LG LFC23760 Series Service Manual

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

REFRIGERATOR

SERVICE MANUAL

MODELS:

LFC23760**

CONTENTS

SAFETY PRECAUTIONS .....................................................................................................

1. SPECIFICATIONS ............................................................................................................

2. PARTS IDENTIFICATION .................................................................................................

3. DISASSEMBLY .................................................................................................................

3.1 Door .............................................................................................................................

3.2 Door alignment .............................................................................................................

3.3 Fan and fan motor .......................................................................................................

3.4 Defrost control assembly .............................................................................................

3.5 Lamp ............................................................................................................................

3.6 Control box refrigerator................................................................................................

3.7 Multi duct......................................................................................................................

4. ADJUSTMENT ..................................................................................................................

4.1 Compressor ..................................................................................................................

4.2 PTC-Starter ..................................................................................................................

4.3 OLP (Overload Protector) ............................................................................................

4.4 To remove the cover PTC ............................................................................................

5. CIRCUIT DIAGRAM .........................................................................................................

6. TROUBLESHOOTING ......................................................................................................

6.1 Compressor and electrical components ......................................................................

6.2 PTC AND OLP.................... .......................................................................................

6.3 Other electrical components .......................................................................................

6.4 Service Diagnosis Chart .............................................................................................

6.5 Refrigeration cycle ......................................................................................................

7. OPERATION PRINCIPLE AND REPAIR METHOD OF ICEMAKER ...............................

7.1 Operation principle ......................................................................................................

7.2 Ice maker functions .....................................................................................................

7.3 Defect diagnosis function ............................................................................................

8. DESCRIPTION OF FUNCTION & CIRCUIT OF MICOM .................................................

8.1 Function .....................................................................................................................

8.2 PCB function ...............................................................................................................

8.3 Resistance specification of sensor ............................................................................

8.4 Troubleshooting...........................................................................................................

8.5 Main PWB assembly and parts list .............................................................................

8.6 PWB diagram .............................................................................................................

9. EXPLODED VIEW AND REPLACEMENT PART LIST ....................................................

2

3

4

5

6

7

7

7

7

7

7

8

8

8

9

9

10

11

11

12

13

14

15

17

17

18

19

20

20

24

32

33

35

38

40

SAFETY PRECAUTIONS

Please read the following instructions before servicing your

refrigerator.

1. Check the refrigerator for current leakage.

2. To prevent electric shock, unplug before servicing.

3. Always check line voltage and amperage.

4. Use standard electrical components.

5. Dont’t touch metal products in the freezer with wet hands.

This may cause frostbite.

6. Prevent water from spiling on to electric elements or the

machine parts.

7. Before tilting the refrigerator, remove all materials drom

on or in the refrigerator.

8. When servicing the evaporator, wear gloves to prevent

injuries from the sharp evaporator fins.

9. Service on the refrigerator should be performed by a

Qualified technician Sealed system repair must be

Performed by a CFC certified technician.

-2-

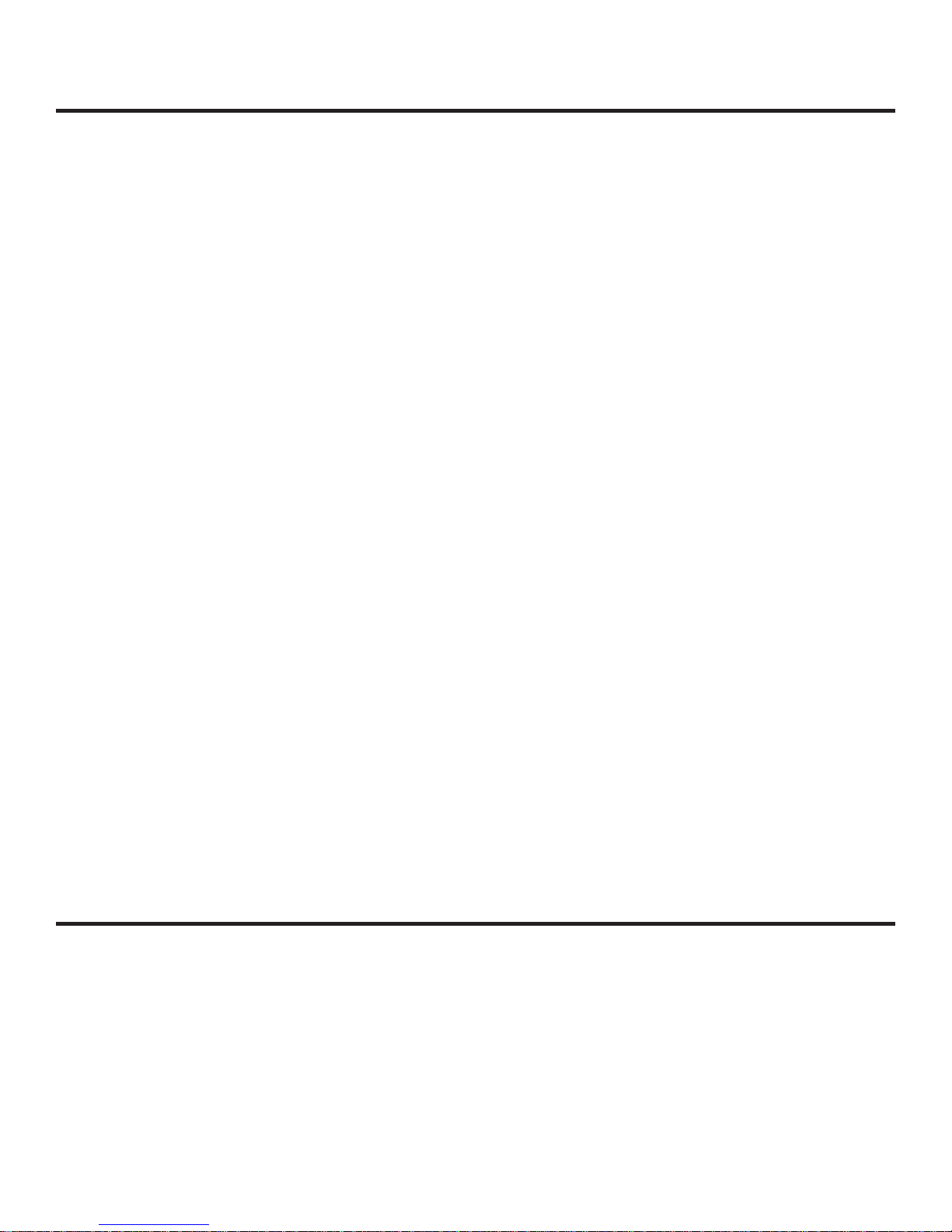

1. SPECIFICATIONS

SPECIFICATIONS

CAPACITY litre;(F/R/T)

DIMENSIONS in;(W*H*D)

GENERAL FEATURES

REVERSIBLE DOOR NO

REFRIGERANT/gr

MODELS

WEIGHT kg;

HANDLE TYPE Vista-Handle

DOOR FINISH STAINLESS

LFC23760**

197.83/436.93/634.76

32 7/8*69*34

140

R134a 120±3

ICE TRAY

SHELF

FREEZERREFRIGERATOR

BASKET DOOR NO

LAMP YES (1) 40W/azul

TRAY MEAT YES

SHELF 4Fix

MAGIC CRISPER YES

LAMP YES (2) 40W/azul

GUIDE BOTTLE YES (2)

DOOR COOOLING NO

TRAY VEGETABLE YES (AUTO CLOSE)

BASKET DOOR 3LEFT + 3RIGHT

- 3 -

Ice bank (1ea)

