LG MLP-F8081CL, MLP-F8081HL, MLP-F8081BL, MLP-F8081AL, MLP-F8081ZL Service Manual

...

LG

Floor Standing Type

Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

e-mail http://www.lgeservice.com/techsup.html

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL: MLP-F8081CL/AL/HL/BL/ZL

LP-C808FA0/LP-H808FA0/LP-Z808FA0

2 Floor Standing Type Air Conditioner

Floor Standing Type Air Conditioner Service Manual

TABLE OF CONTENTS

Safety Precautions....................................................................................................................................3

Functions...................................................................................................................................................7

Product Specifications.............................................................................................................................9

Dimensions..............................................................................................................................................10

Wiring Diagram........................................................................................................................................11

Operation Details ....................................................................................................................................16

Installation...............................................................................................................................................22

Operating.................................................................................................................................................36

3-Way Valve..............................................................................................................................................37

Troubleshooting Guide...........................................................................................................................45

Electronic Control Device ......................................................................................................................58

Schematic Diagram.................................................................................................................................61

Exploded View and Replacement Parts List.........................................................................................62

Service Manual 3

Safety Precautions

Safety Precautions

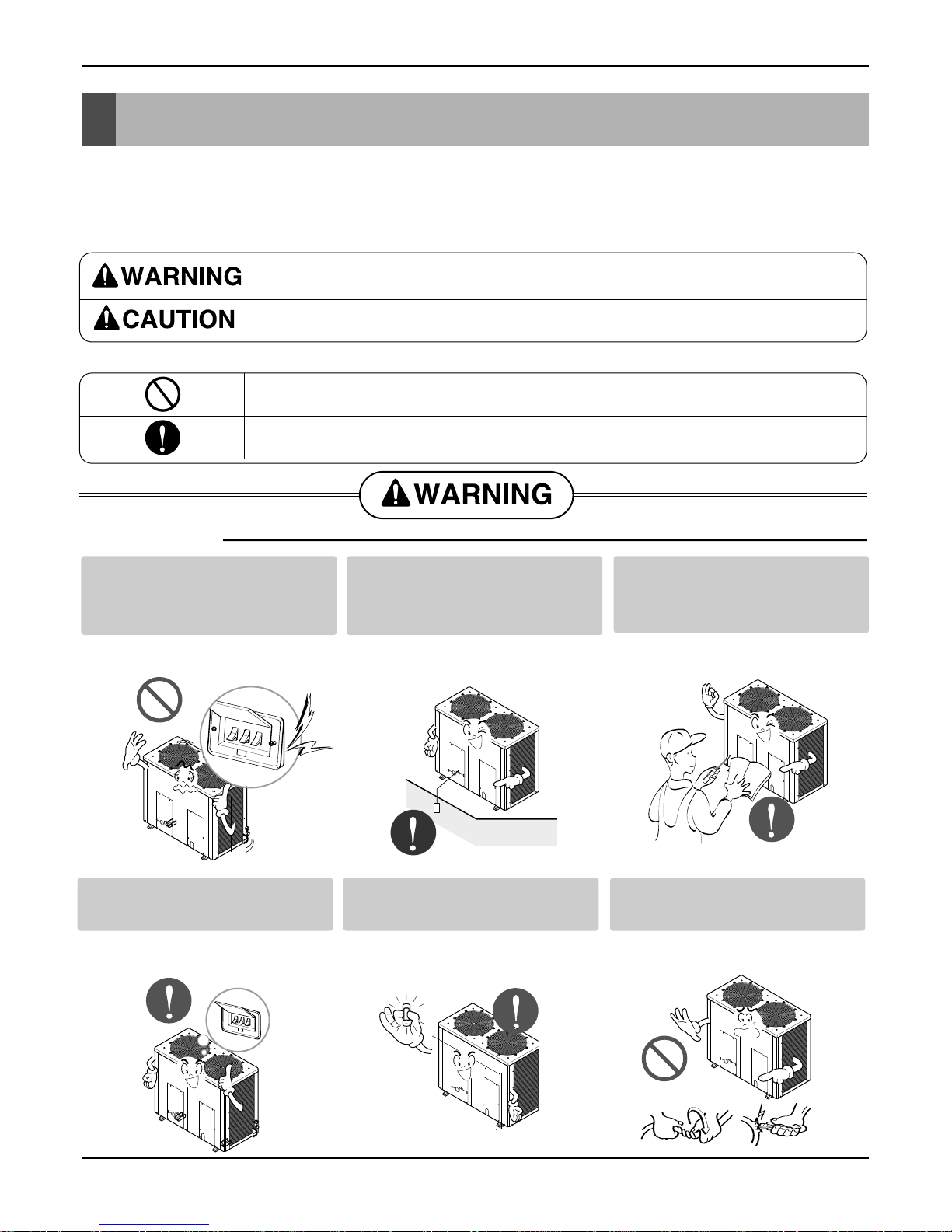

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Installation

Be sure not to do.

Be sure to follow the instruction.

Do not use a defective or underrated circuit breaker. Use this

appliance on a dedicated circuit.

• There is risk of fire or electric

shock.

Always ground the product.

• There is risk of fire or electric

shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric

shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may

cause fire or electric shock

Use the correctly rated breaker or fuse.

• There is risk of fire or electric

shock.

Do not modify or extend the

power cable.

• There is risk of fire or electric

shock.

4 Floor Standing Type Air Conditioner

Safety Precautions

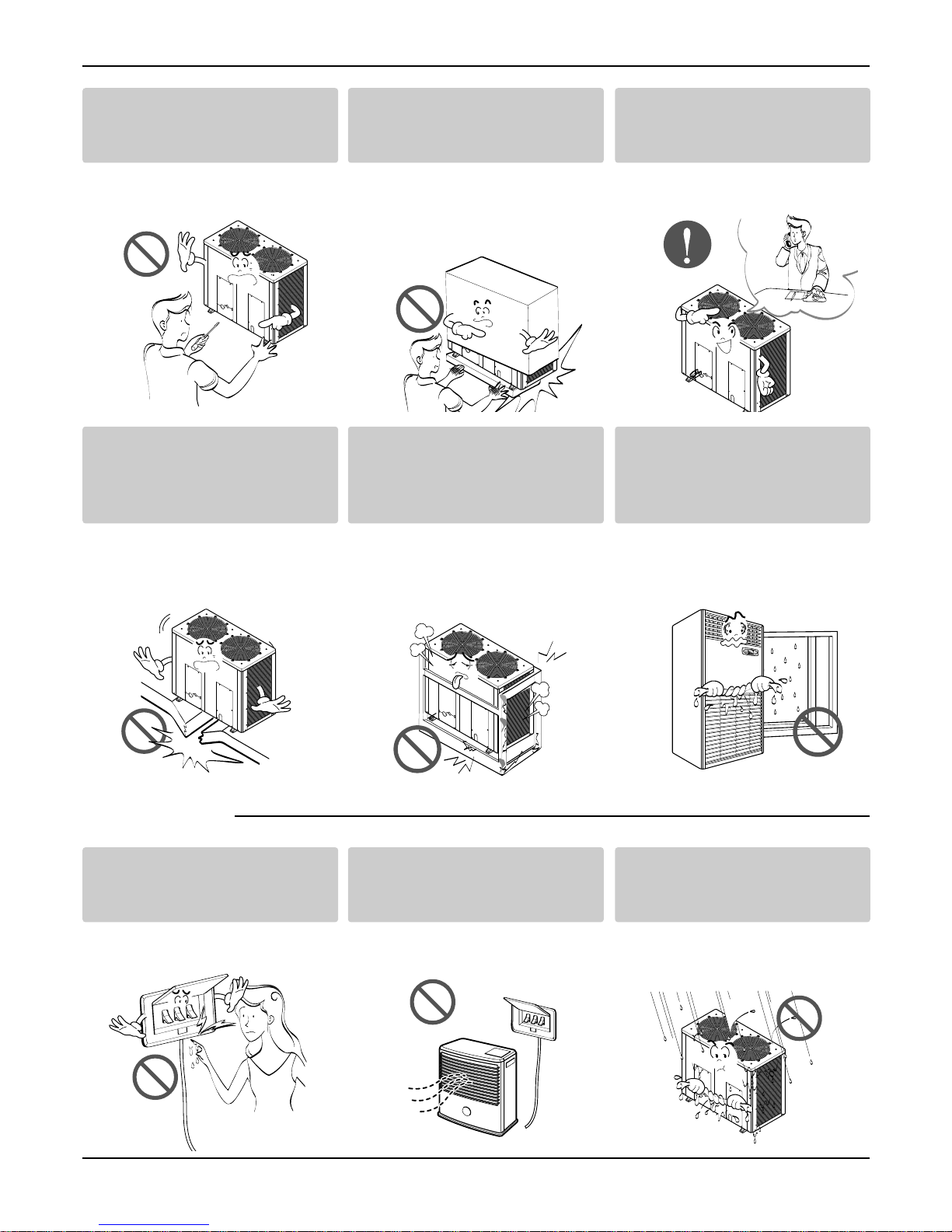

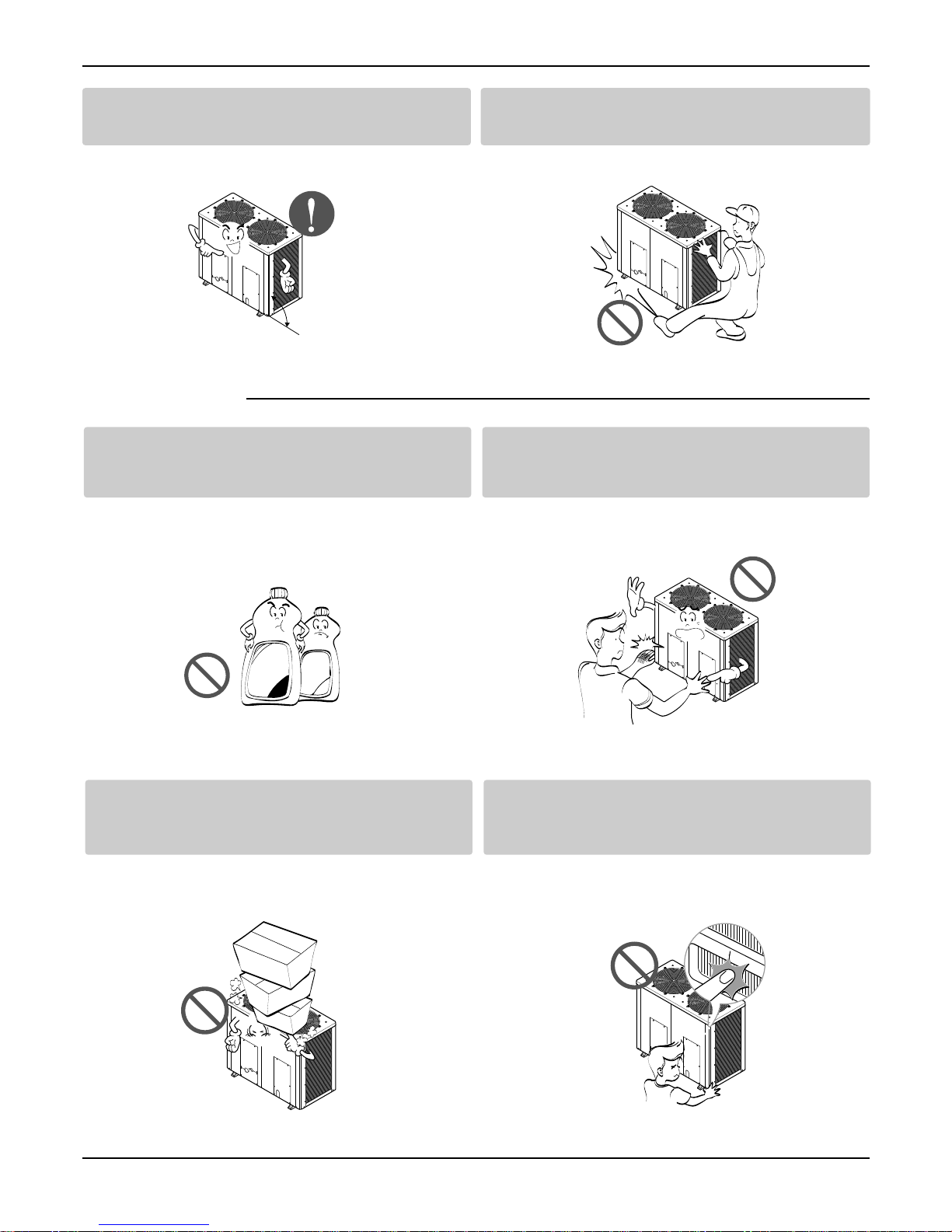

■ Operational

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric shock,

explosion, or injury.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury.

