ENGLISH FRANÇAIS ESPAÑOL

LG Casstte Type

Air Conditioner

INSTALLATION MANUAL

LG

website http://www.lgservice.com

IMPORTANT

• Please read this installation manual completely before

installing the product.

• Installation work must be performed in accordance with

the national wiring standards by authorized personnel

only.

• Please retain this installation manual for future reference

after reading it thoroughly.

2 Cassette type Air Conditioner

Cassette Type Air Conditioner Installation Manual

TABLE OF CONTENTS

Safety Precautions .....3

Installation of Indoor,

Outdoor unit................6

Ceiling opening

dimensions and hanging

bolt location

..................8

The indoor unit

installation...................9

Remote controller

installation...................9

Wiring connection ....11

Connecting Pipes to

the Indoor Unit..........13

Installation of

decorative panel .......15

Indoor unit drain piping

....................................16

Test running..............19

Optional operation....21

•

Connecting cable

• Four Type "A" Screw

• Hanging Bolt

(W 3/8 or M10 length 650mm)

• Pipes: Gas side

Liquid side

• Insulated drain hose

• Additional Drain hose

(Inner Dia.............32mm)

•

Level

•

Screw driver

•

Electric drill

•

Hole core drill (ø70mm)

• Flaring Tools set

• Torque Wrenches

• Hexagonal Wrench (4mm, 5mm)

• Gas-leak detector

•

Owner’s Manual

•

Thermometer

Installation

Requirements

Required Parts Required T ools

Safety Precautions

Installation Manual 3

ENGLISH

To prevent injury to the user or other people and proper ty damage, the following instructions

must be followed.

■

Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness

is classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

WARNING

Be sure not to do.

Be sure to follow the instruction.

Safety Precautions

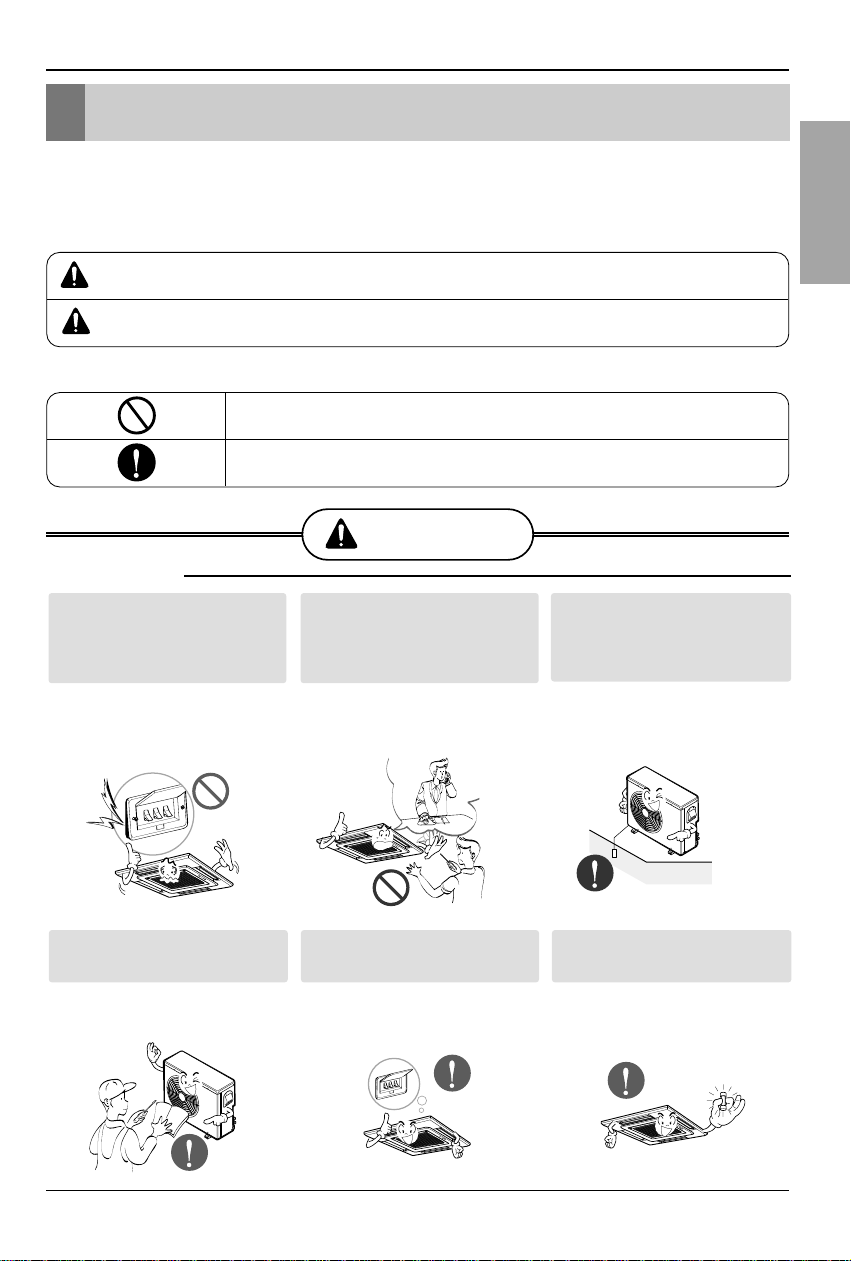

■ Installation

Install the panel and the cover of

control box securely.

• There is risk of fire or

electric shock.

Always install a dedicated

circuit and breaker.

• Improper wiring or

installation may cause fire or

electric shock

Use the correctly rated breaker

or fuse.

• There is risk of fire or

electric shock.

Do not use a defective or

underrated circuit breaker. Use

this appliance on a dedicated

circuit.

• There is risk of fire or

electric shock.

For electrical work, contact the

dealer, seller, a qualified

electrician, or an Authorized

Service Center.

•

Do not disassemble or repair

the product.There is r isk of

fire or electric shock.

Always ground the product.

• There is risk of fire or

electric shock.

WARNING

CAUTION

4 Cassette type Air Conditioner

Safety Precautions

Do not modify or extend the power cable.

• There is risk of fire or electric shock.

Be cautious when unpacking and installing the

product.

•

Sharp edges could cause injury.Be especially

careful of the case edges and the fins on the

condenser and evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric shock, explosion,

or injury.

Do not install the product on a defective

installation stand.

• It may cause injury, accident, or damage to

the product.

Be sure the installation area does not

deteriorate with age.

•

If the base collapses, the air conditioner could fall with

it, causing property damage, product failure, and

personal injury.

Do not let the air conditioner run for a long time when

the humidity is very high and a door or a window is

left open.

• Moisture may condense and wet or damage

furniture.

Do not store or use flammable gas or combustibles

near the product.

• There is risk of fire or failure of product.

■ Operation

Gasolin

Installation Manual 5

ENGLISH

Safety Precautions

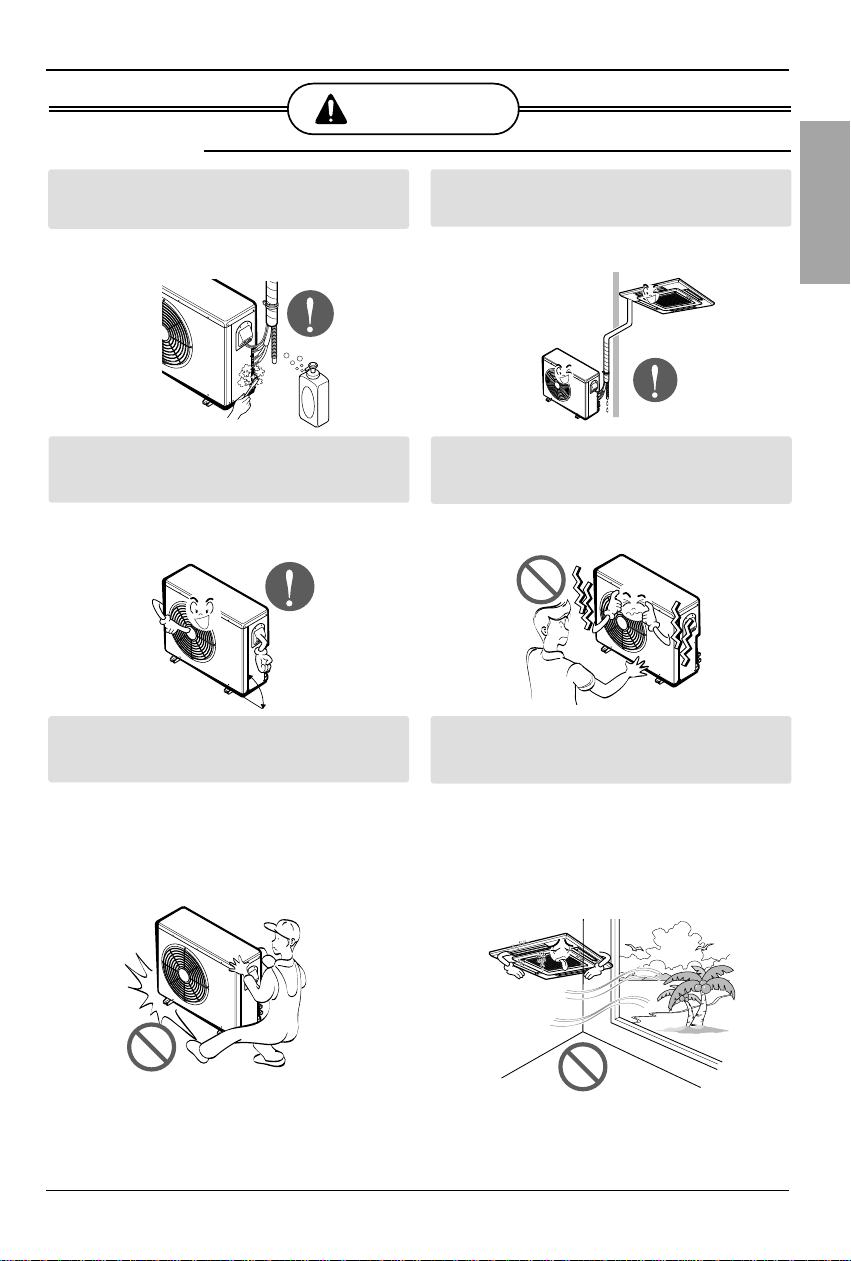

Always check for gas (refrigerant) leakage after

installation or repair of product.

• Low refrigerant levels may cause failure of

product.

Install the drain hose to ensure that water is

drained away properly.

• A bad connection may cause water leakage.

Keep level even when installing the product.

• To avoid vibration or water leakage.

Do not install the product where the noise or hot air

from the outdoor unit could damage the

neighborhoods.

• It may cause a problem for your neighbors.

Use two or more people to lift and transport the

product.

• Avoid personal injury.

Do not install the product where it will be

exposed to sea wind (salt spray) directly.

• It may cause corrosion on the product.

Corrosion, particularly on the condenser and

evaporator fins, could cause product

malfunction or inefficient operation.

