LG LM-2422C2L, LM-2422A2L/A3L, LM-3622A2L, LM-3625C3L/A3L, LM-3626A3L Service Manual

...

Multi Type Room

Air Conditioner

SERVICE MANUAL

MODEL: LM-2422C2L

LM-2422A2L/A3L

LM-3620C2L/C2M/A2L

LM-3622A2L

LM-3625C3L/A3L

LM-3626A3L

LM-4822C3L

LM-4822A3L

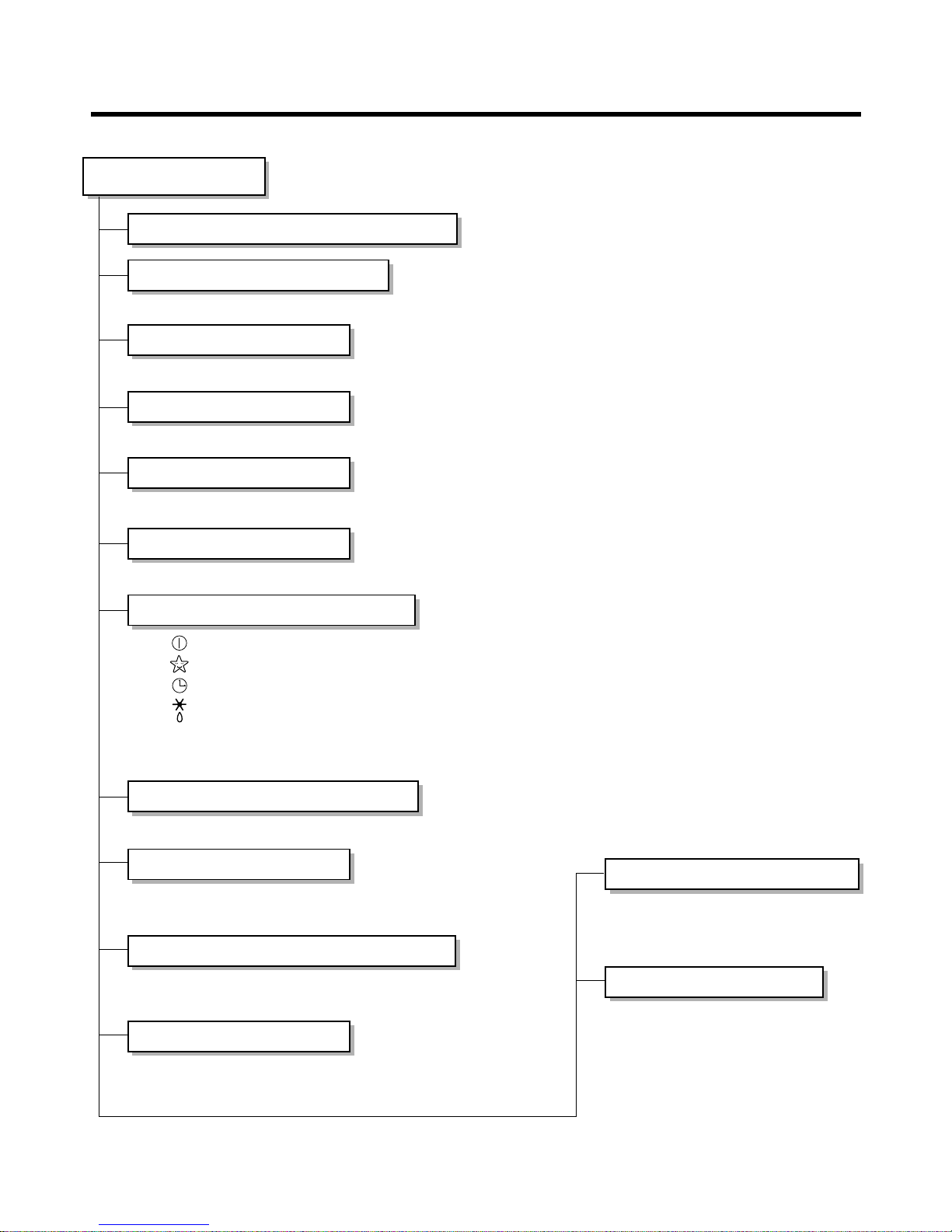

Functions...................................................................................................................................... 3

Product Specifications................................................................................................................ 5

Dimensions................................................................................................................................... 9

Refrigeration Cycle Diagram..................................................................................................... 13

Wiring Diagram .......................................................................................................................... 17

Operation Details ....................................................................................................................... 20

Display Function........................................................................................................................ 27

Self-diagnosis Function ............................................................................................................ 27

Installation.................................................................................................................................. 28

Operation.................................................................................................................................... 42

Disassembly of the parts (Indoor Unit).................................................................................... 44

2-way, 3-way Valve..................................................................................................................... 46

Cycle Troubleshooting Guide ....................................................................................................50

Electronic Parts Troubleshooting Guide.................................................................................. 51

Electronic Control Device ......................................................................................................... 58

Schematic Diagram.................................................................................................................... 61

Exploded View and Replacement Parts List............................................................................ 66

- 2 -

Contents

- 3 -

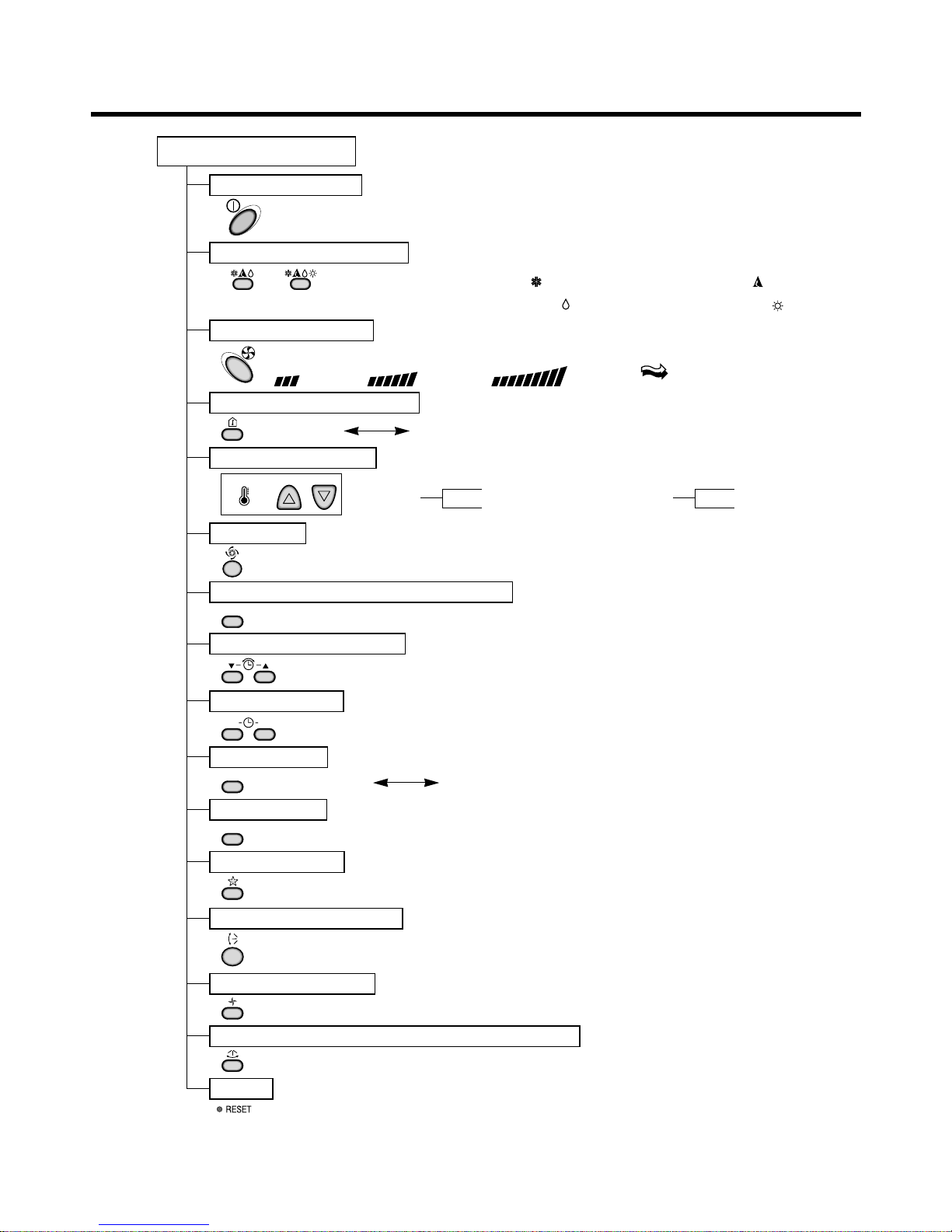

Functions

• Room temperature sensor. (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low, Chaos

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Deice Mode(for Heat pump model)

--- Lights up in Compressor operation(for Cooling model)

• Intermittent operation of fan at low speed.

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation

•

The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing

up and down automatically.

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

OUT

DOOR

Health Dehumidification Operation

• Both the indoor and outdoor fan

stops during deicing.

• Hot start after deice ends.

• The indoor fan stops until the

evaporator piping temperature will be

reached at 22°C.

Sleep Mode Auto Control

Natural Air Control by CHAOS Logic

Airflow Direction Control

Deice (defrost) control (Heating)

Hot-start Control (Heating)

- 4 -

Healthy Dehumidification Operation Mode.

( )

Remote Controller

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

JET COOL

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Fan Operation Mode

Horizontal Airflow Direction Control Button(Option)

Room, Temperature Display

Setting the Time or Timer

PLASMA(Option)/NEGATIVE ION(Option)

ON OFF

SET

PLASMA

CANCEL

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High:39°C Low:11°C)

