LG LP-E5022HA, LP-E5022CL, LP-E5082CL, LP-E5082CA, LP-E5082HL Service Manual

...

Package

Air Conditioner

SERVICE MANUAL

MODEL: LP-E5020CL

LP-E5022CL/CA/HL/HA

LP-E5082CL/CA/HL/HA/ZL/ZA

LP-E5092CL/CA/HL/HA

LP-E50B0CL/CA/HL/HA

1. Preface

............................................................................................................................................

3

2. Dimensions

......................................................................................................................................

8

3. Refrigerant Cycle Diagram

.............................................................................................................

9

4. Wiring Diagram

..............................................................................................................................

10

5. Operation Details

...........................................................................................................................

18

6. Installation

.....................................................................................................................................

24

7. Operating

.......................................................................................................................................

40

8. 3-Way Valve

....................................................................................................................................

43

9. Troubleshootig Guide

...................................................................................................................

51

10. Electronic Control Device

.............................................................................................................

66

11. Schematic Diagram

.......................................................................................................................

68

12. Exploded View & Replacement Parts List

...................................................................................

70

– 2 –

CONTENTS

This service manual provides various service information, containing the mechanical and electrical parts and etc.

This package air conditioner was manufactured and assembled under the strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 Safety Precautions

¤ When servicing the unit, set the main SWITCH to OFF and remove the POWER SUPPLY cables.

¤Ł Observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

¤Ø After servicing the unit, make an insulation resistance test to protect the customer from being exposed to shock

hazards.

1.2 Features

¤ Design for cooling and heating

¤ŁSuper energy efficiency

¤ØMicom Control

¤ŒWhisper quiet operation

¤ºWireless remote control

¤ Removable air filter

¤ 3 minute delay circuit

¤ 7 hour timer

¤ 3 step speeds for cooling/heating

¤ Plasma air purifying system

¤æAuto Restart

– 3 –

1. PREFACE

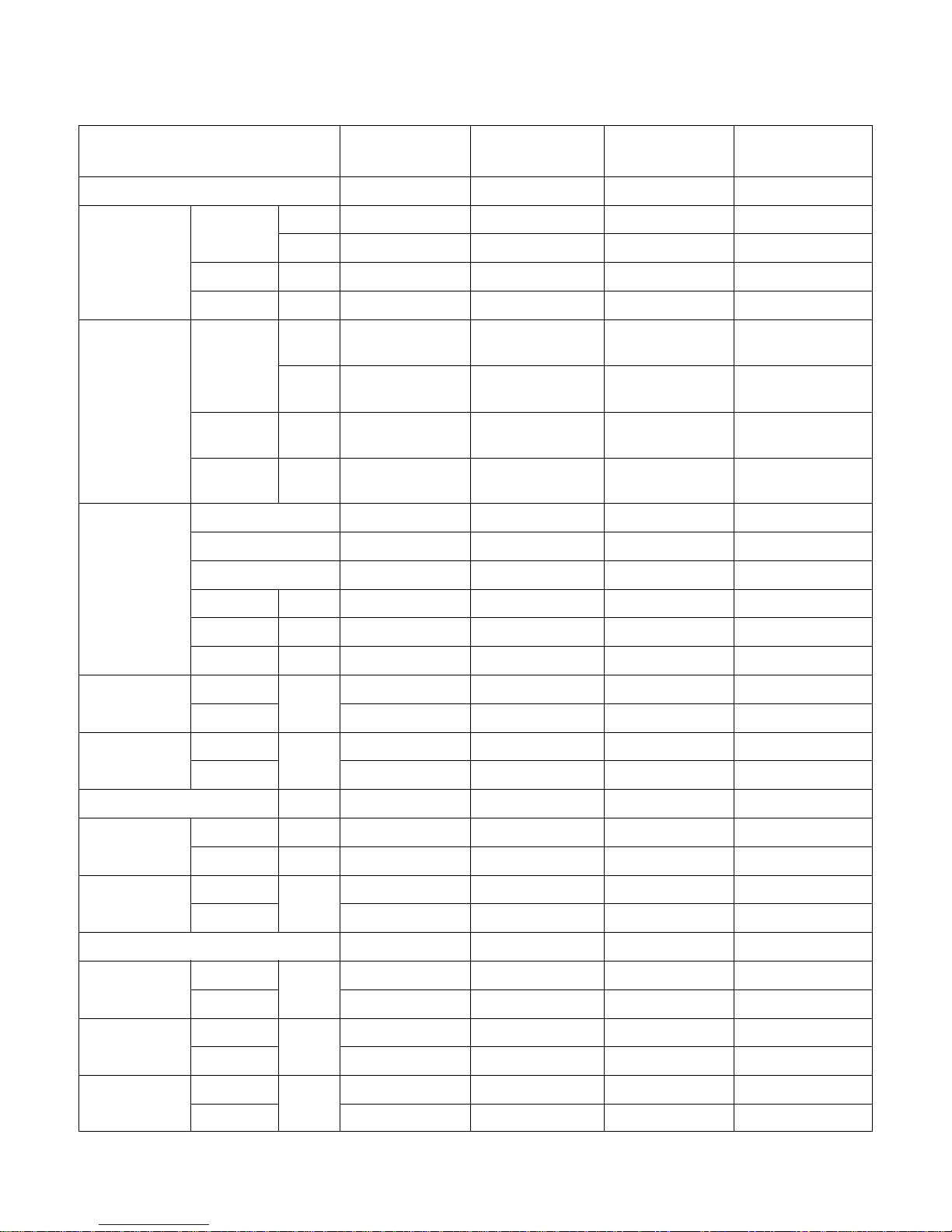

POWER SOURCE (ø, V, Hz)

COOLING CAPACITY Btu/h

W

INPUT W

CURRENT A

HEATING CAPACITY Btu/h

(W)

W

(W)

INPUT W

(W)

CURRENT A

(A)

MAKER

TYPE

COMPRESSOR MODEL

INPUT W

CURRENT A

CAPACITY Kcal/h

NOISE INDOOR dB(A)

LEVEL(1m) OUTDOOR

AIR INDOOR CMM

VOLUME OUTDOOR

REFRIGERANT R-22 Kg

HEAT INDOOR R/C/FPI

EXCHANGER OUTDOOR R/C/FPI

FAN INDOOR TYPE

OUTDOOR

ROOM TEMPERATURE CONTROL

NET INDOOR Kg

WEIGHT OUTDOOR

DIMENSIONS INDOOR mm

(W

× H × D) OUTDOOR

SVC LIQUID Inch

VALVE GAS (mm)

3.380 - 415,50 3,380 - 415,50 1,200,60 1,220,60

44,000 44,000 44,000 44,000

12,896 12,896 12896 12,896

3,600 3,600 3,600 5500

6 6 19 25

–

48,000

– 48,000

+(3,000)

–

14069

– 14,069

+(3,000)

–

3,500

– 4900

+(3,000)

–

5.5

– 24

+(13.5)

Tecumseh Tecumseh Copeland Copeland

Recipro Recipro Recipro Recipro

AVB5558EXG AVB5558EXG CR42K6-PFV CRMQ-0400-PFV

4,340 4,340 3,860 5,370

6.9 6.9 17.8 25.2

11,620 11,620 10,559 12,928

53 53 53 53

58 58 58 58

35 35 35 35

104 104 104 104

2.8 3.2 3.5 3.9

3/28/17 3/28/17 3/28/17 3/28/17

2/44/16 2/44/18 2/44/16 2/44/17

SIROCO SIROCO SIROCO SIROCO

PROPELLER PROPELLER PROPELLER PROPELLER

MICOM CONTROL MICOM CONTROL MICOM COTROL MICOM CONTROL

62 62 62 62

90 90 90 90

590 × 1,810 × 440 590 × 1,810 × 440 590 × 1,810 × 440 590 × 1,800 × 440

1,000 × 965 × 370 1,000 × 965 × 370 900 × 1,225 × 370 900 × 1,225 × 370

3/8 3/8 3/8 3/8

3/4 3/4 3/4 3/4

1.3 Product Specifications

– 4 –

MODEL

LP-E5082CL/CA

LP-E5082HL/HA

LP-E5082ZL/ZA

LP-E5020CL

LP-E5022CA

LP-E5022HL/HA

(Including Electiric

heater)

– 5 –

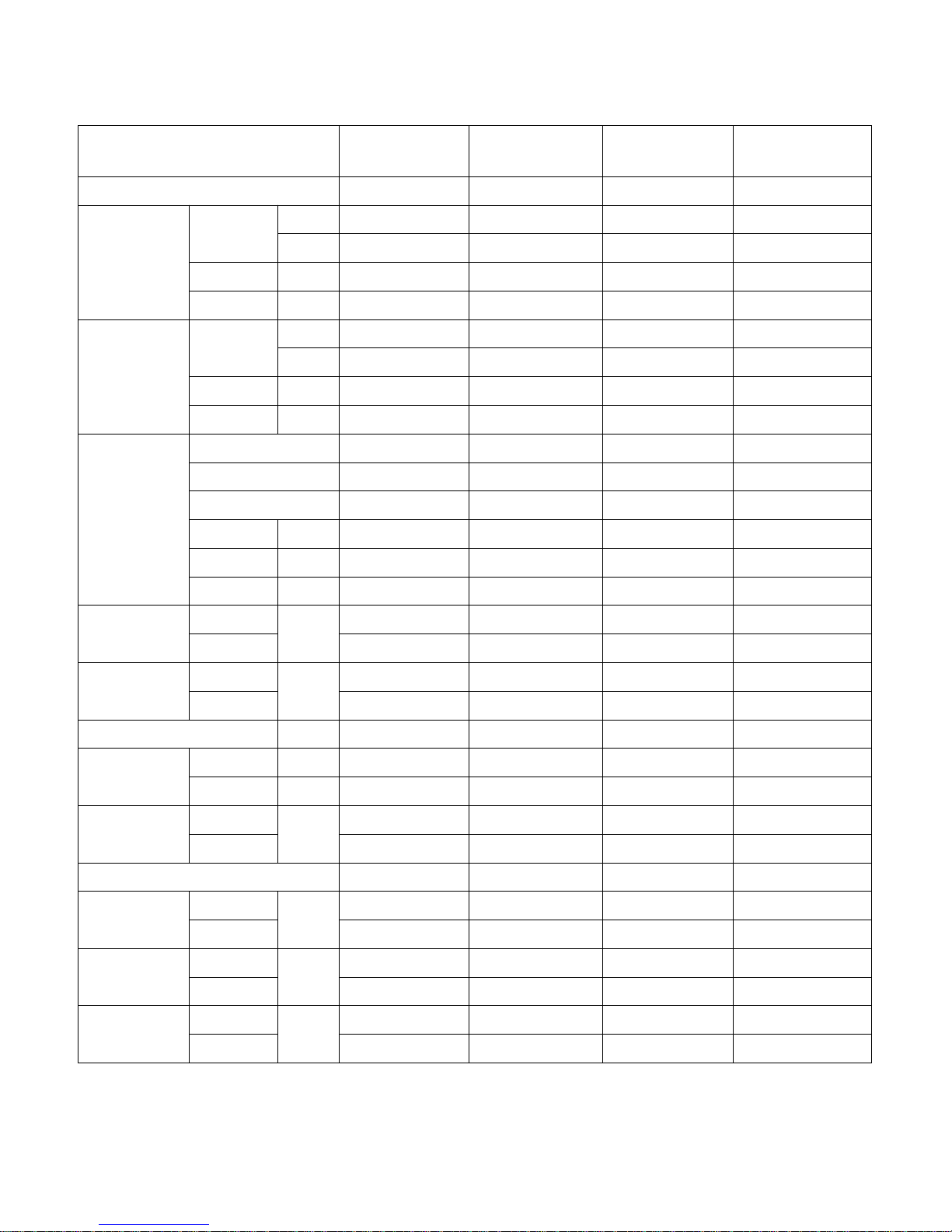

POWER SOURCE (ø, V, Hz)

COOLING CAPACITY Btu/h

W

INPUT W

CURRENT A

HEATING CAPACITY Btu/h

W

INPUT W

CURRENT A

MAKER

TYPE

COMPRESSOR MODEL

INPUT W

CURRENT A

CAPACITY Kcal/h

NOISE INDOOR dB(A)

LEVEL(1m) OUTDOOR

AIR INDOOR CMM

VOLUME OUTDOOR

REFRIGERANT R-22 Kg

HEAT INDOOR R/C/FPI

EXCHANGER OUTDOOR R/C/FPI

FAN INDOOR TYPE

OUTDOOR

ROOM TEMPERATURE CONTROL

NET INDOOR Kg

WEIGHT OUTDOOR

DIMENSIONS INDOOR mm

(W ¥ H ¥ D) OUTDOOR

SVC LIQUID Inch

VALVE GAS (mm)

