LG RCWW, LCWW Maintenance Manual

www.lge.com

OPERATION & MAINTENANCE MANUAL

Water-Cooled SCREW Chiller

Model : RCWW, LCWW

Please read this installation manual completely for safety before installing the product.

The purpose of this manual is to keep the user safe and to prevent any property damage.

After reading this installation manual, please retain it for future reference thoroughly

Installation work must be performed in accordance with this installation manual by

authorized personnel only.

ENGLISH

2

ENGLISH

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

1. CAUTIONS FOR SAFETY _ WARNING/CAUTION

3

1. CAUTIONS FOR SAFETY _ WARNING/CAUTION

It can be dangerous when moving, installing and placing the system for its high pressure, electric

devices and heavy weight especially when lifting the unit in a limited space(rooftop, lifted structure, etc.).

Please read carefully the warnings and cautions on this manual and the labels attached on the

unit, and follow the instructions.

Please follow the following instructions to prevent any injury or property damage

It may result in an injury or damages when neglecting the instructions on in this manual.

The seriousness of the result can be classified as the following signs.

• Please note that any failure of system resulted by user’s careless maintenance, natural disaster

or the failure of the power cable shall not be warranted regardless of the warranty period.

• Please note that any part of this manual can be revised without notice for the product improvement.

WARNING

It can result in serious injury or death when the directions are ignored.

CAUTION

It can result in minor injury or product damage when the directions are ignored.

This is the symbol to call attention for the issues and operations that may cause danger.

To prevent the occurrence of the danger, read carefully and follow the instructions.

This is the symbol showing the how-to-use instruction in order to prevent danger.

1-1. Warning

• Have all electric work done by a licensed electrician according to "Electric Facility Engineering Standard" and "Interior

Wire Regulations" and the instructions given in this manual and always use a special circuit.

-

If the power source capacity is inadequate or electric work is performed improperly, electric shock or fire may result.

• Ask the dealer or an authorized technician to install the chiller unit.

- Improper installation by the user may result in water leakage, electric shock, or fire.

• For re-installation of the installed product, always contact a dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Make sure to equip the circuit breaker and fuse.

- Improper wiring or installation may cause fire or electric shock.

• Do not disassemble, repair or reconfigure the unit.

- LG Electronics is not responsible for the any damage or loss from the arbitrary disassembly, repair or reconfigura-

tion of the unit.

• Make sure to ground the unit properly.

- There is risk of fire or electric shock.

• Do not store or use flammable gas or combustibles near the chiller unit

- There is risk of fire or failure of product.

• Do not reconstruct to change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted and operated forcibly, or parts other

than those specified by LGE are used, fire or explosion may result.

• Install the unit on a foundation where the heavy weight can be supported.

- Insufficient strength of the foundation to support the chiller operation may cause the unit failure or injury.

• Installing the product in small space requires separate measures to keep the leakage of the refrigerant within the

safety limits in case of any leakage.

- Consult the authorized dealer for appropriate measures to prevent the refrigerant leakage from exceeding the

safety limits. The leakage of refrigerant exceeding the safety limit may result in dangerous situations due to the

lack of oxygen level in the room.

!

!

!

ENGLISH

4

1. CAUTIONS FOR SAFETY _ WARNING/CAUTION

ENGLISH

• Securely install the cover of control box and the panel.

-

If the cover and panel are not installed securely, dust or water may enter the unit and fire or electric shock may result.

• Do not operate the unit arbitrarily.

- Incorrect operation of the unit may cause dangerous situations such as unit defects, leakage or electric shock. Always consult the authorized dealer.

• Do not use damaged circuit breaker or fuse works correctly all the time.

- It may cause fire, electric shock or injury.

• Keep the control panel from any water getting in. Do not wash the control panel with water.

- It can cause electric shock or defects.

• When the product is soaked (flooded or submerged), contact an Authorized Service Center.

- There is risk of fire or electric shock.

• Use a dedicated outlet for this unit.

- There is risk of fire or electric shock.

• When installing and moving the chiller unit to another site, do not charge it with a different refrigerant from the refrigerant specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrigerant cycle may malfunction and the

unit may be damaged.

• Do not touch the power switch with wet hands.

- There is risk of fire, electric shock, explosion, or injury.

• Ventilate before operating the chiller unit when gas leaked out.

- Do not use a phone or operate the power switch at this time. It may cause fire or explosion.

• Do not put any heavy object on the top of the unit or climb on the unit.

- It may cause defects or injury.

• Be careful with the rotating part.

- Do not put your finger or a stick in the rotating part. It may cause injury.

• Use fuse and leakage breaker of rated capacity.

- It may cause fire and defects.

• Redesigning the control box is prohibited.

- Lock the control box with possible locking device and if you need to open the control box inevitably, turn off the

main power first.

• Do not touch the wiring or a parts inside the panel.

- It may cause electric shock, fire or defects.

PRECAUTIONS BEFORE INSTALLATION

• Follow the permitted pressure level

- Follow the regulated pressure for cold water, cooling water, refrigerant etc.

• Do not change the set values.

- Do not change the set values of the controller and safety devices. Operating with inappropriate setting can cause

damages. When changing the setting values, please consult with the specialist.

• Be careful of fire, earthquake and lightening.

- In case of any natural disaster such as fire, earthquake or lightening, immediately stop operating the unit. If you

continue to operate the unit, it can cause a fire or electronic shock.

• Follow all safety code.

- When operate the chiller, follow the precautions on the manual, tag, sticker and label.

• Use of undesignated refrigerant and oil is prohibited.

- Do not use undesignated refrigerant, freezer oil and brine. It may cause serious effect to the compressor and

parts defect.

• During the installation and service, shut down the power supply.

- Electric shock can cause injury and death. Mark and check all switches so that the power is not recovered until

the work is completed.

• Wear safety equipment

- Wear safety glasses and work gloves. Be careful when installing or operating the chiller and operating the electrical components.

• Always run fluid through heat exchangers when adding or removing refrigerant charge.

-

Potential damage of the tube within the heat exchanger can be prevented. Use Appropriate brine solution in cooler fluid

loops to prevent the freezing of heat exchangers when equipment is exposed to temperature below 0°C.

1. CAUTIONS FOR SAFETY _ WARNING/CAUTION

5

• Do not vent refrigerant relief valves within a building.

-

Outlet from relief valves must be vented outdoors in accordance with the latest edition of ANSI/ASHRAE(American National Standards Institute/American Society of Heating, Refrigeration and Air Conditioning Engineers) 15 (Safety Code for

Mechanical Refrigeration). The accumulation of refrigerant in an enclosed space can displace oxygen and cause asphyxiation. Provide adequate ventilation in enclosed or low overhead areas. Inhalation of high concentrations of refrigerant

gas is harmful and may cause heart irregularities, unconsciousness or death. Misuse can be critical. Refrigerant gas is

heavier than air and reduces the level of oxygen. It can cause irritation to eyes and skin.

• Be careful of water leakage.

- In case of any water leakage in the pump or pipe, immediately stop operating the unit. It may cause electric

shock, electricity leakage or defects.

• Be careful of electric shock.

- Always ground the chiller during installation. It may cause electric shock.

• Do not leave refrigerant system open to air any longer than necessary.

- If the repair cannot be completed, seal the circuits to prevent any contamination or rust within the product, and

charge dry nitrogen.

• Do not reuse compressor oil.

- It can damage the product.

• During installation, make the specified grounding before supplying the power, and during the dismantling, remove

the grounding line at the end of the task.

• Use appropriate meters for measurement. Otherwise, it may cause injury or electric shock.

• Check all power connected to the control panel or starter panel to be shut off while applying the power.

- It may cause electric shock.

• Make sure to discharge the electric current before inspection or repair work.

- It may cause injury or electric shock.

• Do not open the 2nd phase side of the current transformer when power is on.

- High voltage could be discharged causing an electric shock.

• Remove foreign objects(working tools, wires, bolts, washers) after installation, inspection, and repair work.

- They may cause injury, fire, or damage.

• When using a condenser, make sure to verify the complete discharge before applying the power again. (Re-powering within 5 min. is prohibited.)

- It may cause electric shock, fire, damage, or malfunction.

• Change the condenser in case that the expansion exceeds the recommended limit.

It may cause electric shock, fire, damage, or malfunction.

1-2. Caution

Operation & Maintenance

• Always check for gas(refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Do not install the unit where combustible gas may leak.

- There is risk of fire or failure of product

• Keep level even when installing the product.

- Unleveled refrigerant can cause problems to the product.

•

Do not use the product for special usage or location such as preserving animal/plant, precision machine, artifact, etc.

- It may cause property damage.

• Use exclusive wire for the product. Use power cables of sufficient current carring capacity and rating.

- It may cause fire and electric shock.

•

When installing the unit in a hospital, communication station, or similar place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frquency medical equipment, or radio communication

equipment may cause the chiller to operate erroreously, or fail to operate. On the other hand, the chiller may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• To protect the product from corrosion, do not install the product where it is exposed to sea wind(salt spray) directly.

If necessary, please install shield.

- It may cause product deformation and defects.

• Make the connections securely so that the outside force of the cable may not be applied to the termianls.

- Inadequate connetion and fastening may generate heat and cause fire. If the power cable got damaged, do not directly replace it, but call the service center for replacement first.

• Do not use the product in special environments.

- Oil, steam and sulfuric steam can deteriorate the product performance or cause damage to the parts.

• Be careful when transporting the product.

- When carrying the chiller, always consult with the specialized expert. When transporting the chiller, always follow

the methods described in the manual. If not, it can cause overturn, fall etc.

ENGLISH

6

1. CAUTIONS FOR SAFETY _ WARNING/CAUTION

• Be sure the installation area does not deteriorate with age

- If the base collapses, the chiller could fall with it, causing property damage, product failure, or personal injury.

• Be sure to dispose the packing materials safely.

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries. Tear apart

and throw away plastic packing bags so that children may not play with them. If children play with a plastic bag

which was not torn apart, they face the risk of suffocation.

• Do not touch any of the refrigerant piping during and after operation.

- Pipe during and after the operation can be hot or cold depending on the condition of the refrigerant flowing

through the refrigerant pipe, compressor and refrigerant cycle parts. Touching the pipes at this time can cause

burns or frostbites.

• Turn on the main power 12 hours before starting to operate the product.

- If you operate the product immediately after turning on the main power, it can severely damage the internal parts.

Keep the main power on while operating.

• Do not immediately turn off the main power after the product stops operating.

- Wait at least 5 minutes before turning off the main power. If not, it may cause water leakage or other problems.

• Do not operate the product with the panel or safety devices removed.

- Rotating parts or high temperature/pressure parts can cause safety accidents.

• Be careful when disposing the product.

- When disposing the chiller, request to the specialized expert.

• Use a firm stool or ladder when cleaning or maintaining the chiller.

- It may cause an injury.

• Be careful of high temperature.

- Be careful not to make body contact to the parts of the chiller in high temperature. It may cause a burn.

• Be careful of high voltage.

- Install separate wiring for the power and always install and use dedicated power supply and circuit breaker. It can

cause electric shock and fire.

• Be careful of chiller installation.

- Keep enough clearance around the product for service and especially for air cooling type, install the product at well

ventilated location where there is no obstacle.

• Harsh chemical, household bleach or acid cleaner should not used to clean outdoor or indoor coils of any kind.

- These cleaners can be very difficult to rinse out of the coil and can accelerate corrosion at the fin/tube interface

where dissimilar materials are in contact. Use environment friendly cleaner.

• Be careful when restarting the product.

- When a safety device is triggered, remove the cause and then restart the product. Repeating the operation arbi-

trarily can cause fire and defect.

• Use appropriate tools.

- Use tools appropriate for the repair work and calibrate the measuring devices accurately before using. Using inap-

propriate tools can cause an accident.

• Be careful of sound and odor.

- If you hear a weird sound or smell an odor, immediately stop operating the system and contact the service center.

It may cause fire, explosion or injury.

• Be careful of injury.

- Check the safety label of the safety device. Follow the above precautions and the contents in the label. It may

cause fire and injury. To prevent the formation of the condensed water, the pipe connected to the evaporator as

well as the evaporator itself should be well insulated.

• Check.

- Perform periodic checks. If any problem occurs, stop the operation and contact the service center. Insufficient

check may cause fire, explosion or error.

• Do not attempt to bypass or alter any of the factory wiring.

- Any compressor operation in the reverse direction will result in a compressor failure that will require compressor

replacement.

• Do not use jumpers or other tools to short out components, or bypass the parts differently from recommended procedures.

-

Short-circuiting the control board ground line with other wires can damage the electric module or electric components.

• Water must be within design flow limits, and should be treated cleanly.

- This make it possible to ensure proper machine performance and reduce the potential of tubing damage due to

corrosion, scaling, erosion and algae. LG Electronics is not responsible for any damage caused by cooling water

not treated or improperly treated.

• Consult a water treatment specialist for proper treatment procedures.

- Hard scale may require chemical treatment for its prevention or remove.

ENGLISH

1. CAUTIONS FOR SAFETY _ WARNING/CAUTION

7

ENGLISH

• Do not overcharge refrigerant to the system.

- Refrigerant overcharging results in higher discharge pressure with higher cooling fluid consumption. Also it can

damage the compressor and increase the power consumption. Also it can damage the compressor and increase

the power consumption.

• Do not add different type of oil.

- It may cause abnormal operation of chiller.

• Turn controller power off before service work.

- It secures safety and prevents damage to the controller.

• Maintain the compressor oil pressure to normal level.

- Use proper safety precautions whem relieving pressure.

• Welding the evaporator head or nozzle part is not recommended.

- If the part requires welding, remove the chilled water flow switch and entering/leaving fluid thermistors before

welding. After the welding is completed, reinstall the flow switch and thermistors. Failure to remove these devices may cause component damage.

• Do not open the circuit breaker arbitrarily during the operation.

- It may cause damage or malfunction.

• Do not operate with wet hand.

- It may cause electric shock.

• During maintenance work, check whether all of the power lines connected to the control panel or starter panel are

interrupted.

- It may cause electric shock.

• When power is on, do not open the door of control panel or starter panel, and protective cover.

- It may cause electric shock.

• Do not open the circuit breaker without permission while running.

- It may cause damage or malfunction.

• Tighten bolts and screws with the specified torque.

- Otherwise, it may cause fire, damage, or malfunction.

• Do not change electric or control devices arbitrarily.

- It may cause fire, damage, or malfunction.

