Valve

................................................................................................................

42

Cycle Troubleshooting Guide

..............................................................................................

49

Electronic Parts Troubleshooting Guide

............................................................................

50

Electronic Control Device

....................................................................................................

57

Schematic Diagram

..............................................................................................................

59

Exploded View and Replacement Parts List

......................................................................

61

-2-

Functions

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 sec at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low, CHAOS

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Defrost Mode (for Heating Model)

OUTDOOR --- Lights up in compressor operation (for Cooling Model)

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

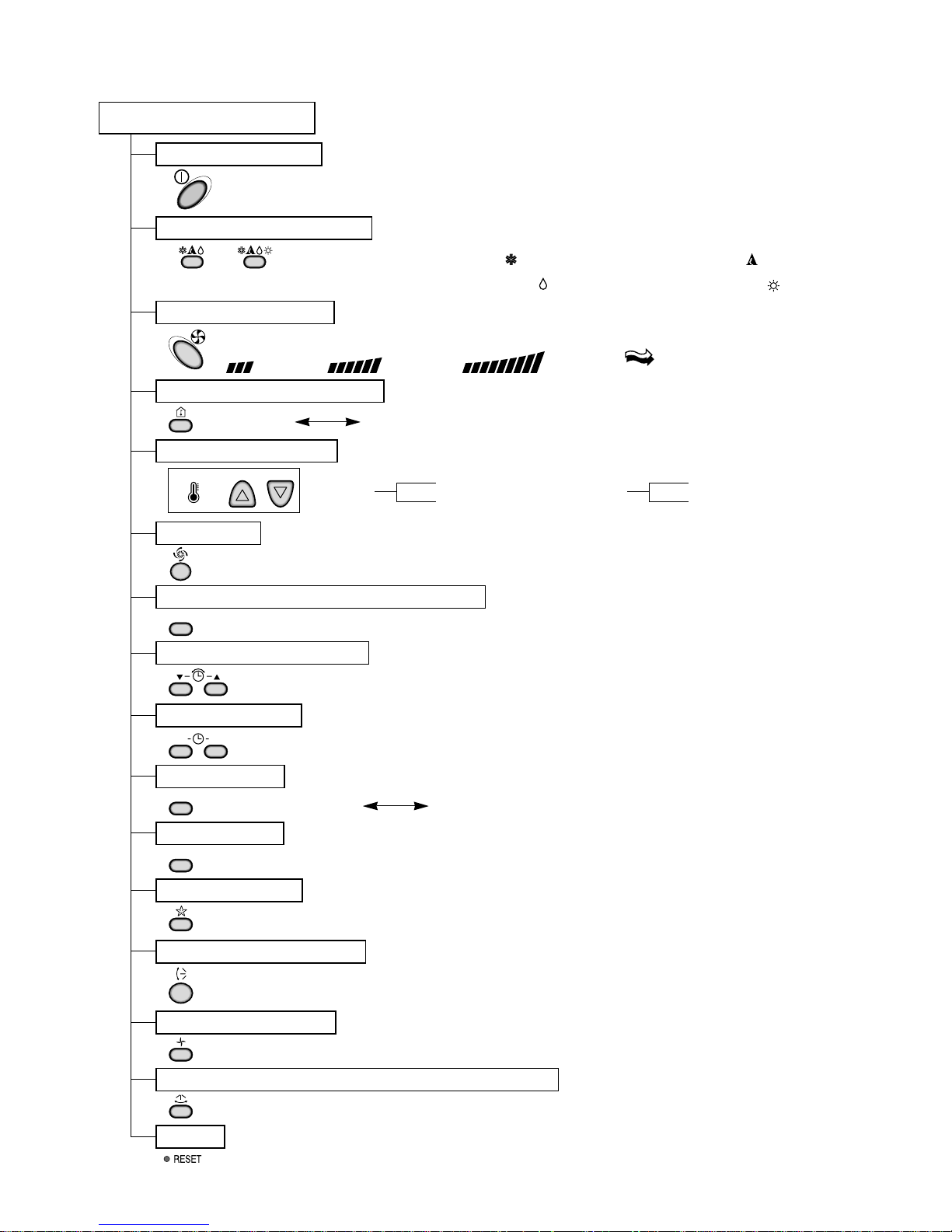

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Soft Dry Operation Mode

• Both the indoor and outdoor fan

stops during defrosting.

• The indoor fan stops until the

evaporator pipe temperature will be

reached at 28°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

-3-

Defrost(Deice) control (Heating)

Hot-start Control (Heating)

-4-

Healthy Dehumidification Operation Mode.

( )

Remote Controller

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

JET COOL

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Fan Operation Mode

Horizontal Airflow Direction Control Button(Option)

Room, Temperature Display

Setting the Time or Timer

PLASMA(Option)/NEGATIVE ION(Option)

ON OFF

SET

PLASMA

CANCEL

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High:39°C Low:11°C)