3,220,60 3,220,60 3,380,60 3,380,60

44,000 44,000 44,000 44,000

12,896 12,896 12,896 12,896

6,000 6,000 4,600 4,600

10 10 8.2 8.2

– 48,000 – 48,000

– 14,069 – 14,069

– 5,000 – 4,500

– 9 – 8

Copeland Copeland Copeland Copeland

Recipro Recipro Recipro Recipro

CRNQ-0501-ES8 CRNQ-0501-ES8 CRNQ-0501-ES8 CRNQ-0501-ES8

6,210 6,210 6,210 6,210

19.0/11.0 19.0/11.0 19.0/11.0 19.0/11.0

61,500 61,500 61,500 61,500

53 53 53 53

58 58 58 58

35 35 35 35

104 104 104 104

3.5 3.9 4 4.2

3/28/17 3/28/17 3/28/17 3/28/17

2/44/16 2/44/18 2/44/16 2/44/18

SIROCO SIROCO SIROCO SIROCO

PROPELLER PROPELLER PROPELLER PROPELLER

MICOM CONTROL MICOM CONTROL MICOM CONTROL MICOM CONTROL

62 62 62 62

90 90 90 90

590 × 1,800 × 440 590 × 1,800 × 440 590 × 1,800 × 440 590 ×1,800 × 440

900 × 1225 × 370 900 × 1225 × 370 900 × 1225 × 370 900 × 1225 × 370

3/8 3/8 3/8 3/8

3/4 3/4 3/4 3/4

MODEL

LP-E50B2CL/CA

LP-E50B2HL/HA

LP-E50B2ZL/ZA

LP-E5090CL

LP-E5092CA

LP-E5092HL/HA

– 6 –

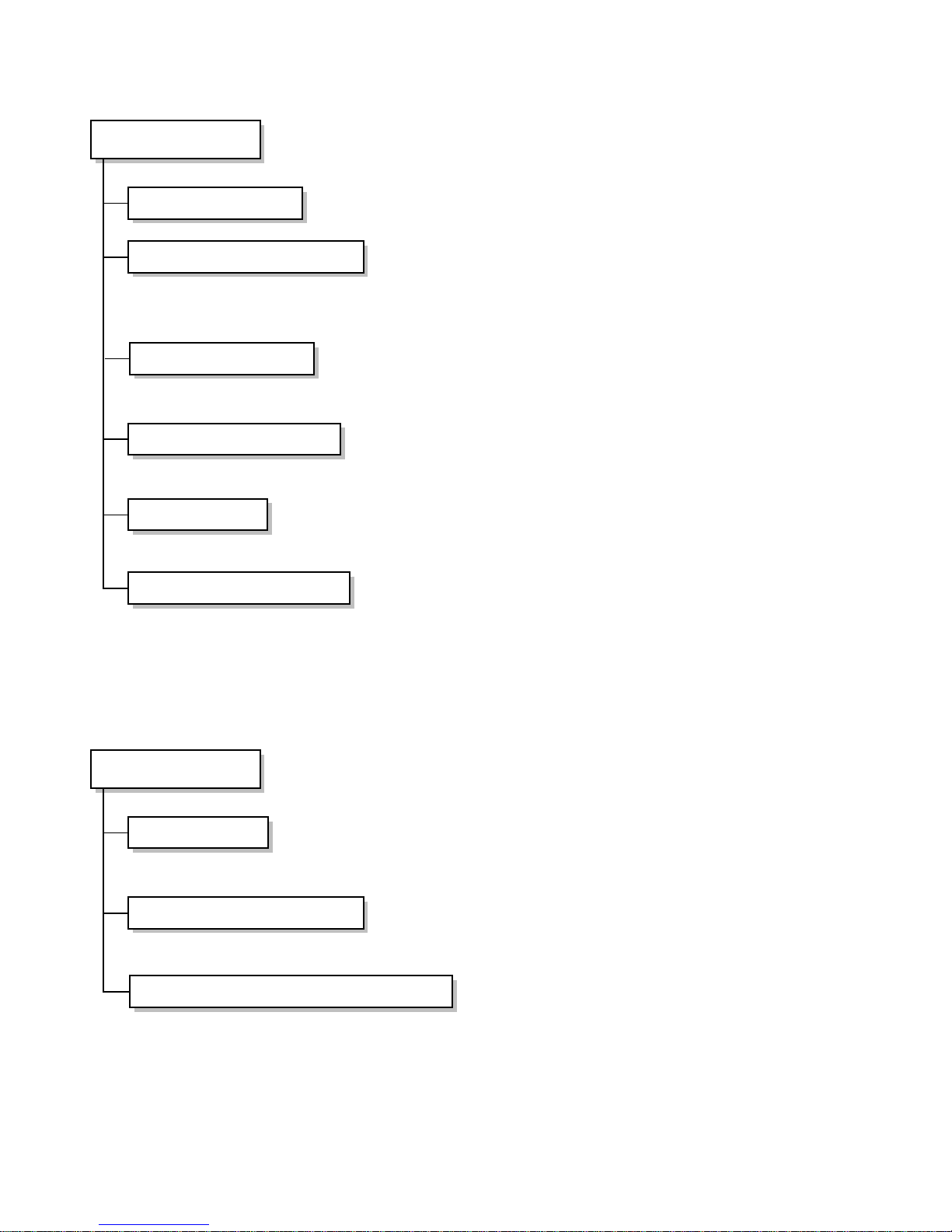

1.4 Functions

Indoor Unit

Power Switch ON/OFF

Operation Mode Control

Sensing the room temperature

Controlling the room temperature

Starting Current Control

Sensing Heat Exchanger Temperature

Timer Delay Safety Control

Indoor Fan Speed Control

Operation Indication lamps

Temperature Setting

Airflow Direction Control

Room temperature Display

Timer Control

Sensing Discharge Air Temperature

• Cooling, Soft Dry, Auto, Fan ¢¡Cooling Model •

Cooling, Heating, Soft Dry, Fan ¢¡Heat Pump Model

• Room temperature sensor (Thermistor)

• Maintains the room temperature in accordance with the setting temperature.

• Indoor fan is delayed for 3 sec at the starting.

• Heat exchanger temperature sensor (Thermistor)

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Up : up to 30°C

• Down : down to 16°C

• Airflow direction Automatic and Manual control

• Low, 10° ~ 35°C, Hi

• Off Timer (1, 2, 3....7 hour)

• Discharge temperature sensor <Thermistor>

• Apply Heat Pump Model Only.

– 7 –

Remote Control

Operation ON/OFF

Operation Mode Selection

• Cooling, Soft Dry, Auto, Fan ¤I Cooling Only Model

• Cooling, Heating, Soft Dry, Fan, ¤I E/heater Heat Pump Model

Fan Speed Selection

Setting the temperature

Timer Control

Airflow Direction Control

• High, Medium, Low

• Up or Down

• Off Timer(1, 2, 3...7 hour)

• Airflow direction Auto-Swing and Manual control

Outdoor Unit

Deice Control

Outdoor Fan Speed Control

Sensing Heat Exchanger Temperature

• De-ice PCB

• One speed

• Heat exchanger temperature sensor (Thermistor)