Be especially careful of the case

edges and the fins on the condenser and evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing

property damage, product failure,

and personal injury.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and wet or

damage furniture.

Do not touch(operate) the

product with wet hands.

• There is risk of fire or electrical

shock.

Do not place a heater or other

appliances near the power

cable.

• There is risk of fire or electric

shock.

Do not let electric parts of the

product get wet.

• There is risk of fire, failure of the

product, or electric shock.

Service Manual 5

Safety Precautions

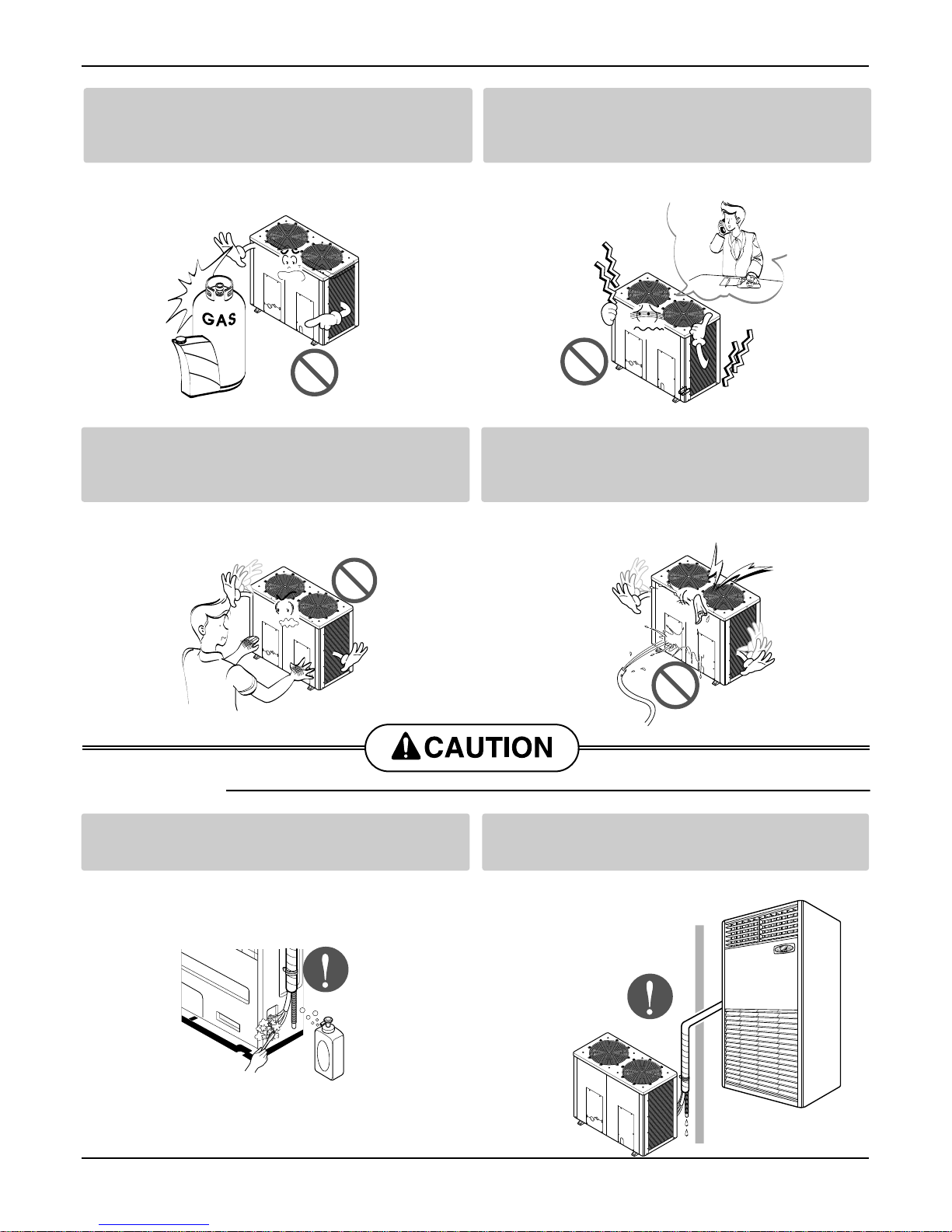

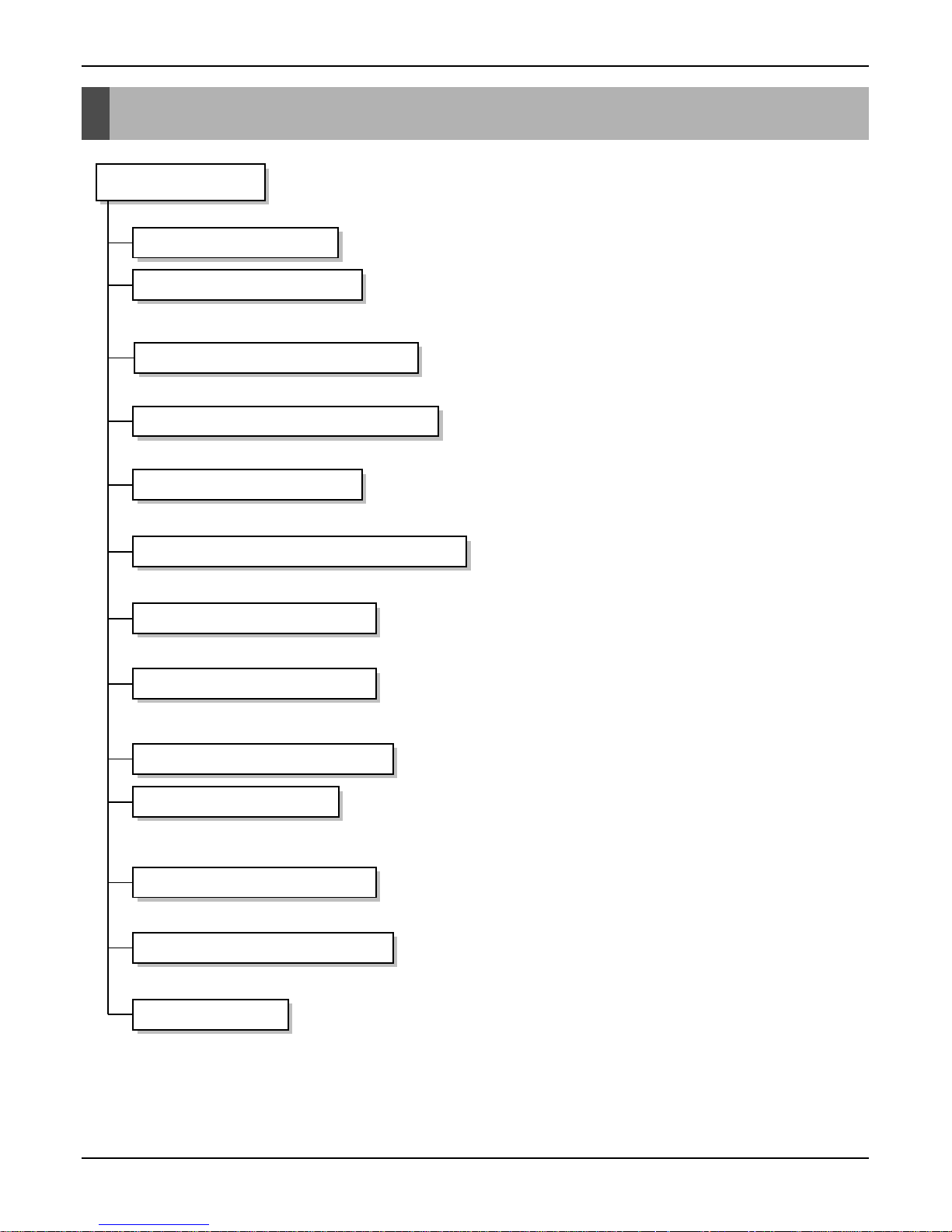

■ Installation

Do not open the inlet grill of the product during

operation. (Do not touch the electrostatic filter,

if the unit is so equipped.)

• There is risk of physical injury, electric shock, or product failure.

Be cautious that water could not enter the

product.

• There is risk of fire, electric shock, or product damage.

Always check for gas (refrigerant) leakage after

installation or repair of product.

• Low refrigerant levels may cause failure of product.

Install the drain hose to ensure that water is

drained away properly.

• A bad connection may cause water leakage.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

If strange sounds, or small or smoke comes

from product. Turn the breaker off or disconnect the power supply cable.

• There is risk of electric shock or fire.

Gasolin

6 Floor Standing Type Air Conditioner

Safety Precautions

Keep level even when installing the product.

• To avoid vibration or water leakage.

Use two or more people to lift and transport

the product.

• Avoid personal injury.

Use a soft cloth to clean. Do not use harsh

detergents, solvents, etc.

• There is risk of fire, electric shock, or damage to the

plastic parts of the product.

Do not touch the metal parts of the product

when removing the air filter. They are very

sharp!

• There is risk of personal injury.

Do not step on or put anyting on the product.

(outdoor units)

• There is risk of personal injury and failure of product.

Do not insert hands or other objects through

the air inlet or outlet while the product is operated.

• There are sharp and moving parts that could cause

personal injury.

