LG LFC25760SB, LFC25760SW, LFC25760TT, LFC21760ST, LFC25760ST User Manual

REFRIGERATOR

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE PRODUCT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODELS:

LFC21760ST LFC25760SW

LFC25760SB LFC25760TT

LFC25760ST

COLORS: WESTERN BLACK(SB)

TITANIUM(TT)

SUPER WHITE(SW)

STAINLESS(ST)

CONTENTS

SAFETY PRECAUTIONS ....................................................................................................................................................... 2

SPECIFICATIONS................................................................................................................................................................... 3

PARTS IDENTIFICATION ....................................................................................................................................................... 4

DISASSEMBLY.................................................................................................................................................................. 5-10

DOOR................................................................................................................................................................................ 5-6

DOOR ALIGNMENT..............................................................................................................................................................6

HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER.................................................................................... 7-9

ADJUSTMENT................................................................................................................................................................. 10-11

COMPRESSOR.................................................................................................................................................................. 10

PTC-STARTER ................................................................................................................................................................... 10

OLP (OVERLOAD PROTECTOR)...................................................................................................................................... 11

TO REMOVE THE COVER PTC .........................................................................................................................................11

CIRCUIT DIAGRAM.............................................................................................................................................................. 12

TROUBLESHOOTING..................................................................................................................................................... 13-18

COMPRESSOR AND ELECTRIC COMPONENTS ........................................................................................................... 13

PTC AND OLP.................................................................................................................................................................... 14

OTHER ELECTRICAL COMPONENTS ............................................................................................................................. 15

SERVICE DIAGNOSIS CHART.......................................................................................................................................... 16

REFRIGERATION CYCLE ............................................................................................................................................ 17-18

OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER ............................................................................. 19-22

DESCRIPTION OF FUNCTION AND CIRCUIT OF MICOM .......................................................................................... 23-40

EXPLODED VIEW AND REPLACEMENT PARTS LIST ................................................................................................... 41-

SAFETY PRECAUTIONS

Please read the following instructions before servicing your refrigerator.

1. Unplug the power before handling any elctrical componets.

2. Check the rated current, voltage, and capacity.

3. Take caution not to get water near any electrical components.

4. Use exact replacement parts.

5. Remove any objects from the top prior to tilting the product.

- 2 -

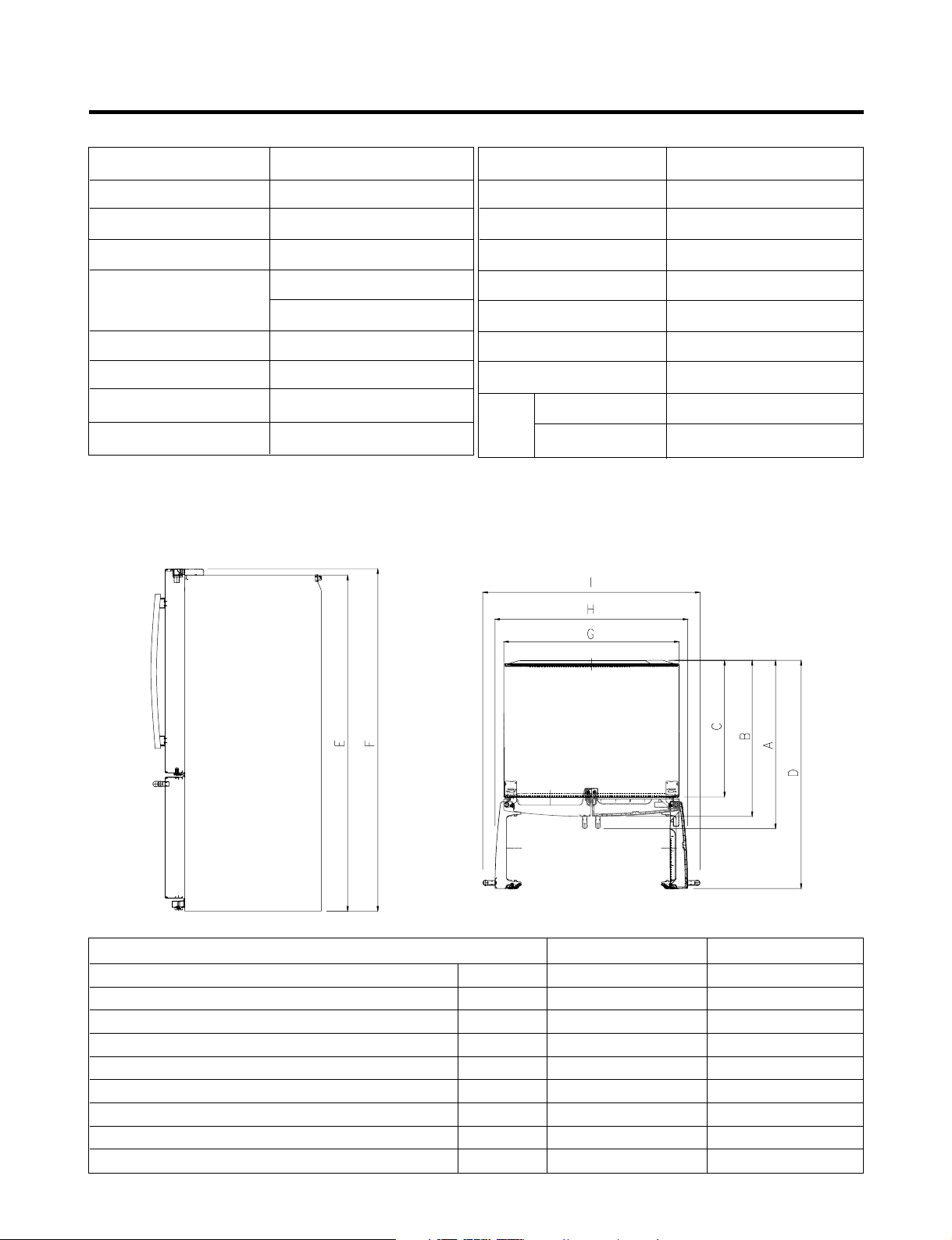

1. SPECIFICATIONS

ITEMS SPECIFICATIONS

DOOR DESIGN Side Rounded

COOLING SYSTEM Fan Cooling

TEMPERATURE CONTROL Micom Control

Full Automatic

DEFROSTING SYSTEM

Heater Defrost

DOOR FINISH PCM, VCM, Stainless

HANDLE TYPE Bar

INNER CASE ABS Resin

INSULATION Polyurethane Foam

DIMENSIONS

ITEMS SPECIFICATIONS

VEGETABLE TRAY Opaque Drawer Type

COMPRESSOR PTC Starting Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERANT R-134a (115 g)

LUBRICATING OIL ISO10 (280 ml)

DEFROSTING DEVICE SHEATH HEATER

REFRIGERATOR 60 W (2 EA)

LAMP

FREEZER 60 W (1 EA)

Description LFC21760** LFC25760**

Depth w/ Handles A 30 in. 34 1/4 in.