• Only the persons who have sufficiently studied the user's manual should operate the control panel or starter panel.

- Otherwise, it may cause injury, fire, malfunction, or damage.

• Do not perform welding work near cables connected to the main unit.

- Otherwise, it may cause fire or damage.

• Connect only the input/output signal cables specified in the drawing to the control panel or starter panel.

- Otherwise, it may cause malfunction or damage.

• Use the rated electrical cables.

- If not, it may cause fire or damage.

• Use specified parts for repair.

- If not, it may cause fire or damage.

• Install the machine, control panel, and starter panel at a place where there is no combustible material.

- Otherwise, it may cause fire.

• Do not exceed the voltage supply limit described in the relevant manual.

- Otherwise, it may cause damage or malfunction.

• Connect the signal cables connected to the control devices following the circuit diagram.

- It may cause damage or malfunction.

• Do not store the product in a place where is a flooding risk or a lot of moisture.

- Otherwise, it may cause damage or malfunction.

• Do not use the indoor control panel or starter panel outside of the building.

- Otherwise, it may cause damage or malfunction.

8

TABLE OF CONTENTS

ENGLISH

Thank you for purchasing the Water Cooled Centrifugal Chiller of LG Electronics.

Installation as instructed after reading this manual will ensure the safety, convenience and long lifetime of the unit.

• Please read this manual carefully for the correct installation and proper operation of the Centrifugal Chiller unit.

• Once the installation completed, please run the commissioning and inspect according to the operating & maintenance manual.

h This manual describes safety cautions for installation, general information, carrying and installation and wiring infor-

mation of the Water Cooled Centrifugal Chiller.

3 1. CAUTIONS FOR SAFETY

_ WARNING/CAUTION

3 1-1. Warning

5 1-2. Caution

9 2. INTRODUCTION

9 2-1. General introduction

9 2-2. System structure

10 2-3. Nomenclature

10 2-4. Name plate

11 2-5. Main unit conversions

13 3. STRUCTURE OF SCREW

CHILLER

13 3-1. Chiller cycle

14 3-2. Main components of Screw chiller

22 4. CONTROL SYSTEM

22 4-1. Components of control panel and main

parts

29 4-2. Outside view of Startup panel - Stan-

dard Type

30 4-3. Basic control algorithm

31 4-4. BMS support function

32 4-5. Control screen (Product function)

34 4-6. Screw Chiller Timing Sequence –

Run & Stop

70 4-7. Product Protection Function

70 Check points before inspection

73 5. CHECK AND TROU-

BLESHOOTING

74 5-1. Check

74 Check points before inspection

74 Check items after inspection

76 6. Commissioning

76 6-1. Delivery and Installation Check

78 6-2. Preparation for Commissioning

85 6-3. Commissioning and startup

86 6-4. Startup procedure after stopping run

for a long time

87 6-5. Stop running the product

88 7. MAINTENANCE

88 7-1. Maintenance and inspection standard

91 7-2. Periodic inspection

95 7-3. Maintenance during off-season

96 7-4. Periodical maintenance table

98 7-5. Operation Inspection Table

99 7-6. Oil maintenance

100 7-7. General maintenance

104 8. TROUBLESHOOTING

104 8-1. Causes and actions for alarms

115 8-2. Chiller problems and actions

117 8-3. Actions for screw compressor status

118 9. OPERATION RECORD

CHECK

118 9-1. Operation record check list

TABLE OF CONTENTS

2. INTRODUCTION

9

ENGLISH

2-1. General Information

This manual describes the installation of water cooled screw chiller with X30 controller applied.

2-2. System structure

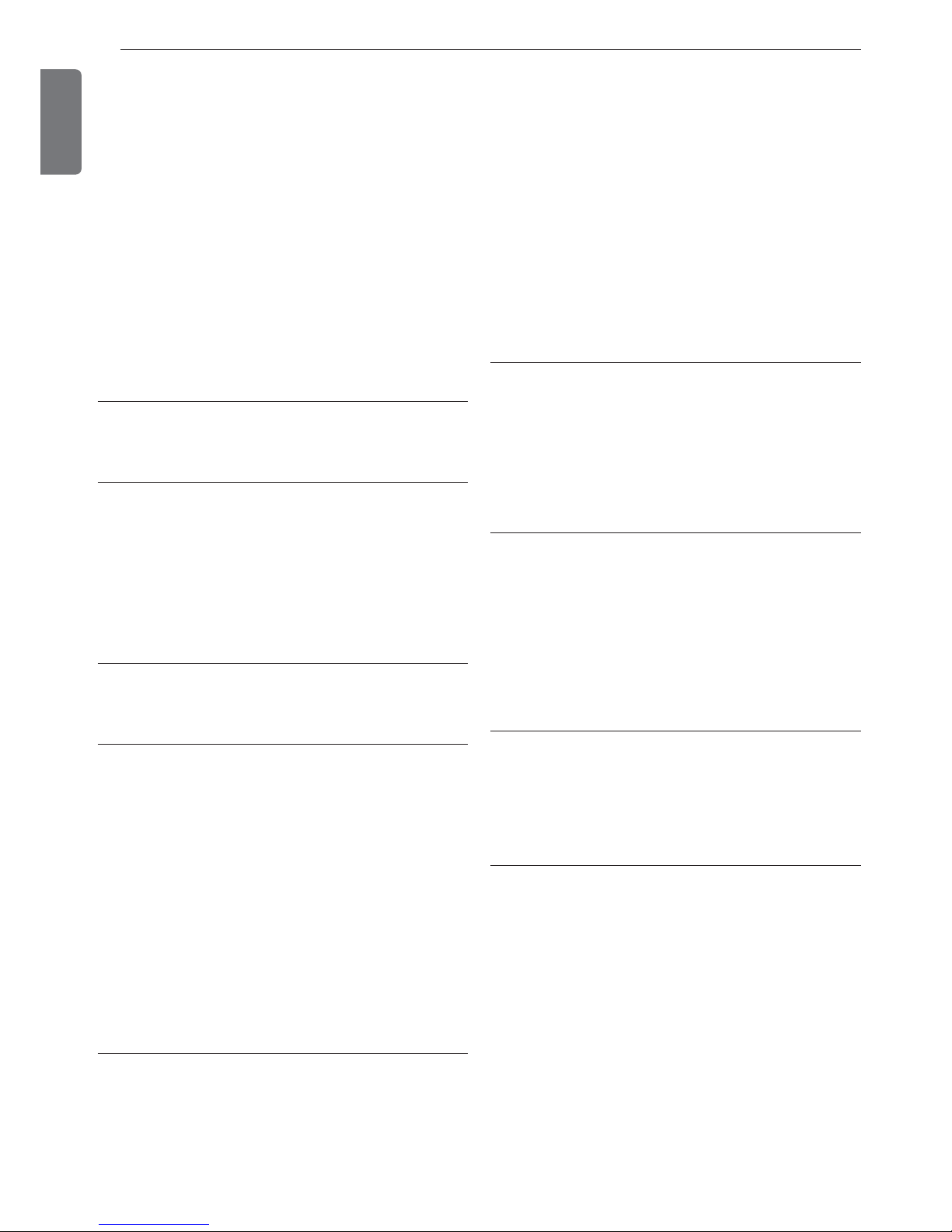

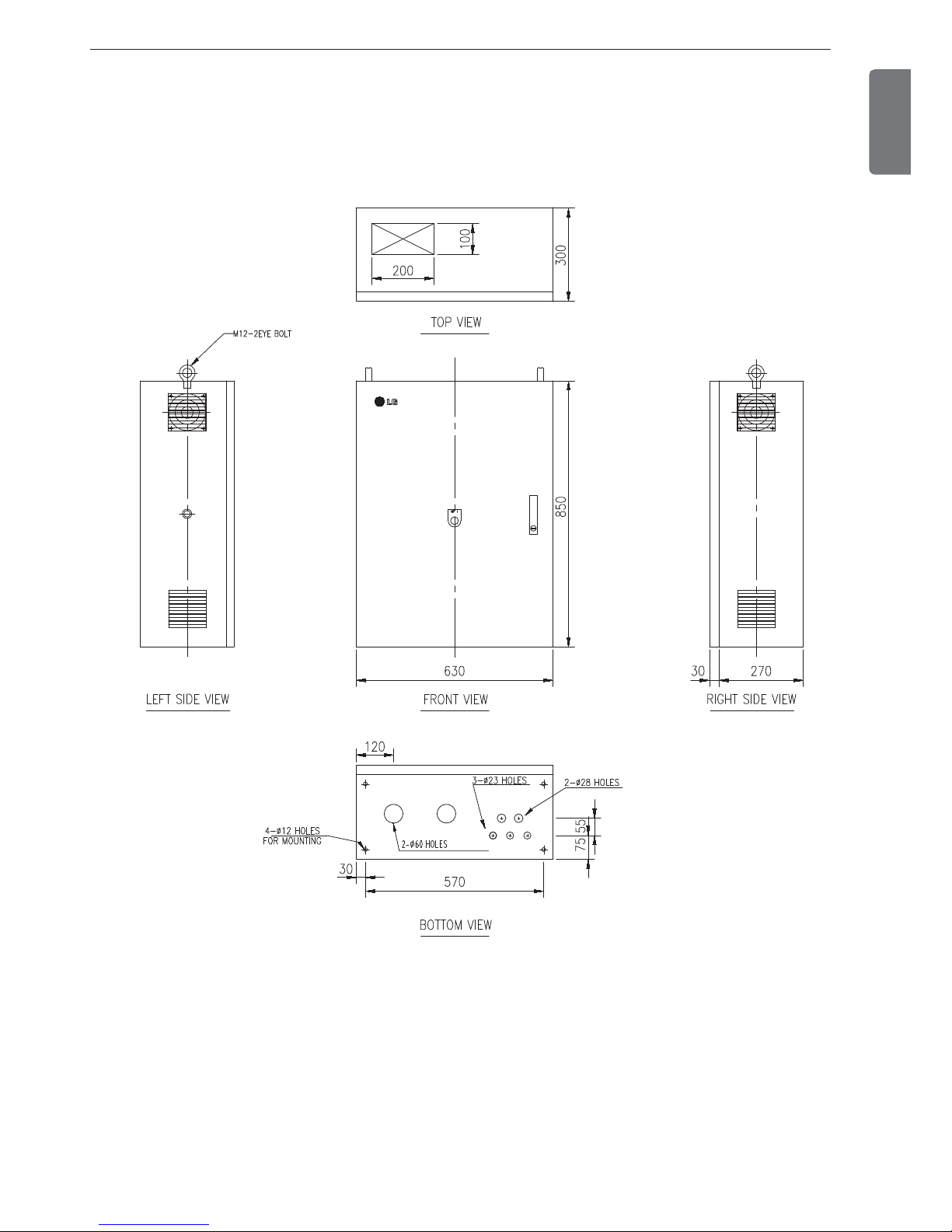

Figure 1 shows the general parts location and components of the water cooled screw chiller.

The location of control panel, type of waterbox, directions of inlet and outlet of the chilled water and cooling water

and some pipes may vary by model or customer order. Please check the approved drawings for the details.

* Prepare and check the approved drawing that fits the site.

1

2

10

4

5

6

7

8

3

9

12 11

13

15

14

16

18

17

19

Part Name

1. Screw compressor

2. Relief valve for condenser

3. Relief valve for evaporator

4. Air vent for cooling water

5. Air vent for chilled water

6. Drain for cooling water

7. Drain for chilled water

8. Lifting hole(4 holes) for condenser

9. Lifting hole(4 holes) for evaporator

10. Sight glass for evaporator

11. Control panel

12. Starter panel

13. Flow switch (Chilled water)

14. Flow switch (Cooling water)

15. Temperature sensor (Chilled water outlet)

16. Temperature sensor (Cooling water outlet)

17. Temperature sensor (Chilled water inlet)

18. Temperature sensor (Cooling water inlet)

19. Sight glass for condenser

Front view

Rear view

Figure 1 General structure of screw chiller

2. INTRODUCTION

10

2. INTRODUCTION

ENGLISH

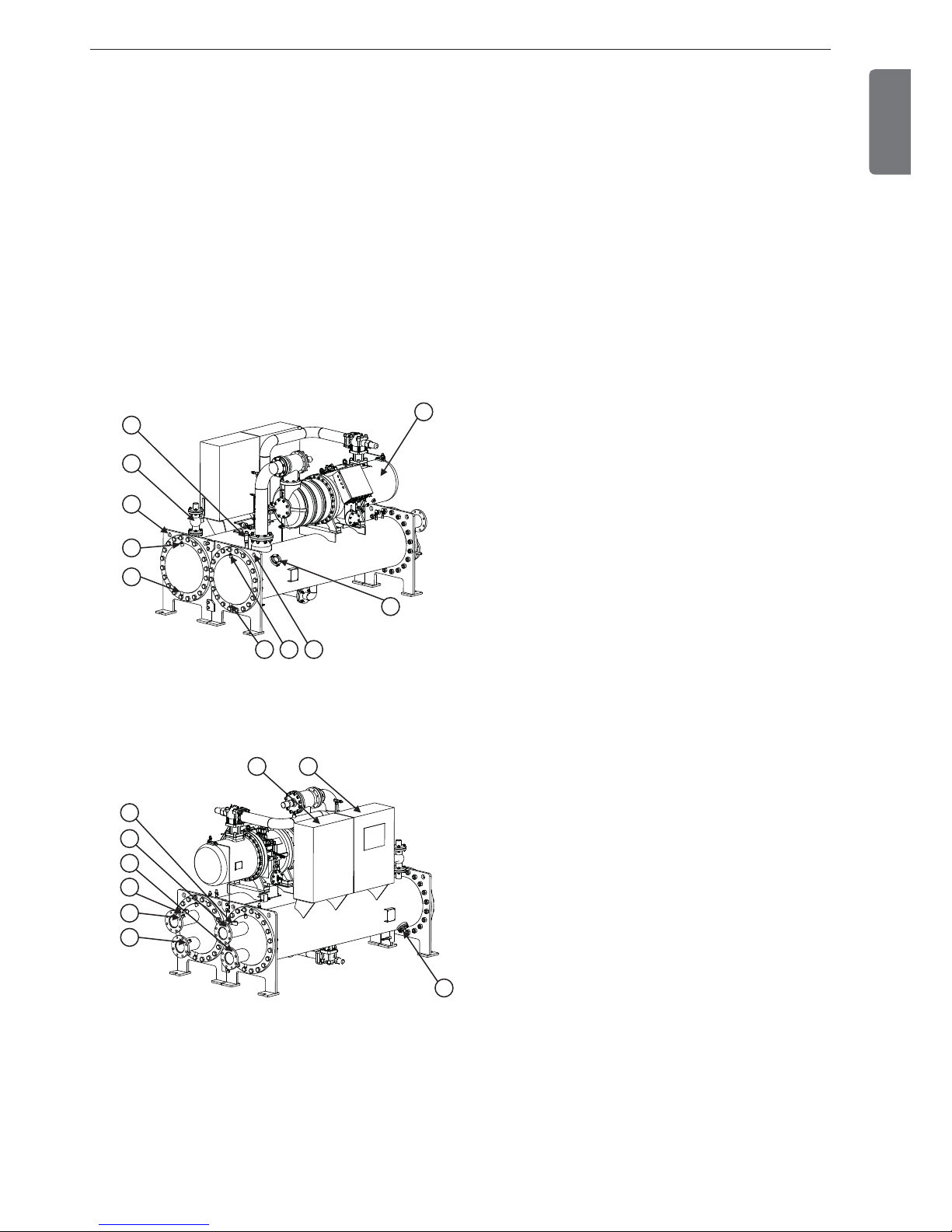

2-4. Name plate

Name plate for the unit is attached on the control panel. General information of the chiller unit can be obtained from

the plate and the information of the unit history can be used for quicker service.