NO

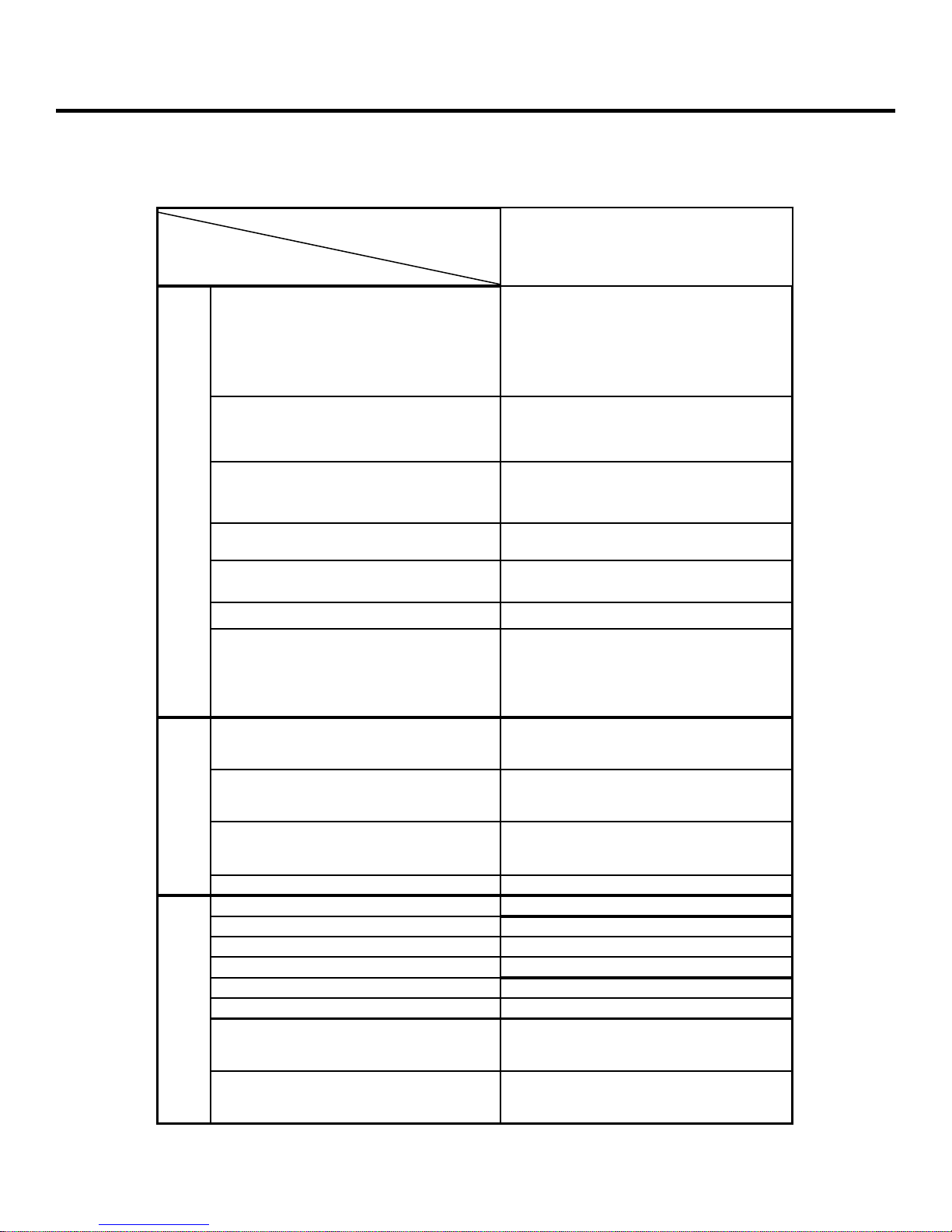

2. PARTS IDENTIFICATION

A

B

C

D

F

G

H

L

M

N

E

O

P

I

Q

J

K

Use this section to become more familiar with the parts and features.

NOTE: This guide covers several different models. The refrigerator you have purchased may have some or all of

the items listed below. The locations of the features shown below may not match ypur model.

A

Digital Sensor Control

B

Refrigerator Light

C

Shelves

D

Temperature Control*

Chef Fresh / Snack Pan

E

F

Can Dispenser*

Optibin Crisper

G

Keeps fruits and vegetable fresh and crisper

Customcube Icemaker

H

*

Filter (Inside)*

L

M

Dairy Bin

N

Egg Box*

O

Refrigerator Door Rack

P

Freezer Light

Q

Pull out Drawer

Ice Bin

I

J

Durabase

K

Divider

*on some models

- 4 -

3. DISASSEMBLY

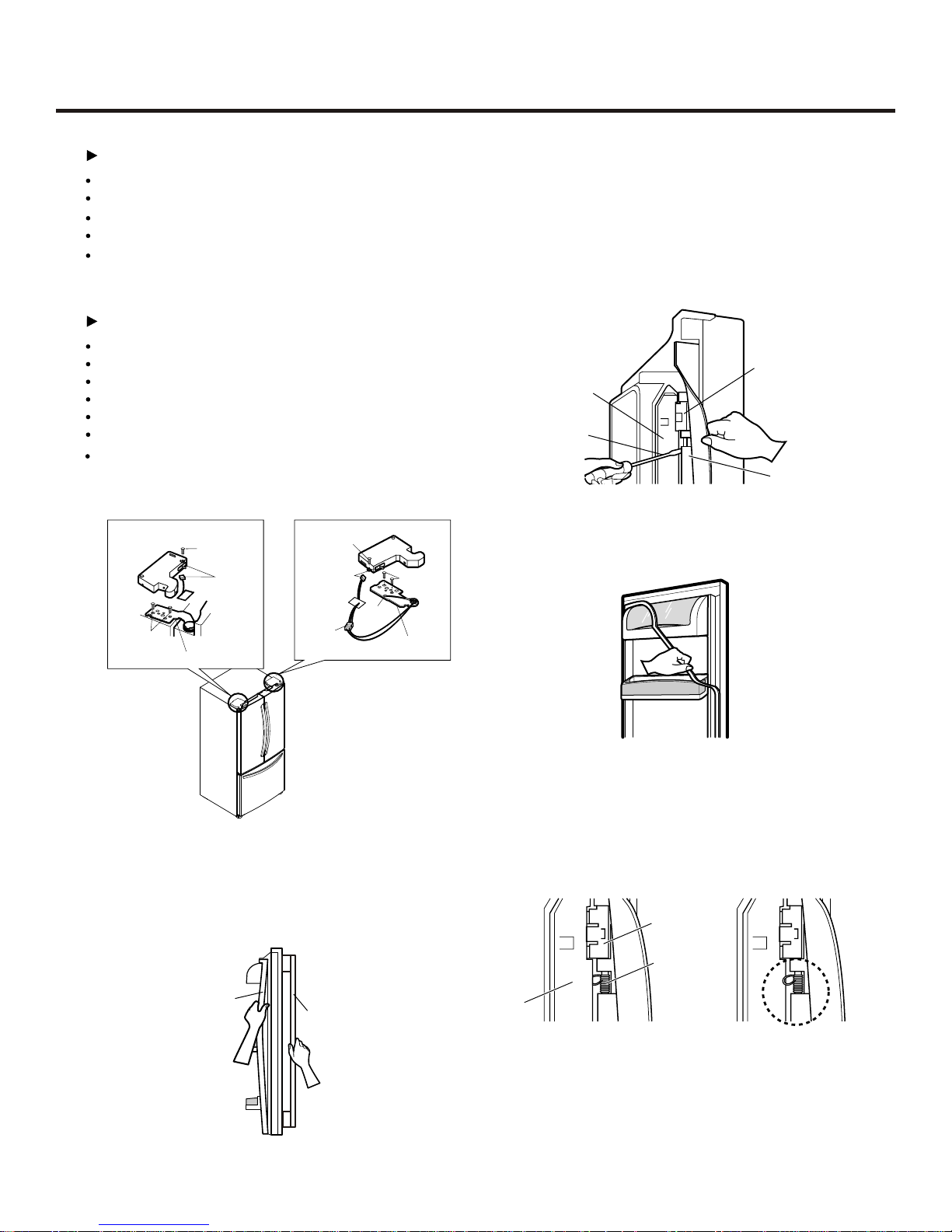

3-1 DOOR

Left Door

Loosen the cover screw (1).

Disconnect door switch wire (2).

Loosen hinge bolts (3).

Lift off the top hinge (4).

Place the door on a non-scratching surface with the

inside up.

Right Door

Loosen the cover screw (1).

Disconnect door switch wire (2).

Disconnect wire harness (5).

Loosen hinge bolts (3).

Loosen ground screw (6).

Lift off the top hinge (4).

Place the door on a non-scratching surface with the

inside up.

(1)

(2)

(1)

(2)

(3)

2. Remove gasket bracket clips

There are two clips on each door. Start bracket removal

near one of the middle clips.

1) Pull gasket back to expose gasket bracket clip and

door frame.

2) Insert a flat tip screwdriver into seam between gasket

bracket and door frame and pry back until clips snaps

out.

3) Continue prying back along seam until all clips snap

out.

Gasket

Door

Bracket Clip

Frame

Figure 3

Flat Tip

Screwdriver

Gasket

Bracket

3. Remove gasket

Pull gasket free from gasket channel on the three

remaining sides of door.

(5)

(3)

(4)

(6)

(5)

Door Gasket Removal

1. Remove door frame cover

Starting at top of cover and working down, snap cover

out and away from door.

Frame Cover

Handle

(4)