90˚

Wax

Thinner

■ Operational

Service Manual 7

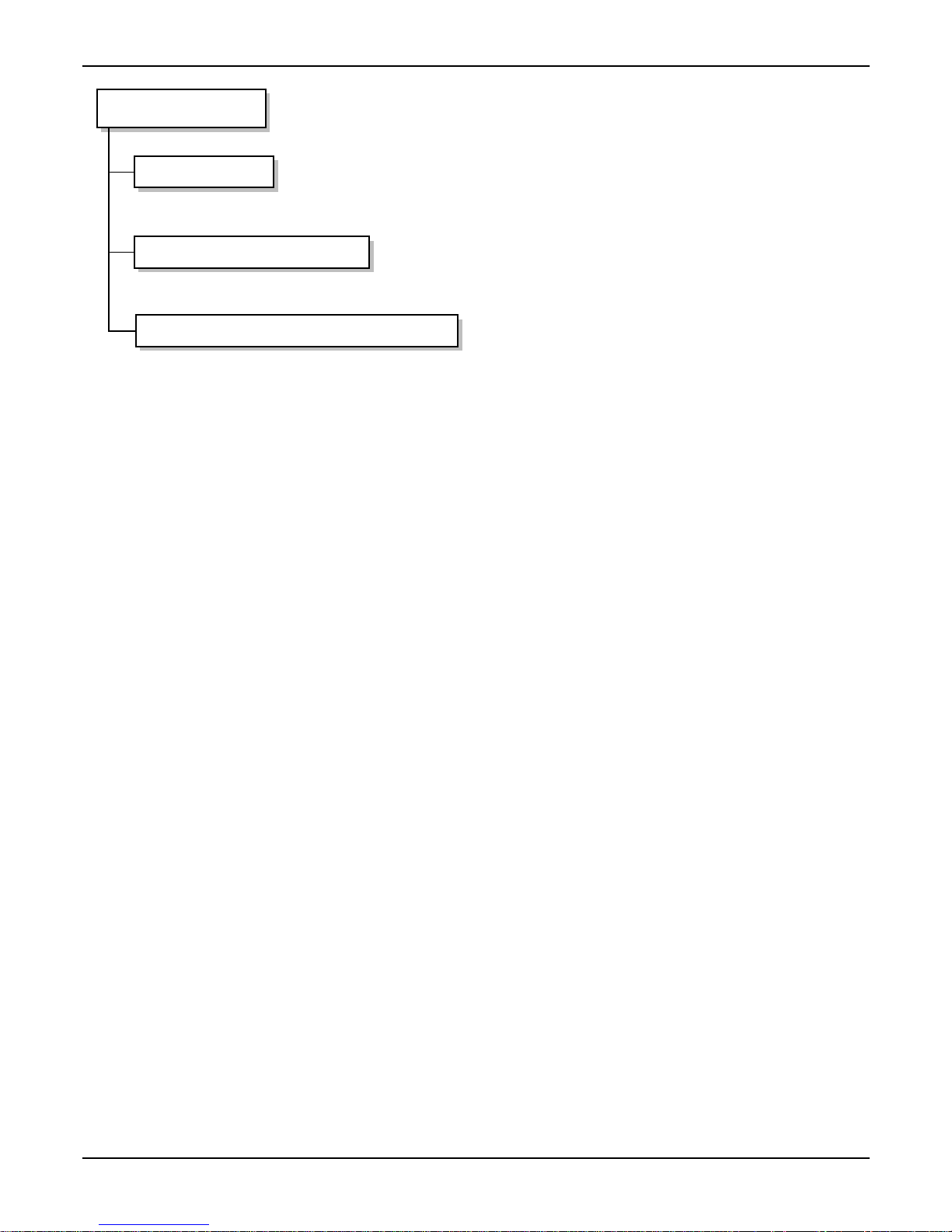

Functions

Functions

Indoor Unit

Power Switch ON/OFF

Operation Mode Control

Sensing the room temperature

Controlling the room temperature

Starting Current Control

Sensing Heat Exchanger Temperature

Timer Delay Safety Control

Indoor Fan Speed Control

Operation Indication lamps

Temperature Setting

Airflow Direction Control

Room temperature Display

Timer Control

• Cooling, Soft Dry, Auto, Fan ➔ Cooling Model •

Cooling, Heating, Soft Dry, Fan➔ Heat Pump Model

• Room temperature sensor (Thermistor)

• Maintains the room temperature in accordance with the setting temperature.

• Indoor fan is delayed for 3 sec at the starting.

• Heat exchanger temperature sensor (Thermistor)

• Restarting is inhibited for approx. 3 minutes.

• High, Low, Duct

• Up : up to 30°C

• Down : down to 16°C

• Airflow direction Manual control

• Low, 10° ~ 35°C, Hi

• Off Timer (1, 2, 3....7 hour)

8 Floor Standing Type Air Conditioner

Functions

Outdoor Unit

Deice Control

Outdoor Fan Speed Control

Sensing Heat Exchanger Temperature

• De-ice PCB

• One speed

• Heat exchanger temperature sensor (Thermistor)

Service Manual 9

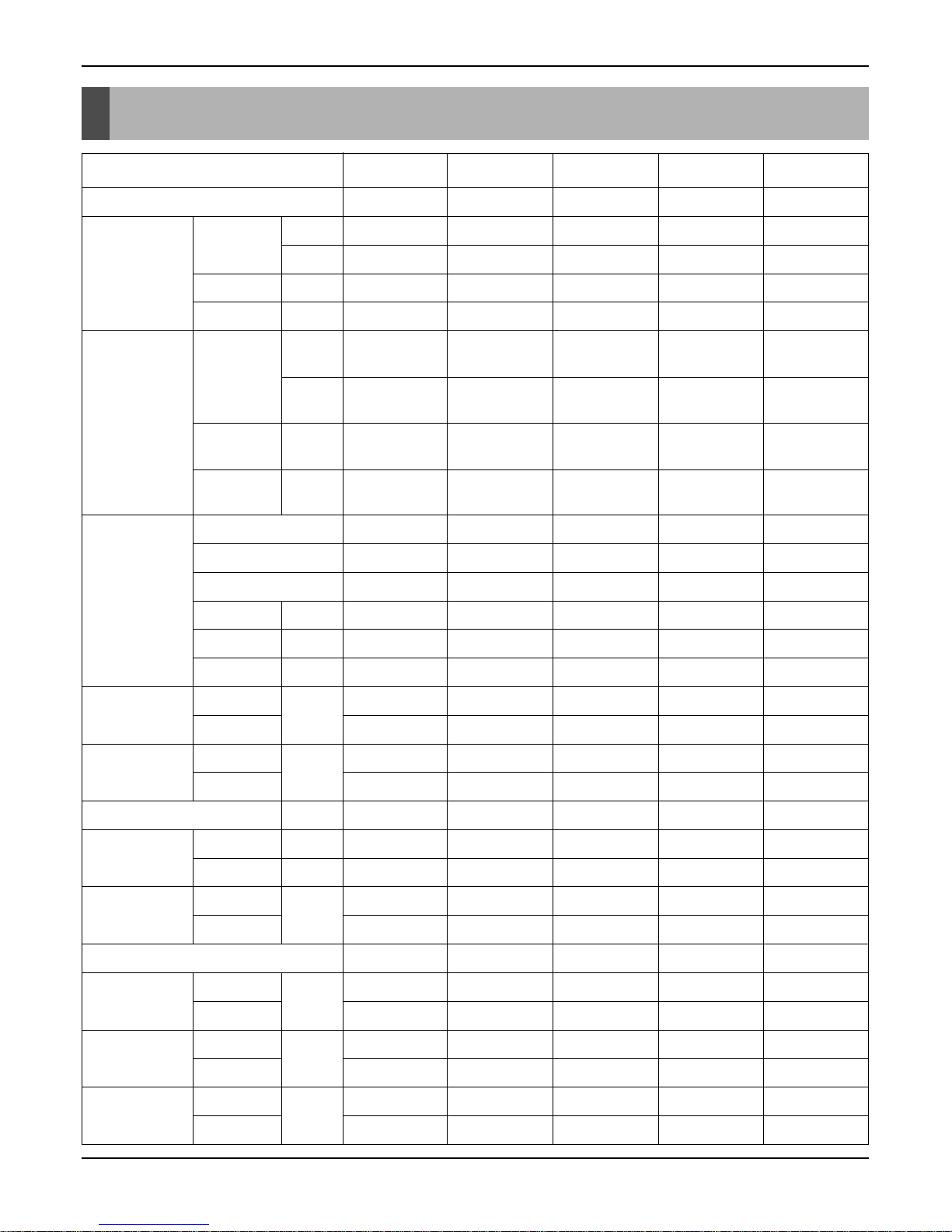

Product Specifications

Product Specifications

POWER SOURCE (ø, V, Hz)

COOLING CAPACITY Btu/h

W

INPUT W

CURRENT A

HEATING CAPACITY Btu/h

(W)

W

(W)

INPUT W

(W)

CURRENT A

(A)

MAKER

TYPE

COMPRESSOR MODEL

INPUT W

CURRENT A

CAPACITY kcal/h

NOISE INDOOR dB(A)

LEVEL(1m) OUTDOOR

AIR INDOOR CMM

VOLUME OUTDOOR

REFRIGERANT R-22 kg

HEAT INDOOR R/C/FPI

EXCHANGER OUTDOOR R/C/FPI

FAN INDOOR TYPE

OUTDOOR

ROOM TEMPERATURE CONTROL

NET INDOOR kg

WEIGHT OUTDOOR

DIMENSIONS INDOOR mm

(W × H × D) OUTDOOR

SVC LIQUID Inch

VALVE GAS (mm)

3,380 – 415,50 3,380 – 415,50 3,380-415,50 3,380-415,50 3,380-415,50

71,400 71,400 75,000 75,000 75,000

20,927 20,927 21,995 21,995 21,995

6,900 7,000 8,300 8,000 8,000

12.0 13.0 14.0 13.5 13.5

– 74,000 – 80,000 80,000

(8,000) (8,000)

– 21,680 – 23,460 23,460

(8,000) (8,000)

– 6,500 – 7,400 7,400

(8,000) (8,000)

– 12.5 – 13.0 13.0

(12.0) (12.0)

COPELAND COPELAND LG LG LG

SCROLL SCROLL SCROLL SCROLL SCROLL

ZR94KC – TFD ZR94KC – TFD SB061Y/SQ042Y SB061Y/SQ042Y SB061Y/SQ042Y

6,990 6,990 4,660/3,064 4,660/3,064 4,660/3,064

13.6 13.6 8.3/5.7 8.3/5.7 8.3/5.7

19,732 19,732 12,801/8,489 12,801/8,489 12,801/8,489

56 56 60 60 60

65 65 65 65 65

57 57 57 57 57

150 150 150 150 150

5.9 7.2 6.6 8.44 8.44

3/33/17 3/33/17 3/33/17 3/33/17 3/33/17

2/18/17 2/18/17 (2/18/17) X2 (2/18/17) X2 (2/18/17) X2

SIRROCO SIRROCO SIRROCO SIRROCO SIRROCO

PROPELLER PROPELLER PROPELLER PROPELLER PROPELLER

MICOM CONTROL MICOM CONTROL MICOM CONTROL MICOM CONTROL MICOM CONTROL

132 132 110 110 110

150 150 150 150 150

1,050 x 1,880 x 495 1,050 x 1,880 x 495 1,050 x 1,880 x 495 1,050 x 1,880 x 495 1,050 x 1,880 x 495

