LG LBUS3061BL, LBNK3661BL, LBNK3660BL, LBUK3660BL, LBUK4260BL Service Manual

...

Ceiling Duct Type

Air Conditioner

SERVICE MANUAL

MODELS: LBNS3061BL LBUS3061BL

LBNK3660BL LBUK3660BL

LBNK3661BL LBUK4260BL

LBNK4260BL LBUK4880BL

LBNK4261BL LBUL6080BL

LBNK4880BL LBUM7280BL

LBNK4881BL LBUM9080BL

LBNL6080BL LBUM1081BL

LBNL6081BL

LBNM7280BL

LBNM7281BL

LBNM9080BL

LBNM9081BL

LBNM1081BL

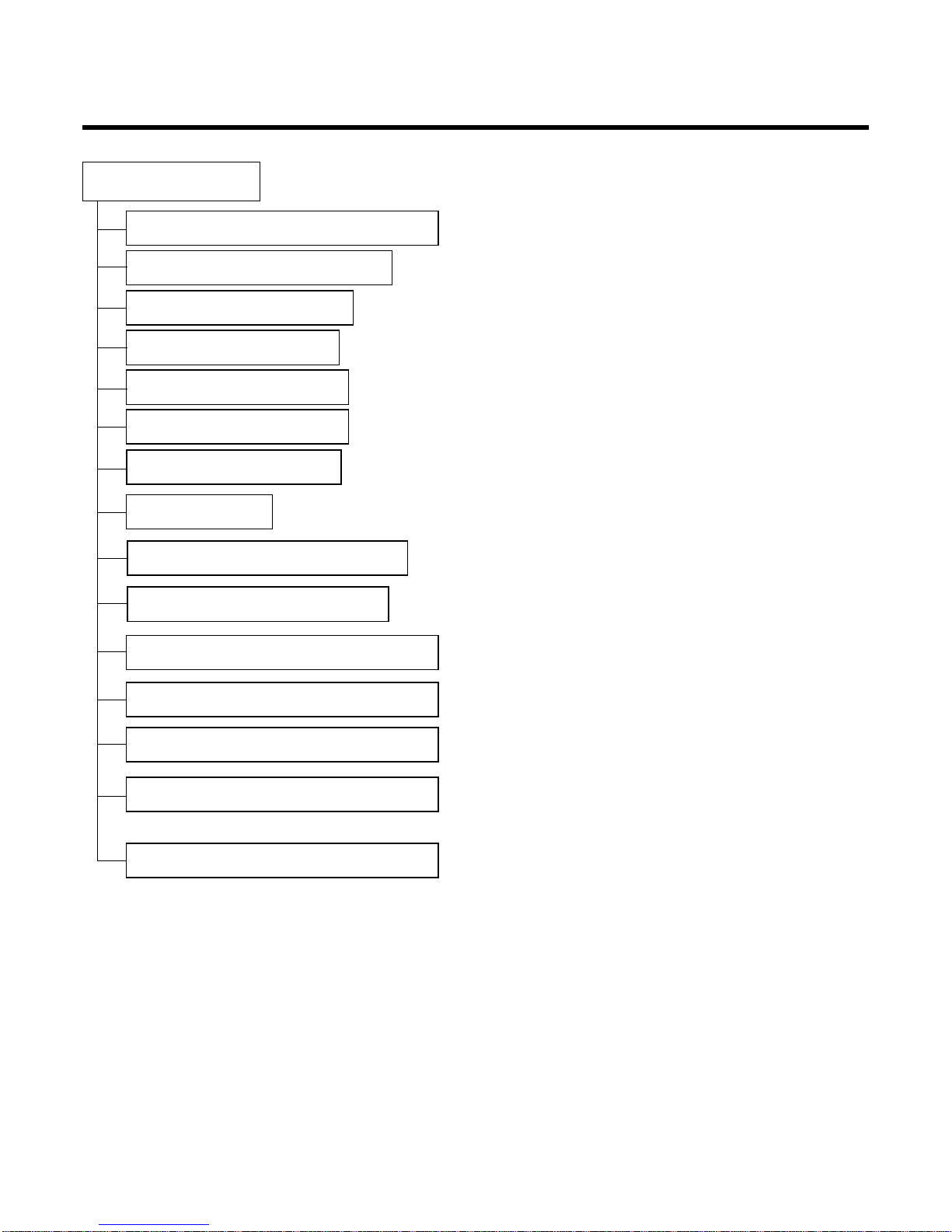

Contents

Functions .................................................................................................................................3

Product Specifications (Cooling & Heating)..........................................................................5

Dimensions ..............................................................................................................................7

Refrigeration Cycle Diagram ..................................................................................................9

Wiring Diagram ......................................................................................................................10

Operation Details ...................................................................................................................17

Installation of Indoor, Outdoor Unit .....................................................................................20

Cycle........................................................................................................................................34

Cycle Troubleshooting Guide ...............................................................................................37

Electronic Parts Troubleshooting Guide .............................................................................38

Electronic Control Device .....................................................................................................41

Exploded View and Replacement Parts List .......................................................................42

–2–

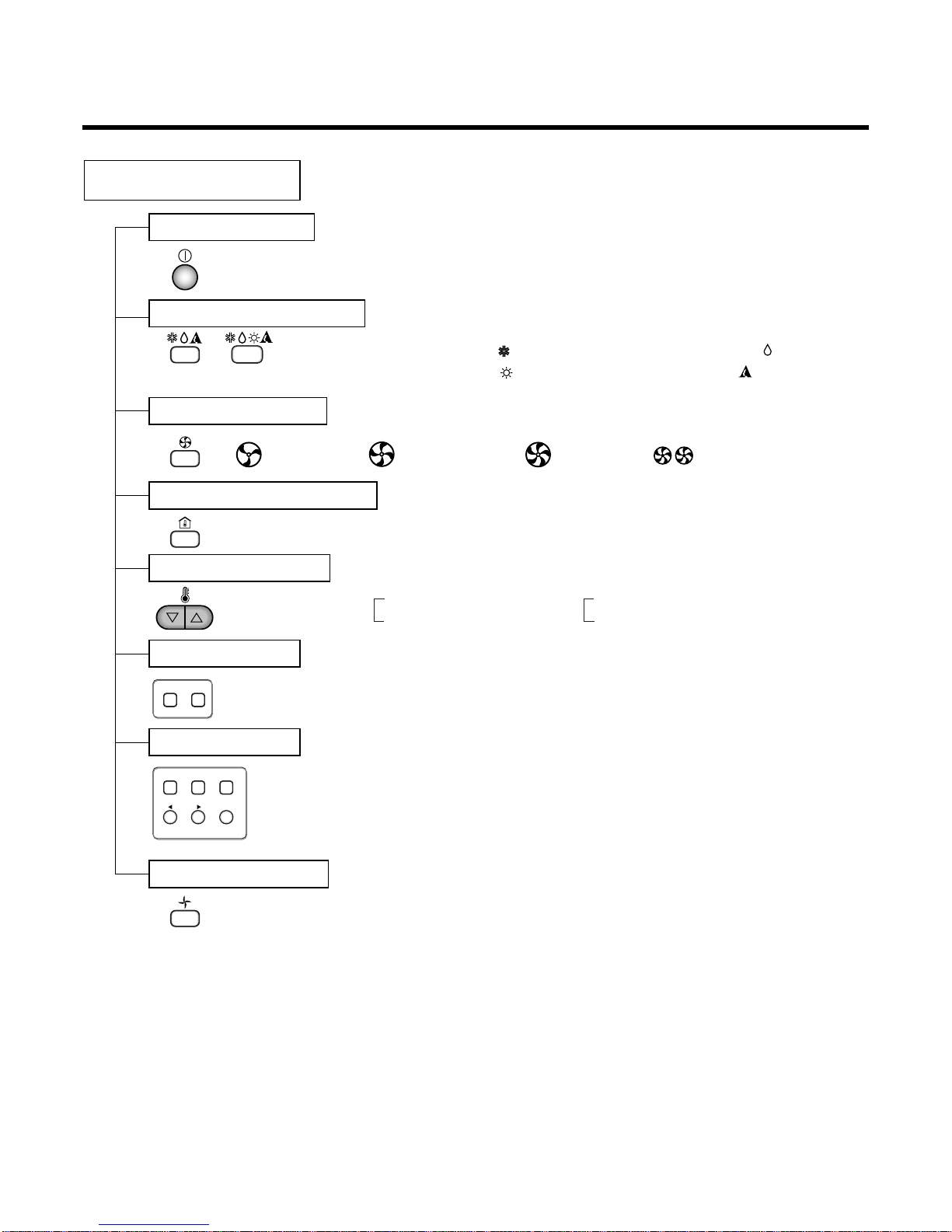

Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Auto Operation(Auto Change Over)

Deice (defrost) control (Heating)

Auto Restart

–3–

Hot-start Control (Heating)

• The indoor fan stops until the evaporator piping temperature will be reached at 28°C.

High head height Drain pump(Optional)

• A standard drain-head height of up to 700mm is possible.

Central Control(Optional)

•

It is operating individually or totally by central control function.

Group Control(Optional Wiring)

Radio Frequency Control (Optional)

•

Each controller can control 16 units and 8 controllers can connect.

•

It operates maximum 16 units by only one wired remote controller and each unit starts random to prevent overcurrent.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Intermittent operation of fan at low speed.

• Although the air-conditioner is turned off by a power failure, it is restarted automatically previous operation mode after power supply.

• The setting temperature and desired operation mode are automatically set by fuzzy rule.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

–4–

Remote Controller

Operation ON/OFF

Operation Mode Selection

Fan Speed Selection

Room Temperature Display

Temperature Setting

Setting the Timer

Weekly Program

(Cooling

model only)

(Heating

model only)

(Low) (Med) (High)

Cooling Operation Mode ( )

Heating Operation Mode ( ) Auto Operation Mode ( )

Soft Dry Operation Mode ( )

Fan Operation Mode

HI AUTOMEDLO

Program Holiday

SET/CLR

MinHour

Week

Timer CancelTimer Cancel

: High:39°C ↔ LOW:11°C

: Fan Operates without cooling & heating

Cooling Heating

Down to 18°C

Up to 30°C

Down to 16°C

Up to 30°C

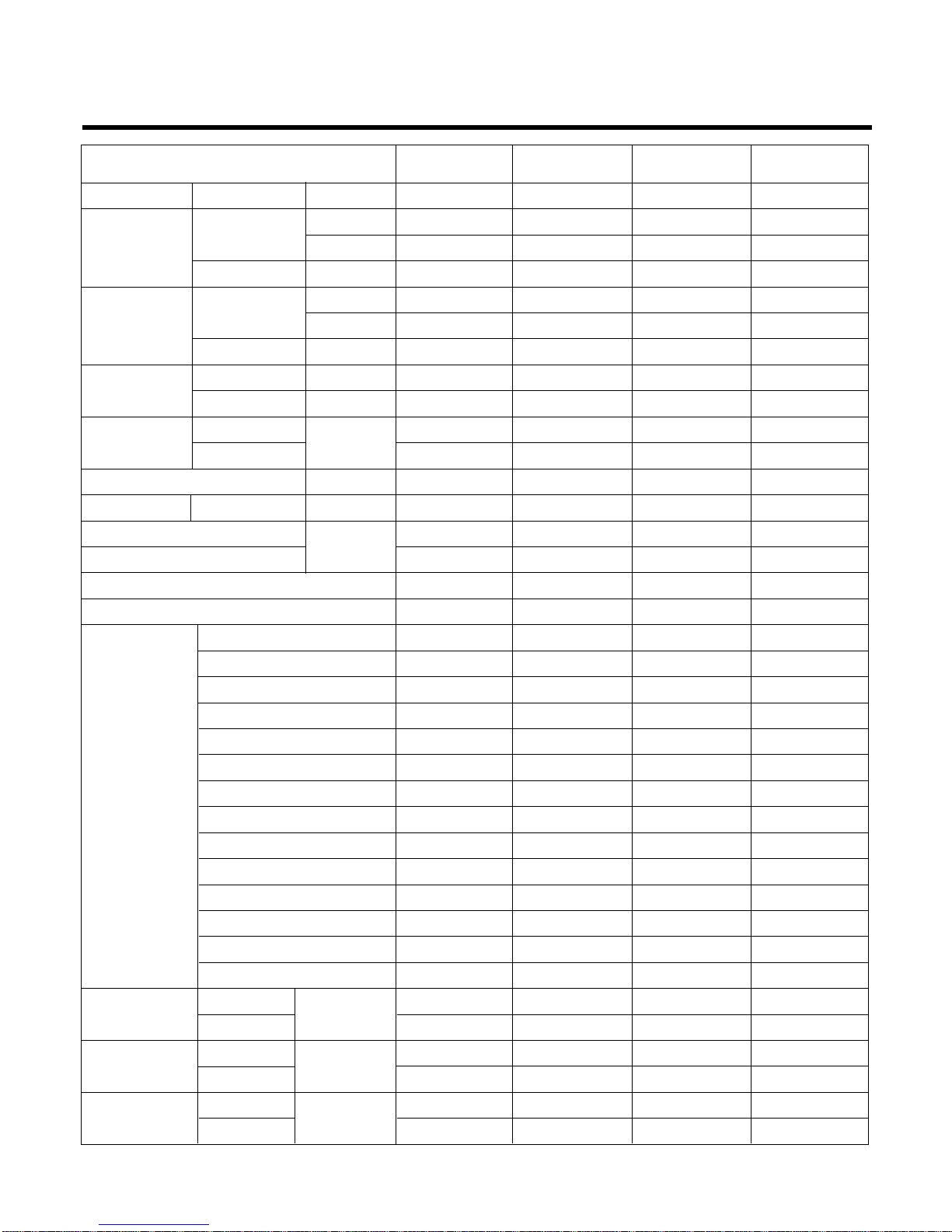

Product Specifications (Cooling & Heating)