118

37.3

50

80

58.2

959

605.5

440

590

540

1513 243

548899

370

125

210

290

1220

460

460

505

90130

640

900

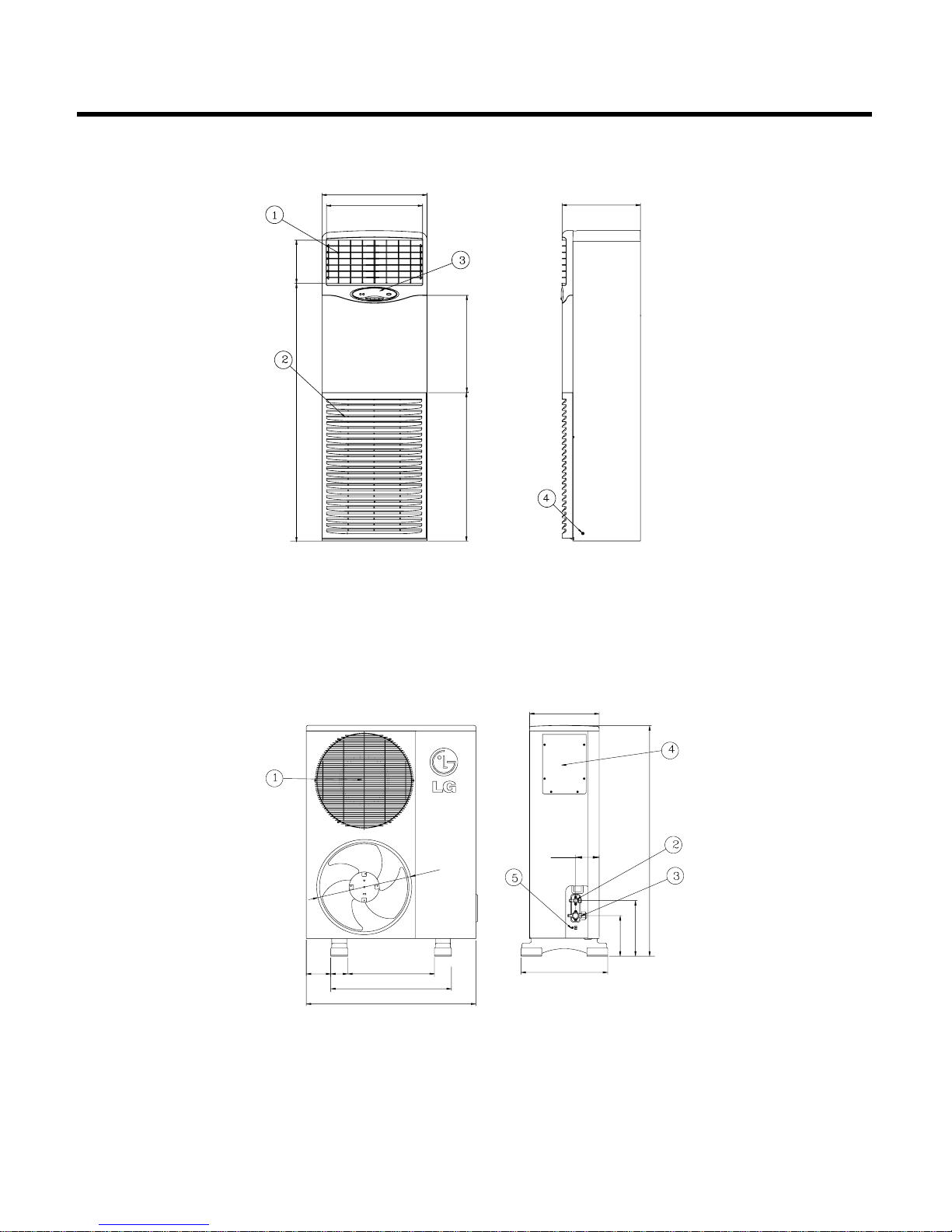

1) Indoor Unit

2) Outdoor Unit

– 8 –

2. DIMENSIONS

¤ Air Outlet Vent

¤ŁAir Inlet Vent

¤ØWindow display

¤ŒEarth Screw

¤ Air Outlet Vent

¤ŁLiquid Side SVC Valve

¤ØGas Side SVC Valve

¤ŒControl Box

¤ºEarth Screw

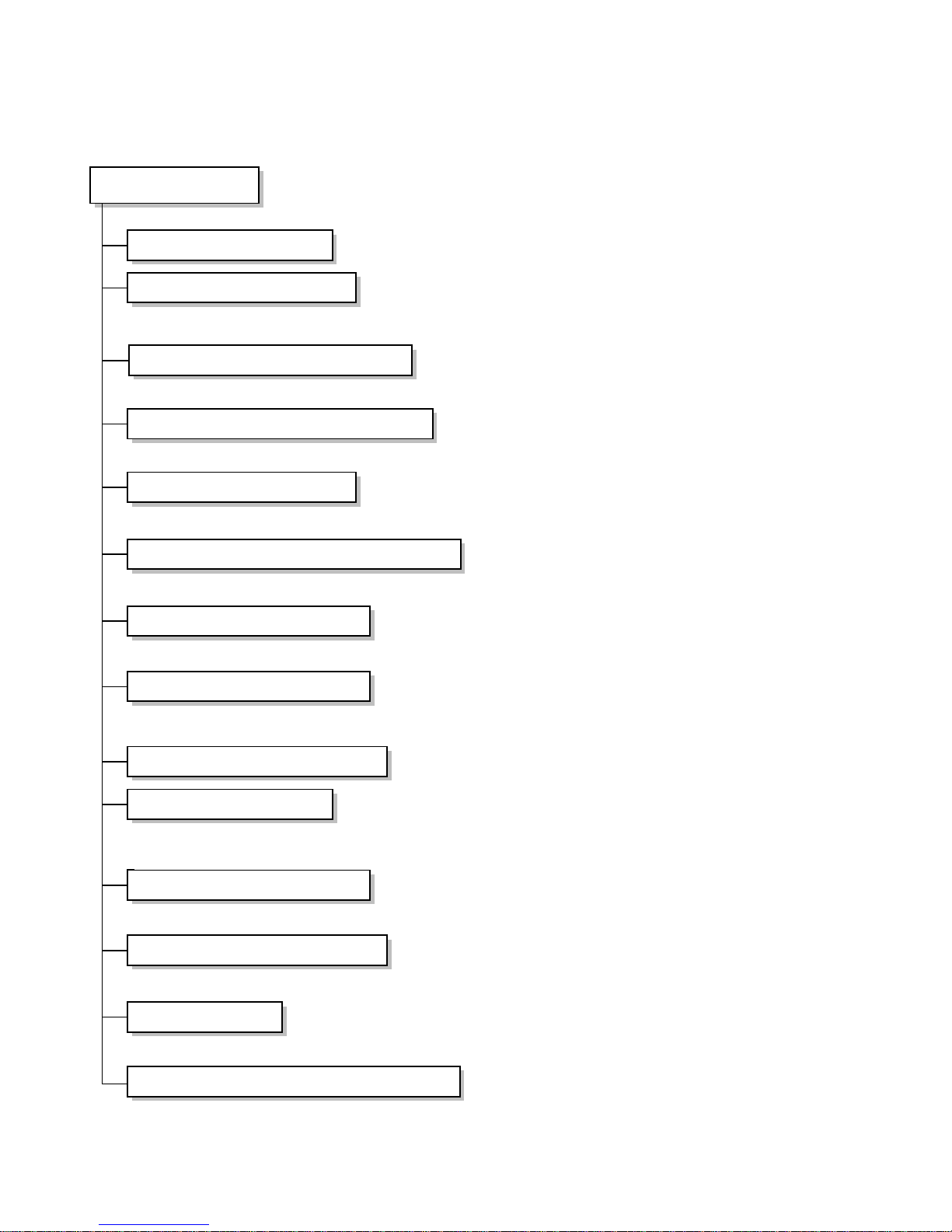

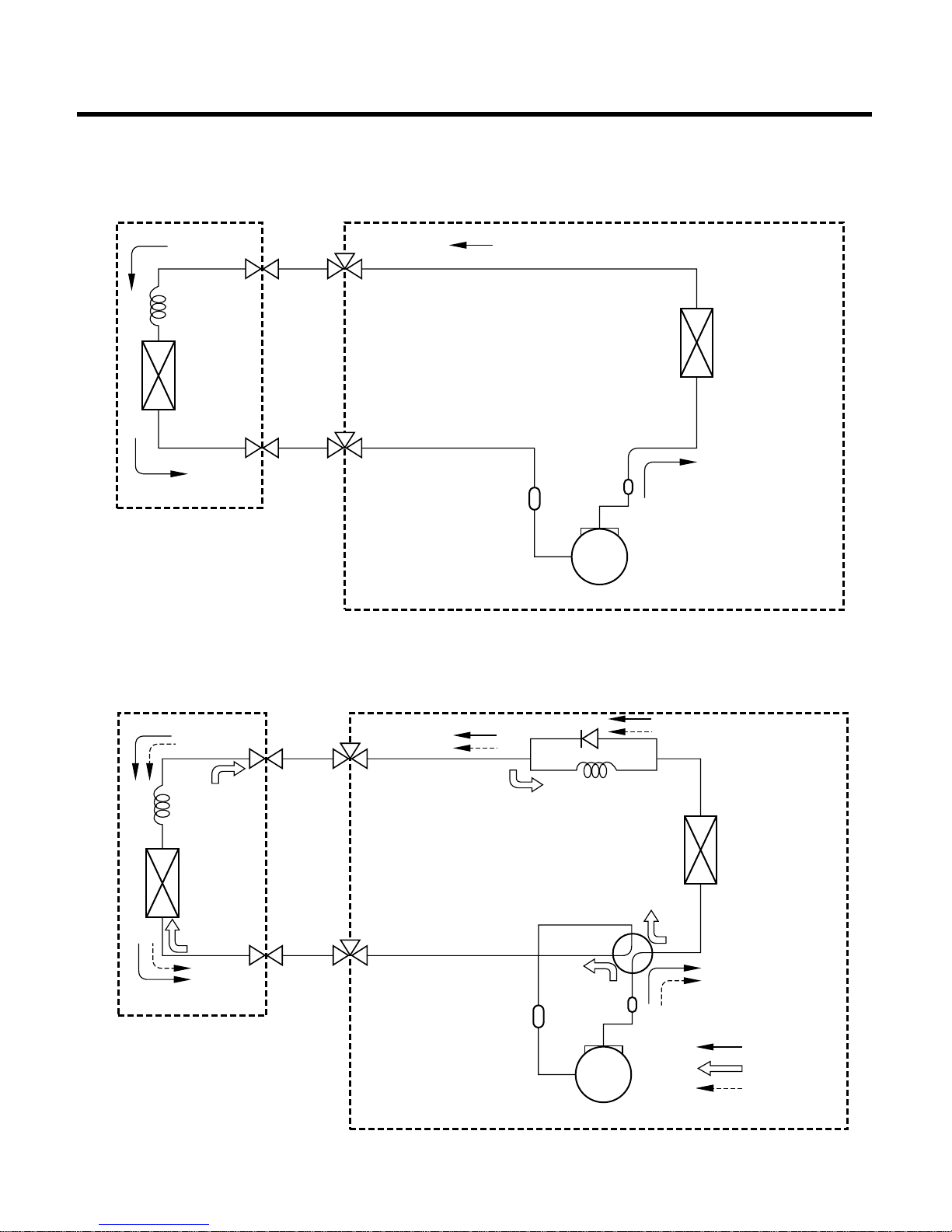

3.1

Cooling Cycle

– 9 –

3. REFRIGERANT CYCLE DIAGRAM

INDOOR UNIT

LIQUID SIDE

CAPILLARY

TUBE

HEAT

EXCHANGER

ACCUMULATOR

MUFFLER

COMPRESSOR

HEAT

EXCHANGER

CAPILLARY

TUBE

HEAT

EXCHANGER

HEAT

EXCHANGER

3-WAY VALVE

GAS SIDE

3-WAY VALVE

LIQUID SIDE

CHECK VALVE

CAPILLARY TUBE

4-WAY VALVE