1,000 ×965 ×370 1,000 ×965 ×370

1,245 x 930 x 650 1,245 x 930 x 650 1,245 x 9

30 x 650

5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88)

1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4)

MODEL

LP-F8081CL/AL

LP-F8081HL/BL

LP-F8081ZL

LP-C808FA0 LP-H808FA0 LP-Z808FA0

(Including Electric

heater)

Indoor Unit

Outdoor Unit

10 Floor Standing Type Air Conditioner

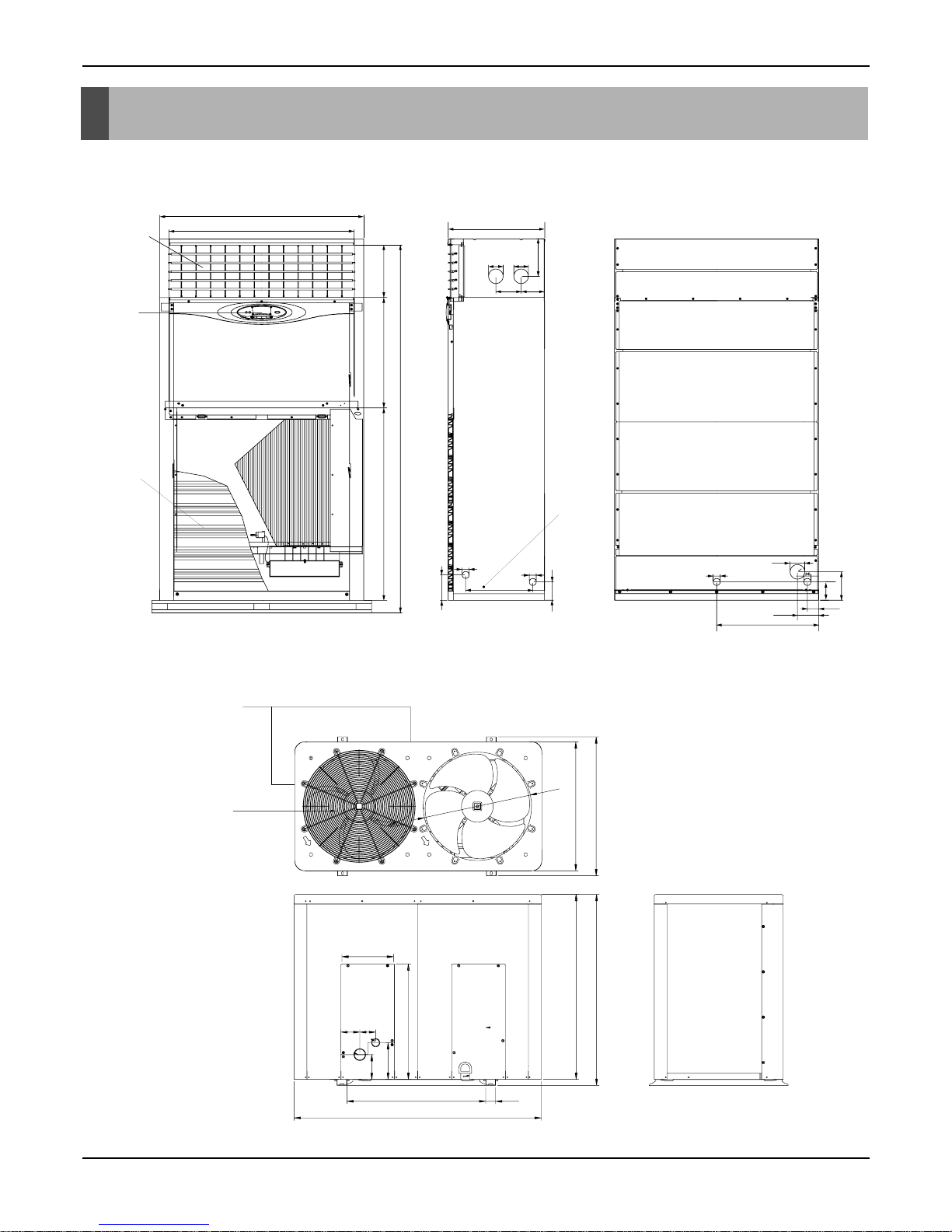

Dimensions

Dimensions

268568990

1890

1051

496

75

130 121

75

193

951

36

36

60

345

93.8

131

36

75

525

109.5

58.5

145.8

93.8

Air Outlet

Vent

Air Inlet

Vent

Window

Display

Earth

Screw

700

650

963

930

582

185

125

546

1245

700

50

260

95 80

Air Outlet Vent

Air Inlet Vent

Service Manual 11

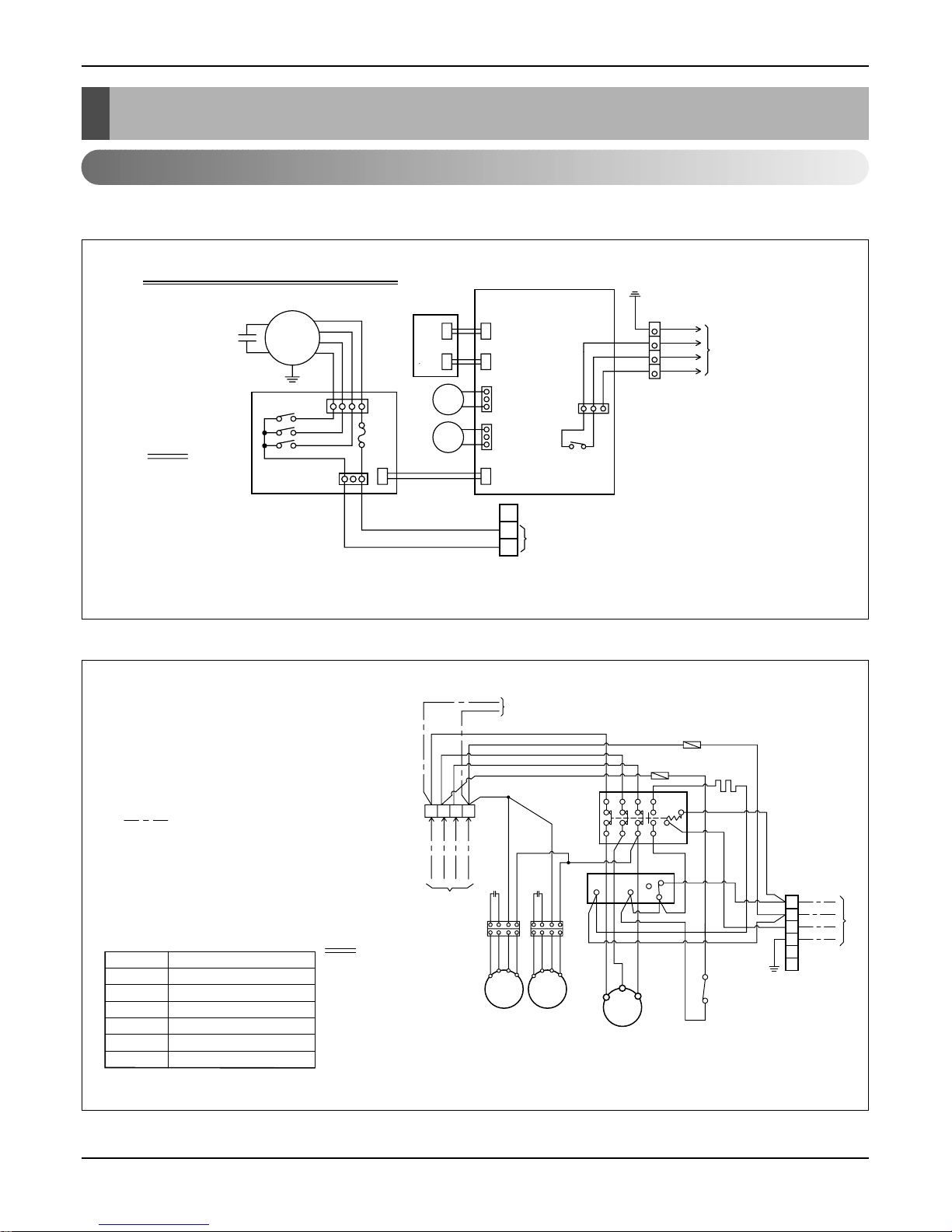

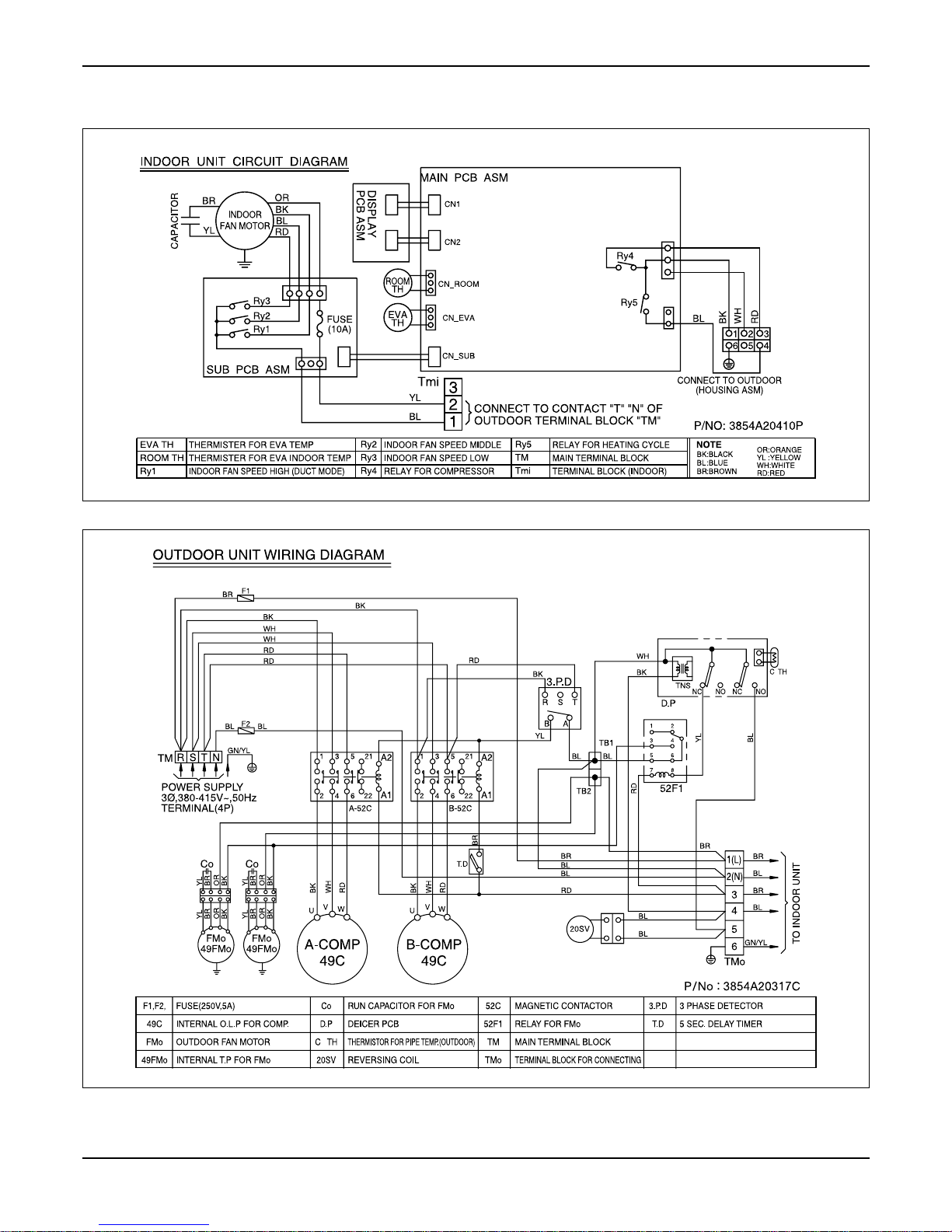

Wiring Diagram

Model: LP-F8081CL/AL

Wiring Diagram

Indoor & Outdoor Unit Circuit Diagram

INDOOR UNIT CIRCUIT DIAGRAM

OR

BK

BL

RD

BR

YL

RY3

CN2

CN3

DISPLAY

PCB ASM

CN1

RD

GN/YL

CONNECT TO

OUTDOOR UNIT

WH

BK

BK

GN/YL

BL

BR

YL

BL

CONNECT TO CONTACT "R" "N" OF

OUTDOOR TERMINAL BLOCK "Tmo1"

