Page 1

DISHWASHER

SERVICE MANUAL

NOTE

BEFORE SER VICING THE UNIT, PLEASE READ THIS MANUAL CAREFULL Y

FOR SAFETY AND CORRECT SER VICES.

For Authorized Service Technician

MODEL : LDF8874ST

LDF8764ST

LDF7774ST/WW/BB

LDS5774ST

LDT9965BD

Page 2

Page 3

For Authorized Service Technician

CONTENTS

CONTENTS

1. CAUTION......................................................................................................................... 4

2. SPECIFICATIONS ........................................................................................................... 5

3. FEATURES & TECHNICAL EXPLANATION ................................................................... 6

4. PARTS NAME ................................................................................................................ 15

5. PROGRAM CHART ..................................................................................................... 16

6. HOW TO DISASSEMBLE ............................................................................................ 18

7. TROUBLE SHOOTING METHODS.............................................................................. 27

A. TROUBLE SHOOTING ACCORDING TO DISPLAYED ERROR MESSAGE...........27

B. STEAM GENERATOR ERROR MESSAGE............................................................ 29

C. TROUBLE DIAGNOSES AND REPAIR BY SYMPTOM .......................................... 42

8. INSTALLATION INSTRUCTION ................................................................................... 46

9. EXPLODED VIEW .......................................................................................................53

10. WIRING DIAGRAM

........................................................................................................

67

- 3 -

Page 4

For Authorized Service Technician

CAUTION !

DISCONNECT POWER CORD BEFORE SERVICING

RECONNECT ALL GROUNDING DEVICES

IMPORTANT SAFETY NOTICE !

This service information is intended for individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience.

Any attempt to repair this appliance may result in

personal injury and property damage.

The manufacturer or seller can not be responsible

for the interpretation of this information, nor can it

assume any liability in connection with its use.

- 4 -

Page 5

2. SPECIFICATION

)1

lE

2. SPECIFICATION

For Authorized Service TechnicianFor Authorized Service Technician

ITEM

Rated Voltage / FrequencyAC 120V/60Hz

Installation Built-In

Place Settings 14

Product Dimension(in) 23 3/4"x 24 5/8"x 33 1/2"

Product Weight(lbs

Door Color White, Black, Stainless, Black Diamond

Tub Material Stainless Steel

Contro

Rated Power(Watt) 1,350

Heater Power(Watt) 1,200

Programs6 (LDS5774 : 7), (LDT9965 : 5)

Upper Rack Position Adjustable

Lower Rack 100 % Fold down

Water Consumption

SPECIFICATION

14lbs

lectronic

6.5 – 20.5 (Normal)

Power Consumption(kWh/year) 258 (Nomal)

Operating Time (min) 110 – 130 (Normal)

Fan Dry System Yes

Delay Start Function Yes

Auto-Off Power Switch Yes

Process Monitor Yes

Wash Level 5

Racks Nylon Coating

Operating Water Pressure (Bar) 20-120 (140-830kPa)

- 5 -

Page 6

For Authorized Service Technician

3. FEATURES & TECHNICAL EXPLANATION

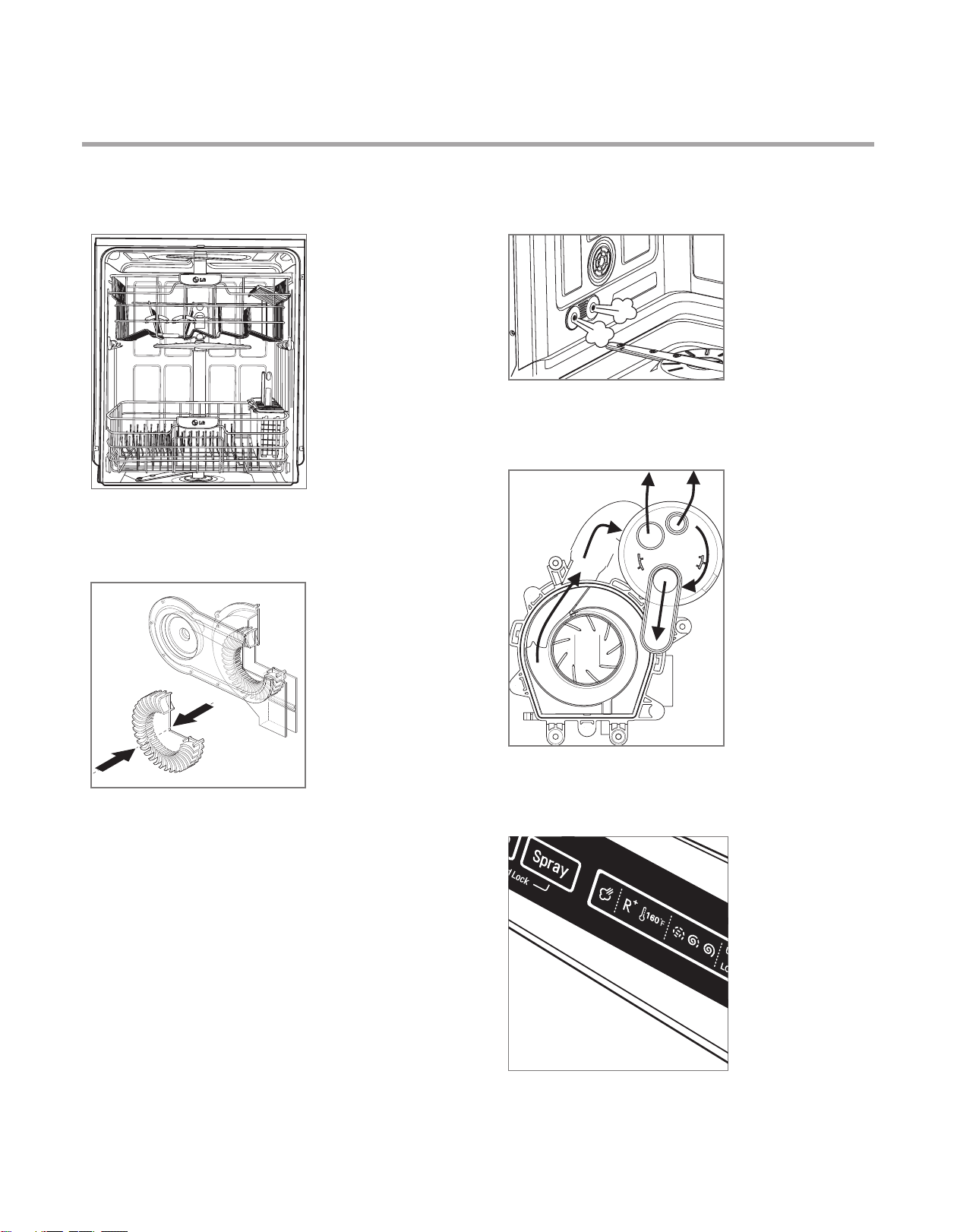

3-1. Product Features

LARGE CAPACITY

HYBRID DRYING SYSTEM

LG dishwashers allow

you to load very large

items in both the upper

and lower racks. The

tall tub provides extra

overall capacity and the

clearance to accommodate large dishes. Extra

large items (max. 14 in.)

may be loaded in the

lower rack by raising the

upper rack.

This system eectively

dries dishes without the

use of a heating element

that would increase energy consumption.

STEAM WASHING (not available on all models)

Steam technology provides better cleaning

performance than regular wash systems. Steam

is the most energy efcient gentle care for

your nest china and

stemware.

VARIABLE SPRAY SYSTEM

Because the water spray

alternates between the

upper and lower racks,

all of the power from

the motor is directed

to one rack at a time.

This concentrates all the

cleaning power of the

motor on each rack in

turn.

- 6 -

LIGHT TOUCH BUTTONS

The light touch buttons

on the control panel

make selections easy

and convenient.

Page 7

3-2. Display Panel

<ZI][M:MNZM[P;\MIUၦხཅ૬ᅰ

CONTROL PANEL (steam models)

Steam Models (LDF8874, LDF8764)

For Authorized Service TechnicianFor Authorized Service Technician

LDF8874 / LDF8764

Cycles

Select your desired cycle.

Auto

This cycle senses the load size, soil amount and soil toughness. This cycle is optimized to achieve the best cleaning.

Heavy

This cycle is for heavily and hard soiled dishes. Heavy defaults

to the highest spray intensity and uses the power of steam to

wash heavily soiled dishes.

Delicate

This cycle adds the gentle power of steam to boost the cleaning power of the delicate cycle. The cycle is intended for effectively cleaning delicate items such as ne china and stemware.

Dual Control

This cycle washes the upper and lower racks at dierent spray

intensities. The default setting for this cycle washes the lower rack with strong spray intensity and the upper rack with

soft spray intensity. This provides optimum cleaning performance for mixed loads, including ne china and stemware. If

other combinations are desired, use the steps listed below to

change the intensities or to use the Half Load feature.

How To Use Dual Control:

1. Select Dual Control.

2. Press the Spray button to toggle between Soft, Medium

and Strong for the upper spray arm.

3. After making your selection for the upper spray arm, press

the Half Load button.

4. Press the Spray button to toggle between Soft, Medium

and Strong for the lower spray arm.

5. Close the door to start the cycle.

Normal

This cycle is for normally soiled, everyday loads.

Quick & Dry

This is a shortened c ycle that is intended for washing and dr ying recently used dishes or lightly soiled loads. During this

cycle, both spray arms will run at the same time.