Figure 4

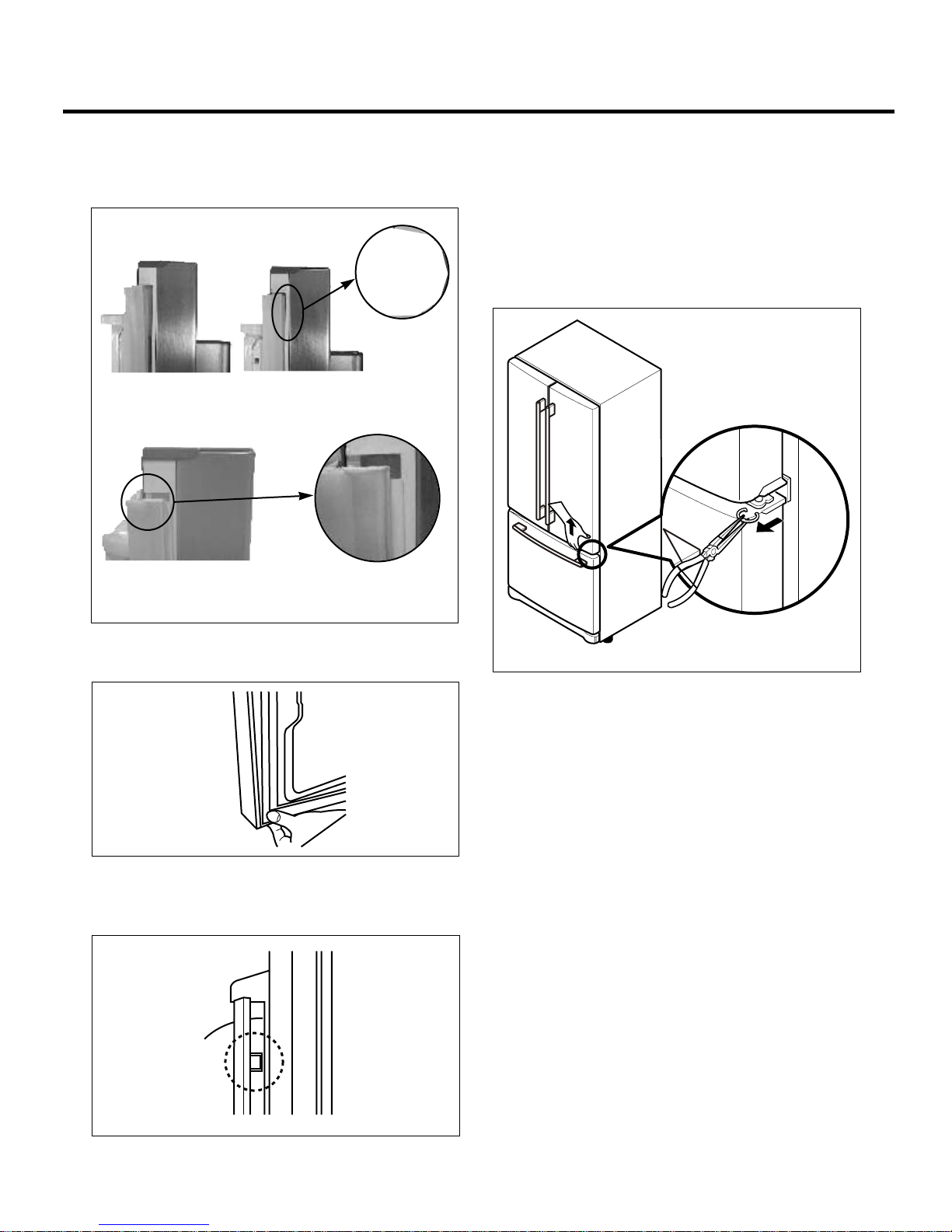

Door Gasket Replacement

1. Insert gasket bracket clips

1) Insert gasket bracket edge beneath door frame edge.

2) Turn upper gasket bracket spring so that both spring

ends are in the door channel.

3) Push in clip until you hear it snap securely into place.

Gasket

Bracket Clip

Spring

Door

Frame

Correct Incorrect

Figure 2

4) Push in remaining two clips until you hear each snap

securely into place.

Note: Make sure that no part of gasket bracket edge

- 5 -

protrudes from beneath door frame edge.

Figure 5

2. Insert gasket into channel

1) Snap gasket assembly into the door bracket.

<Inserting the Gasket Assembly into the Bracket Door>

2) Press gasket into channels on the three remaining

sides of door.

3. Replace door frame cover

Starting at top of cover and working down, snap cover

back into door.

3-2 DOOR ALIGNMENT

If the space between your doors is uneven, follow the

instructions below to align the doors:

1. With one hand, lift up the door you want to raise at

middle hinge.

2. With other hand, use pliers to insert snap ring as shown.

3. Insert additional snap rings until the doors are aligned.

(Three snap rings are provided with unit.)

- 6 -

Figure 6

Correct

Incorrect

Figure 7

Figure 8

Figure 9

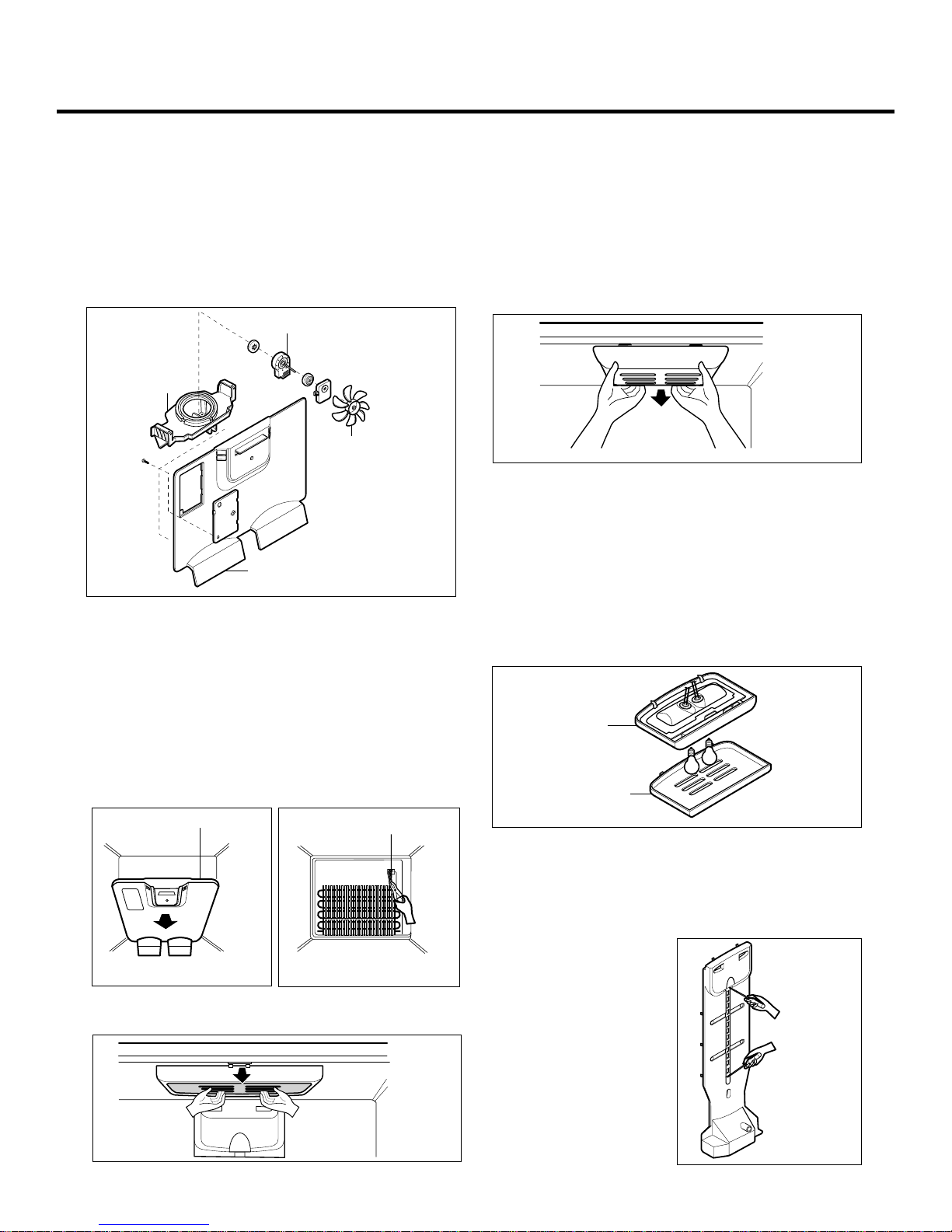

3-3 FAN AND FAN MOTOR

1. Remove the freezer shelf. (If your refrigerator has an

icemaker, remove the icemaker first)

2. Remove the plastic guide for slides on left side by

unscrewing phillips head screws.

3. Remove the grille by removing one screw and pulling the

grille forward.

4. Remove the Fan Motor assembly by loosening 2 screws

and disassembling the shroud.