Depth w/o Handles B 27 1/2 in. 31 3/4 in.

Depth w/o Door C 23 5/8 in. 27 7/8 in.

Depth (Total with Door Open) D 42 1/4 in. 46 1 /2 in.

Height to Top of Case E 68 3/8 in. 68 3/8 in.

Height to Top of Door Hinge F 69 3/4 in. 69 3/4 in.

Width G 35 3/4 in. 35 3/4 in.

Width (door open 90 deg. w/o handle) H 39 1/4 in. 39/1/4 in.

Width (door open 90 deg. w/ handle) I 44 1/4 in. 44 1/4 in.

- 3 -

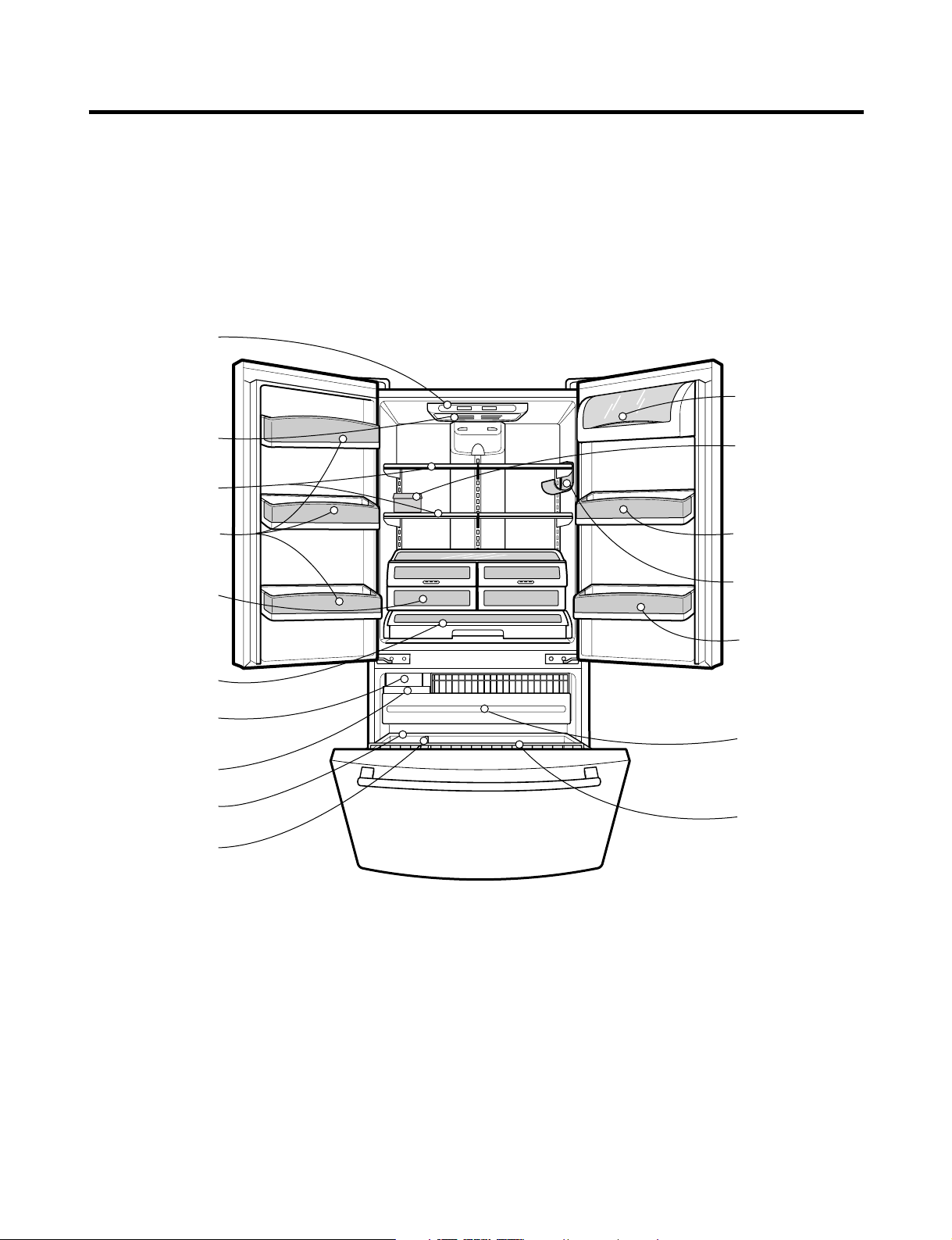

2. PARTS IDENTIFICATION

Egg Box

Digital Sensor

Control

Refrigerator Light

Shelves

Optibin Crisper

Keeps fruits and

vegetable fresh

and crisp

Customcube

Icemaker

Glide'N'Serve

Ice Bin

Durabase

Divider

Pullout Drawer

Tilt- Out

Door Basket

Modular Door Bin

Modular Door Bin

Bottle Holder

Dairy Bin

Modular Door Bin

(Tilting-LFC25760** Only)