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C

Up to 30°C

Heating

Down to 16°C

Up to 30°C

- 5 -

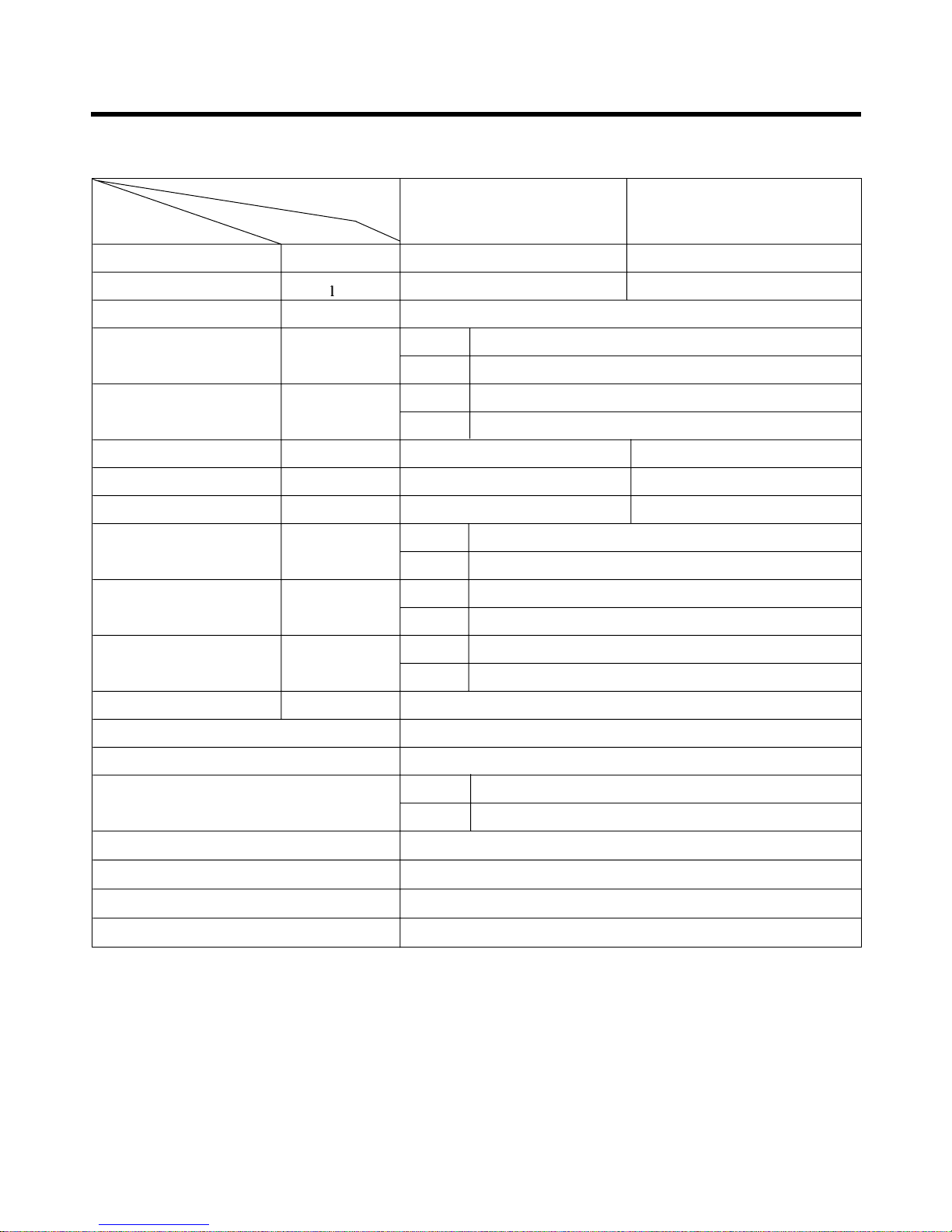

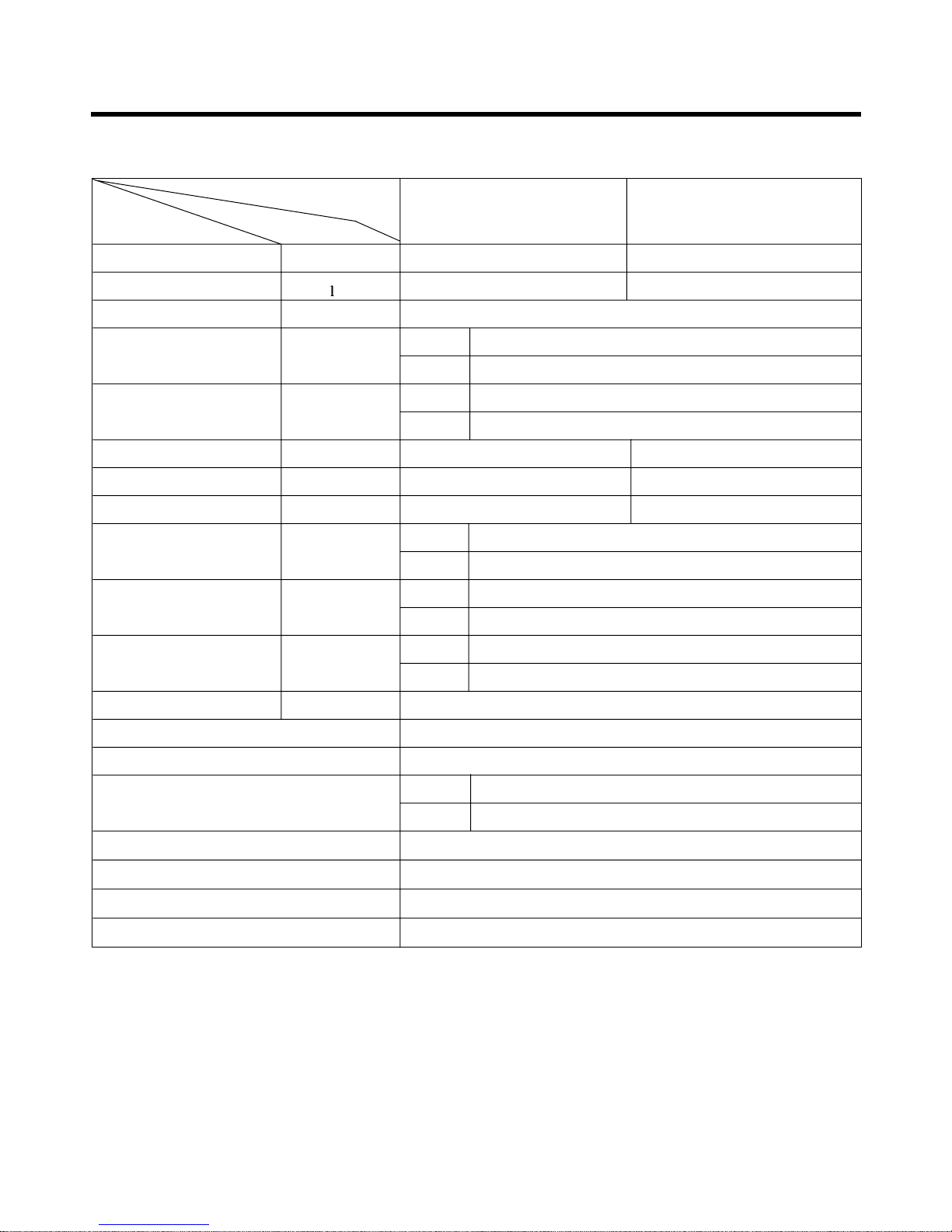

Product Specifications

17,000(4,270) 24,000(6,050)

1.6 1.6 x 2

1Ø, 220, 60HZ

9.0

49

38+1

56+1

2,260 2,410

10.5 11.5

7.5 9.96

14.4

90

888 x 287 x 170

870 x 655 x 320

9

61

1,650(at 7.5m)

O

L.C.D Wireless

1/4"(6.35)

1/2"(12.7)

O

O

0.75mm

2

2.5mm

2

Operation

A or B unit

A + B unit

Unit

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Item

Cooling Capacity Btu/h(kcal/h)

Moisture Removal

/h

Power Source ø, V, Hz

Air Circulation m3/min

Noise Level(Low) dB(A)

Input W

Runnig Current A

E.E.R. Btu/h.w

Motor Output W

Dimensions(W x H x D)

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control(Up & Down)

Remocon Type

Service Valve

Drain Hose

Plasma Filter

Connecting Cable

Power Cord

1. LM-2422C2L, LM-2422A2L

- 6 -

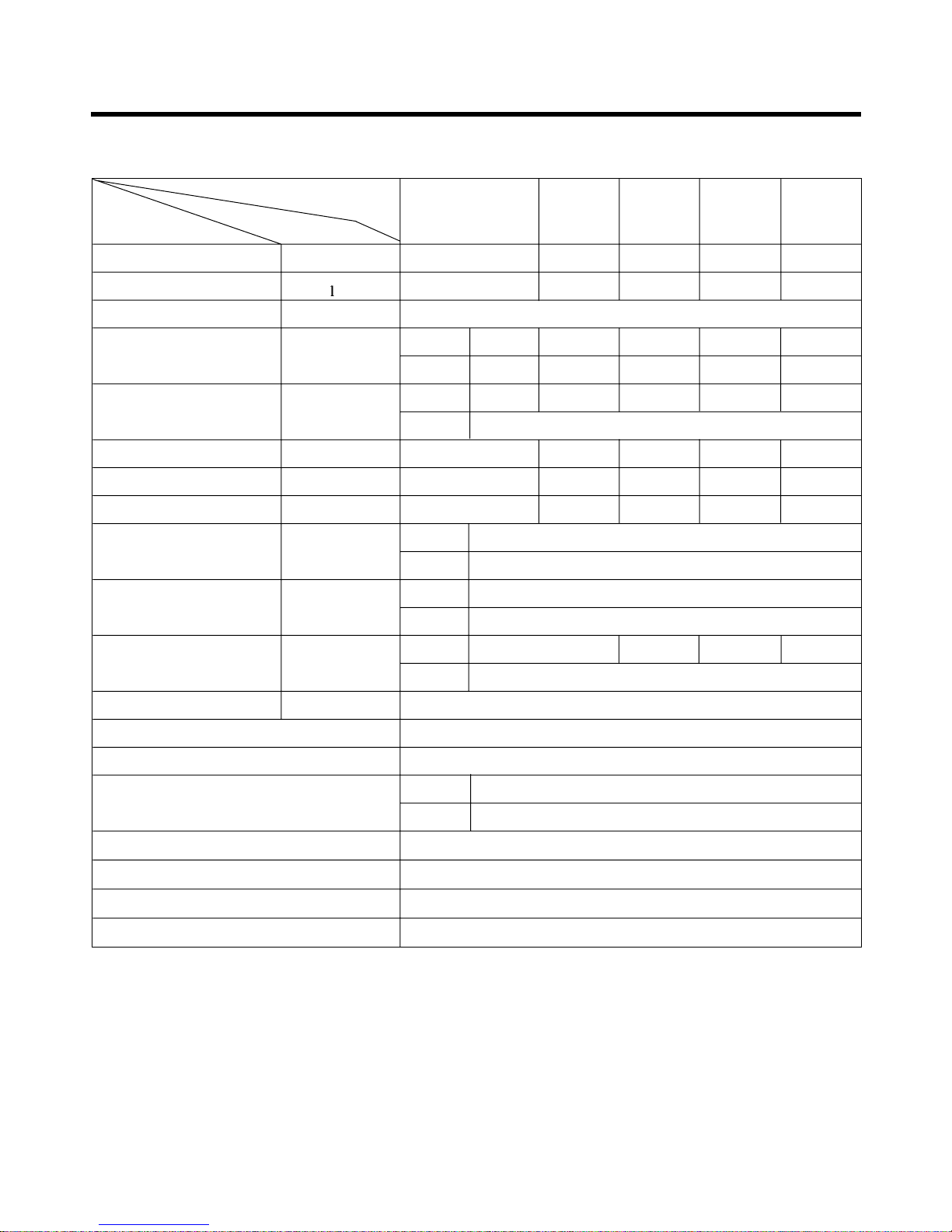

17,800(4,486) 35,600(8,972)

2.0 2.0 x 2

1Ø, 220, 60HZ

13.1

58

40

57

1,900 3,650

8.7 16.8

9.4 9.8

21

90

1,080 x314 x 181

870 x 800 x 320

11

71

A: 820, B: 820 (at 7.5m)

O

L.C.D Wireless

1/4"(6.35)

5/8"(15.88)

O

LM-3622A2L only

1.5mm

2

3.5mm

2

Operation

A or B unit

A + B unit

Unit

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Indoor

Outdoor

Liquid

Gas

Item

Cooling Capacity Btu/h(kcal/h)

Moisture Removal

/h

Power Source ø, V, Hz

Air Circulation m3/min

Noise Level(Low) dB(A)

Input W

Runnig Current A

E.E.R. Btu/h.w

Motor Output W

Dimensions(W x H x D)

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control(Up & Down)