Fig. 3. Product plate

① Model name

② Refrigerant

③ Cooling capacity

④ Power and current required for motor

⑤ Manufacture's serial number

⑥ Internal pressure test pressure

⑦ Maximum working pressure (Design pressure)

⑧ Volume of Evaporator

⑨ Volume of Condenser

⑩ Power electricity

⑪ Control electricity

⑫ Temperatures of Chilled water inlet/outlet

⑬ Temperatures of Cooling water inlet/outlet

⑭ Maximum pressure of chilled water and cooling water

2-3. Nomenclature

The model naming for screw chiller is done as follows.

RCWW030A A 1 1

R : R-134a

Compressor

quantity

C:Chiller

Development sequence

order

W : Screw

compressor

A : Flooded type

B : Direct expansion type

C : Falling film system

M : Ice Storage High Efficiency

R : Heat recovery

N : Nuclear PJT, High Efficiency

W : W type condenser

V : V type Condenser

S : Special

W : Water-cooled

cooling only

K : Water-cooled

heat pump

A : Air-cooled cool-

ing only

Compressor nominal

capacity in Tons(usRT)

10RT ⇨ 001

100RT ⇨ 010

130RT ⇨ 013

1000RT ⇨ 100

Cooling/chilled water maximum working pressures

A : Chilled water 10kg/cm

2

,

Cooling water 10kg/cm

2

B : Chilled water 16kg/cm2,

Cooling water 16kg/cm

2

C : Chilled water 20kg/cm2,

Cooling water 20kg/cm

2

D : Chilled water 8kg/cm2,

Cooling water 8kg/cm

2

E : ETC

Figure 2. Nomenclature

2. INTRODUCTION

11

• °F = (9/5 x °C) + 32

• °C = 5/9 x (°F - 32)

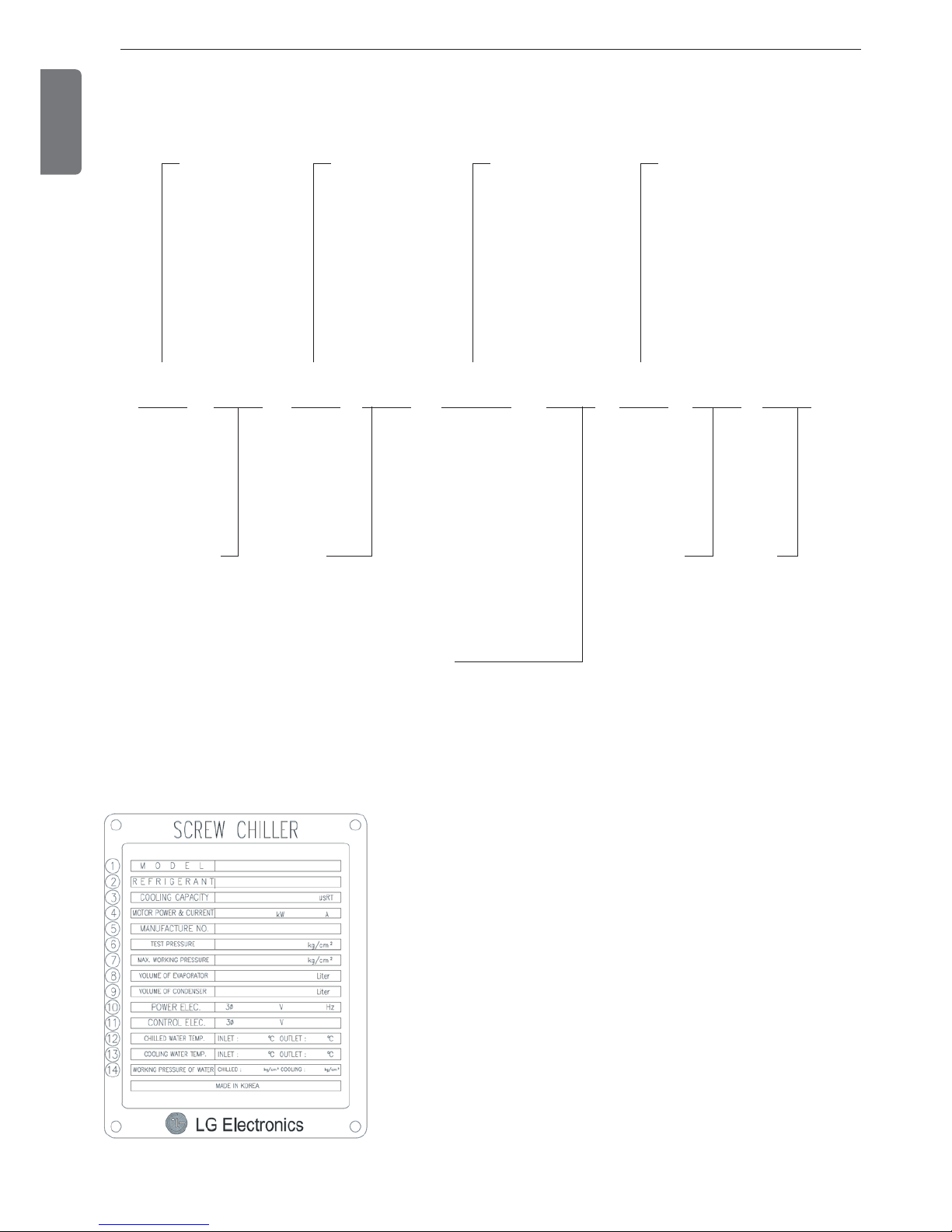

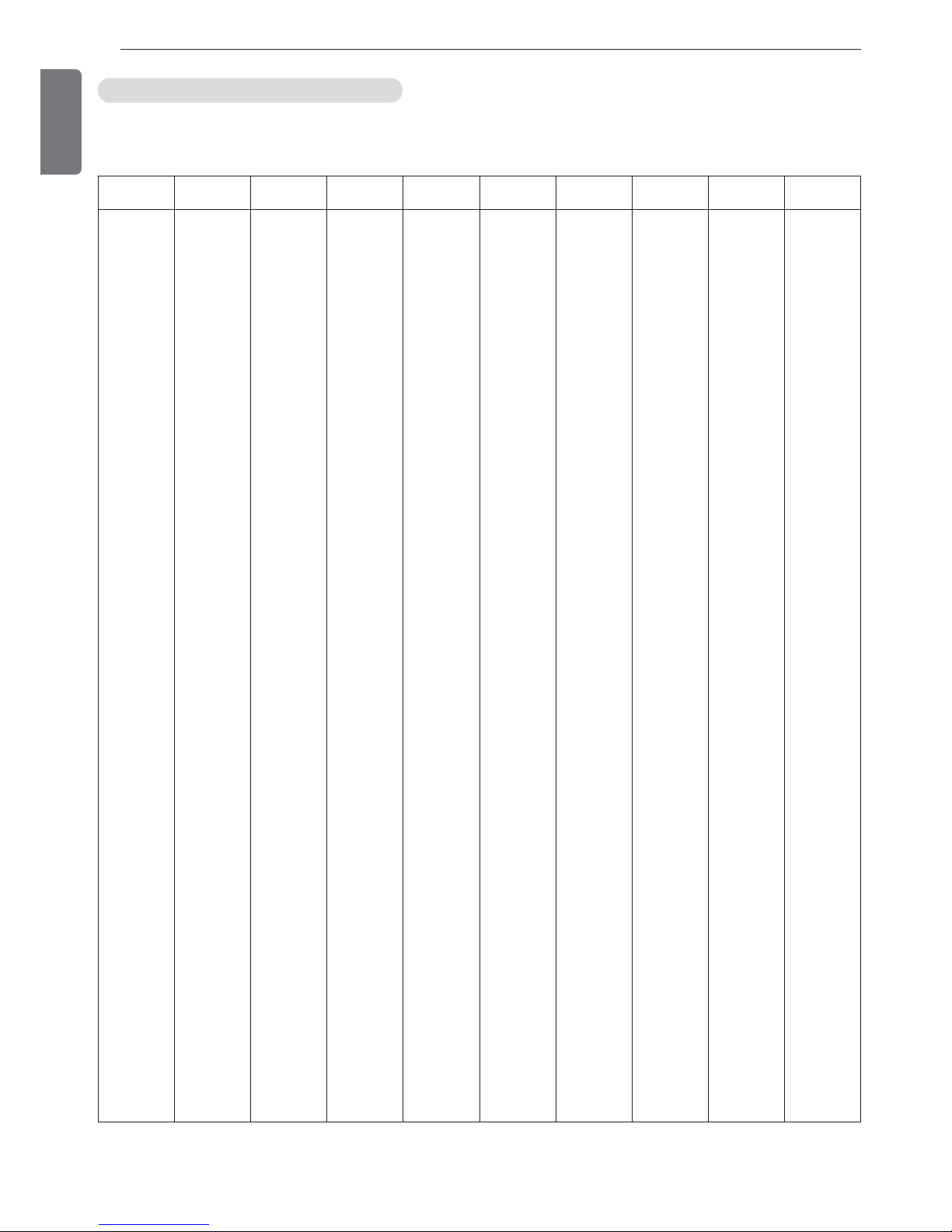

2-5. Main unit conversions

ENGLISH

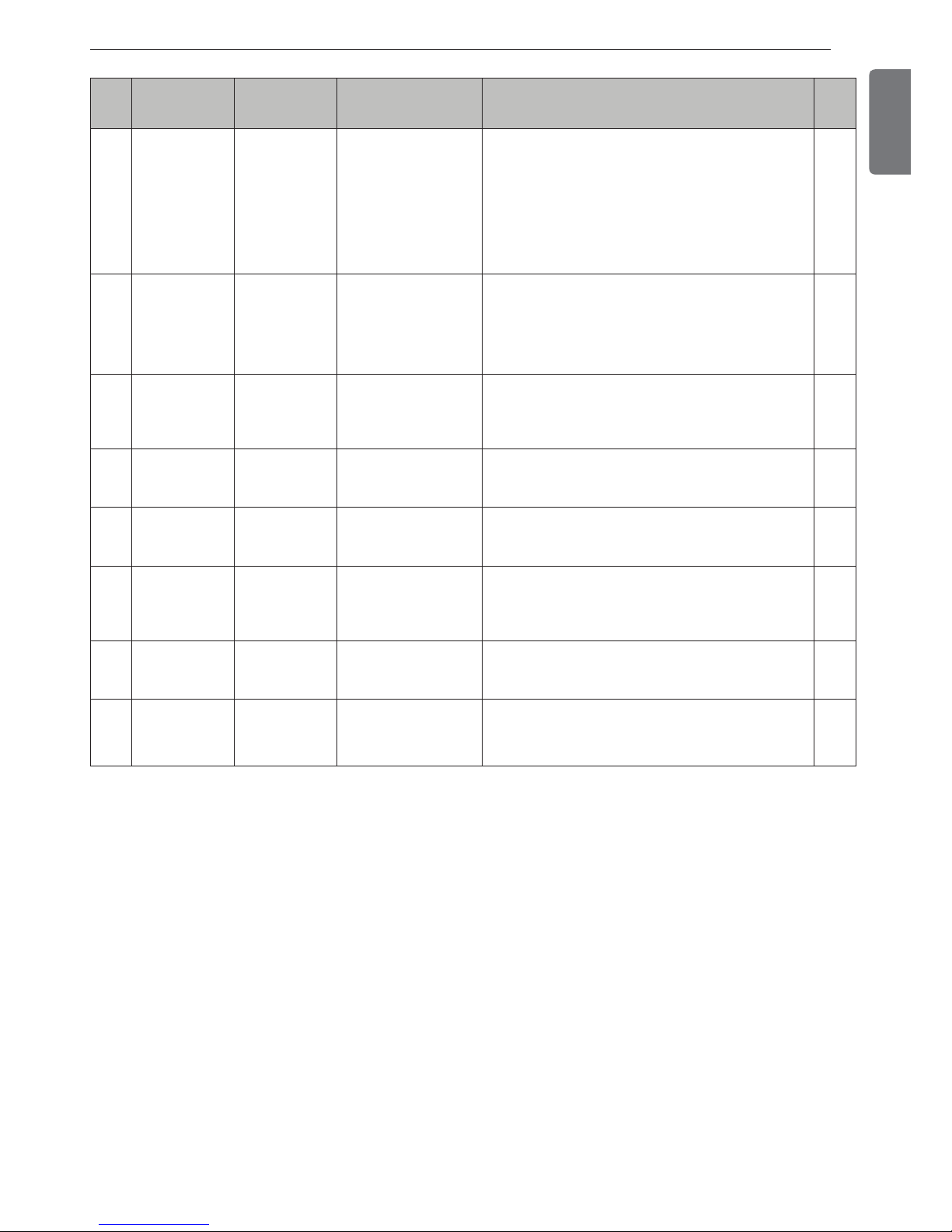

°F °C °F °C °F °C °F °C °F °C

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

-17.2

-16.7

-16.1

-15.6

-15.0

-14.4

-13.9

-13.3

-12.8

-12.2

-11.7

-11.1

-10.6

-10.0

-9.4

-8.9

-8.3

-7.8

-7.2

-6.7

-6.1

-5.6

-5.0

-4.4

-3.9

-3.3

-2.8

-2.2

-1.7

-1.1

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

-0.6

0

0.6

1.1

1.7

2.2

2.8

3.3

3.9

4.4

5.0

5.6

6.1

6.7

7.2

7.8

8.3

8.9

9.4

10.0

10.6

11.1

11.7

12.2

12.8

13.3

13.9

14.4

15.0

15.6

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

16.1

16.7

17.2

17.8

18.3

18.9

19.4

20.0

20.6

21.1

21.7

22.2

22.8

23.3

23.9

24.4

25.0

25.6

26.1

26.7

27.2

27.8

28.3

28.9

29.4

30.0

30.6

31.1

31.7

32.2

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

32.8

33.3

33.9

34.4

35.0

35.6

36.1

36.7

37.2

37.9

38.3

38.9

39.4

40.0

40.6

41.1

41.7

42.2

42.8

43.3

43.9

44.4

45.0

45.6

46.1

46.7

47.2

47.8

48.3

48.9

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

49.4

50.0

50.6

51.1

51.7

52.2

52.8

53.3

53.9

54.4

55.0

55.6

56.1

56.7

57.2

57.8

58.3

58.9

59.4

60.0

60.6

61.1

61.7

62.2

62.8

63.3

63.9

64.4

65.0

65.6

Table 1 Temperature conversion table

Temperature conversion table (°F ↔ °C)