5. Pull out the fan and separate the Fan Motor and Bracket.

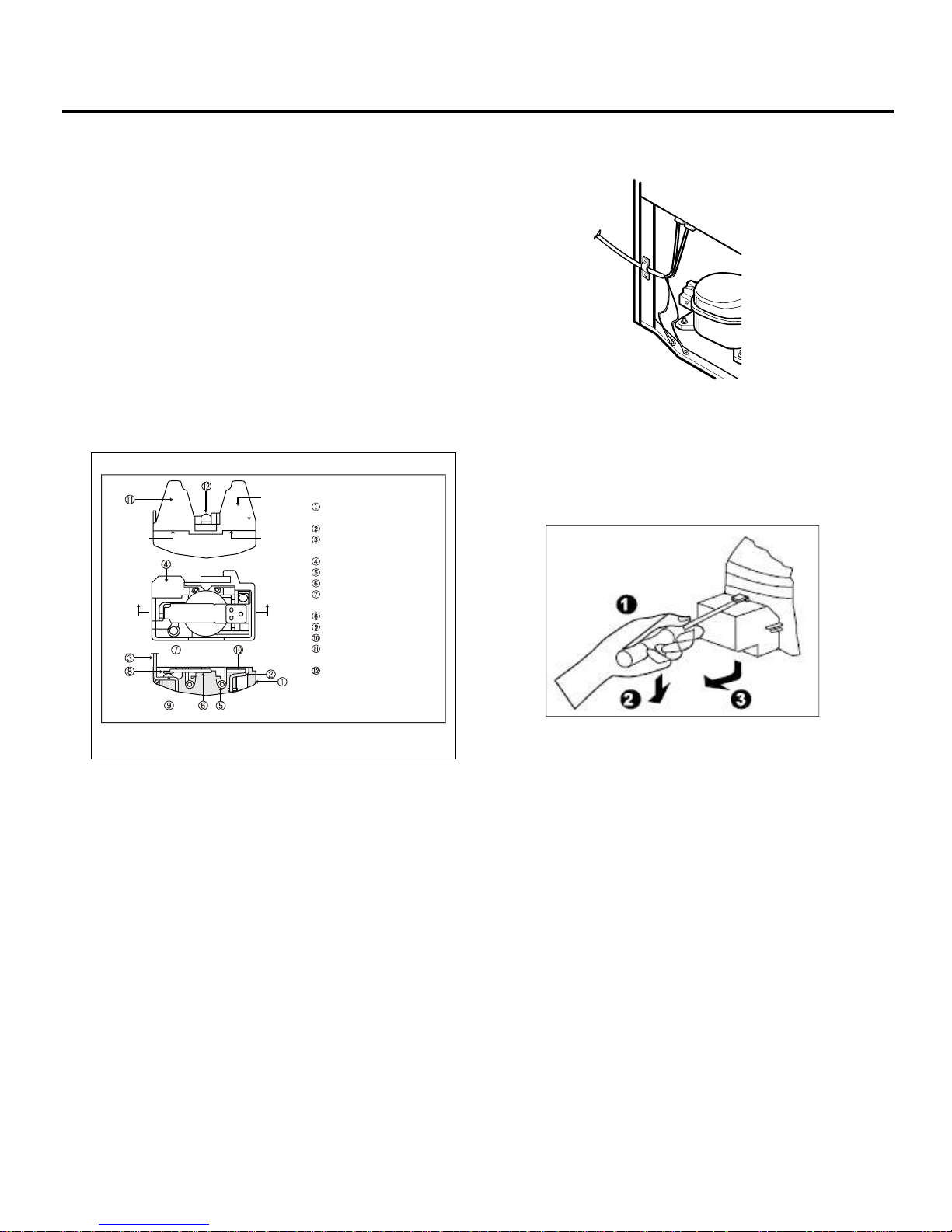

3-4 DEFROST CONTROL ASSEMBLY

Defrost Control assembly consists of Defrost Sensor and

FUSE–M.

The Defrost Sensor works to defrost automatically. It is

attached to the metal side of the Evaporator and senses its

temperature. At 72°C, it turns the Defrost Heater off.

Fuse-M is a safety device for preventing over-heating of

the Heater when defrosting.

1. Pull out the grille assembly. (Figure 12)

2. Separate the connector with the Defrost Control

assembly and replace the Defrost Control assembly

after cutting the Tie Wrap. (Figure 13)

3-5 LAMP

3-5-1 Refrigerator Compartment Lamp

1. Unplug the power cord from the outlet.

2. Remove refrigerator shelves.

3. Release the hooks on both ends of the lamp shield and

pull the shield downward to remove it.

4. Turn the lamp counterclockwise.

5. Assembly is the reverse of disassembly. Replacement

bulb must be the same specification as the original

(Max. 60 W2EA).

3-5-2 Freezer Compartment Lamp

1. Unplug refrigerator or disconnect power.

2. Reach behind light shield to remove bulb.

3. Replace bulb with a 60-watt appliance bulb.

4. Plug in refrigerator or reconnect power.

3-6 CONTROL BOX-REFRIGERATOR

1. First, remove all shelves in the refrigerator, than remove

the Refrigerator control Box by loosening 2 screws.

2. Remove the Refrigerator Control Box by pulling it

downward.

3. Disconnect the lead wire on the right position and

separate the lamp sockets.

3-7 MULTI DUCT

1. Remove the upper and

lower Caps by using a flat

screwdriver, and remove 2

screws. (Figure 17)

2. Disconnect the lead wire

on the bottom position.

-7- -

GRILLE ASSEMBLY

Figure 12

DEFROST-CONTROL

ASSEMBLY

Figure 13

Figure 14

Figure 15

CONTROL BOX

COVER LAMP

Figure 16

Figure 17

GRILLE

FAN MOTOR

FAN

BRACKET

MOTOR

Figure 11

4-1 COMPRESSOR

4-1-1 Role

The compressor intakes low temperature and low pressure

gas from the evaporator of the refrigerator and compresses

this gas to high-temperature and high-pressure gas. It then

delivers the gas to the condenser.

4-1-2 Composition

The compressor includes overload protection. The PTC

starter and OLP (overload protector) are attached to the

outside of the compressor. Since the compressor is

manufactured to tolerances of 1 micron and is hermetically

sealed in a dust and moisture-free environment, use

extreme caution when repairing it.

4-1-3 Note for Usage

(1) Be careful not to allow over-voltage and over-current.

(2) If compressor is dropped or handled carelessly, poor

operation and noise may result.

(3) Use proper electric components appropriate to the

Particular Compressor in your product.

(4) Keep Compressor dry.

If the Compressor gets wet (in the rain or a damp

environment) and rust forms in the pin of the Hermetic

Terminal, poor operation and contact may result.

(5) When replacing the Compressor, be careful that dust,

humidity, and soldering flux don

’

t contaminate the inside

of the compressor. Contamination in the cylinder may

cause noise, improper operation or even cause it to

lock up.

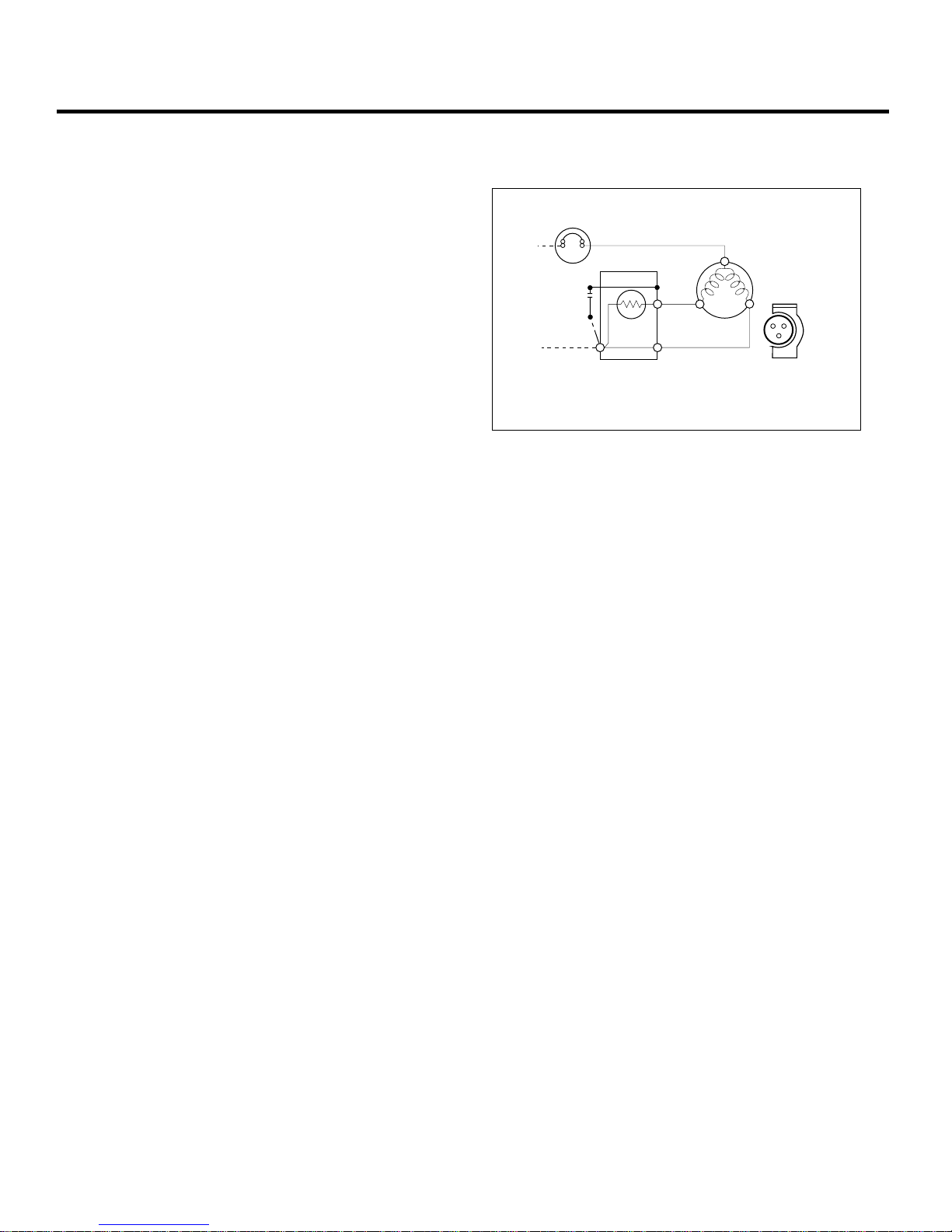

4-2 PTC-STARTER

4-2-1 Composition of PTC-Starter

(1) PTC (Positive Temperature Coefficient) is a no-contact

semiconductor starting device which uses ceramic

material consisting of BaTiO

3.