Remocon Type

Service Valve

Drain Hose

Plasma Filter

Connecting Cable

Power Cord

2. LM-3620C2L, LM-3620A2L, LM-3622A2L

- 7 -

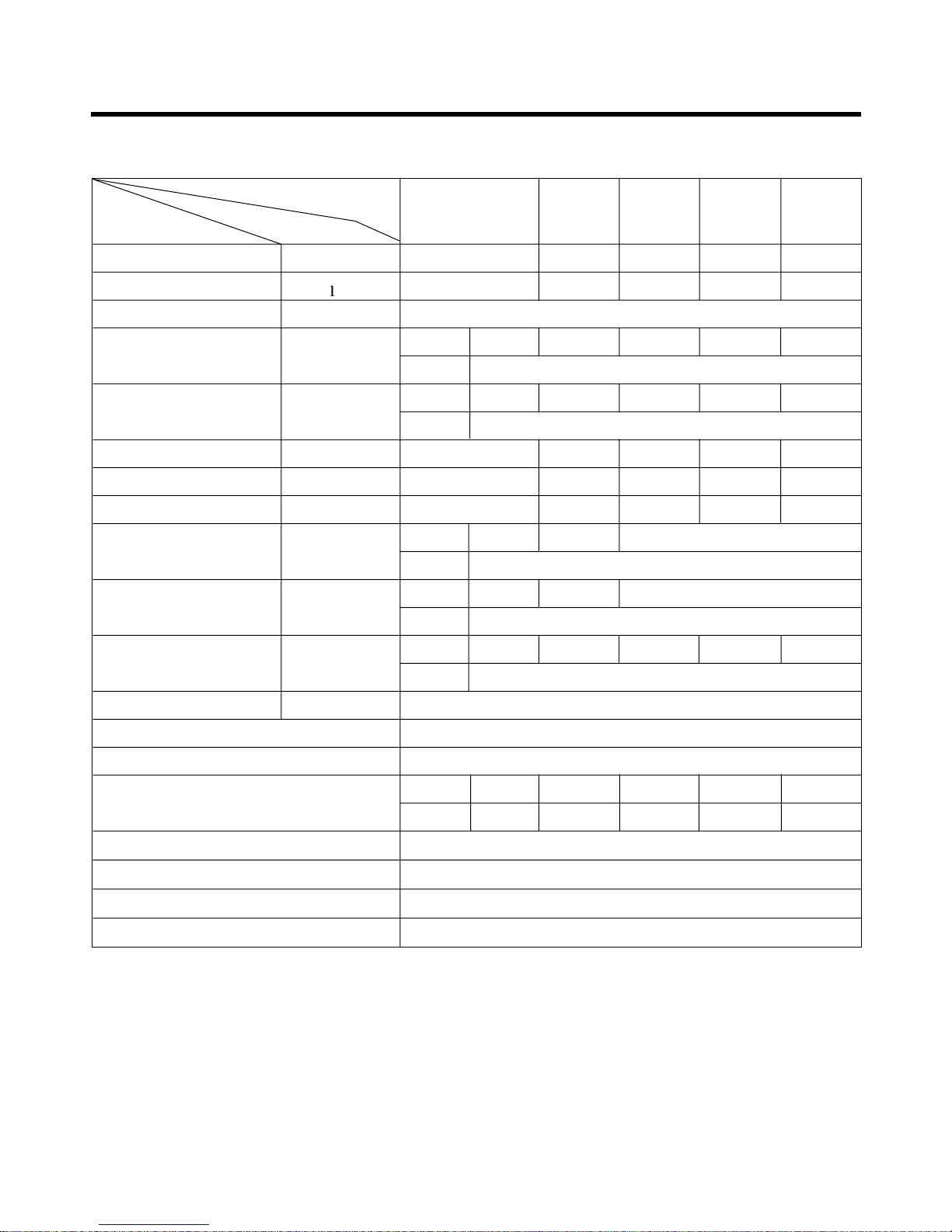

12,000(3,024)

13,000(3,276) 25,000(6,300) 23,800(5,998) 35,800(9,022)

1.4 1.5 2.9 2.5 3.9

1Ø, 220V, 60Hz

Indoor 9.0 9.5 9.0 + 9.5 9 + 9 9.0 x 3

Outdoor 58 - - - Indoor 37 38 - - Outdoor 57

1,300 2,100 3,200 2,400 3,600

5.7 9.3 13.6 10.1 14.8

9.2 6.2 7.8 9.9 9.9

Indoor 14.4 x 3

Outdoor 90

Indoor 888 x 287 x 170

Outdoor 870 x 800 x 320

Indoor 9 - - Outdoor 71

A: 550, B: 1,100 (at 7.5m)

O

L.C.D Wireless

Liquid 1/4"(6.35)

Gas 1/2"(12.7)

O

LM-3626A3L only

0.75mm

2

3.5mm

2

Operation

A-Unit

B or C-Unit

A+B or C B+C A+B+C

Unit

Item

Cooling Capacity Btu/h(kcal/h)

Moisture Removal /h

Power Source ø, V, Hz

Air Circulation m3/min

Noise Level(Low) dB(A)

Input W

Runnig Current A

E.E.R. Btu/h.w

Motor Output W

Dimensions(W x H x D)

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control(Up & Down)

Remocon Type

Service Valve

Drain Hose

Plasma Filter

Connecting Cable

Power Cord

3. LM-3625C3L/A3L, LM-3626A3L

- 8 -

24,000(6,048)

16,000(4,032)

40,000(10,080)

24,000(6,048)

48,000(12,096)

2.5 2.2 4.8 3.4 6.5

1Ø, 220V, 60Hz

Indoor 14.5 9.0 14.5 + 9.0 8.2 + 8.2

14.5 + 8.2 + 8.2

Outdoor 106

Indoor 47/44/40 42/40/38 - - Outdoor 60

2,500 2,300 4,500 2,500 4,700

11.0 10.5 20.0 11.0 21.0

9.6 7.0 8.9 9.6 10.6

Indoor 22 14.4

Outdoor 80 x 2

Indoor

1,180 x 314 x 181

888 x 287 x 170

Outdoor 1,225 x 900 370

Indoor 11 9 - - -

Outdoor 106

1,570 1,300 - - -

O

L.C.D Wireless

Liquid

3/8"(9.52) 1/4"(6.35)

---

Gas

5/8"(15.88) 1/2"(12.7)

---

O

LM-4822C3L/A3L only

0.75mm

2

5.5mm

2

Operation

A-Unit

B or C-Unit

A+B or C B+C A+B+C

Unit

Item

Cooling Capacity Btu/h(kcal/h)

Moisture Removal /h

Power Source ø, V, Hz

Air Circulation m3/min

Noise Level(Low) dB(A)

Input W

Runnig Current A

E.E.R. Btu/h.w

Motor Output W

Dimensions(W x H x D)

mm

Net. Weight kg

Refrigerant(R-22) g

Airflow Direction Control(Up & Down)

