Page 1

LG TRAINING MANUAL

LG TRAINING MANUAL

Dishwasher LDF9810ST

Spring 2008

Page 2

Published January 2008 by LG Electronics USA Training Center

Copyright © 2008 LG Electronics of Alabama, Inc.

Ph o n e Co n t a C t s :

Contact Number Hours of Operation

Customer Service (800) 243-0000 24 hours a day / 7 days a week

Technical Support (800) 847-7597 7am-7pm Mon-Fri / Sat 8-2 CST

Parts Sales (888) 393-6484 7am-7pm Mon-Sat CST

Training Center (256) 774-4051 8am-5pm Mon-Fri CST

e b Co n t a C t s :

W

Web Site Address Description

LG USA www.lgusa.com Product information

Customer Service us.lgservice.com User manuals, FAQs

GCSC aic.lgservice.com Service manuals, parts, bulletins

Customer Service Academy www.lgcsacademy.com Web training, discussion forum

Live Training lge.webex.com Live training

Page 3

LDF9810ST DISHWASHER

LDF9810ST DISHWASHER

Contents 1

Safety Notices, Warnings, and Disclaimers 3

Safety Tips 4

Warranty 5

Specifications 6

Features 6

Installation 8

Electrical Supply Preparation 9

Leveling Kit 9

Drain Connection 10

Water Connection 10

Electrical Connection 10

Final Installation 11

Control Panel 12

Options 12

Indicators 12

Programs 13

Dual Intensity Spray Wash 13

Adding Detergent 14

Adding Rinse Aid 15

Program Chart 16

Test Mode 17

Troubleshooting Error Codes 18

Steam Generator Error Codes 19

Troubleshooting Charts 20

No Power 20

Wash Pump / Motor Does Not Run 21

Washing Results Are Unsatisfactory 22

Drying Results Are Unsatisfactory 22

No Power-Off At End Of Cycle 23

Disassembly / Repair 24

Lower Cover and Insulation 24

Cabinet and Tub Insulation 24

Front Cover 24

Control Panel Assembly 24

Fan Assembly 26

Rev 1.0 080205

Water Supply Preparation 9

LDF9810ST Page 1 DISHWASHER

Page 4

LDF9810ST DISHWASHER

Disassembly / Repair (continued)

Detergent Dispenser 26

Door Springs (Right and Left) 26

Door Liner 26

Lower Frame 27

Drain Hose Holder 27

Base Cover 27

Line Noise Filter 28

Wiring Diagram (Location) 28

Cabinet Base 28

Float Assembly 28

Steam Generator 29

Inlet Valve 29

Air Breaker Assembly 29

Sump Assembly 30

Heater and Drain Motor 30

Vario Motor 30

Soil Sensor 31

Reassembly 31

Cutlery Rail Rack 32

Upper Rail Rack 32

Wiring Diagram 33

Exploded Views 34

Model / Serial Number Decoding Chart 40

Parts List 41

Supplementary Material 45

Ohm’s Law and Watt’s Law 45

Conversion Information 46

Service Bulletin 47

Drain Installation Method and Information 50

Wiring Diagram (Oversized)

Float Switch Assembly 28

LDF9810ST Page 2 DISHWASHER

Page 5

LDF9810ST DISHWASHER

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by persons possessing an adequate b ackground

in electrical equipment, electronic devices, and mechanical systems. In any attempt to repair a major

appliance, personal injury and property damage can result. T he manufacturer or seller maintains no liability

for the interpretation of this information, nor can it assume any liability in conjunction with its use. When

servicing this product, under no circumstances should the original design be modified or altered without

permission from LG Electronics. Unauthorized modifications will not only void the warranty, but may lead to

property damage or user injury. If wires, screws, clips, straps, nuts, or washers used to complete a ground

path are removed for service, they must be returned to their original positions and properly fastened.

CAUTION

To avoid personal injury, disconnect the power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

Also be aware that many household appliances present a weight hazard. At least two people should be

involved in the installation or servicing of such devices. Failure to consider the weight of an appliance could

result in physical injury.

ESD NOTICE

Some of the electronics in appliances are electrostatic discharge (ESD) sensitive. ESD can weaken or

damage the electronics in these appliances in a manner that renders them inoperative or reduces the time

until their next failure. Connect an ESD wrist strap to a ground connection point or unpainted metal in the

appliance. Alternatively, you can touch your finger repeatedly to a ground connection point or unpainted

metal in the appliance. Before removing a replacement part from its package, touch the anti-static bag to a

ground connection point or unpainted metal in the appliance. Handle the electronic control assembly by its

edges only. When repackaging a failed electronic control assembly in an anti-static ba g, observe these

same precautions.

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits for a Class B digital device, pursu ant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmfu l

interference when the equipment is operated in a residential installation. T his equipment generates, uses,

and can radiate radio frequency energy, and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate

the receiving antenna; Increase the separation between the equipment and the receiver; Connect the

equipment to an outlet on a different circuit than that to which the receiver is connected; or consult the

dealer or an experienced radio/TV technician for help.

DISCLAIMER

The information in this training manual was accurate at the time of publication. Every effort has been made

to ensure accuracy. Updates, changes, etc. are available via GCSC and LGCSacademy. The information in

this manual is intended for persons with adequate backgrounds in electronics, mechanical, and electronic

servicing. The manufacturer and seller are not to be held responsible for any liability incurred from its use.

COMPLIANCE

The responsible party for this device’s compliance is LG Electronics Alabama, Inc.; 201 James Record Road,

Huntsville, AL, 35813.

LDF9810ST Page 3 DISHWASHER

Page 6

LDF9810ST DISHWASHER

SAFETY TIPS

• Disconnect the power before servicing the dishwasher.

• Reconnect all grounding devices after repairs are complete. This includes

all grounding wires that are attached by screw and ring connector as well

as the power input, whether cordset and outlet or hardwired.

• Install the dishwasher on a properly fused and grounded dedicated circuit.

• Steam is HOT! Use care when working with live steam.

• Do not use the open door as a step or a resting place for dishes, pots and

pans, and other heavy items.

• Use ONLY detergent and drying agents developed for automatic

dishwashers. DO NOT use detergents made for hand-washing dishes.

• The dishwasher must be set on firm and even flooring that is at the same

level as the kitchen flooring for the ease of installation and servicing.