(2) The higher the temperature is, the higher the resistance

value. These features are used as a starting device for

the Motor.

4-2-2 Role of PTC-Starter

(1) The PTC is attached to the Sealed Compressor and is

used for starting the Motor.

(2) The compressor is a single-phase induction motor.

Durign the starting operation, the PTC allows current

flow to both the start winding and main winding.

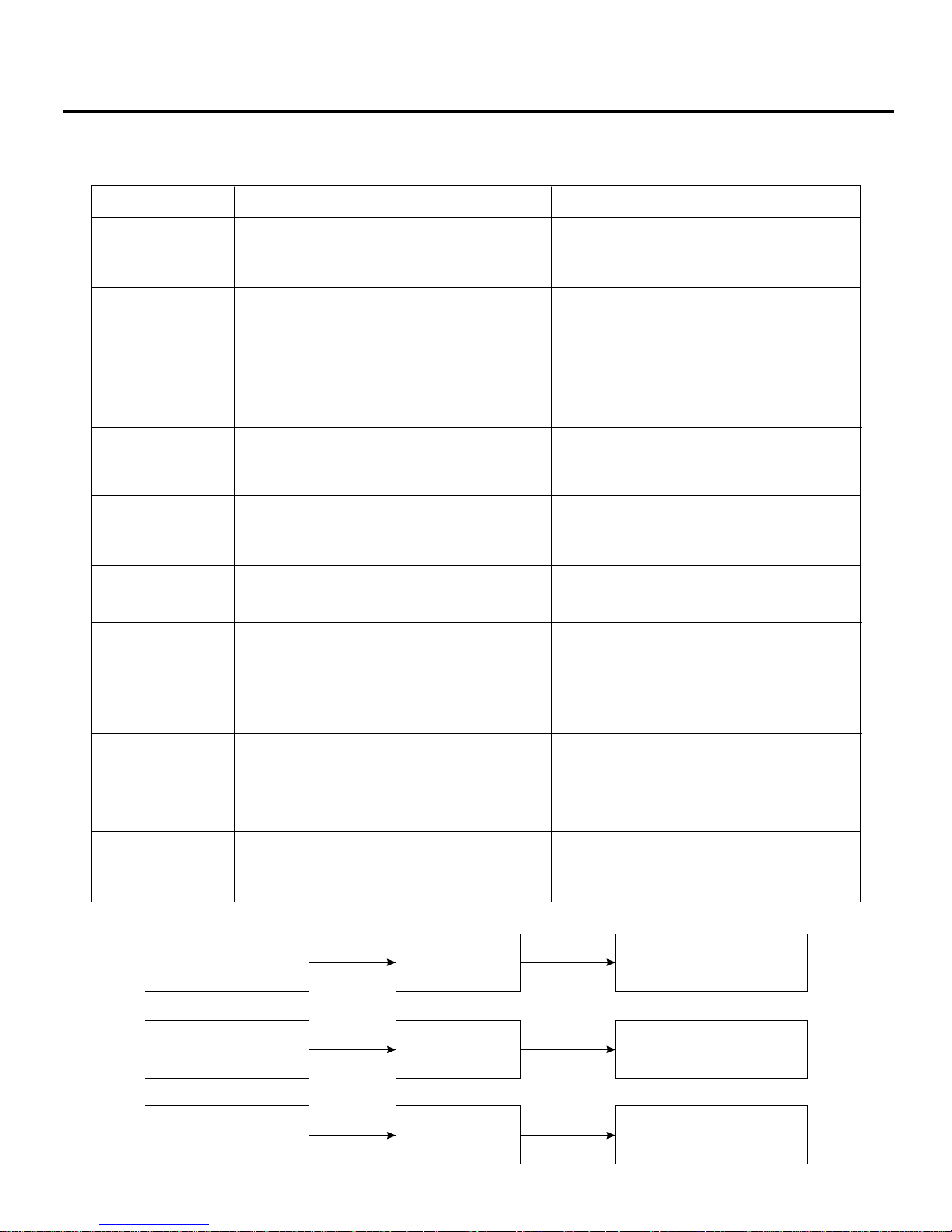

4-2-3 PTC-Applied Circuit Diagram

•Starting Method for the Motor

4-2-4 Motor Restarting and PTC Cooling

(1) It requires approximately 5 minutes for the pressure to

equalize before the compressor can restart.

(2) The PTC device generates heat during operation.

Therefore, it must be allowed to cool before the

compressor can restart.

4-2-5 Relation of PTC-Starter and OLP

(1) If the compressor attempts to restart before the PTC

device is cooled, the PTC device will allow current to

flow only to the main winding.

(2) The OLP will open because of the over current

condition. This same process will continue (3 to 5

times) when the compressor attempts to restart until

the PTC device has cooled. The correct OLP must be

properly attached to prevent damage to the

compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part

number and model number. Using an incorrect part

could result in damage to the product, fire, injury, or

possibly death.

4-2-6 Note for Using the PTC-Starter

(1) Be careful not to allow over-voltage and over-current.

(2) Do not drop or handle carelessly.

(3) Keep away from any liquid.

If liquid such as oil or water enters the PTC,

PTC materials may fail due to breakdown of their

insulating capabilities.

(4) If the exterior of the PTC is damaged, the resistance

value may be altered. This can cause damage to the

compressor and result in a no-start or hard-to-start

condition.

(5) Always use the PTC designed for the compressor and

make sure it is properly attached to the compressor.

Parts may appear physically identical but could have

different electrical ratings. Replace parts by part

number and model number. Using an incorrect part

could result in damage to the product, fire, injury, or

possibly death.

4. ADJUSTMENT

- 8 --

PTC STARTER

SEALED

TERMINAL

COMPRESSOR

MOTOR

C

M

S

M

3

6

5

2

S

PTC

N

L1

OVERLOAD PROTECTOR

Resistance Starter Capacitor Running

Figure 17

4-3 OLP (OVERLOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

Compressor and protects the Motor by opening the

circuit to the Motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the Compressor motor, the

Bimetal works by heating the heater inside the OLP,

and the OLP protects the Motor by cutting off the

current flowing to the Compressor Motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the Sealed Compressor used

for the Refrigerator. It prevents the Motor Coil from

being started in the Compressor.

(2) For normal operation of the OLP, do not turn the Adjust

Screw of the OLP in any way.

4-4 TO REMOVE THE COVER PTC

1) Remove the Cover Back M/C.

(2) Disconnect two housing upper side of comp connected

in.

(3) Loosen two screws on comp base.

(4) Use a L-shaped flap tool to pry off the cover.

(5) Assembly in reverse order of disassembly.

- 9 -

Part

Customer part

number

Lot code/

date code

330 FBYY -S1 BOX98

12345678

Physical

termination

part number

Electrical

characteristics

part number

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V-0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

(OVERLOAD PROTECTOR cross section)