Remocon Type

Service Valve

Drain Hose

Plasma Filter

Connecting Cable

Power Cord

4. LM-4822C3L, LM-4822A3L

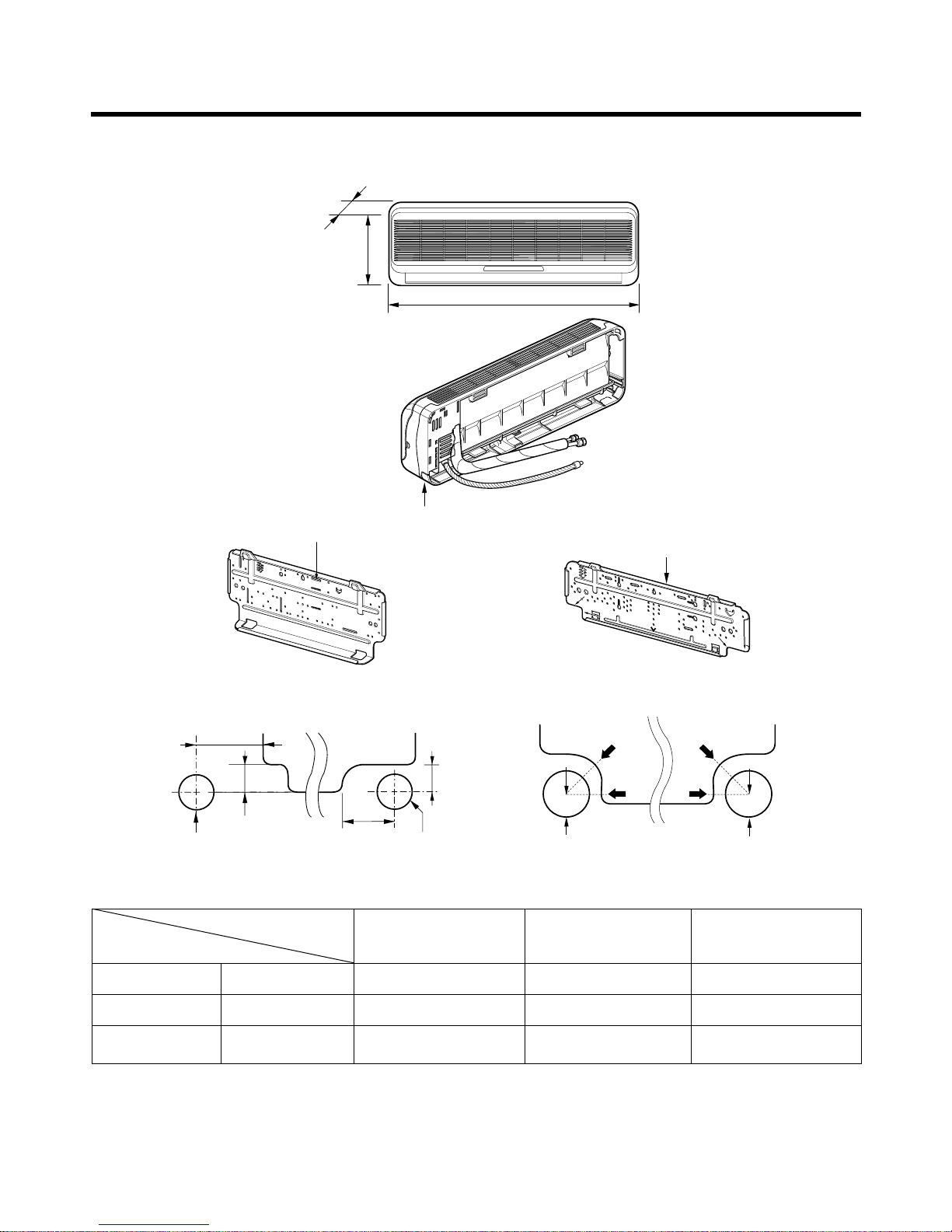

1. Indoor Unit

- 9 -

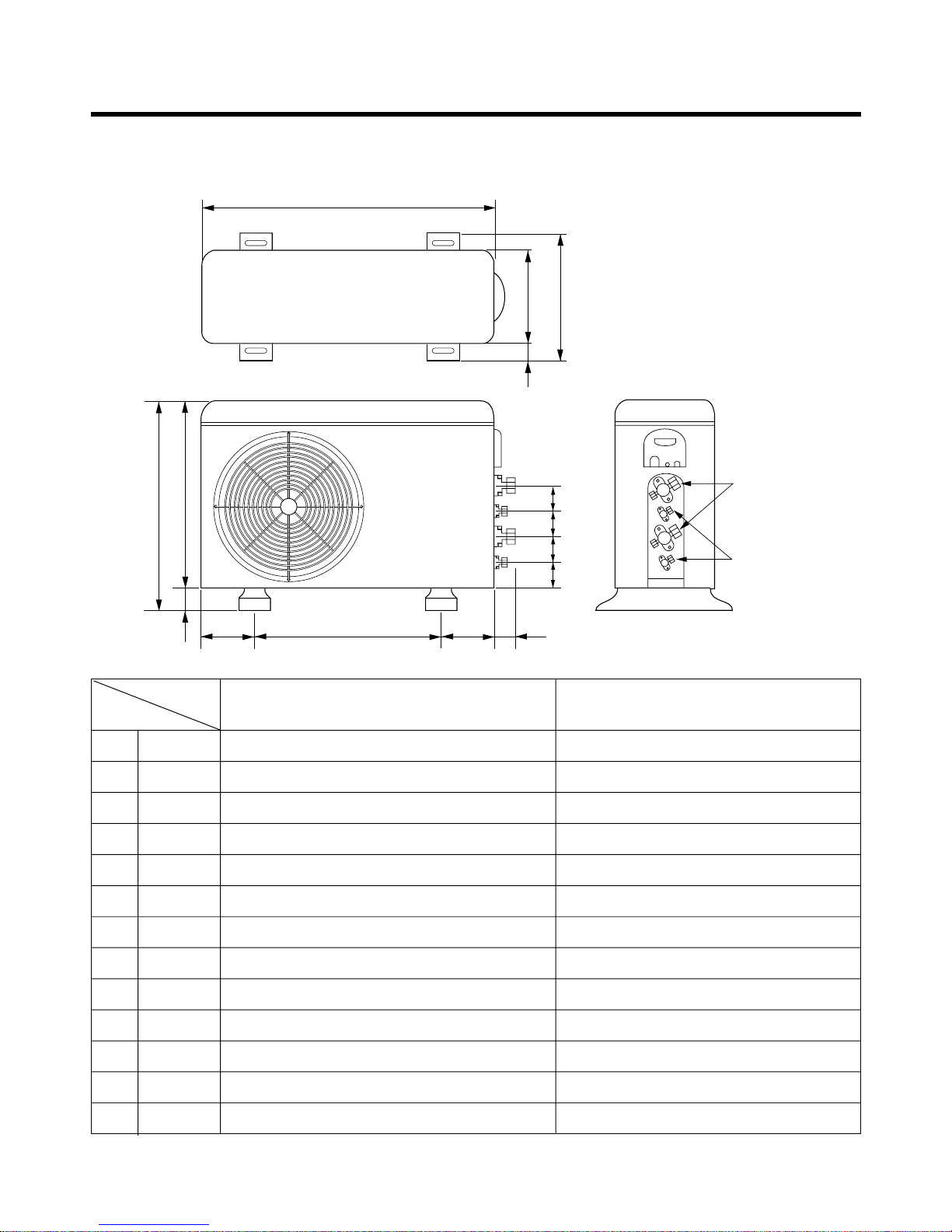

Dimensions

Installation plate

Installation plate

Right rear piping

Left rear piping

ø70mm

ø70mm

50mm

20mm

20mm

80mm

A

A

ø70mm

Center

Center

ø70mm

Left rear piping Right rear piping

A

A

D

H

W

Tubing hole cover

W mm 802 888 1,080

H mm 262 287 314

D mm 165 170 181

4.5K, 6K, 7K, 8K, 9K

Btu Series

9K, 10K, 12K Btu

Series

18K, 24K Btu

MODEL

DIM

( 4.5K, 6K, 7K, 8K, 9K )

( 4.5K, 6K, 7K, 8K, 9K )

( 9K, 10K, 12K, 18K, 24K )

( 9K, 10K, 12K, 18K, 24K )