• Do not leave the racks out of the dishwasher. Children may be tempted

top play inside the dishwasher.

• If the dishwasher is not used for long periods (vacation, seasonal home, et

al.) turn off the water valve.

• Touch the buttons with your fingers only. Do not poke them with forks,

screwdrivers, or similar items.

• Do not use the dishwasher to wash items other than dishes and items

used in food preparation. Do not put other items, like aquaria, toilet seats,

bedpans, and other items in it. It is a dishwasher and not an autoclave.

LDF9810ST Page 4 DISHWASHER

Page 7

LDF9810ST DISHWASHER

WARRANTY

LDF9810ST Page 5 DISHWASHER

Page 8

LDF9810ST DISHWASHER

SPECIFICATIONS

Rated Input 120 VAC, 60Ø

Installation Built-in

Capacity 14 place settings

Dimensions (inches) 23⅞ X 25 X 33⅞

Weight (pounds) 128

Door Color Black, White, Stainless

Tub Stainless Steel

Control Electronic

Programs 6 Cycles

Rated Power (Watts) 1,350

Heater Power (Watts) 1,200

Upper Rack Adjustable

Lower Rack 50% Fold Down

Cutlery Rack Yes

Water Consumption 2.6 ~ 6.0 Gals. (10 ~ 26 Liters)

Power Consumption (kWh/year) 285 ~ 310

Operating Time (Minutes) 101 ~ 135 (normal cycle)

Fan Dry System Yes

Steam Generator Yes

Delay Start Function Yes

Auto-Off Power Switch Yes

Process Monitor Yes

Wash Level 5

Racks Nylon Coating

Operating Pressure (Bar) 20 ~ 120 (140 ~ 830 kPa)

ITEM SPECIFICATION

FEATURES

Ultra Large Capacity

Removable Cutlery Rack

Slim Direct-Drive Motor

Hybrid Drying System

Vario Spray System

Self-Cleaning Filter

Dual Intensity™ Wash Cycle

Steam Washing and Steam Delicate™

Light Tough Buttons and Blue LCD

Auto-Off

LDF9810ST Page 6 DISHWASHER

Page 9

LDF9810ST DISHWASHER

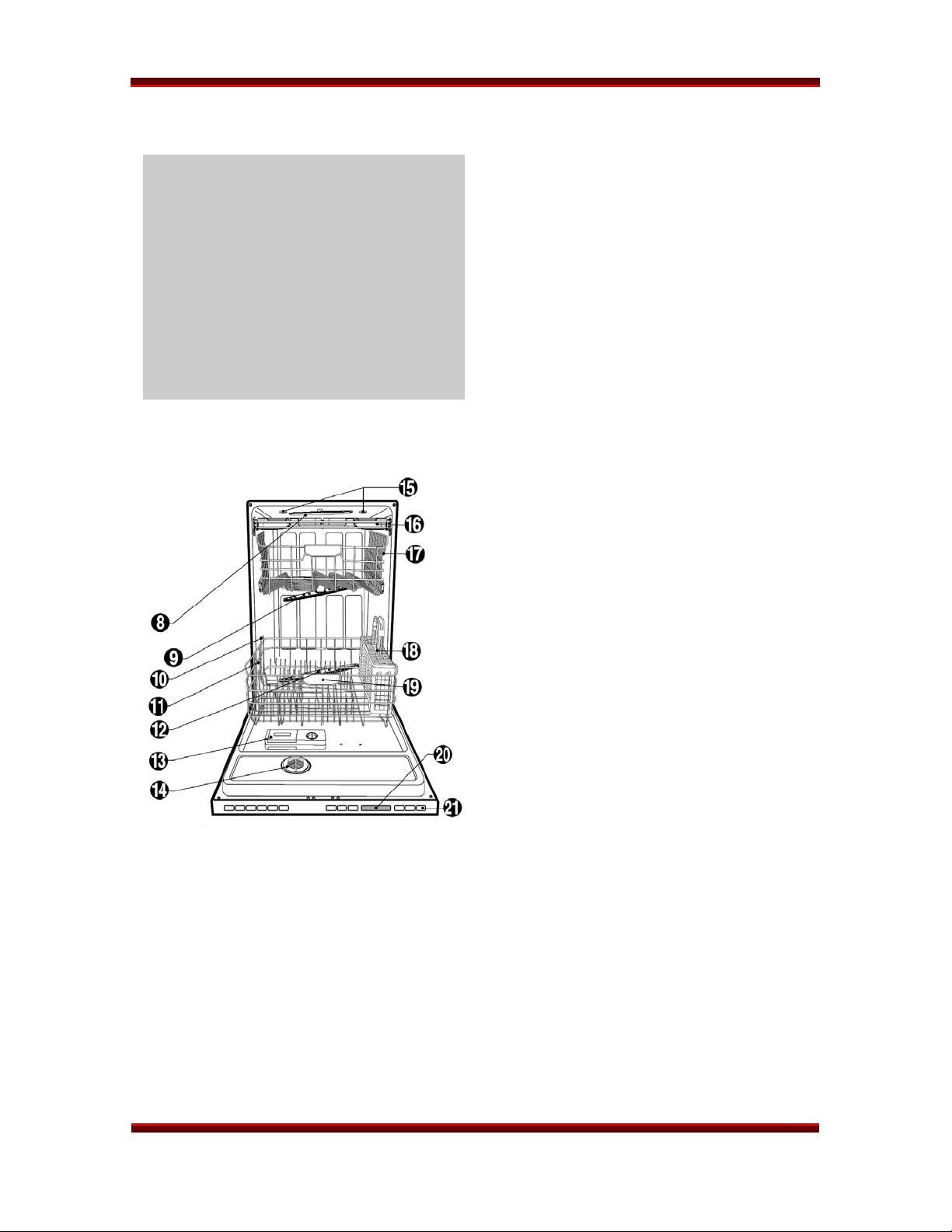

FEATURES, continued

1. Control Panel

2. Door Handle

3. Front Cover

4. Lower Cover

5. Leveling Foot

6. Side Cabinet

7. Base

8. Top Spray Arm

9. Upper Spray Arm

10. Removable Tines

11. Steam Nozzle

12. Lower Spray Arm

13. Dispenser (Detergent / Rinse Aid)

14. Vapor Vent Cover

15. Tub Lamps (IllumiTub™)

16. Cutlery Rack

17. Upper Rack

18. Cutlery Basket

19. Lower Rack

20. Blue LCD Display

21. Power Button

LDF9810ST Page 7 DISHWASHER

Page 10

LDF9810ST DISHWASHER

INSTALLATION

Installation is covered briefly for the servicer who may need to uninstall and

reinstall the dishwasher for repairs. For new installations, please refer to the

installation guide that was supplied with the dishwasher.