CAUTION

90°

■ Installation

6 Cassette type Air Conditioner

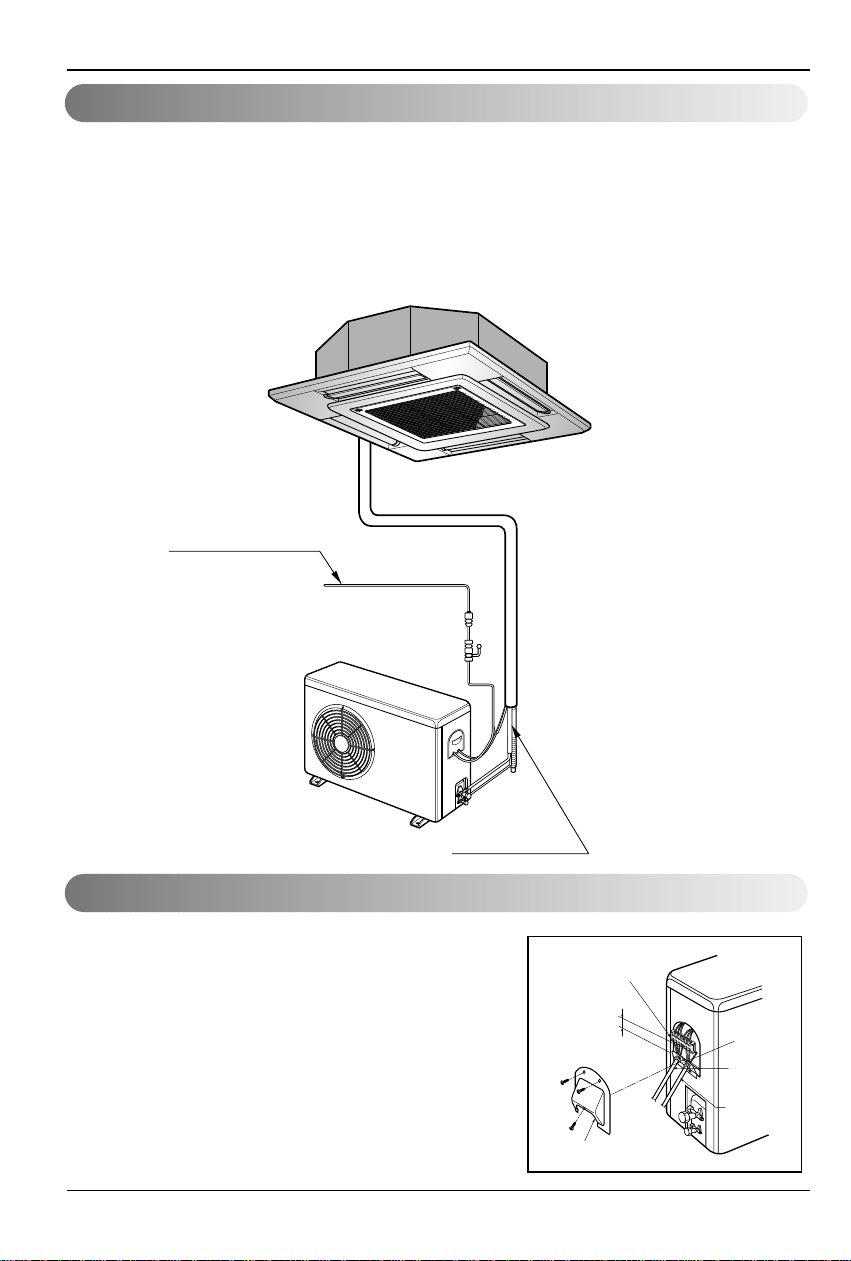

Installation of Indoor, Outdoor Unit

Installation of Indoor, Outdoor Unit

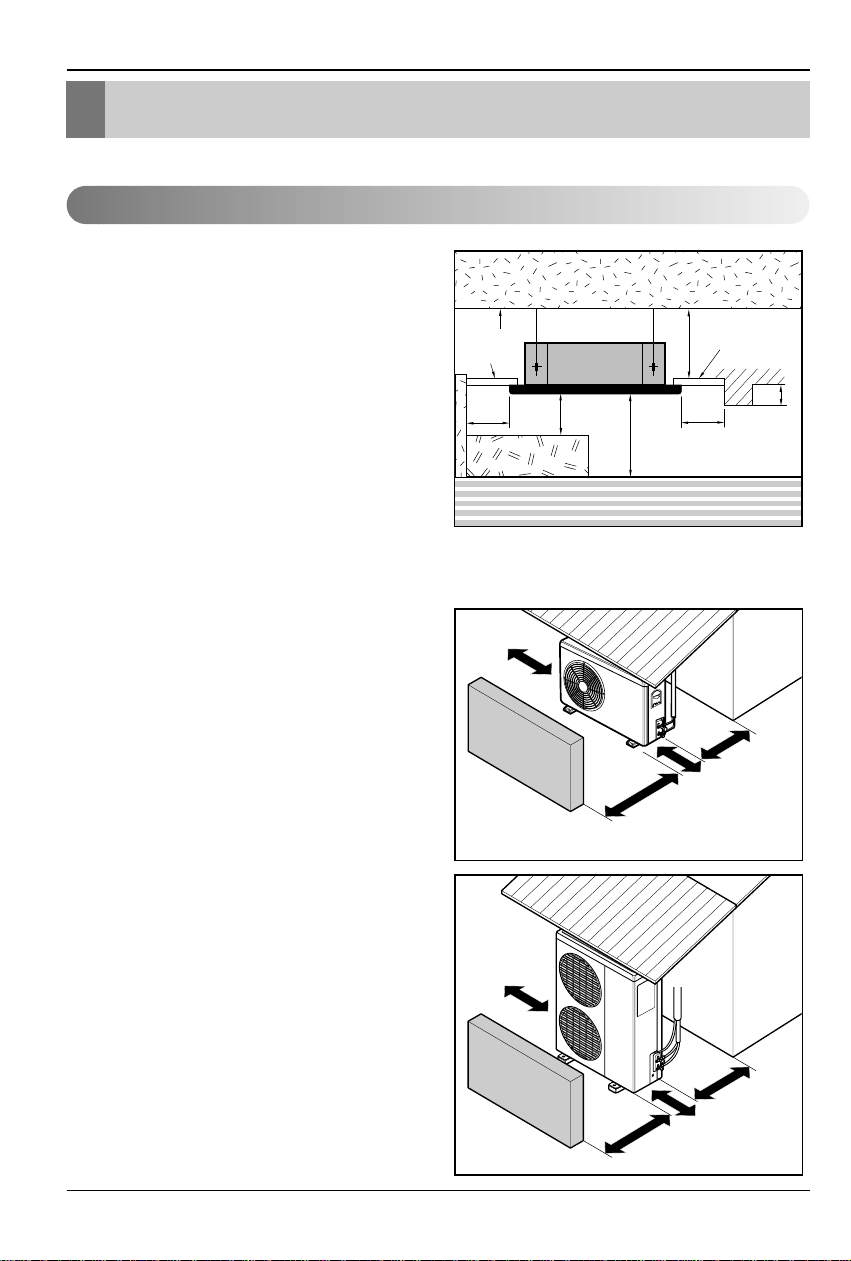

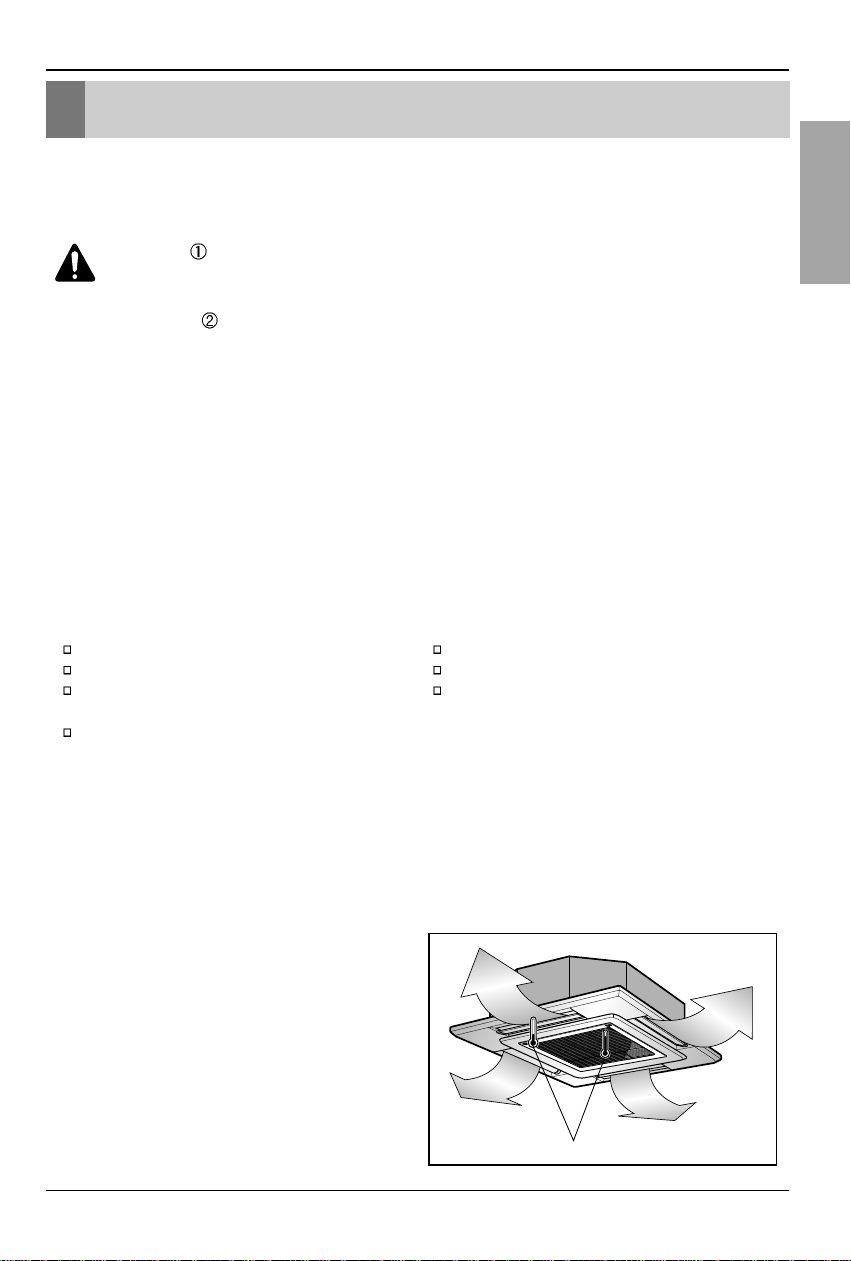

1. Indoor unit

• There should not be any heat source or

steam near the unit.

• There should not be any obstacles to

prevent the air circulation.

• A place where air circulation in the room

will be good.

• A place where drainage can be easily

obtained.

• A place where noise prevention is taken

into consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows

from the wall, ceiling, or other obstacles.

• The indoor unit must keep the

maintenance space.

2. Outdoor unit

• If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful

that heat radiation from the condenser is

not restricted.

• There should not be any animals or plants

which could be affected by hot air

discharged.

• Ensure the spaces indicated by arrows

from the wall, ceiling, fence or other

obstacles.

Selection of the best location

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

330 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

More than

30cm

Fence or

obstacles

More than

50cm

Fence or

obstacles

Sunroof

Sunroof

More than

More than

30cm

30cm

More than 50cm

More than 70cm

More than

More than

30cm

50cm

More than 50cm

More than 100cm

Installation Manual 7

ENGLISH

Installation of Indoor, Outdoor Unit

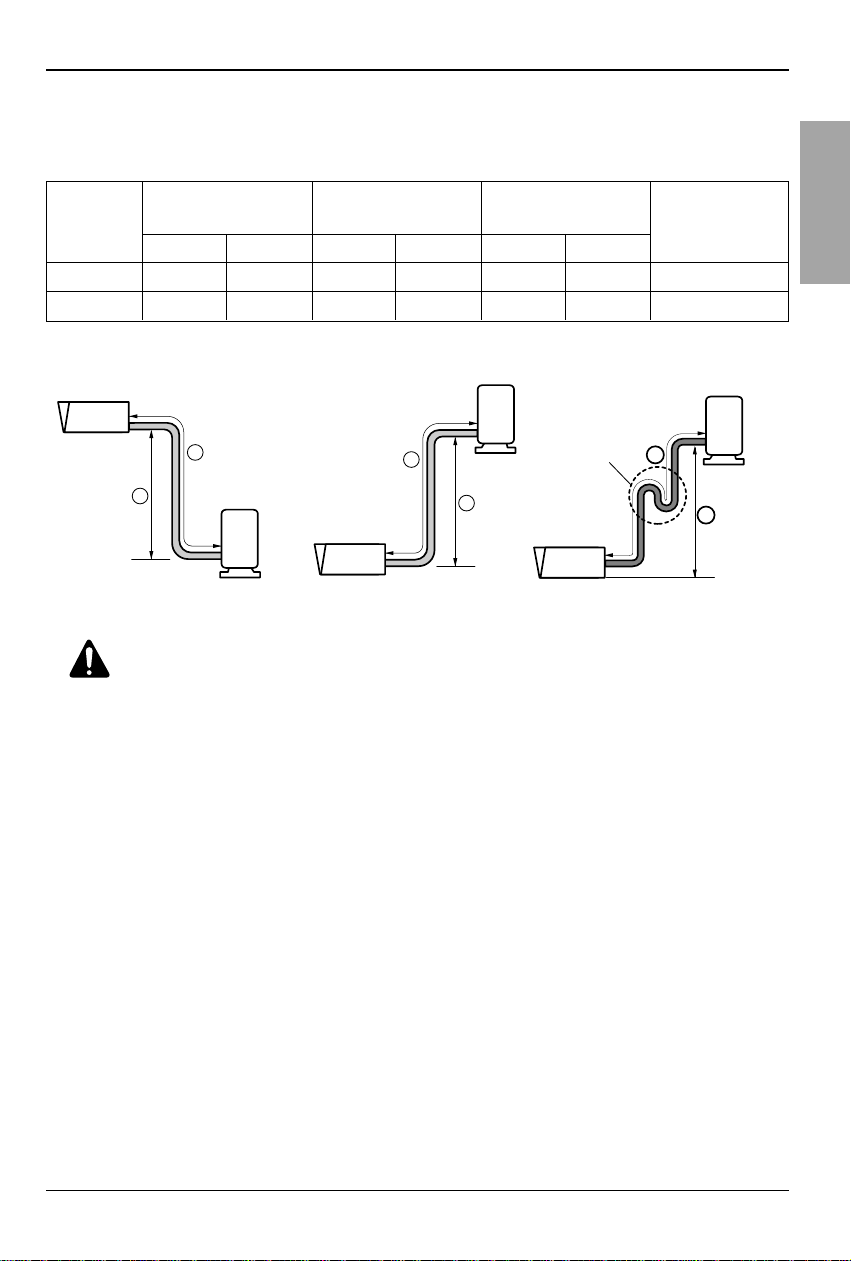

3. Piping length and the elevation

Gas Liquid Standard Max. Standard Max.

24k Btu/h

1/2"(12.7mm) 1/4"(6.35mm)

7.5(25') 30(100') 5(16') 15(50') 20(0.22 oz./ft.)

34k Btu/h

5/8"(15.88mm) 1/4"(6.35mm)

7.5(25') 35(115') 5(16') 20(66') 30(0.32 oz./ft.)

Capacity

Pipe Size

Length A(m) Elevation B(m)

*Additional

(Diameter:Ø)

refrigerant(g/m)

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

Oil trap

If piping length is more than 5m

Outdoor unit

Indoor unit

B

CAUTION:

• Rated performance for refrigerant line length of:7.5m

• Capacity is based on standard length and maximum allowance length is on the

basis of reliability.

• Improper refrigerant charge may result in abnormal cycle.

• Oil trap should be installed every 10 meters.

8 Cassette type Air Conditioner

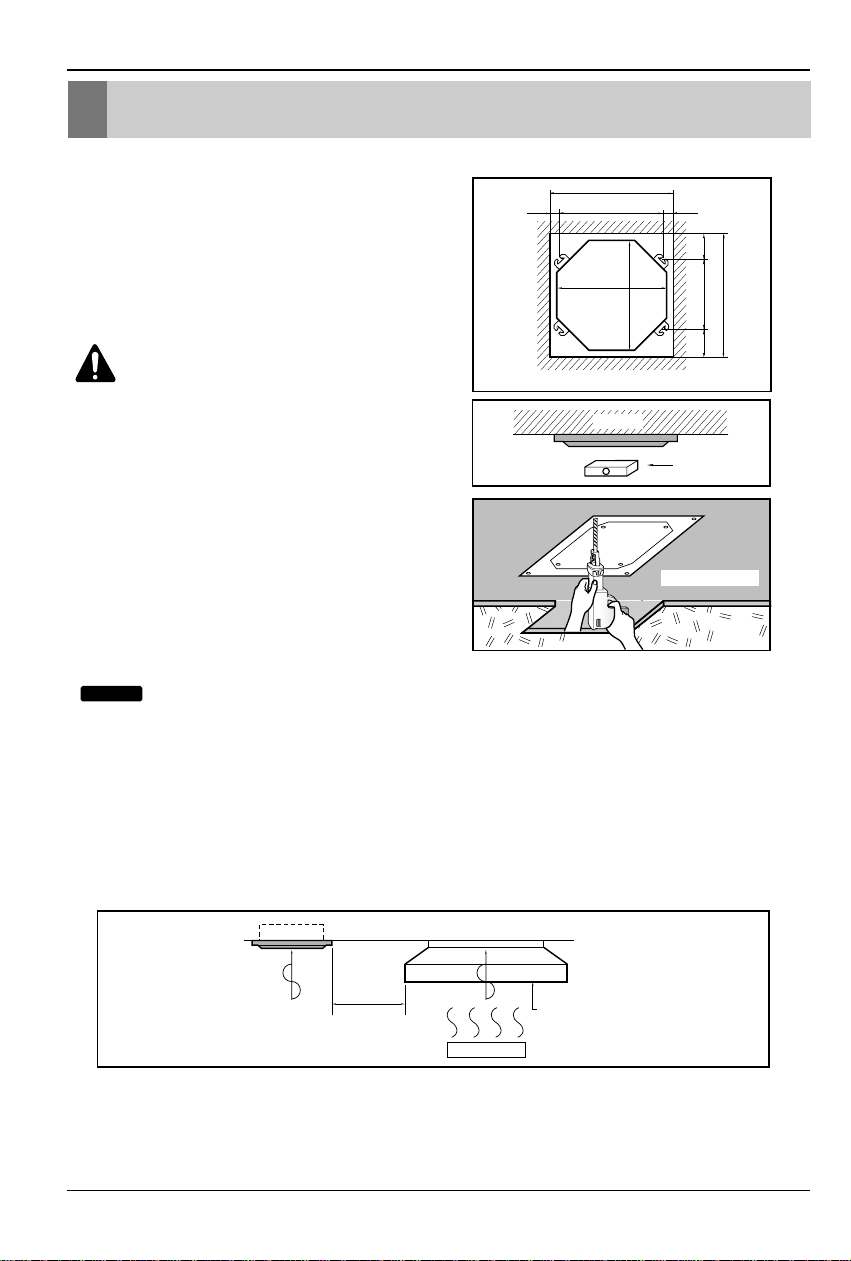

• Select and mark the position for fixing bolts

and piping hole.

• Decide the position for fixing bolts slightly

tilted to the drain direction after considering

the direction of drain hose.

• Drill the hole for anchor bolt on the wall.

CAUTION:

•

This air-conditioner uses a drain pump.

• Horizontly install the unit using a

level gauge.

•

During the installation, care should be

taken not to damage electric wires.

• Thoroughly study the following installation locations:

1. In such places as restaurants and kitchens, considerable amount of oil steam and flour

adhere to the turbo fan, the fin of the heat exchanger and the drain pump, resulting in heat

exchange reduction, spraying, dispersing of water drops, drain pump malfunction, etc.

In these cases, take the following actions:

• Make sure that the ventilation fan for smoke-collecting hood on a cooking table has

sufficient capacity so that it draws oily steam which should not flow into the suction of the

air conditioner.

• Make enough distance from a cooking room to install the air conditioner in such a place

where it may not suck in oily steam.

2. Avoid installing air conditioner in such circumstances where cutting oil mist or iron powder is

in suspension in factories, etc.

3. Avoid places where inflammable gas is generated, flows in, is stored or vented.

4. Avoid places where sulfurous acid gas or corrosive gas is generated.

5. Avoid places near high frequency generators.

NOTICE

Ceiling opening dimensions and hanging bolt location

• The dimensions of the paper model for installing are the same as those of the ceiling opening dimensions.