12

2. INTRODUCTION

ENGLISH

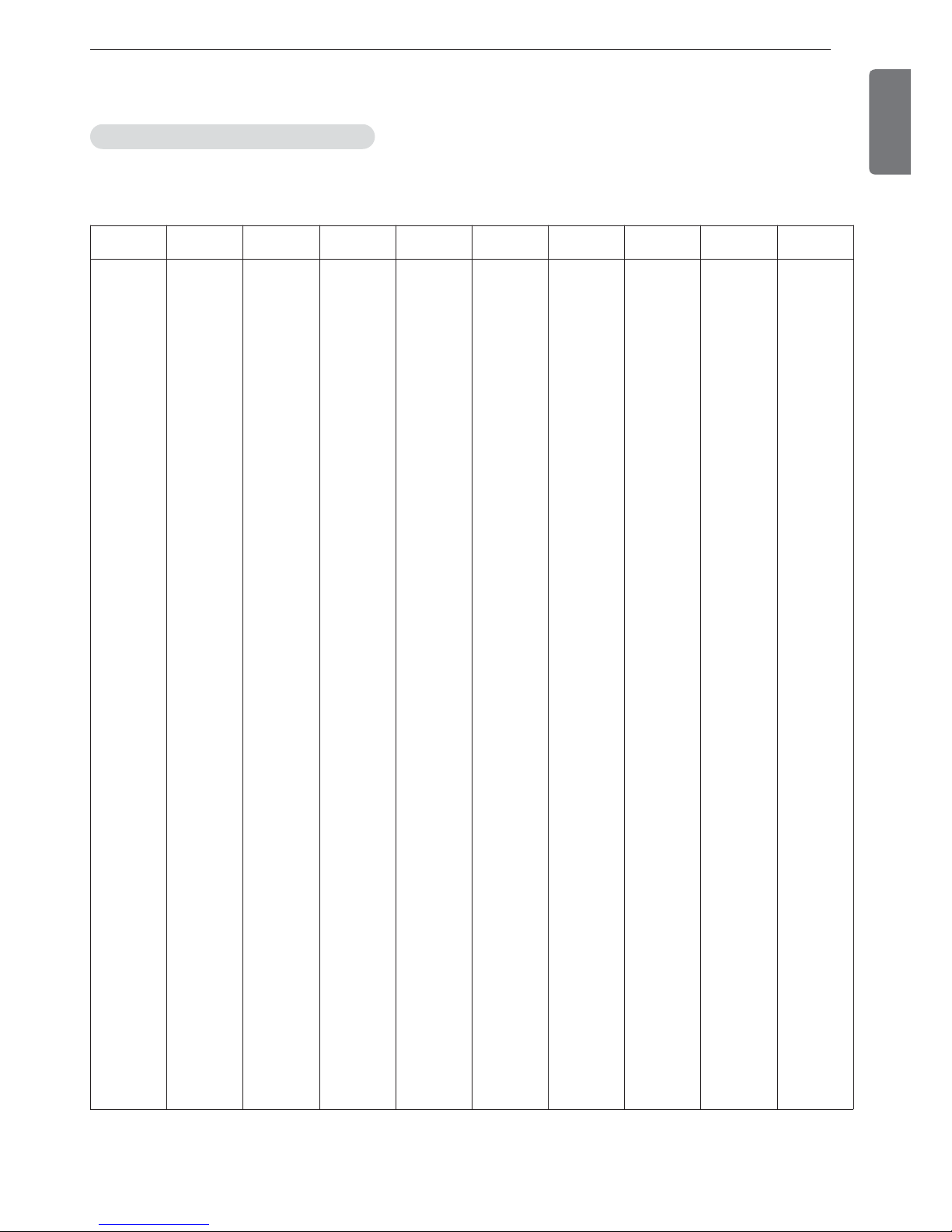

• lb/in2= psi

ex) 1 lb/in2 = 0.07030696 kg/cm

2

lb/in

2

kg/cm

2

lb/in

2

kg/cm

2

lb/in

2

kg/cm

2

lb/in

2

kg/cm

2

lb/in

2

kg/cm

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

0.070

0.141

0.211

0.281

0.352

0.422

0.492

0.563

0.633

0.703

0.773

0.844

0.914

0.984

1.055

1.125

1.195

1.266

1.336

1.406

1.477

1.547

1.617

1.687

1.758

1.828

1.898

1.969

2.039

2.109

2.180

2.250

2.320

2.390

2.461

2.531

2.601

2.672

2.742

2.812

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

2.883

2.953

3.023

3.094

3.164

3.234

3.304

3.375

3.445

3.515

3.586

3.646

3.726

3.797

3.867

3.987

4.008

4.078

4.148

4.218

4.289

4.359

4.429

4.500

4.570

4.640

4.711

4.781

4.851

4.921

4.992

5.062

5.132

5.203

5.273

5.343

5.414

5.484

5.554

5.625

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

5.695

5.765

5.836

5.906

5.976

6.046

6.117

6.187

6.257

6.328

6.398

6.468

6.539

6.609

6.679

6.750

6.820

6.890

6.968

7.031

7.101

7.171

7.242

7.312

7.382

7.453

7.523

7.593

7.663

7.734

7.804

7.874

7.945

8.015

8.085

8.156

8.226

8.296

8.367

8.437

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

8.507

8.577

8.648

8.718

8.788

8.859

8.929

8.999

9.070

9.140

9.210

9.281

9.351

9.421

9.491

9.562

9.632

9.702

9.773

9.843

9.913

9.984

10.05

10.12

10.19

10.26

10.34

10.41

10.48

10.55

10.62

10.69

10.76

10.83

10.90

10.97

11.04

11.11

11.18

11.25

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

11.32

11.39

11.46

11.53

11.60

11.67

11.74

11.81

11.88

11.95

12.02

12.09

12.16

12.23

12.30

12.37

12.44

12.51

12.58

12.66

12.73

12.80

12.87

12.94

13.01

13.08

13.15

13.22

13.29

13.36

13.43

13.50

13.57

13.64

13.71

13.78

13.85

13.92

13.99

14.06

Table 2. Pressure conversion table

Pressure conversion table (lb/in2↔ kg/cm2)

3. STRUCTURE OF SCREW CHILLER

13

3. STRUCTURE OF SCREW CHILLER

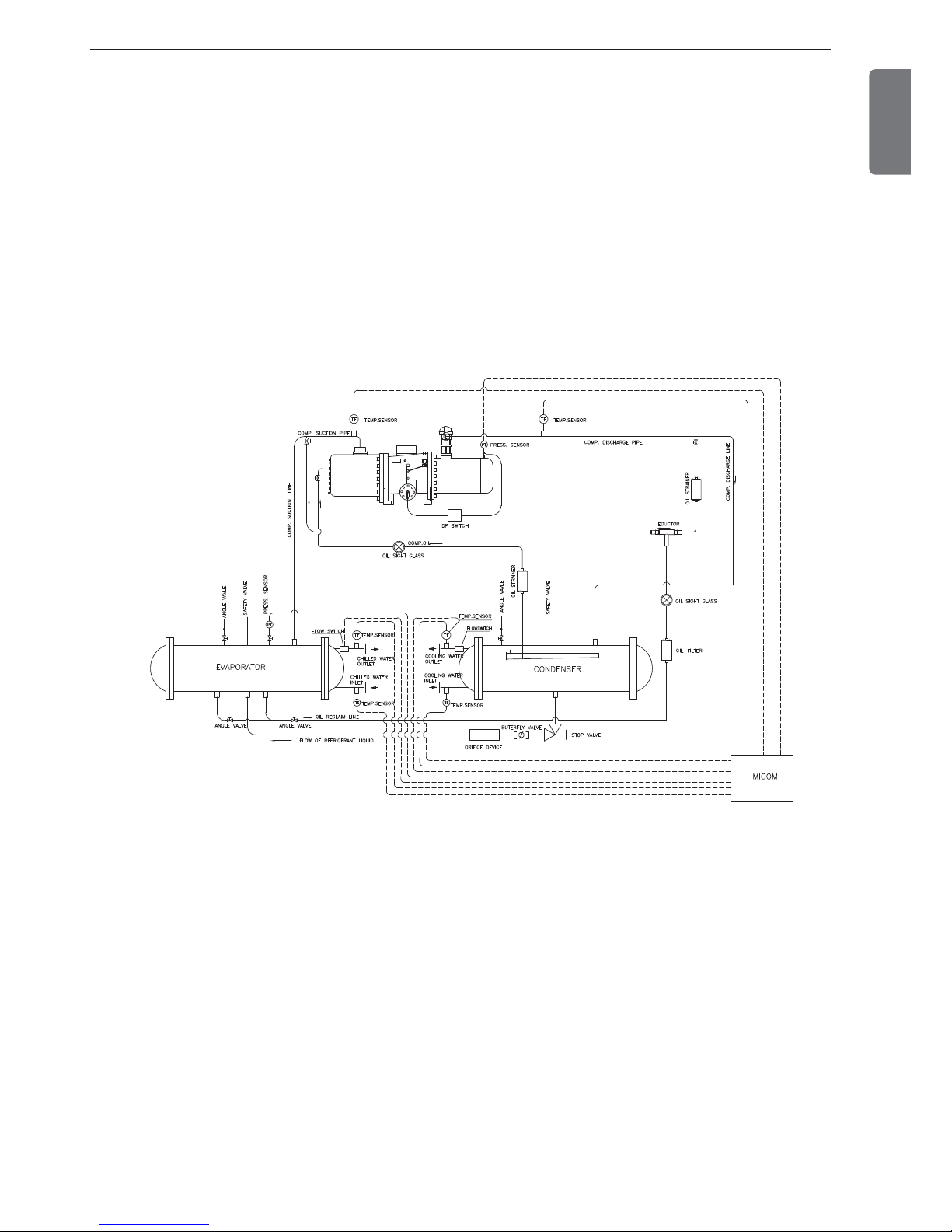

3-1. Chiller cycle

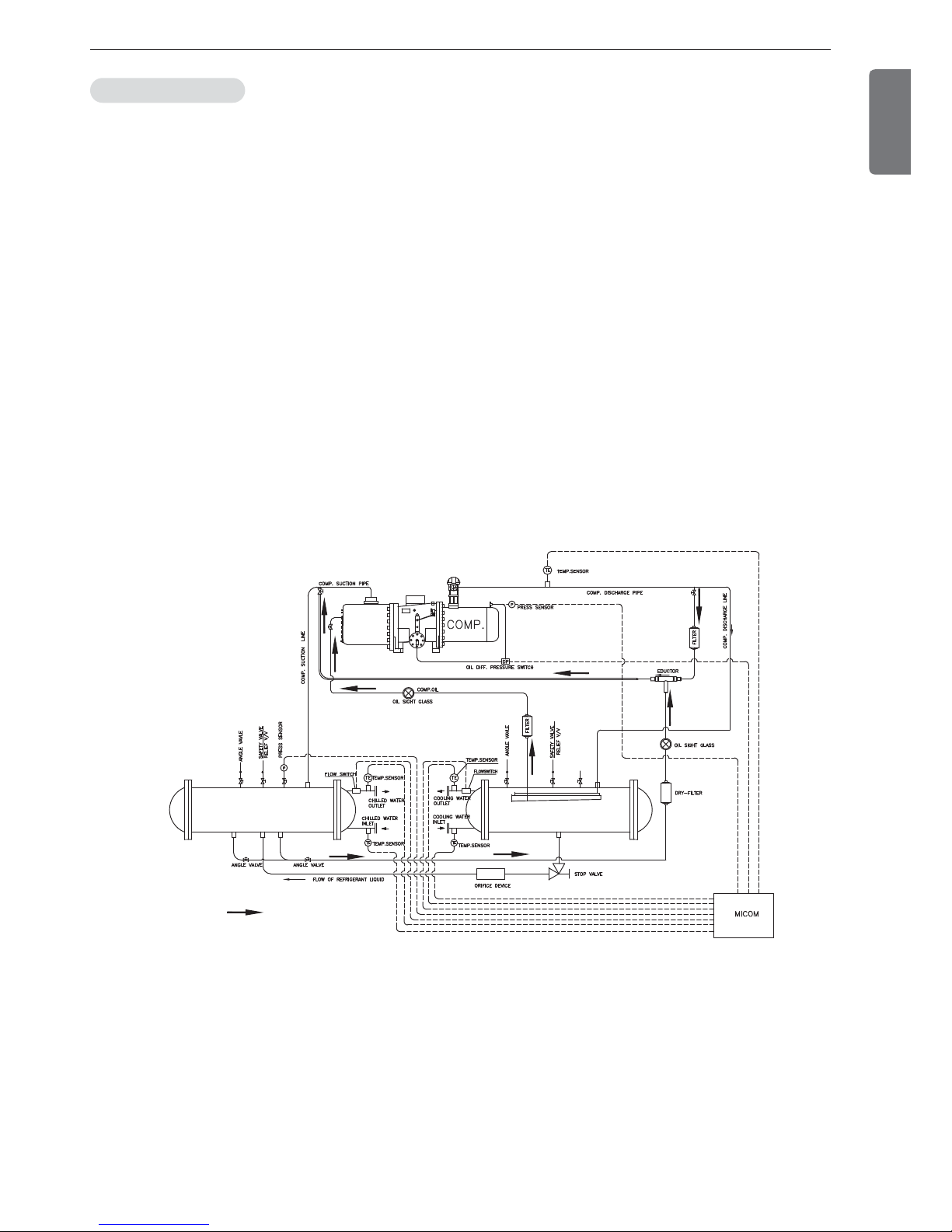

As shown in the chiller cycle figure below, the compressor discharges the high temperature/pressure refrigerant to

the condenser through the exhaust outlet in gas state. The refrigerant in the gas state in the condenser flows outside of the tube, while the cooling water flows inside of the tube. The refrigerant in high temperature and pressure

is condensed as the heat is taken away by the cooling water inside the heat pipe of the condenser. The condensed

refrigerant is gathered in the bottom of the condenser and goes through the dryer filter, orifice or expansion valve

by differential pressure, and into the evaporator. The chilled water is finally obtained in the chiller’s evaporator. During the gasification stage, the refrigerant in liquid state absorbs a large amount of heat from the cooling water and is

converted into gas state. And during the cooling water is getting colder, the refrigerant in gas state is absorbed into

the compressor. There, the gas state refrigerant is compressed by the compressor into high temp/high pressure refrigerant and sent again to the condenser. And the same cycle begins again.