CHIME ON/OFF

To enable or disable the chime, rst, turn on the dishwasher.

Press and hold the Delicate and Quick&Dry Buttons simultaneously for approximately three seconds.

TO CANCEL A CYCLE

To cancel a cycle, open the door and then press and hold the

Delicate and Dual Control Buttons together for approximately three seconds. The drain pump will activate and the cycle

will cancel. The display will show “dr” and the dishwasher will

drain the water. After the dishwasher is drained, the power

will turn o.

If the power is turned on and no cycle has been selected, the

dishwasher will power o within four minutes.

Cycle Options

(Refer to the control panel on the next page)

Press the desired cycle and then select the options for that

cycle.

Extra Dry

Select the Extra Dry option for better drying performance.

This option adds 60 minutes of extra drying time to the cycle.

The Extra Dry button will illuminate when the option has

been selected.

Rinse

Repeated pressing of the Rinse button will select the desired

Rinse option. The Sanitary, Extra Rinse, or Sanitary and Extra

Rinse lights will show in the bottom left portion of the display.

Sanitary ( )

This high-temperature rinse sanitizes dishes and glassware in

accordance with NSF/ANSI Standard 184 for residential dishwashers. Certied dishwashers are not intended for licensed

food establishments.

Extra Rinse ( R+ )

The Extra Rinse symbol indicates that an extra rinse has been

added to the cycle. An extra rinse can help reduce hard water

spotting on dishes. To add an extra rinse, press the Rinse button repeatedly until the Extra Rinse symbol appears in the

display.

Rinse Only (LDF****)

This cycle is a quick rinse for dishes that will not be washed

immediately. This cycle will rinse dishes that have excess soil

to soften dried on residue. Rinsing the dishes will help prevent odors in the dishwasher. No detergent should be used.

To select the Rinse Only cycle, turn the dishwasher on, and

press the Rinse button once without pressing any other cycle

buttons.

cycles.

The Rinse Only cycle is not available with any other

- 7 -

Page 8

CONTROL PANEL (non-steam models)

<ZI][M:MNZM[P;\MIUၦხཅ૬ᅰ

<ZI][M:MNZM[P6WV[\MIUၦხཅ૬ᅰ

Display varies by model (LDF7774)

For Authorized Service Technician

LDF7774 / LDS5774

Display varies by model (LDS5774)

Cycles

Select your desired cycle.

Auto

This cycle senses the load size, soil amount and soil toughness. This cycle is optimized to achieve the best cleaning.

Heavy

This cycle is for heavily and hard soiled dishes.

Delicate

The cycle is intended for eectively cleaning delicate items

such as ne china and stemware.

Dual Control

This cycle washes the upper and lower racks at dierent spray

intensities. The default setting for this cycle washes the lower rack with strong spray intensity and the upper rack with

soft spray intensity. This provides optimum cleaning performance for mixed loads, including ne china and stemware. If

other combinations are desired, use the steps listed below to

change the intensities or to use the Half Load feature.

How To Use Dual Control:

1. Select Dual Control.

2. Press the Spray button to toggle between Soft, Medium

and Strong for the upper spray arm.

3. After making your selection for the upper spray arm, press

the Half Load button.

4. Press the Spray button to toggle between Soft, Medium

and Strong for the lower spray arm.

5. Close the door to start the cycle.

Normal

This cycle is for normally soiled, everyday loads.

Quick & Dry

This is a shortened c ycle that is intended for washing and dr ying recently used dishes or lightly soiled loads. During this

cycle, both spray arms will run at the same time.

Rinse Only (LDS5774)

This cycle is a quick rinse for dishes that will not be washed

immediately. This cycle will rinse dishes that have excess soil

to soften dried on residue. Rinsing the dishes will help prevent odors in the dishwasher. No detergent should be used.

CHIME ON/OFF

To enable or disable the chime, rst, turn on the dishwasher.

Press and hold the Delicate and Quick&Dry Buttons (LDS5774:

Spray and Delay Start) simultaneously for approximately

three seconds.

TO CANCEL A CYCLE

To cancel a cycle, open the door and then press and hold the

Delicate and Dual Control Buttons (LDS5774: Spray and Half

Load) together for approximately three seconds. The drain

pump will activate and the cycle will cancel. The display will

show “dr” and the dishwasher will drain the water. After the

dishwasher is drained, the power will turn o.

If the power is turned on and no cycle has been selected, the

dishwasher will power o within four minutes.

- 8 -

Page 9

CONTROL PANEL

Display varies by model (LDF8874, LDF8764)

Display varies by model (LDF7774)

For Authorized Service TechnicianFor Authorized Service Technician

LDF8874 / LDF8764 / LDF7774

Spray (INTENSITY)

First, select the desired cycle. Press the Spray button repeatedly until the desired spray intensity is selected.

Soft ( ), Medium ( ), Strong ( )

Half Load

For small loads, you may use just the upper or lower rack to

save energy. Each press of the Half Load button cycles between upper rack only and lower rack only.

Delay Start

The Delay Start feature allows you to delay the start of a selected cycle. Each time the Delay Start button is pressed, the

delay time will increase an hour. The delay start time can be

set from 1 to 19 hours, in one-hour increments.

High Temp ON/OFF

Raises the main wash temperature to improve cleaning.

Press and hold the Extra Dry and Rinse buttons simultaneously for approximately three seconds.

Child Lock

The Child Lock feature helps prevent your settings from being changed during a cycle. Selecting this feature locks all

of the buttons, except for the POWER button, on the control

panel. This feature does not lock the door.

To activate the Child Lock:

1. Open the dishwasher door.

2. Press the POWER button.

3. Select the cycle (and desired options).

4. Press and hold the Rinse and Spray buttons for three seconds. The Child Lock indicator will illuminate in the display

once the Child Lock is activated.

5. Close the door to begin the cycle.

Digital Display

The Digital Display on the control panel shows the ESTIMATED cycle time. When the dishwasher is powered up, the display will be blank. When the cycle and options are selected,

the display will show the total estimated time to complete

those selections. During operation, the display shows the remaining estimated operating time.

NOTE

• The estimated time shown in the display does not include delay times for heating water, etc.

• If Delay Start is selected, the display shows the delay

time in hours.

• Time may vary depending on the soil level of your load.

Energy Saving

The Energy Saving option saves energy by using less water.

This option should only be used with light to medium soiled

dishes.

NOTE

The RINSE AID symbol

needs to be relled.

POWER

• Press the POWER button to turn on the control panel. If no

cycle is selected within four minutes, the dishwasher will

power o.

• After the cycle is complete, the power automatically turns

o for purposes of safety and economy.

• If there is a power surge, power outage, or disruption of

any kind, the PF indicator will display and power will be automatically turned o for safety. The cycle will need to be

restarted.

Smart Diagnosis

Should you experience any problems with your dishwasher,

it has the capability of transmitting data to your Smart Phone

using the LG Smart Laundry & DW Application or via your

telephone to the LG call center.

indicates that the rinse aid

WARNING

Steam can cause burns. Use caution in the area of the steam nozzle, on the left side of the dishwasher, if the door is opened during

the steam portion of a cycle. Contact with the steam or the steam

nozzle can cause burns.

- 9 -

Page 10

CONTROL PANEL

Display varies by model (LDS5774)

For Authorized Service Technician

LDS5774

Cycle Options

Press the desired cycle and then select the options for that

cycle.

Extra Dry ( )

Select the Extra Dry option for better drying performance.

This option adds 60 minutes of extra drying time to the cycle.

The Extra Dry button will illuminate when the option has

been selected.

Press and hold the Rinse and Spray but tons for three seconds.

Rinse

Repeated pressing of the Rinse button will select the desired

Rinse option. The Sanitary, Extra Rinse, or Sanitary and Extra

Rinse lights will show in the bottom left portion of the display.

Sanitary ( )

This high-temperature rinse sanitizes dishes and glassware in

accordance with NSF/ANSI Standard 184 for residential dishwashers. Certied dishwashers are not intended for licensed

food establishments.

Extra Rinse ( R+ )

The Extra Rinse symbol indicates that an extra rinse has been

added to the cycle. An extra rinse can help reduce hard water

spotting on dishes. To add an extra rinse, press the Rinse button repeatedly until the Extra Rinse symbol appears in the

display.

Child Lock

The Child Lock feature helps prevent your settings from being

changed during a cycle. Selecting this feature locks all of the

buttons, except for the POWER button, on the control panel.

This feature does not lock the door.

To activate the Child Lock:

1. Press the POWER button.

2. Select the cycle (and desired options).

3. Press and hold the Half Load and Delay Start buttons for

three seconds. The Child Lock indicator will illuminate in

the display once the Child Lock is activated.

4. Close the door to begin the cycle.

Digital Display

The Digital Display on the control panel shows the ESTIMATED

cycle time. When the dishwasher is powered up, the display

will be blank. When the cycle and options are selected, the

display will show the total estimated time to complete those

selections. During operation, the display shows the remaining

estimated operating time.

NOTE

• The estimated time shown in the display does not include delay times for heating water, etc.

• If Delay Start is selected, the display shows the delay

time in hours.

• Time may vary depending on the soil level of your load.

Spray (INTENSITY)

First, select the desired cycle. Press the Spray button repeatedly until the desired spray intensity is selected.