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C

Up to 30°C

Heating

Down to 16°C

Up to 30°C

-5-

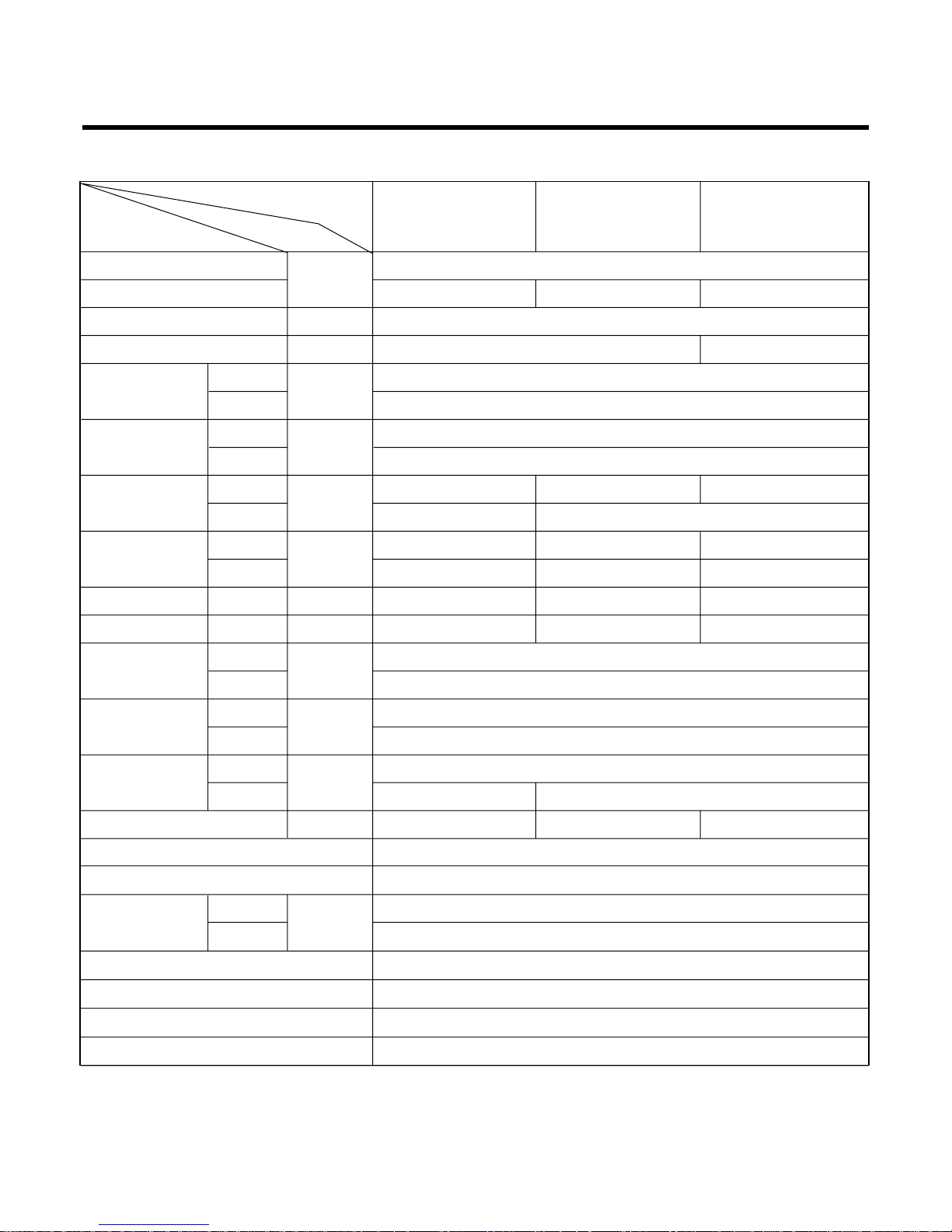

Product Specifications

Model Name

Item Unit

Cooling Capacity

Btu/h

12,000

Heating Capacity - 13,000 12,500

Moisture Removal l/h 1.5

Power Source Ø, V, Hz 1Ø, 220-240V, 50Hz 1Ø, 220V, 60Hz

9.5

25

36

46

Cooling

W

1,190 1,280 1,260

Heating - 1,150

Running Cooling

A

5.4 5.8 5.9

Current Heating - 5.2 5.5

E.E.R. Cooling Btu/hW 10.1 9.4 9.5

C.O.P Heating - 3.31 3.19

13

26

888 x 287 x 170

770 x 540 x 245

9

34 35

Refrigerant (R22) kg 0.73 0.81 0.84

Airflow Direction Control (Up & Down) O

Remocon Type L.C.D Wireless

inch(mm)

1/4" (6.35)

1/2" (12.7)

Sleeping Operation O

Drain Hose O

Connecting Cable 1.0mm

2

Power Cord 1.0mm

2

Air Circulation

Noise Level

Input

m3/min

dB (A)±3

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Service Valve

Motor Output

Dimensions

(W x H x D)