ENGLISH

Figure 4 Chiller cycle(1 cycle)

14

3. STRUCTURE OF SCREW CHILLER

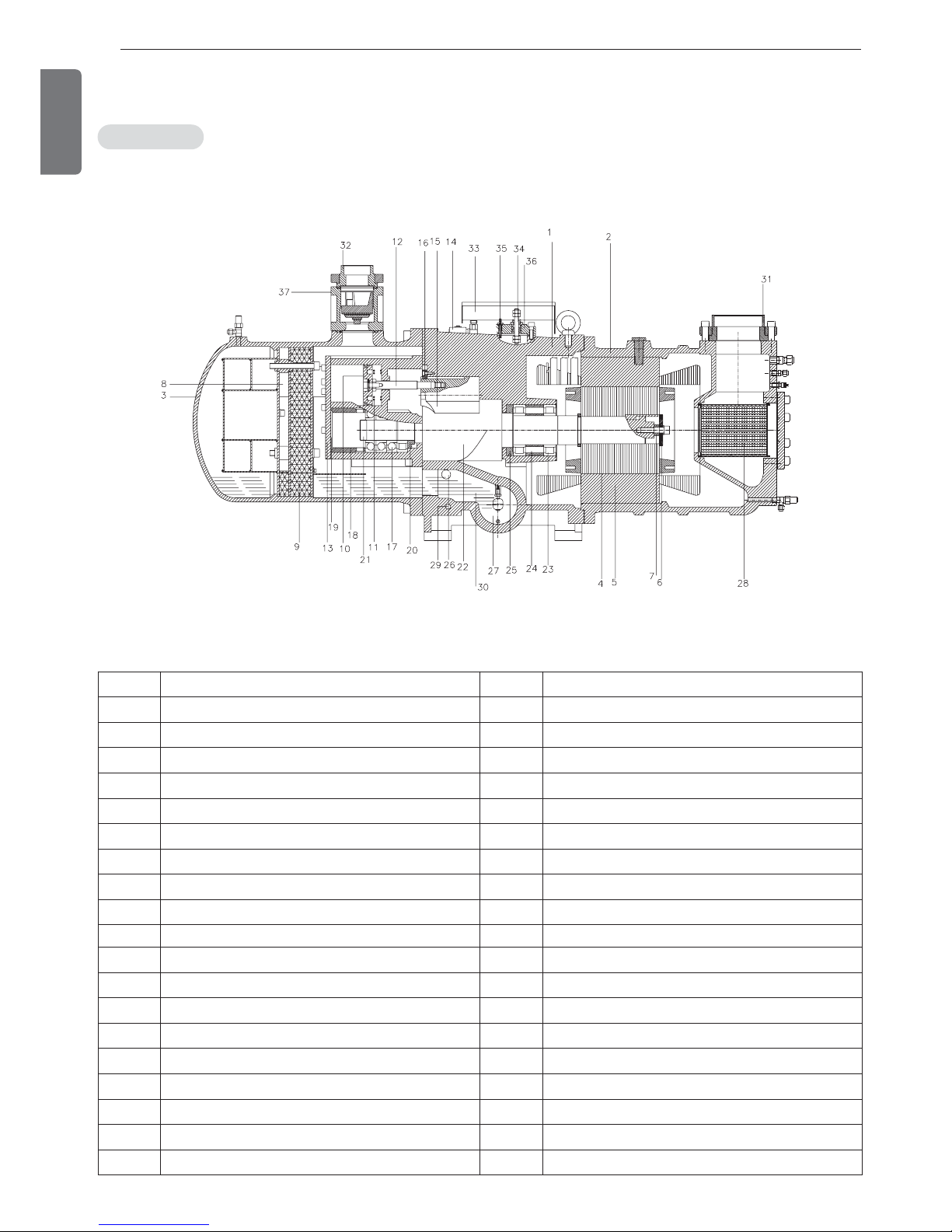

3-2. Main components of Screw chiller

ENGLISH

Compressor

Item Description Item Description

1 Compressor casing 20 α-Balance piston

2 Motor casing 21 Bearing lock nut

3 Oil separator 22 Male rotor

4 Motor rotor 23 Suction side bearings

5 Motor stator 24 Suction side bearings spacer ring

6 Motor rotor washer 25 Oil guide ring

7 Motor rotor spacer ring 26 Oil level sight glass

8 Oil separator baffle 27 Oil filler cartridge

9 Oil separator cartridge 28 Suction filter

10 Piston 29 Oil heater

11 Piston spring 30 Refrigeration lubricant

12 Piston rod 31 Suction flange

13 Bearing seat’s cover plate 32 Discharge flange

14 Solenoid valve 33 Cable box

15 Slide valve 34 Power connection bolt

16 Slide valve key 35 Thermostat terminals

17 Discharge bearings 36 Motor cable cover plate

18 Discharge fixed ring 37 Discharge check valve

19 Disc spring

Figure 5 Screw compressor

In this machine, semi-hermetic twin screw compressor, which was developed especially for air conditioning use, is

installed. The structure of the compressor is shown in the picture below.

3. STRUCTURE OF SCREW CHILLER

15

ENGLISH

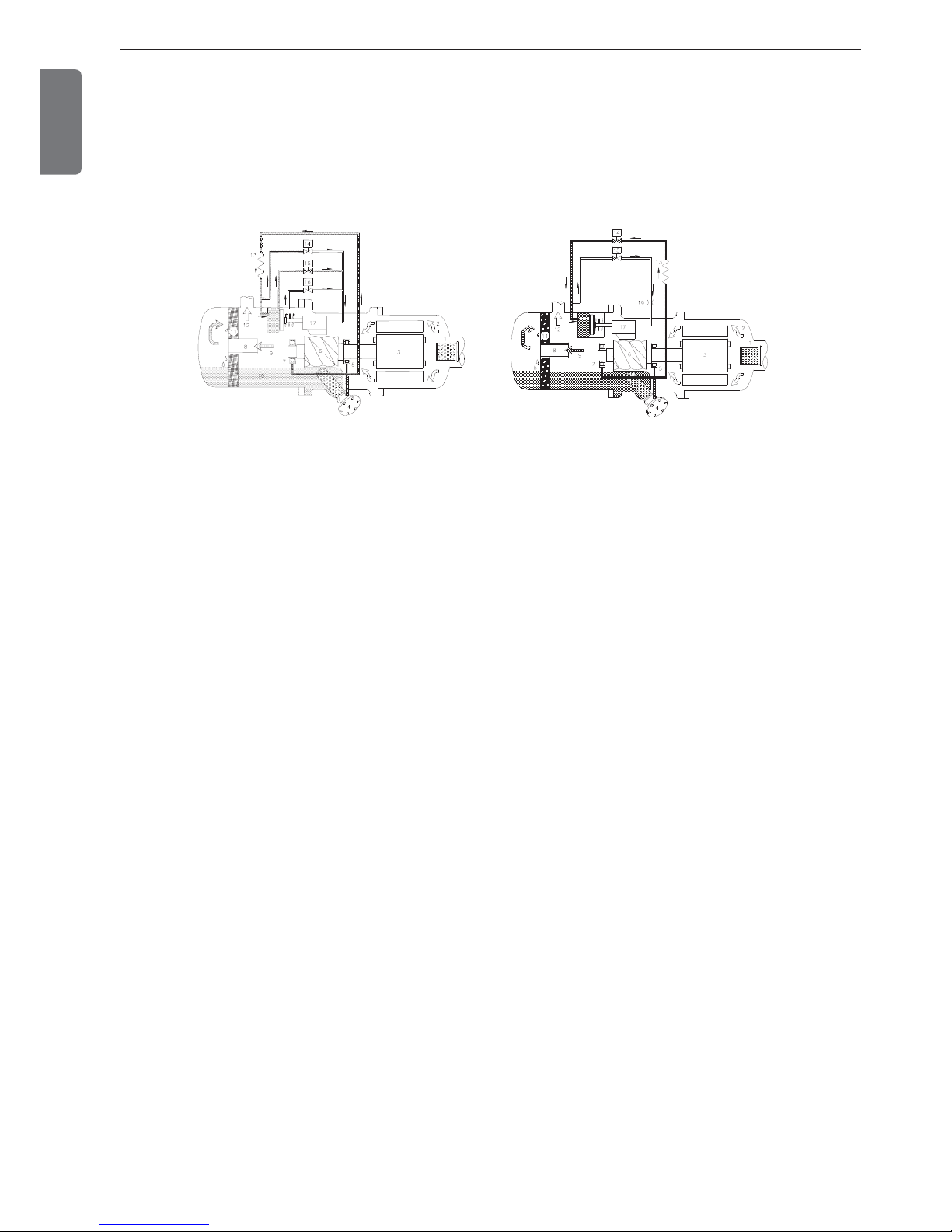

- Compression process

- Capacity control system

As shown in Figure 6 below, during the rotation of the rotors, the absorbed gas is pushed to the discharge side. In other

words, the V-shaped space formed between the male and female rotors is continuously moving to the discharge side.

The gas sealed in the lobe space which is reduced by the discharge side is compressed, and the highly compressed gas at

the end part is discharged to the oil separator. The size and geometry of the outlet port determine the so-called “internal

volume ratio (Vi)” of the compressor. In actual operation, if the compression ratio is either bigger or smaller than this value,

the efficiency will be lowered.

The screw series compressors are equipped with either 3-step/4-step capacity control system or continuous capacity

control system.

The capacity control system consists of slide valve, piston rod, cylinder, piston and piston rings while slide valve and

the piston are connected by the piston rod. The principle of operation is using the oil pressure to drive the piston in

the cylinder as shown in Figure 6, the lubrication oil flows from the oil tank through the oil filter and capillary, then is

charged into the cylinder due to the positive oil pressure which is bigger than the opposite side of spring force plus

the high pressure of the gas.

This pressure difference causes the piston to move toward the right side in the cylinder and the slide valve to move

toward the right side, increasing the amount of compressor outlet, thereby increasing the refrigeration capacity.

Also, when a solenoid valve (in 3-step/4-step capacity control system) is opened, the high pressure oil in the cylinder

is bypassed, which causes the piston and the slide valve to move toward the left side, and some of the refrigerant

gas returns to the suction side. As a result, the discharge amount is reduced and the refrigeration capacity decreases.

When the compressor is stopped, the piston spring pushes the piston back to the original position, thereby reducing

the starting current for the next startup.

If the compressor started at full load capacity it may result in over-current start.

The capillary inhibits the oil flow and makes the piston move smoothly under stepless control or controlled by micom

or temperature switch.

If the oil filter, capillary, or solenoid valves are not working properly, the capacity control system will be operated ab-

normally and make the system useless.

(C) Discharge (B) Compression (A) Suction and sealing

Figure 6 Compression process

16

3. STRUCTURE OF SCREW CHILLER

ENGLISH

4-steps capacity control Step-less capacity control

Figure 7 Capacity control system

Since the compressor should be started at the minimum load condition, the solenoid valve (capacity reducing solenoid valve in stepless control system, or minimum load solenoid valve in the stage control capacity control system)

should be kept open for 20-30 seconds before stopping or starting the compressor so that there is no oil left inside

the cylinder when starting the compressor.

- Lubrication

The main function of the lubrication oil inside the screw compressor is sealing of the inside body, cooling and capacity control. The oil pressure inside the cylinder moves the piston and slide valve which are connected to piston rod inside the compression chamber. Since the screw compressor is designed to include the lubrication system which is

based upon the pressure difference between the high and the low pressure levels, a separate oil pump is not required inside the compressor(such as reciprocating compressor). However, for some special equipment, it is necessary to install an oil pump in the compressor additionally for the safety purpose.

The bearings used in the compressor are of a rather small size, but it needs a definite amount of lubrication oil. The

purpose of feeding oil into the compression chamber is to increase the efficiency and to form oil sealing layer in order

to absorb a part of the compression heat. In order to separate the oil from the refrigerant in which oil is mixed together, the oil separator is designed to allow the oil flow into the system to the minimum. The oil temperature which

is a very important factor to the life of the compressor bearings should be watched very closely.

High oil temperature reduces the oil viscosity and worsens the lubricity and heat absorbability inside the compressor.

It is recommended to keep the oil viscosity above 10mm

2

/s at any temperature. The oil temperature should be kept

above the system condensation temperature in summer season in order to avoid the refrigerant mixed with oil entering into the system. When the outside temperature is low, the oil viscosity rises high, and the compressor which is

of the high durability should be started, thus reducing the oil pressure inside the oil piping which is needed to load oil

into the compressor. A better solution is preheating the oil in order to reach the condensing temperature in a short

period of time.

In the compressor, at least 2 oil level gages are equipped, one is high oil level gage, the other low oil level gage.

The normal amount of oil in the compressor oil tank when the compressor is running, should be in the state that

when the oil level is maintained in the middle range between the top of the low level oil gage and the top of high oil

level gage.