Soft ( ), Medium ( ), Strong ( )

Half Load ( )

For small loads, you may use just the upper or lower rack to

save energy. Each press of the Half Load button cycles between upper rack only and lower rack only.

Delay Start

The Delay Start feature allows you to delay the start of a selected cycle. Each time the Delay Start button is pressed, the

delay time will increase an hour. The delay start time can be

set from 1 to 19 hours, in one-hour increments.

- 10 -

POWER

• Press the POWER button to turn on the control panel. If no

cycle is selected within four minutes, the dishwasher will

power o.

• After the cycle is complete, the power automatically turns

o for purposes of safety and economy.

• If there is a power surge, power outage, or disruption of any

kind, the PF indicator will display and power will be automatically turned o for safety. The cycle will need to be restarted.

Smart Diagnosis

Should you experience any problems with your dishwasher, it

has the capability of transmitting data to your Smart Phone

using the LG Smart Laundry & DW Application or via your telephone to the LG call center.

Page 11

CONTROL PANEL

For Authorized Service TechnicianFor Authorized Service Technician

LDT9965

Cycles

Select your desired cycle.

Auto

This cycle senses the load size, soil amount and soil toughness. This cycle is optimized to achieve the best cleaning.

Heavy

This cycle is for heavily and hard soiled dishes. Heavy defaults

to the highest spray intensity and uses the power of steam to

wash heavily soiled dishes.

Delicate

This cycle adds the gentle power of steam to boost the cleaning power of the delicate cycle. The cycle is intended for effectively cleaning delicate items such as ne china and stemware.

Dual Wash

This cycle washes the upper and lower racks at dierent spray

intensities. The default setting for this cycle washes the lower

rack with strong spray intensity and the upper rack with soft

spray intensity. This provides optimum cleaning performance

for mixed loads, including ne china and stemware.

Normal

This cycle is for normally soiled, everyday loads.

Quick & Dry

This is a shortened c ycle that is intended for washing and dr ying recently used dishes or lightly soiled loads. During this

cycle, both spray arms will run at the same time.

CHIME ON/OFF

To enable or disable the chime, rst, turn on the dishwasher.

Press and hold the Delicate and Quick&Dry Buttons simultaneously for approximately three seconds.

TO CANCEL A CYCLE

To cancel a cycle, open the door and then press and hold the

Delicate and Dual Wash Buttons together for approximately

three seconds. The drain pump will activate and the cycle

will cancel. The display will show “dr” and the dishwasher will

drain the water. After the dishwasher is drained, the power

will turn o.

If the power is turned on and no cycle has been selected, the

dishwasher will power o within four minutes.

Cycle Options

(Refer to the control panel on the next page)

Press the desired cycle and then select the options for that

cycle.

Extra Dry

Select the Extra Dry option for better drying performance.

This option adds 60 minutes of extra drying time to the cycle.

The Extra Dry button will illuminate when the option has

been selected.

Rinse

Repeated pressing of the Rinse button will select the desired

Rinse option. The Sanitary, Extra Rinse, or Sanitary and Extra

Rinse lights will show in the bottom left portion of the display.

Sanitary ( )

This high-temperature rinse sanitizes dishes and glassware in

accordance with NSF/ANSI Standard 184 for residential dishwashers. Certied dishwashers are not intended for licensed

food establishments.

Extra Rinse ( R+ )

The Extra Rinse symbol indicates that an extra rinse has been

added to the cycle. An extra rinse can help reduce hard water

spotting on dishes. To add an extra rinse, press the Rinse button repeatedly until the Extra Rinse symbol appears in the

display.

Rinse Only

This cycle is a quick rinse for dishes that will not be washed

immediately. This cycle will rinse dishes that have excess soil

to soften dried on residue. Rinsing the dishes will help prevent odors in the dishwasher. No detergent should be used.

To select the Rinse Only cycle, turn the dishwasher on, and

press the Rinse button once without pressing any other cycle

buttons.

cycles.

The Rinse Only cycle is not available with any other

- 11 -

Page 12

CONTROL PANEL

For Authorized Service Technician

LDT9965

Half Load

For small loads, you may use just the upper or lower rack to

save energy. Each press of the Half Load button cycles between upper rack only and lower rack only.

Delay Start

The Delay Start feature allows you to delay the start of a selected cycle. Each time the Delay Start button is pressed, the

delay time will increase an hour. The delay start time can be

set from 1 to 19 hours, in one-hour increments.

High Temp ON/OFF

Raises the main wash temperature to improve cleaning.

Child Lock

The Child Lock feature helps prevent your settings from being changed during a cycle. Selecting this feature locks all

of the buttons, except for the POWER button, on the control

panel. This feature does not lock the door.

To activate the Child Lock:

1. Open the dishwasher door.

2. Press the POWER button.

3. Select the cycle (and desired options).

4. Press and hold the Rinse and High Temp buttons for three

seconds. The Child Lock indicator

play once the Child Lock is activated.

5. Close the door to begin the cycle.

will illuminate in the dis-

NOTE

• The estimated time shown in the display does not include delay times for heating wat

• If Delay Start is selected, the display shows the delay

time in hours.

• Time may vary depending on the soil level of your load.

er, etc.

Energy Saving

The Energy Saving option saves energy by using less water.

This option should only be used with light to medium soiled

dishes.

NOTE

The RINSE AID symbol

POWER

• Press the POWER button to turn on the control panel. If no

cycle is selected within four minutes, the dishwasher will

• After the cycle is complete, the power automatically turns

• If there is a power surge, power outage, or disruption of

any kind, the PF indicator will display and power will be au-

restarted.

indicates that the rinse aid

Digital Display

The Digital Display on the control panel shows the ESTIMATED cycle time. When the dishwasher is powered up, the display will be blank. When the cycle and options are selected,

the display will show the total estimated time to complete

those selections. During operation, the display shows the re-

maining estimated operating time.

Smart Diagnosis

Should you experience any problems with your dishwasher,

it has the capability of transmitting data to your Smart Phone

using the LG Smart Laundry & DW Application or via your

telephone to the LG call center.

WA RNING

Steam can cause burns. Use caution in the area of the steam nozzle, on the left side of the dishwasher, if the door is opened during

the steam portion of a cycle. Contact with the steam or the steam

nozzle can cause burns.

- 12 -

Page 13

3-3. TEST MODE

CHECK PROGRAM

For Authorized Service TechnicianFor Authorized Service Technician

LDT9965/LDF8874/LDF8764

BUTTON

Auto+

Heavy+POWER

DELAY START

The number of

pushing button

1 TIME

1 TIME

2 TIME N02 Fan Motor All LEDs Closed

3 TIME N03 Dispenser All LEDs Closed

4 TIME Soil Level Soil Sensor All LEDs Closed

5 TIME

6 TIME

7 TIME N07

8 TIME Pump RPM Drain Pump All LEDs Either

9 TIME Frequency Inlet Valve All LEDs Closed

Top Display

N03/U00/D00

(Version)

Steam

Generator

Temp(℃)

Steam

Generator

Water Level

Sump

Temp(℃)

Load and Checking points

Load LED lighting

All LEDs are lighting

Steam

Generator

Thermistor

Water Level All LEDs Closed

Sump

Thermistor

Steam

Generator

Inlet Valve

All LEDs Closed

All LEDs Closed

All LEDs Closed

Door open/

closed

Either

Remark

10 TIME Motor RPM Washing Pump All LEDs Closed

11 TIME

12 TIME - Auto O All LEDs Closed

Normal water level : 170~260

Pure water : more than 130

H: High water level / L: Low water level

Un

Cr LO

Vario Valve All LEDs Closed

- 13 -

Page 14

CHECK PROGRAM

For Authorized Service Technician

LDF7774/LDS5774

Button

Auto+ Heavy+

POWER

HALF LOAD +

DELAY START

+ POWER

Delay Start

The number of

pushing button

1 TIME

1 TIME

1 TIME N01 Fan Motor All LEDs Closed

2 TIME N02 Dispenser All LEDs Closed

3 TIME Soil Level Soil Sensor All LEDs Closed

4 TIME

5 TIME Pump RPM Drain Pump All LEDs Either

6 TIME Frequency Inlet Valve All LEDs Closed

Top Display

No3/U01/D01

(Version)

No3/U02/D01

(Version)

Sump

Temp(℃)

Load and Checking points

Load LED lighting

All LEDs are

lighting

All LEDs are

lighting

Sump

Thermistor

All LEDs Closed

Door open/

closed

Either

Either

Remark

LDF7774

Series only

LDS5774

Series only

7 TIME Motor RPM Washing Pump All LEDs Closed

8 TIME Un → Cr → LO Vario valve All LEDs Closed

9 TIME

Normal water Level : 170 ~ 260

①

Pure water : more than 130

②

-

Auto Off All LEDs Closed

- 14 -

Page 15

5. PARTS NAME

4. PARTS NAME

1

For Authorized Service TechnicianFor Authorized Service Technician

14

6

15

7

2

3

4

5

1. CONTROL PANEL

2. DOOR HANDLE

3. FRONT COVER

4. LOWER COVER

5. LEVELING FEET

6.

7. BASE

20

8

9

10

11

12

13

16

17

18

19

Mesh filter

Outer filter

Upper STS

filter

SignaLight (front display)

When a cycle is running, the SignaLight will illuminate for the

active stage.