MUFFLER

COMPRESSOR

COOLING

HEATLNG

DE-ICE

ACCUMULATOR

3-WAY VALVE

GAS SIDE

3-WAY VALVE

OUTDOOR UNIT

INDOOR UNIT OUTDOOR UNIT

3.2

Cooling and Heating Cycle

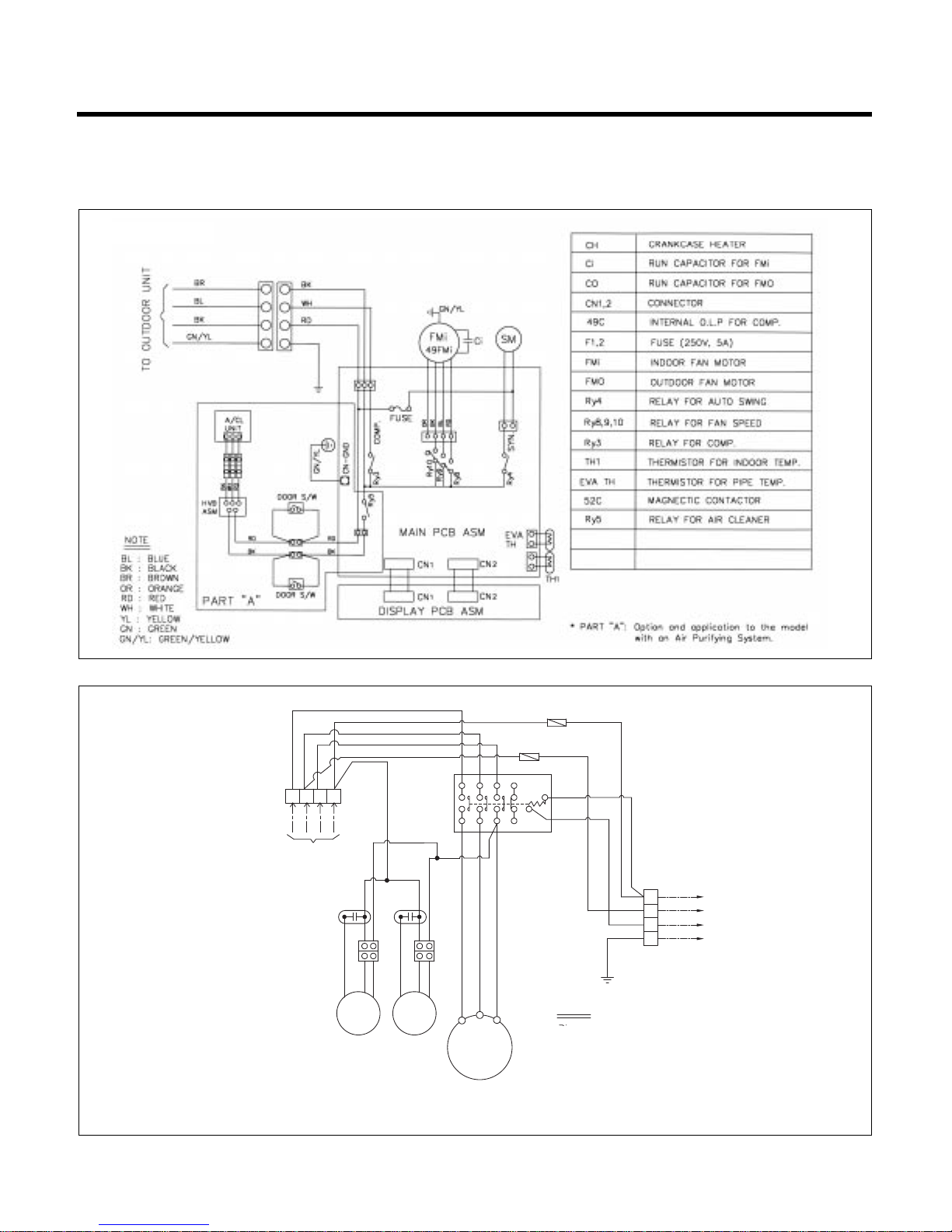

Indoor & Outdoor Unit Circuit Diagram

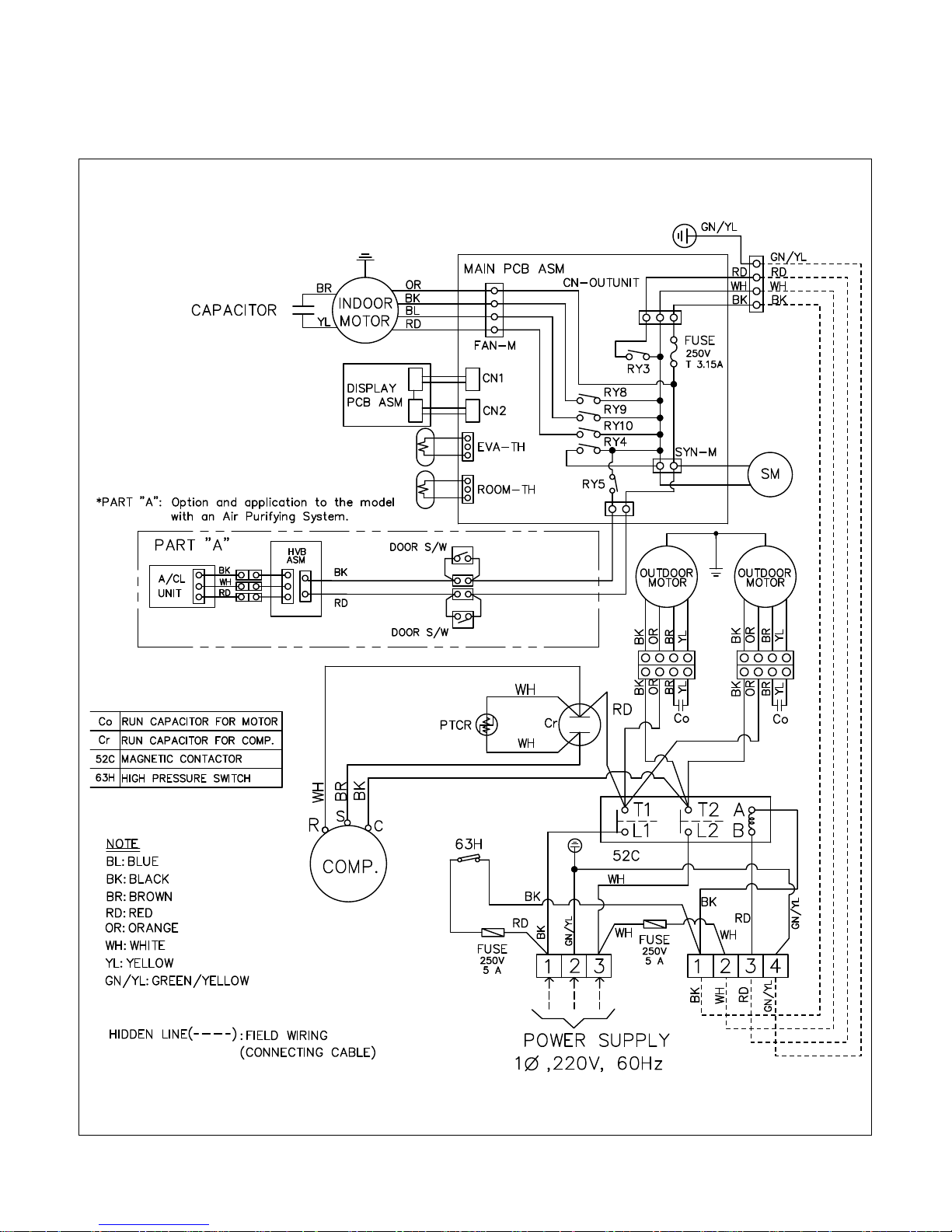

(1) LP-E5082CL/CA

– 10 –

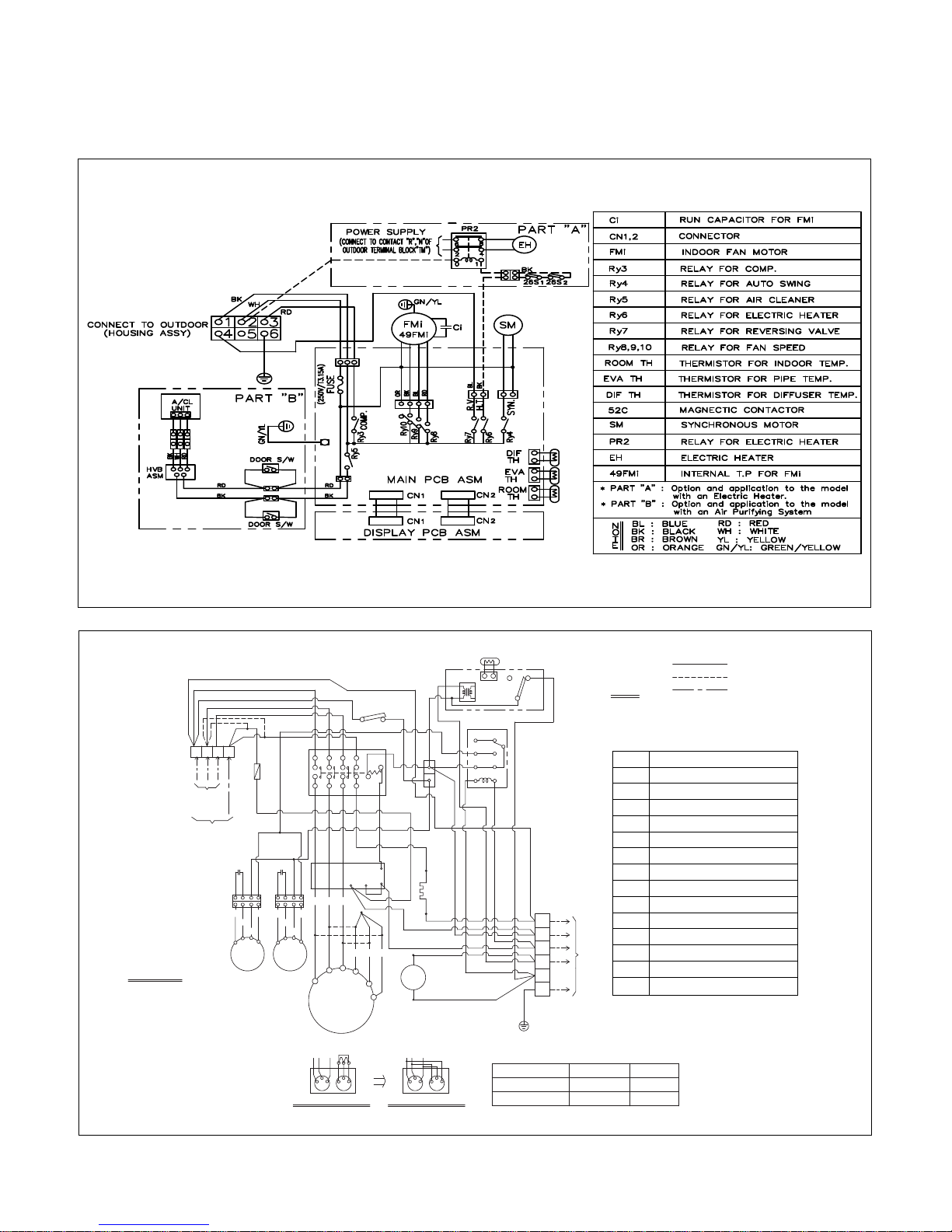

4. WIRING DIAGRAM

INDOOR UNIT

POWER

RELAY

NOTE

BL

BK

BR

OR

RD

WH

YL

GN/YL

BLUE

BLACK

BROWN

ORANGE

RED

WHITE

YELLOW

GREEN/YELLOW

:

:

:

:

:

:

:

:

TERMINAL

BLCOCK

BR

BK

BK

BK

BK

RD

RD

BK

BK

BK

BK

OROR BK

OR BK

FAN

MOTOR

FAN

MOTOR

COMP.

T1

T2

T3

OR BK

YLYL

WH

CAPACITOR CAPACITOR

TERMINAL

BLOCK

TO INDOOR UNIT

1

2

3

4

WH

WH

RD

WH

FUSE

(250V 5A)

FUSE

(250V 5A)