- 4 -

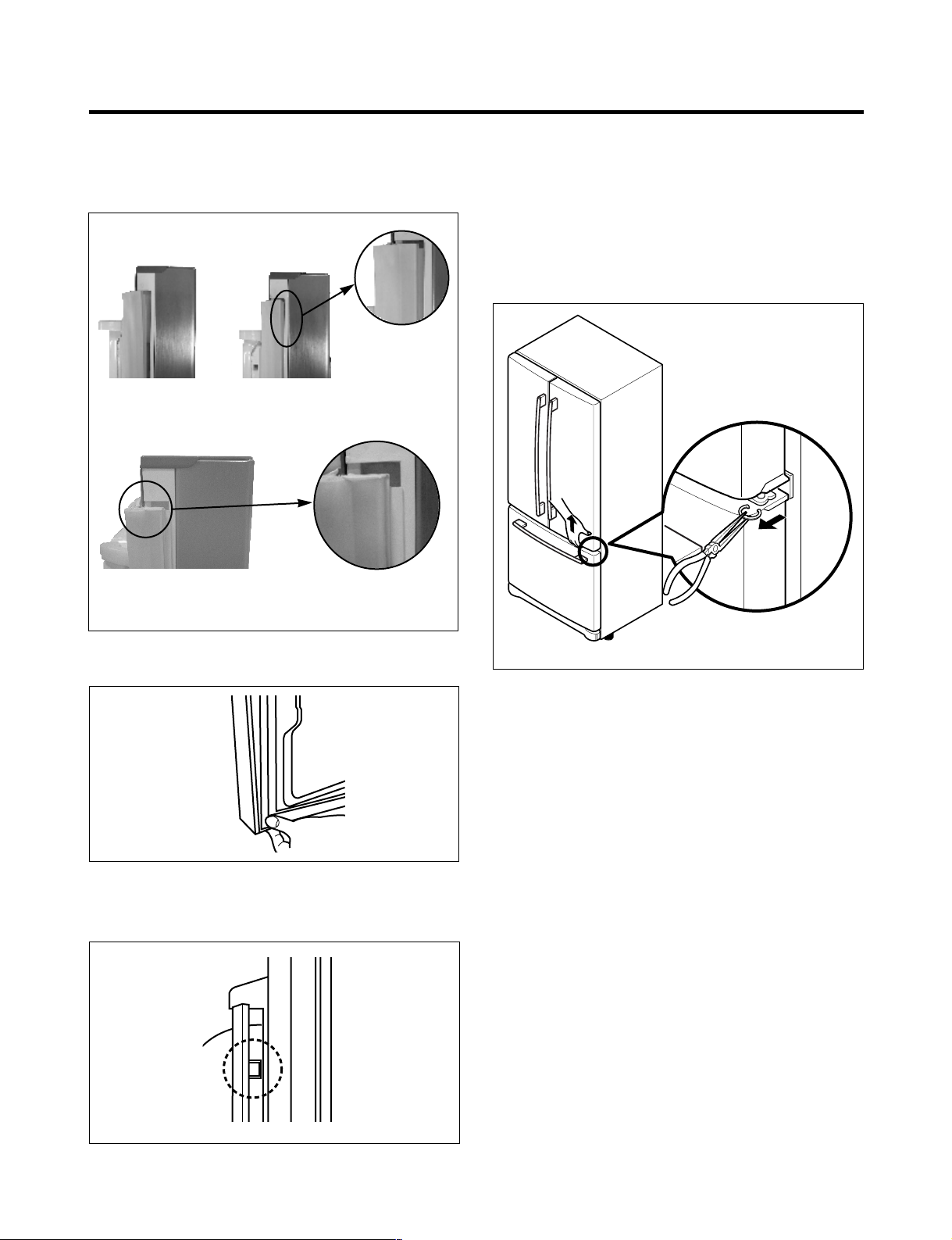

3. DISASSEMBLY

HINGE

HINGE COVER

Frame Cover

Handle

Door

Frame

Gasket

Bracket Clip

Spring

IncorrectCorrect

3-1 DOOR

● Refrigerator door

1. Remove the top hinge cover and disconnect the wire

harness.

2. Remove the ground screw.

3. Rotate the lever hinge and lift off hinge.

4. Lift off the refrigerator door.

5. Replace in the reverse order.

Figure 1

Door

Frame

Flat Tip

Screwdriver

3. Remove gasket

Pull gasket free from gasket channel on the three

remaining sides of door.

Bracket Clip

Gasket

Gasket

Bracket

Figure 3

● Door gasket removal

1. Remove door frame cover

Starting at top of cover and working down, snap cover

out and away from door.

2. Remove gasket bracket clips

There are two clips on each door. Start bracket removal

near one of the middle clips.

1) Pull gasket back to expose gasket bracket clip and

door frame.

2) Insert a flat tip screwdriver into seam between gasket

bracket and door frame and pry back until clips snaps

out.

3) Continue prying back along seam until all clips snap

out.

Figure 4

● Door gasket replacement

1. Insert gasket bracket clips

1) Insert gasket bracket edge beneath door frame edge.

2) Turn upper gasket bracket spring so that both spring

ends are in the door channel.

3) Push in clip until you hear it snap securely into place.

Figure 2

Figure 5

4) Push in remaining two clips until you hear each snap

securely into place.

Note: Make sure that no part of gasket bracket edge

protrudes from beneath door frame edge.

- 5 -

2. Insert gasket into channel

1) Snap gasket assembly into the door bracket.

Inserting the gasket assembly into the bracket door

Correct

Incorrect

Figure 6

3-2 DOOR ALIGNMENT

If the space between your doors is uneven, follow the

instructions below to align the doors:

1. With one hand, lift the door you want to raise at middle

hinge.

2. With other hand, use pliers to insert snap ring as shown.

3. Insert additional snap rings until the doors are aligned.

(Three snap rings are provided with the product.)

2) Press gasket into channels on the three remaining

sides of door.

Figure 7

3. Replace door frame cover

Starting at top of cover and working down, snap the

cover back into door.