Model with 4 LEDs : WASH – RINSE – DRY – CLEAN

Models with 2 LEDs : OPERATING - CLEAN

Models with 1 LED : OPERATING (Flickering) / CLEAN

(Lighting)

Once the cycle is complete, the CLEAN light will illuminate for

four minutes.

To keep the CLEAN light on until the door is open, turn the

power on, and then press and hold the EXTRA DRY and HALF

On appears in the display. The dishwasher will remember this

setting until manually changed.

- 15 -

8. TOP SPRAY ARM

9. UPPER SPRAY ARM

10.

11. LOWER SPRAY ARM

12. DETERGENT AND RINSE AID DISPENSER

13. DRYING VENT COVER

14.

15. UPPER RACK

16. SILVERWARE BASKET

17. LOWER RACK

18. TOP DISPLAY

19. POWER BUTTON

20. FILT RATION SYSTEM

on steam models)

some models)

Page 16

For Authorized Service Technician

5. PROGRAM CHART

(SCHEMATIC DIAGRAM)

LDT9965/LDF8874/LDF8764

Program Chart

- 16 -

Page 17

For Authorized Service TechnicianFor Authorized Service Technician

LDF7774/LDS5774

Program Chart

- 17 -

Page 18

6. HOW TO DISASSEMBLE

7. HOW TO DISASSEMBLE

BEFORE DISASSEMBLING THE DISHWASHER ;

1) Remove the cord from electric outlet to avoid electric shock.

7-1. FULL DISASSEMBLE

2) Close the Water Tap (faucet).

3) Remove all dishes and items in the dishwasher.

4) Remove the Lower Rack and the Upper Rack.

5) Remove the inlet hose and drain hose connetion to avoid the hose damages.

6) Prepare some towels to avoid floor wet by the water left in the dishwasher.

1. Lower Cover and Lower Felt

1) Remove the front 2 screws.

2) Remove the Inlet Hose and Power Supply

Cable.

For Authorized Service Technician

Lower Cover

2. Tub Felt

1) Tub Felt

- 18 -

Page 19

Control Panel Front Cover

For Authorized Service Technician

(LDT**** Series, LDF**** Series)

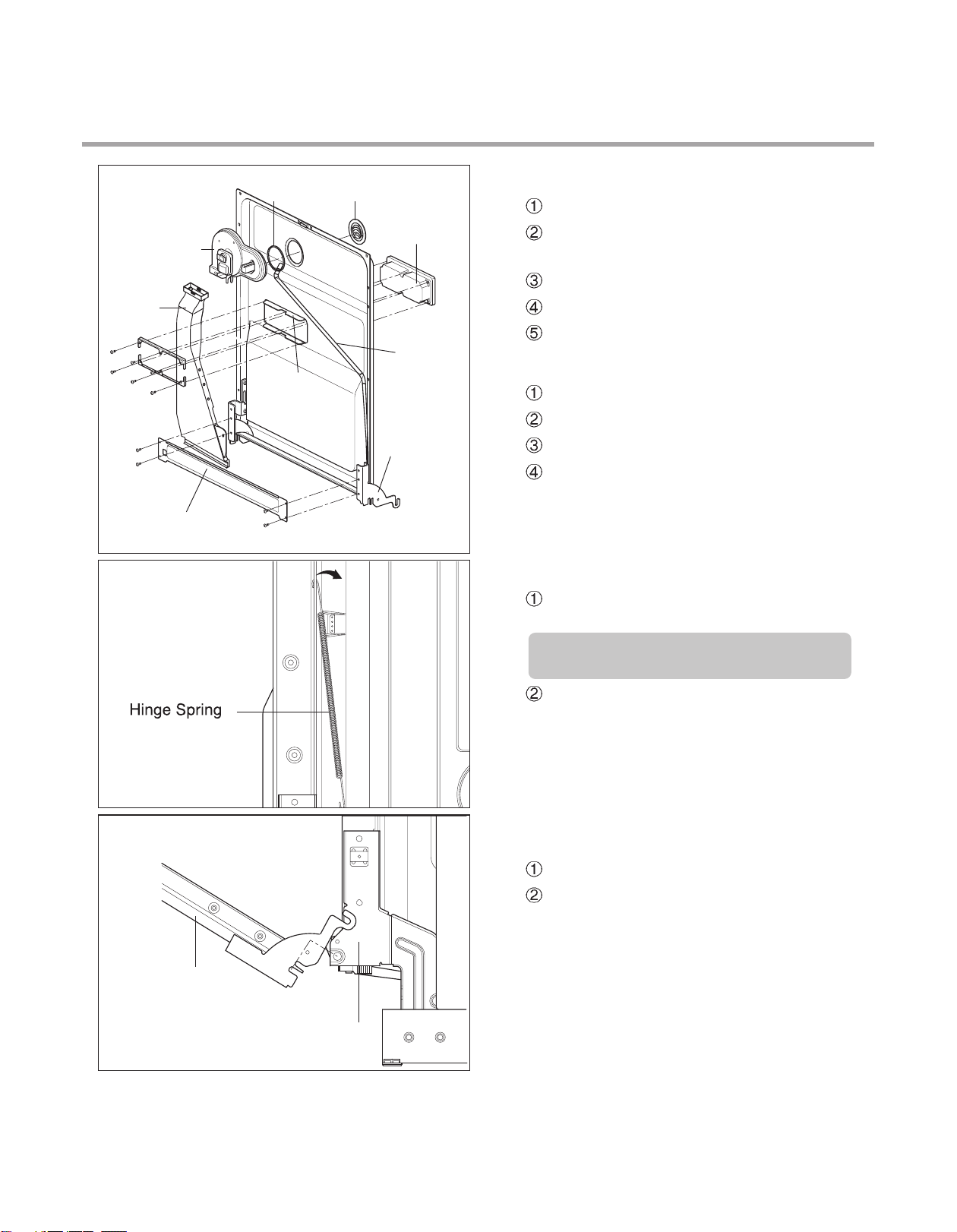

3. Door Assembly

1) Front Cover

Open the door.

Remove 2 screws at the bottom.

Remove 12 screws(stainless).

2) Control Panel Assembly

Remove 2 screws(Stainless).

Controller

Remove the wire connections.

Be sure the wiring should not be

changed in reassembling

Remove the Latch assembly.

Remove the Front Display.

Remove 8 screws for Controller.

Latch Assembly

Controller

- 19 -

Page 20

For Authorized Service Technician

3-1. Door Assembly

1) Front Cover

①

Open the door.

②

Remove 2 screws at the bottom.

③

Remove 6 screws(stainless).

(LDS**** Series)

Control Panel

Front Cover

Controller

Latch

Assembly

2) Control Panel Assembly

①

Remove 8 screws(Stainless).

②

Remove the wire connections.

Be sure the wiring should not

be changed in reassembling.

③

Remove the Latch assembly.

④

Remove 7 screws for Controller.

Controller

- 20 -

Page 21

For Authorized Service TechnicianFor Authorized Service Technician

Fan Assembly

Air Duct

Door Bracket

Flange

Inner CoverGasket

Open the door.

3) Fan Assembly

Detergent

Dispenser

Remove 4 screws and a earth screw for

Door Bracket.

Remove the wire connetions.

Remove the Air Duct.

Turn the Inner Cover counterclockwise.

Hose

4) Detergent Dispenser

Close the door

Remove the wire connections.

Door Hinge

Remove 6 screws with brackets.

Push the Detergent slowly pulling up the

the Flange by Standard Screwdriver.

5) Door Spring (Right & Left)

Push the Spring upwards and take it off

from the the slot.

Be careful not to be injured by the

sharpedge of Tub.

Door Liner Assembly

Take off the Hinge Link from the Hinge.

6) Door Liner

Open the door.

Pull the Door Liner and take it off from

the Hinge Supporter.

Hinge Supporter

- 21 -

Page 22

Lower Frame

For Authorized Service Technician

4. Lower Frame

1) Press the holder hook as shown in figure.

2) Remove 4 screws.

3) Hold the lower frame by one hand.

Push the base cabinet inside from other hand.

Pull the lower frame out.

Lead Wire Holer

Lead Wire Holer Hook

5. Tub Assembly

1) Rack

① Remove the top rack and the

upper / lower rack

2) Nozzle and Water Guide

① Pull up the nozzle.

② Remove the water guide form

the tub bracket. (Top & Rear)

.

- 22 -

Page 23

For Authorized Service TechnicianFor Authorized Service Technician

3) Sump Assembly

① Remove the wire connections.

② Remove 2 hoses assembly.

③ Rotate 2 holders between sump and tub.

④ Lift up sump assembly.

⑤ Remove the wire connections in the back

of the sump assembly.

4) Air guide Nut

.

① Turn the air guide nut counterclockwise.

(Special tool might be needed.)

Be careful the rubber packing of

air guide assembly should not be lost.

5) Tub Sub Assembly

① Remove Side 4 screws.

② Remove rear 4 screws.

③ Disconnect 1 hose assembly of left side.

(Steam nozzle hose)

④ Lift tub assembly upward.

Be careful not be injured or scratch floor

by the sharp edge of tub.

- 17 -- 17 -

- 23 -

Page 24

For Authorized Service Technician

6) Steam Nozzle

① Remove side 4 screws.

② Push the steam nozzle.

7) Holder Supporter, Tub Packing

and Hinge Supporter Assembly.

Rotate the screwdriver, after slide it into the

gap between Stopper Roller and Rail Roller.