Figure 18

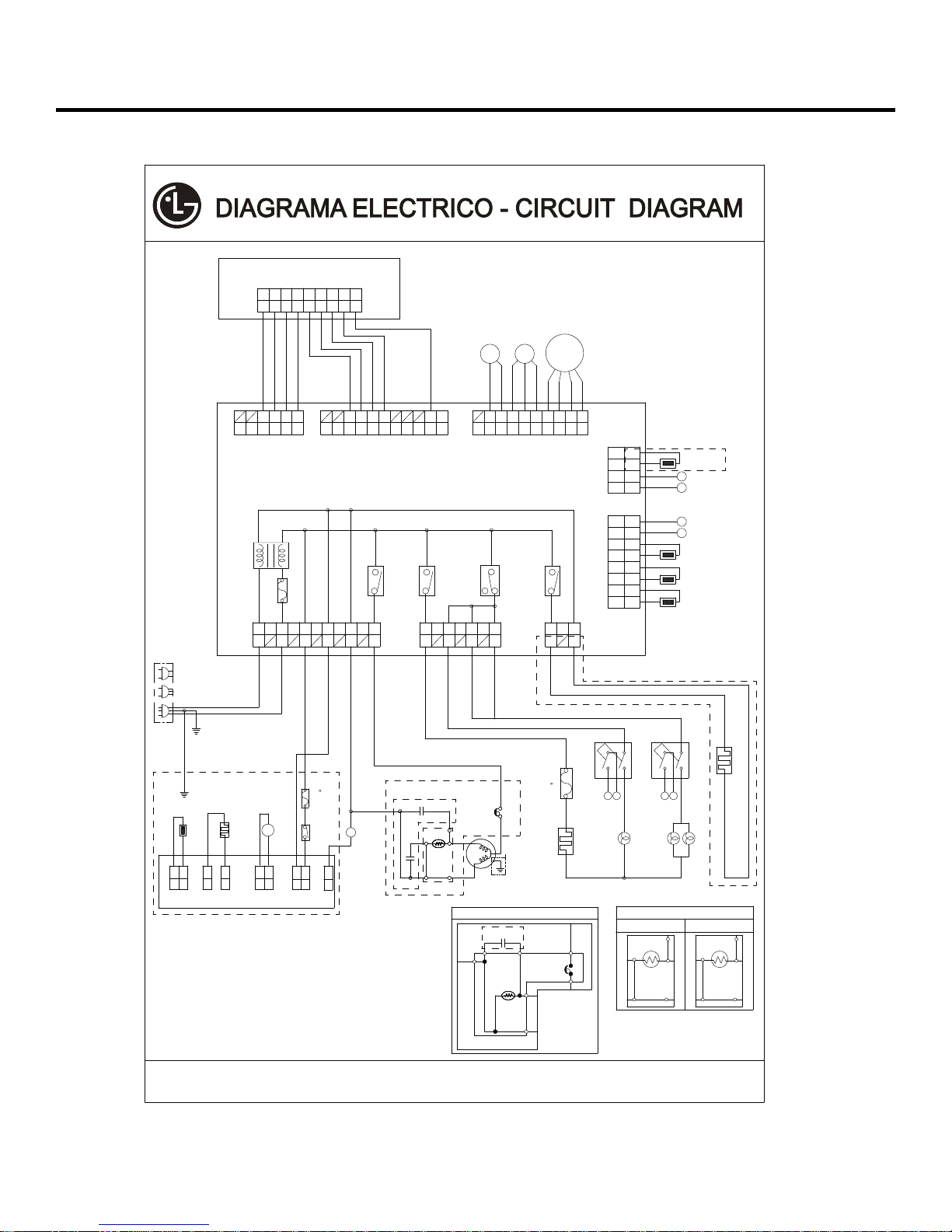

5. CIRCUIT DIAGRAM

PWB(PCB) ASSEMBLY,DISPLAY

4

1 9

BO3SB

RD

CON101

6

5

2 8

BL

7

BK

PK

PR

WH

YL

CON5

BL

BO

SB

RD

4

2 4

5

BK

PR

96BK3 1 2

11

10

CON6

PWB(PCB) ASSEMBLY, MAIN

L1

FUSE1

5

4

POWER

SUPPLY

CORD

N

L

GN/YL

(GN)

ICE MAKER PART

GN/YL

(GN)

ICE SENSOR

WH

WH

2

1

CON4

CON5

PWB (PCB) ASSEMBLY, ICE MAKER

*PLUG TYPE, ICE MAKER PART, CAPACITOR PART,

P.T.C START OPTION, DOOR HEATER, RT-SENSOR,

DOOR S/W-R QTY. (1 OR 2), COMP' EARTH PART AND

COMP' ACCESSORIES ON CIRCUIT DIAGRAM ARE SUBJECT

TO CHANGE IN DIFFERENT LOCALITIES AND MODEL TYPE.

11

SB

CON1

SB

SHEATH

HEATER,

WH

WH

1

1

CON2

CON3

7

8

10

9

YL

BN

YL

BN

M

MOTOR

ICE MAKER

BL

BK

WH

2

1

2

CON1

3

6

2

BL

BL

BL

BL

BK

(98 C)

FUSE-M

BK

V

S/W

POWER

BK

RD

1

1

CON6

PK

7

1

I/MAKER

W/VALVE

YL

WH

68

5

3

7

BN

CON2

BN

CAPACITOR PARTCAPACITOR PART

Cr

RD

Cs

BL

PTC STARTER

COMP' ACCESSORIES

C-FAN

F-FAN

SB

GY

1

5

6

RD

RD

PK

22

556644

33

BN

21

5

2

SBSB

CON3

SB

BK

4

SB

CON4

3

OLP

S

S

GN

GN

/YL

/YL

M

(GN)(GN)

COMP' EARTHCOMP' EARTH

PARTPART

* ALTERNATIVE COMP' ACCESSORIES

Cr

BL

N

PTC

WH

6

BN

STEPPING

MOTOR

BL

BK

8 9PR743

1

213

BN

BL

(72 C)

FUSE-M

RD

BL

BK

OLP

YL

RD

10

CON8

BN

BL

CON7

DOOR S/W-F

HEATER,SHEATH

1

BN

2

3

GY

4

GY

PK

1

2

PK

BO

3

4

BO

WH

5

6

WH

BL

7

BL

8

com

com

nc

nc

BA

BO

BL

RT-SENSOR

C

R-DOOR

D

PERCEPTION S/W

A

F-DOOR

PERCEPTION S/W

B

DEF-SENSOR

R-SENSOR

F-SENSOR

com

com

nc

nc

DOOR S/W-R

DC

PR

F-LAMP

BL

FRENCH DOOR HEATER

R-LAMPS

BL

* P.T.C START OPTION

MC,MQ COMP'

2

L

4

3

EG COMP'

3

5

6

4

56

2

BK:BLACK

WH:WHITE

PK:PINKYL:YELLOW

BN:BROWN

GN:GREEN

COMBO KIT(PTC+OLP)

BO:BRIGHT ORANGE

PR:PURPLE

- 10 -

SB:SKY BLUE

GY:GREY

RD:RED

BL:BLUE

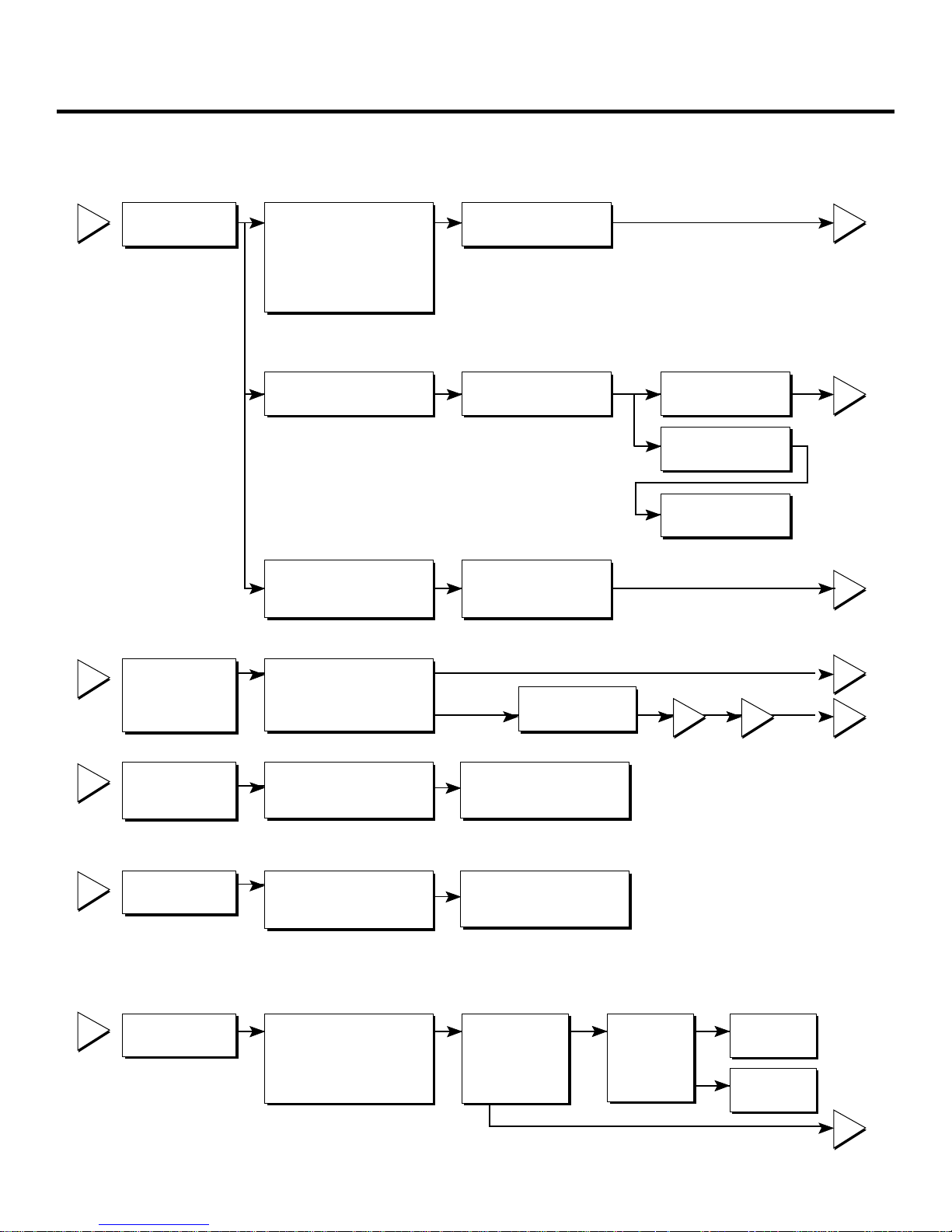

6. TROUBLESHOOTING

- 11-

6-1 COMPRESSOR AND ELECTRIC COMPONENTS

1

2

3

4

5

2

5

5

3

5

1

43

YES

NO

YES

The range of resistance is between 1~50? (ok)

Open or short

YES

YES

NO

NO

Power Source.

No Voltage.

(Rated Voltage

±10%)?

Replace OLP.

Reconnect.

Reference Page12.

Reference Page12.

Did

compressor

start?

Compressor

is OK

Replace the

compressor

Check connection

condition.

OLP disconnected?

Advise customer that

power supply needs to be

checked by an electrician.

Replace

Compressor.

Supply

voltage rating

with ±10%.

Applied voltage isn't

in acceptable range.

(115V ±10%)

Remove PTC-Starter

from Compressor and

measure voltage

between Terminal C of

Compressor and

Terminal 5 or 6 of PTC.

Check resistance

between M-C, S-C and

M-S in Motor

Compressor.