Figure 9

Figure 8

- 6 -

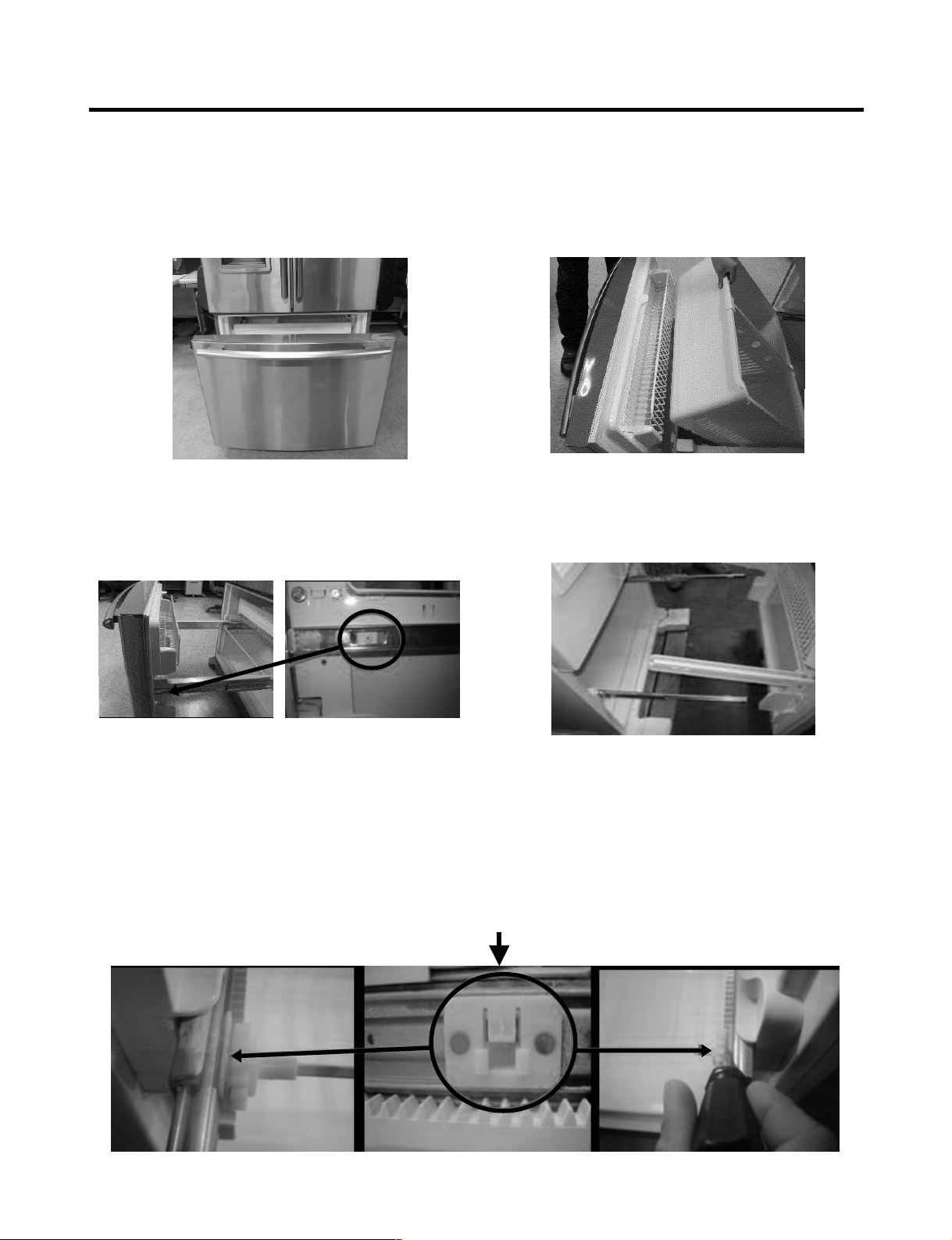

3-3 HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER

3-3-1 FOLLOW STEPS TO REMOVE

Step 1) Open the freezer door.

Step 3) Remove the two screws from the guide rails (one

from each side).

Step 2) Remove the lower basket.

Step 4) Lift the freezer door up to unhook it from the rail

support and remove.

Pull both rails to full extension.

Step 5) First: Remove the gear from the left side first by releasing the tab behind the gear, place a screwdriver between the

gear and the tab and pull up on the gear.

Second: Remove the center rail.

Third: Remove the gear from the right side by following the same steps for the left side.

NOTE: THIS TAB MUST BE PUSHED IN TO RELEASE THE GEAR.

- 7 -

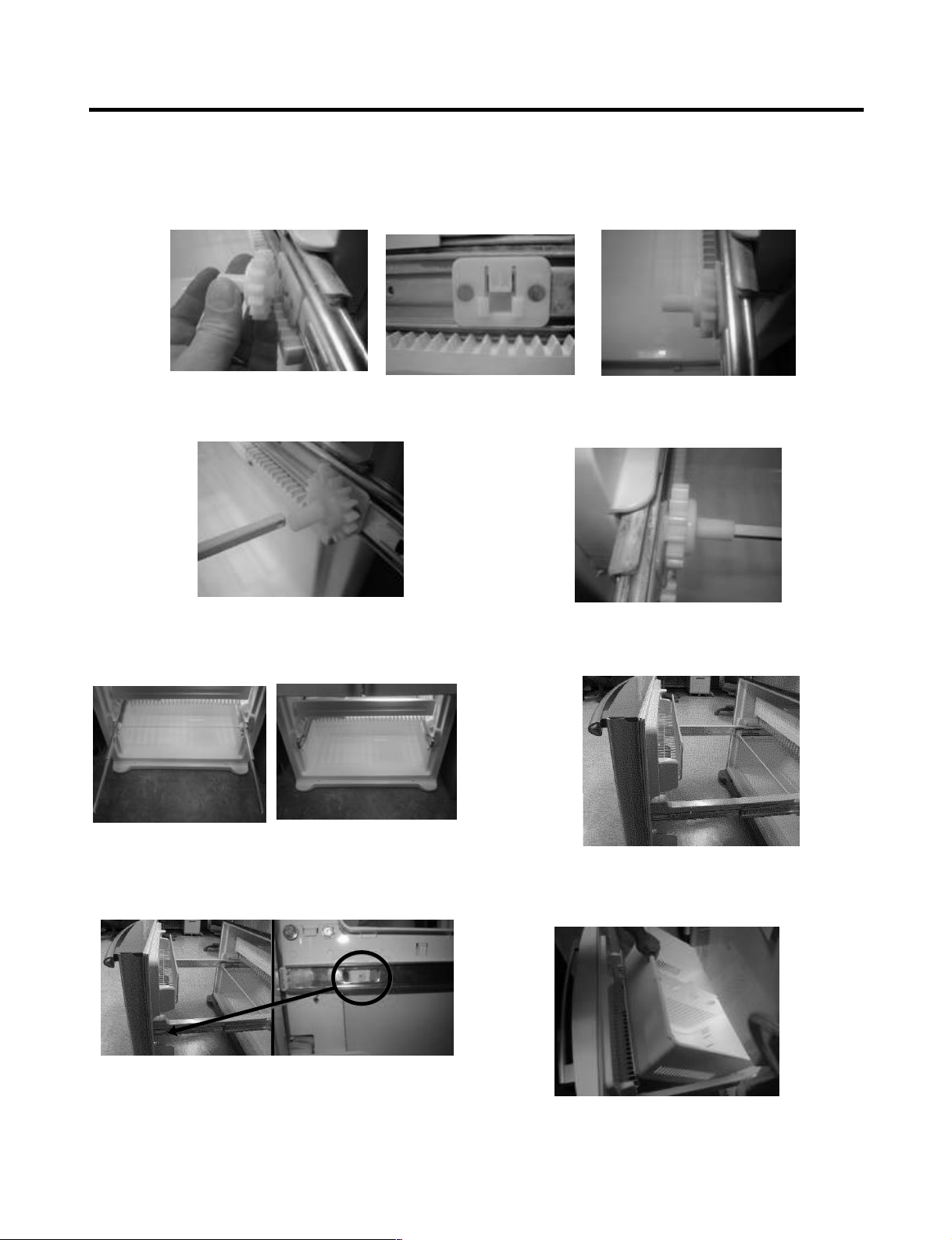

3-3-2 FOLLOW STEPS TO REINSTALL

Step 1) Reinstall the right side gear into the clip.