12345631

32

B

A

POWER SUPPLY

R S T N

OUTDOOR ELECTRIC

CIRCUIT

– 11 –

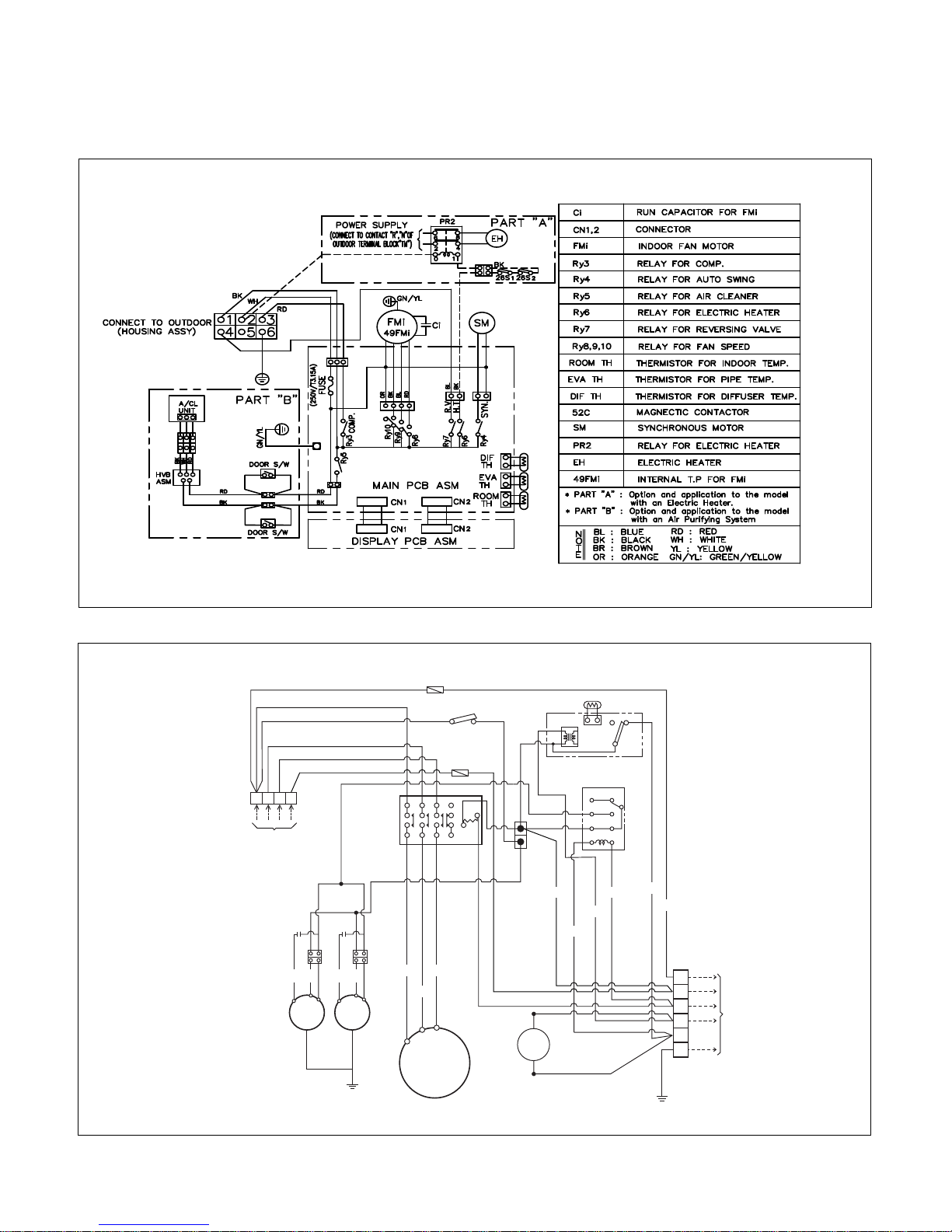

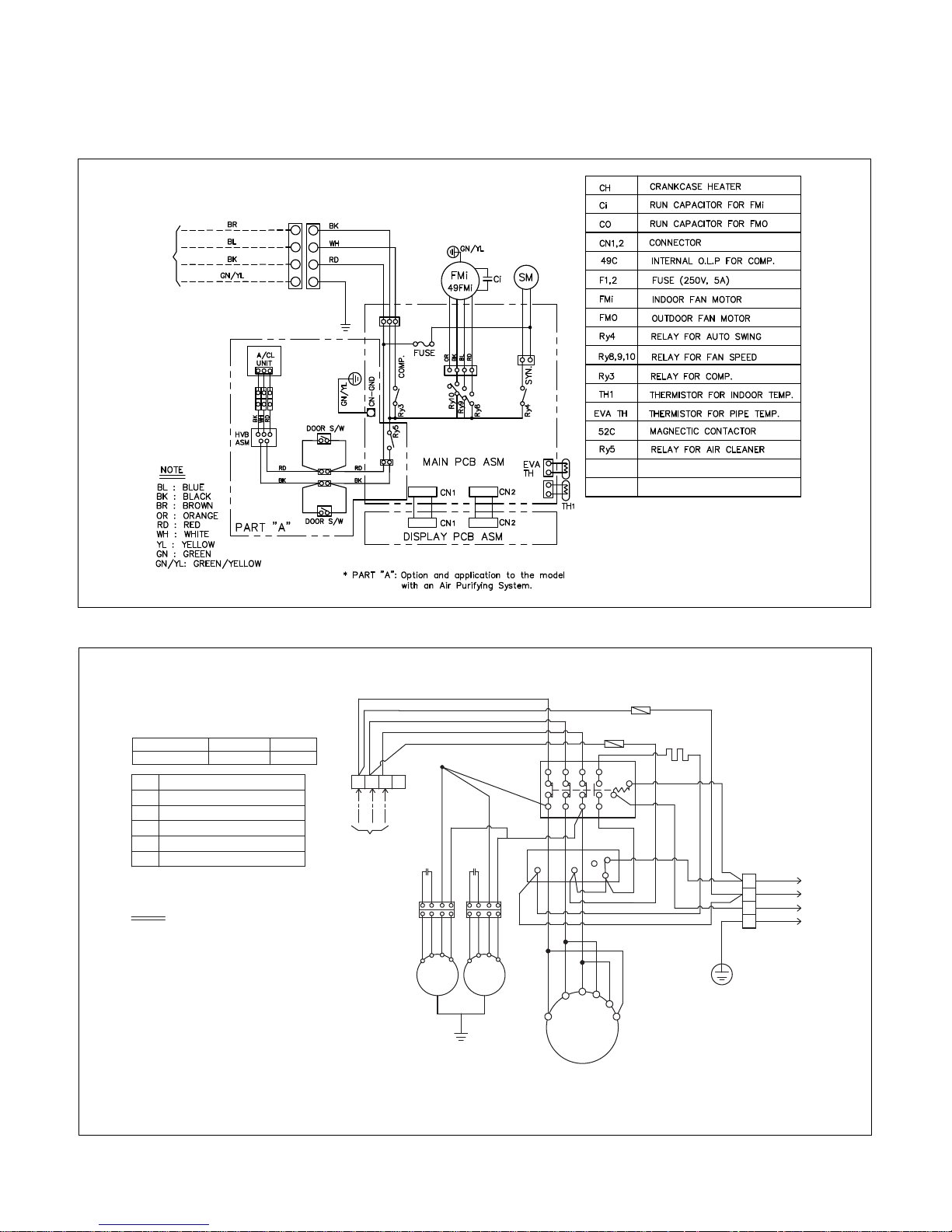

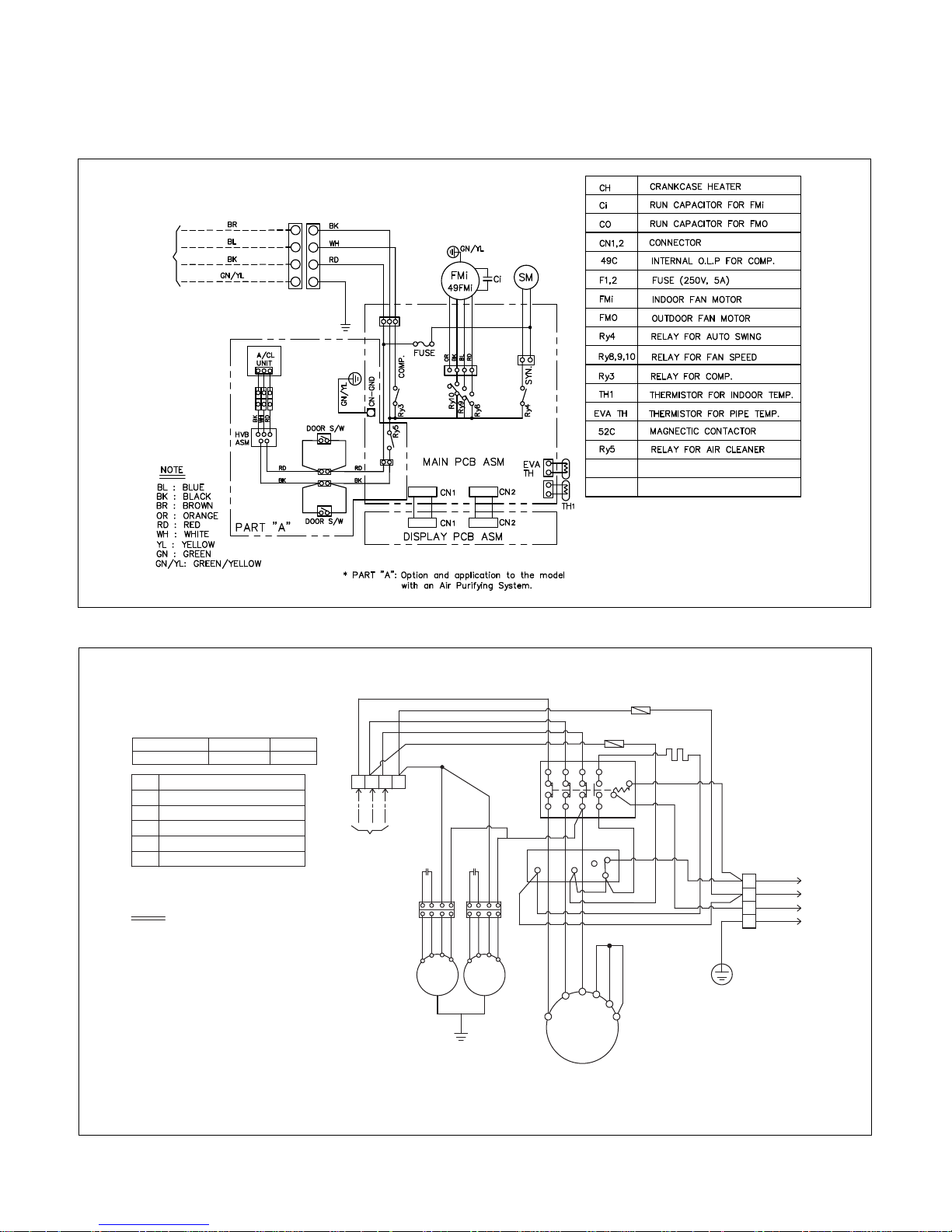

(2) LP-E5082HL/HA/ZL/ZA

INDOOR ELECTRIC CIRCUIT

R

TERMINAL

BLOCK

POWER SUPPLY

POWER

RELAY

S T N

BK

BK

BK

WH

WH WH

RD

OR

BK

HIGH PRESSURE S/W

WH

Deice PCB

C TH

TNS

NO

NC

WH

OR

BK

POWER

RELAY

12345631

T/B1

T/B2

32

B

A

FAN

MOTOR

FAN

MOTOR

YL BK

OR

BK

T3

T2

T1

RD

WH

COMP.

1 2

3 4

5 6

7 8

YL BK

OR

BK

BK

BL

BL

BK

WH

CAPACITOR CAPACITOR

REVERSING

VALVE

BR

BL

BR

BL

GN/YL

GN/YL

TERMINAL BLOCK

To the indoor unit

1

2

3

4

5

6

BK

WHWH

YL

BK

RD

Fuse

(250V 5A)

Fuse

(250V 5A)

OUTDOOR UNIT WIRING DIAGRAM

– 12 –

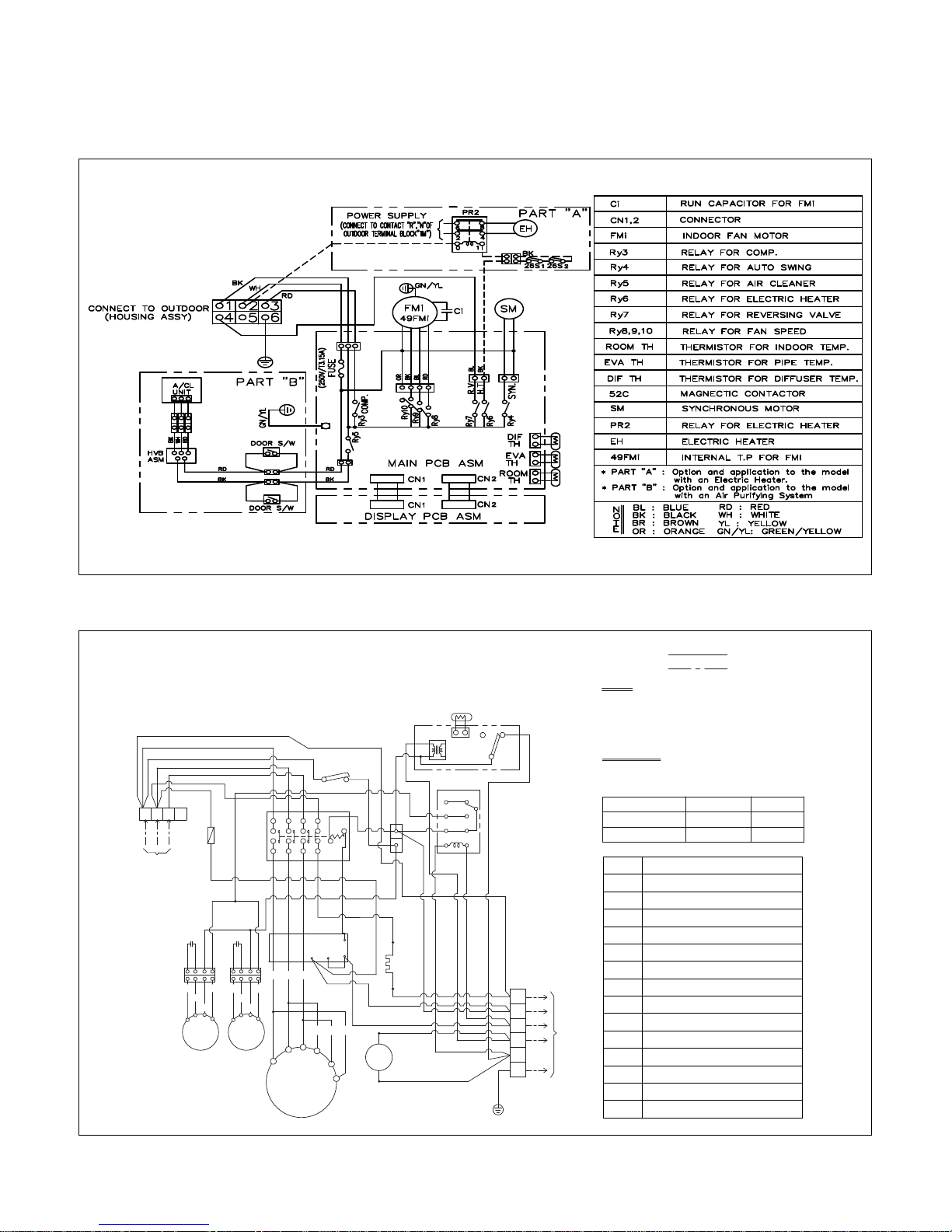

(3) LP-E5020CL / LP-E5022CL/CA

WIRING DIAGRAM

– 13 –

(4) LP-E5022HL/HA

– 14 –

(5) LP-E50B0CL/CA

TO OUTDOOR UNIT

INDOOR UNIT

EOCR Current Setting.

POWER SUPPLY

Co

52C

51C

Tmo

Tm

CH

NOTE

BL

BK

BR

RD

OR

WH

YL

GN/YL

BLUE

BLACK

BROWN

RED

ORANGE

WHITE

YELLOW

GREEN/YELLOW

3ø,3Wires 220V

Tm

52C

COMP.

51C

BK

RD

WH

RD

OR

BK

BK

Co

WH

BK

RD RDRDRD

GN/YL

WH

U

V

Z

W X

Y

L1 L2

2 4 6 32

1 3 5 31

B

A

Tb

Ta

Tc

BL

Co

Outdoor

Motor

YL BROR BK YL BR OR BK

Outdoor

Motor

RD

FUSE

250V 5A

FUSE

250V 5A

BL

RD

BL

BK

BK

BK

To Indoor Unit

WH

RD

GN/YL

Tmo

1

2

3

4

RD

WH

CH

R S T N

:

:

:

:

:

:

:

:

RUN CAPACITOR FOR MOTOR

MAGNETIC CONTACTOR

EOCR

TERMINAL BLOCK(Outdoor Unit)

MAIN TERMINAL BLOCK

CRANKCASE HEATER

3ø,220V,60Hz

CURRENT(A

)

30

TIME(sec

)

5

OUTDOOR WIRING DIAGRAM

– 15 –

(6) LP-E50B0HL/HA

INDOOR ELECTRIC CERCUIT

TM

3ø, 3 wires,

220V.

WH

BK

1 3 5 31

A

1 2

3 4

5 6

7 8

B

T/B1

T/B2

2

L1 L2

Ta

Tc

4 6 32

BK

BK

BK

YL

FMo1

49FMo

FMo2

49FMo

OR

BR

BK

YL OR

BR

BK

CM

BK

WH

WH

BL

BK

RD BK

BR

BR

BL

Tmo

To the indoor unit

GN/YL

GN/YL

BL

BL

WH

20SV

RD

WH

RD

U

V

W

X

Y

Z

BK

Co Co

RD

BK

D.P

C TH

TNS

NO

NC

WH

WH WH

YL

WH

BK

BK

OR

RD

WH

WH

52C

CH

63H2

52F1

51C

F1

R S T N

1

2

3

4

5

6

63H2

C TH

63H1

CH

20SV

52C

TM

52F1

51C

CM

Co

FMo

F1

DP

TMo

HIGH PRESSURE SWITCH FOR HEATING

THERMISTOR FOR PIPE TEMP.

INTERNAL T.P FOR FMo

CRANKCASE HEATER

REVERSING COIL

MAGNETIC CONTACTOR

MAIN TERMINAL BLOCK

RELAY FOR FMO

E.O.C.R

COMPRESSOR

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

FUSE (250V, 10A)

DEICER PCB

TERMINAL BLOCK

(

Caution

)

1. Basic wiring is 3ø,3 wires, 220V.

2. For setting E.O.C.R current

POWER SUPPLY

3ø,220V,60HZ

3ø,380V,60HZ

CURRENT(A)

30.0

17.5

TIME(sec)

5

5

WIRING FOR 220V

WIRING OF FIELD

(CONNECTING WIRE)

NOTE

BL

BK

BR

OR

BLUE

BLACK

BROWN

ORANGE

:

:

:

:

RD

WH

YL

GN/YL

RED

WHITE

YELLOW

GREEN/YELLOW

:

:

:

:

Outdoor Unit Wiring Diagram

– 16 –

(7) LP-E5092CL/CA

TO OUTDOOR UNIT

INDOOR UNIT

EOCR Current Setting.

POWER SUPPLY

Co

52C

51C

Tmo

Tm

CH

NOTE

BL

BK

BR

RD

OR

WH

YL

GN/YL

BLUE

BLACK

BROWN

RED

ORANGE

WHITE

YELLOW

GREEN/YELLOW

3ø,3Wires 220V

Tm

52C

COMP.