• We recommend a location as close to the sink as possible (but not directly

under it) for easy connection to water and drain lines.

• The installation must be within 10’ (3 m) of the sink for proper drainage.

• If the dishwasher is installed in a corner (next to an adjacent wall), there

must be 2” (50 mm) clearance.

• The floor under the dishwasher should be at the same level as the rest of

the room so the dishwasher can slide in and out easily for service.

Drill a 1½” hole on either side to allow

for the drain hose, water supply hose,

and electrical cable. The opening must

be in an area within 4” (100 mm) of the

back wall and 4” (100 mm) of the floor.

If there is a floor in the cabinet under

the sink, it will be necessary to cut

through it to connect the water, drain,

and electrical cable under the sink.

The dishwasher must be supplied with

120 V

on the rating plate and connected to a

properly fused and grounded dedicated

20-amp circuit.

The wire or water supply can be fed

from either side, and both from the

same side, depending upon source

location.

They must be run in the channels

under the dishwasher, as shown in the

drawing.

LDF9810ST Page 8 DISHWASHER

60 Hz 1Ø current as indicated

AC

Page 11

LDF9810ST DISHWASHER

ELECTRICAL SUPPLY PREPATATION

The dishwasher can be hardwired if necessary and if permitted by local code. We

recommend the use of a dishwasher installation kit, available at most hardware

and home supply stored. This kit includes a cordset, a flexible water supply line,

and the elbow connector necessary to connect it. Using a cordset requires an

electric outlet under the sink accessible when the dishwasher is installed. The

cordset makes it easier to disconnect the dishwasher from power while working

on it and makes removal and replacement easier. As stated earlier, installation

requires a properly fused and grounded dedicated circuit.

WATER SUPPLY PREPARATION

The dishwasher may be connected to either hot or cold water. If the hot water

can not maintained below 149° F, the dishwasher must be connected to the cold

water supply. Lay out the water supply line as indicated on page 14 of this

training manual. Use sealing tape or joint compound to avoid leaks.

INSTALLATION

Adjust the legs to the required height

for the dishwasher to slide under the

countertop and be level. Check the

level using a spirit level.

Attach the leveling feet kit to allow for

fine tuning when the dishwasher is

pushed into place.

To complete the installation:

Remove the lower cover.

Make sure the legs are adjusted and

the dishwasher is level.

Lay out the electrical cable, water

supply tube, and drain hose as

shown.

Slide the dishwasher carefully back

into place.

Make the appropriate connections, as

directed below.

LDF9810ST Page 9 DISHWASHER

Page 12

LDF9810ST DISHWASHER

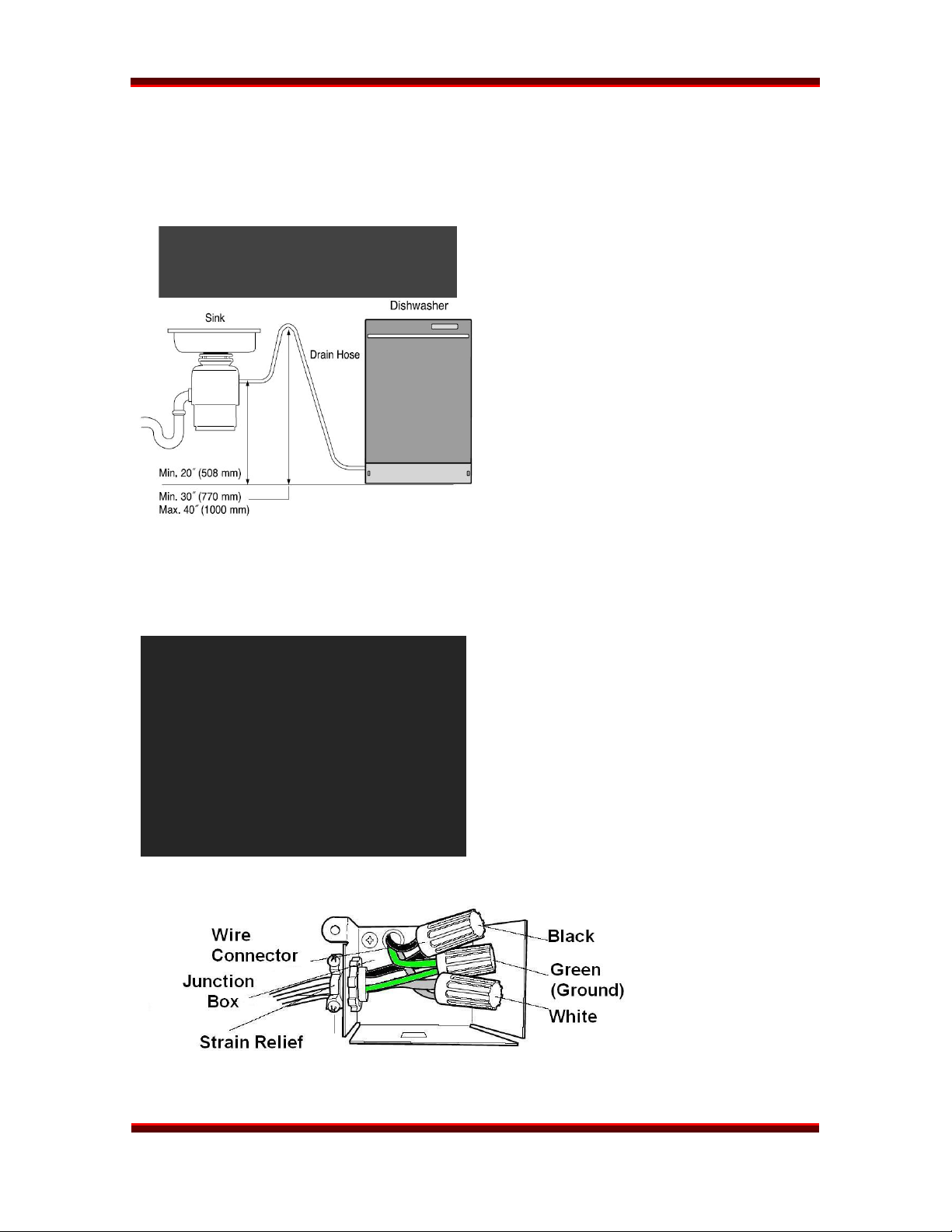

DRAIN CONNECTION

The drain hose must be connected in a manner that meets the local plumbing

code. If the end of the drain hose does not fit the available connector, an adapter

may be obtained from a local hardware or plumbing supplier.