Step 2) Insert the rail into the right side gear. Gears do not

need to be perpendicular to each other.

Step 4) The rail system will align itself by pushing the rails

all the way into the freezer section.

Pull the rails back out to full extension.

Step 3) Insert the rail into the left side gear, and insert the

gear into the clip.

Step 5) Reinstall the freezer door by inserting the rail tabs

into the guide rail.

Step 6) Reinstall the two screws into the guide rails

(one from each side).

Step 7) Reinstall the lower basket, and close the freezer

door.

- 8 -

3-3-3 PULL OUT DRAWER

1

To separate the drawer, push the front left and right hooks in

Then gently lift the gear part of rear left and right side of the drawer and pull it out in

To install, reposition the gear part of rear left and right side of the drawer after pulling out both rails as much as possible,

and gently push down both left and right side while checking the hook on the front part.

direction to pull up and remove.

direction.

3

2

Hook

- 9 -

4. ADJUSTMENT

PTC STARTER

SEALED

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

3

6

5

2

S

N

L1

OVERLOAD PROTECTOR

Resistance Starter Capacitor Running

PTC

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use

extreme caution when repairing it.

4-1-3 Note for usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

particular compressor in your product.

(4) Keep compressor dry.

If the compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result.

If the hermetic connector rusts out or fails, refrigerant

and oil will be expelled into the contact area, probably

resulting in smoke and fire.

(5) When replacing the compressor, be careful that dust,

humidity, and soldering flux don’t contaminate the inside

of the compressor. Contamination in the cylinder may

cause noise, improper operation or even cause it to

lock up.

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic

material consisting of BaTiO3.

(2) The higher the temperature is, the higher the resistance

value. These features are used as a starting device for

the motor.

4-2-2 Role of PTC-Starter

(1) The PTC is attached to the sealed compressor and is

used for starting the motor.

(2) The compressor is a single-phase induction motor.

Durign the starting operation, the PTC allows current

flow to both the start winding and main winding.

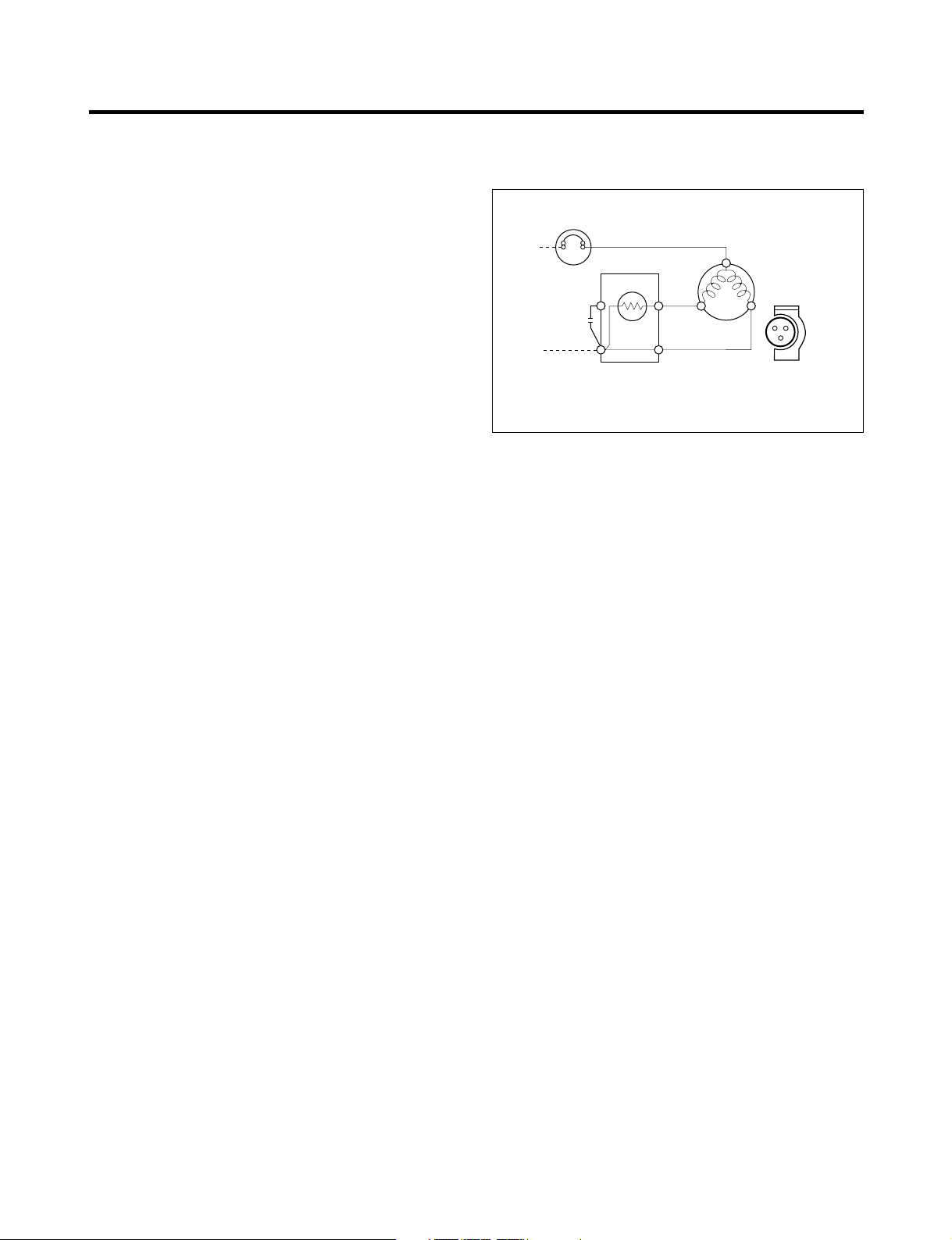

4-2-3 PTC-Applied circuit diagram

● Starting method for the motor

Figure 17

4-2-4 Motor restarting and PTC cooling

(1) It requires approximately 5 minutes for the pressure to

equalize before the compressor can restart.