51C

BK

RD

WH

RD

OR

BK

BK

Co

WH

BK

RD RDRDRD

GN/YL

WH

U

V

Z

W X

Y

L1 L2

2 4 6 32

1 3 5 31

B

A

Tb

Ta

Tc

BL

Co

Outdoor

Motor

YL BR OR BK YL BR OR BK

Outdoor

Motor

RD

FUSE

250V 5A

FUSE

250V 5A

BL

RD

BL

BK

BK

BK

To Indoor Unit

WH

RD

GN/YL

Tmo

1

2

3

4

RD

WH

CH

R S T N

:

:

:

:

:

:

:

:

RUN CAPACITOR FOR MOTOR

MAGNETIC CONTACTOR

EOCR

TERMINAL BLOCK(Outdoor Unit)

MAIN TERMINAL BLOCK

CRANKCASE HEATER

3ø,380V,60Hz

CURRENT(A

)

17.5

TIME(sec

)

5

OUTDOOR WIRING DIAGRAM

– 17 –

(8) LP-E5092HL/ZL/HA/ZA

INDOOR ELECTRIC CIRCUIT

TM

3ø, 3 wires,

220V.

a

WH

BK

1 3 5 31

A

1 2

3 4

5 6

7 8

B

T/B1

T/B2

2

L1 L2

Ta

Tc

4 6 32

BK

BK

BK

YL

FMo1

49FMo

FMo2

49FMo

OR

BR

BK

YL OR

BR

BK

CM

(

Caution

)

1. Basic wiring is 3ø,4 wires, 380V.

2. For changing the running

voltage to 220V, please change

the wiring by the next steps.

1st) Remove the 2 wires from

the "N" of the main terminal

block

2nd) Fit the removed 2 wires

on the "S' of the main

terminal block

3rd) Change the compressor

wires

BK

WH

WH

BL

BK

RD BK

BR

BR

BL

Tmo

To the indoor unit

GN/YL

GN/YL

BL

BL

WH

20SV

RD

WH

RD

U

V

W

X

Y

Z

BK

Co Co

RD

BK

D.P

C TH

TNS

NO

NC

WH

WH WH

YL

WH

BK

BK

OR

RD

WH

WH

52C

CH

63H2

52F1

51C

F1

b

3ø, 4 wires,

380V.

R S T N

1

2

3

4

5

6

3ø,4 wires,380V. 3ø,3 wires,220V.

V

U WYX Z

V

U WYX Z

3. For setting E.O.C.R current

POWER SUPPLY

3ø,220V,60HZ

3ø,380V,60HZ

CURRENT(A)

30.0

17.5

TIME(sec)

5

5

63H2

C TH

63H1

CH

20SV

52C

TM

52F1

51C

CM

Co

FMo

F1

DP

TMo

HIGH PRESSURE SWITCH FOR HEATING

THERMISTOR FOR PIPE TEMP.

INTERNAL T.P FOR FMo

CRANKCASE HEATER

REVERSING COIL

MAGNETIC CONTACTOR

MAIN TERMINAL BLOCK

RELAY FOR FMO

E.O.C.R

COMPRESSOR

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

FUSE (250V, 10A)

DEICER PCB

TERMINAL BLOCK

WIRING FOR 380V

WIRING FOR 220V

WIRING OF FIELD

(CONNECTING WIRE)

NOTE

BL

BK

BR

OR

BLUE

BLACK

BROWN

ORANGE

:

:

:

:

RD

WH

YL

GN/YL

RED

WHITE

YELLOW

GREEN/YELLOW

:

:

:

:

Outdoor Unit Wiring Diagram

– 18 –

5. OPERATION DETAILS

(1) The function of main control

1. Time Delay Safety Control

• 3min

...

The compressor is ceased for 3 minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 3sec

...

The indoor fan is ceased for 1~3 seconds to prevent relay noise.

(Protection of fan relay and micro chip)

• 1min

...

The 4-way valve is ceased for 30 sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode.

2. Airflow Direction Control

• This function is to swing the louver left and right automatically and to set it at the desired position.

• The procedure is as the following.

1st : Press the ON/OFF Button to operate the product.

2nd : Press the Airflow Direction Control Button to swing the louver left and right automatically.

(Remote controller)

3rd : Repress the Airflow Direction Control Button to set the louver as the desired position.

(Remote controller)

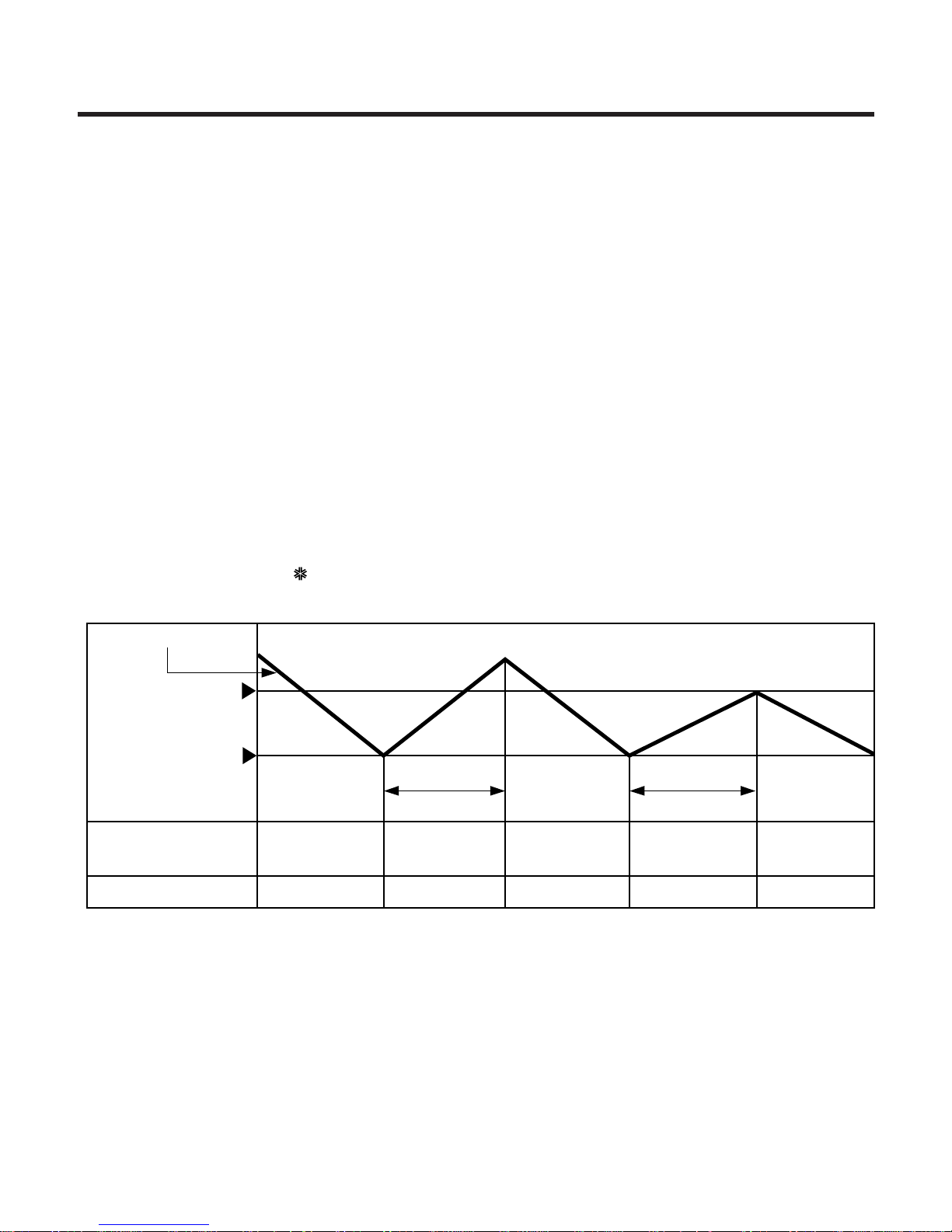

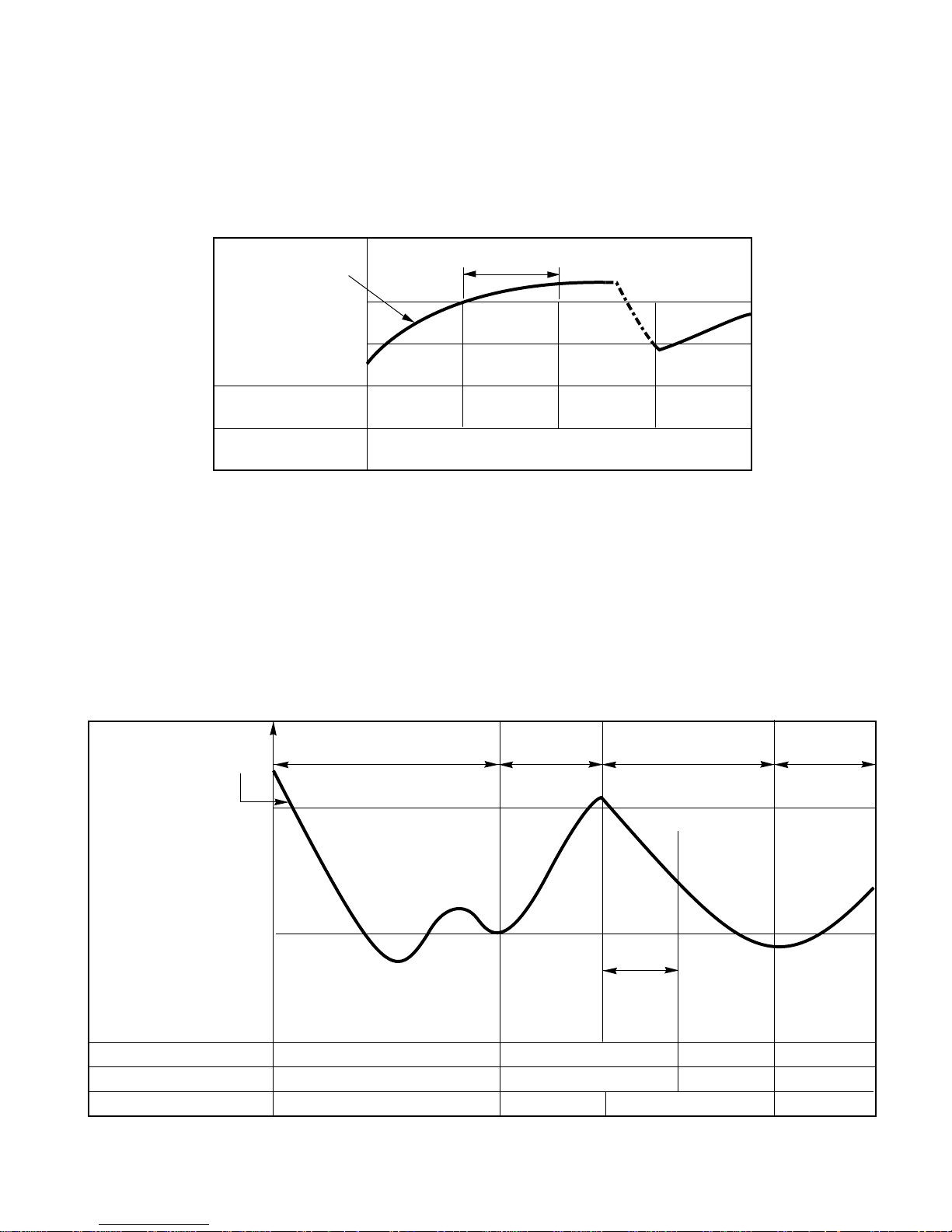

3. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the

controller and the operation diagram is as following

Intake Air temp.

Setting Temp. +1°C

(Compressor ON)

Setting Temp. -1°C

(Compressor OFF)

Indoor Fan Speed

Selecting

fan speed

Selecting

fan speed

Selecting

fan speed

Selecting

fan speed

Selecting

fan speed

3 minutes 3 minutes

Compressor ON OFF ON OFF ON

– 19 –

4. Auto Operation (Cooling Model only)

ƒUThe operation procedure is as following.

ƒƒUU

Auto Operation for Cooling

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

Operation Condition Intake-air Temperature Setting temperature Fan speed

Over 26°C 25°C

Over 24°C~below 25.5°C Intake air -1.0°C

Over 22°C~below 23.5°C Intake air -0.5°C

below 21.5°C Intake air Temperature(18°C, MAX)

When Switch to

Auto Operation

Controlled

by Fuzzy logic

Intake Air Temp.