- 24 -

Page 25

Nut

Foot

Holder

Leg Adjust

Shaft Assembly

Shaft Assembly

For Authorized Service TechnicianFor Authorized Service Technician

7) Foot & Nut

Pull the Foot twisting

Pull the Nut pushing the hook.

8) Rear Leg Adjustment System

Remove 2 screws.

Pull the Holder.

Pull the Leg Adjust.

Pull the Shaft Assembly

.

- 25 -

Page 26

For Authorized Service Technician

7. Sump Assembly

- 21 -- 21 -

1) Heater

① Remove the wire connections.

② Pull the heater out of the sump after

releasing the nut.

2) Pressure Switch & Soil Sensor

① Remove the wire connections.

② Disconnect 1 hose assembly.

③ Remove 1 screw.

④ Pull up Pressure Switch and Soil Sensor.

3) Impeller & Washing Motor

① Remove 4 screws & 1 hose assembly.

② Lift up pump assembly.

③ Remove 6 screws.

④ Remove 1 screw under a motor.

⑤ Lift up 2 pump cases.

⑥ Remove 1 screw.

⑦ Lift up impeller.

⑧ Remove 1 screw under a motor.

⑨ Lift up pump cover.

4) Vario Valve

① Remove 6 screws on the nozzle holders.

② Lift up nozzle holders.

③ Lift up Vario Valve.

5) Vario Motor & Vaio Cam

① Remove 2 screws for Vario Motor.

② Pull the Vario Motor/Cam and Micro switch.

- 26 -

Page 27

For Authorized Service TechnicianFor Authorized Service Technician

8.TROUBLE SHOOTING METHODS

7. TROUBLE SHOOTING METHODS

A. TROUBLE SHOOTING ACCORDING TO DISPLAYED ERROR MESSAGE

ERROR MESSAGE

INLET ERROR

displayed

Condition

Not reached to the normal water level in spite

of 10 min. water supply

DRAIN ERROR

displayed

Condition

Not fully drained out in

spite of 5 min. drain

operation

POSSIBLE CAUSE

FOR ERROR OCCURRENCE

The Water Supply Tap is closed.

The Water Supply is shut off.

The Inlet Hose is kinked.

The Water Pressure is very low

(below 10 psi) or high(above 120 psi)

Inlet Valve is OK?

The filter of Inlet Valve is clogged

by impure water.

The Hall sensor is OK?

The Impeller of Air Guide is bound.

The Drain Hose kinked or blocked.

Wiring connection is OK?

The drain outlet of sump is

blocked.

The Drain Pump/Motor or circuit is

troubled.

No drainage though drain pump is

working properly? Air in the

impeller of the drain pump might

cause this case.

The Air gap is clogged.

Knockout plug of garbage disposal

not removed.

Take action on Water Supply

device.

Measure the electric resistance of

Inlet Valve. (23~27

Clean the filter of Inlet Valve.

Check the frequency of Inlet Water

by the Test Mode.

Replace the Air Braker.

Remove the cause of kink or block.

Check the wiring connection.

Measure the electric resistance of

Drain Motor. (20-40

Replace the Drain Motor or repair

the Circuit.

Remove all the water remained in

the drain hose that is connected to

the drain pump / motor.

Keep the unit upright, don't lay it

down.

Cautious about leaking on the floor.

Clean the air gap.

Remove knock out plug.

REMEDY

)

)

LEAKAGE ERROR

or

displayed

Condition

The excessive RPM of

Washing Motor

happened during Wash

cycle due to water

leakage.

Water leakage in Hose connections.

Water is leaked by damages.

The Motor Water Seal leakage of

Sump assembly

The height of Drain Hose connection

(sink-Drain Hose) is not over 20

Impeller of the W

worn away

The float assembly is not working.

The lower tub gasket came

loose or fell off.

.

.

ashing Pump is

.

- 27 -

Replace the connections of Hose.

Check the point of damages and

repair or replace the related parts.

Read the Installation Instructions

(page 44) and fix it to the

recommended Height.

Replace the Impeller of the

Washing Pump.

Change the float assembly.

Replace the lower tub gasket.

※ Remove water near the Float

ASM before the repair.

Page 28

For Authorized Service Technician

ERROR MESSAGE

EXCESS ERROR

displayed

Condition

Excessive water is supplied than normal water

level.(Automatically drain

Pump operated.)

THERMAL ERROR

displayed

Condition

The resistance of thermistor not normally out put.

POSSIBLE CAUSE

FOR ERROR OCCURRENCE

The Inlet Valve is troubled.

The Controller is troubled.

The float assembly is not working

The Inlet Water Temperature is

very high. (over 194

Wiring connection is OK?

The Thermistor is OK?

)

REMEDY

Replace the Inlet Valve.

Repair or replace the Controller

Change the float assembly.

Check the temperature. (Test Mode)

If the temperature is displayed,

adjust the Inlet Water

Temperature to 120

If the temperature is not

displayed,

check the wiring connection.

check the electric resistance

of Thermistor.

(11~14k

Replace the PCB.

at 77 )

.

.

MOTOR ERROR

displayed

Condition

The Motor is working

abnormally

.

HEATER ERROR

displayed

Condition

The water is not heated or

the temperature in the Tub

is overheated to over 194ßF

VARIO ERROR

displayed

Condition

The position of vario cam is

not properly.

Wiring connection is OK?

The Impeller of Washing Pump is

locked.

The rotor of Washing Motor is

locked.

The Blade is locked.

The Circuit of Heater is troubled.

The Thermistor is troubled.

The Heater is shorted.

The Relay Circuit is troubled.

Wiring connection is OK?

Does the vario S/W assembled

properly?

Is the vario motor operated

properly?

(range is 12~15Ω)

Check the wiring connection.

Replace the cause of restriction.

Replace the Washing Motor.

Replace the PCB.

Repair the Circuit of Heater.

Replace the Thermistor.

Replace the Heater.

Repair the Relay Circuit..

Check the wiring connection.

Reassemble vario S/W.

Replace the vario motor.

.

- 28 -

Page 29

For Authorized Service TechnicianFor Authorized Service Technician

B. STEAM GENERATOR ERROR MESSAGE

Steam Generator Error mode is not displayed in normal condition and it can be confirmed

by following additional operation.

To confirm steam generator error, press the SPRAY and HALF LOAD buttons

When Steam Generator is out of order, dishwasher operates the selected cycle without

steam.

ERROR MESSAGE CONDITIONREMEDY

simultaneously.

SE0

SE1

SE3

SE4

The normal condition

The generator heater temperature

is high. (over 239

Not reached to the normal water

level.

The generator heater temperature

is low. (lower than 158

)

)

Check the water level sensor and

thermistor check.

Check the inlet valve and sensor

connection.

Check the heater and thermistor.

.

- 29 -

Page 30

7. TROUBLE SHOOTING METHODS

For Authorized Service Technician

Inlet Error

The water is supplied.

Frequency is not increased

Is the connector connected to

main PCB assembly disconnected

or disassembled? (NA8)

No

Is displayed?

Ye s

Does the water supplied?

Check the frequency of Inlet Water by

the Test Mode.

Reconnect or

Ye s

repair the connector.

Condition.

Not reached to the normal water level

in spite of 10 min. water supply.

The water is not

supplied.

Is the water tap opened? Open the water tap.

No

Ye s

Is the inlet hose kinked?

No

Repair the inlet hose.

Ye s

Is the water pressure

very low or high?

(below 0.5kgf/㎠(20bar),

above12kgf/㎠(120bar))

Ye s

Install the pressure pump.

Is the voltage between connectors

out of range? (NA8 pin1 ~ pin2)

- After remove terminal position

assurance (TPA) of connector,

check the voltage when water is injected.

(The voltage is 2.5V AC (±15%)

Is the resistance vales between

connectors out of range?

(range is over 5MΩ)

(White 8P, Pin1~Pin2)

No

Ye s

Replace the main

PCB assembly

Is the lter of inlet valve

clogged by impure water?

Is the Inlet sensor operate properly?

Blue 6P 1-2 is 12V

Inlet Valve 25±5% (Ω)

No

No

Ye s

a) Close the water tap.

b) Unscrew the inlet hose.

(Inlet valve side)

c) Clean the lter of inlet valve.

No

Replace the inlet valve

- 30 -

Page 31

Drain Error

Is displayed?

Ye s

For Authorized Service TechnicianFor Authorized Service Technician

Condition.

Not fully drained out in spite of 5 min.

drain operation.

Motor rpm is not increased.

Is the connector connected to

main PCB assembly disconnected

or disassembled? (YL3)

Ye s Ye s

No

Is the voltage between connectors

out of range? (YL3 pin1~pin2~pin3)

- After remove terminal position

assurance (TPA) of connector,

check the voltage when water is

drained. (The voltage is over 12V DC)

Ye s

Is the resistance vales between

connectors out of range?

(range is 4~5Ω)

(Yellow 3P, pin1~pin2~pin3)

Does the drain motor operate?

Check the rpm of drain motor by the

test Mode.

Reconnect or

repair the connector.

No

Replace the main

PCB assembly.

No

Replace the drain

motor

Is the lter clogged? Clean the lter

Is the outer drain hose

kinked or blocked or frozen?

Is the inner drain hose

and drain case

kinked or blocked or frozen?

Motor rpm is

increased.