–5–

Power Source Ø, V, Hz

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-22) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Radio Frequency Control(Optional)

Weekly Programning

Thermistor

Drain Pump(Optional)

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (W x H x D)

Net Indoor Kg

Weight

Outdoor

Model

LB-S3061BL LB-K3660BL LB-K4260BL LB-K4880BL

1, 220-240, 50 1, 220-240, 50 1, 220-240, 50 3, 380-415, 50

7,307(2,900) 9,072(36,000) 10,584(42,000) 12,096(48,000)

8,500 10,551 12,309 14,067

3,200 3,600 5,100 4,900

8,064(32,000) 9,072(36,000) 11,314(45,500) 12,096(48,000)

9,378 10,551 13,190 14,067

3,000 3,400 4,700 4,400

14 16 22.5 8

13.5 14 21 7.3

30/26/22 35/32/28 46/38/32 49/47/44

30/26/22 35/32/28 46/38/32 49/47/44

2,020 2,240 3,600 3,351

22.6 22.6 22.6 22.6

3*3.5 3*5.5 3*8.5 4*3.5

5*1.25 5*1.25 5*1.25 5*1.25

L.C.D Wired L.C.D Wired L.C.D Wired L.C.D Wired

Orifice/Capillary Orifice/Capillary Orifice/Capillary Orifice/Capillary

Ye s Ye s Ye s Ye s

24 Hours On/Off 24 Hours On/Off 24 Hours On/Off 24 Hours On/Off

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

Optional Optional Optional Optional

Optional Optional Optional Optional

Ye s Ye s Ye s Ye s

Optional Optional Optional Optional

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

Optional Optional Optional Optional

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

3/8(9.52) 3/8(9.52) 3/8(9.52) 3/8(9.52)

5/8(15.88) 5/8(15.88) 3/4(19.05) 3/4(19.05)

890*350*560 1,030*350*435 1,030*350*435 1,030*350*435

870*800*320 870*800*320 900*1,220*370 900*1,220*370

32 37 37 40

72 72 90 92

–6–

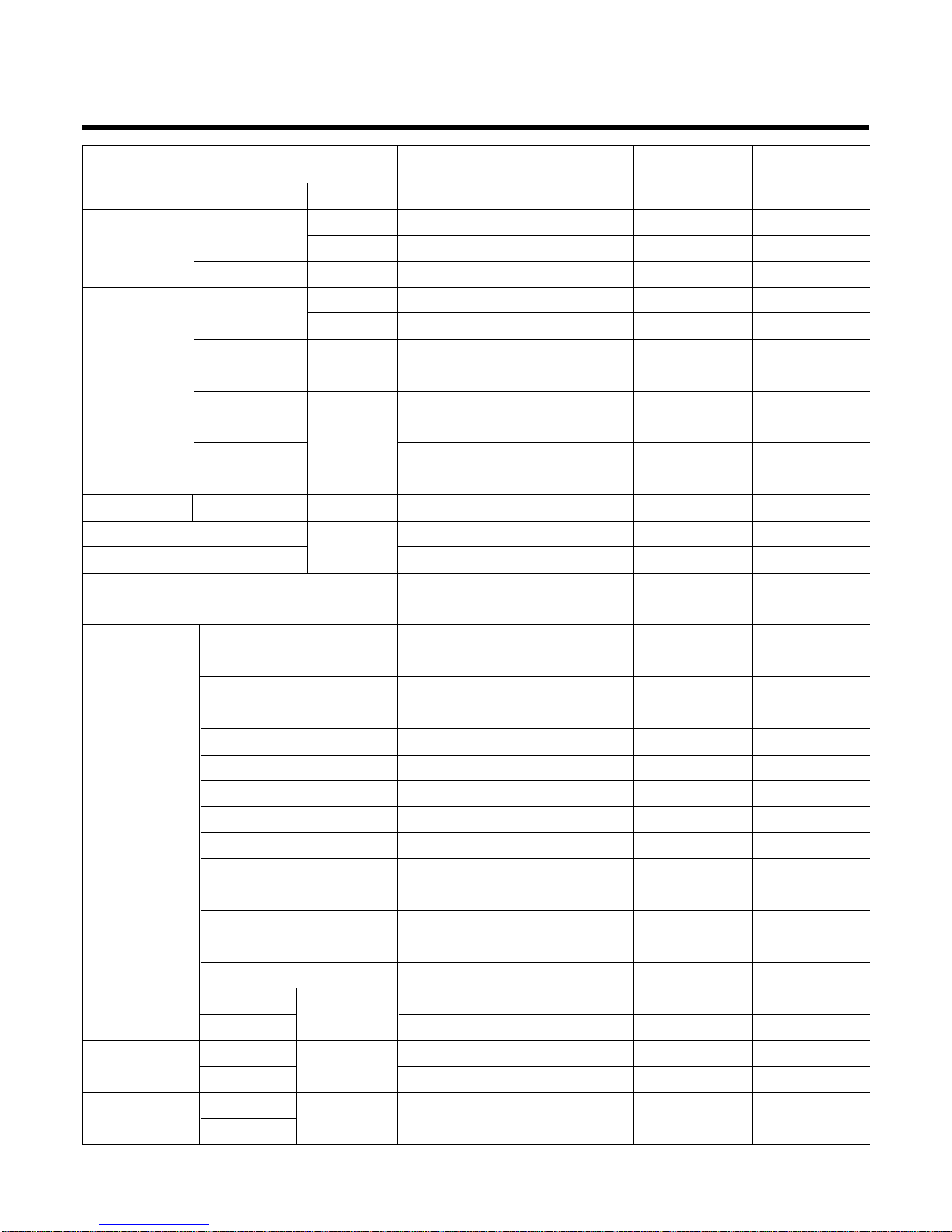

3, 380-415, 50 3, 380-415, 50 3,380-415, 50 3, 380-415, 50

15,120(60,000) 18,143(72,000) 21,924(87,000) 25,200(100,000)

17,585 21,101 25,497 29,307

7,000 7,000 8,800 10,500

15,120(60,000) 18,143(72,000) 21,924(87,000) 26,208(104,000)

17,585 21,101 25,497 30,479

6,500 6,800 7,400 8,700

12.7 13.0 14.5 17.0

12.5 13.0 12.7 14.7

55/50/46 73/68/62 84/76/65 84/76/65

55/50/46 73/68/62 84/76/65 84/76/65

4,629 6,931 8,100 8,000

22.6 22.6 22.6 22.6

4*3.5 4*3.5 4*5.5 4*5.5

5*1.25 5*1.25 5*1.25 5*1.25

L.C.D Wired L.C.D Wired L.C.D Wired L.C.D Wired

Orifice/Capillary Orifice/Capillary Orifice/Capillary Orifice/Capillary

Ye s Ye s Ye s Ye s

24 Hours On/Off 24 Hours On/Off 24 Hours On/Off 24 Hours On/Off

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

Optional Optional Optional Optional

Optional Optional Optional Optional

Ye s Ye s Ye s Ye s

Optional Optional Optional Optional

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

Optional Optional Optional Optional

Ye s Ye s Ye s Ye s

Ye s Ye s Ye s Ye s

3/8(9.52) 1/2(12.7) 5/8(15.88) 5/8(15.88)

3/4(19.05) 1(25.4) 9/8(28.0) 9/8(28.0)

1,120*400*575 1,420*400*575 1,596*450*658 1,596*450*658

900*1,220*370 1,245*930*650 1,245*930*650 1,245*930*650

51 58 84 88

92 185 190 195

Power Source Ø, V, Hz

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-22) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Radio Frequency Control(Optional)

Weekly Programning

Thermistor

Drain Pump(Optional)

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (W x H x D)

Net Indoor Kg

Weight

Outdoor

Model

LB-L6080BL LB-M7280BL LB-M9080BL LB-M1081BL

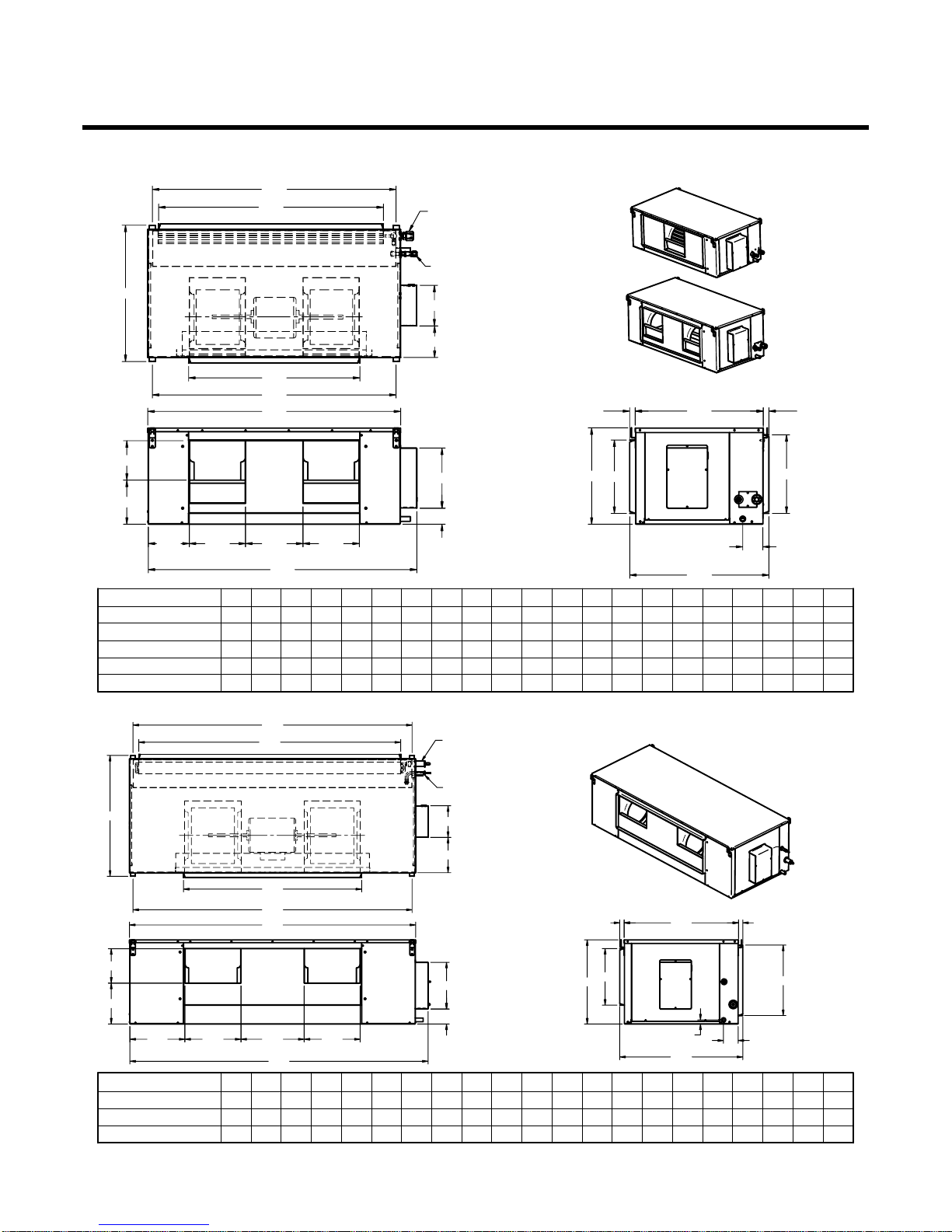

Dimensions

–7–

1. Indoor

"A" "B" "C" "D" "E" "F" "G" "J" "K" "L" "M" "N" "P" "Q" "R" "S" "T"