Ceiling board

Level gauge

Ceiling

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

Cooking table

Air conditioner

Take enough

distance

Unit:mm

840 Unit size

840 Unit size

672 (Hanging bolt)

101.5101.5

875 (Ceiling opening)

875 (Ceiling opening)

785 (Hanging bolt)

45

45

Ceiling opening dimensions and hanging bolt location

Installation Manual 9

ENGLISH

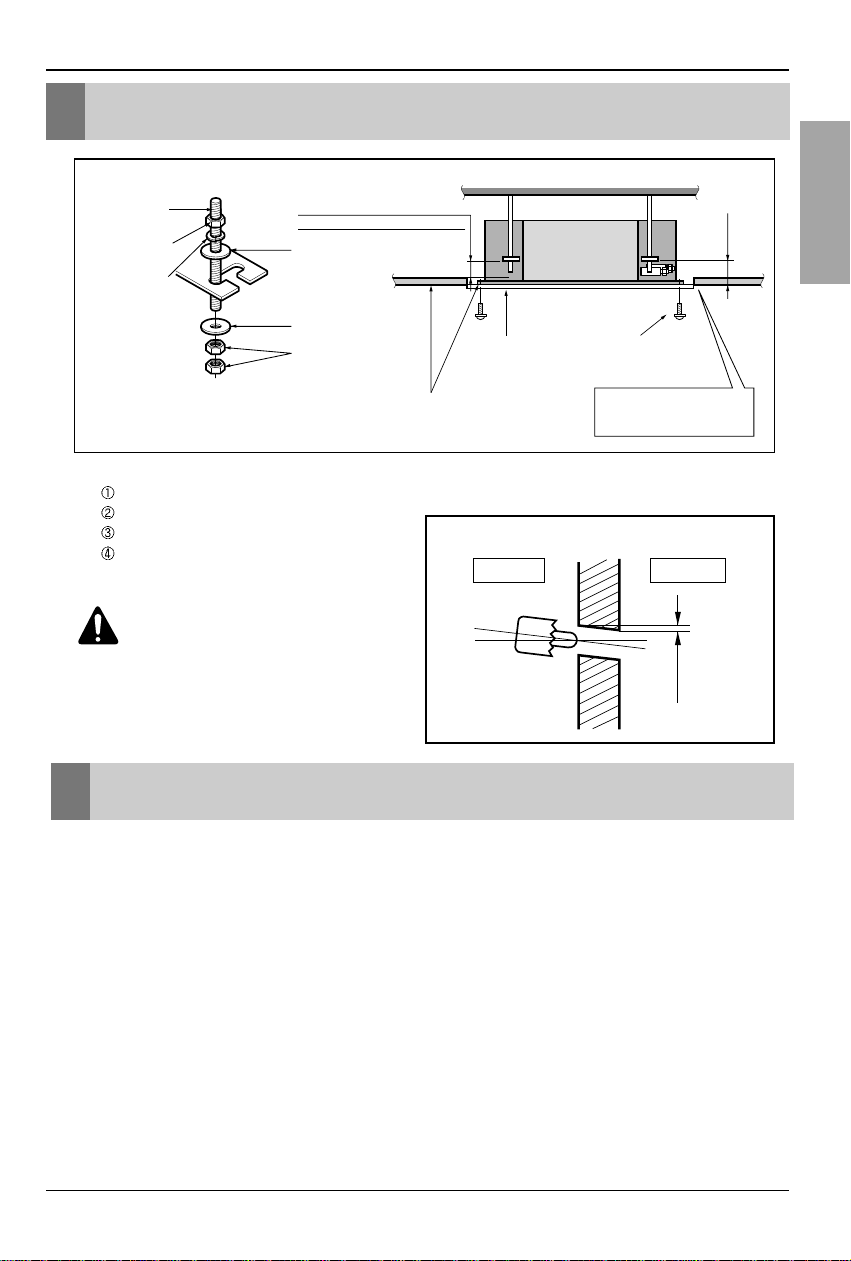

Wall

5~7mm

Indoor Outdoor

Set screw of

paper model (4 pieces)

Paper model

for installation

Ceiling board

150mm

Adjust the same height

Ceiling board

Ceiling

Flat washer for M10

(accessory)

Keep the length of the bolt

from the bracket to 40mm

Open the ceiling board

along the outer edge of the

paper model

Flat washer for M10

(accessory)

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Air Conditioner body

The Indoor Unit Installation

• The following parts is option.

Hanging Bolt - W 3/8 or M10

Nut - W 3/8 or M10

Spring Washer - M10

Plate Washer - M10

CAUTION:

Tighten the nut and bolt

to prevent unit falling.

• Drill the piping hole on the wall slightly tilted to the

outdoor side using a Ø 70 hole-core drill.

• Although the room temperature sensor is in the indoor unit, the remote controller should

be installed in such places away from direct sunlight and high humidity.

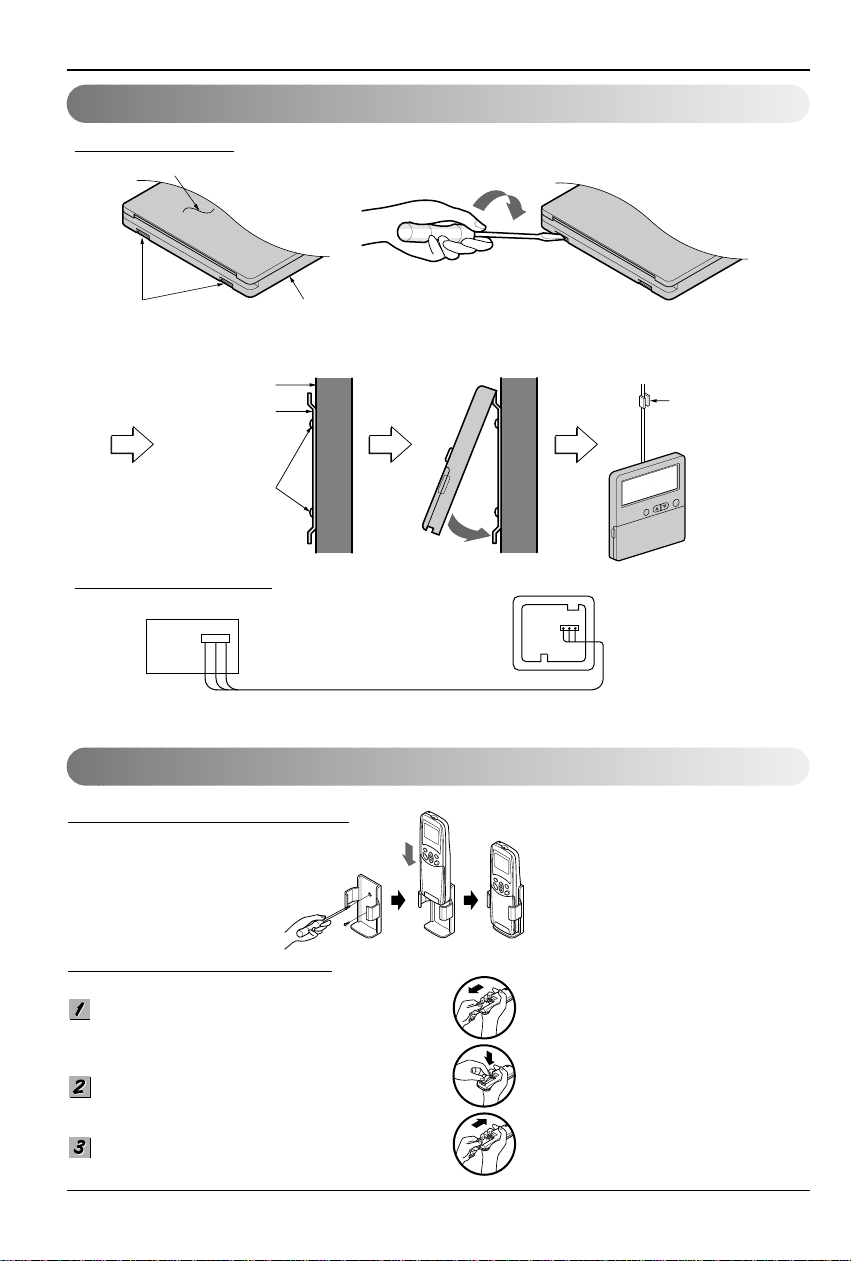

Installation of the remote controller

• Select places that are not splashed with water.

• Select control position after receiving customer approval.

• The room temperature sensor is built in the indoor unit.

• This remote controller equipped with liquid crystal display. If this position is higher or lower,

display is difficult to see.(The standard height is 1.2 ~ 1.5m high)

Routing of the remote controller cord

• Keep the remote controller cord away from the refrigerant piping and the drain piping.

• To protect the remote controller cord from electrical noise, place the cord at least 5cm away

from other power cables (audio equipment, television set, etc.)

• If the remote controller cord is secured to the wall, provide a trap at the top of the cord to

prevent water droplets from running.

The Indoor Unit Installation

Remote Controller Installation

10 Cassette type Air Conditioner

Wired Remote Control Installation

Remote Control Preparation

Remote control

box body

Cord clamp

(accessory)

Lever carefully

the box open

using a screw

driver, etc.

Front case

The lower part

Face of wall

Under plate

Screw (accessory)

Remote Controller Installation

HO

W TO MOUNT ONTO A WALL

HO

W TO INSERT BATTERIES

Remove the battery cover from the remote

controller.

• Slide the cover according to the arrow

direction.

Insert the two batteries.

• Be sure that the (+) and (-) directions are

correct.

• Be sure that both batteries are new.

Re-attach the cover.

• Slide it back into position.

• Fix the under plate on the wall

• Separate the under plate from Remote control box.

• Fix the cord clamps on the wall by

ø 3 tapping screws (accessory).

• Fix the remote control cord.

DISASSEMBLING

ELECTRICAL WIRING

Wire and make sure that terminal

numbers are matched on unit side and

remote controller side.

The maximum length of the cord is 100m.

If the length of the cord exceeds 50m,

use a wire size greater than 0.5mm

2

.

Remote controller

(Main board)

CN REMO

• Do not use rechargeable batteries,

such batteries differ from standard

dry cells in shape, dimensions, and

performance.

• Romove the batteries from the

remote controller if the air

conditioner is not going to be used

for some long time.

Installation Manual 11

ENGLISH

Wiring Connection

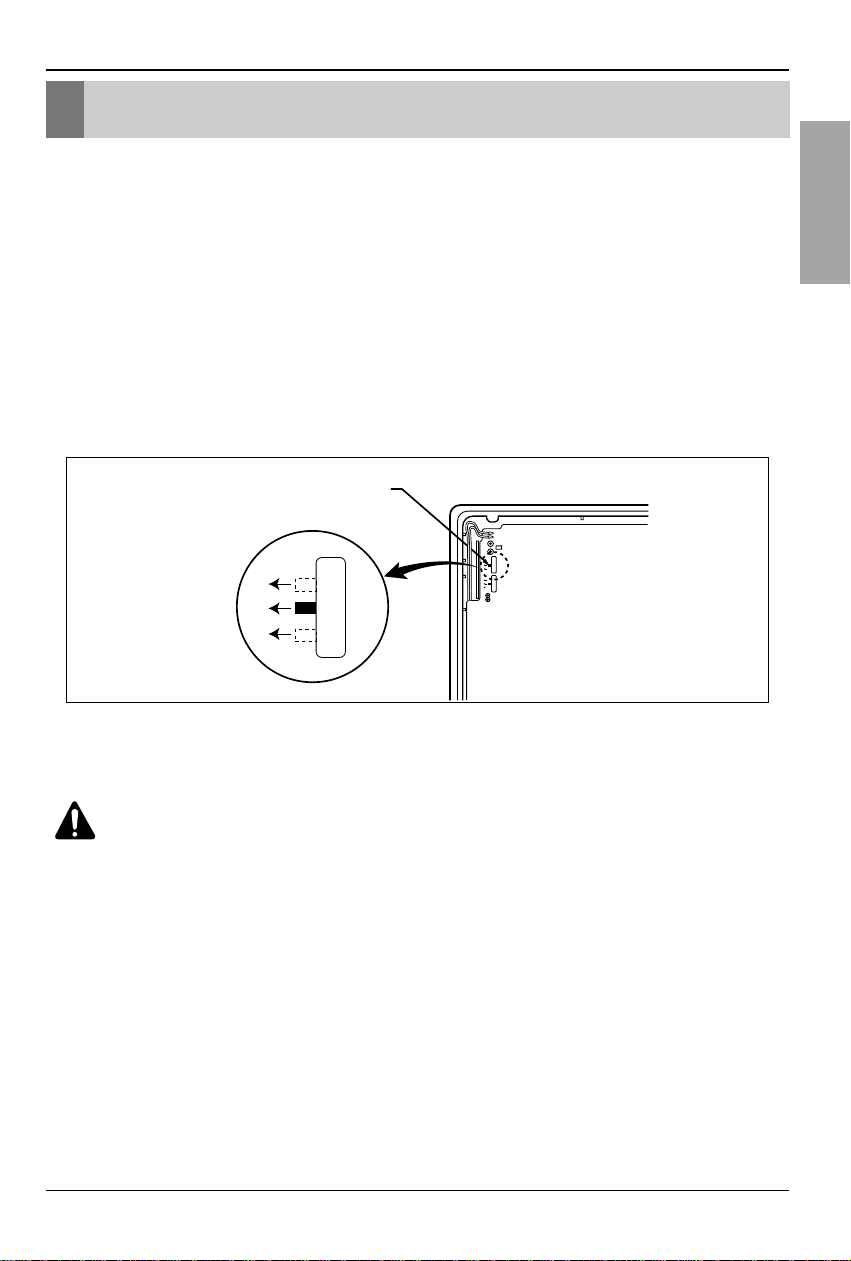

• Open the control box cover and connect the Remote controller cord and Indoor power wires.

[Air inlet side view]

Control box cover

Indoor

power cord

Remote

controller

cord

Control box cover screw

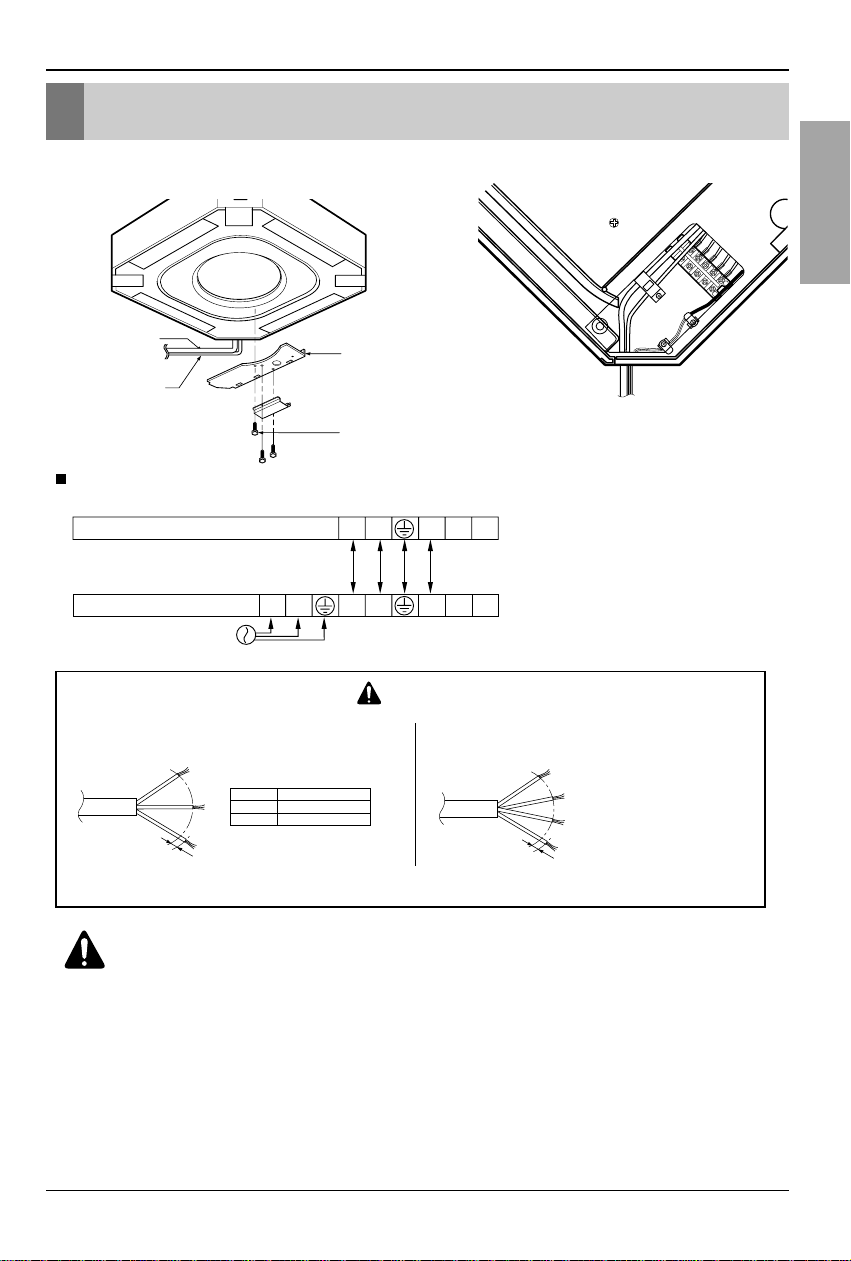

• Cooling & Heating type

The power cord connected to the outdoor unit should be

complied with the following specifications (Rubber

insulation, type H05RN-F approved by HAR or SAA).