No

No

Ye s

Ye s

Remove the cause of kink

or block.

Remove the cause of kink

or block.

Ye s

Is the connector connected to

drain motor disconnected

or disassembled?

Ye s

Reconnect or

repair the connector.

- 31 -

Page 32

Leakage Error

Water is not ooded

in the base.

Is or

displayed?

Ye s

Is the water ooded

in the base?

How to check.

Disassembly the lower cover.

For Authorized Service Technician

Condition.

The water level in Tub goes down

during operation or standby mode.

Water is ooded

in the base.

Is the oat assembled properly?

Replace or

Ye s Ye s

repair the oat.

Tilt the machine and drain

water in the base.

And nd the cause of

leakage.

Remove the cause of leakage.

- 32 -

Page 33

Excess Error

Is displayed?

For Authorized Service TechnicianFor Authorized Service Technician

Condition.

Excessive water is supplied than normal water

level. (Automatically drain Pump operated.)

No

Is the connector connected to

main PCB assembly disconnected

or disassembled? (NA8)

No

Is the voltage between connectors

out of range? (NA8 pin1 ~ pin2)

- After remove terminal position

assurance (TPA) of connector,

check the voltage when water is

injected.

(The voltage is 2.5V AC (±15%)

Is the water supplied when

the machine is shut down?

Ye s

Reconnect or

repair the connector.

No

Replace the main

PCB assembly

Yes

(Close the water tap.)

Does the inlet valve

working properly?

(damaged or operating

abnormally)

Ye s

Replace the inlet valve

Is the resistance vales between

connectors out of range?

(range is over 5MΩ)

(White 8P, Pin1~Pin2)

Is the Inlet sensor operate properly?

(red+black range is 8~10kΩ)

(white+black range is 15~30MΩ)

Ye s

- 33 -

Replace the inlet valve

No

Page 34

Thermal Error

Is displayed?

Ye s

For Authorized Service Technician

Condition.

The resistance of thermistor not

normally out put.

Is the connector

connected to main PCB

assembly disconnected or

disassembled? (RD6)

No

Is the resistor between

connectors out of range?

(RD6 pin2 ~ pin3)

- After remove the

connector from the PCB,

check the resistor.

(range is 12~13kΩ)

Reconnect

Ye s Yes

or repair the

connector.

Is the connector

connected to heater

assembly disconnected or

disassembled?

No

Ye s

Replace the

main PCB

assembly.

Is the thermistor operated

properly?

(range is 12~13kΩ)

Ye s

Reconnect

or repair the

connector.

Replace the

thermistor.

No

- 34 -

Page 35

Heater Error

Ye s

Is displayed?

Ye s

Is the heater resistance

Measured properly?

(range is 11~12.5Ω)

For Authorized Service TechnicianFor Authorized Service Technician

Condition.

The water is not heated

or the temperature

in the inner tub is

overheated to over 95℃

No

Is the connector connected

to main PCB assembly

disconnected or

disassembled?

(X1 : stand-by relay,

X2 : Sump Heater relay,

RD6 : Thermistor )

No

When door is closed, check

the resistor between

X1 4pin and X2 4pin.

`

Ye s

No

Reconnect or

repair the

connector.

Reconnect or

repair the

trans cable.

Does the inlet valve

working properly?

(damaged or operating

abnormally)

Ye s

- 35 -

Page 36

For Authorized Service Technician

Does the PCB assembly

working properly?

When door is closed, check

the resistor between X1 4pin

and X2 4pin.

-. Heater working

: 120V AC 15%

-. Heater stop : 0~1V

Ye s

Is the pressure S/W

operating properly?

No

Ye s

Replace the PCB

assembly

Replace the pressure S/W.

- 36 -

Page 37

Locked motor Error

Is displayed?

Ye s

For Authorized Service TechnicianFor Authorized Service Technician

Condition.

The revolution of washing motor is

not increased.

Check the connectors below.

Is the connector disconnected or

disassembled?

Main PCB assembly : RD3

Main PCB assembly : WH4

Ye s

No No

Reconnect

or repair the

connector.

Is the resistance values

in the range of 15 to 20Ω?

※ 1-2, 2-3, 3-1 pin

( After pull out the RD3 connector,

check the terminal of the connector

in wire. (Red 3P, male)

Ye s

Is the voltage between connectors

out of range?

(WH4 pin1 ~ WH4 pin4)

- After remove terminal

position assurance (TPA)

of connector, check the voltage,

when just power

on. (The voltage is 8~15V)

Ye s

Check or

replace the

motor.

Replace the

main PCB

assembly.

Is the resistance vales

short? (0~50Ω)

(After pull out the RD3

connector, check the

housing connector

(Pin1~Pin2, Pin2~Pin3,

Pin3~Pin1) individually.

No

Ye s

Replace the

main PCB

assembly.

- 37 -

No

Is the motor blocked?

No

Replace the motor.

Ye s

Remove the

cause of

block or

replace the

motor.

Page 38

Nozzle(Vario) Error

Is displayed?

Ye s

For Authorized Service Technician

Condition.

The position of vario cam is not

properly.

Check the connectors below.

Is the connector

disconnected or disassembled?

(BL4 : vario motor,

NA8 : Vario S/W sensing)

Ye s

Does the PCB assembly working

properly?

When Door is closed,

check the voltage between

BL4 pin1 and BL4 pin4.

-. Vario motor stop working

: 120V AC

-. Vario motor stop stop : 0~1V

No

Reconnect

or repair the

connector.

Does the vario S/W assembled properly?

No

Is the vario motor operated properly?

(range is 12~15K Ω)

Ye s

Ye s

Reassemble

vario S/W.

Replace the

vario motor.

Ye s

- 38 -

Page 39

No Power

For Authorized Service TechnicianFor Authorized Service Technician

Is the supplied voltage

120V AC(+10%, -15%)

Ye s

Is the current rating of multi-outlet power

strip enough?

(Avoid connecting several electric devices )

Check the

No No

fuse or reset

the circuit

breaker.

Is the connector connected to Main PCB

Assembly disconnected or disassembled?

Ye s

No

No

Alternate

with

explanation.

Is LED on while the power is on?

Reconnect

or repair the

connector.

Replace the

main PCB

assembly.

Ye s

Is nine pin wire of display

PCB Assembly broken? (CON1)

No

Ye s

Replace the

display PCB

assembly.

- 39 -

Ye s

Is the connector connected to PCB/Noise

lter disconnected or disassembled?

No

Reconnect

or repair the

connector.

Page 40

Washing result is not satisfactory.

For Authorized Service Technician

After washing, is there

any white deposits

on the dishes or inner tub?

No

After washing, is there

any streaks on the dishes

or inner tub?

No

After washing, is there

small particles (food) on the

dishes of inner tub?

No

Is the washing result of

cups & glasses not

satisfactory? (Upper basket)

No

Ye s

Ye s

Ye s

Ye s

Using a wash booster will help

remove spots, residue and hard

water (white) lm.

Reduce the amount of Rinse aid.

a) Wash lter assembly.

b) Check the rotation of spray arms.

(lower, upper, top nozzle)

a) Does the upper nozzle t properly

to the water guide?

Reassemble or replace

→

the upper nozzle or water guide

b) Does the water guide t properly

to the sump?

Reassemble or replace

→

the water guide.

Is the washing result of

utensils not satisfactory?

(Top basket)

Ye s

a) Does the top nozzle t properly

to the water guide?

Reassemble or replace

→

the top nozzle or water guide

b) Does the water guide t properly

to the sump?

Reassemble or replace

→

the water guide.

- 40 -

Page 41

Drying result is not satisfactory.

For Authorized Service TechnicianFor Authorized Service Technician

After washing, is there

any streaks on the dishes

or inner tub?

No

After washing, is there

water drops on the dishes

or inner tub?

No

Is the drying result of

cups & glasses not

satisfactory? (Upper basket)

No

Is the drying result of

utensils not satisfactory?

(Top basket)

Ye s

Ye s

Ye s

Ye s

Reduce the amount of Rinse aid.

Increase the amount of Rinse aid.

a) Does the upper nozzle t properly

to the water guide?

Reassemble or replace

→

the upper nozzle or water guide

b) Does the water guide t properly

to the sump?

Reassemble or replace

→

the water guide.

a) Does the top nozzle t properly

to the water guide?

Reassemble or replace

→

the top nozzle or water guide

b) Does the water guide t properly

to the sump?

Reassemble or replace

→

the water guide.

- 41 -

Page 42

For Authorized Service Technician

C. TROUBLE DIAGNOSES AND REPAIR BY SYMPTOM

No Power on when the power button pressed.

The Power connection

is correctly connected.

YES

The Fuse or

Circuit Breaker

of house is O.K?

YES

The Power Switch or

the Circuit is O.K?

NO

NO

NO

• Re-connect the Powr connection.

• Check the electricity is failed or not.

• Replace the Fuse or Circuit Breaker of house.

• Check the Power Switch or the circuit and repair it.

YES

Check the Controller.(Power Circuit)

- 42 -

Page 43

The Wash Pump/Motor does not run.

For Authorized Service TechnicianFor Authorized Service Technician

The Door is tightly

closed?

YES

The Wiring connections

is OK?

YES

The Blade is not locked

by a small and sharp

object?

NO

NO

NO

• close the Door tightly.

• Check the Door Switch in Latch Handle.

• Re-connect the wiring connections related to the

Washing Motor.