"V" "W" "X" "Y"

MODEL NO

LBNS3061BL

LBNK3661BL

LBNK4261BL

LBNK4881BL

LBNL6081BL

890

1040

1040

1040

1120

350

350

350

350

400

560

560

560

560

580

253

282

282

282

305

482

712

712

712

712

282

282

282

282

327

718

868

868

868

935

168

366

131

131

171

234

234

250

250

234

-

210

210

239

170

170

170

170

183

163

165

161

161

165

798

934

934

934

1014

798

937

937

937

1014

–

548

548

548

567

40

40

40

40

67

120

120

120

120

130

22

22

22

22

22

79

79

79

79

84

822

972

972

972

1052

514

514

514

514

533

"A" "B" "C" "D" "E" "F" "G" "J" "K" "L" "M" "N" "P" "Q" "R" "S" "T"

"V" "W" "X" "Y"

MODEL NO

LBNM7281BL

LBNM9081BL

LBNM1081BL

1415

1596

1596

400

450

450

580

658

658

303

303

303

833

835

835

327

377

377

1221

1403

1403

258

348

348

300

300

300

228

230

230

182

219

219

165

185

185

1327

1504

1504

1327

1504

1504

567

-

-

67

80

80

130

190

190

22

22

22

78

78

78

1351

1532

1532

533

612

612

"D"

"F"

"X"

"Y"

2323

LIQUID

LINE

SUCTION

LINE

"C"

"B"

"A"

"G"

"E"

169

"T"

"W"

"S"

250

"J" "K" "L" "K"

"Q"

"P"

"R"

"M"

"N"

"M"

"N"

"J" "K" "L" "K"

"X"

"A"

"S"

250

"P"

"E"

"Q"

"G"

"T"

169

"R"

LIQUID

LINE

SUCTION

LINE

"B"

"D"

23 23 "Y"

"C"

"F"

"V"

"W"

(30K/36K)

(42K/48K/60K)

(72K/90K/100K)

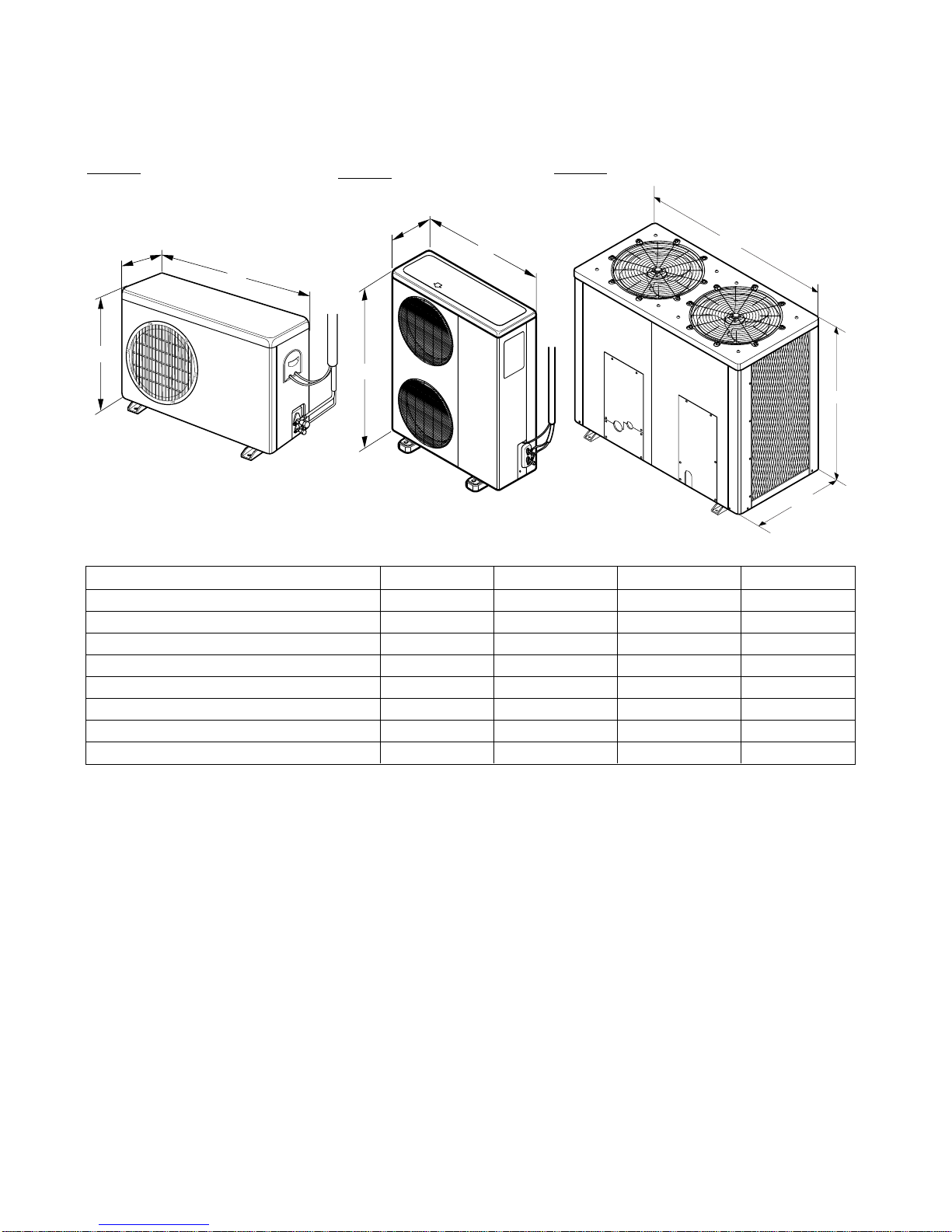

2. Outdoor Unit

–8–

Type: A

Type: B

T

ype: C

Model No. a b c TYPE

LBUS3061BL 870 320 800 A

LBUK3660BL 870 320 800 A

LBUK4260BL 900 370 1220 B

LBUK4880BL 900 370 1220 B

LBUL6080BL 900 370 1220 B

LBUM7280BL 1,245 650 930 C

LBUM9080BL 1,245 650 930 C

LBUM1081BL 1,245 650 930 C

(Unit: mm)

b

a

c

b

a

c

c

b

a

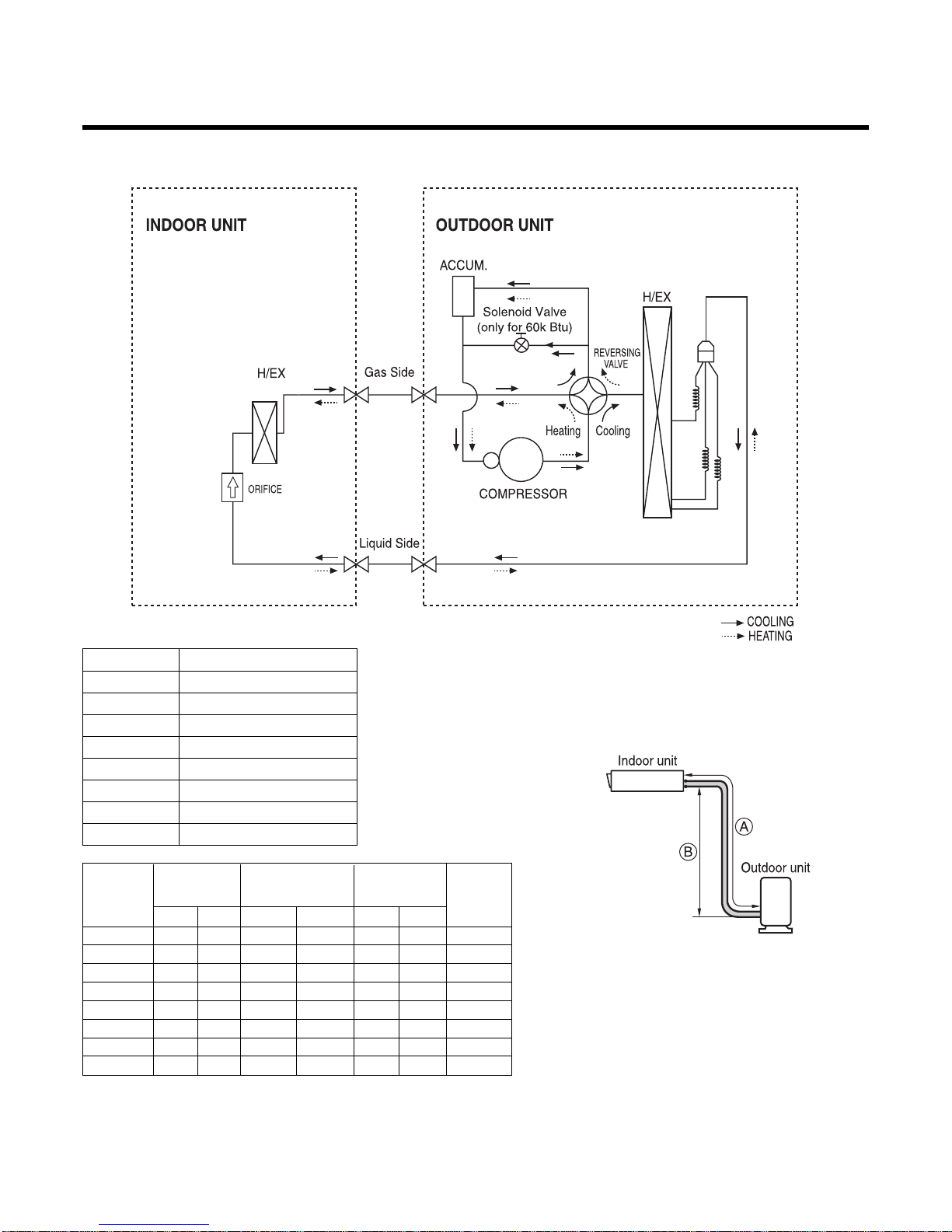

Refrigeration Cycle Diagram

–9–

Heat Pump

• If 60K Model is installed at a distance of 15m, 525g of refrigerant should be added

(15-7.5) x 70g = 525g

30K BTU/h

5/8" 3/8" 7.5 15 7.5 12.5 70

36K BTU/h

5/8" 3/8" 7.5 15 7.5 12.5 50

42K BTU/h 3/4'' 3/8" 7.5 15 7.5 12.5 70

48K BTU/h 3/4'' 3/8" 7.5 15 7.5 12.5 70

60K BTU/h 3/4'' 3/8" 7.5 15 7.5 12.5 70

72K BTU/h 1'' 1/2" 7.5 25 7.5 20 70

90K BTU/h 9/8'' 5/8" 7.5 30 7.5 20 90

100K BTU/h 9/8'' 5/8" 7.5 30 7.5 20 100

Capacity

Gas Liquid

Elevation B(m)

Piping Length

A(m)

* Additional

Refrigerant

(g/m)

Pipe Size (Diam-

eter: Ø)

inch

Standard

Standard

Max.

Max.