NOTE

BL

BK

BR

OR

RD

WH

YL

GN/YL

BLUE

BLACK

BROWN

ORANGE

RED

WHITE

YELLOW

GREEN/YELLOW

:

:

:

:

:

:

:

:

RY3

1

MAIN PCB ASM

RY2

FUSE

(10A)

RY1

SUB PCB ASM

CAPACITOR

INDOOR

FAN MOTOR

ROOM

TH

EVA

TH

2 3 4

3

2

1

Tmo1,2

52C

51C

63H

CH

FMo1,2

Co1,2

TERMINAL BLOCK

MAGNETIC CONTACTOR

EOCR(COMP.)

HIGH PRESSURE SWITCH

CRANKCASE HEATER

OUTDOOR FAN MOTOR

RUN CAPACITOR FOR FAN(OUTDOOR)

NOTE

BL

BK

BR

OR

RD

WH

YL

GN

GN/YL

BLUE

BLACK

BROWN

ORANGE

RED

WHITE

YELLOW

GREEN

GREEN/YELLOW

:

:

:

:

:

:

:

:

:

Tmo1

3Ø, 4W

380-415V, 50Hz

POWER SUPPLY

R S T N

OR

Co1

YLBRORBKYLBROR

BK

BK

OR

BK

BK

WH

WH

RD

WH

FUSE(5A)

WH

BK

BR

BL

BK

GN/YL

GN/YL

CH

WH

BK

RD

BK

BK

CONNECT TO

INDOOR UNIT

WH

BK

BK

RD

T1

T3

T2

COMP

WH

WH

BK

L1 L2

Tb

Ta

Tc

51C

63H

Tmo2

1

2

3

4

5

6

FUSE(5A)

CONNECT TO

INDOOR UNIT

Co2

13531

24632

A

B

52C

FIELD WIRING

NOTE

1. This product is 3ø,4W,380-415V,50Hz.

2. "Check List" before test run.

1st: Reconfirm the wiring connecting

of compressor, outdoor unit motor.

2nd: Fasten the screw of "Terminal Block

Tmo1,2" once more.

FMo2FMo1

12 Floor Standing Type Air Conditioner

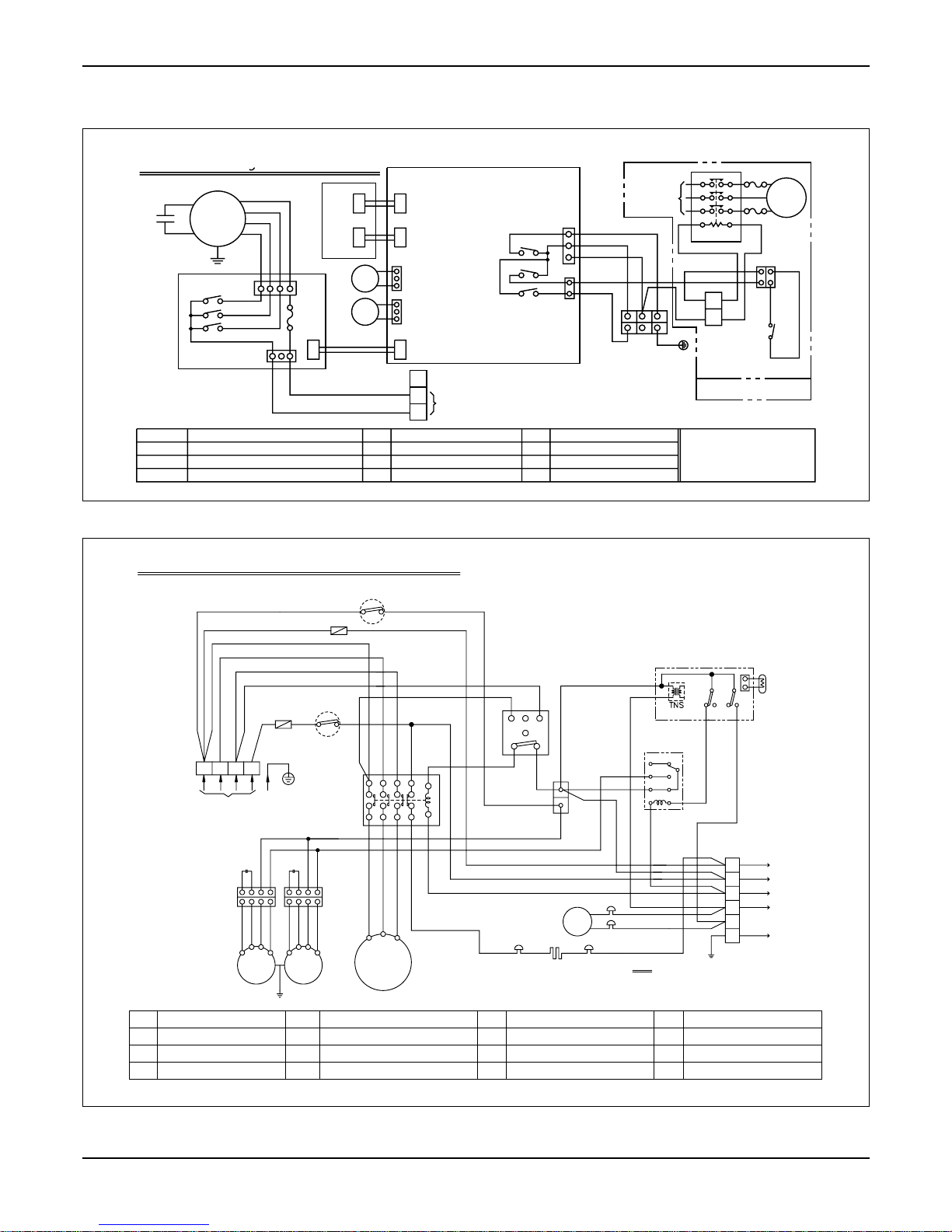

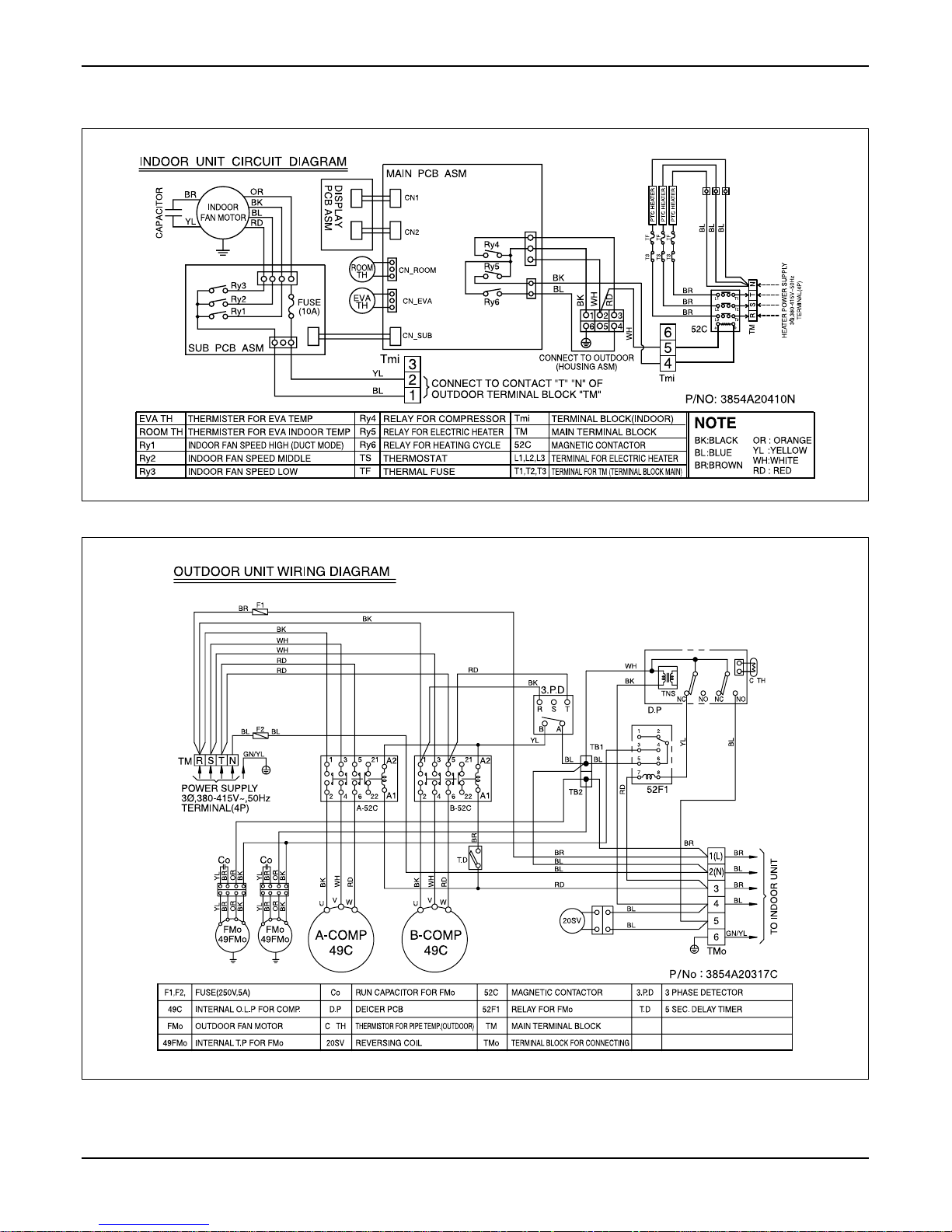

Wiring Diagram

Model: LP-F8081HL/ZL/BL

INDOOR UNIT CIRCUIT DIAGRAM

CAPACITOR

BR

OR

BK

BL

RD

YL

INDOOR

FAN MOTOR

RY3

RY2

RY1

SUB PCB ASM

FUSE

(10A)

DISPLAY

PCB ASM

MAIN PCB ASM

CN1

CN2

ROOM

TH

EVA

TH

CN3

Tmi

YL

BL

3

2

1

CONNECT TO CONTACT "T" "N" OF

OUTDOOR TERMINAL BLOCK "A"

Ry3

Ry6

Ry7

BKBKBK

TF

TF

BK

BL

BK

BKWHRD

POWER SUPPLY

3Ø 380~415V

50Hz

L1

L2

L3

a

T1

T2

T3

b

EH

123

456

5

4

Tmi

CONNECT TO OUTDOOR

(HOUSING ASM)

TP

Option part

DEF TH

EH

EVA TH

ROOM TH

Ry3

Ry6

Ry7

THi

Tmi

TP

TF

TERMINAL BLOCK(INDOOR)

BIMETAL SWITCH FOR HEATER

THERMAL FUSE

RELAY FOR COMP

RELAY FOR HEATER

RELAY FOR HEATING

THERMISTOR FOR INDOOR TEMP

THERMISTER FOR DISCHARGE AIR

ELECTRIC HEATER

THERMISTER FOR EVA TEMP.