Net. Weight

W

mm

kg

LS-L1261/1262CL/1263DL LS-L1261/1262HL/1261EL LS-L1220HL

-6-

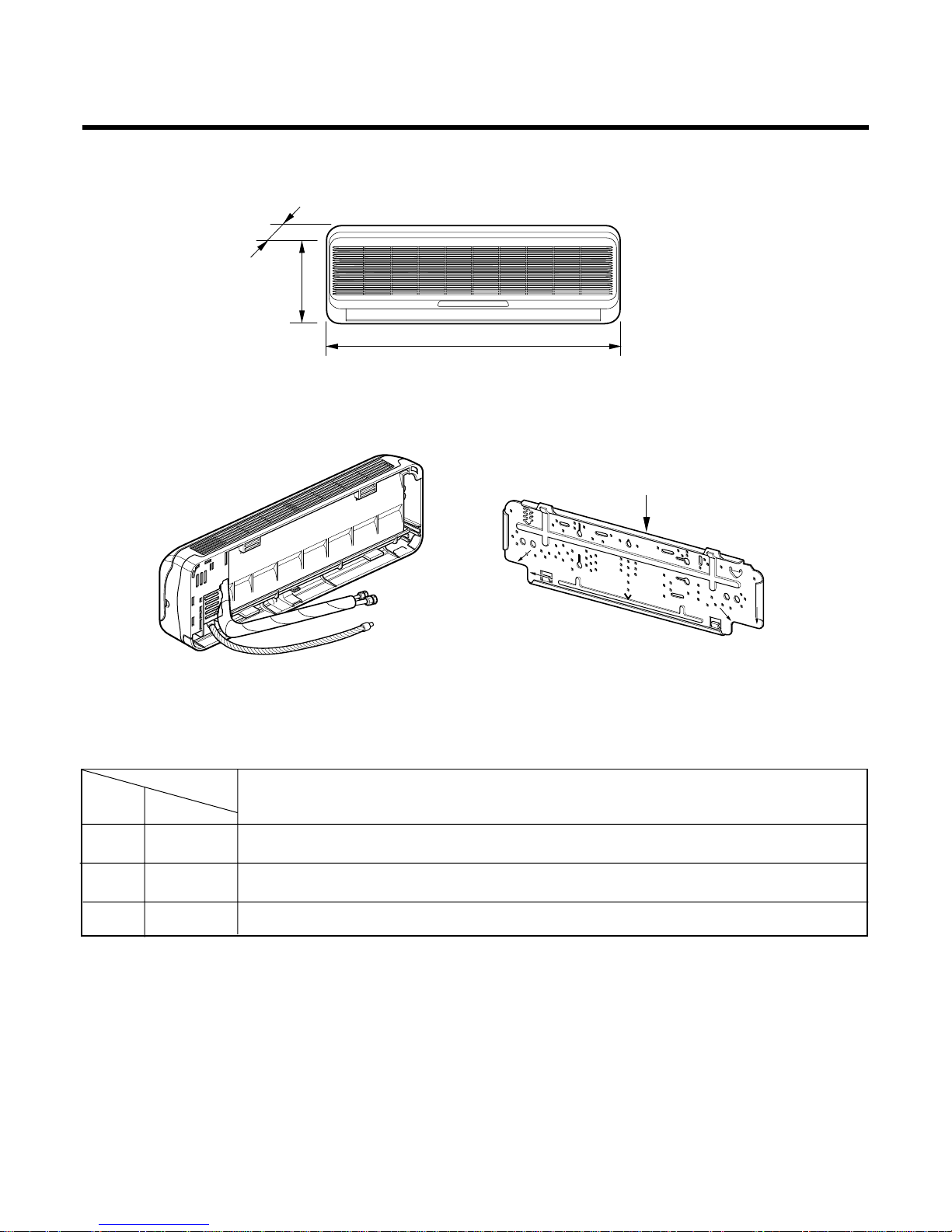

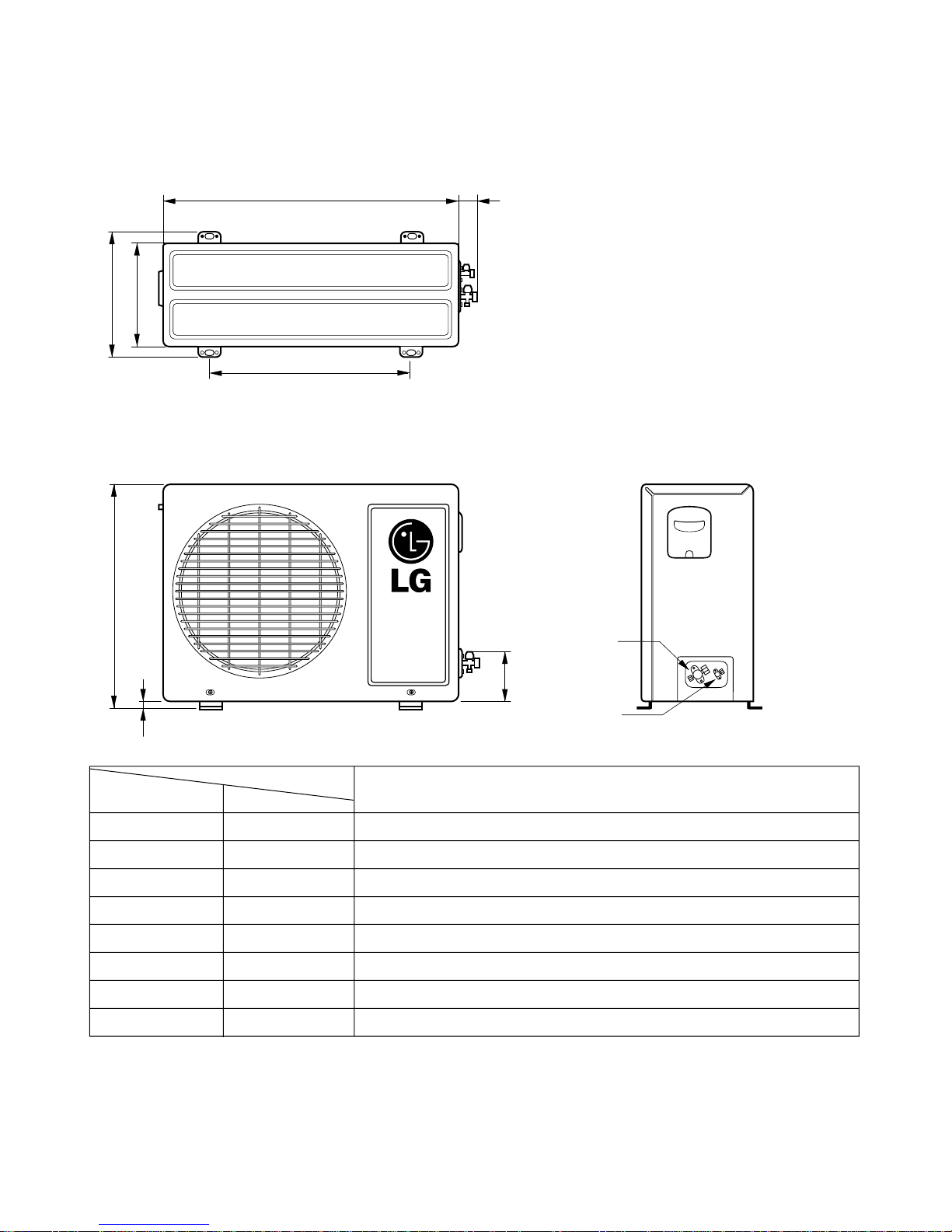

Installation plate

D

H

W

MODEL

DIM Unit

W mm 888

H mm 287

D mm 170

12K Btu Series

Dimensions

(1) Indoor Unit

-7-

(2) Outdoor Unit

W

L2

L3

L1

D

H

L4

L5

Gas side

(3-way valve)

Liquid side

(2-way valve)

MODEL

12K Btu Series

DIM unit

W mm 770

H mm 540

D mm 245

L1 mm 287

L2 mm 64

L3 mm 518

L4 mm 10

L5 mm 100

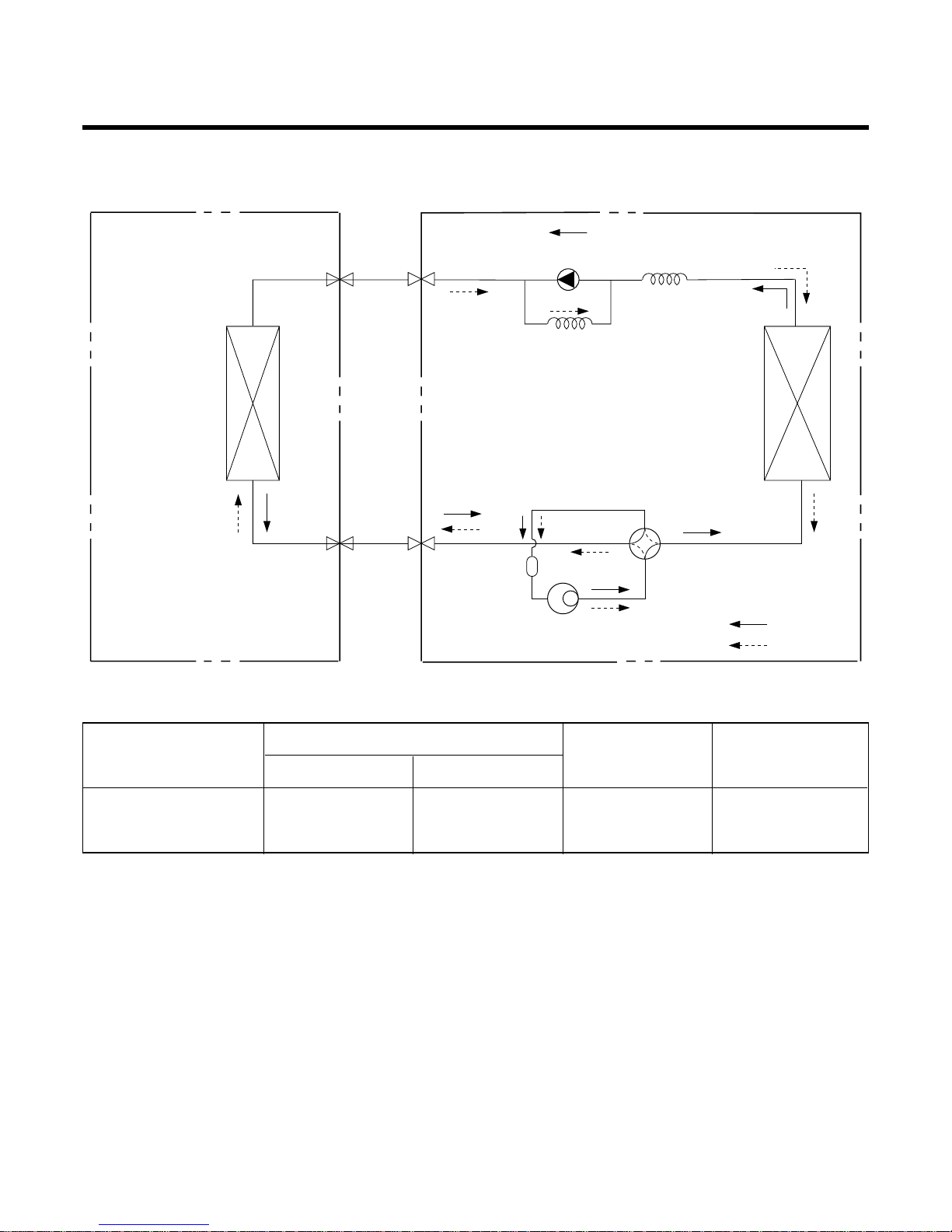

Refrigeration Cycle Diagram

-8-

Pipe size(Diameter:Ø)

MAX. Max

MODEL Piping length Elevation

Gas(inch) Liquid(inch)

(m) (m)

1/2" 1/4" 15 7

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

ACCUMU

LATOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

CAPILLARY TUBE

CHECK VALVE

(Heating Model only)

