LG LP-K3023CL Installation Manual

P/No. : 3828A20155A

ENGLISH

FLOOR STANDING TYPE AIR CONDITIONERS

INSTALLATION INSTRUCTIONS

• Please read this instruction sheet completely before installing the product.

• When the power cable is wanted to replace, replacement work shall be

performed by authorized personnel only.

• Installation work must be performed in accordance with national wiring standards

by authorized personnel only.

Applied Model:

(1) 20K/28K/30K/40K(Btu/h)

(2) 50K(Btu/h)

(3) 80K(Btu/h)

2

Contents

1. Safety precautions

.............................................................................................

3

2. Installation of Indoor, Outdoor Unit

..................................................................

4

1) Selection of the best location

2) Indoor unit installation

3) Outdoor unit installation

4) Refrigerant amount

3. Installation Method

.............................................................................................

6

1) Procedure

2) Preparation of installation parts and tools

4. Piping of Indoor Unit

..........................................................................................

8

1) Preparation of piping

2) Connection of piping

3) Precautions in bending

5. Connecting the Cable to Indoor Unit

................................................................

10

6. Connecting the Cable to tele control Unit

........................................................

11

7. Connecting piping and the Cable to Outdoor Unit

..........................................

12

1) Connecting the piping to the outdoor unit

2) Connecting the cable to the outdoor unit

8. Power Supply and Wiring

..................................................................................

13

1) Power spply

2) Wiring

9. Vacuum Drying of the Connecting Pipes and the Indoor Unit

.......................

14

10. Checking the Drainage and Form the Piping

.................................................

15

1) Checking the Drainage

2) Form the Piping

11. Final Check and Test Run

................................................................................

17

3

ENGLISH

1. Safety precautions

• Please report to or take consent by the supply authority before connection to the system.

• Be sure to read "THE FOLLOWING SHOULD ALWAYS BE OBSERVED FOR SAFETY" before installing

the air conditioner.

• Be sure to observe the cautions specified here as they include important items related to safety.

• The indications and meanings are as follows.

• After reading this manual, be sure to keep it together with the instruction manual in a handy place on the

customer's site.

Could lead to death, serious injury, etc.

Do not install it yourself (customer).

Perform the installation securely referring to the

installation manual.

Install the unit securely in a place which can bear the

weight of the unit.

Perform electrical work according to the installation

manual and be sure to use an exclusive circuit.

Attach the electrical part cover to the indoor unit and the

service panel to the outdoor unit securely.

Be sure to use the part provided or specified parts for

the installation work.

Check that the refrigerant gas due not leak after

installation is completed.

Perform grounding

Do not install the unit in a place where an inflammable

gas leaks.

Perform the drainage/piping work securely according to

the installation manual.

Use the specified wires to connect the indoor and

outdoor units securely and attach the wires firmly to the

terminal board connecting sections so the stress of the

wires is not applied to the sections.

• Incomplete installation could cause injury due to fire, electric shock, the

unit falling or a leakage of water. Consult the dealer from whom you

purchased the unit or special installer.

• Incomplete installation could cause a personal injury due to fire,

electric shock, the unit falling or a leakage of water.

• When installed in an insufficient strong place, the unit could fall

causing injured.

• Incomplete connecting and fixing could cause fire.

• If the capacity of the power circuit is insufficient or there is incomplete

electrical work, it could result in a fire or an electric shock.

• The use of defective parts could cause an injury or leakage of water

due to a fire, electric shock, the unit falling, etc.

Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge.

Do not compress air or Oxygen and Do not use Flammable gases. Otherwise, it may cause fire or explosion.

• There is the risk of death, injury, fire or explosion.

• If gas leaks and accumulates in the area surrounding the

unit, it could cause an explosion.

• If there is a defect in the drainage/piping work, water

could drop from the unit and household goods could be

wet and damaged.

The means for connection to power supply shall be

incorporated in the fixed wiring and have an air gap contact

separation of at least 3mm in all active(phase) conductors.

• This product should be grounded.

• Defective grounding could cause an electric shock.

• If the electrical part cover if the indoor unit and/or the service panel if

the outdoor unit are not attached securely, it could result in a fire or

electric shock due to dust, water, etc.

Could lead to serious injury in particular environments when operated incorrectly.