(2) The PTC device generates heat during operation.

Therefore, it must be allowed to cool before the

compressor can restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the compressor attempts to restart before the PTC

device is cooled, the PTC device will allow current to

flow only to the main winding.

(2) The OLP will open because of the overcurrent

condition. This same process will continue (3 to 5

times) when the compressor attempts to restart until

the PTC device has cooled. The correct OLP must be

properly attached to prevent damage to the

compressor.

Parts may appear physically identical but could

have different electrical ratings. Replace parts by

part number and model number. Using an incorrect

part could result in damage to the product, fire,

injury, or possibly death.

4-2-6 Note for using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the PTC,

PTC materials may fail due to breakdown of their

insulating capabilities.

(4) If the exterior of the PTC is damaged, the resistance

value may be altered. This can cause damage to the

compressor and result in a no-start or hard-to-start

condition.

(5) Always use the PTC designed for the compressor and

make sure it is properly attached to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part

number and model number. Using an incorrect part

could result in damage to the product, fire, injury, or

possibly death.

- 10 -

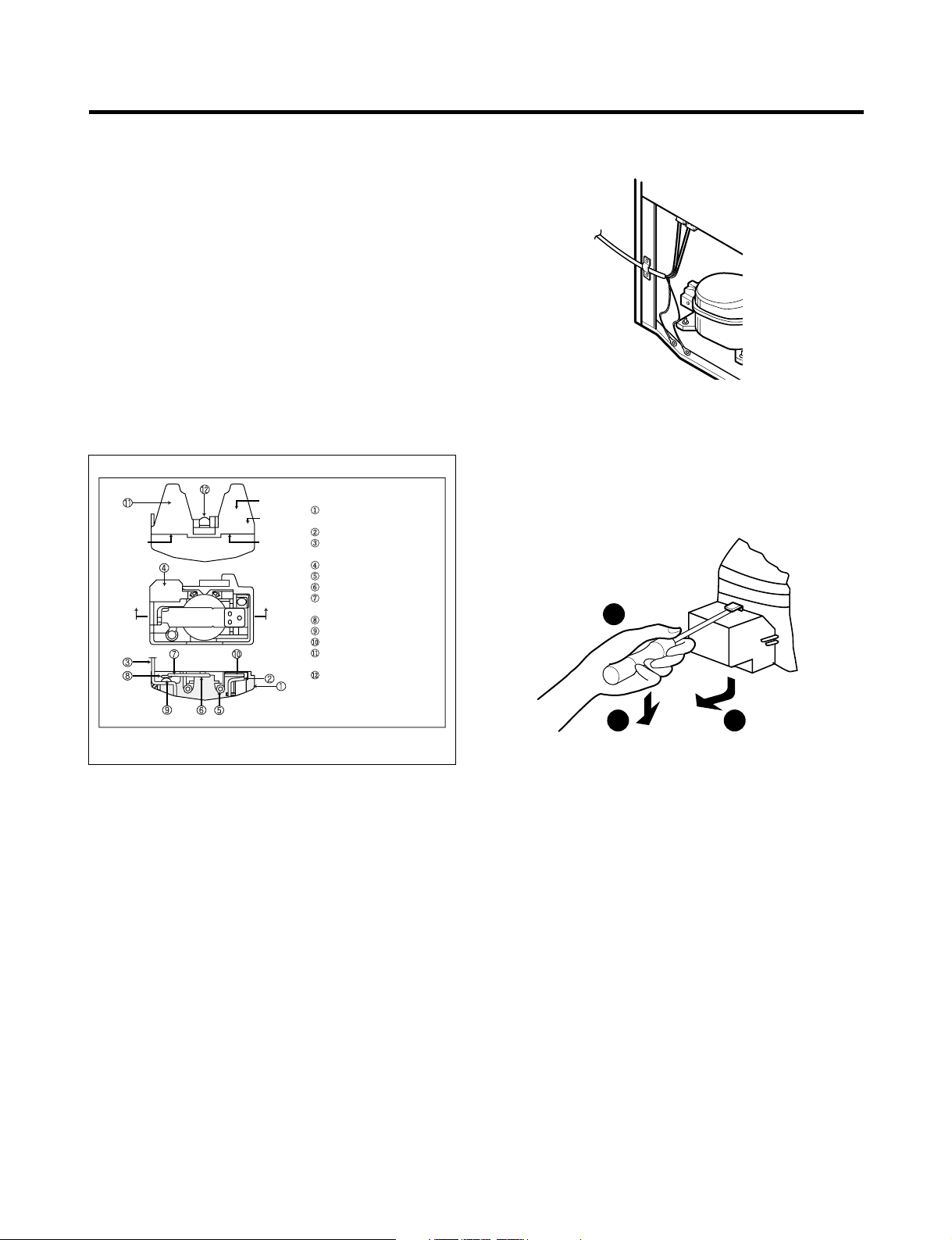

4-3 OLP (OVERLOAD PROTECTOR)

Part

Customer part

number

Lot code/

date code

330 FBYY -S1 BOX98

12345678

Physical

termination

part number

Electrical

characteristics

part number

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V -0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

(OVERLOAD PROTECTOR cross section)

1

2 3

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

compressor and protects the motor by opening the

circuit to the motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the compressor motor, the

bimetal works by heating the heater inside the OLP, and

the OLP protects the motor by cutting off the current

flowing to the compressor motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the sealed compressor used for

the refrigerator. It prevents the motor coil from being

started in the compressor.

(2) For normal operation of the OLP, do not turn the

adjustment screw of the OLP in any way.

4-4 TO REMOVE THE COVER PTC

(1) Remove the back cover of the mechanical area..

(2) Disconnect the two connectors on the top of the

compressor..

(3) Loosen two screws on compressor base.

Figure 18

(4) Use a flat screwdriver to pry off the cover.

(5) Assembly is the reverse order of disassembly.