3. STRUCTURE OF SCREW CHILLER

17

ENGLISH

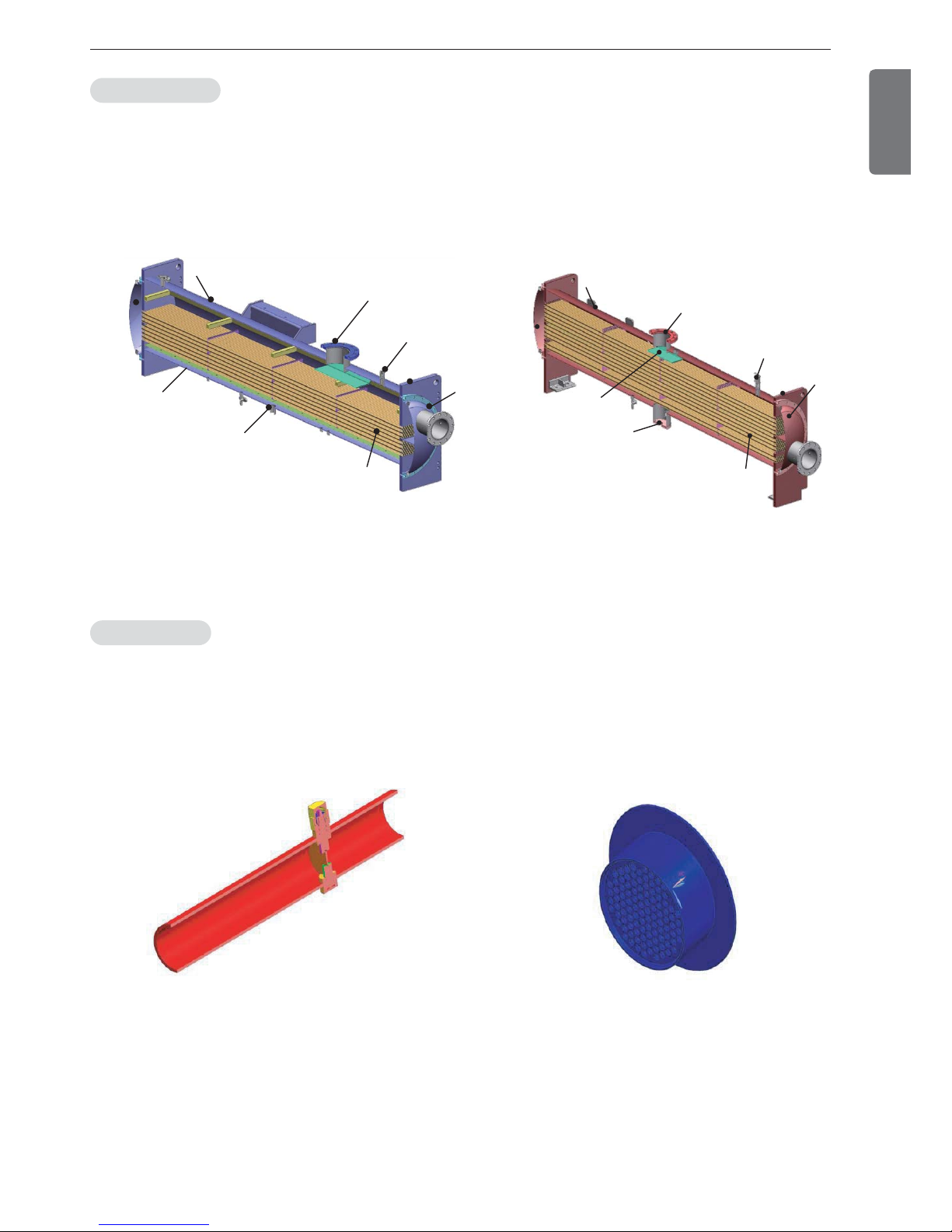

Screw chiller heat exchanger is composed of evaporator and condenser, and has 2 shells which can be conveniently

separated. To maximize the heat exchanging capability, the tube arrangement is optimized, and to prevent the decrease of COP, refrigerant distributor is installed for the even distribution of liquid refrigerant in the entire tubes. And

an efficiency increasing subsidiary cooler is installed for over-cooling of condensed liquid refrigerant.

At the upper part of the heat exchanger, relief valve is installed in cases for abnormal situations.

Heat exchanger

Expansion unit

Safety valve

Refrigerant outlet

Body

Refrigerant distributor

Refrigerant inlet

tube

Refrigerant inlet

Collision

prevention plate

Refrigerant inlet

tube

Safety valve

Inlet

Body

Inlet

Figure 8. Evaporator Figure 9. Condenser

Figure 10. Butterfly valve Figure 11. Orifice

Expansion unit consists of butterfly valve and orifice. At 100% load situation, the pressure loss at the orifice is

smaller than the refrigerant pressure loss in the condenser, thus the super-cooled refrigerant passes through the orifice. At this stage the maximum amount of refrigerant is flowing into the evaporator. As the load reduces gradually,

the circulating amount of refrigerant also reduces and accordingly the refrigerant level in the condenser is getting

low. When the amount of liquid refrigerant reduces, the gas amount in the orifice is getting larger, raising the resistance thus controlling the flow rate.

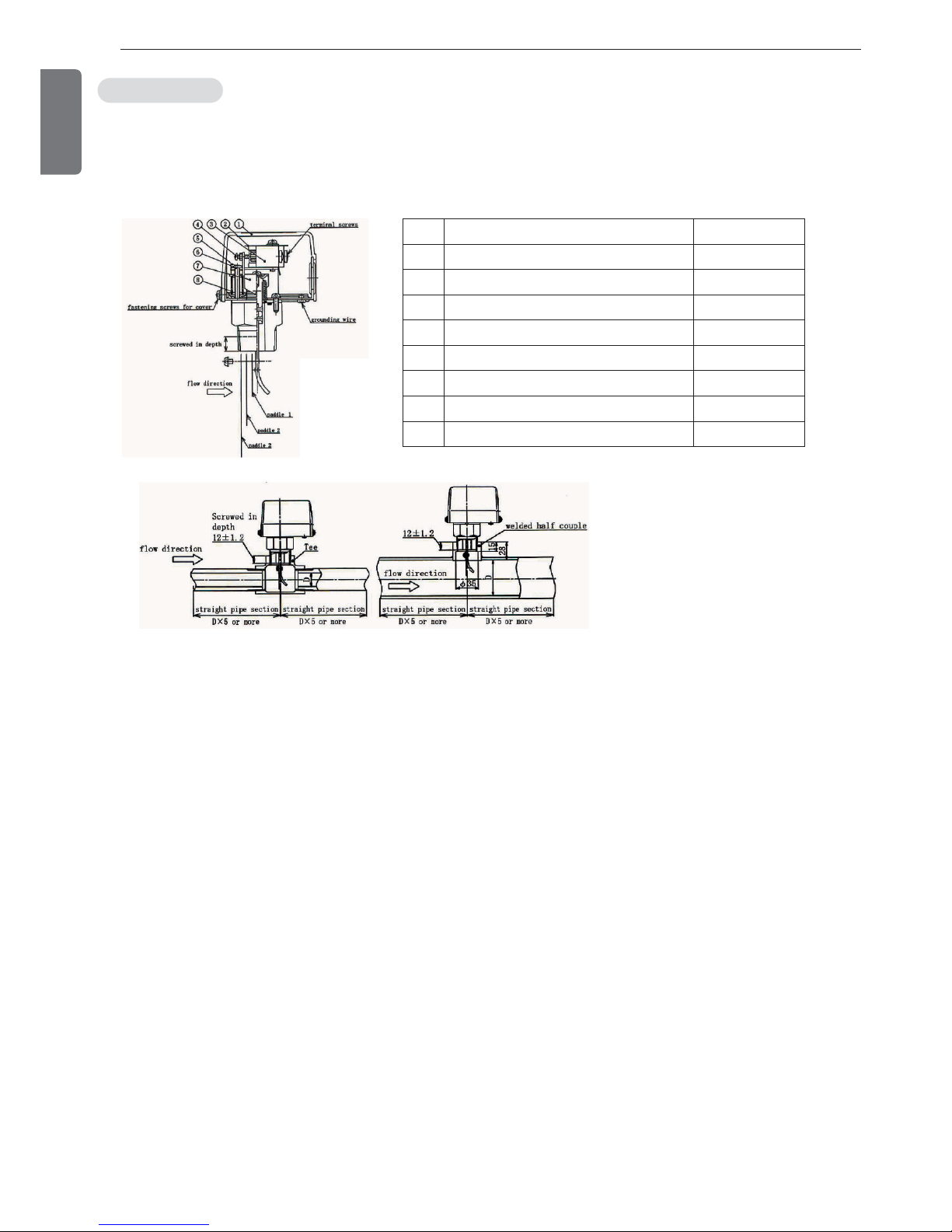

The flow switch is installed at the water outlet nozzles in all equipment as the basic setting. The following figure

shows the flow switch installed in the normal method.

Oil flow switch

Figure 12 Flow switch

18

3. STRUCTURE OF SCREW CHILLER

ENGLISH

Num-

ber

Description Quantity

1 Cover 1

2 Insulation board 1

3 Micro switch 1

4 Adjustment screw 1

5 Metal plate installation for flow control switch 1

6 Flow control screw 1

7 Operation plate 1

8 Adjustment spring 1

3. STRUCTURE OF SCREW CHILLER

19

Screw compressor

Oil recovery eductor

Evaporator

Condenser

Oil line

Oil is gathered in the lower part of the compressor casing while all the oil needed for bearings and capacity control is

filtered by passing through the oil filter. After removing the foreign material the oil is sprayed to the bearings after

passing through the internal oil passage, while at the same time sprayed to the capacity control piston after passing

through the capillary in the outside. Oil flows through the capacity control solenoid valve and is discharged to the

compressor inlet side and absorbed into the rotor groove to lubricate the two rotors. The oil moved into the bearings

at the rear side returns to the inlet side.

The oil level of the compressor should be kept at a proper level during the compressor operation, and if the oil

amount is not enough, the oil should be added to the oil tank. If oil amount is insufficient, abrasion occurs at bearings

and rotor, which is the cause of the compressor damage. Oil filter which is to filter the foreign material in oil is easily

disassembled for cleaning.

Oil is filled inside of the compressor.

Depending upon the customer’s need, a different type of oil can be used, but in this case, the following items should

be followed.

- Use of a new oil should be consulted with LG Electronics first.

- The oil inside the compressor should be cleaned before filling the new oil.

- Different types of oil should not be blended together for use.

- After filling the new oil, the moisture content in the oil should be removed by a sufficient vacuum operation.

Oil recovery system

Figure 13 Oil recovery system(1 cycle)

ENGLISH

20

3. STRUCTURE OF SCREW CHILLER

ENGLISH

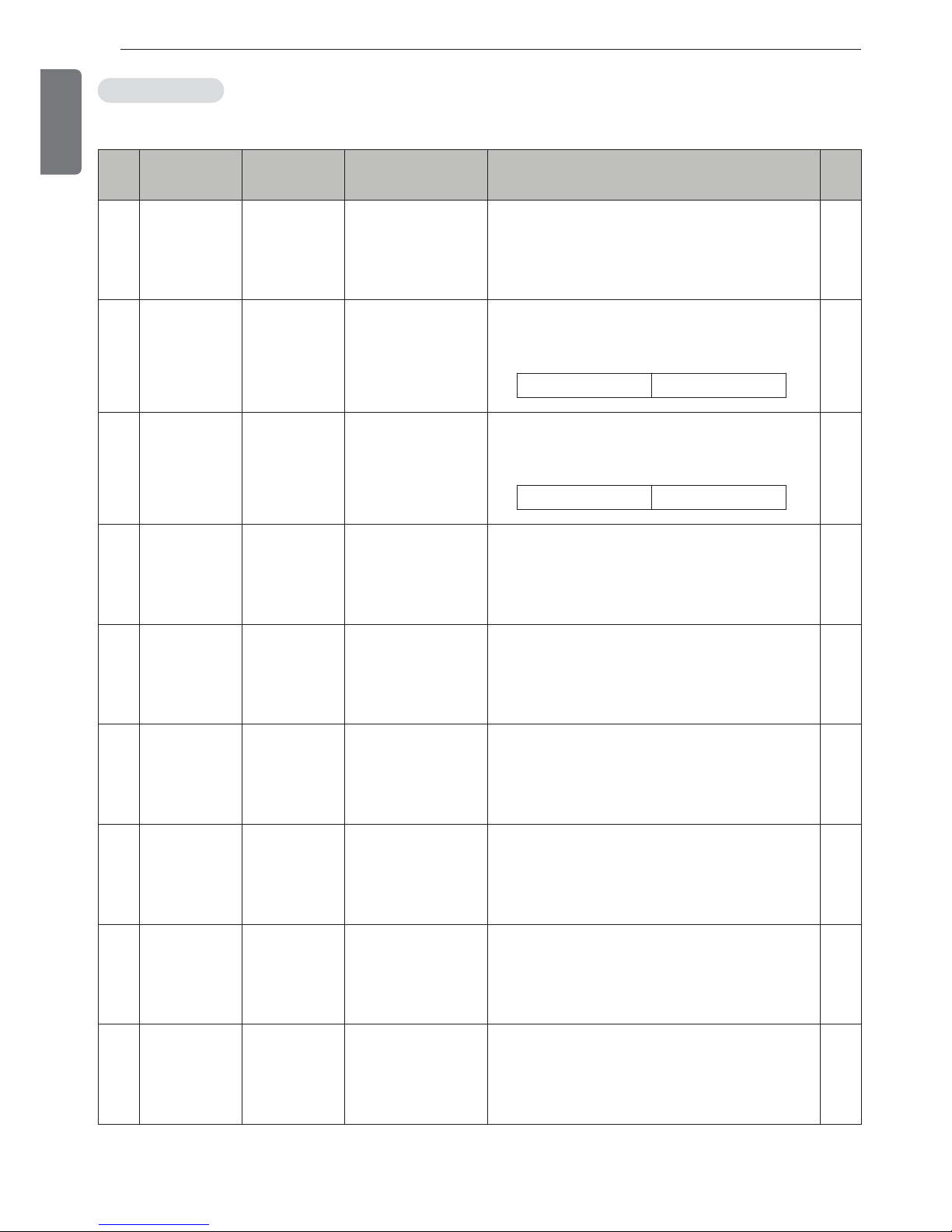

The following devices are installed for safe operation and equipment protection(1 cycle).

Safety devices

No. Item

Installed

location

Measurement

objects

Contents

Quan-

tity

1

Chilled water

low temp.