WARNING

WARNING

CAUTION

CAUTION

20K 5/8" 1/4" 25 15

28K/30K/40K 5/8" 3/8" 30 20

50K 3/4" 3/8" 40 25

80K 1" 5/8" 50 30

4

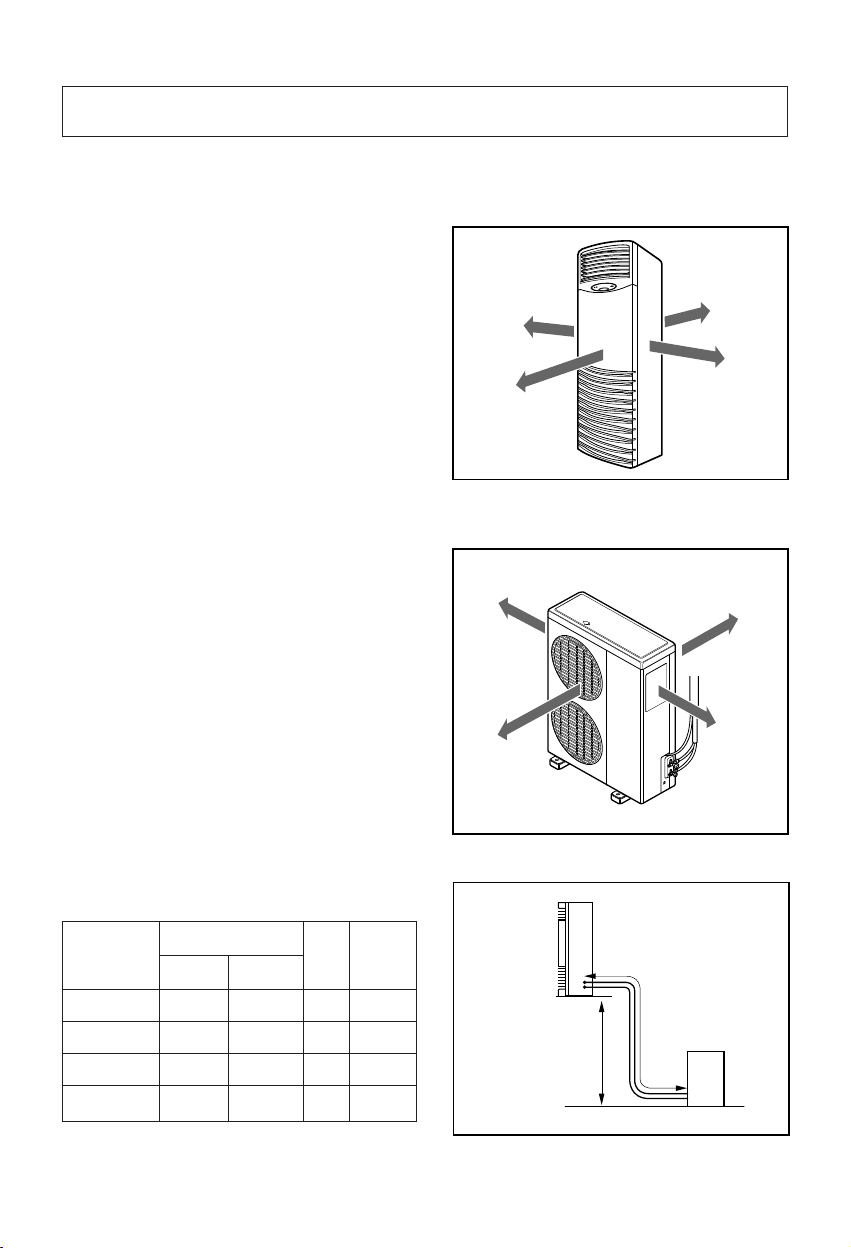

2. Installation of Indoor, Outdoor unit

5cm

40cm

5cm

100cm

50cm

50cm

50cm

100cm

1) Selection of the best location

① Indoor unit

② Outdoor unit

③ Piping length and the elevation

• There should not be any heat source or

steam near the unit.

• There should not be any obstacles to prevent

the air circulation.

• A place where air circulation in the room will

be good.

• A place where drainage can be easily

obtained.

• A place where noise prevention is taken into

consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from

the wall, ceiling, fence, or other obstacles.

• If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful

that heat radiation from the condenser is not

restricted.

• There should not be any animals or plants

which could be affected by discharged hot air.

• Ensure the space indicated by arrows from

the wall, ceiling, fence, or other obstacles.

PIPE SIZE

MODEL

GAS SIDE LIQUID SIDE

Max.

Length

A (m)

Max.