- 10 -

2. Outdoor Unit

2-1. LM-2422C2L, LM-2422A2L, LM-3622A2L, LM-3620C2L, LM-3620A2L

W

D

L1

L2

L9

L4

L3

H

L10

L10

L10

L8

Gas side

3-Way valve

Liquid side

2-Way valve

L7L5L6

W mm 870 870

H mm 655 800

D mm 320 320

L1 mm 370 370

L2 mm 25 25

L3 mm 630 775

L4 mm 25 25

L5 mm 546 546

L6 mm 160 160

L7 mm 160 160

L8 mm 64 64

L9 mm 76.5 76.5

L10 mm 50 50

LM-2422C2L, LM-2422A2L

LM-3620C2L, LM-3622A2L, LM-3620A2L

MODEL

DIM

- 11 -

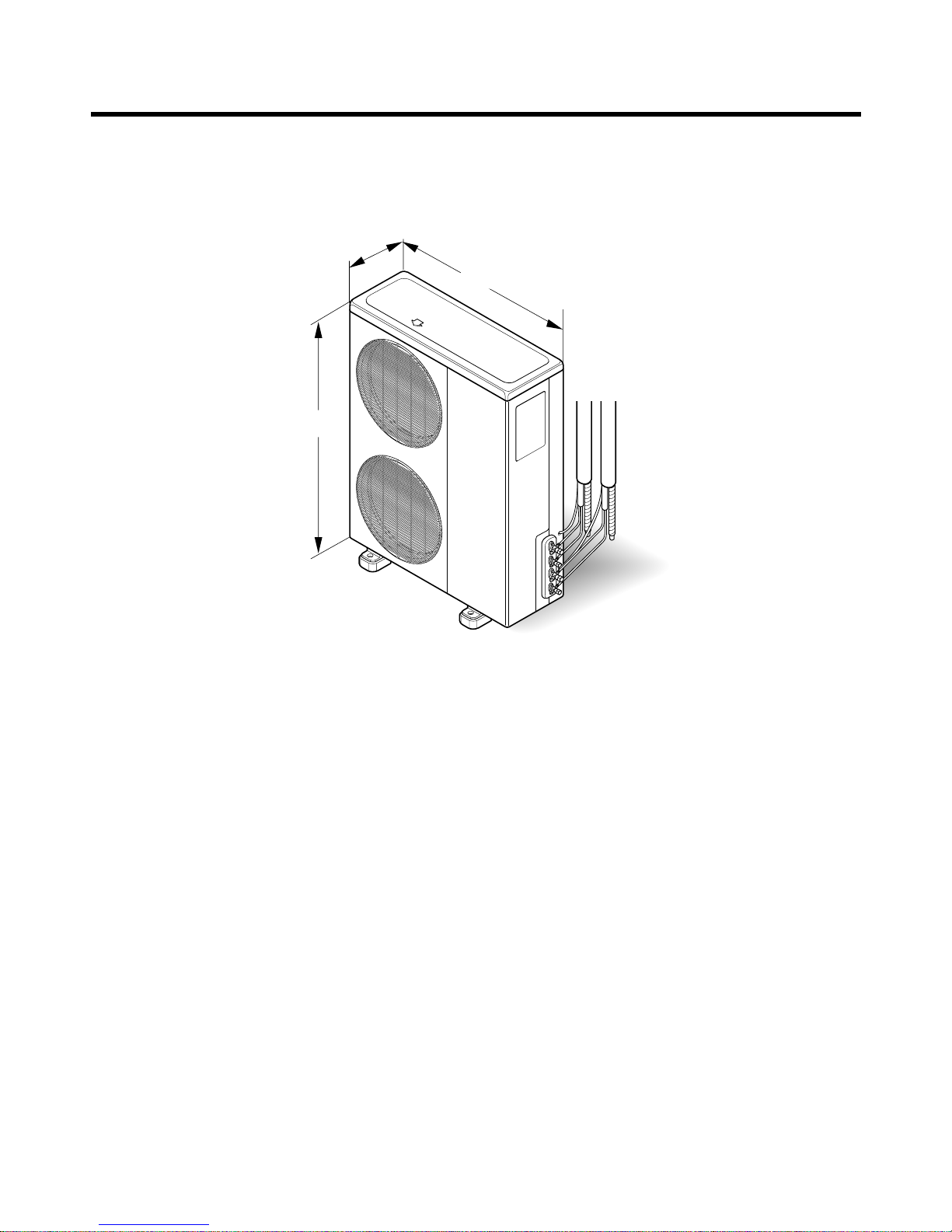

2-2. LM-3625C3L/A3L, LM-3626A3L

W

L5L6 L7 L8

L3

H

D

L1

L2

L4

L10L9

Gas side

3-way valve

Liquid side

2-way valve

L10L10L10L10

W mm 870

H mm 800

D mm 320

L1 mm 370

L2 mm 25

L3 mm 775

L4 mm 25

L5 mm 546

L6 mm 160

L7 mm 160

L8 mm 64

L9 mm 76.5

L10 mm 50

LM-3625C3L/A3L, LM-3626A3L

MODEL

DIM

- 12 -

900

1,225

370

2-3. LM-4822C3L, LM-4822A3L

- 13 -

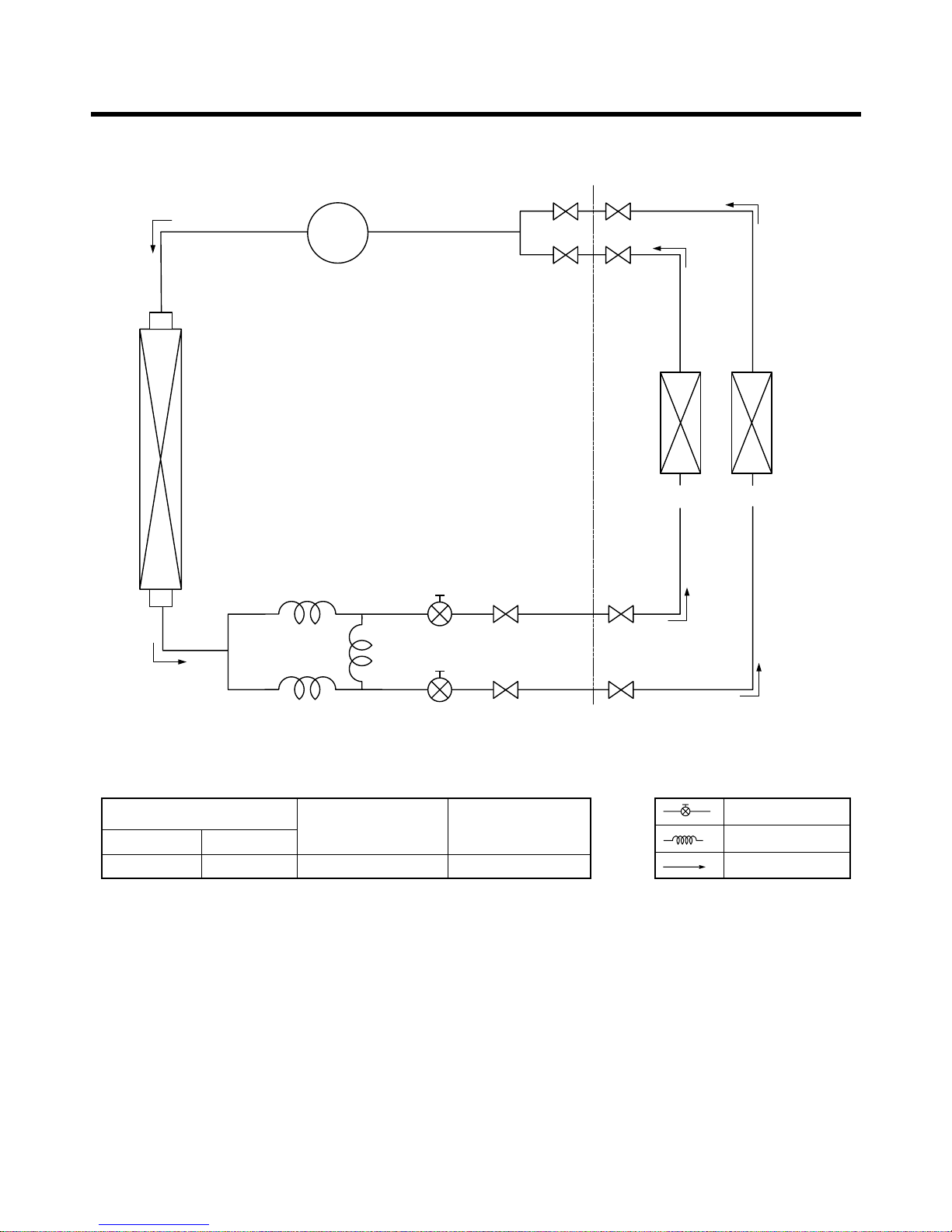

Refrigeration Cycle Diagram

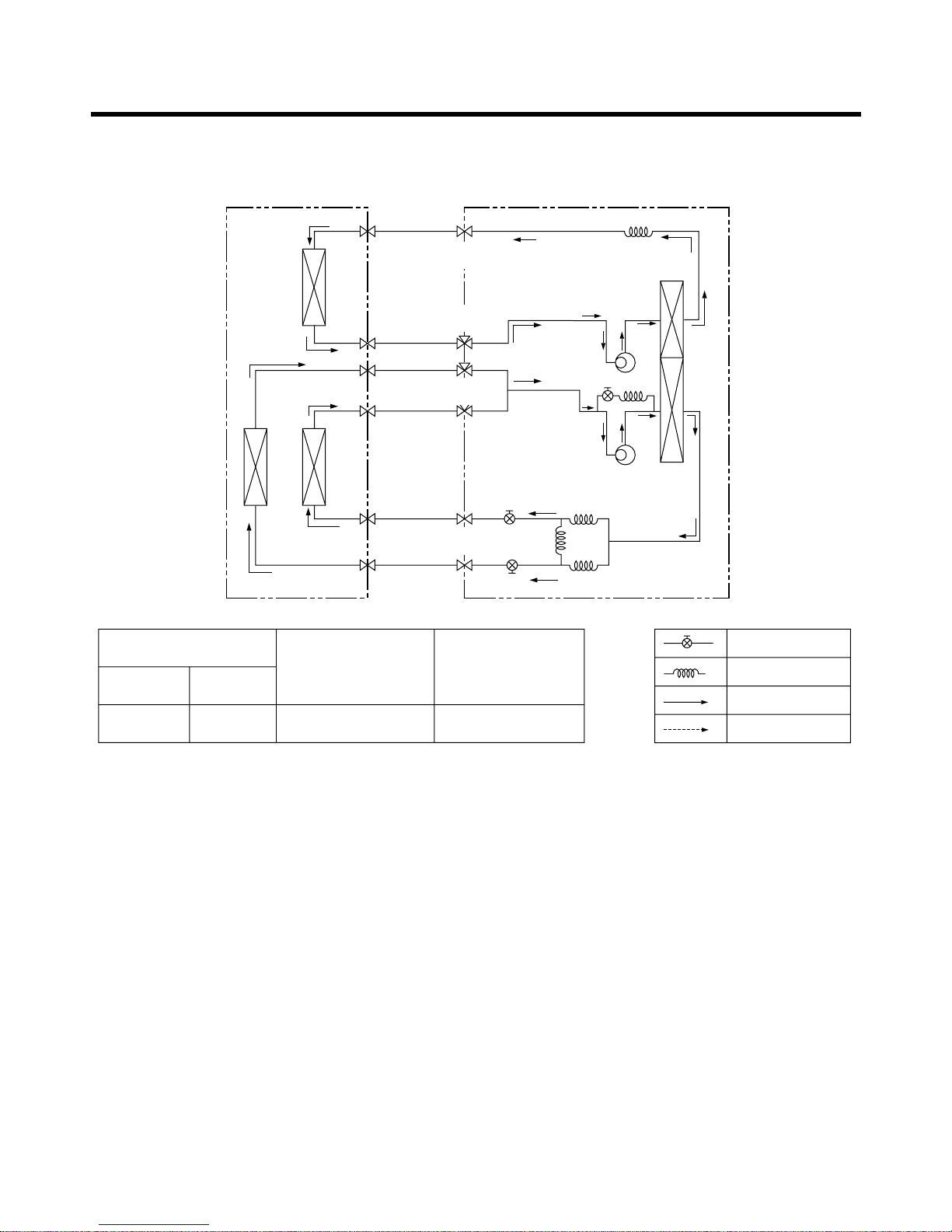

1. LM-2422C2L, LM-2422A2L

COMP

3-WAY

Valve

ø6.35

ø12.7

ø12.7

ø6.35

HEAT

EXCHANGER

HEAT

EXCHANGER

(A Unit) (B Unit)

Pipe Size (Diameter : inch)

Max.

piping length

(m)

Max.

piping elevation

(m)

Gas Liquid

1/2" 1/4" 10~15 5~7

ex)

Solenoid Valve

Capillary

Cooling

- 14 -

2. LM-3620C2L, LM-3622A2L, LM-3620A2L

Pipe Size (Diameter : inch)

Max.

piping length

(m)

Max.

piping elevation

(m)

Gas Liquid

5/8" 1/4" 20 10

ex)

Solenoid Valve

Capillary

Cooling & Deice

A-UNIT B-UNIT

CAPILLARY TUBE

LIQUID SIDE

2-WAY VALVE

GAS SIDE

3-WAY VALVE

HEAT

EXCHANGER

(EVAPORATOR)

HEAT

EXCHANGER

(CONDENSER)

COMPRESSOR

B

COMPRESSOR

A

- 15 -

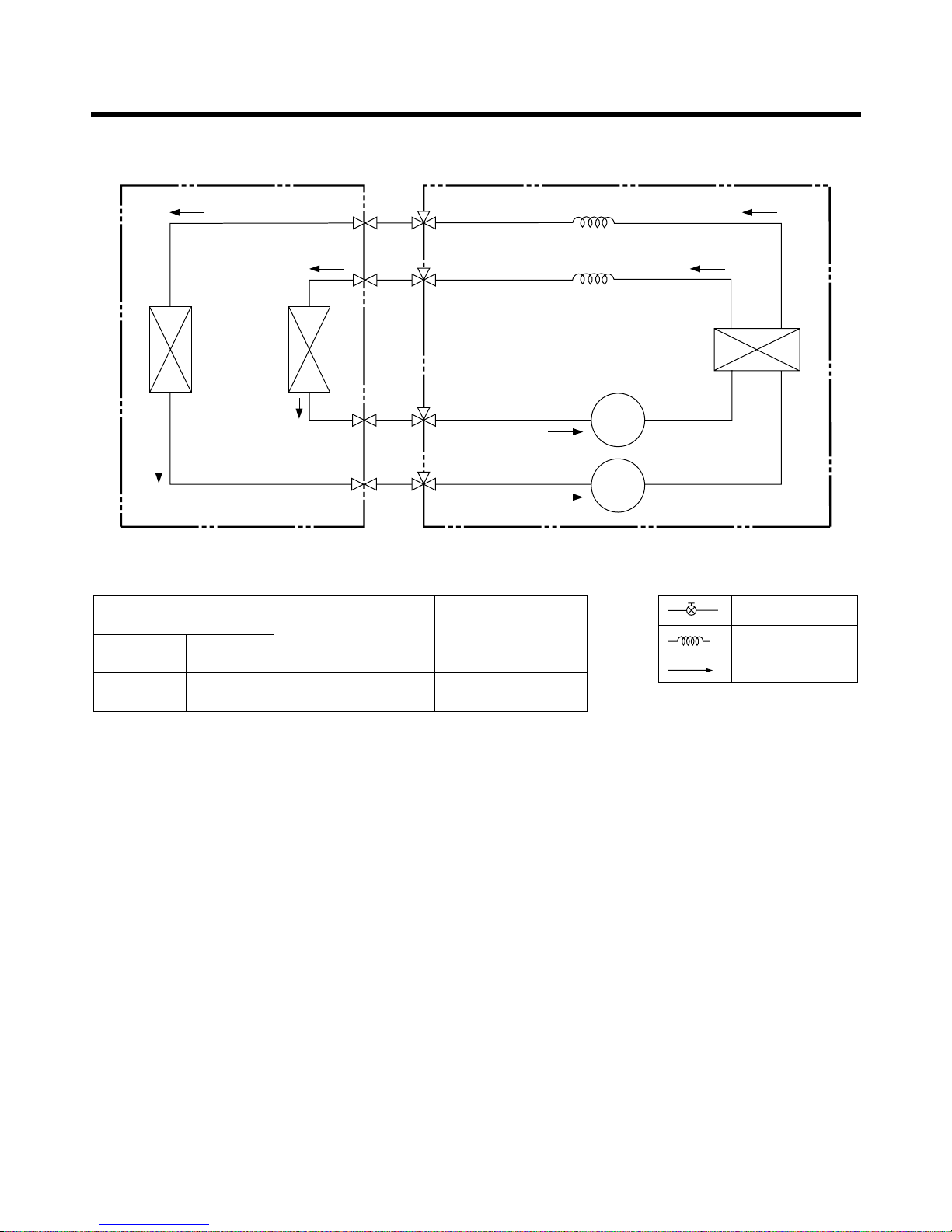

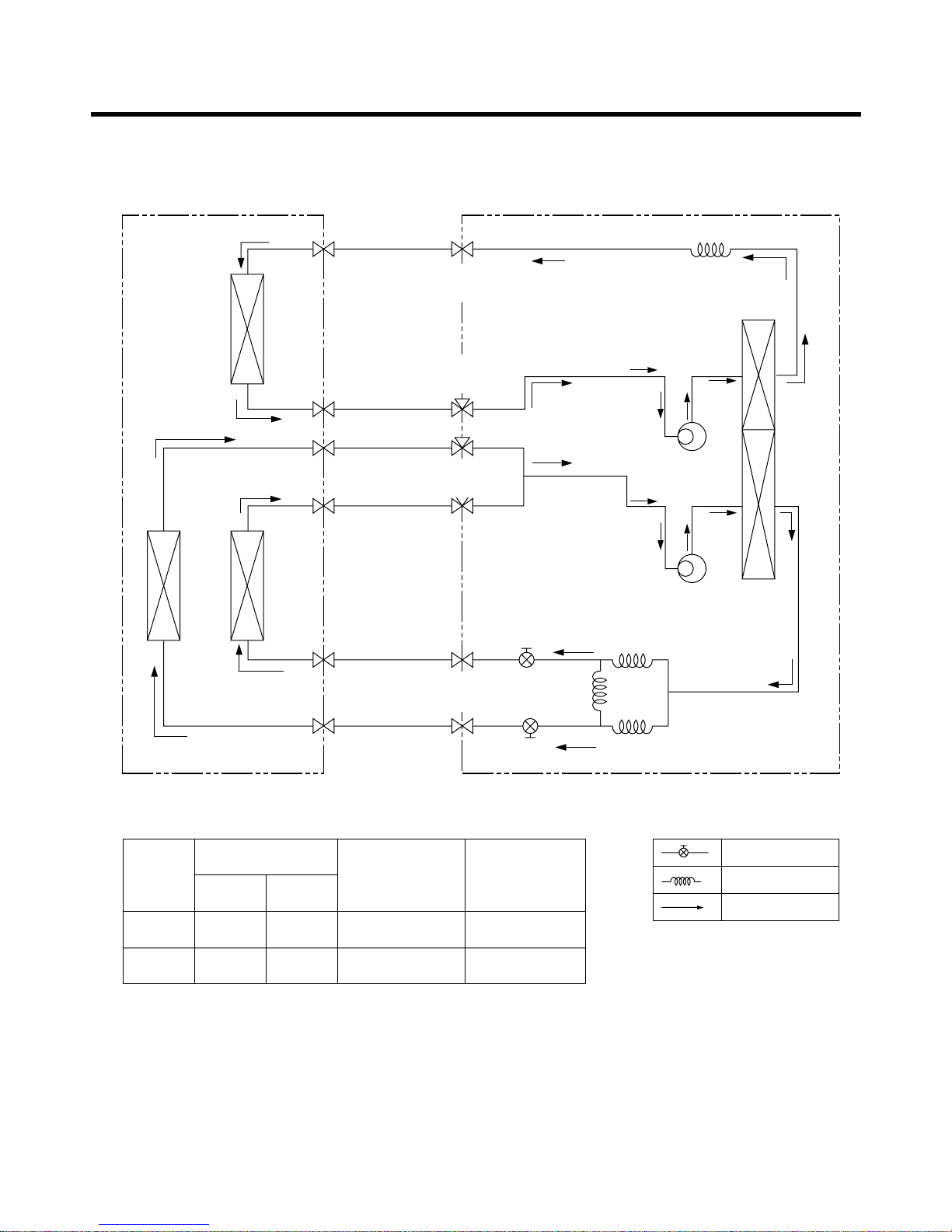

3. LM-3625C3L/A3L, LM-3626A3L

Pipe Size (Diameter : inch)

Max.

piping length

(m)

Max.

piping elevation

(m)

Gas Liquid

(1/2") 1/4" 10~15 5~7

ex)

Solenoid Valve

Capillary

Cooling & Deice

Heating

Indoor Unit Outdoor Unit

Heat

Exchanger

A-Unit

Heat

Exchanger

Comp-A

Comp-B

B-Unit

C-Unit

Heat

Exchanger

2- WAY

Valve

3- WAY

Valve

2- WAY

Valve

3- WAY

Valve

- 16 -

4. LM-4822C3L, LM-4822A3L

Pipe Size

(Diameter : inch)