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

12K Btu SERIES

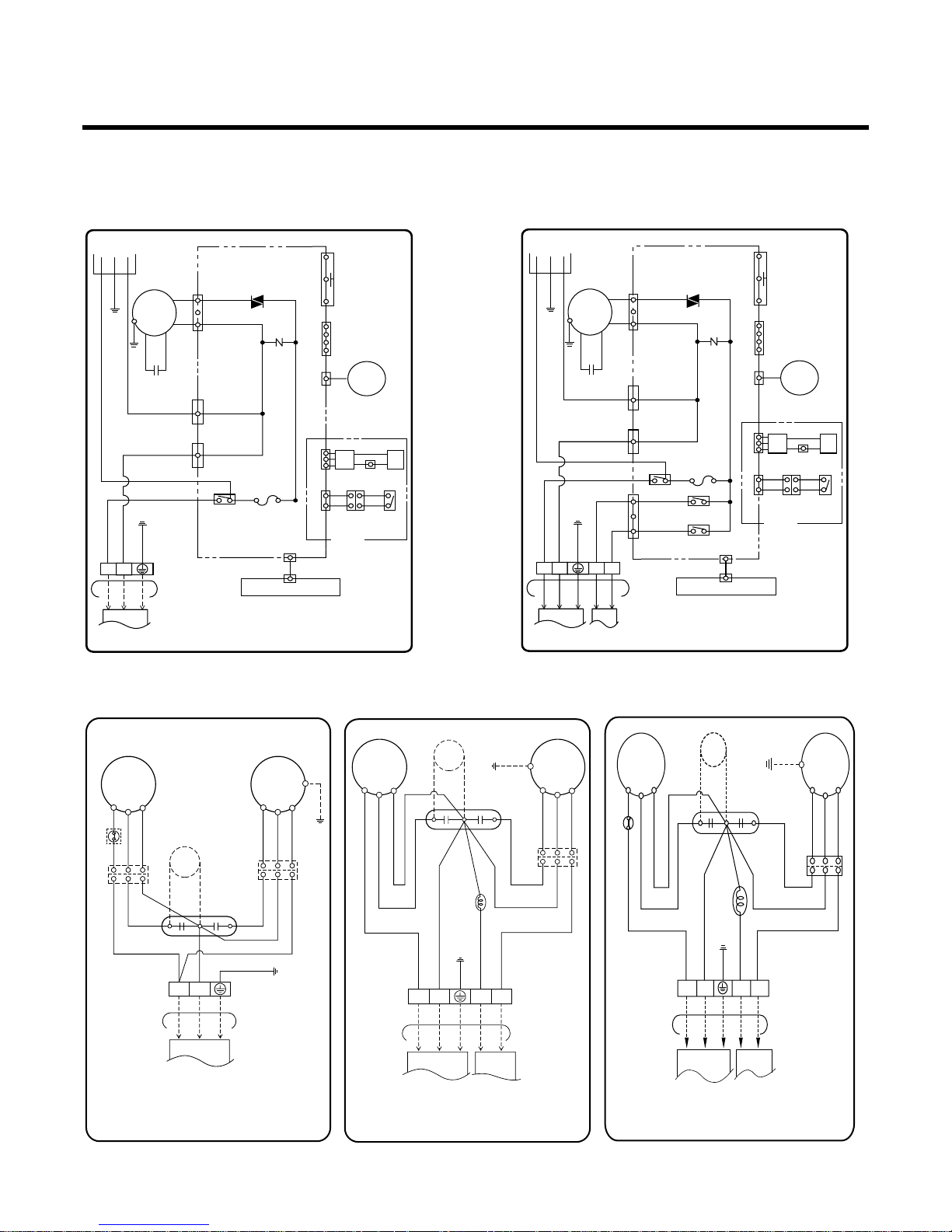

Wiring Diagram

-9-

BL

BK

(RD)

BK

(RD)

BL

YL

YL

BR

RD

RD BL YL

GN/YL

BL BK

RD

BR

GN/YL

BL BL

GN/YL

PTC

3854A30077D

FAN

MOTOR

RD

BL

BR

C

S

R

COMP.

REVERSING

VALVE

OUTDOOR WIRING DIAGRAM

TERMINAL

BLOCK

TO INDOOR UNIT

OLP

H

CF

CAPACITOR

1(L) 2(N) 3 4

3854A30077A

INDOOR WIRING DIAGRAM

CN-DISP1

FUSE

AC250V/T2A

CN-TH1

TRIAC

SH-CAPA.

BL/RIBBED

BR/PLAIN

GN/YL

BR

YL

OR

BK

CN-TAB1

CN-MOTOR

CN-TAB2

RY-COMP.

ZNR

THERMISTOR

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

MOTOR

MAIN PCB

ASM

DISPLAY PCB ASM

POWER

TO OUTDOOR UNIT

PILLAR

TERMINAL

BRBLGN/YL

BR

BL

GN/YL

1(L) 2(N

)

3

4

BL

CN-U/D

STEP

MOTOR

H.V.B A/CL

OPTION

RD

BKBK

BK BK

BK BK

LIMIT

S/W

3854AR6093Y

INDOOR WIRING DIAGRAM

CN-DISP1

FUSE

AC250V/T2A

CN-TH1

TRIAC

SH-CAPA.

BL

BR

GN/YL

BR

YL

OR

BK

CN-TAB1

CN-MOTOR

CN-TAB2

CN-4WAY

RY-COMP.

RY-4WAY

RY-FAN

ZNR

THERMISTOR

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

MOTOR

MAIN PCB

ASM

DISPLAY PCB ASM

POWER

TO OUTDOOR UNIT

PILLAR

TERMINAL

BR

BL

BK

RD

GN/YL

BR

BL

BK

RD

GN/YL

1(L) 2(N

)

34

3

4

BL

BR

CN-U/D

STEP

MOTOR

OPTION

BK BK

BK BK

LIMIT

S/W

H.V.B A/CL

RD

BKBK

COMP

C

S

R

FAN

MOTOR

OLP

BRBRRD BL

BR RD

BL

BL

GN/YL

BR BL

GN/YL

BL BL

RD BL YL

GN/YL

CAPACITOR

BR

RD

BL

YL

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM

3854A30077B

TERMINAL

BLOCK

HCF

PTC

1(L)2(N

)

COMP

C

S

R

FAN

MOTOR

BR RD BL

BR BL

BK(RD)

YL

GN/YL

BR BL BK RD

GN/YL

BL BL

REVERSING

VALVE

RD BL YL

GN/YL

BK(RD)

CAPACITOR

RD

BL

YL

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM

3854A30077T

TERMINAL

BLOCK

HCF

PTC

1(L)2(N

)

34

1. LS-L1261/1262CL/1263DL 2. LS-L1261/1262/1220HL/1261EL

1. LS-L1261/1262CL/1263DL 2. LS-L1261/1262HL/1261EL 3. LS-L1220HL

(1) Indoor Unit

(2) Outdoor Unit

Operation Details

1. MAIN UNIT FUNCTION

• DISPLAY

1) C/O Model

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled.

Comp. Running Incidator

• While in appliance operation, on while in outdoor unit compressor running, off while in compressor off

2) H/P Model

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled

Defrost Indicator

• Off except when hot start during heating mode operation or while in defrost control

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan

stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C

Compressor OFF Temp ➲ Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote control. While in compressor

not running, operating with the low airflow speed regardless of the setting.

■ Healthy Dehumidification Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Intake Air Temp<26°C ➲ Intake Air Temp-1°C

18°C ≤ Intake Intake Air Temp<24°C ➲ Intake Air Temp-0.5°C

Intake Air Temp<18°C ➲ 18°C

-10-

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidifica-

tion operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C

Compressor OFF Temp. ➲ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation

• When the intake air temp reaches +3°…above the setting temp, the compressor is turned off. When below

the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 20°C, when above 28°C , it

operates with the low or setting airflow speed. When the indoor pipe temp is between 20°C and 28°C, it operates with Super-Low(while in sleep mode, with the medium airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C, when above 35°C , it

operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the

outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control

• While in heating mode operation in order to protect the evaporator pipe of the outdoor unit from freezing,

reversed to cooling cycle to defrost the evaporator pipe of the outdoor unit.

• After 40 min heating mode operation, at 4 min interval, whether to carry out defrost control or not and the time

of defrost control are determined according to the following conditions.

1) While in heating mode operation, the maximum of the indoor pipe temperature is measured and it is com-

pared with the present indoor pipe temperature to get the difference of the indoor pipe temperatures (=the

maximum temperature of indoor pipe ? the present temperature of indoor pipe), according to which, whether

to carry out defrost control or not is determined.

2) According to the need of defrost control shown above and the elapsed time of heating mode operation at that

moment, the defrost control time is determined.

3) When the determined time of defrost control is below 7 min, heating mode operation continues without carry-

ing out defrost control. According to the procedure stated above, the determination is made again. When the

defrost control time is 7 min or longer, defrost control is then carried out.

• While in defrost control, the minimum temp of the indoor pipe is measured and it is compared with the present

temp of the indoor pipe to get the difference of the indoor pipe temperatures (=the present temperature of the

indoor pipe ? the minimum temperature of the indoor pipe). When the difference is 5°C or higher, defrost control is completed and heating mode operation is carried out.

• While in defrost control, if the defrost time determined before the start of defrost control is completed, defrost

control stops and heating mode operation is carried out regardless of the above condition.

• When the indoor pipe temp is 42°C or above, defrost control is not carried out even if the condition is one of

the defrost conditions above.

• While in defrost control, the compressor is on and the indoor fan, the outdoor fan, and the 4 way valve are off.

-11-

-12-

■ Fuzzy Operation (C/O Model)

• According to the temperature set by Fuzzy rule, when the intake air temp is 0.5°C or more below the setting

temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp < 26°C ➲ Intake Air Temp + 1°C

22°C ≤ Intake Air Temp < 24°C ➲ Intake Air Temp + 0.5°C

18°C ≤ Intake Air Temp < 22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the

temperature.

■ Fuzzy Operation (H/P Model)

• When any of operation mode is not selected like the moment of the power on or when 3 hrs has passed since

the operation off, the operation mode is selected.

• When determining the operation mode, the compressor, the outdoor fan, and the 4 way valve are off and only

the indoor fan is operated for 15 seconds. Then an operation mode is selected according to the intake air

temp at that moment as follows.