Capacity Orifice Number

30K 63

36K 62

42K 74

48K 86

60K 86

72K 98

90K 84

100K 104

Orifice Number

–10–

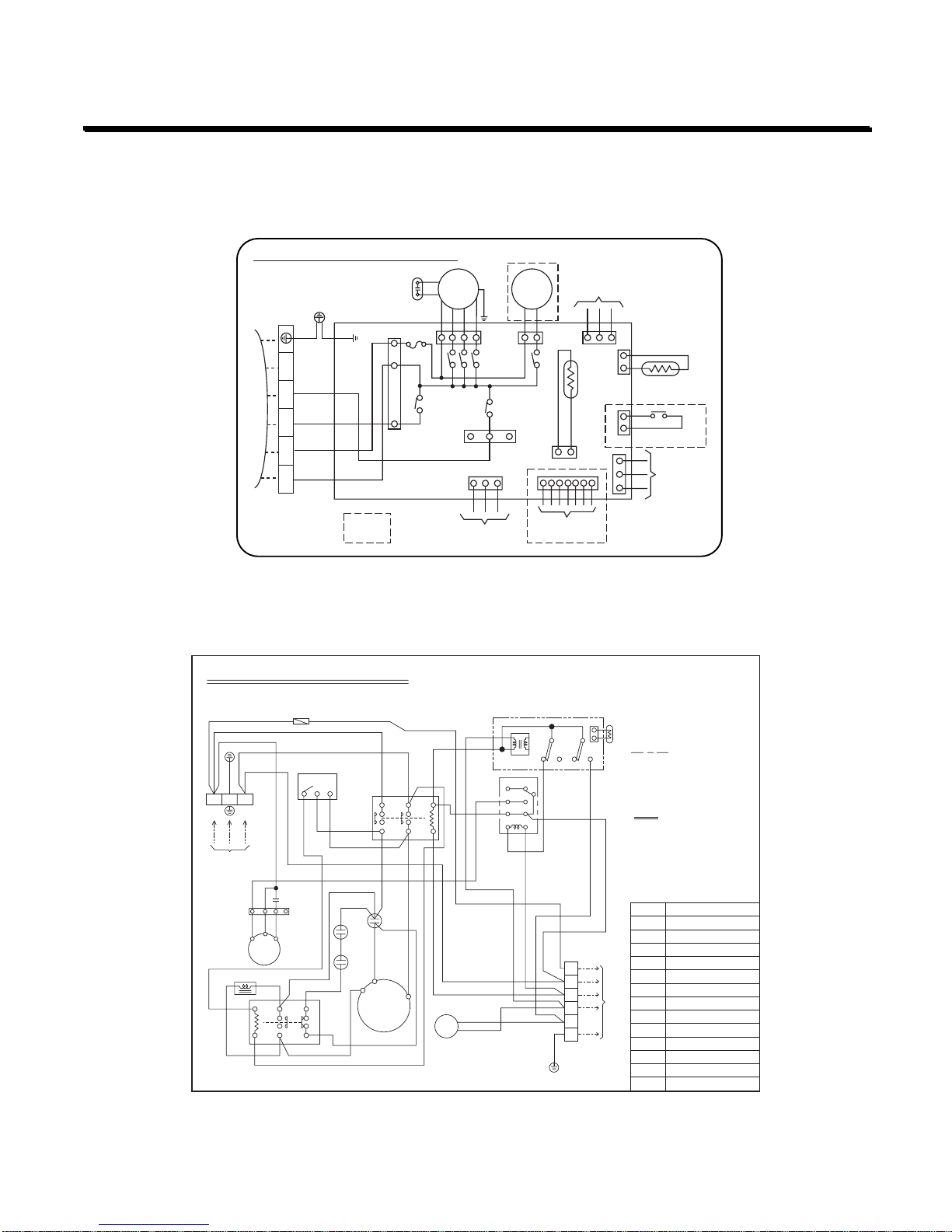

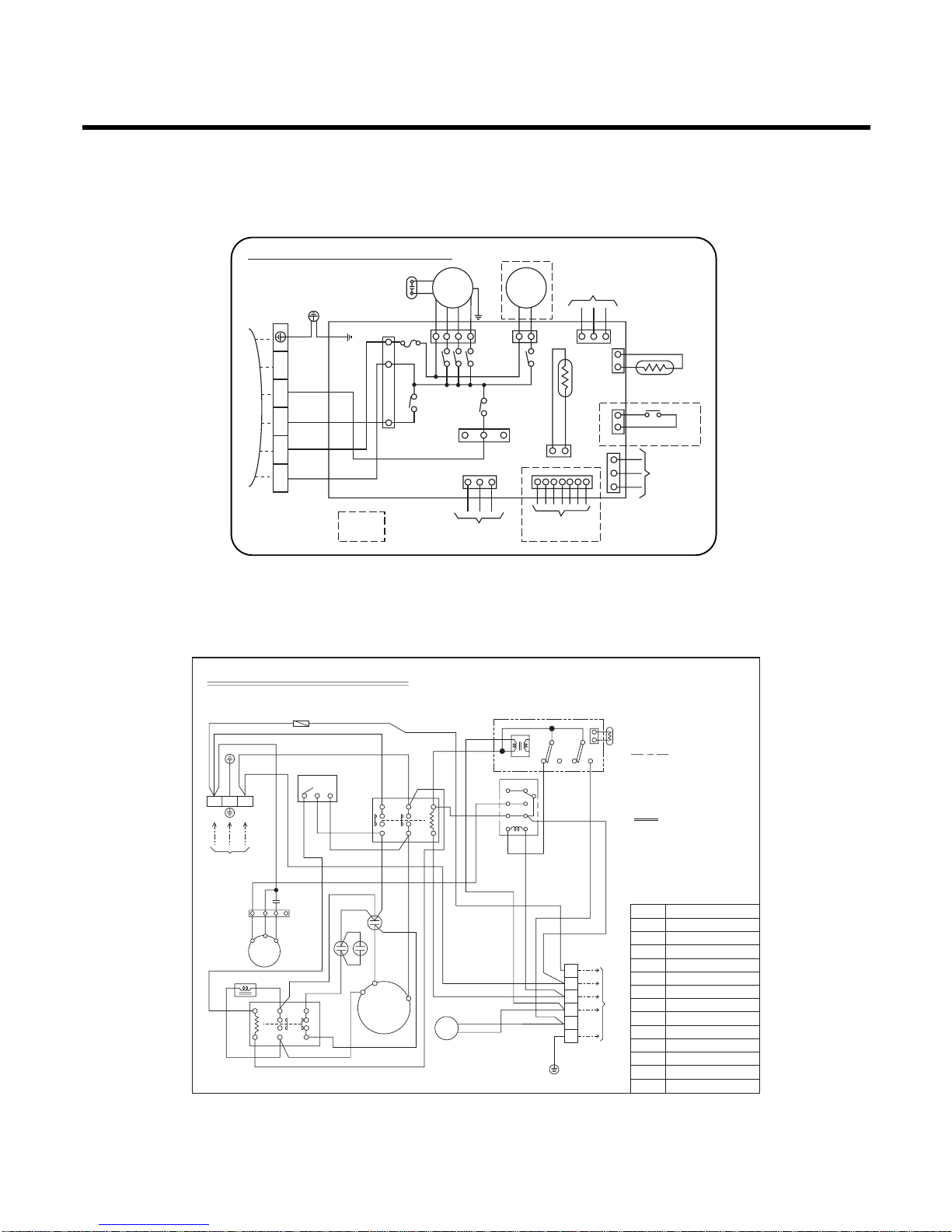

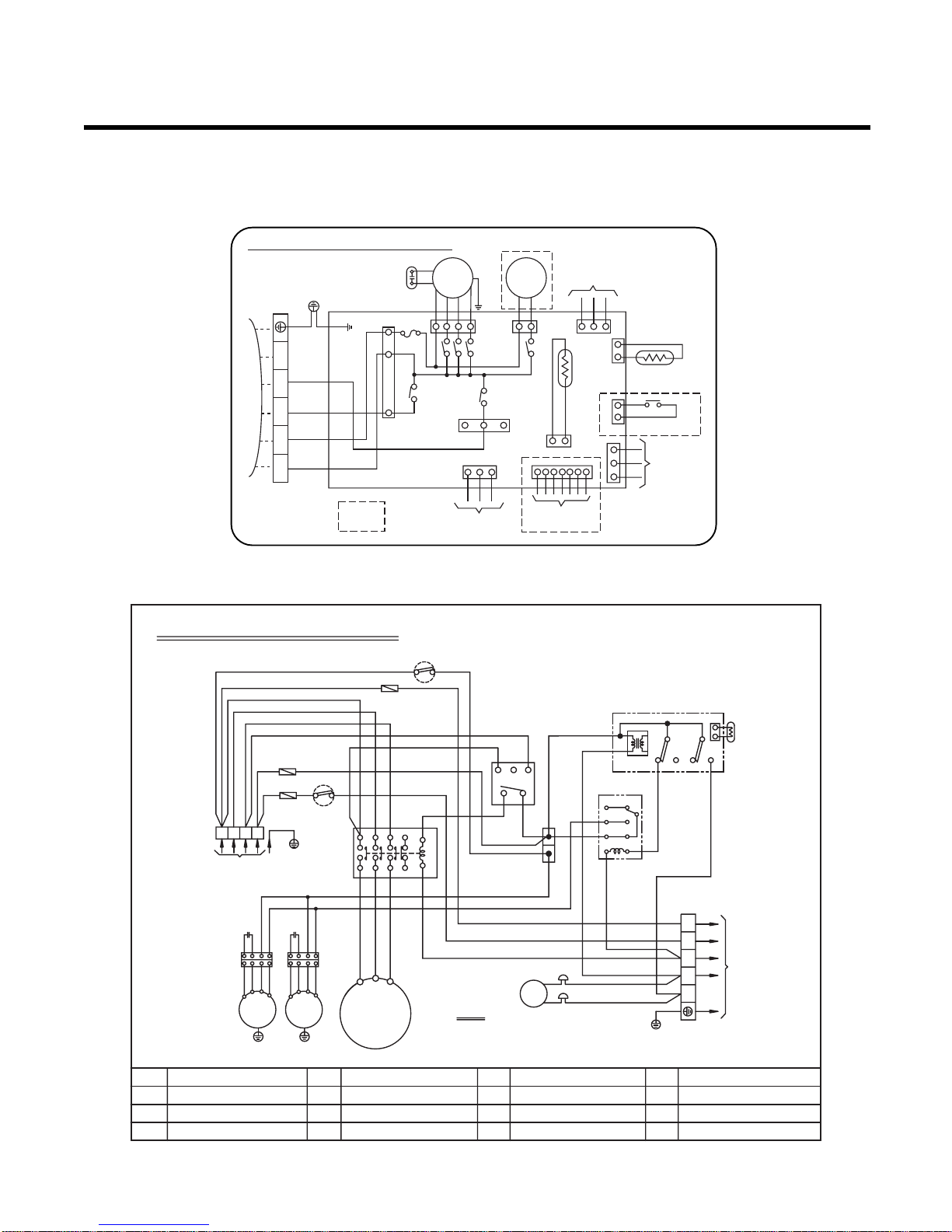

Wiring Diagram

Model : LB-S3061BL

1. Indoor(LBNS3061BL)

2. Outdoor(LBUS3061BL)

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

78

1

TM

240V 1Ø, 50Hz

POWER SUPPLY

BK

52C

Outdoor Unit Wiring Diagram

L1 L2

T1 T2

A2

A1

BK

WH

BK

52F1

12

34

56

WH

TIMER

BK

WH

YL

YL

BL

BL

WH

F1

BK

WH

WH

WH

C TH

20SV

52S,52C

Tmo

TM

52F1

Cr

CM

Co

FMo

F1

D.P

CH1

Cs

THERMISTOR FOR PIPE TEMP.

REVERSING COIL

MAGNECTIC CONTACTOR

TERMINAL BLOCK

MAIN TERMINAL BLOCK

RELAY FOR FMo

RUN CAPACITOR FOR CM

COMPRESSOR

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

FUSE (250V, 5A)

DEICER PCB

CRANK CASE HEATER FOR CM

START CAPACITOR FOR CM

P/NO : 3854A20026V

20SV

WH

BK

RD

BL

BK

BK

WH

BK

BK

WIRING OF FIELD

(CONNECTING WIRE)