If the supply cord is damaged, it must be replaced by a special cord or assembly available from the manufacturer of its service agent.

The connecting cable connected to the indoor and outdoor

unit should be complied with the following specifications

(Rubber insulation, type H05RN-F approved by HAR or SAA).

CAUTION

20mm

G

N

/Y

L

NORMAL

CROSS-SECTIONAL

AREA 2.1mm

2

(24k/34k)

20mm

G

N

/Y

L

Capacity

24k Btu/h

34k Btu/h

1 Phase

2.1mm

2

3.3mm

2

NORMAL CROSS-SECTIONAL AREA

24k/34k Btu/h (1Ø)

POWER

INPUT

Terminals on the indoor unit

Terminals on the outdoor unit

1(L) 2(N) 2(N) 31(L)

2(N) 3 4 51(L)

45

WARNING:

Make sure that the screws of the terminal are free from looseness.

Wiring Connection

12 Cassette type Air Conditioner

Electrical Wiring

Connecting the cable to Outdoor Unit

Wiring Connection

1. All wiring must comply with LOCAL REGULATIONS.

2. Select a power source that is capable of supplying the current required by the air conditioner.

3. Feed the power source to the unit via a distribution switch board designed for this purpose.

4.The ter minal screws inside the control box may be loose due to vibration during transport.

Check the screws for loose connection.

(Running the air conditioner with loose connection can overload and damage electrical

components.)

5. Always ground the air conditioner with a grounding wire and connector to meet the LOCAL

REGULATION.

Main power source

Switch box

Refrigerant pipe

Circuit Breaker

Use circuit breaker or time delay fuse.

1. Remove the Cover control from the unit by loosening a

screw.

Connect the wires to the terminals on the control

board individually as following.

2. Secure the cable onto the control board with the

holder (clamper).

3. Refix the cover control to the original position with the

screw.

4. Use a recongnized circuit breaker between the power

source and the unit. A disconnection device to

adequately disconnect all supply lines must be fitted.

Outdoor unit

Terminal block

Over 5mm

(0.2")

Cover control

Conduit panel

Connecting

cable

Power supply

cord

Installation Manual 13

ENGLISH

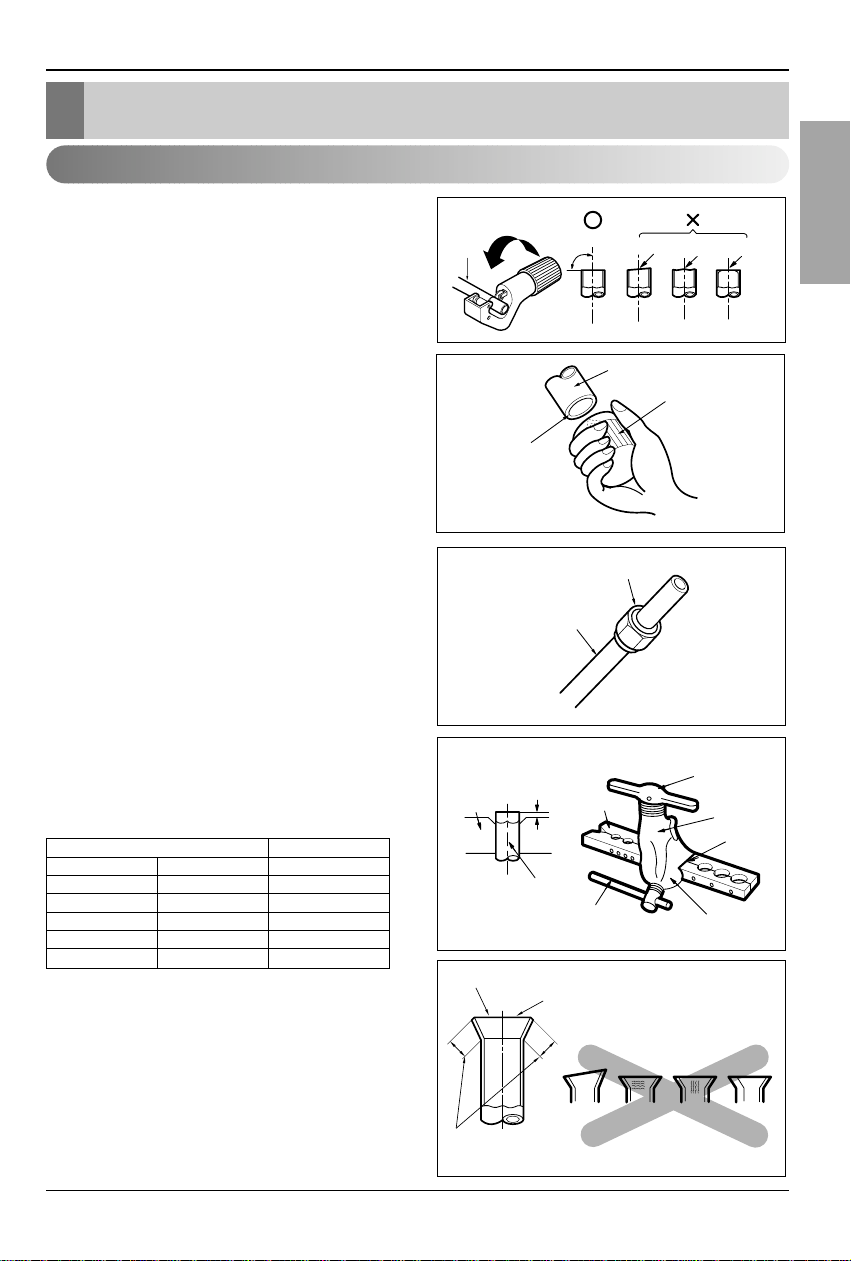

Connecting Pipes to the Indoor Unit

Main cause of gas leakage is defect in flaring

work. Carry out correct flaring work in the

following procedure.

1. Cut the pipes and the cable.

• Use the accessory piping kit or the pipes

purchased locally.

• Measure the distance between the indoor

and the outdoor unit.

• Cut the pipes a little longer than measured

distance.

•

Cut the cable 1.5m longer than the pipe

length.

2. Burrs removal

• Completely remove all burrs from the cut

cross section of pipe/tube.

•

Put the end of the copper tube/pipe to

downward direction as you remove burrs in

order to avoid to let burrs drop in the tubing.

3. Putting nut on

• Remove flare nuts attached to indoor and

outdoor units, than put them on pipe/tube

having completed burr removal.

(Not possible to put them on after flaring work)

4. Flaring work

•

Carry out flaring work using dedicated

flaring tool for R-410A as shown below.

Firmly hold copper tube in a bar(or die) as

indicated dimension in the table above.

5. Check

• Compare the flared work with figure below.

• If flare is noted to be defective, cut off the

flared section and do flaring work again.

Copper

tube

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shining without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Connecting Pipes to the Indoor Unit

Preparation of Piping

Outside diameter A

mm inch mm

Ø6.35 1/4 1.0~1.5

Ø9.52 3/8 1.0~1.5

Ø12.7 1/2 1.0~1.5

Ø15.88 5/8 1.0~1.5

Ø19.05 3/4 2.0~3.0

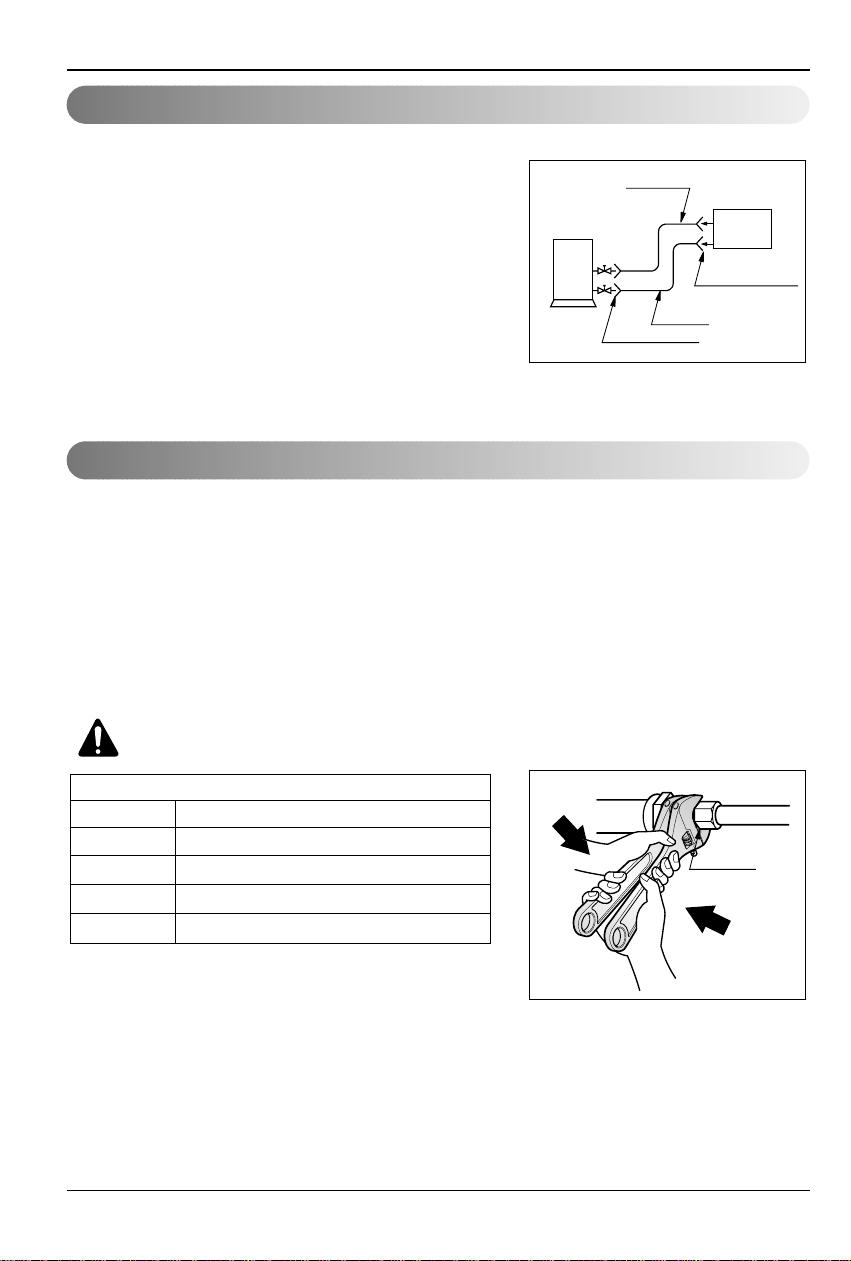

14 Cassette type Air Conditioner

Connecting Pipes to the Indoor Unit

1. Form the piping according to its routing. Avoid

bending and bending back the same piping point

more than three times. (This will result in

hardening the pipe.)

2. After deforming the piping, align centers of the

union fitting of the indoor unit and the piping,

and tighten them firmly with wrenches.

3. Connect pipe to the service valve or ball valve

which is located below the outdoor unit.

4. After completing the piping connection, be sure

to check if there is gas leakage in indoor and

outdoor connection.

After completing the piping connection, execute

vacuum drying for the connecting piping and the

indoor unit.

The vacuum drying must be carried out using

the service ports of both the liquid and gas side

valves.

CAUTION:

Use two wrenches and

tighten with regular torque.

Outdoor

unit

Liquid side

Flare connection

Flare connection

Gas side

Indoor

unit

Union

Flare nut fastening torque

Ø6.35mm 1.8kg.m

Ø9.52mm 2.7kg.m

Ø12.7mm 3.7kg.m

Ø15.88mm 4.7kg.m

Ø19.05mm 5.7kg.m

Piping Connection

Vacuum drying

Installation Manual 15

ENGLISH

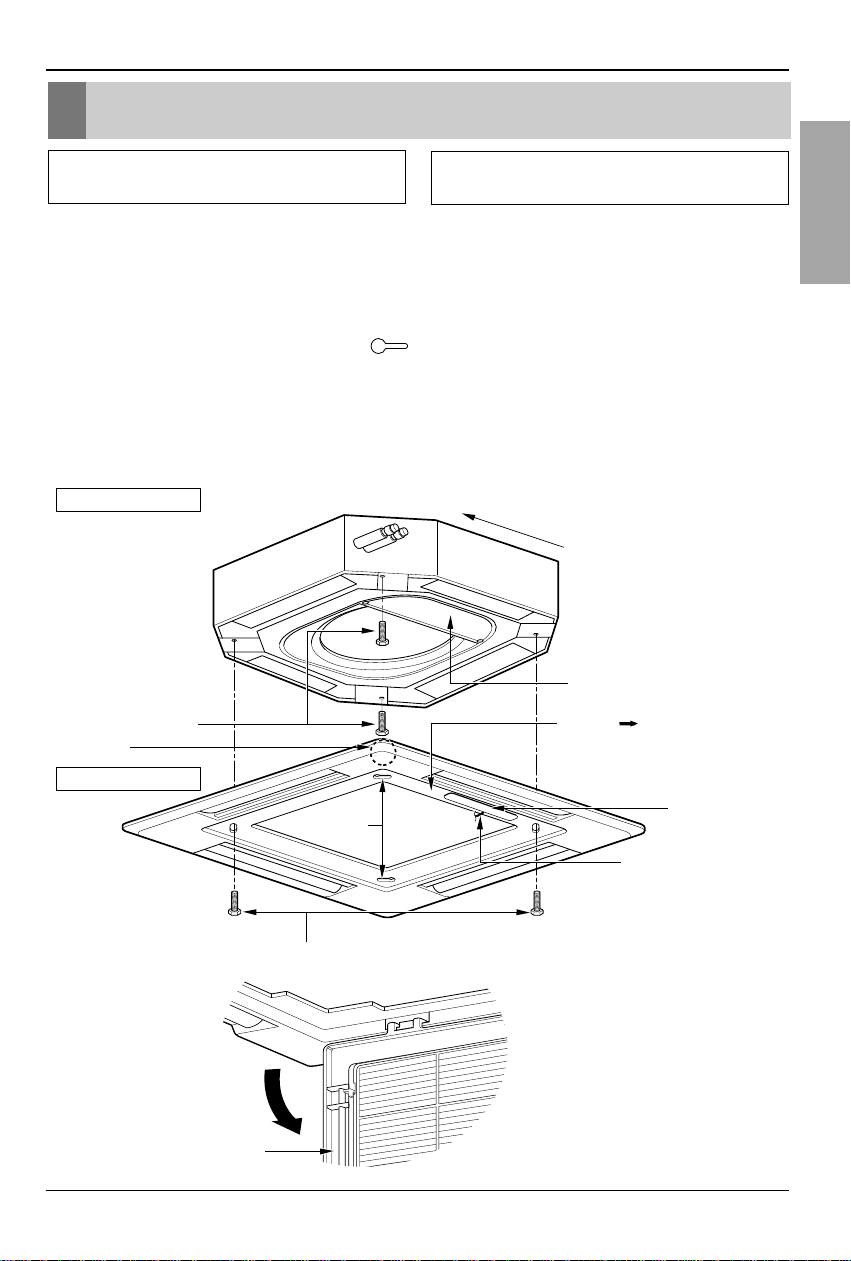

Installation to Decorative Panel

1.Temporarily fix two decorative panel fixing screws (hexagon M5 screw) on the unit body.