24°C ≤ Inatake Air Temp ➲ Fuzzy Operation for Cooling

21°C ≤ Inatake Air Temp<24°C ➲ Fuzzy Operation for Dehumidification

Inatake Air Temp<21°C ➲ Fuzzy Operation for Heating

• If any of the operation modes among cooling / dehumidification / heating mode operations is carried out for 10

sec or longer before Fuzzy operation, the mode before Fuzzy operation is operated.

1) Fuzzy Operation for Cooling

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp +0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C≤ Intake Air Temp ➲ 25°C

24°C≤ Intake Air Temp<26°C ➲ Intake Air Temp + 1°C

22°C≤ Intake Air Temp<24°C ➲ Intake Air Temp + 0.5°C

18°C≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

-13-

2) Fuzzy Operation for Dehumidification

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp<26°C ➲ Intake Air Temp+1°C

22°C ≤ Intake Air Temp<24°C ➲ Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan repeats the low airflow speed or pause as in

dehumidification operation.

3) Fuzzy Operation for Heating

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 3°C or more above

the setting temp, the compressor is turned off. When below the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp

Compressor OFF Temp ➲ Setting Temp + 3°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

20°C≤Intake Air Temp ➲ Intake Air Temp + 0.5°C

Intake Air Temp<20°C ➲ 20°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is set to the high or the medium according to the

intake air temperature and the setting temperature.

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

■ On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

-14-

■ Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

■ Off-Timer <=> On-Timer Operation

• When the set time is reached after the on/off time is input by the remote control, the on/off-timer operation is

carried out according to the set time.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to the

low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

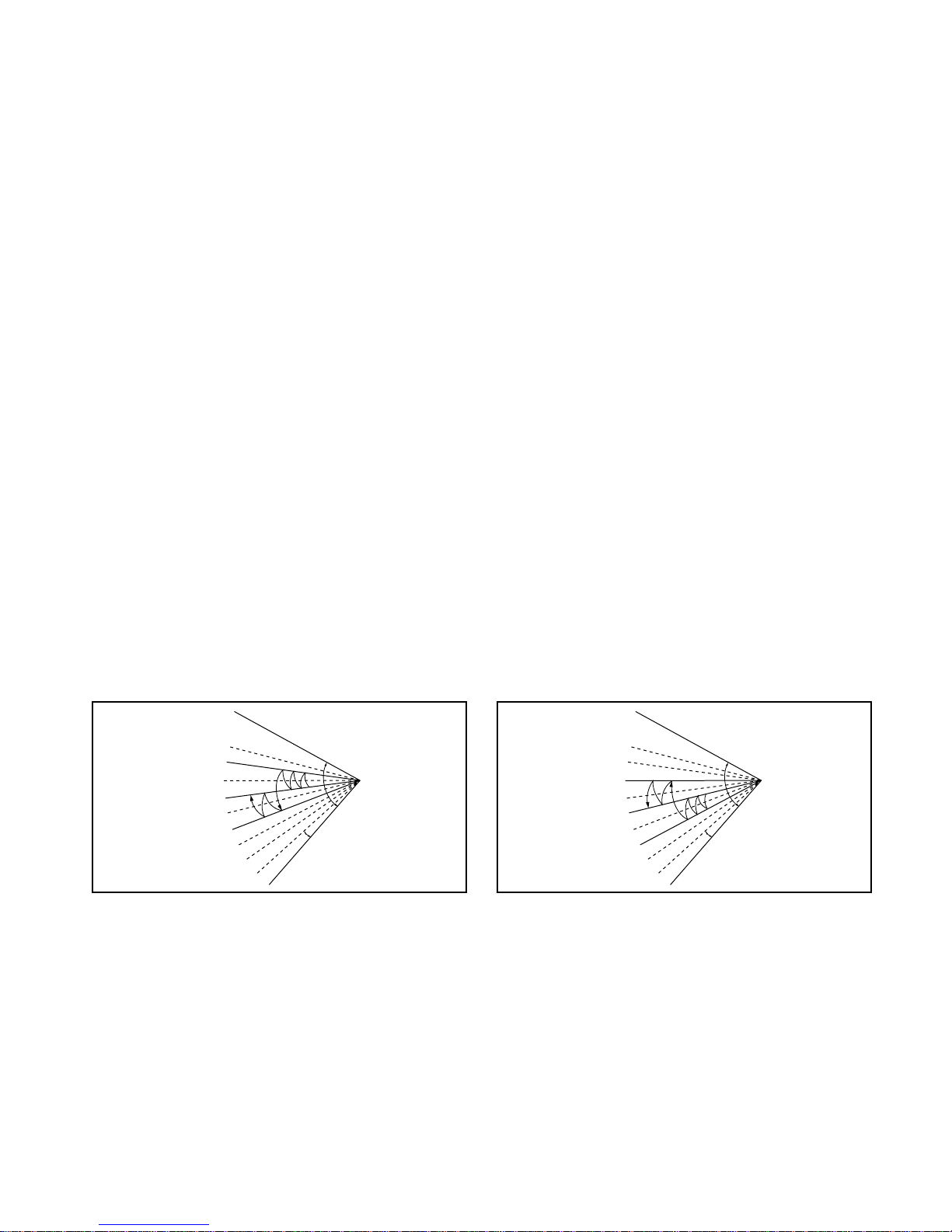

■ Chaos Swing Mode

• By the Chaos Swing key input, the upper/lower vane automatically operates with the Chaos Swing or they are

fixed to the desired direction.

• While in Chaos Swing mode, the angles of cooling and heating cycle operations are different.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

CLOSED

OPEN

< Cooling Mode >

7°

CLOSED

OPEN

< Heating Mode >

7°

-15-

■ Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (H/P Model)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the other

mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then

operated in order that the air outflow could reach further.

■ Auto Restarting Operation

• When the power is restored after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance automatically operates in the mode on the memory.

• The slide switch on the main unit of the appliance should be on the Auto Restarting position in order that the

Auto Restarting operation is available.

• Operation Mode that is kept on the memory

- State of Operation ON/OFF

- Operation Mode/Setting Temp/Selected Airflow Speed

- Sleep Timer Mode/Remaining Time of Sleep Timer (unit of hour)

Slide Switch

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

■ Forced Operation (C/O Model)

• To operate the appliance by force in case that the remote control is lost, the forced operation selection switch is

on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide switch

position is switched to the Auto Restarting position (or test operation) or switched from the remote control position to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position or

the remote control position, the forced operation is canceled and the appliance stops operating.

• The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of

airflow.

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds 10 times to

indicate the forced operation.

-16-

■ Forced Operation (H/P Model)

• To operate the appliance by force in case that the remote control is lost, the forced operation selection switch

is on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide switch

position is switched to the Auto Restarting (or test operation) position or switched from the remote control

position to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position or

the remote control position, the forced operation is canceled and the appliance stops operating.

• The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of

airflow.

• In the forced operation mode, the indoor fan is operated at low speed for around 15 sec and then the operation condition is set according to the intake air temperature as follows.

24°C≤Intake Air Temp ➲ Cooling Mode Operation, 22°C, High Speed

21°C≤Intake Air Temp<24°C ➲ Dehumidification Operation, 23°C, High Speed

Intake Air Temp<21°C ➲ Heating Mode Operation, 24°C, High Speed

• While in forced operation, the key input by the remote control has no effect and the buzzer sounds 10 times to

indicate the forced operation.

■ Remote Control Operation Mode

• When the remote control is selected by the slide switch on the main unit, the appliance operates according to

the input by the remote control.

■ Protection of the evaporator pipe from frosting

• If the indoor pipe temp is below 0°C in 7 min. after the compressor operates without any pause while in cooling cycle operation mode, the compressor and the outdoor fan are turned off in order to protect the indoor

evaporator pipe from frosting.

• When the indoor pipe temp is 7°C or higher after 3 min. pause of the compressor, the compressor and the

outdoor fan is turned on according to the condition of the room temperature.

■ Buzzer Sounding Operation

• When the appliance-operation key is input by the remote control, the short "beep-beep-" sounds.

• When the appliance-pause key is input by the remote control, the long "beep—" sounds.