Indoor Fan Speed

Compressor ON OFF

Fuzzy Speed

ON OFF

Setting Temp. +1°C

(Compressor ON)

Setting Temp. -1°C

(Compressor OFF)

3 minutes 3 minutes

– 20 –

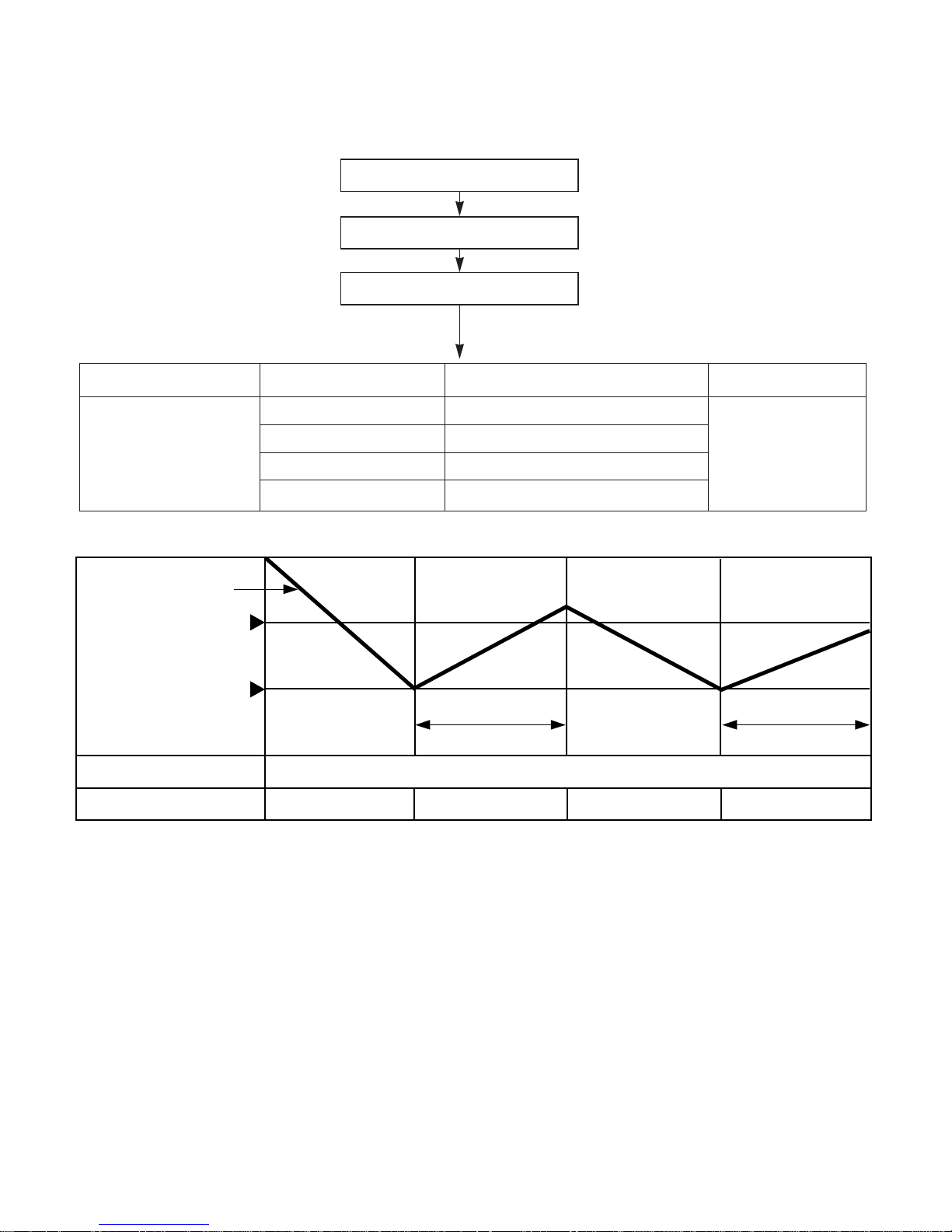

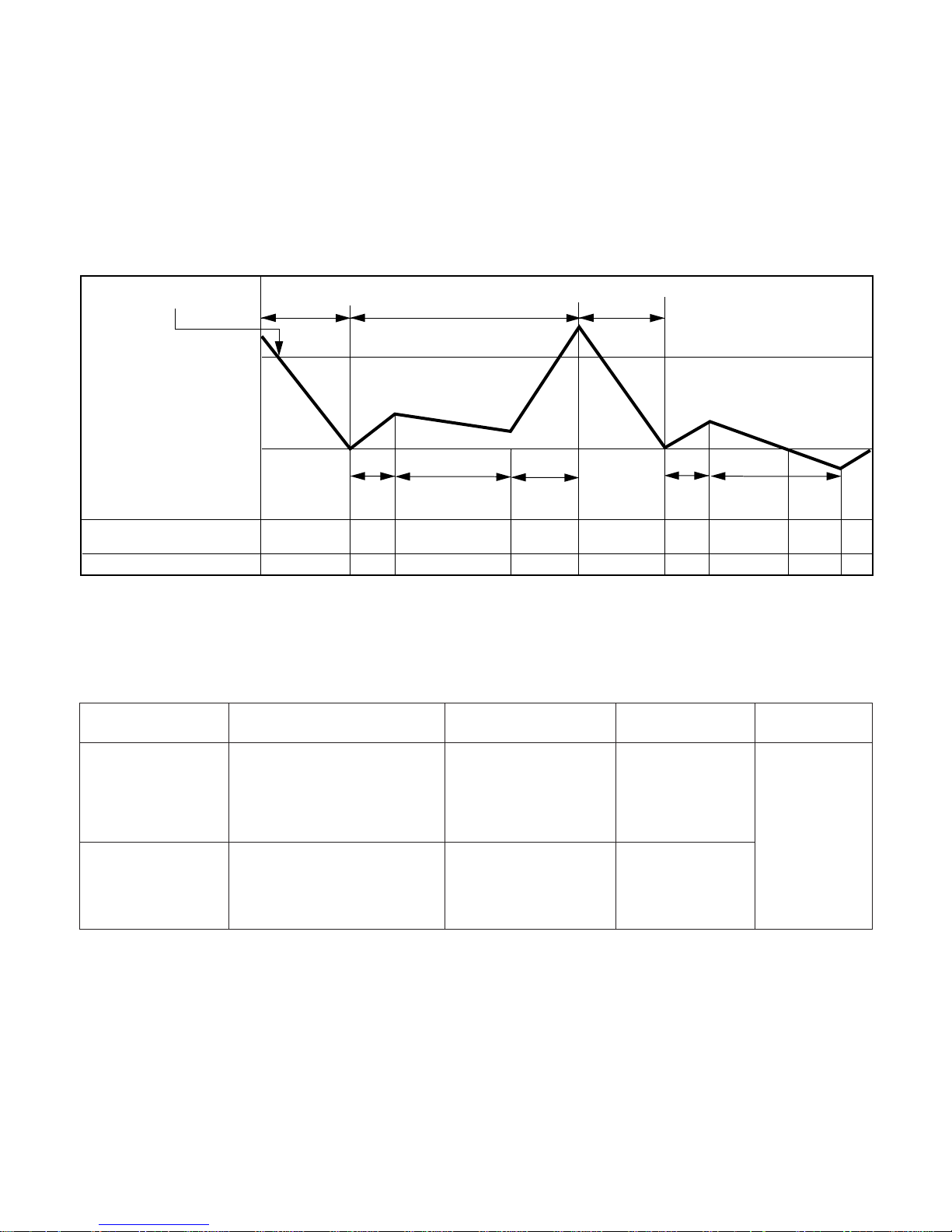

5. Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as

following.

Intake Air Temp.

Setting Temp.

(Compressor ON)

Setting Temp. -1°C

Indoor Fan Speed

Compressor

Electric Heater(Option)

ON

ON

OFF ON OFF

OFFOFF ON OFF

OFF

Hot

Start

minimum

10sec.

minimum

1min

minimum

10sec.

OFF

A A

OFFLOW

LOW

LOW

Setting Temp. +1°C

(Compressor OFF)

Selecting

fan speed

Selecting

fan speed

• A point: The indoor pipe temperature to be less then 35°C or Discharge air Temperature to be less than 29°C.

The indoor fan operates for minimum 10sec. even if the indoor pipe temperature falls lower than35°C

or the discharge air Temperature falls lower than 29°C.

Low(V)Stop(VI)

39˚C

Discharge Air Temp.

Indoor Pipe Temp.

34˚C

28˚C

26˚C

Selecting Fan Speed(IV)

Low(II)Stop(I)

(Hot-Start Operating)

Heating Start

(Hot-Start Release Point)

Selecting Fan Speed(III)

¡ During heating operation, the operating procedure of the indoor fan is as the following.

Step Indoor fan speed Pipe temp. Air discharge temp.

¥ Off ≤28°C(Hot start operating) –

¥– Low ≥28°C <39°C

¥† Selecting speed ≥28°C ≥39°C

¥‡ Selecting speed ≥28°C >34°C

¥· Low ≥26°C ≤34°C

¥ Off ≤26°C –

6. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature will be reached to 28°C.

• During heating operation, if piping temperatures fall below 26°C fan stops.

• The operation diagram is as following.

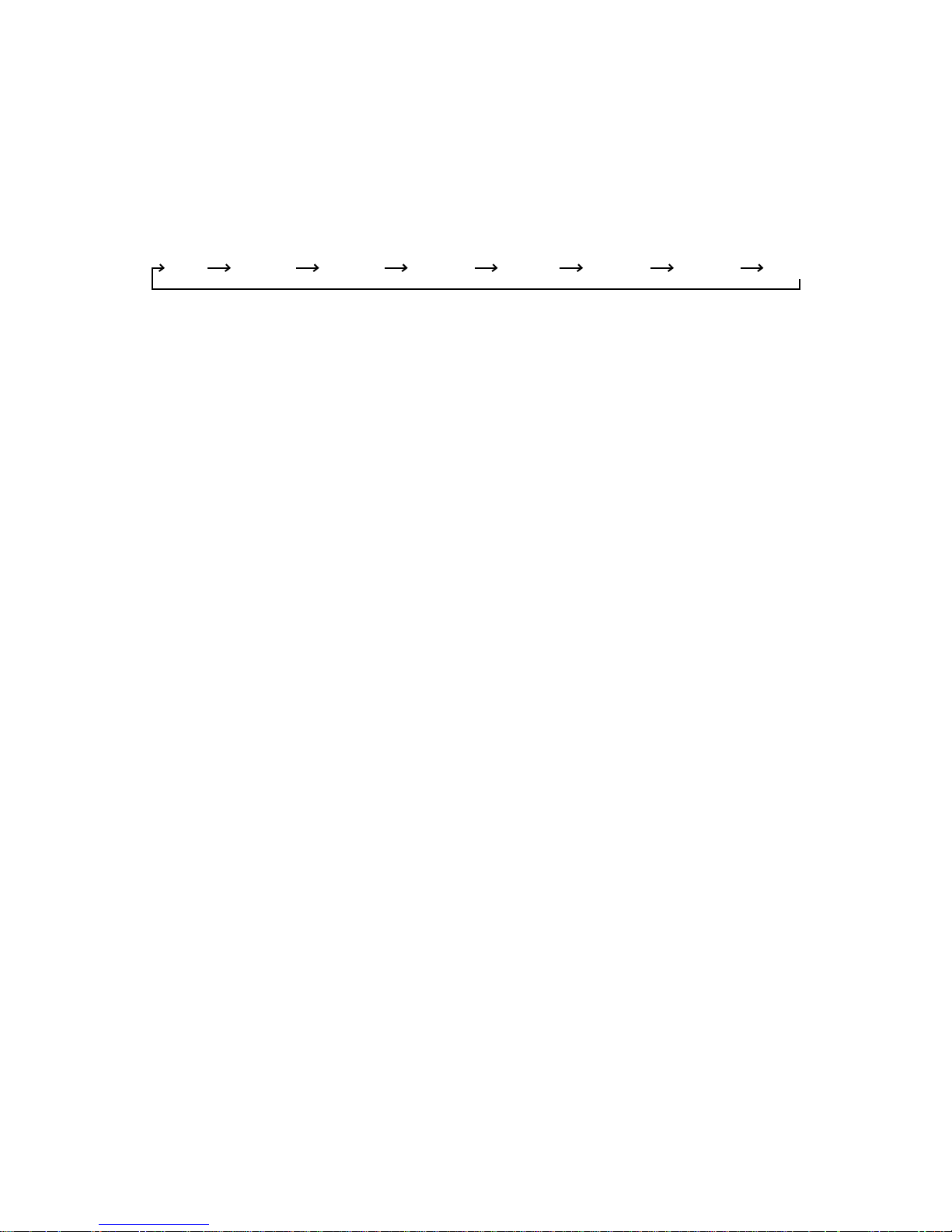

7. Defrost Control

• Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

• The first defrost starts only when the outdoor pipe temperature falls below -6°C after 45 minutes passed from

starting of heating operation and more than.

• Defrost ends after 10 minutes pass from starting of defrost operation or when the outdoor pipe temperature rises

over 12°C even if before 10 minutes.

• The second defrost starts only when the outdoor pipe temperature falls below -6°C after 45 minutes pass from

ending of the first defrost and more than.

– 21 –

INDOOR PIPE

TEMP.

INDOOR FAN

SPEED

Selecting

fan speed

OFF OFFLOW

1min

Maximum

COMPRESSOR ON

28°C

26°C

More than 45 minutes of

heating operation

Outdoor Pipe Temp.