(Tighten by amount 10mm in length.)

The fixing screws (hexagon M5 screw) are included the decorative panel box.

2. Remove the air inlet grille from the decorative panel.(Remove the hook for the air inlet grille

cord.)

3. Hook the decorative panel key hole ( ) on the screws fixed in step above, and slide the

panel so that the screws reach the key hole edge.

4. Retighten completely two temporarily fixed screws and other two screws. (Total 4 screws)

5. Connect the louver motor connector and display connector.

6. After tightening these screws, install the air inlet grille (including the air filter).

Decorative panel fixing screws

(hexagon M5 screws)

Temporally fitting at 2 places

(Tightening about 10mm)

Install the panel after

making sure that the

piping side of the unit body

matches the piping

indication of the decorative

panel

Control box cover

Piping side

Inlet GrilleInlet GrilleInlet Grille

Inlet GrilleInlet Grille

Louver motor

Decorative panel fixing screws

(Hexagon M5 screw)

The arrow ( ) should point

to the side where the pipes are.

Air conditioner unit

Decorative panel

Key holes

Display

Lead wire for

louver motor and

display

The decorative panel has its installation

direction.

Before installing the decorative panel,

always remove the paper template.

Installation to Decorative Panel

16 Cassette type Air Conditioner

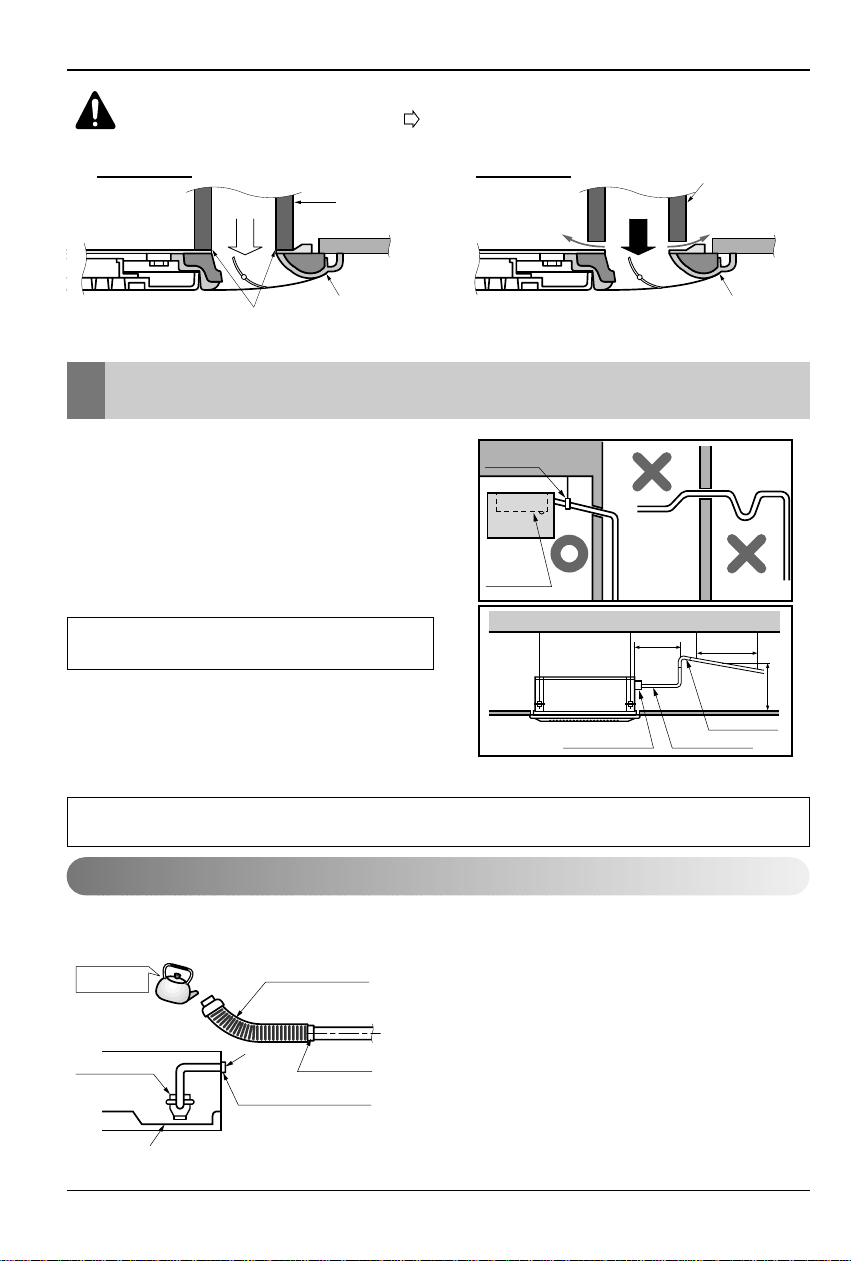

Indoor Unit Drain Piping

CAUTION:

Install certainly the decorative panel.

Cool air leakage causes sweating.

Water drops fall.

• Drain piping must have down-slope (1/50 to

1/100): be sure not to provide up-and-down

slope to prevent reversal flow.

• During drain piping connection, be careful

not to exert extra force on the drain port on

the indoor unit.

• The outside diameter of the drain

connection on the indoor unit is 32mm.

• Be sure to execute heat insulation on the

drain piping.

• Install the drain raising pipes at a right

angle to the indoor unit and no more than

300mm from the unit.

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior and leave

it provisionally until the test comes to an end.

• Feed water to the flexible drain hose and check the

piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring is

complete.

• When the test is complete, connect the flexible drain

hose to the drain port on the indoor unit.

Air conditioner

unit

Ceiling

board

Decorative panel

Decorative

panel

Fit the insulator (this part) and

be careful for cool air leakage

Good example

Air

Cool air leakage

(no good)

Bad example

Ceiling

board

Air conditioner unit

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

700 or less

1 -1.5m

300mm or less

Clamp metal(attached) Drain hose(attached)

Drain raising pipe

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip (accessory)

Piping material: Polyvinyl chloride pipe VP-25

and pipe fittings

Heat insulation material: Polyethylene foam with thickness more than 8 mm.

Drain test

Indoor Unit Drain Piping

Installation Manual 17

ENGLISH

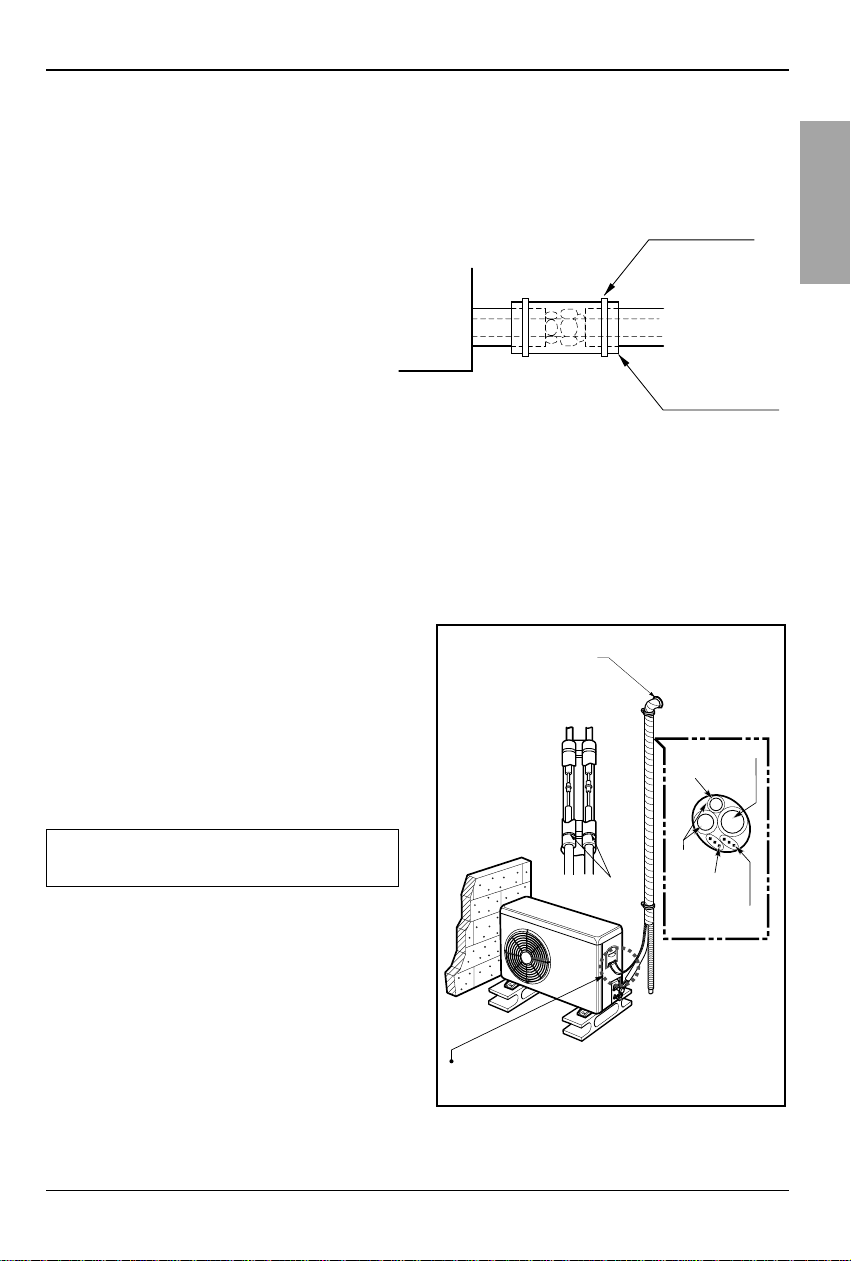

Indoor Unit Drain Piping

HEAT INSULATION

1. Use the heat insulation material for the refrigerant piping which has an excellent heatresistance (over 120°C).

2. Precautions in high humidity

circumstance:

This air conditioner has been tested

according to the "KS Standard

Conditions with Mist" and confirmed

that there is not any default.However, if

it is operated for a long time in high

humid atmosphere (dew point

temperature: more than 23°C), water

drops are liable to fall.In this case, add

heat insulation material according to the

following procedure:

• Heat insulation material to be

prepared... Adiabatic glass wool with

thickness 10 to 20mm.

• Stick glass wool on all air conditioners

that are located in ceiling atmosphere.

FORM THE PIPINGS

1.Wrap the connecting portion of indoor

unit with the Insulation material and

secure it with two Plastic Bands. (for the

right pipings)

• If you want to connect an additional drain hose,

the end of the drain-outlet should keep distance

from the ground. (Do not dip it into water, and fix

it on the wall to avoid swinging in the wind.)

2.Tape the Pipings, drain hose and

Connecting Cable from bottom to top.

3. Form the pipings gathered by taping

along the exterior wall and fix it onto the

wall by saddle or equivalent.

• In addition to the normal heat insulation

(thickness: more than 8mm) for refrigerant

piping (gas piping: thick piping) and drain

piping, add further 10mm to 30mm thickness

material.

Indoor unit

Thermal insulator

(accessory)

Fastening band

(accessory)

Refrigerant piping

In case of the Outdoor unit being installed

below position of the Indoor unit.

Seal a small opening

around the pipings

with gum type sealer.

Taping

Drain hose

Pipings

Plastic Band

Trap is required to prevent water from entering

into electrical parts.

Connecting

cable

Power supply

cord

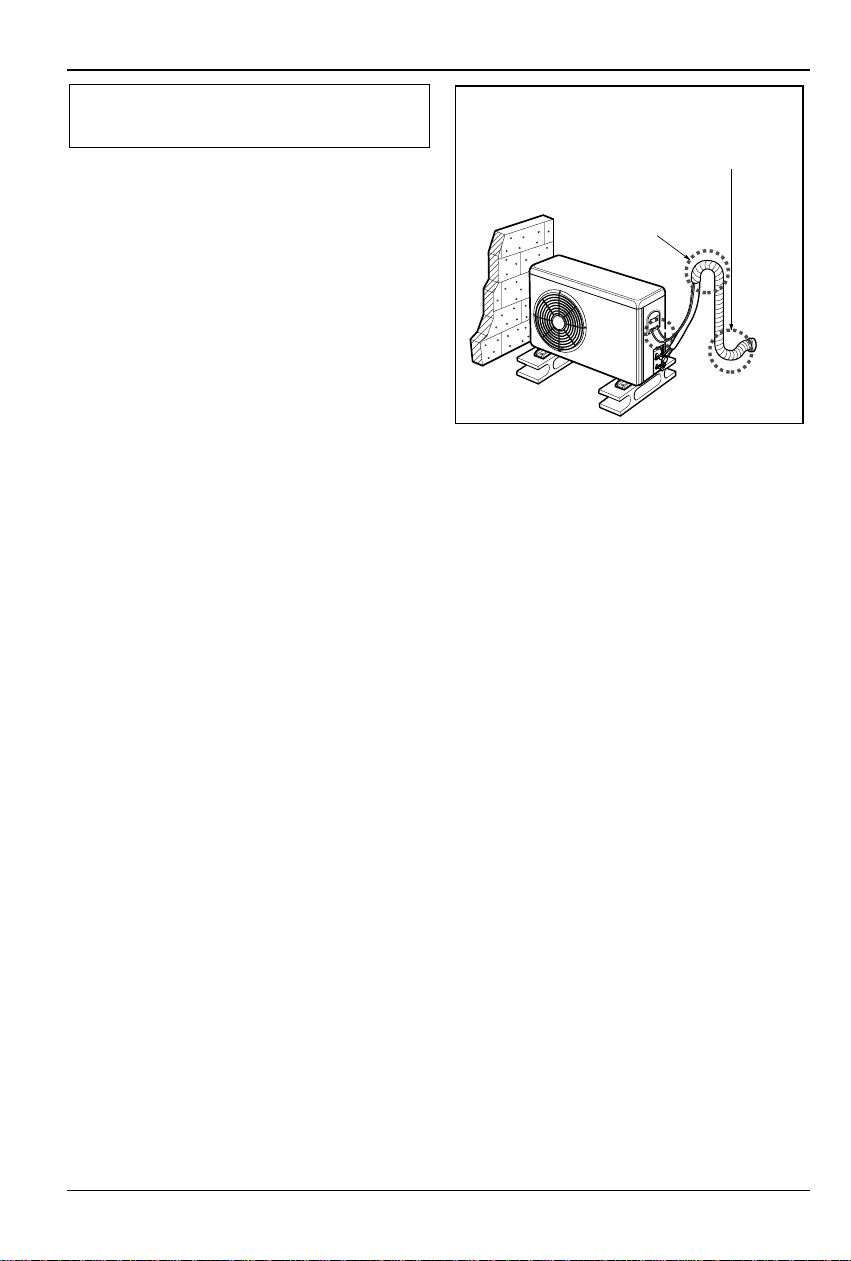

18 Cassette type Air Conditioner

Indoor Unit Drain Piping

2.Tape the Pipings and Connecting cable

from bottom to top.

3. Form the pipings gathered by taping along

the exterior wall, and make the trap prevent

water from entering into the room.