The rubber end can be cut off for the

correct size attachment.

This drawing shows the drain line

installed with a rise in the drain pipe

but no air gap. It can also be with an

air gap installed. Be sure to observe

the clearances listed.

Most garbage disposers have a

dishwasher drain fitting built in to

them. If your installation does not

include a disposer, you can use a

See supplementary drain information on

page 50 of this training manual.

special tail piece with a drain

attachment available at most

hardware and home supply stores.

WATER CONNECTION

Turn off the water supply and connect

the elbow to the inlet valve.

Connect the flexible supply tube to the

elbow.

Use sealing tape to make all

connections.

Make sure the supply line is not kinked.

ELECTRICAL CONNECTION

Use wire

connectors and

replace the

cover on the

junction box.

(12/2 w/ ground,

20-amps)

LDF9810ST Page 10 DISHWASHER

Page 13

LDF9810ST DISHWASHER

FINAL INSTALLATION

1. Turn on the water at the valve under the sink.

2. Turn on the power at the fuse or breaker (or plug in the cordset at the

outlet under the sink.

3. Run the dishwasher through one QUICK cycle to check the operation and

to check for water leaks.

4. Replace the lower cover.

When the door is closed, the top edge with the controls should be under the

countertop.

LDF9810ST Page 11 DISHWASHER

Page 14

LDF9810ST DISHWASHER

CONTROL PANEL

SOAK Heavily soiled loads, with cooked-on foods

POWER SCRUB Normal soil level, everyday loads

NORMAL Normal soil level, everyday loads

STEAM DELICATE Washing delicate items, crystal, stemware

QUICK Light soil level, recently used dishes and cutlery

RINSE ONLY Rinses only, no washing

OPTIONS

STEAM Adds steam to SOAK, POWER SCRUB, and Normal cycles

RINSE Pressing cycles through Sanitary, Extra Rinse, or both

SPRAY Pressing cycles through Strong, Medium, or Soft spray

HALF LOAD Pressing chooses either upper or lower rack instead of both

DELAY START Each press delays the start by one hour up to 24 hours

CHILD LOCK Press and hold to engage/disengage

CANCEL Press and hold ST EAM DELICATE and NORMAL

INDICATORS

n

o

p

q

r

s

Steam option indicator – blinks if selected

Rinse indicator – blinks if selected

Spray indicator – blinks if selected

Half load indicator

Child Lock – illuminated when engaged

Rinse Aid – illuminated when refill is required

Time remaining before cycle ends

LDF9810ST Page 12 DISHWASHER

Page 15

LDF9810ST DISHWASHER

PROGRAMS

DUAL INTENSITY SPRAY WASH

The spray intensity for the upper lower racks is programmable by the customer.

By selecting SOFT SPRAY for the upper rack and STRONG SPRAY for the

lower rack, you can wash delicate items like stemware on top while washing pots

and pans on the bottom.

1. Press and hold SPRAY to illuminate the indicator.

2. Press SPRAY to set the intensity for the upper rack.

(Strong/Medium/Soft/Off)