• Remove the cause of lock or replace the Blade.

YES

Replace the Wahing Pump/Motor

- 43 -

Page 44

Washing Results are not Satisfactory

For Authorized Service Technician

After washing, are there still

White deposits or streaks on

the dishes?

NO

After washing, are there still

food soils on the dishes?

YES

Check that : - the amount of detergent Correctly used or not

- Filters clogged or not.

- the holes of spray arms blocked or not.

- Utensils are correctly arranged or not.

- Utensils are overloaded or not.

- the spray arm rotating is obstructed or not.

- the program is correctly selected or not.

YES

Reduce the amount of Rinse-Aid

(for Streak)

Dry Results are not satisfactory

Increase the amount of Rinse-Aid.(Set the number higher)

Select the Program that the Rinse temperature is higher.

- 44 -

Page 45

For Authorized Service TechnicianFor Authorized Service Technician

Power Button not automatically off after operation.

Check the button is blocked by foreign materials.

Check the Power Switch.(Replace it, if necessary.)

Check the Controller.(Replace it, if necessary.)

- 45 -

Page 46

For Authorized Service Technician

9. INSTALLATION INSTRUCTION

Figure A

Step 2: PREPARE THE ELECTRICAL WIRING

1. This appliance must be operated with correct voltage as shown in this manual and on the

rating plate, and connected to an individual, properly grounded branch circuit, protected

by time delay fuse. Wiring must be 3 wires including ground.

2. The wiring or cord should be in an accessible location adjacent to, and not behind the

dishwasher and within 4 ft. (1.2m) of the dishwasher side.

3. The wiring or cord must be grounded properly, if in doubt, have it checked by a qualified

electrician. No other appliance shall be connected to the same outlet by a double adapter

or similar plug.

4. The wiring or cord must be oriented as shown in Figure A below.

5. Check the dishwasher for any damage before trying to install it.

6. Make sure water line and Electrical line are oriented in the bottom channels as shown in

the figure below.

If you find any damage to the dishwasher, Please contact your dealer or builder

immediately.

WARNING

For personal safety, remove house fuse or open circuit breaker before installation.

Do not use an extension cord or adapter plug with this dishwasher.

Electrical and grounding connections must comply with the national electrical

code/provincial and municipal code and/or other local codes.

8. INSTALLATION INSTRUCTION

Step 1: PREPARE CUPBOARD OPENING

1. This dishwasher is designed to fit a standard dishwasher opening as shown below.

2. Select a location as close to sink as possible for easy connections to water and drain lines.

3. The dishwasher should not be installed more than 10 ft. (3m) from the sink for proper

drainage.

4. If dishwasher is to be installed in a corner, a minimum of 2 in. (50mm) is required between

the dishwasher and an adjacent a wall.

If dishwasher will sit directly on

subflooring, subfloor should be

sealed with a waterproof paint or

sealer to prevent damage from

steam.

Drill a 1-1/2 (38mm) dia hole or cut

out for drain hose, inlet hose and

electrical cables on either side.

approx. 4 (100mm, W) X 4 (100mm, H)

These openings must be within 4

(100mm) from the floor and 1-5/8

(40mm) from the back wall. If there is

a floor in the cabinet under the sink,

it will also be necessary to drill or cut

through the floor to connect the

water and drain under the sink.

Ensure the floor under the dishwasher is at the same level as the rest of the room to

allow for any service requirements.

- 46 -

Page 47

For Authorized Service TechnicianFor Authorized Service Technician

Step 2: PREPARE THE ELECTRICAL WIRING

WARNING

For personal safety, remove house fuse or open circuit breaker before installation.

Do not use an extension cord or adapter plug with this dishwasher.

Electrical and grounding connections must comply with the national electrical

code/provincial and municipal code and/or other local codes.

1. This appliance must be operated with correct voltage as shown in this manual and on the

rating plate, and connected to an individual, properly grounded branch circuit, protected

by time delay fuse. Wiring must be 3 wires including ground.

2. The wiring or cord should be in an accessible location adjacent to, and not behind the

dishwasher and within 4 ft. (1.2m) of the dishwasher side.

3. The wiring or cord must be grounded properly, if in doubt, have it checked by a qualified

electrician. No other appliance shall be connected to the same outlet by a double adapter

or similar plug.

4. The wiring or cord must be oriented as shown in Figure A below.

5. Check the dishwasher for any damage before trying to install it.

6. Make sure water line and Electrical line are oriented in the bottom channels as shown in

the figure below.

If you find any damage to the dishwasher, Please contact your dealer or builder

immediately.

Figure A

- 47 -

Page 48

For Authorized Service Technician

1. Remove the Lower Cover and orient dishwasher as shown below.

2. Before sliding the dishwasher into the cupboard opening, make all necessary height

adjustments using the legs.

3. Slide the dishwasher into the cabinet opening carefully. Make sure that the drain hose

inside the cabinet is not kinked.

4. Follow the instruction as in Figure B.

Step 5: INSTALL THE DISHWASHER IN CUPBOARD

Step 3: PREPARE THE WATER SUPPLY CONNECTION

1. This dishwasher may be connected to either hot or cold water. If the water can not be

maintained below 149

2. When connecting the dishwasher water line, sealing tape or compound should be used to

avoid leaks.

3. When connecting the dishwasher water line, the house supply should be shut off.

4. The Water Supply Tube must be oriented as shown in Figure A on page 6.

Step 4: PREPARE DISHWASHER FOR INSTALLATION

(65 ), the dishwasher must be connected to cold water.

1. Adjust the legs to the required height to fit properly under the countertop as shown below.

2. Check the level of dishwasher by using level.

Left side – turn the

adjusting screw

counterclockwise to lower

the leg and raise the rear

of the dishwasher.

Right side – turn the

adjusting screw clockwise

to lower the leg and raise

the rear of the dishwasher.

Front feet can be adjusted

from the top using a 1/4

square drive wrench.

- 48 -

Page 49

For Authorized Service TechnicianFor Authorized Service Technician

Step 5: INSTALL THE DISHWASHER IN CUPBOARD

1. Remove the Lower Cover and orient dishwasher as shown below.

2. Before sliding the dishwasher into the cupboard opening, make all necessary height

adjustments using the legs.

3. Slide the dishwasher into the cabinet opening carefully. Make sure that the drain hose

inside the cabinet is not kinked.

4. Follow the instruction as in Figure B.

- 49 -

Page 50

For Authorized Service Technician

Step 7: WATER SUPPLY CONNECTION

1. When connecting, sealing tape or

sealing compound should be

used to avoid water leaks.

2. Before connecting, turn off the water

supply.

3. After fitting the Elbow into the

Inlet Valve, slide the Flexible

Stainless Tube or Copper Tube

into the Elbow.

4. Tighten the nut and make sure

that the line is not kinked or

sharply bent.

Inlet Valve

Water Supply Tube

Elbow

1. Before beginning, turn off electrical

power to the unit at the circuit breaker.

2. Remove the Junction Cover and then

Install the Strain Relief.

3. Twist Wire Connectors tightly on the

wires. Wrap each connection with

Electrical tape.

4. Check again and make sure that all

wires are connected correctly, black to

black, white to white, green to green

(ground to ground).

5. Replace the Junction Cover.

Junction Box

Junction Cover

Step 8: ELECTRICAL POWER CONNECTION

Step 6: DRAIN LINE CONNECTION

1. If the end of the drain hose does not fit to the drain line, use an adapter (not supplied) that

must be resistant to heat and detergent and may be obtained from a plumbing shop.

2. There are 2 typical connections as shown in Figures C & D.

There may be other options than shown here for connection the drain hose. The drain

connection must meet local plumbing regulations.

The S trap spigot must be drilled out cleanly and free of obstruction to its maximum

internal diameter, if used for drainage.

To prevent syphoning, one of the following instruction methods must be followed:

Figure C:

Connection to Disposer or waste Tee.

Figure D:

Connection to Air Gap.

Drain Requirements

Follow local codes and ordinances.

Do not exceed 10 ft. (3m) distance

to drain.

Do not connect drain lines from

other devices to the dishwasher

drain hose.

- 50 -

Page 51

Step 7: WATER SUPPLY CONNECTION

1. When connecting, sealing tape or

sealing compound should be

used to avoid water leaks.

2. Before connecting, turn off the water

supply.

3. After fitting the Elbow into the

Inlet Valve, slide the Flexible

Stainless Tube or Copper Tube

into the Elbow.

4. Tighten the nut and make sure

that the line is not kinked or

sharply bent.

Water Supply Tube

Inlet Valve

For Authorized Service TechnicianFor Authorized Service Technician

Elbow

Step 8: ELECTRICAL POWER CONNECTION

1. Before beginning, turn off electrical

power to the unit at the circuit breaker.

2. Remove the Junction Cover and then

Install the Strain Relief.

3. Twist Wire Connectors tightly on the

wires. Wrap each connection with

Electrical tape.

Junction Cover

4. Check again and make sure that all

wires are connected correctly, black to

black, white to white, green to green

(ground to ground).

5. Replace the Junction Cover.

Junction Box

- 51 -

Page 52

For Authorized Service Technician

Step 9: FINAL CHECKS

1. Turn electrical power back on at the circuit breaker.

2. Turn house water supply back on.

3. Operate the dishwasher through one cycle (Quick cycle is recommended) to check for

water leaks and operating conditions.