4. Fix the pipings onto the wall by saddle or

equivalent.

In case of the Outdoor Unit being installed

above position of the Indoor Unit.

Seal a small opening

around the pipings

with gum type sealer.

Trap

Test running

Installation Manual 19

ENGLISH

1. PRECAUTIONS IN TEST RUN

• The initial power supply must provide at least 90% of the rated voltage.

Otherwise, the air conditioner should not be operated.

CAUTION For test run, carry out the cooling operation firstly even during heating

season. If heating operation is carried out firstly, it leads to the trouble

of compressor.Then attention must be paid.

Carry out the test run more than 5 minutes without fail.

(Test run will be cancelled 18 minutes later automatically)

• The test run is started by pressing the room temperature checking button and down timer

button for 3 seconds at the same time.

• To cancel the test run, press any button.

CHECK THE FOLLOWING ITEMS WHEN INSTALLATION IS COMPLETE

• After completing work, be sure to measure and record trial run properties, and store measured

data, etc.

• Measuring items are room temperature, outside temperature, suction temperature, blow out

temperature, wind velocity, wind volume, voltage, current, presence of abnormal vibration and

noise, operating pressure, piping temperature, compressive pressure.

• As to the structure and appearance, check following items.

2. Connection of power supply

1. Connect the power supply cord to the independent power supply.

• Circuit breaker is required.

2. Operate the unit for fifteen minutes or more.

3. Evaluation of the performance

1. Measure the temperature of the

intake and discharge air.

2. Ensure the difference between the

intake temperature and the discharge

one is more than 8°C (Cooling) or

reversely (Heating).

Is the circulation of air adequate?

Is the draining smooth?

Is the heat insulation complete

(refrigerant and drain piping)?

Is there any leakage of refrigerant?

Is the remote controller switch operated?

Is there any faulty wiring?

Are not terminal screws loosened?

M4......118N.cm{12kgf.cm} M5......196N.cm{20kgf.cm}

M6......245N.cm{25kgf.cm} M8......588N.cm{60kgf.cm}

Test running

Thermometer

20 Cassette type Air Conditioner

CAUTION: After the confirmation of the above conditions, prepare the wiring

as follows:

1) Never fail to have an individual power specialized for the air conditioner. As

for the method of wiring, be guided by the circuit diagram pasted on the

inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screw which fasten the wiring in the casing of electrical fittings are

liable to come loose from vibrations to which the unit is subjected during

the course of transportation. Check them and make sure that they are all

tightly fastened. (If they are loose, it could give rise to burn-out of the

wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of

the rated voltage marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources

specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point there of, fuse

breaking, disturbance to the normal function of a overload protection device.

• Proper starting power is not given to the compressor.

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual

(air filter cleaning, temperature control, etc.).

Test r unning

Installation Manual 21

ENGLISH

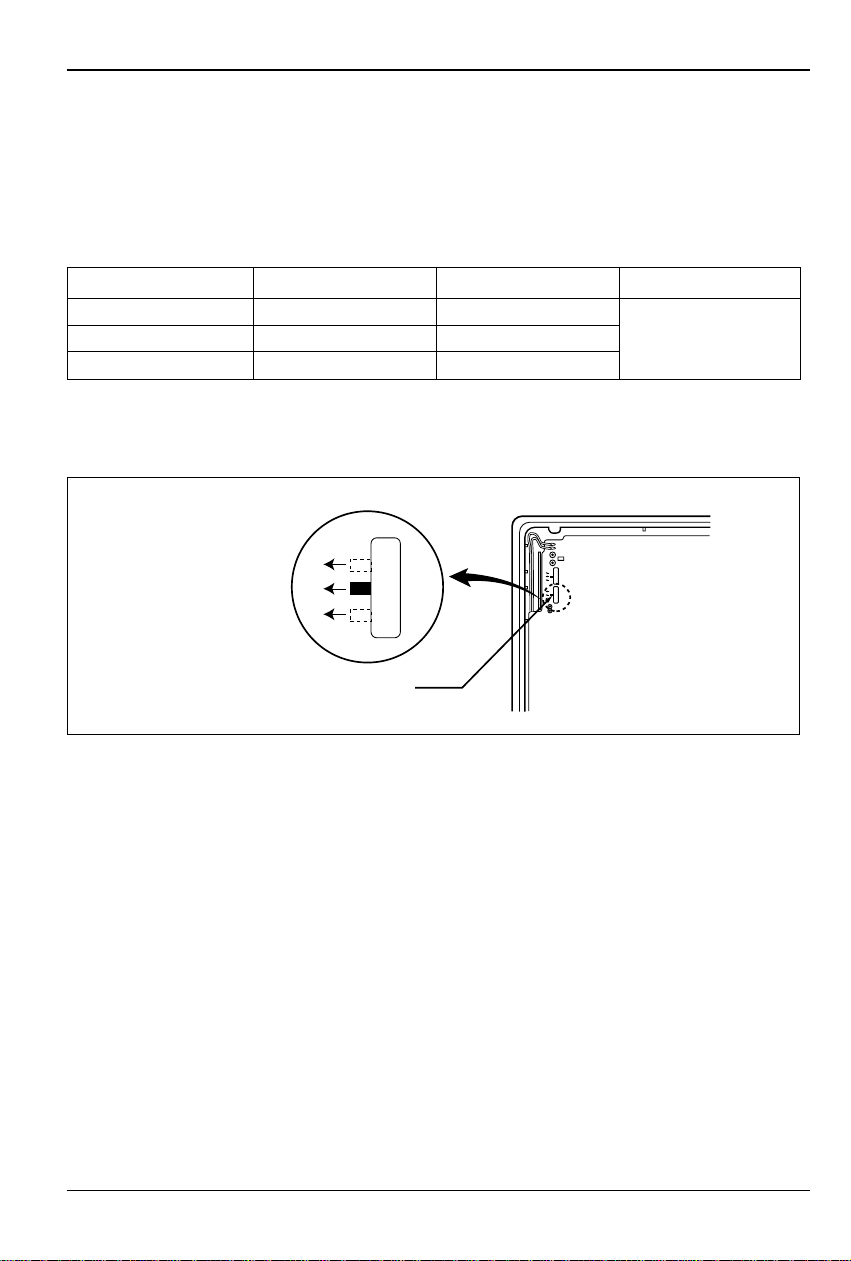

1.Two Thermistor System

(1) Open the rear cover of the wired remote-controller to set the mode.

(2) Select one of three selectable modes as follows.

• Position 1:The room themperature is controlled by the thermistor of the wired remotecontroller, control the temperature according to the position of wired remotecontroller.

• Position 2:The room temperature is controlled by the thermistor of the main body.

• Position 3:The room temperature is controlled by lower temperature between the

temperature of main body and of remote-controller sensor.

(3) Move the slide switch to set position.

(4) Close the rear cover and check if it works normally.

CAUTIO

N

:

• Select the position after counselling with a customer.

• In case of cooling mode, room temperature is controlled by the main body sensor.

• To control the room temperature by a wired remote controller, install controller(room

temp. sensor) to sense the temperature more accurately.

• Manufactured in the position 3.

Optional Operation

Optional Operation

Slide switch for 2 Thermistor

1

2

3

1

2

3

1

2

3

22 Cassette type Air Conditioner

2. Adjusting air volume to the height of ceiling

You can choose the RPM(or air volume) of indoor motor according to the height of ceiling to

supply the comfortable atmosphere to consumers.

Procedure

1. Choose the selectable position in the table after measuring the height of ceiling.

2. In the case of changing the height as "high" or "low", open the rear cover of the wired remotecontroller.

3. Move the slide switch to the set position.

4. Close the rear cover and check if it works normally.

Optional Operation

Ceiling height Mode of slide switch Change of air volume Remark

more than 3.3m High Ceiling Increasing

2.7~3.3m Standard -

Manufactured in

less than 2.7m Low Ceiling Decreasing

standard mode

1

2

3

Slide switch for ceiling height

1

2

3

1

2

3

Installation Manual 23

ENGLISH

Optional Operation

3. Group Control(Optional Wiring)

• You can use a group control operation after connecting the brown and yellow wire of

each air-conditioner.

• Remove the resistor "OP 7" in remote controller.

• It operates maximum 16 Units by only one Wired Remote Controller,

and each Unit starts sequentially to prevent overcurrent.

Wiring design

Features

• Use Only One Wired Remote Controller with several air conditioners(max. 16 Units)

• Random starting to prevent overcurrent.

CAUTIO

N

:

• Be careful not to exchange the color of wires.

• The maximum length of connecting wire should be below 200m(25Ω) on connecting

each units.

• Use a wire more than 0.5mm

2

Operation unit

ZONE

1234

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

Wired Remote Controller

Slide Switch

OP7

Remote

Controller

PCB

Main PCB

Indoor Unit 1

Terminal(Local Supply)

Block

Terminal(Local Supply)

Block

Terminal(Local Supply)

Block

Main PCB

#1

Main PCB

#2

Main PCB

#16

Indoor Unit 2

Main PCB

Indoor Unit 16

Connector

RED(12V)

YL(SIGNAL)

BR(GND)

RED(12V)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

Connecting Cable(Local Supply)

Connector Connector

....

....

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

24 Cassette type Air Conditioner

Memo

FRANÇAIS

LG

Climatiseur Type Cassette

MANUALE D’INSTALLAZIONE

IMPORTANTE

• Veuillez lire au complet ce manuel d’instructions avant

installer le produit.

• Conformément aux standards nationaux sur le câblage,

l’installation ne doit être effectuée que par du personnel

autorisé.

• Après l’avoir lu au complet, veuillez conserver ce

manuel d’installation pour référence ultérieure.

2 Climatiseur Type Cassette

Climatiseur Type Cassette Manuel d'installation

TABLE DES MATIÈRES

Mesures de sécurité

......................................3

Installation des unités

interne et externe............6

Dimensions de l'ouverture

dans le plafond et

emplacement des boulons

de fixation........................8

Installation de I'unité

interne..............................9

Installation de la

télécommande.................9

Connexion des câbles..11

Connexion des conduits à

l'unité interne.................13

Installation du panneau

décoratif.........................15

Conduits de drainage

unité interne ..................16

Test de fonctionnement....

........................................19

Fonctionnement optionnel

........................................21

• Plaque de montage

• Quatre vis de type “A”

• Câble de raccordement

• Conduites : gaz Iiquide

• Tube d'évacuation isolés

• Matériaux isolants

•

Tube d'évacuation complémentaire

(Diam. extérieur5,5mm

)

• Deux vis de type "B"

• Niveau à bulle

• Tournevis

• Perecuse électrique

• Embout scie trépan (ø70mm)

• Jeux d'outils pour évasement

• Clés dynamométriques

• Clés dynamométriques

• Tournevis

• Clé six pans (4mm)

• Détecteur de fuite de gaz

• Guide de l'utilisateur

• Thermomètre

Travaux d'installation Eléments à installer Outillage

Mesures de sécurité

Manuel d'installation

3

FRANÇAIS

Les instructions ci-après doivent être observées dans le but de prévenir tout risque de

dommages corporels ou matériels.

■

L'utilisation non conforme, résultant de la négligence des instructions, est susceptible de

provoquer des dommages corporels ou matériels dont la gravité est signalée par les

indications suivantes :

■ Les significations des symboles utilisés dans ce manuel sont indiquées ci-dessous.

Ce symbole indique un risque de blessure grave, voire mortelle.

Ce symbole indique un risque de blessure ou des dommages

matériels seulement.

ATTENTION

Veillez à ne pas faire cela.

Veillez à suivre les instructions de ce manuel.

Mesures de sécurité

■ Installation

N'utilisez pas un coupe-circuit

défectueux ou à valeur nominale

inférieure. Utilisez cet appareil sur

un circuit dédié.

• Ceci risquerait de provoquer

un incendie ou un choc

électrique.

Pour un travail électrique, contactez

le distributeur, le vendeur, un

électricien qualifié ou un Centre de

Service Après Vente Agrée.

• Ne démontez ni réparez le

produit. Ceci risquerait de

provoquer un incendie ou un

choc électrique.

Faites toujours une connexion

reliée à la terre.

• Autrement vous risquerez de

provoquer un incendie ou un

choc électrique.

Installez fermement le panneau

et le couvercle du tableau de

commande.

• Autrement vous risquerez de

provoquer un incendie ou un

choc électrique.

Installez toujours un circuit et

un disjoncteur dédiés.

• Un câblage ou une installation

inappropriés peuvent

provoquer un incendie ou un

choc électrique.

Utilisez un disjoncteur ou

fusible à valeur nominale

appropriée.

• Autrement vous risquerez de

provoquer un incendie ou un

choc électrique.

ATTENTION

PRECAUTION

4 Climatiseur Type Cassette

Mesures de sécurité

Ne modifiez ni prolongez le cordon

d'alimentation.

• Ceci risquerait de provoquer un incendie ou

un choc électrique.

Prenez soin lorsque vous déballez et installez

ce produit.

•

Les bords aiguisés peuvent provoquer des

blessures.Faites attention en particulier aux

bords du boîtier et aux ailettes du condenseur et

de l'évaporateur.

Contactez toujours le revendeur ou un centre

de service après vente agréé pour effectuer

l'installation.

• Autrement, Vous

pourriez provoquer

un incendie, un

choc électrique,

une explosion ou

vous blesser.

N'installez pas le produit sur un support

d'installation défectueux.

• Ceci peut provoquer des blessures, un

accident ou bien endommager le produit.

Vérifiez que la zone d'installation n'est pas

abîmée par le temps.

•

Si la base s'écroule, le

climatiseur pourrait

tomber avec elle,

provoquant des

dommages matériels,

une défaillance du

produit et des blessures.

Ne laissez pas le climatiseur marcher trop

longtemps lorsque l'humidité est très élevée et

qu'il y a une porte ou une fenêtre ouverte.

• De l'humidité peut se condenser et mouiller

ou endommager le mobilier.

N'emmagasinez ni utilisez de substances

inflammables ou combustibles près de ce

produit.

• Ceci entraînerait un risque d'incendie ou de

défaillance du produit.

■ Fonctionnement

Gasolin

FRANÇAIS

Manuel d'installation

5

Mesures de sécurité

Vérifiez toujours s'il y a des fuites de gaz

(frigorigène) suite à l'installation ou réparation

du produit.

• Des niveaux de frigorigène trop bas peuvent

provoquer une défaillance du produit.

Installez le raccord de drainage de manière à

assurer un drainage approprié.

• Une mauvaise connexion peut provoquer

des fuites d'eau.

Maintenez le produit au niveau lors de son.

• Installation afin d'éviter des vibrations ou des

fuites d'eau.

N'installez pas le produit à un endroit où le

bruit ou l'air chaud dégagés de l'unité

extérieure dérangent les voisins.

• Ceci pourrait entraîner des problèmes avec

vos voisins.

Faites appel à deux ou plusieurs personnes

pour enlever et transporter ce produit.

• Evitez des blessures.

N'installez pas ce produit à un endroit où il

serait exposé directement au vent de la mer

(pulvérisation d'eau de mer).

• Ceci peut provoquer de la corrosion sur le

produit. La corrosion, particulièrement sur les

ailettes du condenseur et de l'évaporateur,

peut provoquer un dysfonctionnement ou un

fonctionnement inefficace du produit.

PRECAUTION

90°

■ Installation

6 Climatiseur Type Cassette

Installation des unités interne et externe

Installation des unités interne et externe

Sélection du meilleur emplacement

1. Unité interne

• Il ne doit pas y avoir d'autres sources de

chaleur ou de vapeur à côté de l'unité.

• Il ne doit y avoir aucun obstacle qui puisse

bloquer la circulation de l'air.

• Un emplacement où la circulation de l'air

dans la pièce est bonne.

• Un emplacement où le drainage peut être

facilement réalisé.

• Un emplacement où une protection contre

le bruit est prise en considération.

• N'installez pas l'unité à côté d'une porte.

• Assurez-vous des espaces indiqués par

les flèches depuis le mur, le plafond ou

d'autres obstacles.