3. Press HALF LOAD to confirm the selection for the upper rack.

4. Press SPRAY to set the intensity for the lower rack.

5. Press HALF LOAD to confirm the selection for the lower rack.

6. Select other options.

7. Close the door.

8. The dishwasher will start.

LDF9810ST Page 13 DISHWASHER

Page 16

LDF9810ST DISHWASHER

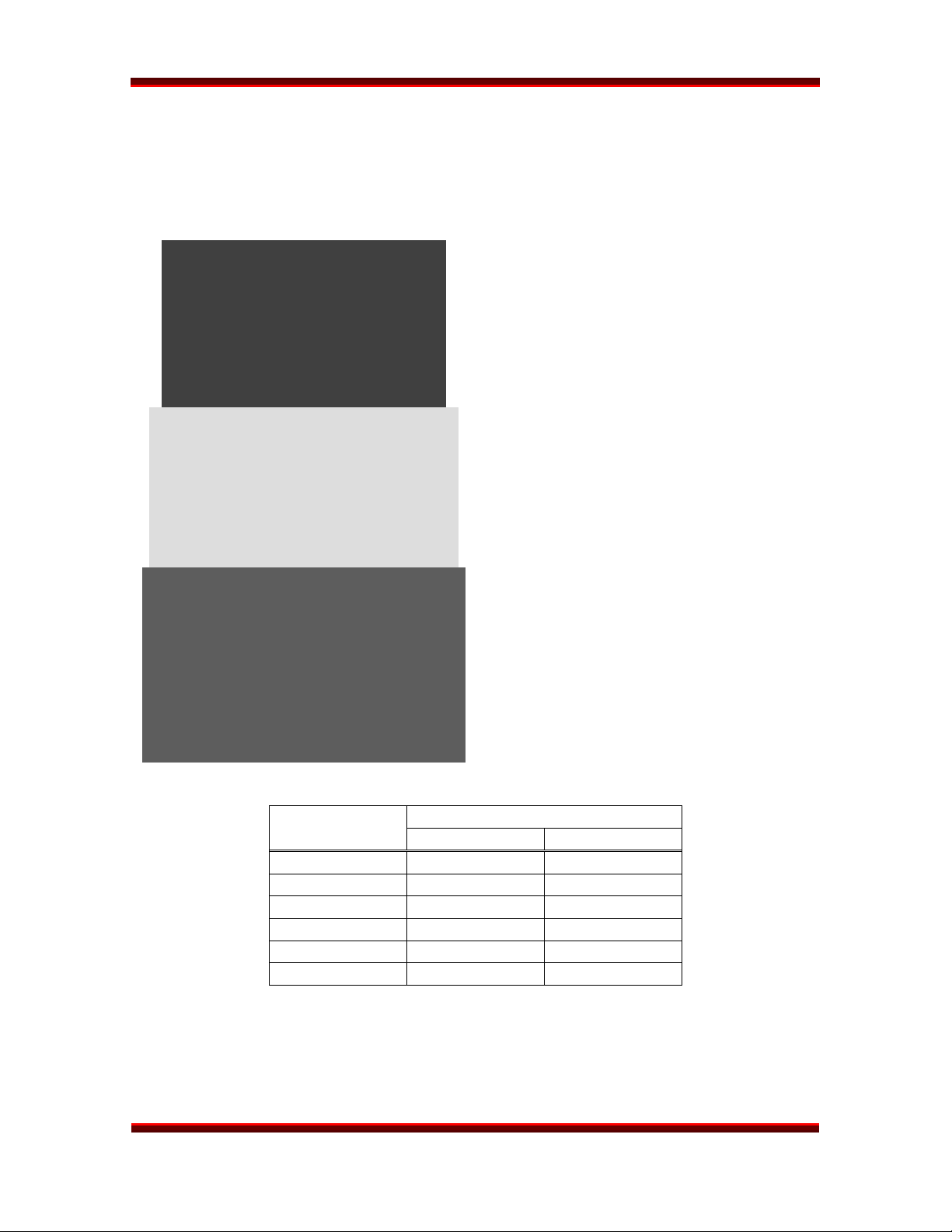

ADDING DETERGENT

Detergent must be added to the dispenser before the start of every cycle except

RINSE ONLY. The detergent chamber holds 1.4 oz. (40 g) when full. If the

dishes are only moderately dirty, it might be possible to use less detergent.

Press the latch button to open the

detergent chamber.

Add detergent in the proper amount.

(See chart, below.)

Close the cover and be sure the latch

clicks.

If pre-wash cycle is selected (in SOAK

or POWER SCRUB only), add the

appropriate amount of pre-wash

detergent in the recess on the door

cover. When you close the dishwasher

door, the detergent will fall into the tub.

NOTE: Too much detergent can leave

a film on the dishes.

CYCLE

Amt. Detergent

Soak Full (0.35 oz.) ¾ full (1.05 oz.)

Power Scrub Full (0.35 oz.) ¾ full (1.05 oz.)

Normal None ½ full (0.7 oz.)

Steam Delicate None ½ full (0.7 oz.)

Quick None ¼ full (0.3 oz.)

Rinse Only None ½ full (0.7 oz.)

LDF9810ST Page 14 DISHWASHER

Page 17

LDF9810ST DISHWASHER

ADDING RINSE AID

Turn the round cap counterclockwise

and remove it.

Fill the reservoir. It holds 4.8 oz.

(145 ml)

Replace the cap and lock it.

Adjust the rinse-aid setting

as necessary.

The factory setting for rinse aid dispensing is 3. Too little rinse aid contributes to

spotting, streaking, and poor drying performance. Too much rinse aid causes

foaming, which leads to poor washing performance.

How often you refill the dispenser depends upon your washing habits, including

the rinse aid setting, the number of loads per month you wash, and other factors.

The indicator light will illuminate when the level is low at the start of a load.

LDF9810ST Page 15 DISHWASHER

Page 18

LDF9810ST DISHWASHER

PROGRAM CHART

LDF9810ST Page 16 DISHWASHER

Page 19

LDF9810ST DISHWASHER

TEST MODE

LDF9810ST Page 17 DISHWASHER

Page 20

LDF9810ST DISHWASHER

TROUBLESHOOTING ERROR CODES

ERROR CODE POSSIBLE CAUSE SOLUTION

INLET ERROR

Water not to

normal level after

10 minutes’ fill

time

DRAIN ERROR

Not completely

drained after 5

minutes’ drain

time

LEAKAGE

ERROR

Excessive motor

RPM due to

water leakage

FILL ERROR

Excess water

supplied and

drain pump runs

automatically

• Water supply valve closed

• Water supply shut off

• Inlet hose kinked

• Water pressure low (below

10 psi)

• Inlet valve defective

• Inlet valve filter clogged

• Hall sensor defective

• Input impeller is bound

• Drain hose kinked or

blocked

• Wiring connection defective

• Drain outlet of sump

blocked

• Drain pump, drain motor, or

drain circuit is defective

• Water leakage in hose

connections

• Water leak from damage

• Sump seal leakage

• Drain hose not high enough

• Washing pump impeller is

damaged or worn

• Inlet valve defective

• Main board defective

• Check valve

• Check resistance of valve

(950~1,300Ω)

• Clean the inlet filter

• Check frequency in test

mode (page 13)

• Replace air breaker

• Remove the kink or

blockage

• Check the wiring

connection

• Check the sump for

blockage

• Measure the resistance of

drain motor (20 ~ 40 Ω)

Replace motor or repair

circuit

• Replace hose connections

• Repair damage

• Reseat or replace seal

• Adjust hose to meet

installation requirements

• Replace impeller of

washing pump

• Replace inlet valve

• Replace main board

LDF9810ST Page 18 DISHWASHER

Page 21

LDF9810ST DISHWASHER

ERROR CODE POSSIBLE CAUSE SOLUTION

• Inlet water temperature too

hot (over 194° F or 90 °C)

THERMAL

ERROR

Water not to

normal level after

10 minutes’ fill

time

LOCK ERROR

Motor is locked

or hall sensor is

defective.

STEAM GENERATOR ERROR CODES

ERROR CODE

00 : EO

00 : E1

00 : E2

00 : E3

00 : E4

00 : E5

• Wiring connection defective

• Thermistor defective

• Wiring connection loose

• Wash pump impeller locked

• Wash motor rotor is locked

• Blade is locked

CONDITION SOLUTION

Normal

Steam generator

temperature is too high

(over 239° F or 115° C)

Water level sensor failure Check water level sensor

Water level too low Check water level sensor

Steam generator

temperature is too low

(under 158° F or 70° C)

Normal

• Check water temperature

using TEST MODE (See

Page 13.)

If temperature is

displayed, adjust water

temp. to 120° F (40° C).

If temp. is not displayed,

check wiring connections

and resistance of the

thermistor (11~14 KΩ @

77° F or 25° C).