GN/YL

Tmo

To the indoor unit

WH

GN/YL

23

LN

1

2

3

4

5

6

BK

BK

BK

BK

YL

YL

YL

BK

RD

WH

RD

RD

OR

R

C

S

CM

Cr

FMo

BK

BK

BKBK

WH

52S

REACTOR

A2A1T3L3T2

L2

NOTE

BL : BLUE

BK : BLACK

BR : BROWN

RD : RED

WH : WHITE

YL : YELLOW

OR : ORANGE

GN/YL : GREEN/YELLOW

TNS

NC NO NC NO

C TH

D.P

–11–

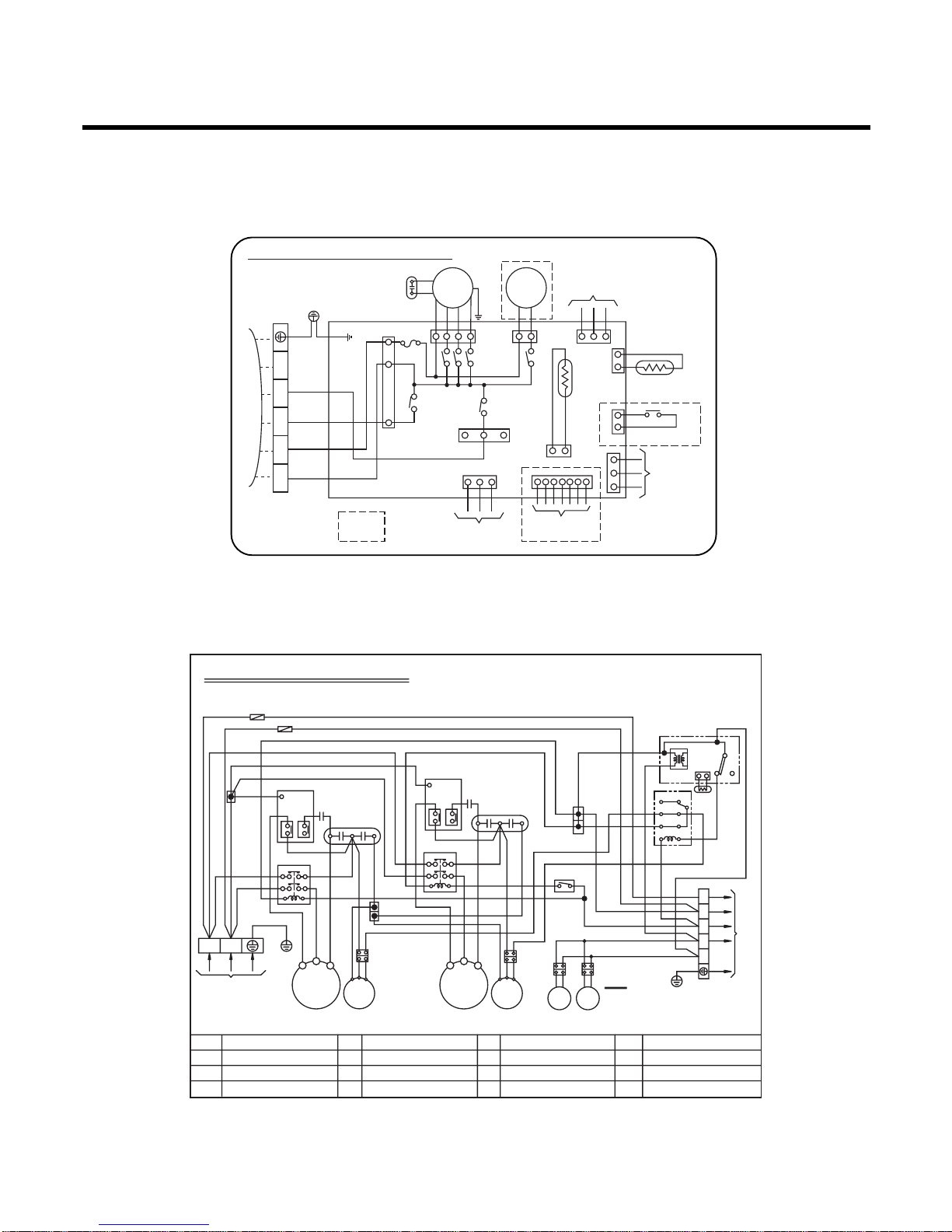

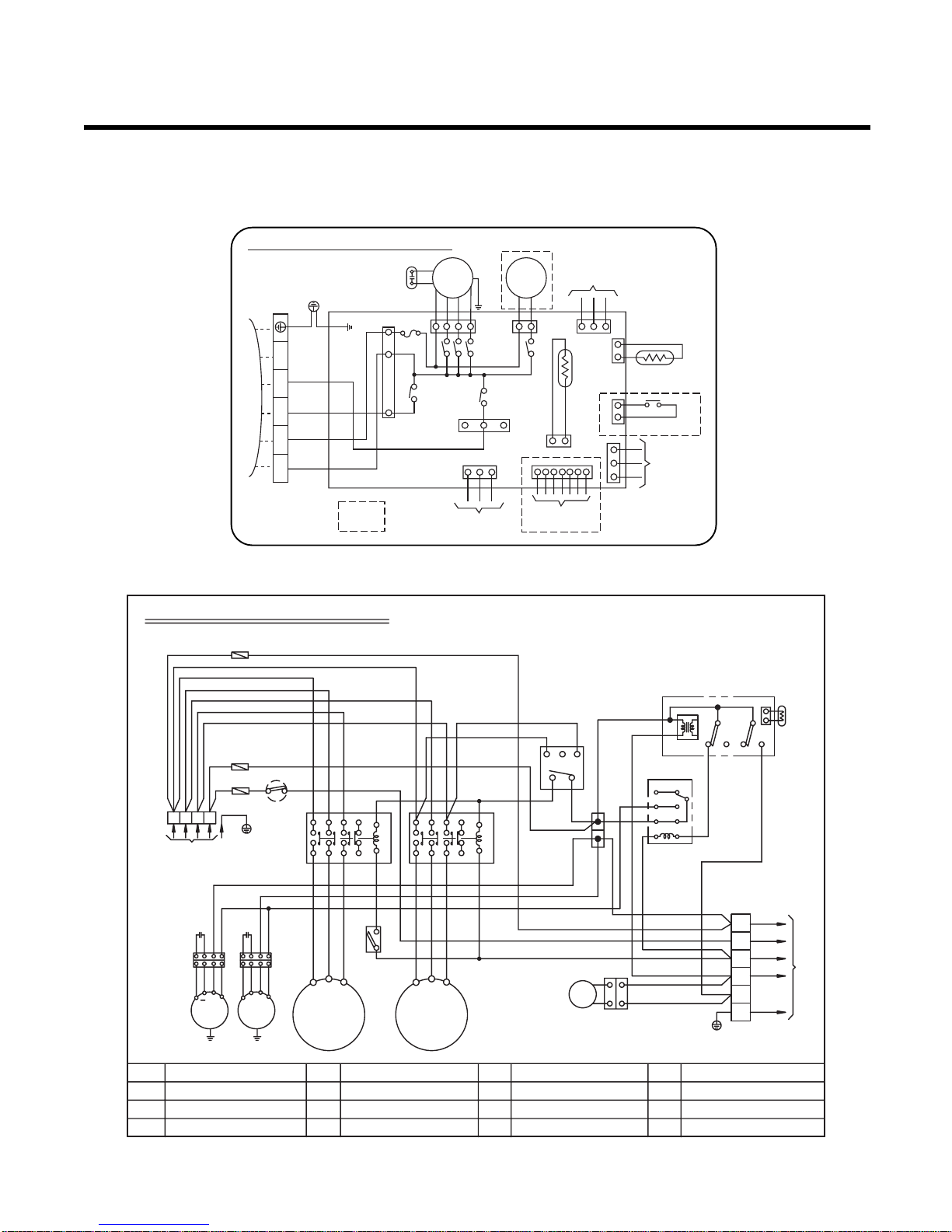

Model : LB-K3660BL

1. Indoor (LBNK3661BL)

2. Outdoor (LBUK3660BL)

78

1

TM

240V 1Ø, 50Hz

POWER SUPPLY

BK

52C

Outdoor Unit Wiring Diagram

L1 L2

T1 T2

A2

A1

BK

WH

BK

52F1

12

34

56

WH

TIMER

BK

WH

YL

YL

BL

BL

WH

F1

BK

WH

WH

WH

C TH

20SV

52S,52C

Tmo

TM

52F1

Cr

CM

Co

FMo

F1

D.P

CH1

Cs

THERMISTOR FOR PIPE TEMP.

REVERSING COIL

MAGNECTIC CONTACTOR

TERMINAL BLOCK

MAIN TERMINAL BLOCK

RELAY FOR FMo

RUN CAPACITOR FOR CM

COMPRESSOR

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

FUSE (250V, 5A)

DEICER PCB

CRANK CASE HEATER FOR CM

START CAPACITOR FOR CM

P/NO : 3854A20026W

20SV

WH

BK

RD

BL

BK

BK

WH

BK

BK

WIRING OF FIELD

(CONNECTING WIRE)

GN/YL

Tmo

To the indoor unit

WH

GN/YL

23

LN

1

2

3

4

5

6

BK

BK

BK

BK

YL

BK

YL

YL

BK

RD

WH

RD

RD

OR

R

C

S

CM

Cr

Cs

FMo

BK

BK

BKBK

WH

52S

REACTOR

A2A1T3L3T2

L2

NOTE

BL : BLUE

BK : BLACK

BR : BROWN

RD : RED

WH : WHITE

YL : YELLOW

OR : ORANGE

GN/YL : GREEN/YELLOW

TNS

NC NO NC NO

C TH

D.P

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

–12–

Model : LB-K4260BL

1. Indoor (LBNK4261BL)

2. Outdoor (LBUK4260BL)

OUTDOOR UNIT WIRING DIAGRAM

P/No.:3854A20135J

F1

S.S(A)

S.S(B)

52C(A)

52C(B)

52F1

D.P

TNS

COMP

49C

R

S

Tm

1(L)

F1,2

49C

FMo

49FMo

FUSE(250V,5A)

INTERNAL O.L.P FOR COMP.

OUTDOOR FAN MOTOR

INTERNAL T.P FOR FMo

DEICER PCB.

THERMISTOR FOR PIPE TEMP.(OUTDOOR)

4-WAY VALVE COIL

START CAPACITOR FOR FMo

RELAY FOR COMP

RELAY FOR FMo

SOFT START PCB.

RUN CAPACITOR FOR FMo

MAIN TERMINAL BLOCK

TERMINAL BLOCK FOR CONNECTING

3 PHASE DETECTOR

5 SEC. DELAY TIMER

D.P

C TH

20SV

Cs

52C

52F1

S.S

Cr

Tm

Tmo

3.P.D

T.D

2(N)

C

COMP

49C

R

S

C

POWER SUPPLY

1Ø,230V,50Hz~

FMo

49FMo

FMo

49FMo

20SV 20SV

NOTE

TO INDOOR UNIT

CHF

Cs(A)

Cr(A)

Cr(B)

T.D

Tmo

F2

BK

BL

BK

NC NO

CTH

BK

RD

RD

BK

WH

WH

BK

BL : BLUE

BK : BLACK

BR : BROWN

OR : ORANGE

RD : RED

WH : WHITE

YL : YELLOW

GN/YL : GREEN/YELLOW

BR

BR

BL

BL

BRRDBK

BL

BK

OR

BK

OR

YL

BK

BKBKBK

BK

1(L) 2(N) 3 4 5

OR OR

YL

YL

YL

RD

RD

BK

CHF

WH

BKBKBK

WH

WH

WH

WH

WH

WH

WH

WHWHWH

WH

YL

YL

TB3

TB5

TB1

TB2

TB6

CN-Power

CN-Power

RYComp

434

4

132

56

78

3

434

3

RYS/Cap

Cs(B)