Check resistance of

two terminals in

PTC-Starter.

Check resistance of two

terminals in OLP.

Check the power supply

under load.

(Compressor attempting

to re-start after being off

for 5 minutes).

Check

resistance of

Motor

Compressor.

Check

resistance of

PTC-Starter.

Check OLP.

Check

starting state.

- 12-

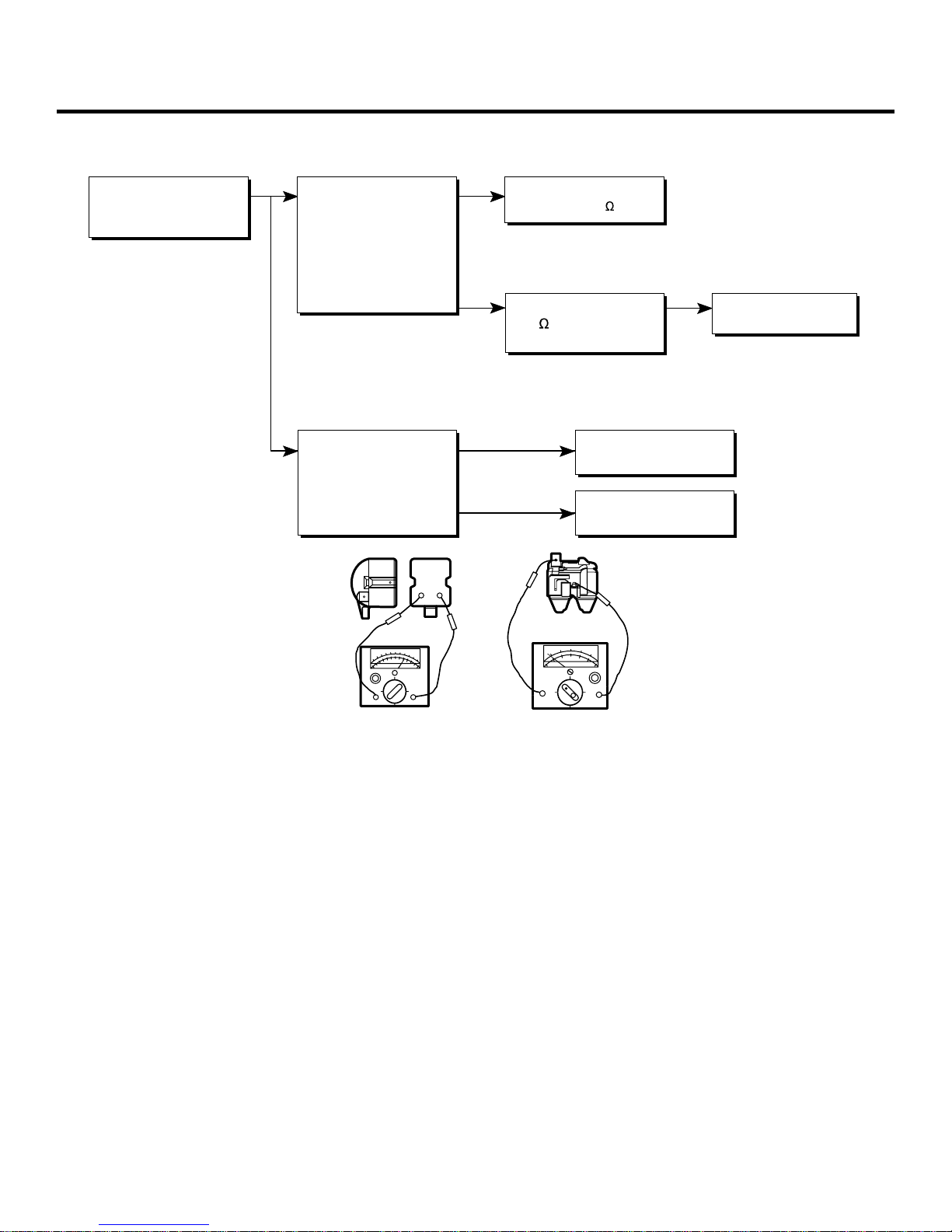

6-2 PTC AND OLP

65

Shows continuity

Open

Normal operation of

Compressor is

impossible or poor.

Separate PTC-Starter

from Compressor and

measure resistance

between No. 5 and 6

of PTC-Starter with a

Tester.

(Figure 19)

Separate OLP from

Compressor and check

resistance value

between two terminals

of OLP with a Tester.

(Figure 20)

Observation value is

115V/60Hz : 6.8 ±30%

The resistance value

is 0 (short) or

∞(open).

Check another

electric component.

Replace OLP.

Replace PTCStarter.

Figure 19

Figure 20

- 13 -

• Not cooling at all

• Poor cooling performance

Compressor

doesn't run.

Compressor runs

poorly.

Check starting

voltage.

Check for open short or

incorrect resistance readings

in the following components

a. Starting devices

b. OLP

c. Compressor coil

d.Wiring harness

Low voltage.

Short, open, or broken.

Poor contact

or shorted.

Coil open or shorted.

Poor contact

or shorted.

Poor or broken or

open contact.

Shorted.

Lack of capacity.

Replace

indicated component.

Advise customer that

the Power supply

needs to be checked

by an electrician.

Replace

indicated component.

Cause

Check voltage at

starting devices.

Check current flowing

in sub-coil of

Compressor.

Check rating of OLP.

Fan motor

doesn't run.

Heavy frost buildup on

EVAPORATOR.

Wire is open or

shorted.

Coil is shorted

or open.

Open.

Open.

Replace

Defrost Heater.

Replace

indicated component.

Replace

indicated component.

Check wiring circuit.

Check Fan Motor.

Check current flow in

the following

components:

Sensor

Fuse-M

Check current flow in

the Defrost Heater.

6-3 OTHER ELECTRICAL COMPONENTS

6-4 SERVICE DIAGNOSIS CHART

- 14 -

COMPLAINT POINTS TO BE CHECKED REMEDY

•Other possible problems:

Check if frost forms in

the freezer.

Check Components

of the defrosting

circuit.

Check the

refrigeration system.

Check the

Thermistor.

Not

defrosting

The system

is faulty.

Perform sealed

system repair.

Replace the

Thermistor.

The operation of

the Thermistor is

incorrect.

No Cooling.

Cools poorly.

Food in the

Refrigerator

is frozen.

Condensation or ice

forms inside

the unit.

Condensation forms

in the Exterior Case.

There is abnormal

noise.

Door does not

close well.

Ice and foods

smell unpleasant.

•

Is the power cord unplugged from the outlet?

Check if the power switch is set to OFF.

Check if the fuse of the power switch is shorted.

Measure the voltage of the power outlet.

Check if the unit is placed too close to the wall.

Check if the unit is placed too close to the stove,

gas cooker, or in direct sunlight.

Is the ambient temperature too high or

the room door closed?

Check if food put in the refrigerator is hot.

Did you open the door of the unit too often

or check if the door is sealed properly?

Check if the Control is set to Warm position.

Is food placed in the cooling air outlet?

Check if the control is set to colder position.

Is the ambient temperature below 5ºC?

Is liquid food sealed?

Check if food put in the refrigerator is hot.

Did you open the door of the unit too

often or check if the door is sealed properly?

Check if the ambient temperature and humidity

of the surrounding air are high.

Is there a gap in the door gasket?

Is the unit positioned in a firm and even place?

Are any unnecessary objects placed

in the back side of the unit?

Check if the Drip Tray is not firmly fixed.

Check if the cover of the compressor enclosure

in the lower front side is taken out.

Check if the door gasket is dirty with

an item like juice.

Is the refrigerator level?

Is there too much food in the refrigerator?

Check if the inside of the unit is dirty.

Are foods with a strong odor unwrapped?

The unit smells of plastic.

Plug into the outlet.

Set the switch to ON.

Replace the fuse.

If the voltage is low, correct the wiring.

Place the unit about 4 inches (10 cm) from the wall.

Place the unit away from these heat sources.

Lower the ambient temperature.

Put in foods after they have cooled down.

Don't open the door too often and close

it firmly.

Set the control to Recommended position.

Place foods in the high-temperature section.

(front part)

Set the control to Recommended position.

Set the control to Warm position.

Seal liquid foods with wrap.

Put in foods after they have cooled down.

Don't open the door too often and close

it firmly.

Wipe moisture with a dry cloth. It will disappear

in low temperature and humidity.

Fill up the gap.

Adjust the Leveling Screw, and position the

refrigerator in a firm place.

Remove the objects.

Fix the Drip Tray firmly in the original position.

Place the cover in its original position.

Clean the door gasket.

Position in a firm place and level the

Leveling Screw.

Make sure food stored in shelves does not prevent

the door from closing.

Clean the inside of the unit.

Wrap foods that have a strong odor.