Elevation

B (m)

A

B

Indoor unit

Outdoor unit

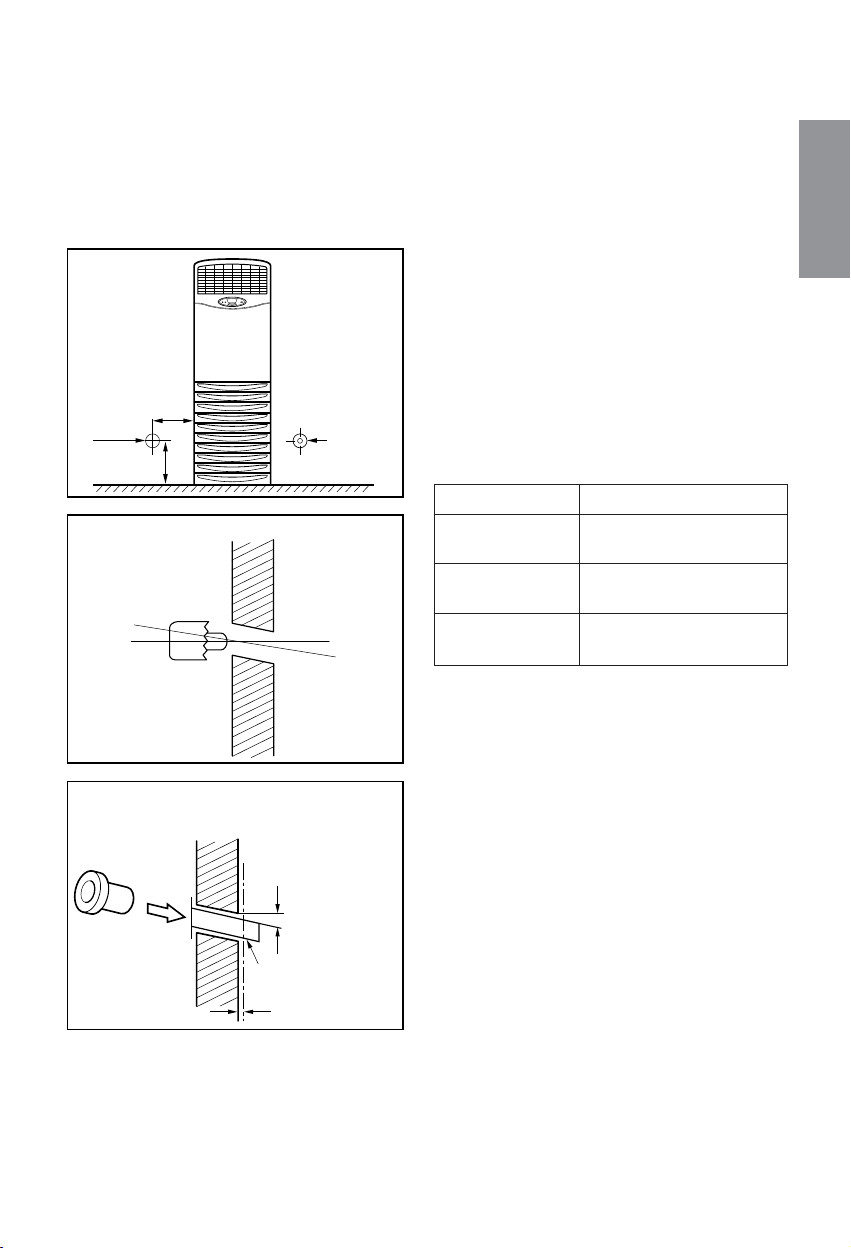

2) Indoor Unit installation

The mounting floor should be strong and

solid enough to prevent it from vibration.

Drill the piping hole with 70mm diameter

hole-core drill at either the right or the left of

indoor unit. The hole should be sightly slant

to the outdoor side.

Insert the plastic tube through the hole.

Cut the extruded outside part of the plastic

tube, if necessary.

3) Outdoor unit Installation

Install the outdoor unit on the concrete or any

solid base securely and horizontally by

securing it with bolts (Ø12mm) and nuts.

If there is any vibration transmitted to the

building, mount the rubber underneath the

outdoor unit.

4) Refrigerant amount

Before shipment, this air conditioner is filled

with the rated amount of refrigerant including

additional amount required for air-purging,

subject to 5m piping length. (The rated

amount of refrigerant is indicated on the

name plate.) But when the piping length

exceeds 5 meters, additional charge is

required according to the following table.

(Unit: g)

Example) 28K/30K

In case of 10m long pipe(one-way), the amount

of refrigerant to be replenished is:

(10 - 5) x 30 = 150g

REFRIGERANT CHARGE

30g per 1m

40g per 1m

50g per 1m

5

ENGLISH

200mm

70mm

70mm

90mm

Wall

Core Drill

Tilt

Cut if necessary

More than 15mm

Wall

Plastic tube

(Bushing)

INSIDE OUTSIDE

MODEL

20K/28K/30K/40K

(Btu/h)

50K

(Btu/h)

80K

(Btu/h)