• L'unité interne doit avoir un espace pour

l'entretien.

2. Unité externe

• Si un store est placé au-dessus de l'unité

pour la protéger contre les rayons solaires

ou la pluie, faites attention que les

radiations de chaleur provenant du

condensateur ne soient pas bloquées.

• Aucun animal ou plante ne doit être affecté

par l'air chaud déchargé.

• Assurez-vous des espaces indiqués par

les flèches depuis le mur, le plafond ou

d'autres obstacles.

unité : cm.

Plafond

panneau

du plafond

panneau du plafond

30 ou plus

250-300 ou

moins

100 ou

plus environ

50 ou

plus

50 ou

plus

30 ou moins

plancher

Sunroof

plus de 30 cm

clôture ou

obstacles

plus de

50cm

clôture ou

obstacles

Sunroof

plus de

More than

30cm

30 cm

plus de 50 cm

plus de 70 cm

More than

plus de

30cm

50cm

plus de 50cm

plus de 100cm

Manuel d'installation

7

FRANÇAIS

Installation des unités interne et externe

3. Longueur et élévation des conduites

A

B

A

B

A

B

Unité intérieure

Unité intérieure

Unité intérieure

Unité extérieure

Unité extérieure

Unité extérieure

Piège à huile

Si la tuyauterie mesure plus de 5 m

PRECAUTION:

• Performance nominale pour longueur ligne réfrigérant

de 7,5 m

• La capacité est basée sur la longueur standard et la longueur maximale permise

est en fonction de la fiabilité.

• Une charge frigorifique inappropriée peut provoquer un cycle anormal.

• Un piège à huile doit être installé tous les 10 mètres.

24k Btu/h

1/2"(12.7mm) 1/4"(6.35mm)

7.5(25') 30(100') 5(16') 15(50') 20(0.22 oz./ft.)

34k Btu/h

5/8"(15.88mm) 1/4"(6.35mm)

7.5(25') 35(115') 5(16') 20(66') 30(0.32 oz./ft.)

CAPACITÉ

Réfrigérant

supplémentaire

(g/m)

Dimensions du tuyau

(Diamètre: Ø)

Longueur A (m) Elevazione B (m)

Gaz Liquide Standard Maximum Standard Maximum

8 Climatiseur Type Cassette

• Sélectionnez et marquez la position des boulons de

fixation et de l'ouverture pour les conduits.

• Décidez la position des boulons de fixation

légèrement inclinés dans la direction du drainage

après avoir considéré la direction du tuyau de

drainage.

• Percez le trou pour le boulon d'ancrage dans le

mur.

PRECAUTION:

•

Ce climatiseur utilise une pompe de drainage.

• Installez horizontalement l'unité en utilisant

une jauge de niveau.

• Pendant l'installation faites attention de ne

pas endommager les câbles électriques.

• Étudiez attentivement les emplacements d'installation suivants :

1.Dans certains lieux comme des restaurants et des cuisines, une grand quantité de vapeur d'huile et de

farine adhère au ventilateur, aux ailettes de l'échangeur de chaleur et à la pompe de drainage, ce qui

provoque une réduction de l'échange de chaleur, une vaporisation, une dispersion d'eau, un mauvais

fonctionnement de la pompe de drainage, etc.

Dans ces situations, effectuez les interventions suivantes :

• Faites attention que le ventilateur de ventilation de la hotte sur le dessus de cuisson ait une capacité

suffisante pour aspirer les vapeurs d'huile qui n'entrent ainsi pas dans l'aspiration du climatiseur.

• Laissez suffisamment de distance depuis le dessus de cuisson pour installer le climatiseur là où il

n'aspirera pas la vapeur d'huile.

2. Évitez d'installer le climatiseur dans des usines où se trouvent des suspensions d'acier en poudre ou

d'huiles, etc...

3. Évitez les lieux où des gaz inflammables se trouvent, pénètrent ou sont conservés.

4. Évitez les lieux où sont produits des gaz d'acide sulfurique ou des gaz corrosifs.

5. Évitez les lieux proches de générateurs de haute fréquence.

REMARQUE

Dimensions de l'ouverture dans le plafond et emplacement des boulons de fixation

• Les dimensions du modèle sur papier pour l'installation sont les mêmes que celles de l'ouverture dans le plafond.

Unité : cm

840 taille unité

840 taille unité

101.5101.5

875 (ouverture dans le plafond)

875 (ouverture dans le plafond)

785 (boulons de fixations)

45

45

672 (boulons de

fixations)

Panneau du plafond

Jauge de

niveau

Plafond

dessus de cuisson

Climatiseur

distance

suffisante

Utilisez le ventilateur de la

hotte avec une capacité

suffisante.

Dimensions de l'ouverture dans le plafond et emplacement des boulons de fixation

Manuel d'installation

9

FRANÇAIS

• Vous pouvez choisir les pièces suivantes.

Boulon de fixation W 3/8 ou M10

Écrou - W 3/8 ou M10

Rondelle M10

Rondelle plate M10

AVVISO:

Serrez les écrous et les

boulons pour éviter que l'unité ne

tombe.

• Percez l'ouverture pour les conduits dans le mur

légèrement inclinée vers l'extérieur en utilisant une

mèche de perceuse de 70.

Mur

5~7mm

Interne

Externe

Réglez les vis sur le

modèle en papier

(4 pièces)

modèle en papier

pour installation

panneau plafond

150mm

Réglez

à la même hauteur

panneau

du plafond

Plafond

Rondelle plate pour M10

(accessoire)

Conservez la longueur du boulon

depuis le support à 40 mm

Ouvrez le panneau du

plafond le long du bord

externe du modèle en papier

Rondelle plate pour M10

(accessoire)

boulon de fixation

(W3/8 ou M10)

Écrou

(W3/8 ou M10)

Écrou

(W3/8 ou M10)

Rondelle

(M10)

corps climatiseur

Installation de l'unité interne

• Puisque le capteur de température de la pièce est dans l'unité interne, la télécommande

doit être installée au même endroit, éloignée des rayons solaires et de l'humidité élevée.

Installation de la télécommande

• Sélectionnez un emplacement qui ne soit pas éclaboussé par de l'eau.

• Sélectionnez la position de contrôle après avoir obtenu l'approbation du client.

• Le capteur de température de la pièce est à l'intérieur de l'unité interne.

• Cette télécommande est équipé d'un affichage à cristaux liquides. Si la position est trop élevée

ou trop basse, on lit mal l'affichage. (Le standard est une hauteur de 1,2 1,5 m)

Acheminement du câble de la télécommande

• Placez le câble de la télécommande éloigné des conduits du réfrigérant et de drainage.

• Pour protéger le câble de la télécommande des parasites électriques, placez-le à au moins 5 cm

des autres câbles d0alimentation (équipement audio, téléviseur, etc.).

• Si le câble de la télécommande est fixé au mur, mettez un collecteur au-dessus du câble pour

éviter que de l'eau ne lui tombe dessus.

Installation de I'unité interne

Installation de la télécommande

10 Climatiseur Type Cassette

Installation de la Télécommande avec fils

Preparation de la Télécommande

• Fixez le plateau inférieur au mur.

• Séparez le plateau inférieur du boîtier de la télécommande.

• Fixez les pinces du câble au mur avec des vis filetées Ø

3 (accessoires).

• Fixez le câble de la télécommande.

corps boîtier

télécommande

Pince du câble

(accessoire)

Soulevez délicatement

le boîtier en utilisant

un tournevis, etc.

boîtier avant

partie inf

érieur

Mur

Plateau inférieur

Vis (accessoires)

Installation de la télécommande

COMMENT LA MONTER AU MUR

COMMENT INTR

ODUIRE LES PILES

Enlevez le couvercle de la télécommande

Faites glisser le couvercle dans la direction

de la flèche.

Introduisez 2 piles.

• Faites attention que les directions (+) et (-)

soient correctes

• Faites attention que les deux piles soient

neuves.

Remettez en place le couvercle

Faites-le glisser en position

DÉMONT

AGE

CÂBLAGE ÉLECTRIQUE

Télécommande

Panneau principal

CN REMO

Faites l'installation électrique et contrôlez que

les numéros des bornes correspondent sur

l'unité interne et sur la télécommande.

La longueur maximale du câble est de 100 m.

Si la longueur du câble dépasse les 50 m,

utilisez un câble de taille supérieure à 0,5 mm .

2

• N'utilisez pas de piles

rechargeables, ces piles sont

différentes des piles sèches

standard comme forme, dimensions

et performances.

• Enlevez les piles de la

télécommande si le climatiseur

n'est pas utilisé pendant longtemps.

Manuel d'installation

11

FRANÇAIS

Connexion des câbles

• Ouvrez le couvercle du boîtier de contrôle et connectez le câble de la télécommande et les

câbles d'alimentation internes.

[Vue côté admission d'air]

Couvercle boîtier

de contrôle

Cordon

d'alimentation

interne

Cordon

télécommande

Vis de montage du couvercle

du boîtier de contrôle

Le cordon d'alimentation connecté à l'unité externe doit être

conforme aux spécifications suivantes (isolation en

caoutchouc, type H05RN-F approuvé par HAR ou SAA).

Le cordon d'alimentation connecté à l'unité externe et à

l'unité externe doit être conforme aux spécifications

suivantes (isolation en caoutchouc, type H05RN-F

approuvé par HAR ou SAA).

PRECAUTION

Alimentation

en entr

SURFACE SECTION

TRANSVERSALE NORMALE

• Si le câble d’alimentation est endommagé, il doit être remplacé par un câble spécial ou d’assemblage fourni par le fabricant ou le service

d’assistance.

•

Type réfrigérant et chauffant

20mm

G

N/YL

SURFACE SECTION

TRANSVERSALE

NORMALE

2.1mm2 (24k/34k)

Capacity

24k Btu/h

34k Btu/h

1 Phase

2.1mm

2

3.3mm

2

24k/34k Btu/h (1Ø)

Terminal sur le groupe interne

Terminal sur le groupe externe

1(L) 2(N) 2(N) 31(L)

2(N) 3 4 51(L)

45

20mm

G

N/YL

ATTENTION:

Contrôlez que les vis des bornes ne soient pas serrées.

Connexion des câbles

12 Climatiseur Type Cassette

Cäblages électriques

Connexion du Cäble a l'unité externe

Connexion des câbles

1.Tous les câblages doivent être conformes aux RÈGLES LOCALES.

2. Sélectionnez une source d'alimentation capable de fournir le courant nécessaire au climatiseur.

3. Fournissez le courant à l'appareil à travers un tableau de distribution conçu dans ce but.

4. Les vis des bornes à l'intérieur du boîtier de contrôle pourraient être desserrées à cause de

vibrations pendant le transport. Contrôlez ces vis des connexions desserrées.

(Faire fonctionner le climatiseur avec des connexions desserrées peut surcharger et

endommager les composants électriques).

5. Effectuez toujours la mise à terre du climatiseur avec un câble de terre et un connecteur qui

satisfont aux RÈGLES LOCALES.

Source principale d'alimentation

boîtier des interrupteurs

tuyau réfrigérant

Coupe-circuit

Utilisez le coupe-circuit ou un fusible de retard

1. Enlevez le couvercle de contrôle de l'unité en

dévissant la vis. Branchez les câbles aux bornes

sur le panneau de contrôle de la manière

suivante.

2. Assurez le câble au panneau de contrôle avec

des supports (pinces).

3. Remettez en place le couvercle de contrôle avec

la vis.

4. Utilisez un coupe-circuit reconnu entre la source

d'alimentation et l'unité. Un appareil de

débranchement. pour débrancher toutes les

lignes de fourniture doit être monté.

Unité extérieure

Boîte à bornes

Au-dessus

de 5mm

(2")

Couvercle du panneau

de commandes

Panneau de

commandes

Câble de

connexion

Câble

d’alimentation

électrique

Manuel d'installation

13

FRANÇAIS

Connexion des conduits á l'unité interne

Préparation des conduits

La cause principale des fuites de gaz est un

défaut dans le travail d'évasement. Effectuez

correctement le travail d'évasement en

suivant la procédure ci-dessous.

1. Coupez les conduits et le câble

• Utilisez le kit de tuyaux ou des tuyaux

achetés par vous.

• Mesurez la distance entre l'unité interne et

l'unité externe.

• Coupez les tuyaux un peu plus longs que

la distance mesurée.

• Coupez le câble 1,5 m plus long que la

longueur des tuyaux.

2. Enlevez les bavures

• Éliminez complètement les bavures de la

section transversale coupée des tuyaux.

• Placez l'extrémité des tuyaux en cuivre

vers le bas pour que vous puissiez éliminer

les bavures afin d'éviter d'en laisser à

l'intérieur des tuyaux.

3. Montez l'écrou

• Enlevez les écrous évasés montés sur les

unités interne et externe, puis placez-les

sur les tuyaux après avoir éliminé les

bavures.(Il n'est plus possible de les

monter après avoir effectuer le travail

d'évasement)

4.Travail d'évasement

• Exécutez le travail d’évasement en utilisant

l’outil évasé pour R-410A comme suit.

Tenez fermement le tuyau en cuivre dans

une barre (ou une matrice) de dimensions

indiquées dans le tableau ci-dessus.

5. Contrôle

• Comparez le travail d'évasement avec la

figure.

•

Si vous avez noté que l'évasement est

défectueux, coupez la section évasée et

effectuez de nouveau le travail d'évasement.

Tuyau en

cuivre

90°

biseauté non uniforme rugueux

Tuyau

Alésoir

Pointez vers

le bas

écrou évasé

Tuyau en cuivre

Barre

tuyau en cuivre

Poignée pince

Flèche rouge

Cône

Étau

Poignée

Barre

"A"

incliné

intérieur est brillant sans rayures

lisse tout autour

longueur uniforme

tout autour

surface

endommagée

fissuréépaisseur

non uniforme

= Mauvais évasement =

Connexion des conduits à l'unité interne

Diamètre externe A

mm inch mm

Ø6.35 1/4 1.0~1.5

Ø9.52 3/8 1.0~1.5

Ø12.7 1/2 1.0~1.5

Ø15.88 5/8 1.0~1.5

Ø19.05 3/4 2.0~3.0

14 Climatiseur Type Cassette

Connexion des conduits

Séchage avec aspirateur

Connexion des conduits á l'unité interne

1. Façonnez les conduits selon leur cheminement.

Évitez de cambrer et de recambrer le même

point du conduit plus de trois fois (Cela

provoquerait un durcissement du tuyau).

2. Après avoir façonné les conduits, alignez les

centres d'union de l'unité interne et des conduits,

et serrez-les fermement avec une clé.

3. Connectez le tuyau à la soupape de connexion

ou à la soupape à boule qui est placée sous

l'unité externe.

4. Après avoir achevé la connexion des conduits,

contrôlez s'il y a des fuites de gaz dans les

connexions interne et externe.

Completati i collegamenti dei tubi, eseguire

lasciugatura con vuoto per i tubi di connessione

e unità interna.

Lasciugatura sotto vuoto deve essere eseguita

utilizzando le aperture di servizio apposite delle

valvole sia del lato liquido che del lato gas.

PRECAUTION:

Utilisez deux clés et

serrez avec un couple de serrage régulier.

unité

externe

côté liquide

connexion évasée

connexion évasée

côté gaz

unité

interne

Union

Couple de serrage écrou évasé

Ø6,35mm 1,8kg.m

Ø9,52mm 2,7kg.m

Ø12,7mm 3,7kg.m

Ø15,88mm 4,7kg.m

Ø19,05mm 5,7kg.m

Manuel d'installation

15

FRANÇAIS

Installation du panneau décoratif

1. ixez temporairement deux vis de fixation du panneau décoratif (vis hexagonales M5) sur le

corps de l'unité. (Serrez sur une longueur d'environ 10 mm). Les vis de fixation (vis

hexagonales M5) sont fournies avec le panneau de décoration.