• Check wiring connections

• Check wash pump for

blockage

• Replace wash motor

• Check the sump for

blockage

• Replace the main board

Check water level sensor

and thermistor

and connection

and inlet valve

Check heater and

thermistor

LDF9810ST Page 19 DISHWASHER

Page 22

LDF9810ST DISHWASHER

TROUBLESHOOTING

NO POWER WHEN THE POWER BUTTON IS PRESSED

LDF9810ST Page 20 DISHWASHER

Page 23

LDF9810ST DISHWASHER

WASH PUMP / MOTOR DOES NOT RUN

LDF9810ST Page 21 DISHWASHER

Page 24

LDF9810ST DISHWASHER

WASHING RESULTS ARE UNSATISFACTORY

DRYING RESULTS ARE UNSATISFACTORY

LDF9810ST Page 22 DISHWASHER

Page 25

LDF9810ST DISHWASHER

POWER BUTTON NOT AUTOMATICALLY OFF AFTER OPERATION

LDF9810ST Page 23 DISHWASHER

Page 26

LDF9810ST DISHWASHER

DISASSEMBLY / REPAIR

Before disassembling the dishwasher:

• Unplug the dishwasher or turn off the breaker (or fuse)

Disconnect the wire if the dishwasher is hard-wired.

• Turn of the water supply

• Remove all dishes and racks

• Disconnect the water supply line to avoid hose damage

• Have some towels ready to catch the spillage from water left in the

dishwasher and to keep the floor safe.

LOWER COVER AND INSULATION

Remove the two screws in the

lower cover.

Remove the insulation.

Disconnect the water supply hose and

the electric cable if you are removing

the dishwasher for service.

CABINET AND TUB INSULATION

Right Cabinet –

Remove two screws at the front and

three screws at the rear.

Left Cabinet –

Remove two screws at the front and

three screws at the rear.

Insulation –

Remove the insulation blanket

carefully by lifting straight up.

LDF9810ST Page 24 DISHWASHER

Page 27

LDF9810ST DISHWASHER

DOOR ASSEMBLY

FRONT COVER

Open the door.

Remove 12 screws (stainless steel).

CONTROL PANEL ASSEMBLY

Remove 2 screws (stainless steel).

Remove the wire connections.

(Do not reverse at reassembly!)

Remove the latch assembly.

Remove the front display.

Remove 8 screws to take out the

controller (main board).

Reassembly is the reverse order of

disassembly. Be careful to avoid

reversing the connectors.

LDF9810ST Page 25 DISHWASHER

Page 28

LDF9810ST DISHWASHER

DOOR ASSEMBLY, continued

FAN ASSEMBLY

Remove the front cover.

(See page 25.)

Remove 4 screws and a ground screw

for the door bracket.

Remove the wire connections from the

fan.

Remove the air duct.

Unscrew the inner cover to remove the

fan assembly.

DETERGENT DISPENSER

Remove the wire connections.

Remove the 2 brackets (6 screws).

Use a screwdriver to pry the flange up

to release the dispenser (above left.)

DOOR SPRING (Right and Left)

Pull the spring upward and take it off

the hinge bracket.

Take the spring off the hinge.

DOOR LINER

Open the door.

Pull the door liner upward off the hinge

supporter.

LDF9810ST Page 26 DISHWASHER

Page 29

LDF9810ST DISHWASHER

LOWER FRAME

Press the holder hooks as shown.

Remove the 4 screws.

Turn the dishwasher upside down.

DRAIN HOSE HOLDER

Press the holder hook as shown.

Pull the drain hose and remove the

drain hose holder.

BASE COVER

Remove 2 screws.

Lift the base cover out of the base.

LDF9810ST Page 27 DISHWASHER

Page 30

LDF9810ST DISHWASHER

LINE NOISE FILTER

Disconnect both connectors of the line

noise filter.

FLOAT SWITCH ASSEMBLY

Remove the connections from the float

assembly micro switches. Mark them to

ensure you can reconnect them

correctly after repairs.

WIRING DIAGRAM

The wiring diagram is attached to the

back of the lower cover.

CABINET BASE

Remove 8 screws around the base.

Lift the base upward off the

dishwasher.

FLOAT ASSEMBLY

Press the hook to separate the float

assembly.

Pull the float assembly free.

LDF9810ST Page 28 DISHWASHER

Page 31

LDF9810ST DISHWASHER

STEAM GENERATOR

Squeeze the hose clamps and remove

the 3 hoses from the steam generator.

Remove 2 screws to take out the

steam generator.

NOTE: Be careful in case the steam

generator is still hot or has hot water

in it.

The steam generator is sold as an

assembly. The individual parts (heater,

thermistor, and sensor) are not

repairable or replaceable.

INLET VALVE

Disconnect the water supply line.

Remove the electrical ground wire.

Remove 2 screws that hold the valve to

the base and take out the valve.

AIR BREAKER ASSEMBLY

Disconnect three hoses from the air

breaker assembly.

Unscrew the cover on the inside of the

dishwasher.

Be sure not to lose the gasket (O-ring)

that fits between the outside of the tub

and the air breaker assembly.

LDF9810ST Page 29 DISHWASHER

Page 32

LDF9810ST DISHWASHER

SUMP ASSEMBLY

Remove the wiring connections,

including the ground wires attached

by screws.

Remove the hose connections.

Lift the sump assembly out of the base

of the dishwasher.

Remove the 2 screws and sump holder

clips. Be careful not to let the sump

assembly fall into the tub.

Press the hooks gently toward the

center of the sump assembly and lower

the sump assembly into the tub while

supporting it with one hand.

HEATER and DRAIN MOTOR

Loosen the nut on the heater retainer

to the end of the shaft and wiggle the

heater out of the sump.

Remove 3 screws and detach the drain

pump from the sump.

VARIO MOTOR

Remove 2 screws that attach the vario

motor to the sump.

Remove the vario motor and the micro

switch.

LDF9810ST Page 30 DISHWASHER

Page 33

LDF9810ST DISHWASHER

SOIL SENSOR

Lift the retaining clips and pull the soil

sensor (turbidity sensor) from the

sump.

REASSEMBLY

When reassembling the sump. be

careful to avoid kinking or damaging

the small seals and gaskets inside it.