- 11 -

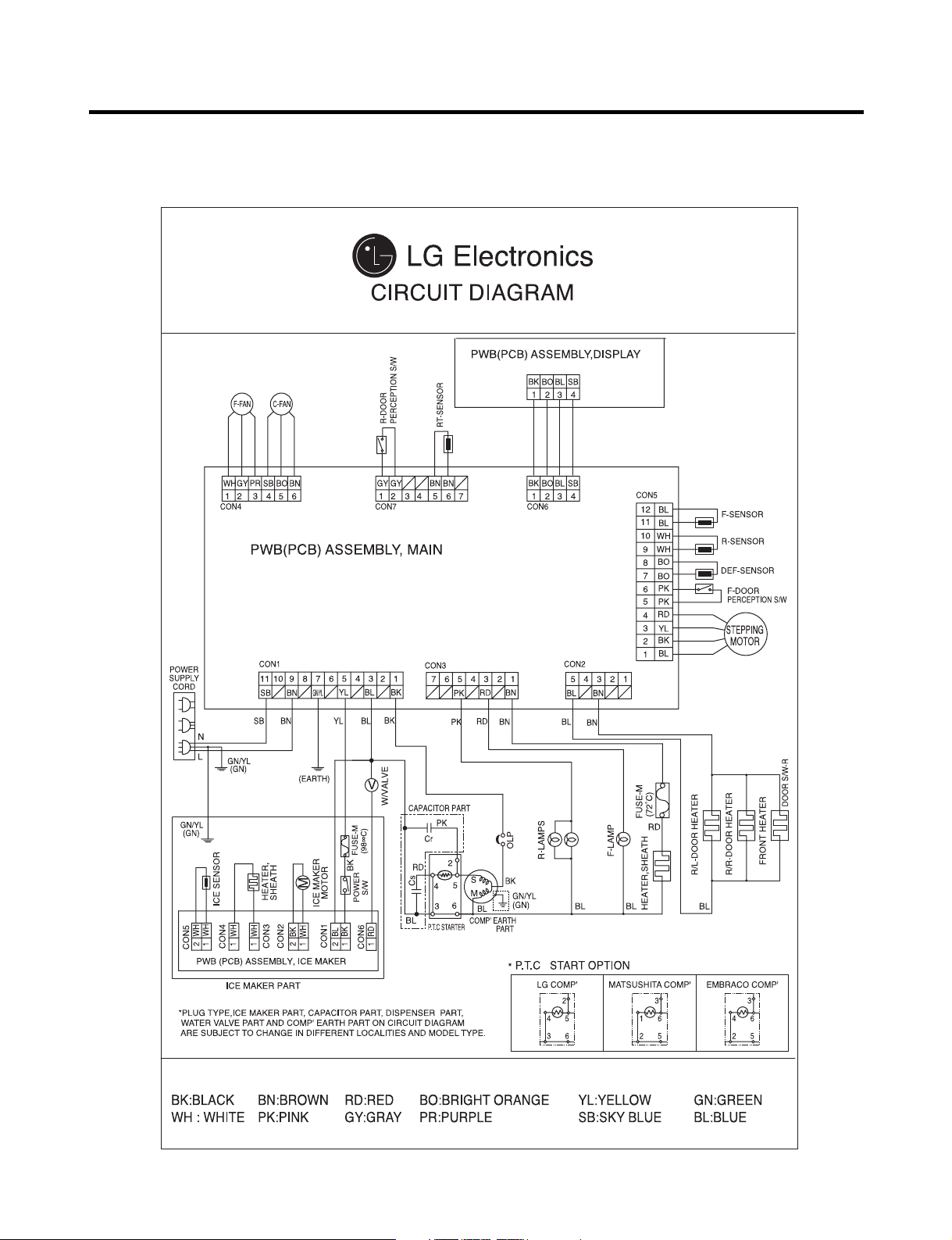

5. CIRCUIT DIAGRAM

BETTER MODEL

- 12 -

6. TROUBLESHOOTING

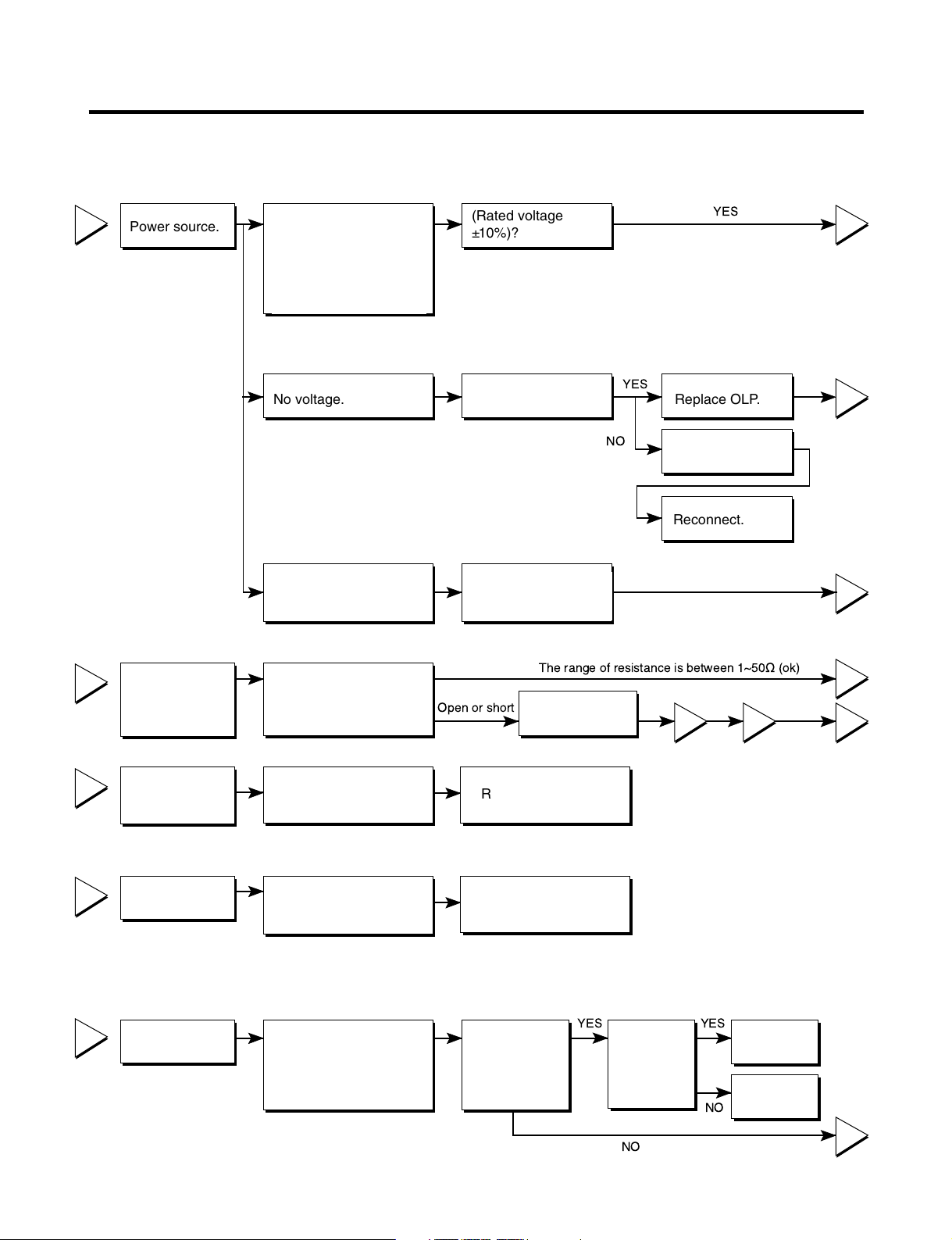

1

2

3

4

5

2

5

5

3

5

1

43

YES

NO

YES

The range of resistance is between 1~50½ (ok)

Open or short

YES

YES

NO

NO

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

Power source.

Remove PTC-Starter

from compressor and

measure voltage

between terminal C of

compressor and

terminal 5 or 6 of PTC.

No voltage.

Applied voltage isn't

in acceptable range.

(115V ±10%)

(Rated voltage

±10%)?

OLP disconnected?

Advise customer that

power supply needs to be

checked by an electrician.

Replace OLP.

Check connection

condition.

Reconnect.

Check

resistance of

motor

compressor.

Check

resistance of

PTC-Starter.

Check resistance

between M-C, S-C and

M-S in motor

compressor.

Check resistance of

two terminals in

PTC-Starter.

Replace

compressor.