Chilled water

inlet nozzle

Chilled water inlet

temp.

This function stops the chiller when chilled water

outlet temp. becomes 2.9°C or less to avoid the

danger of freezing of chilled water.

Never change this setting.

1

2

Evaporator refrigerants low

pressure (low

temperature)

Evaporator

shell

Evaporation

pressure (temp.)

If the pressure in the evaporator becomes lower

than the value in the table below, the chiller will

stop.

1

3

Condenser

high pressure

(high tempera-

ture)

Condenser

shell

Condensing

pressure (temp.)

If the pressure in the condenser becomes higher

than the value in the table below, the chiller will

stop.

1

4

Evaporator re-

frigerant low

temperature

Evaporator

inlet

Evaporator

refrigerant temp.

When evaporator pressure is used to protect

compressor motor, and the temperature drops to

1.5 °C or below, the chiller will stop

1

5

Compressor

discharge high

temperature

Compressor

outlet

Compressor dis-

charge temp.

If compressor discharge gas temperature becomes 100 °C or higher, the chiller will stop.

1

6

Refrigerant

high/low pres-

sure difference

low

Evaporator

shell, Con-

denser shell

Pressure difference

between Evapora-

tor/Condenser

If the pressure difference is smaller than 4 bar,

the chiller will stop.

1

7

Chilled water

pump problem

Chilled water

header

Chilled water loss

head

When the chilled water flow amount passing

through evaporator tubes decreases and if water

head loss becomes less than the set value, the

chiller will stop.

1

8

Cooling water

pump problem

Cooling water

header

Over-current

When the cooling water flow amount passing

through condenser tubes decreases and water

head loss becomes less than the set value, the

chiller will stop.

1

9

Current limit

function

Control panel Motor current

Compressor motor current is measured, and according to the excess percentage over the set

current value, different ignore times are applied,

and the chiller stops accordingly .

1

Standard setting 1.90kg/cm

2

Standard setting 10.10kg/cm

2

3. STRUCTURE OF SCREW CHILLER

21

ENGLISH

No. Item

Installed

location

Measurement

objects

Contents

Quan-

tity

10

Temp. sensor

problem

5 places includ-

ing chilled

water nozzle.

Temperature sensors

It shows up when the temperature sensor is not

connected or there is a defect in the temperature

sensor.

5

11

Pressure sen-

sor problem

2 places

including

evaporator

shell

Each pressure sensor

It shows up when pressure sensor is not connected or there is a defect in the pressure sensor.

2

12 Motor status Control panel Motor status When motor has a problem, the chiller will stop. 1

13

Motor power

problem

Control panel Motor power

When there is a problem in the motor power supply, the chiller will stop.

1

14

External

problem

Control panel External fault signal

If a buyer makes a fault signal from the buyer’s

system, the chiller will stop.

1

15

Chilled

water/Cooling

water pump

interlock

Control panel

Chilled water/Cooling

water pump interlock

When chilled water/cooling water pump interlock

has a problem during running, the chiller will

stop.

2

16 Oil status Control panel Oil level When oil level is abnormal, the chiller will stop. 1

17

Refrigerant

pressure

status

Control panel Refrigerant pressure

When refrigerant pressure abnormal switch

makes signal, the chiller will stop.

1

Table 3. Safety devices

22

4. CONTROL SYSTEM

ENGLISH

4. CONTROL SYSTEM

4-1. Components of control panel and main parts

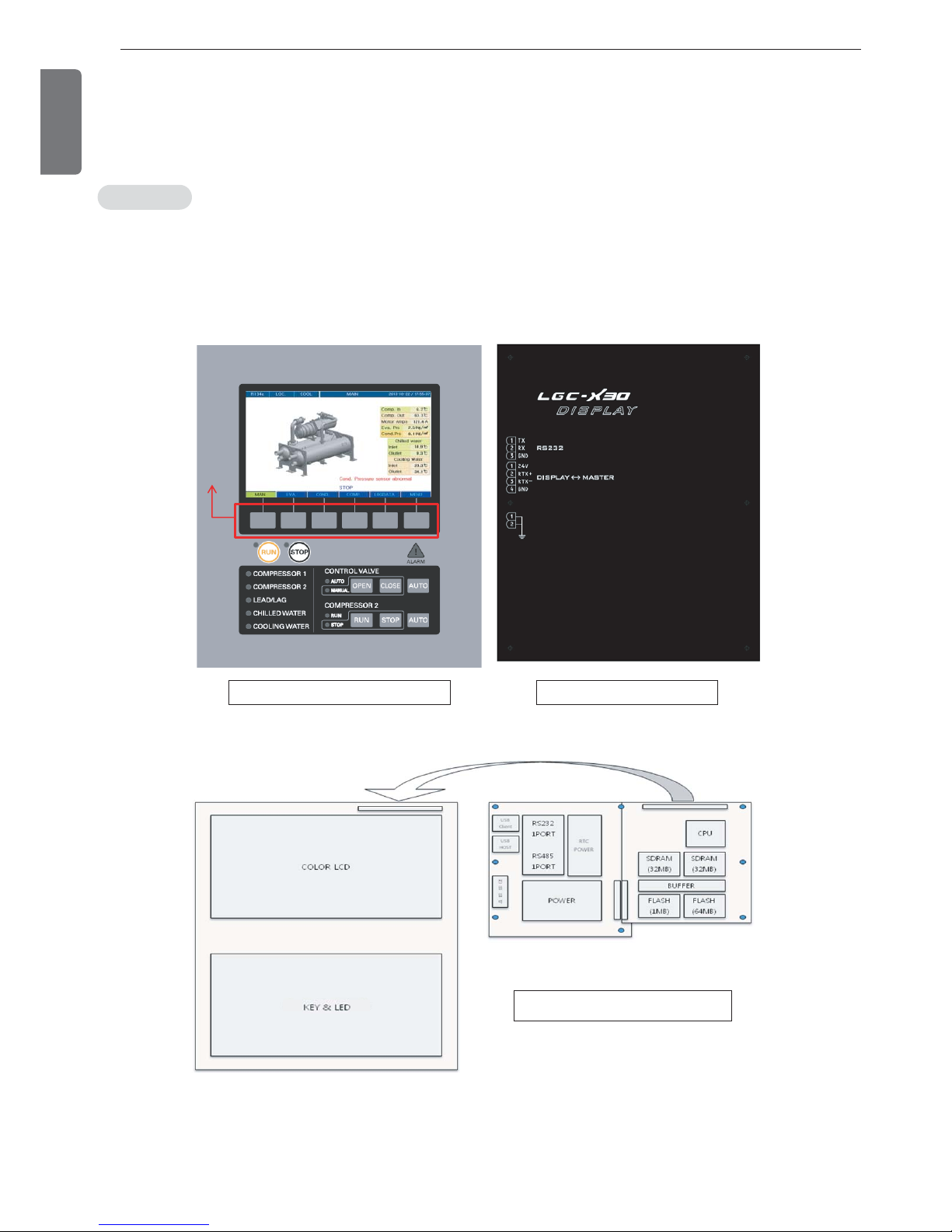

HMI with 7 inch Color LCD is composed as a graphic type.

There are start/stop, control valve 2 and Compressor 2, compressor, lead/lag lamp, and chilled water / coolant flow

lamp keys.

There are ‘function keys’ at the bottom of the screen that change according to the current screen to be able to access lower categories.

Controller

Function keyFunction key

Function key

Figure 14. Controller

Front view of controller Back view of controller

Internal diagram of controller

4. CONTROL SYSTEM

23

ENGLISH

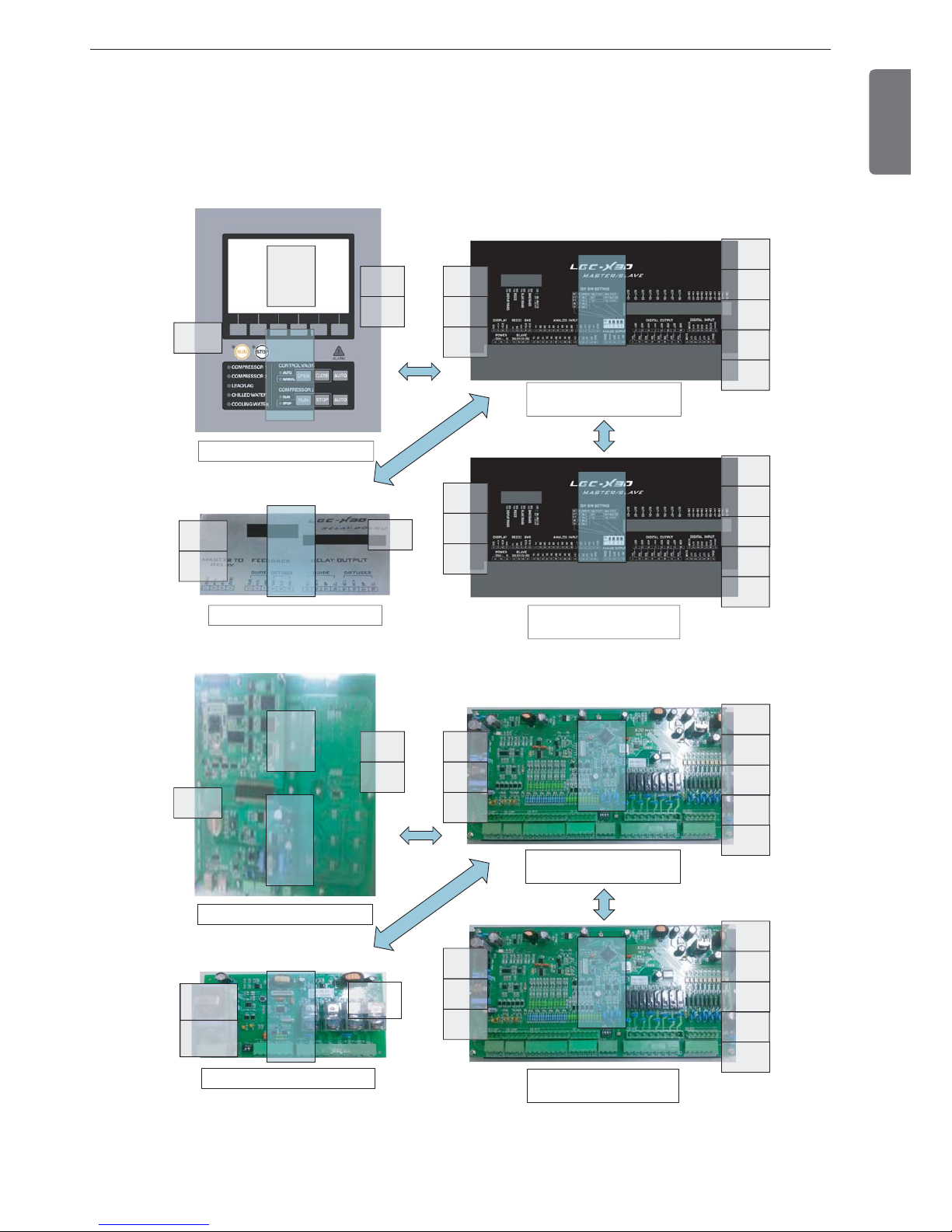

Schematic diagram of the main board(main control unit) - PCB

Figure 15 Internal diagram of Master/Slave boards

Power supply unit

POWER SUPPLY PART

POWER

FILTER

Power input

COMMUN

-ICATION

Communication

Power filter

24

4. CONTROL SYSTEM

ENGLISH

The Control unit of LG chiller controls temperature, pressure, flow rate, current, voltage, power and capacity control

valve using high capacity microprocessor. It is constructed to provide the high reliability chiller operation using LG's

unique optimum control algorithm.

Our controller unit has the following features.

1. 7 inch Color wide LCD Display (800*480 Graphic)

2. Remote operation/stop function which allows the chiller to be operated remotely.

3. Scheduled operaton function which allows setting the operation time period in holiday and weekdays.

4. Soft loading function for the low load startup

5. Various preventive control function for preventing overload, condenser high pressure, evaporator low pressure,

surge, etc.

6. Advanced control function for the optimum control

7. Improved control function to protect the chiller

8. Self diagnosis function for easy checking of abnormal situation

9. Help function describing actions to take when problem occurs

10 Operation data and operaton status(error and control action) saving function

11. Automatic sensor setting function to set the sensors automatically(set by software)

12. Automatic repeat key function for setting values easily

13. Modbus protocol communication function for remote surveillance control

- RS485: Standard installation

- BACnet & RS232C: Optional

14. Graphictrend function showing the chilled water outlet temperature and operation current change in real time.

15. Print function for printing operation or problem data(Optional)

16. Cooling tower fan control function for keeping stable cooling water temperature

17. Interlock check function for checking peripherals and malfunction

18. Time display function showing number of operations and total run time of the pump and motor which are at-

tached to main body.

Features of control unit

25

ENGLISH

Controller system composition diagram

Master, slave, HMI, Relay board communicates with RS485, and in one master/slave board, there are analog

input(temp. 12 channel, current 10 channel), analog output(current 4 channel), digital input(20 channel), digital output(16 channel).

Relay board controls Solenoid valve in 2 comp.

UART

(MAIN)

RS485

RS485

RS485

HMI: Display & Communication

Relay: Solenoid valve

SLAVE: temp. pressure digital

input/output control

Master: temp. pressure digital

input/output control

LCD

DISPLAY

(7inch)

KEY-

PAD

DATA

DOWN

UART

(DISPLAY)

UART

(BMS)

UART

(Slave)

MICOM

PT100

INPUT

4-20mA

INPUT

4-20mA

OUTPUT

DIGITAL

INPUT

DIGITAL

OUTPUT

UART

(BMS)

UART

(Slave)

UART

(DISPLAY)

MICOM

DC 0~5V

INPUT

DIGITAL

OUTPUT

MICOM

UART

(Master)

PT100

INPUT

4-20mA

INPUT

4-20mA

OUTPUT

DIGITAL

INPUT

DIGITAL

OUTPUT

MICOM

(ARM)

RS485

RS485

RS485

DC 0~5V

INPUT

DIGITAL

OUTPUT

UART

(Master)

LCD

DISPLAY

(7inch)

KEY-PAD

MICOM

(ARM)

UART

(MAIN)

DATA

DOWN

UART

(DISPLAY)

UART

(BMS)

UART

(Slave)

MICOM

PT100

INPUT

4-20mA

INPUT

4-20mA

OUTPUT

DIGITAL

INPUT

DIGITAL

OUTPUT

UART

(BMS)

UART

(Slave)

UART

(DISPLAY)

MICOM

PT100

INPUT

4-20mA

INPUT

4-20mA

OUTPUT

DIGITAL

INPUT

DIGITAL

OUTPUT

HMI: screen display and communication

Relay: Solenoid valve

SLAVE: temp. pressure digital

input/output control

Master: temp. pressure digital

input/output control

Figure 16. Controller block diagram

26

4. CONTROL SYSTEM

ENGLISH

Control panel - Standard type

* The above configuration may change according to design enhancement, type, or user convenience, so please refer

to the approved drawing for details.