• When a key is input by the remote control while the slide switch on the main unit of the appliance is on the

forced operation position, the error sound "beep-beep-beep-beep-beep-" is made 10 times to indicate that the

remote control signal cannot be received.

■ Air Cleaner Operation

• When an air cleaner function is selected during Air Conditioner operation

- Plasma air cleaner function will be operated while in any operation mode with selecting the function.

- The function is to be stopped while it is operating with selecting the function.

• When an air cleaner function is selected during operation off

- The function will be only operated.

• When inlet grille of air conditioner is opened during plasma operation, High Voltage Generator(H.V.B) is to be

stopped. When inlet grille of air conditioner is closed during plasma operation, High Voltage Generator(H.V.B)

will be operated again.

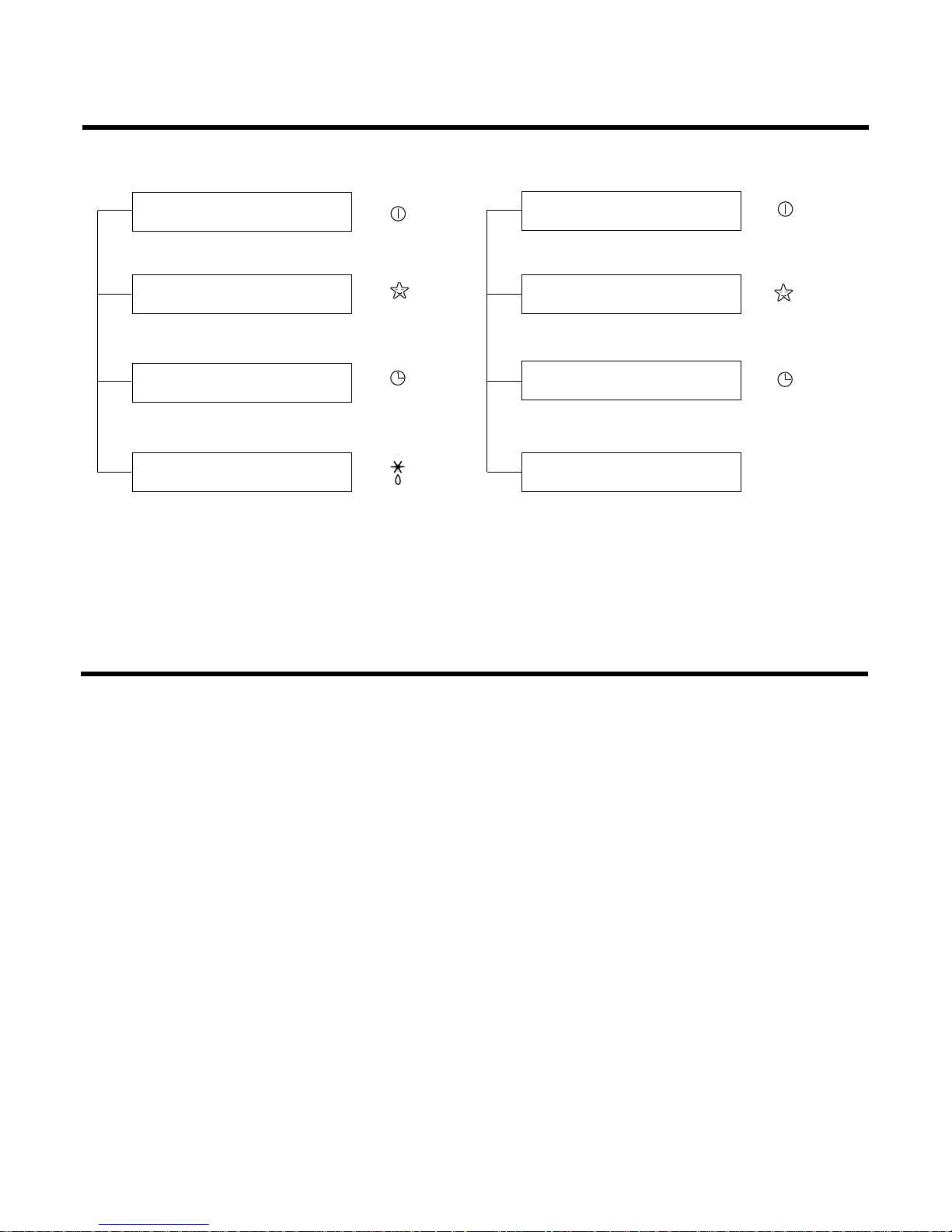

Display Function

1. Heating Model 2. Cooling Model

• Cooling, Soft Dry, Fan, Heating • Cooling, Soft Dry, Fan

• Sleep Mode • Sleep Mode

• Timer Mode • Timer Mode

• Hot-start, Defrost

Self-diagnosis Function

■ Thermistor Error Indicator

• When the indoor pipe sensor or the room temperature sensor is open or is shorted, the error is indicated.

• To indicate the error, the operation LED (or the cooling LED) flashed at 3 sec interval.

• When the error is cleared, the LED stops flashing, the operation (or cooling) LED is on.

• While in appliance pause, the error is not indicated.

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Defrost Indicator

-17-

Operation Indicator

Timer Indicator

Sleep Timer Indicator

Compressor on Indicator

OUT

DOOR

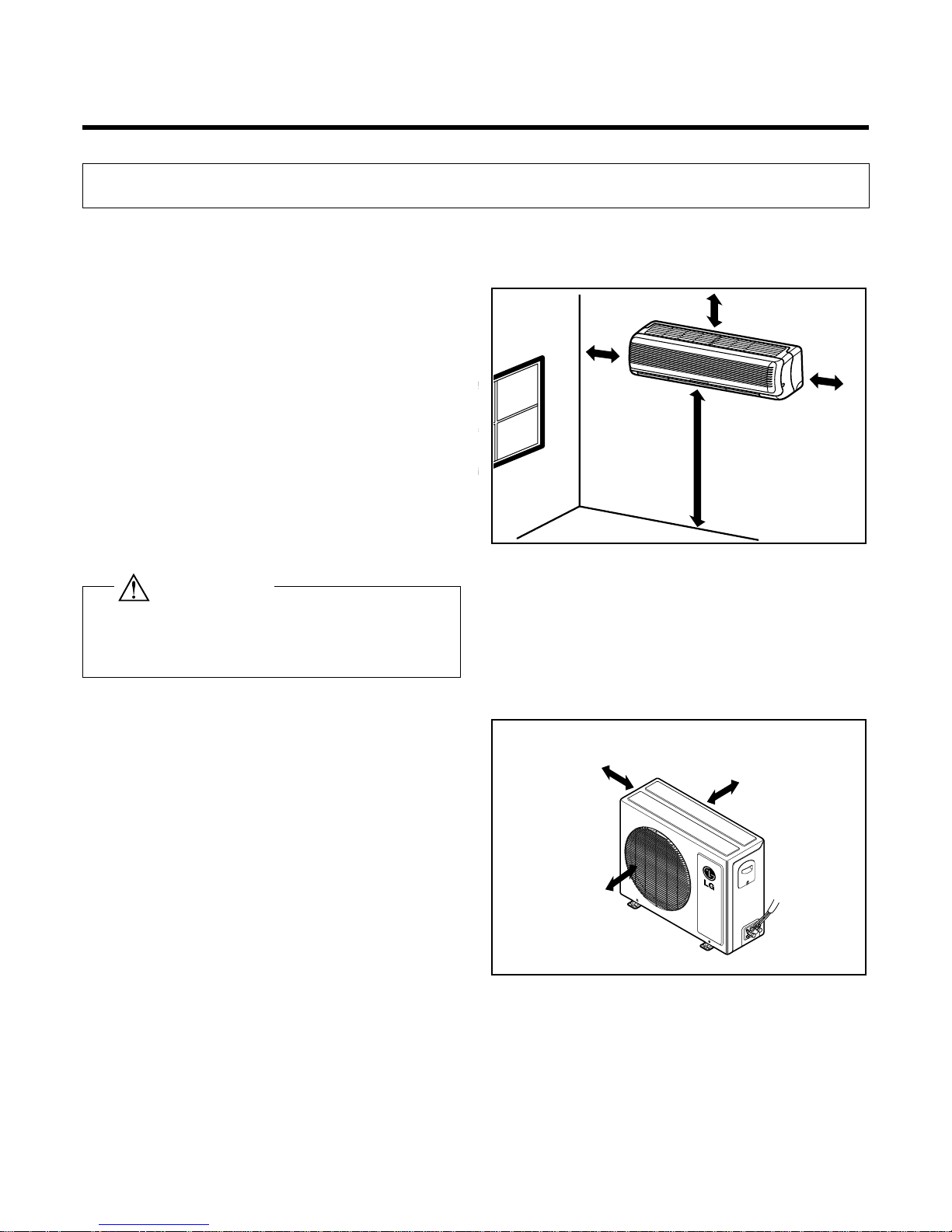

Installation

1. Installation of indoor, Outdoor unit

-18-

More than 2.3 m

More than 5 cm

More than

5 cm

More than

5 cm

More than 10 cm

More than 10 cm

More than 70 cm

1) Selection of the best location

1. Indoor unit

2. Outdoor unit

• There should not be any heat source or steam

near the unit.