THERMISTER FOR EVA INDOOR TEMP

NOTE

BK:BLACK

BL:BLUE

BR:BROWN

YL :YELLOW

WH:WHITE

OUTDOOR UNIT WIRING DIAGRAM

R S T N

POWER SUPPLY

3ø,380-415V,50Hz

TERMINAL(4P)

NC

12

34

56

78

NO NC NO

1

2

3

4

5

6

NOTE

BL

BK

BR

OR

RD

WH

YL

GN/YL : GREEN/YELLOW

RED

WHITE

YELLOW

BLUE

BLACK

BROWN

ORANGE

:

:

:

:

:

:

:

CH

F1,2

Co

FMo

D.P

C TH

20SV

49FMo

DEICER PCB

THERMISTOR FOR PIPE TEMP.(OUTDOOR)

REVERSING COIL

INERNAL T.P FOR FMo

52F1

63H1

63H2

49C

RELAY FOR FMo

HIGH PRESSURE SWITCH

HIGH PRESSURE SWITCH FOR HEATING

INTERNAL O.L.P FOR COMP.

TM

52C

3.P.D

MAIN TERMINAL BLOCK

MAGNETIC CONTACTOR

3 PHASE DETECTOR

CRANKCASE HEATER

FUSE (250V, 5A)

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

TM

GN/YL

F2

F2

63H1

63H2

RD RD RD

BK

BK

BK

BK

BK

3.P.D

R

AB

ST

BK

WH

RD

RD

52C

BK

BK

WH

WH WH

WH

C TH

D.P

52F1

YL

OR

BL

WH

BK

BK

YL

BK

BL

BR

BL

BR

BL

GN/YL

BL

20SV

13531A

24632B

YLBRORBKYLBROR

BK

BKWHRD

L1

L2

L3

YLBRORBKYLBROR

BK

FMo

49FMo

FMo

49FMo

COMP

Service Manual 13

Wiring Diagram

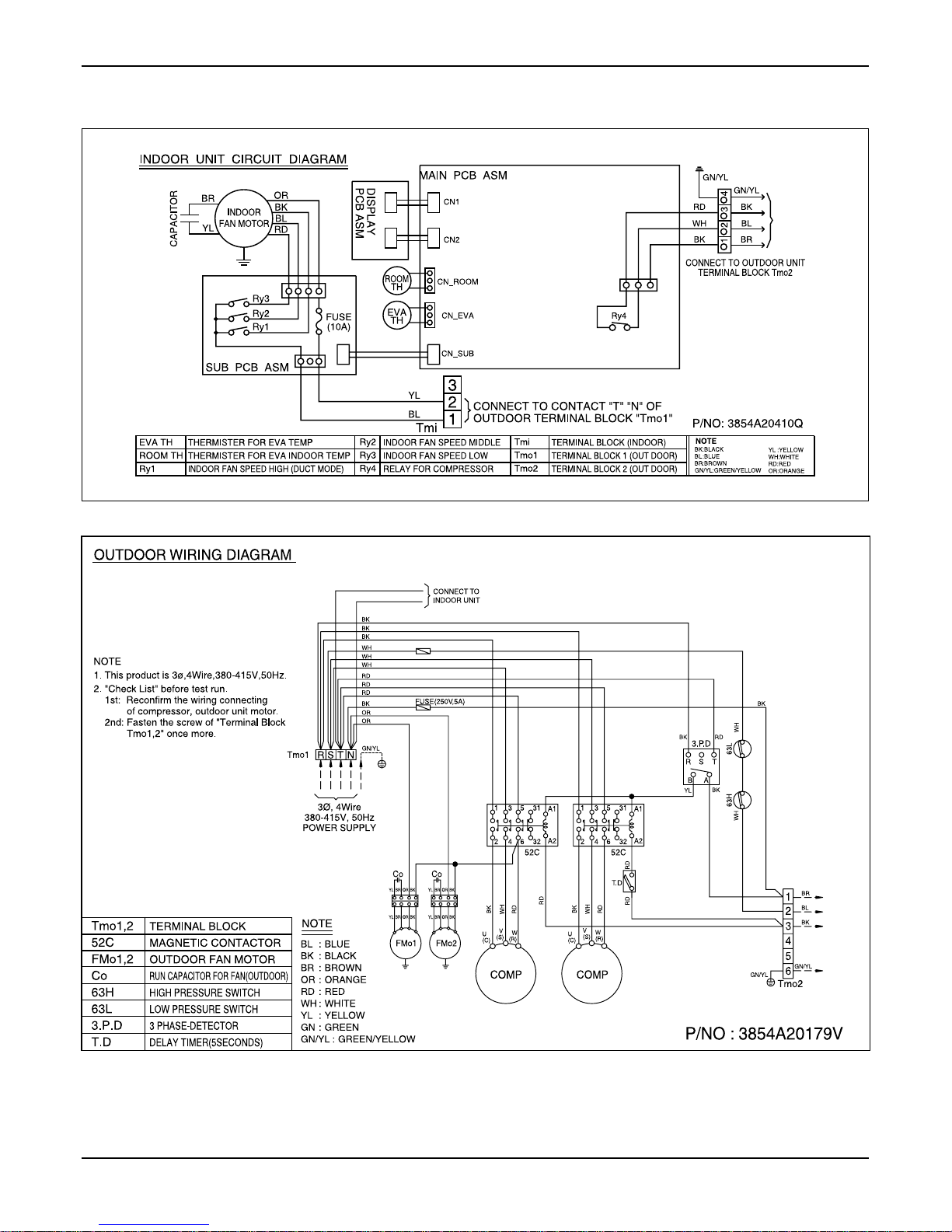

Model: LP-C808FA0

14 Floor Standing Type Air Conditioner

Model: LP-H808FA0

Wiring Diagram

Service Manual 15

Model: LP-Z808FA0

Wiring Diagram

16 Floor Standing Type Air Conditioner

Operation Details

Operation Details

(1) The function of main control

1. Time Delay Safety Control

• 3min

...

The compressor is ceased for 3 minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 3sec

...

The indoor fan is ceased for 1~3 seconds to prevent relay noise.

(Protection of fan relay and micro chip)

• 1min

...

The 4-way valve is ceased for 30 sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode.

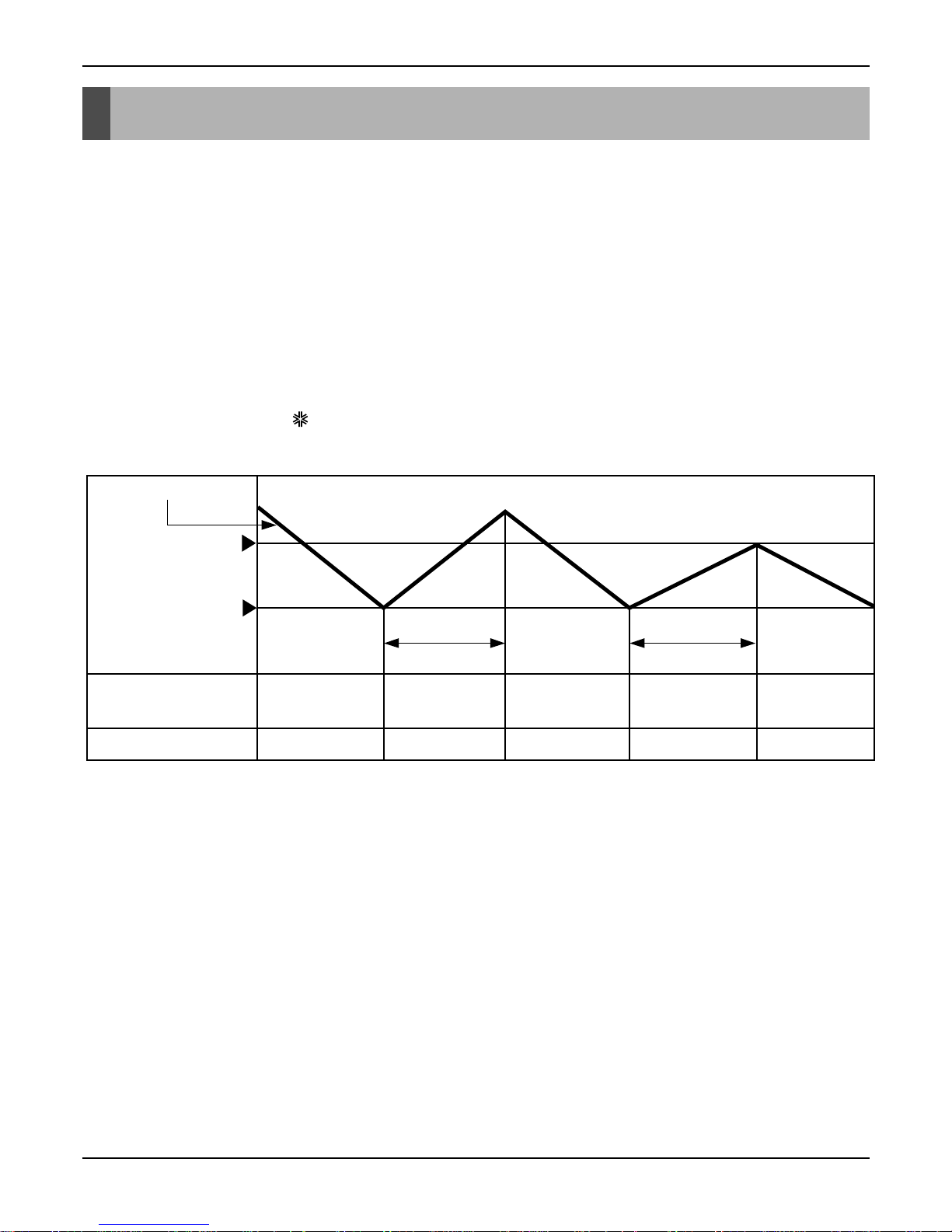

2. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the

controller and the operation diagram is as following

Intake Air temp.