Indoor

B/C

Max.

piping length

(m)

Max.

piping elevation

(m)

Gas Liquid

3/8"(1/2") 1/4" 15 7

A

5/8" 3/8" 30 15

ex)

Solenoid Valve

Capillary

Cooling

Indoor Unit Outdoor Unit

Heat

Exchanger

A-Unit

Heat

Exchanger

Comp-A

Comp-B

B-Unit

C-Unit

Heat

Exchanger

2- WAY

Valve

3- WAY

Valve

2- WAY

Valve

3- WAY

Valve

- 17 -

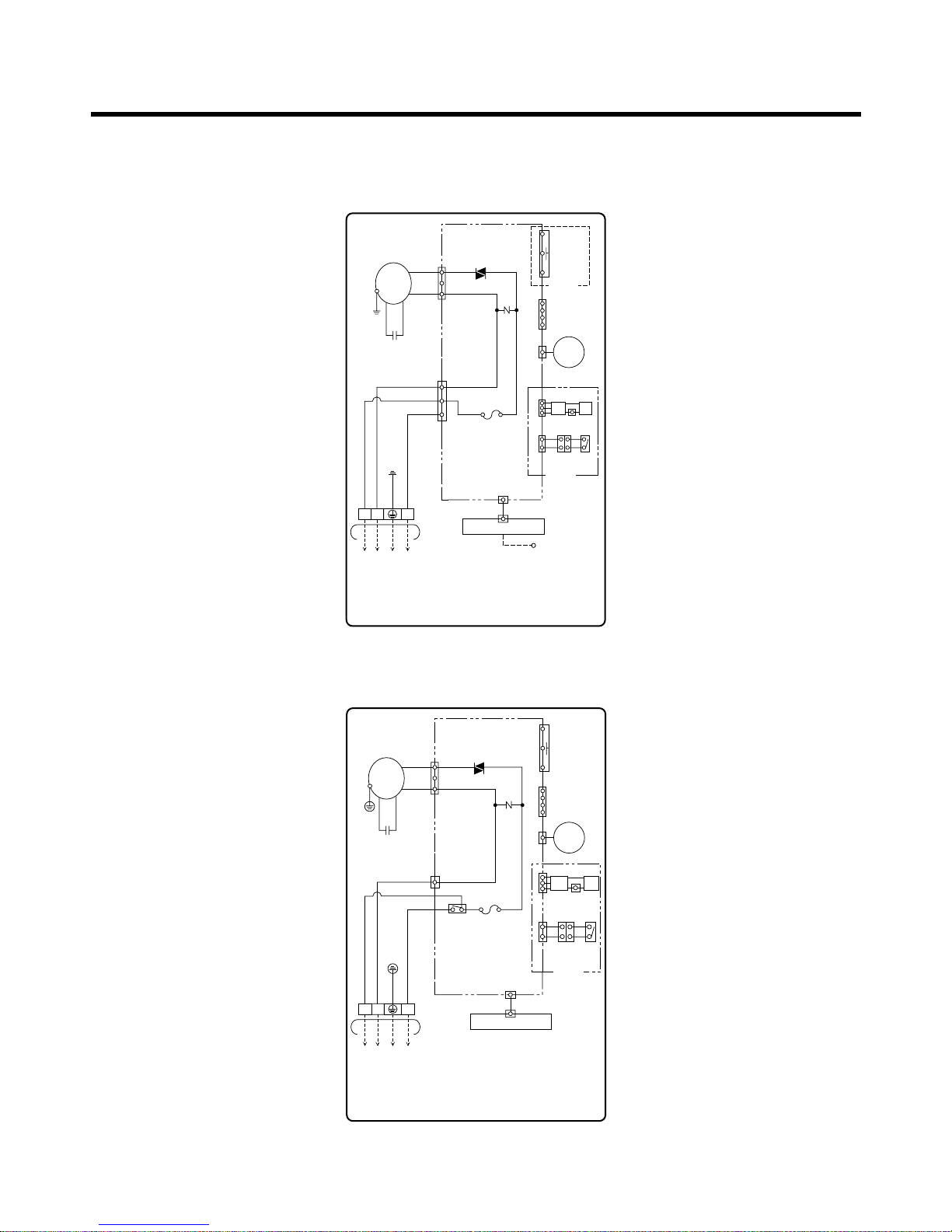

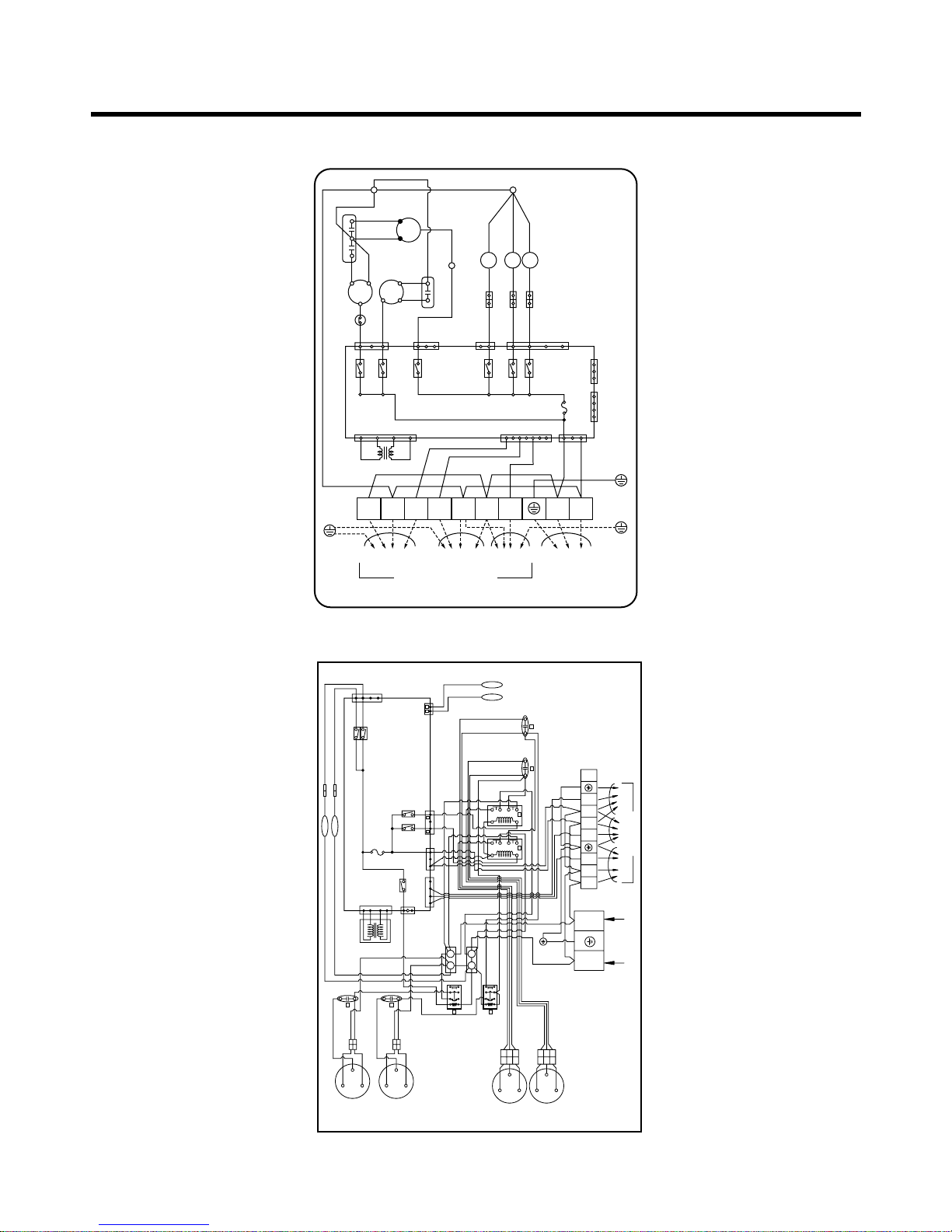

Wiring Diagram(Indoor Unit)

1. LM-2422C2L, LM-2422A2L, LM-3625C3L/A3L, LM-3626A3L,

LM-4822C3L, LM-4822A3L

2. LM-3620C2L, LM-3622A2L, LM-3620A2L

3854A20080W

INDOOR WIRING DIAGRAM

CN-DISP1

CN-U/D

FUSE

AC250V/T2A

CN-TH1

TRIAC

SH-CAPA.

BR

YL

OR

BK

CN-TAB1

ZNR

CN-MOTOR

THERMISTOR

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

STEP

MOTOR

MOTOR

MAIN PCB

ASM

DISPLAY PCB ASM

TO OUTDOOR UNIT

PILLAR

TERMINAL

BR

BL

YL

GN/YL

1(L) 2(N

)

3

RY-COMP.

4

3

H.V.B A/CL

RD

BK BK

BK BK

BK BK

LIMIT

S/W

OPTION

3854A20023X

INDOOR WIRING DIAGRAM

CN-DISP1

CN-U/D

FUSE

AC250V/T2A

CN-TH

SSR

SH-CAPA.

BR

YL

OR

BK

CN-POWER CN-FAN

ZNR

THERMISTOR

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

STEP

MOTOR

MOTOR

MAIN PCB

ASM

DISPLAY PCB ASM

TO OUTDOOR UNIT

PILLAR

TERMINAL

BR

BL

YL

GN/YL

1(L) 2(N

)

3

OPTION

ON/OFF S/W(OPTION)