RYComp

RYS/Cap

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

–13–

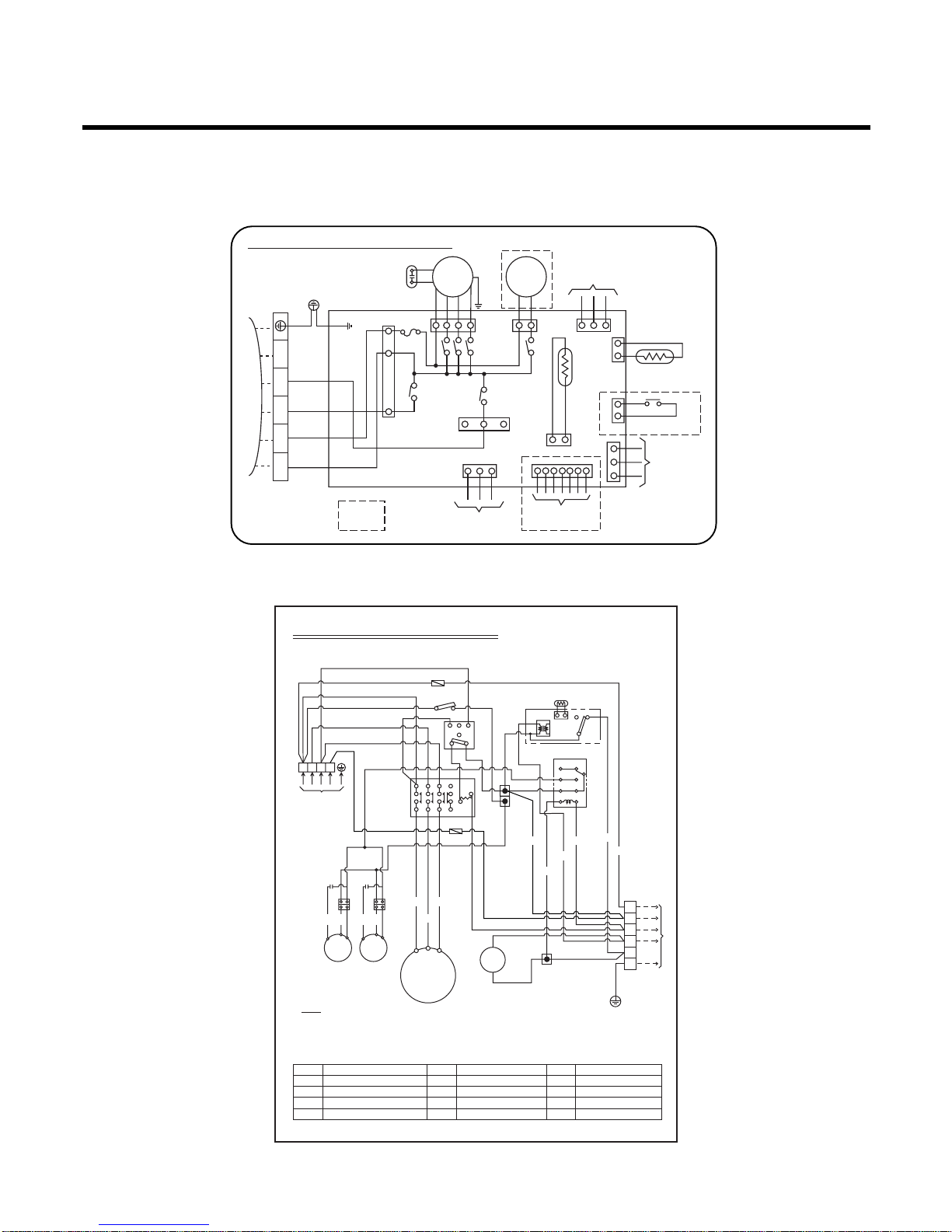

Model : LB-K4880BL

1. Indoor (LBNK4881BL)

2. Outdoor (LBUK4880BL)

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

NOTE

BL : BLUE

BK : BLACK

OR : ORANGE

GN/YL : GREEN/YELLOW

RD : RED

WH : WHITE

YL : YELLOW

Outdoor Unit Wiring Diagram

RTM

3Ø,380-415V, 50Hz

POWER SUPPLY

STN

BK

BK

BK

BK

RD

WH

WH

RD

OR

BK

63H2

3.D.P

WH

WH

YL

D.P

CTH

TNS

NO

NC

WH

OR

BK

52F1

52C

12345631

T/B1

T/B2

T/B3

32

B

A

FMo

49FMo

FMo

49FMo

YL BK

OR

BK RD

WH

CM

12

34

56

78

YL BK

OR

BK

BK

BL

BL

BL

BL

WH

WH

Co Co

20SV

GN/YL

TMo

To the indoor unit

1

2

3

4

5

6

BK

WHWH

YL

RD

F1

BK

63H2

C TH

49FMo

20SV

CM

HIGH PRESSURE SWITCH FOR HEATING

THERMISTOR FOR PIPE TEMP.

INTERNAL T.P FOR FMo

REVERSING COIL

COMPRESSOR

52C

TM

52F1

D.P

3.D.P

MAGNECTIC CONTACTOR

MAIN TERMINAL BLOCK

RELAY FOR FMo

DEICER PCB

3 PHASE DETECTOR

Co

FMo

F1

TMo

SOL

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

FUSE (250V,10A)

TERMINAL BLOCK

SOLENOID VALVE

P/NO : 3854A20021Z

F1

RABST

VUW

–14–

Model : LB-L6080BL

1. Indoor (LBNL6081BL)

2. Outdoor (LBUL6080BL)

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

NOTE

BL : BLUE

BK : BLACK

OR : ORANGE

GN/YL : GREEN/YELLOW

RD : RED

WH : WHITE

YL : YELLOW

Outdoor Unit Wiring Diagram

RTM

3Ø,380-415V, 50Hz

POWER SUPPLY

STN

BK

BK

BK

BK

RD

WH

WH

RD

OR

BK

63H2

WH

WH

YL

D.P

CTH

TNS

NO

NC

WH

OR

BK

52F1

52C

12345631

T/B1

T/B2

T/B3

32

B

A

FMo

49FMo

FMo

49FMo

YL BK

OR

BK

T3

T2

T1

RD

WH

CM

12

34

56

78

YL BK

OR

BK

BK

BL

BL

BL

BL

WH

WH

Co Co

20SV

SOL

GN/YL

TMo

To the indoor unit

1

2

3

4

5

6

BK

WHWH

YL

RD

F1

BK

63H2

C TH

49FMo

20SV

CM

HIGH PRESSURE SWITCH FOR HEATING

THERMISTOR FOR PIPE TEMP.

INTERNAL T.P FOR FMo

REVERSING COIL

COMPRESSOR

52C

TM

52F1

D.P

3.D.P

MAGNECTIC CONTACTOR

MAIN TERMINAL BLOCK

RELAY FOR FMo

DEICER PCB

3 PHASE DETECTOR

Co

FMo

F1

TMo

SOL

RUN CAPACITOR FOR FMo

OUTDOOR FAN MOTOR

FUSE (250V,10A)

TERMINAL BLOCK

SOLENOID VALVE

P/NO : 3854A20021W

F1

RABST

–15–

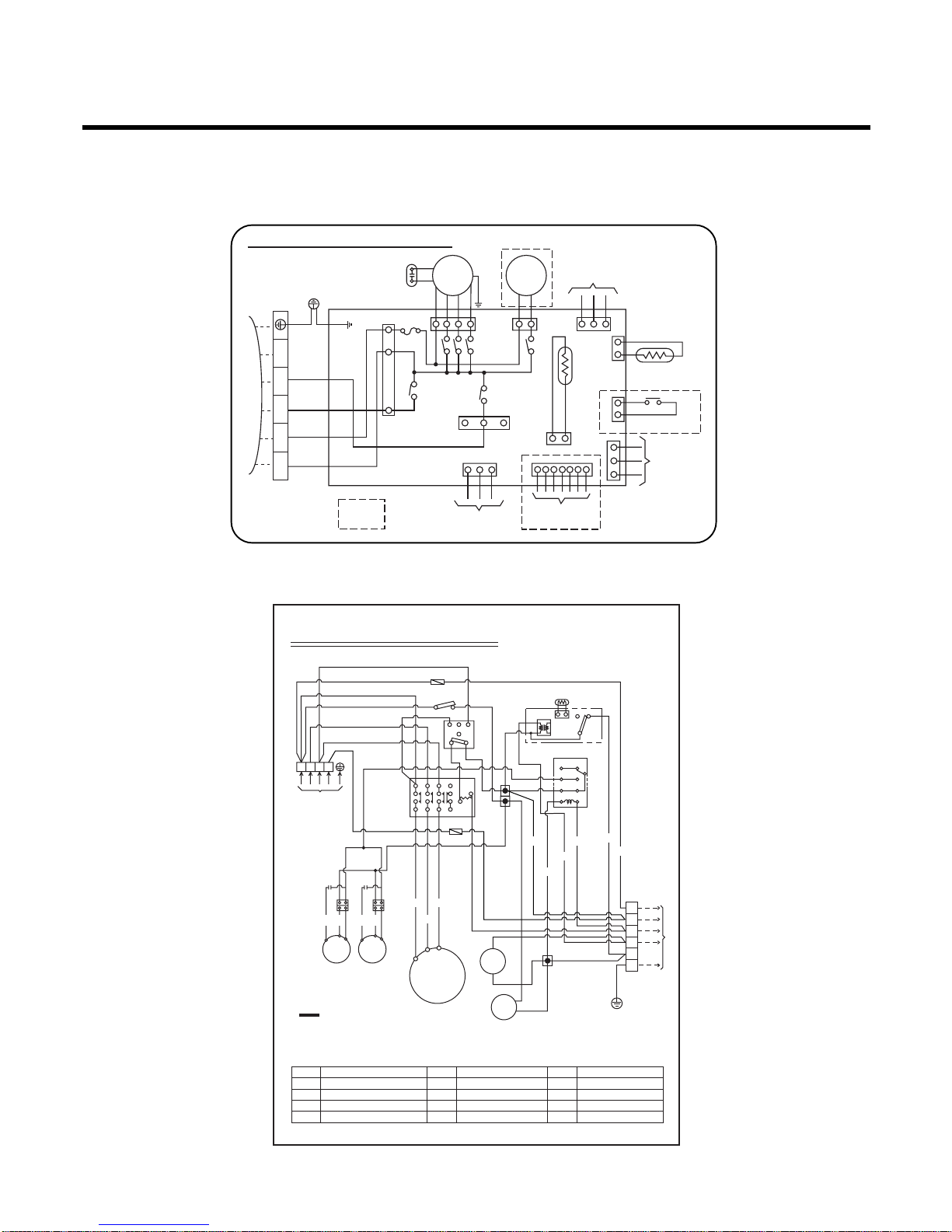

Model : LB-M7280BL

1. Indoor (LBNM7281BL)

2. Outdoor (LBUM7280BL)

OUTDOOR UNIT WIRING DIAGRAM

P/NO.:3854A20021V

BK

F1

BK

BK

TNS

NC NO NC NO

C TH

BK

BK

BK

12

34

56

78

R

BA

ST

BK

WH

WH

WH WH

WH

WH

F2

RD

RD

RD

BK

GN/YL

1(L)

2(N)

3

4

5

Tmo

TO INDOOR UNIT

YL

OR

YL

BL

BK

BL

BL

BL : BLUE

BK : BLACK

BR : BROWN

OR : ORANGE

F1,2,3

49C

FMo

49FMo

Co

D.P

C TH

20SV

52C

52F1

TM

TMo

63H1

63H2

3.P.D

HIGH PRESSURE SWITCH

HIGH PRESSURE SWITCH FOR HEATING

3 PHASE DETECTOR

MAGNETIC CONTACTOR

RELAY FOR FMo

MAIN TERMINAL BLOCK

TERMINAL BLOCK FOR CONNECTING

RUN CAPACITOR FOR FMo

DEICER PCB

THETMISTOR FOR PIPE TEMP.(OUTDOOR)

4-WAY VALVE COIL

FUSE(250V,10A)

INTERNAL O.L.P FOR COMP.

OUTDOOR FAN MOTOR

INTERNAL T.P FOR FMo

RD : RED

WH : WHITE

YL : YELLOW

GN/YL : GREEN/YELLOW

20SV

NOTE

YLBROR

BK

YLBROR

BK

YLBROR

BK

YLBROR

BK

RD

13521

24622

A1

A2

RDBKWH

GN/YL

F3

Tm

Co

FMo

49FMo

FMo

49FMo

COMP

49C

Co

T1

T3

T2

POWER SUPPLY

3Ø,380-415,50Hz

TERMINAL(4P)

RSTN

63H1

63H2

52C

52F1

3.P.D

D.P

RD

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

–16–

Model : LB-M9080BL/LB-M1081BL

1. Indoor (LBNM9081BL/LBNM1081BL)

2. Outdoor (LBUM9080BL/LBUM1081BL)

3854A20317B

OUTDOOR UNIT WIRING DIAGRAM

BR

BK

BK

BK

BK

TNS

NC NO NC NO

C TH

D.P

WH

YL

BL

BL

BL

BL

RD

20SV

BR

BR

TO INDOOR UNIT

BR

1(L)

2(N)

3

4

5

6

BL

BK

GN/YL

RD

BL

12

34

56

78

TB1

TB2

52F1

3.P.D

RST

AB

WH

WH

RD

RD

F2

63H1

F3

BL BL

BL

YLYL

BRBR

BKBK

OROR

YLYL

BRBR

BK

BK

BR

BL

RD

YL

WH

RD

BK

OROR

R

POWER SUPPLY

3Ø,380-415,50Hz

TERMINAL(4P)

Tm

Tmo

Co

FMo

49FMo

F1,F2,F3

49C

FMo

49FMo

FUSE(250V,10A)

INTERNAL O.L.P FOR COMP.

OUTDOOR FAN MOTOR

INTERNAL T.P FOR FMo

52C

52F1

TM

TMo

MAGNETIC CONTACTOR

RELAY FOR FMo

MAIN TERMINAL BLOCK

TERMINAL BLOCK FOR CONNECTING

63H1

63H2

3.P.D

T. D

HIGH PRESSURE SWITCH

HIGH PRESSURE SWITCH FOR HEATING

3 PHASE DETECTOR

5 SEC. DELAY TIMER

Co

D.P

C TH

20SV

RUN CAPACITOR FOR FMo

DEICER PCB

THERMISTOR FOR PIPE TEMP.(OUTDOOR)

REVERSING COIL

FMo

49FMo

A-COMP

49C

B-COMP

49C

Co

V

U

W

V

U

W

BKWHRD

STN

BL

GN/YL

A-52C

A2

21

22

12345

6

A1

A2

21

22

A1

B-52C

12345

6

T.D

RD

F1

INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

OR

OR

BR

BL

RD

BK

BLWHGY

BL

BL

BR

GN/YL

COMP

4 WAY

FUSE

250V10A

ROOM.