2. Enlevez la grille interne du panneau décoratif.(Enlevez le crochet pour le câble de la grille

interne).

3. Accrochez les ouvertures en forme de clé ( ) du panneau décoratif sur les vis fixées

au point ci-dessus et faites glisser le panneau jusqu'à ce que les vis atteignent le bord de

l'ouverture en forme de clé.

4. Serrez complètement les deux vis temporaires fixées et les deux autres vis (total 4 vis).

5. Connectez le connecteur du moteur des volets et le connecteur d'affichage.

6. Après avoir serré ces vis, installez la grille interne (comprenant le filtre à air).

Vis de fixation (vis hexagonales M5)

du panneau décoratif

Fixation temporaire en 2 points

(serrage sur environ 10 mm)

Couvercle boîtier de contrôle

Côté conduits

Inlet GrilleInlet Grillegrille interne

Inlet GrilleInlet Grille

Moteur volets

Vis de fixations Panneau décoratif

(vis hexagonales M5)

La flèche ( ➡ ) pointe vers le

côté où se trouvent les tuyaux.

Unité climatiseur

Panneau décoratif

Ouvertures

à clé

Affichage

Câble double pour

moteur volets et

affichage

Installer le panneau après

avoir vérifié que le côté

tuyaux de l'unité

corresponde bien avec les

indications tuyaux du

panneau décoratif.

Le panneau décoratif a sa direction

d'installation.

Avant d'installer le panneau décoratif,

enlevez toujours le patron en papier.

Installation du panneau décoratif

16 Climatiseur Type Cassette

Le climatiseur utilise une pompe de drainage pour drainer l'eau.

Suivez les procédures suivantes pour tester le fonctionnement de la pompe de drainage.

• Connectez le tuyau principal de drainage à

l'extérieur et laissez-le provisoirement jusqu'à

ce que le test ne s'achève.

• Remplissez d'eau le tuyau flexible de drainage

et contrôlez s'il y a des fuites.

• Contrôlez que la pompe de drainage

fonctionne normalement quand le câblage

électriques est complet.

• Quand le test est terminé, connectez le tuyau

flexible de drainage à l'ouverture de drainage

de l'unité externe.

Conduits de drainage unité interne

• Les conduits de drainage doivent être en

pente vers le bas (1/50 à 1/100) : contrôlez

de ne pas donner une pente vers le haut et

vers le bas pour éviter le flux inverse.

• Pendant la connexion des conduits de

drainage, faites attention de ne pas exercer

trop de force sur les ouvertures de drainage

de l'unité interne.

• Le diamètre externe de la connexion de

drainage de l'unité interne est de 32 mm.

• Contrôlez de bien avoir effectué l'isolation

des conduits de drainage.

PRECAUTION:

Installez le panneau décoratif.

Des fuites d'air froid provoquent des suintements

è Des gouttes d'eau tombent.

Unité climatiseur

Panneau

du plafond

Panneau décoratif

Panneau

décoratif

Montez l'isolant (cette pièce) et

faites attention aux fuites d'air froid.

Bon exemple

Air

Fuites d'air froid

(mauvais)

Mauvais exemple

Panneau

du plafond

Unité climatiseur

Ouverture

d'entretien de

drainage

Pince de tuyau

unité interne

acheminement

vers le haut n'est

pas permis

700 or less

1 -1.5m

300mm or less

Clamp metal(attached) Drain hose(attached)

Drain raising pipe

Remplissez

d'eau

Pompe de drainage

Filtre de drainage

Tuyau flexible de drainage

(accessoire)

tuyau principal

de drainage

Collez la jonction

ouverture

de drainage

connexion tuyau de drainage

utilisez une pince (accessoire)

Matériel des conduits : tuyaux en chlorure

de polyvinyle Vp-25 et accessoires des

tuyaux.

Matériel d'isolation de chaleur : Mousse de polyéthylène avec une épaisseur de plus de 8 mm.

Conduits de drainage unité interne

Test de Drainage

Manuel d'installation

17

FRANÇAIS

Conduits de drainage unité interne

ISOLATION A LA CHALEUR

1. Utilisez le matériel d'isolation à la chaleur pour les tuyaux du liquide réfrigérant qui ont une

résistance à la chaleur excellente (plus de 120°C).

2. Précautions dans le cas d'humidité

élevée :Ce climatiseur a été testé dans

les "conditions standard KS avec

vapeur" et il est confirmé qu'il n'a pas

de défauts.Toutefois, s'il fonctionne

pendant longtemps dans une

atmosphère très humide (température

du point de condensation : plus de

23°C), un écoulement d'eau peut se

vérifier.Dans ce cas, ajoutez du

matériel d'isolation en suivant la

procédure suivante :

• Matériel d'isolation à la chaleur à préparer...Laine de verre adiabatique avec une épaisseur de

10 à 20 mm.

• Collez de la laine de verre sur tous les climatiseurs qui sont placés au plafond.

• En plus de la normale isolation à la chaleur (épaisseur : plus de 8 mm) pour le tuyau du

réfrigérant (tuyau de gaz : tuyau épais) et le tuyau de drainage, ajoutez de 10 à 30 mm

d'épaisseur de matériel.

FAÇONNAGE DES TUYAUX

1. Enveloppez la portion de connexion de

l'unité interne avec du matériel d'isolation

et assurez-le avec deux bandes en

plastique (pour les tuyaux de droite).

• Si vous voulez connecter un tuyau

supplémentaire de drainage, l'extrémité de

la sortie de drainage doit être à une

certaine de distance du sol. (Ne le plongez

pas dans l'eau et fixez-le au mur pour éviter

les oscillations provoquées par le vent).

2. Enveloppez les tuyaux,le tuyau de

drainage et le câble de connexion du bas

au sommet.

3. Façonnez les tuyaux en les enveloppant

sur le mur extérieur et en les fixant au

mur par une selle ou quelque chose

d'équivalent.

unité interne

isolant thermique

(accessoire)

bande de serrage

(accessoire)

tuyau du réfrigérant

Dans le cas d'une unité externe en cours

d'installation, abaissez la position de

l'unité interne.

Scellez une petite

ouverture autour

des tuyaux avec de

gomme pour sceller

tuyau de drainage

enveloppe

tuyaux

bande en

plastique

Il faut un séparateur pour éviter que l’eau

pénètre dans les composants électriques.

câble de

connexion

d'alimentation

cordon

18 Climatiseur Type Cassette

Conduits de drainage unité interne

2. Enveloppez les tuyaux et le câble de

connexion du bas au sommet.

3. Façonnez les tuyaux en les enveloppant

sur le mur extérieur et réalisez un

collecteur pour éviter que de l'eau n'entre

dans la pièce.

4. Fixez les tuyaux au mur par une selle ou

quelque chose d'équivalent.

Dans le cas d'une unité externe en cours

d'installation, soulevez la position de l'unité

interne.

Seal a small opening

around the pipings

with gum type sealer.

Trap

Test de fonctionnement

Manuel d'installation

19

FRANÇAIS

1. PRÉCAUTIONS PENDANT LE TEST DE FONCTIONNEMENT

• L'alimentation initiale devrait fournir au moins 90% de la tension nominale.

Autrement, le climatiseur ne peut pas fonctionner.

PRECAUTION:

Á Pour le test de fonctionnement,effectuez d'abord les opérations de refroidissement

même en hiver. Si vous effectuez d'abord les opérations de chauffage, cela pourrait

conduire à des problèmes du compresseur. Donc, faites attention.

Ë Effectuez le test de fonctionnement pendant 5 minutes sans interruption.

(Le test sera effacé 18 minutes plus tard automatiquement).

• Le test de fonctionnement commence en appuyant sur la touche de contrôle de la température de

la pièce et sur la touche minuterie pendant 3 secondes en même temps.

• Pour annuler le test de fonctionnement, appuyez sur n'importe quelle touche.

CONTRÔLEZ LES ÉLÉMENTS SUIVANTS QUAND L'INSTALLATION EST COMPLÈTE

• Après avoir achevé le travail, mesurez et enregistrez les propriétés du test de fonctionnement et

conservez les données mesurées, etc.

• Les éléments à mesurer sont la température de la pièce, la température externe, la température

d'aspiration, la température d'expulsion, la vitesse du vent, la tension, le courant, la présence de

vibrations anormales ou de bruits, la pression de fonctionnement, la température des tuyaux, la

pression de compression.

• Pour la structure et l'apparence, contrôlez les éléments suivants :

La circulation de l'air est-elle suffisante ?

Le drainage se fait-il sans problèmes ?

L'isolation à la chaleur est-elle complète

(tuyaux de réfrigérant et de drainage ) ?

Y a-t-il des fuites de réfrigérant ?

L'interrupteur de la télécommande

fonctionne-t-il ?

Y a-t-il de mauvais câblages ?

Des vis de bornes sont-elles desserrées ?

M4......118N.cm{12kgf.cm} M5......196N.cm{20kgf .cm}

M6......245N.cm{25kgf.cm} M8......588N.cm{60kgf .cm}

Test de fonctionnement

2) Connexion de l'alimentation

1. Branchez le cordon d'alimentation à

une prise de courant indépendante.

• Un coupe-circuit est nécessaire.

2. Faites fonctionner l'appareil

pendant quinze minutes ou plus.

3) Évaluation des performances

1. Mesurez la température de l'air en

admission et en sortie

2. Assurez-vous que la différence entre

la température de l'air en admission

et celle de l'air en sortie est

supérieure à 8°C (refroidissement) ou

inversement.(Chauffage)

Thermomètre

20 Climatiseur Type Cassette

PRECAUTION: Après la confirmation des conditions ci-dessus, préparez les

câblages de la manière suivante :

1) Il faut absolument que le climatiseur ait une prise de courant

spécialisée. Pour la méthode de câblage, faites-vous guider par les

diagrammes de circuit à l'intérieur du couvercle du boîtier de contrôle.

2) Mettez un coupe-circuit entre la source d'alimentation et l'appareil.

3) Les vis qui serrent le câblage dans la chemise des installations

électriques peuvent se desserrer à cause de vibrations auxquelles

l'appareil est soumis pendant le transport. Contrôlez-les et faites

attention qu'elles soient toutes bien serrées. (Si elles sont desserrées,

cela pourrait provoquer un court-circuit des câbles).

4) Spécifications de la source d'alimentation.

5) Confirmation que la capacité électrique est suffisante.

6) Contrôlez que la tension de mise en marche soit bien maintenue à au

moins 90% de la tension nominale indiquée sur la plaque.

7) Confirmation que l'épaisseur du câble est bien celle spécifiée dans les

spécifications de la source d'alimentation. (Remarquez en particulier la

relation entre la longueur du câble et son épaisseur).

8) Il faut toujours monter un coupe-fuites dans des endroits humides ou

mouillées.

9) Les problèmes suivants pourraient être provoqués par une chute de

tension.

• Vibrations de l'interrupteur magnétique, dommage au point de contact,

rupture de fusible, problèmes de fonctionnement du système de protection

contre les surcharges.

• Une puissance de mise en marche suffisante n'est pas fournie au

compresseur.

TRANSMISSION DES INFORMATIONS

Enseignez à l'utilisateur les procédures de fonctionnement et d'entretien en utilisant le manuel de

fonctionnement (nettoyage du filtre à air, contrôle de la température, etc.)

Test de fonctionnement

Manuel d'installation

21

FRANÇAIS

1. Système à deux thermistors

(1) Ouvrez le couvercle arrière de la télécommande pour régler le mode.

(2) Sélectionnez un des trois modes sélectionnables de la manière suivante :

• Position 1 :La température de la pièce est contrôlée par le thermistor de la télécommande,

il contrôle la température selon la position de la télécommande.

• Position 2 :La température de la pièce est contrôlée par le thermistor du corps principal.

• Position 3 :La température de la pièce est contrôlée par la température inférieur entre la

température du corps principal et du capteur de la télécommande.

(3) Déplacez l'interrupteur coulissant sur la position réglée.

(4) Fermez le couvercle arrière et contrôlez si l'appareil fonctionne normalement.

PRECAUTION:

• Sélectionnez la position après vous être conseillé avec l'utilisateur.

• Dans le cas du mode refroidissement, la température de la pièce est contrôlée par le

capteur du corps principal.

• Pour contrôler la température de la pièce par la télécommande, installez la

télécommande (capteur température de la pièce) pour capter plus précisément la

température.

• Fabriqué en position 3.

Fonctionnement optionnel

Fonctionnement optionnel

Interrupteur coulissant pour 2 thermistors

1

2

3

1

2

3

1

2

3

22 Climatiseur Type Cassette

2. Réglage du volume d'air à la hauteur du plafond

Vous pouvez choisir les tours/minute (ou le volume d'air) du moteur interne selon la hauteur du

plafond pour fournir une atmosphère confortable aux utilisateurs.

Procédure

1. Choisissez la position sélectionnante dans le tableau après avoir mesuré la hauteur du

plafond.

2. En cas de changement de hauteur en "haut" ou "bas", ouvrez le couvercle arrière de la

télécommande.

3. Déplacez l'interrupteur coulissant sur la position réglée

4. Fermez le couvercle arrière et contrôlez si l'appareil fonctionne correctement.

Fonctionnement optionnel

Interrupteur coulissant pour plafond haut

1

2

3

1

2

3

1

2

3

Hauteur du plafond Mode interrupteur coulissant Changement volume d'air Remarque

3,3 m Plafond haut Augmentation

2,7~3,3 m Standard -

2,7 m Plafond bas Diminution

Construit en mode

standard

Manuel d'installation

23

FRANÇAIS

Fonctionnement optionnel

Fonctions

• Utilisation d'une seule télécommande avec fils avec plusieurs climatiseurs.

(max. 16 appareils)

• Démarrage en séquence pour éviter des surcharges de courant.

PRECAUTION:

• Faites attention de pas échanger les couleurs des câbles.

• La longueur maximale du câble de connexion doit être inférieure à 200 m (25) pour

connecter chaque appareil.

• Utilisez un câble de plus de 0,5 mm2.

3. Contrôle groupe (câblages optionnels)

• Vous pouvez utiliser le fonctionnement de contrôle de groupe après avoir connecté les

câbles marron et jaune de chaque climatiseur.

• Enlevez la résistance "OP7" de la télécommande.

• Ce système fait fonctionner au maximum 16 appareils avec une seule télécommande

avec fils et chaque appareil se met en marche en séquence pour éviter une surcharge

de courant.

Dessin câblag

es

Operation unit

ZONE

1234

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 1719 2123

Télécommande avec fils

interrupteur coulissant

OP7

PCB

télécommande

Unité interne 1

Bloc bornes (Fourniture locale)

PCB principal

#1

PCB principal

#2

PCB principal

#16

Unité interne 2

PCB principal

Unité interne 16

Connecteur

Bloc bornes (Fourniture locale)

Connecteur

Bloc bornes (Fourniture locale)

Connecteur

RED(12V)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

Câble de connexion (fourniture locale)

....

....

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

24 Climatiseur Type Cassette

Note

ESPAÑOLESPAÑOL

LG

Aire acondicionado de Tipo Cassete

MANUAL DE INSTALACIÓN

IMPORTANTE

• Lea este manual de instrucciones completamente antes de

instalar el producto.

• El trabajo de instalación debe realizarse de acuerdo con el

Reglamento Eléctrico nacional y únicamente por personal

autorizado.

• Después de leer completamente este manual de instalación,

guárdelo para futuras consultas.

2 Aire acondicionado de Tipo Cassete

Aire acondicionado de Tipo Cassete Manual de instalación

ÍNDICE

Precauciones de

seguridad

......................................3

Instalación de las unidades

Interior y Exterior ...............6

Dimensiones del hueco del

techo y ubicación del

perno de suspensión.........8

Instalación de la unidad

Interior..................................9

Conexión del cableado....11

Conexión de las tuberías a

la unidad Interio................13

Instalación del Panel

Decorativo.........................15

Tubería de drenaje du la

unidad interior ..................16

Prueba de Funcionamiento

.............................................19