4. CONTROL SYSTEM

27

ENGLISH

Micom(Master Board)

Micom(Slave Board)

Fuse

CB

Noise Filter(NF)

Relay(KM1~3)

SMPS

Terminal Block(TB)

Fiqure 17. control panel

h The above configuration may change according to design enhancement, type, or user convenience, so please refer

to the approved drawing for details.

Control panel component layout - Standard type

TAG NAME USE

CB Main power(for wiring) circuit breaker

NF Micom power protection Noise Filter

SMPS Control power supply Transformer

Fuse Control power protection fuse

Realy Auxiliary relay for start

TB Terminal blocks for control signal and main power source

MICOM Control device using micro processor

28

4. CONTROL SYSTEM

ENGLISH

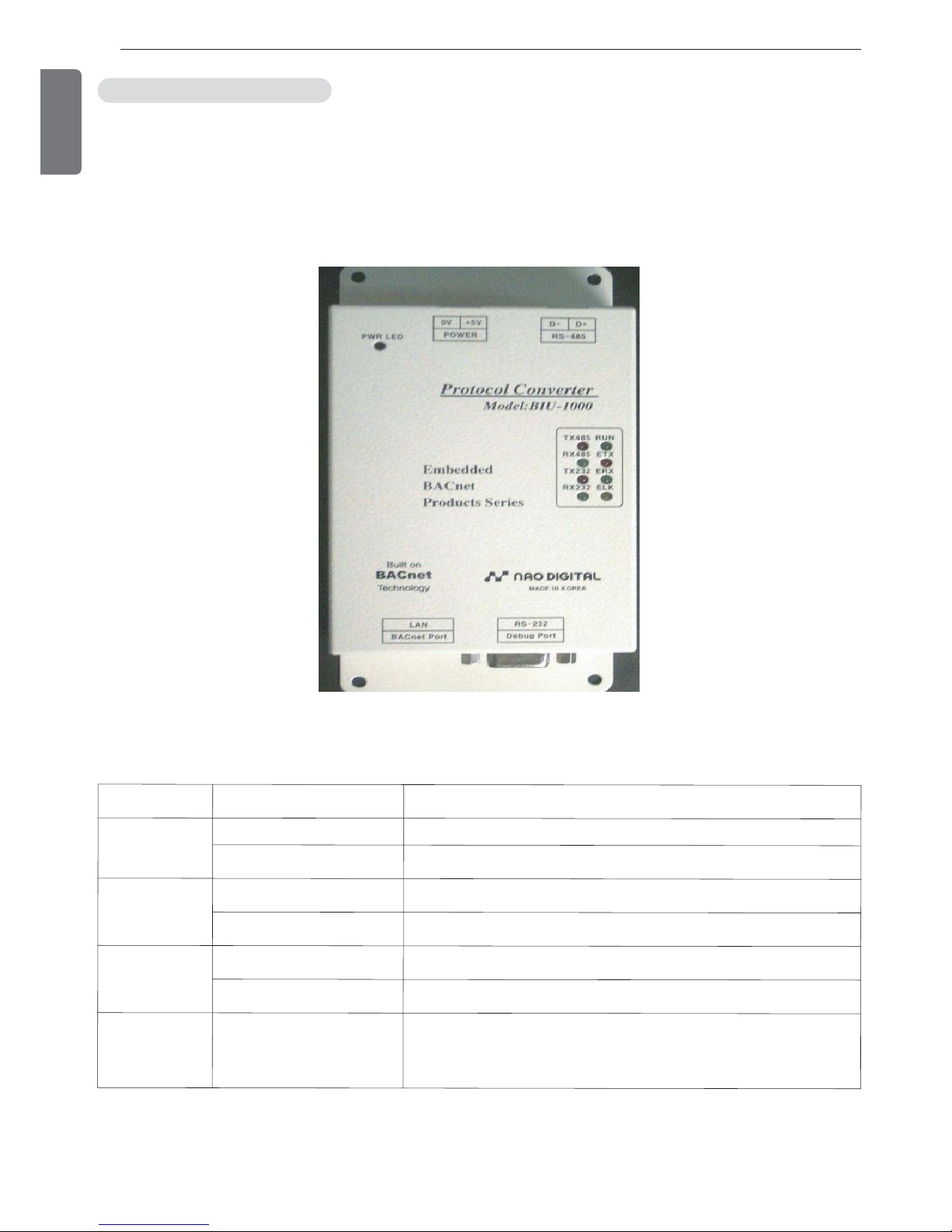

BACnet converter

Our controller basically supports Modbus communication protocol.

If the higher level communication protocol is BACnet, you need to apply a separate BACnet converter to change the

protocol.

Communication converter is attached inside the control panel.

Please refer to the following table for meaning and description of each lamp.

Optional parts related controller

Figure 18. Converter

Table 3 Converter lamp names

LED name Status Description

TX485

RX485

Flashing Normal data communication with micom

Off Error, check communication line

TX232

RX232

Flashing Normal data communication with BACnet

Off Error, check communication line

RUN

Flashing every second Board has finished Power-on test, and is normally operating

Keeping On/Off state Error, press reset button or interrupt power, and on again

ETX

ERX

ELK

Ethernet Line status LED

ELK is always On when LAN cable is connected, and ERX flashes On

when receiving, and ETX flashes On when sending data.

4. CONTROL SYSTEM

29

ENGLISH

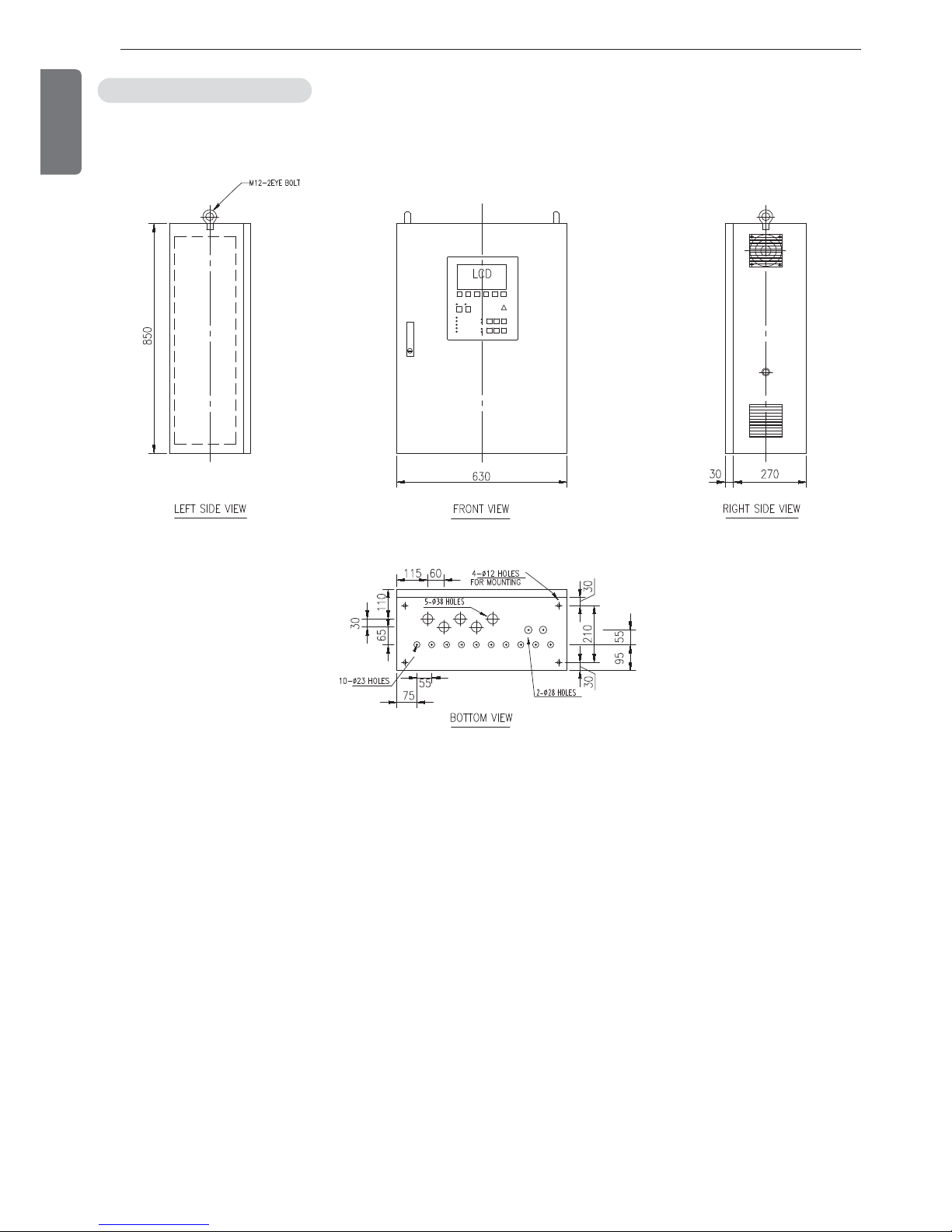

4-2. Outside view of Startup panel - Standard Type

Since the starter panel has various layouts based on starter method, option, etc., please refer to the drawing provided

together with the product.

h The above configuration may change according to design enhancement, type, or user convenience, so please refer

to the approved drawing for details.

30

4. CONTROL SYSTEM

ENGLISH

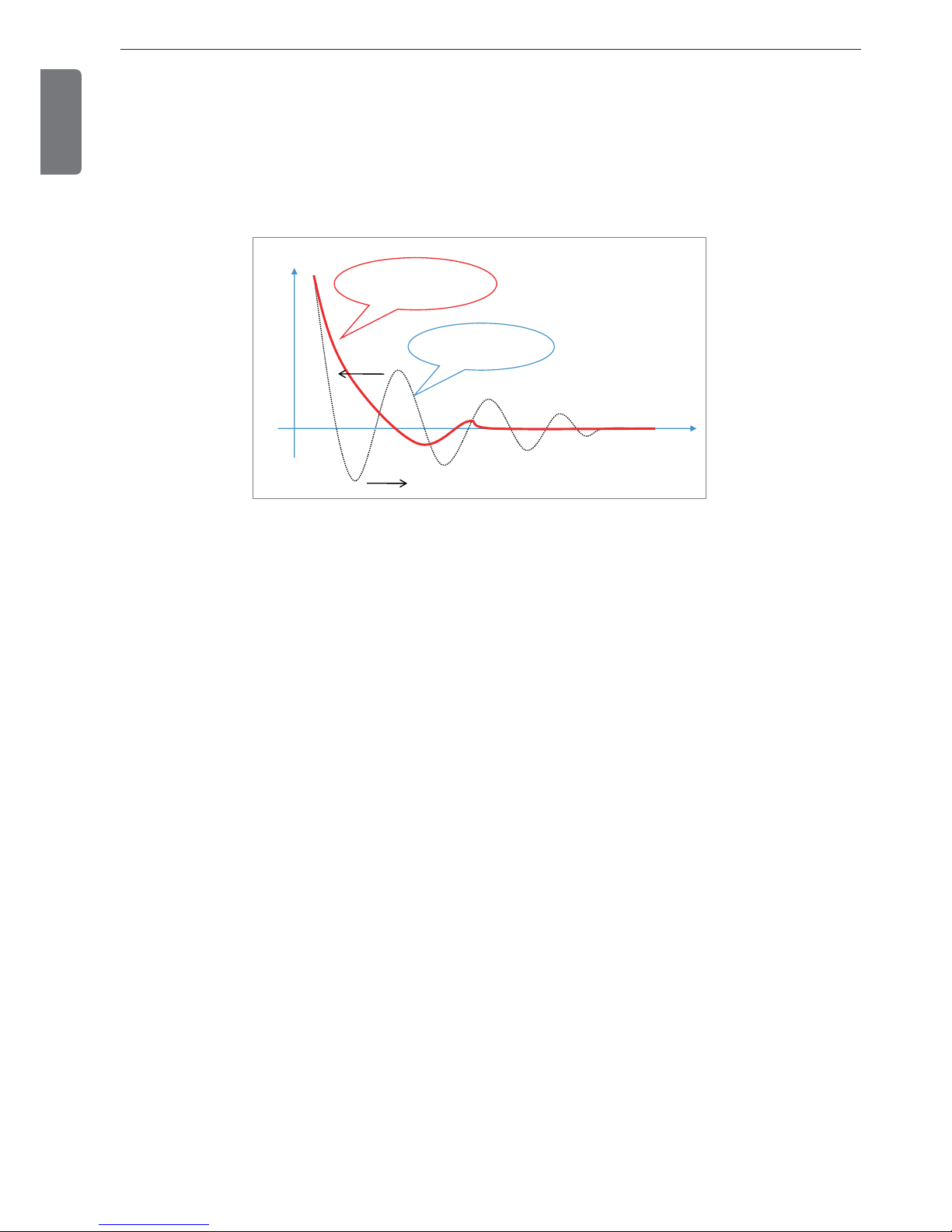

4-3. Basic control algorithm

Unique P(proportional), I(integral), and D(differential) algorithms are applied to chilled water temperature control.

Compared to the conventional method, it allows optimal control by minimizing time to approach the target value, remaining deviation, Under-Shoot and Over-Shoot during initial startup and automatic/manual conversion of operation.

Under-shoot

Over-shoot

LG’s New Control

Algorithm

General Control

Algorithm

Figure 19. Control algorithm

• Soft Loading

- Approach to the control target value with Soft startup

- Solved unnecessary stops caused by voltage change during startup

• Advanced Control

- Advanced high class control algorithm developed for high precision control compared to existing PID control

method.

- Prevention of temperature Cycling phenomenon caused by Overshoot/Undershoot during conversion from manual

mode to automatic mode.

- Reinforced safety control(Intensive Safety Control): By executing preventive control before chiller reaching abnormal stop point, it minimizes unnecessary stops of the chiller.

Loading...

Loading...