THERMISTOR

PIPE

THERMISTOR

RF REMOTE

CONTROL

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTIONAL

EXTRA

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20172T

3(L) 4(N) 5 6 7

TELE

CONTROL

GN/YLGN/YL

–17–

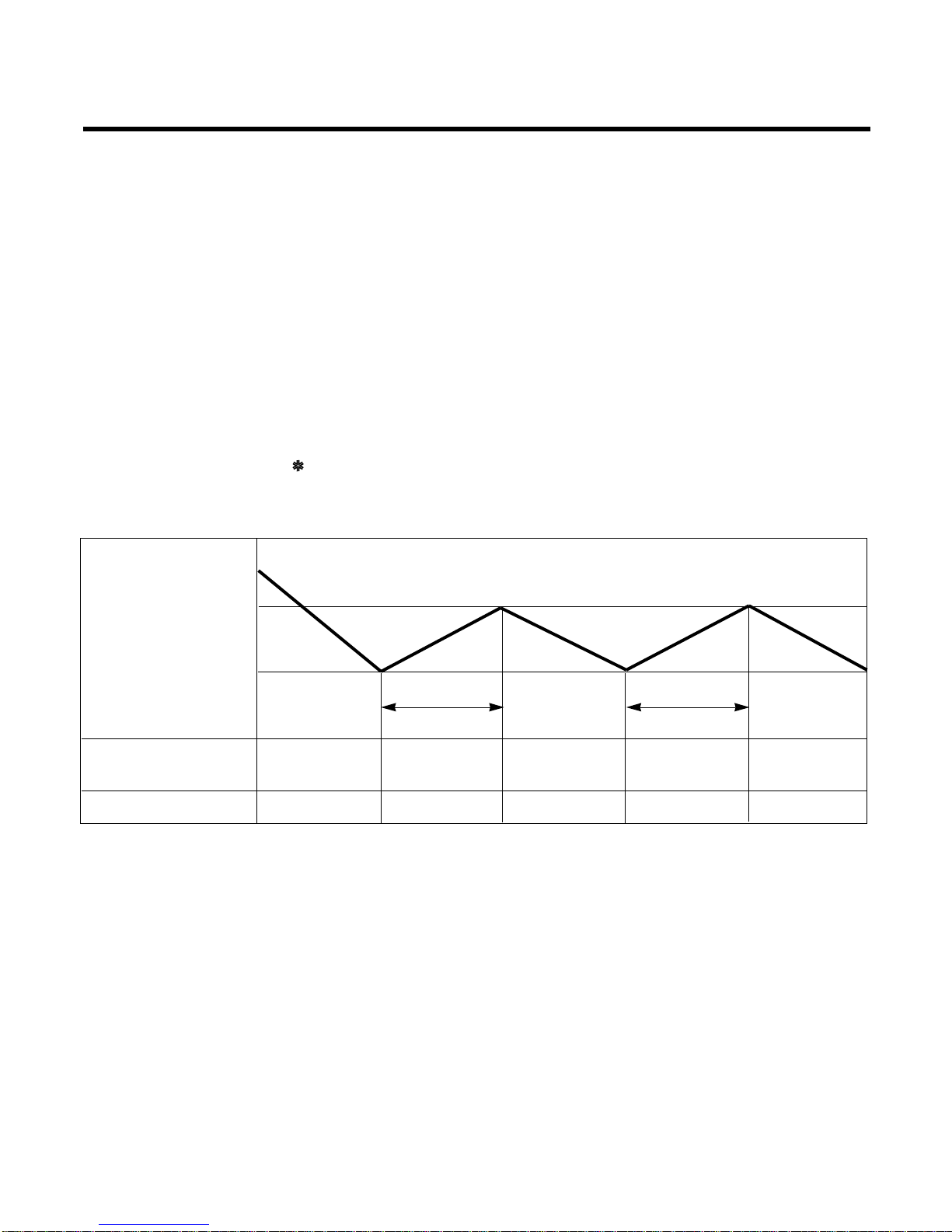

Operation Details

(1) The function of main control

1. Time Delay safety Control

• 3min

...

The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 30sec

...

The 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch.

2. Soft-Dry Operation

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by Micom Control.

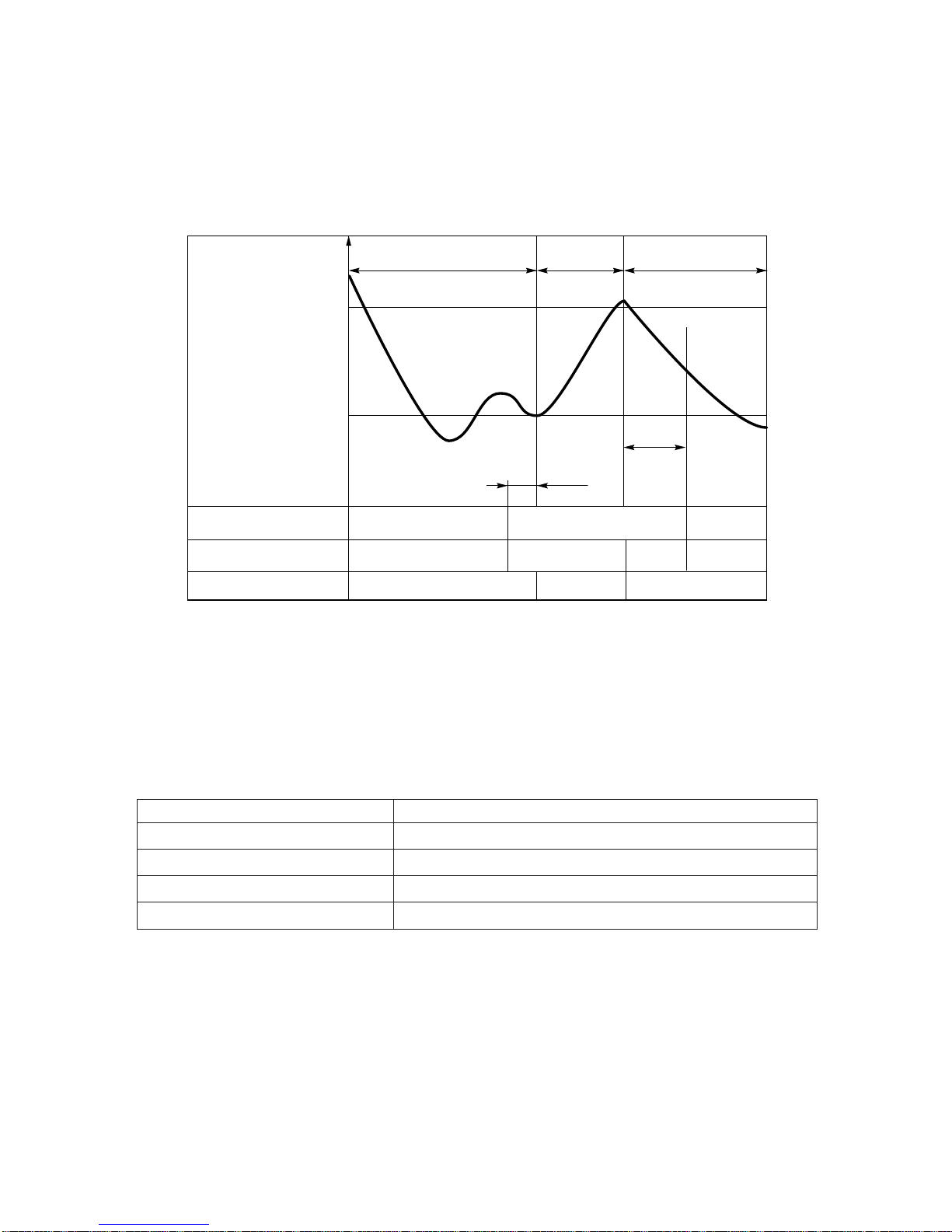

3. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote controller and the operation diagram is as following.

Intake Air temp.

SET TEMP.+0.5°C

(COMP. ON)

SET TEMP. -0.5°C

(COMP. OFF) More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

–18–

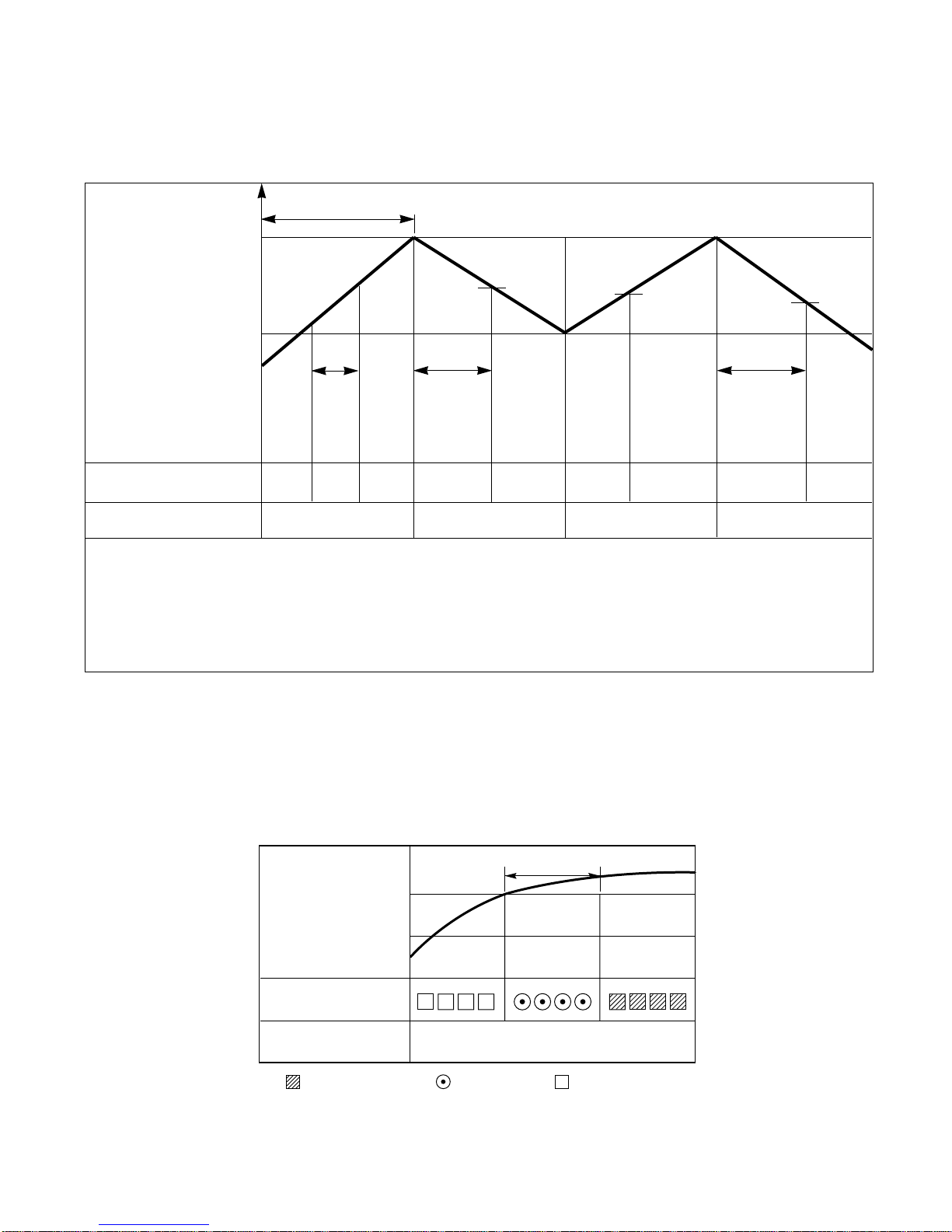

Intake Air temp.

Setting temp.+3°C

(Compressor OFF)

Setting temp.

(Compressor ON)

INDOOR FAN Low OFF Low Low OFF

COMPRESSOR ON OFF ON OFF

• A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed, when

it becomes lower than 40˚C fan stops.

• B point; When the indoor Heat-Exchanger temperature is higher than 42°C, fan operates at seleted fan

speed, when it becomes lower than 39°C, the fan operates at low speed.

4. Heating Mode Operation (Except Cooling Model)

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

Hot Start

Low

Selecting

Fan Speed

minimum 3min

Selecting fan

speed

minimum

10sec.

1min

AA

minimum

10sec.

B

5. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature will be reached to 31°C.

• The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

28°C

: Selected Fan : Low Fan : Fan Stop

31°C

–19–

6. Defrost Control

• Defrost control is availavle 45 minutes later since heating mode operation started, and it will not prolong over

10 minutes.

• Defrost control is carried out when the outdoor pipe temp. falls below -6°C for more than 3 minutes after 45

minutes passed from starting of heating operation.

• Defrost ends after 10 minutes passed from starting of defrost operation or when the outdoor pipe temp. rises

over 12°C after 5 minutes passed from starting of defrost.

7. Self-diagnosis Function

• 'CHECK' will flash in the remote controller display when a problem occurs. Then please contact your dealer.

• Correct the accident point as shown in the table below before restarting operation.