RD

BK BK

LIMIT

S/W

H.V.B A/CL

OPTION

BK BK

BK BK

- 18 -

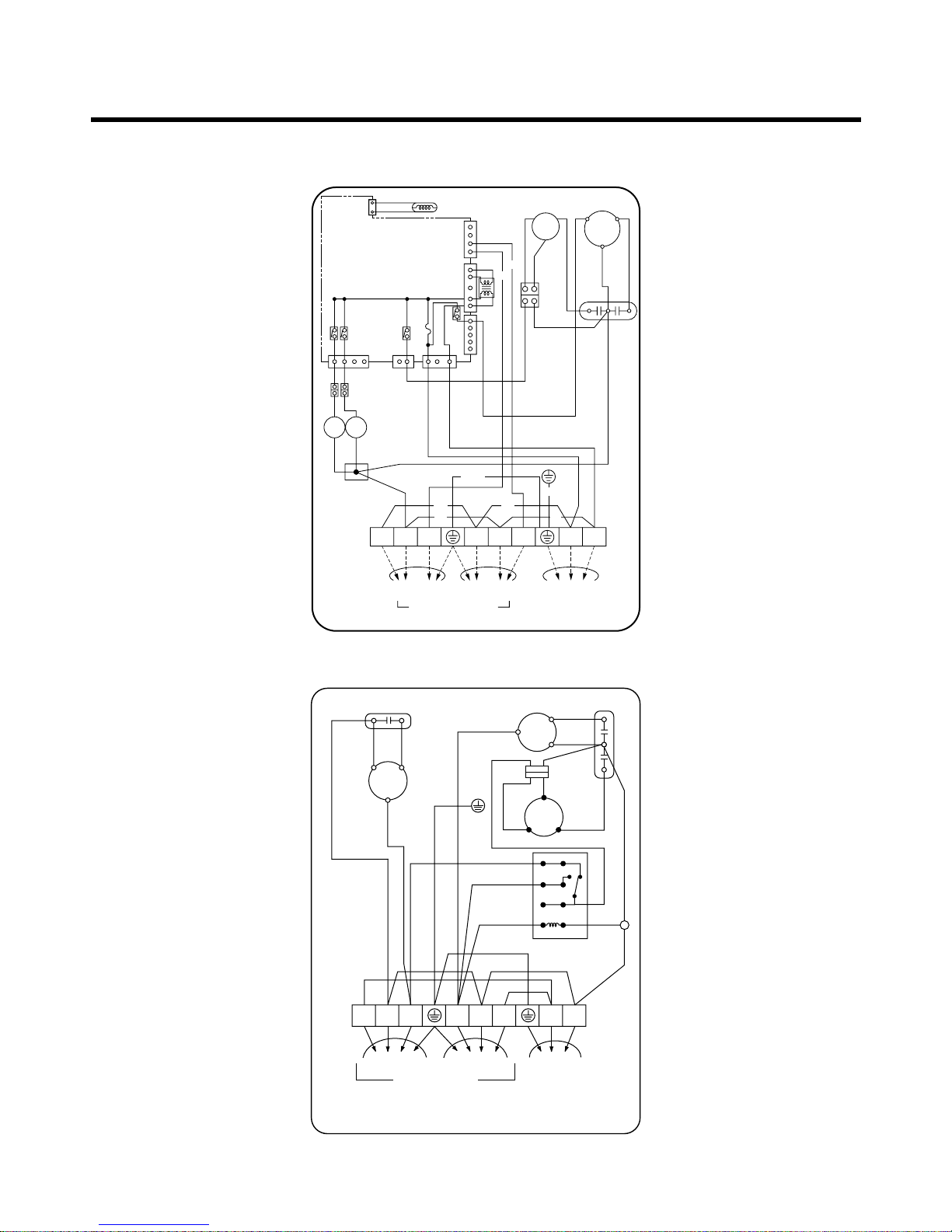

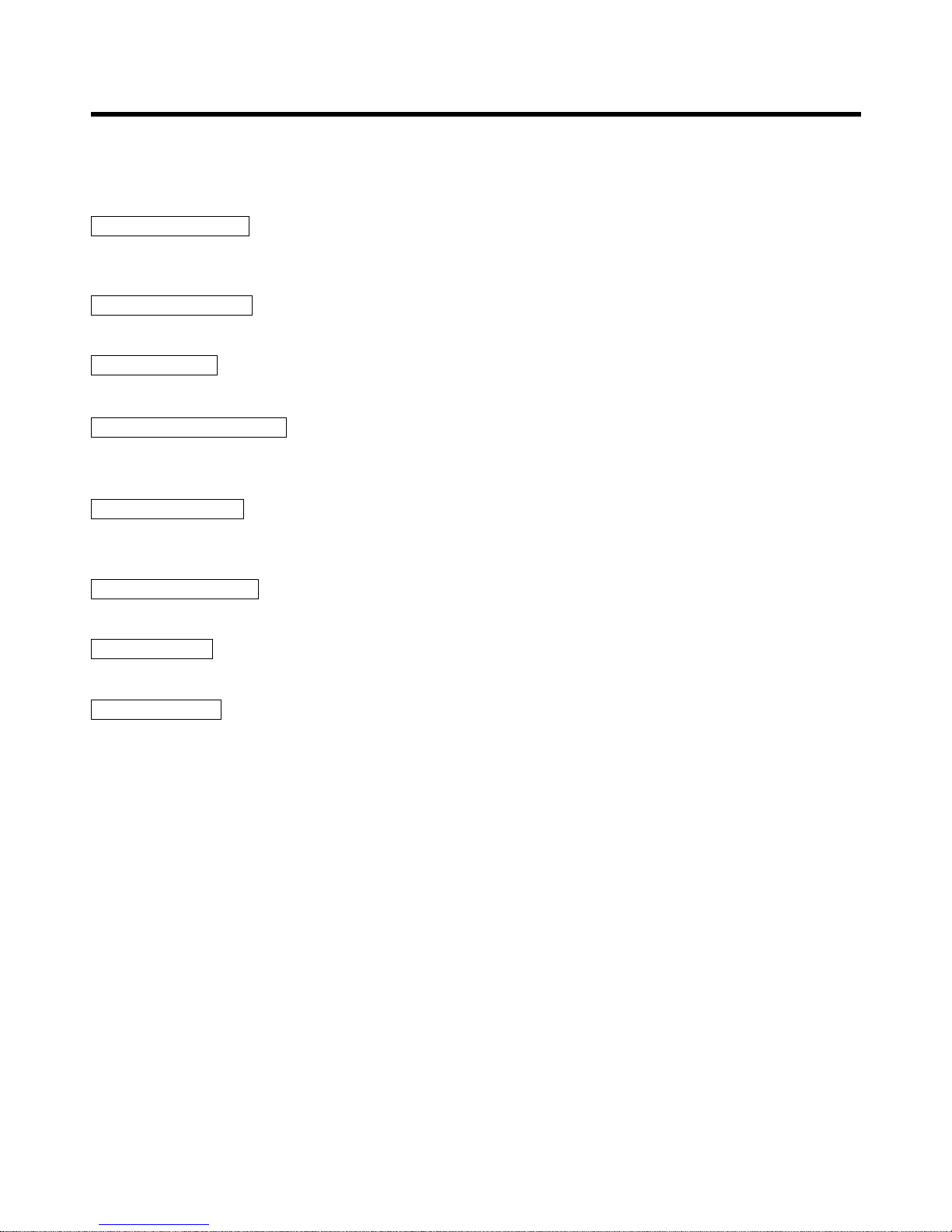

Wiring Diagram(Outdoor Unit)

3. LM-2422C2L, LM-2422A2L

4. LM-3620C2L, LM-3622A2L, LM-3620A2L

RD

R

C

BR

BK

A-UNIT

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM 3854A20023Y

B-UNIT MAIN POWER

BL

OR

OR

RD

RD

BK

BK

WH

MOTOR

T/B

C

R

FCH

S

BL

WH

YL

BR

COMP

"B"

CAPACITOR

12

34

56

78

WH

WH

BK

WH

WH

WH

TERMINAL

BLOCK

POWER

RELAY

GN/YL

GN/YL

S

COMP

"A"

YL

CAPACITOR

1(L

)

1(L

)

1(L

)

2(N

)

2(N

)

2(N

)

33

CN-TH

CCS

R

F

TERMINAL

BLOCK(

10P

)

1(L

)

2(N

)

2(N

)

1(L

)

31(L)2(N

)

3

A-UNIT

T/BLOCK

BL BL

BK

BK

TRANS FORMER

OR

THERMISTOR

YL

OR BK BR

WH

CAPA.

BK

MOTOR

COMP

BK

WH

BLYL

BK

B-UNIT

TO INDOOR UNIT

OUTDOOR WIRING DIAGRAM

3854A30076L

MAIN

POWER

A

CH

R

S

B

A

5

7

CN-COM

CN-TRANSCN-COMP

CN-POWER

RY-COMP

CN-S.V

S/VBS/V

CN-FAN

RY-S.V1

RY-S.V2

432 11321

5

RY-HI

FUSE(250V/3.15A)

MAIN P.C.B ASM

BK BK

WH

WH

WH

BL

BR

GN/YL

GN/YL

- 19 -

5. LM-3625C3L/A3L, LM-3626A3L

6. LM-4822C3L, LM-4822A3L

OUTDOOR WIRING

DIAGRAM

MAIN PCB

ASSY

B - THERMISTOR

C - UNITB - UNIT

TO INDOOR UNIT

POWER INPUT

1Ø, 220V, 60Hz

3(N) 4(L)

1(L) 1(L)2(N) 2(N)33 3

A - UNIT

A - THERMISTOR

BK

BK

BK

BK

BK

BK

LOW

HI

BK

BK

BK

BK

YL

OR

OR

OR

BK

BK

A - MOTOR

B - MOTOR

A - COMP

RY - COMP(B)

RY - COMP(A)

FUSE 250V / 3.15A

3854A30042Z

B - COMP

YL

OR

OR OR

BK

BK

BK

BK

RD

S

CR

S

CR

S

CR

S

CR

BR YLWHBL

BK

BR

BR

BR

BR

BR

WH

WH

WH

WH

WH

TB1 TB3

TB4

TB2

WH

WH

WH

WH

BL

BL

BL BL

BLBL

BL

BL

BL

YL

RD

YL

RD

RD WH

B S / V C S / V

YL

86142

86142

RD

GN / YL

GN / YL

GN / YL

CN - FAN

CN - COM

RY - HI

CN - POWER

CN - COMP

CN - TH1

753

BA

CN - TRANS

CN - SV

RD

C S / V B S / V

RY - SV1

RY - SV2

B

A

12

34

56

78

12

34

56

78

0

0

A

B

B

A

A

B

A

B

BK

T/B1BK

CAPA.

CAPA.

OLP

RY1

RY2

RY3

RY8

RY7

RY9

CN-TH2

CN-SV

CN-TH1

FCH

1

BK

BK

BK

T/B2

WHBR

BR

BL

RD WH

GN/YL

TERMINAL

BLOCK

WH

BK

WH

BK

BK

BK

RD

BK

BK

BR

YL

YL

OR

RD

SSR

R

C

C

BK

BL RD

CN-FAN

CN-BYPASS

CN-COMP

BK

"A"

COMP

"B"

COMP

MOTOR

FUSE T3.15A

CN-POWERCN-COM

MAIN PCB ASSY

CN-TRANS

TRANS-

FORMER

A-UNIT B-UNIT

TO INDOOR UNIT

C-UNIT MAIN

POWER

OUTDOOR WIRING DIAGRAM

3854A20023Z

T/B3

BYPASS

B ROOM

C ROOM

S.V

S.V

S.V

1(L) 1(L) 1(L)

2(N) 2(N) 2(N)

33 3

- 20 -

Operation Details

1. MAIN UNIT FUNCTION

• DISPLAY

1) C/O Model

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled.

Comp. Running Incidator

• While in appliance operation, on while in outdoor unit compressor running, off while in compressor off

2) H/P Model

Operation Indicator

• On while in appliance operation, off while in appliance pause

• Flashing while in disconnection or short in Thermistor (3 sec off / 0.5 sec on)

Sleep Timer Indicator

• On while in sleep timer mode, off when sleep timer cancel or appliance operation pause

Timer Indicator

• On while in timer mode (on/off), off when timer mode is completed or canceled

Defrost Indicator

• Off except when hot start during heating mode operation or while in defrost control

■ Cooling Mode Operation

• When the intake air temperature reaches 0.5°C below the setting temp, the compressor and the outdoor fan

stop.

• When it reaches 0.5°C above the setting temp, they start to operate again.

Compressor ON Temp ➲ Setting Temp+0.5°C

Compressor OFF Temp ➲ Setting Temp-0.5°C

• While in compressor running, operating with the airflow speed set by the remote control. While in compressor not running, operating with the low airflow speed regardless of the setting.

■ Healthy Dehumidification Mode

• When the dehumidification operation input by the remote control is received, the intake air temperature is

detected and the setting temp is automatically set according to the intake air temperature.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Intake Air Temp<26°C ➲ Intake Air Temp-1°C

18°C ≤ Intake Intake Air Temp<24°C ➲ Intake Air Temp-0.5°C

Intake Air Temp<18°C ➲ 18°C

- 21 -

• While in compressor off, the indoor fan repeats low airflow speed and pause.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidifica-

tion operation and 4-min compressor off repeat.

Compressor ON Temp. ➲ Setting Temp+0.5°C

Compressor OFF Temp. ➲ Setting Temp-0.5°C

• In 10-min dehumidification operation, the indoor fan operates with the low airflow speed.

■ Heating Mode Operation(H/P model)

• When the intake air temp reaches +3°…above the setting temp, the compressor is turned off. When below

the setting temp, the compressor is turned on.

Compressor ON Temp. ➲ Setting Temp.

Compressor OFF Temp. ➲ Setting Temp.+3°C

• While in compressor on, the indoor fan is off when the indoor pipe temp. is below 20°C, when above 28°C ,

it operates with the low or setting airflow speed. When the indoor pipe temp is between 20°C and 28°C, it

operates with Super-Low(while in sleep mode, with the medium airflow speed).