Setting Temp. +1°C

(Compressor ON)

Setting Temp. -1°C

(Compressor OFF)

Indoor Fan Speed

Selecting

fan speed

Selecting

fan speed

Selecting

fan speed

Selecting

fan speed

Selecting

fan speed

3 minutes 3 minutes

Compressor ON OFF ON OFF ON

Service Manual 17

Operation Details

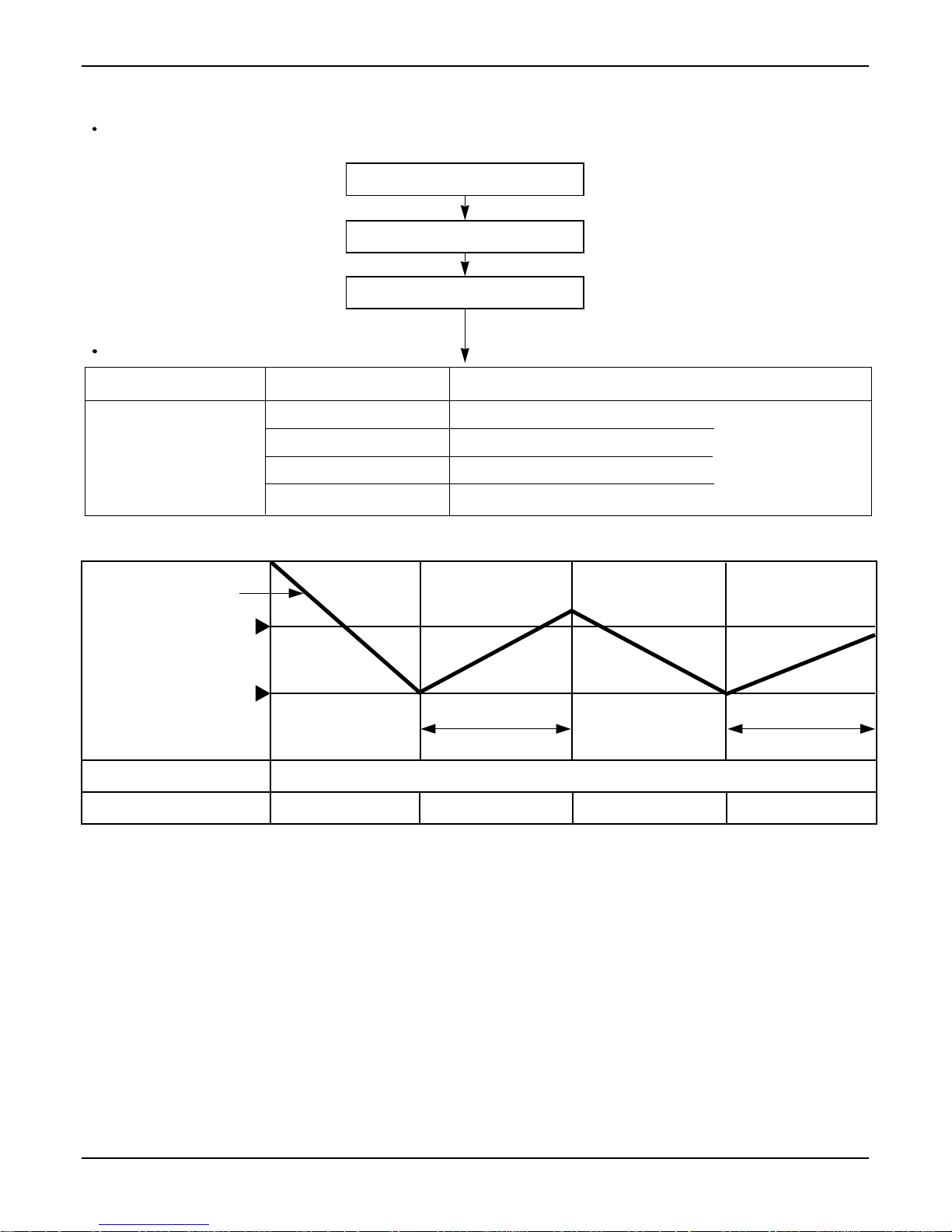

3. Auto Operation (Cooling Model only)

The operation procedure is as following.

Auto Operation for Cooling

Press Start/Stop Button

Select Auto Operation Mode

Check the Room temperature

Operation Condition Intake-air Temperature Setting temperature Fan speed

Over 26°C25°C

Over 24°C~below 25.5°C Intake air -1.0°C

Over 22°C~below 23.5°C Intake air -0.5°C

below 21.5°C Intake air Temperature(18°C, MAX)

When Switch to

Auto Operation

Intake Air Temp.

Indoor Fan Speed

Compressor ON OFF

Fuzzy Speed

ON OFF

Setting Temp. +1°C

(Compressor ON)

Setting Temp. -1°C

(Compressor OFF)

3 minutes 3 minutes

18 Floor Standing Type Air Conditioner

Operation Details

4. Heating Mode Operation

The unit will operate according to the setting by the remote controller and the operation diagram is shown as

following.

Intake Air Temp.

Setting T emp .

(Compressor ON)

Setting T emp . -1°C

Indoor Fan Speed

Compressor

Electric Heater(Option)

ON

ON

OFF ON OFF

OFFOFF ON OFF

OFF

LOW

Hot

Start

minimum

10sec.

minimum

1min

minimum

10sec.

OFF

AA

OFFLOW LOW

Setting T emp . +1°C

(Compressor OFF)

Selecting

fan speed

Selecting

fan speed

• A point: The indoor pipe temperature to be less then 35°C or Discharge air Temperature to be less than 29°C.

The indoor fan operates for minimum 10sec. even if the indoor pipe temperature falls lower than35°C

or the discharge air Temperature falls lower than 29°C.

Low(V)Stop(VI)

39˚C

Discharge Air Temp.

Indoor Pipe Temp.

34˚C

28˚C

26˚C

Selecting Fan Speed(IV)

Low(II)Stop(I)

(Hot-Start Operating)

Heating Start

(Hot-Start Release Point)

Selecting Fan Speed(III)

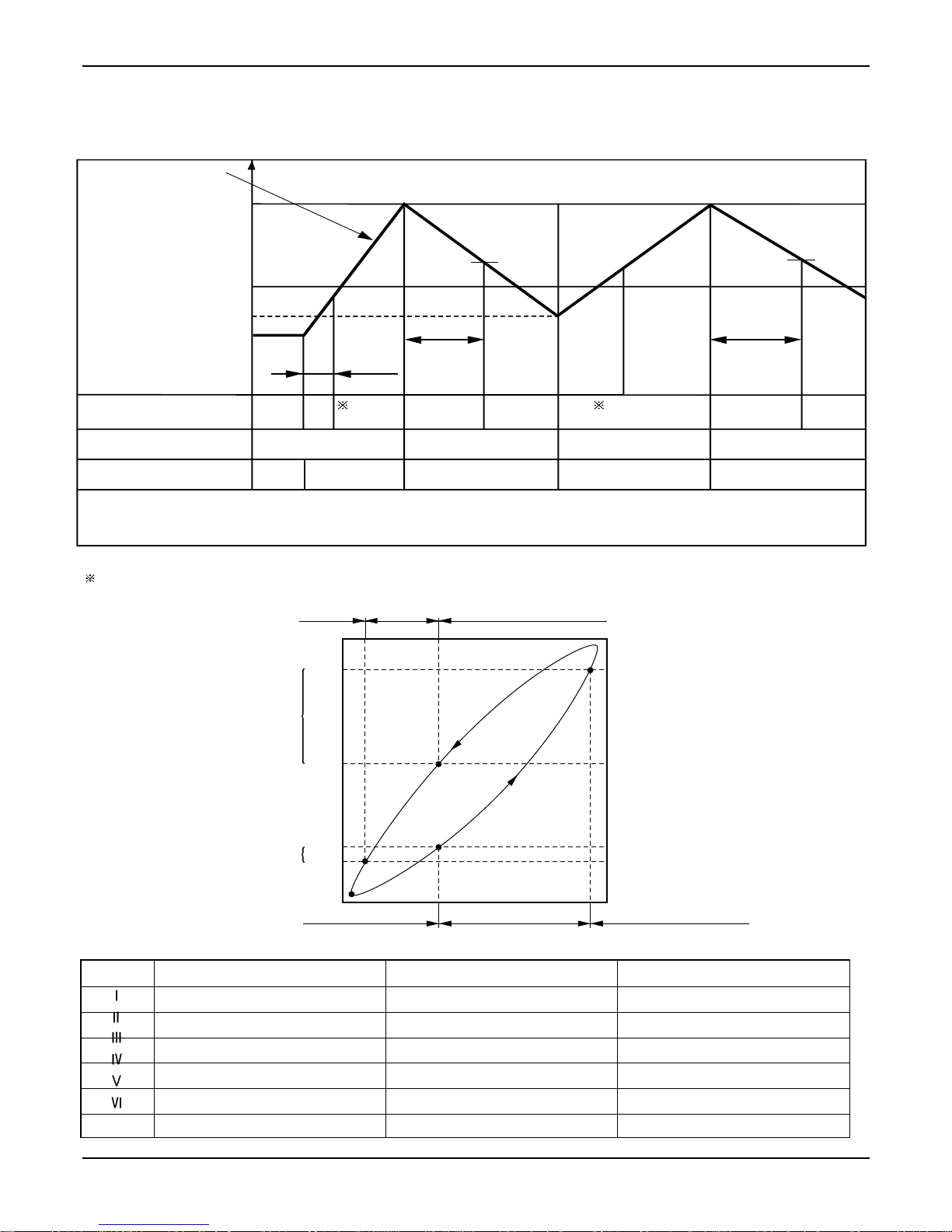

During heating operation, the operating procedure of the indoor fan is as the following.

Step Indoor fan speed Pipe temp. Air discharge temp.