(See page 39 in the exploded view.)

LDF9810ST Page 31 DISHWASHER

Page 34

LDF9810ST DISHWASHER

CUTLERY RACK RAIL

Insert a screwdriver in the gap behind

the rail at the back end and pry the end

cap off. It is easily broken, so have a

replacement available.

UPPER RACK RAIL

Pull the upper rack out until it stops.

Squeeze the tab of the stopper and pull

the stopper out. Be careful the upper

rack does not fall out of the rail while

you do this.

Pull the upper rack out of the slides.

LDF9810ST Page 32 DISHWASHER

Page 35

LDF9810ST DISHWASHER

WIRING DIAGRAM

LDF9810ST Page 33 DISHWASHER

Page 36

LDF9810ST DISHWASHER

EXPLODED VIEWS

LDF9810ST Page 34 DISHWASHER

Page 37

LDF9810ST DISHWASHER

EXPLODED VIEWS, continued

LDF9810ST Page 35 DISHWASHER

Page 38

LDF9810ST DISHWASHER

EXPLODED VIEWS, continued

LDF9810ST Page 36 DISHWASHER

Page 39

LDF9810ST DISHWASHER

EXPLODED VIEWS, continued

LDF9810ST Page 37 DISHWASHER

Page 40

LDF9810ST DISHWASHER

EXPLODED VIEWS, continued

LDF9810ST Page 38 DISHWASHER

Page 41

LDF9810ST DISHWASHER

EXPLODED VIEWS, continued

LDF9810ST Page 39 DISHWASHER

Page 42

LDF9810ST DISHWASHER

r

)

SERIAL NUMBERS

[Example] 801KW3400251

801

KW

34

00251

Production Numbe

[Internal code]

Made in Korea

Manufactured January 2008

New Serial Code (ETA Mid 2008)

12345 KR 406 YP 000002 + Options

Sequential number

Internal code

Year and month of production (YMM

Production site (2 Letters)

Model ID

LDF9810ST Page 40 DISHWASHER

Page 43

LDF9810ST DISHWASHER

PARTS LIST

Loc. Part Number Description Qty.

*001 AFN31666719 Owner's Manual 1

*002 3890DZ3015A Box, Carton 1

*003 MFL37554802 Manual, Service 0

*005 5001DD4001A Accessory Assembly 1

A003 ACV34326901 Damper (Insulation) 1

A005 4810DD4002B Bracket, Top 2

A006 4980ED2015A Supporter, Holder 1

A007 4980ED2014A Supporter, Holder 1

A008 4980ED2018B Supporter, Holder 1

A010 3090ED1001F Cabinet 1

A020 3091DD1001F Cabinet Assembly 1

A040 3551DD2001E Cover Assembly, Lower 1

A050 5249DD1002Q Nozzle Assembly, Lower 1

A060 5249DD1001A Nozzle Assembly, Upper 1

A070 4975DD1002A Guide Assembly, Upper Nozzle 1

A073 1WZZDD3001A Washer, Common 1

A074 4370ED3007A Shaft, Nozzle 1

A101 MEB38945801 Handle (Rack) 1

A102 MEB38945901 Handle (Rack) 1

A103 MEB38946001 Handle (Rack) 1

A110 5005DD1001B Basket Assembly, Spoon 1

A120 EAD38156501 Harness, Multi 1

A130 AEM30700301 Hose Assembly, Drain 1

A140 AHB33839701 Rack Assembly, Lower 1

A141 MGR38994701 Rack 1

A142 4581DD3003B Roller Assembly 8

A144 3750DD2003A Rack 2

A145 4930ED3003D Holder 1

A146 4930ED3004D Holder 1

A147 4930DD3006A Holder 1

A148 3750DD1001A Rack 1

A149 3750DD1002A Rack 1

A150 AHB33839501 Rack Assembly, Upper 1

A151 MGR38994101 Rack 1

A155 AEC32598702 Guide Assembly, Right 1

A156 AEC32598602 Guide Assembly, Left 1

A157 4930DD3003B Holder 2

A158 4930DD3005A Holder 2

A159 3750DD2002A Rack 2

A160 6201EC1006A Filter Assembly, AC Line 1

LDF9810ST Page 41 DISHWASHER

Page 44

LDF9810ST DISHWASHER

Loc. Description Part Number Qty.

A165 MGR38994201 Rack, Tine 1

A170 AHB33839401 Rack Assembly, Cutlery 1

A171 MJS38945601 Tray, Cutlery 2

A172 MGR38994001 Rack, Cutlery 1

A173 AEC33858601 Guide As’mbly, Cutlery Rack, Right 1

A174 AEC33858701 Guide As’mbly, Cutlery Rack, Left 1

A175 MEG38945701 Holder, Cutlery Rack 2

A301 1SBF0402418 Screw, Taptite, Latch Lock 1

E010 4830ED4001A Bush 2

F001 3211DD1001A Frame Assembly 1

F004 5249DD2001A Nozzle Assembly, Top 1

F005 4370ED3006A Shaft, Nozzle, Top 1

F011 4970ED4004G Spring, Hinge 2

F013 4933DD3001A Connector Assembly 2

F014 4810ED4004A Bracket, Hinge 2

F022 6501DD2001A Sensor Assembly 1

F040 4975ED1005B Guide Assembly 1

F041 AEM34434401 Hose Assembly, Connector 1

F042 5214DD3003A Hose, Connector 1

F043 MEJ39603301 Hose, Connector 1

F045 3550DD2001A Cover, Protect 1

F050 4020FD3641C Nut, Common 1

F060 4986DD3001A Gasket 1

F101 3920DD3002A Packing 1

F110 4581DD3001A Roller Assembly, Third Rack, Left 2

F118 4620ED3003A Stopper, Roller 1

F121 MJB32864101 Stopper, Roller, Upper Rack Rail 1

F122 MGT32863801 Rail, Upper Rack 2

F123 AEN32597901 Housing Assembly, Bearing 2

F132 3920DD3005A Packing, Tub 1

F141 4775DD2001A Hinge Assembly, Door 1

F142 4775DD2002A Hinge Assembly, Door 1

F143 4775ED3004A Hinge Assembly, Tub 1

F144 4775ED3003A Hinge Assembly, Tub 1

F171 4026DD3001A Locker, Lock 1

F174 4810DD1001A Bracket, Hinge 1

F191 MEA36937101 Guide, Water 1

F192 4974DD3001A Guide, Nozzle 1

F210 4581DD3001B Roller Assembly, Third Rack, Right 2

F230 4810DD4005A Bracket, Tub 2

F240 6913ER4001B Lamp, Incandescent 2

F300 AGB33696301 Steam Nozzle Assembly 1

K001 4924FD2123E Dispenser 1

LDF9810ST Page 42 DISHWASHER

Page 45

LDF9810ST DISHWASHER

Loc. Description Part Number Qty.