Refer to page 12.

Check OLP.

Check resistance of two

terminals in OLP.

Refer to page 12.

Check

starting state.

Check the power supply

under load.

(Compressor attempting

to re-start after being off

for 5 minutes).

Supply

voltage rating

with ±10%.

Did

compressor

start?

Compressor

is OK

Replace the

compressor

- 13 -

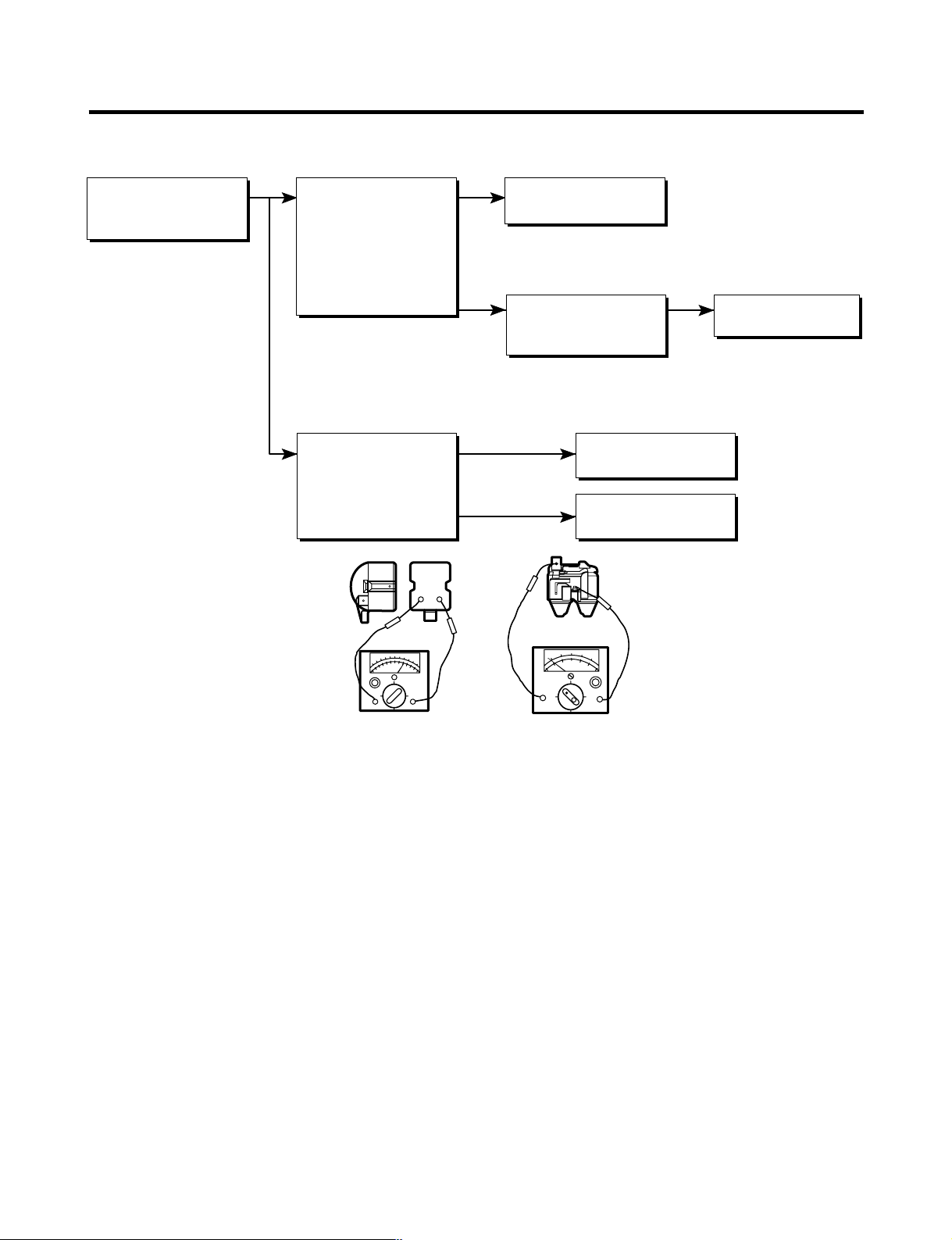

6-2 PTC AND OLP

65

Shows continuity

Open

Normal operation of

compressor is

impossible or poor.

Separate PTC-Starter

from compressor and

measure resistance

between No. 5 and 6

of PTC-Starter with a

tester.

(Figure 19)

Separate OLP from

compressor and check

resistance value

between two terminals

of OLP with a tester.

(Figure 20)

Observation value is

115V/60Hz : 6.8Ω±30%

The resistance value

is 0Ω (short) or

∞ (open).

Check another

electric component.

Replace OLP.

Replace PTCStarter.

Figure 19

Figure 20

- 14 -

Loading...

Loading...