• While in compressor off, the indoor fan is off when the indoor pipe temp is below 33°C, when above 35°C ,

it operates with the low airflow speed.

• If overloaded while in heating mode operation, in order to prevent the compressor from OLP operation, the

outdoor fan is turned on/off according to the indoor pipe temp.

• While in defrost control, both of the indoor and outdoor fans are turned off.

■ Defrost Control(H/P model)

• Defrost operation is controlled by timer and sensing temperature of outdoor pipe.

• The first defrost starts only when the outdoor pipe temperature falls below -6°C after 60 minutes passed

from starting of heating operation and more than 10 minutes operation of compressor.

• Defrost ends after 12 minutes passed from starting of defrost operation or after the outdoor fan operates

within max. 2 minutes 30 seconds when the outdoor pipe temperature rises over 12°C even it before 12

minutes.

• The second defrost starts only when the outdoor pipe temperature falls below -6°C after 60 minutes passed

from ending of the first defrost and more than 10 minutes operation of compressor.

■ Cooling overload

• Control indoor fan by sensing outdoor pipe temperature.

• One step down from setting fan speed if pipe temperature is oven 50°C and if below 45°C, operate on set-

ting temperature.

• One of the outdoor fan is OFF if pipe temperature is below 0°C and outdoor fan is ON if pipe temperature is

over 0°C.

■ Heating overload(H/P models)

• Outdoor fan ON/OFF by sensing outdoor pipe temperature.

• Outdoor fan is OFF if pipe temperature is over 6.5°C and outdoor fan is ON if pipe temperature is below

0°C.

• Outdoor fan is off if any one part is heating overload condition.

- 22 -

■ Fuzzy Operation (C/O Model)

• According to the temperature set by Fuzzy rule, when the intake air temp is 0.5°C or more below the setting

temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp < 26°C ➲ Intake Air Temp + 1°C

22°C ≤ Intake Air Temp < 24°C ➲ Intake Air Temp + 0.5°C

18°C ≤ Intake Air Temp < 22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the

temperature.

■ Fuzzy Operation (H/P Model)

• When any of operation mode is not selected like the moment of the power on or when 3 hrs has passed since

the operation off, the operation mode is selected.

• When determining the operation mode, the compressor, the outdoor fan, and the 4 way valve are off and only

the indoor fan is operated for 15 seconds. Then an operation mode is selected according to the intake air

temp at that moment as follows.

24°C ≤ Inatake Air Temp ➲ Fuzzy Operation for Cooling

21°C ≤ Inatake Air Temp<24°C ➲ Fuzzy Operation for Dehumidification

Inatake Air Temp<21°C ➲ Fuzzy Operation for Heating

• If any of the operation modes among cooling / dehumidification / heating mode operations is carried out for 10

sec or longer before Fuzzy operation, the mode before Fuzzy operation is operated.

1) Fuzzy Operation for Cooling

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more below

the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the compressor

is turned on.

Compressor ON Temp ➲ Setting Temp +0.5°C

Compressor OFF Temp ➲ Setting Temp + 0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to the

intake air temp at that time.

26°C≤ Intake Air Temp ➲ 25°C

24°C≤ Intake Air Temp<26°C ➲ Intake Air Temp + 1°C

22°C≤ Intake Air Temp<24°C ➲ Intake Air Temp + 0.5°C

18°C≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

- 23 -

2) Fuzzy Operation for Dehumidification

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 0.5°C or more

below the setting temp, the compressor is turned off. When 0.5°C or more above the setting temp, the

compressor is turned on.

Compressor ON Temp ➲ Setting Temp + 0.5°C

Compressor OFF Temp ➲ Setting Temp+0.5°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to

the intake air temp at that time.

26°C ≤ Intake Air Temp ➲ 25°C

24°C ≤ Intake Air Temp<26°C ➲ Intake Air Temp+1°C

22°C ≤ Intake Air Temp<24°C ➲ Intake Air Temp+0.5°C

18°C ≤ Intake Air Temp<22°C ➲ Intake Air Temp

Intake Air Temp<18°C ➲ 18°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan repeats the low airflow speed or pause as in

dehumidification operation.

3) Fuzzy Operation for Heating

• According to the setting temperature selected by Fuzzy rule, when the intake air temp is 3°C or more above

the setting temp, the compressor is turned off. When below the setting temp, the compressor is turned on.

Compressor ON Temp ➲ Setting Temp

Compressor OFF Temp ➲ Setting Temp + 3°C

• At the beginning of Fuzzy mode operation, the setting temperature is automatically selected according to

the intake air temp at that time.

20°C≤Intake Air Temp ➲ Intake Air Temp + 0.5°C

Intake Air Temp<20°C ➲ 20°C

• When the Fuzzy key (Temperature Control key) is input after the initial setting temperature is selected, the

Fuzzy key value and the intake air temperature at that time are compared to select the setting temperature

automatically according to the Fuzzy rule.

• While in Fuzzy operation, the airflow speed of the indoor fan is set to the high or the medium according to

the intake air temperature and the setting temperature.

■ Airflow Speed Selection

• The airflow speed of the indoor fan is set to high, medium, low, or chaos (auto) by the input of the airflow

speed selection key on the remote control.

■ On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

- 24 -

■ Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

■ Off-Timer <=> On-Timer Operation

• When the set time is reached after the on/off time is input by the remote control, the on/off-timer operation

is carried out according to the set time.

■ Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in

appliance operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature

increases by 1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to

the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to

the medium.

■ Chaos Swing Mode

• By the Chaos Swing key input, the upper/lower vane automatically operates with the Chaos Swing or they

are fixed to the desired direction.

• While in Chaos Swing mode, the angles of cooling and heating cycle operations are different.

■ Chaos Natural Wind Mode

• When the Chaos Natural Wind mode is selected and then operated, the high, medium, or low speed of the

airflow mode is operated for 2~15 sec. randomly by the Chaos Simulation.

■ Jet Cool Mode Operation (C/O Model)

• If the Jet Cool key is input at any operation mode while in appliance operation, the Jet Cool mode operates.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priori-

ty.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and

then operated in order that the air outflow could reach further.

■ Jet Cool Mode Operation (H/P Model)

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input. When it is input while in the

other mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priori-

ty.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and

then operated in order that the air outflow could reach further.

- 25 -

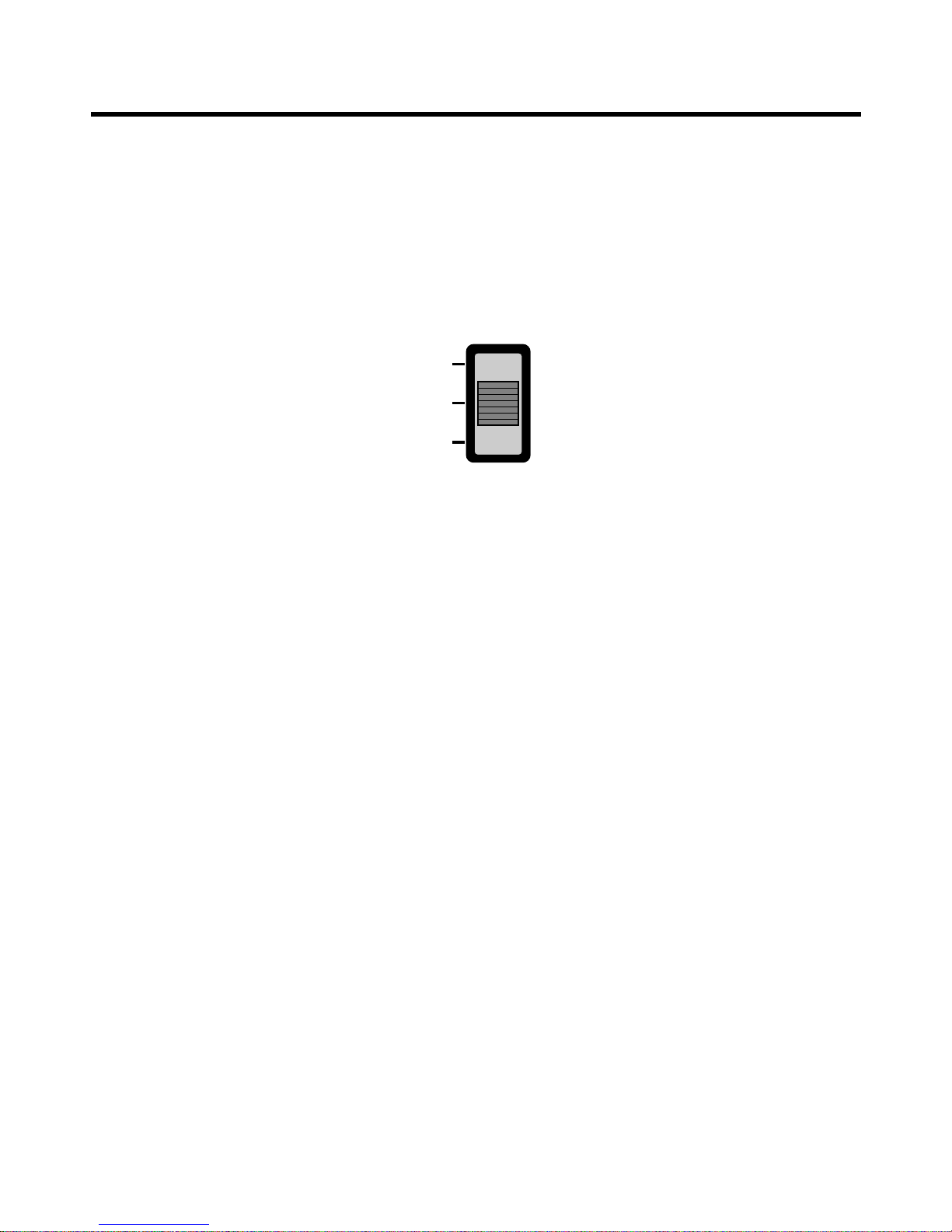

■ Auto Restarting Operation

• When the power is restored after a sudden power failure while in appliance operation, the mode before the

power failure is kept on the memory and the appliance automatically operates in the mode on the memory.

• The slide switch on the main unit of the appliance should be on the Auto Restarting position in order that

the Auto Restarting operation is available.

• Operation Mode that is kept on the memory

- State of Operation ON/OFF

- Operation Mode/Setting Temp/Selected Airflow Speed

- Sleep Timer Mode/Remaining Time of Sleep Timer (unit of hour)

Slide Switch

FORCED

OPERATION

AUTO

RESTART

REMOTE

CONTROL

■ Forced Operation (C/O Model)

• To operate the appliance by force in case that the remote control is lost, the forced operation selection

switch is on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide

switch position is switched to the Auto Restarting position (or test operation) or switched from the remote

control position to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position

or the remote control position, the forced operation is canceled and the appliance stops operating.

• The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of

airflow.

■ Forced Operation (H/P Model)

• To operate the appliance by force in case that the remote control is lost, the forced operation selection

switch is on the main unit of the appliance to operate the appliance in the standard conditions.

• When the power is supplied while the slide switch is on the forced operation position, or when the slide

switch position is switched to the Auto Restarting (or test operation) position or switched from the remote

control position to the forced operation position while the power is on, the forced operation is carried out.

• When the slide switch position is switched from the forced operation position to the Auto Restarting position

or the remote control position, the forced operation is canceled and the appliance stops operating.

•

The forced operation is carried out in cooling mode with the setting temperature 22°C and the high speed of airflow.

• In the forced operation mode, the indoor fan is operated at low speed for around 15 sec and then the operation condition is set according to the intake air temperature as follows.

24°C≤Intake Air Temp ➲ Cooling Mode Operation, 22°C, High Speed

21°C≤Intake Air Temp<24°C ➲ Dehumidification Operation, 23°C, High Speed

Intake Air Temp<21°C ➲ Heating Mode Operation, 24°C, High Speed

Loading...

Loading...