New products smell of plastic, but this

will go away after 1-2 weeks.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

••

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

••

•

•

•

•

•

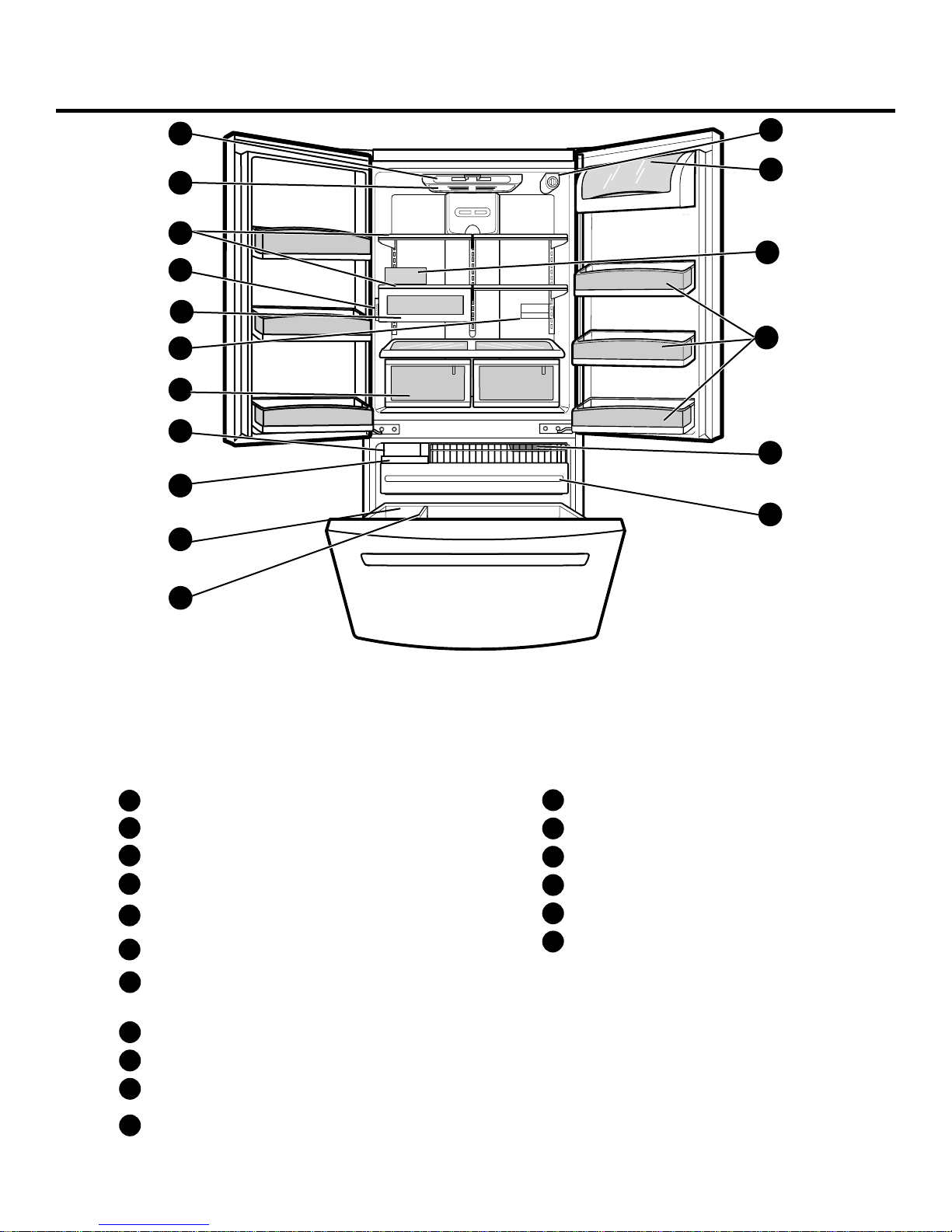

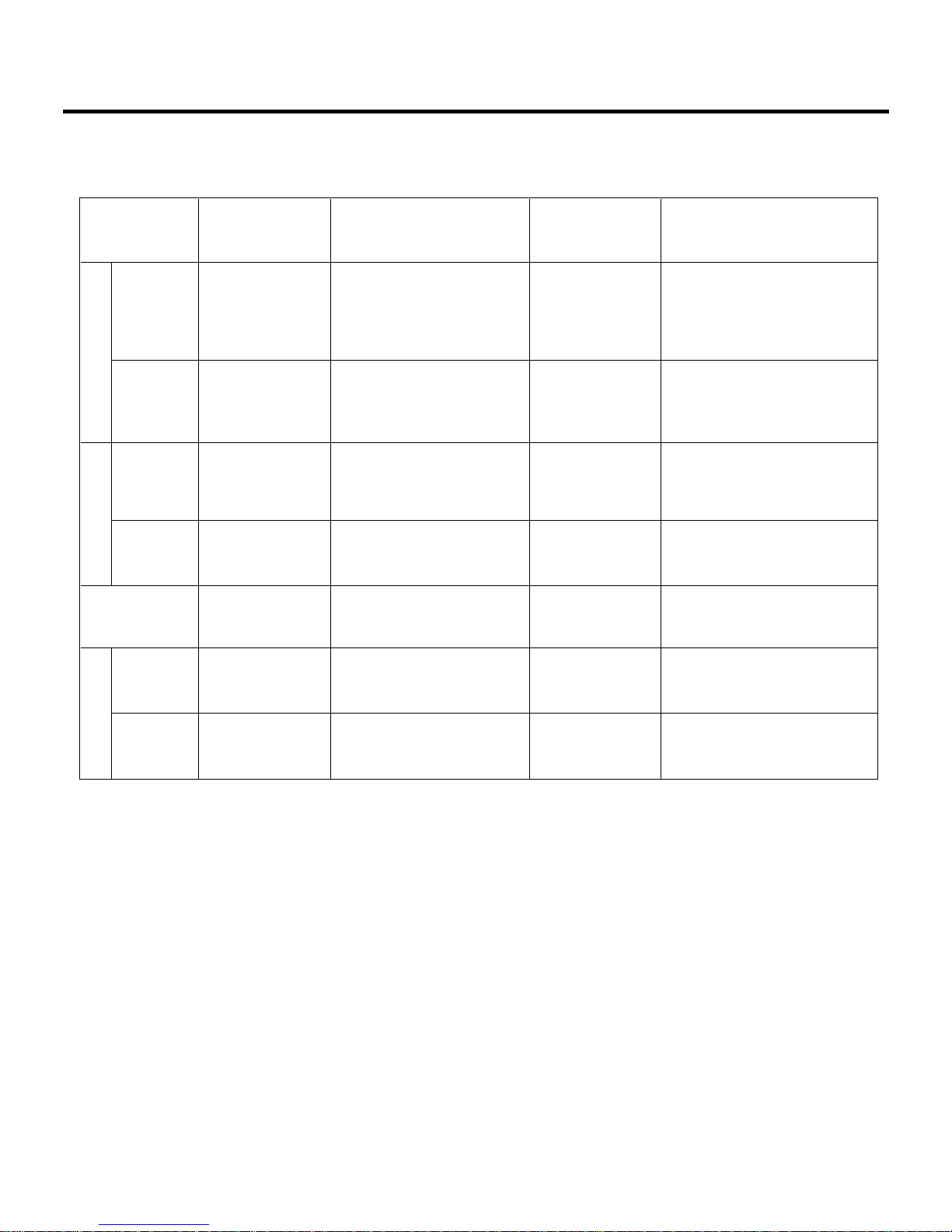

6-5 REFRIGERATION CYCLE

- 15 -

•

Troubleshooting Chart

PARTIAL Freezer Low flowing sound of A little higher • Refrigerant level is low due

LEAKAGE compartment and Refrigerant is heard and than ambient ¥ to a leak.

Refrigerator don't frost forms in inlet only. temperature. • Normal cooling is possible by

cool normally. ¥ restoring the normal amount of

¥

refrigerant and repairing the leak.

COMPLETE Freezer Flowing sound of refrigerant Equal to ambient• No discharging of Refrigerant.

LEAKAGE compartment and is not heard and frost isn't temperature. • Normal cooling is possible by

Refrigerator don't formed. ¥ restoring the normal amount of

cool normally. ¥

refrigerant and repairing the leak.

PARTIAL Freezer Flowing sound of refrigerant A little higher • Normal discharging of the

CLOG compartment and is heard and frost forms than ambient ¥ refrigerant.

Refrigerator don't in inlet only. temperature. • The capillary tube is faulty.

cool normally.

WHOLE

Freezer

Flowing sound of refrigerant Equal to ambient • Normal discharging of the

CLOG

compartment and

is not heard and frost isn't temperature. ¥ Refrigerant.

Refrigerator don't cool.

formed.

MOISTURE Cooling operation Flowing sound of refrigerant Lower than • Cooling operation restarts

CLOG stops periodically. is not heard and frost melts. ambient ¥ when heating the inlet of the

temperature. ¥ capillary tube.

COMP- Freezer and Low flowing sound of A little higher • Low pressure at high side

RESSION Refrigerator refrigerant is heard and than ambient ¥ of compressor due to low

don't cool. frost forms in inlet only. temperature. ¥ refrigerant level.

NO COMP- No compressing Flowing sound of refrigerant Equal to ambient • No pressure in the high

RESSION operation. is not heard and there is temperature. ¥ pressure part of the

no frost. ¥ compressor.

CAUSE

TEMPERATURE

OF THE

COMPRESSOR

REMARKS

STATE OF

THE UNIT

STATE OF THE

EVAPORATOR

LEAKAGE

CLOGGEDBYDUST

DEFECTIVE

COMPRESSION

Loading...

Loading...