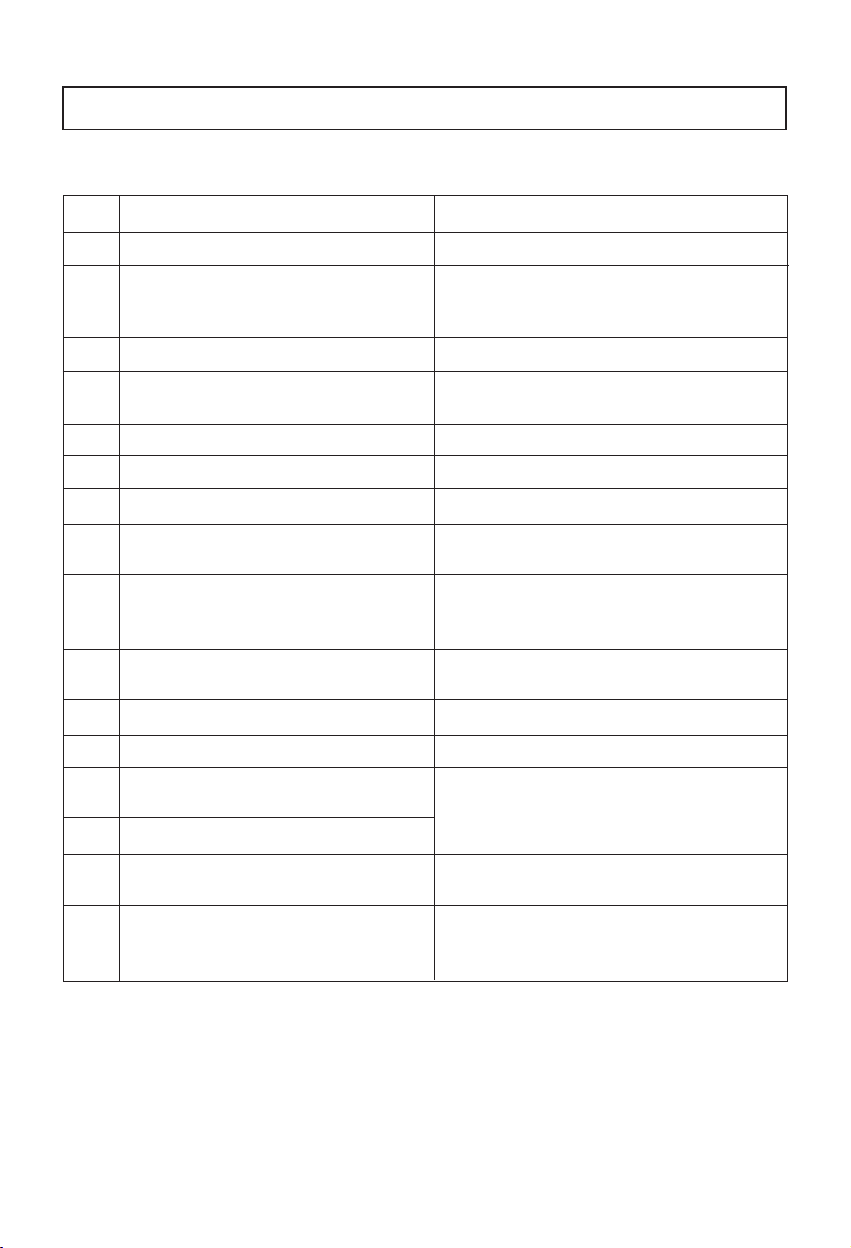

3. Installation Method

No. Installation works Descriptions

1 Preparation of tools and installation parts Preparation of installation

2 Flaring the pipes To insert the flare nuts, mounted on the

connection parts of both indoor and

outdoor unit, onto the copper pipes.

3 Pipe bending To reduce the flow resistance of refrigerant.

4 Connection of installation parts Connection of long piping

(elbows, socket etc)

5 Tighten the flare nut (outdoor) Connecting the pipings of the outdoor unit.

6 Blowing the pipings To remove dust and scale in working.

7 Tighten the flare nut (indoor) Connecting the pipings of the indoor unit.

8 Check a gas-leakage of the connecting

part of the pipings.

9 Vacuum drying of the piping and indoor unit The air which contains moisture and which

remains in the refrigeration cycle may cause a

malfunction on the compressor

10 Open the 3-way (liquid side) and

3-way (gas side) valves.

11 Form the pipings To prevent heat loss and sweat

12 Checking the drainage (indoor unit) To ensure if water flow drain hose of indoor unit.

13 Connecting the cable between outdoor Preparation of the operating

and indoor unit

14 Connecting the main cable to outdoor unit

15 Supply the power to the crankcase heater To prevent the liquid back to the compressor.

(Before the operating the unit) (Heat pump only)

16 Cooling operation

(Use the remote control or display of the

indoor unit)

1) Procedure

6

Loading...

Loading...