• There should not be any obstacles to prevent the

air circulation.

• A place where air circulation in the room will be

good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

• If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful

that heat radiation from the condenser is not

restricted.

• There should not be any animals or plants

which could be affected by hot air discharged.

• Ensure the correct distance is left from the

wall, ceiling, fence, or other obstacles as indicated in the diagram.

Install the indoor unit on the wall where the height

from the floor is more than 2.3 meters.

CAUTION

-19-

5-7mm

Indoor Outdoor

WALL

ø70mm

A

A

A

A

Center

Right rear pipingLeft rear piping

Center

ø70mm

Installation plate

Marking-off line

Thread

Weight

Type "A" screw

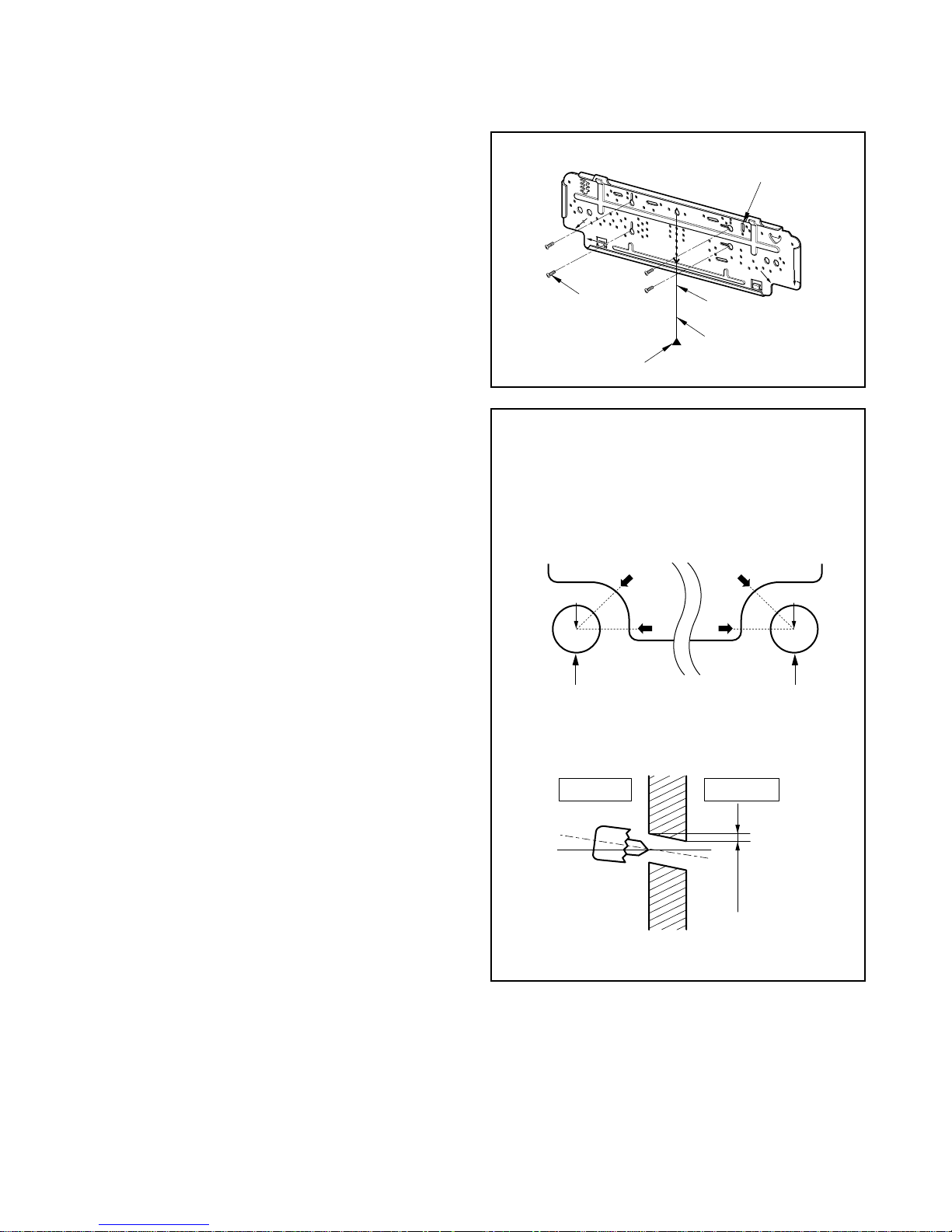

2) Indoor Unit Installation

The mounting wall should be strong and solid enough

to protect it from the vibration.

1.Mount the installation plate on the wall with four

Type "A" screws.

(if mounting the unit on the concrete wall, consider

using anchor bolts.)

• Always mount the Installation plate horizontally by

aligning the marking-off line by means of the

thread and a level.

2. Drill the piping hole with 70mm dia. holecore

drill.

• Line according to the arrows marked on lower the

left and the right side of the Installation Plate.

The meeting point of the extended line is the center of the hole.

• Drill the Piping hole at either the r ight or the left

and the hole should be slightly slanted to the outdoor side.