K002 4810FD3805A Bracket Assembly 2

K005 AED33189701 Handle Assembly 1

K010 3550ED0001J Cover, Front 1

K030 3551DD1003K Cover Assembly, Front 1

K100 4937DD1001B Door Liner, Casing/Dispenser/Vent 1

K101 AGM34891601 Assembly (door liner, insul, gasket) 1

K110 5835ED2002D Impeller Casing Assembly 1

K121 5834FD3666A Impeller Gasket 1

K122 3550ED3011A Cover, Blower 1

K124 MJZ36939301 Vent 1

K200 AGL33667101 Panel Assembly, Control 1

K207 MCK40133201 Cover, Guide 7

K215 MCK40228201 Cover, Guide 5

K220 AFZ34353901 Name Plate Assembly 1

K251 EBR38144401 PCB Assembly, Main 1

K252 EBR38145001 PCB Assembly, Display 1

K253 EBR38145201 PCB Assembly, Display 1

K260 4027ED3002D Locker Assembly 1

K301 4000FD4268A Screw, Custom, Door Liner Hinge 4

K302 1SZZED3001A Screw, Custom, Door Liner, Cover 6

K303 1SZZED3002A Screw, Custom, Door Latch 2

K304 1SZZED3003A Screw, Custom, Front Cover 6

M001 4930DD3002A Holder 1

M005 MDS37912401 Sump Gasket 1

M006 AJH31248603 Sump Assembly 1

M007 AJH32598001 Sump Assembly 1

M025 MJX32862501 Valve, Check 1

M026 4681ED3001B Vario Motor 1

M027 3W40025C Switch, Micro 1

M028 MBJ32856401 Cam, Switch 1

M031 3920ED4009B Vario Motor Packing 1

M034 5832DD4001A Blade 1

M035 MFZ32863101 Packing 1

M036 4930DD3008A Holder 2

M038 4930DD3012A Holder 1

M050 4681EA2002D Motor Assembly, AC, Drain Pump 1

M060 4681ED1004A Motor Assembly, DC, Washer 1

M081 5301DD1001A Heater Assembly 1

M086 3W40025P Switch, Micro 2

M087 6501ED2002F Sensor Assembly, Turbidity 1

M088 3740ED3003A Cover 1

M090 4769DD2001B Float Assembly 1

M110 ADQ32598202 Filter Assembly, Mesh 1

LDF9810ST Page 43 DISHWASHER

Page 46

LDF9810ST DISHWASHER

Loc. Description Part Number Qty.

M120 ABQ32598101 Pump Case Assembly 1

M130 5911ED3003A Impeller Assembly 1

M210 AJU33450701 Valve Assembly, Inlet 1

M220 5220ED4004A Valve, Check 1

M260 MAM34326301 Base, Cabinet 1

M261 ACQ31707201 Cover Assembly, Base 1

M262 3110DD3002A Case 1

M270 4778DD3001A Leg 4

M300 5001DD2001C Accessory Assembly 1

M301 4W51229F Screw, Customized 4

M302 1SZZED3005A Screw, Customized 8

M303 1SZZED3006A Screw, Customized 1

M304 1SZZFA4305A Screw, Customized 3

M305 4W51194D Screw, Customized 4

M500 ADZ32992801 Steam Generator Assembly 1

LDF9810ST Page 44 DISHWASHER

Page 47

LDF9810ST DISHWASHER

OHM’S LAW and WATT’S LAW

P = WATTS

Watts = Volts2 x Ohms

Watts = Amperes

Watts = Volts x Amperes

2

x Ohms

I = AMPERES

Amperes = Volts / Ohms

Amperes = Watts / Volts

Amperes =

2

IR

•

2

E/R

PR

•

P/I

•

EI

P

WATTS

VOLTS

E

E/R

I

CURRENT

OHMS

R

P/E

P/R

2

P/I

2

E/P

•

IR

E = VOLTS

Volts =

Volts = Watts / Amperes

Volts = Amperes x Ohms

LDF9810ST Page 45 DISHWASHER

E/I

R = OHMS

Ohms = Volts / Amperes

Ohms = Volts2 / Amperes

Ohms = Watts / Amperes

2

Page 48

LDF9810ST DISHWASHER

CONVERSION INFORMATION

FORMULAE

°F = (9/5) °C + 32

°C = (5/9) x (°F – 32)

ml X 30 = ounces

LDF9810ST Page 46 DISHWASHER

Page 49

LDF9810ST DISHWASHER

SERVICE BULLETINS

The bulletins included here were current and accurate at the time this manual

was printed. The servicer is encouraged to check GCSC regularly for new and

updated bulletins.

LDF9810ST Page 47 DISHWASHER

Page 50

LDF9810ST DISHWASHER

LDF9810ST Page 48 DISHWASHER

Page 51

LDF9810ST DISHWASHER

LDF9810ST Page 49 DISHWASHER

Page 52

LDF9810ST DISHWASHER

SERVICE BULLETIN

DRAIN INSTALLATION

LDF9810ST Page 50 DISHWASHER

Page 53

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 51 DISHWASHER

Page 54

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 52 DISHWASHER

Page 55

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 53 DISHWASHER

Page 56

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 54 DISHWASHER

Page 57

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 55 DISHWASHER

Page 58

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 56 DISHWASHER

Page 59

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 57 DISHWASHER

Page 60

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 58 DISHWASHER

Page 61

LDF9810ST DISHWASHER

SERVICE BULLETIN

LDF9810ST Page 59 DISHWASHER

Page 62

LDF9810ST DISHWASHER

NOTES

LDF9810ST Page 60 DISHWASHER

Page 63

Page 64

Dishwasher - Spring 2008

Page 65

Page 66

Loading...

Loading...