Off ≤28°C(Hot start operating) –

Low ≥28°C <39°C

Selecting speed ≥28°C ≥39°C

Selecting speed ≥28°C >34°C

Low ≥26°C ≤34°C

Off ≤26°C –

Service Manual 19

Operation Details

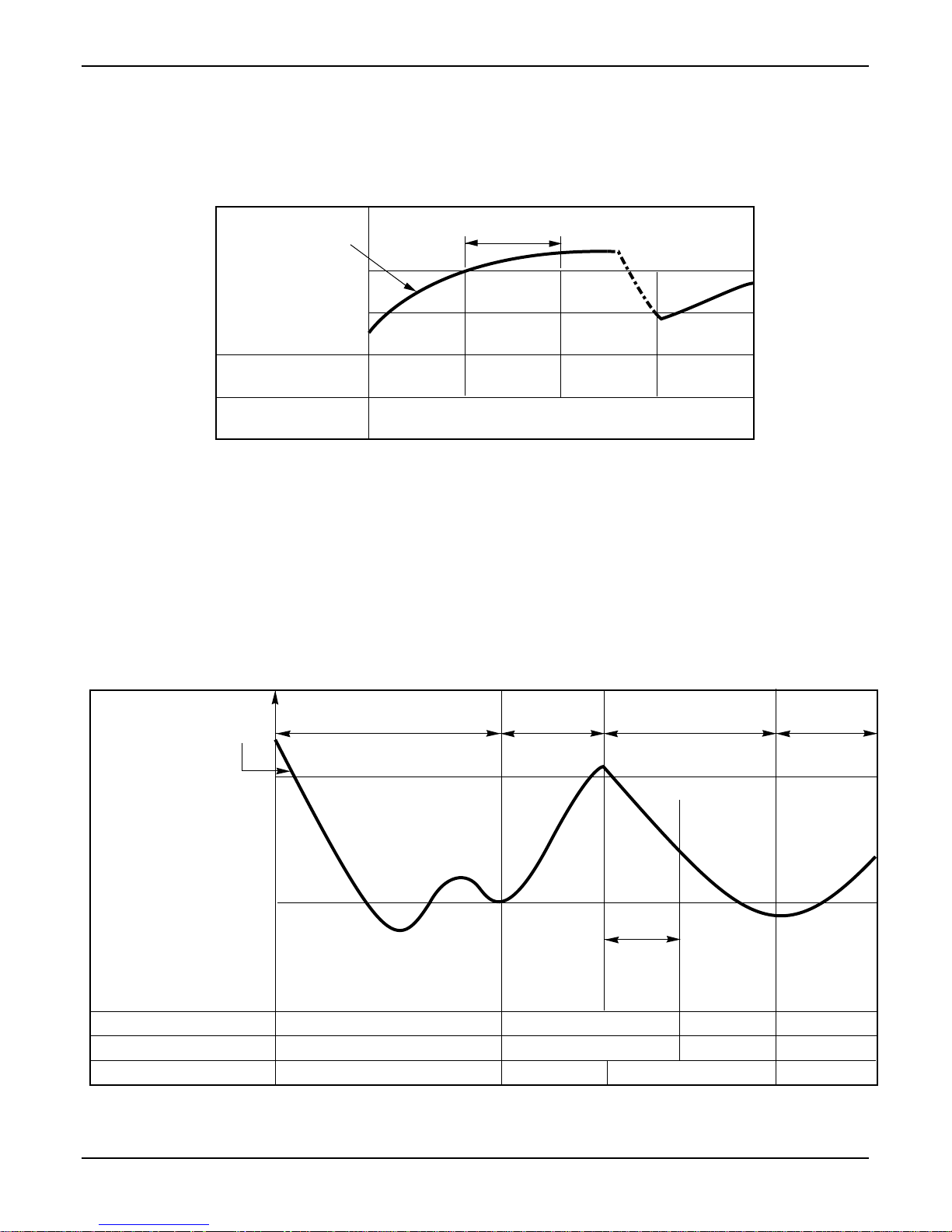

5. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature will be reached to 28°C.

• During heating operation, if piping temperatures fall below 26°C fan stops.

• The operation diagram is as following.

6. Defrost Control

• Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

• The first defrost starts only when the outdoor pipe temperature falls below -6°C after 45 minutes passed from

starting of heating operation and more than.

• Defrost ends after 10 minutes pass from starting of defrost operation or when the outdoor pipe temperature rises

over 12°C even if before 10 minutes.

• The second defrost starts only when the outdoor pipe temperature falls below -6°C after 45 minutes pass from

ending of the first defrost and more than.

INDOOR PIPE

TEMP.

INDOOR FAN

SPEED

Selecting

fan speed

OFF OFFLOW

1min

Maximum

COMPRESSOR ON

28°C

26°C

More than 45 minutes of

heating operation

Outdoor Pipe Temp.

Indoor Fan

Compressor

4-Wa y V alve

ON

ON

ON

ON

OFF

ON

OFF

HOT-

START

ON

ON OFF OFFON

12°C

(Defrost OFF)

-6°C

(Defrost ON)

Within

10minutes

Defrost

Defrost

More than 45 minutes of

heating operation

Less than 5 minutes

20 Floor Standing Type Air Conditioner

Operation Details

9. Child Lock function

This function is to operate Air conditioner only by Remocon.

The procedure is as the following

1st: Press the 2 buttons of the temperature control simultaneously, to raise-to lower on the Display Panel of the

product for more 3 seconds.

2nd: The buzzer sounds and then the window of Display Panel shows LOC (LOC) mark.

3rd: To release this function, the reverse again the operating procedure could be done.

During this function is operating, any buttons of Display Panel don't work. But it is possible to operate with

Remote controller.

10. Off Timer Function

This function is to set the time of stopping the unit operation.

The procedure is as the following.

1st: Press the timer set button on the Remocon.

2nd:

The buzzer sounds and then the display window shows the Off-Time to be set as 1:00

...

7:00 0:00.

- The Off-Time is shifted as the following by each press.

- If you select '0:00', the Off-Timer function will be cancelled.

- During Off-Timer Operation, if you repress the timer set button, the rest time will be displayed.

8. Protection of the evaporator pipe from frosting

• Compressor and outdoor fan stop when indoor pipe temperature is below -2°C and restart at the pipe temperature

is above 12°C.

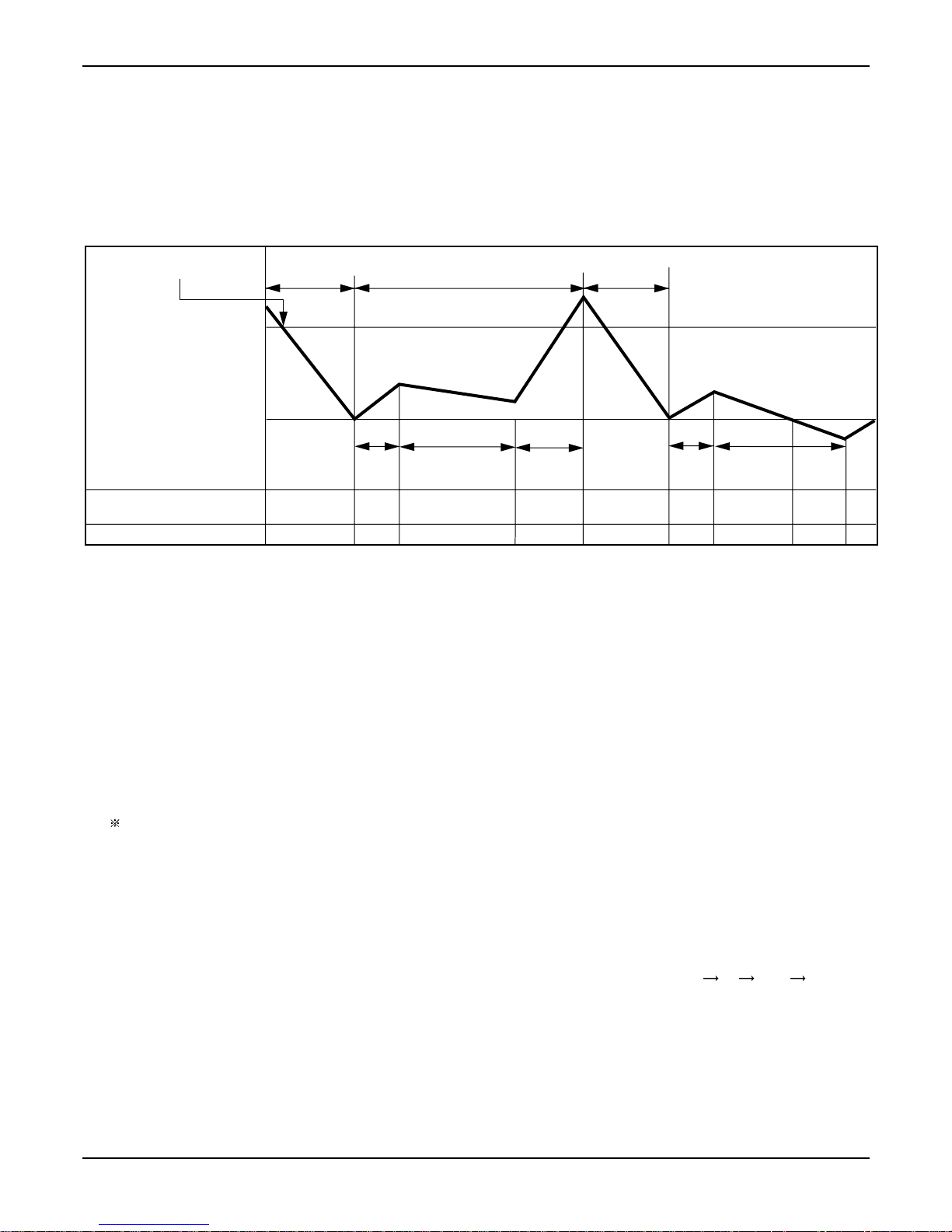

7. Soft Dry Operation Mode

• During Soft Dry Operation, the compressor ON temperature is the setting temperature plus 2°C, the compressor OFF temperature is the setting temperature minus 1°C.

• When the room temperature rises over the compressor ON temperature, the operation mode is switched to the

Cooling mode.

• When the room temperature falls between the compressor ON temperature and OFF temperature, the operation mode is switched to the Soft Dry Operation.

• The operation diagram is shown below.

Intake Air Temp.

Indoor Fan Speed

LOW

Selecting

fan speed

Selecting

fan speed

LOW LOW LOW LOW

Compressor OFFON ONON OFF OFF ON

LOW

OFF

Setting Temp. +2°C

(Compressor ON)

Setting Temp. -1°C

(Compresso OFF)

Operation

Cooling

Cooling

operation

Dry operation

3 min. 3 min.

10 min.

maximum

7 min.

maximum

10 min.

Service Manual 21

Operation Details

11. Alarm mode display / only displayed while operating.

CH 0 : The sensor for sensing room temperature is open or short.

CH 1 : The sensor for sensing piping temperature of evaporator is open or short.

12. Function for test operation.

This function shall be operated while the set not operating and start while set temperature set button(▼) down

and start/stop buttons pressing continuously for 3 seconds.

If you press start/stop button continuously for 3 seconds while set temp down button pressing once more test

operation and the set shall be stopped.

After test operation operating and 18 minutes, test operation and the set shall be stopped.

If you press start/stop button while test operation operating, test operation shall be stopped and the set shall

start.

When test operation operating, the display of 88:88 shall be shifted to tESt

4-way valve is always off when test operation.

Fan speed is high, air purifying system and auto air flow operations are off when test operation.

Regardless of outside temperature, the set operates when test operation.

All but start/stop and air purifying system buttons cannot be set.

13. Function of changing set temperature when re-operation after stop.

Heating operation is set to the previous set temperature when re-operation after stop. Cooling operation is set

to the previous set temperature when re-operation with start/stop button.

1.Operation mode.

Cooling/soft dry mode → Cooling mode

Heating mode → Heating mode

2. Setting the set temperature when cooling operation.

Room temperature > Set temperature: to be set to the previous set temperature.

Room temperature ≤ Set temperature

a) Room temperature ≥ 26°C: to be set to 24°C

b) 22°C ≤ Room temperature ≤ 25°C: to be set to 21°C

c) Room temperature ≤ 21°C:to be set to -1°C less than room temperature.

3. Setting the set temperature when heating operation.

Set the previous set temperature when stopped.

14. Auto Restart

In case the power comes on again a power failure, Auto Restarting Operation is the function to operate procedures automatically to the previous operating conditions.

Loading...

Loading...