The lower left and right side of Installation

Plate

12K Btu

-20-

2. Piping and Drainage of Indoor Unit

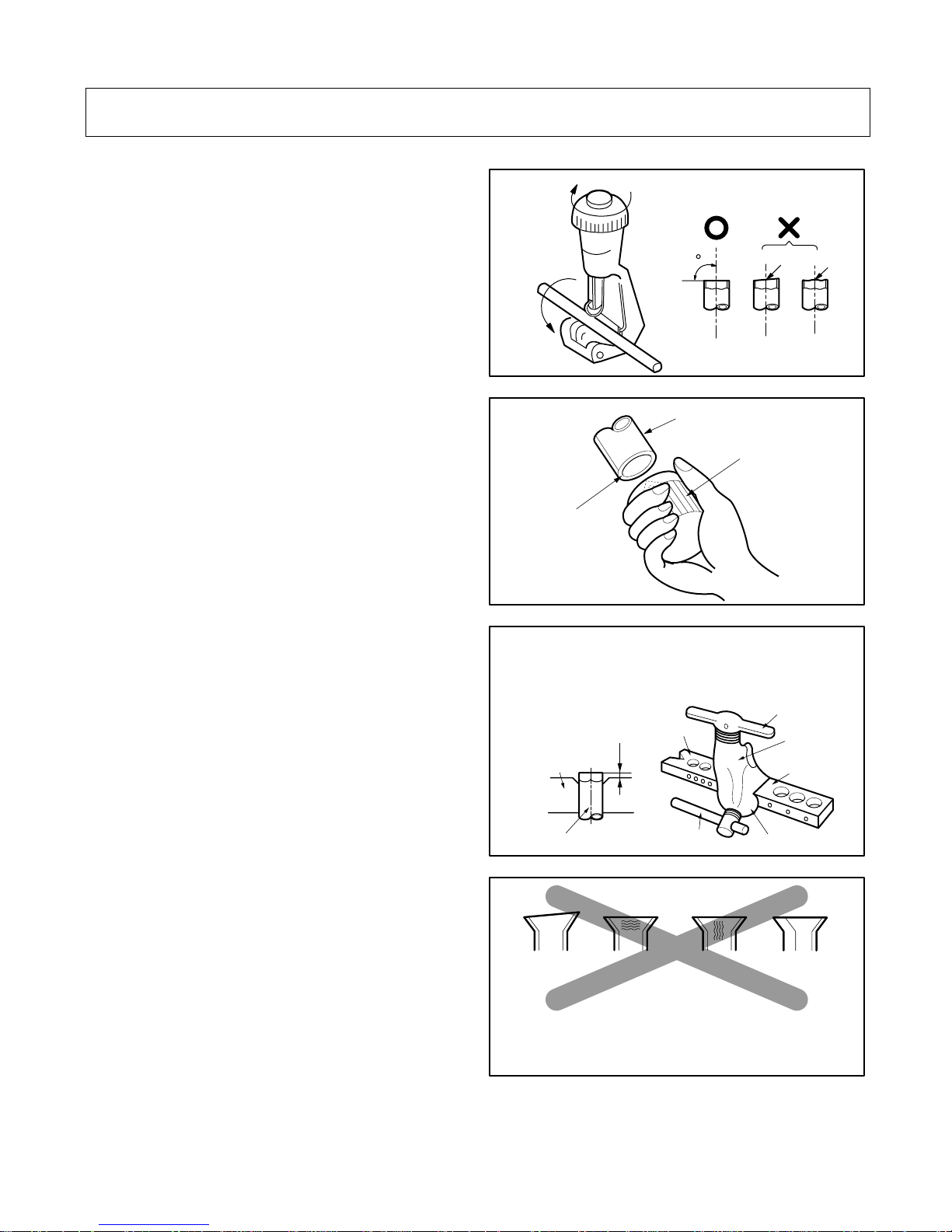

1) Preparation of Piping

1. Cut the pipes and the cable.

• Use the accessory piping kit or the pipes purchased locally.

• Measure the distance between the indoor and the

outdoor unit.

• Cut the pipes a little longer than measured distance.

• Cut the cable 1.5m longer than the length of the

pipe.

2. Remove burrs.

• Remove burrs from cut edges of pipes.

• Turn the pipe end toward down to avoid the metal

powder entering the pipe.

Caution:

If burrs are not removed, they may cause a gas leakage.

3. Flaring the pipes.

• Inser t the flare nuts, mounted on the connection

ports of both indoor and outdoor unit, onto the

copper pipes. (When the flare nuts are removed

from the indoor unit.) Some gas may leak, as

some gas is charged to prevent the inside of the

pipe from rusting.

• Fit the copper pipe end into the Bar of flare tool

about 0~1.0mm higher.

(See illustration)

• Flare the pipe ends.

4. Tape the flaring portion to protect it from the

dust or damages.

90

Slanted Rough

Pipe cutter

Pipe

Reamer

Point down

"A"

Bar

Bar

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Copper pipe

Inclined Cracked Uneven

thickness

Surface

damaged

= Improper flaring =

When properly flared, the internal surface of the flare will

evenly shine and be of even thickness.

After the flare part comes into contact with the connectors, carefully check the flare finish.

"A"; ø15.88 mm (5/8") →

0~1.0 mm

ø12.7 mm (1/2") →0~0.5 mm

ø9.52 mm (3/8") →0~0.5 mm

ø6.35 mm (1/4") →0~0.5 mm

-21-

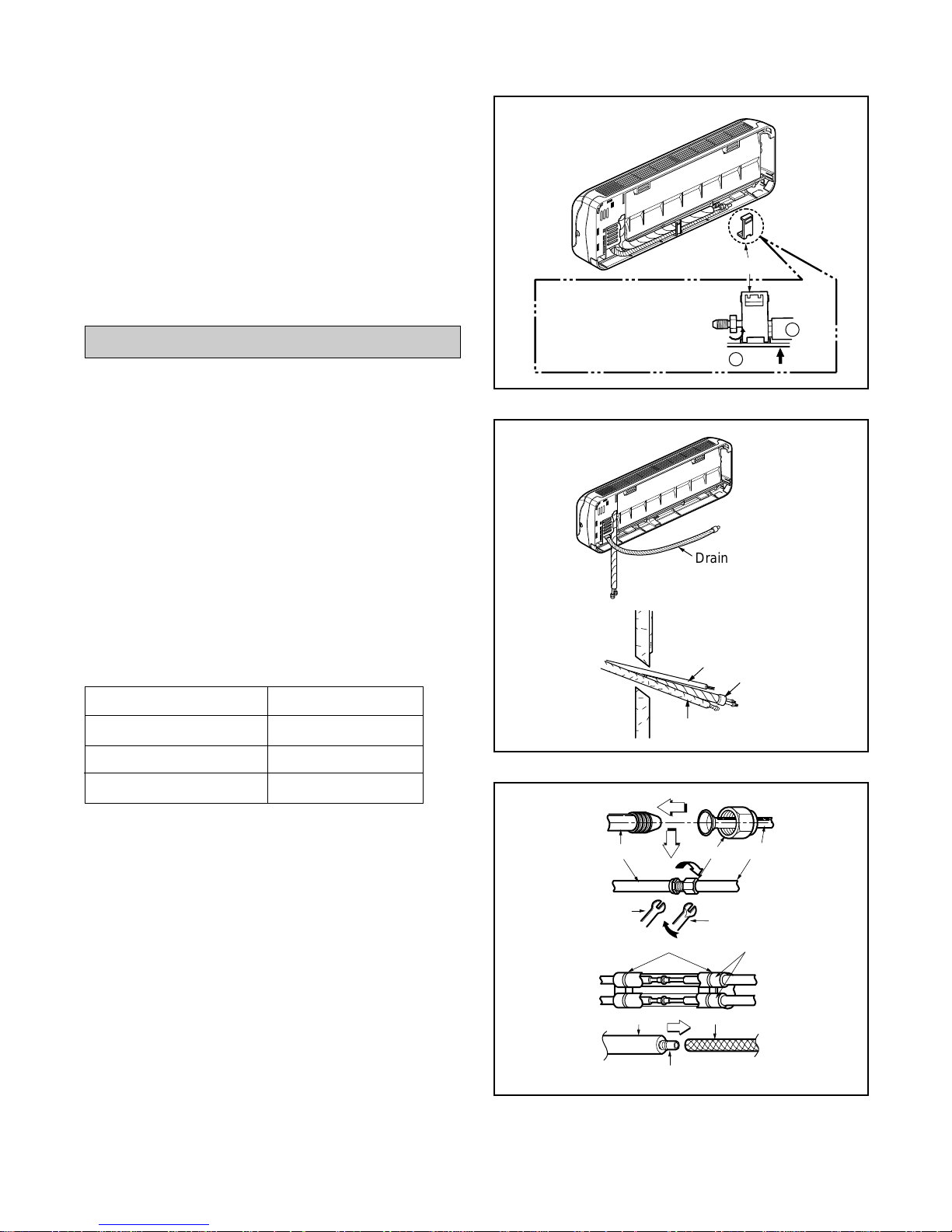

To remove the holder,

press the bottom of

chassis near the holder

upward and pull the tab

out of its hole.

Tubing holder

Pull

Press

2

1

Drain hose

Indoor Outdoor

Connecting cable

Connecting

piping

Drain pipe

Indoor unit tubing Flare nut

Spanner

Torque wrench

Plastic bands

Drain hose

Adhesive

Drain pipe

Insulation material

Pipings

2)

Connection of Pipings

1. Remove the tubing holder.

2. Route the drain hose and the indoor tubing.

For right rear piping

3. Insert the piping, the connecting cables and the

drain pipe through the piping hole on the wall.

4. Connect the piping and the indoor tubing, and

drain hose and drain pipe.

• Don't connect the cable to the indoor unit.

• Wrap the insulation material around the connect-

ing portion.

• Glue up the connection portion of drain hose and

drain pipe.

Pipe Size Torque

Liquid Side (1/4") 1.8kg.m

Gas Side (3/8") 4.2kg.m

Gas Side (1/2") 5.5kg.m

Loading...

Loading...