• During the normal operation 'CHECK' won't be displayed in the remote controller.

Remote controller LCD Accident Point

CH 01 Indoor room temperature thermistor error

CH 02 Indoor piping thermistor error

CH 03

Indoor main body / Remote controller unit communication error

CH 04(Optional) Water level float switch error

More than 45 minutes

of heating operation

Within

9min. 45sec.

ON OFF

ON ON

ON

ON OFF

OFF

COMPRESSOR

4-WAY VALVE

INDOOR FAN

-6°C ON

12°C OFF

The outdoor

piping Temp.

ON

More than 10 min.

running of compressor

More than 45 minutes

of heating operation

5sec.

HOT-

START

ON

–20–

Installation of Indoor, Outdoor Unit

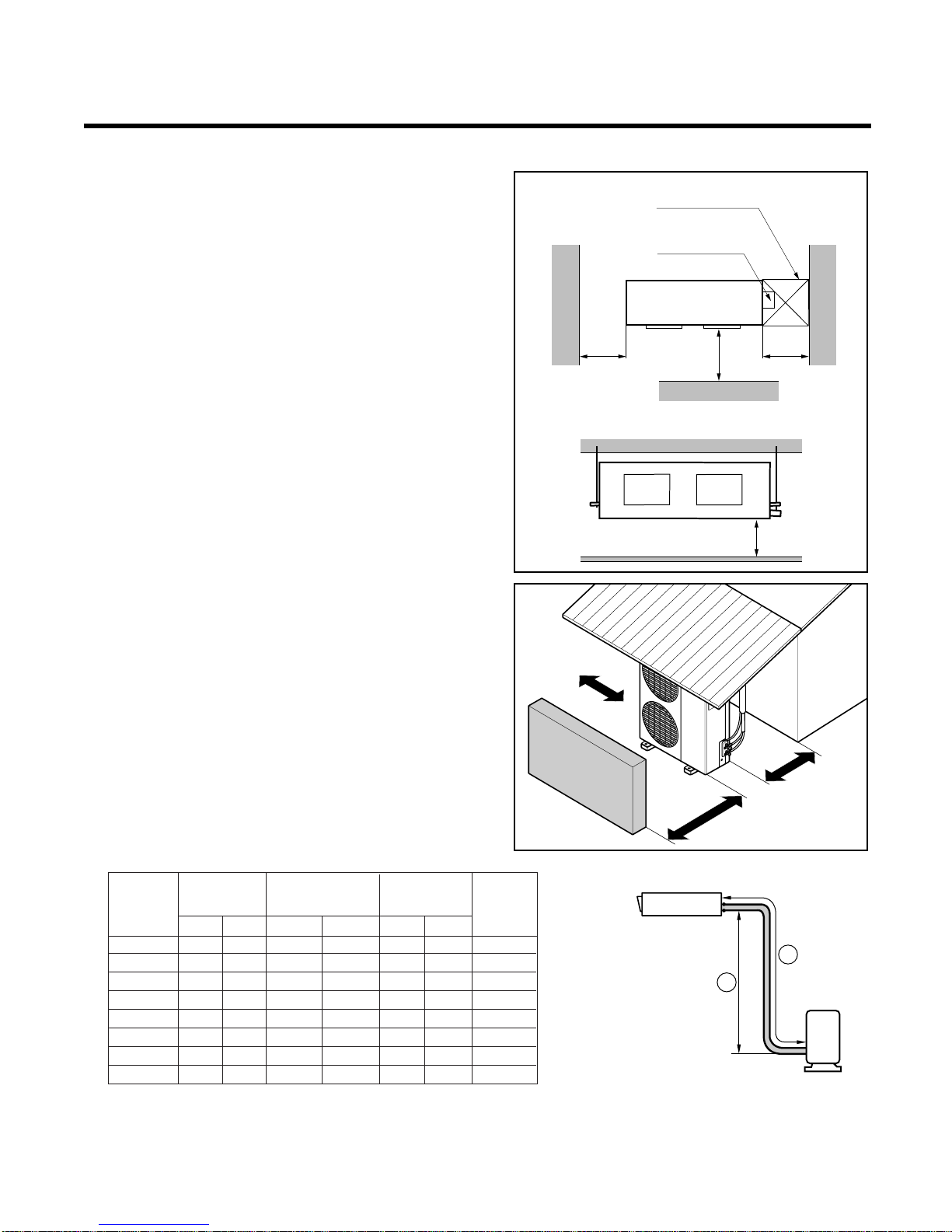

1. Selection of the best location

1) Indoor unit

Select location

Install the air conditioner in the location that satisfies the following conditions.

• The place shall easily bear a load exceeding four

times the indoor unit’s weight.

• The place shall be able to inspect the unit as the

figure.

• The place where the unit shall be leveled.

• The place shall allow easy water drainage.(Suit-

able dimension “H” is necessary to get a slope to

drain as figure.)

• The place shall easily connect with the outdoor

unit.

• The place where the unit is not affected by an

electrical noise.

• The place where air circulation in the room will be

good .

• There should not be any heat source or steam

near the unit.

2) Outdoor unit

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat

radiation from the condenser is not restricted.

• There should not be any animals or plants which

could be affected by hot air discharged.

• Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

3) Piping length and the elevation

Indoor unit

Outdoor unit

B

A

More than

30cm

More than

30cm

More than

70cm

Sunroof

Fence or

obstacles

Top view

(unit: mm)

H

Front view

600600

Front

Inspection hole

(600X600)

Control box

1000

30K BTU/h

5/8" 3/8" 7.5 15 7.5 12.5 70

36K BTU/h

5/8" 3/8" 7.5 15 7.5 12.5 50

42K BTU/h 3/4'' 3/8" 7.5 15 7.5 12.5 70

48K BTU/h 3/4'' 3/8" 7.5 15 7.5 12.5 70

60K BTU/h 3/4'' 3/8" 7.5 15 7.5 12.5 70

72K BTU/h 1'' 1/2" 7.5 25 7.5 20 70

90K BTU/h 9/8'' 5/8" 7.5 30 7.5 20 90

100K BTU/h 9/8'' 5/8" 7.5 30 7.5 20 100

Capacity

Gas Liquid

Elevation B(m)

Piping Length

A(m)

* Additional

Refrigerant

(g/m)

Pipe Size (Diam-

eter: Ø)

inch

Standard

Standard

Max.

Max.

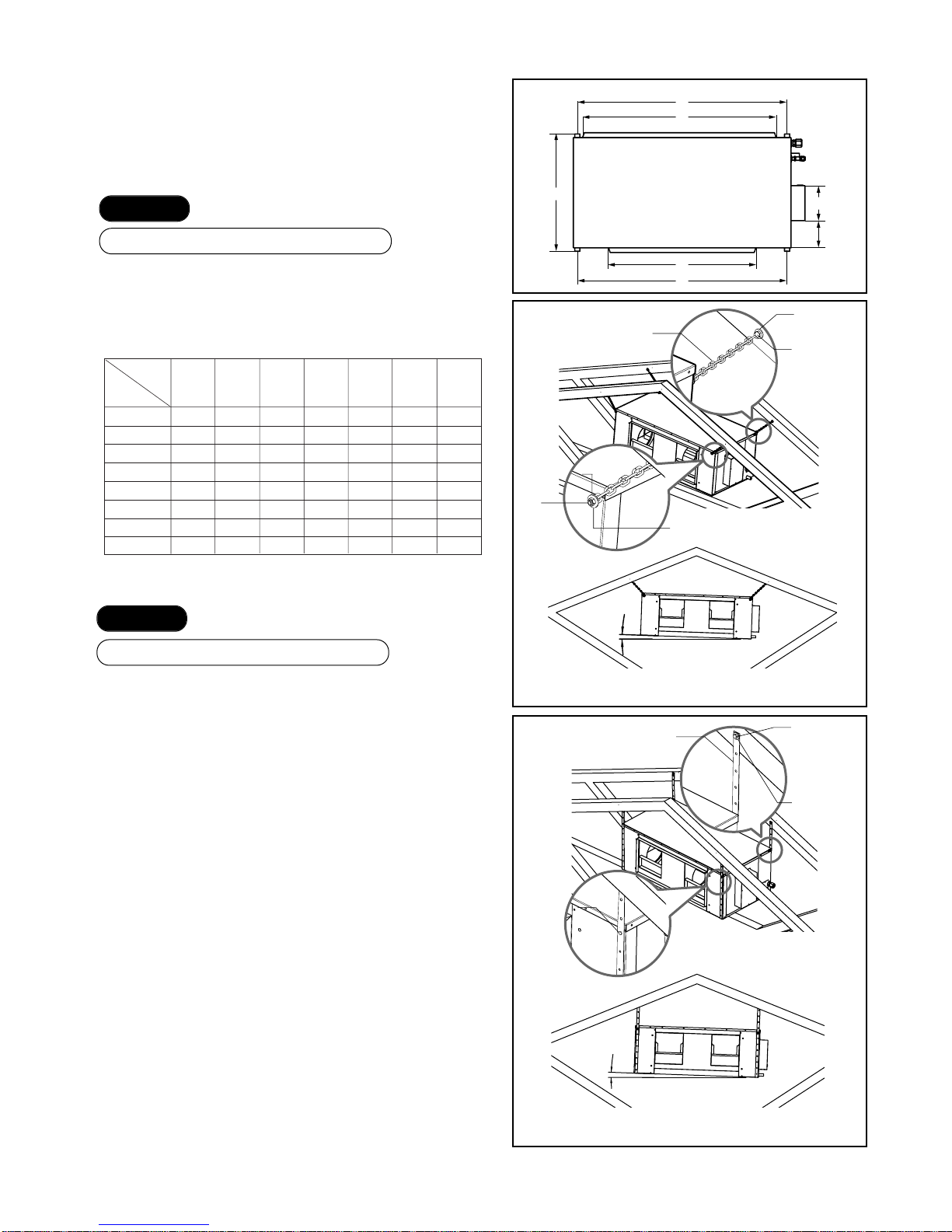

2. Ceiling dimension and hanging

bolt location

■ Installation of Unit

Install the unit above the ceiling correctly.

• Apply a joint-canvas between the unit and duct to

absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

• Install the unit leaning to a drainage hole side as a

figure for easy water drainage.

• A place where the unit will be leveled and that can

support the weight of the unit.

• A place where the unit can withstand its vibration.

• A place where service can be easily performed.

–21–

CASE 1

POSITION OF SUSPENSION BOLT

CASE 2

POSITION OF CONSOLE BOLT

(Unit:mm)

Q

G

R

169

T

E

P

Flat washer

(Zinc plated)

3mm steel chain

1/4" coach

screw

(Self-tapping

wood screw

with hexagonal

head)

Flat washer

(Zinc plated)

Flat washer

(Zinc plated)

Flat washer

(Zinc plated)

2˚

2˚

M6

(Zinc plated)

screw & Nut

M6

(Zinc plated)

screw & Nut

Galvanized steel

(Pre-punched) strap

1/4" coach

screw

(Self-tapping

wood screw

with hexagonal

head)

Flat washer

(Zinc plated)

Self-tapping

screw or M6

(Zinc plated)

screw & Nut

Self-tapping

screw or M6

(Zinc plated)

screw & Nut

TYPE-A (Using steel chain)

TYPE-B (Using Galvanized steel strap)

NOTE:

• Throughly study the following installation locations:

1. In such places as restaurants and kitchens, considerable

amount of oil steam and flour adhere to the fan, the fin of the

heat exchanger, resulting in heat exchange reduction, spraying,

dispersing of water drops, etc.

In these cases, take the following actions:

• Make sure that the ventilation fan for smoke-collecting hood on

a cooking table has sufficient capacity so that it draws oily

steam which should not flow into the suction of the air conditioner.

• Make enough distance from a cooking room to install the air

conditioner in such a place where it may not suck in oil steam.

2. Avoid installing air conditioner in such circumstances where

cutting oil mist or iron powder is in suspension in factories, etc.

3. Avoid places where inflammable gas is generated, flows in, is

stored or vented.

4. Avoid places where sulfurous acid gas or corrosive gas is

generated.

5. Avoid places near high frequency generators.

EFGPQRT

Dimension

Model No.

LBNS3061BL 482 282 718 798 798 - 120

LBNK3661BL 712 284 868 934 937 548 120

LBNK4261BL 712 282 868 934 937 548 120

LBNK4881BL 712 282 868 934 937 548 120

LBNL6081BL 712 327 935 1014 1014 567 130

LBNM7281BL 833 327 1221 1313 1313 567 130

LBNM9081BL 835 377 1403 1504 1504 - 190

LBNM1081BL 835 377 1403 1504 1504 - 190

Loading...

Loading...