4. Replace the Lower Cover.

- 52 -

Page 53

10. EXPLODED VIEW

9. EXPLODED VIEW

For Authorized Service TechnicianFor Authorized Service Technician

“The following parts are not illustrated"

Printed

materials

*Owner’s Manual

*Service Manual

Description

- 53 -

Loc No.

G001

G004

Page 54

EXPLODED VIEW

EXPLODED VIEW

For Authorized Service Technician

LDT9965/LDF8874

E005

F101

F001

A040

E010

A003

A130

E005

M050

- 54 -

M051

M052

M053

M054

Page 55

EXPLODED VIEW

EXPLODED VIEW

For Authorized Service TechnicianFor Authorized Service Technician

LDF8764

F101

F001

E005

E010

A040

A003

E005

M050

- 55 -

M051

M052

A130

M053

M054

Page 56

EXPLODED VIEW

EXPLODED VIEW

For Authorized Service Technician

LDF7774 / LDS5774

F001

E005

E010F101

A040

ACCESSORIES

A003

E005

M050

- 56 -

M051

M052

A130

M053

M054

Page 57

EXPLODED VIEW - TUB ASSEMBLY

EXPLODED VIEW - TUB ASSEMBLY

For Authorized Service Technician

LDT9965/LDF8874

F110

F060

F022

F041

F171

F011

F013

F144

F040

F050

F230

F300

F112

F118

F113

F117

F111

F117

F111

F210

F113

F132

F105

M006

F137

F117

F166

M071

M070

F138

- 57 -

F165

F011

F013

F143

F117

F215

Page 58

EXPLODED VIEW - TUB ASSEMBLY

EXPLODED VIEW - TUB ASSEMBLY

For Authorized Service Technician

LDF7774 / LDS5774

F110

F060

F040

F050

F022

F041

F171

F011

F013

F144

F112

F118

F113

F117

F111

F117

F111

F210

F113

F132

F105

M006

F137

F117

F166

M071

M070

F138

F165

- 58 -

F143

F117

F215

F011

F013

Page 59

EXPLODED VIEW - TUB ASSEMBLY

EXPLODED VIEW - TUB ASSEMBLY

F060

F040

For Authorized Service TechnicianFor Authorized Service Technician

LDF8764

F041

F171

F011

F013

F132

F022

F144

F137

F050

F230

F300

F143

F105

M006

F117

M071

F166

F138

M070

- 59 -

F165

F011

F013

F117

F215

Page 60

EXPLODED VIEW - BASE ASSEMBLY

EXPLODED VIEW - BASE ASSEMBLY

For Authorized Service Technician

LDT9965/LDF8874/LDF8764

F047

M500

M210

M100

F046

M090

A160

M260

M105

F148

F149

M266

- 60 -

Page 61

EXPLODED VIEW - BASE ASSEMBLY

EXPLODED VIEW - BASE ASSEMBLY

For Authorized Service TechnicianFor Authorized Service Technician

LDF7774 / LDS5774

F148

M210

M100

M105

M090

A160

M260

F149

M266

- 61 -

Page 62

EXPLODED VIEW - RACK ASSEMBLY

EXPLODED VIEW - RACK ASSEMBLY

For Authorized Service Technician

A159

A156

A151

A157

A158

A145

A070

A101

A102

A103

A150

A060

A165

A080

A155

F192

F004

F005

A141 A147 A146 A142

A140

- 62 -

A050

F191

A110

Page 63

EXPLODED VIEW - CUTLERY RACK ASSEMB LY

LDT9965/LDF8874/LDF7774/LDS5774

EXPLODED VIEW - CUTLERY RACK ASSEMBLY

A170

A171

For Authorized Service Technician

A172

A152

- 63 -

Page 64

LDT9965/LDF8874/LDF8764/LDF7774

EXPLODED VIEW - PANEL / DOOR ASSEMBLY

K260

K207

K280

K270

For Authorized Service Technician

K215

K280

K222

K005

K010

K254

K230

K100

K124

K002

K110

K121

K251

K122

K101

K001

K141

K140

F142

F141

K030

F174

- 64 -

Page 65

EXPLODED VIEW - PANEL / DOOR ASSEMBLY

For Authorized Service TechnicianFor Authorized Service Technician

LDS5774

K200

K030

K212

K006

K100

K262

K254

K280

K110

K121

K260

K252

K251

K122

K101

K001

K217

K124

K002

K

F174

K141

K140

F142

F141

- 65 -

Page 66

EXPLODED VIEW - SUMP ASSEMBLY

For Authorized Service Technician

A120

M071

M081

M089

M091

M072

M074

M075

M070

M125

M120

M025

M126

M087

M031

M028

M006

M060

M130

M131

M132

M026

M027

M030

M088

M133

M134

- 66 -

Page 67

For Authorized Service Technician

10. WIRING DIAGRAM

BN

YL

BL

RD

NO NO

NO NO

COM COM

X3

X2

1 2 3 4 5 6 7 8 9

NA9

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

10 9 8 7 6 5 4 3 2 1

BK

WH

NO NO

COM COM

COM COM

X1

RD6

1 2 3 4 5 6

NA8

1 2 3 4 5 6 7 8

GY

BK

1 2 3

WH

RD

BK

BL

1 2 3 4 5 6

YL

Float

S/W

YL

1 2 3 4 5 6 7 8

120 ± 10%

SB

BN

WH

BK

BL

VT

3 2 1

BL

(LDT9965,LDF8874,LDF8764 Series)

YL

BN

5 Vdc

Sensor

Turbidity

RD6

BL to RD

(Sump)

2 1

BK

1 2

Vac

Vario

2 1

Flow

Meter

12~13

Thermistor

RD

Rinse

Refill

Vac

S/W

120 ± 10%

(Steam)

49 ± 5%

Thermistor

NA8

12 Vdc

7~13

VT to BL

BL to VT

BL(2) to BL(3)

RD

BL

BK

Vac

S/W

Pressure

120 ± 10%

BK

YL

11 ~ 12.5 Ω

Sump Heater

X1 WH to X2 BL

Stop : 0 ~ 1 V ac

Working : 120 ± 10% V ac

BK

Vac

S/W

Pressure

120 ± 10%

BK

BN

BK

Steam Heater

BN

120 ± 10% Vac

L

N

1

3

2

1

3

2

BK

WH

Error Message

• IE – INLET ERROR

• OE – DRAIN ERROR

• AE or E1 – LEAKAGE ERROR

• FE – EXCESS ERROR

• tE - THERMAL ERROR

• LE – MOTOR ERROR

• HE – HEATER ERROR

• nE – VARIO ERROR

RD1

0 Ω

Fuse

Noise Filter

Test Mode

WH1 BK to RD1 BK

WH1 WH to RD1 BN

Component Tests

WH1

• Ohm Tests wit h connectors removed

• Press Del ay Start 1Time to 12Times

• Voltage Tests wi th connectors installed

• Press Auto & Heavy & POWER

NOTES

Power Code

120 Vac / 60Hz

WH

YL3

1 2 3

11 10 9 8 7 6 5 4 3 2 1

Main PCB

PK

WH

GY

VT

BL

GN

YL

OR

RD

BN

1 2 3 4 5 6 7 8 9 10 11

BK

GY WH

VT

BL

GN

YL

OR

RD

BN

1 2 3 4 5 6 7 8 9 10

BK

Display PCB Display PCB

Power Button

BK

BN

RD

OR

YL

6 5 4 3 2 1

GN

NA6

1 2 3 4 5 6

1 2 3 4 5 6

LED Supporter

BL6

1 2 3 4 5 6

BL4 WH4

1 2 3 4

YL4

1 2 3 4

1 2 3 4

RD3

1 2 3

Note : All Switch are Normally Closed / Press Butt on & Switch OPENS!

U V W

BL

1 2 3

1 2 3 4 5 6

1 2 3 4

YL/

1 2 3 4

1 2 3 4

1 2 3

1 2 3

SB

GY

YL

BL

OR

RD

BL

GY

RD

1

VT

GN

BL

RD

SB

BL

WH

1 2

YL3

4~5 Ω

Drain

BLDC

Motor

U V W

Inlet V/V

BL

1 2 1 2

Inlet V/V

)

5 Vdc 5 Vdc

Level

Wash

Steam

(High

Level

Wash

(Low)

Steam

WH

SB to BL

BL to WH

WH to SB

COM

Door

S/W

(1/2)

120 ± 10%

-ser

1 2

Dispen

RD

BL6

12 Vdc

OR to BL

(Sump)

(Steam)

RD

25 ± 5% Ω

BL6

12 Vdc

RD to BL

25 ± 5% Ω

RD

RD

NO

NC

Vac

NO

COM

BN

NC

Vac

Door

S/W

(2/2)

120 ± 10%

BL

YL

GY

Vario

1 2

Motor

12 ~ 15

Working : 120 ± 10% V ac

Fan

Motor

120± 5% Ω

120 ± 10% Vac

RD

Vcc

N

BK

GY

VT

BL

SB

1 2 3 4 5 6 7

U V W Ha Hb G

WH

Wiring Color Legend

BK – Black BL – Blue BN – Brown GN – Green GY – Gray

OR – Orange PK – Pink RD – Red SB – Sky Blue WH – W hite

V – V iolet YL - Yellow

BL4

RD to BL

Stop : 0 ~ 1 V ac

osition

D

Wash

motor