Indoor Fan

Compressor

4-Way Valve

ON

ON

ON

ON

OFF

ON

OFF

HOT-

START

ON

ON OFF OFFON

12°C

(Defrost OFF)

-6°C

(Defrost ON)

Within

10minutes

Defrost

Defrost

More than 45 minutes of

heating operation

Less than 5 minutes

11. Child Lock function

This function is to operate Air conditioner only by Remocon.

The procedure is as the following

1st: Press the 2 buttons of the temperature control simultaneously, to raise-to lower on the Display Panel of the

product for more 3 seconds.

2nd: The buzzer sounds and then the window of Display Panel shows

LLOOCC

(LOC) mark.

3rd: To release this function, the reverse again the operating procedure could be done.

¡ During this function is operating, any buttons of Display Panel don't work. But it is possible to operate with

Remote controller.

– 22 –

9. Protection of the evaporator pipe from frosting

• Compressor and outdoor fan stop when indoor pipe temperature is below -2°C and restart at the pipe temperature

is above 12°C.

10. Air Purifying Operation(CA, HA, ZA Model only)

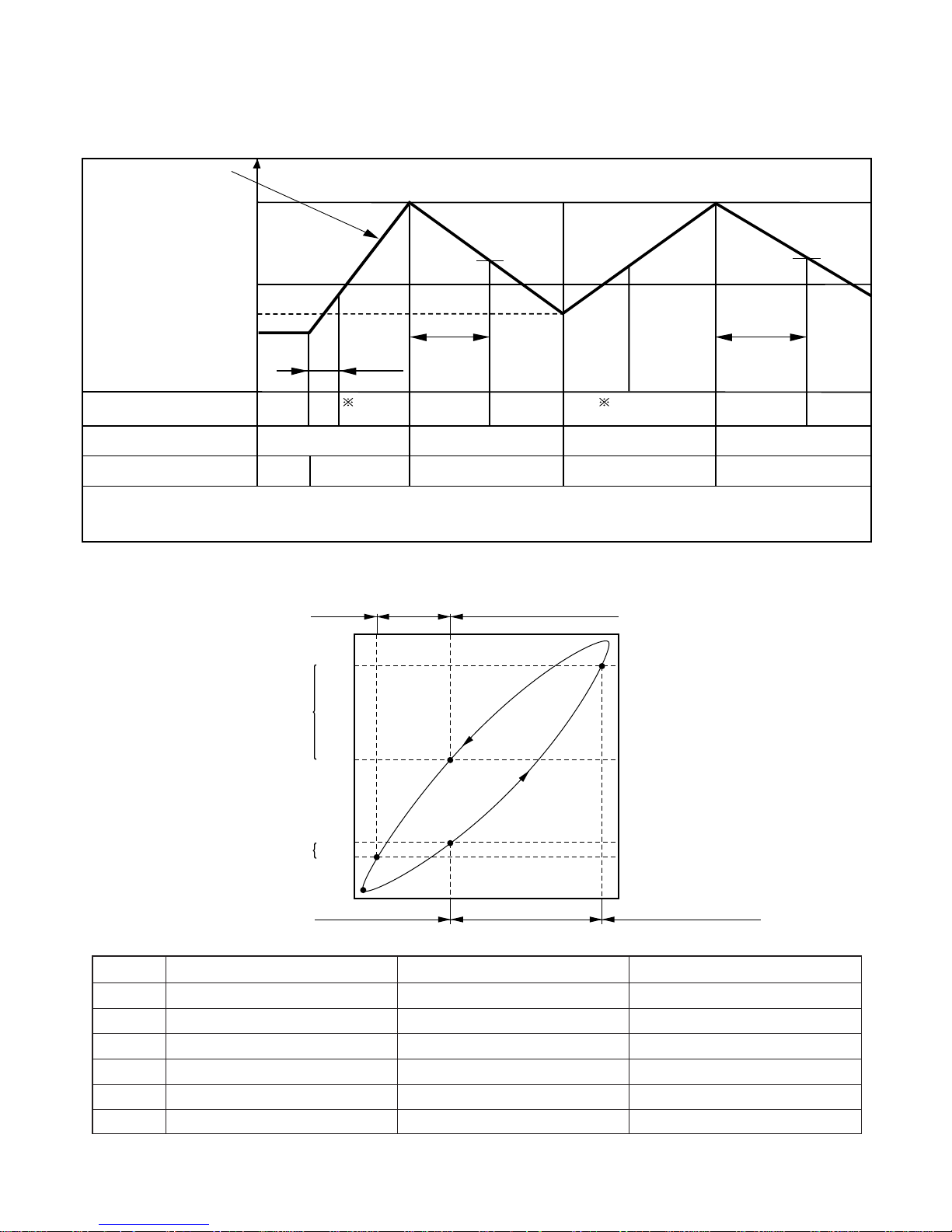

8. Soft Dry Operation Mode

• During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 2°C, the compressor OFF temperature is the setting temperature minus 1°C.

• When the room temperature rises over the compressor ON temperature, the operation mode is switched to the

Cooling mode.

• When the room temperature falls between the compressor ON temperature and OFF temperature, the operation mode is switched to the Soft Dry Operation.

• The operation diagram is shown below.

Intake Air Temp.

Indoor Fan Speed

LOW

Selecting

fan speed

Selecting

fan speed

LOW LOW LOW LOW

Compressor OFFON ONON OFF OFF ON

LOW

OFF

Setting Temp. +2°C

(Compressor ON)

Setting Temp. -1°C

(Compresso OFF)

Operation

Cooling

Cooling

operation

Dry operation

3 min. 3 min.

10 min.

maximum

7 min.

maximum

10 min.

Mode Selecting

Operating Mode

Fan Speed

Outdoor OFF

Initial Starting of

Air purifying

Operation

- Low at the initial

- But could be

switched to Med. Hi

OFF

- Outdoor not operating

- Fan operating + Air purifying

operating

Repress Air

purifying

Button or

ON/OFF

Button

When switched to

Air purifying operation

Selecting Speed of

Main Operating Mode

ON or OFF

depend on main

operating

condition.

- Outdoor operating

- Main Operating +

Air purifying operating

12. Off Timer Function

This function is to set the time of stopping the unit operation.

The procedure is as the following.

1st: Press the timer set button on the Remocon.

2nd:

The buzzer sounds and then the display window shows the Off-Time to be set as 1:00¡

...

¡ 7:00 ¡ 0:00.

- The Off-Time is shifted as the following by each press.

- If you select '0:00', the Off-Timer function will be cancelled.

- During Off-Timer Operation, if you repress the timer set button, the rest time will be displayed.

13. Alarm mode display / only displayed while operating.

CCHH 00

: The sensor for sensing room temperature is open or short.

CCHH 11

: The sensor for sensing piping temperature of evaporator is open or short.

14. Function for test operation.

This function shall be operated while the set not operating and start while set temperature set button(▼) down

and start/stop buttons pressing continuously for 3 seconds.

If you press start/stop button continuously for 3 seconds while set temp down button pressing once more test

operation and the set shall be stopped.

After test operation operating and 18 minutes, test operation and the set shall be stopped.

If you press start/stop button while test operation operating, test operation shall be stopped and the set shall

start.

When test operation operating, the display of

8888::8888

shall be shifted to tESt

4-way valve is always off when test operation.

Fan speed is high, air purifying system and auto air flow operations are off when test operation.

Regardless of outside temperature, the set operates when test operation.

All but start/stop and air purifying system buttons cannot be set.

15. Function of changing set temperature when re-operation after stop.

Heating operation is set to the previous set temperature when re-operation after stop. Cooling operation is set

to the previous set temperature when re-operation with start/stop button.

1.Operation mode.

Cooling/soft dry mode → Cooling mode

Heating mode → Heating mode

2. Setting the set temperature when cooling operation.

Room temperature > Set temperature: to be set to the previous set temperature.

Room temperature ≤ Set temperature

a) Room temperature ≥ 26°C: to be set to 24°C

b) 22°C ≤ Room temperature ≤ 25°C: to be set to 21°C

c) Room temperature ≤ 21°C:to be set to -1°C less than room temperature.

3. Setting the set temperature when heating operation.

Set the previous set temperature when stopped.

16. Auto Restart

In case the power comes on again a power failure, Auto Restarting Operation is the function to operate procedures automatically to the previous operating conditions.

– 23 –

1:00 2:00 3:00 4:00 5:00 6:00 7:00 0:00

– 24 –

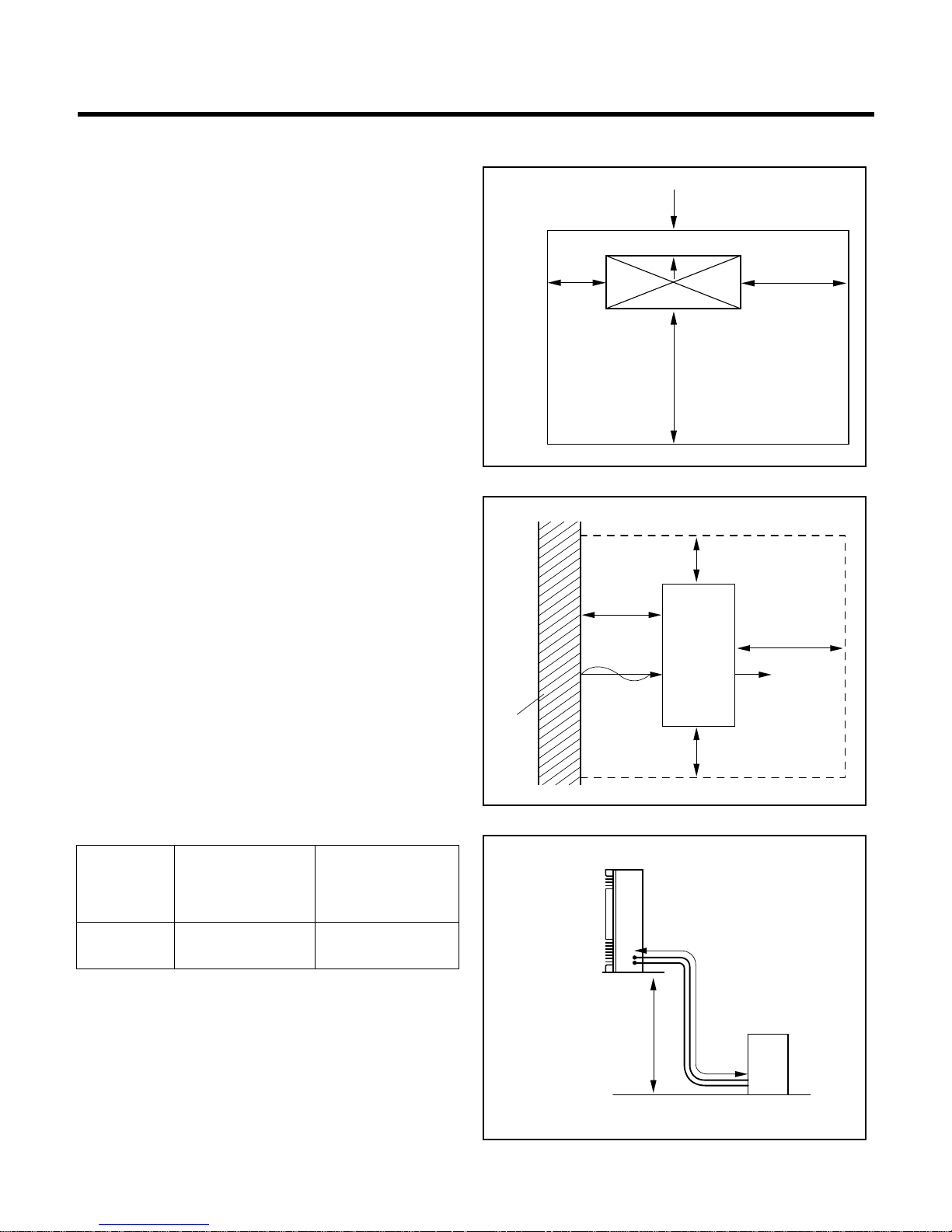

6.1 Installation of indoor , Outdoor Unit

1) Select the best location

¥LIndoor unit

• There should not be any heat source or steam near

the unit.

• There should not be any obstacles to prevent the air

circulation.

• The place where air circulation in the room will be

good.

• The place where drainage can be easily obtained.

• The place where noise prevention is taken into consideration.

• Do not install the unit near the door way.

• Ensure the space indicated by arrows from the wall,

ceiling, fence, or the obstacles.

¥MOutdoor unit

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat radiation from the condenser is not restricted.

• There should not be any animals or plants which

could be affected by discharged hot air.

• Ensure the space indicated by arrows from the wall,

ceiling, fence, or other obstacles.

¥NPiping length and the elevation.

6. INSTALLATION

MODEL

MAX. Piping

length

A (m)

5HP 30 25

MAX.

elevation

B (m)

A

B

Indoor unit

Outdoor unit

Wall

More

than

50cm

More than

50cm

More than

50cm

More than

100cm

Outdoor

unit

5cm

5cm

40cm

100cm

Indoor unit

Loading...

Loading...